Datasheet BQ2000PN-B3, BQ2000SN-B5TR, BQ2000SN-B5, BQ2000SN-B3, BQ2000PN-B5 Datasheet (Texas Instruments)

1

Features

➤

Safe management of fast

charge for NiCd, NiMH, or LiIon battery packs

➤

High-frequency switching con

troller for efficient and simple

charger design

➤

Pre-charge qualification for

detecting shorted, damaged, or

overheated cells

➤

Fast-charge termination by

peak voltage (PVD), minimum

current (Li-Ion), maximum

temperature, and maximum

charge time

➤ Selectable top-off mode for

achieving maximum capacity in

NiMH batteries

➤ Programmable trickle-charge

mode for reviving deeply discharged batteries and for postcharge maintenance

➤ Built-in battery removal and

insertion detection

➤

Sleep mode for low power

consumption

General Description

The bq2000 is a programmable,

monolithic IC for fast-charge manage

ment of nickel cadmium (NiCd),

nickel metal-hydride (NiMH), or lith

ium-ion (Li-Ion) batteries in single- or

multi-chemistry applications. The

bq2000 detects the battery chemistry

and proceeds with the optimal charg

ing and termination algorithms. This

process eliminates undesirable under

charged or overcharged conditions

and allows accurate and safe termi

nation of fast charge.

Depending on the chemistry, the

bq2000 provides a number of charge

termination criteria:

n

Peak voltage, PVD (for NiCd and

NiMH)

n Minimum charging current (f or

Li-Ion)

n

Maximum temperature

n

Maximum charge time

For safety, the bq2000 inhibits fast

charge until the battery voltage and

temperature are within user-defined

limits. If the battery voltage is below

the low-voltage threshold, the

bq2000 uses trickle-charge to

condition the battery. For NiMH

batteries, the bq2000 provides an

optional top-off charge to maximize

the battery capacity.

The integrated high-frequency com

parator allows the bq2000 to be the

basis for a complete, high-efficiency

power-conversion circuit for both

nickel-based and lithium-based

chemistries.

bq2000

SNS Current-sense input

V

SS

System ground

LED

Charge-status

output

BAT Battery-voltage

input

1

PN-2000.eps

8-Pin DIP or Narrow SOIC

or TSSOP

2

3

4

8

7

6

5

SNS

LED

BAT

V

SS

MOD

V

CC

TS

RC

Pin Connections

Pin Names

Programmable Multi-Chemistry

Fast-Charge Management IC

SLUS138A–FEBRUARY 2000 E

TS Temperature-sense

input

RC Timer-program input

V

CC

Supply-voltage input

MOD Modulation-control

output

2

Pin Descriptions

SNS

Current-sense input

Enables the bq2000 to sense the battery cur

rent via the voltage developed on this pin by

an external sense-resistor connected in se

ries with the battery pack

V

SS

System Ground

LED

Charge-status output

Open-drain output that indicates the charg

ing status by turning on, turning off, or

flashing an external LED

BAT

Battery-voltage input

Battery-voltage sense input. A simple resistive

divider, across the battery terminals, generates

this input.

TS

Temperature-sense input

Input for an external battery-temperature

monitoring circuit. An external resistive divider network with a negative temperature-coefficient thermistor sets the lower

and upper temperature thresholds.

RC

Timer-program input

RC input used to program the maximum

charge-time, hold-off period, and trickle

rate during the charge cycle, and to disable

or enable top-off charge

V

CC

Supply-voltage input

MOD

Modulation-control output

Push-pull output that controls the charging

current to the battery. MOD switches high

to enable charging current to flow and low to

inhibit charging- current flow.

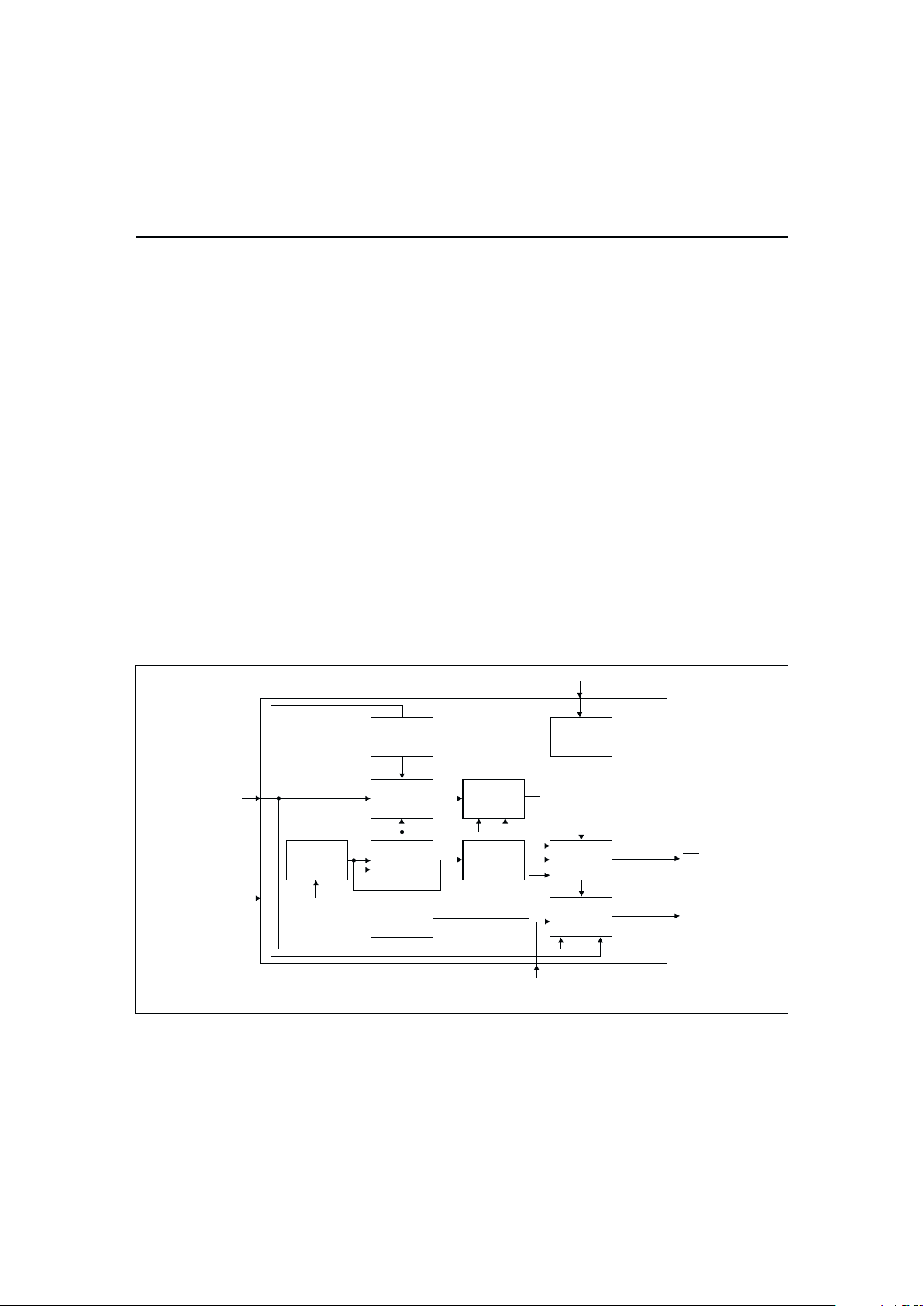

Functional Description

The bq2000 is a versatile, multi-chemistry batterycharge control device. See Figure 1 for a functional block

diagram and Figure 2 for a state diagram.

bq2000

bq2000BD.eps

Voltage

Reference

Internal

OSC

Clock

Phase

Generator

ADC

OSC

SNS

TS

MOD

RC

BAT

LED

V

CCVSS

Timer

PVD

ALU

Voltage

Comparator

Voltage

Comparator

Charge

Control

Figure 1. Functional Block Diagram

3

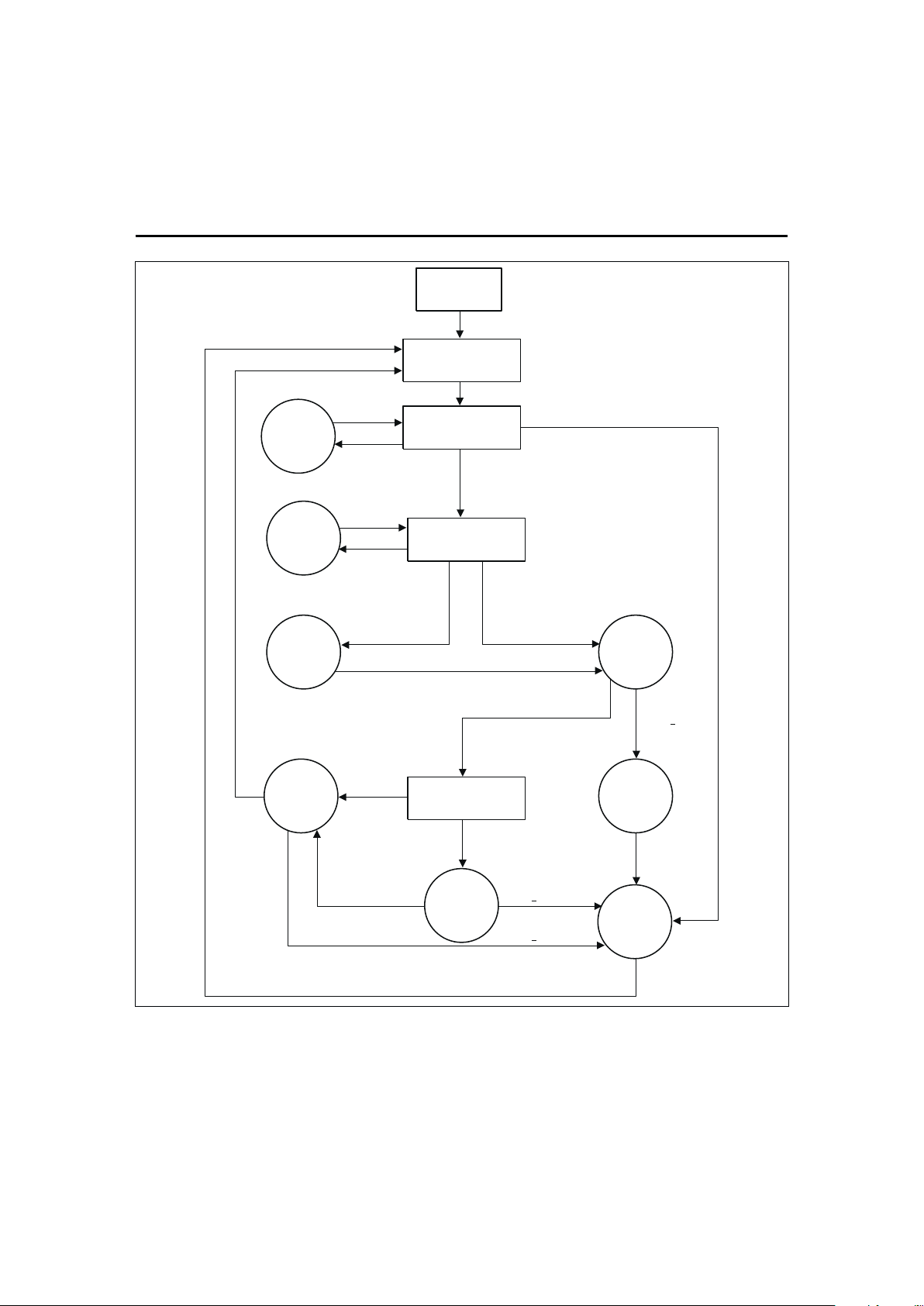

bq2000

Charge

Initialization

4.0V < V

C

C

< 6.0V

Sleep

Mode

Charge

Suspended

Battery

Conditioning

Current

Regulation

Voltage

Regulation

Current Taper

or

Time = MTO

Time < MTO

and

V

B

A

T

> V

M

C

V

Maintenance

Charge

Done

Top-Off

Yes

No

V

C

C

Reset or Battery Replacement or Capacity Depletion (Li-Ion)

V

C

C

Reset

V

B

A

T

>

V

M

C

V

Time = MTO or

V

T

S

< V

T

C

O

PVD (after hold-off period),

or V

T

S

< V

T

C

O

or

Time = MTO

Battery Voltage

(checked at all times)

Battery Temperature

(checked at all times)

Top-Off

Selected?

V

B

A

T

< V

S

L

P

V

B

A

T

< V

M

C

V

V

T

S

> V

H

T

F

V

B

A

T

< V

L

B

A

T

or

V

T

S

> V

L

T

F

V

L

B

A

T

< V

B

A

T

< V

M

C

V

and

V

H

T

F

< V

T

S

< V

L

T

F

V

LB

A

T

< V

B

A

T

< V

M

C

V

and

V

H

T

F

< V

T

S

< V

L

T

F

V

T

S

< V

H

T

F

V

S

L

P

< V

B

A

T

< V

C

C

V

M

C

V

< V

B

A

T

< V

S

LP

SD2000.eps

V

B

A

T

>

V

M

C

V

Figure 2. State Diagram

Initiation and Charge Qualification

The bq2000 initiates a charge cycle when it detects

n

Application of power to V

CC

n

Battery replacement

n

Exit from sleep mode

n

Capacity depletion (Li-Ion only)

Immediately following initiation, the IC enters a

charge-qualification mode. The bq2000 charge qualifica

-

tion is based on battery voltage and temperature. If

voltage on pin BAT is less than the internal threshold,

V

LBAT

, the bq2000 enters the charge-pending state. This

condition indicates the possiblility of a defective or

shorted battery pack. In an attempt to revive a fully

depleted pack, the bq2000 enables the MOD pin to

trickle-charge at a rate of once every 1.0s. As explained

in the section “Top-Off and Pulse-Trickle Charge,” the

trickle pulse-width is user-selectable and is set by the

value of the resistance connected to pin RC.

During this period, the LED

pin blinks at a 1Hz rate,

indicating the pending status of the charger.

Similarly, the bq2000 suspends fast charge if the battery

temperature is outside the V

LTF

to V

HTF

range. (See Table

4.) For safety reasons, however, it disables the pulse

trickle, in the case of a battery over-temperature condition

(i.e., V

TS<VHTF

). Fast charge begins when the battery

temperature and voltage are valid.

Battery Chemistry

The bq2000 detects the battery chemistry by monitoring

the battery-voltage profile during the initial stage of the

fast charge. If the voltage on BAT input rises to the in

-

ternal V

MCV

reference, the IC assumes a Li-Ion battery.

Otherwise the bq2000 assumes NiCd/NiMH chemistry.

As shown in Figure 6, a resistor voltage-divider between

the battery pack’s positive terminal and V

SS

scales the

battery voltage measured at pin BAT. In a

mixed-chemistry design, a common voltage-divider is

used as long as the maximum charge voltage of the

nickel-based pack is below that of the Li-Ion pack. Oth

-

erwise, different scaling is required.

Once the chemistry is determined, the bq2000 completes

the fast charge with the appropriate charge algorithm

(Table 1). The user can customize the algorithm by

programming the device using an external resistor and

a capacitor connected to the RC pin, as discussed in

later sections.

NiCd and NiMH Batteries

Following qualification, the bq2000 fast-charges NiCd or

NiMH batteries using a current-limited algorithm. During the fast-charge period, it monitors charge time, temperature, and voltage for adherence to the termination

criteria. This monitoring is further explained in later

sections. Following fast charge, the battery is topped off,

if top-off is selected. The charging cycle ends with a

trickle maintenance-charge that continues as long as

the voltage on pin BAT remains below V

MCV

.

4

bq2000

GR2000CA.eps

I

MAX

I

MIN

Trickle

V

LBAT

V

MCV

Current

Voltage

Qualification

Time

Phase 1 Phase 2

Fast Charge

Voltage

Current

Figure 3. Lithium-Ion Charge Algorithm

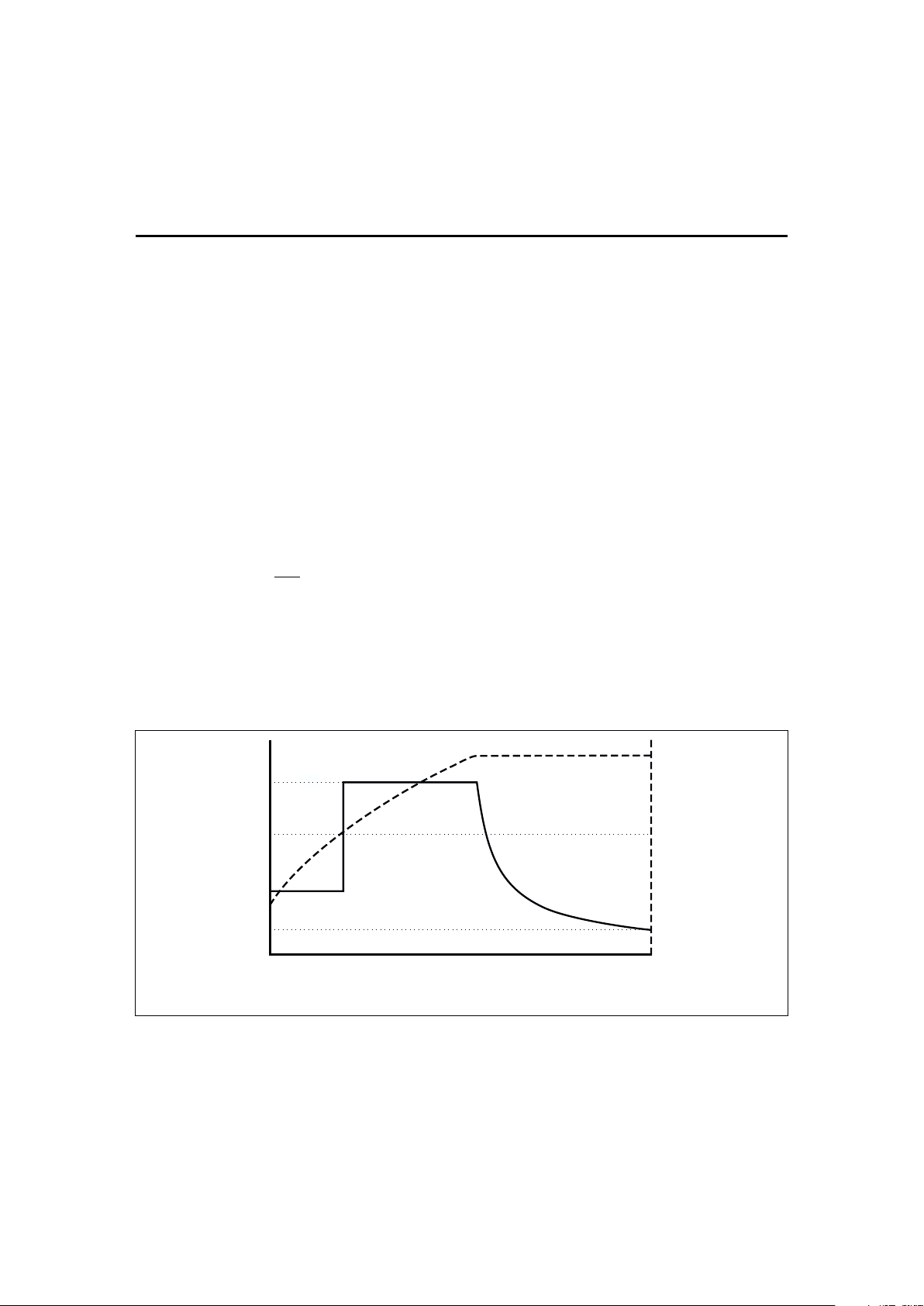

Lithium-Ion Batteries

The bq2000 uses a two-phase fast-charge algorithm for

Li-Ion batteries (Figure 3). In phase one, the bq2000 reg

-

ulates constant current until V

BAT

rises to V

MCV

. The

bq2000 then moves to phase two, regulates the battery

with constant voltage of V

MCV

, and terminates when the

charging current falls below the I

MIN

threshold. A new

charge cycle is started if the cell voltage falls below the

V

RCH

threshold.

During the current-regulation phase, the bq2000

monitors charge time, battery temperature, and battery

voltage for adherence to the termination criteria. During

the final constant-voltage stage, in addition to the

charge time and temperature, it monitors the charge

current as a termination criterion. There is no

post-charge maintenance mode for Li-Ion batteries.

Charge Termination

Maximum Charge Time (NiCD, NiMH, and

Li-Ion)

The bq2000 sets the maximum charge-time through pin

RC. With the proper selection of external resistor and ca

pacitor, various time-out values may be achieved. Figure

4 shows a typical connection.

The following equation shows the relationship between

the R

MTO

and C

MTO

values and the maximum charge

time (MTO) for the bq2000:

MTO = R

MTO

∗ C

MTO

∗ 35,988

MTO is measured in minutes, R

MTO

in ohms, and C

MTO

in farads. (Note: R

MTO

and C

MTO

values also determine

other features of the device. See Tables 2 and 3 for de

tails.)

For Li-Ion cells, the bq2000 resets the MTO when the

battery reaches the constant-voltage phase of the

charge. This feature provides the additional charge time

required for Li-Ion cells.

Maximum Temperature (NiCd, NiMH, Li-Ion)

A negative-coefficient thermistor, referenced to VSSand

placed in thermal contact with the battery, may be used

as a temperature-sensing device. Figure 5 shows a typical temperature-sensing circuit.

During fast charge, the bq2000 compares the battery

temperature to an internal high-temperature cutoff

threshold, V

TCO

. As shown in Table 4, high-temperature

termination occurs when voltage at pin TS is less than

this threshold.

Peak Voltage (NiCd, NiMH)

The bq2000 uses a peak-voltage detection (PVD) scheme

to terminate fast charge for NiCd and NiMH batteries.

The bq2000 continuously samples the voltage on the

BAT pin, representing the battery voltage, and triggers

the peak detection feature if this value falls below the

maximum sampled value by as much as 3.8mV (PVD).

As shown in Figure 6, a resistor voltage-divider between

the battery pack’s positive terminal and V

SS

scales the

battery voltage measured at pin BAT.

For Li-Ion battery packs, the resistor values R

B1

and

R

B2

are calculated by the following equation:

R

R

N

V

V

B1

B2

CELL

MCV

=∗

− 1

where N is the number of cells in series and V

CELL

is the

manufacturer-specified charging voltage. The end-to-end

input impedance of this resistive divider network should

be at least 200kΩ and no more than 1MΩ.

A NiCd or NiMH battery pack consisting of N seriescells may benefit by the selection of the R

B1

value to be

N-1 times larger than the R

B2

value.

In a mixed-chemistry design, a common voltage-divider

is used as long as the maximum charge voltage of the

5

Battery Chemistry Charge Algorithm

NiCd or NiMH

1. Charge qualification

2. Trickle charge, if required

3. Fast charge (constant current)

4. Charge termination (peak voltage, maximum charge time)

5. Top-off (optional)

6. Trickle charge

Li-Ion

1. Charge qualification

2. Trickle charge, if required

3. Two-step fast charge (constant current followed by constant voltage)

4. Charge termination (minimum current, maximum charge time)

Table 1. Charge Algorithm

bq2000

6

bq2000

F2000TMC.eps

bq2000

2

7

Battery

Pack

5

R

T2

R

T1

V

SS

V

CC

V

CC

TS

N

T

C

Figure 5. Temperature Monitoring Configuration

F2000 RCI.eps

bq2000

2

V

CC

RC

7

6

C

MTO

R

MTO

V

SS

Figure 4. Typical Connection for the RC Input

F2000BVD.eps

BAT+

bq2000

2

4

R

B1

R

B2

V

SS

BAT

Figure 6. Battery Voltage Divider

nickel-based pack is below that of the Li-Ion pack. Oth

-

erwise, different scaling is required.

Minimum Current (Li-Ion Only)

The bq2000 monitors the charging current during the

voltage-regulation phase of Li-Ion batteries. Fast charge

is terminated when the current is tapered off to 14% of

the maximum charging current.

Initial Hold-Off Period

The values of the external resistor and capacitor

connected to pin RC set the initial hold-off period.

During this period, the bq2000 avoids early termination

due to an initial rise in the battery voltage by disabling

the peak voltage-detection feature. This period is fixed

at the programmed value of the maximum charge time

divided by 32.

hold-off period =

maximum time - out

32

Top-Off and Pulse-Trickle Charge

An optional top-off charge is available for NiCd or NiMH

batteries. Top-off may be desirable on batteries that

have a tendency to terminate charge before reaching full

capacity. To enable this option, the capacitance value of

C

MTO

connected to pin RC (Figure 4) should be greater

than 0.13µF, and the value of the resistor connected to

this pin should be less than 15kΩ. To disable top-off, the

capacitance value should be less than 0.07µF. The tolerance of the capacitor needs to be taken into account in

component selection.

Once enabled, the top-off is performed over a period

equal to the maximum charge time at a rate of

1

16

that

of fast charge.

Following top-off, the bq2000 trickle-charges the battery

by enabling the MOD to charge at a rate of once every

1.0 second. The trickle pulse-width is user-selectable

and is set by the value of the resistor R

MTO

, connected to

pin RC. Figure 7 shows the relationship between the

trickle pulse-width and the value of R

MTO

. The typical

tolerance of the pulsewidth below 150kΩ is ±10%.

During top-off and trickle-charge, the bq2000 monitors

battery voltage and temperature. These charging func

tions are suspended if the battery voltage rises above

the maximum cell voltage (V

MCV

) or if the temperature

exceeds the high-temperature fault threshold (V

HTF

).

Charge Current Control

The bq2000 controls the charge current through the

MOD output pin. The current-control circuit supports a

switching-current regulator with frequencies up to

500kHz. The bq2000 monitors charge current at the

SNS input by the voltage drop across a sense-resistor,

R

SNS

, in series with the battery pack. See Figure 9 for a

typical current-sensing circuit. R

SNS

is sized to provide

the desired fast-charge current (I

MAX

):

I

MAX

=

0.05

R

SNS

If the voltage at the SNS pin is greater than V

SNSLO

or

less than V

SNSHI

, the bq2000 switches the MOD output

high to pass charge current to the battery. When the

7

bq2000

1

246810 50 100 150 200 250

2

3

4

20

40

60

Pulsewidth—ms

R

MTO

—kΩ

80

100

120

140

160

180

200

2000PNvB3.eps

Shows Tolerance

Figure 7. Relationship Between Trickle Pulse-Width and Value of R

MTO

8

bq2000

BAT+

Q1

FMMT718

D2

ZHCS1000

L1

47UH

C9

1000PF

R12

120 OHMS

Q2

MMBT3904LT1

C6

47UF

D5

MMSD914LT

D3

MMSD914LT

D4

S1A

DC+

R10

1K

D1

RED

R2

2K

C3

10UF

D6

BZT52-C5V1

R1

100K

RC

6

LED

3

BAT

4

VSS

2

TS

5

VCC

7

SNS

1

MOD

8

U1

bq2000

C4

0.0022UF

R4

12.4K

VCC

C7

4.7PF

C8

0.33UF

Q3

MMBT3904LT1

R11

220 OHMS

R6

210K

C5

10UF

BAT

-

THERM

CHEMISTRY

R7

200K

R9

221K

R5

20K

C1

0.1

R8

6.81K

C2

0.1

NOTES: 1. For Li-Ion, the CHEMISTRY is left floating.

For NiCd/NiMH, the CHEMISTRY is tied to BAT-

2. DC input voltage: 9–16V

4. L1: 3L Global P/N PKSMD-1005-470K-1A

3. Charge current: 1A

R13

1.1K

R3

Pn1031a01.eos

0.05 OHM

Figure 8. Single-Cell Li-Ion, Three-Cell NiCd/NiMH 1A Charger

SNS voltage is less than V

SNSLO

or greater than V

SNSHI

,

the bq2000 switches the MOD output low to shut off

charging current to the battery. Figure 8 shows a typical

multi-chemistry charge circuit.

Temperature Monitoring

The bq2000 measures the temperature by the voltage at

the TS pin. This voltage is typically generated by a nega-

tive-temperature-coefficient thermistor. The bq2000

compares this voltage against its internal threshold

voltages to determine if charging is safe. These

thresholds are the following:

n

High-temperature cutoff voltage: V

TCO

= 0.225 ∗ V

CC

This voltage corresponds to the maximum

temperature (TCO) at which fast charging is allowed.

The bq2000 terminates fast charge if the voltage on

pin TS falls below V

TCO

.

9

bq2000

Parameter Value*

Maximum cell voltage (V

MCV

)2V

Minimum pre-charge qualification voltage (V

LBAT

) 950mV

High-temperature cutoff voltage (V

TCO

)

0.225 ∗ V

CC

High-temperature fault voltage (V

HTF

)

0.25 ∗ V

CC

Low-temperature fault voltage (V

LTF

)

0.5 ∗ V

CC

bq2000 fast-charge maximum time out (MTO)

R

MTO

∗ C

MTO

∗ 35,988

Fast-charge charging current (I

MAX

) 0.05/R

SNS

Hold-off period MTO/32

Top-off charging current (optional) I

MAX

/16

Top-off period (optional) MTO

Trickle-charge frequency 1Hz

Trickle-charge pulse-width See Figure 7

*Please refer to DC Thresholds Specification for details.

Table 2. Summary of NiCd or NiMH Charging Characteristics

Parameter Value*

Maximum cell voltage (V

MCV

)2V

Minimum pre-charge qualification voltage (V

LBAT

) 950mV

High-temperature cutoff voltage (V

TCO

)

0.225 ∗ V

CC

High-temperature fault voltage (V

HTF

)

0.25 ∗ V

CC

Low-temperature fault voltage (V

LTF

)

0.5 ∗ V

CC

bq2000 fast-charge maximum time-out (MTO)

2 ∗ R

MTO

∗ C

MTO

∗ 35,988

Fast-charge charging current (I

MAX)

0.05/R

SNS

Hold-off period MTO/32

Minimum current (for fast-charge termination) I

MAX

/7

Trickle-charge frequency (before fast charge only) 1Hz

Trickle-charge pulse-width (before fast charge only) See Figure 7

*Please refer to DC Thresholds Specification for details.

Table 3. Summary of Li-Ion Charging Characteristics

n

High-temperature fault voltage: V

HTF

= 0.25 ∗ VCCThis

voltage corresponds to the temperature (HTF) at which

fast charging is allowed to begin.

n

Low-temperature fault voltage: V

LTF

= 0.5 ∗V

CC

This voltage corresponds to the minimum temperature

(LTF) at which fast charging or top-off is allowed. If the

voltage on pin TS rises above V

LTF,

the bq2000

suspends fast charge or top-off but does not terminate

charge. When the voltage falls back below V

LTF,

fast

charge or top-off resumes from the point where

suspended. Trickle-charge is allowed during this

condition.

Table 4 summarizes these various conditions.

Charge Status Display

The charge status is indicated by open-drain output

LED. Table 5 summarizes the display output of the

bq2000.

Sleep Mode

The bq2000 features a sleep mode for low power con

sumption. This mode is enabled when the voltage at pin

BAT is above the low-power-mode threshold, V

SLP

. Dur

ing sleep mode, the bq2000 shuts down all internal circuits, drives the LED output to high-impedance state,

and drives pin MOD to low. Restoring BAT below the

V

MCV

threshold initiates the IC and starts a fast-charge

cycle.

10

bq2000

Table 5. Charge Status Display

Charge Action State LED Status

Battery absent High impedance

Pre-charge qualification 1Hz flash

Trickle charge (before fast charge) 1Hz flash

Fast charging Low

Top-off or trickle (after fast charge,

NiCd, NiMH only)

High impedance

Charge complete High impedance

Sleep mode High impedance

Charge suspended (V

TS

> V

LTF

) 1Hz flash

Temperature Condition Action

V

TS

> V

LTF

Cold battery—checked at all times

Suspends fast charge or top-off and timer

Allows trickle charge—LED flashes at 1Hz rate

during pre-charge qualification and fast charge

V

HTF<VTS<VLTF

Optimal operating range Allows charging

V

TS<VHTF

Hot battery—checked during charge quali

-

fication and top-off and trickle-charge

Suspends fast-charge initiation, does not allow

trickle charge—LED flashes at 1Hz rate during

pre-charge qualification and fast charge

V

TS<VTCO

Battery exceeding maximum allowable

temperature—checked at all times

Terminates fast charge or top-off

Table 4. Temperature-Monitoring Conditions

2000CS.eps

BAT-

Power Supply ground

bq2000 ground

SNS

R

SNS

R

f

C

f

1

2

V

SS

bq2000

Figure 9. Current-Sensing Circuit

11

Absolute Maximum Ratings

Symbol Parameter Minimum Maximum Unit Notes

V

CC

VCCrelative to V

SS

-0.3 +7.0 V

V

T

DC voltage applied on any pin, ex

-

cluding V

CC

relative to V

SS

-0.3 +7.0 V

T

OPR

Operating ambient temperature -20 +70 °C

T

STG

Storage temperature -40 +125 °C

T

SOLDER

Soldering temperature - +260 °C 10s max.

Note: Permanent device damage may occur if Absolute Maximum Ratings are exceeded. Functional operation

should be limited to the Recommended DC Operating Conditions detailed in this data sheet. Exposure to

conditions beyond the operational limits for extended periods of time may affect device reliability.

DC Thresholds (T

A=TOPR;VCC

= 5V±20% unless otherwise specified)

Symbol Parameter Rating Tolerance Unit Notes

V

TCO

Temperature cutoff 0.225*V

CC

±

5% V Voltage at pin TS

V

HTF

High-temperature fault 0.25 * V

CC

±

5% V Voltage at pin TS

V

LTF

Low-temperature fault 0.5*V

CC

±

5% V Voltage at pin TS

V

MCV

Maximum cell voltage 2.00

±

0.75%

V

V

BAT

> V

MCV

inhibits

fast charge

V

LBAT

Minimum cell voltage 950

±

5% mV Voltage at pin BAT

PVD BAT input change for PVD detection 3.8

±

20% mV

V

SNSHI

High threshold at SNS, resulting in

MOD-low

50

±10

mV Voltage at pin SNS

V

SNSLO

Low threshold at SNS, resulting in

MOD-high

-50

±10

mV Voltage at pin SNS

V

SLP

Sleep-mode input threshold

V

CC

- 1

±0.5

V Applied to pin BAT

V

RCH

Recharge threshold

V

MCV

- 0.1

±0.02

V At pin BAT

bq2000

12

bq2000

Impedance

Symbol Parameter Minimum Typical Maximum Unit

R

BAT

Battery input impedance 10 - - M

Ω

R

TS

TS input impedance 10 - - M

Ω

R

SNS

SNS input impedance 10 - - M

Ω

Recommended DC Operating Conditions (T

A=TOPR)

Symbol Condition Minimum Typical Maximum Unit Notes

V

CC

Supply voltage 4.0 5.0 6.0 V

I

CC

Supply current - 0.5 1 mA Exclusive of external loads

I

CCS

Sleep current - - 5

µA

V

BAT=VSLP

V

TS

Thermistor input 0.5 - V

CC

VVTS< 0.5V prohibited

V

OH

Output high VCC- 0.6 - - V MOD, IOH= 10mA

V

OL

Output low - - 0.2 V MOD, LED, IOL= 10mA

I

OZ

High-impedance leakage

current

--5µALED

I

snk

Sink current - - 20 mA MOD, LED

R

MTO

Charge timer resistor 2 - 250 k

Ω

C

MTO

Charge timer capacitor 0.001 - 1.0

µF

Note: All voltages relative to VSSexcept as noted.

Timing (T

A=TOPR;VCC

= 5V±20% unless otherwise specified)

Symbol Parameter Minimum Typical Maximum Unit

d

MTO

MTO time-base variation -5 - +5 %

f

TRKL

Pulse-trickle frequency 0.9 1.0 1.1 Hz

13

D

E1

E

C

e

L

G

B

A

A1

B1

S

8-Pin DIP(PN

)

8-Pin PN(0.300" DIP

)

Dimension

Inches Millimeters

Min. Max. Min. Max.

A 0.160 0.180 4.06 4.57

A1 0.015 0.040 0.38 1.02

B 0.015 0.022 0.38 0.56

B1 0.055 0.065 1.40 1.65

C 0.008 0.013 0.20 0.33

D 0.350 0.380 8.89 9.65

E 0.300 0.325 7.62 8.26

E1 0.230 0.280 5.84 7.11

e 0.300 0.370 7.62 9.40

G 0.090 0.110 2.29 2.79

L 0.115 0.150 2.92 3.81

S 0.020 0.040 0.51 1.02

8-Pin SOIC Narrow (SN)

8-Pin SN(0.150" SOIC

)

Dimension

Inches Millimeters

Min. Max. Min. Max.

A 0.060 0.070 1.52 1.78

A1 0.004 0.010 0.10 0.25

B 0.013 0.020 0.33 0.51

C 0.007 0.010 0.18 0.25

D 0.185 0.200 4.70 5.08

E 0.150 0.160 3.81 4.06

e 0.045 0.055 1.14 1.40

H 0.225 0.245 5.72 6.22

L 0.015 0.035 0.38 0.89

bq2000

14

bq2000

Dimension

Millimeters Inches

Min. Max. Min. Max.

A - 1.10 - 0.043

A1 0.05 0.15 0.002 0.006

B 0.18 0.30 0.007 0.012

C 0.09 0.18 0.004 0.007

D 2.90 3.10 0.115 0.122

E 4.30 4.48 0.169 0.176

e 0.65BSC 0.0256BSC

H 6.25 6.50 0.246 0.256

L 0.50 0.70 0.020 0.028

Notes:

1. Controlling dimension: millimeters. Inches shown for reference only.

2 'D' and 'E' do not include mold flash or protrusions. Mold flash or protrusions shall not exceed 0.15mm per side

3 Each lead centerline shall be located within ±0.10mm of its exact true position.

4. Leads shall be coplanar within 0.08mm at the seating plane.

5 Dimension 'B' does not include dambar protrusion. The dambar protrusion(s) shall not cause the lead width

to exceed 'B' maximum by more than 0.08mm.

6 Dimension applies to the flat section of the lead between 0.10mm and 0.25mm from the lead tip.

7 'A1' is defined as the distance from the seating plane to the lowest point of the package body (base plane).

8-Pin TSSOP ~ TS Package Suffix

15

bq2000

Ordering Information

bq2000

Package Option:

PN = 8-pin narrow plastic DIP

SN = 8-pin narrow SOIC

TS = 8-pin TSSOP

Device:

bq2000 Multi-Chemistry Fast-Charge IC with Peak Voltage

Detection

Change No. Page No. Description Nature of Change

1 4 MTO equation

Was: MTO = R ∗ C ∗ 71,976

Is: MTO = R

MTO

∗ C

MTO

∗ 35,988

16

Trickle-pulse width

equation

Replaced equation with Figure 6

1 7 Figure 7 Schematic updated

110V

TCO

, V

HTF

, V

LTF

Tolerance updated

111R

MTO

, C

MTO

Values updated

28V

LBAT

Corrected values in Tables 2 and 3

3 1, 13 Package option Added TSSOP

3 3 State diagram Added

3 8 Schematic updated

311V

TSO

, V

HTF,VLTF

Tolerance updated

3 7 Top-off charge Updated requirement for enabling top-off

4 7 Figure 7 Updated tolerance on the curve

412

V

OH

Was: Minimum VOH= VCC- 0.2 at IOH= 20mA

Is: Minimum V

OH

= VCC- 0.6 at IOH= 10mA

412

V

OL

Was: IOH= 20mA

Is: I

OH

= 10mA

Note: Change 1 = Jan. 1999 B changes to Final from Sept. 1998 Preliminary data sheet.

Change 2 = Mar. 1999 C changes from Jan. 1999 B.

Change 3 = May 1999 D changes from Mar. 1999 C.

Change 4 = February 2000 E changes from May 1999 D.

Data Sheet Revision History

16

IMPORTANT NOTICE

Texas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue any

product or service without notice, and advise customers to obtain the latest version of relevant information to verify,

before placing orders, that information being relied on is current and complete. All products are sold subject to the

terms and conditions of sale supplied at the time of order acknowledgement, including those pertaining to warranty,

patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in accor

dance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent TI deems

necessary to support this warranty. Specific testing of all parameters of each device is not necessarily performed, ex

cept those mandated by government requirements.

CERTAIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF DEATH,

PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL APPLICATIONS”). TI

SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR WARRANTED TO BE SUITABLE FOR

USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER CRITICAL APPLICATIONS. INCLUSION OF TI

PRODUCTS IN SUCH APPLICATIONS IS UNDERSTOOD TO BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating safeguards

must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent that

any license, either express or implied, is granted under any patent right, copyright, mask work right, or other intellec

tual property right of TI covering or relating to any combination, machine, or process in which such semiconductor

products or services might be or are used. TI’s publication of information regarding any third party’s products or ser

vices does not constitute TI’s approval, warranty or endorsement thereof.

Copyright © 2000, Texas Instruments Incorporated

Loading...

Loading...