BQ21062

VINLS

PMID

LS/LDO

VDD

BAT

TS

+

±

NTC

GND

IN

VIO

Host

USB

I2C Bus

<150mA

Load

System

MR

PG

INT

LP

CE

C

4

C

5

C

3

C

2

C

1

BQ21062

www.ti.com

SLUSE42 – JULY 2020

SLUSE42 – JULY 2020

BQ21062

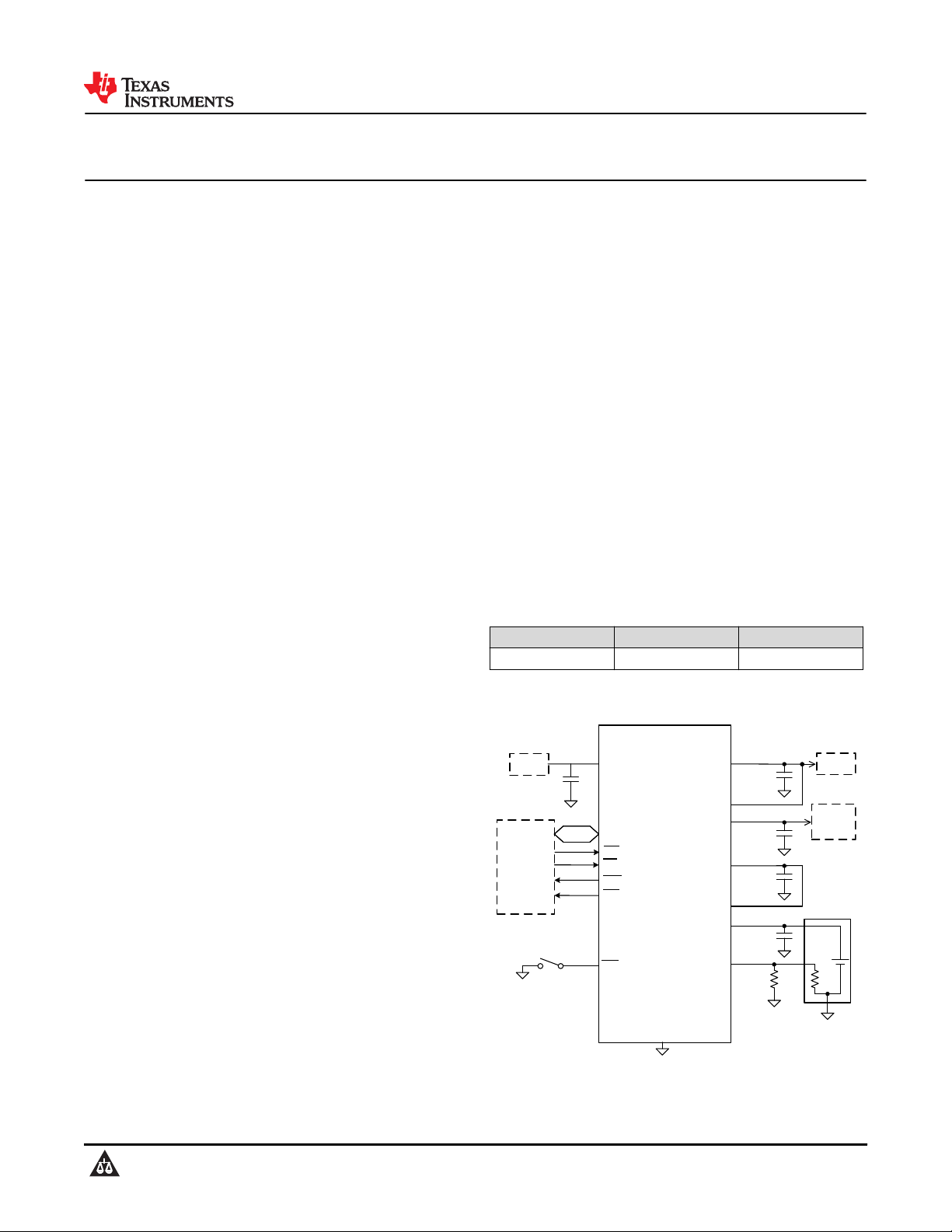

BQ21062 I2C Controlled 1-Cell 500-mA Linear Battery Charger with Power Path, Load

Switch, 10-nA Ship Mode, and Regulated System (PMID) Voltage

1 Features

• Linear battery charger with 1.25-mA to 500-mA

fast charge current range

– 0.5% Accurate I2C programmable battery

regulation voltage ranging from 3.6 V to 4.6 V in

10-mV steps

– Configurable termination current supporting

down to 0.5 mA

– 20-V Tolerant input with typical 3.4-V to 5.5-V

input voltage operating range

– Programmable thermal charging profile, fully

configurable hot, warm, cool and cold

thresholds

• Power Path management for powering system and

charging battery

– I2C Programmable regulated system voltage

(PMID) ranging from 4.4V to 4.9V in addition to

battery voltage tracking and Input pass-though

options

– Dynamic power path management optimizes

charging from weak adapters

– Advanced I2C control allows host to disconnect

the battery or adapter as needed

• I2C Configurable load switch or up to 150-mA LDO

output

– Programmable range from 0.6 V to 3.7 V in

100-mV steps

• Ultra low Iddq for extended battery life

– 10-nA Ship mode battery Iq

– 400-nA Iq While powering the system (PMID

and VDD on)

• One push-button wake-up and reset input with

adjustable timers

– Supports system power cycle and HW reset

• 20-Pin 2-mm x 1.6-mm CSP package

• 11-mm2 Total solution size

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: BQ21062

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

2 Applications

• Headsets, earbuds and hearing aids

• Smart watches and smart trackers

• Wearable fitness and activity monitors

• Blood glucose monitors

3 Description

The BQ21062 is a highly integrated battery charge

management IC that integrates the most common

functions for wearable, portable and small medical

devices, namely a charger, a regulated output voltage

rail for system power, a Load Switch/LDO, and pushbutton controller.

The BQ21062 IC integrates a linear charger with

Power Path that enables quick and accurate charging

for small batteries while providing a regulated voltage

to the system. The regulated system voltage (PMID)

output may be configured through I2C based on the

recommended operating condition of downstream IC's

and system loads for optimal system operation.

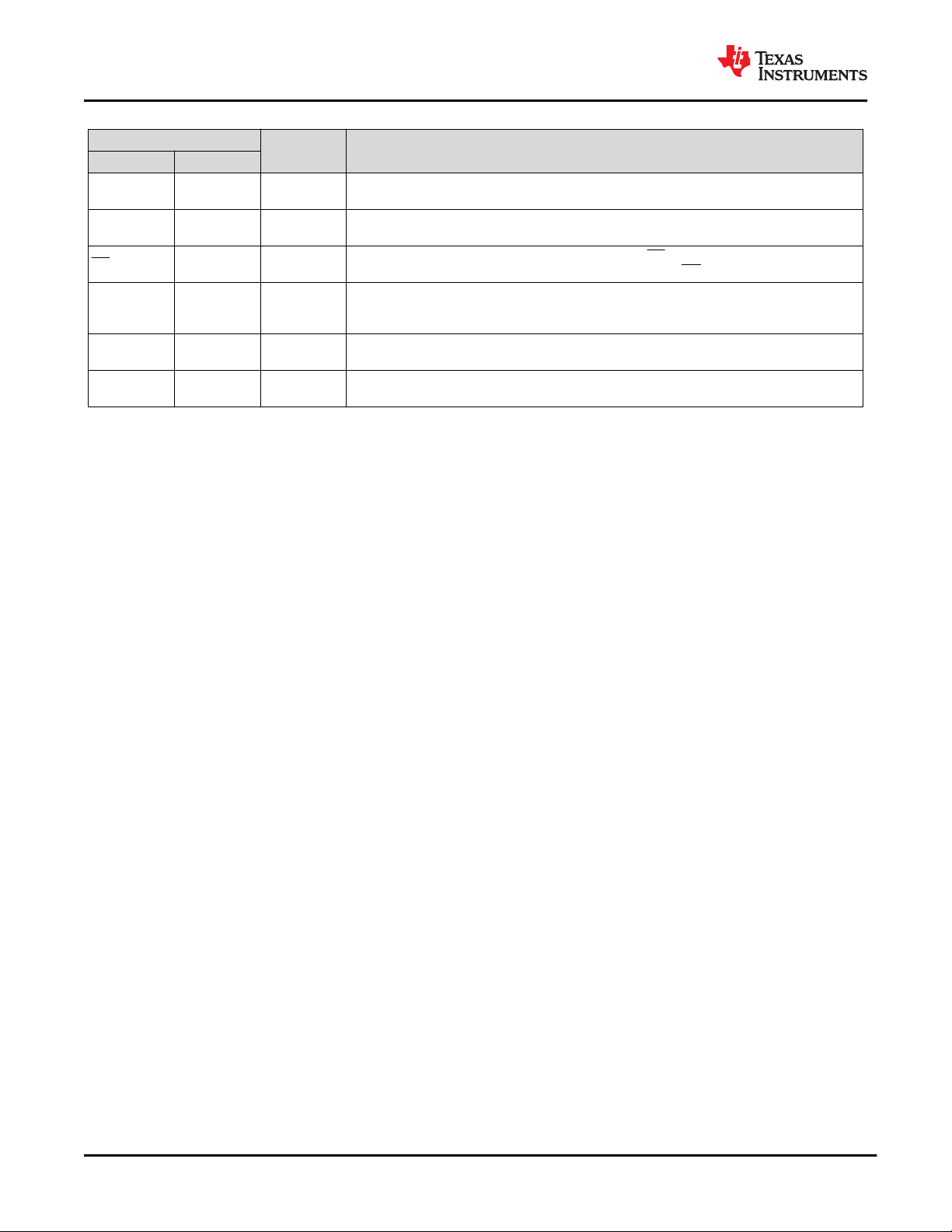

Device Information

PART NUMBER PACKAGE BODY SIZE (NOM)

BQ21062 DSBGA (20) 2.00 mm x 1.60 mm

(1) For all available packages, see the orderable addendum at

the end of the data sheet.

Simplified Schematic

Submit Document Feedback

(1)

1

BQ21062

SLUSE42 – JULY 2020

www.ti.com

Table of Contents

1 Features............................................................................1

2 Applications..................................................................... 1

3 Description.......................................................................1

4 Revision History.............................................................. 2

5 Description (continued).................................................. 3

6 Device Comparison Table...............................................4

7 Pin Configuration and Functions...................................5

8 Specifications.................................................................. 7

8.1 Absolute Maximum Ratings........................................ 7

8.2 ESD Ratings............................................................... 7

8.3 Recommended Operating Conditions.........................7

8.4 Thermal Information....................................................7

8.5 Electrical Characteristics.............................................8

8.6 Timing Requirements................................................10

8.7 Typical Characteristics..............................................12

9 Detailed Description......................................................15

9.1 Overview................................................................... 15

9.2 Functional Block Diagram......................................... 15

9.3 Feature Description...................................................15

9.4 Device Functional Modes..........................................29

4 Revision History

DATE REVISION NOTES

July 2020 * Initial release

9.5 Register Map.............................................................32

10 Application and Implementation................................ 53

10.1 Application Information........................................... 53

10.2 Typical Application.................................................. 53

11 Power Supply Recommendations..............................58

12 Layout...........................................................................59

12.1 Layout Guidelines................................................... 59

12.2 Layout Example...................................................... 59

13 Device and Documentation Support..........................60

13.1 Device Support....................................................... 60

13.2 Documentation Support.......................................... 60

13.3 Receiving Notification of Documentation Updates..60

13.4 Support Resources................................................. 60

13.5 Trademarks.............................................................60

13.6 Electrostatic Discharge Caution..............................60

13.7 Glossary..................................................................60

14 Mechanical, Packaging, and Orderable

Information.................................................................... 61

14.1 Package Option Addendum.................................... 62

2 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: BQ21062

www.ti.com

SLUSE42 – JULY 2020

BQ21062

5 Description (continued)

The device supports charge current up to 500 mA and supports termination current down to 0.5 mA for

maximum charge. The battery is charged using a standard Li-Ion charge profile with three phases: pre-charge,

constant current and constant voltage regulation.

The device integrates advanced power path management and control that allows the device to provide power to

the system while charging the battery even with poor adapters. The host may also control the power path

through I2C allowing it to disconnect the input adapter and/or battery without physically removing them. The

single push-button input eliminates the need of a separate button controller IC reducing the total solution

footprint. The push-button input can be used for wake functions or to reset the system. The low quiescent current

during operation and shutdown enables maximum battery life. The input current limit, charge current, LDO output

voltage, and other parameters are programmable through the I2C interface making the BQ21062 a very flexible

charging solution. A voltage-based JEITA compatible (or standard HOT/COLD) battery pack thermistor

monitoring input (TS) is included that monitors battery temperature and automatically changes charge

parameters to prevent the battery from charging outside of its safe temperature range. The temperature

thresholds are also programable through I2C allowing the host to customize the thermal charging profile. The

charger is optimized for 5-V USB input, with 20-V absolute maximum tolerance to withstand line transients. The

device also integrates a linear regulator to provide a quiet rail for radios or processors and can be independently

sourced and controlled through I2C.

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: BQ21062

Submit Document Feedback

3

BQ21062

SLUSE42 – JULY 2020

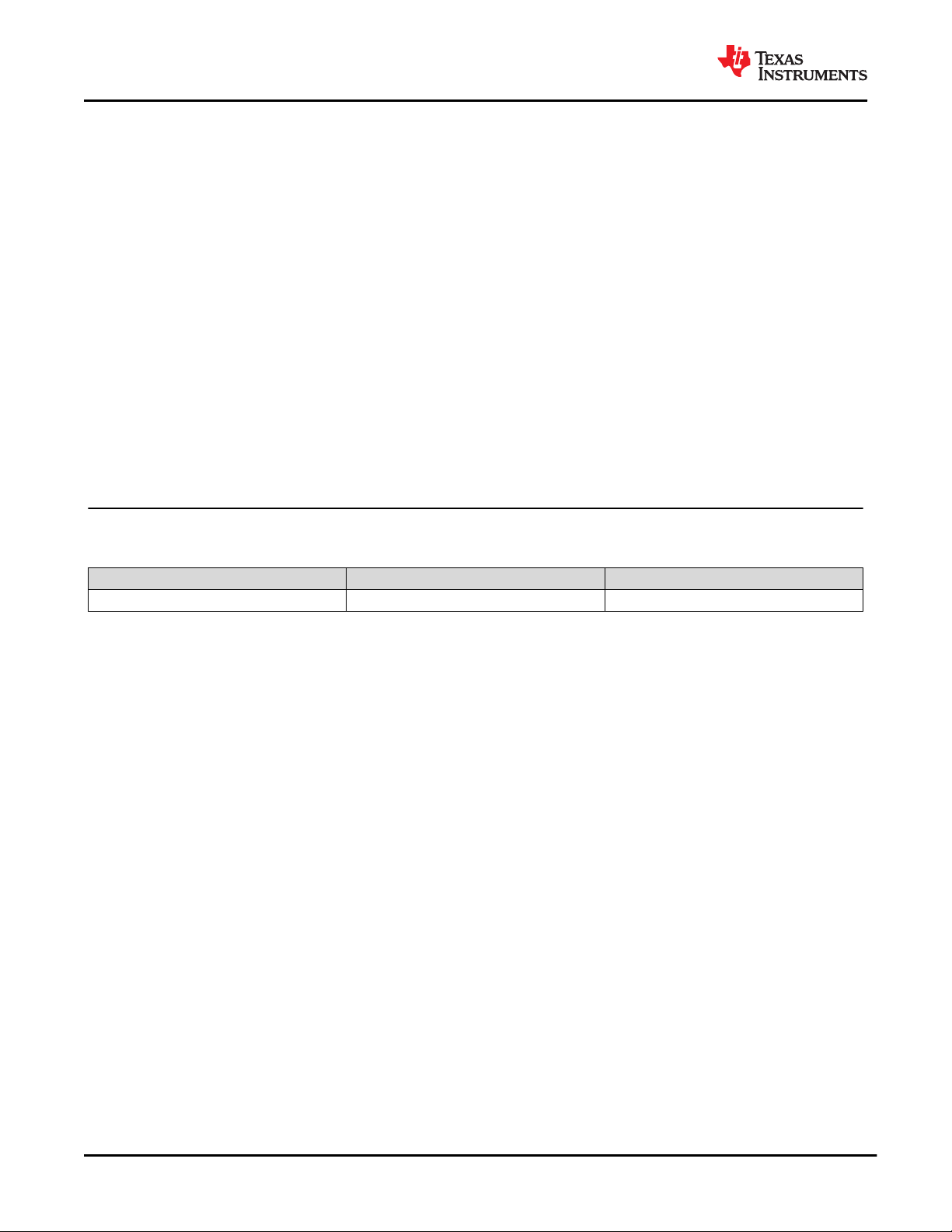

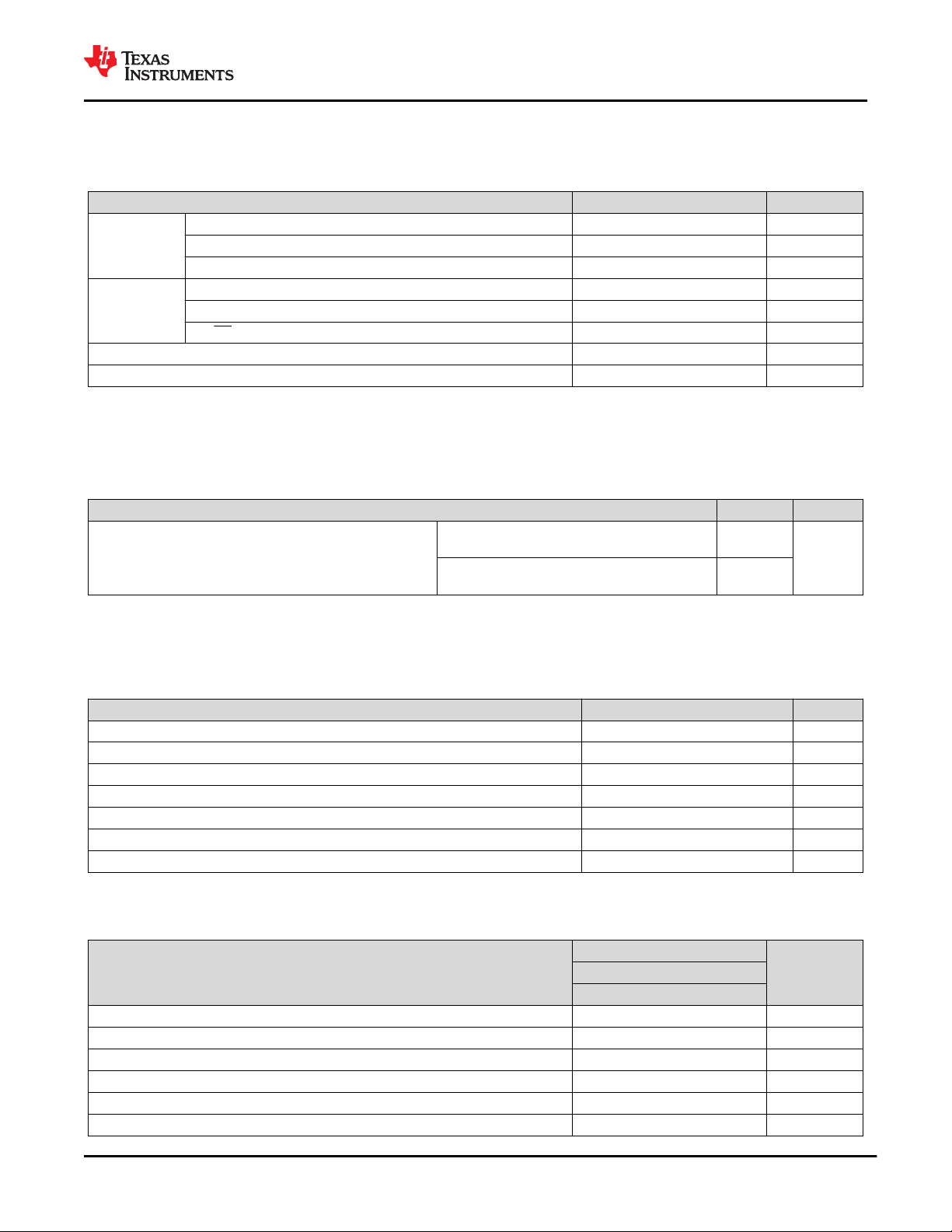

6 Device Comparison Table

Table 6-1. Device Comparison

PARAMETER BQ21061 BQ21062

ICHARGE (default) 10mA 67.5mA

IPRECHARGE (default) 2.5mA 8.75mA

INLIM (default) 500mA 100mA

WATCHDOG TIMER (default) Enabled Disabled

VINDPM (default) Disabled Enabled

DPPM Enabled Disabled

LS/LDO (default) Enabled Disabled

LDO CONFIG (default) LDO Load Switch

BATUVLO (default) 3V 2.8V

MR HW RESET (default) 8s 14s

AUTOWAKE TIME (default) 1.2s 2.4s

TS THRESHOLD (default) TWARM = 45°C; THOT = 60°C TWARM = THOT = 45°C

www.ti.com

4 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: BQ21062

IN PMID BAT GND

/PG PMID BAT TS

/MR /CE NC1 NC2

VDD /INT /LP LSLDO

VIO SDA SCL VINLS

A

B

C

D

E

1 2 3 4

www.ti.com

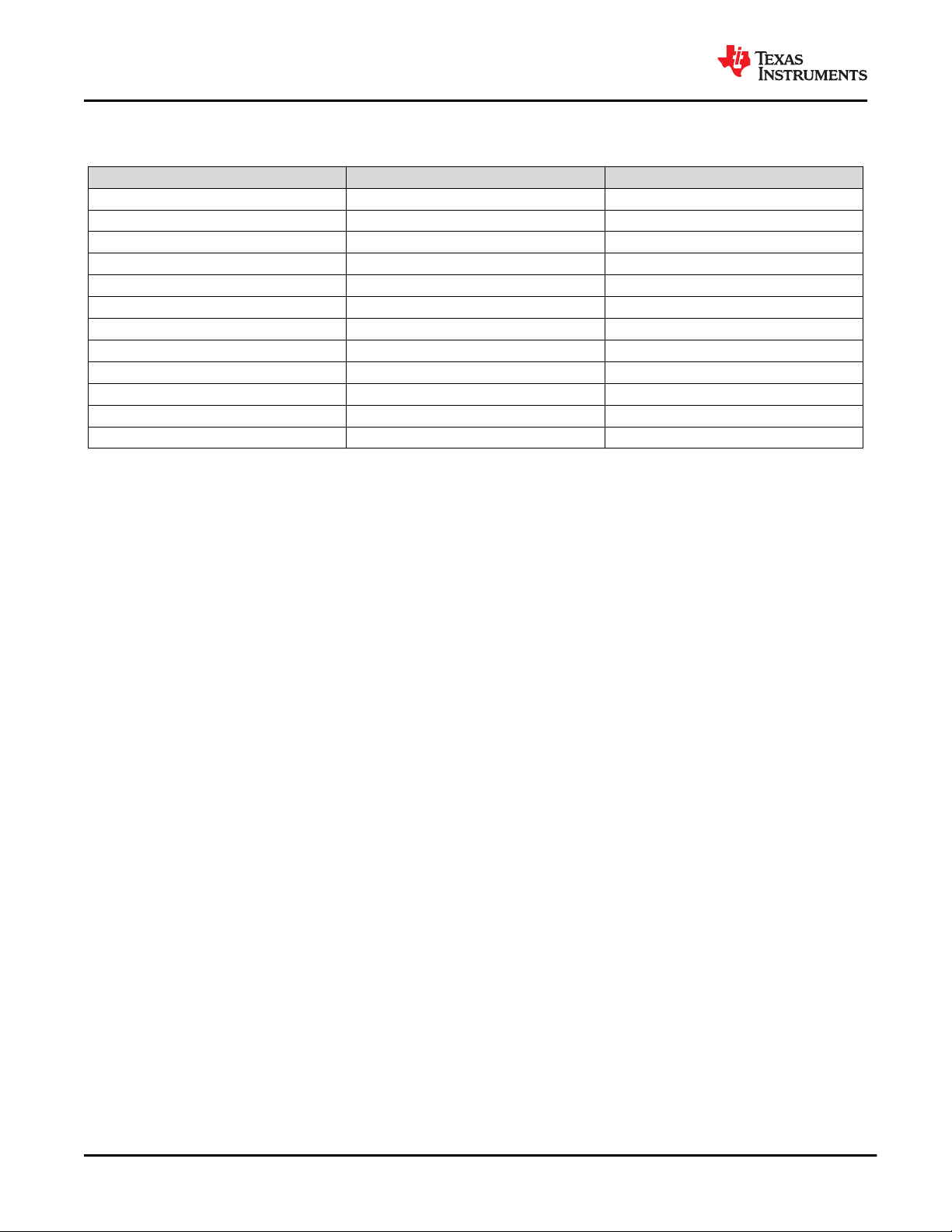

7 Pin Configuration and Functions

SLUSE42 – JULY 2020

BQ21062

Figure 7-1. YFP Package 20-Pin DSBGA Top View

Pin Functions

PIN

NAME NO.

IN A1 I

PMID A2, B2 I/O

GND A4 PWR Ground connection. Connect to the ground plane of the circuit.

VDD D1 O Digital supply LDO. Must connect a 2.2-µF from this pin to ground, do not leave floating.

CE C2 I

SCL E3 I/O I2C Interface Clock. Connect SCL to the logic rail through a 10-kΩ resistor.

SDA E2 I I2C Interface Data. Connect SDA to the logic rail through a 10-kΩ resistor.

LP D3 I

INT D2 O

MR C1 I

LS/LDO D4 O

VINLS E4 I

I/O DESCRIPTION

DC Input Power Supply. IN is connected to the external DC supply. Bypass IN to GND with

at least 1-µF of capacitance using a ceramic capacitor.

Regulated System Output. Connect 22-µF capacitor from PMID to GND as close to the

PMID and GND pins as possible. If operating in VIN Pass-Through Mode (PMID_REG =

111) a lower capacitor value may be used (at least 3-µF of ceramic capacitance with DC bias

de-rating).

Charge Enable. Drive CE low or leave disconnected to enable charging when VIN is valid.

CE is pulled low internally with 900-kΩ resistor.

Low Power Mode Enable. Drive this pin low to set the device in low power mode when

powered by the battery. This pin must be driven high to allow I2C communication when VIN

is not present. LP is pulled low internally with 900-kΩ resistor. This pin has no effect when

VIN is present.

INT is an open-drain output that signals fault interrupts. When a fault occurs, a 128-µs pulse

is sent out as an interrupt for the host.

Manual Reset Input. MR is a general purpose input used to reset the device or to wake it up

from Ship Mode. MR has in internal 125-kΩ pull-up resistor to BAT. The battery voltage V

must be above V

in order for MR low logic level to be detected.

BATUVLO

Load Switch or LDO output. Connect 2.2 µF of ceramic capacitance to this pin to assure

stability. Be sure to account for capacitance bias voltage derating when selecting the

capacitor. If LDO is not used, short to VINLS

Input to the Load Switch / LDO output. Connect at least 1 µF of ceramic capacitance from

this pin to ground.

BAT

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: BQ21062

Submit Document Feedback

5

BQ21062

SLUSE42 – JULY 2020

PIN

NAME NO.

BAT A3, B3 I/O

TS B4 I

PG B1 O

VIO E1 I

NC1 C3 I

NC2 C4 I

www.ti.com

Pin Functions (continued)

I/O DESCRIPTION

Battery Connection. Connect to the positive terminal of the battery. Bypass BAT to GND with

at least 1 µF of ceramic capacitance.

Battery Pack NTC Monitor. Connect TS to a 10-kΩ NTC thermistor in parallel to a 10-kΩ

resistor. If TS function is not to be used connect a 5-kΩ resistor from TS to ground.

Open-drain Power Good status indication output. The PG pin can also be configured as a

general purpose open drain output or level shifter version of MR.

System IO supply. Connect to system IO supply to allow level shifting of input signals (SDA,

SCL, LP and CE) to the device internal digital domain. Connect to VDD when external IO

supply is not available.

No Connect. Connect to ground if possible for better thermal dissipation or leave floating. Do

not connect to a any voltage source or signal to avoid higher quiescent current.

No Connect. Connect to ground if possible for better thermal dissipation. May be shorted

to /LP for easier routing as long as Absolute Maximum Rating requirements are met..

6 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: BQ21062

www.ti.com

SLUSE42 – JULY 2020

8 Specifications

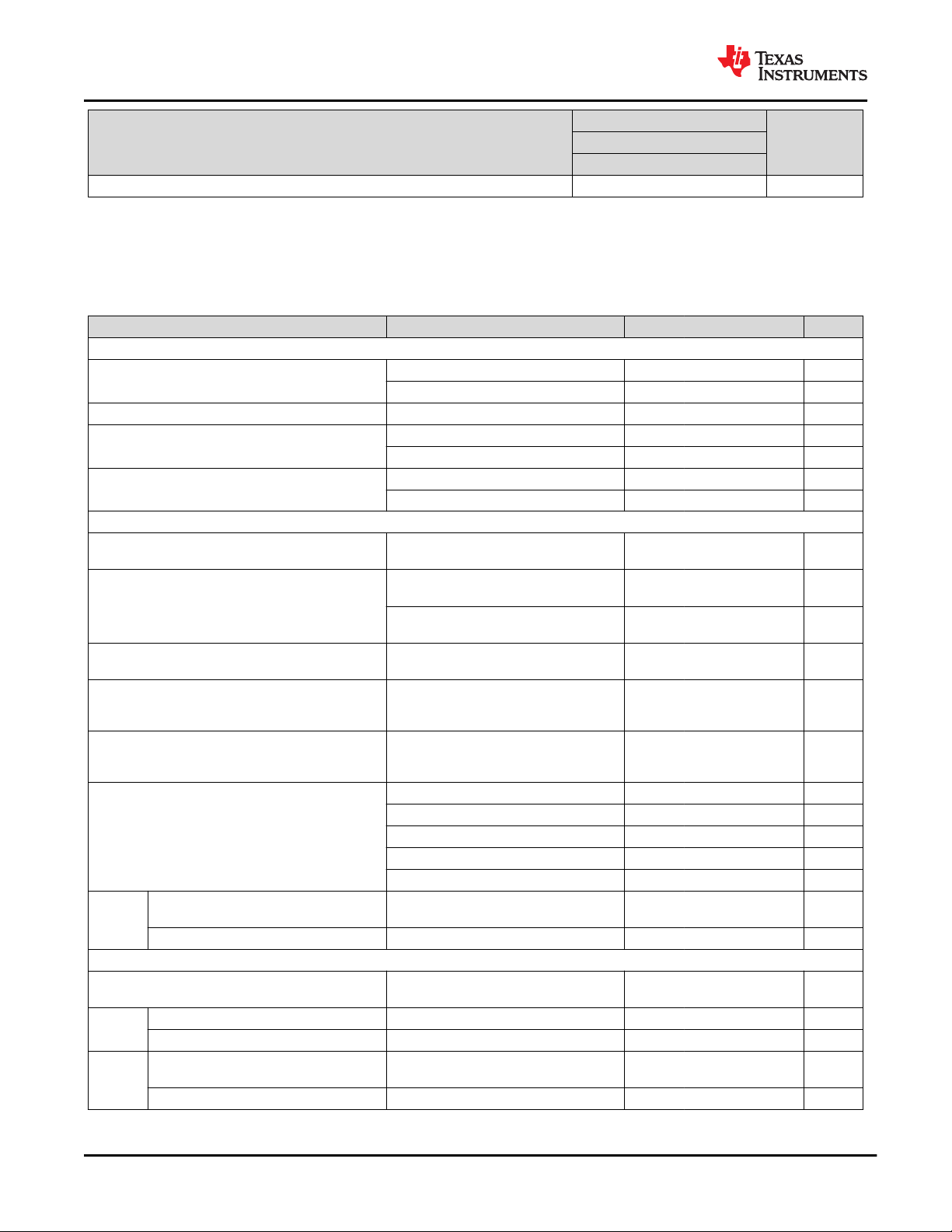

8.1 Absolute Maximum Ratings

BQ21062

over operating free-air temperature range (unless otherwise noted)

IN –0.3 20 V

Voltage

TS,VDD, NC –0.3 1.95 V

All other pins –0.3 5.5 V

IN 0 800 mA

Current

BAT, PMID –0.5 1.5 A

INT, PG 0 10 mA

Junction temperature, T

Storage temperature, T

J

stg

(1) Stresses beyond those listed under Absolute Maximum Rating may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under

Recommended Operating Condition. Exposure to absolute-maximum-rated conditions for extended periods may affect device

reliability.

8.2 ESD Ratings

Human body model (HBM), per ANSI/ESDA/

V

(ESD)

Electrostatic discharge

JEDEC JS-001, all pins

Charged device model (CDM), per JEDEC

specification JESD22-C101, all pins

(1)

MIN MAX UNIT

–40 125 °C

–55 150 °C

VALUE UNIT

(1)

(2)

±2000

V

±500

(1) JEDEC document JEP155 states that 500-V HBM allows safe manufacturing with a standard ESD control process.

(2) JEDEC document JEP157 states that 250-V CDM allows safe manufacturing with a standard ESD control process.

8.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN NOM MAX UNIT

V

BAT

V

IN

V

INLS

V

IO

I

LDO

I

PMID

T

A

(1) Based on minimum V

Battery voltage range 2.4 4.6 V

Input voltage range 3.15 5.25

LDO input voltage range 2.2 5.25

IO supply voltage range 1.2 3.6 V

LDO output current 0 100 mA

PMID output current 0 1.5 A

Operating free-air temperature range –40 85 °C

value. 5.5V under typical conditions

OVP

8.4 Thermal Information

BQ21062

(1)

20-PIN

(2)

36.1 °C/W

R

θJA

R

θJA

R

θJC(top)

R

θJB

Ψ

JT

Ψ

JB

THERMAL METRIC

Junction-to-ambient thermal resistance

Junction-to-ambient thermal resistance 74.4 °C/W

Junction-to-case (top) thermal resistance 0.5 °C/W

Junction-to-board thermal resistance 17.6 °C/W

Junction-to-top characterization parameter 0.3 °C/W

Junction-to-board characterization parameter 17.7 °C/W

(1)

V

(1)

V

UNITYFP (DSBGA)

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: BQ21062

Submit Document Feedback

7

BQ21062

SLUSE42 – JULY 2020

BQ21062

THERMAL METRIC

(1)

20-PIN

R

θJC(bot)

Junction-to-case (bottom) thermal resistance N/A °C/W

(1) For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

(2) Measured in BQ21062EVM board.

www.ti.com

UNITYFP (DSBGA)

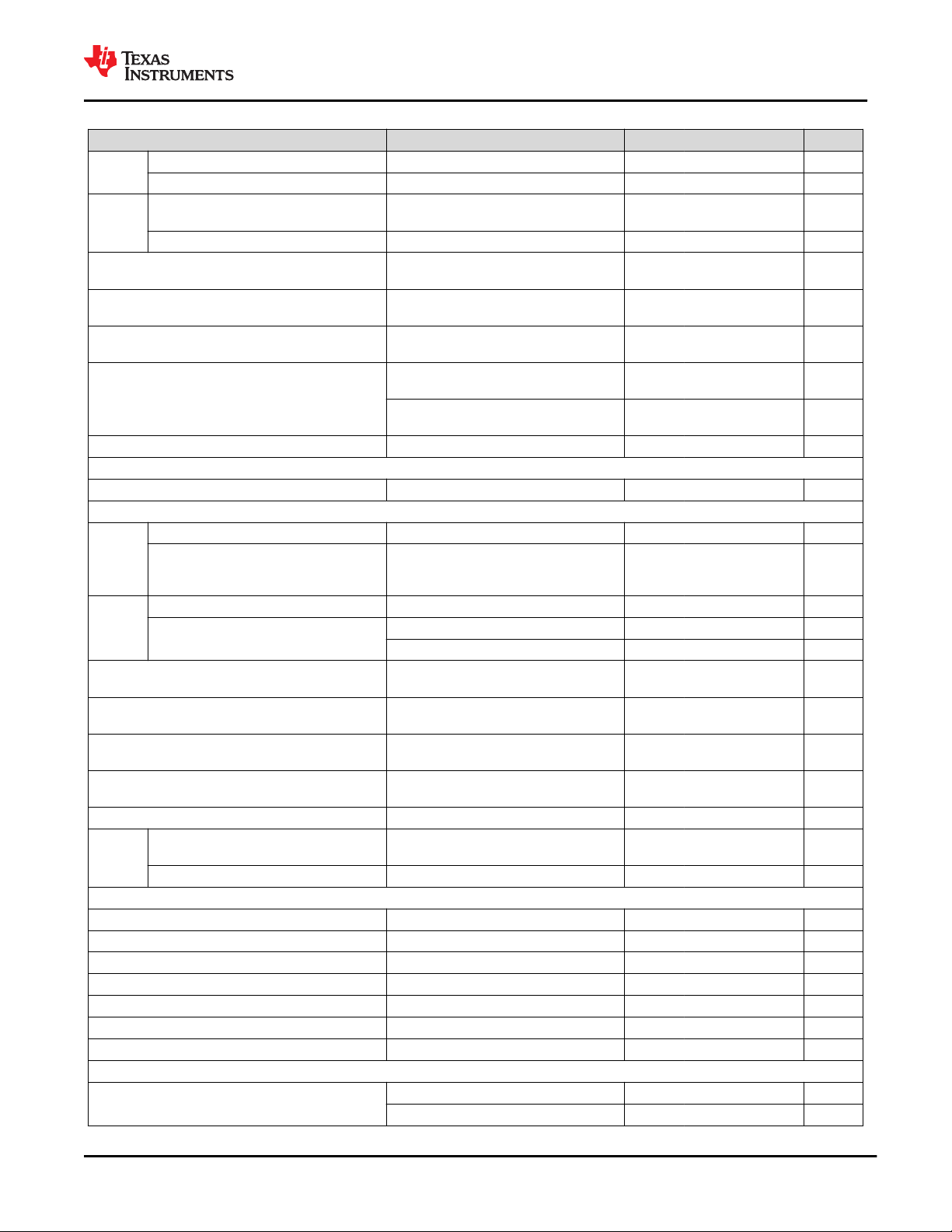

8.5 Electrical Characteristics

VIN = 5V, V

= 3.6V, -40°C < TJ < 125°C unless otherwise noted. Typical data at TJ = 25°C.

BAT

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

INPUT CURRENTS

I

IN

I

BAT_SHIP

I

BAT_LP

I

BAT_ACTI

VE

Input supply current

Battery Discharge Current in Ship Mode VIN = 0V , V

Battery Quiescent Current in Low-power

Mode

Battery Quiescent Current in Active Mode

PMID_MODE = 01, VIN = 5V, V

VIN = 5V, V

VIN = 0V , V

VIN = 0V , V

VIN = 0V , V

VIN = 0V , V

POWER PATH MANAGEMENT AND INPUT CURRENT LIMIT

V

PMID_RE

G

Default System (PMID) Regulation

Voltage

VIN = 5V, V

V

PMID_RE

G_ACC

System Regulation Voltage Accuracy

100mA, TJ = 25°C

VIN = 5V, V

500mA

R

ON(IN-

PMID)

V

BSUP1

V

BSUP2

Input FET ON resistance

Enter supplements mode threshold V

Exit supplements mode threshold V

I

= 500mA (ILIM = 110), VIN = 5V, IIN =

ILIM

150mA

> V

BAT

> V

BAT

Programmable Range 50 600 mA

I

= 50mA 45 50 mA

ILIM

I

ILIM

V

IN_DPM

Input Current Limit

Input DPM voltage threshold where

current in reduced

I

= 100mA 90 100 mA

ILIM

I

= 150mA 135 150 mA

ILIM

I

= 500mA 450 500 mA

ILIM

Programmable Range 4.2 4.9 V

Accuracy –3 3 %

BATTERY CHARGER

R

ON(BAT-

PMID)

V

BATREG

I

CHARGE

Battery Discharge FET On Resistance V

= 4.35V, I

BAT

Charge Voltage Programmable charge voltage range 3.6 4.6 V

Voltage Regulation Accuracy 0.5 0.5 %

Fast Charge Programmable Current

Range

Fast Charge Current Accuracy I

V

LOWV

CHARGE

= 3.6V 500 µA

BAT

= 3.6V Charge Disabled 1.6 mA

BAT

= 3.6V 10 nA

BAT

= 3.6V, LDO Disabled 0.46 0.9 µA

BAT

= 3.6V, LDO Enabled 1.7 1.9 µA

BAT

= 3.6V, LDO Disabled 18 23 µA

BAT

= 3.6V, LDO Enabled 21 25 µA

BAT

4.5 V

PMID_REG

PMID_REG

= 4.5V. I

= 4.5V. I

PMID

PMID

=

= 0-

-1 1 %

–3 3 %

280 520 mΩ

V

<

BATUVLO

, Charge disabled

PMID

V

BAT

–

40mV

V

<

BATUVLO

, Charge disabled

PMID

V

BAT

–

20mV

= 100mA 100 175 mΩ

BAT

< V

BAT

< V

BATREG

1.25 mA

> 5mA –5 5 %

mV

mV

8 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: BQ21062

www.ti.com

SLUSE42 – JULY 2020

BQ21062

VIN = 5V, V

= 3.6V, -40°C < TJ < 125°C unless otherwise noted. Typical data at TJ = 25°C.

BAT

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

I

PRECHAR

GE

I

TERM

Precharge current Precharge current programmable range 1.25 mA

Precharge Current Accuracy -40°C < TJ < 85°C –10 10 %

Termination Charge Current

Accuracy I

V

LOWV

V

SHORT

I

SHORT

V

RCH

R

PMID_PD

Programmable voltage threshold for precharge to fast charge transitions

Battery voltage threshold for short

detection

Charge Current in Battery Short Condition V

Recharge Threshold voltage

PMID pull-down resistance V

VDD

V

DD

VDD LDO output voltage 1.8 V

LS/LDO

Input voltage range for Load switch Mode 0.8 5.5 V

V

INLS

Input voltage range for LDO Mode

LDO programmable output voltage range 0.6 3.7 V

V

LDO

ΔV

ΔI

OUT

ΔV

ΔV

R

DOSN_LD

O

R

DSCH_LS

LDO

I

OCL_LDO

LDO output accuracy

/

OUT

DC Load Regulation

/

OUT

DC Line Regulation

IN

Switch On resistance V

Discharge FET On-resistance for LS V

Output Current Limit V

LDO VINLS quiescent current in LDO

I

IN_LDO

mode

OFF State Supply Current V

BATTERY PACK NTC MONITOR

V

HOT

V

WARM

V

COOL

V

COLD

V

OPEN

V

HYS

I

TS_BIAS

High temperature threshold VTS falling, -10°C < TJ < 85°C 0.256

Warm temperature threshold VTS falling, -10°C < TJ < 85°C 0.256

Cool temperature threshold VTS rising, -10°C < TJ < 85°C 0.510

Cold temperature threshold VTS rising, -10°C < TJ < 85°C 0.581

TS Open threshold VTS rising, -10°C < TJ < 85°C 0.9 V

Threshold hysteresis 4.7 mV

TS bias current -10°C < TJ < 85°C 78.4 80 81.6 µA

PROTECTION

V

UVLO

IN active threshold voltage

Termination Current Programmable

Range

TERM

= 10% I

CHARGE

, I

CHARGE

= 100mA –5

1 31 %

(1)

(1)

5

VBAT rising. Programmable Range 2.8 3 V

VBAT falling, VIN = 5V 2.41 2.54 2.67 V

I

< V

BAT

SHORT

V

falling, V

BAT

BATREG

= 4.2V, V

RCH

=

140mV setting

V

falling, V

BAT

BATREG

= 4.2V, V

RCH

=

200mV setting

= 3.6V 25 Ω

PMID

PRECHAR

GE

140 mV

200 mV

mA

2.2 or

V

LDO

+

5.5 V

500mV

TJ = 25°C –2 2 %

V

= 1.8V, V

LDO

0°C < TJ < 85°C, 1 mA < I

V

= 1.8V

LDO

0°C < TJ < 85°C, Over V

100mA, V

V

LDO

= 3.6V 250 450 mΩ

INLS

= 3.6V 40 Ω

INLS

= 0V 200 300 mA

LS/LDO

= V

BAT

INLS

= V

BAT

INLS

INLS

= 1.8V

=3.6V. I

= 1mA –3 3 %

LOAD

< 150mA,

OUT

INLS

range, I

OUT

=

1.2 %

0.5 %

=3.6V 0.9 µA

=3.6V 0.25 µA

(1)

(1)

(1)

(1)

0.265 0.268

0.265 0.268

0.514 0.523

0.585 0.594

(1)

(1)

(1)

(1)

VIN rising 3.4 V

VIN falling 3.25 V

%

V

V

V

V

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: BQ21062

Submit Document Feedback

9

BQ21062

SLUSE42 – JULY 2020

www.ti.com

VIN = 5V, V

= 3.6V, -40°C < TJ < 125°C unless otherwise noted. Typical data at TJ = 25°C.

BAT

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Battery undervoltage Lockout Threshold

Voltage

V

BATUVLO

Accuracy –3 3 %

Battery undervoltage Lockout Threshold

Voltage at Power Up

V

SLP_ENT

RY

V

SLP_EXIT

V

OVP

Sleep Entry Threshold (VIN - V

Sleep Exit Threshold (VIN - V

Input Supply Over Voltage Threshold

Battery Over Current Threshold

I

BAT_OCP

Programmable range

Current Limit Accuracy –30 30 %

T

SHUTDO

WN

T

HYS

Thermal shutdown trip point 125 °C

Thermal shutdown trip point hysteresis 15 °C

I2C INTERFACE (SCL and SDA)

I2C Frequency 100 400 kHz

V

V

V

I

IL

IH

OL

LKG

Input Low threshold level V

Input High Threshold level V

Output Low threshold level V

High-level leakage Current V

/MR INPUT

R

PU

V

IL

Internal pull up resistance 90 125 170 kΩ

/MR Input Low threshold level V

/INT, /PG OUTPUTS

V

I

OL

LKG

Output Low threshold level V

/INT Hi level leakage Current High Impedance, V

/CE, /LP INPUTS

R

PDOWN

V

IL

V

IH

/CE pull down resistance 900 kΩ

Input Low threshold level VIO = 1.8V 0.45 V

/CE Input High Threshold level VIO = 1.8V 1.35 V

Programmable range, 150 mV Hysteresis 2.4 3 V

V

) 2.0V < V

BAT

) 2.0V < V

BAT

VIN rising 5.35 5.5 5.8 V

VIN falling (125mV hysteresis) 5.4 V

I

rising, VIN = 0V, TJ = 25°C 3.15 V

BAT

< V

BAT

< V

BAT

increasing 1200 1600 mA

BAT_OCP

= VIO = 1.8V

PULLUP

= VIO = 1.8V

PULLUP

= VIO = 1.8V, I

PULLUP

= VIO = 1.8V 1 µA

PULLUP

> V

BAT

BUVLO

= VIO = 1.8V, I

PULLUP

, VIN falling 80 mV

BATREG

BATREG

130 mV

0.75 *

V

IO

= 5mA

LOAD

= 5mA

LOAD

= VIO = 1.8V 1 µA

PULLUP

0.25 *

0.25 *

0.25 *

V

IO

V

IO

0.3 V

V

IO

V

V

V

V

(1) Based on Characterization Data

8.6 Timing Requirements

PARAMETER

BATTERY CHARGE TIMERS

t

MAXCHG

t

PRECHG

WATCHDOG TIMERS

t

WATCHDO

G_SW

t

HW_RESE

T_WD

LDO

10 Submit Document Feedback

Charge safety timer Programmable range 180 720 min

Precharge safety timer 0.25 * t

SW Watchdog timer 25 50 s

HW reset watchdog timer WATCHDOG_15S_ENABLE = 1 15 s

TEST CONDITIONS MIN TYP MAX UNIT

MAXCHG

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: BQ21062

www.ti.com

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

t

ON_LDO

t

OFF_LDO

t

PMID_LDO

_DELAY

Turn ON time 100mA load, to 90% V

Turn OFF time 100mA load, to 10% V

Delay between PMID and LDO enable

during power up

PUSHBUTTON TIMERS (/MR)

t

WAKE1

t

WAKE2

t

RESET_W

ARN

t

HW_RESE

T

t

RESTART(

AUTOWAKE

)

WAKE1 Timer. Timer for Ship Mode

wake.

WAKE2 Timer. Time from /MR falling

edge to INT being asserted.

RESET_WARN Timer. Time prior to HW

RESET

HW RESET Timer. Time from /MR falling

edge to HW Reset

RESTART Timer. Time from /MR HW

Reset to PMID power up

PROTECTION

t

DGL_SLP

t

DGL_OVP

t

DGL_OCP

t

REC_SC

t

RETRY_SC

t

DGL_SHT

DWN

Deglitch time for supply rising above V

+ V

SLP_HYS

Deglitch time for V

Battery OCP deglitch time 30 µs

Recovery time, BAT Short Circuit during

Discharge Mode

Retry window for PMID or BAT short

circuit recovery

Deglitch time, Thermal shutdown TJ rising above T

I2C INTERFACE

t

WATCHDO

G

t

I2CRESET

I2C interface reset timer for host When enabled 50 s

I2C interface inactive reset timer 500 ms

INPUT PINS (/CE and /LP)

t

LP_EXIT_I

2C

Time for device to exit Low-power mode

and allow I2C communication

Startup 20 ms

MR_WAKE1_TIMER = 0 106 125 144 ms

MR_WAKE2_TIMER = 1 1.7 2 2.3 s

MR_RESET_WARN = 01 0.85 1 1.15 s

MR_HW_RESET = 01 6.8 8 9.2 s

AUTOWAKE = 01 1.05 1.2 1.35 s

SLP

Threshold VIN falling below V

OVP

VIN = 0V. 1 ms

LDO

LDO

OVP

SHUTDOWN

SLUSE42 – JULY 2020

BQ21062

500 µs

30 µs

120 µs

32 ms

250 ms

2 s

10 µs

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: BQ21062

Submit Document Feedback

11

V

BATREG

(V)

Error (%)

3.6 3.7 3.8 3.9 4 4.1 4.2 4.3 4.4 4.5 4.6

-0.5

-0.45

-0.4

-0.35

-0.3

-0.25

-0.2

-0.15

-0.1

-0.05

0

D011

TJ = 25C

TJ = 0C

TJ = -40C

TJ = 60C

TJ = 125C

I

CHARGE

(A)

Error (%)

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45 0.5

-1.75

-1.5

-1.25

-1

-0.75

-0.5

-0.25

0

0.25

0.5

0.75

1

1.25

D014

TJ = -40C

TJ = 0C

TJ = 25C

TJ = 60C

TJ = 125C

I

PRECHARGE

(mA)

Error (%)

0 5 10 15 20 25 30 35 40

-1.5

-1

-0.5

0

0.5

1

1.5

D012

TJ = 25C

TJ = 0C

TJ = -40C

TJ = 60C

TJ = 125C

I

PRECHARGE

(A)

Error (%)

0 5 10 15 20 25 30 35 40 45 50 55 60 65 70 75 80

-1.2

-1

-0.8

-0.6

-0.4

-0.2

0

0.2

0.4

0.6

0.8

1

1.2

D013

TJ = 25C

TJ = 0C

TJ = -40C

TJ = 60C

TJ = 125C

BQ21062

SLUSE42 – JULY 2020

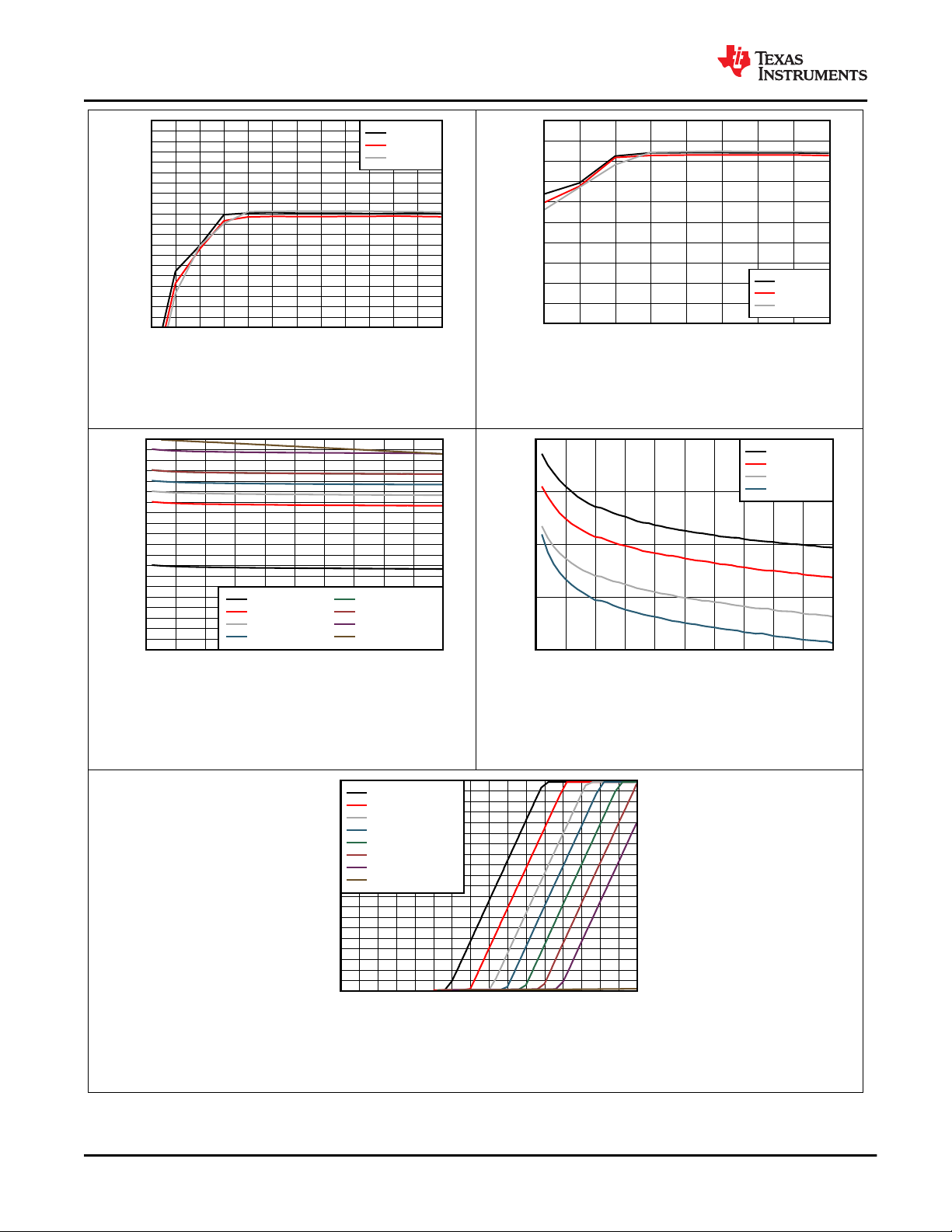

8.7 Typical Characteristics

www.ti.com

CIN = 1 µF, C

PMID

= 10 µF, C

LSLDO

= 2.2 µF, C

BAT

VIN = 5 V PMID_REG_CTRL = 111 (Pass-Through)

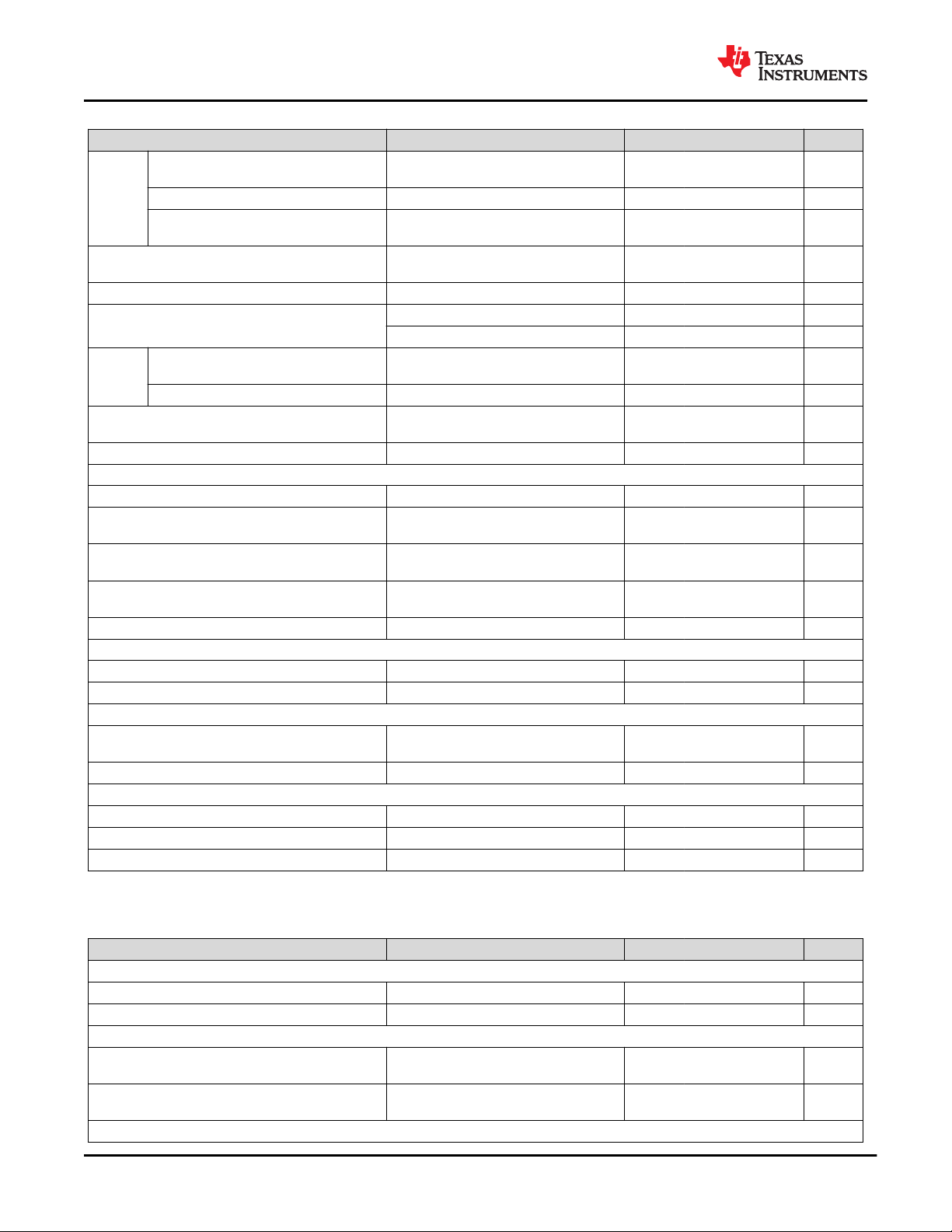

Figure 8-1. Battery Regulation Voltage Accuracy

vs. VBATREG Setting

= 1 µF (unless otherwise specified)

VIN = 5 V VBAT = 3.6 V ICHARGE_RANGE = 1

Figure 8-2. Charge Current Accuracy vs. ICHARGE

Setting

VIN = 5 V VBAT = 2.7 V ICHARGE_RANGE = 0

Figure 8-3. Pre-Charge Current Accuracy vs.

IPRECHARGE setting (ICHARGE_RANGE = 0)

12 Submit Document Feedback

VBUS = 5 V VBAT = 2.7 V ICHARGE_RANGE = 1

Figure 8-4. Pre-Charge Current Accuracy vs.

IPRECHARGE Setting (ICHARGE_RANGE = 1)

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: BQ21062

V

INLS

(V)

R

DSON

(:)

1 1.5 2 2.5 3 3.5 4 4.5 5

0

0.2

0.4

0.6

0.8

1

1.2

D015

TJ = -40C

TJ = 25C

TJ = 85C

I

LOAD

(A)

V

LDO

(V)

0.1 0.11 0.12 0.13 0.14 0.15 0.16 0.17 0.18 0.19 0.2

0.7984

0.7992

0.8

0.8008

0.8016

0.8024

0.8032

0.804

0.8048

0.8056

0.8064

D009

TJ = -40C

TJ = 25C

TJ = 85C

I

LOAD

(A)

V

LDO

(V)

0.01 0.03 0.05 0.07 0.09 0.11 0.13 0.15 0.17 0.19

1.79

1.792

1.794

1.796

1.798

1.8

1.802

1.804

1.806

1.808

1.81

1.812

1.814

1.816

1.818

1.82

D008

TJ = -40C

TJ = 25C

TJ = 85C

I

LOAD

(A)

V

LDO

(V)

0.01 0.03 0.05 0.07 0.09 0.11 0.13 0.15 0.17 0.19

3.29

3.294

3.298

3.302

3.306

3.31

3.314

3.318

3.322

3.326

3.33

D010

TJ = -40C

TJ = 25C

TJ = 85C

V

INLS

(V)

V

LDO

(V)

2.2 2.4 2.6 2.8 3 3.2 3.4 3.6 3.8 4 4.2 4.4

1.19

1.192

1.194

1.196

1.198

1.2

1.202

1.204

1.206

1.208

1.21

D004

TJ = -40C

TJ = 25C

TJ = 85C

V

INLS

(V)

V

LDO

(V)

2.2 2.4 2.6 2.8 3 3.2 3.4 3.6 3.8 4 4.2 4.4

1.79

1.792

1.794

1.796

1.798

1.8

1.802

1.804

1.806

1.808

1.81

D005

TJ = -40C

TJ = 25C

TJ = 85C

www.ti.com

SLUSE42 – JULY 2020

BQ21062

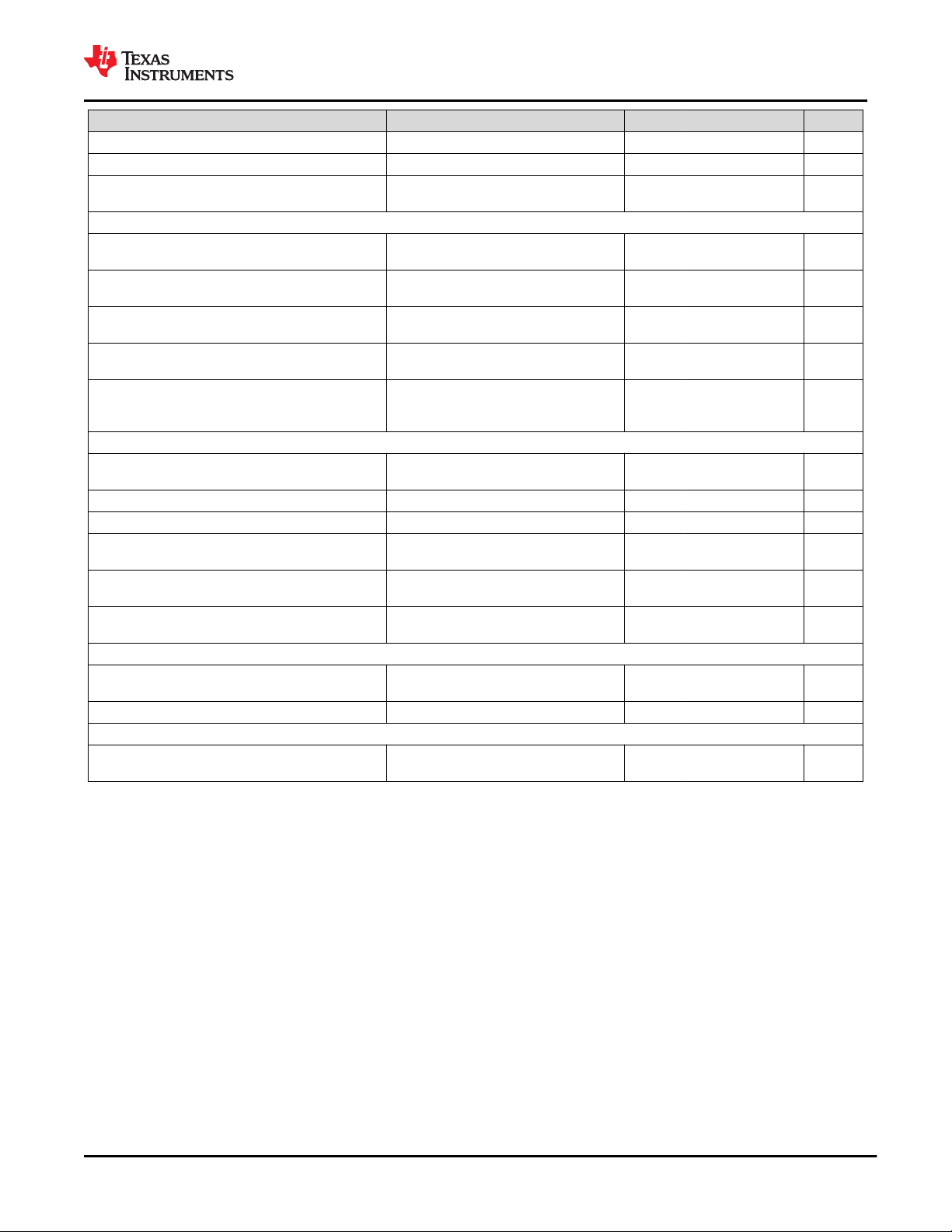

VBUS = 5 V

Figure 8-5. LS/LDO Switch On Resistance vs.

VINLS

VIN = 0 V VBAT = 3.6 V VINLS = VPMID

Figure 8-7. LDO Load Regulation (VLDO = 1.8 V)

VIN = 0 V VBAT = 3.6 V VINLS = VPMID

Figure 8-6. LDO Load Regulation (VLDO = 0.8 V)

VIN = 0 V VBAT = 3.6 V VINLS= VPMID

Figure 8-8. LDO Load Regulation (VLDO = 3.3 V)

Copyright © 2020 Texas Instruments Incorporated

VBAT = 4.4 V ILOAD = 150 mA

Figure 8-9. LDO Line Regulation (VLDO = 1.2 V)

VBAT = 4.4 V ILOAD = 150 mA

Figure 8-10. LDO Line Regulation (VLDO = 1.8 V)

Product Folder Links: BQ21062

Submit Document Feedback

13

V

INLS

(V)

VLDO (V)

3.2 3.3 3.4 3.5 3.6 3.7 3.8 3.9 4 4.1 4.2 4.3 4.4

3.2

3.22

3.24

3.26

3.28

3.3

3.32

3.34

3.36

3.38

3.4

D006

TJ = -40C

TJ = 25C

TJ = 85C

V

INLS

(V)

V

LDO

(V)

3.6 3.7 3.8 3.9 4 4.1 4.2 4.3 4.4

3.4

3.425

3.45

3.475

3.5

3.525

3.55

3.575

3.6

3.625

3.65

D007

TJ = -40C

TJ = 25C

TJ = 85C

PMID Load Current (A)

V

PMID

(V)

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45 0.5

3

3.2

3.4

3.6

3.8

4

4.2

4.4

4.6

4.8

5

D001

PMID_REG = 0

PMID_REG = 1

PMID_REG = 2

PMID_REG = 3

PMID_REG = 4

PMID_REG = 5

PMID_REG = 6

PMID_REG = 7

PMID Load (A)

V

PMID

(V)

0 0.05 0.1 0.15 0.2 0.25 0.3 0.35 0.4 0.45 0.5

4.44

4.46

4.48

4.5

4.52

D003

TJ = -40°C

TJ = 25°C

TJ = 85°C

TJ = 125°C

Temperature(qC)

Charge Current Reduction (%)

50 60 70 80 90 100 110 120 130

0

10

20

30

40

50

60

70

80

90

100

D004

THERM_REG = 0

THERM_REG = 1

THERM_REG = 2

THERM_REG = 3

THERM_REG = 4

THERM_REG = 5

THERM_REG = 6

THERM_REG = 7

BQ21062

SLUSE42 – JULY 2020

www.ti.com

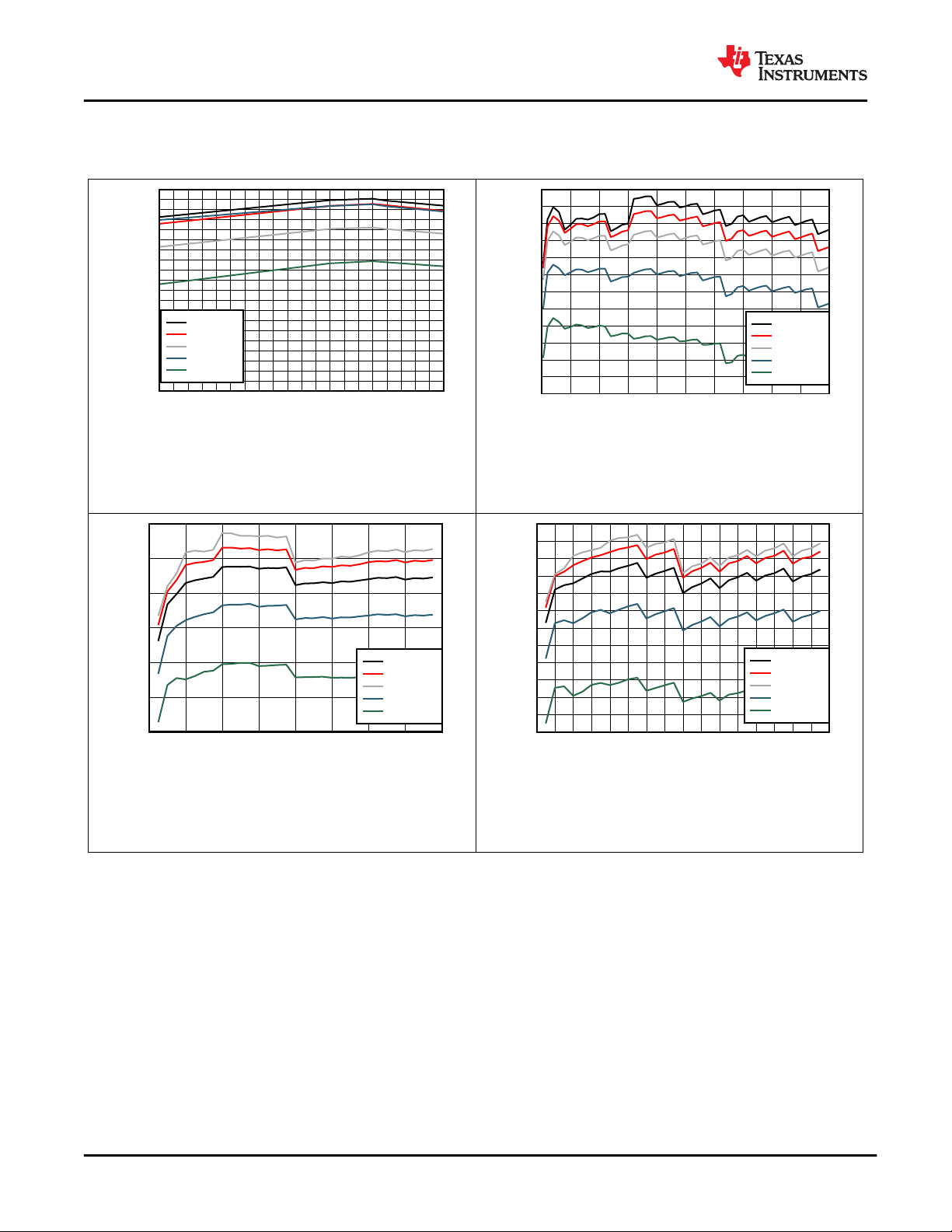

VBAT = 4.4 V ILOAD = 150 mA

Figure 8-11. LDO Line Regulation (VLDO = 3.3 V)

VBAT = 0 V

Figure 8-13. PMID Load Regulation

VBAT = 4.4 V ILOAD = 150 mA

Figure 8-12. LDO Line Regulation (VLDO = 3.6 V)

VBAT = 3.6 V VIN = 5 V

Figure 8-14. PMID Load Regulation vs.

Temperature

14 Submit Document Feedback

VBAT = 3.6 V VIN = 5 V

Figure 8-15. Charge Current Thermal Regulation

Product Folder Links: BQ21062

Copyright © 2020 Texas Instruments Incorporated

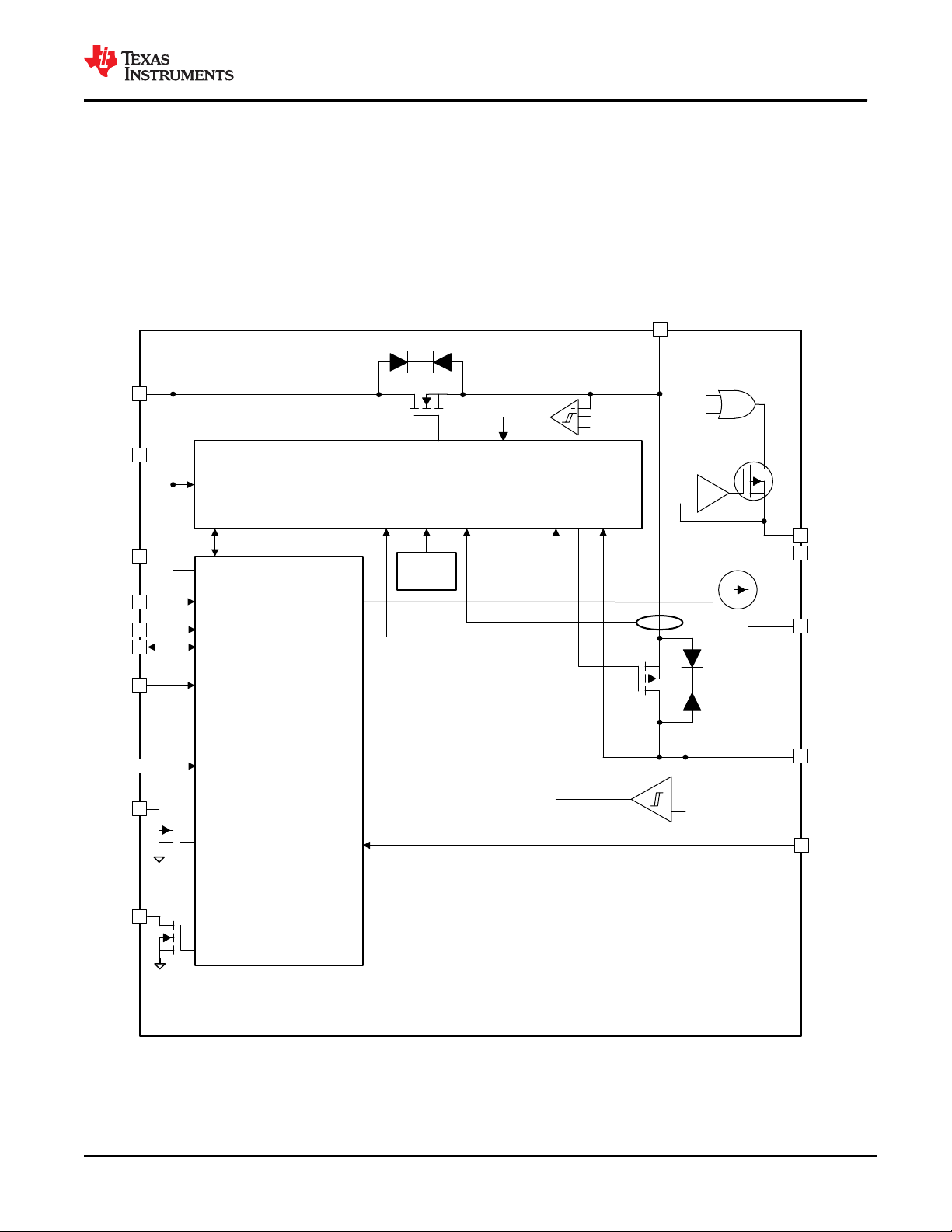

LDO, and BAT FET Control

Device Control

V

IN

Charge

Enable

I2C

Interface

Low Power Mode

Control

Charge Control

LDO / Load Switch

Control

Thermal

Shutdown

I

BATREG

LDO

Control

UVLO

V

BATREG

V

IN_DPM

BAT

VIN

+

±

/Power Good

GP Output

Interrupt

JEITA/Temp

Information

For Charge Control

S

G

D

S

G

D

Q7

Q8

IN

GND

VIO

/CE

SCL

SDA

/LP

/MR

/INT

/PG

PMID

VDD

VINLS

LDO

BAT

TS

V

BATUVLO

Q5/Q6

1.045 x V

BAT

PMID_REG

www.ti.com

SLUSE42 – JULY 2020

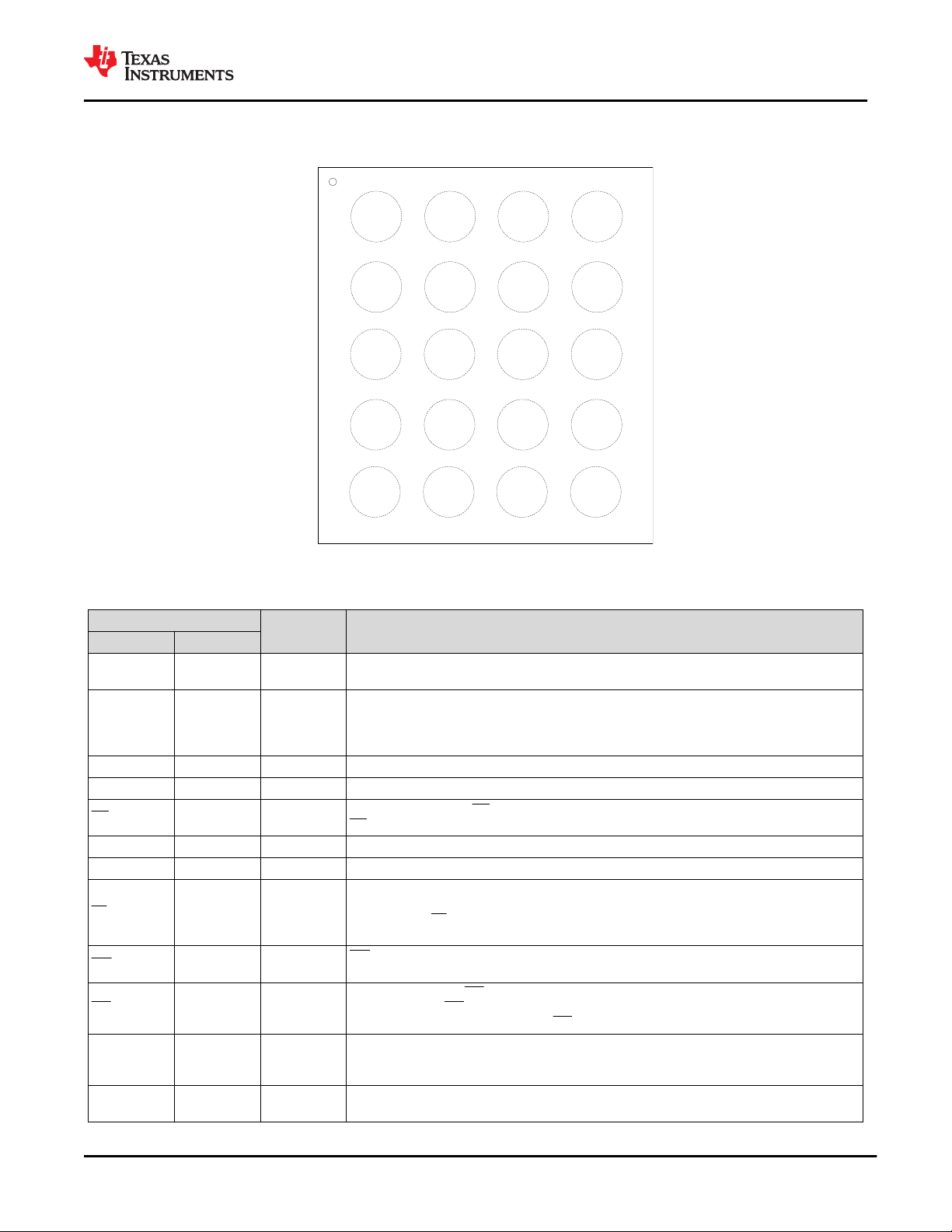

9 Detailed Description

9.1 Overview

The IC is a highly programmable battery management device that integrates a 500-mA linear charger for single

cell Li-Ion batteries, a general purpose LDO that may be configured as a load switch, and a push-button

controller. Through it's I2C interface the host may change charging parameters such as battery regulation voltage

and charge current, and obtain detailed device status and fault information. The push-button controller allows the

user to reset the system without any intervention from the host and wake up the device from Ship Mode.

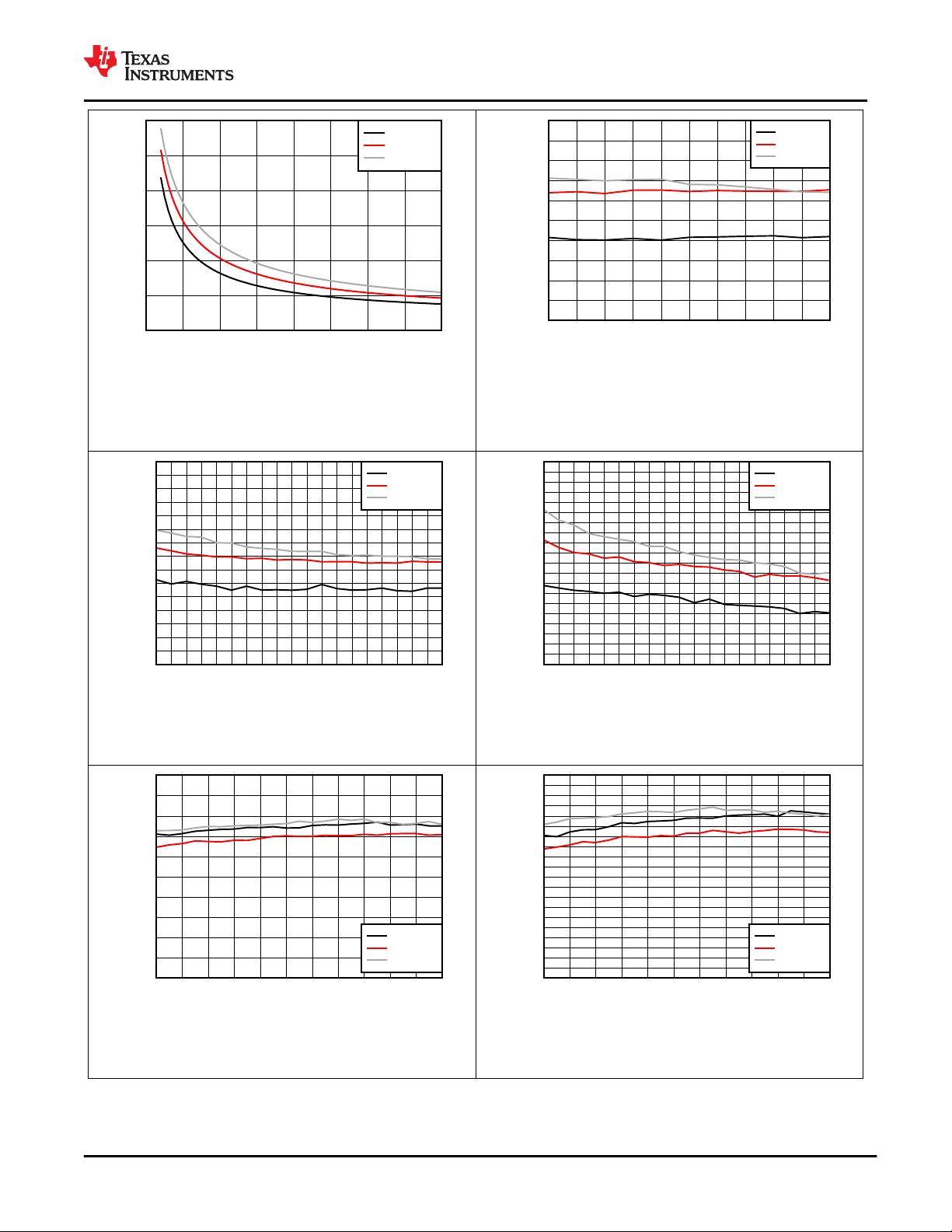

9.2 Functional Block Diagram

BQ21062

9.3 Feature Description

9.3.1 Linear Charger and Power Path

The BQ21062 IC integrates a linear charger that allows the battery to be charged with a programmable charge

current of up to 500 mA. In addition to the charge current, other charging parameters can be programmed

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: BQ21062

Submit Document Feedback

15

V

BAT

< V

LOWV

Start Precharge

Icharge set by I2C

Connect VIN

Precharge safety

timer expired?

Stop Charging and set

Fault bits

/CE toggled or VIN and

removed and

reconnected?

V

BAT

> V

LOWV

Start FastCharge

Icharge set by I2C

I

BAT

< I

TERM

Fast Charge safety

timer expired?

Charge Done (Set bit

and interrupt and

disconnect BATFET)

V

BAT

< V

BAT

- V

RCH

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes

No

Yes No

BQ21062

SLUSE42 – JULY 2020

www.ti.com

through I2C such as the battery regulation voltage, pre-charge current, termination current, and input current limit

current.

The power path allows the system to be powered from PMID, even when the battery is dead or charging, by

drawing power from IN pin. It also prioritizes the system load connected to PMID, reducing the charging current,

if necessary, in order to support the load when input power is limited. If the input supply is removed and the

battery voltage level is above V

BATUVLO

, PMID will automatically and seamlessly switch to battery power.

A more detailed description of the charger functionality is presented in the following sections of this document.

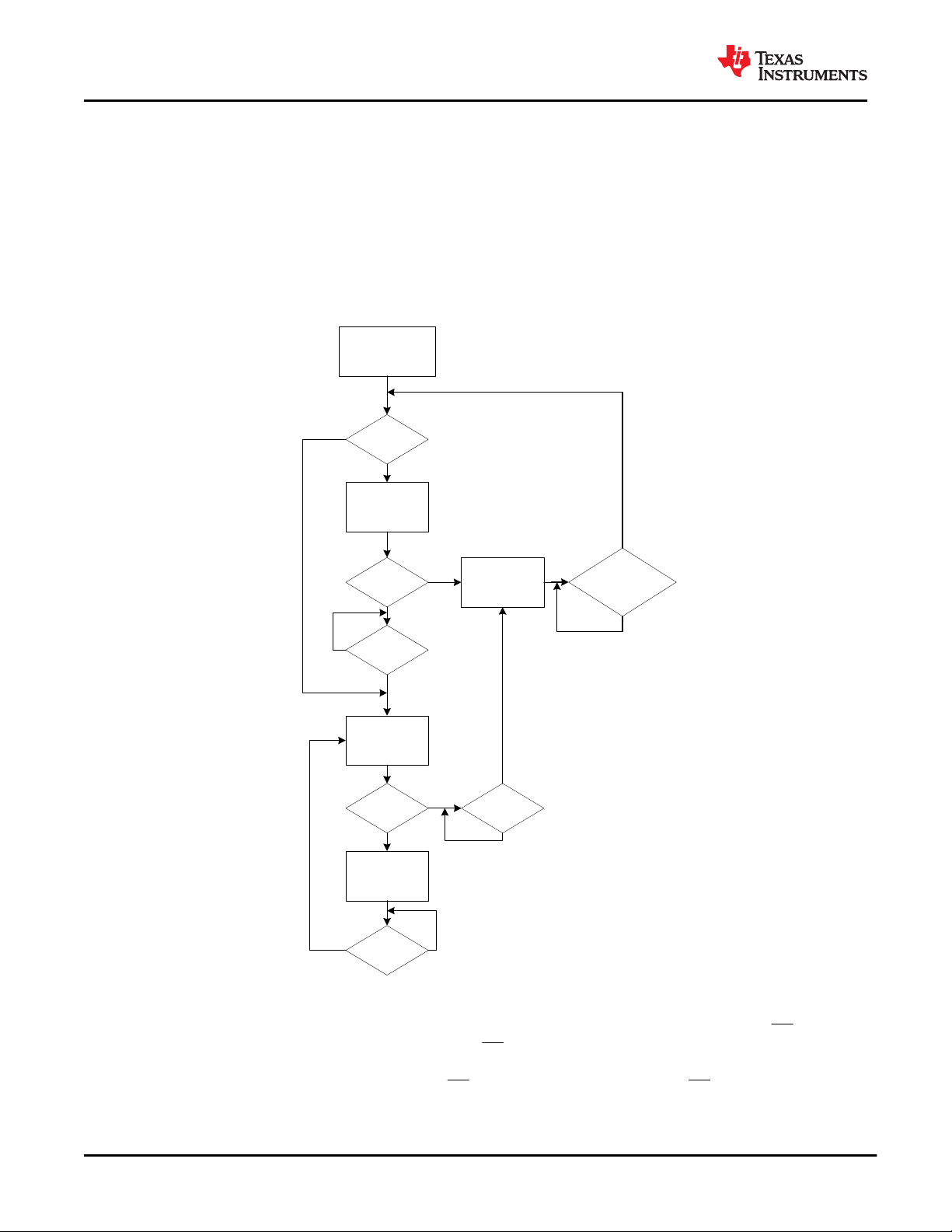

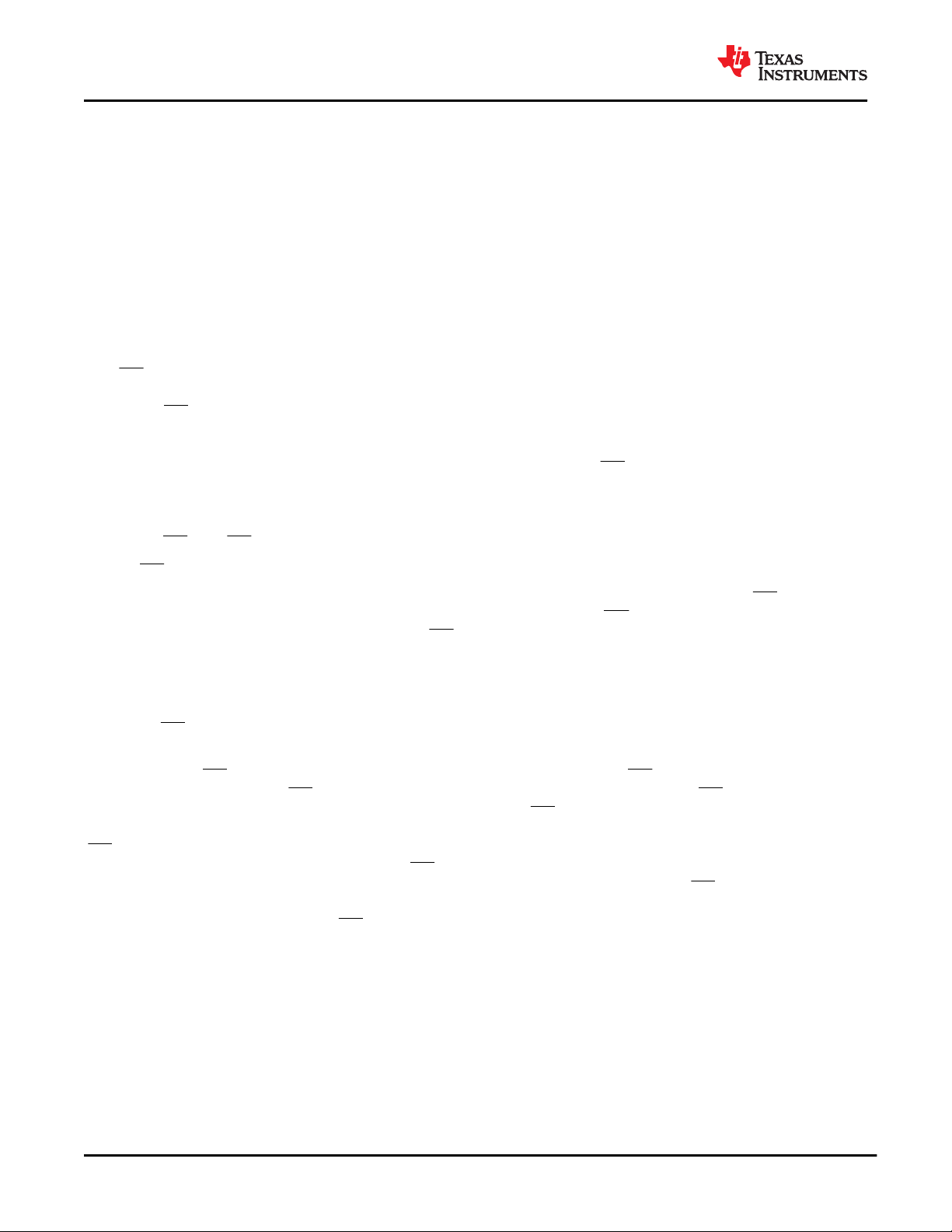

9.3.1.1 Battery Charging Process

The following diagram summarizes the charging process of the BQ21062 charger.

When a valid input source is connected (VIN > V

determines whether a charge cycle is initiated. When the CE input is high and a valid input source is connected,

the battery charge FET is turned off, preventing any kind of charging of the battery. A charge cycle is initiated

when the CHARGE_DISABLE bit is written to 0 and CE pin in low. Table 9-1 shows the CE pin and bit priority to

Figure 9-1. BQ21062 Charger Flow Diagram

UVLO

and V

BAT+VSLP

< VIN < V

), the state of the CE pin

OVP

enable/disable charging.

16 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: BQ21062

www.ti.com

Table 9-1. Charge Enable Function Through CE Pin and CE Bit

CE PIN CHARGE _DISABLE BIT CHARGING

0 0 Enabled

0 1 Disabled

1 0 Disabled

1 1 Disabled

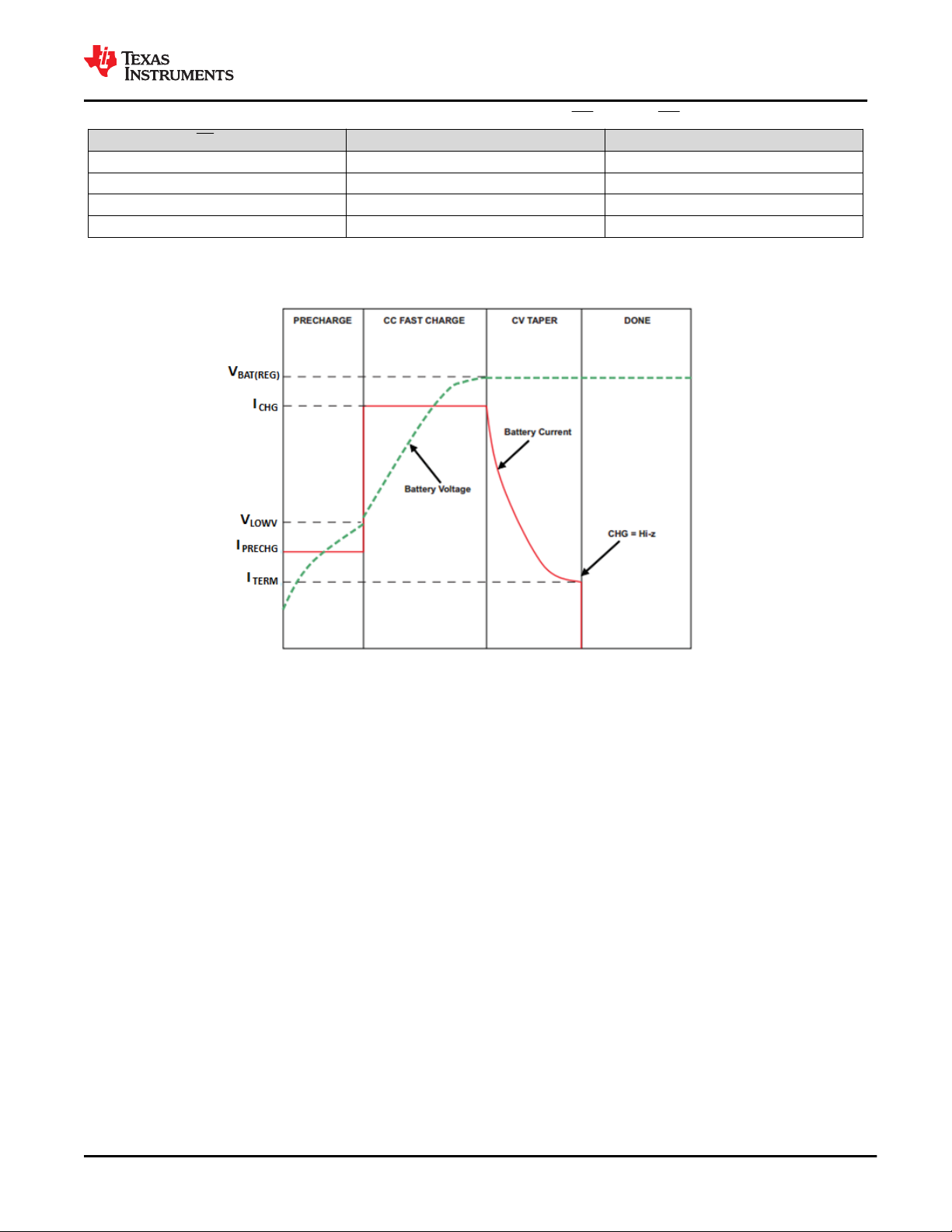

Figure 9-2 shows a typical charge cycle.

SLUSE42 – JULY 2020

BQ21062

Figure 9-2. BQ21062 Typical Charge Cycle

During Pre-Charge, where the battery voltage is below the V

I

PRECHARGE

current which can be programmed through I2C. During pre-charge, the safety timer is set to 25% of

the safety timer value during fast charge. Once the battery voltage reaches V

in Fast Charge Mode, charging the battery at I

battery voltage approaches the V

level, the charging current starts tapering off as shown in Figure 9-2.

BATREG

CHARGE

which may also be programmed through I2C. Once the

Once the charging current reaches the termination current (I

the battery is charged to V

V

BATREG

. Termination is only enabled when the charger CV loop is active in fast charge operation. No

BATREG

termination will occur if the charge current reaches I

level, the regulated PMID voltage should be set to at least 200mV above

while VINDPM is active as well as the thermal

TERM

level, the battery willl be charge with

LOWV

, the charger will then operate

LOWV

) charging is stopped. Note that to ensure that

TERM

regulation loop. Termination is also disabled when operating in the TS WARM region. The charger only goes to

termination when the current drops to I

due to the battery reaching the target voltage and not due to the

TERM

charge current limitation imposed by the previously mentioned control loops

Whenever a change in the charge current setting is triggered, whether it occurs due to I2C programming by the

host, Pre-Charge/Fast Charge transition or JEITA TS control, the device will temporarily disable charging (for ~ 1

ms) before updating the charge current value.

9.3.1.2 JEITA and Battery Temperature Dependent Charging

The charger can be configured through I2C setting to provide JEITA support, automatically reducing the charging

current and voltage depending on the battery temperature as monitored by an NTC thermistor connected to the

BQ21062 TS pin. See Section 9.3.11 for details.

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: BQ21062

Submit Document Feedback

17

BQ21062

SLUSE42 – JULY 2020

www.ti.com

9.3.1.3 Input Voltage Based Dynamic Power Management (VINDPM)

The VINDPM loop prevents the input voltage from collapsing to a point where charging would be interrupted by

reducing the current drawn by charger in order to keep VIN from dropping below V

drops to V

, the VINDPM loops will reduce the input current through the blocking FETs, to prevent the

IN_DPM

. Once the IN voltage

IN_DPM

further drop of the supply voltage. The VINDPM function is enabled by default and may be disabled through I2C

command. The V

threshold is programmable through the I2C register from 4.2 V to 4.9 V in 100-mV steps.

IN_DPM

DPPM is disabled by default in this device and cannot be re-enabled through I2C. When the device enters this

mode, the charge current may be lower than the set value and the corresponding status bits and flags are set. If

the 2X timer is set, the safety timer is extended while the loop is active. Additionally, termination is disabled.

9.3.1.4 Battery Supplement Mode

When the PMID voltage drops below the battery voltage by V

, the battery supplements the system load.

BSUP1

The battery stops supplementing the system load when the voltage on the PMID pin rises above the battery

voltage by V

. During supplement mode, the battery supplement current is not regulated, however, the

BSUP2

Battery Over-Current Protection mechanism is active. Battery charge termination is disabled while in supplement

mode.

9.3.2 Protection Mechanisms

9.3.2.1 Input Over-Voltage Protection

The input over-voltage protection protects the device and downstream components connected to PMID, and BAT

against damage from over-voltage on the input supply. When VIN > V

an OVP fault is determined to exist.

OVP

During the OVP fault, the device turns the input FET off, sends a single 128-µs pulse on INT, and the

VIN_OVP_FAULT FLAG and STAT bits are updated over I2C. Once the OVP fault is removed, the STAT bit is

cleared and the device returns to normal operation. The FLAG bit is not cleared until it is read through I2C after

the OVP condition no longer exists. The OVP threshold for the device is 5.5 V to allow operation from standard

USB sources.

9.3.2.2 Safety Timer and I2C Watchdog Timer

At the beginning of the charge cycle, the device starts the safety timer. If charging has not terminated before the

programmed safety time, t

t

MAXCHG

. When a safety timer fault occurs, a single 128-µs pulse is sent on the INT pin and the

MAXCHG

, expires, charging is disabled. The pre-charge safety time, t

PRECHG

, is 25% of

SAFETY_TMR_FAULT_FLAG bit in the FLAG3 register is updated over I2C. The CE pin or input power must be

toggled in order to reset the safety timer and exit the fault condition. Note that the flag bit will be reset when the

bit is read by the host even if the fault has not been cleared. The safety timer duration is programmable using the

SAFETY_TIMER bits. When the safety timer is active, changing the safety timer duration resets the safety timer.

The device also contains a 2X_TIMER bit that doubles the timer duration to prevent premature safety timer

expiration when the charge current is reduced by VIN DPM, thermal regulation, or a NTC (JEITA) condition.

When 2X_TIMER function is enabled, the timer is allowed to run at half speed when any loop is active other than

CC or CV.

In addition, the BQ21062 has a 50s watchdog timer which resets after every I2C transaction. This feature, which

is disabled by default, resets all charger parameters registers to their default values when the timer expires.

9.3.2.3 Thermal Protection and Thermal Charge Current Foldback

In order to protect the device from damage due to overheating, the junction temperature of the die, TJ, is

monitored. When TJ reaches T

operation when TJ falls below T

SHUTDOWN

SHUTDOWN

During the charging process, the device will reduce the charging current at a rate of (0.04 x I

exceeds the thermal foldback threshold, T

the device stops operation and is turned off. The device resumes

by T

REG

.

HYS

CHARGE

)/°C once T

to prevent further heating. If the charge current is reduced to 0,

the battery supplies the current needed to supply the PMID output. The thermal regulation threshold may be set

through I2C by setting the THERM_REG bits to the desired value.

The die junction temperature, TJ, can be estimated based on the expected board performance using Equation 1:

18 Submit Document Feedback

Product Folder Links: BQ21062

Copyright © 2020 Texas Instruments Incorporated

J

J A JA DISS

T T P

T

u

www.ti.com

SLUSE42 – JULY 2020

BQ21062

(1)

Where P

is the total power dissipation in the IC. The θJA is largely driven by the board layout. For more

DISS

information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics

Application Report. Under typical conditions, the time spent in this state is very short.

9.3.2.4 Battery Short and Over Current Protection

In order to protect the device from over current and prevent excessive battery discharge current, the BQ21062

detects if the current on the battery FET exceeds I

(t

DGL_OCP

t

REC_SC

), the battery discharge FET is turned off and start operating in hiccup mode, re-enabling the BATFET

(250 ms) after being turned off by the over-current condition. If the over-current condition is triggered

BAT_OCP

. If the short circuit limit is reached for the deglitch time

upon retry for 3 to 7 consecutive times, the BATFET will then remain off until the part is reset or until Vin is

connected and valid. If the over-current condition and hiccup operation occurs while in supplement mode where

VIN is already present, VIN must be toggled in order for BATFET to be enabled and start another detection

cycle.

In the case where the battery is suddenly shorted while charging and VBAT drops below V

comparator quickly reduces the charge current to I

PRECHARGE

preventing fast charge current to be momentarily

SHORT

, a fast

injected to the battery while shorted.

9.3.2.5 PMID Short Circuit

A short on the PMID pin is detected when the PMID voltage drops below 1.6 V (PMID short threshold). PMID

short threshold has a 200-mV hysteresis. When this occurs, the input FET temporarily disconnects IN for up to

200 µs to prevent stress on the device if a sudden short condition happens, before allowing a softstart on the

PMID output.

9.3.3 VDD LDO

The device integrates a low current always-on LDO that serves as the digital I/O supply to the device. This LDO

is supplied by VIN or by BAT. The VDD LDO will remain on through all power states with the exception of Ship

Mode.

9.3.4 Load Switch/LDO Output and Control

The device integrates a low Iq load switch which can also be used as a regulated output. The LDO/LS has a

dedicated input pin VINLS and can support up to 150 mA of load current.

The LS/LDO may be enabled/disabled through I2C. The output voltage is programmable using the LS_LDO bits

in the registers. To limit voltage drop or voltage transients, a small ceramic capacitor must be placed close to

VINLS pin.

Table 9-2. LDO Mode Control

I2C EN_LS_LDO LDO_SWITCH_CONFIG LS/LDO OUTPUT

0 0 Pulldown

0 1 Pulldown

1 0 LDO

1 1 Load Switch

The current capability of the LDO will depend on the VINLS input voltage and the programmed output voltage.

When the LS/LDO output is disabled through the register, an internal pull-down will discharge the output. The

LDO has output current limit protection, limiting the output current in the event of a short in the output. When the

LDO output current limit trips and is active for at least 1 ms, the device will set a flag and send an interrupt to the

host. The host must take action to enable the LDO if desired. The LS/LDO may be set to operate as a LDO by

setting the LDO_SWITCH_CONFIG bit to 0. Note that in order to change the configuration, the LS/LDO must be

disabled first, then the LDO_SWITCH_CONFIG bit is set for it to take effect. This is not the case when updating

the LDO output voltage which can be done on the fly without the need of disabling the LDO first.

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: BQ21062

Submit Document Feedback

19

BQ21062

SLUSE42 – JULY 2020

www.ti.com

9.3.5 PMID Power Control

The BQ21062 offers the option to control PMID through the I2C PMID_MODE bits. These bits can force PMID to

be supplied by BAT instead of IN, even if VIN > V

BAT

+ V

. They can also disconnect PMID, pulling it down or

SLP

leaving it floating. See Table 9-30 for details.

9.3.6 System Voltage (PMID) Regulation

The BQ21062 has a regulated system voltage output (PMID) that is programmable through I2C. PMID regulation

is only active when the adapter is connected and VIN > V

UVLO

, VIN > V

BAT

_ V

and VIN < V

SLP

. In Battery

OVP

Tracking operation (PMID_REG_CTRL = 000), the PMID voltage will be regulated to about 4.7% over battery

level (V

be at least 200mV higher than V

PMID

= V

x 1.047) or 3.8 V, whichever is higher. Note that the PMID regulation target should be set to

BAT

.

BATREG

9.3.7 MR Wake and Reset Input

The MR input has three main functions in the BQ21062. First, it serves as a means to wake the device from Ship

Mode. Second, it serves as a short button press detector, sending an interrupt to the host when the button

driving the MR pin has been pressed for a given period of time. This allows the implementation of different

functions in the end application such as menu selection and control. And finally it serves as a means to get the

BQ21062 to reset the system by performing a power cycle (shut down PMID and automatically powering it back

on) or go to Ship Mode after detecting a long button press. In order for the MR to be functional, the battery

voltage V

must be above the V

BAT

BATUVLO

level. The timing for the short and long button press duration is

programmable through I2C for added flexibility. Note that if a specific timer duration is changed through I2C while

that timer is active and has not expired, the new programmed value will be ignored until the timer expires and/or

is reset by MR. The MR input has an internal pull-up to BAT.

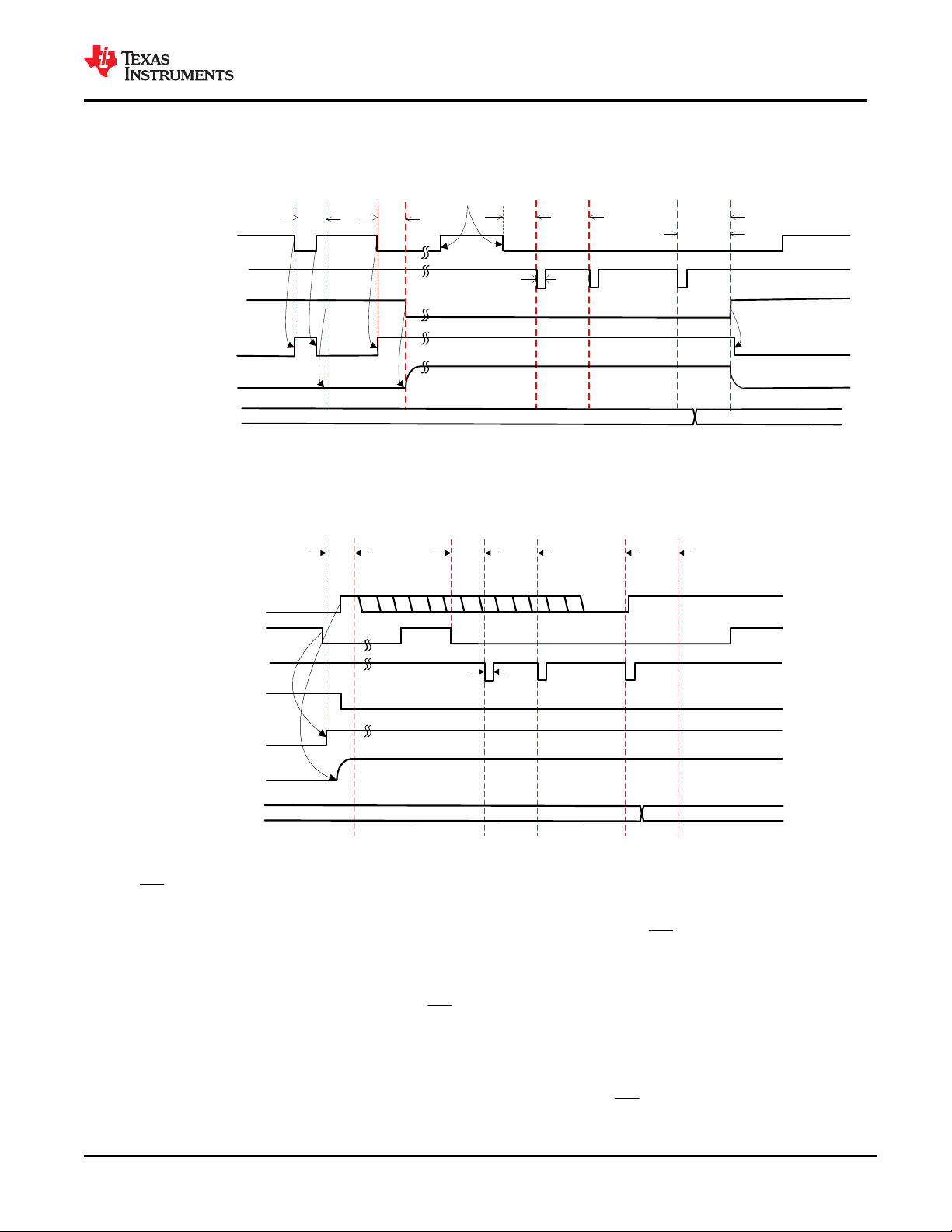

9.3.7.1 MR Wake or Short Button Press Functions

There are two programmable wake or short button press timers, WAKE1 and WAKE2. When the MR pin is held

low for t

the device sends an interrupt (128 µs active low pulse in the INT pin) and sets the

WAKE1

MRWAKE1_TIMEOUT flag when it expires. If the MR pin continues to be driven low after WAKE1 and the

WAKE2 timer expires, the BQ21062 sends a second interrupt and sets the MRWAKE2_TIMOUT flag. WAKE1 is

used as the timer to wake the device from ship mode. WAKE2’s only function is to send the interrupt and has no

effect on other BQ21062 functions. These flags are not cleared until they have been read by the host. Note that

interrupts are only sent when the flags are set and the flags must be cleared in order for another interrupt to be

sent upon MR press. The timer durations can be set through the MR_WAKEx_TIMER bits in the MRCTRL

Register section.

One of the main MR functions is to wake the device from Ship Mode when the MR is asserted. The device will

exit the Ship Mode when the MR pin is held low for at least t

. Immediately after the MR is asserted, VDD

WAKE1

will be enabled and the digital will start the WAKE counter. If the MR signal remains low until after the WAKE1

timer expires, the device will power up PMID and LDO (If enabled) completing the exit from the ship mode. If the

MR signal goes high before the WAKE1 timer expires, the device will go back to the Ship Mode operation, never

powering up PMID or the LDO. Note that if the MR pin remains low after exiting Ship Mode the wake interrupts

will not be sent and the long button press functions like HW reset will not occur until the MR pin is toggled. In the

case where a valid VIN (VIN > V

) is connected prior to WAKE2 timer expiring, the device will exit the ship

UVLO

mode immediately regardless of the MR or wake timer state. Figure 9-3 and Figure 9-4 show these different

scenarios.

20 Submit Document Feedback

Copyright © 2020 Texas Instruments Incorporated

Product Folder Links: BQ21062

twake1

twake2

thwreset

128us

twake1

No WAKE interrupts

are sent or reset

actions are taken

until /MR is toggled

after Ship Mode exit

Go to Ship Mode

/MR

INT

SHIPMODE

VDD

Output Rails

(PMID, LDO if enabled)

MR_LPRESS_ACTION

'RQ¶WFDUH

twake1

Thwreset_warn

/MR

INT

SHIPMODE

VDD

twake1

twake2

treset_warn

thwreset

128us

twake1

Output Rails

(PMID, LDO if enabled)

VIN

MR_LPRESS_ACTION

Go to Ship Mode

'RQ¶WFDUH

www.ti.com

SLUSE42 – JULY 2020

BQ21062

Figure 9-3. MR Wake from Ship Mode (MR_LPRESS_ACTION = Ship Mode, VIN not valid)

9.3.7.2 MR Reset or Long Button Press Functions

The BQ21062 device may be configured to perform a system hardware reset (Power Cycle/Autowake), go into

Ship Mode, or simply do nothing after a long button press (for example, when the MR pin is driven low until the

MR_HW_RESET timer expires).The action taken by the device when the timer expires is configured through the

MR_LPRESS_ACTION bits in the ICCTRL1 Register section. Once the MR_HW_RESET timer expires the

device immediately performs the operation set by the MR_LPRESS_ACTION bits. The BQ21062 sends an

interrupt to the host when the device detects that MR has been pressed for a period that is within

t

HW_RESET_WARN

close to t

WAKE1 and WAKE2 timers. This interrupt is sent before the MR_HW_RESET timer expires and sets the

MRRESET_WARN flag. The t

MRCTRL register. The host may change the reset behavior at any time after MR going low and prior to the

MR_HW_RESET timer expiring. It may not change it however from another behavior to a HW reset (Power

Copyright © 2020 Texas Instruments Incorporated

from reaching t

HW_RESET

Figure 9-4. MR Wake from Ship Mode – VIN Dependencies

HW_RESET

. This may warn the host that the button has been pressed for a period

which would trigger a HW Reset or used as another button press timer interrupt like the

HW_RESET_WARN

may be set through I2C by the MR_RESET_WARN bits in the

Submit Document Feedback

Product Folder Links: BQ21062

21

Loading...

Loading...