Datasheet DV2004ES1, BQ2004HSN, BQ2004HPN, BQ2004ESNTR, BQ2004ESN Datasheet (Texas Instruments)

...

Features

➤

Fast charge and conditioning of

nickel cadmium or nickel-metal

hydride batteries

➤

Hysteretic PWM switch-mode

current regulation or gated con

-

trol of an external regulator

➤

Easily integrated into systems or

used as a stand-alone charger

➤

Pre-charge qualification of tem

-

perature and voltage

➤

Configurable, direct LED outputs

display battery and charge status

➤

Fast-charge termination by ∆ tem

-

perature/∆ time, peak volume de

tection, -∆V, maximum voltage,

maximum temperature, and maximum time

➤ Optional top-off charge and

pulsed current maintenance

charging

➤ Logic-level controlled low-power

mode (< 5µA standby current)

General Description

The bq2004E and bq2004H Fast

Charge ICs provide comprehensive

fast charge control functions together

with high-speed switching power con

trol circuitry on a monolithic CMOS

device.

Integration of closed-loop current

control circuitry allows the bq2004

to be the basis of a cost-effective so

lution for stand-alone and systemintegrated chargers for batteries of

one or more cells.

Switch-activated discharge-beforecharge allows bq2004E/H-based charg

ers to support battery conditioning

and capacity determination.

High-efficiency power conversion is

accomplished using the bq2004E/H as

a hysteretic PWM controller for

switch-mode regulation of the charging current. The bq2004E/H may alternatively be used to gate an externally regulated charging current.

Fast charge may begin on application

of the charging supply, replacement

of the battery, or switch depression.

For safety, fast charge is inhibited

unless/until the battery tempera

-

ture and voltage are within config

-

ured limits.

Temperature, voltage, and time are

monitored throughout fast charge.

Fast charge is terminated by any of

the following:

n

Rate of temperature rise

(∆T/∆t)

n

Peak voltage detection (PVD)

n

Negative delta voltage (-∆V)

n

Maximum voltage

n

Maximum temperature

n

Maximum time

After fast charge, optional top-off

and pulsed current maintenance

phases with appropriate display

mode selections are available.

The bq2004H differs from the

bq2004E only in that fast charge,

hold-off, and top-off time units have

been scaled up by a factor of two,

and the bq2004H provides different

display selections. Timing differences between the two ICs are illustrated in Table 1. Display differ

-

ences are shown in Table 2.

1

Fast-Charge ICs

bq2004E/H

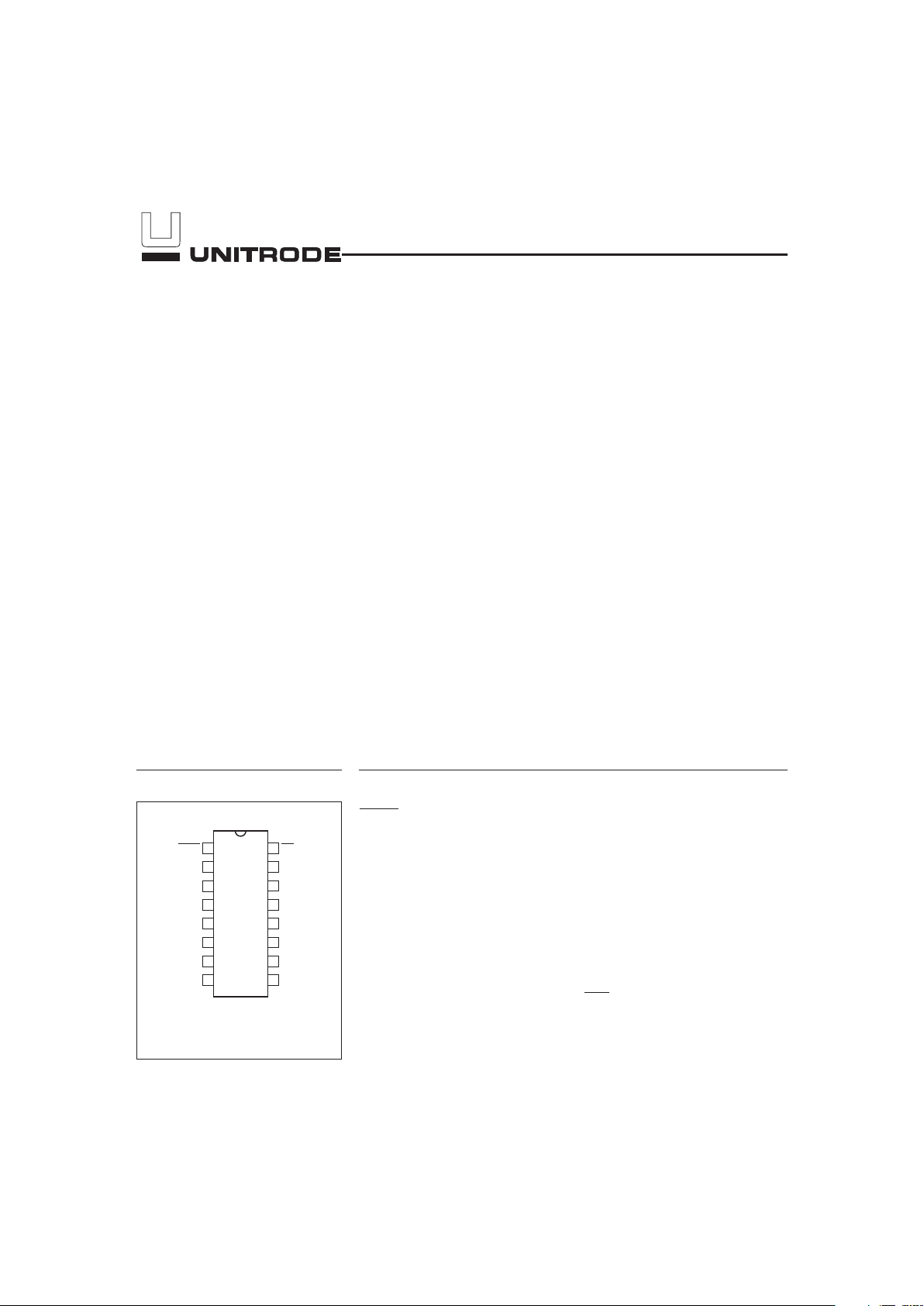

DCMD Discharge command

DSEL Display select

VSEL Voltage termination

select

TM

1

Timer mode select 1

TM

2

Timer mode select 2

TCO Temperature cutoff

TS Temperature sense

BAT Battery voltage

1

PN2004E01.eps

16-Pin Narrow DIP

or Narrow SOIC

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

INH

DIS

MOD

VCC

V

SS

LED

2

LED

1

SNS

DCMD

DSEL

VSEL

TM

1

TM

2

TCO

TS

BAT

SNS Sense resistor input

LED

1

Charge status output 1

LED

2

Charge status output 2

V

SS

System ground

V

CC

5.0V±10% power

MOD Charge current control

DIS Discharge control

output

INH

Charge inhibit input

Pin Connections

6/99 E

Pin Names

Pin Descriptions

DCMD

Discharge-before-charge control input

The DCMD

input controls the conditions

that enable discharge-before-charge. DCMD

is pulled up internally. A negative-going

pulse on DCMD

initiates a discharge to endof-discharge voltage (EDV) on the BAT pin,

followed by a new charge cycle start. Tying

DCMD

to ground enables automatic

discharge-before-charge on every new charge

cycle start.

DSEL

Display select input

This three-state input configures the charge

status display mode of the LED

1

and LED2out

puts and can be used to disable top-off and

pulsed-trickle. See Table 2.

VSEL

Voltage termination select input

This three-state input controls the voltagetermination technique used by the

bq2004E/H. When high, PVD is active.

When floating, -∆V is used. When pulled low,

both PVD and -∆V are disabled.

TM

1

–

TM

2

Timer mode inputs

TM

1

and TM2are three-state inputs that

configure the fast charge safety timer, voltage

termination hold-off time, “top-off ”, and

trickle charge control. See Table 1.

TCO

Temperature cut-off threshold input

Input to set maximum allowable battery

temperature. If the potential between TS

and SNS is less than the voltage at the TCO

input, then fast charge or top-off charge is ter

-

minated.

TS

Temperature sense input

Input, referenced to SNS, for an external

thermister monitoring battery temperature.

BAT

Battery voltage input

BAT is the battery voltage sense input, refer

enced to SNS. This is created by a highimpedance resistor-divider network con

nected between the positive and the negative

terminals of the battery.

SNS

Charging current sense input

SNS controls the switching of MOD based on

an external sense resistor in the current

path of the battery. SNS is the reference po

tential for both the TS and BAT pins. If

SNS is connected to V

SS

, then MOD switches

high at the beginning of charge and low at

the end of charge.

LED

1

–

LED

2

Charge status outputs

Push-pull outputs indicating charging

status. See Table 2.

Vss

Ground

V

CC

VCCsupply input

5.0V, ±10% power input.

MOD

Charge current control output

MOD is a push-pull output that is used to

control the charging current to the battery.

MOD switches high to enable charging current to flow and low to inhibit charging

current flow.

DIS

Discharge control output

Push-pull output used to control an external

transistor to discharge the battery before

charging.

INH

Charge inhibit input

When low, the bq2004E/H suspends all

charge actions, drives all outputs to high im

-

pedance, and assumes a low-power opera

tional state. When transitioning from low to

high, a new charge cycle is started.

2

bq2004E/H

Functional Description

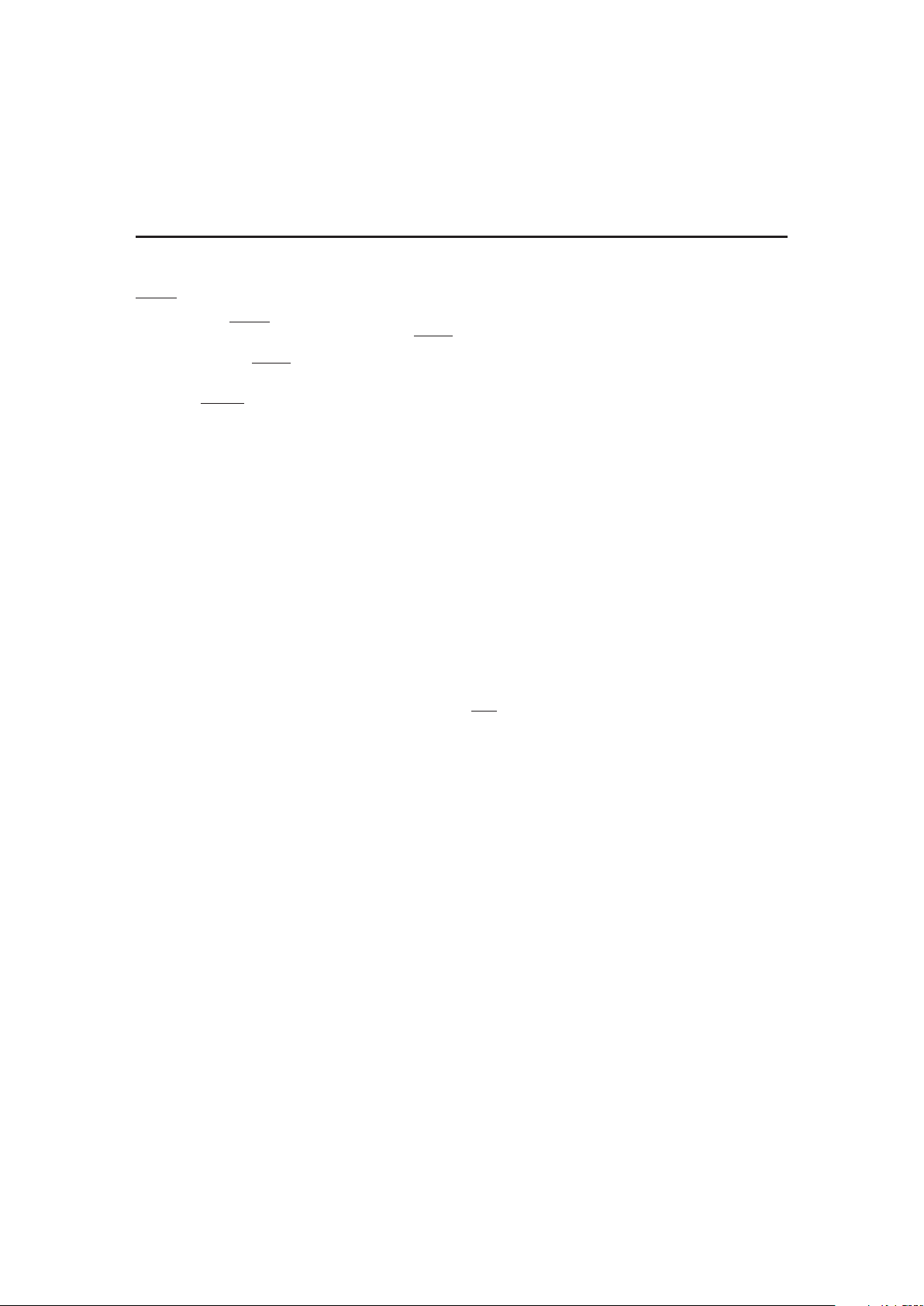

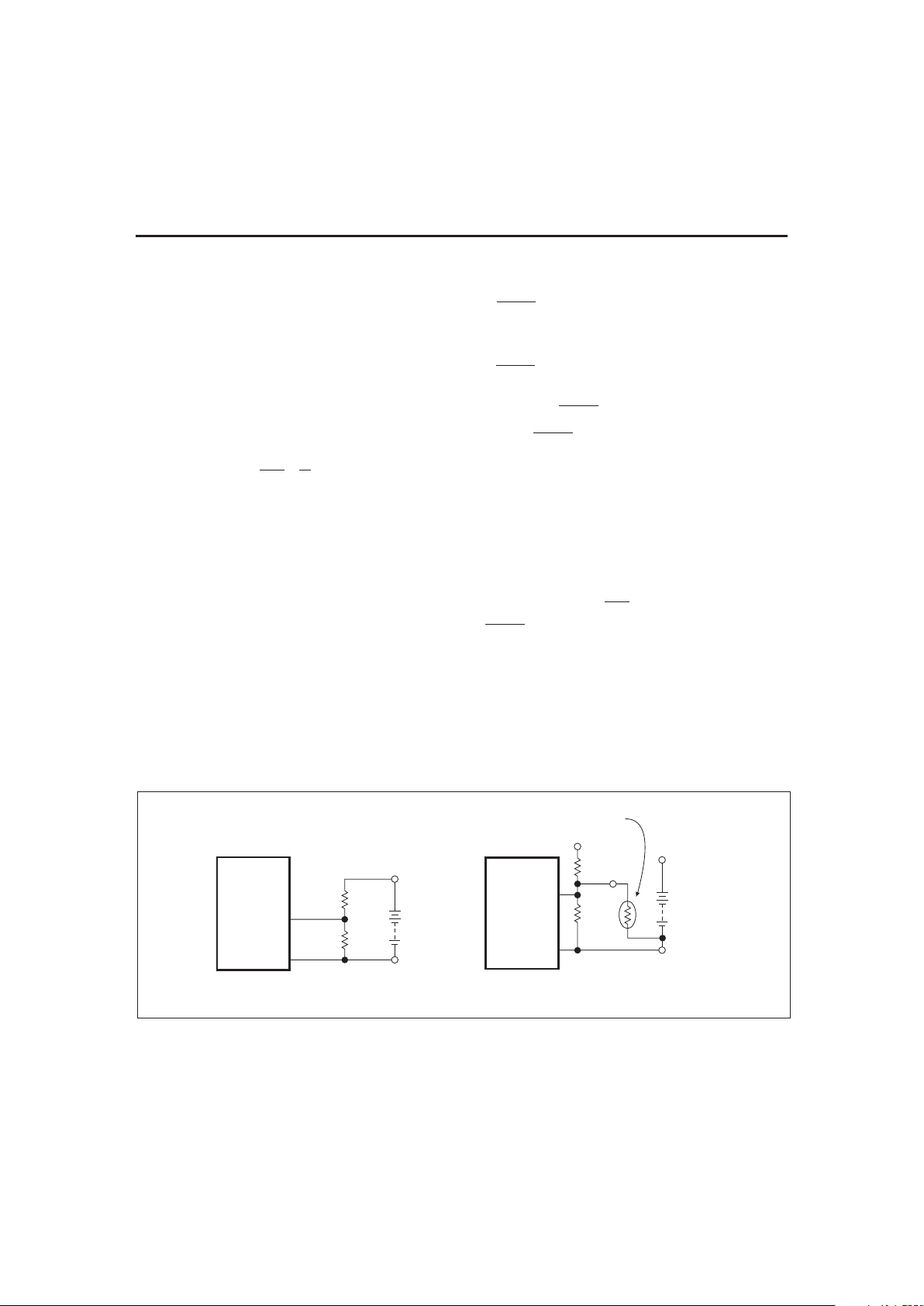

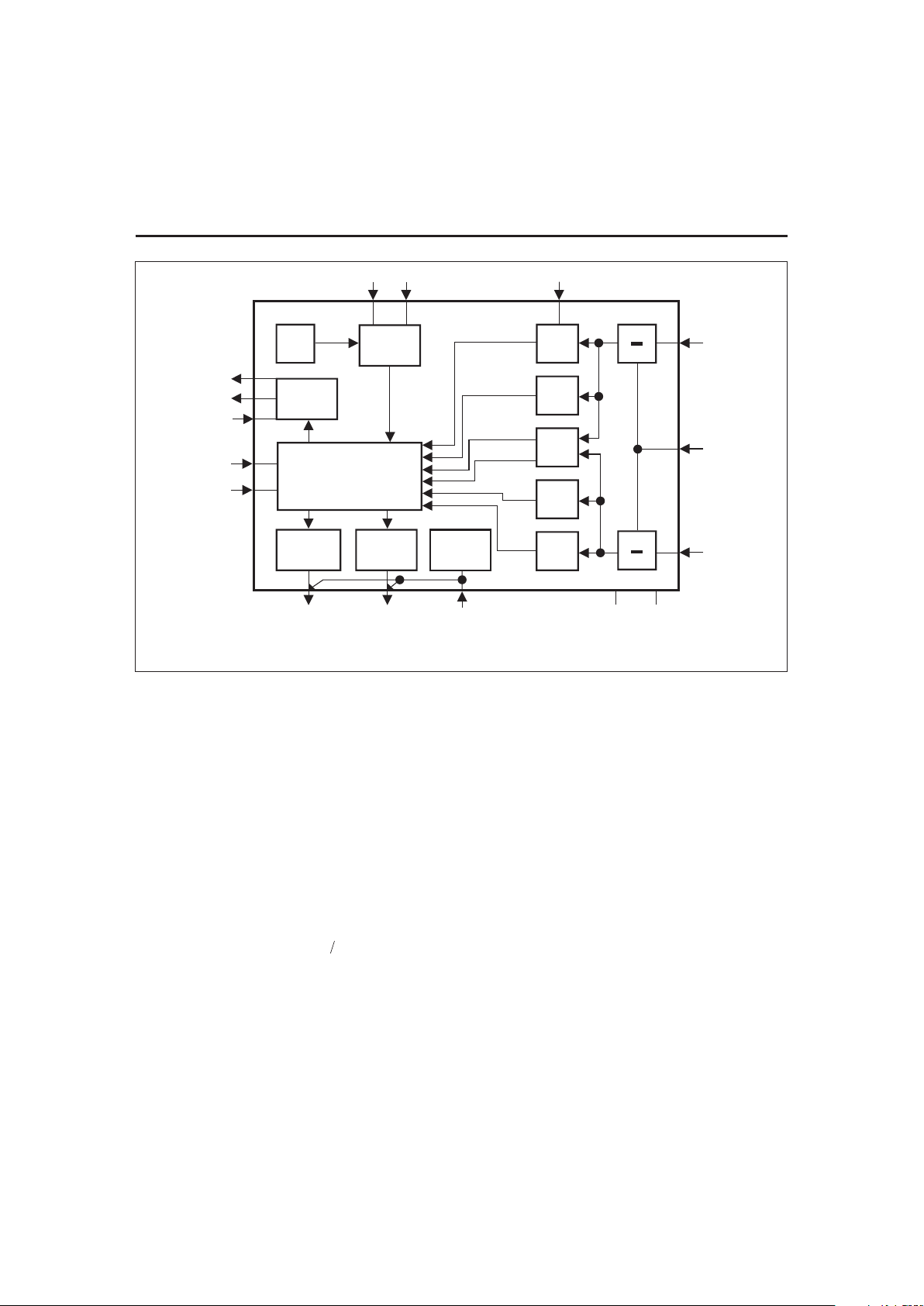

Figure 2 shows a block diagram and Figure 3 shows a

state diagram of the bq2004E/H.

Battery Voltage and Temperature

Measurements

Battery voltage and temperature are monitored for

maximum allowable values. The voltage presented on

the battery sense input, BAT, should represent a

two-cell potential for the battery under charge. A

resistor-divider ratio of:

RB1

RB2

=

N

2

- 1

is recommended to maintain the battery voltage within

the valid range, where N is the number of cells, RB1 is

the resistor connected to the positive battery terminal,

and RB2 is the resistor connected to the negative bat

-

tery terminal. See Figure 1.

Note: This resistor-divider network input impedance to

end-to-end should be at least 200kΩ and less than 1MΩ.

A ground-referenced negative temperature coefficient thermistor placed in proximity to the battery may be used as a

low-cost temperature-to-voltage transducer. The temperature sense voltage input at TS is developed using a

resistor-thermistor network between V

CC

and VSS. See

Figure 1. Both the BAT and TS inputs are referenced to

SNS, so the signals used inside the IC are:

V

BAT-VSNS=VCELL

and

V

TS-VSNS=VTEMP

Discharge-Before-Charge

The DCMD input is used to command discharge-beforecharge via the DIS output. Once activated, DIS becomes

active (high) until V

CELL

falls below V

EDV,

at which time

DIS goes low and a new fast charge cycle begins.

The DCMD

input is internally pulled up to VCC(its inac

tive state). Leaving the input unconnected, therefore,

results in disabling discharge-before-charge. A negative

going pulse on DCMD

initiates discharge-before-charge

at any time regardless of the current state of the

bq2004. If DCMD

is tied to VSS, discharge-before-charge

will be the first step in all newly started charge cycles.

Starting A Charge Cycle

A new charge cycle is started by:

1. Application of V

CC

power.

2. V

CELL

falling through the maximum cell voltage,

V

MCV

where:

V

MCV

= 0.8 ∗ VCC± 30mV

3. A transition on the INH

input from low to high.

If DCMD

is tied low, a discharge-before-charge will be

executed as the first step of the new charge cycle. Otherwise, pre-charge qualification testing will be the first

step.

The battery must be within the configured temperature

and voltage limits before fast charging begins.

The valid battery voltage range is V

EDV<VBAT<VMCV

where:

V

EDV

= 0.4 ∗ VCC± 30mV

3

bq2004E/H

Fg2004a.eps

N

T

C

bq2004E/H

V

CC

PACK +

PACK -

T

S

SNS

RT1

RT2

RB2

RB1

bq2004E/H

Negative Temperature

Coefficient Thermister

PACK+

PACK-

BAT

SNS

Figure 1. Voltage and Temperature Monitoring

The valid temperature range is V

HTF<VTEMP<VLTF

,

where:

V

LTF

= 0.4 ∗ VCC± 30mV

V

HTF

= [(1/3 ∗ V

LTF

) + (2/3 ∗ V

TCO

)] ± 30mV

V

TCO

is the voltage presented at the TCO input pin, and is

configured by the user with a resistor divider between V

CC

and ground. The allowed range is 0.2 to 0.4 ∗ VCC.

If the temperature of the battery is out of range, or the

voltage is too low, the chip enters the charge pending

state and waits for both conditions to fall within their al

lowed limits. During the charge-pending mode, the IC

first applies a top-off charge to the battery.

The top-off charge, at the rate of

18

of the fast charge,

continues until the fast-charge conditions are met or the

top-off time-out period is exceeded. The IC then trickle

charges until the fast-charge conditions are met. There

is no time limit on the charge pending state; the charger

remains in this state as long as the voltage or tempera

ture conditons are outside of the allowed limits. If the

voltage is too high, the chip goes to the battery absent

state and waits until a new charge cycle is started.

Fast charge continues until termination by one or more

of the six possible termination conditions:

n

Delta temperature/delta time (∆T/∆t)

n

Peak voltage detection (PVD)

n

Negative delta voltage (-∆V)

n

Maximum voltage

n

Maximum temperature

n

Maximum time

PVD and -∆V Termination

The bq2004E/H samples the voltage at the BAT pin once

every 34s. When -∆V termination is selected, if V

CELL

is

lower than any previously measured value by 12mV

±4mV (6mV/cell), fast charge is terminated. When PVD

termination is selected, if V

CELL

is lower than any previ

ously measured value by 6mV ±2mV (3mV/cell), fast

charge is terminated. The PVD and -∆V tests are valid

in the range 0.4 ∗ V

CC<VCELL

< 0.8 ∗ VCC.

4

bq2004E/H

BD200401.eps

Timing

Control

OSC

Display

Control

Charge Control

State Machine

Discharge

Control

MOD

Control

TCO

Check

LTF

Check

A/D

EDV

Check

MCV

Check

DIS MOD INH V

CCVSS

BAT

SNS

TS

TCOTM2TM1

LED1

DCMD

DVEN

VTS - V

SNS

V

BAT

- V

SNS

LED2

DSEL

PWR

Control

Figure 2. Block Diagram

5

VSEL Input Voltage Termination

Low Disabled

Float

-∆V

High PVD

Voltage Sampling

Each sample is an average of voltage measurements.

The IC takes 32 measurements in PVD mode and 16

measurements in -∆V mode. The resulting sample peri

-

ods (9.17ms and 18.18ms, respectively) filter out har

-

monics centered around 55Hz and 109Hz. This tech

nique minimizes the effect of any AC line ripple that

may feed through the power supply from either 50Hz or

60Hz AC sources. Tolerance on all timing is ±16%.

Temperature and Voltage Termination

Hold-off

A hold-off period occurs at the start of fast charging.

During the hold-off period, -∆V and ∆T/∆t termination

are disabled. The MOD pin is enabled at a duty cycle of

260µs active for every 1820µs inactive. This modulation

results in an average rate 1/8th that of the fast charge

rate. This avoids premature termination on the voltage

spikes sometimes produced by older batteries when

fast-charge current is first applied. Maximum voltage

and maximum temperature terminations are not affected by the hold-off period.

∆T/∆t Termination

The bq2004E/H samples at the voltage at the TS pin

every 34s, and compares it to the value measured two

samples earlier. If V

TEMP

has fallen 16mV ±4mV or

more, fast charge is terminated. The ∆T/∆t termination

test is valid only when V

TCO<VTEMP<VLTF

.

Temperature Sampling

Each sample is an average of 16 voltage measurements.

The resulting sample period (18.18ms) filters out har

-

monics around 55Hz. This technique minimizes the ef

fect of any AC line ripple that may feed through the

power supply from either 50Hz or 60Hz AC sources. Tol

erance on all timing is ±16%.

Maximum Voltage,Temperature, and Time

Anytime V

CELL

rises above V

MCV,

the LEDs go off and cur

rent flow into the battery ceases immediately. If V

CELL

then falls back below V

MCV

before t

MCV

= 1.5s ±0.5s, the

chip transitions to the Charge Complete state (maximum

voltage termination). If V

CELL

remains above V

MCV

at the

expiration of t

MCV,

the bq2004E/H transitions to the Bat-

tery Absent state (battery removal). See Figure 3.

Maximum temperature termination occurs anytime

V

TEMP

falls below the temperature cutoff threshold

V

TCO

. Charge will also be terminated if V

TEMP

rises

above the low temperature fault threshold, V

LTF

, after

fast charge begins.

Corresponding

Fast-Charge

Rate

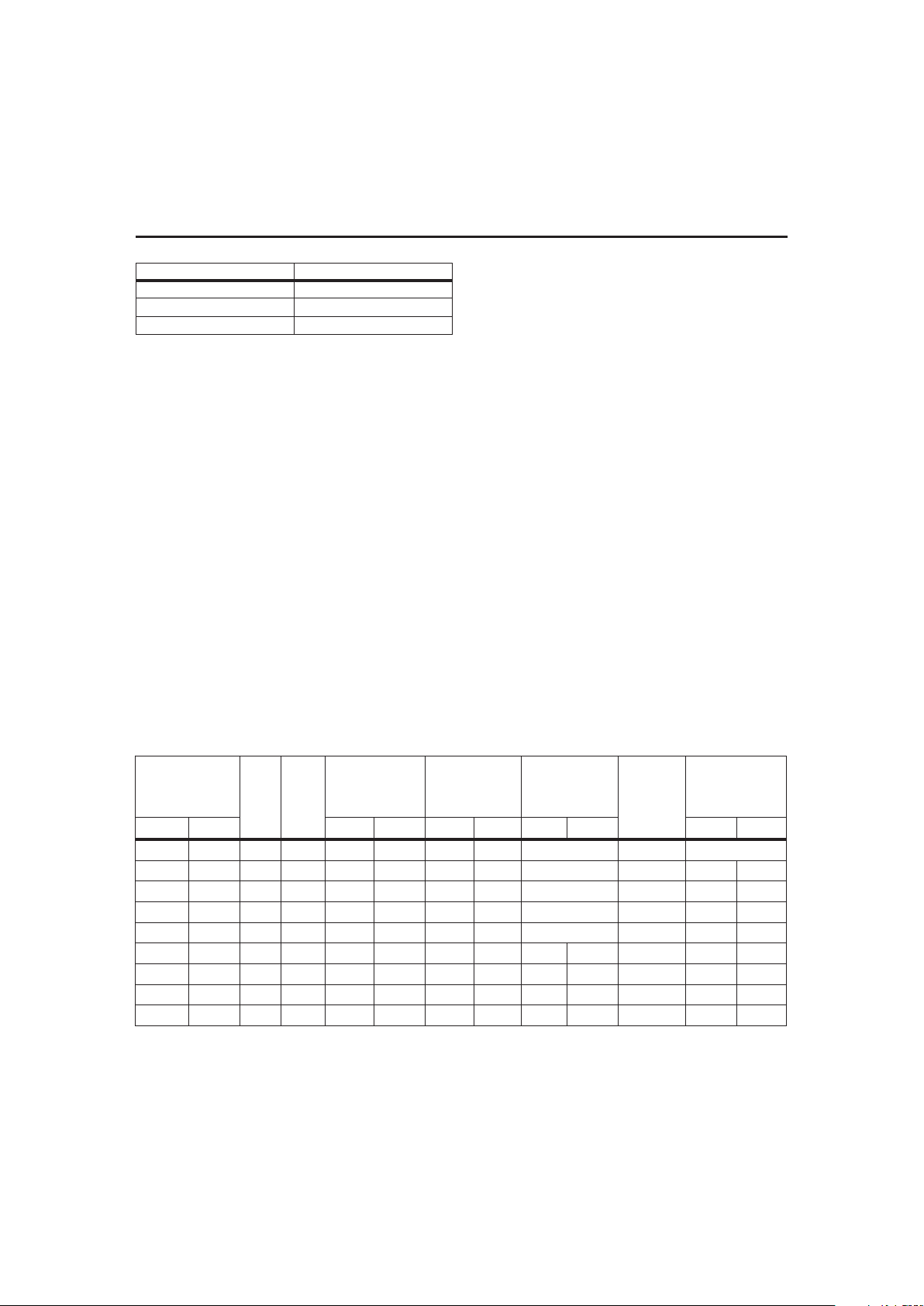

TM1 TM2

Typical

Fast-Charge

Safety

Time (min)

Typical

PVD, -∆V

Hold-Off

Time (s)

Top-Off

Rate

PulseTrickle

Rate

Pulse-

Trickle

Period (Hz)

2004E 2004H 2004E 2004H 2004E 2004H 2004E 2004H 2004E 2004H

C/4 C/8 Low Low 325 650 137 273 Disabled Disabled Disabled

C/2 C/4 Float Low 154 325 546 546 Disabled C/512 15 30

1C C/2 High Low 77 154 273 546 Disabled C/512 7.5 15

2C 1C Low Float 39 77 137 273 Disabled C/512 3.75 7.5

4C 2C Float Float 19 39 68 137 Disabled C/512 1.88 3.75

C/2 C/4 High Float 154 325 546 546 C/16 C/32 C/512 15 30

1C C/2 Low High 77 154 273 546 C/8 C/16 C/512 7.5 15

2C 1C Float High 39 77 137 273 C/4 C/18 C/512 3.75 7.5

4C 2C High High 19 39 68 137 C/2 C/4 C/512 1.88 3.75

Note: Typical conditions = 25°C, VCC= 5.0V.

Table 1. Fast Charge Safety Time/Hold-Off/Top-Off Table

bq2004E/H

6

bq2004E/H

Mode 1

bq2004E Charge Action State LED

1

LED

2

DSEL = V

SS

Battery absent Low Low

Fast charge pending or a discharge-before-charge in progress High High

Fast charging Low High

Fast charge complete, top-off, and/or trickle High Low

Mode 1

bq2004H Charge Action State LED

1

LED

2

DSEL = V

SS

Battery absent Low Low

Discharge-before-charge in progress High High

Fast charge pending Low

1

8

second high

1

8

second low

Fast charging Low High

Fast charge complete, top-off, and/or trickle High Low

Mode 2

bq2004E Charge Action State (See note) LED

1

LED

2

DSEL = Floating

Battery absent Low Low

Fast charge pending or discharge-before-charge in progress High High

Fast charging Low High

Fast charge complete, top-off, and/or trickle High Low

Mode 2

bq2004H Charge Action State (See note) LED

1

LED

2

DSEL = Floating

Battery absent Low Low

Discharge-before-charge in progress High High

Fast charge pending Low

1

8

second high

1

8

second low

Fast charging Low High

Fast charge complete, top-off, and/or trickle High Low

Mode 3

bq2004E/H Charge Action State LED

1

LED

2

DSEL = V

CC

Battery absent Low Low

Fast charge pending or discharge-before-charge in progress Low

1

8

second high

1

8

second low

Fast charging Low High

Fast charge complete, top-off, and/or trickle High Low

Note: Pulse trickle is inhibited in Mode 2.

Table 2. bq2004E/H LED Output Summary

Maximum charge time is configured using the TM pin.

Time settings are available for corresponding charge

rates of C/4, C/2, 1C, and 2C. Maximum time-out termi

nation is enforced on the fast-charge phase, then reset,

and enforced again on the top-off phase, if selected.

There is no time limit on the trickle-charge phase.

Top-off Charge

An optional top-off charge phase may be selected to

follow fast charge termination for the C/2 through 4C

rates. This phase may be necessary on NiMH or other

battery chemistries that have a tendency to terminate

charge prior to reaching full capacity. With top-off en

abled, charging continues at a reduced rate after

fast-charge termination for a period of time equal to

0.235∗ the fast-charge safety time (See Table 1.) Dur

ing top-off, the MOD pin is enabled at a duty cycle of

260µs active for every 1820µs inactive. This modula

tion results in an average rate 1/8th that of the fast

charge rate. Maximum voltage, time, and temperature

are the only termination methods enabled during topoff.

Pulse-Trickle Charge

Pulse-trickle charging may be configured to follow the

fast charge and optional top-off charge phases to compensate for self-discharge of the battery while it is idle

in the charger.

In the pulse-trickle mode, MOD is active for 260µsofa

period specified by the settings of TM1 and TM2. See

Table 1. The resulting trickle-charge rate is C/512.

Both pulse trickle and top-off may be disabled by tying

TM1 and TM2 to V

SS

or by selecting Mode 2 in the dis

play.

Charge Status Indication

Charge status is indicated by the LED1and LED2out

puts. The state of these outputs in the various charge cy

cle phases is given in Table 2 and illustrated in Figure 3.

In all cases, if V

CELL

exceeds the voltage at the MCV

pin, both LED

1

and LED2outputs are held low regard

less of other conditions. Both can be used to directly

drive an LED.

Charge Current Control

The bq2004E/H controls charge current through the MOD

output pin. The current control circuitry is designed to sup

port implementation of a constant-current switching regulator

or to gate an externally regulated current source.

When used in switch mode configuration, the nominal

regulated current is:

I

REG

= 0.225V/R

SNS

Charge current is monitored at the SNS input by the

voltage drop across a sense resistor, R

SNS

, between the

low side of the battery pack and ground. R

SNS

is sized to

provide the desired fast charge current.

If the voltage at the SNS pin is less than V

SNSLO

, the

MOD output is switched high to pass charge current to

the battery.

When the SNS voltage is greater than V

SNSHI

, the MOD

output is switched low—shutting off charging current to

the battery.

V

SNSLO

= 0.04 ∗ VCC± 25mV

V

SNSHI

= 0.05 ∗ VCC± 25mV

When used to gate an externally regulated current

source, the SNS pin is connected to V

SS

, and no sense re-

sisitor is required.

7

bq2004E/H

8

Charge

Pending

DCMD Tied to Ground?

Falling Edge

on DCMD

Discharge-

Before-Charge

Top-Off and

Pulse-Trickle

Charge

Pulse

Trickle

Charge

Pulse

Trickle

Charge

Pulse

Trickle

Charge

Top-Off

Charge

Fast

Charge

Battery Voltage?

Battery Temperature?

Top-Off

Selected?

New Charge Cycle Started by

Any One of:

V

CC

Rising to Valid Level

Battery Replacement

(V

CELL

Falling through V

MCV

)

Inhibit (INH) Released

V

EDV

< V

CELL

< V

MCV

and

V

HTF

< V

TEMP

< V

LTF

V

HTF

< V

TEMP

< V

LTF

V

EDV

< V

CELL

< V

MCV

V

TEMP

> V

LTF

or

V

TEMP

< V

HTF

V

CELL

< V

EDV

V

CELL

< V

EDV

Yes

Yes

No

No

t >

t

MCV

> V

MCV

V

CELL

> V

MCV

V

CELL

>

V

CELL

V

MCV

>

V

CELL

V

MCV

>

V

CELL

V

MCV

V

CELL

<

V

MCV

Charge

Complete

Battery

Absent

or 0.235 Maximum

Time Out

V

TEMP

< V

TCO

SD2004EH.eps

>

V

CELL

V

MCV

- V or

T/ t or

V

TEMP

<

V

TCO

or

Maximum

Time Out

Figure 3. Charge Algorithm State Diagram

bq2004E/H

9

Absolute Maximum Ratings

Symbol Parameter Minimum Maximum Unit Notes

V

CC

VCCrelative to V

SS

-0.3 +7.0 V

V

T

DC voltage applied on any pin ex

-

cluding V

CC

relative to V

SS

-0.3 +7.0 V

T

OPR

Operating ambient temperature -20 +70 °C Commercial

T

STG

Storage temperature -55 +125 °C

T

SOLDER

Soldering temperature - +260 °C 10 sec max.

T

BIAS

Temperature under bias -40 +85 °C

Note: Permanent device damage may occur if Absolute Maximum Ratings are exceeded. Functional opera

-

tion should be limited to the Recommended DC Operating Conditions detailed in this data sheet. Expo

-

sure to conditions beyond the operational limits for extended periods of time may affect device reliability.

DC Thresholds (T

A=TOPR;VCC

±

10%)

Symbol Parameter Rating Tolerance Unit Notes

V

SNSHI

High threshold at SNS resulting in MOD = Low

0.05*V

CC

±0.025

V

V

SNSLO

Low threshold at SNS resulting in MOD = High

0.04 * V

CC

±0.010

V

V

LTF

Low-temperature fault

0.4*V

CC

±0.030

V

V

TEMP

≥ V

LTF

inhib

-

its/terminates charge

V

HTF

High-temperature fault

(1/3*V

LTF

) + (2/3*V

TCO

)

±0.030

V

V

TEMP

≤ V

HTF

inhibits

charge

V

EDV

End-of-discharge voltage

0.4*V

CC

±0.030

V

V

CELL<VEDV

inhibits

fast charge

V

MCV

Maximum cell voltage

0.8*V

CC

±0.030

V

V

CELL>VMCV

inhibits/

terminates charge

V

THERM

TS input change for∆T/∆t

detection

-16

±4

mV

V

CC

= 5V, TA= 25°C

-∆V

BAT input change for -∆V

detection

-12

±4

mV

V

CC

= 5V, TA= 25°C

PVD

BAT input change for PVD

detection

-6

±2

mV

V

CC

= 5V, TA= 25°C

bq2004E/H

10

Recommended DC Operating Conditions (T

A

= T

OPR)

Symbol Condition Minimum Typical Maximum Unit Notes

V

CC

Supply voltage 4.5 5.0 5.5 V

V

BAT

Battery input 0 - V

CC

V

V

CELL

BAT voltage potential 0 - V

CC

VV

BAT

- V

SNS

V

TS

Thermistor input 0 - V

CC

V

V

TEMP

TS voltage potential 0 - V

CC

VVTS- V

SNS

V

TCO

Temperature cutoff 0.2*V

CC

- 0.4*V

CC

V Valid∆T/∆t range

V

IH

Logic input high 2.0 - - V DCMD, INH

Logic input high VCC- 0.3 - - V TM1, TM2, DSEL, VSEL

V

IL

Logic input low - - 0.8 V DCMD, INH

Logic input low - - 0.3 V TM1, TM2, DSEL, VSEL

V

OH

Logic output high

V

CC

- 0.8

--V

DIS, MOD, LED

1

, LED2,

I

OH

≤

-10mA

V

OL

Logic output low - - 0.8 V

DIS, MOD, LED

1

, LED2,

I

OL

≤

10mA

I

CC

Supply current - 1 3 mA Outputs unloaded

I

SB

Standby current - - 1

µ

A INH = V

IL

I

OH

DIS, LED1, LED2, MOD source -1 0 - - m A @VOH= VCC- 0.8V

I

OL

DIS, LED1, LED2, MOD sink 10 - - mA @VOL= VSS+ 0.8V

I

L

Input leakage - -

±

1

µ

A INH, BAT, V = VSSto V

CC

Input leakage 50 - 400

µ

A DCMD, V = VSSto V

CC

I

IL

Logic input low source - - 70

µ

A

TM

1

, TM2, DSEL, VSEL,

V = V

SS

to VSS+ 0.3V

I

IH

Logic input high source -70 - -

µ

A

TM

1

, TM2, DSEL, VSEL,

V = V

CC

- 0.3V to V

CC

I

IZ

Tri-state -2 - 2

µ

A

TM

1

,TM2, DSEL, and VSEL

should be left disconnected

(floating) for Z logic input state

Note: All voltages relative to VSSexcept as noted.

bq2004E/H

11

Impedance

Symbol Parameter Minimum Typical Maximum Unit

R

BAT

Battery input impedance 50 - - M

Ω

R

TS

TS input impedance 50 - - M

Ω

R

TCO

TCO input impedance 50 - - M

Ω

R

SNS

SNS input impedance 50 - - M

Ω

Timing (T

A

= 0 to +70°C; V

CC

±

10%)

Symbol Parameter Minimum Typical Maximum Unit Notes

t

PW

Pulse width for DCMD

and INH pulse command

1- -

µ

s

Pulse start for charge or discharge

before charge

d

FCV

Time base variation -16 - 16 % VCC= 4.75V to 5.25V

f

REG

MOD output regulation

frequency

- - 300 kHz

t

MCV

Maximum voltage termination time limit

1- 2s

Time limit to distinguish battery removed from charge complete.

Note: Typical is at TA= 25°C, VCC= 5.0V.

bq2004E/H

12

bq2004E/H

16-Pin DIP Narrow (PN)

16-Pin PN(0.300" DIP

)

Dimension

Inches Millimeters

Min. Max. Min. Max.

A 0.160 0.180 4.06 4.57

A1 0.015 0.040 0.38 1.02

B 0.015 0.022 0.38 0.56

B1 0.055 0.065 1.40 1.65

C 0.008 0.013 0.20 0.33

D 0.740 0.770 18.80 19.56

E 0.300 0.325 7.62 8.26

E1 0.230 0.280 5.84 7.11

e 0.300 0.370 7.62 9.40

G 0.090 0.110 2.29 2.79

L 0.115 0.150 2.92 3.81

S 0.020 0.040 0.51 1.02

13

bq2004E/H

16-Pin SOIC Narrow (SN)

A

A1

.004

C

B

e

D

E

H

L

16-Pin SN(0.150" SOIC

)

Dimension

Inches Millimeters

Min. Max. Min. Max.

A 0.060 0.070 1.52 1.78

A1 0.004 0.010 0.10 0.25

B 0.013 0.020 0.33 0.51

C 0.007 0.010 0.18 0.25

D 0.385 0.400 9.78 10.16

E 0.150 0.160 3.81 4.06

e 0.045 0.055 1.14 1.40

H 0.225 0.245 5.72 6.22

L 0.015 0.035 0.38 0.89

14

bq2004E/H

Data Sheet Revision History

Change No. Page No. Description Nature of Change

1 All Combined bq2004E and bq2004H, revised and

expanded format of this data sheet

Clarification

2 7 Separated bq2004E and bq2004H in Table 2, LED

Output Summary

Clarification

3 5 Description of charge-pending state Clarification

4

Note: Change 1 = Oct. 1997 B changes from Sept. 1996 (bq2004E), Feb. 1997 (bq2004H).

Change 2 = Feb. 1998 C changes from Oct. 1997 B.

Change 3 = Dec. 1998 D changes from Feb. 1998 C.

Change 4 = June 1999 E changes from Dec. 1998 D.

15

bq2004E/H

Ordering Information

bq2004

Package Option:

PN = 16-pin narrow plastic DIP

SN = 16-pin narrow SOIC

Device:

E = bq2004E Fast-Charge IC

H= bq2004H Fast-Charge IC

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MA Y INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERSTOOD T O

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...