AD

S7807

A

D

S

7

8

0

7

SBAS022B – NOVEMBER 1992 – REVISED SEPTEMBER 2003

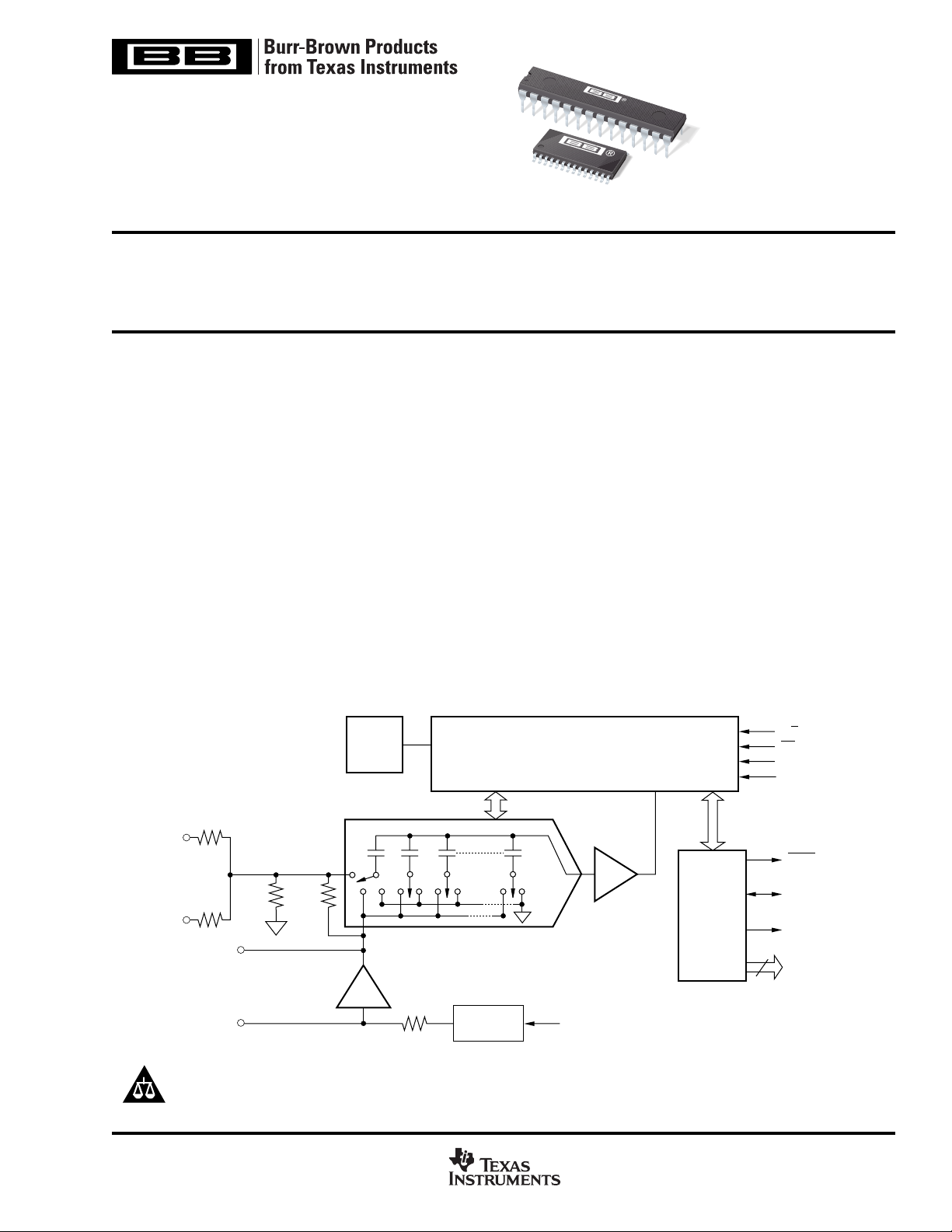

Low-Power, 16-Bit, Sampling CMOS

ANALOG-to-DIGITAL CONVERTER

ADS7807

FEATURES

● 35mW max POWER DISSIPATION

● 50µW POWER-DOWN MODE

● 25µs max ACQUISITION AND CONVERSION

● ±1.5LSB max INL

● DNL: 16 bits “No Missing Codes”

● 86dB min SINAD WITH 1kHz INPUT

●±10V, 0V TO +5V, AND 0V TO +4V INPUT RANGES

● SINGLE +5V SUPPLY OPERATION

● PARALLEL AND SERIAL DATA OUTPUT

● PIN-COMPATIBLE WITH THE 12-BIT ADS7806

● USES INTERNAL OR EXTERNAL REFERENCE

● 0.3" DIP-28 AND SO-28

R1

R2

Clock

40kΩ

IN

20kΩ

10kΩ

IN

CAP

40kΩ

Buffer

Successive Approximation Register and Control Logic

CDAC

DESCRIPTION

The ADS7807 is a low-power, 16-bit, sampling Analog-toDigital (A/D) converter using state-of-the-art CMOS structures. It contains a complete 16-bit, capacitor-based, Successive Approximation Register (SAR) A/D converter with

sample-and-hold, clock, reference, and microprocessor interface with parallel and serial output drivers.

The ADS7807 can acquire and convert 16-bits to within

±1.5LSB in 25µs max while consuming only 35mW max.

Laser trimmed scaling resistors provide standard industrial

input ranges of ±10V and 0V to +5V. In addition, a 0V to +4V

range allows development of complete single-supply systems.

The ADS7807 is available in a 0.3" DIP-28 and SO-28, both

fully specified for operation over the industrial –40°C to

+85°C temperature range.

R/C

CS

BYTE

Power

Down

BUSY

Comparator

Parallel

and

Serial

Data

Out

Serial Data

Clock

Serial Data

Parallel Data

8

REF

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

All trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

6kΩ

Internal

+2.5V Ref

www.ti.com

Reference

Power-Down

Copyright © 1992-2003, Texas Instruments Incorporated

ABSOLUTE MAXIMUM RATINGS

Analog Inputs: R1IN........................................................................... ±12V

Ground Voltage Differences: DGND, AGND1, and AGND2 ............. ±0.3V

V

ANA

V

to V

DIG

V

........................................................................................................ 7V

DIG

Digital Inputs ............................................................. –0.3V to V

Maximum Junction Temperature ................................................... +165°C

Internal Power Dissipation ............................................................. 825mW

Lead Temperature (soldering, 10s) ............................................... +300°C

NOTE: (1) Stresses above those listed under “Absolute Maximum Ratings”

may cause permanent damage to the device. Exposure to absolute maximum

conditions for extended periods may affect device reliability.

R2

.......................................................................... ±5.5V

IN

CAP .................................. V

REF .........................................Indefinite Short to AGND2,

....................................................................................................... 7V

...................................................................................... +0.3V

ANA

(1)

+ 0.3V to AGND2 – 0.3V

ANA

Momentary Short to V

DIG

ANA

+ 0.3V

ELECTROSTATIC

DISCHARGE SENSITIVITY

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling

and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits

may be more susceptible to damage because very small

parametric changes could cause the device not to meet its

published specifications.

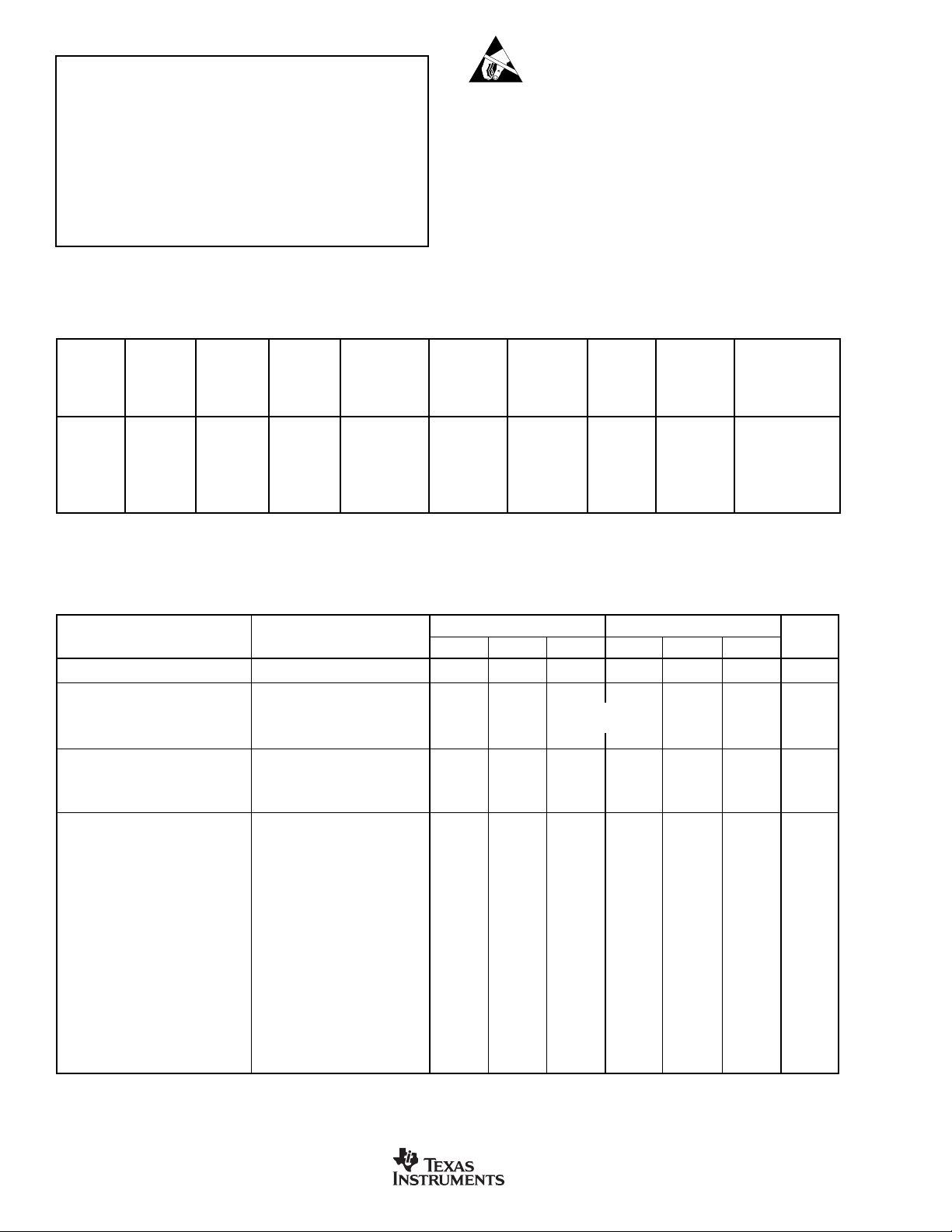

PACKAGE/ORDERING INFORMATION

MAXIMUM SPECIFIED SIGNAL-TOINTEGRAL NO MISSING (NOISE + SPECIFIED

LINEARITY CODE LEVEL DISTORTION) PACKAGE TEMPERATURE PACKAGE ORDERING TRANSPORT

PRODUCT ERROR (LSB) (LSB) RATIO (DB) PACKAGE-LEAD DESIGNATOR

ADS7807P ±31583Dip-28NT–40°C to +85°C ADS7807P ADS7807P Tubes, 13

ADS7807PB ±1.5 16 86

ADS7807U ±3 15 83 SO-28 DW –40°C to +85°C ADS7807U ADS7807U Tubes, 28

" " " " " " " " ADS7807U/1K Tape and Reel, 1000

ADS7807UB ±1.5 16 86

" " " " " " " " ADS7807UB/1K Tape and Reel, 1000

NOTE: (1) For the most current specifications and package information, refer to our web site at www.ti.com.

MINIMUM

(1)

RANGE MARKING NUMBER MEDIA, QUANTITY

"""ADS7807PB ADS7807PB Tubes, 13

"""ADS7807UB ADS7807UB Tubes, 28

ELECTRICAL CHARACTERISTICS

At TA = –40°C to +85°C, fS = 40kHz, V

PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

RESOLUTION 16 ✻ Bits

ANALOG INPUT

Voltage Ranges ±10, 0 to +5, 0 to +4 V

Impedance (See Table II)

Capacitance 35 ✻ pF

THROUGHPUT SPEED

Conversion Time 20 ✻ µs

Complete Cycle Acquire and Convert 25 ✻ µs

Throughput Rate 40 ✻ kHz

DC ACCURACY

Integral Linearity Error ±3 ±1.5 LSB

Differential Linearity Error +3, –2 +1.5, –1LSB

No Missing Codes 15 16 Bits

Transition Noise

Gain Error ±0.2 ±0.1 %

Full-Scale Error

Full-Scale Error Drift ±7 ±5 ppm/°C

Full-Scale Error

Full-Scale Error Drift Ext. 2.5000V Ref ±0.5 ✻ ppm/°C

Bipolar Zero Error

Bipolar Zero Error Drift ±10V Range ±0.5 ✻ ppm/°C

Unipolar Zero Error

Unipolar Zero Error Drift 0V to 5V, 0V to 4V Ranges ±0.5 ✻ ppm/°C

Recovery Time to Rated Accuracy 2.2µF Capacitor to CAP 1 ✻ ms

from Power-Down

Power-Supply Sensitivity +4.75V < VS < +5.25V ±8 ✻ LSB

(V

DIG

= V

ANA

(2)

(3,4)

(3,4)

(3)

(3)

(5)

= VS)

= V

DIG

= +5V, and using internal reference and fixed resistors (see Figure 7b), unless otherwise specified.

ANA

ADS7807P, U ADS7807PB, UB

0.8 ✻ LSB

±0.5 ±0.25 %

Ext. 2.5000V Ref ±0.5 ±0.25 %

±10V Range ±10 ✻ mV

0V to 5V, 0V to 4V Ranges ±3 ✻ mV

(1)

2

www.ti.com

ADS7807

SBAS022B

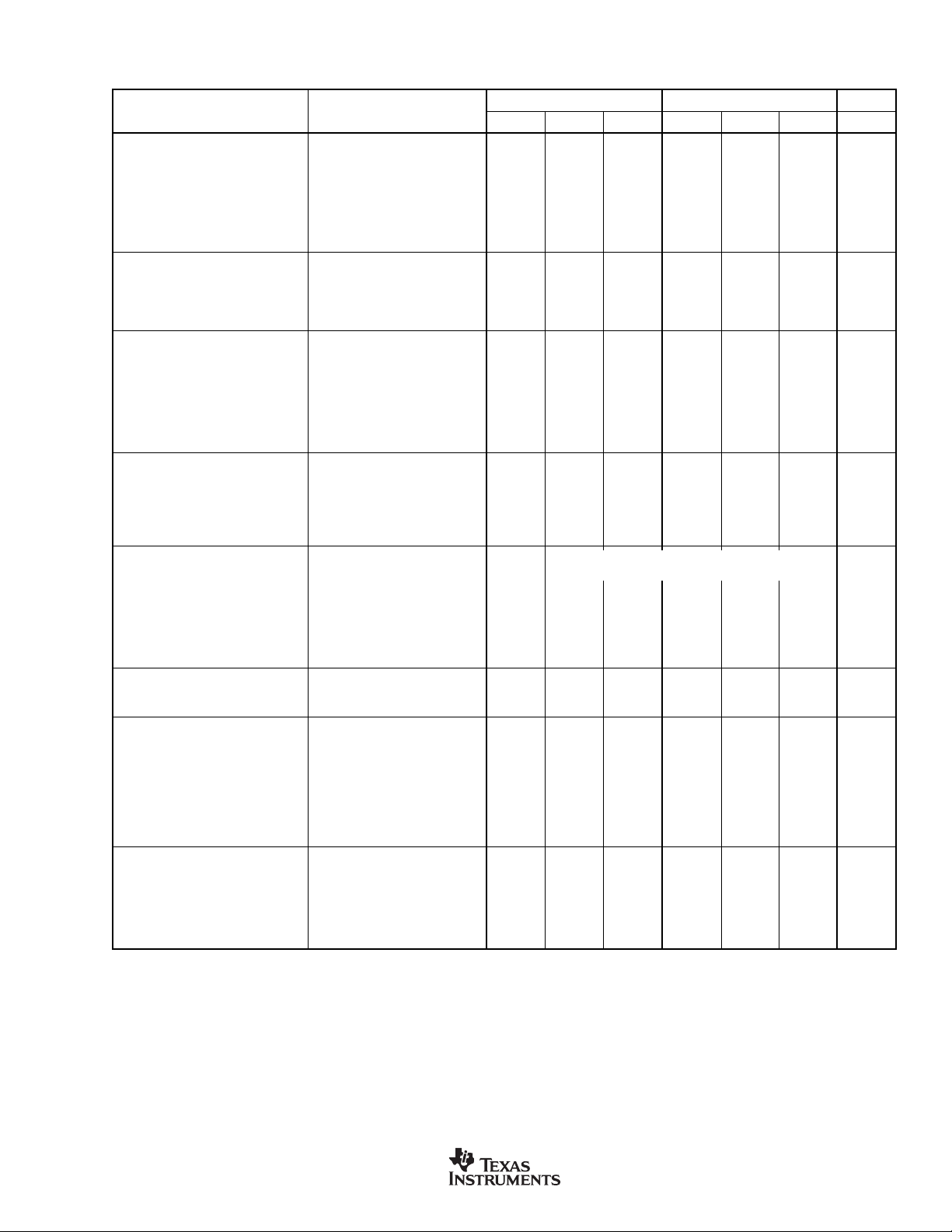

ELECTRICAL CHARACTERISTICS (Cont.)

At TA = –40°C to +85°C, fS = 40kHz, V

PARAMETER CONDITIONS MIN TYP MAX MIN TYP MAX UNITS

AC ACCURACY

Spurious-Free Dynamic Range f

Total Harmonic Distortion f

Signal-to-(Noise + Distortion) f

Signal-to-Noise f

Usable Bandwidth

(7)

Full-Power Bandwidth (–3dB) 600 ✻ kHz

SAMPLING DYNAMICS

Aperture Delay 40 ✻ ns

Aperture Jitter 20 ✻ ps

Transient Response FS Step 5 ✻ µs

Over-Voltage Recovery

(8)

REFERENCE

Internal Reference Voltage No Load 2.48 2.5 2.52 ✻✻✻ V

Internal Reference Source Current 1 ✻ µA

(Must use external buffer.)

Internal Reference Drift 8 ✻ ppm/°C

External Reference Voltage Range 2.3 2.5 2.7 ✻✻ ✻ V

for Specified Linearity

External Reference Current Drain External 2.5000V Ref 100 ✻ µA

DIGITAL INPUTS

Logic Levels

V

IL

(9)

V

IH

I

IL

I

IH

DIGITAL OUTPUTS Parallel 16 bits in 2-bytes; Serial

Data Format Binary Two’s Complement or Straight Binary

Data Coding

V

OL

V

OH

Leakage Current High-Z State, ±5 ✻ µA

Output Capacitance High-Z State 15 ✻ pF

DIGITAL TIMING

Bus Access Time R

Bus Relinquish Time R

POWER SUPPLIES

Specified Performance

V

DIG

V

ANA

I

DIG

I

ANA

Power Dissipation V

TEMPERATURE RANGE

Specified Performance –40 +85 ✻✻ °C

Derated Performance –55 +125 ✻✻ °C

Storage –65 +150 ✻✻ °C

Thermal Resistance (

DIP 75 ✻ °C/W

θ

)

JA

SO 75 ✻ °C/W

✻ Same specifications as ADS7807P, U.

NOTES: (1) LSB means Least Significant Bit. One LSB for the ±10V input range is 305µV. (2) Typical rms noise at worst-case transition. (3) As measured with

fixed resistors, see Figure 7b. Adjustable to zero with external potentiometer. (4) Full-scale error is the worst case of –Full-Scale or +Full-Scale untrimmed deviation

from ideal first and last code transitions, divided by the transition voltage (not divided by the full-scale range) and includes the effect of offset error. (5) This is the

time delay after the ADS7807 is brought out of Power-Down mode until all internal settling occurs and the analog input is acquired to rated accuracy. A Convert

command after this delay will yield accurate results. (6) All specifications in dB are referred to a full-scale input. (7) Usable bandwidth defined as full-scale input

frequency at which Signal-to-(Noise + Distortion) degrades to 60dB. (8) Recovers to specified performance after 2 • FS input overvoltage. (9) The minimum V

level for the DATACLK signal is 3V.

= V

DIG

= +5V, and using internal reference and fixed resistors (see Figure 7b), unless otherwise specified.

ANA

ADS7807P, U ADS7807PB, UB

= 1kHz, ±10V 90 100 96 ✻ dB

IN

= 1kHz, ±10V –100 –90 ✻ –96 dB

IN

= 1kHz, ±10V 83 88 86 ✻ dB

IN

–60dB Input 30 32 dB

= 1kHz, ±10V 83 88 86 ✻ dB

IN

130 ✻ kHz

750 ✻ ns

–0.3 +0.8 ✻✻V

+2.0 VD + 0.3V ✻✻V

VIL = 0V ±10 ✻ µA

VIH = 5V ±10 ✻ µA

I

= 1.6mA +0.4 ✻ V

SINK

I

= 500µA+4 ✻ V

SOURCE

V

= 0V to V

OUT

= 3.3kΩ, CL = 50pF 83 ✻ ns

L

= 3.3kΩ, CL = 10pF 83 ✻ ns

L

Must be ≤ V

ANA

DIG

+4.75 +5 +5.25 ✻✻✻ V

+4.75 +5 +5.25 ✻✻✻ V

0.6 ✻ mA

5.0 ✻ mA

= V

ANA

= 5V, fS = 40kHz 28 35 ✻✻mW

DIG

REFD HIGH 23 ✻ mW

PWRD and REFD HIGH 50 ✻ µW

(6)

IH

ADS7807

SBAS022B

www.ti.com

3

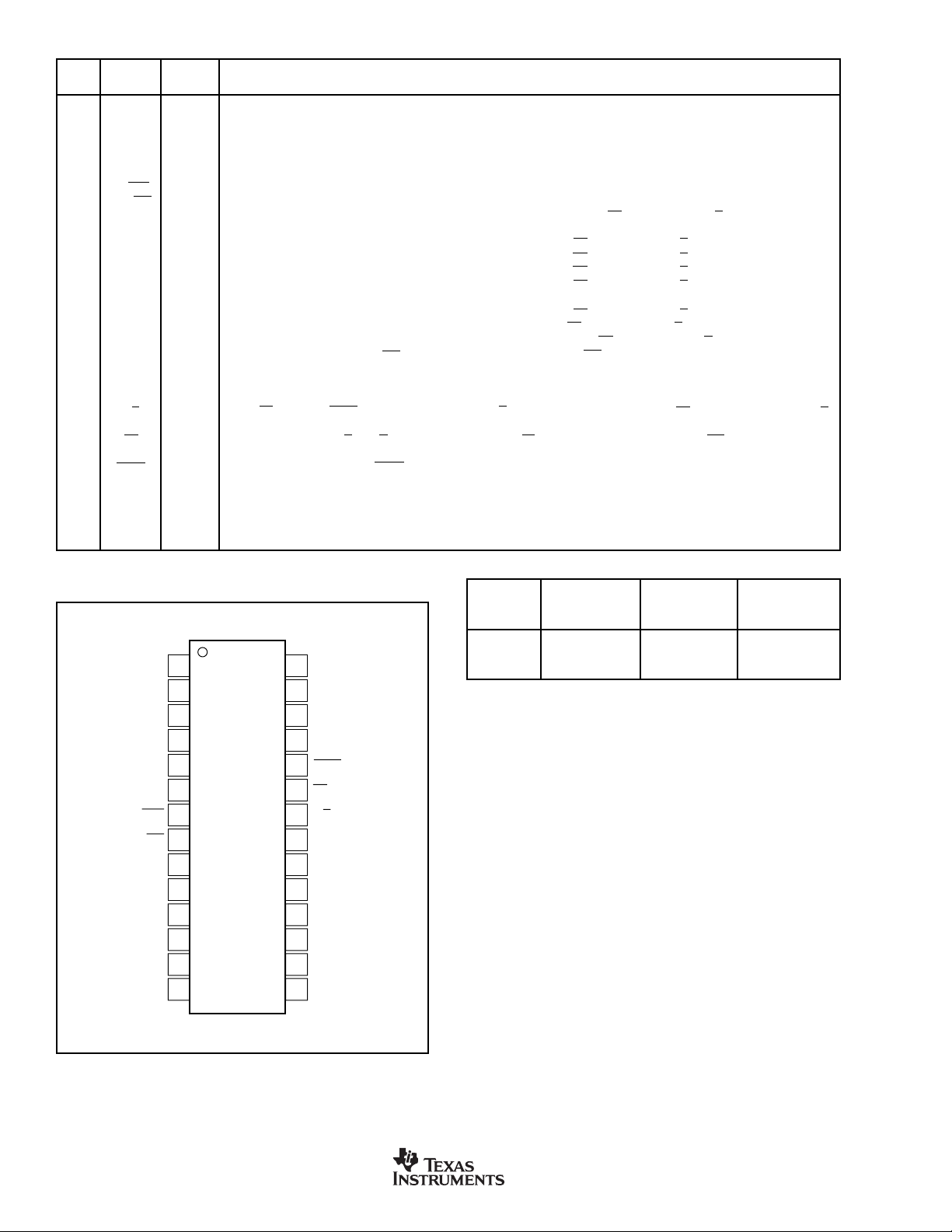

PIN DESCRIPTIONS

ANA

DIG

DIGITAL

IN

IN

Analog Input. See Figure 7.

Analog Input. See Figure 7.

unconnected when using serial output.

enables the parallel output.

falling edge will start the transmission of serial data results from the previous conversion.

have been updated.

Analog Supply. Nominally +5V. Decouple with 0.1µF ceramic and 10µF tantalum capacitors.

Digital Supply. Nominally +5V. Connect directly to pin 27. Must be ≤ V

ANA

.

PIN # NAME I/O DESCRIPTION

1R1

2 AGND1 Analog Sense Ground.

3R2

4 CAP Reference Buffer Output. 2.2µF tantalum capacitor to ground.

5 REF Reference Input/Output. 2.2µF tantalum capacitor to ground.

6 AGND2 Analog Ground

7 SB/BTC I Selects Straight Binary or Binary Two’s Complement for Output Data Format.

8 EXT/INT I External/Internal data clock select.

9 D7 O Data Bit 7 if BYTE is HIGH. Data bit 15 (MSB) if BYTE is LOW. Hi-Z when CS is HIGH and/or R/C is LOW. Leave

10 D6 O Data Bit 6 if BYTE is HIGH. Data bit 14 if BYTE is LOW. Hi-Z when CS is HIGH and/or R/C is LOW.

11 D5 O Data Bit 5 if BYTE is HIGH. Data bit 13 if BYTE is LOW. Hi-Z when CS is HIGH and/or R/C is LOW.

12 D4 O Data Bit 4 if BYTE is HIGH. Data bit 12 if BYTE is LOW. Hi-Z when CS is HIGH and/or R/C is LOW.

13 D3 O Data Bit 3 if BYTE is HIGH. Data bit 11 if BYTE is LOW. Hi-Z when CS is HIGH and/or R/C is LOW.

14 DGND Digital Ground

15 D2 O Data Bit 2 if BYTE is HIGH. Data bit 10 if BYTE is LOW. Hi-Z when CS is HIGH and/or R/C is LOW.

16 D1 O Data Bit 1 if BYTE is HIGH. Data bit 9 if BYTE is LOW. Hi-Z when CS is HIGH and/or R/C is LOW.

17 D0 O Data Bit 0 (LSB) if BYTE is HIGH. Data bit 8 if BYTE is LOW. Hi-Z when CS is HIGH and/or R/C is LOW.

18 DATACLK I/O Data Clock Output when EXT/INT is LOW. Data clock input when EXT/INT is HIGH.

19 SDATA O Serial Output Synchronized to DATACLK

20 TAG I Serial Input When Using an External Data Clock

21 BYTE I Selects 8 most significant bits (LOW) or 8 least significant bits (HIGH) on parallel output pins.

22 R/C I With CS LOW and BUSY HIGH, a Falling Edge on R/C Initiates a New Conversion. With CS LOW, a rising edge on R/C

23 CS I Internally OR’d with R/C. If R/C is LOW, a falling edge on CS initiates a new conversion. If EXT/INT is LOW, this same

24 BUSY O At the start of a conversion, BUSY goes LOW and stays LOW until the conversion is completed and the digital outputs

25 PWRD I PWRD HIGH shuts down all analog circuitry except the reference. Digital circuitry remains active.

26 REFD I REFD HIGH shuts down the internal reference. External reference will be required for conversions.

27 V

28 V

PIN CONFIGURATION

Top View DIP, SO

R1

AGND1

R2

CAP

REF

AGND2

SB/BTC

EXT/INT

D7

D6

D5

D4

D3

DGND

1

IN

2

3

IN

4

5

6

7

ADS7807

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

V

DIG

V

ANA

REFD

PWRD

BUSY

CS

R/C

BYTE

TAG

SDATA

DATACLK

D0

D1

D2

ANALOG CONNECT R1INCONNECT R2

INPUT VIA 200Ω VIA 100Ω

IN

RANGE TO TO IMPEDANCE

±10V V

0V to 5V AGND V

0V to 4V V

IN

IN

CAP 45.7kΩ

IN

V

IN

20.0kΩ

21.4kΩ

TABLE I. Input Range Connections. See Figure 7.

4

www.ti.com

ADS7807

SBAS022B

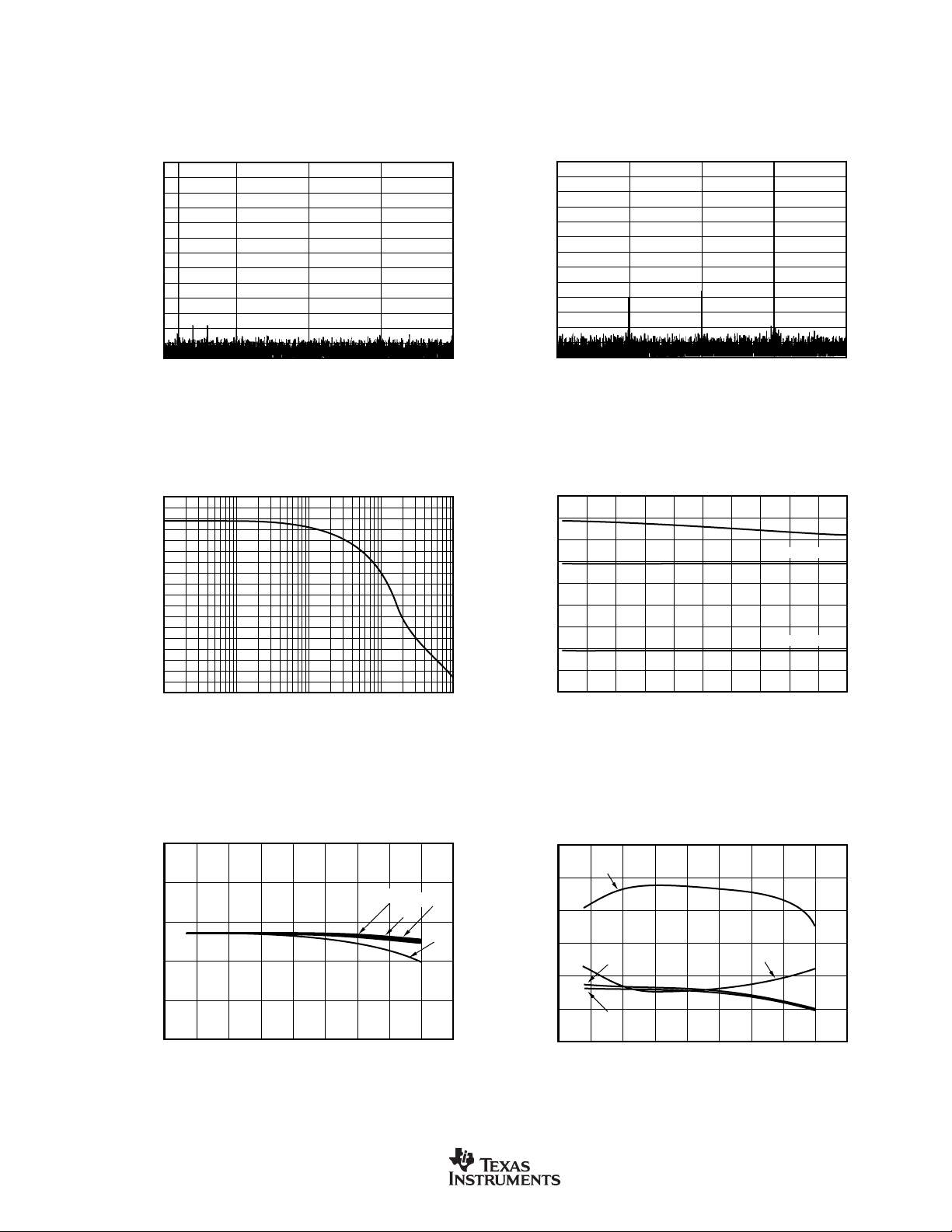

TYPICAL CHARACTERISTICS

SIGNAL-TO-(NOISE + DISTORTION)

vs INPUT FREQUENCY AND INPUT AMPLITUDE

Input Signal Frequency (kHz)

02468101214161820

100

80

90

70

60

50

40

30

20

10

SINAD (dB)

0dB

–20dB

–60dB

AC PARAMETERS vs TEMPERATURE

(f

IN

= 1kHz, 0dB)

SFDR

THD

Temperature (°C)

–75 –50 –25 0 25 50 75 100 125 150

110

105

100

95

90

85

80

–80

–85

–90

–95

–100

–105

–110

SFDR, SINAD, and SNR (dB)

THD (dB)

SNR

SINAD

At TA = +25°C, fS = 40kHz, V

DIG

= V

= +5V, and using internal reference and fixed resistors (see Figure 7b), unless otherwise specified.

ANA

FREQUENCY SPECTRUM

0

–10

–20

–30

–40

–50

–60

–70

–80

Amplitude (dB)

–90

–100

–110

–120

–130

0 5 10 15 20

100

90

80

70

60

50

SINAD (dB)

40

30

20

10

100 1k 10k 100k 1M

(8192 Point FFT; f

Frequency (kHz)

SIGNAL-TO-(NOISE + DISTORTION)

vs INPUT FREQUENCY (f

Input Signal Frequency (Hz)

= 1kHz, 0dB)

IN

= 0dB)

IN

FREQUENCY SPECTRUM

0

–10

–20

–30

–40

–50

–60

–70

–80

Amplitude (dB)

–90

–100

–110

–120

–130

0 5 10 15 20

(8192 Point FFT; f

Frequency (kHz)

= 15kHz, 0dB)

IN

SIGNAL-TO-(NOISE + DISTORTION) vs TEMPERATURE

100

95

90

85

SINAD (dB)

80

75

–75 –50 –25 0 25 50 75 100 125 150

ADS7807

SBAS022B

(f

= 1kHz, 0dB; fS = 10kHz to 40kHz)

IN

Temperature (°C)

10kHz

20kHz

30kHz

40kHz

www.ti.com

5

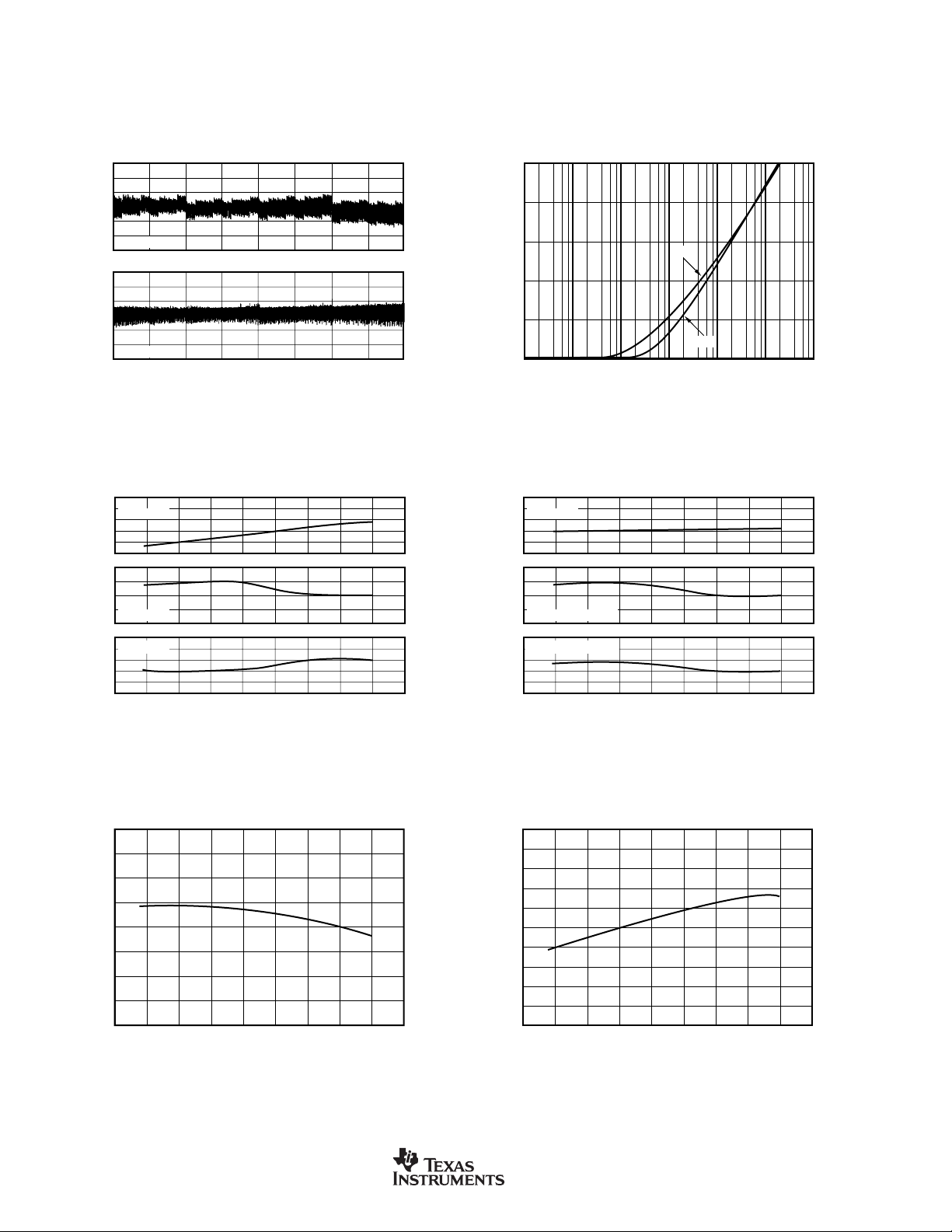

TYPICAL CHARACTERISTICS (Cont.)

At TA = +25°C, fS = 40kHz, V

3

2

1

0

–1

16-Bit (LSBs)16-Bit (LSBs)

–2

All Codes INL

–3

3

2

1

0

–1

–2

All Codes DNL

–3

0 8192 16384 24576 32768

DIG

= V

= +5V, and using internal reference and fixed resistors (see Figure 7b), unless otherwise specified.

ANA

40960 49152 57344 65535

Decimal Code

POWER-SUPPLY RIPPLE SENSITIVITY

INL/DNL DEGRADATION PER LSB OF P-P RIPPLE

1

–1

10

–2

10

–3

10

–4

10

Linearity Degradation (LSB/LSB)

–5

10

1

10

2

10

3

10

Power-Supply Ripple Frequency (Hz)

INL

DNL

4

10

5

10

6

10

7

10

3

2

BPZ Error

1

0

–1

–2

mV From Ideal

0.20

0

ENDPOINT ERRORS (20V Bipolar Range)

Percent

From Ideal

–0.20

0.20

+F

–F

Error

S

Error

S

0

Percent

From Ideal

–0.20

–75 –50 –25 0 25

50 75 100 125 150

Temperature (°C)

INTERNAL REFERENCE VOLTAGE vs TEMPERATURE

2.520

2.515

2.510

2.505

2.500

2.495

Internal Reference (V)

2.490

2.485

2.480

–75 –50 –25 0 25 50 75 100 125 150

Temperature (°C)

3

2

UPO Error

1

0

–1

–2

mV From Ideal

0.40

0.20

ENDPOINT ERRORS (Unipolar Ranges)

Percent

Percent

+F

From Ideal

0.40

0.20

From Ideal

Error (4V Range)

S

0

–F

Error (5V Range)

S

0

–75 –50 –25 0 25

50 75 100 125 150

Temperature (°C)

CONVERSION TIME vs TEMPERATURE

19.4

19.2

19

18.8

Conversion Time (µs)

18.6

–75 –50 –25 0 25 50 75 100 125 150

Temperature (°C)

6

www.ti.com

ADS7807

SBAS022B

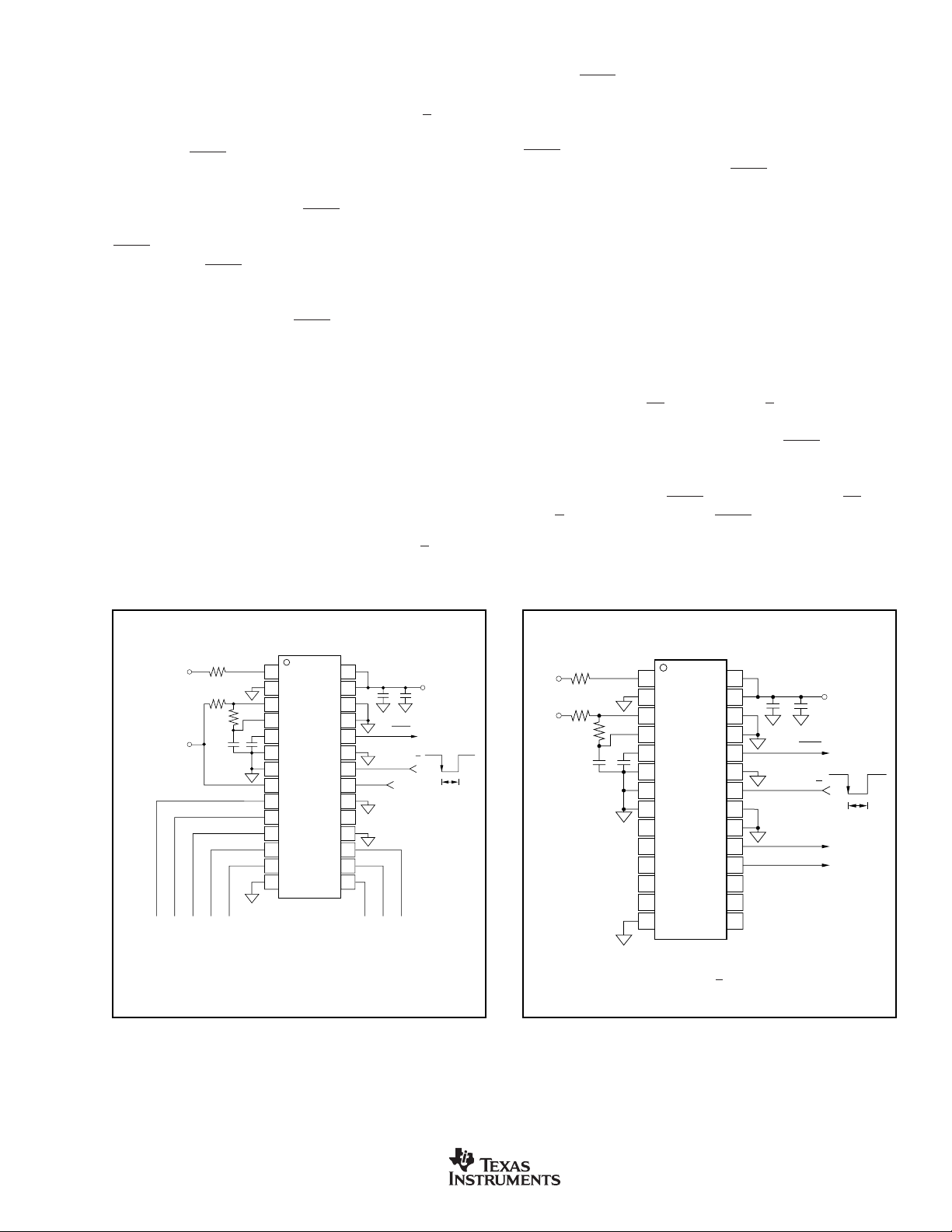

BASIC OPERATION

PARALLEL OUTPUT

Figure 1a shows a basic circuit to operate the ADS7807 with

a ±10V input range and parallel output. Taking

LOW for a minimum of 40ns (12µs max) will initiate a

conversion.

BUSY

(pin 24) will go LOW and stay LOW until

the conversion is completed and the output register is updated. If BYTE (pin 21) is LOW, the eight Most Significant

Bits (MSBs) will be valid when

BUSY

rises; if BYTE is HIGH,

the eight Least Significant Bits (LSBs) will be valid when

BUSY

rises. Data will be output in Binary Two’s Complement

(BTC) format.

BUSY

going HIGH can be used to latch the

data. After the first byte has been read, BYTE can be toggled

allowing the remaining byte to be read. All convert commands will be ignored while

BUSY

is LOW.

The ADS7807 will begin tracking the input signal at the end

of the conversion. Allowing 25µs between convert commands assures accurate acquisition of a new signal.

The offset and gain are adjusted internally to allow external

trimming with a single supply. The external resistors compensate for this adjustment and can be left out if the offset and gain

will be corrected in software (refer to the Calibration section).

SERIAL OUTPUT

Figure 1b shows a basic circuit to operate the ADS7807 with

a ±10V input range and serial output. Taking

LOW for 40ns (12µs max) will initiate a conversion and

R/C

R/C

(pin 22)

(pin 22)

output valid data from the previous conversion on SDATA

(pin 19) synchronized to 16 clock pulses output on DATACLK

(pin 18).

BUSY

(pin 24) will go LOW and stay LOW until the

conversion is completed and the serial data has been transmitted. Data will be output in BTC format, MSB first, and will

be valid on both the rising and falling edges of the data clock.

BUSY

going HIGH can be used to latch the data. All convert

commands will be ignored while

BUSY

is LOW.

The ADS7807 will begin tracking the input signal at the end

of the conversion. Allowing 25µs between convert commands assures accurate acquisition of a new signal.

The offset and gain are adjusted internally to allow external

trimming with a single supply. The external resistors compensate for this adjustment and can be left out if the offset and

gain will be corrected in software (refer to the Calibration

section).

STARTING A CONVERSION

The combination of CS (pin 23) and

minimum of 40ns puts the sample-and-hold of the ADS7807

in the hold state and starts conversion ‘n’.

go LOW and stay LOW until conversion ‘n’ is completed and

the internal output register has been updated. All new convert commands during

or

R/C

must go HIGH before

BUSY

LOW will be ignored. CS and/

conversion will be initiated without sufficient time to acquire

a new signal.

R/C

(pin 22) LOW for a

BUSY

BUSY

goes HIGH, or a new

(pin 24) will

Parallel Output

200Ω

Pin 21

LOW

HIGH

±10V

+5V

B14 B11

(MSB)

B6 B3

66.5kΩ

2.2µF

B13 B12B15

B5 B4B7Pin 21

100Ω

2.2µF

++

1

2

3

4

5

6

7

ADS7807

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

B10 B9 B8

0.1µF

+

BUSY

BYTE

(1)

NC

B2 B1 B0

(LSB)

10µF

+

R/C

+5V

Convert Pulse

40ns min

NOTE: (1) SDATA (pin 19) is always active.

FIGURE 1a. Basic ±10V Operation, both Parallel and Serial

Output.

Serial Output

200Ω

±10V

+5V

66.5kΩ

2.2µF

100Ω

2.2µF

++

(1)

NC

(1)

NC

(1)

NC

(1)

NC

(1)

NC

1

2

3

4

5

6

7

ADS7807

8

9

10

11

12

13

14

28

0.1µF

10µF

27

+

26

25

24

23

22

21

20

19

18

17

16

15

DATACLK

(1)

NC

(1)

NC

(1)

NC

+

BUSY

SDATA

+5V

Convert Pulse

R/C

40ns min

NOTE: (1) These pins should be left unconnected.

They will be active when

R/C

is HIGH.

FIGURE 1b. Basic ±10V Operation with Serial Output.

ADS7807

SBAS022B

www.ti.com

7

The ADS7807 will begin tracking the input signal at the end

of the conversion. Allowing 25µs between convert commands assures accurate acquisition of a new signal. Refer to

Tables II and III for a summary of

CS, R/C

, and

BUSY

states,

and Figures 2 through 6 for timing diagrams.

CS R/C BUSY OPERATION

1 X X None. Databus is in Hi-Z state.

↓ 0 1 Initiates conversion ‘n’. Databus remains

0 ↓ 1 Initiates conversion ‘n’. Databus enters Hi-Z

01↑ Conversion ‘n’ completed. Valid data from

↓ 1 1 Enables databus with valid data from

↓ 1 0 Enables databus with valid data from

0 ↑ 0 Enables databus with valid data from

00↑ New conversion initiated without acquisition

X X 0 New convert commands ignored. Conversion

NOTE: (1) See Figures 2 and 3 for constraints on data valid from

conversion ‘n – 1’.

in Hi-Z state.

state.

conversion ‘n’ on the databus.

conversion ‘n’.

conversion ‘n – 1’

conversion ‘n – 1’

of a new signal. Data will be invalid. CS and/or

R/C must be HIGH when BUSY goes HIGH.

‘n’ in progress.

(1)

. Conversion n in progress.

(1)

. Conversion ‘n’ in progress.

TABLE III. Control Functions When Using Parallel Output

(DATACLK tied LOW,

EXT/INT

tied HIGH).

CS

and

R/C

are internally OR’ed and level triggered. There

is not a requirement which input goes LOW first when

initiating a conversion. If, however, it is critical that

CS

or

R/C

initiates conversion ‘n’, be sure the less critical input is LOW

at least 10ns prior to the initiating input. If

EXT/INT

(pin 8) is

LOW when initiating conversion ‘n’, serial data from conversion ‘n – 1’ will be output on SDATA (pin 19) following the

start of conversion ‘n’. See Internal Data Clock in the Reading Data section.

To reduce the number of control pins,

using

R/C

to control the read and convert modes. This will

CS

can be tied LOW

have no effect when using the internal data clock in the serial

output mode. The parallel output and the serial output (only

when using an external data clock), however, will be affected

whenever

R/C

goes HIGH. Refer to the Reading Data

section.

READING DATA

The ADS7807 outputs serial or parallel data in Straight Binary

(SB) or Binary Two’s Complement data output format. If

SB/BTC

if LOW, the output will be in BTC format. Refer to Table IV for

ideal output codes.

The parallel output can be read without affecting the internal

output registers; however, reading the data through the serial

port will shift the internal output registers one bit per data

(pin 7) is HIGH, the output will be in SB format, and

CS R/C BUSY EXT/INT DATACLK OPERATION

↓ 0 1 0 Output Initiates conversion ‘n’. Valid data from conversion ‘n – 1’ clocked out on SDATA.

0 ↓ 1 0 Output Initiates conversion ‘n’. Valid data from conversion ‘n – 1’ clocked out on SDATA.

↓ 0 1 1 Input Initiates conversion ‘n’. Internal clock still runs conversion process.

0 ↓ 1 1 Input Initiates conversion ‘n’. Internal clock still runs conversion process.

↓ 1 1 1 Input Conversion ‘n’ completed. Valid data from conversion ‘n’ clocked out on SDATA synchronized

↓ 1 0 1 Input Valid data from conversion ‘n – 1’ output on SDATA synchronized to external data clock.

0 ↑ 0 1 Input Valid data from conversion ‘n – 1’ output on SDATA synchronized to external data clock.

00↑ X X New conversion initiated without acquisition of a new signal. Data will be invalid. CS and/or R/C

X X 0 X X New convert commands ignored. Conversion ‘n’ in progress.

NOTE: (1) See Figures 4, 5, and 6 for constraints on data valid from conversion “n-1”.

to external data clock.

Conversion ‘n’ in progress.

Conversion ‘n’ in progress.

must be HIGH when BUSY goes HIGH.

TABLE III. Control Functions When Using Serial Output.

DESCRIPTION ANALOG INPUT

Full-Scale Range ±10 0V to 5V 0V to 4V

Least Significant Bit (LSB) 305µV76µV61µV

+Full-Scale (FS – 1LSB) 9.999695V 4.999924V 3.999939V 0111 1111 1111 1111 7FFF 1111 1111 1111 1111 FFFF

Midscale 0V 2.5V 2V 0000 0000 0000 0000 0000 1000 0000 0000 0000 8000

One LSB Below Midscale –305µV 2.499924V 1.999939V 1111 1111 1111 1111 FFFF 0111 1111 1111 1111 7FFF

–Full-Scale –10V 0V 0V 1000 0000 0000 0000 8000 0000 0000 0000 0000 0000

BINARY TWO’S COMPLEMENT STRAIGHT BINARY

(SB/BTC LOW) (SB/BTC HIGH)

BINARY CODE CODE BINARY CODE CODE

DIGITAL OUTPUT

HEX HEX

TABLE IV. Output Codes and Ideal Input Voltages.

8

www.ti.com

ADS7807

SBAS022B

clock pulse. As a result, data can be read on the parallel port

prior to reading the same data on the serial port, but data

cannot be read through the serial port prior to reading the

same data on the parallel port.

PARALLEL OUTPUT

To use the parallel output, tie

DATACLK (pin 18) LOW. SDATA (pin 19) should be left

unconnected. The parallel output will be active when

22) is HIGH and

of

CS

and

CS

(pin 23) is LOW. Any other combination

R/C

will tri-state the parallel output. Valid conversion data can be read in two 8-bit bytes on D7-D0 (pins 9-13

and 15-17). When BYTE (pin 21) is LOW, the 8 most significant bits will be valid with the MSB on D7. When BYTE is

HIGH, the 8 least significant bits will be valid with the LSB on

D0. BYTE can be toggled to read both bytes within one

conversion cycle.

Upon initial power up, the parallel output will contain indeterminate data.

EXT/INT

(pin 8) HIGH and

R/C

(pin

PARALLEL OUTPUT (AFTER A CONVERSION)

After conversion ‘n’ is completed and the output registers

have been updated,

BUSY

(pin 24) will go HIGH. Valid data

from conversion ‘n’ will be available on D7-D0 (pins 9-13 and

15-17).

BUSY

going high can be used to latch the data. Refer

to Table V and Figures 2 and 3 for timing constraints.

PARALLEL OUTPUT (DURING A CONVERSION)

After conversion ‘n’ has been initiated, valid data from conversion ‘n – 1’ can be read and will be valid up to 12µs after

the start of conversion ‘n’. Do not attempt to read data

beyond 12µs after the start of conversion ‘n’ until

24) goes HIGH; this may result in reading invalid data. Refer

to Table V and Figures 2 and 3 for timing constraints.

BUSY

(pin

t

1

R/C

t

BUSY

MODE

Parallel

Data Bus

BYTE

Acquire

Previous

High Byte Valid

3

t

6

Convert

t

12

t

11

Hi-Z Not Valid

t

9

Previous High

Byte Valid

t

4

t

7

Previous Low

Byte Valid

t

2

t

12

t

5

t

10

High Byte

Valid

t

12

FIGURE 2. Conversion Timing with Parallel Output (CS and DATACLK tied LOW,

R/C

CS

t

21

t

1

t

21

t

21

t

21

t

1

t

3

t

t

8

Acquire Convert

Low Byte

Valid

t

12

EXT/INT

t

21

tied HIGH).

6

t

Hi-Z

t

9

t

21

High Byte

t

12

Valid

12

BUSY

BYTE

DATA

BUS

FIGURE 3. Using

ADS7807

SBAS022B

t

3

CS

to Control Conversion and Read Timing with Parallel Outputs.

t

4

Hi-Z State

t

21

High Byte

t

12

www.ti.com

t

21

Hi-Z State Low Byte Hi-Z State

t

9

t

21

t

12

t

21

t

9

9

SYMBOL DESCRIPTION MIN TYP MAX UNITS

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t

t7 + t

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

17

18

19

20

21

22

8

Convert Pulse Width 0.04 12 µs

Data Valid Delay after

BUSY

Delay from 85 ns

Start of Conversion

Bus Relinquish Time 10 83 ns

BUSY

Previous Data Valid 12 19 µs

after Start of Conversion

Bus Access Time and BYTE Delay 83 ns

Start of Conversion 1.4 µs

to DATACLK Delay

Data Valid to DATACLK 20 75 ns

Data Valid after DATACLK 400 600 ns

External DATACLK Period 100 ns

External DATACLK LOW 40 ns

External DATACLK HIGH 50 ns

CS

DATACLK Setup Time

R/C

Valid Data after DATACLK HIGH 25 ns

LOW 19 20 µs

BUSY

BUSY

Delay after 90 ns

End of Conversion

Aperture Delay 40 ns

Conversion Time 19 20 µs

Acquisition Time 5 µs

Delay after Data Valid 20 60 ns

DATACLK Period 1.1 µs

HIGH Delay

LOW Delay

and

to External 25 ns

R/C

to CS Setup Time 10 ns

Throughput Time 25 µs

LOW 19 20 µs

R/C

TABLE VI. Conversion and Data Timing. TA = –40°C to +85°C.

SERIAL OUTPUT

Data can be clocked out with the internal data clock or an

external data clock. When using serial output, be careful with

the parallel outputs, D7-D0 (pins 9-13 and 15-17), as these

pins will come out of Hi-Z state whenever

and

R/C

(pin 22) is HIGH. The serial output can not be tristated and is always active. Refer to the Applications Information section for specific serial interfaces.

CS

(pin 23) is LOW

INTERNAL DATA CLOCK

(During a Conversion)

To use the internal data clock, tie

combination of

R/C

(pin 22) and CS (pin 23) LOW will initiate

conversion ‘n’ and activate the internal data clock (typically

900kHz clock rate). The ADS7807 will output 16 bits of valid

data, MSB first, from conversion ‘n-1’ on SDATA (pin 19),

synchronized to 16 clock pulses output on DATACLK (pin 18).

The data will be valid on both the rising and falling edges of the

internal data clock. The rising edge of

used to latch the data. After the 16th clock pulse, DATACLK will

remain LOW until the next conversion is initiated, while SDATA

will go to whatever logic level was input on TAG (pin 20) during

the first clock pulse. Refer to Table VI and Figure 4.

EXT/INT

BUSY

(pin 8) LOW. The

(pin 24) can be

EXTERNAL DATA CLOCK

To use an external data clock, tie

external data clock is not a conversion clock; it can only be

used as a data clock. To enable the output mode of the

ADS7807,

CS

(pin 23) must be LOW and

be HIGH. DATACLK must be HIGH for 20% to 70% of the

total data clock period; the clock rate can be between DC and

10MHz. Serial data from conversion ‘n’ can be output on

SDATA (pin 19) after conversion ‘n’ is completed or during

conversion ‘n + 1’.

An obvious way to simplify control of the converter is to tie

CS

LOW and use

R/C

to initiate conversions.

While this is perfectly acceptable, there is a possible problem

when using an external data clock. At an indeterminate point

from 12µs after the start of conversion ‘n’ until

the internal logic will shift the results of conversion ‘n’ into the

output register. If

CS

is LOW,

clock is HIGH at this point, data will be lost. So, with

LOW, either

R/C

and/or DATACLK must be LOW during this

period to avoid losing valid data.

EXT/INT

(pin 8) HIGH. The

R/C

(pin 22) must

BUSY

R/C

HIGH, and the external

rises,

CS

t

+ t

7

(1)

CS or R/C

t

14

1

t

DATACLK

SDATA

BUSY

NOTE: (1) If controlling with CS, tie

If controlling with

13

t

15

MSB Valid

(Results from previous conversion.)

, tie CS LOW. Data bus pins will be active when

R/C

2 3 15 16

t

16

Bit 14 Valid Bit 1 ValidBit 13 Valid LSB Valid

LOW. Data bus pins will remain Hi-Z at all times.

R/C

8

is HIGH, and should be left unconnected.

R/C

FIGURE 4. Serial Data Timing Using Internal Data Clock (TAG tied LOW).

10

www.ti.com

1

MSB Valid

2

Bit 14 Valid

ADS7807

SBAS022B

20

t

Tag 1

Tag 0

Tag 17 Tag 18

Bit 0 (LSB)

Bit 14 Bit 1

22

t

20

1 2 3 4 16 17 18

19

t

17

t

18

t

0

t

21

t

Bit 15 (MSB)

Tag 1 Tag 2 Tag 15 Tag 16

Tag 0

1

t

DATACLK

EXTERNAL

CS

21

t

R/C

FIGURE 5. Conversion and Read Timing with External Clock (

ADS7807

SBAS022B

www.ti.com

3

t

BUSY

EXT/INT

SDATA

TAG

Tied HIGH) Read after Conversion.

11

EXTERNAL

DATACLK

t

17

t

18t19

t

20

CS

R/C

BUSY

DATA

TAG

t

21

t

1

t

3

Tag 0

t

22

t

20

Bit 15 (MSB)

Tag 1 Tag 16

FIGURE 6. Conversion and Read Timing with External Clock (

EXTERNAL DATA CLOCK

(After a Conversion)

After conversion ‘n’ is completed and the output registers

have been updated,

LOW and

R/C

BUSY

(pin 24) will go HIGH. With

CS

HIGH, valid data from conversion ‘n’ will be

output on SDATA (pin 19) synchronized to the external data

clock input on DATACLK (pin 18). The MSB will be valid on

the first falling edge and the second rising edge of the

external data clock. The LSB will be valid on the 16th falling

edge and 17th rising edge of the data clock. TAG (pin 20) will

input a bit of data for every external clock pulse. The first bit

input on TAG will be valid on SDATA on the 17th falling edge

and the 18th rising edge of DATACLK; the second input bit

will be valid on the 18th falling edge and the 19th rising edge,

etc. With a continuous data clock, TAG data will be output on

SDATA until the internal output registers are updated with

the results from the next conversion. Refer to Table VI and

Figure 5.

EXTERNAL DATA CLOCK

(During a Conversion)

After conversion ‘n’ has been initiated, valid data from conversion ‘n – 1’ can be read and will be valid up to 12µs after

the start of conversion ‘n’. Do not attempt to clock out data

from 12µs after the start of conversion ‘n’ until

rises; this will result in data loss. NOTE: For the best possible

performance when using an external data clock, data should

not be clocked out during a conversion. The switching noise

of the asynchronous data clock can cause digital feedthrough

degrading the converter’s performance. Refer to Table V and

Figure 6.

BUSY

(pin 24)

t

11

EXT/INT

Bit 0 (LSB)

tied HIGH) Read During a Conversion.

Tag 0

Tag 17 Tag 18

Tag 1

TAG FEATURE

TAG (pin 20) inputs serial data synchronized to the external

or internal data clock.

When using an external data clock, the serial bit stream input

on TAG will follow the LSB output on SDATA until the internal

output register is updated with new conversion results. See

Table V and Figures 5 and 6.

The logic level input on TAG for the first rising edge of the

internal data clock will be valid on SDATA after all 16 bits of

valid data have been output.

INPUT RANGES

The ADS7807 offers three input ranges: standard ±10V and

0V-5V, and a 0V-4V range for complete, single-supply systems. See Figures 7a and 7b for the necessary circuit

connections for implementing each input range and optional

offset and gain adjust circuitry. Offset and full-scale error

specifications are tested with the fixed resistors, see Figure

7b. Adjustments for offset and gain are described in the

Calibration section of this data sheet.

The offset and gain are adjusted internally to allow external

trimming with a single supply. The external resistors compensate for this adjustment and can be left out if the offset and

gain will be corrected in software (refer to the Calibration

section).

The input impedance, summarized in Table II, results from

the combination of the internal resistor network (see the front

page of this product data sheet) and the external resistors

NOTE: (1) Full-scale error includes offset and gain errors measured at both

+FS and –FS.

(1)

12

www.ti.com

ADS7807

SBAS022B

used for each input range (see Figure 8). The input resistor

divider network provides inherent over-voltage protection to

at least ±5.5V for R2

and ±12V for R1IN.

IN

Analog inputs above or below the expected range will yield

either positive full-scale or negative full-scale digital outputs,

respectively. Wrapping or folding over for analog inputs

outside the nominal range will not occur.

INPUT RANGE RANGE (mV) RANGE (mV)

OFFSET ADJUST GAIN ADJUST

±10V ±15 ±60

0 to 5V ±4 ±30

0 to 4V ±3 ±30

TABLE VI. Offset and Gain Adjust Ranges for Hardware

Calibration (see Figure 7a).

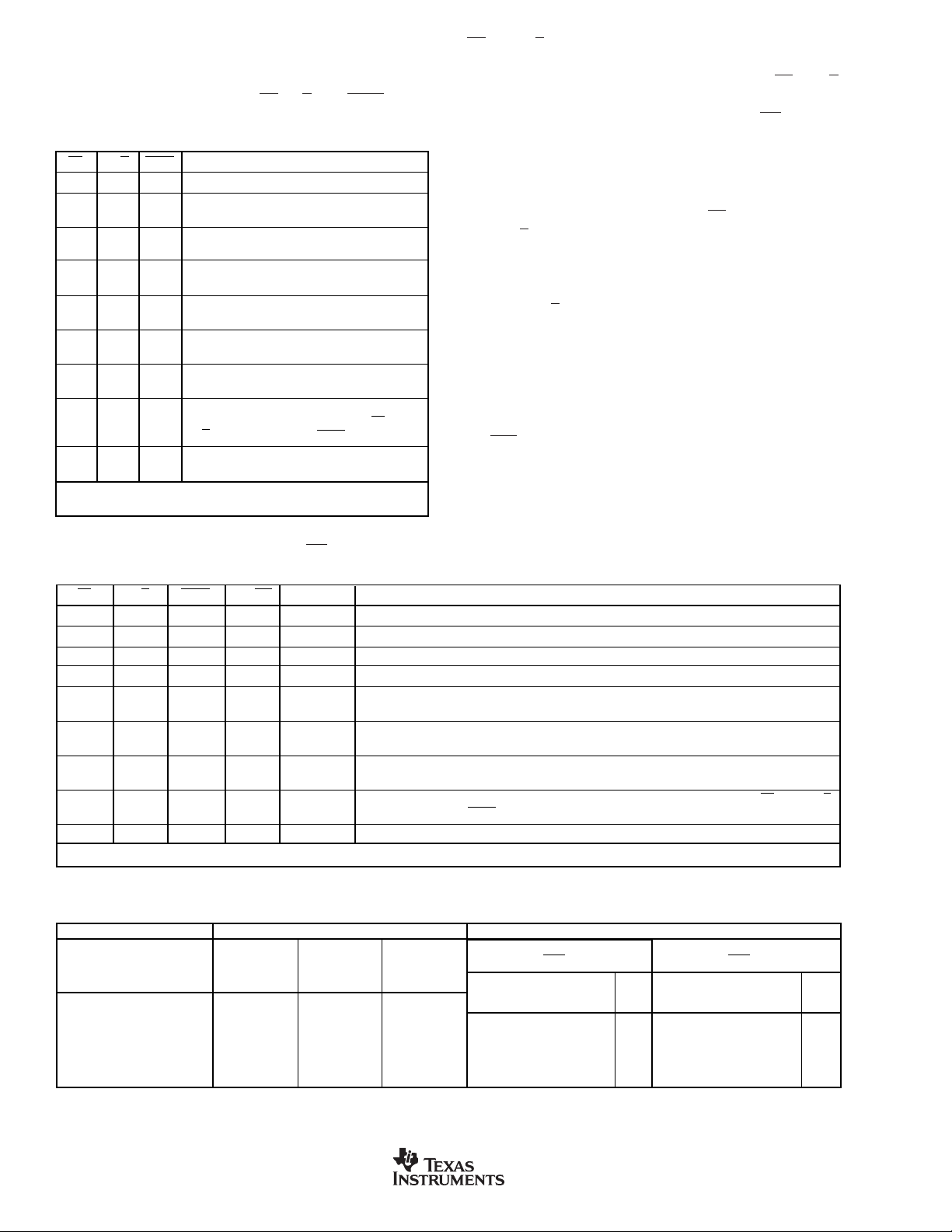

CALIBRATION

HARDWARE CALIBRATION

To calibrate the offset and gain of the ADS7807 in hardware,

install the resistors shown in Figure 7a. Table VI lists the

hardware trim ranges relative to the input for each input

range.

SOFTWARE CALIBRATION

To calibrate the offset and gain in software, no external

resistors are required. However, to get the data sheet specifications for offset and gain, the resistors shown in Figure 7b

±10V 0V-5V 0V-4V

200Ω

33.2kΩ

100Ω

50kΩ

+5V

50kΩ

+5V

1MΩ

V

IN

2.2µF

2.2µF

1

R1

IN

2

AGND1

3

R2

IN

4

CAP

+

5

REF

+

6

AGND2

50kΩ

V

+5V

50kΩ

are necessary. See the No Calibration section for more

details on the external resistors. Refer to Table VIII for the

range of offset and gain errors with and without the external

resistors.

NO CALIBRATION

Figure 7b shows circuit connections. Note that the actual

voltage dropped across the external resistors is at least two

orders of magnitude lower than the voltage dropped across

the internal resistor divider network. This should be consid-

50kΩ

1MΩ

33.2kΩ

200Ω

V

100Ω

2.2µF

2.2µF

IN

200Ω

33.2kΩ

IN

100Ω

1MΩ

2.2µF

2.2µF

1

R1

IN

2

AGND1

3

R2

IN

4

CAP

+

5

REF

+

6

AGND2

+5V

50kΩ

1

R1

IN

2

AGND1

3

R2

IN

4

CAP

+

5

REF

+

6

AGND2

FIGURE 7a. Circuit Diagrams (With Hardware Trim).

±10V 0V-5V 0V-4V

200Ω

1

R1

IN

2

AGND1

3

R2

IN

4

CAP

+

5

REF

+

6

AGND2

V

IN

+5V

66.5kΩ

100Ω

V

IN

2.2µF

2.2µF

FIGURE 7b. Circuit Diagrams (Without Hardware Trim).

ADS7807

SBAS022B

200Ω

33.2kΩ

100Ω

+

2.2µF

+

2.2µF

www.ti.com

1

2

3

4

5

6

R1

IN

AGND1

R2

IN

CAP

REF

AGND2

33.2kΩ

200Ω

V

IN

100Ω

2.2µF

2.2µF

1

R1

IN

2

AGND1

3

R2

IN

4

CAP

+

5

REF

+

6

AGND2

13

ered when choosing the accuracy and drift specifications of

the external resistors. In most applications, 1% metal-film

resistors will be sufficient.

The external resistors, see Figure 7b, may not be necessary

in some applications. These resistors provide compensation

for an internal adjustment of the offset and gain which allows

calibration with a single supply. Not using the external

resistors will result in offset and gain errors in addition to

those listed in the electrical characteristics section. Offset

refers to the equivalent voltage of the digital output when

converting with the input grounded. A positive gain error

To further analyze the effects of removing any combination of

the external resistors, consider Figure 9. The combination of

the external and the internal resistors form a voltage divider

which reduces the input signal to a 0.3125V to 2.8125V input

range at the Capacitor Digital-to-Analog Converter (CDAC).

The internal resistors are laser trimmed to high relative accuracy to meet full scale specifications. The actual input impedance of the internal resistor network looking into pin 1 or pin

3 however, is only accurate to ±20% due to process variations.

This should be taken into account when determining the

effects of removing the external resistors.

occurs when the equivalent output voltage of the digital

output is larger than the analog input. Refer to Table VII for

REFERENCE

nominal ranges of gain and offset errors with and without the

external resistors. Refer to Figure 8 for typical shifts in the

transfer functions which occur when the external resistors

are removed.

OFFSET ERROR GAIN ERROR

INPUT

RANGE (V) RANGE (mV) RANGE (mV) TYP (mV) RANGE (% FS) RANGE (% FS) TYP

±10 –10 ≤ BPZ ≤ 10 0 ≤ BPZ ≤ 35 15 –0.4 ≤ G ≤ 0.4 –0.3 ≤ G ≤ 0.5 +0.05

0 to 5 –3 ≤ UPO ≤ 3 –12 ≤ UPO ≤ –3 –7.5 –0.4 ≤ G ≤ 0.4 –1.0 ≤ G ≤ 0.1 –0.2

0 to 4 –3 ≤ UPO ≤ 3 –10.5 ≤ UPO ≤ –1.5 –6 –0.4 ≤ G ≤ 0.4 –1.0 ≤ G ≤ 0.1 –0.2

NOTE: (1) High Grade.

WITH RESISTORS WITHOUT RESISTORS WITH RESISTORS WITHOUT RESISTORS

The ADS7807 can operate with its internal 2.5V reference or

an external reference. By applying an external reference to

pin 5, the internal reference can be bypassed; REFD (pin 26)

0.15 ≤ G

0.15 ≤ G

–0.15 ≤ G

(1)

≤ 0.15 –0.1 ≤ G

(1)

≤ 0.15 –0.55 ≤ G

(1)

≤ 0.15 –0.55 ≤ G

(1)

≤ 0.2 +0.05

(1)

≤ –0.05 –0.2

(1)

≤ –0.05 –0.2

TABLE VII. Range of Offset and Gain Errors With and Without External Resistors.

(a) Bipolar

+Full-Scale

Digital Output

–Full-Scale

Analog Input

Typical Transfer Functions

With External Resistors

–Full-Scale

(b) Unipolar

Digital Output

+Full-Scale

Analog Input

Typical Transfer Functions

Without External Resistors

FIGURE 8. Typical Transfer Functions With and Without External Resistors.

14

www.ti.com

ADS7807

SBAS022B

V

IN

39.8kΩ200Ω

CDAC

(0.3125V to 2.8125V)

+5V

V

V

66.5kΩ

100Ω

+2.5V

33.2kΩ

100Ω

IN

+2.5V

IN

33.2kΩ

100Ω

+2.5V

9.9kΩ

39.8kΩ200Ω

9.9kΩ

39.8kΩ200Ω

9.9kΩ

20kΩ

20kΩ

20kΩ

FIGURE 9. Circuit Diagrams Showing External and Internal Resistors.

40kΩ

+2.5V

CDAC

(0.3125V to 2.8125V)

40kΩ

+2.5V

CDAC

(0.3125V to 2.8125V)

40kΩ

+2.5V

tied HIGH will power-down the internal reference reducing

the overall power consumption of the ADS7807 by approximately 5mW.

The internal reference has approximately an 8ppm/°C drift

(typical) and accounts for approximately 20% of the full-scale

error (FSE = ±0.5% for low grade, ±0.25% for high grade).

The ADS7807 also has an internal buffer for the reference

voltage. Figure 10 shows characteristic impedances at the

input and output of the buffer with all combinations of powerdown and reference down.

REF

REF (pin 5) is an input for an external reference or the output

for the internal 2.5V reference. A 2.2µF tantalum capacitor

should be connected as close as possible to the REF pin

from ground. This capacitor and the output resistance of REF

create a low-pass filter to bandlimit noise on the reference.

Using a smaller value capacitor will introduce more noise to

the reference, degrading the SNR and SINAD. The REF pin

should not be used to drive external AC or DC loads, as

shown in Figure 10.

The range for the external reference is 2.3V to 2.7V and

determines the actual LSB size. Increasing the reference

voltage will increase the full-scale range and the LSB size of

the converter which can improve the SNR.

Z

CAP

(Pin 4)

REF

(Pin 5)

(Ω) 1 1 200 200

Z

CAP

Z

(Ω) 6k 100M 6k 100M

REF

CAP

CDAC

Buffer

Internal

Z

REF

PWRD 0 PWRD 0 PWRD 1 PWRD 1

REFD 0 REFD 1 REFD 0 REFD 1

Reference

FIGURE 10. Characteristic Impedances of Internal Buffer.

CAP

CAP (pin 4) is the output of the internal reference buffer. A

2.2µF tantalum capacitor should be placed as close as

possible to the CAP pin from ground to provide optimum

switching currents for the CDAC throughout the conversion

ADS7807

SBAS022B

www.ti.com

15

cycle. This capacitor also provides compensation for the

output of the buffer. Using a capacitor any smaller than 1µF

can cause the output buffer to oscillate and may not have

sufficient charge for the CDAC. Capacitor values larger than

2.2µF will have little affect on improving performance. See

Figures 10 and 11.

7000

6000

5000

4000

µs

3000

2000

1000

0

0.1 1 10 100

“CAP” Pin Value (µF)

FIGURE 11. Power-Down to Power-Up Time vs Capacitor

Value on CAP.

The output of the buffer is capable of driving up to 1mA of

current to a DC load. Using an external buffer will allow the

internal reference to be used for larger DC loads and AC

loads. Do not attempt to directly drive an AC load with the

output voltage on CAP. This will cause performance degradation of the converter.

REFERENCE

AND POWER-DOWN

The ADS7807 has analog power-down and reference power

down capabilities via PWRD (pin 25) and REFD (pin 26),

respectively. PWRD and REFD HIGH will power-down all

analog circuitry maintaining data from the previous conversion in the internal registers, provided that the data has not

already been shifted out through the serial port. Typical

power consumption in this mode is 50µW. Power recovery is

typically 1ms, using a 2.2µF capacitor connected to CAP.

Figure 11 shows power-down to power-up recovery time

relative to the capacitor value on CAP. With +5V applied to

V

, the digital circuitry of the ADS7807 remains active at all

DIG

times, regardless of PWRD and REFD states.

PWRD

PWRD HIGH will power-down all of the analog circuitry

except for the reference. Data from the previous conversion

will be maintained in the internal registers and can still be

read. With PWRD HIGH, a convert command yields meaningless data.

REFD

REFD HIGH will power-down the internal 2.5V reference. All

other analog circuitry, including the reference buffer, will be

active. REFD should be HIGH when using an external

reference to minimize power consumption and the loading

effects on the external reference. See Figure 10 for the

characteristic impedance of the reference buffer’s input for

both REFD HIGH and LOW. The internal reference consumes approximately 5mW.

LAYOUT

POWER

For optimum performance, tie the analog and digital power

pins to the same +5V power supply and tie the analog and

digital grounds together. As noted in the electrical characteristics, the ADS7807 uses 90% of its power for the analog

circuitry. The ADS7807 should be considered as an analog

component.

The +5V power for the A/D converter should be separate

from the +5V used for the system’s digital logic. Connecting

V

(pin 28) directly to a digital supply can reduce converter

DIG

performance due to switching noise from the digital logic. For

best performance, the +5V supply can be produced from

whatever analog supply is used for the rest of the analog

signal conditioning. If +12V or +15V supplies are present, a

simple +5V regulator can be used. Although it is not suggested, if the digital supply must be used to power the

converter, be sure to properly filter the supply. Either using a

filtered digital supply or a regulated analog supply, both V

and V

should be tied to the same +5V source.

ANA

GROUNDING

Three ground pins are present on the ADS7807. D

digital supply ground. A

A

is the ground to which all analog signals internal to the

GND1

A/D converter are referenced. A

is the analog supply ground.

GND2

is more susceptible to

GND1

current induced voltage drops and must have the path of

least resistance back to the power supply.

All the ground pins of the A/D converter should be tied to an

analog ground plane, separated from the system’s digital

logic ground, to achieve optimum performance. Both analog

and digital ground planes should be tied to the “system”

ground as near to the power supplies as possible. This helps

to prevent dynamic digital ground currents from modulating

the analog ground through a common impedance to power

ground.

SIGNAL CONDITIONING

The FET switches used for the sample hold on many CMOS

A/D converters release a significant amount of charge injection which can cause the driving op amp to oscillate. The

GND

DIG

is the

16

www.ti.com

ADS7807

SBAS022B

amount of charge injection due to the sampling FET switch

52

FFFE

H

173

FFFF

H

581

0000

H

176

0001

H

18

0002

H

00

0003

H

FFFD

H

438

FFFE

H

1681

FFFF

H

5671

0000

H

176

0001

H

2010

182

0002

H

018

0003

H

FFFD

H

on the ADS7807 is approximately 5% to 10% of the amount

on similar A/D converters with the charge redistribution

Digital-to-Analog Converter (DAC) CDAC architecture. There

is also a resistive front end which attenuates any charge

which is released. The end result is a minimal requirement for

the drive capability on the signal conditioning preceding the

A/D converter. Any op amp sufficient for the signal in an

application will be sufficient to drive the ADS7807.

The resistive front end of the ADS7807 also provides a specified ±25V over-voltage protection. In most cases, this eliminates the need for external over-voltage protection circuitry.

INTERMEDIATE LATCHES

The ADS7807 does have tri-state outputs for the parallel

port, but intermediate latches should be used if the bus will

be active during conversions. If the bus is not active during

conversion, the tri-state outputs can be used to isolate the

A/D converter from other peripherals on the same bus.

Intermediate latches are beneficial on any monolithic A/D

converter. The ADS7807 has an internal LSB size of 38µV.

Transients from fast switching signals on the parallel port,

even when the A/D converter is tri-stated, can be coupled

through the substrate to the analog circuitry causing degradation of converter performance.

FIGURE 12. Histogram of 1000 Conversions with Input Grounded.

APPLICATIONS INFORMATION

TRANSITION NOISE

Apply a DC input to the ADS7807 and initiate 1000 conversions. The digital output of the converter will vary in output

codes due to the internal noise of the ADS7807. This is true

for all 16-bit SAR converters. The transition noise specification found in the electrical characteristics section is a statistical figure which represents the one sigma limit or rms value

of these output codes.

Using a histogram to plot the output codes, the distribution

should appear bell-shaped with the peak of the bell curve

representing the nominal output code for the input voltage

value. The ±1σ, ±2σ, and ±3σ distributions will represent

68.3%, 95.5%, and 99.7% of all codes. Multiplying TN by 6

will yield the ±3σ distribution or 99.7% of all codes. Statistically, up to 3 codes could fall outside the 5 code distribution

when executing 1000 conversions. The ADS7807 has a TN

of 0.8LSBs which yields 5 output codes for a ±3σ distribution.

Figures 12 and 13 show 1000 and 10000 conversion histogram results.

AVERAGING

The noise of the converter can be compensated by averaging the digital codes. By averaging conversion results, transition noise will be reduced by a factor of 1/

√Hz

where n is

FIGURE 13. Histogram of 10000 Conversions with Input Grounded.

the number of averages. For example, averaging four conversion results will reduce the TN by 1/2 to 0.4LSBs. Averaging should only be used for input signals with frequencies

near DC.

For AC signals, a digital filter can be used to low-pass filter

and decimate the output codes. This works in a similar

manner to averaging: for every decimation by 2, the signalto-noise ratio will improve 3dB.

ADS7807

SBAS022B

www.ti.com

17

QSPI™ INTERFACING

Figure 14 shows a simple interface between the ADS7807

and any QSPI equipped microcontroller. This interface assumes that the convert pulse does not originate from the

microcontroller and that the ADS7807 is the only serial

peripheral.

Before enabling the QSPI interface, the microcontroller must

be configured to monitor the slave select line. When a

transition from LOW to HIGH occurs on Slave Select (

from

BUSY

(indicating the end of the current conversion), the

port can be enabled. If this is not done, the microcontroller

and the A/D converter may be “out-of-sync”.

SS

QSPI™

PCS0

PCS1

SCK

MISO

ADS7807

R/C

CS

DATACLK

D7 (MSB)

+5V

EXT/INT

)

CPOL = 0

CPHA = 0

QSPI is a registered trademark of Motorola.

BYTE

Convert Pulse

QSPI™

PCS0/SS

MOSI

SCK

CPOL = 0 (Inactive State is LOW)

CPHA = 1 (Data valid on falling edge)

QSPI port is in slave mode.

QSPI is a registered trademark of Motorola.

ADS7807

R/C

BUSY

SDATA

DATACLK

CS

EXT/INT

BYTE

FIGURE 14. QSPI Interface to the ADS7807.

Figure 15 shows another interface between the ADS7807

and a QSPI equipped microcontroller which allows the

microcontroller to give the convert pulses while also allowing

multiple peripherals to be connected to the serial bus. This

interface and the following discussion assume a master clock

for the QSPI interface of 16.78MHz. Notice that the serial

data input of the microcontroller is tied to the MSB (D7) of the

ADS7807 instead of the serial output (SDATA). Using D7

instead of the serial port offers tri-state capability which

allows other peripherals to be connected to the MISO pin.

When communication is desired with those peripherals, PCS0

and PCS1 should be left HIGH; that will keep D7 tri-stated.

In this configuration, the QSPI interface is actually set to do

two different serial transfers. The first, an 8-bit transfer, causes

PCS0 (

R/C

) and PCS1 (CS) to go LOW, starting a conversion. The second, a 16-bit transfer, causes only PCS1 (

CS

) to

go LOW. This is when the valid data will be transferred.

QSPI is a registered trademark of Motorola.

FIGURE 15. QSPI Interface to the ADS7807. Processor

Initiates Conversions.

For both transfers, the DT register (delay after transfer) is

used to cause a 19µs delay. The interface is also set up to

wrap to the beginning of the queue. In this manner, the QSPI

is a state machine which generates the appropriate timing for

the ADS7807. This timing is thus locked to the crystal-based

timing of the microcontroller and not interrupt driven. So, this

interface is appropriate for both AC and DC measurements.

For the fastest conversion rate, the baud rate should be set

to 2 (4.19MHz SCK), DT set to 10, the first serial transfer set

to 8 bits, the second set to 16 bits, and DSCK disabled (in the

command control byte). This will allow for a 23kHz maximum

conversion rate. For slower rates, DT should be increased.

Do not slow SCK as this may increase the chance of

affecting the conversion results or accidently initiating a

second conversion during the first 8-bit transfer.

In addition, CPOL and CPHA should be set to zero (SCK

normally LOW and data captured on the rising edge). The

command control byte for the 8-bit transfer should be set to

20

and for the 16-bit transfer to 61H.

H

SPI™ INTERFACE

The SPI interface is generally only capable of 8-bit data

transfers. For some microcontrollers with SPI interfaces, it

might be possible to receive data in a similar manner as

shown for the QSPI interface in Figure 14. The microcontroller

will need to fetch the 8 most significant bits before the

contents are overwritten by the least significant bits.

A modified version of the QSPI interface shown in Figure 15

might be possible. For most microcontrollers with SPI interface, the automatic generation of the start-of-conversion

pulse will be impossible and will have to be done with

software. This will limit the interface to ‘DC’ applications due

to the insufficient jitter performance of the convert pulse

itself.

SPI is a registered trademark of Motorola.

18

www.ti.com

ADS7807

SBAS022B

DSP56000 INTERFACING

The DSP56000 serial interface has SPI compatibility mode

with some enhancements. Figure 16 shows an interface

between the ADS7807 and the DSP56000 which is very

Convert Pulse

DSP56000

SC1

SRD

SCO

SYN = 0 (Asychronous)

GCK = 1 (Gated clock)

SCD1 = 0 (SC1 is an input)

SHFD = 0 (Shift MSB first)

WL1 = 1 WL0 = 0 (Word length = 16 bits)

ADS7807

R/C

BUSY

SDATA

DATACLK

CS

EXT/INT

BYTE

similar to the QSPI interface seen in Figure 14. As mentioned

in the QSPI section, the DSP56000 must be programmed to

enable the interface when a LOW to HIGH transition on SC1

is observed (

BUSY

going HIGH at the end of conversion).

The DSP56000 can also provide the convert pulse by including a monostable multi-vibrator, as seen in Figure 17. The

receive and transmit sections of the interface are decoupled

(asynchronous mode) and the transmit section is set to

generate a word length frame sync every other transmit

frame (frame rate divider set to 2). The prescale modulus

should be set to 3.

The monostable multi-vibrator in this circuit will provide

varying pulse widths for the convert pulse. The pulse width

will be determined by the external R and C values used with

the multi-vibrator. The 74HCT123N data sheet shows that

the pulse width is (0.7) RC. Choosing a pulse width as close

to the minimum value specified in this data sheet will offer the

best performance. See the Starting A Conversion section of

this data sheet for details on the conversion pulse width.

The maximum conversion rate for a 20.48MHz DSP56000 is

exactly 40kHz. Note that this will not be the case for the

ADS7806. See the ADS7806 data sheet (SBAS021A) for

more information.

FIGURE 16. DSP56000 Interface to the ADS7807.

DSP56000

SC2

SC0

SRD

SYN = 0 (Asychronous)

GCK = 1 (Gated clock)

SCD2 = 1 (SC2 is an output)

SHFD = 0 (Shift MSB first)

WL1 = 1 WL0 = 0 (Word length = 16 bits)

+5V

B1

CLR1

A1

74HCT123N

+5V

R

EXT1

C

EXT1

Q1

R

C

ADS7807

R/C

DATACLK

SDATA

CS

EXT/INT

BYTE

FIGURE 17. DSP56000 Interface to the ADS7807. Processor Initiates Conversions.

ADS7807

SBAS022B

www.ti.com

19

PACKAGE OPTION ADDENDUM

www.ti.com

3-Oct-2005

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

ADS7807P ACTIVE PDIP NT 28 13 TBD CU SNPB Level-NA-NA-NA

ADS7807PB ACTIVE PDIP NT 28 13 TBD CUSNPB Level-NA-NA-NA

ADS7807U ACTIVE SOIC DW 28 28 TBD CU NIPDAU Level-3-220C-168 HR

ADS7807U/1K ACTIVE SOIC DW 28 1000 TBD CU NIPDAU Level-3-220C-168 HR

ADS7807U/1KE4 ACTIVE SOIC DW 28 1000 Pb-Free

ADS7807UB ACTIVE SOIC DW 28 28 TBD CU NIPDAU Level-3-220C-168 HR

ADS7807UB/1K ACTIVE SOIC DW 28 1000 TBD CU NIPDAU Level-3-220C-168 HR

ADS7807UB/1KE4 ACTIVE SOIC DW 28 1000 Pb-Free

ADS7807UBE4 ACTIVE SOIC DW 28 28 Pb-Free

ADS7807UE4 ACTIVE SOIC DW 28 28 Pb-Free

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(RoHS)

(RoHS)

(RoHS)

(RoHS)

(2)

Lead/Ball Finish MSL Peak Temp

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

CU NIPDAU Level-3-260C-168 HR

(3)

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS) or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

MECHANICAL DATA

MPDI004 – OCTOBER 1994

NT (R-PDIP-T**) PLASTIC DUAL-IN-LINE PACKAGE

24 PINS SHOWN

24

DIM

A MAX

A MIN

B MAX

B MIN

PINS **

24

1.260

(32,04)

1.230

(31,24)

0.310

(7,87)

0.290

(7,37)

0°–15°

28

1.425

(36,20)

1.385

(35,18)

0.315

(8,00)

0.295

(7,49)

B

A

13

0.280 (7,11)

0.250 (6,35)

1

0.070 (1,78) MAX

0.020 (0,51) MIN

0.100 (2,54)

0.021 (0,53)

0.015 (0,38)

0.010 (0,25)

M

12

0.200 (5,08) MAX

Seating Plane

0.125 (3,18) MIN

0.010 (0,25) NOM

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

4040050/B 04/95

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2005, Texas Instruments Incorporated

WWW.ALLDATASHEET.COM

Copyright © Each Manufacturing Company.

All Datasheets cannot be modified without permission.

This datasheet has been download from :

www.AllDataSheet.com

100% Free DataSheet Search Site.

Free Download.

No Register.

Fast Search System.

www.AllDataSheet.com

Loading...

Loading...