Page 1

®

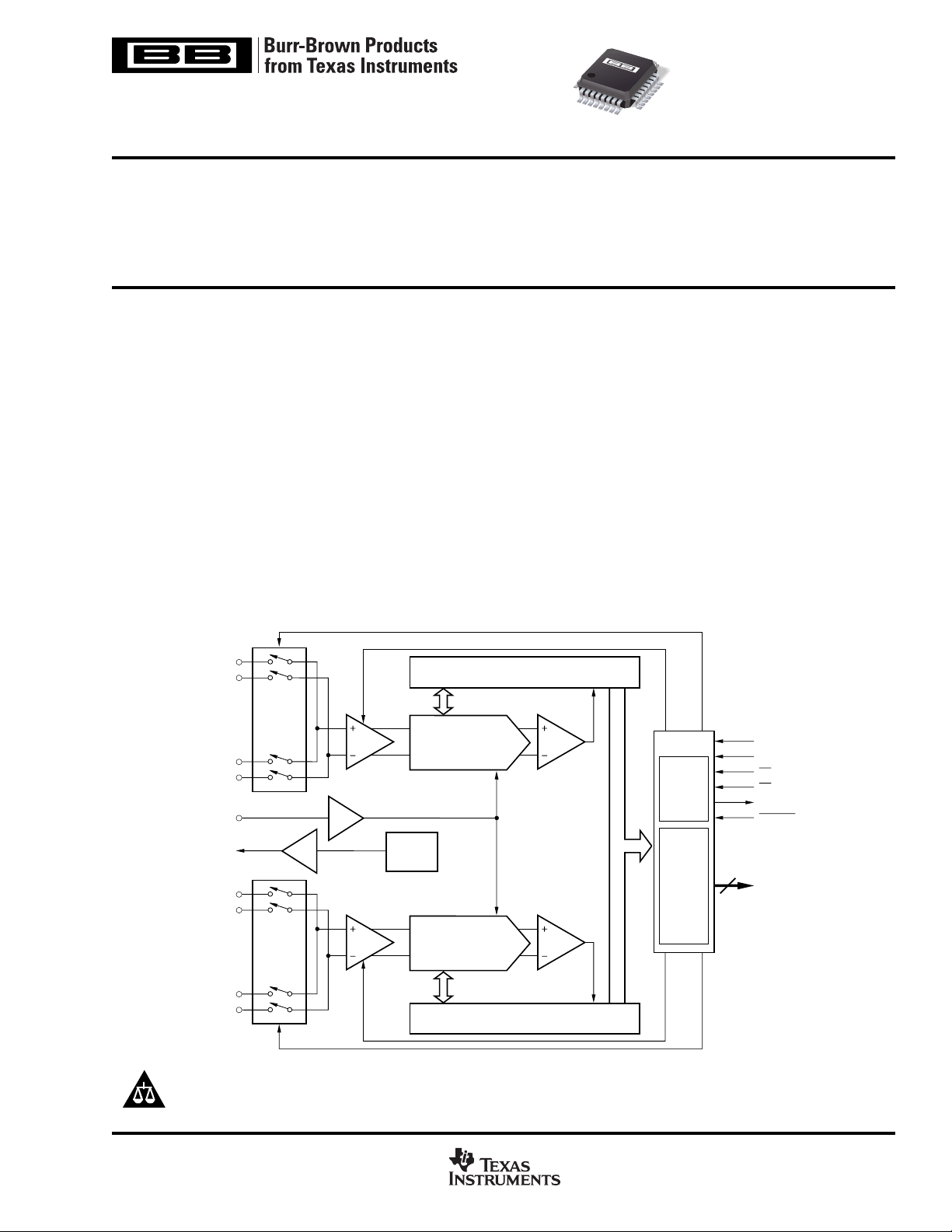

ADS7862

SBAS101B – JANUARY 1998 – REVISED AUGUST 2005

Dual 500kHz, 12-Bit, 2 + 2 Channel

Simultaneous Sampling

ANALOG-TO-DIGITAL CONVERTER

ADS7862

FEATURES

● 4 INPUT CHANNELS

● FULLY DIFFERENTIAL INPUTS

● 2µs TOTAL THROUGHPUT PER CHANNEL

● GUARANTEED NO MISSING CODES

● PARALLEL INTERFACE

● 1MHz EFFECTIVE SAMPLING RATE

● LOW POWER: 40mW

APPLICATIONS

● MOTOR CONTROL

● MULTI-AXIS POSITIONING SYSTEMS

● 3-PHASE POWER CONTROL

CH A0+

CH A0–

S/H

Amp

CH A1+

CH A1–

REF

REF

CH B0+

CH B0–

OUT

MUX

IN

Internal

2.5V

Reference

S/H

Amp

CDAC

DESCRIPTION

The ADS7862 is a dual 12-bit, 500kHz analog-to-digital

converter (A/D) with 4 fully differential input channels grouped

into two pairs for high speed simultaneous signal acquisition.

Inputs to the sample-and-hold amplifiers are fully differential

and are maintained differential to the input of the A/D converter. This provides excellent common-mode rejection of

80dB at 50kHz, which is important in high noise environments.

The ADS7862 offers parallel interface and control inputs to

minimize software overhead. The output data for each channel

is available as a 12-bit word. The ADS7862 is offered in an

TQFP-32 package and is fully specified over the –40°C to

+85°C operating range.

SAR

COMP

COMP

Interface

Conversion

and

Control

Output

Registers

12

A0

CLOCK

CS

RD

BUSY

CONVST

Data Output

CH B1+

CH B1–

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

All trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

MUX

CDAC

SAR

Copyright © 1998-2005, Texas Instruments Incorporated

www.ti.com

Page 2

ORDERING INFORMATION

MAXIMUM MAXIMUM

RELATIVE GAIN SPECIFICATION

PRODUCT (LSB) (%) PACKAGE DESIGNATOR RANGE NUMBER MEDIA, QUANTITY

ADS7862Y ±2 ±0.75 TQFP-32 PBS –40°C to +85°C ADS7862Y/250 Tape and Reel, 250

ADS7862Y

ADS7862YB ±1 ±0.5 TQFP-32 PBS –40°C to +85°C ADS7862YB/250 Tape and Reel, 250

ADS7862YB

NOTE: (1) For the most current package and ordering information, see the Package Option Addendum at the end of this data sheet, or see the TI website at www.ti.com.

ACCURACY ERROR PACKAGE TEMPERATURE ORDERING TRANSPORT

"" " " "ADS7862Y/2K5 Tape and Reel, 2500

"" " " "ADS7862YB/2K5 Tape and Reel, 2500

(1)

ABSOLUTE MAXIMUM RATINGS

Analog Inputs to AGND: Any Channel Input ........ –0.3V to (+VD + 0.3V)

Digital Inputs to DGND .......................................... –0.3V to (+V

Ground Voltage Differences: AGND, DGND ................................... ±0.3V

Power Dissipation .......................................................................... 325mW

Maximum Junction Temperature................................................... +150°C

Operating Temperature Range ........................................–40°C to +85°C

Storage Temperature Range ......................................... –65°C to +150°C

Lead Temperature (soldering, 10s)............................................... +300°C

REF

............................. –0.3V to (+VD + 0.3V)

IN

+V

to AGND ......................... –0.3V to +6V

D

+ 0.3V)

D

ELECTROSTATIC

DISCHARGE SENSITIVITY

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and

installation procedures can cause damage.

ESD damage can range from subtle performance degradation to

complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes

could cause the device not to meet its published specifications.

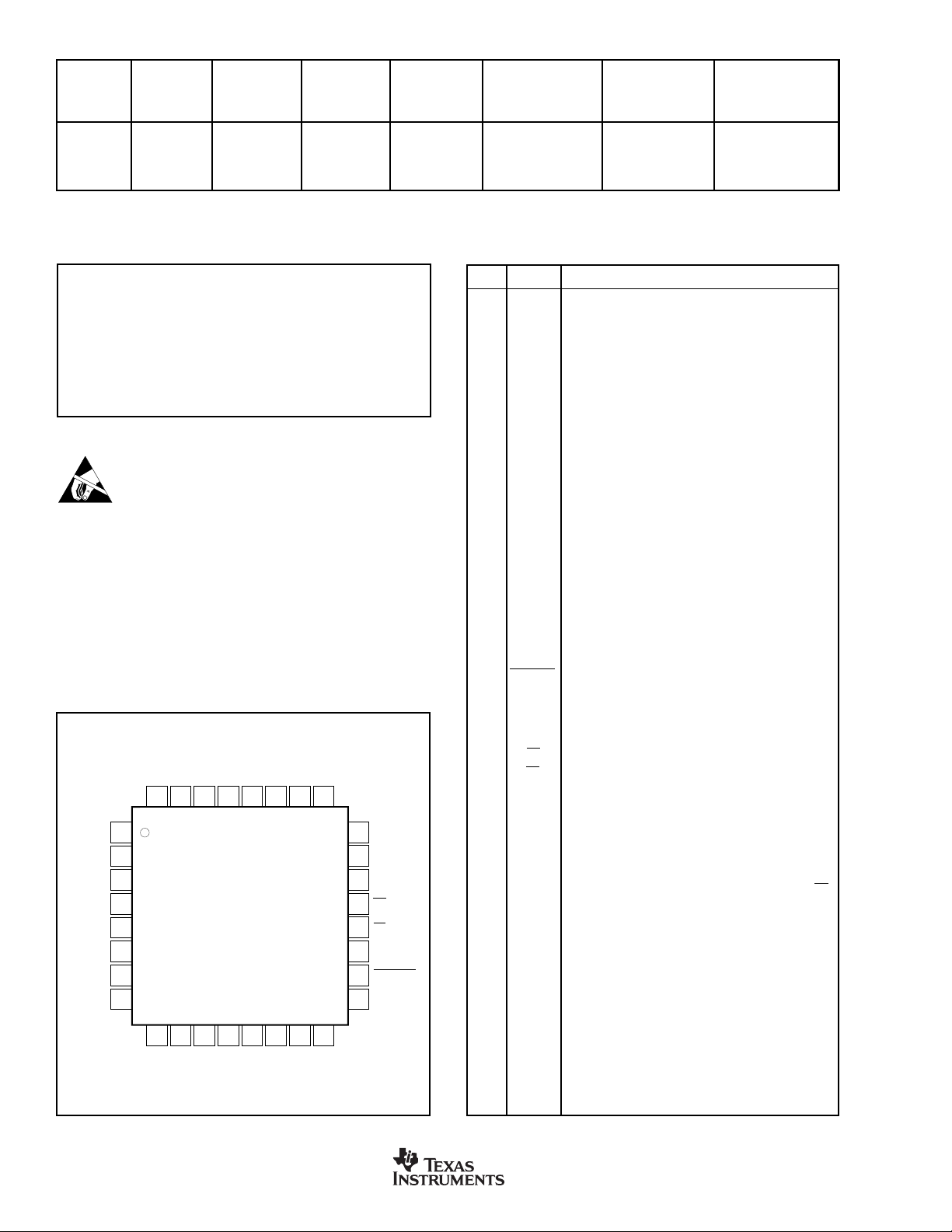

PIN CONFIGURATION

Top View

CH A0+

CH A0–

CH A1+

CH A1–

CH B0–

CH B0+

CH B1–

CH B1+

REF

REF

AGND

DB11

DB10

OUT

+V

DB9

DB8

32 31 30 29 28

1

IN

2

3

4

A

5

6

7

8

9 10111213141516

DB7

DB6

ADS7862

DB5

DB4

27 26 25

DB3

DB2

DB1

DB0

24

23

22

21

20

19

18

17

+V

D

DGND

A0

RD

CS

CLOCK

CONVST

BUSY

PIN DESCRIPTIONS

PIN NAME DESCRIPTION

1REF

2 REF

3 AGND Analog Ground

4+V

5 DB11 Data Bit 11, MSB

6 DB10 Data Bit 10

7 DB9 Data Bit 9

8 DB8 Data Bit 8

9 DB7 Data Bit 7

10 DB6 Data Bit 6

11 DB5 Data Bit 5

12 DB4 Data Bit 4

13 DB3 Data Bit 3

14 DB2 Data Bit 2

15 DB1 Data Bit 1

16 DB0 Data Bit 0, LSB

17 BUSY HIGH when a conversion is in progress.

18 CONVST Convert Start

19 CLOCK An external CMOS-compatible clock can be applied to

20 CS Chip Select

21 RD Synchronization pulse for the parallel output. During a

22 A0 On the falling edge of Convert Start, when A0 is LOW

23 DGND Digital Ground. Connect directly to analog ground (pin 3).

24 +V

25 CH B1+ Non-Inverting Input Channel B1

26 CH B1– Inverting Input Channel B1

27 CH B0+ Non-Inverting Input Channel B0

28 CH B0– Inverting Input Channel B0

29 CH A1– Inverting Input Channel A1

30 CH A1+ Non-Inverting Input Channel A1

31 CH A0– Inverting Input Channel A0

32 CH A0+ Non-Inverting Input Channel A0

Reference Input

IN

+2.5V Reference Output. Connect directly to REF

OUT

(pin 1) when using internal reference.

Analog Power Supply, +5VDC. Connect directly to

A

digital power supply (pin 24). Decouple to analog

ground with a 0.1µF ceramic capacitor and a 10µF

tantalum capacitor.

the CLOCK input to synchronize the conversion process to an external source. The CLOCK pin controls

the sampling rate by the equation: CLOCK 16 • f

Read operation, the first falling edge selects the A

register and the second edge selects the B register,

A0, then controls whether input 0 or input 1 is read.

Channel A0 and Channel B0 are converted and when

it is HIGH, Channel A1 and Channel B1 are converted.

During a Read operation, the first falling edge selects

the A register and the second edge selects the B of RD

register, A0, then controls whether input 0 or input 1 is

read.

Digital Power Supply, +5VDC

D

SAMPLE

IN

.

2

www.ti.com

ADS7862

SBAS101B

Page 3

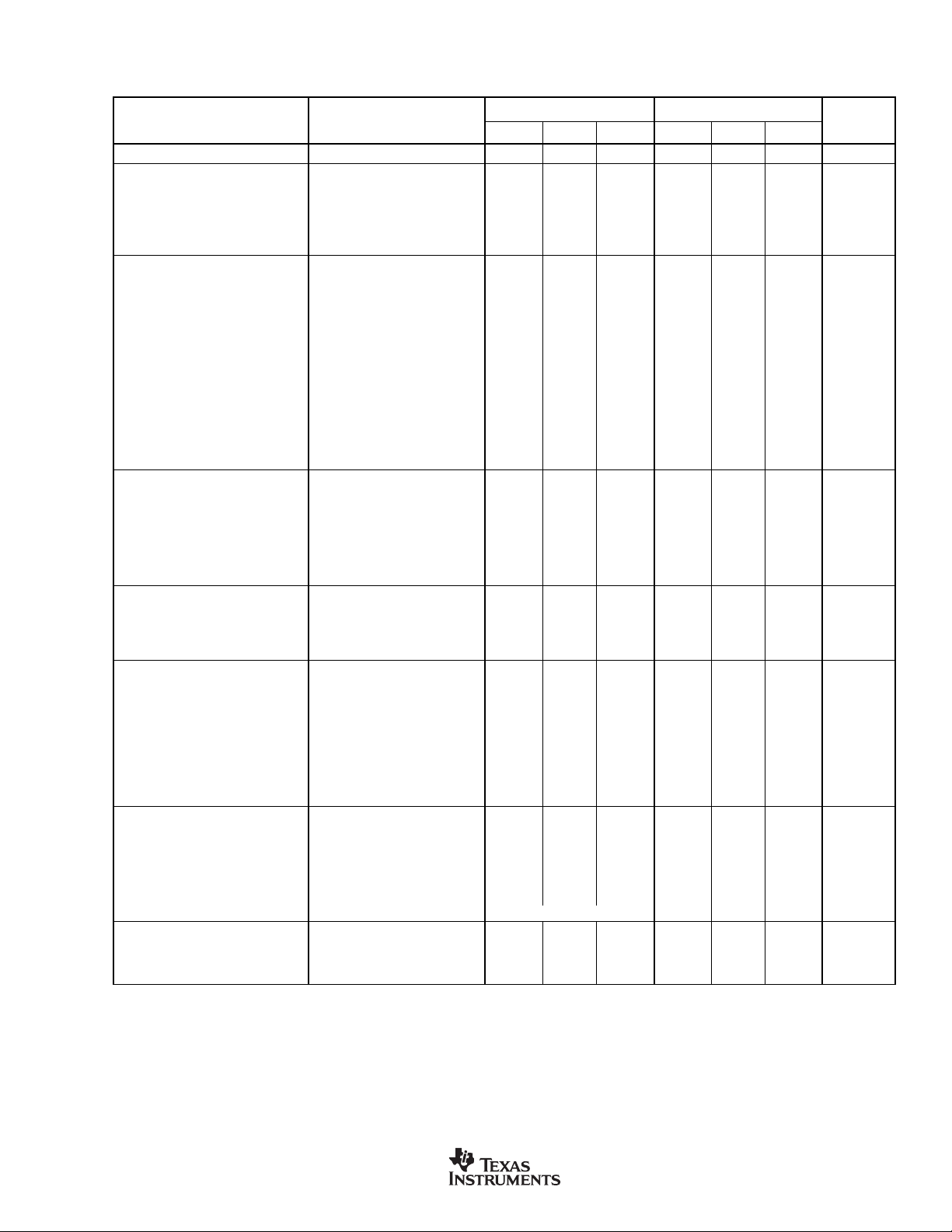

ELECTRICAL CHARACTERISTICS

All specifications T

PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

RESOLUTION 12 ✻ Bits

ANALOG INPUT

Input Voltage Range-Bipolar V

Absolute Input Range +IN –0.3 V

Input Capacitance 15 ✻ pF

Input Leakage Current CLK = GND ±1 ✻ µA

SYSTEM PERFORMANCE

No Missing Codes 12 ✻ Bits

Integral Linearity ±0.75 ±2 ±0.5 ±1 LSB

Integral Linearity Match 0.5 1 ✻✻ LSB

Differential Linearity ±0.75 ±0.5 ±1 LSB

Bipolar Offset Error Referenced to REF

Bipolar Offset Error Match 3 2 LSB

Positive Gain Error Referenced to REF

Positive Gain Error Match 2 1 LSB

Negative Gain Error Referenced to REF

Negative Gain Error Match 2 1 LSB

Common-Mode Rejection Ratio At DC 80 ✻ dB

Noise 120 ✻ µV

Power Supply Rejection Ratio ±0.5 ±2 ✻✻ LSB

SAMPLING DYNAMICS

Conversion Time per A/D 1.75 ✻ µs

Acquisition Time 0.25 ✻ µs

Throughput Rate 500 ✻ kHz

Aperture Delay 3.5 ✻ ns

Aperture Delay Matching 100 ✻ ps

Aperture Jitter 50 ✻ ps

Small-Signal Bandwidth 40 ✻ MHz

DYNAMIC CHARACTERISTICS

Total Harmonic Distortion V

SINAD V

Spurious Free Dynamic Range V

Channel-to-Channel Isolation V

VOLTAGE REFERENCE

Internal 2.475 2.5 2.525 ✻✻✻ V

Internal Drift ±25 ✻ ppm/°C

Internal Noise 50 ✻ µV

Internal Source Current 2 ✻ mA

Internal Load Rejection 0.005 ✻ mV/µA

Internal PSRR 65 ✻ dB

External Voltage Range 1.2 2.5 2.6 ✻✻✻ V

Input Current 0.05 1 ✻✻ µA

Input Capacitance 5 ✻ pF

DIGITAL INPUT/OUTPUT

Logic Family CMOS ✻

Logic Levels: V

External Clock 0.2 8 ✻✻MHz

Data Format Binary Two’s Complement ✻

POWER SUPPLY REQUIREMENTS

Power Supply Voltage, +V 4.75 5 5.25 ✻✻✻ V

Quiescent Current, +V

Power Dissipation 25 40 ✻✻ mW

✻ Specifications same as ADS7862Y.

to T

MIN

, +VA = +VD = +5V, V

MAX

= internal +2.5V and f

REF

= 8MHz, f

CLK

= 500kHz, unless otherwise noted.

SAMPLE

ADS7862Y ADS7862YB

= Internal V

CENTER

–IN –0.3 V

V

= ±1.25VPP at 50kHz 80 ✻ dB

IN

= ±2.5VPP at 100kHz 75 ✻ dB

IN

= ±2.5VPP at 100kHz 71 ✻ dB

IN

= ±2.5VPP at 100kHz –78 ✻ dB

IN

= ±2.5VPP at 100kHz –80 ✻ dB

IN

IH

V

IL

V

OH

V

OL

A

IIH = +5µA 3.0

IIL = +5µA –0.3 0.8 ✻✻V

IOH = –500µA 3.5 ✻ V

IOL = 500µA 0.4 ✻ V

at 2.5V –V

REF

IN

IN

IN

REF

+V

REF

+ 0.3 V

CC

+ 0.3 V

CC

✻✻V

±0.75 ±3 ±0.5 ±2 LSB

±0.15 ±0.75 ±0.1 ±0.5 % of FSR

±0.15 ±0.75 ±0.1 ±0.5 % of FSR

+VDD + 0.3

✻✻V

58 ✻✻ mA

RMS

PP

ADS7862

SBAS101B

www.ti.com

3

Page 4

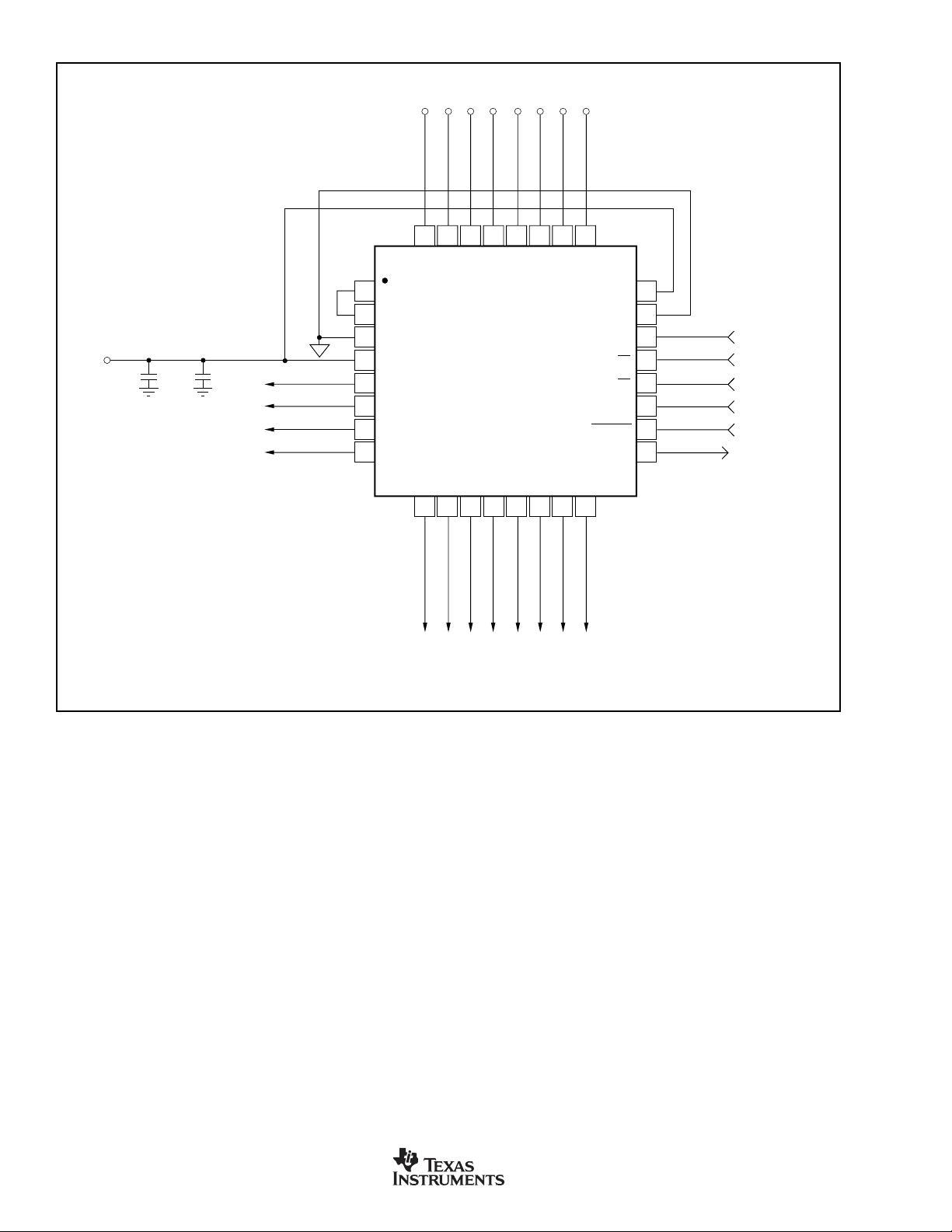

BASIC OPERATION

+5V

Analog Supply

+

10µF

+

0.1µF

32

31

30

29

28

27

26

25

CH A0–

CH A1–

CH B0–

DB3

13

CH B1–

CH B0+

DB2

DB1

14

15

CH B1+

+V

DGND

A0

RD

CS

CLOCK

CONVST

BUSY

DB0

16

24

D

23

22

21

20

19

18

17

Address Select

Read Input

Chip Select

Clock Input

Conversion Start

Busy Output

CH A0+

DB7

9

CH A1+

ADS7862Y

DB6

DB5

10

11

DB4

12

1

REF

IN

2

REF

OUT

3

AGND

4

+V

A

5

DB11

6

DB10

7

DB9

8

DB8

4

www.ti.com

ADS7862

SBAS101B

Page 5

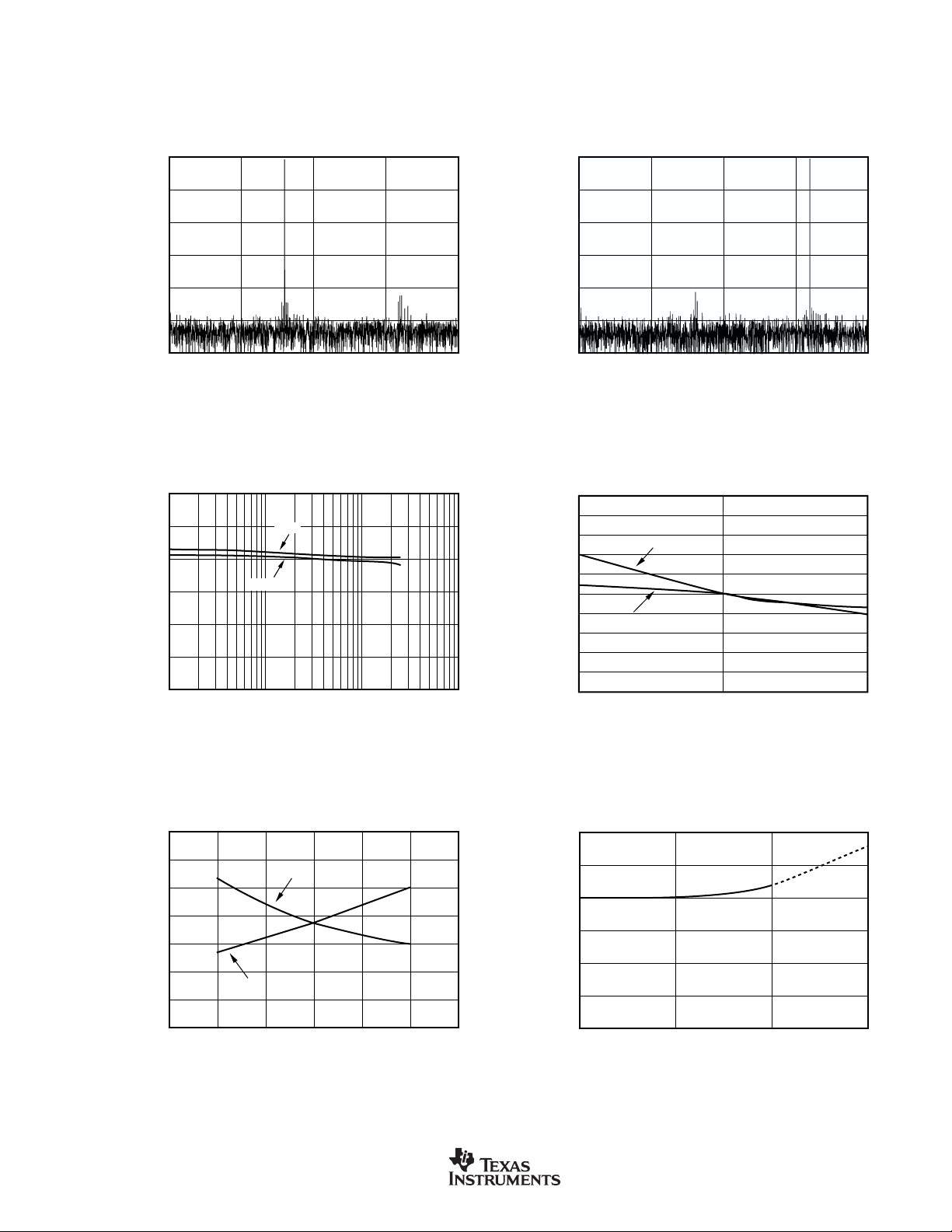

TYPICAL PERFORMANCE CHARACTERISTICS

At TA = +25°C, +VA = +VD = +5V, V

= internal +2.5V and f

REF

= 8MHz, f

CLK

= 500kHz, unless otherwise noted.

SAMPLE

FREQUENCY SPECTRUM

0

–20

–40

–60

Amplitude (dB)

–80

–100

–120

0 62.5 125 250187.5

76

74

72

70

68

SNR and SINAD (dB)

66

64

(4096 Point FFT; f

Frequency (kHz)

SIGNAL-TO-NOISE RATIO AND

SIGNAL-TO-(NOISE+DISTORTION)

vs INPUT FREQUENCY

SNR

SINAD

10k 100k1k 1M

Input Frequency (Hz)

= 99.9kHz, –0.5dB)

IN

FREQUENCY SPECTRUM

0

–20

–40

–60

Amplitude (dB)

–80

–100

–120

0 62.5 125 250187.5

0.25

0.2

0.15

0.1

0.05

0

–0.05

–0.1

Delta from +25°C (dB)

–0.15

–0.2

–0.25

–40 25 85

(4096 Point FFT; f

CHANGE IN SIGNAL-TO-NOISE RATIO

AND SIGNAL-TO-(NOISE+DISTORTION)

vs TEMPERATURE

SINAD

SNR

= 199.9kHz, –0.5dB)

IN

Frequency (kHz)

Temperature (°C)

0.65

0.45

0.25

0.05

–0.15

–0.35

SFDR Delta from +25°C (dB)

–0.55

–0.75

ADS7862

SBAS101B

CHANGE IN SPURIOUS FREE DYNAMIC RANGE

AND TOTAL HARMONIC DISTORTION

vs TEMPERATURE

SFDR

THD

–40 25 85

Temperature (°C)

0.65

0.45

0.25

0.05

–0.15

–0.35

THD Delta from +25°C (dB)

–0.55

–0.75

www.ti.com

CHANGE IN POSITIVE GAIN MATCH

vs TEMPERATURE

(Maximum Deviation for All Four Channels)

0.6

0.5

0.4

0.3

0.2

0.1

Change in Positive Gain Match (LSB)

0

–40 25 85 150

Temperature (°C)

5

Page 6

TYPICAL PERFORMANCE CHARACTERISTICS (Cont.)

At TA = +25°C, +VA = +VD = +5V, V

= internal +2.5V and f

REF

= 8MHz, f

CLK

= 500kHz, unless otherwise noted.

SAMPLE

CHANGE IN NEGATIVE GAIN MATCH

0.2

0.18

0.16

0.14

0.12

0.1

0.08

0.06

0.04

0.02

Change in Negative Gain Match (LSB)

0

–40 25 85 150

0.75

0.5

0.25

(Maximum Deviation for All Four Channels)

B Channel

vs TEMPERATURE

Temperature (°C)

CHANGE IN BIPOLAR ZERO

vs TEMPERATURE

CHANGE IN REFERENCE VOLTAGE

2.51

2.505

2.5

2.495

Change in Reference (V)

2.49

2.485

–40 25 85 150

1

0.75

CHANGE IN BPZ MATCH vs TEMPERATURE

vs TEMPERATURE

Temperature (°C)

0

–0.25

–0.5

Change in Bipolar Zero (LSB)

–0.75

–40 25

86

85

84

83

82

81

Change in CMRR (dB)

80

79

78

–40 –5255585

A Channel

85 150

Temperature (°C)

CHANGE IN CMRR vs TEMPERATURE

Temperature (°C)

0.5

0.25

Change in Bipolar Zero Match (LSB)

0

–40 25 85 150

Temperature (°C)

1

0.8

0.6

0.4

0.2

0

ILE (LSB)

–0.2

–0.4

–0.6

–0.8

–1

800 000 7FF

INTEGRAL LINEARITY ERROR vs CODE

Typical of All Four Channels

Hex BTC Code

6

www.ti.com

ADS7862

SBAS101B

Page 7

TYPICAL PERFORMANCE CHARACTERISTICS (Cont.)

INTEGRAL LINEARITY ERROR vs TEMPERATURE

Positive ILE

Negative ILE

Temperature (°C)

0.6

0.4

0.2

0

–0.2

–0.4

–0.6

–0.8

Change in ILE (LSB)

–40 25 85 150

INTEGRAL LINEARITY ERROR MATCH

vs TEMPERATURE

CHANNEL A0/CHANNEL B0

(Different Converter, Different Channels)

Temperature (°C)

0.19

0.18

0.17

0.16

0.15

0.14

0.13

0.12

Change in ILE Match (LSB)

–40 25 85 150

At TA = +25°C, +VA = +VD = +5V, V

DIFFERENTIAL LINEARITY ERROR vs CODE

1

Typical of All Four Channels

0.75

0.5

0.25

0

DLE (LSB)

–0.25

–0.5

–0.75

–1

800 000 7FF

= internal +2.5V and f

REF

Hex BTC Code

= 8MHz, f

CLK

= 500kHz, unless otherwise noted.

SAMPLE

0.8

Positive DLE

0.6

0.4

0.2

0

–0.2

DLE Error (LSB)

–0.4

–0.6

–0.8

0.25

0.15

0.05

–0.05

ILE (LSB)

–0.1

–0.15

–0.2

–0.25

Negative DLE

–40 25

INTEGRAL LINEARITY ERROR MATCH

(Different Converter, Different Channels)

0.2

0.1

0

800 000 7FF

DIFFERENTIAL LINEARITY ERROR

vs TEMPERATURE

85 150

Temperature (°C)

vs CODE CHANNEL A0/CHANNEL B1

Hex BTC Code

INTEGRAL LINEARITY ERROR MATCH

vs CODE CHANNEL A0/CHANNEL A1

0.25

0.2

0.15

0.1

0.05

0

–0.05

ILE (LSB)

–0.1

–0.15

–0.2

–0.25

800 000 7FF

(Same Converter, Different Channels)

Hex BTC Code

ADS7862

SBAS101B

www.ti.com

7

Page 8

INTRODUCTION

The ADS7862 is a high speed, low power, dual 12-bit A/D

converter that operates from a single +5V supply. The input

channels are fully differential with a typical common-mode

rejection of 80dB. The part contains dual 2µs successive

approximation A/Ds, two differential sample-and-hold amplifiers, an internal +2.5V reference with REFIN and REF

pins and a high speed parallel interface. There are four

analog inputs that are grouped into two channels (A and B)

selected by the A0 input (A0 LOW selects Channels A0 and

B0, while A0 HIGH selects Channels A1 and B1). Each

A/D converter has two inputs (A0 and A1 and B0 and B1)

that can be sampled and converted simultaneously, thus

preserving the relative phase information of the signals on

both analog inputs. The part accepts an analog input voltage

in the range of –V

REF

to +V

, centered around the internal

REF

+2.5V reference. The part will also accept bipolar input

ranges when a level shift circuit is used at the front end (see

Figure 7).

A conversion is initiated on the ADS7862 by bringing the

CONVST pin LOW for a minimum of 15ns. CONVST

LOW places both sample-and-hold amplifiers in the hold

state simultaneously and the conversion process is started on

both channels. The BUSY output will then go HIGH and

remain HIGH for the duration of the conversion cycle.

Depending on the status of the A0 pin, the data will either

reflect a conversion of Channel 0 (A0 LOW) or Channel 1

(A0 HIGH). The data can be read from the parallel output

bus following the conversion by bringing both RD and CS

LOW.

Conversion time for the ADS7862 is 1.75µs when an 8MHz

external clock is used. The corresponding acquisition time is

0.25µs. To achieve maximum output rate (500kHz), the read

function can be performed immediately at the start of the

next conversion.

NOTE: This mode of operation is described in more detail

in the Timing and Control section of this data sheet.

OUT

REFERENCE

Under normal operation, the REF

pin (pin 2) should be

OUT

directly connected to the REFIN pin (pin 1) to provide an

internal +2.5V reference to the ADS7862. The ADS7862

can operate, however, with an external reference in the range

of 1.2V to 2.6V for a corresponding full-scale range of 2.4V

to 5.2V.

The internal reference of the ADS7862 is double-buffered.

If the internal reference is used to drive an external load, a

buffer is provided between the reference and the load applied to pin 2 (the internal reference can typically source

2mA of current—load capacitance should not exceed 100pF).

If an external reference is used, the second buffer provides

isolation between the external reference and the CDAC.

This buffer is also used to recharge all of the capacitors of

both CDACs during conversion.

ANALOG INPUT

The analog input is bipolar and fully differential. There are

two general methods of driving the analog input of the

ADS7862: single-ended or differential (see Figures 1 and 2).

When the input is single-ended, the –IN input is held at the

common-mode voltage. The +IN input swings around the

same common voltage and the peak-to-peak amplitude is the

(common-mode +V

The value of V

) and the (common-mode –V

REF

determines the range over which the

REF

REF

common-mode voltage may vary (see Figure 3).

When the input is differential, the amplitude of the input is the

difference between the +IN and –IN input, or: (+IN) – (–IN).

The peak-to-peak amplitude of each input is ±1/2V

REF

around

this common voltage. However, since the inputs are 180° out

of phase, the peak-to-peak amplitude of the differential voltage

is +V

REF

to –V

. The value of V

REF

also determines the

REF

range of the voltage that may be common to both inputs (see

Figure 4).

).

SAMPLE-AND-HOLD SECTION

The sample-and-hold amplifiers on the ADS7862 allow the

A/Ds to accurately convert an input sine wave of full-scale

amplitude to 12-bit accuracy. The input bandwidth of the

sample-and-hold is greater than the Nyquist rate (Nyquist

equals one-half of the sampling rate) of the A/D even when

the A/D is operated at its maximum throughput rate of

500kHz. The typical small-signal bandwidth of the sampleand-hold amplifiers is 40MHz.

Typical aperture delay time or the time it takes for the

ADS7862 to switch from the sample to the hold mode

following the CONVST pulse is 3.5ns. The average delta of

repeated aperture delay values is typically 50ps (also known

as aperture jitter). These specifications reflect the ability of

the ADS7862 to capture AC input signals accurately at the

exact same moment in time.

8

www.ti.com

to +V

–V

REF

peak-to-peak

Common

Voltage

REF

Common

Voltage

Single-Ended Input

V

REF

peak-to-peak

V

REF

peak-to-peak

Differential Input

ADS7862

ADS7862

FIGURE 1. Methods of Driving the ADS7862 Single-Ended

or Differential.

ADS7862

SBAS101B

Page 9

CM

CM +V

Voltage

CM

–VREF

REF

+V

REF

+IN

–V

REF

Single-Ended Inputs

–IN = CM Voltage

t

CM +1/2V

CM

REF

CM

Voltage

–1/2V

REF

NOTES: Common-Mode Voltage (Differential Mode) = Common-Mode Voltage (Single-Ended Mode) = IN–.

The maximum differential voltage between +IN and –IN of the ADS7862 is V

explanation of the common voltage range for single-ended and differential inputs.

+IN

–IN

+V

REF

–V

REF

Differential Inputs

(IN+) + (IN–)

2

. See Figures 3 and 4 for a further

REF

FIGURE 2. Using the ADS7862 in the Single-Ended and Differential Input Modes.

5

= 5V

V

CC

4

3

2

4.1

Single-Ended Input

2.7

2.3

5

4.7

4

3

2

Differential Input

t

= 5V

V

CC

4.05

1

Common Voltage Range (V)

0

–1

1.0 1.5

1.2

0.9

2.0 2.5

V

(V)

REF

2.6

3.0

FIGURE 3. Single-Ended Input: Common-Mode Voltage

Range vs V

REF

.

In each case, care should be taken to ensure that the output

impedance of the sources driving the +IN and –IN inputs are

matched. Otherwise, this may result in offset error, which

will change with both temperature and input voltage.

The input current on the analog inputs depend on a number

of factors: sample rate, input voltage, and source impedance.

Essentially, the current into the ADS7862 charges the internal capacitor array during the sampling period. After this

2.6

0.90

3.0

1

Common Voltage Range (V)

–1

0.3

0

1.2

1.0 1.5

2.0 2.5

V

(V)

REF

FIGURE 4. Differential Input: Common-Mode Voltage

Range vs V

REF

.

capacitance has been fully charged, there is no further input

current. The source of the analog input voltage must be able

to charge the input capacitance (15pF) to a 12-bit settling

level within 2 clock cycles. When the converter goes into the

hold mode, the input impedance is greater than 1GΩ.

Care must be taken regarding the absolute analog input

voltage. The +IN input should always remain within the

range of GND – 300mV to VDD + 0.3V.

ADS7862

SBAS101B

www.ti.com

9

Page 10

TRANSITION NOISE

Figure 5 shows a histogram plot for the ADS7862 following

8,000 conversions of a DC input. The DC input was set at

output code 2046. All but one of the conversions had an

output code result of 2046 (one of the conversions resulted

in an output of 2047). The histogram reveals the excellent

noise performance of the ADS7862.

8000

7000

6000

5000

4000

3000

2000

Number of Conversions

1000

0

2044 2045 2046 2047 2048

Code (decimal)

1.4V

3kΩ

DATA

100pF

C

DATA

t

R

Voltage Waveforms for DATA Rise and Fall Times t

LOAD

Test Point

t

F

, and tF.

R

FIGURE 6. Test Circuits for Timing Specifications.

R

1

V

OH

V

OL

FIGURE 5. Histogram of 8,000 Conversions of a DC Input.

BIPOLAR INPUTS

The differential inputs of the ADS7862 were designed to

accept bipolar inputs (–V

and +V

REF

) around the internal

REF

reference voltage (2.5V), which corresponds to a 0V to 5V

input range with a 2.5V reference. By using a simple op amp

circuit featuring a single amplifier and four external resistors, the ADS7862 can be configured to except bipolar

inputs. The conventional ±2.5V, ±5V, and ±10V input

ranges can be interfaced to the ADS7862 using the resistor

values shown in Figure 7.

TIMING AND CONTROL

The ADS7862 uses an external clock (CLOCK, pin 19)

which controls the conversion rate of the CDAC. With an

8MHz external clock, the A/D sampling rate is 500kHz

which corresponds to a 2µs maximum throughput time.

t

CKP

t

CKH

CLOCK

4kΩ

1

OPA132

R

2

R

2

Bipolar Input

20kΩ

BIPOLAR INPUT R

±10V 1kΩ 5kΩ

±5V 2kΩ 10kΩ

±2.5V 4kΩ 20kΩ

FIGURE 7. Level Shift Circuit for Bipolar Input Ranges.

Three timing diagrams are used to explain the operation of

the ADS7862. Figure 8 shows the timing relationship between the CLOCK, CONVST (pin 18) and the conversion

t

CKL

+IN

–IN

REF

2.5V

ADS7862

(pin 2)

OUT

CONVST

CONVERSION

MODE

NOTE: The ADS7862 will switch from the sample to the hold mode the instant CONVST goes LOW regardless of

the state of the external clock. The conversion process is initiated with the first rising edge of the external clock

following CONVST going LOW.

FIGURE 8. Conversion Mode.

10

t

3

SAMPLE HOLD CONVERT

www.ti.com

ADS7862

SBAS101B

Page 11

mode. Figure 9, in conjunction with Table I, shows the basic

read/write functions of the ADS7862 and highlights all of

the timing specifications. Figure 10 shows a more detailed

description of initiating a conversion using CONVST. Figure 11 illustrates three consecutive conversions and, with the

accompanying text, describes all of the read and write

capabilities of the ADS7862.

DESCRIPTION ANALOG INPUT

Full-Scale Input Span –V

Least Significant (–V

Bit (LSB)

REF

REF

to +V

to +V

REF

(1)

REF

)/4096

(2)

DIGITAL OUTPUT

BINARY TWO’S COMPLEMENT

BINARY CODE HEX CODE

+Full Scale 4.99878V 0111 1111 1111 7FF

Midscale 2.5V 0000 0000 0000 000

Midscale – 1 LSB 2.49878V 1111 1111 1111 FFF

–Full Scale 0V 1000 0000 0000 800

NOTES: (1) –V

sponds to a 0V to 5V input span. (2) 1.22mV with a 2.5V reference.

REF

to +V

around V

REF

. With a 2.5V reference, this corre-

REF

TABLE I. Ideal Input Voltages and Output Codes.

The Figure 11 timing diagram can be divided into three

sections: (a) initiating a conversion (n – 2), (b) starting a

second conversion (n – 1) while reading the data output from

the previous conversion (n – 2), and (c) starting a third

conversion (n) while reading both previous conversions

(n – 2 and n – 1). In this sequence, Channel 0 is converted

first followed by Channel 1. Channel 1 can be converted

prior to Channel 0 if the user wishes by simply starting the

conversion process with the A0 pin at logic HIGH (Channel

1) followed by logic LOW (Channel 0).

TIMING SPECIFICATIONS

SYMBOL DESCRIPTION MIN TYP MAX UNITS

t

CONV

t

ACQ

t

CKP

t

CKL

t

CKH

t

1

t

2

t

3

t

4

t

5

t

6

t

7

t

8

t

9

t

10

t

11

t

12

t

13

t

F

t

R

CONVST LOW Prior to CLOCK Rising Edge

Conversion Time 1.75 µs

Acquisition Time 0.25 µs

Clock Period 125 5000 ns

Clock LOW 40 ns

Clock HIGH 40 ns

CS to RD Setup Time 0 ns

CS to RD Hold Time 0 ns

CONVST LOW 15 ns

RD Pulse Width 30 ns

RD to Valid Data (Bus Access) 16 25 ns

RD to HI-Z Delay (Bus Relinquish) 10 20 ns

Time Between Conversion Reads 40 ns

Address Setup Time 250 ns

CONVST HIGH 20 ns

Address Hold Time 20 ns

CONVST to BUSY Propagation Delay 30 ns

10 ns

CONVST LOW After CLOCK Rising Edge

5ns

Data Fall Time 13 25 ns

Data Rise Time 20 30 ns

CONVST

BUSY

CS

RD

DATA

1CLOCK

2 3 4 5 14 15 16 1 2 3 4 5 14 15 16

t

CONV

t12t

13

t

3

t

11

A0

Conversion n

t

1

t

4

t

5

CHA1 CHB1 CHA0 CHB0

Conversion n – 1 Results Conversion n Results

t

9

t

2

t

6

t

ACQ

Conversion n + 1

t

10

t

8

t

7

FIGURE 9. Reading and Writing to the ADS7862 During the Same Cycle.

ADS7862

SBAS101B

www.ti.com

11

Page 12

t

CKP

125ns

CLOCK

Cycle 1 Cycle 2

10ns

5ns

CONVST

NOTE: All CONVST commands which occur more than 10ns before the rising edge of cycle ‘1’ of the external clock

(Region ‘A’) will initiate a conversion on the rising edge of cycle ‘1’. All CONVST commands which occur 5ns after

the rising edge of cycle ‘1’ or 10ns before the rising edge of cycle 2 (Region ‘B’) will initiate a conversion on the

rising edge of cycle ‘2’. All CONVST commands which occur 5ns after the rising edge of cycle ‘2’ (Region ‘C’) will

initiate a conversion on the rising edge of the next clock period. The CONVST pin should never be switched from

HIGH to LOW in the region 10ns prior to the rising edge of the CLOCK and 5ns after the rising edge (gray areas). If

CONVST is toggled in this gray area, the conversion could begin on either the same rising edge of the CLOCK or

the following edge.

A B C

FIGURE 10. Timing Between CLOCK and CONVST to Start a Conversion.

SECTION A

1 11

SECTION B SECTION C

10ns

5ns

1616

CLOCK

CONVST

A0 = 0 Conversion of Ch0

A0

RD

CS

DATA

BUSY

Low Data Level Tri-state of Output

TIME 0 1µ 2µ 3µ 4µ 5µ

1st RD After CONVST ChA at Output

Conversion of Ch0

min 250ns

A0 = 1 Conversion of Ch1

2nd RD After CONVST ChB at Output

CS Needed Only During Reading

High Data Level Output Active

ChA0 ChB0

Conversion of Ch1

Time (seconds)

min 250ns

A0 = 0 Conversion of Ch0

ChA1 ChA0

Conversion of Ch0

A0 Selects Between

Ch0 and Ch1 at Output

4 Output-Register

Data of Ch0 Still Stored

ChB0ChB1

FIGURE 11. ADS7862 Timing Diagram Showing Complete Functionality.

12

www.ti.com

ADS7862

SBAS101B

Page 13

SECTION A

Conversions are initiated by bringing the CONVST pin (pin

18) LOW for a minimum of 5ns (after the 5ns minimum

requirement has been met, the CONVST pin can be brought

HIGH). The ADS7862 will switch from the sample to the

hold mode on the falling edge of the CONVST command.

Following the first rising edge of the external clock after a

CONVST LOW, the ADS7862 will begin conversion (this

first rising edge of the external clock represents the start of

clock cycle one; the ADS7862 requires sixteen cycles to

complete a conversion). The input channel is also latched in

at this point in time. The A0 input (pin 22) must be selected

250ns prior to the CONVST pin going LOW so that the

correct address will be selected prior to conversion. The

BUSY output will go HIGH immediately following CONVST

going LOW. BUSY will stay HIGH through the conversion

process and return LOW when the conversion has ended.

After CONVST has remained LOW for the minimum time,

the ADS7862 will switch from the hold mode to the conversion mode synchronous to the next rising edge of the

external clock and conversion ‘n – 2’ will begin. Both RD

(pin 21) and CS (pin 20) can be HIGH during and before a

conversion. However, they must both be LOW to enable the

output bus and read data out.

SECTION B

The CONVST pin is switched from HIGH to LOW a second

time to initiate conversion ‘n – 1’. Again, the address must be

selected 250ns prior to CONVST going LOW to ensure that

the new address is selected for conversion. Both the RD and

CS pins are brought LOW in order to enable the parallel output

bus with the ‘n – 2’ conversion results of Channel A0. While

continuing to hold CS LOW, RD is held LOW for a minimum

of 30ns which enables the output bus with the Channel A0

results of conversion ‘n – 2’. The RD pin is toggled from

HIGH to LOW a second time in order to enable the output bus

with the Channel B0 results of conversion ‘n – 2’.

SECTION C

CONVST is brought LOW for a third time to initiate

conversion ‘n’ (Channel 0). While the conversion is in

process, the results for both conversions ‘n – 2’ and ‘n – 1’

can be read. The address pin is brought HIGH while CS and

RD are brought LOW which enables the output bus with the

Channel A1 results of conversion ‘n – 1’. The RD pin is

toggled from HIGH to LOW for a second time in Section C

and the ‘n – 1’ conversion results for Channel B1 appear at

the output bus. The address pin (A0) is then brought LOW

and the read process repeats itself with the most recent

conversion results for Channel 0 (n – 2) appearing at the

output bus.

READING DATA

The ADS7862 outputs full parallel data in Binary Two’s

Complement data output format. The parallel output will be

active when CS (pin 20) and RD (pin 21) are both LOW. The

output data should not be read 125ns prior to the falling edge

of CONVST and 10ns after the falling edge. Any other

combination of CS and RD will tri-state the parallel output.

Valid conversion data can be read on pins 5 through 16

(MSB–LSB). Refer to Table I for ideal output codes.

In applications where multiple devices are present on the

data bus, care should be taken to ensure that the signal

applied to RD (pin 21) is toggled only when the target device

is properly chip-selected. Toggling the RD pin will advance

the internal read pointer regardless of the state of the chip

select, causing the output data to appear channel-swapped.

If multiple devices share a single read enable from the host

processor, the signal may be ORed with an address-decoded

chip select to ensure channel data integrity. For more information, refer to Application Report SBAA138, Reading

Data from the ADS7862, available for download from the TI

website at www.ti.com.

LAYOUT

For optimum performance, care should be taken with the

physical layout of the ADS7862 circuitry. This is particularly true if the CLOCK input is approaching the maximum

throughput rate.

The basic SAR architecture is sensitive to glitches or sudden

changes on the power supply, reference, ground connections

and digital inputs that occur just prior to latching the output

of the analog comparator. Thus, driving any single conversion for an n-bit SAR converter, there are n “windows” in

which large external transient voltages can affect the conversion result. Such glitches might originate from switching

power supplies, nearby digital logic or high power devices.

The degree of error in the digital output depends on the

reference voltage, layout, and the exact timing of the external event. This error can change if the external event changes

in time with respect to the CLOCK input.

With this in mind, power to the ADS7862 should be clean

and well bypassed. A 0.1µF ceramic bypass capacitor should

be placed as close to the device as possible. In addition, a

1µF to 10µF capacitor is recommended. If needed, an even

larger capacitor and a 5Ω or 10Ω series resistor may be used

to low-pass filter a noisy supply. On average, the ADS7862

draws very little current from an external reference as the

reference voltage is internally buffered. If the reference

voltage is external and originates from an op amp, make sure

that it can drive the bypass capacitor or capacitors without

oscillation. A bypass capacitor is not necessary when using

the internal reference (tie pin 1 directly to pin 2).

The AGND and DGND pins should be connected to a clean

ground point. In all cases, this should be the ‘analog’

ground. Avoid connections which are too close to the grounding point of a microcontroller or digital signal processor. If

required, run a ground trace directly from the converter to

the power supply entry point. The ideal layout will include

an analog ground plane dedicated to the converter and

associated analog circuitry.

ADS7862

SBAS101B

www.ti.com

13

Page 14

PACKAGE OPTION ADDENDUM

www.ti.com

8-Jan-2007

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

ADS7862Y/250 ACTIVE TQFP PBS 32 250 Green (RoHS &

no Sb/Br)

ADS7862Y/250G4 ACTIVE TQFP PBS 32 250 Green (RoHS &

no Sb/Br)

ADS7862Y/2K ACTIVE TQFP PBS 32 2000 Green (RoHS &

no Sb/Br)

ADS7862Y/2KG4 ACTIVE TQFP PBS 32 2000 Green (RoHS &

no Sb/Br)

ADS7862YB/250 ACTIVE TQFP PBS 32 250 Green (RoHS &

no Sb/Br)

ADS7862YB/250G4 ACTIVE TQFP PBS 32 250 Green (RoHS &

no Sb/Br)

ADS7862YB/2K ACTIVE TQFP PBS 32 2000 Green (RoHS &

no Sb/Br)

ADS7862YB/2KG4 ACTIVE TQFP PBS 32 2000 Green (RoHS &

no Sb/Br)

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

(3)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

Page 15

Page 16

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to

discontinue any product or service without notice. Customers should obtain the latest relevant information

before placing orders and should verify that such information is current and complete. All products are sold

subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent

TI deems necessary to support this warranty. Except where mandated by government requirements, testing

of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible

for their products and applications using TI components. To minimize the risks associated with customer

products and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent

right, copyright, mask work right, or other TI intellectual property right relating to any combination, machine,

or process in which TI products or services are used. Information published by TI regarding third-party

products or services does not constitute a license from TI to use such products or services or a warranty or

endorsement thereof. Use of such information may require a license from a third party under the patents or

other intellectual property of the third party, or a license from TI under the patents or other intellectual

property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices.

Reproduction of this information with alteration is an unfair and deceptive business practice. TI is not

responsible or liable for such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for

that product or service voids all express and any implied warranties for the associated TI product or service

and is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products

Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Low Power Wireless www.ti.com/lpw Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright © 2007, Texas Instruments Incorporated

Loading...

Loading...