VBUS

VBUS

GND

HOST

bq24180

SW

PSEL

SCL

DCOUT

C1

1 µF

C2

10µF

C3

4.7µF

R3

4 kW

SYSTEM

PMID

SDA

D+

D-

USBPHY

BOOT

PGND

CSIN

CSOUT

VAUX

STAT

POWERFOR

ACCESSORY

C4

10nF

C 6

1 µF

C 5

0.1µF

RSNS

68 mW

R1

10kW

R2

VBUS

TS

TEMP

PACK+

PACK-

DRV

C7

1 µF

VBUS

INT

R4

C 8

1 µF

CD

HardwareDisable

10kW 10kW

bq24180

www.ti.com

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

Fully Integrated Switch-Mode One-Cell Li-Ion Charger with Full USB Compliance and

Accessory Power Connection

Check for Samples: bq24180

1

FEATURES

2

• Charge Faster than Linear Chargers From

Current Limited Input Sources • Programmable Charge Parameters through

• High-Accuracy Voltage and Current Regulation

– Input Current Regulation Accuracy: ±5%

(100mA, 500mA)

– Charge Voltage Regulation Accuracy:

±0.5% (25°C), ±1% (0–125°C)

– Charge Current Regulation Accuracy: ±5%

• Accessory Power Output (DCOUT)

• Input Voltage Based Dynamic Power

Management

• Safety Limit Register for Maximum Charge

Voltage and Current Limiting

• High-Efficiency Mini-USB/AC Battery Charger

for Single-Cell Li-Ion and Li-Polymer Battery

Packs

• 20-V Absolute Maximum and 16.5V Operation

Input Voltage Rating

• Built-in Input Current Sensing and Limiting

• Integrated Power FETs for Up to 1.5-A Charge

Rate

I2C™ compatible Interface (up to 3.4 Mbps)

• Synchronous Fixed-Frequency PWM

Controller Operating at 3 MHz With 0% to

99.5% Duty Cycle

• Safety Timer and Software Watchdog

• Reverse Leakage Protection Prevents Battery

Drainage

• Thermal Regulation and Protection

• Status Outputs for Charging and Faults

• 25-Pin WCSP Package

APPLICATIONS

• Mobile Phones and Smart Phones

• Portable Media Players

• Handheld Devices

DESCRIPTION

The bq24180 is a compact, flexible, high-efficiency, USB-friendly switch-mode charge management device for

single-cell Li-ion and Li-polymer batteries used in a wide range of portable applications. The charge parameters

is programmable using an I2C compatible interface. The bq24180 integrates a synchronous PWM controller,

power MOSFETs, input current sensing and overvoltage protection, high-accuracy current and voltage regulation,

and charge termination, into a small WCSP package.

1

2

2I

C is a trademark of Phillips Electronics.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 2010, Texas Instruments Incorporated

bq24180

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

www.ti.com

DESCRIPTION (CONTINUED)

The bq24180 charges the battery in three phases: conditioning, constant current and constant voltage. Charge

current is programmable using the I2C interface. Additionally, the input current can be limited to a host

programmable threshold to maintain maximum charge current from current-limited sources, such as USB ports.

Charge is terminated based on user-selectable minimum current level. A software watchdog provides a safety

backup for I2C interface while a safety timer prevents overcharging the battery. During normal operation,

bq24180 automatically restarts the charge cycle if the battery voltage falls below an internal threshold and

automatically enters sleep mode or high impedance mode when the input supply is removed. The charge status

is reported to the host using the I2C interface. During the charging process, the bq24180 monitors its junction

temperature (TJ) and reduces the charge current if TJincreases to 125°C. The bq24180 is available in 25-pin

WCSP package.

ORDERING INFORMATION

PART NUMBER

bq24180YFFR 16.5 V 6B

bq24180YFFT 16.5 V 6B

(1) The YFF package is available in the following options:

R – taped and reeled in quantities of 3,000 devices per reel.

T – taped and reeled in quantities of 250 devices per reel.

(2) This product is RoHS compatible, including a lead concentration that does not exceed 0.1% of total product weight, and is suitable for

use in specified lead-free soldering processes. In addition, this product uses package materials that do not contain halogens, including

bromine (Br) or antimony (Sb) above 0.1% of total product weight.

(1)(2)

V

OVP

I2C ADDRESS

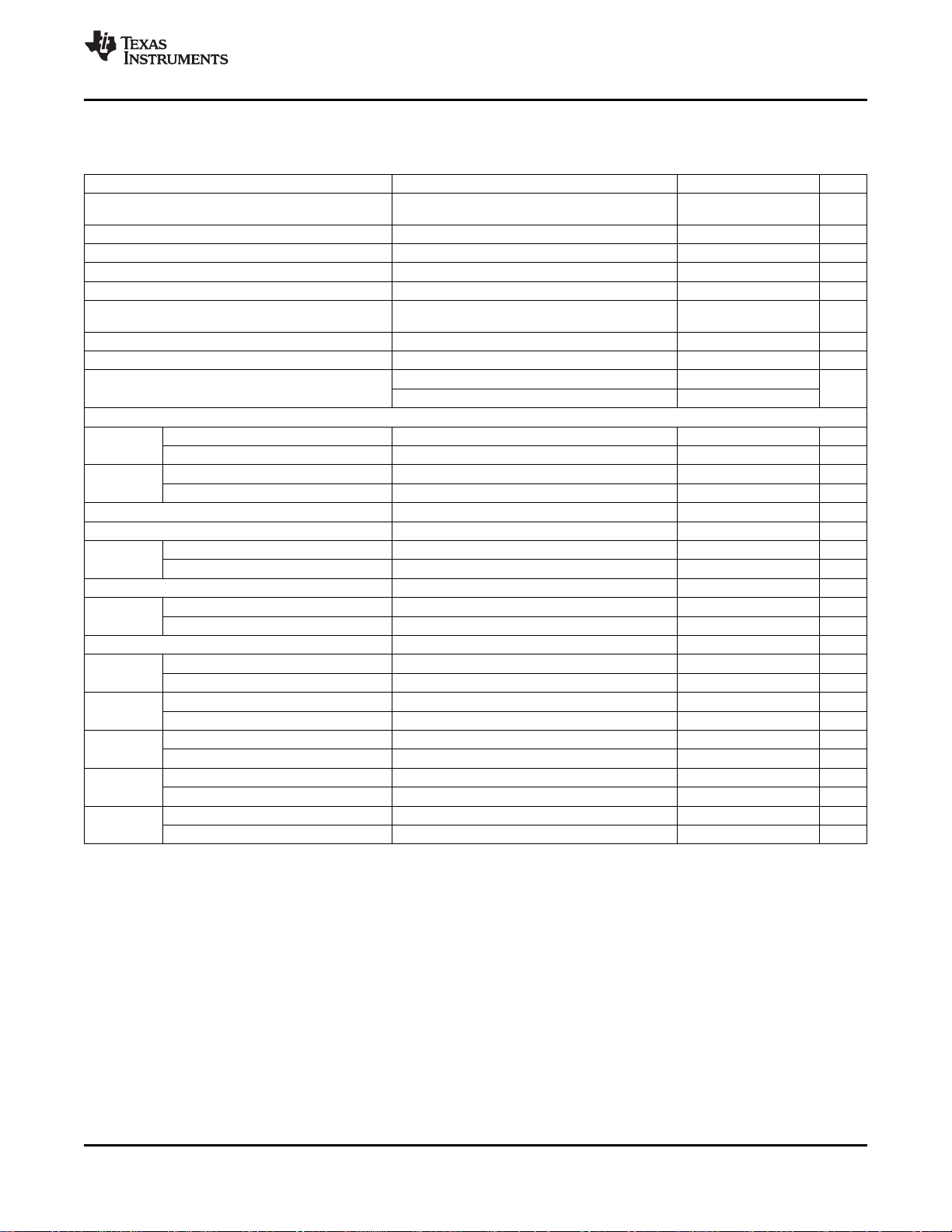

ABSOLUTE MAXIMUM RATINGS

(1)(2)

over operating free-air temperature range (unless otherwise noted)

LIMITS UNIT

Supply voltage range (with respect to PGND) VBUS –2 to 20 V

Input voltage range (with respect to and PGND) SCL, SDA, PSEL, CSIN, CSOUT, DRV, DCOUT, INT –0.3 to 7 V

Output voltage range (with respect to and PGND) V

Voltage difference between CSIN and CSOUT inputs (VCSIN –VCSOUT) ±7 V

Voltage difference between BOOT and SW inputs (VBOOT –VSW) –0.3 to 7 V

Output sink mA

Output current DCOUT 1.5 A

Output current (average) SW 2 A

T

A

T

J

T

stg

(1) Stresses beyond those listed under absolute maximum ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under recommended operating

conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

(2) All voltages are with respect to GND if not specified. Currents are positive into, negative out of the specified terminal. Consult Packaging

Section of the data book for thermal limitations and considerations of packages.

Operating free-air temperature range –30 to +85 °C

Junction temperature range –40 to +125 °C

Storage temperature –45 to +150 °C

PMID, STAT –0.3 to 20

SW, BOOT –0.7 to 20

INT 5

STAT 10

DRV 10 mA

2 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): bq24180

bq24180

www.ti.com

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

DISSIPATION RATINGS

PACKAGE R

WCSP-25 60°C/W

(1) Using JEDEC 2s2p PCB standard.

qJA

R

qJC

(1)

1.57°C/W 540 mW 5.4 mW/°C

TA< 25°C DERATING FACTOR

POWER RATING ABOVE TA= 25°C

RECOMMENDED OPERATING CONDITIONS

over operating free-air temperature range (unless otherwise noted)

MIN NOM MAX UNIT

Supply voltage, VBUS 4.0 16

Operating junction temperature range, T

J

0 125 °C

(1) The inherent switching noise voltage spikes should not exceed the absolute maximum rating on either the BOOT or SW pins. A tight

layout minimizes switching noise.

(1)

ELECTRICAL CHARACTERISTICS

Circuit of Figure 2, V

noted)

INPUT CURRENTS

I

VBUS

I

VBUS_LEAK

I

BAT_DCOUT

I

BAT_HIZ

VOLTAGE REGULATION

V

OREG

CURRENT REGULATION - FAST CHARGE

I

OCHARGE

PSEL, CD LOGIC LEVEL

V

IL

V

IH

CHARGE TERMINATION DETECTION

I

TERM

I

TERM_dgl

INPUT BASED DYNAMIC POWER MANAGEMENT

V

VBUS

Leakage current from battery to VBUS pin 0°C< TJ< 85°C, V

Battery Current when using DCOUT 800 µA

Battery discharge current in High Impedance

mode, (CSIN, CSOUT, SW pins)

Output charge voltage programmable range Operating in voltage regulation, programmable 3.5 4.44 V

Voltage regulation accuracy

Output charge current programmable range 550 1550 mA

Regulation accuracy for charge current V

across RSNS

V

IREG

Input low threshold level PSEL, CD falling 0.4 V

Input high threshold level PSEL, CD rising 1.2 V

Termination charge current 25 200 mA

Deglitch time for charge termination 30 ms

Regulation accuracy for termination current

across R

V

IREG_TERM

Battery Detection sink current before charge

done

= 5V, HZ_MODE=0, CD=0, TJ= –40°C to 125°C and TJ= 25°C for typical values (unless otherwise

VBUS

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

V

supply current for control V

VBUS

VBUS

> V

> V

, PWM switching 10 mA

VBUS(min)

, PWM NOT switching 5 mA

VBUS(min)

0°C< TJ< 85°C, EN=0 or HZ_MODE=1 650 µA

= 4.2 V, No input connected 5 µA

CSOUT

DCOUT = enabled, V

I

=750mA

DCOUT

0°C< TJ< 85°C, V

DCOUT disabled SCL,SDA=0V or 1.8V

= 4.2V, DCOUT_ILIM=1A,

BAT

= 4.2 V, No Input connected,

CSOUT

30 µA

0°C< TJ < 85°C, VCSOUT = 4.2 V, High Impedance

mode, DCOUT disabled, V

SCL,SDA=0V or 1.8V

= 5V, 60 µA

VBUS

TA= 25°C –0.5% 0.5%

–1% 1%

V

= I

OCHARGE

× R

SNS

≤ V

PRECHG

R

= 68 mΩ, Programmable

SNS

= 37.4 mV to 44.2 mV –3.5% 3.5%

ICHRG

V

> 44.2 mV –3.0% 3.0%

ICHRG

V

> V

CSOUT

R

= 68 MΩ, Programmable

SNS

< V

CSOUT

OREG–VRCH

OREG

, V

VBUS>VSLP

, V

VBUS>VSLP

,

,

Both rising and falling, 2-mV over- drive,

t

, t

= 100 ns

FALL

= 1.7 mV –40% 40%

TERM

= 3.4 mV to 6.8 mV –16% 16%

TERM

= 6.8 mV to 13.6 mV –11% 11%

TERM

≥ 13.6 mV –5.5% 5.5%

TERM

SNS

= I

OTERM

× R

SNS

RISE

V

V

V

V

–550 µA

V

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Link(s): bq24180

bq24180

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

ELECTRICAL CHARACTERISTICS (continued)

Circuit of Figure 2, V

noted)

V

IN_DPM

FAULTY ADAPTER PROTECTION

V

VBUS (MIN)

t

INT

INPUT CURRENT LIMITING

I

IN_LIMIT

DCOUT

R

DCOUT

I

LIM_DCOUT

t

DGL_DCOUT

I

LIM_DCOUT

BATTERY RECHARGE THRESHOLD

V

RCH

STAT OUTPUTS

V

OL(STAT)

V

OL(INT)

I2C BUS LOGIC LEVELS AND TIMING CHARACTERISTICS

V

OL

I

(bias)

f

SCL

SLEEP COMPARATOR

V

SLP

V

SLP-EXIT

UVLO

V

UVLO

V

UVLO_HYS

PWM

The threshold when input based DPM loop

kicks in

DPM loop kick-in threshold tolerance –2% 2%

Faulty adapter threshold 3.6 3.8 4.0 V

Deglitch time for Faulty adapter 30 ms

Hysteresis for faulty adapter protection V

Current source for faulty adapter protection 20 30 40 mA

Detection Interval 2 s

Input current limiting threshold I

DCOUT Pass FET on-resistance I

DCOUT current limit programmable range 350 1400 mA

Deglitch time from DCOUT current-limit event

to DCOUT latch-off

DCOUT current limit range mA

Recharge threshold voltage Below VOREG 100 120 150 mV

Deglitch time 130 ms

Low-level output saturation voltage, STAT IO= 10 mA, sink current 0.5 V

High-level leakage current Voltage on STAT pin is 5V 1 µA

Low-level output saturation voltage, INT IO= 1 mA, sink current 0.4 V

High-level leakage current Voltage on INT pin is 5V 1 µA

Output low threshold level IO= 10 mA, sink current 0.4 V

Input low threshold level V

Input high threshold level V

Input bias current V

SCL clock frequency 3.4 MHz

Sleep-mode entry threshold,

V

BUS-VCSOUT

Sleep-mode exit hysteresis 2.3 V ≤ V

Deglitch time for VBUS rising above

V

SLP+VSLP_EXIT

IC active threshold voltage V

IC active hysteresis V

Internal top reverse blocking MOSFET

on-resistance

Internal top N-channel Switching MOSFET

on-resistance

= 5V, HZ_MODE=0, CD=0, TJ= –40°C to 125°C and TJ= 25°C for typical values (unless otherwise

VBUS

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Charge mode, programmable 4.15 4.71 V

Rising 100 200 mV

VBUS

USB charge mode, current

pulled from PMID

= 500 mA 300 mΩ

DCOUT

Programmable via I2C

Programmable via I2C

V

decreasing below threshold,

CSOUT

t

= 100 ns, 10-mV overdrive

FALL

= 1.8 V, SDA and SCL 0.4 V

(pull-up)

= 1.8 V, SDA and SCL 1.2 V

(pull-up)

= 1.8 V, SDA and SCL 1 µA

(pull-up)

2.3 V ≤ V

CSOUT

CSOUT

Rising voltage, 2-mV over drive, t

rising 3.05 3.3 3.55 V

VBUS

falling from above V

VBUS

I

= 500 mA, Measured from V

IN_LIMIT

Measured from PMID to SW 130 250 mΩ

≤ V

< V

OREG

OREG

I

= 100 mA 90 95 100

IN_LIMIT

= 500 mA 450 475 500 mA

IN_LIMIT

I

= 800 mA 700 755 800

IN_LIMIT

14.5 ms

I

LIM_DCOUT

I

LIM_DCOUT

I

LIM_DCOUT

I

LIM_DCOUT

, V

falling 0 40 100 mV

VBUS

= 350mA 270 350

= 750mA 650 750

= 1050mA 800 1050

= 1400mA 1050 1400

140 200 260 mV

= 100 ns 30 ms

RISE

UVLO

to PMID 110 210 mΩ

VBUS

120 150 mV

www.ti.com

4 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): bq24180

bq24180

www.ti.com

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

ELECTRICAL CHARACTERISTICS (continued)

Circuit of Figure 2, V

noted)

Internal bottom N-channel MOSFET

on-resistance

f

OSC

D

MAX

D

MIN

V

DRV

I

DRV

V

DO_DRV

PROTECTION

V

OVP

V

IN_HIGH

t

OVP-dgl

I

LIMIT

V

PRECHG

I

PRECHG

T

SHTDWN

T

CF

t

WATCHDOG

V

HOT

V

WARM

V

COLD

I

TS

(1) Bottom N-channel MOSFET always turns on for ~60 ns and then turns off if current is too low.

Oscillator frequency 3.0 MHz

Frequency accuracy –10% 10%

Maximum duty cycle 99.5%

Minimum duty cycle 0

Synchronous mode to non-synchronous

mode transition current threshold

Internal bias voltage regulator I

DRV Output Current External load on DRV 10 mA

DRV Dropout Voltage (V

Input OVP threshold voltage Threshold over V

V

hysteresis V

OVP

Input High threshold V

VIN_HIGH_USB hysteresis V

OVP deglitch time V

Cycle-by-cycle current limit for charge Charge mode operation 1.8 2.4 3.0 A

Precharge to fast charge threshold V

VPRECHG hysteresis V

Precharge charge charging current V

Thermal trip 165 °C

Thermal hysteresis 10 °C

Thermal regulation threshold Charge current begins to taper down 120 °C

Timeout for the watchdog timer Watchdog timer 12 s

Safety timer accuracy –20% 20%

TS Hot Threshold Corresponds to 55°C, VTSFalling 0.153 0.160 0.169 V

TS Hot Threshold Hysteresis VTS Rising 12.5 mV

TS Warm Threshold Corresponds to 45°C VTSFalling 0.210 0.225 0.240 V

TS Warm Threshold Hysteresis VTSRising 12.5 mV

TS Cold Threshold Corresponds to 5°C, VTSRising 1.06 1.10 1.14 V

TS Cold Threshold Hysteresis VTSFalling 75 mV

TS Bias Current 95 100 105 µA

TS Open Resistance Resistance on TS that translates to open circuit on TS 200 kΩ

= 5V, HZ_MODE=0, CD=0, TJ= –40°C to 125°C and TJ= 25°C for typical values (unless otherwise

VBUS

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Measured from SW to PGND 125 210 mΩ

Low-side MOSFET cycle-by-cycle current sensing 100 mA

= 10 mA 5 5.2 5.45 V

DRV

I

= 1A, V

VBUS

V

< V

UVLO

falling from above V

VBUS

Rising, Threshold where I

VBUS

falling from above V

VBUS

rising or falling 32 ms

VBUS

rising 1.9 2.0 2.1 V

CSOUT

falling from above V

CSOUT

≤ V

CSOUT

VBUS

VBUS<VSLP

VBUS

and V

SHORT

= 5 V, I

= 10 mA 340

DRV

to turn off converter during charge 16 16.5 17 V

OVP

falls to 50 mA 9.5 9.8 10.1 V

BAT

IN_HIGH

PRECHG

< V

IN_HIGH

VBUS

< V

OVP

VBUS

(1)

– V

) mV

DRV

750

185 mV

150 mV

100 mV

33.5 50.0 66.5 mA

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Link(s): bq24180

VBUS

SW

+

+

BOOT

DRV

VDRV

CSIN

CSOUT

V

PRECHG

+ -

+

InputCurrentLimit

Amplifier

INT

+

+

+

REF

TS

TSHOT

TSWARM

TSCOLD

DISABLE

V

PRECHG

Comparator

+

V

BATREG

Amplifier

PMID

DC-DC

CONVERTER

PWMLOGIC

AND

COMPENSATION

400mA

maxcharge

V

OREG

I

IN_LIMIT

Gm

amp

I

OUTREG

Amplifier

Charge

Pump

+

Sleep

Comparator

V

BAT

V

IN

5.2V

Reference

+

Recharge

Comparator

Termination

Comparator

I2Cand

CHARGE

CONTROLLER

PGND

PSEL

SDA

SCL

DCOUT

+

V

IN

50mA Precharge

CurrentSource

-

+

130mV

V

ICHRG

V

ITERM

VDRV

Charge

Pump

+

16.5V

OVP

Comparator

High-Input

Comparator

9.8V

+

VIN-DPM

Amplifier

V

INDPM

V

HIGH

Comparator

+

DCOUT _ILIM

TMR

SAFETY

TIMERS

2X

TIMER

FAULT

Q1

Q2

Q3

Q4

Q5

REF

100uA

+

+

ThermalReg

Amplifier

125°C

T

J

STAT

CD

bq24180

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

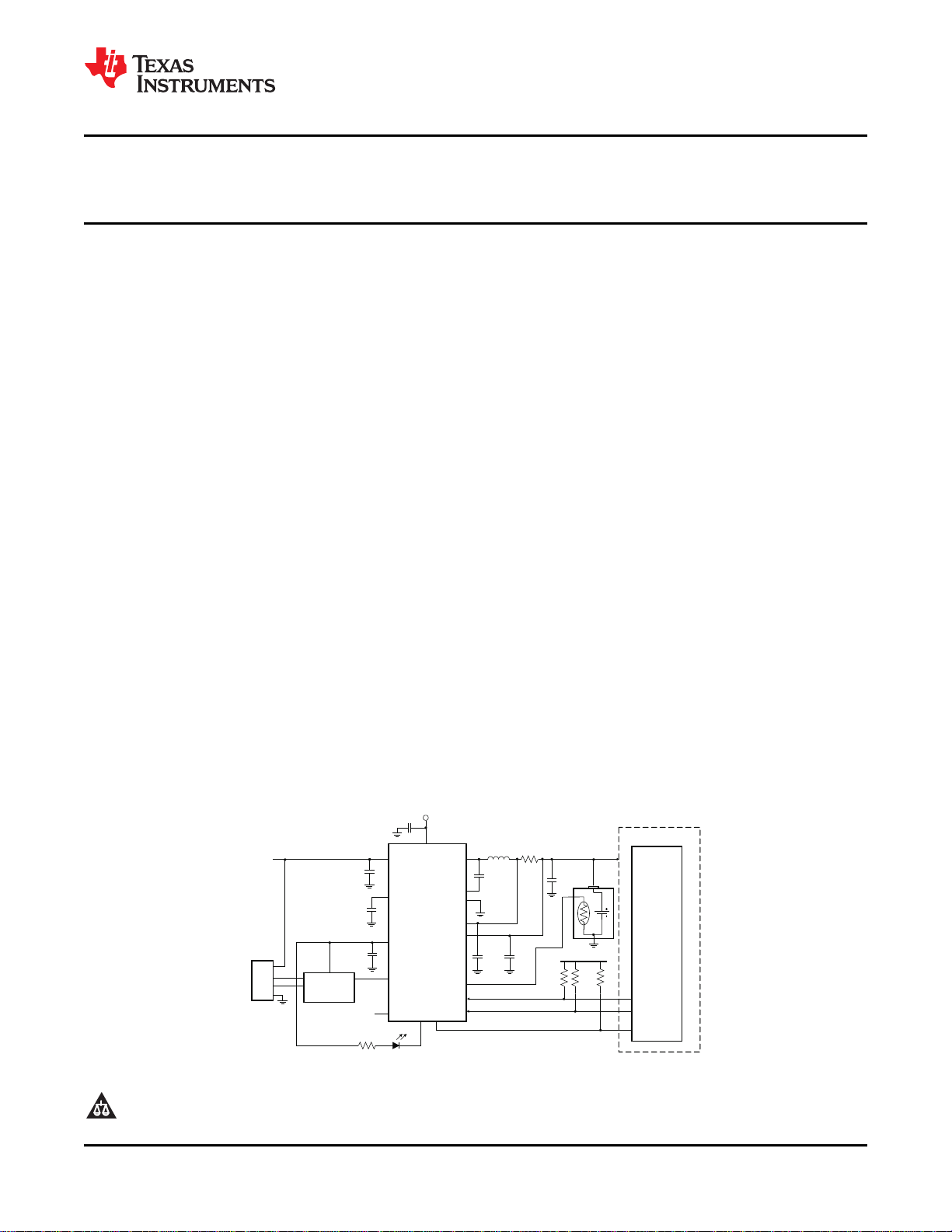

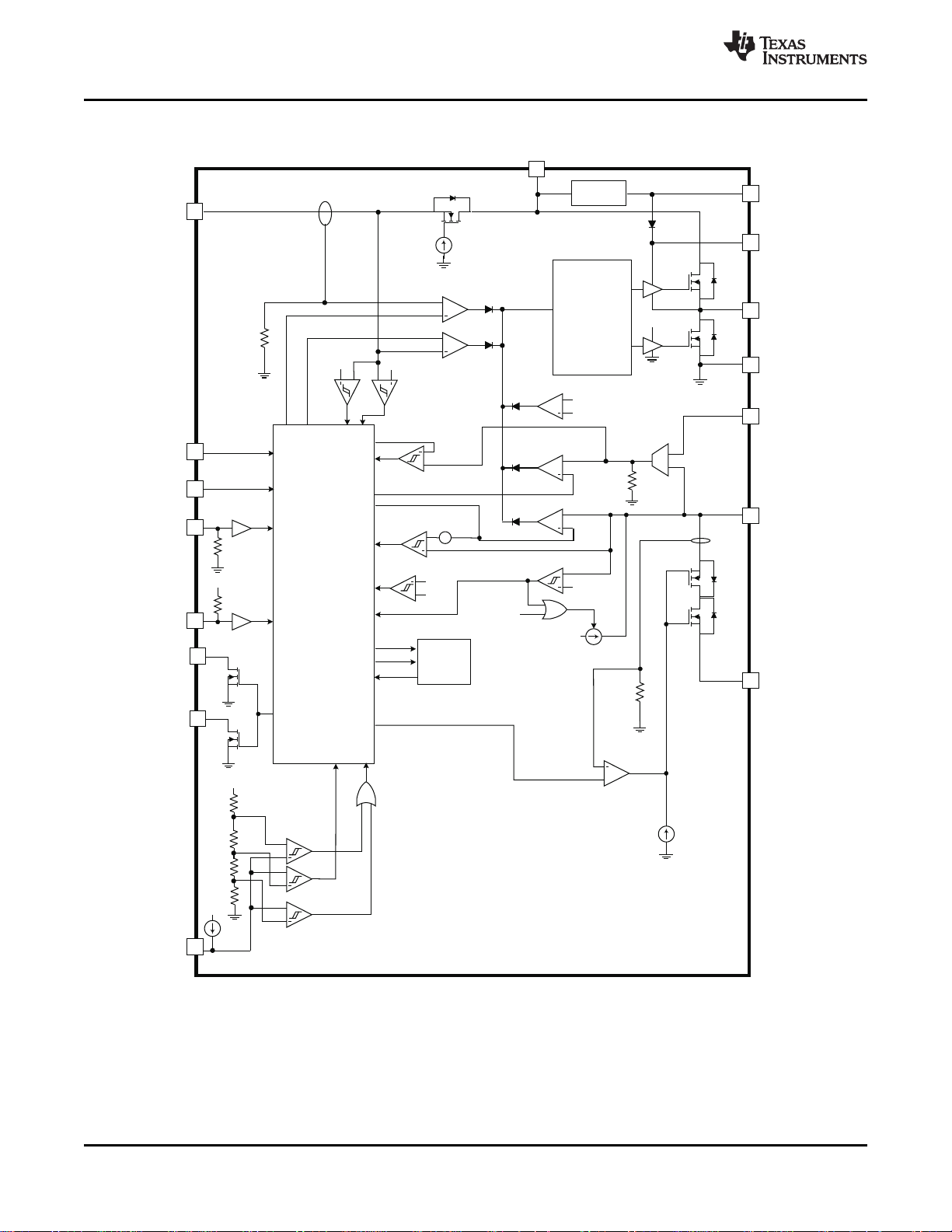

SIMPLIFIED BLOCK DIAGRAM

www.ti.com

6 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Figure 1. Simplified Block Diagram

Product Folder Link(s): bq24180

VBUS VBUS BOOT SCL

PMID PMID PMID CD

SW SW SW PSEL

PGND PGND PGND

STAT

DRV

DCOUT

CSIN CSOUT

SDA

INT

DCOUT

CSOUTTS

1 2 3 4 5

A

B

C

D

E

2.2mmx2.4mm25-pinWCSP

TOP VIEW

bq24180

www.ti.com

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

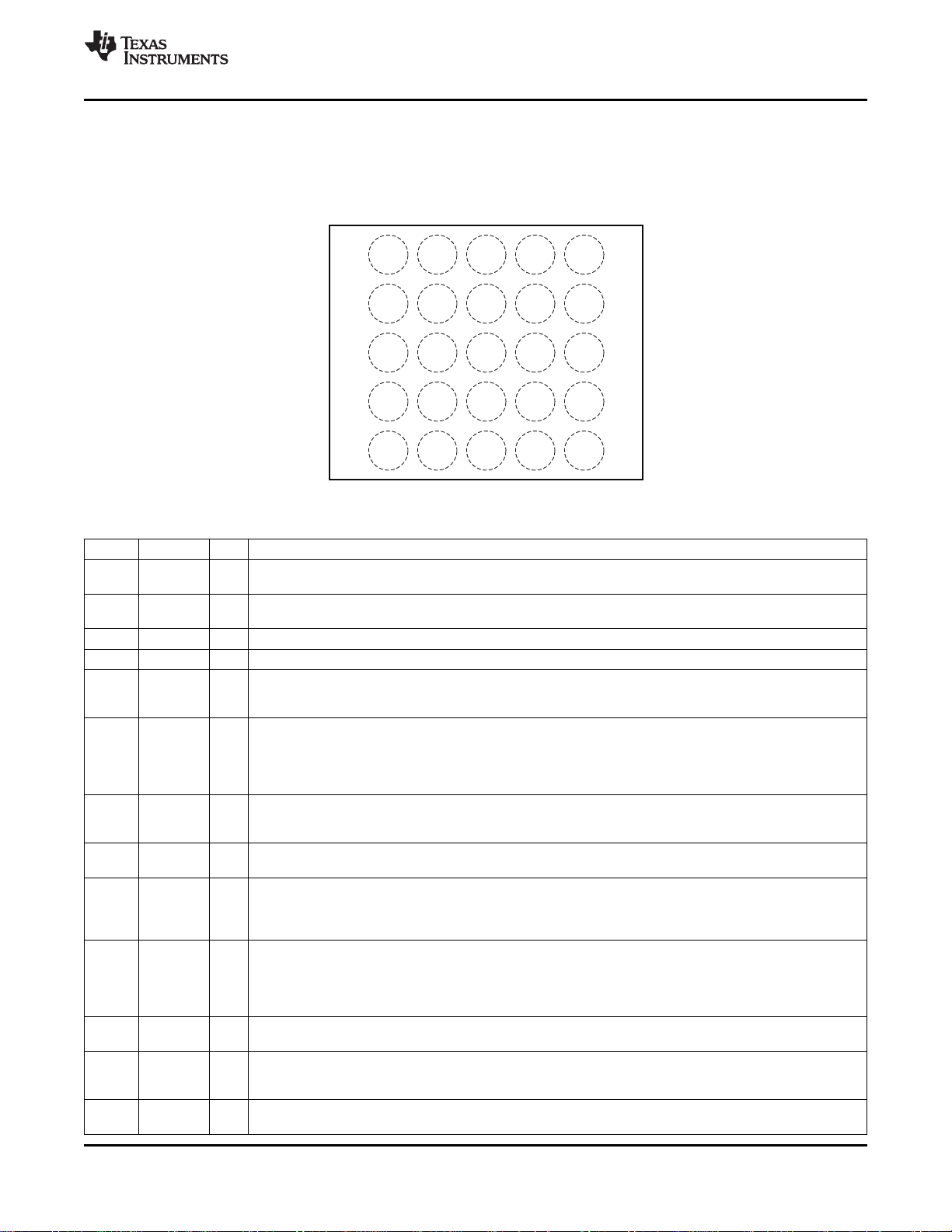

DEVICE INFORMATION

PIN CONFIGURATION

PIN FUNCTIONS

NAME PIN NO. I/O DESCRIPTION

VBUS A1, A2 I/O Charger Input Voltage. Connect to an input supply up to 16V. Bypass VBUS to PGND with a 1µF ceramic

BOOT A3 O High-Side MOSFET Gate Driver Supply. Connect a 10nF ceramic capacitor (voltage rating above 10V) from

SCL A4 I I2C interface clock. Connect SCL to the logic rail through a 10kΩ resistor.

SDA A5 I/O I2C interface data. Connect SCL to the logic rail through a 10kΩ resistor.

PMID B1, B2, B3 O Connection Point Between Reverse Blocking MOSFET and High-Side Switching MOSFET. Bypass PMID to

INT B4 O Host Interface Status Output. INT is a low voltage open drain output used to signal charge status to the host

CD B5 O Hardware Disable Input. Connect CD to GND to enable charge. Drive CD high to disable charge and place

SW C1, C2, O Inductor Connection. Connect the switched side of the inductor to SW.

C3

PSEL C4 I USB Source Detection Input. Drive PSEL high to indicate a USB source is connected to the input and the PC

STAT C5 O Status Output. STAT is an open drain output that is pulled low during charging. When charging is complete or

PGND D1, D2, Power ground. Connect to the ground plane for the circuit.

D3

DCOUT D4, D5 O Accessory Power Output. DCOUT is connected to the battery through an internal pass FET. When enabled

CSIN E1 I Charge Current-Sense Input. Battery current is sensed via the voltage drop across an external sense resistor.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 7

capacitor.

BOOT pin to SW pin to supply the gate drive for the high side MOSFET.

PGND with a minimum of 3.3µF ceramic capacitor. Use caution when connecting an external load to PMID.

The PMID output is not current limited. Any short on PMID will result in damage to the IC.

processor. INT is pulled low during charging. When charging is complete or when charging is disabled, INT is

high impedance. When a fault occurs, a 128µs pulse is sent out as an interrupt for the host. INT is

enabled/disabled using the EN_STAT bit in the control register. Connect INT to a logic rail through a 10kΩ

resistor to communicate with the host processor.

the bq24180 into high impedance mode. Toggling CD resets the safety timer when in DEFAULT mode, but

does not reset the timer when in host mode. CD is pulled to PGND through a 100kΩ internal resistor.

mode default values should be used. When PSEL is high, the IC starts up with a 100mA input current limit.

Drive PSEL low to indicate that an AC Adapter is connected to the input. When PSEL is low, the IC starts up

with no input current limit and a 1A charge current. PSEL has an internal 100kΩ pullup resistor.

when charging is disabled, STAT is high impedance. When a fault occurs, a 128µs pulse is sent out as an

interrupt for the host. STAT is enabled/disabled using the EN_STAT bit in the control register. Connect STAT

to a logic rail using an LED for visual indication or through a 10kΩ resistor to communicate with the host

processor.

through I2C, DCOUT is connected to the battery. When disabled, DCOUT is high-impedance. Bypass DCOUT

to PGND with at least a 1µF ceramic capacitor.

Bypass CSIN to PGND with a 0.1µF ceramic capacitor.

Product Folder Link(s): bq24180

bq24180

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

www.ti.com

PIN FUNCTIONS (continued)

NAME PIN NO. I/O DESCRIPTION

TS E2 I Battery Pack NTC Monitor. Connect TS to a 4.7kΩ NTC thermistor. During DEFAULT mode, when VTS>

DRV E3 O Gate Drive Supply. DRV is the supply for the gate drive of the internal MOSFETs. Bypass DRV to PGND with

CSOUT E4, E5 I Battery voltage and Current Sense Input. Connect to the positive terminal of the battery pack. CSOUT is also

V

or VTS<V

COLD

reported by the I2C interface. During host mode, the TS function is active, but does not affect charging. The

charging is suspended. If V

HOT

HOT

< VTS< V

charging current is reduced. The faults are

WARM

faults are only reported by the I2C interface.

a 1µF ceramic capacitor. DRV may be used to drive external loads up to 10mA. DRV is active whenever the

input is connected.

the supply for the DCOUT output. Bypass CSOUT to PGND with 1µF ceramic capacitor.

8 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): bq24180

VBUS

VBUS

GND

HOST

bq24180

SW

PSEL

SCL

DCOUT

C1

1 µF

C2

10 µF

C3

4.7 µF

R3

4 kW

SYSTEM

PMID

SDA

D+

D-

USBPHY

BOOT

PGND

CSIN

CSOUT

VAUX

STAT

POWERFOR

ACCESSORY

C4

10 nF

C6

1 µF

C5

0.1 µF

RSNS

68 mW

R1

10kW

R2

VBUS

TS

TEMP

PACK+

PACK-

DRV

C7

1 µF

VBUS

INT

R4

C8

1µF

CD

HardwareDisable

10kW

10kW

bq24180

www.ti.com

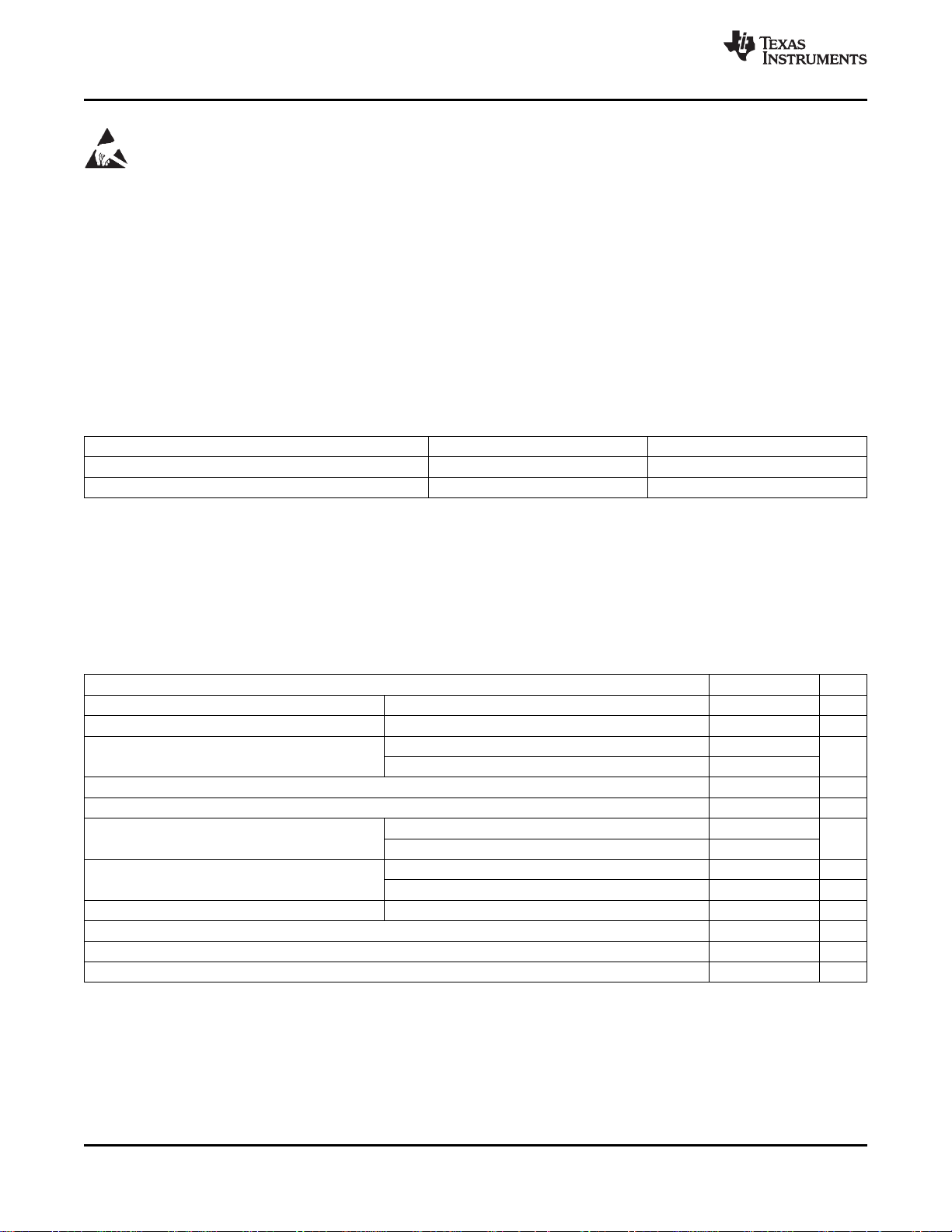

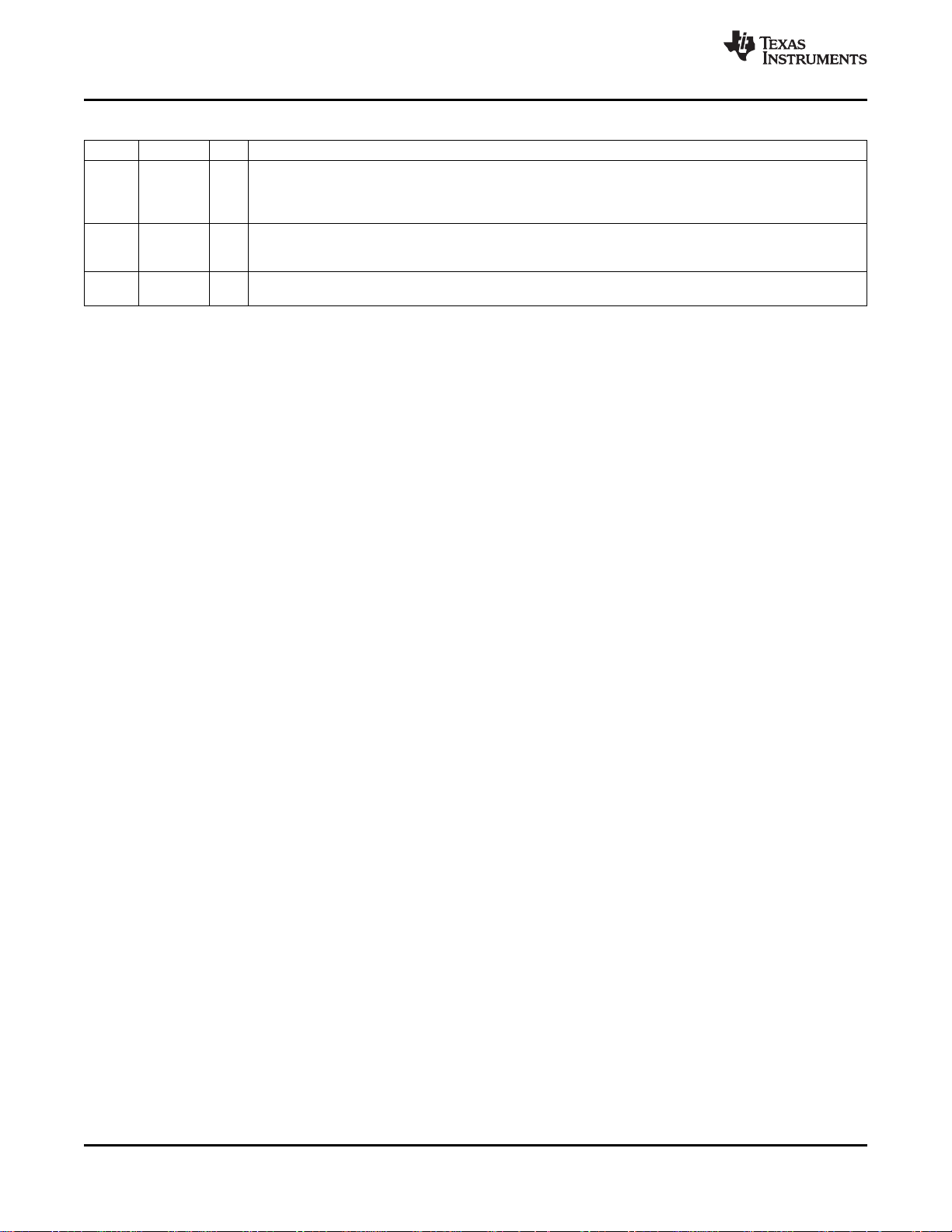

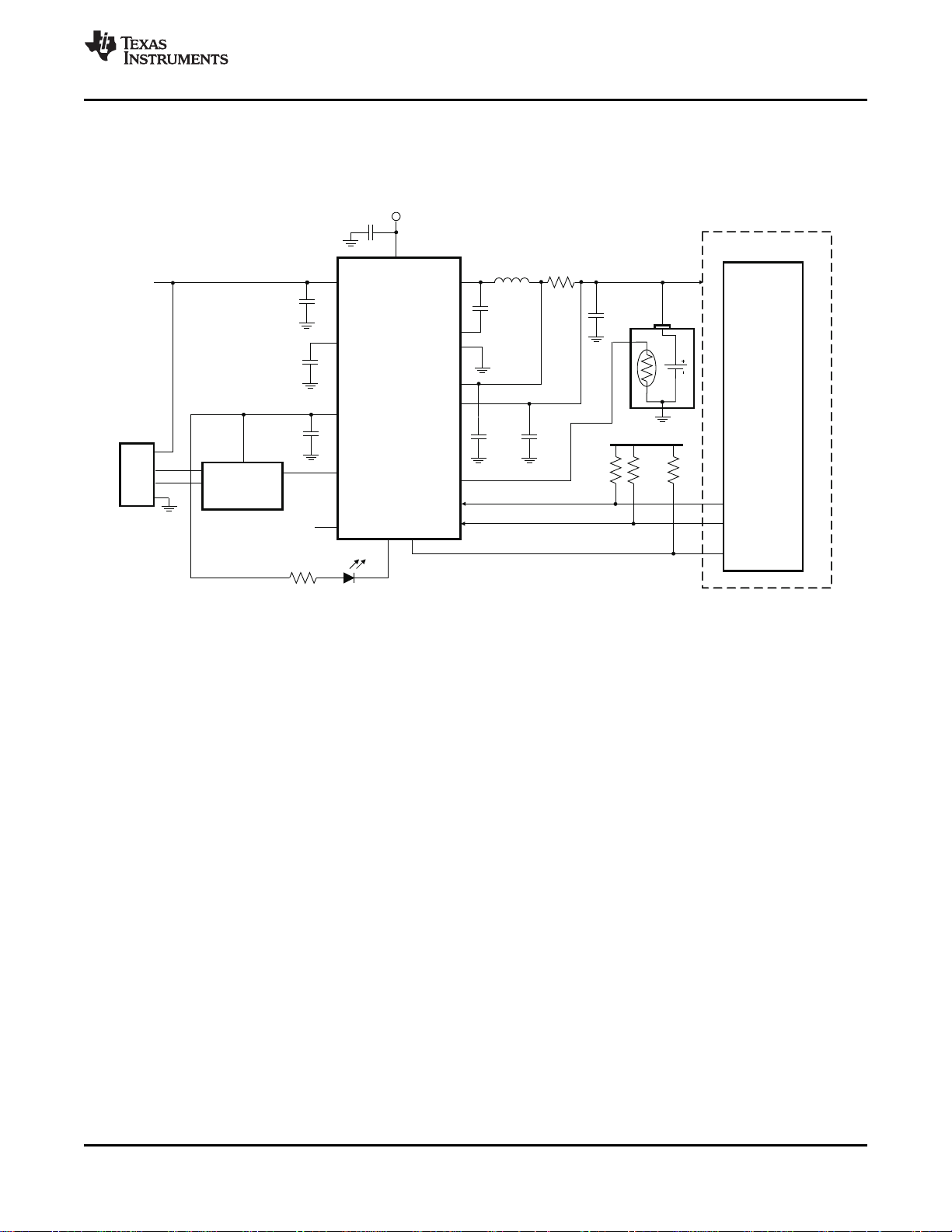

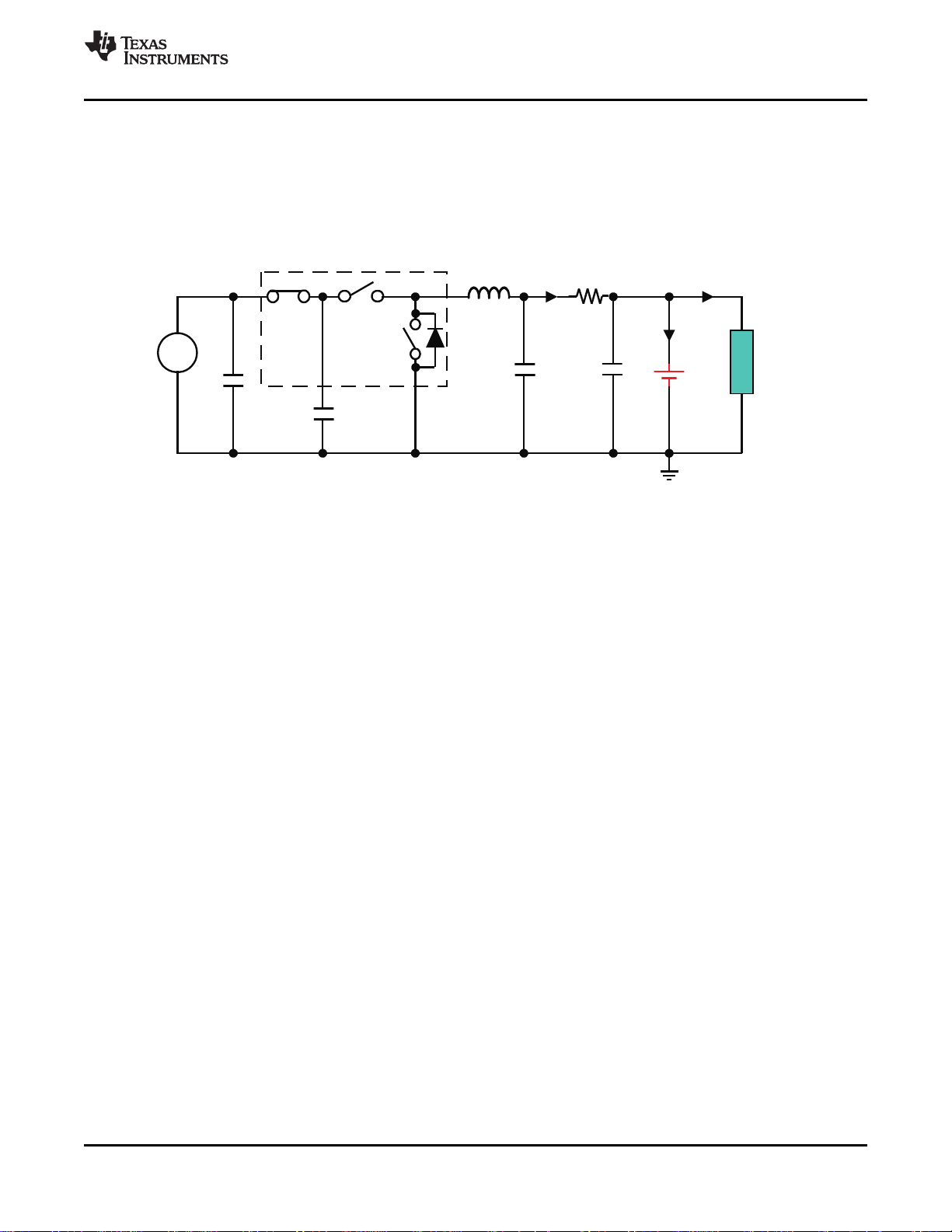

TYPICAL APPLICATION CIRCUITS

VBUS = 5V, I

IN_LIMIT

12 seconds watchdog

= 500mA, I

CHARGE

= 1A, V

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

= 3.5--4.44V (Adjustable), Safety Timer = 27 minute default w/

BAT

Figure 2. I2C Controlled 1-Cell USB Charger Application Circuit

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Link(s): bq24180

t-Time-4ms/div

V

VBUS

V

BAT

I

OUT

V

INT/ STAT

5V/div

500mA/div

5V/div

2V/div

“NoBattery” FaultInterrupt

V

BAT

I

OUT

V

INT/ STAT

5V/div

200mA/div

2V/div

t-Time-2s/div

t-Time-4ms/div

V

VBUS

V

INT/ STAT

20mA/div

1V/div

2V/div

V

VBUS

<3.8V

"Faulty Adapter"FaultInterrupt

I

VBUS

t-Time-4ms/div

V

VBUS

V

BAT

I

OUT

V

INT/ STAT

5V/div

500mA/div

5V/div

2V/div

V

VBUS

V

INT/ STAT

20mA/div

1V/div

2V/div

t-Time-1s/div

I

VBUS

"Faulty Adapter"FaultInterrupt

V

SW

I

L

500mA/div

2V/div

t-Time-2 s/divm

V =5V,

V =3.6V

VBUS

BAT

bq24180

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

TYPICAL CHARACTERISTICS

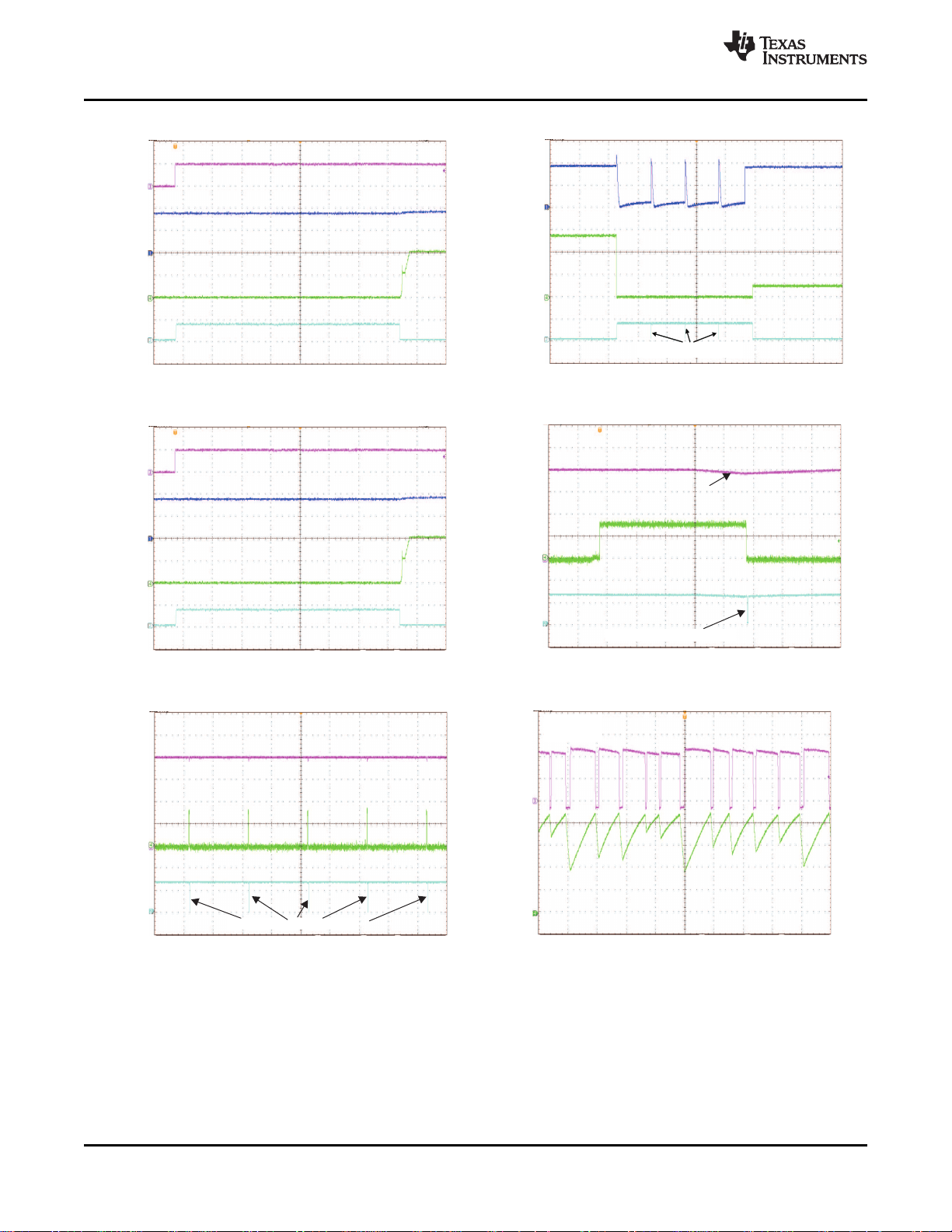

Figure 3. Adapter Insertion Figure 4. Battery Insertion/Removal

www.ti.com

Figure 5. PWM Charging Waveforms Figure 6. Faulty Adapter Detection

Figure 7. Faulty Adapter Detection Figure 8. Cycle by Cycle Current Limit

(Showing Continuous Detection)

Product Folder Link(s): bq24180

10 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

I

VBUS

V

SW

V

BAT

1V/div

200mA/div

2V/div

t-Time-400 s/divm

I

VBUS

V

SW

1V/div

200mA/div

2V/div

t-Time-400 s/divm

V

BAT

V

SCL

I

OUT

200mA/div

1V/div

t-Time-200 s/divm

I

VBUS

V

SW

V

BAT

1V/div

200mA/div

2V/div

t-Time-400 s/divm

V

PSEL

V

BAT

200mA/div

1V/div

2V/div

t-Time-1ms/div

I

VBUS

V

VBUS

V

BAT

50mA/div

2V/div

1V/div

t-Time-10ms/div

I

VBUS

Faulty Adapter

Detection

bq24180

www.ti.com

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

TYPICAL CHARACTERISTICS (continued)

Figure 9. Input Current Limit Transition Figure 10. Input Current Limit Transition

USB500 to USB100 USB100 to USB500

Figure 11. Input Current Limit Transition Figure 12. Charge Current Transition

USB500 to 750mA

Figure 13. Startup Into Default Mode Figure 14. PSEL Transition

No Battery Connected

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Link(s): bq24180

550mA to 1.05A Using I2C

I

DCOUT

V

DCOUT

500mA/div

1V/div

t-Time-4ms/div

R =11 to1 ,

V =4V

LOAD

BAT

W W

I

VBUS

V

CD

V

BAT

1V/div

200mA/div

2V/div

t-Time-10ms/div

I

DCOUT

V

DCOUT

500mA/div

1V/div

t-Time-2ms/div

I

SW

I

OUT

5V/div

500mA/div

10V/div

t-Time-10 s/divm

V

VBUS

V

VBUS

=5.5Vto17V

V

SW

5V/div

500mA/div

5V/div

t-Time-10 s/divm

V

VBUS

I

OUT

TrickleCharge

USB100

V

VBUS

=5.5Vto10.5V

100

150

200

250

300

350

400

-40 -20 0 20 40 60 80 100 120 140

V -V

DO(VBUS-DRV)

T -Free-AirTemperature-°C

A

V =5V,

I =1 A,

I =10mA

VBUS

VBUS

DRV

bq24180

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

TYPICAL CHARACTERISTICS (continued)

Figure 15. Enable/Disable Using CD Figure 16. DCOUT OCP Response

www.ti.com

Figure 17. Hotplug 1000µF Capacitor into DCOUT Figure 18. OVP Response

12 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Figure 19. VINHIGH Response Figure 20. DRV Dropout vs T

A

Product Folder Link(s): bq24180

V

VBUS

V

DRV

2V/div

t-Time-2ms/div

2V/div

V

VBUS

=0Vto5.5Vto0V

I

DRV

10mA/div

t-Time-20 s/divm

V

DRV

5.1VOffset

10mV/div

0

10

20

30

40

50

60

70

80

90

100

0.01 0.1 1 10

Current- A

Efficiency-%

V

VBUS

=5V

V =3.5V

OUT

V =4.45V

OUT

5.05

5.07

5.09

5.11

5.13

5.15

0 1 2 3 4 5 6 7 8 9 10

I -mA

DRV

V -V

DRV

V =5.5V

BUS

bq24180

www.ti.com

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

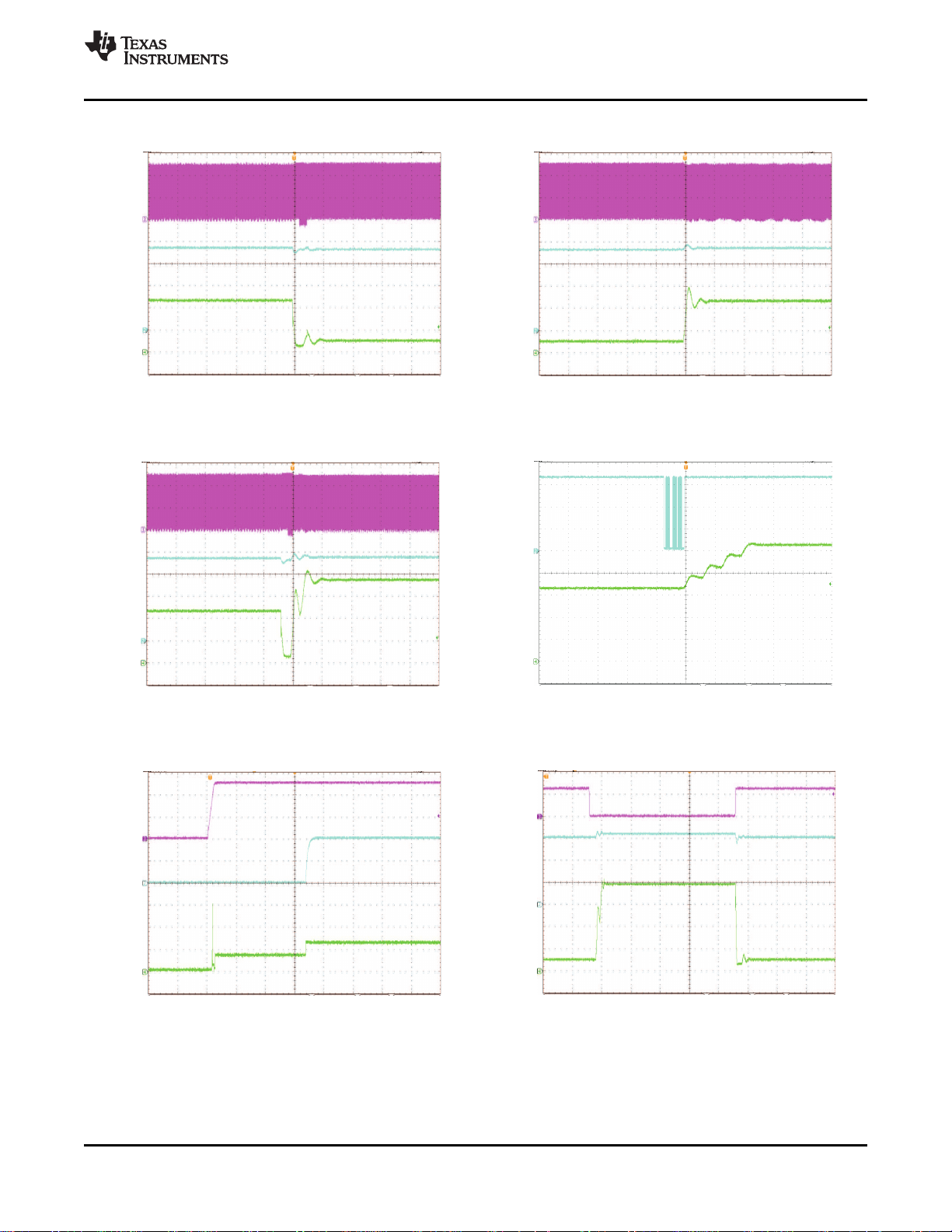

TYPICAL CHARACTERISTICS (continued)

Figure 21. DRV Startup/Shutdown Figure 22. DRV Load Transient

Figure 23. DRV Load Regulation Figure 24. Charger Efficiency

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Link(s): bq24180

VUVLO < VIN < VOVP?

Yes

No

VBAT > 2V?

Yes

Enable 50mA

prechargecurrent

STAT = 0

No

BeginSafety Timer

V

HIGH<VIN<VOVP

No

Enable 50mA

prechargecurrent

Timer 2x

STAT = 0

Yes

Good Adapter

connected?

No

AdapterPlugIN

Watchdog TimerExpired

andNot Active, noactive

hostcommunication

Yes

BeginDEFAULT

ModeBattery

ChargeCycle

Wait 2s

bq24180

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

www.ti.com

DETAILED DESCRIPTION

The bq24180 is a highly integrated synchronous switch-mode charger featuring integrated MOSFETs and small

external components, targeted at extremely space-limited portable applications powered by 1-cell Li-Ion or

Li-polymer battery pack. For current limited power source, such as a USB host or hub, the high efficiency

converter is critical in fully utilizing the input power capacity and quickly charging the battery. Due to the high

efficiency in a wide range of the input voltage and battery voltage, the switching mode charger is a good choice

for high speed charging with less power loss and better thermal management.

The bq24180 has two operation modes: charge mode and high impedance mode. In charge mode, the bq24180

supports a precision Li-ion or Li-polymer charging system for single-cell applications. In high impedance mode,

the bq24180 stops charging and operates in a mode with very low current from IN and battery, to effectively

reduce the power consumption when the portable device in standby mode. Through proper control, bq24180

achieves the smooth transition among different operation modes.

Charge Mode Operation

14 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Figure 25. Startup on Adapter Plug-In in DEFAULT Mode

Product Folder Link(s): bq24180

VUVLO < VIN < VOVP?

Yes

No

VBAT > 2V?

Enable 50mA

prechargecurrent

STAT = 0

No

/CEbit = 0?

No

Yes

BeginSafety Timer

V

HIGH<VIN<VOVP

No

Enable 50mA

prechargecurrent

Timer 2x

STAT = 0

Yes

Good Adapter

connected?

AdapterPlugIN

Watchdog Active

ActiveHost

Communication

Yes

BeginHOST

ModeBattery

Charging

Hi-Zbit = 0?

Yes

No

Wait 2s

No

EnableHi-ZMode

bq24180

www.ti.com

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

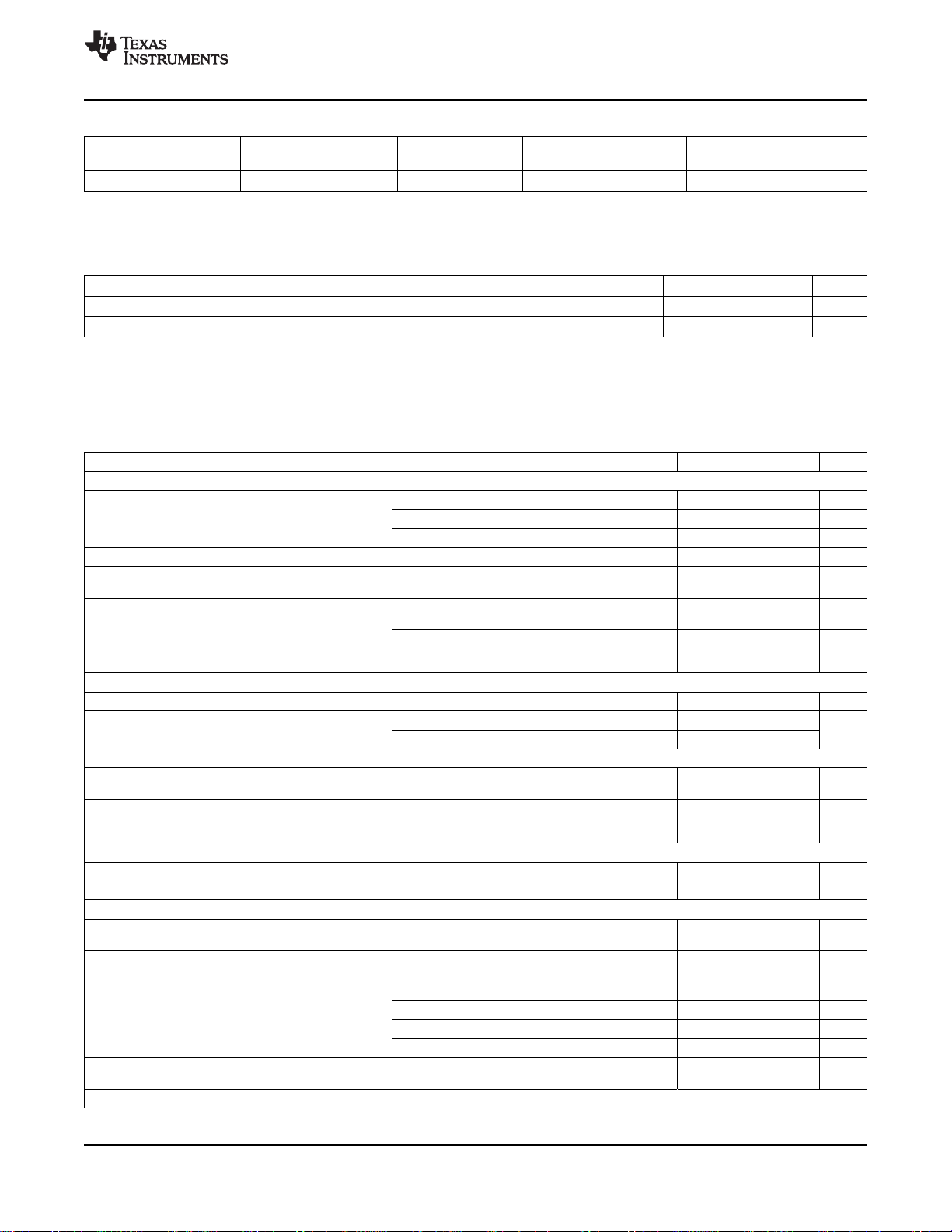

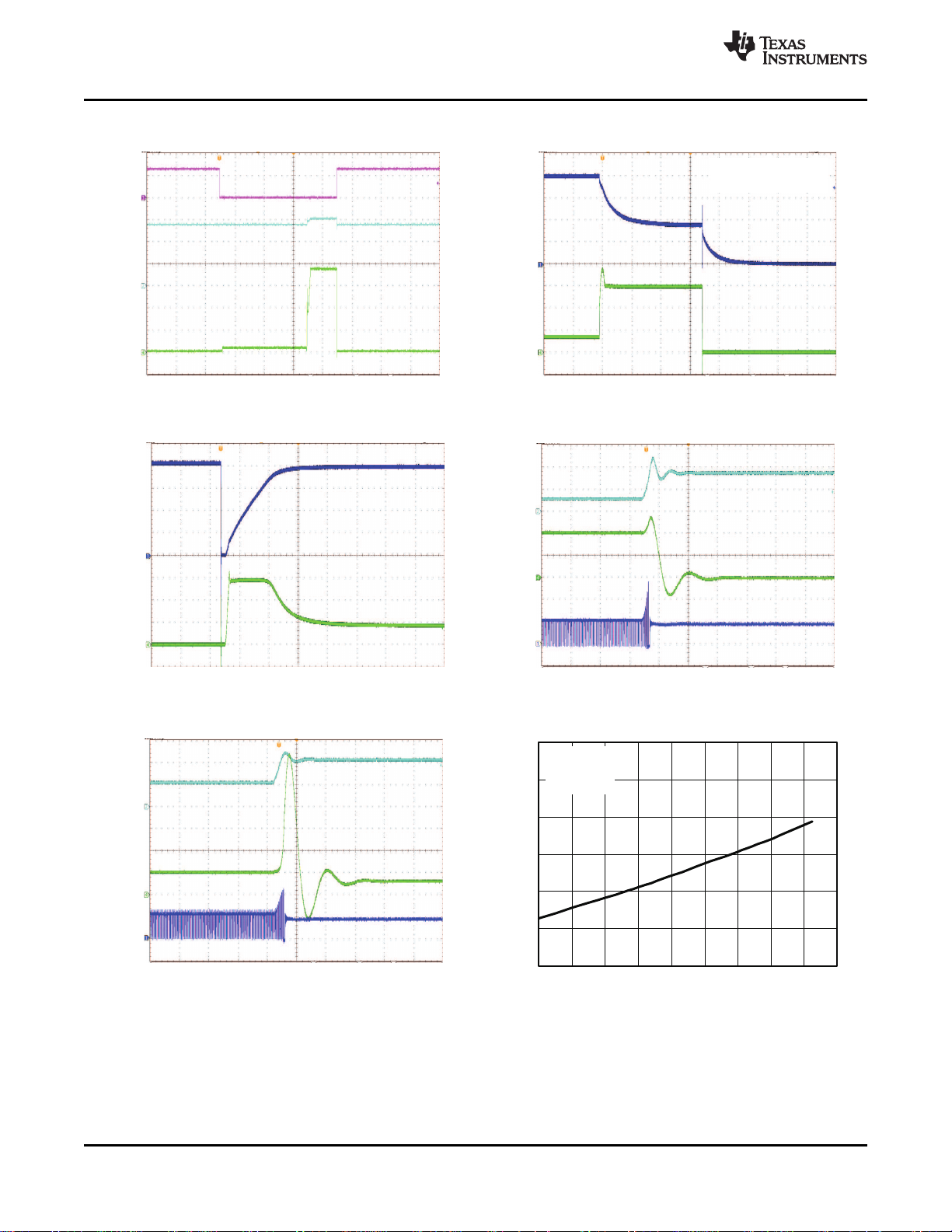

Charge Profile

In charge mode, bq24180 has five control loops to regulate input voltage, input current, charge current, charge

voltage and device junction temperature. During the charging process, all five loops are enabled and the one that

is dominant will take over the control. The bq24180 supports a precision Li-ion or Li-polymer charging system for

single-cell applications. Figure 27 indicates a typical charge profile without input current regulation loop and it is

similar to the traditional CC/CV charge curve, while Figure 27 shows a typical charge profile when input current

limiting loop is dominant during the constant current mode, and in this case the charge current is higher than the

input current so the charge process is faster than the linear chargers. For bq24180, the input current limits, the

charge current, termination current, and charge voltage are all programmable using I2C interface.

Figure 26. Startup on Adapter Plug-In in Host-Controlled Mode

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Link(s): bq24180

Precharge

(LinearCharge)

FastCharge

(PWMCharge)

I

SHORT

Termination

V

SHORT

Regulation

Current

Regulation

voltage

Precharge

Phase

CurrentRegulation

Phase

VoltageRegulation

Phase

ChargeCurrent

ChargeVoltage

(a)Withoutinputcurrentlimit(defaultwhenPSEL =1)

Precharge

(LinearCharge)

FastCharge

(PWMCharge)

I

SHORT

Termination

V

SHORT

Regulation

voltage

Precharge

Phase

CurrentRegulation

Phase

VoltageRegulation

Phase

ChargeCurrent

ChargeVoltage

(b)Withinputcurrentlimit(defaultwhenPSEL =0)

bq24180

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

www.ti.com

Figure 27. Typical Charging Profile of bq24180

PWM Controller in Charge Mode

The bq24180 provides an integrated, fixed 3 MHz frequency voltage-mode controller with Feed-Forward function

to regulate charge current or voltage. This type of controller is used to help improve line transient response,

thereby simplifying the compensation network used for both continuous and discontinuous current conduction

operation. The voltage and current loops are internally compensated using a Type-III compensation scheme that

provides enough phase margin for stable operation, allowing the use of small ceramic capacitors with very low

ESR. There is a 0.5V offset on the bottom of the PWM ramp to allow the device to operate between 0% to 99.5%

duty cycles.

The bq24180 has two back to back common-drain N-channel MOSFETs at the high side and one N-channel

MOSFET at low side. An input N-MOSFET (Q1) prevents battery discharge when VBUS is lower than V

The second high-side N-MOSFET (Q2) behaves as the switching control switch (see Figure 1). A charge pump

circuit is used to provide gate drive for Q1, while a boot strap circuit with external boot-strap capacitor is used to

boost up the gate drive voltage for Q2.

VBUS (MIN)

.

16 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): bq24180

bq24180

www.ti.com

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

Cycle-by-cycle current limit is sensed through the internal sense MOSFETs for Q2 and Q3. The threshold for Q2

is set to a nominal 2.5-A peak current. The low-side MOSFET (Q3) also has a current limit that decides if the

PWM Controller will operate in synchronous or non-synchronous mode. This threshold is set to 100mA and it

turns off the low-side N-channel MOSFET (Q3) before the current reverses, preventing the battery from

discharging. Synchronous operation is used when the current of the low-side MOSFET is greater than 100mA to

minimize power losses.

Battery Charging Process

At the beginning of precharge, while battery voltage is below the V

50mA precharge current, I

PRECHARGE

When the battery voltage is above V

current, I

OCHARGE

, or a charge current that corresponds to the input current of I

, to the battery.

PRECHARGE

and below V

PRECHARGE

, the charge current ramps up to fast charge

OREG

charge current is controlled to minimize the current and voltage over-shoot during transient. The input current

limit, I

to the regulation voltage, V

, and fast charge current, I

IN_LIMIT

OCHARGE

, the charge current is tapered down as shown in Figure 27. The voltage

OREG

, are programmable by the host. Once the battery voltage is close

regulation feedback occurs by monitoring the battery-pack voltage between the CSOUT and PGND pins. The

bq24180 is a fixed single-cell voltage version, with adjustable regulation voltage (3.5V to 4.44V) programmed

using the I2C interface.

The bq24180 monitors the charging current during the voltage regulation phase. Once the termination threshold,

I

, is detected and the battery voltage is above the recharge threshold, the bq24180 terminates charge. The

TERM

termination current level is programmable. To disable the charge current termination, the host sets the charge

termination bit (TE) of charge control register to 0, refer to I2C section for details.

A new charge cycle is initiated when one of the following conditions is detected:

1. The battery voltage falls below the V

OREG-VRCH

2. VBUS Power-on reset (POR), if battery voltage is below the V

threshold.

PRECHARGE

3. CE bit toggle or RESET bit is set (Host controlled)

threshold, the bq24180 applies the

. The slew rate for fast

IN_LIMIT

threshold

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 17

Product Folder Link(s): bq24180

ChargeDone?

I

CHG

< I

TERM

No

Start 32 second

watchdogtimer

32stimerexpired?

No

Yes

ReceivedSWwatchdog

RESET?

No

Yes

Yes

Reset 32 second

watchdogtimer

Safetytimer

fault

Chargingsuspended

Entersuspended

mode

Faultindicatedin

STAT registers

Safety Timerexpired?

No

Yes

HOST ModeBattery

Charging

BeginDEFAULT

ModeBattery

ChargeCycle

CVMode?

No

TermEnabled?

Yes

Yes

No

STAT = Hi

UpdateSTAT

bits

Terminate

Safety Timer

BatteryPresent?

Yes

Indicate

BatteryNot

PresentFault

ResetI2Cto

default

V

BAT<VRCH

?

No

DEFAULTMode ?

Yes

Indicate TimerFault

ResetI2Ctodefault

Begin

DEFAULT

ModeBattery

ChargeCycle

BeginHOST

ModeBattery

Charging

Yes

No

bq24180

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

www.ti.com

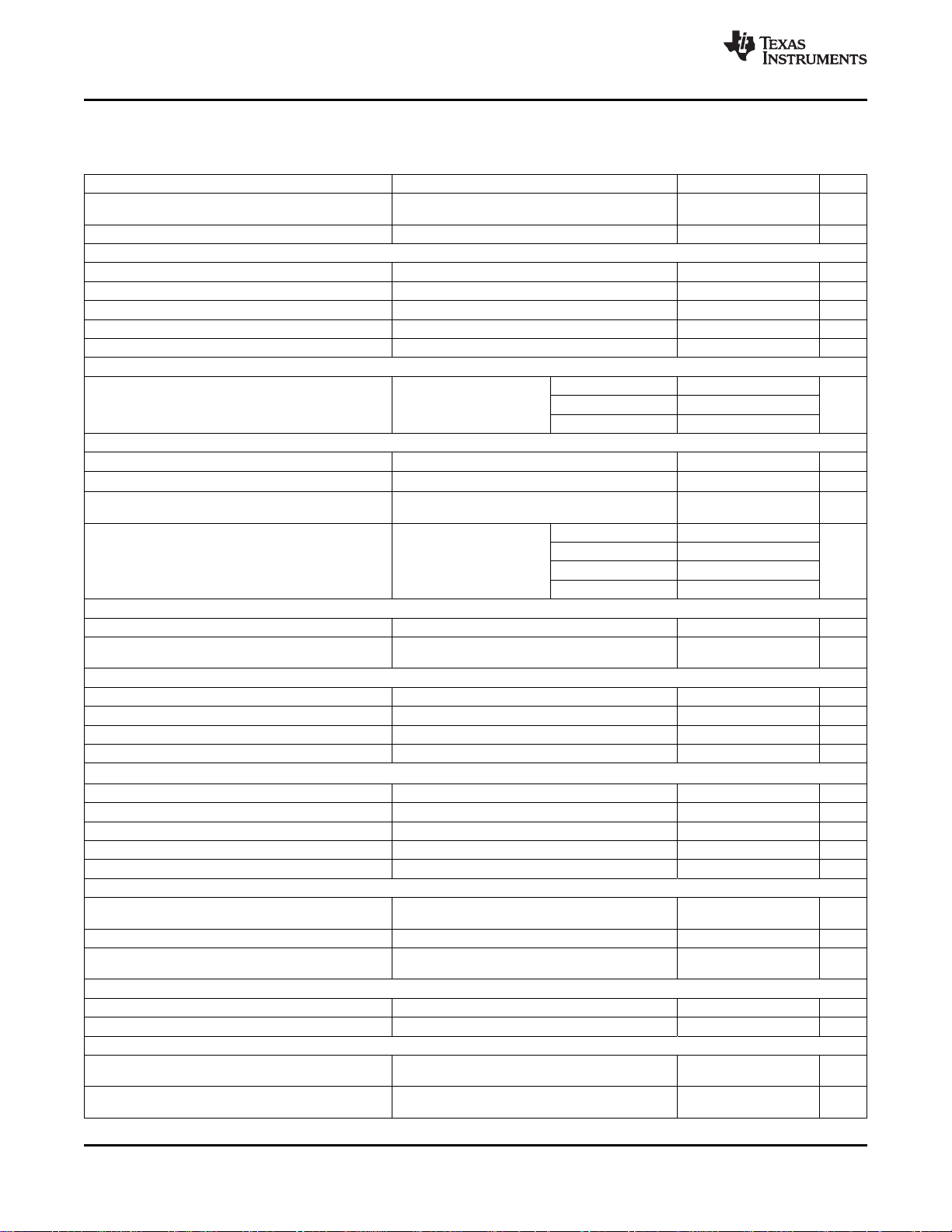

DEFAULT Mode

DEFAULT mode is used when I2C communication is not available. DEFAULT mode is entered in the following

situations:

1. When the charger is enabled and V

2. When the watchdog timer expires without a reset from the I2C interface and the safety timer has not expired.

3. When the device comes out of any fault condition (sleep mode, OVP, faulty adapter mode, etc.) before I2C

communication is established

In default mode, the I2C registers are reset to the default values. The 27 min safety timer is reset and starts when

DEFAULT mode is entered. The default value for V

input current limit is determined by the PSEL input. If PSEL selects adapter mode, there is no input current limit.

If PSEL selects PC mode, the input current limit is set to 100mA. Default mode is exited by programming the I2C

interface. Startup into DEFAULT mode is shown in Figure 29. Note that if termination is enabled and charging

has terminated, a new charge cycle is NOT initiated when entering DEFAULT mode.

Figure 28. Host Mode Charging Process

>3.6V before I2C communication is established

BAT

OREG

is 3.6V, and the default value for I

CHARGE

18 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): bq24180

is 1A. The

PSEL = Hi?

No

Yes

PCMode

LoadPCdefault

valuesforinput

currentlimitfromI2C

registers.

STAT = 0

AC Adapter

Mode

(AAM)

Loaddefaultvaluesto

I2Cregisters.

NoInputCurrentLimit

STAT = 0

No

Yes

Safety Timerexpired?

No

Yes

Safetytimer

fault

Chargingsuspended

Entersuspended

mode

Faultindicatedin

STAT registers

BeginDEFAULT

ModeBattery

ChargeCycle

BeginHOST Mode

BatteryCharging

LoadOptimizedCharge

Parameters?

No

Resetsafetytimerto

27minandstart

bq24180

www.ti.com

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

Safety Timer and Watchdog Timer in Charge Mode

At the beginning of charging process, the bq24180 starts the safety timer. This timer is active during the entire

charging process. If charging has not terminated before the safety timer expires, the IC enters suspend mode

where charging is halted. The safety timer time is selectable using the I2C interface. A single 128µs pulse is sent

on the STAT and INT outputs and the STATx bits of the status registers are updated in the I2C. The EN bit or

power must be toggled in order to clear the safety timer fault. The safety timer duration is selectable using the

TMR_X bits in the V

timer.

In addition to the safety timer, the bq24180 contains a watchdog timer that monitors the host through the I2C

interface. Once a read/write is performed on the I2C interface, a 12-second timer (t

12-second timer is reset by the host using the I2C interface. This is done by writing a "1" to the reset bit

(TMR_RST) in the control register. The TMR_RST bit is automatically set to “0” when the 12-second timer is

reset. This process continues until battery is fully charged or the safety timer expires. If the 12-second timer

expires, the IC enters DEFAULT mode where the default charge parameters are loaded, the safety timer restarts

at 27 minutes and charging continues. The I2C may be accessed again to reinitialize the desired values and

restart the watchdog timer as long as the 27 minute safety timer has not expired. Once the safety timer expires,

charging is disabled. This function prevents continuous charging of a defective battery if the host fails to reset the

safety timer. The watchdog timer flow chart is shown in Figure 30.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 19

Figure 29. DEFAULT Mode Charging Process

Voltage/ Safety Timer Register. Changing the safety timer duration resets the safety

IN-DPM

WATCHDOG

Product Folder Link(s): bq24180

) is started. The

StartSafety Timer

ChargeDone?

I

CHG

< I

TERM

No

STAT = Hi

UpdateSTAT

bits

I2CRead/Write

performed?

Start 12 second

watchdogtimer

No

Yes

12stimerexpired?

No

Yes

ReceivedSWwatchdog

RESET?

No

Yes

Safetytimerexpired?

No

Yes

Safetytimer

fault

Chargingsuspended

Entersuspended

mode

Faultindicatedin

STAT registers

Yes

ChargeDone?

I

CHG

< I

TERM

No

STAT = Hi

UpdateSTAT

bits

Yes

Reset 12 second

watchdogtimer

Resettodefault

valuesinI2C

register

Restart 27min

safetytimer

Safetytimerexpired?

Safetytimer

fault

Chargingsuspended

Entersuspended

mode

Faultindicatedin

STAT registers

No

Yes

bq24180

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

www.ti.com

Figure 30. The Watchdog Timer Flow Chart for bq24180

Power Source Selector Input (PSEL)

The bq24180 contains a PSEL input that is used to program the input current limit during DEFAULT mode. Drive

PSEL high to indicate a USB source is connected to the input and the PC mode default values should be used.

When PSEL is high, the IC starts up with a 100mA input current limit and a 1A charge current. Drive PSEL low to

indicate that an AC Adapter is connected to the input. When PSEL is high, the IC starts up with no input current

limit and a 1A charge current. PSEL is internally pulled up to the DRV supply with a 100kΩ resistor.

20 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): bq24180

bq24180

www.ti.com

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

Hardware Disable Input (CD)

The bq24180 contains a CD input that is used to disable the charger and place the bq24180 into high-impedance

mode. Drive CD low to enable charge and enter normal operation. Drive CD high to disable charge and place the

bq24180 into high-impedance mode. Driving CD high during DEFAULT mode resets the safety timer. Driving CD

high during HOST mode suspends, but does NOT reset the safety timer. CD is internally pulled down to GND

with a 100kΩ resistor.

LDO Output (DRV)

The bq24180 contains a linear regulator (DRV) that is used to supply the internal MOSFET drivers and other

circuitry. Additionally, DRV supplies up to 10mA external loads to power the STAT LED or the USB transceiver

circuitry. The maximum value of the DRV output is 5.5V so it ideal to protect voltage sensitive USB circuits. The

LDO is on whenever a VBUS supply is connected to the bq24180. The DRV is disabled under the following

conditions:

1. Faulty adapter detected or VBUS < UVLO

2. Thermal Shutdown

AC Adapter Mode, Charge Current Limiting

After power is connected and startup is initiated, the PSEL input is read to determine the default startup values. If

PSEL is 0, AC Adapter mode is selected. In AC Adapter mode, the charge current is regulated to maximize the

charging time. The default parameters in AC Adapter mode are I

may be changed at any time using the I2C interface. Additionally, if input current monitoring is required, this may

be used during AC Adapter mode as well, but is disabled in DEFAULT mode.

CHARGE

=1A and V

=3.6V. These values

OUTREG

PC Mode, Input Current Limiting

After power is connected and startup is initiated, the PSEL input is read to determine the default startup values.

In PC mode, the input current is limited to maximize the charge rate of bq24180 without overloading the USB

port. The input current for bq24180 can be limited to 100mA, 500mA or 800mA and is programmed in the control

register. Once the input current reaches the input current limiting threshold, the charge current is reduced to

prevent the input current from exceeding the programmed threshold. The input current sensing resistor and

control loop are integrated into bq24180. The input current limit is disabled using I2C control; refer to the

definition of control register (01H) for detail. The default parameters in USB mode are I

V

=3.6V. Charge current may be monitored in PC mode as well, but by default it is set to a maximum such

OUTREG

=100mA and

INLIM

that the input current limit loop is active.

DCOUT Functionality

The bq24180 contains a DCOUT function that is used to connect a load to the battery through a switch. DCOUT

is implemented using back to back MOSFETs (Q4 and Q5 in Figure 1) to connect DCOUT to the battery. This

prevents reverse feeding the battery from DCOUT when DCOUT is disabled. DCOUT is a current limited source

and can provide up to 1A to power additional accessories. The current limit is programmable from 370mA to 1.5A

in 4 steps using the I2C interface. Additionally, the DCOUT output is enabled or disabled using the I2C interface.

If the load on DCOUT reaches the current limit, the FET that connects DCOUT to the battery is turned off after

the deglitch time (t

dgl_DCOUT

), a single 128µs pulse is sent on the STAT and INT outputs and the FAULT_x bits of

the status register are updated in the I2C. The DCOUT may be enabled after the fault using the I2C interface.

External NTC Monitoring (TS)

The bq24180 provides a TS input for monitoring an external NTC thermistor. A current is sourced to the NTC

from the TS input and the voltage is monitored. There are 3 temperature thresholds that are monitored; the cold

battery threshold (T

(T

> 55°C). These temperatures correspond to the V

NTC

NTC thermistor (b=3500). The TS input is monitored at all times, however, it only affects charging during default

mode. During default mode, charging is suspended and timers are suspended when T

When 45°C < T

NTC

remains at 100mA in this mode.

< 5°C), the warm battery threshold (45°C < T

NTC

HOT

, V

WARM

< 55°C) and the hot battery threshold

NTC

, and V

thresholds when using a 4.7kΩ

COLD

< 5°C or T

NTC

NTC

> 55°C.

< 55°C, the charging current is reduced to 400mA (max). In PC mode, the charge current

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Link(s): bq24180

400 mA

T 1

(5ºC)

T 2

(45ºC)

T 3

(55ºC)

1A

bq24180

TS

TEMP

PACK+

PACK-

+

+

V

HOT

V

COLD

I

NTC

+

V

WARM

bq24180

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

www.ti.com

Figure 31. Charge Current During TS Conditions in Default Mode

When the bq24180 is not in default mode, the TS input is monitored and faults are displayed in the I2C registers.

If any of the 3 TS fault conditions occur, a single 128µs pulse is sent on the STAT and INT outputs and the

STATx and FAULT_x bits of the status registers are updated in the I2C. The FAULT_x bits signal a general

temperature fault. The TS_FAULTX bits in the NTC Monitor Register show the exact TS fault that has occurred.

Figure 32. TS Circuit

Thermal Regulation and Protection

During the charging process, to prevent overheat of the chip, bq24180 monitors the junction temperature, TJ, of

the die and begins to taper down the charge current once TJreaches the thermal regulation threshold, TCF. The

charge current is reduced to zero when the junction temperature increases about 10°C above TCF. At any state, if

TJexceeds T

shutdown mode, PWM is turned off, all timers are terminated and reset, and a single 128µs pulse is sent on the

STAT and INT outputs and the STATx and FAULT_x bits of the status registers are updated in the I2C. A new

charging cycle begins when TJfalls below T

after a thermal shutdown fault.

22 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

SHTDWN

, bq24180 terminates charging and disables DCOUT in the I2C register. During thermal

SHTDWN

Product Folder Link(s): bq24180

by approximately 10°C. DCOUT must be enabled by the host

bq24180

www.ti.com

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

Input Voltage Protection in Charge Mode

Sleep Mode

The bq24180 enters the low-power sleep mode if the voltage on V

threshold, V

CSOUT+VSLP

prevents draining the battery during the absence of V

, and V

is higher than the undervoltage lockout threshold, V

VBUS

. During sleep mode, both the reverse blocking

VBUS

switch Q1 and PWM are turned off. Once the input rises above the sleep threshold, the device returns to

normal operation.

Input Voltage Based DPM

During normal charging process, if the input power source is not able to support the programmed or default

charging current, VBUS voltage will decease. Once the VBUS drops to V

current is tapered down to prevent the further drop of VBUS. When the IC enters this mode, the charge

current is lower than the set value and the DPM_STATUS bit is set (B4 in Register 05H). This feature

ensures IC compatibility with adapters with different current capabilities.

Faulty Adapter Detection

When an input source is connected to the bq24180, the device enter faulty adapter detection mode. In this

mode, the IC sources 30mA to the battery for t

the device continues the startup sequence. If V

. After t

INT

VBUS<VIN(MIN)

, the input voltage is monitored. If V

INT

, a single 128µs pulse is sent on the STAT and

INT outputs and the STATx and FAULT_x bits of the status registers are updated in the I2C and the process

repeats until a good adapter is detected.

High-Input and Input Over-Voltage Protection

The bq24180 provides two levels over-voltage protection on the input. A high-input comparator disables the

PWM operation and sources the 50mA precharge current to the battery when V

allows for unregulated adapters to be used. The 50mA pulls the adapter voltage down to the usable voltage

and then normal operation begins.

The built-in input over-voltage protection to protect the device and other components against damage from

overvoltage on the input supply (Voltage from V

to PGND). When V

VBUS

the PWM converter, a single 128µs pulse is sent on the STAT and INT outputs and the STATx and FAULT_x

bits of the status registers are updated in the I2C. Once the OVP fault is removed, the STATx and FAULT_x

bits are cleared and the device returns to normal operation.

falls below sleep-mode entry

VBUS

UVLO

VBUS_LOW

VBUS

(default 4.76V), the charge

< V

> V

HIGH

, the bq24180 latches off

OVP

VBUS

. This feature

VBUS>VIN(MIN)

< V

OVP

,

. This

Charge Status Outputs (STAT, INT)

The STAT and INT outputs are used to indicate operation conditions for bq24180. STAT and INT are pulled low

during charging when EN_STAT bit in the control register (00H) is set to “1”. When charge is complete or

disabled, INT and STAT are high impedance. When a fault occurs, a 128-µs pulse (interrupt) is sent out to notify

the host. The status of STAT and INT during different operation conditions is summarized in Table 1. STAT

drives an LED for visual indication. INT is available for connecting to the logic rail for host communication.

Table 1. STAT Pin Summary

CHARGE STATE STAT and INT BEHAVIOR

Charge in progress and EN_STAT=1 Low

Other normal conditions Open-drain

Charge mode faults: Timer fault, sleep mode, 128-µs pulse, then open-drain

VBUS over voltage, VBUS UVLO, thermal

shutdown

Control Bits in Charge Mode

CE Bit (Charge Enable)

The bit of CE in control register is used to disable or enable the charge process. A low logic level (0) on this

bit enables the charge and a high logic level (1) disables the charge.

RESET Bit

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 23

Product Folder Link(s): bq24180

o

OU T OU T

1

=

2 L C

¦

´ ´p

ITERM0

OT ERM_STE P

SN S

V

I =

R

ICHR G0

OCHARG E_STEP

SNS

V

I =

R

bq24180

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

www.ti.com

The bit of RESET in control register is used to reset all the charge parameters. Write ‘1” to RESET bit to

reset all the charge parameters to default values and RESET bit is automatically cleared to zero once the

charge parameters get reset. It is designed for charge parameter reset before charge starts and it is not

recommended to set RESET bit when charging or boosting in progress.

Output Inductor and Capacitor Selection Guidelines

The bq24180 provides internal loop compensation. With this scheme, best stability occurs when LC resonant

frequency, of, is approximately 40 kHz (20 kHz to 80 kHz). Equation 1 can be used to calculate the value of the

output inductor, L

, and output capacitor, C

OUT

OUT

.

(1)

To reduce the output voltage ripple, a ceramic capacitor with the capacitance between 4.7µF and 47µF is

recommended for C

, refer to the application section for components selection.

OUT

Selecting Current Sense Resistor

Both the termination current range and charge current range are depending on the sensing resistor (R

termination current step (I

OTERM_STEP

) can be calculated using Equation 2:

Table 2 shows the termination current settings with two sensing resistors.

SNS

). The

(2)

Table 2. Termination Current Settings for 68mΩ and 100mΩ Sense Resistors

BIT V

V

ITERM2

V

ITERM1

V

ITERM0

Offset 1.7 25 17

The charge current step (I

OCHARGE_STEP

) can be calculated using Equation 3:

(mV) I

ITERM

6.8 100 68

3.4 50 43

1.7 25 17

TERM

R

= 68 mΩ R

SNS

Table 3 shows the charge current settings with two sensing resistors.

Table 3. Charge Current Settings for 68 mΩ and 100 mΩ Sense Resistors

BIT V

V

ICHRG3

V

ICHRG2

V

ICHRG1

V

ICHRG0

Offset 37.4 550 374

(mV) I

IREG

54.4 800 544

27.2 400 272

13.6 200 136

6.8 100 68

OCHARGE

R

= 68 mΩ R

SNS

(mA) I

(mA) I

TERM

= 100 mΩ

SNS

OCHARGE

= 100 mΩ

SNS

(mA)

(3)

(mA)

24 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): bq24180

DATA

CLK

STARTCondition STOP Condition

DATA

CLK

DataLine

Stable;

DataValid

Charge

ofData

Allowed

bq24180

www.ti.com

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

SERIAL INTERFACE DESCRIPTION

I2C is a 2-wire serial interface developed by Philips Semiconductor (see I2C-Bus Specification, Version 2.1,

January 2000). The bus consists of a data line (SDA) and a clock line (SCL) with pull-up structures. When the

bus is idle, both SDA and SCL lines are pulled high. All the I2C compatible devices connect to the I2C bus

through open drain I/O pins, SDA and SCL. A master device, usually a microcontroller or a digital signal

processor, controls the bus. The master is responsible for generating the SCL signal and device addresses. The

master also generates specific conditions that indicate the START and STOP of data transfer. A slave device

receives and/or transmits data on the bus under control of the master device.

The bq24180 device works as a slave and is compatible with the following data transfer modes, as defined in the

I2C Bus™ Specification: standard mode (100 kbps), fast mode (400 kbps), and high-speed mode (up to 3.4 Mbps

in write mode). The interface adds flexibility to the battery charge solution, enabling most functions to be

programmed to new values depending on the instantaneous application requirements. Register contents remain

intact as long as battery voltage remains above 2.5 V (typical). The I2C circuitry is powered from VBUS when a

supply is connected. If the VBUS supply is not connected, the I2C circuitry is powered from the battery through

CSOUT. The battery voltage must stay above 2.5V with no input connected in order to maintain proper operation.

The data transfer protocol for standard and fast modes is exactly the same; therefore, they are referred to as the

F/S-mode in this document. The protocol for high-speed mode is different from the F/S-mode, and it is referred to

as the HS-mode. The bq24150/1 device only supports 7-bit addressing. The device 7-bit address is defined as

‘1101011’ (6BH).

F/S Mode Protocol

The master initiates data transfer by generating a start condition. The start condition is when a high-to-low

transition occurs on the SDA line while SCL is high, as shown in Figure 33. All I2C -compatible devices should

recognize a start condition.

Figure 33. START and STOP Condition

The master then generates the SCL pulses, and transmits the 8-bit address and the read/write direction bit R/W

on the SDA line. During all transmissions, the master ensures that data is valid. A valid data condition requires

the SDA line to be stable during the entire high period of the clock pulse (see Figure 34). All devices recognize

the address sent by the master and compare it to their internal fixed addresses. Only the slave device with a

matching address generates an acknowledge (see Figure 34) by pulling the SDA line low during the entire high

period of the ninth SCL cycle. Upon detecting this acknowledge, the master knows that communication link with a

slave has been established.

Figure 34. Bit Transfer on the Serial Interface

The master generates further SCL cycles to either transmit data to the slave (R/W bit 1) or receive data from the

slave (R/W bit 0). In either case, the receiver needs to acknowledge the data sent by the transmitter. So an

acknowledge signal can either be generated by the master or by the slave, depending on which one is the

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Link(s): bq24180

DataOutput

byTransmitter

DataOutput

byReceiver

SCL From

Master

START

Condition

ClockPulsefor

Acknowledgement

Not Acknowledge

Acknowledge

bq24180

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

www.ti.com

receiver. the 9-bit valid data sequences consisting of 8-bit data and 1-bit acknowledge can continue as long as

necessary. To signal the end of the data transfer, the master generates a stop condition by pulling the SDA line

from low to high while the SCL line is high (see Figure 35). This releases the bus and stops the communication

link with the addressed slave. All I2C compatible devices must recognize the stop condition. Upon the receipt of

a stop condition, all devices know that the bus is released, and wait for a start condition followed by a matching

address. If a transaction is terminated prematurely, the master needs sending a STOP condition to prevent the

slave I2C logic from remaining in a incorrect state. Attempting to read data from register addresses not listed in

this section will result in FFh being read out.

Figure 35. Acknowledge on the I2C Bus

Figure 36. Bus Protocol

F/S Mode Protocol

When the bus is idle, both SDA and SCL lines are pulled high by the pull-up devices.

The master generates a start condition followed by a valid serial byte containing HS master code '00001XXX'.

This transmission is made in F/S mode at no more than 400 Kbps. No device is allowed to acknowledge the HS

master code, but all devices must recognize it and switch their internal setting to support 3.4-Mbps operation.

26 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): bq24180

bq24180

www.ti.com

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

The master then generates a repeated start condition (a repeated start condition has the same timing as the start

condition). After this repeated start condition, the protocol is the same as F/S mode, except that transmission

speeds up to 3.4 Mbps are allowed. A stop condition ends the HS mode and switches all the internal settings of

the slave devices to support the F/S mode. Instead of using a stop condition, repeated start conditions should be

used to secure the bus in HS mode. If a transaction is terminated prematurely, the master needs sending a

STOP condition to prevent the slave I2C logic from remaining in a incorrect state.

Attempting to read data from register addresses not listed in this section results in FFh being read out.

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Link(s): bq24180

bq24180

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

www.ti.com

REGISTER DESCRIPTION

blank paragraph for spacer

Status/Control Register (READ/WRITE) – Memory location: 00, Reset state: x1xx 0xxx

BIT NAME Read/Write FUNCTION

B7(MSB) TMR_RST Read/Write Write: TMR_RST function, write "1" to reset the watchdog timer (auto clear)

B6 EN_STAT Read/Write 1-Enable STAT function, 0-Disable STAT function (default 1)

B5 STAT2 Read only

B4 STAT1 Read only

B3 NA Read only NA

B2 FAULT_3 Read only

B1 FAULT_2 Read only VBUS<V

B0(LSB) FAULT_1 Read only

blank paragraph for spacer

Control Register (READ/WRITE) – Memory location: 01, Reset state: 0011 0000

BIT NAME Read/Write FUNCTION

B7(MSB) Iin_Limit_2 Read/Write 00-USB host with 100-mA current limit, 01-USB host with 500-mA current limit, 10-USB

B6 Iin_Limit_1 Read/Write

B5 DCOUT_ILIM1 Read/Write 00-DCOUT 350mA current limit, 01- DCOUT 750mA current limit, 10- DCOUT 1050mA

B4 DCOUT_ILIM2 Read/Write

B3 TE Read/Write 1-Enable charge current termination, 0-Disable charge current termination (default 0)

B2 CE Read/Write 1-Charger is disabled, 0-Charger enabled (default 0)

B1 HZ_MODE Read/Write 1-High impedance mode, 0-Not high impedance mode (default 0)

B0 (LSB) DCOUT_EN Read/Write 1-DCOUT Enabled, 0-DCOUT Disabled. (default 0)

(1) When in DEFAULT mode, the PSEL input determines the input current limit.

Read: 0 – PSEL indicates low, 1- PSEL indicates high

00-Ready, 01-Charge in progress, 10-Charge done, 11-Fault

Charge mode: 000-Normal, 001-VBUS OVP, 010-Sleep mode, 011- Faulty Adapter or

110-Timer fault, 111-No battery

host/charger with 800-mA current limit, 11-No input current limit (default 00

current limit, 11- DCOUT 1400mA current limit (default 11)

, 100-DCOUT Current Limit tripped, 101-Thermal shutdown or TS Fault,

UVLO

(1)

)

Control/Battery Voltage Register (READ/WRITE) – Memory location: 02, Reset state: 0001 01XX

BIT NAME Read/Write FUNCTION

B7(MSB) V

B6 V

B5 V

B4 V

B3 V

B2 V

B1 NA Read/Write NA

B0(LSB) NA Read/Write NA

OREG5

OREG4

OREG3

OREG2

OREG1

OREG0

Read/Write Battery Regulation Voltage: 640mV (default 0)

Read/Write Battery Regulation Voltage: 320mV (default 0)

Read/Write Battery Regulation Voltage: 160mV (default 0)

Read/Write Battery Regulation Voltage: 80mV (default 1)

Read/Write Battery Regulation Voltage: 40mV (default 0)

Read/Write Battery Regulation Voltage: 20mV (default 1)

blank paragraph for spacer

• Charge voltage range is 3.5V–4.44V with the offset of 3.5V and step of 20mV (default 3.6V).

blank paragraph for spacer

28 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): bq24180

bq24180

www.ti.com

Vender/Part/Revision Register (READ only) – Memory location: 03, Reset state: 0100 0000

BIT NAME Read/Write FUNCTION

B7(MSB) Vender2 Read only Vender Code: bit 2 (default 0)

B6 Vender1 Read only Vender Code: bit 1 (default 1)

B5 Vender0 Read only Vender Code: bit 0 (default 0)

B4 PN1 Read only

B3 PN0 Read only

B2 Revision2 Read only

B1 Revision1 Read only

B0(LSB) Revision0 Read only

For I2C Address 6BH: 00 – bq24180

000: Revision 1.0; 001: Revision 1.1

010-111: Future Revisions

Battery Termination/Fast Charge Current Register (READ/WRITE)

Memory location: 04, Reset state: 1010 1011

BIT NAME Read/Write FUNCTION

B7(MSB) Reset Write only Write: 1-Charger in reset mode, 0-No effect

B6 V

B5 V

B4 V

B3 V

B2 V

B1 V

B0(LSB) V

ICHRG3

ICHRG2

ICHRG1

ICHRG0

ITERM2

ITERM1

ITERM0

Read/Write Charge current sense voltage: 54.4mV— (default 0)

Read/Write Charge current sense voltage: 27.2mV—(default 1)

Read/Write Charge current sense voltage: 13.6mV— (default 0)

Read/Write Charge current sense voltage: 6.8mV (default 1)

Read/Write Termination current sense voltage: 6.8mV (default 0)

Read/Write Termination current sense voltage: 3.4mV (default 1)

Read/Write Termination current sense voltage: 1.7mV (default 1)

Read: always get "1"

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

blank paragraph for spacer

• Charge current sense voltage offset is 37.4mV and default charge current is 1050mA, if 68mΩ sense resistor

is used.

• Termination threshold voltage offset is 1.7mV and default termination current is 100mA if a 68mΩ sense

resistor is used.

blank paragraph for spacer

V

BIT NAME Read/Write FUNCTION

B7(MSB) NA Read/Write NA

B6 NA Read/Write NA

B5 LOW_CHG Read/Write 1 – Low charge current sense voltage of 23.8mV,

B4 DPM_STATUS Read Only 1 – VIN-DPM mode is active,

B3 CD_STATUS Read Only 1 – CD high, Charger disabled,

B2 V

B1 V

B0(LSB) V

• V

voltage offset is 4.15V and default V

IN-DPM

Voltage/ Safety Timer Register – Memory location: 05, Reset state: XX0X X111

IN-DPM

0 – Normal charge current sense voltage at 04H (default 0)

0 – VIN-DPM mode is not active

0 – CD low, Charger enabled

INDPM2

INDPM1

INDPM0

Read/Write V

Read/Write V

Read/Write V

voltage: 320 mV (default 1)

IN-DPM

voltage: 160 mV (default 1)

IN-DPM

voltage: 80 mV (default 1)

IN-DPM

threshold is 4.71V.

IN-DPM

blank paragraph for spacer

Copyright © 2010, Texas Instruments Incorporated Submit Documentation Feedback 29

Product Folder Link(s): bq24180

bq24180

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

www.ti.com

Safety Limit Register (READ/WRITE, Write only once after reset!)

Memory location: 06, Reset state: 0101 0000

BIT NAME Read/Write FUNCTION

B7(MSB) V

B6 V

B5 V

B4 V

B3 V

B2 V

B1 V

B0(LSB) V

MCHRG3

MCHRG2

MCHRG1

MCHRG0

MREG3

MREG2

MREG1

MREG0

Read/Write Maximum charge current sense voltage: 54.4mV (default 0)

Read/Write Maximum charge current sense voltage: 27.2mV (default 1)

Read/Write Maximum charge current sense voltage: 13.6mV (default 0)

Read/Write Maximum charge current sense voltage: 6.8mV (default 1)

Read/Write Maximum battery regulation voltage: 160mV (default 0)

Read/Write Maximum battery regulation voltage: 80mV (default 0)

Read/Write Maximum battery regulation voltage: 40mV (default 0)

Read/Write Maximum battery regulation voltage: 20mV (default 0)

• Maximum charge current sense voltage offset is 550mA (default at 950mA) and the maximum charge current

option is 1.55A, if 68-mΩ sensing resistor is used.

• Maximum battery regulation voltage offset is 4.2V (default at 4.2V) and maximum battery regulation voltage

option is 4.44V.

• Memory location 06 resets only when V

voltage drops below V

BAT

threshold (typ. 2.0V) goes to logic '0'.

SHORT

During reset, the maximum values in 06H keep the default value regardless of the write action to this register.

After reset (V

BAT>VSHORT

), the maximum values for battery regulation voltage and charge current can be

programmed many times until any writing to other register locks the safety limits. Programmed values exclude

higher values from memory locations 02 (battery regulation voltage), and from memory location 04 (Fast

charge current).

If host accesses (write command) to some other register before Safety limit register, the default values hold!

blank paragraph for spacer

NTC Monitor Register (READ/WRITE) – Memory location: 07, Reset state: 100X 0000

BIT NAME Read/Write FUNCTION

B7(MSB) 2XTMR_EN Read/Write 1 – Timer slowed by 2x when in thermal regulation or VIN_HIGH protection,

0 – Timer not slowed at any time (default 1)

B6 TMR_1 Read/Write Safety Timer Time Limit

B5 TMR_2 Read/Write

B4 NA Read/Write NA

B3 TS_/EN Read/Write 1 – TS function disabled,

B2 TS_FAULT2 Read only TS Fault Mode:

B1 TS_FAULT1 Read only

B0(LSB) TS_FAULT0 Read only

00 – 27 minute fast charge,

01 – 3 hour fast charge,

10 – 6 hour fast charge,

11 – Disable safety timers (default 00)

0 – TS function enabled (default 0)

000 – TS temp < 5°C or TS temp > 55°C,

010 – Normal, No TS fault,

011 – 45°C < TS temp < 55°C,

100–111 – TS Open

30 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated

Product Folder Link(s): bq24180

V

IN

+

-

C1

C2

PMID

VBUS

SW

L1

PGND

bq24180

C4

Isns

Rsns

C3

Ichg

BAT

+

Isys

System

Load

bq24180

www.ti.com

SLUSA02 A –FEBRUARY 2010–REVISED FEBRUARY 2010

POWER TOPOLOGIES

System Load After Sensing Resistor

One of the simple high-efficiency topologies connects the system load directly across the battery pack, as shown

in Figure 37. The input voltage has been converted to a usable system voltage with good efficiency from the

input. When the input power is on, it supplies the system load and charges the battery pack at the same time.

When the input power is off, the battery pack powers the system directly.

Figure 37. System Load After Sensing Resistor

The advantages:

• When the AC adapter is disconnected, the battery pack powers the system load with minimum power

dissipations. Consequently, the time that the system runs on the battery pack can be maximized.

• It saves the external path selection components and offers a low-cost solution.

• Dynamic power management (DPM) can be achieved. The total of the charge current and the system current

can be limited to a desired value by adjusting charge current. When the system current increases, the charge

current drops by the same amount. As a result, no potential over-current or over-heating issues are caused

by excessive system load demand.