Page 1

bq2002E/G

NiCd/NiMH Fast-Charge Management ICs

Features

Fast charge of nickel cadmium

➤

or nickel-metal hydride batter

ies

Direct LED output displays

➤

chargestatus

Fast-charge terminationby -∆V,

➤

maximum voltage, maximum

temperature, and maximum

time

Internal band-gap voltage ref

➤

erence

Optional top-off charge

➤

Selectable pulse trickle charge

➤

rates

➤

Low-power mode

➤

8-pin 300-mil DIP or 150-mil

SOIC

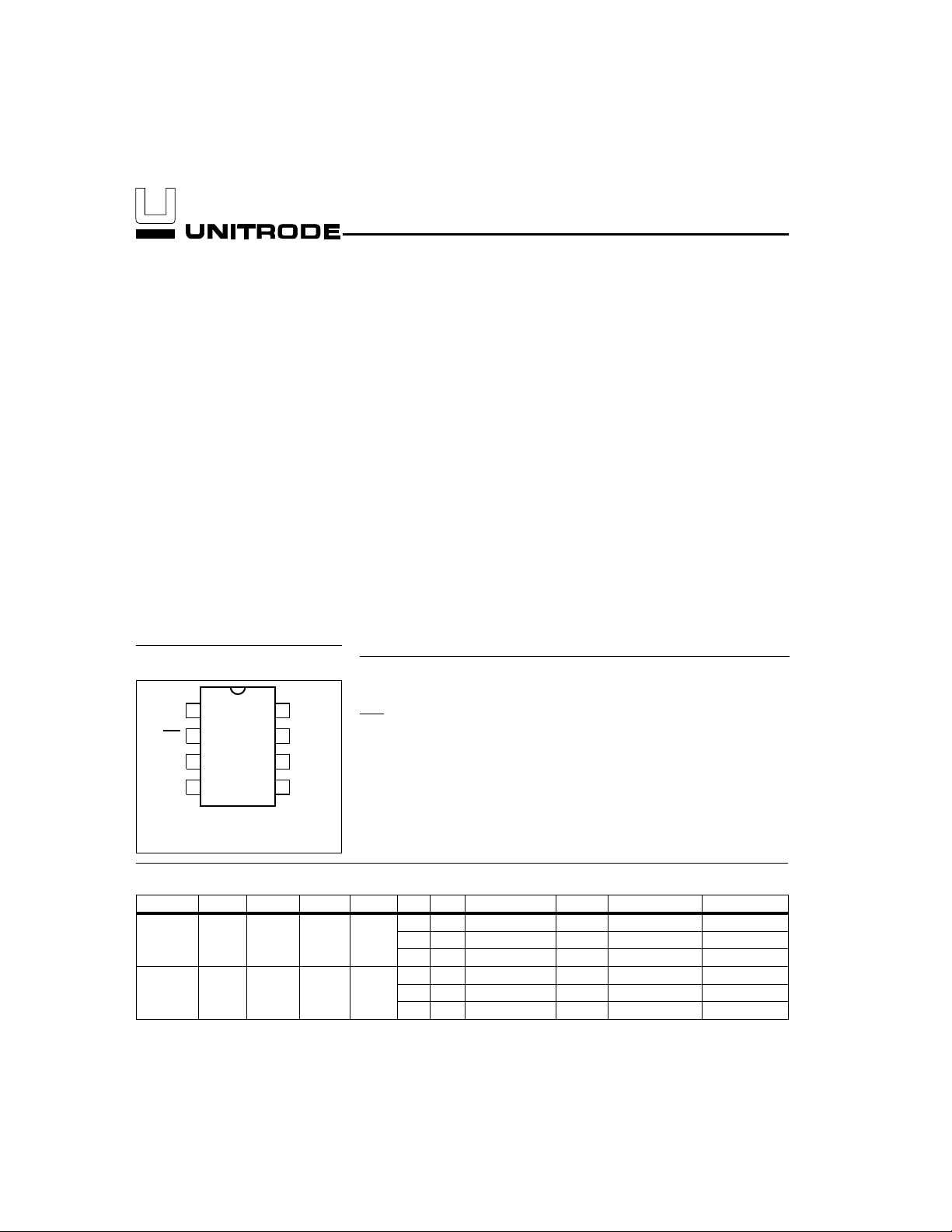

Pin Connections

TM

LED

BAT

V

SS

1

2

3

4

8

7

6

5

CC

INH

V

TS

CC

General Description

The bq2002E a n d bq2002G FastCharge ICs are low-cost CMOS bat

tery-charge controllers providing reli

able charge termination for both NiCd

and NiMH battery applications. Co n

trolling a current-limited or con

stant-current supply allows th e

bq2002E/G to be the basis for a costeffective stand-alone or system-inte

grated charger. The bq2002E/G inte

grates fast charge with optional top-off

and pulsed- trickle control in a single

IC for charging one or more NiCd or

NiMH battery cells.

Fast charge is initiated on application

of the charging supply or battery re

placement. Fo r safety, fast charge is

inhibited if the battery temperature

and voltage are outside configured

limits.

Pin Names

TM Timer mode select input

LED

BAT Battery voltage input

V

SS

Charging status output

System ground

Fast charge is terminated by any of

the following:

Peak voltage detection(PVD)

n

-

Negative delta voltage(-∆V)

n

-

Maximum voltage

n

Maximum temperature

n

Maximum time

n

-

-

After fast charge, the bq2002E/G op

tionally tops-off and pulse-trickles the

battery per the pre-configured limits.

Fast charge may be inhibited using

the INH pin. The bq2002E/G may

also be placed in low-standby-power

mode to reduce system power con-

-

sumption.

The bq2002E differs from the

bq2002G only in that a slightly different se t of fast-charge and top-off

time limits is available. All differences between the two ICs are illustrated in Table 1.

TS Temperature senseinput

V

CC

Supply voltage input

INH Charge inhibit input

CC Charge control output

-

8-Pin DIP or

Narrow SOIC

PN-200201.eps

bq2002E/G Selection Guide

Part No. LBAT TCO HTF LTF

bq2002E

bq2002G

SLUS132 - FEBRUARY 1999

0.175

V

0.175

V

∗

0.5

∗

0.6

V

CC

CC

CC

∗

0.5

∗

V

CC

V

0.6

V

∗

CC

∗

CC

None

None

PVD Fast Charge t

-∆V

✔

✔

✔

✔

✔

✔

1

MTO

Top-Off Maintenance

C/2 200 None C/32

1C 80 C/16 C/32

2C 40 None C/32

C/2 160 None C/32

1C 80 C/16 C/32

2C 40 None C/32

Page 2

bq2002E/G

Pin Descriptions

TM

LED

BAT

V

SS

TS

V

CC

INH

T ime rmodeinput

A three-level input that controls the settings

for the fast charge safety timer, voltage ter

mination mode, top-off, pulse-trickle, and

voltage hold-off time.

Charging output status

Open-drain output that indicates the charging

status.

Battery input voltage

Thebattery voltage sense input. The input to

this pin is created by a high-impedance re

sistor divider network connected between

the positive and negative terminals of the

battery.

System ground

Temperature sense input

Input for an external battery temperature

monitoring thermistor.

Supply voltage input

5.0V±20%power input.

Charge inhibit input

When high, INH suspends the fast charge in

progress. When returned low, the IC re-

sumes operation at the point where initially

suspended.

CC

-

Charge control output

An open-drain output used to control the

charging current to the battery. CC switch

ing to high impedance (Z) enables charging

current to flow, and low to inhibit charging

current. CC is modulated to provide top-off,

ifenabled,and pulse trickle.

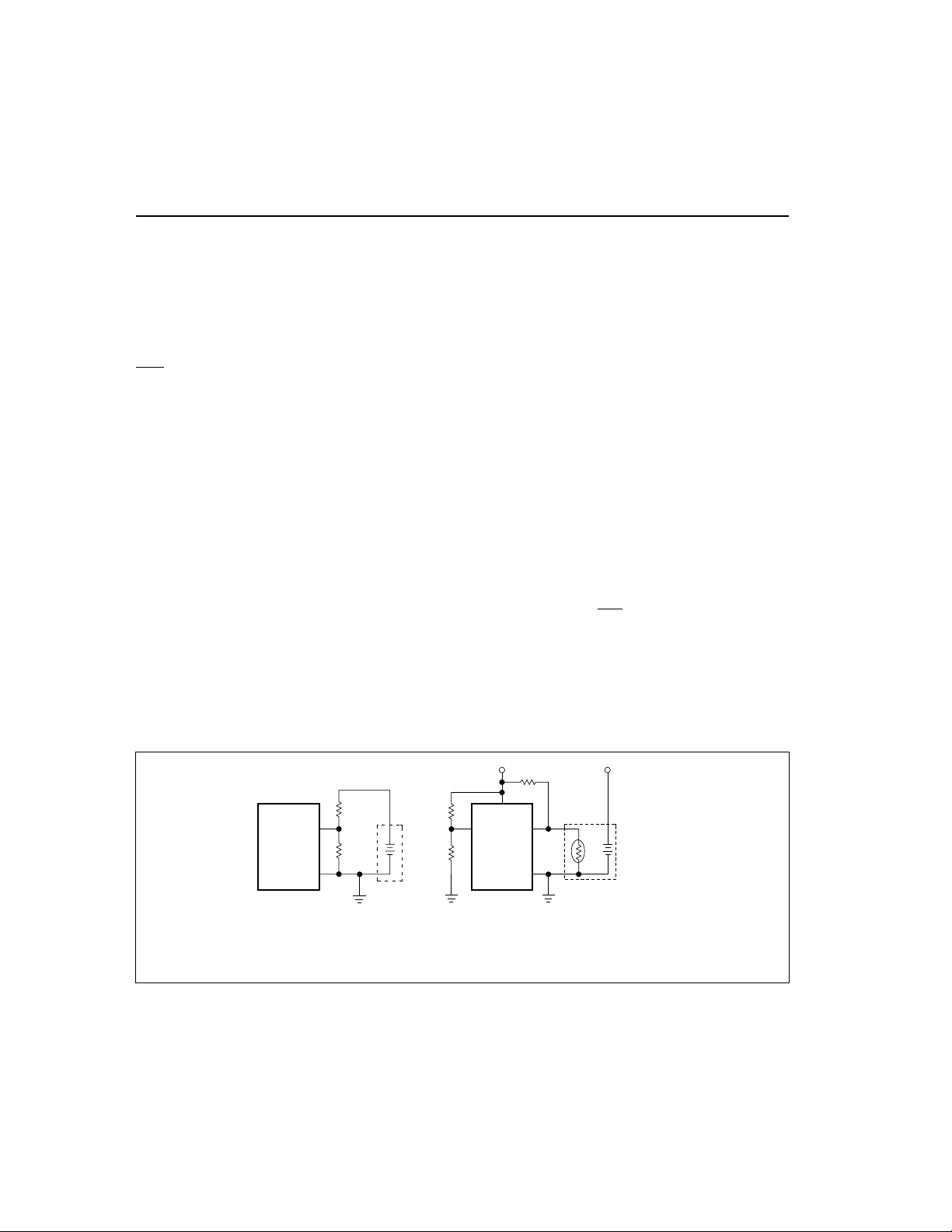

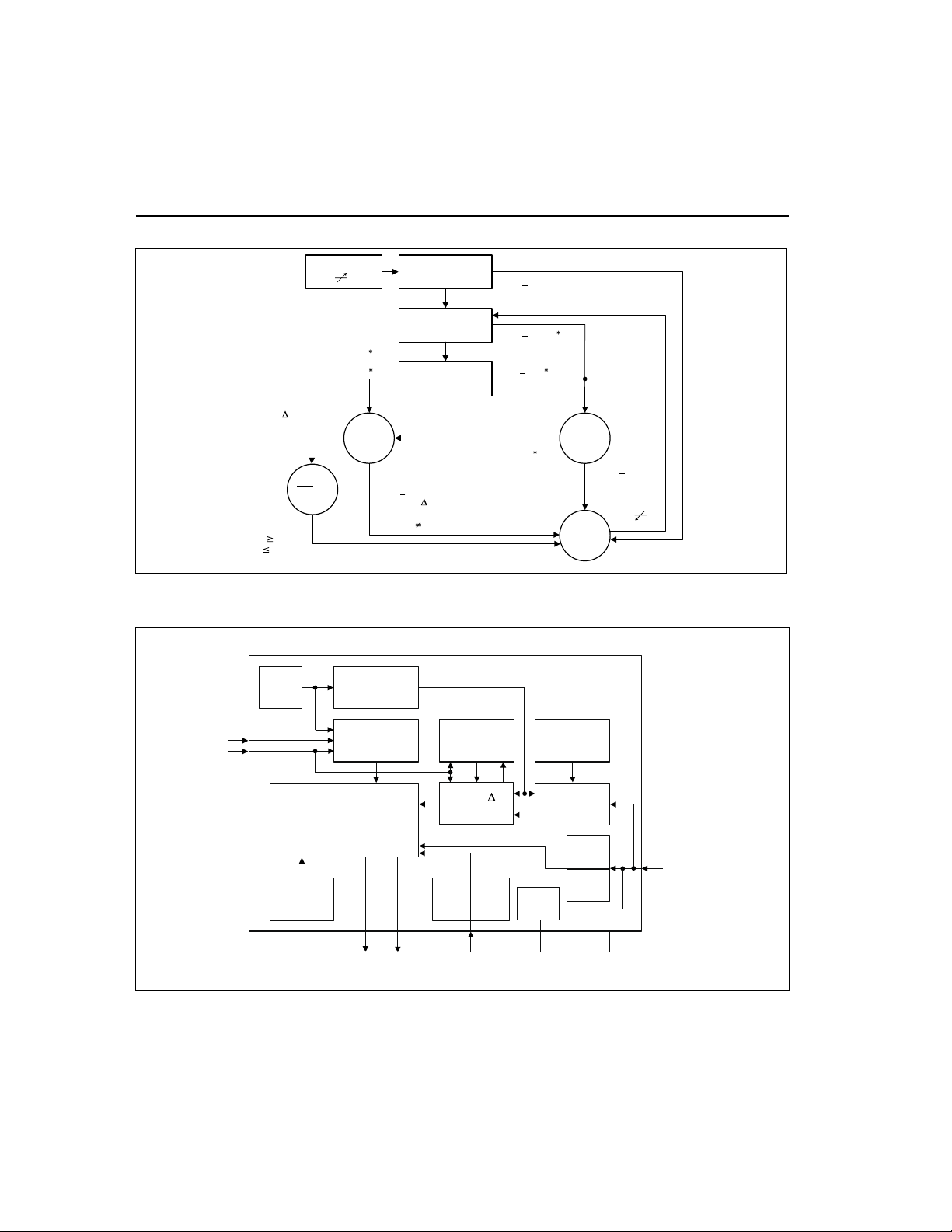

Functional Description

Figure 2 shows a state diagram and Figure 3 shows a

block diagram ofth e bq2002E/G.

-

Battery Voltageand Temperature

Measurements

Battery voltage and temperature are monitored for

maximum allowable values. The voltage presented on

the battery sense input, BAT, should represent a

single-cell potential for the battery under charge. A

resistor-dividerratio of

RB1

= N - 1

RB2

is recommended to maintain the battery voltage within

the valid range, where N is th e number of cells, RB1 is

the resistor connected to the positive battery terminal,

and RB2 is the resistor connected to the negative battery terminal. SeeFigure 1.

Note:

This resistor-divider network input impedance to

end-to-end should be at least 200k

Ω

and less than 1MΩ.

-

V

CC

RT

BAT

bq2002E/G

V

BAT pin connection Thermistor connection

RB1

RB2

SS

NTC = negative temperature coefficient thermistor.

R3

R4

Mid-level

setting for TM

V

CC

TM

bq2002E/G

V

T

S

SS

PACK +

N

T

C

Fg2002E/G01.eps

Figure 1. Voltage and Temperature Monitoring and TM Pin Configuration

2

Page 3

bq2002E/G

V or

(PVD or Maximum Time Out)

and TM = Low

Top-off

LED = Z

V

2V or

BAT

V

VCC/2 or

TS

Maximum Time Out

OSC

V

CC

Chip on

4.0V

V

TS

Battery Voltage

too High?

< 2V

V

BAT

Battery Voltage

too Low?

V

0.175

> 0.6

< V

CC

V

CC

Fast

LED =

Low

V

> 2V or

BAT

VTS < VCC/2 or

((PVD or - V or

Maximum Time Out)

and TM

BAT

Battery

Temperature?

Low)

Figure 2. State Diagram

Clock

Phase

Generator

V

V

V

BAT

BAT

TS

V

BAT

V

BAT

V

TS

> 0.175

< 2V, and

> V

CC

2V

>

< 0.175

< 0.6

/2

VCC,

V

V

CC

CC

Trickle

LED =

Flash

Trickle

LED = Z

Charge

Pending

V

BAT

V

> 2V

BAT

2V

2

SD

s

p

.e

2C

00

TM

INH

Charge-Control

State Machine

Power-On

Reset

Timing

Control

Sample

History

PVD, - V

ALU

HTF

Check

CC

LED

Figure 3. Block Diagram

3

TCO

Check

TS

Power

Down

Voltage

Reference

A to D

Converter

LBAT

Check

MCV

Check

V

CC

V

SS

Bd2002CEG.eps

BAT

Page 4

bq2002E/G

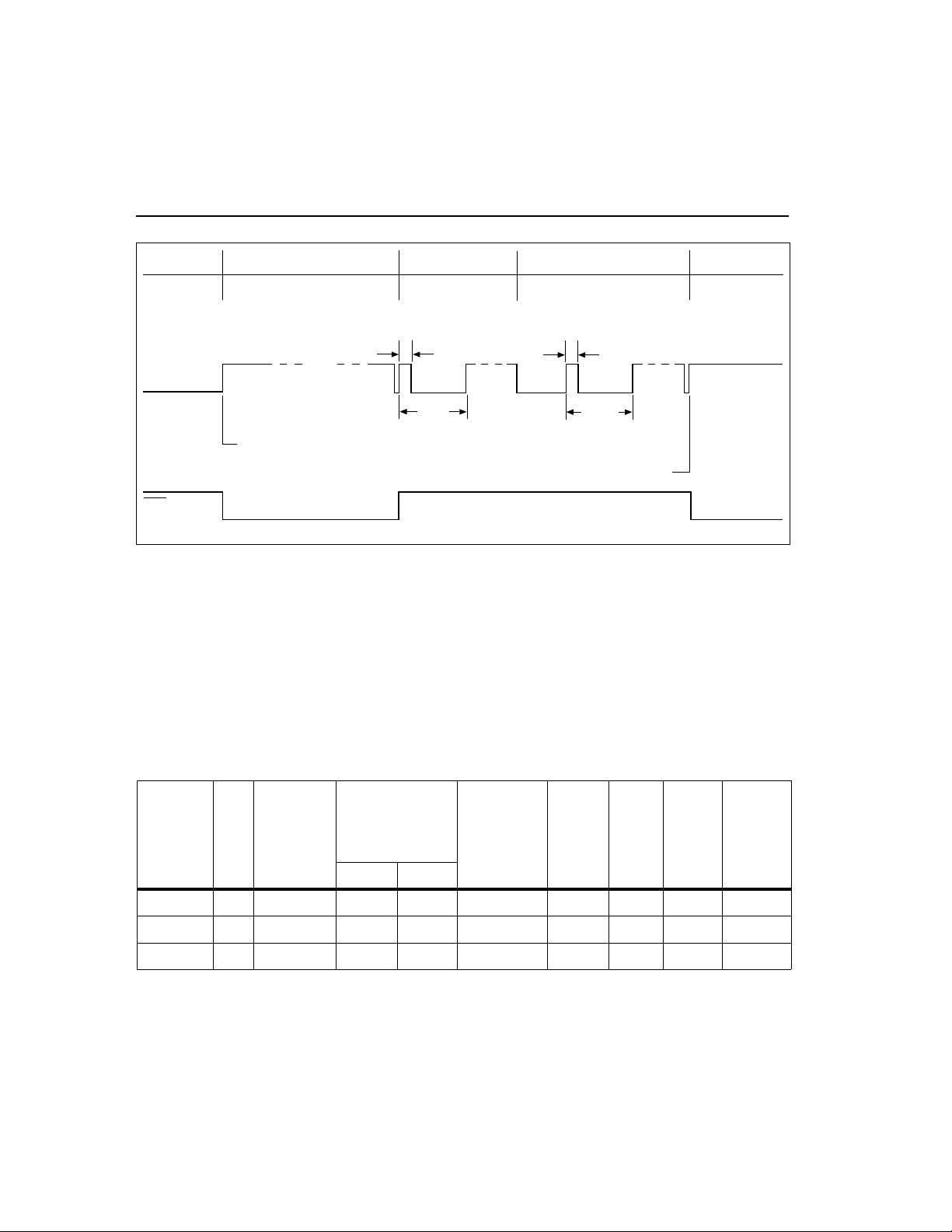

Fast ChargingVCC = 0 Fast Charging

(optional)

CC Output

73ms

1.17s 1.17s

Charge initiated by application of power

LED

Figure 4. Charge Cycle Phases

Aground-referenced negative temperature coefficient thermistor placed near the battery may be used as a low-cost

temperature-to-voltage transducer. The temperature

sense voltage input at TS is developed using a resistorthermistor network between V

and VSS. See Figure 1.

CC

Starting A Charge Cycle

Either of twoevents starts a chargecycle(see Figure 4):

Pulse-TrickleTop-Off

See Table 1

Charge initiated by battery replacement

1.Application ofpower to V

or

CC

2. Voltage at th e BAT pin falling through the maximum

cell voltage V

MCV

where

V

MCV

= 2V±5%.

If the battery is within th e configured temperature and

voltage limits, the IC begins fast charge. The valid battery voltage range is V

LBAT<VBAT<VMCV

,where

TD2002EG.eps

Table 1. Fast-Charge Safety Time/Hold-Off/Top-Off Table

Typical Fast-

Charge and

-

Corre

sponding

Fast-Charge

Rate TM Termination

Time Limits

(minutes)

bq2002E bq2002G

Typical PVD

and -∆V

Hold-Off Time

(seconds)

Top-Off

Rate

PulseTrickle

Rate

C/2 Mid PVD 200 160 300 Disabled C/32 73 18.7

1C Low PVD 80 80 150 C/16 C/32 37 18.7

Top-Off

2C High -

Notes:

Typical conditions = 25°C, VCC= 5.0V

Mid = 0.5*V

Tolerance on all timing is

V 40 40 75 Disabled C/32 18 9.4

∆

0.5V

±

CC

±

12%.

4

Pulse-

Trickle

Width

(ms)

Maximum

Synchro

nized

Sampling

Period

(seconds)

-

Page 5

bq2002E/G

V

= 0.175∗VCC±

LBAT

The valid temperature range isV

= 0.6∗VCC±

V

HTF

20%

TS>VHTF

5%.

where

If the battery voltage or temperature is outside of these

limits, th e IC pulse-trickle charges until the next new

chargecyclebegins.

If V

MCV<VBAT<VPD

newbattery is inserted, a delay of0.35 to 0.9s is imposed

(see “Low-Power Mode”) when a

before the new charge cyclebegins.

Fast charge continues until termination by one or more of

the five possible termination conditions:

Peak voltage detection (PVD)

n

Negative delta voltage (-∆V)

n

Maximum voltage

n

Maximum temperature

n

Maximum time

n

PVD and -∆V Termination

There are two modes for voltage termination, depending

on the state ofTM. For than any previously measured value by 12mV

∆

V (TM = high), if V

is lower

BAT

±

3mV, fast

charge is terminated. For PVD (TM = low or mid), a decrease of 2.5mV

and -

∆

Vtests are valid in the range 1V<V

±

2.5mV terminates fast charge. The PVD

BAT

<2V.

Synchronized Voltage Sampling

Voltage sampling at the BAT pin for PVD and -∆Vtermi

nation may be synchronized to an external stimulus using the INH input. Low-high-low input pulses between

100ns a nd 3.5ms in width must be applied at the INH

pin with a frequency greater than the “maximum syn

chronized sampling period” set by the state of the TM

pin as shown in Table 1. Voltage is sampled on the fal

ling edgeofsuch pulses.

If the time between pulses is greater than the synchro

nizing period, voltage sampling “free-runs” at once every

17 seconds. A sample is taken by averaging together

voltage measurements taken 57

32 measurements in PVD mode and 16 measurements

in -

∆

V mode. The resulting sample periods (9.17 and

18.18ms, respectively) filter out harmonics centered

around 55 and 109Hz. This technique minimizes the ef

fect of any AC line ripple that may feed through the

power supply from either 50or60Hz ACsources.

If the INH input remains high for more than 12ms, the

voltage sample history kept by the IC a nd used for PVD

and -

∆

V termination decisions is erased and a new his

tory is started. Such a reset is required when transition

ing from free-running to synchronized voltage sampling.

µ

s apart. The IC takes

The response of the IC to pulses less than 100ns i n

width or between 3.5ms and 12ms is indeterminate. Tol

±

erance on all timing is

12%.

Voltage TerminationHold-off

A hold-off period occurs at the start of fast charging.

During the hold-off time, the PVD a n d -

∆

Vterminations

are disabled. This avoids premature termination on the

voltage spikes sometimes produced by older batteries

when fast-charge current is first applied. Maximum

voltage and temperature terminations are not affected

by the hold-off period.

Maximum Voltage, Temperature,and Time

Any time the voltage on the BA T pin exceeds the maxi

mum cell voltage,V

chargeis terminated.

Maximum temperature termination occurs anytime t h e

voltage on the TS pin falls below the temperature cut-off

threshold V

TCO

Maximum charge time is configured using the TM pin.

Time settings a re available for corresponding charge

rates of C/2, 1C, and 2C. Maximum time-out termination is enforced on the fast-charge phase, then reset, and

enforced again on the top-off phase, if selected. There is

notime limit onthe trickle-charge phase.

, fast charge or optional top-off

MCV

where

V

TCO

= 0.5∗VCC±

5%.

Top-off Charge

An optional top-off charge phase may be selected to

follow fast charge termination for 1C and C/2 rates.

This phase may be necessary on NiMH or other ba t-

tery chemistries that have a tendency to terminate

charge before reaching full capacity. With top-off en

abled, charging continues at a r educed ra te after

fast-charge termination for a period of time selected

by t h e TM pin. (See Table 1.) During top-off, the CC

pin is modulated at a duty cycle of 73ms active for

every 1097ms inactive. This modulation results in a n

-

average rate 1/16th that ofthe fast charge rate. Maxi

mum voltage, time, an d temperature are the only ter

mination methods enabled during top-off.

Pulse-Trickle Charge

Pulse-trickle is used to compensate for self-discharge

while the battery is idle in the charger. The battery is

pulse-trickle charged by driving the CC pin active once

every 1.17s for the period specified in Table 1. This re

sults in a trickle rate ofC/32.

TM Pin

The TM pin is a three-level pin used to select th e

chargetimer,top-off, voltage termination mode, trickle

-

-

-

-

-

-

5

Page 6

bq2002E/G

rate, and voltage hold-off period options. Table 1 d e

scribes the states selected by t he TM pin. The midlevel selection input is developed by a resistor di

vider between V

on TM at V

CC

and ground that fixes the voltage

CC

/2±0.5V. See Figure 4.

Charge Status Indication

Afast charge in progress is uniquely indicated when the

LED

pin goes low. The LED pin is driven to the high-Z

state for all conditions other than fast charge. Figure 2

outlines the state of the LED

pinduring charge.

Charge Inhibit

Fast charge and top-off may be inhibited by using th e

INH pin. When high, INH suspends all fast charge and

top-off activity a n d the internal charge timer. INH

freezes the current state of LED

Temperature monitoring is not affected by the INH pin.

During charge inhibit, the bq2002E/G continues to

pulse-trickle charge the battery per the TM selection.

When INH returns low, charge control and the charge

timer resume from the point where INHbecame active.

until inhibit is removed.

-

Low-Power Mode

The IC enters a low-power state when V

above the power-down threshold (V

V

= VCC- (1V±0.5V)

PD

Both the CC pin and the LED

pin are driven to t he

PD

)where

BAT

high-Z state. The operating current is reduced to less

than 1

µ

A in this mode. When V

below V

newchargecyclebegins.

, t he IC pulse-trickle charges until the next

PD

returns to a value

BAT

is driven

6

Page 7

bq2002E/G

Absolute Maximum Ratings

Symbol Parameter Minimum Maximum Unit Notes

V

CC

V

T

T

OPR

T

STG

T

SOLDER

T

BIAS

Note:

VCCrelative to V

SS

DC voltage applied on any pin

excluding V

relative to V

CC

SS

-0.3 +7.0 V

-0.3 +7.0 V

Operating ambient temperature 0 +70 °C Commercial

Storage temperature -40 +85 °C

Soldering temperature - +260 ° C 10 sec max.

Temperature under bias -40 +85 °C

Permanent device damage may occur if

Absolute Maximum Ratings

are exceeded. Functional opera

tion should be limited to the Recommended DC Operating Conditions detailed in this data sheet. Expo

sure to conditions beyond the operational limits for extended periods of time may affect device reliability.

-

-

DC Thresholds (T

= 0 to 70°C; V

A

CC

20%)

±

Symbol Parameter Rating Tolerance Unit Notes

V

TCO

V

HTF

V

MCV

V

LBAT

-

∆

V

PVD BAT input change for

Temperature cutoff 0.5*V

High temperature fault

0.6

∗

Maximum cell voltage 2

Minimum cell voltage

BAT input change for

-

∆

Vdetection

0.175

-12

-2.5

VCC

∗

5% V V

CC

V

CC

±

±

5%

5% V

±

±

20%

±

3

±

2.5

TS

fast charge and top-off

VV

TS<VHTF

start

V

BAT

fast charge and top-off

VV

BAT<VLBAT

start

mV

mV

inhibits/terminates

V

≤

TCO

inhibits fast charge

≥

V

inhibits/terminates

MCV

inhibits fast charge

PVDdetection

7

Page 8

bq2002E/G

Recommended DC Operating Conditions (T

= 0 to 70°C)

A

Symbol Condition Minimum Typical Maximum Unit Notes

V

V

V

V

V

V

V

Supply voltage 4.0 5.0 6.0 V

CC

-∆V, PVD detect voltage 1 - 2 V

DET

Battery input 0 - V

BAT

Thermistor input 0.5 - V

TS

Logic input high 0.5 - - V INH

IH

Logic input high V

Logic input mid

IM

Logic input low - - 0.1 V INH

IL

- 0.5 - - V TM

CC

V

CC

- 0.5

2

-

CC

CC

V

CC

+

05

2

V

VVTS< 0.5V prohibited

.

VTM

Logic input low - - 0.5 V TM

V

V

I

CC

I

SB

Logic output low - - 0.8 V LED,CC,IOL= 10mA

OL

Power down VCC- 1.5 - VCC- 0.5 V V

PD

Supply current - - 500

Standby current - - 1

BAT

down bq2002E/G;

V

BAT

normal operation.

A Outputs unloaded,

µ

V

CC

AVCC= 5.1V, V

µ

V

max. powers

≥

PD

< VPDmin. =

= 5.1V

BAT

= V

PD

I

OL

I

L

I

OZ

Note:

LED,CCsink 10 - - mA @VOL= VSS+ 0.8V

Input leakage - -

Output leakage in

-5 - -

1

±

A INH, CC,V = VSSto V

µ

A LED,CC

µ

high-Z state

All voltages relative to VSS.

8

CC

Page 9

bq2002E/G

Impedance

Symbol Parameter Minimum Typical Maximum Unit

R

BAT

R

TS

Battery input impedance 50 - - M

TS input impedance 50 - - M

Ω

Ω

Timing (T

Symbol Parameter Minimum Typical Maximum Unit Notes

d

FCV

t

DLY

Note:

= 0 to +70°C; V

A

Time base variation -12 - 12 %

Start-up delay 0.35 - 0.9 s Starting from V

Typical is at TA= 25°C, VCC= 5.0V.

CC

±

10%)

MCV<VBAT<VPD

9

Page 10

bq2002E/G

8-Pin DIP(PN

E1

E

e

)

D

C

8-Pin SOIC Narrow (SN)

8-Pin PN(0.300" DIP

Dimension

A 0.160 0.180 4.06 4.57

A1 0.015 0.040 0.38 1.02

B 0.015 0.022 0.38 0.56

B1 0.055 0.065 1.40 1.65

A

A1

L

S

B1

B

G

C 0.008 0.013 0.20 0.33

D 0.350 0.380 8.89 9.65

E 0.300 0.325 7.62 8.26

E1 0.230 0.280 5.84 7.11

e 0.300 0.370 7.62 9.40

G 0.090 0.110 2.29 2.79

L 0.115 0.150 2.92 3.81

S 0.020 0.040 0.51 1.02

Min. Max. Min. Max.

)

Inches Millimeters

8-Pin SN(0.150" SOIC

Inches Millimeters

Dimension

A 0.060 0.070 1.52 1.78

A1 0.004 0.010 0.10 0.25

B 0.013 0.020 0.33 0.51

C 0.007 0.010 0.18 0.25

D 0.185 0.200 4.70 5.08

E 0.150 0.160 3.81 4.06

e 0.045 0.055 1.14 1.40

H 0.225 0.245 5.72 6.22

L 0.015 0.035 0.38 0.89

Min. Max. Min. Max.

)

10

Page 11

PACKAGE OPTION ADDENDUM

www.ti.com

7-May-2007

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

BQ2002EPN ACTIVE PDIP P 8 50 Pb-Free

BQ2002EPNE4 ACTIVE PDIP P 8 50 Pb-Free

BQ2002ESN ACTIVE SOIC D 8 75 Green (RoHS &

no Sb/Br)

BQ2002ESNG4 ACTIVE SOIC D 8 75 Green (RoHS &

no Sb/Br)

BQ2002ESNTR ACTIVE SOIC D 8 2500 Green (RoHS &

no Sb/Br)

BQ2002ESNTRG4 ACTIVE SOIC D 8 2500 Green (RoHS &

no Sb/Br)

BQ2002GPN ACTIVE PDIP P 8 50 Pb-Free

BQ2002GPNE4 ACTIVE PDIP P 8 50 Pb-Free

BQ2002GSN ACTIVE SOIC D 8 75 Green(RoHS &

no Sb/Br)

BQ2002GSNG4 ACTIVE SOIC D 8 75 Green (RoHS &

no Sb/Br)

BQ2002GSNTR ACTIVE SOIC D 8 2500 Green (RoHS &

no Sb/Br)

BQ2002GSNTRG4 ACTIVE SOIC D 8 2500 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(RoHS)

(RoHS)

(RoHS)

(RoHS)

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU N / A for Pkg Type

CU NIPDAU N / A for Pkg Type

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU N / A for Pkg Type

CU NIPDAU N / A for Pkg Type

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

CU NIPDAU Level-1-260C-UNLIM

(3)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

Addendum-Page 1

Page 12

PACKAGE OPTION ADDENDUM

www.ti.com

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

7-May-2007

Addendum-Page 2

Page 13

PACKAGE MATERIALS INFORMATION

www.ti.com

TAPE AND REEL INFORMATION

19-Mar-2008

*All dimensions are nominal

Device Package

BQ2002ESNTR SOIC D 8 2500 330.0 12.4 6.4 5.2 2.1 8.0 12.0 Q1

BQ2002GSNTR SOIC D 8 2500 330.0 12.4 6.4 5.2 2.1 8.0 12.0 Q1

Type

Package

Drawing

Pins SPQ Reel

Diameter

(mm)

Reel

Width

W1 (mm)

A0 (mm) B0 (mm) K0 (mm) P1

(mm)W(mm)

Pin1

Quadrant

Pack Materials-Page 1

Page 14

PACKAGE MATERIALS INFORMATION

www.ti.com

19-Mar-2008

*All dimensions are nominal

Device Package Type Package Drawing Pins SPQ Length (mm) Width (mm) Height (mm)

BQ2002ESNTR SOIC D 8 2500 340.5 338.1 20.6

BQ2002GSNTR SOIC D 8 2500 340.5 338.1 20.6

Pack Materials-Page 2

Page 15

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Clocks and Timers www.ti.com/clocks Digital Control www.ti.com/digitalcontrol

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Telephony www.ti.com/telephony

RF/IF and ZigBee® Solutions www.ti.com/lprf Video & Imaging www.ti.com/video

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2008, Texas Instruments Incorporated

Wireless www.ti.com/wireless

Loading...

Loading...