Page 1

www.ti.com

Table of Contents

Application Report

Using the Fast Serial Interface (FSI) With Multiple

Devices in an Application

Aki Li and Kevin Allen

ABSTRACT

In industrial applications, it is often necessary for multiple devices to communicate with each other in a fast, low

latency, and synchronized manner. One example is in a decentralized / distributed control system architecture. A

new communication peripheral created for C2000™ Real-Time Control Microcontrollers (MCU), the Fast Serial

Interface (FSI) can expand its reliable high-speed communication features to multiple devices in a system. This

application report demonstrates how to implement a daisy-chain or star network topology using FSI. Test results

are provided to validate the high-speed communication capability of FSI with different configuration methods.

You can quickly verify and design FSI in different applications using the provided source code, which can be

downloaded from C2000WARE.

The target processors for the corresponding software include the TMS320F28002x, TMS320F28004x, and

TMS320F2838x. The implementation methods and software can be applied and ported to future C2000

processors that include FSI. Example code discussed in this document can be found in the latest C2000WARE

release, located within the following local directory after installation:

C:\ti\c2000\C2000Ware_<version_number>\driverlib\f28xxxx\examples\fsi

The available example projects are:

• fsi_ex_daisy_handshake_lead

• fsi_ex_daisy_handshake_node

• fsi_ex_star_broadcast

Table of Contents

1 Introduction to the FSI Module..............................................................................................................................................3

2 FSI Applications......................................................................................................................................................................5

3 Handshake Mechanism.......................................................................................................................................................... 7

3.1 Daisy-Chain Handshake Mechanism................................................................................................................................. 7

3.2 Star Handshake Mechanism.............................................................................................................................................. 9

4 Sending and Receiving FSI Data Frames........................................................................................................................... 10

4.1 FSI Data Frame Configuration APIs.................................................................................................................................10

4.2 Start Transmitting Data Frames....................................................................................................................................... 10

5 Daisy-Chain Topology Tests................................................................................................................................................ 11

5.1 Two Device FSI Communication......................................................................................................................................13

5.2 Three Device FSI Communication................................................................................................................................... 17

6 Star Topology Tests..............................................................................................................................................................20

7 References............................................................................................................................................................................ 21

8 Revision History................................................................................................................................................................... 21

List of Figures

Figure 1-1. FSITX and FSIRX CPU Interface.............................................................................................................................. 4

Figure 2-1. Daisy-Chain Connection Example.............................................................................................................................5

Figure 2-2. Star Topology Example............................................................................................................................................. 6

Figure 3-1. Daisy-Chain Handshake Sequence.......................................................................................................................... 8

SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Using the Fast Serial Interface (FSI) With Multiple Devices in an Application 1

Page 2

Trademarks

Figure 3-2. Star Handshake Sequence....................................................................................................................................... 9

Figure 5-1. Software Flow Chart With Different Project Settings...............................................................................................12

Figure 5-2. Test Platform for Two Device Communication.........................................................................................................13

Figure 5-3. Data Transmission Test Using CPU Control............................................................................................................14

Figure 5-4. FSI Communication Using DMA Control................................................................................................................. 15

Figure 5-5. Test Platform for Three Devices Communication.................................................................................................... 17

Figure 5-6. FSI Communication With CPU Control Among Three Devices...............................................................................18

Figure 5-7. Time of Data Going Through One Device - CPU Control........................................................................................18

Figure 5-8. FSI Communication with DMA Control Among Three Devices............................................................................... 19

Figure 5-9. Time of Data Going Through One Device - DMA Control....................................................................................... 19

www.ti.com

List of Tables

Table 5-1. Example Projects Description - Daisy-Chain.............................................................................................................11

Table 5-2. Data Frame Structure............................................................................................................................................... 15

Table 5-3. Calculated Transmission Time for 8 Words.............................................................................................................. 15

Table 5-4. Comparison of Using CPU Control and DMA Control in FSI for Two Devices..........................................................16

Table 5-5. Comparison of Using CPU Control and DMA Control in FSI Among Three Devices................................................20

Table 6-1. Software Example Projects - Star Topology..............................................................................................................20

Trademarks

C2000™ and Code Composer Studio™ are trademarks of Texas Instruments.

All other trademarks are the property of their respective owners.

2 Using the Fast Serial Interface (FSI) With Multiple Devices in an Application SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 3

www.ti.com

Introduction to the FSI Module

1 Introduction to the FSI Module

The FSI module is a serial communication peripheral capable of reliable and robust high-speed communications,

up to 200 Mbps. Utilizing very few unidirectional signals, FSI provides a low cost way of communicating across

an isolation barrier when leveraging digital isolation devices. Thus, FSI enables new ways of distributing the

powerful sensing, processing, and actuation capabilities of C2000 MCUs in industrial applications, where realtime control with critical communication speed is required.

Generally, FSI can be implemented in two kinds of system conditions:

• Wired communications between MCUs that exist on the same voltage and ground planes.

• Wired communications across an isolation barrier, leveraging digital isolators (like ISO77xx), commonly used

for MCUs placed on the hot-side needing to communicate with MCUs on the cold-side, or between boards

with different voltage and ground planes.

There are a number of real-time systems that can benefit from the FSI peripheral. A multi-axis servo drive can be

constructed with C2000 device nodes controlling each axis. Having FSI serve as the communication link, control

loop information can be quickly transmitted and received between the devices to maintain precise motion control.

For an example of this system see the Distributed Multi-axis Servo Drive over Fast Serial Interface (FSI)

reference design.

Additionally, with increasing global power consumption, the need for higher efficiency power supplies, in

conjunction with the availability of wide bandgap GaN and SiC products, is driving the use of more sophisticated

power distribution architectures. Decentralized power control solutions using C2000 MCUs can be connected

and made flexible with FSI to meet these requirements. For a discussion on such power related systems see the

Distributed Power Control Architecture with Multiple MCUs Over FSI white paper.

The FSI peripheral offers a broad range of features, including programmable data length, hardware managed

CRC, ECC support, and more. A PING watchdog and Frame watchdog can enable automatic line-break

detection. The unique delay line control feature implemented within the FSI receive module can adjust for

channel-to-channel skew introduced by trace-length mismatch, transceivers, or digital isolation ICs, allowing FSI

to maintain high-speed and robust communication.

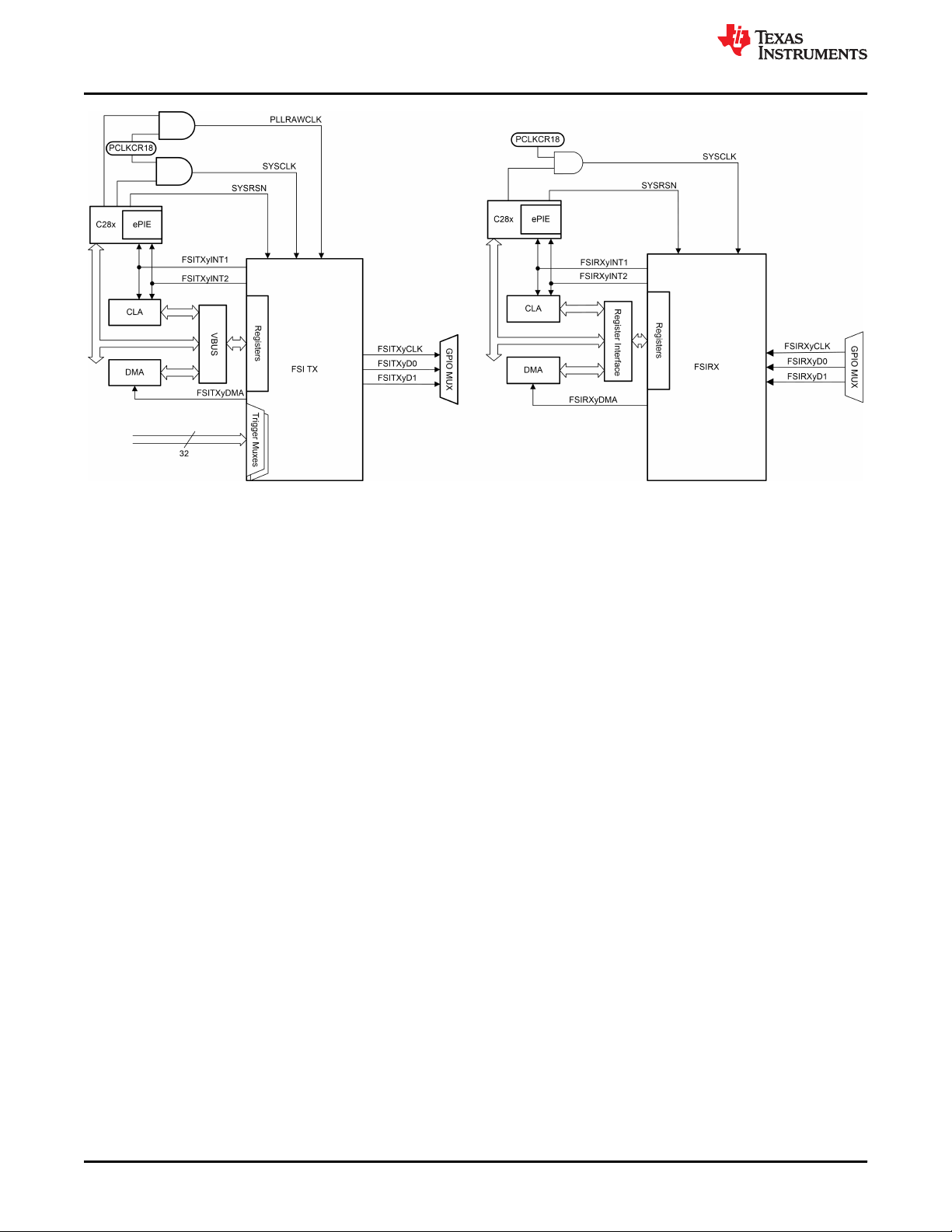

The FSI consists of the independent transmitter (FSITX) and receiver (FSIRX) cores, which are configured and

operated independently. Because of this, the FSI protocol does not have a notion of master and slave, unlike

some other synchronous communication protocols, and allows for simultaneous full speed communications in

both directions. Figure 1-1 shows the CPU interface of each FSI module. Each module owns up to three signal

lines: one clock and two data signals, where the second data lines, FSITXyD1 and FSIRXyD1, are optional, and

can be enabled for multi-lane transmission and double the speed for data bits. Thus, at least four signal lines are

needed to create 2-way point-to-point communication. Considering the timing spec for FSITX (see the devicespecific data sheets referenced in Section 7 ), the maximum data rate of 200 Mbps can be achieved with the

maximum clock of 50 MHz, using two data lines, since the data is transmitted on both edges of the clock signal.

For a full overview of FSI including all features and functions available, see the device-specific Technical

Reference Manual (TRM).

SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Using the Fast Serial Interface (FSI) With Multiple Devices in an Application 3

Page 4

Introduction to the FSI Module

www.ti.com

Figure 1-1. FSITX and FSIRX CPU Interface

4 Using the Fast Serial Interface (FSI) With Multiple Devices in an Application SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 5

www.ti.com

FSI Applications

2 FSI Applications

In terms of the trend in power electronic applications, the increasing demand for higher power levels makes

multiple power modules in parallel much more popular. Examples of such applications include industrial drives,

telecom rectifiers, server power supplies, on-board chargers, and so forth. Meanwhile, to achieve a complex

system with high performance, multiple MCUs are commonly used and must operate in a synchronized fashion.

Thus, critical data, including protection signals, sampling parameters, and even control loop data, needs to be

transferred with the fastest speed and least amount of latency among multiple devices/modules. FSI will be more

suitable to handle this when compared to the traditional Controller Area Network (CAN), Serial Peripheral

Interface (SPI) or Universal Asynchronous Receiver/Transmitter (UART).

There are a number of communication network topologies for connecting multiple devices, each with their own

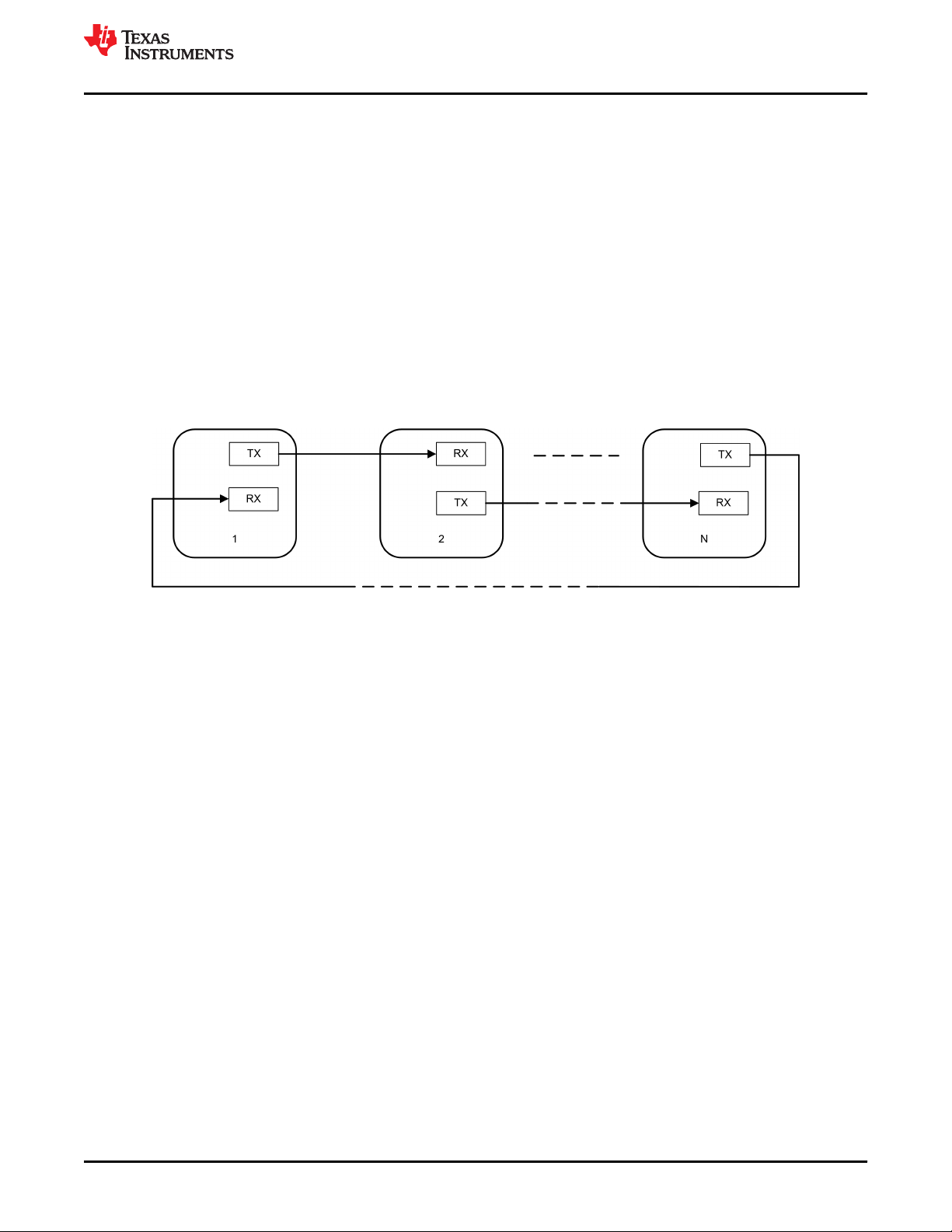

benefits. A ring topology can be created by connecting multiple devices with FSI communication in a daisy-chain

fashion. The advantages of a ring topology are that each device only needs one FSI transmitter and receiver and

also the simplicity from a physical connection perspective. Figure 2-1 shows a daisy-chain connection system for

N (N≥2) node devices, where each device (index i) connects with the FSITX of device i-1 and FSIRX of device i

+1.

Figure 2-1. Daisy-Chain Connection Example

One disadvantage of the above daisy-chain topology is that if one device in the chain fails then the entire

communication link is broken. Another downside is that devices must forward data along to the next device in the

chain if the received data is intended for a subsequent device. This can add to the overall latency of when a data

packet is transmitted and when the respective device in the chain receives the data.

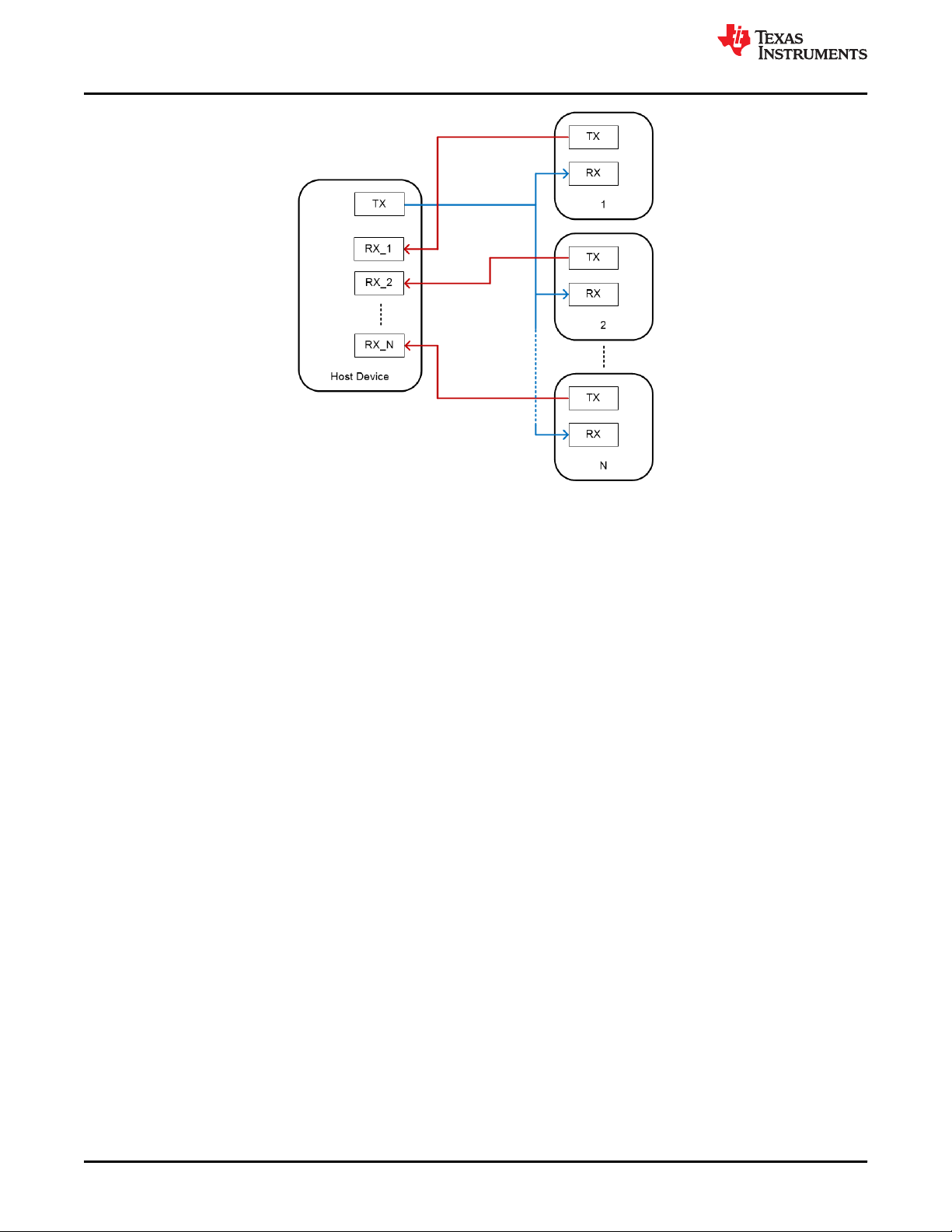

One communication topology that solves the broken link issue and can reduce the device-to-device latency is a

star topology, where several nodes connect directly to one central host device. Figure 2-2 shows a star topology

system with N (N≥2) node devices.

SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Using the Fast Serial Interface (FSI) With Multiple Devices in an Application 5

Page 6

FSI Applications

www.ti.com

Figure 2-2. Star Topology Example

The host device's FSI transmitter is connected to the FSI receiver of each node device in order for the host to

broadcast data packets to all nodes simultaneously. The node device transmitter's, on the other hand, are

connected to independent receivers of the host device enabling them to send data directly back to the host at

any time. This star implementation comes with a resource cost as the host needs N number of independent FSI

receiver modules. The F2838x family of C2000 devices fit into the host socket with having two FSI transmitters

and eight FSI receivers.

6 Using the Fast Serial Interface (FSI) With Multiple Devices in an Application SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 7

www.ti.com

Handshake Mechanism

3 Handshake Mechanism

A handshake mechanism can be implemented in order to configure the devices and validate the link in an FSI

communication topology. The different handshake sequences are discussed in the following sections.

3.1 Daisy-Chain Handshake Mechanism

Once the FSITX and FSIRX modules of each device have been configured, the handshake mechanism should

be implemented to prepare each device in the chain before actual data transmission, since devices may power

up in an arbitrary order in a real scenario.

In order to simplify the data flow, one device is assigned as the lead, working as the driver of the handshake

sequence, and the other N-1 devices, within the daisy-chain loop, are assigned as nodes. Following the example

in Figure 2-1, Device 1 will be the lead device. It should be noted that the other N-1 node devices will share the

same handshake configuration.

The handshake process can be described as follows:

1. For all devices, configure the Frame Type of FSITX as Ping Frame, and enable the receiver interrupts for

Ping Frame Received event on the FSI INT1 vector to detect the incoming transmission.

2. Begin the ping loop 0:

a. The lead device sends the flush sequence to the second device followed by a ping frame with Tag0(0000);

wait for some time. If the lead device receives a valid ping frame tag Tag0, continue to the second loop;

otherwise iterate the ping loop 0 again.

b. The node devices enter a wait loop for a receiver interrupt. If a valid ping frame tag of Tag0 is received

from the previous device, continue to the loop 1; otherwise iterate the ping loop 0 again.

3. Begin the ping loop 1:

a. The lead device sends a ping frame with Tag1(0001); wait for some time. If the lead device receives a

valid ping frame Tag1 the handshake sequence is complete and the application can continue; otherwise

iterate the ping loop 1 again.

b. The node devices send the flush sequence followed by a ping frame Tag0 and wait for a receiver interrupt.

If a valid ping frame Tag1 is received send a ping frame Tag1 to signal the completion of the handshake

sequence; or else iterate the ping loop 1 again.

4. Handshake completed.

SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Using the Fast Serial Interface (FSI) With Multiple Devices in an Application 7

Page 8

Handshake Mechanism

www.ti.com

Figure 3-1. Daisy-Chain Handshake Sequence

The simplified data flow is shown in Figure 3-1. Two ping loops are necessary for the daisy-chain connection

handshake mechanism. Ping loop 0 has the purpose of establishing the communication path along the chain of

devices and ping loop 1 acts as the acknowledgment to the nodes that the communication path is good. In ping

loop 0, the node devices wait to receive a Ping Tag0 from the previous device in the chain. Once a Ping Tag0 is

successfully received, it will be forwarded on to the next device in the chain. The ping loop 0 will fail if a device in

the chain has not powered up or is not ready for the reception. Once ping loop 0 has succeeded, in which ping

tag0 has made its way back to the lead device, ping loop 1 is initiated to inform the node devices that the

handshake sequence has completed and to begin expecting actual data.

The handshake function can be found in the tested projects, with handshake_lead() for the lead device and

handshake_node() for the other N-1 devices in the daisy-chain loop.

8 Using the Fast Serial Interface (FSI) With Multiple Devices in an Application SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 9

www.ti.com

Handshake Mechanism

3.2 Star Handshake Mechanism

A handshake sequence very similar to what's described in Section 3.1 can be applied for the star topology case.

In this implementation the host, or lead, device sends broadcast pings to all of the node devices and they each

respond along their independent TX paths. The lead device waits to receive ping frames from all nodes before

moving on to the next step. The sequence is shown below in Figure 3-2.

Figure 3-2. Star Handshake Sequence

SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Using the Fast Serial Interface (FSI) With Multiple Devices in an Application 9

Page 10

Sending and Receiving FSI Data Frames

www.ti.com

4 Sending and Receiving FSI Data Frames

4.1 FSI Data Frame Configuration APIs

Several configurations are needed for data frames to be sent and received properly, including the frame type,

frame tag, user data, word length, number of data lines, and writing to or reading from the data buffer. The

configuration example code uses driverLib API functions for FSITX and FSIRX, defined in the fsi.h driverLib

header file in C2000WARE, which are shown below. Note that the content of frame tag and user data is fully

user-configurable, which can be used to differentiate which device the data received is sent from or which device

it is meant for.

// TX setting part

FSI_setTxFrameType(FSITXA_BASE, FSI_FRAME_TYPE_NWORD_DATA);

FSI_setTxSoftwareFrameSize(FSITXA_BASE, nWords);

FSI_setTxDataWidth(FSITXA_BASE, nLanes);

FSI_setTxUserDefinedData(FSITXA_BASE, txUserData);

FSI_setTxFrameTag(FSITXA_BASE, txDataFrameTag);

// RX setting part

FSI_setRxSoftwareFrameSize(FSIRXA_BASE, nWords);

FSI_setRxDataWidth(FSIRXA_BASE, nLanes);

4.2 Start Transmitting Data Frames

There are three methods to trigger the data transmission, including software triggered, externally triggered

(EPWMx-SOCA/B), or using the DMA. For the software triggering method, writing 1 to the

TX_FRAME_CTRL.START register bit, or using the driverLib function “FSI_startTxTransmit()”, will start the

transmission. If using an external trigger, like EPWMx-SOCA, once the external trigger signal occurs, the data

will be sent.

Since the DMA trigger can be generated every time a data frame transmission or receiving is completed from the

FSITX or FSIRX module, it provides a convenient method to transfer and store data, especially with a mass

amount of data. Here a configuration example is given for the FSI communication using DMA.

TX_OPER_CTRL_LO.START_MODE must be set to 0x2, which means writing to frame tag/user data fields can

trigger the transmission and then enables a DMA event on FSITX:

FSI_setTxStartMode(FSITXA_BASE, FSI_TX_START_FRAME_CTRL_OR_UDATA_TAG);

FSI_enableTxDMAEvent(FSITXA_BASE);

Two consecutive DMA channels are needed to fill the transmit buffer and frame tag/user data fields, respectively.

Using the two channels in sequence allows for the transmission to start right after the frame tag and user data

are set, as configured in the TX_OPER_CTRL_LO.START_MODE register bits. In the example code, DMA CH1

and DMA CH2 are used. Another important point is that the wrap control must be enabled for data of more than

16 words, since the FSI transmit buffer is a 16-word circular buffer.

DMA_configWrap(DMA_CH1_BASE, DMA_TRANSFER_SIZE_IN_BURSTS, 0, dest_WrapSize, 0);

Here, dest_WrapSize represents the number of bursts to be transferred before a wrap of the destination

address, so dest_WrapSize should be 16/ nWords. This can be implemented such that the transmit buffer is

continuously fed by the DMA, which is triggered by FSITX in return, with DMA Continuous Mode enabled.

The FSIRX is configured very similarly to the FSITX, except for that there is no order requirement for the DMA

channels for RX buffer and tag and user data. In the example projects, DMA CH3 and DMA CH4 are used.

10 Using the Fast Serial Interface (FSI) With Multiple Devices in an Application SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 11

www.ti.com Daisy-Chain Topology Tests

5 Daisy-Chain Topology Tests

In order to demonstrate the communication speed and different configurations for FSI, daisy-chain connections

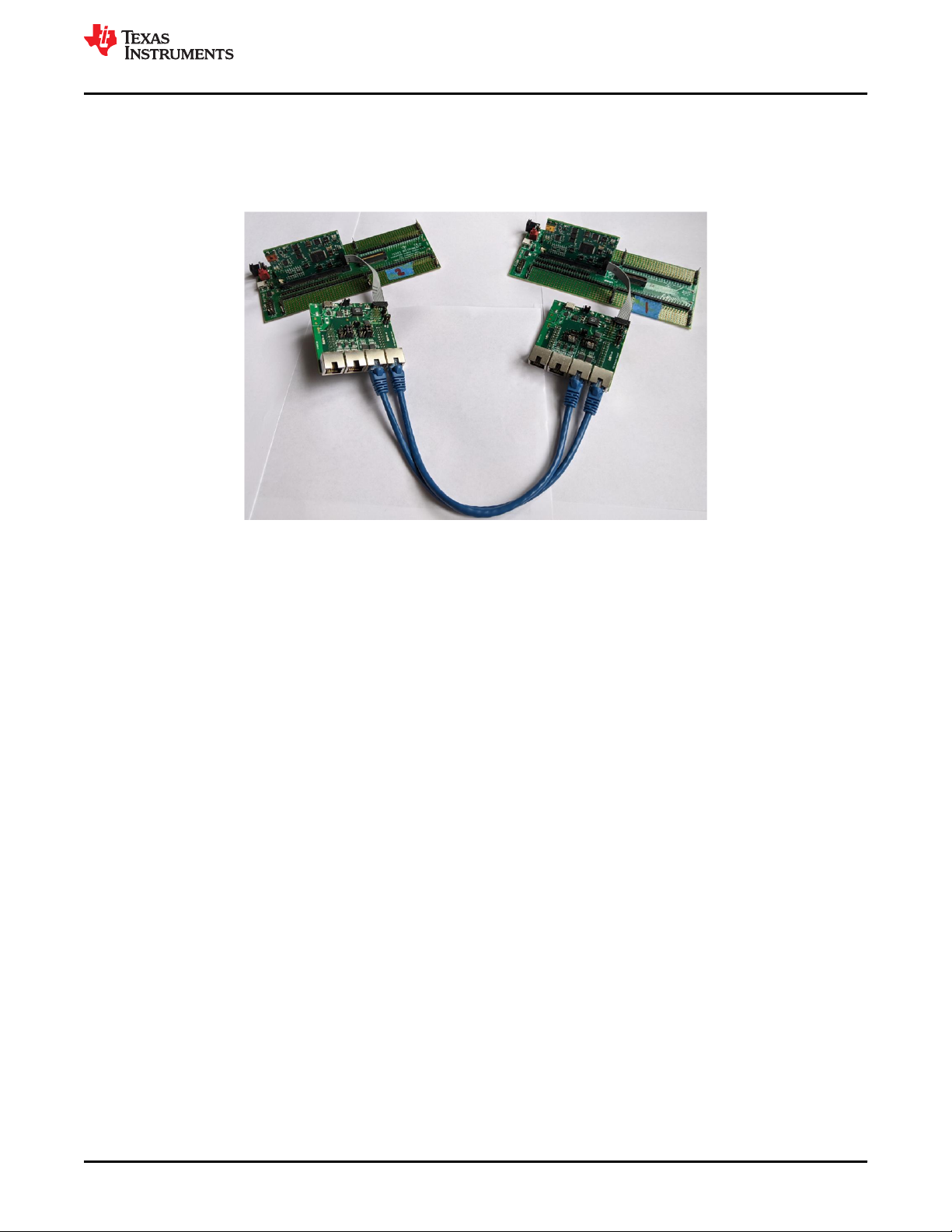

for two device and three device configurations have been tested and validated. The test hardware utilized is

composed of multiple F280025C ControlCARD Evaluation Modules and TMDSFSIADAPEVMs.

Note

These same tests can be performed with LAUNCHXL-F280049Cs and TMDSFSIADAPEVMs as well

with similar hardware setups.

The tested example projects can be found within the C2000WARE download. All test results were collected

using optimization level 2, configured within Code Composer Studio™ (CCS). Changing the optimization level

may yield different results. An overall description of the tested projects is shown in Table 5-1. For better

understanding, a general software flow chart with different project settings is shown in Figure 5-1.

Table 5-1. Example Projects Description - Daisy-Chain

Project Description Settings

fsi_ex_daisy_handshake_

lead

fsi_ex_daisy_handshake_

node

Project for the lead device in the daisy-chain

loop.

Project for the N-1 other devices (N>=2) in the

daisy-chain loop.

① [#define FSI_DMA_ENABLE 0] represents FSI

communication using CPU control.

② [#define FSI_DMA_ENABLE 1 && #define

TX_DMA_TRIGGER_ENABLE 0] represents FSI

communication using DMA control, and using software to

trigger DMA for the transmitted data (manually).

③ [#define FSI_DMA_ENABLE 1 && #define

TX_DMA_TRIGGER_ENABLE 1] represents FSI

communication using DMA control, and enabling FSITX

to trigger DMA for the transmitted data.

SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Using the Fast Serial Interface (FSI) With Multiple Devices in an Application 11

Page 12

Daisy-Chain Topology Tests

www.ti.com

Figure 5-1. Software Flow Chart With Different Project Settings

12 Using the Fast Serial Interface (FSI) With Multiple Devices in an Application SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 13

www.ti.com

Daisy-Chain Topology Tests

5.1 Two Device FSI Communication

For a minimal daisy-chain connection test, a system of two F280025C ControlCARD Evaluation Modules and

TMDSFSIADAPEVMs are used as shown in Figure 5-2. The comparison of the communication speeds for both

CPU control and DMA control is provided in the following sub-sections.

Figure 5-2. Test Platform for Two Device Communication

5.1.1 CPU Control

• Test condition:

Device 1 sends data -> Device 2 receives data -> Device 2 CPU moves RX data to TX buffer and registers ->

Device 2 triggers FSI TX with SW which forwards the received data back to Device 1 -> Device1 receives data

back and the CPU verifies it matches the originally sent TX data.

• Test case:

Data length of 8 words, two data lines, TXCLK = 50 MHz, with Setting ① (Table 5-1) enabled.

In the test, GPIOs are toggled within software when specific events occur during the communication and

measured using an oscilloscope to obtain the respective timing data. In Figure 5-3, the green signal represents

the GPIO toggling of Device 1 (Lead device) and the magenta signal represents the GPIO toggling of Device 2

(Node device).

SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Using the Fast Serial Interface (FSI) With Multiple Devices in an Application 13

Page 14

Daisy-Chain Topology Tests

www.ti.com

Figure 5-3. Data Transmission Test Using CPU Control

From the results shown in Figure 5-3, the time obtained for the data transmission is ~1.4 µs. In order to calculate

the transmission speed, the total data length should be considered. Table 5-2 shows the general structure of a

data frame, which can be divided into two parts: effective data bits and overhead bits.

• Effective Data Bits: Includes the 8-bit User Data, 16-bit Data Words, and 8-bit CRC fields

• Overhead Bits: Includes the Preamble, SOF, Frame Type, EOF, and Postamble fields

Therefore, the ideal transmission time for 8 words can be derived theoretically, as shown in Table 5-3.

It should be noted that since two data lines only work for effective data bits, one FSITXCLK cycle delivers 4

effective data bits, while one FSITXCLK cycle only delivers 2 overhead bits. Thus, with a total 48 FSITXCLK

cycles for 8 data words, the transmission time can be calculated as shown in Equation 1.

(FSITXCLK cycles) / (FSITXCLK frequency) = 48 /

(

50 M H z

) = 0 . 96 μ

s

(1)

Therefore, the theoretical transmission speed is 175 Mbps (168/0.96 µs), while the speed from the test is 120

Mbps with 1.4 µs transmission time, due to the fact that the tested transmission time includes entering the ISR

(to toggle an IO pin), delay introduced by isolators, transceivers, cables, and so forth. If changing to one data

line, the theoretical transmission speed is 100 Mbps, while the test speed is 80 Mbps with a transmission time of

2.1 µs.

Another finding from Figure 5-3 is that moving data from the FSIRX buffers to the FSITX buffers in the node

device takes some time, approximately 4.9 µs using the FSI driverLib functions. This will be a key factor that

distinguishes DMA control as shown in the next section.

Note

The time to move data between the FSI buffers and registers can be optimized by writing to and

reading from the FSI registers directly instead of using the provided driverLib functions.

14 Using the Fast Serial Interface (FSI) With Multiple Devices in an Application SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 15

www.ti.com

Daisy-Chain Topology Tests

Table 5-2. Data Frame Structure

IDLE Preamble SOF

1111 1001 0011 8 bits N words 8 bits 4 bits 0110 1111

Frame

Type User Data

Data

Words CRC Frame Tag EOF Postamble IDLE

Table 5-3. Calculated Transmission Time for 8 Words

Effective Data Bits

(bits) Overhead Bits (bits) Total Length (bits)

144 24 168 36 12 0.96

FSITXCLK Cycles

for Effective Data

Bits (cycles)

FSITXCLK Cycles

for Overhead Bits

(cycles)

Total Data

Transmission Time

(us)

5.1.2 DMA Control

• Test condition

Device 1 sends data -> Device 2 receives data -> Device 2 DMA moves RX data to TX buffer and registers ->

Device 2 triggers TX when TX_FRAME_TAG_UDATA FSI register is written to which forwards the received

data back to Device 1 -> Device 1 receives data back -> Device 1 DMA moves RX data to memory -> CPU

verifies data in memory matches the originally sent TX data.

• Test case

Data length of 8 words (8 words per burst, 1 burst per transfer), two data lines, TXCLK = 50 MHz, with Setting ②

(Table 5-1) enabled.

In this test, DMA interrupts from CH2 and CH4 are enabled to trigger at the end of a transfer in the lead device,

which means that interrupts occur every time data has been copied from memory to the FSITX buffer (CH2) or

data has been transferred out of the FSRX buffer to a location in memory (CH4). In the node device, the DMA

channels are configured to transfer received data from the RX buffers and registers to the TX buffers and

registers anytime an FSI data frame is received, ultimately forwarding the data back to the lead device.

Therefore the node device only has one DMA interrupt enabled while the lead device has two. With GPIOs

toggling in the DMA ISRs, Figure 5-4 shows the test results of FSI communication using DMA control.

Figure 5-4. FSI Communication Using DMA Control

SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Using the Fast Serial Interface (FSI) With Multiple Devices in an Application 15

Page 16

Daisy-Chain Topology Tests

www.ti.com

It should be noted that the time of 1.86 µs shown includes the time for the lead device to transmit the data frame,

the node device to move RX data to the TX buffer / registers, entering of the ISR, and toggling the GPIO.

According to the DMA pipeline timing requirements (See device specific TRM referenced in Section 7 for more

info), the time for moving data of 9 words (8 words data + 1 word of user data and frame tag) using 2 channels

can be calculated as shown in Equation 2.

( 9 × 3 c y c l e s / w o r d + 2 c y c l e s ) ÷ ( 100 M H z ) = 0 . 29 μ s (2)

Thus, considering other delay times, the actual transmission time is almost aligned with the former test result

(1.4 µs) using CPU control. Also, it should be highlighted that utilizing the DMA in this case drastically saves the

time for transferring received data, especially in an application with mass data transmissions..

Further test results are given in Table 5-4, for the comparison of using CPU control and DMA control of FSI. With

overhead bits being fixed in the FSI data frame structure, it is beneficial to use a longer data length to maximize

the effective data throughput.

Table 5-4. Comparison of Using CPU Control and DMA Control in FSI for Two Devices

CPU Control

DMA Control

FSITXCLK

(MHz) # of Data Lines

50 2 8 1.4 4.9 175 120

50 2 16 2.1 8.3 185 141

50 1 8 2.1 4.9 100 80

10 1 8 8.9 4.9 20 18.9

50 2 8 1.9 / /

50 2 16 3.0 / /

50 1 8 2.6 / /

10 1 8 9.3 / /

Data Length

(16-bit words)

Transmission

Time (µs)

(1)

Buffer Data

Move Time

(1)

(µs)

Theoretical

Transmission

Speed (Mbps)

Transmission

(2)

Speed (Mbps)

Test

(1) Measured times are rounded to the nearest 0.1 us.

(2) Accounts for FSI frame overhead bits being transmitted on both lines in the two data lines cases.

There may be cases where FSI communication may need some additional robustness and noise immunity and

for that reason a lower clock frequency has also been tested. The FSI protocol is designed to communicate only

when there is data exchange. This helps to reduce power and over all EMI in the system. Additionally, lower FSI

clock frequencies and half-duplex communication could improve overall system level EMI performance while

continuing to provide higher throughput than generic serial ports at the same operating frequencies. Generally, it

is best to use a twisted pair or shielded wire per line for board-to-board connections, while on board FSI signal

trace lengths should match and have special care taken in the layout to enhance noise immunity.

In the tests performed there are isolation and differential transceiver devices being used on the

TMDSFSIADAPEVM boards, which could introduce channel-to-channel skew. In a real world application that

utilizes these same or similar devices, and/or varying signal trace lengths, the integrated skew compensation

block within the FSI receiver module can be used to manage the skew that may occur between the clock and

data signals. For more information on this topic, see Fast Serial Interface (FSI) Skew Compensation.

16 Using the Fast Serial Interface (FSI) With Multiple Devices in an Application SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 17

www.ti.com

Daisy-Chain Topology Tests

5.2 Three Device FSI Communication

Based on the test and comparison results given in Section 5.1, FSI communication for three devices has also

been investigated. The test platform used is shown in Figure 5-5.

Figure 5-5. Test Platform for Three Devices Communication

Due to the nature of a daisy-chain connection, data will need to pass through a number of devices for the

transmission from the first device to reach the last device. Therefore, to reduce latency it is important to make

the data handling and forwarding time in each device as short as possible, especially when there are a number

of devices in a connection loop. From the conclusion drawn in Section 5.1, to avoid having the CPU spending

too much bandwidth moving data, it is recommended to use the DMA to serve FSI communication. The following

tests utilize the same software discussed in Section 5 for the lead and node devices.

• Test condition

Device 1 sends data -> Device 2 receives data -> Device 2 moves RX data to TX buffer and sends data to

Device 3->…..-> Device 3 moves RX data to TX buffer and sends data to Device 1 -> Device1 receives data

and verifies the data matches the originally sent TX data.

• Test case

Data length of 8 words, 1 data line, TXCLK = 50 MHz, with setting ① for CPU control case and ② for DMA

control case (Table 5-1) enabled.

In the tests, GPIOs are toggled within software when specific events occur during the communication and

measured using an oscilloscope to obtain the respective timing data. In the figures below, the green signal

represents the GPIO toggling of Device 1 (Lead device), the blue signal represents the GPIO toggling of Device

2 (Node device), and the magenta signal represents the GPIO toggling of Device 3 (Node device).

SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Using the Fast Serial Interface (FSI) With Multiple Devices in an Application 17

Page 18

Daisy-Chain Topology Tests

Figure 5-6. FSI Communication With CPU Control Among Three Devices

www.ti.com

Figure 5-7. Time of Data Going Through One Device - CPU Control

For the CPU control case, the time needed for the data transmission to complete the three device daisy-chain

loop is 16.2 µs, as shown in Figure 5-6. This time will increase by 7.1 us for each device added to the daisychain connection system, as shown in Figure 5-7. The 7.1 µs increased time per device includes the time for

transmission and moving RX data to the TX buffer and registers.

18 Using the Fast Serial Interface (FSI) With Multiple Devices in an Application SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 19

www.ti.com

Daisy-Chain Topology Tests

Figure 5-8. FSI Communication with DMA Control Among Three Devices

Figure 5-9. Time of Data Going Through One Device - DMA Control

For the DMA control case, the time needed for the data transmission to complete the three device daisy-chain

loop is 6.5 µs, as shown in Figure 5-8. This time will increase by 2.3 us for each device added to the daisy-chain

connection system, as shown in Figure 5-9. The 2.3 µs increased time per device includes the time for

transmission and moving RX data to the TX buffer and registers.

SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Using the Fast Serial Interface (FSI) With Multiple Devices in an Application 19

Page 20

Star Topology Tests

www.ti.com

Further test results can be found in Table 5-5.

Table 5-5. Comparison of Using CPU Control and DMA Control in FSI Among Three Devices

CPU control

DMA control

FSITXCLK (MHz) # of Data Lines

50 1 8 7.1 16.2

50 1 16 11.8 26.8

50 1 8 2.3 6.5

50 1 16 4.0 11.8

Data Length (16-bit

words)

Time of data going

through one device

(µs)

Time of the full

connection loop - 3

devices (us)

6 Star Topology Tests

The star topology over FSI application example demonstrates a different kind of communication topology,

showcasing how a central host device can receive information from multiple node devices at the same time

rather than wait for packets to be forwarded through subsequent devices, like in the daisy-chain example. The

advantages and disadvantages of the star topology are discussed in Section 2.

The defining requirements of the star implementation provided are hardware related, i.e. host device TX needing

to have multi-drop functionality to each node, and MCU resource related, i.e. host device needing N number of

RX instances. From a software perspective the central host device uses a new star_broadcast project while the

N node devices use the same node device software utilized in the daisy-chain tests, details provided in Table

6-1.

Table 6-1. Software Example Projects - Star Topology

Project Description Supported Devices

fsi_ex_star_broadcast Project for central host device in the star network F2838x

fsi_ex_daisy_handshake_node Project for N number of node devices in the star network F28002x, F28004x, F2838x

The software flow of the star_broadcast project is similar to that of the lead device CPU Control daisy-chain

project discussed in Section 5. The handshake mechanism will be slightly different as shown in Section 3.2.

Upon completion of the handshake, the central host device will transmit a broadcast data frame to all of the node

devices connected to its FSITX. The host will then wait to receive the data frame back from all connected node

devices and then validate that each received frame matches the originally transmitted one, after which it will

prepare and send a new data frame.

By default, the star_broadcast project has pre-made configurations for FSI RX instances A, B and C of the

device. Each instance can be configured by setting the individual pre-processor directives below to "1".

Additional FSI RX instances can be added if they are available on the host device.

//

// Enable FSI RX Instances

//

#define FSI_RXA_ENABLE 1

#define FSI_RXB_ENABLE 0

#define FSI_RXC_ENABLE 1

Timing measurements of the star topology will be very similar, if not the same, as those collected in the previous

daisy-chain tests. Therefore the data provided in Table 5-4 can be utilized for this purpose.

20 Using the Fast Serial Interface (FSI) With Multiple Devices in an Application SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Copyright © 2020 Texas Instruments Incorporated

Submit Document Feedback

Page 21

www.ti.com

References

7 References

• Texas Instruments: TMS320F28002x Microcontrollers Data Sheet

• Texas Instruments: TMS320F28002x Microcontrollers Technical Reference Manual

• Texas Instruments: TMS320F2838x Microcontrollers Data Sheet

• Texas Instruments: TMS320F2838x Microcontrollers Technical Reference Manual

• Texas Instruments: TMS320F28004x Microcontrollers Data Sheet

• Texas Instruments: TMS320F28004x Microcontrollers Technical Reference Manual

• Texas Instruments: TIDM-02006 Distributed multi-axis servo drive over fast serial interface (FSI) reference

design

• Texas Instruments: Distributed Power Control Architecture With Multiple MCUs Over FSI

• TMDSFSIADAPEVM: FSI Adapter Board

• F280025C ControlCARD Evaluation Modules

8 Revision History

NOTE: Page numbers for previous revisions may differ from page numbers in the current version.

Changes from September 00, 2020 to October 12, 2020 (from Revision B (September 2020) to

Revision C (October 2020)) Page

• Updates were made in the Abstract................................................................................................................0

• Updated the numbering format for tables, figures and cross-references throughout the document...................3

• Update was made to Section 1...........................................................................................................................3

SPRACM3C – SEPTEMBER 2020 – REVISED OCTOBER 2020

Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Using the Fast Serial Interface (FSI) With Multiple Devices in an Application 21

Page 22

IMPORTANT NOTICE AND DISCLAIMER

TI PROVIDES TECHNICAL AND RELIABILITY DATA (INCLUDING DATASHEETS), DESIGN RESOURCES (INCLUDING REFERENCE

DESIGNS), APPLICATION OR OTHER DESIGN ADVICE, WEB TOOLS, SAFETY INFORMATION, AND OTHER RESOURCES “AS IS”

AND WITH ALL FAULTS, AND DISCLAIMS ALL WARRANTIES, EXPRESS AND IMPLIED, INCLUDING WITHOUT LIMITATION ANY

IMPLIED WARRANTIES OF MERCHANTABILITY, FITNESS FOR A PARTICULAR PURPOSE OR NON-INFRINGEMENT OF THIRD

PARTY INTELLECTUAL PROPERTY RIGHTS.

These resources are intended for skilled developers designing with TI products. You are solely responsible for (1) selecting the appropriate

TI products for your application, (2) designing, validating and testing your application, and (3) ensuring your application meets applicable

standards, and any other safety, security, or other requirements. These resources are subject to change without notice. TI grants you

permission to use these resources only for development of an application that uses the TI products described in the resource. Other

reproduction and display of these resources is prohibited. No license is granted to any other TI intellectual property right or to any third

party intellectual property right. TI disclaims responsibility for, and you will fully indemnify TI and its representatives against, any claims,

damages, costs, losses, and liabilities arising out of your use of these resources.

TI’s products are provided subject to TI’s Terms of Sale (www.ti.com/legal/termsofsale.html) or other applicable terms available either on

ti.com or provided in conjunction with such TI products. TI’s provision of these resources does not expand or otherwise alter TI’s applicable

warranties or warranty disclaimers for TI products.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2020, Texas Instruments Incorporated

Loading...

Loading...