Page 1

®

For most current data sheet and other product

information, visit www.burr-brown.com

12-Bit High Speed Low Power Sampling

ANALOG-TO-DIGITAL CONVERTER

ADS7818

ADS7818

FEATURES

● 500kHz THROUGHPUT RATE

● 2.5V INTERNAL REFERENCE

● LOW POWER: 11mW

● SINGLE SUPPLY +5V OPERATION

● DIFFERENTIAL INPUT

● SERIAL INTERFACE

● GUARANTEED NO MISSING CODES

● MINI-DIP-8 AND MSOP-8

● UNIPOLAR INPUT RANGE

APPLICATIONS

● BATTERY OPERATED SYSTEMS

● DIGITAL SIGNAL PROCESSING

● HIGH SPEED DATA ACQUISITION

● WIRELESS COMMUNICATION SYSTEMS

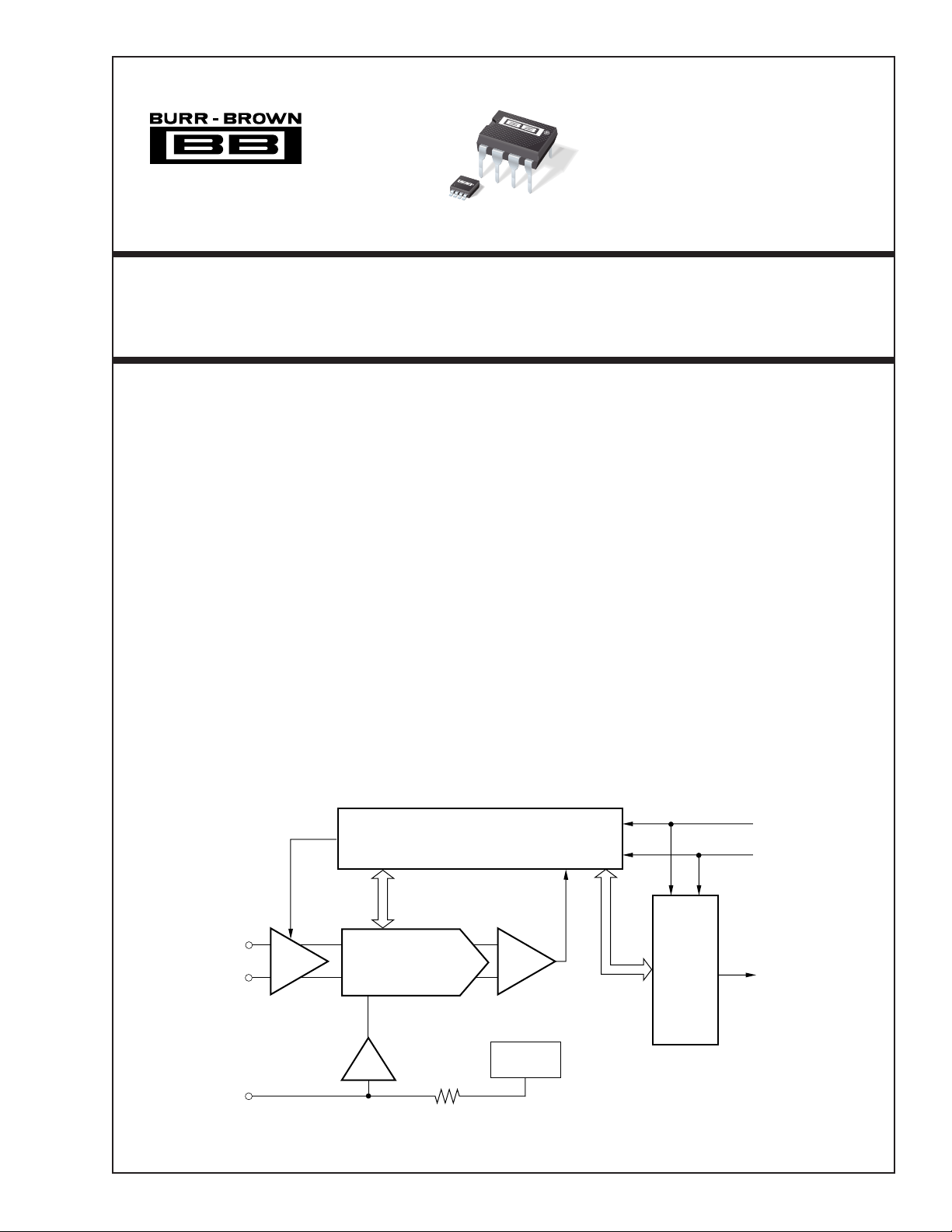

DESCRIPTION

The ADS7818 is a 12-bit sampling analog-to-digital

converter (A/D) complete with sample/hold, internal

2.5V reference, and synchronous serial interface. Typical power dissipation is 11mW at a 500kHz throughput rate. The device can be placed into a power down

mode which reduces dissipation to just 2.5mW. The

input range is zero to two times the reference voltage,

and the internal reference can be overdriven by an

external voltage.

Low power, small size, and high-speed make the

ADS7818 ideal for battery operated systems such as

wireless communication devices, portable multi-channel data loggers, and spectrum analyzers. The serial

interface also provides low-cost isolation for remote

data acquisition. The ADS7818 is available in a plastic mini-DIP-8 or an MSOP-8 package and is guaranteed over the –40°C to +85°C temperature range.

CLK

SAR

CONV

SBAS078

+In

–In

S/H Amp

V

REF

International Airport Industrial Park • Mailing Address: PO Box 11400, Tucson, AZ 85734 • Street Address: 6730 S. Tucson Blvd., Tucson, AZ 85706 • Tel: (520) 746-1111

Twx: 910-952-1111 • Internet: http://www.burr-brown.com/ • Cable: BBRCORP • Telex: 066-6491 • FAX: (520) 889-1510 • Immediate Product Info: (800) 548-6132

©

1998 Burr-Brown Corporation PDS-1408B Printed in U.S.A. May, 2000

CDAC

Buffer

Comparator

Internal

+2.5V Ref

10kΩ ±30%

1

Serial

Interface

DATA

ADS7818

®

Page 2

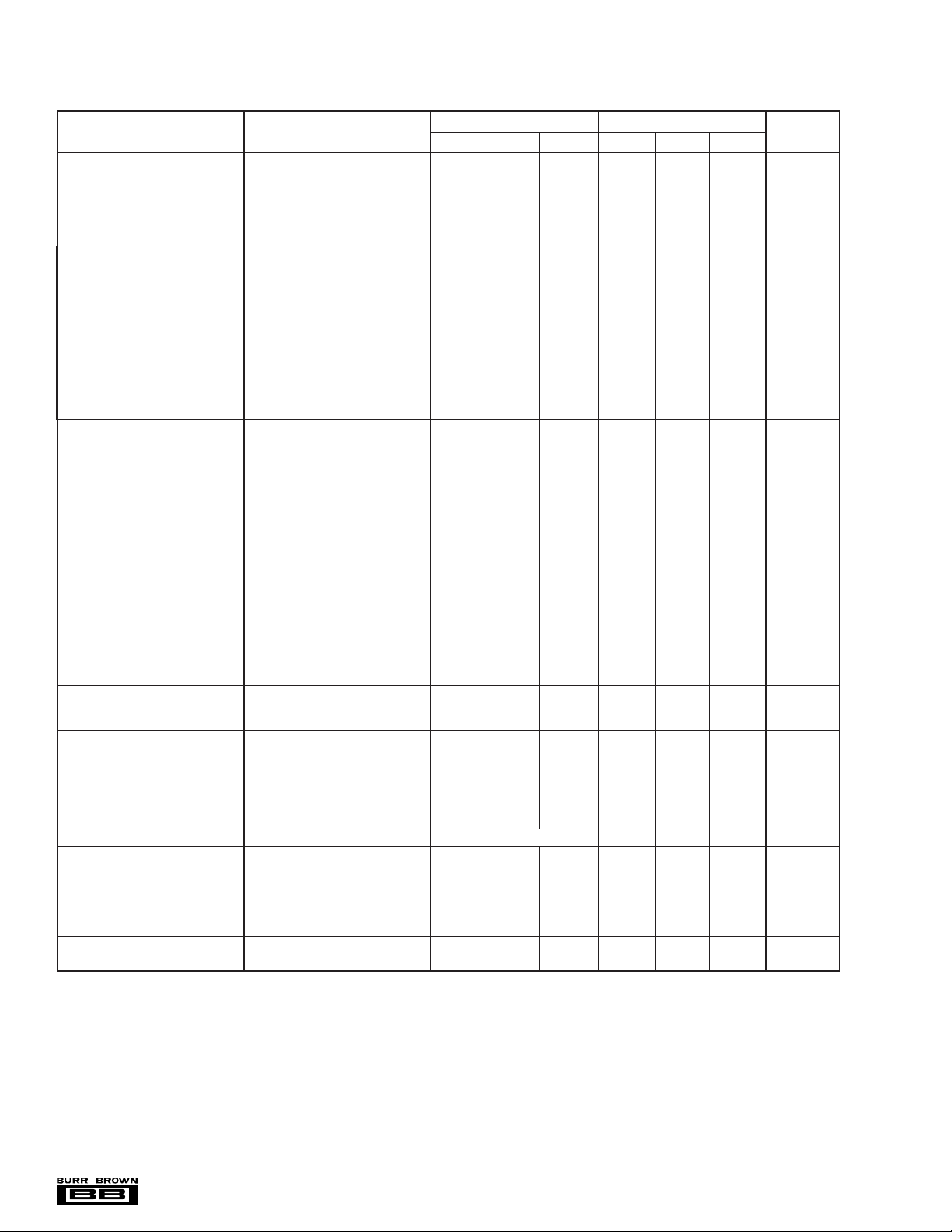

SPECIFICATIONS

At TA = –40°C to +85°C, +VCC = +5V, f

PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

ANALOG INPUT

Full-Scale Input Span

(1)

Absolute Input Range +In –0.2 V

Capacitance 15 ✻ pF

Leakage Current 1 ✻ µA

SYSTEM PERFORMANCE

Resolution 12 ✻ Bits

No Missing Codes 12 ✻ Bits

Integral Linearity Error ±1 ±2 ±0.5 ±1 LSB

Differential Linearity Error ±0.8 ±0.5 ±1 LSB

Offset Error ±2 ±5 ±1 ✻ LSB

Gain Error

(3)

Common-Mode Rejection DC, 0.2Vp-p 70 ✻ dB

Noise 150 ✻ µVrms

Power Supply Rejection Worst Case ∆, +V

SAMPLING DYNAMICS

Conversion Time 1.625 ✻ µs

Acquisition Time 0.350 ✻ µs

Throughput Rate 500 ✻ kHz

Aperture Delay 5 ✻ ns

Aperture Jitter 30 ✻ ps

Step Response 350 ✻ ns

DYNAMIC CHARACTERISTICS

Signal-to-Noise Ratio V

Total Harmonic Distortion

(4)

Signal-to-(Noise+Distortion) V

Spurious Free Dynamic Range V

Usable Bandwidth SINAD > 68dB 350 ✻ kHz

REFERENCE OUTPUT

Voltage I

Source Current

(5)

Drift I

Line Regulation 4.75V ≤ V

REFERENCE INPUT

Range 2.0 2.55 ✻✻V

Resistance

(6)

DIGITAL INPUT/OUTPUT

Logic Family CMOS ✻

Logic Levels:

V

IH

V

IL

V

OH

V

OL

Data Format Straight Binary ✻

POWER SUPPLY REQUIREMENT

+V

CC

Quiescent Current f

Power Dissipation f

TEMPERATURE RANGE

Specified Performance –40 +85 ✻✻°C

✻ Specifications same as ADS7818P,E.

NOTES: (1) Ideal input span, does not include gain or offset error. (2) LSB means Least Significant Bit, with V

relative to an ideal, full-scale input (+In – (–In)) of 4.999V. Thus, gain error includes the error of the internal voltage reference. (4) Calculated on the first nine

harmonics of the input frequency. (5) If the internal reference is required to source current to an external load, the reference voltage will change due to the internal

10kΩ resistor. (6) Can vary ±30%.

SAMPLE

= 500kHz, f

CLK

= 16 • f

, internal reference, unless otherwise specified.

SAMPLE

ADS7818P, E ADS7818PB, EB

+In – (–In) 0 5 ✻✻V

+0.2 ✻✻V

–In –0.2 +0.2 ✻✻V

CC

25°C ±12 ±30 ±7 ±15 LSB

–40°C to +85°C ±50 ±35 LSB

1MHz, 0.2Vp-p 50 ✻ dB

= 5V ±5% 1.2 ✻ LSB

CC

= 5Vp-p at 100kHz 72 ✻ dB

IN

VIN = 5Vp-p at 100kHz –78 –72 –82 –75 dB

= 5Vp-p at 100kHz 68 70 70 72 dB

IN

= 5Vp-p at 100kHz 72 78 75 82 dB

IN

= 0 2.475 2.50 2.525 2.48 ✻ 2.52 V

OUT

Static Load 50 ✻ µA

= 0 20 ✻ ppm/°C

OUT

≤ 5.25V 0.6 ✻ mV

CC

to Internal Reference Voltage 10 ✻✻✻ kΩ

|IIH| ≤ +5µA 3.0 V

|IIL| ≤ +5µA –0.3 0.8 ✻✻V

+0.3 ✻✻V

CC

IOH = –500µA 3.5 ✻✻V

IOL = 500µA 0.4 ✻✻V

Specified Performance 4.75 5.25 ✻✻V

= 500kHz 2.2 ✻ mA

SAMPLE

Power Down 0.5 ✻ mA

= 500kHz 11 20 ✻✻ mW

SAMPLE

Power Down 2.5 ✻ mW

equal to +2.5V, one LSB is 1.22mV. (3) Measured

REF

(2)

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN

assumes no responsibility for the use of this information, and all use of such information shall be entirely at the user’s own risk. Prices and specifications are subject

to change without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not

authorize or warrant any BURR-BROWN product for use in life support devices and/or systems.

®

ADS7818

2

Page 3

ABSOLUTE MAXIMUM RATINGS

+VCC to GND............................................................................ –0.3V to 6V

Analog Inputs to GND .............................................. –0.3V to (V

Digital Inputs to GND ............................................... –0.3V to (V

Power Dissipation .......................................................................... 325mW

Maximum Junction Temperature ................................................... +150°C

Operating Temperature Range ......................................... –40°C to +85°C

Storage Temperature Range .......................................... –65°C to +150°C

Lead Temperature (soldering, 10s) ............................................... +300°C

NOTE: (1) Stresses above those listed under “Absolute Maximum Ratings” may

cause permanent damage to the device. Exposure to absolute maximum conditions for extended periods may affect device reliability.

(1)

+ 0.3V)

CC

+ 0.3V)

CC

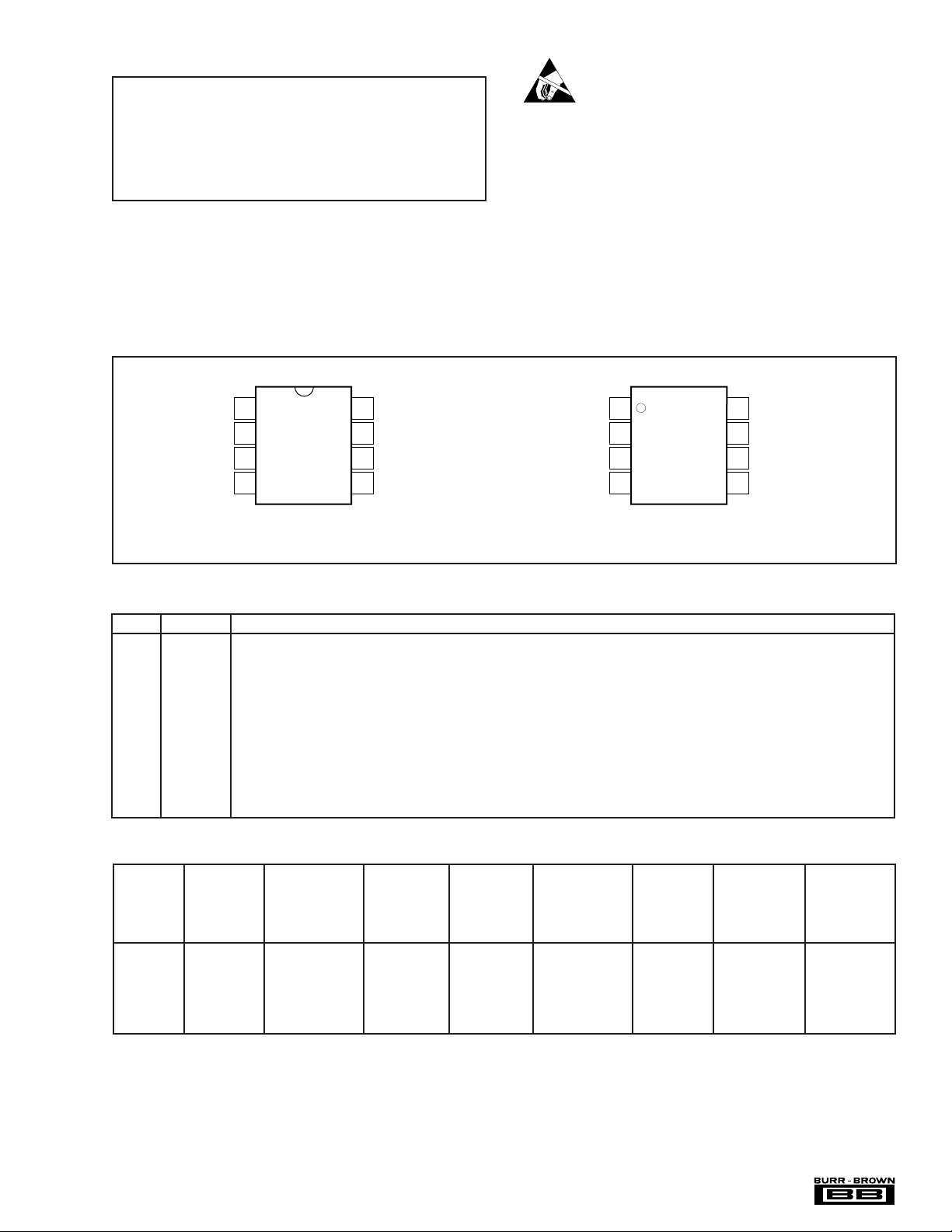

PIN CONFIGURATION

Top View

ELECTROSTATIC

DISCHARGE SENSITIVITY

Electrostatic discharge can cause damage ranging from performance degradation to complete device failure. BurrBrown Corporation recommends that all integrated circuits

be handled and stored using appropriate ESD protection

methods.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits

may be more susceptible to damage because very small

parametric changes could cause the device not to meet

published specifications.

V

REF

+In

–In

GND

1

2

ADS7818

3

4

Plastic Mini-DIP-8

+V

8

CC

CLK

7

DATA

6

CONV

5

V

REF

+In

–In

GND

1

2

ADS7818

3

4

MSOP-8

+V

8

CC

CLK

7

DATA

6

CONV

5

PIN ASSIGNMENTS

PIN NAME DESCRIPTION

1V

2 +In Non-Inverting Input.

3 –In Inverting Input. Connect to ground or to remote ground sense point.

4 GND Ground.

5 CONV Convert Input. Controls the sample/hold mode, start of conversion, start of serial data transfer, type of serial transfer, and power

6 DATA Serial Data Output. The 12-bit conversion result is serially transmitted most significant bit first with each bit valid on the rising edge

7 CLK Clock Input. Synchronizes the serial data transfer and determines conversion speed.

8+V

REF

Reference Output. Decouple to ground with a 0.1µF ceramic capacitor and a 2.2µF tantalum capacitor.

down mode. See the Digital Interface section for more information.

of CLK. By properly controlling the CONV input, it is possibly to have the data transmitted least significant bit first. See the Digital

Interface section for more information.

Power Supply. Decouple to ground with a 0.1µF ceramic capacitor and a 10µF tantalum capacitor.

CC

PACKAGE/ORDERING INFORMATION

MAXIMUM MAXIMUM

INTEGRAL DIFFERENTIAL

LINEARITY LINEARITY PACKAGE SPECIFICATION

PRODUCT (LSB) (LSB) PACKAGE NUMBER

ADS7818E ±2 N/S

ERROR ERROR DRAWING TEMPERATURE PACKAGE ORDERING TRANSPORT

(4)

MSOP-8 337 –40°C to +85°C A18 ADS7818E/250 Tape and Reel

"" " " " " "ADS7818E/2K5 Tape and Reel

ADS7818EB ±1 ±1 MSOP-8 337 –40°C to +85°C A18 ADS7818EB/250 Tape and Reel

"" " " " " "ADS7818EB/2K5 Tape and Reel

ADS7818P ±2 N/S

ADS7818PB ±1 ±1

NOTE: (1) For detail drawing and dimension table, please see end of data sheet or Package Drawing File on Web. (2) Performance Grade information is marked

on the reel. (3) Models with a slash(/) are available only in Tape and reel in quantities indicated (e.g. /250 indicates 250 units per reel, /2K5 indicates 2500 devices

per reel). Ordering 2500 pieces of ”ADS7818E/2K5“ will get a single 2500-piece Tape and Reel. For detailed Tape and Reel mechanical information, refer to the

www.burr-brown.com web site under Applications and Tape and Reel Orientation and Dimensions. (4) N/S = Not Specified, typical only. However, 12-Bits no missing

codes is guaranteed over temperature.

(4)

Plastic DIP-8 006 –40°C to +85°C ADS7818P ADS7818P Rails

"" "ADS7818PB ADS7818PB Rails

(1)

RANGE MARKING

(2)

NUMBER

(3)

MEDIA

®

3

ADS7818

Page 4

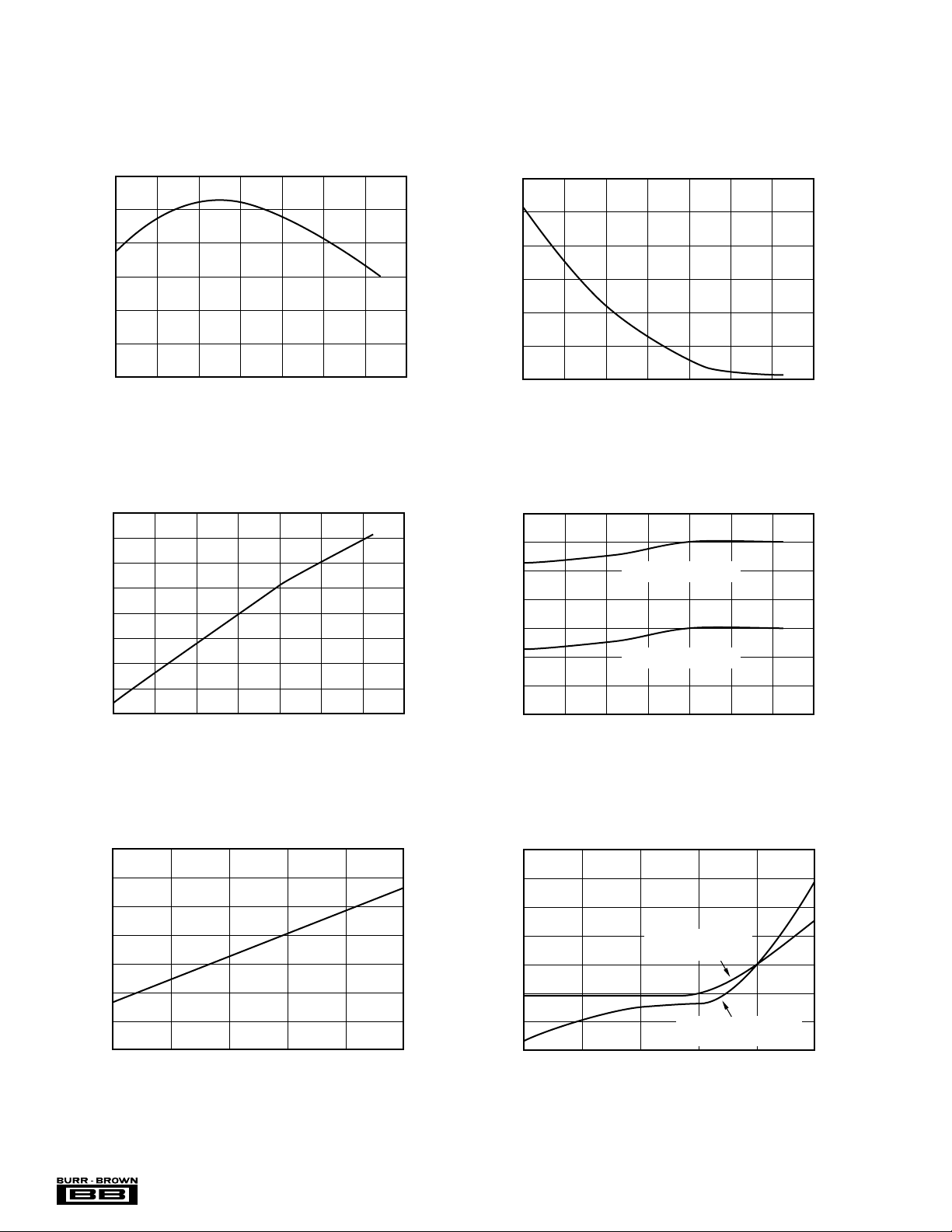

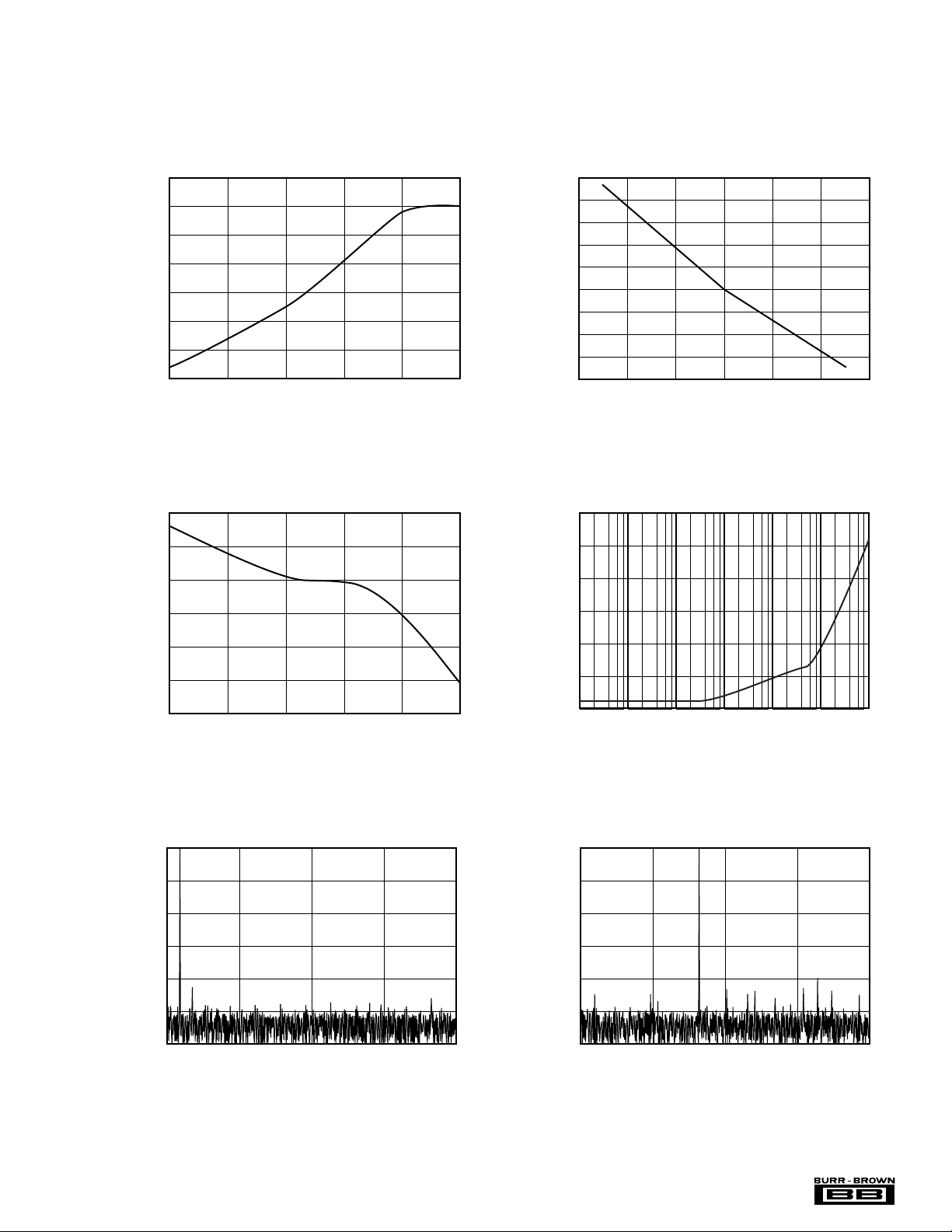

TYPICAL PERFORMANCE CURVES

At TA = +25°C, VCC = +5V, f

2

= 500kHz, f

SAMPLE

CHANGE IN FULL-SCALE ERROR

vs TEMPERATURE

CLK

= 16 • f

SAMPLE

, and internal +2.5V reference, unless otherwise specified.

2.0

CHANGE IN OFFSET vs TEMPERATURE

0

–2

–4

–6

Delta from 25°C (LSB)

–8

–10

Temperature (°C)

POWER-DOWN SUPPLY CURRENT

470

460

450

440

430

420

410

400

Power-down Supply Current (µA)

390

vs TEMPERATURE

Temperature (°C)

20–40 100–20 0 40

20–40 100–20 0 40

60 80

60 80

1.6

1.2

0.8

0.4

Delta from 25°C (LSB)

0.0

–0.4

2.3

2.2

2.1

2.0

1.9

1.8

Supply Current (mA)

1.7

1.6

20–40 100–20 0 40

Temperature (°C)

SUPPLY CURRENT vs TEMPERATURE

f

= 500kHz

SAMPLE

f

= 125kHz

SAMPLE

20–40 100–20 0 40

Temperature (°C)

60 80

60 80

2.4

2.3

2.2

2.1

2.0

1.9

Supply Current (mA)

1.8

1.7

SUPPLY CURRENT vs SAMPLE RATE

®

ADS7818

400100 600200 300 500

Sample Rate (kHz)

4

0.4

0.3

0.2

0.1

= 500kHz (LSB)

0.0

SAMPLE

–0.1

–0.2

Delta from f

–0.3

CHANGE IN INTEGRAL LINEARITY and

DIFFERENTIAL LINEARITY vs SAMPLE RATE

Change in Integral

Linearity (LSB)

Change in Differential

Linearity (LSB)

400100 600200 300 500

Sample Rate (kHz)

Page 5

TYPICAL PERFORMANCE CURVES (Cont.)

At TA = +25°C, VCC = +5V, f

SAMPLE

= 500kHz, f

CLK

= 16 • f

, and internal +2.5V reference, unless otherwise specified.

SAMPLE

0.2

0.0

–0.2

–0.4

= 2.5V (mV)

REF

–0.6

–0.8

Delta from V

–1.0

–1.2

0.70

0.65

0.60

CHANGE IN FULL-SCALE ERROR

vs EXTERNAL REFERENCE VOLTAGE

2.32.0 2.52.1 2.2 2.4

External Reference Voltage (V)

PEAK-TO-PEAK NOISE

vs EXTERNAL REFERENCE VOLTAGE

0.5

0.4

0.3

0.2

0.1

= 2.5V (mV)

REF

0.0

–0.1

–0.2

Delta from V

–0.3

–0.4

30

25

20

CHANGE IN OFFSET

vs EXTERNAL REFERENCE VOLTAGE

2.51.9 3.12.1 2.3 2.7 2.9

External Reference Voltage (V)

POWER SUPPLY REJECTION

vs POWER SUPPLY RIPPLE FREQUENCY

0.55

0.50

Peak-to-Peak Noise (LSB)

0.45

0.40

0

–20

–40

–60

–80

Amplitude (dB)

–100

–120

0 25062.5 187.5125

(4096 Point FFT; f

2.32.0 2.52.1 2.2 2.4

External Reference Voltage (LSB)

FREQUENCY SPECTRUM

= 10.9kHz, –0.2dB)

IN

Frequency (kHz)

15

10

5

Power Supply Rejection (mV/V)

0

1 10 100 1k 10k 100k 1M

Power Supply Ripple Frequency (Hz)

FREQUENCY SPECTRUM

0

–20

–40

–60

–80

Amplitude (dB)

–100

–120

0 25062.5 187.5125

(4096 Point FFT; f

= 102kHz, –0.2dB)

IN

Frequency (kHz)

®

5

ADS7818

Page 6

TYPICAL PERFORMANCE CURVES (Cont.)

At TA = +25°C, VCC = +5V, f

(4096 Point FFT; f

0

= 500kHz, f

SAMPLE

FREQUENCY SPECTRUM

= 16 • f

CLK

= 247kHz, –0.2dB)

IN

, and internal +2.5V reference, unless otherwise specified.

SAMPLE

76

SIGNAL-TO-NOISE RATIO and

SIGNAL-TO-(NOISE+DISTORTION)

vs INPUT FREQUENCY

–20

–40

–60

–80

Amplitude (dB)

–100

–120

0 25062.5 187.5125

SPURIOUS FREE DYNAMIC RANGE AND

TOTAL HARMONIC DISTORTION

90

85

❉

THD

80

75

SFDR (dB)

70

❉

First nine harmonics

of the input frequency

65

Frequency (kHz)

vs INPUT FREQUENCY

SFDR

10k 100k1k 1M

Input Frequency (Hz)

74

72

70

68

SNR and SINAD (dB)

66

64

CHANGE IN SIGNAL-TO-NOISE RATIO

and SIGNAL-TO-(NOISE+DISTORTION)

–

90

–

85

–

80

–

75

–

70

–

65

THD (dB)

Delta from +25°C (dB)

0.3

0.2

0.1

0.0

–0.1

–0.2

fIN = 100kHz, –0.2dB

–0.3

SNR

SINAD

–20–40 100

SNR

SINAD

10k 100k1k 1M

Input Frequency (Hz)

vs TEMPERATURE

0 20 40 60 80

Temperature (°C)

1.0

0.5

0.0

–0.5

–1.0

–1.5

SFDR Delta from +25°C (dB)

–2.0

CHANGE IN SPURIOUS FREE DYNAMIC RANGE

AND TOTAL HARMONIC DISTORTION

fIN = 100kHz, –0.2dB

❉

First nine harmonics

of the input frequency

–20–40 100

®

vs TEMPERATURE

THD

SFDR

0 20 40 60 80

Temperature (°C)

ADS7818

–1.0

–0.5

❉

0.0

0.5

1.0

1.5

2.0

THD Delta from +25°C (dB)

6

Page 7

THEORY OF OPERATION

The ADS7818 is a high speed successive approximation

register (SAR) analog-to-digital converter (A/D) with an

internal 2.5V bandgap reference. The architecture is based

on capacitive redistribution which inherently includes a

sample/hold function. The converter is fabricated on a 0.6µ

CMOS process. See Figure 1 for the basic operating circuit

for the ADS7818.

The ADS7818 requires an external clock to run the conversion process. This clock can vary between 200kHz (12.5Hz

throughput) and 8MHz (500kHz throughput). The duty cycle

of the clock is unimportant as long as the minimum HIGH

and LOW times are at least 50ns and the clock period is at

least 125ns. The minimum clock frequency is set by the

leakage on the capacitors internal to the ADS7818.

The analog input is provided to two input pins: +IN and –IN.

When a conversion is initiated, the differential input on these

pins is sampled on the internal capacitor array. While a

conversion is in progress, both inputs are disconnected from

any internal function.

The range of the analog input is set by the voltage on the

V

pin. With the internal 2.5V reference, the input range

REF

is 0 to 5V. An external reference voltage can be placed on

V

, overdriving the internal voltage. The range for the

REF

external voltage is 2.0V to 2.55V, giving an input voltage

range of 4.0V to 5.1V.

The digital result of the conversion is provided in a serial

manner, synchronous to the CLK input. The result is provided most significant bit first and represents the result of

the conversion currently in progress—there is no pipeline

delay. By properly controlling the CONV and CLK inputs,

it is possible to obtain the digital result least significant bit

first.

ANALOG INPUT

The +IN and –IN input pins allow for a differential input

signal to be captured on the internal hold capacitor when the

converter enters the hold mode. The voltage range on the

–IN input is limited to –0.2V to 0.2V. Because of this, the

differential input can be used to reject only small signals that

are common to both inputs. Thus, the –IN input is best used

to sense a remote ground point near the source of the +IN

signal. If the source driving the +IN signal is nearby, the

–IN should be connected directly to ground.

The input current into the analog input depends on input

voltage and sample rate. Essentially, the current into the

device must charge the internal hold capacitor during the

sample period. After this capacitance has been fully charged,

there is no further input current. The source of the analog

input voltage must be able to charge the input capacitance to

a 12-bit settling level within the sample period—which can

be as little as 350ns in some operating modes. While the

converter is in the hold mode or after the sampling capacitor

has been fully charged, the input impedance of the analog

input is greater than 1GΩ.

Care must be taken regarding the input voltage on the +In

and –IN pins. To maintain the linearity of the converter, the

+In input should remain within the range of GND – 200mV

to +VCC + 200mV. The –IN input should not drop below

GND – 200mV or exceed GND + 200mV. Outside of these

ranges, the converter’s linearity may not meet specifications.

REFERENCE

The reference voltage on the V

scale range of the analog input. The ADS7818 can operate

with a reference in the range of 2.0V to 2.55V, for a fullscale range of 4.0V to 5.1V.

The voltage at the V

pin is internally buffered and this

REF

buffer drives the capacitor DAC portion of the converter.

This is important because the buffer greatly reduces the

dynamic load placed on the reference source. However, the

voltage at V

will still contain some noise and glitches

REF

from the SAR conversion process. These can be reduced by

carefully bypassing the V

REF

sections that follow.

INTERNAL REFERENCE

The ADS7818 contains an on-board 2.5V reference, resulting in a 0V to 5V input range on the analog input. The

specification table gives the various specifications for the

pin directly sets the full-

REF

pin to ground as outlined in the

+

2.2µF

0.1µF 10µF

0 to 5V

Analog Input

FIGURE 1. Basic Operation of the ADS7818.

+5V

ADS7818

1

V

REF

2

+In

3

–In

4

GND

+V

CLK

DATA

CONV

8

CC

7

6

5

0.1µF

Serial Clock

Serial Data

Convert Start

7

+

from

Microcontroller

or DSP

®

ADS7818

Page 8

internal reference. This reference can be used to supply a

small amount of source current to an external load, but the

load should be static. Due to the internal 10kΩ resistor, a

dynamic load will cause variations in the reference voltage,

and will dramatically affect the conversion result. Note that

even a static load will reduce the internal reference voltage

seen at the buffer input. The amount of reduction depends on

the load and the actual value of the internal “10kΩ” resistor.

The value of this resistor can vary by ±30%.

The V

pin should be bypassed with a 0.1µF capacitor

REF

placed as close as possible to the ADS7818 package. In

addition, a 2.2 µF tantalum capacitor should be used in

parallel with the ceramic capacitor. Placement of this capacitor is not as critical.

EXTERNAL REFERENCE

The internal reference is connected to the V

pin and to the

REF

internal buffer via a 10kΩ series resistor. Thus, the reference

voltage can easily be overdriven by an external reference

voltage. The voltage range for the external voltage is 2.0V

to 2.55V, corresponding to an analog input range of 4.0V to

5.1V.

While the external reference will not source significant

current into the V

pin, it does have to drive the series

REF

10kΩ resistor that is terminated into the 2.5V internal

reference (the exact value of the resistor will vary up to

±30% from part to part). In addition, the V

pin should

REF

still be bypassed to ground with at least a 0.1 µF ceramic

capacitor (placed as close to the ADS7818 as possible). The

reference will have to be stable with this capacitive load.

Depending on the particular reference and A/D conversion

speed, additional bypass capacitance may be required, such

as the 2.2µF tantalum capacitor shown in Figure 1.

Reasons for choosing an external reference over the internal

reference vary, but there are two main reasons. One is to

achieve a given input range. For example, a 2.048V reference provides for a 0V to 4.095V input range—or 1mV per

LSB. The other is to provide greater stability over temperature. The internal reference is typically 20ppm/°C which

translates into a full-scale drift of roughly 1 output code for

every 12°C (this does not take into account other sources of

full-scale drift). If greater stability over temperature is needed,

then an external reference with lower temperature drift will

be required.

DIGITAL INTERFACE

Figure 2 shows the serial data timing and Figure 3 shows the

basic conversion timing for the ADS7818. The specific

timing numbers are listed in Table I. There are several

important items in Figure 3 which give the converter additional capabilities over typical 8-pin converters. First, the

transition from sample mode to hold mode is synchronous to

the falling edge of CONV and is not dependent on CLK.

Second, the CLK input is not required to be continuous

during the sample mode. After the conversion is complete,

the CLK may be kept LOW or HIGH.

t

CKP

CLK

DATA

t

CKH

t

CKL

t

CKDS

t

CKDH

FIGURE 2. Serial Data and Clock Timing.

SYMBOL DESCRIPTION MIN TYP MAX UNITS

t

ACQ

t

CONV

t

CKP

t

CKL

t

CKH

t

CKDH

t

CKDS

t

CVL

t

CVH

t

CKCH

t

CKCS

t

CKDE

t

CKDD

t

CKSP

t

CKPD

t

CVHD

t

CVSP

t

CVPU

t

CVDD

t

CVPD

t

DRP

Note: (1) This timing is not required under some situations. See text for more information.

Acquisition Time 350 ns

Conversion Time 1.5 µs

Clock Period 125 5000 ns

Clock LOW 50 ns

Clock HIGH 50 ns

Clock Falling to Current Data 5 15 ns

Bit No Longer Valid

Clock Falling to Next Data Valid 30 50 ns

CONV LOW 40 ns

CONV HIGH 40 ns

CONV Hold after Clock Falls

CONV Setup to Clock Falling

Clock Falling to DATA Enabled 20 50 ns

Clock Falling to DATA 70 100 ns

High Impedance

Clock Falling to Sample Mode 5 ns

Clock Falling to Power-down Mode 50 ns

CONV Falling to Hold Mode 5 ns

(Aperture Delay)

CONV Rising to Sample Mode 5 n s

CONV Rising to Full Power-up 50 ns

CONV Changing State to DATA 70 100 ns

High Impedance

CONV Changing State to 50 ns

Power-down Mode

CONV Falling to Start of CLK 5 µs

(for hold droop < 0.1 LSB)

(1)

10 ns

(1)

10 ns

TABLE I. Timing Specifications (TA = –40°C to +85°C,

C

= 30pF).

LOAD

The asynchronous nature of CONV to CLK raises some

interesting possibilities, but also some design considerations. Figure 3 shows that CONV has timing restraints in

relation to CLK (t

CKCH

and t

). However, if these times

CKCS

are violated (which could happen if CONV is completely

asynchronous to CLK), the converter will perform a conversion correctly, but the exact timing of the conversion is

indeterminate. Since the setup and hold time between CONV

and CLK has been violated in this example, the start of

conversion could vary by one clock cycle. (Note that the

start of conversion can be detected by using a pull-up

resistor on DATA. When DATA drops out of high-impedance and goes LOW, the conversion has started and that

clock cycle is this first of the conversion.)

In addition if CONV is completely asynchronous to CLK

and CLK is continuous, then there is possibility that CLK

will transition just prior to CONV going LOW. If this occurs

®

ADS7818

8

Page 9

faster than the 10ns indicated by t

, then there is a

CKCH

chance that some digital feedthrough may be coupled onto

the hold capacitor. This could cause a small offset error for

that particular conversion.

Thus, there are two basic ways to operate the ADS7818.

CONV can be synchronous to CLK and CLK can be continuous. This would be the typical situation when interfacing

the converter to a digital signal processor. The second

method involves having CONV asynchronous to CLK and

gating the operation of CLK (a non-continuous clock). This

method would be more typical of an SPI-like interface on a

microcontroller. This method would also allow CONV to be

generated by a trigger circuit and to initiate (after some

delay) the start of CLK. These two methods are covered

under DSP Interfacing and SPI Interfacing.

POWER-DOWN TIMING

The conversion timing shown in Figure 3 does not result in

the ADS7818 going into the power-down mode. If the

conversion rate of the device is high (approaching 500kHz),

then there is very little power that can be saved by using the

power-down mode. However, since the power-down mode

incurs no conversion penalty (the very first conversion is

valid), at lower sample rates, significant power can be saved

by allowing the device to go into power-down mode between conversions.

Figure 4 shows the typical method for placing the A/D into

the power-down mode. If CONV is kept LOW during the

conversion and is LOW at the start of the 13 clock cycle,

then the device enters the power-down mode. It remains in

this mode until the rising edge of CONV. Note that CONV

must be HIGH for at least t

in order to sample the signal

ACQ

properly as well as to power-up the internal nodes.

There are two different methods for clocking the ADS7818.

The first involves scaling the CLK input in relation to the

conversion rate. For example, an 8MHz input clock and the

timing shown in Figure 3 results in a 500kHz conversion

rate. Likewise, a 1.6MHz clock would result in a 100kHz

conversion rate. The second method involves keeping the

clock input as close to the maximum clock rate as possible

and starting conversions as needed. This timing is similar to

that shown in Figure 4. As an example, a 50kHz conversion

rate would require 160 clock periods per conversion instead

of the 16 clock periods used at 500kHz.

The main distinction between the two is the amount of time

that the ADS7818 remains in power down. In the first mode,

the converter only remains in power down for a small

number of clock periods (depending on how many clock

periods there are per each conversion). As the conversion

rate scales, the converter always spends the same percentage

of time in power down. Since less power is drawn by the

digital logic, there is a small decrease in power consumption, but it is very slight. This effect can be seen in the

typical performance curve “Supply Current vs Sample Rate.”

CONV

CLK

DATA

SAMPLE/HOLD

MODE

INTERNAL

CONVERSION

STATE

t

CVL

t

t

CKCH

(1)

t

CVHD

(2)

NOTES: (1) Clock periods 14 and 15 are shown for clarity, but are not required for proper operation of the ADS7818, provided that the

minimum t

mode occurs on the falling edge of CONV. This transition is not dependent on CLK. (3) The device remains fully powered when

operated as shown. If the sample time is longer than 3 clock periods, power consumption can be reduced by allowing the device to

enter a power down mode. See the power down timing for more information.

time is met. The CLK input may remain HIGH or LOW during this period. (2) The transition from sample mode to hold

ACQ

CKCS

1 2 3 4 11 12 13 14 1514 15 1616 1

t

CKDE

D11

(MSB)

D10 D9 D2 D1

HOLD

t

CONV

CONVERSION IN PROGRESS IDLE IDLE

t

D0

(LSB)

CVCK

t

CKSP

t

CKDD

t

ACQ

SAMPLESAMPLE

(

3)

HOLD

FIGURE 3. Basic Conversion Timing.

®

9

ADS7818

Page 10

CONV

CLK

DATA

SAMPLE/HOLD

MODE

INTERNAL

CONVERSION

STATE

POWER MODE FULL POWER FULL POWERLOW POWER

NOTES: (1) The low power mode (“power-down”) is entered when CONV remains LOW during the conversion and is still LOW at the

start of the 13th clock cycle. (2) The low power mode is exited when CONV goes HIGH. (3) When in power-down, the transition from

hold mode to sample mode is initiated by CONV going HIGH.

123 1213

D11

(MSB)

CONVERSION IN PROGRESS IDLE IDLE

D10 D1

HOLD SAMPLESAMPLE HOLD

t

CKPD

D0

(LSB)

(1) (2)

FIGURE 4. Power-down Timing.

t

CVH

CONV

t

CVSP

t

ACQ

(3)

t

CVPU

t

CKCH

CLK

DATA

SAMPLE/HOLD

MODE

INTERNAL

CONVERSION

STATE

POWER MODE FULL POWER LOW POWER

NOTES: (1) The serial data can be transmitted LSB first by pulling CONV LOW during the 13th clock cycle. (2) After the MSB has been

transmitted, the DATA output pin will remain LOW until CONV goes HIGH. (3) When CONV is taken LOW to initiate the LSB first transfer,

the converter enters the power-down mode.

1 2 3 121314 2324

t

CKCS

CONVERSION IN PROGRESSIDLE

D11

(MSB)

D10 D1

HOLDSAMPLE

t

CVPD

D0

(LSB)

(1) (2)

(3)

D1 D10

IDLE

FIGURE 5. Serial Data “LSB-First” Timing.

In contrast, the second method (clocking at a fixed rate)

means that each conversion takes X clock cycles. As the

time between conversions get longer, the converter remains

in power-down an increasing percentage of time. This re-

duces total power consumption by a considerable amount.

For example, a 50kHz conversion rate results in roughly

1/10 of the power (minus the reference) that is used at a

500kHz conversion rate.

D11

(MSB)

LOW...

t

CVDD

®

ADS7818

10

Page 11

Table II offers a look at the two different modes of operation

and the difference in power consumption.

POWER WITH POWER WITH

f

SAMPLE

500kHz 11mW 11mW

250kHz 10mW 7mW

100kHz 9mW 4mW

CLK = 16 • f

SAMPLE

CLK = 8MHz

TABLE II. Power Consumption versus CLK Input.

LSB FIRST DATA TIMING

Figure 5 shows a method to transmit the digital result in a

least-significant bit (LSB) format. This mode is entered

when CONV is pulled HIGH during the conversion (before

the end of the 12th clock) and then pulled LOW during the

13th clock (when D0, the LSB, is being transmitted). The

next 11 clocks then repeat the serial data, but in an LSB first

format. The converter enters the power-down mode during

the 13th clock and resumes normal operation when CONV

goes HIGH.

SHORT-CYCLE TIMING

The conversion currently in progress can be “short-cycled”

with the technique shown in Figure 6. This term means that

the conversion will terminate immediately, before all 12-bits

have been decided. This can be a very useful feature when

a resolution of 12-bits is not needed. An example would be

when the converter is being used to monitor an input voltage

until some condition is met. At that time, the full resolution

of the converter would then be used. Short-cycling the

conversion can result in a faster conversion rate or lower

power dissipation.

There are several very important items shown in Figure 6.

The conversion currently in progress is terminated when

CONV is taken HIGH during the conversion and then taken

LOW prior to t

before the start of the 13th clock cycle.

CKCH

Note that if CONV goes LOW during the 13th clock cycle,

then the LSB first mode will be entered (Figure 5). Also,

when CONV goes LOW, the DATA output immediately

transitions to high impedance. If the output bit that is present

during that clock period is needed, CONV must not go LOW

until the bit has been properly latched into the receiving

logic.

DATA FORMAT

The ADS7818 output data is in straight binary format as

shown in Figure 7. This figure shows the ideal output code

for the given input voltage and does not include the effects

of offset, gain, or noise.

(1)

CONV

t

CVH

CLK

DATA

SAMPLE/HOLD

MODE

INTERNAL

CONVERSION

STATE

POWER MODE FULL POWER LOW POWER

NOTE: (1) The conversion currently in progress can be stopped by pulling CONV LOW during the conversion. This must occur at

least t

mode when CONV is pulled LOW.

prior to the start of the 13th clock cycle. The DATA output pin will tri-state and the device will enter the power-down

CKCS

123 5467

t

CVDD

D11

(MSB)

D10 D8D9 D7

CONVERSION IN PROGRESSIDLE IDLE

t

CVPD

D6

HOLDSAMPLE

t

CVL

FIGURE 6. Short-cycle Timing.

11

®

ADS7818

Page 12

11...111

11...110

11...101

Output Code

00...010

00...001

00...000

FS = Full-Scale Voltage = 2 • V

1 LSB = FS/4096

1 LSB

REF

microcontrollers form various manufacturers. CONV would

be tied to a general purpose I/O pin (SPI) or to a PCX pin

(QSPI), CLK would be tied to the serial clock, and DATA

would be tied to the serial input data pin such as MISO

(master in slave out).

Note the time t

shown in Figure 9. This represents the

DRP

maximum amount of time between CONV going LOW and

the start of the conversion clock. Since CONV going LOW

places the sample and hold in the hold mode and because the

hold capacitor looses charge over time, there is a requirement that time t

period (t

CKP

).

be met as well as the maximum clock

DRP

(1)

0V

Input Voltage

NOTES: (1) For external reference, value is 2 • V

at converter input: +IN–(–IN).

(2)

4.999V

(V)

– 1 LSB. (2) Voltage

REF

FIGURE 7. Ideal Input Voltages and Output Codes.

DSP INTERFACING

Figure 8 shows a timing diagram that might be used with a

typical digital signal processor such as a TI DSP. For the

buffered serial port (BSP) on the TMS320C54X family,

CONV would tied to BFSX, CLK would be tied to BCLKX,

and DATA would be tied to BDR.

SPI/QSPI INTERFACING

Figure 9 shows the timing diagram for a typical serial

peripheral interface (SPI) or queued serial peripheral interface (QSPI). Such interfaces are found on a number of

CONV

LAYOUT

For optimum performance, care should be taken with the

physical layout of the ADS7818 circuitry. This is particularly true if the CLK input is approaching the maximum

input rate.

The basic SAR architecture is sensitive to glitches or sudden

changes on the power supply, reference, ground connections, and digital inputs that occur just prior to latching the

output of the analog comparator. Thus, during any single

conversion for an n-bit SAR converter, there are n “windows” in which large external transient voltages can easily

affect the conversion result. Such glitches might originate

from switching power supplies, nearby digital logic, and

high power devices. The degree of error in the digital output

depends on the reference voltage, layout, and the exact

timing of the external event. The error can change if the

external event changes in time with respect to the CLK

input.

CLK

DATA

1215 16 3 12 13 14 15 16 1 2 3 4

D11

(MSB)

D10 D1

FIGURE 8. Typical DSP Interface Timing.

t

DRP

CONV

CLK

DATA

231 4 13 14 15 16 1 2 3

D11

(MSB)

D10 D1

FIGURE 9. Typical SPI/QSPI Interface Timing.

®

ADS7818

12

D0

(LSB)

D0

(LSB)

D11

(MSB)

t

ACQ

D10 D9

D11

(MSB)

Page 13

With this in mind, power to the ADS7818 should be clean

and well bypassed. A 0.1µF ceramic bypass capacitor should

be placed as close to the device as possible. In addition, a

1µF to 10µF capacitor is recommended. If needed, an even

larger capacitor and a 5Ω or 10Ω series resistor my be used

to lowpass filter a noisy supply.

The ADS7818 draws very little current from an external

reference on average as the reference voltage is internally

buffered. However, glitches from the conversion process

appear at the V

input and the reference source must be

REF

able to handle this. Whether the reference is internal or

external, the V

pin should be bypassed with a 0.1µF

REF

capacitor. An additional larger capacitor may also be used,

if desired. If the reference voltage is external and originates

from an op-amp, make sure that it can drive the bypass

capacitor or capacitors without oscillation.

The GND pin should be connected to a clean ground point.

In many cases, this will be the “analog” ground. Avoid

connections which are too near the grounding point of a

microcontroller or digital signal processor. If needed, run a

ground trace directly from the converter to the power supply

entry point. The ideal layout will include an analog ground

plane dedicated to the converter and associated analog

circuitry.

13

®

ADS7818

Page 14

PACKAGE OPTION ADDENDUM

www.ti.com

19-Apr-2005

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

ADS7818E/250 ACTIVE MSOP DGK 8 250 TBD Call TI Level-1-220C-UNLIM

ADS7818E/250G4 ACTIVE MSOP DGK 8 250 Green (RoHS &

no Sb/Br)

ADS7818E/2K5 ACTIVE MSOP DGK 8 2500 TBD CallTI Level-1-220C-UNLIM

ADS7818E/2K5G4 ACTIVE MSOP DGK 8 2500 Green (RoHS &

no Sb/Br)

ADS7818EB/250 ACTIVE MSOP DGK 8 250 Green (RoHS &

no Sb/Br)

ADS7818EB/250G4 ACTIVE MSOP DGK 8 250 Green (RoHS &

no Sb/Br)

ADS7818EB/2K5 ACTIVE MSOP DGK 8 2500 Green (RoHS &

no Sb/Br)

ADS7818EB/2K5G4 ACTIVE MSOP DGK 8 2500 Green (RoHS &

no Sb/Br)

ADS7818P ACTIVE PDIP P 8 50 TBD Call TI Level-NA-NA-NA

ADS7818PB ACTIVE PDIP P 8 50 TBD Call TI Level-NA-NA-NA

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Lead/Ball Finish MSL Peak Temp

Call TI Level-2-260C-1 YEAR

Call TI Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

CU NIPDAU Level-2-260C-1 YEAR

(3)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS) or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

Page 15

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2005, Texas Instruments Incorporated

Loading...

Loading...