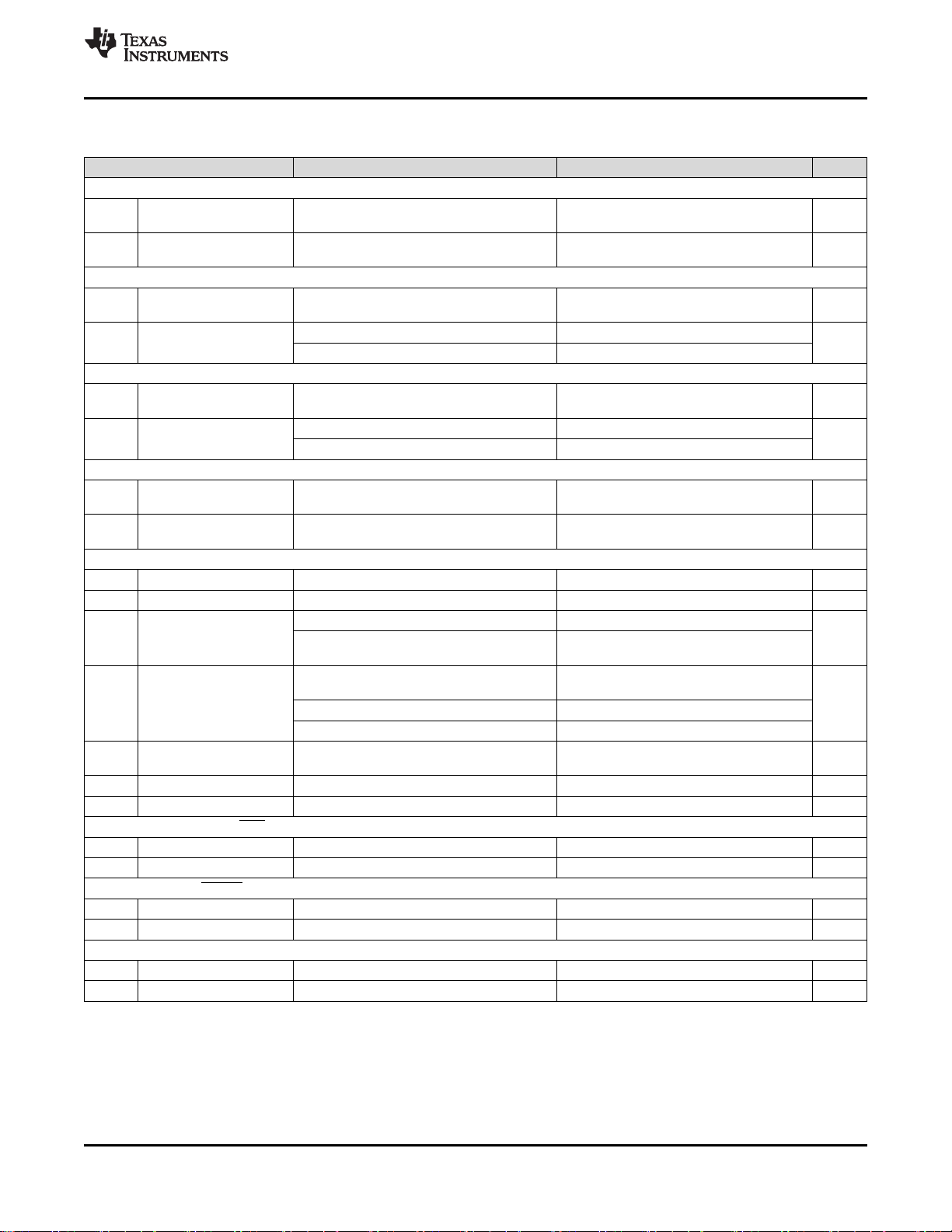

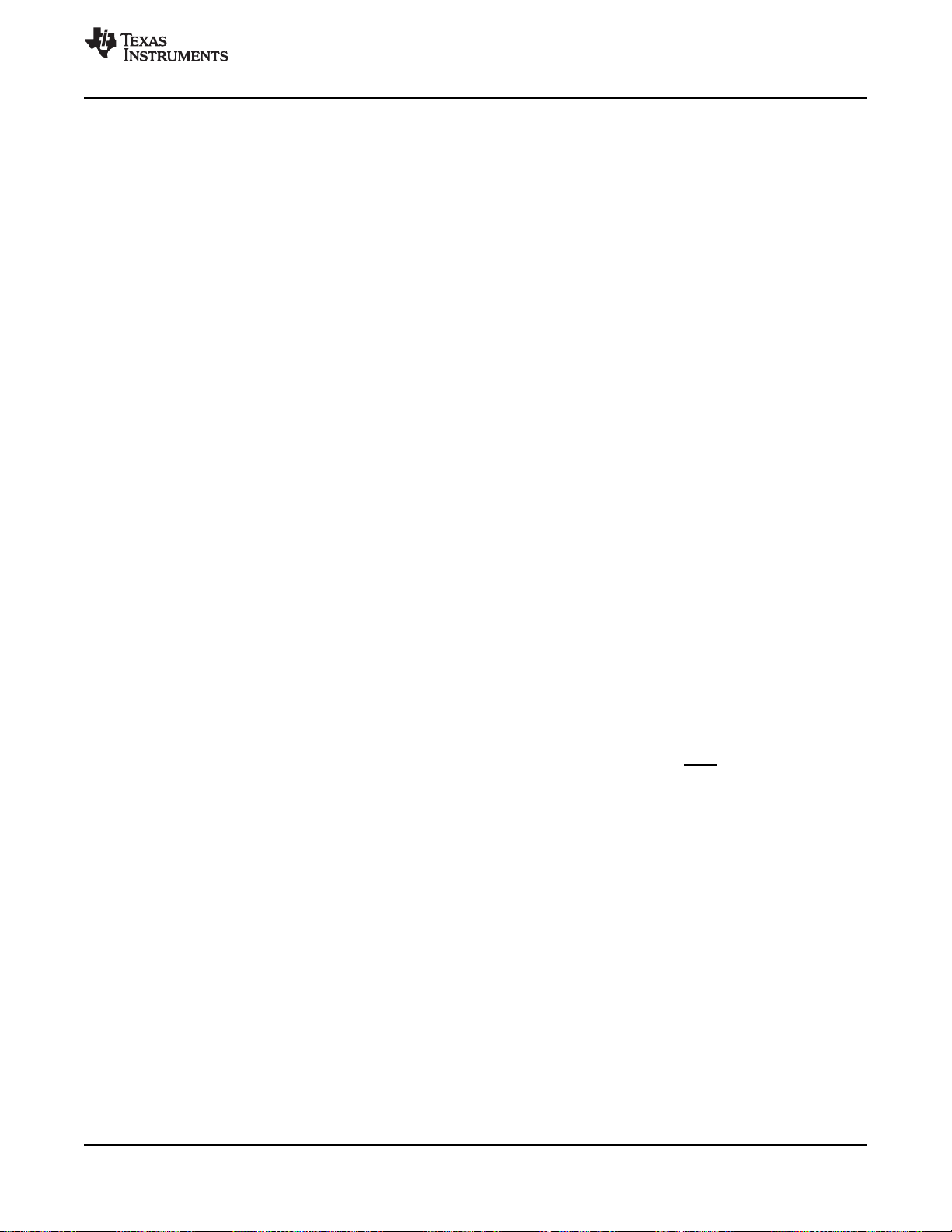

SAR-ADC

Oscillator and

Timing Control

I2C Interface

Conversion Result

ALERT

ADDR

SCL

SDA

AINP/AIN0

AINM/AIN1

AVDD

DVDD

GND

BUSY/RDY

Accumulator

Conversion Result [0]

«««.

Conversion Result [15]

Data Buffer

Analog Input and

Multiplexer

«««.

«««.

High/Low Threshold

± Hysteresis

Digital

Window

Comparator

I2C Address

Selector

Offset

Calibration

Product

Folder

Order

Now

Technical

Documents

Tools &

Software

Support &

Community

ADS7142-Q1

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

ADS7142-Q1 Automotive, 2-Channel, 12-Bit, 140-kSPS, I2C-Compatible ADC With

Programmable Threshold and Host Wake-Up Features

1 Features

1

• AEC-Q100 qualified for automotive applications:

– Device temperature grade 1:

–40°C to 125°C, T

• Small package size: 3 mm × 2 mm

• 12-bit noise-free resolution

• Up to 140-kSPS sampling rate

• Efficient host sleep and wake-up:

– Autonomous monitoring at 900 nW

– Windowed comparator for event-triggered host

wake-up

• Independent configuration and calibration:

– Dual-channel, pseudo-differential, or ground-

sense input configuration

– Programmable thresholds for calibration

– Internal calibration improves offset and drift

• False trigger prevention:

– Programmable thresholds per channel

– Programmable hysteresis for noise immunity

– Event counter for transient rejection

• I2C interface:

– Compatible from 1.65 V to 3.6 V

– 8 configurable addresses

– Up to 3.4 MHz (high speed)

• Analog supply: 1.65 V to 3.6 V

A

2 Applications

General-purpose voltage, current and temperature

monitoring in:

• Automotive camera modules

• Driver monitoring and assistance systems

• Infotainment systems and clusters

• Electric and ICE powertrain systems

3 Description

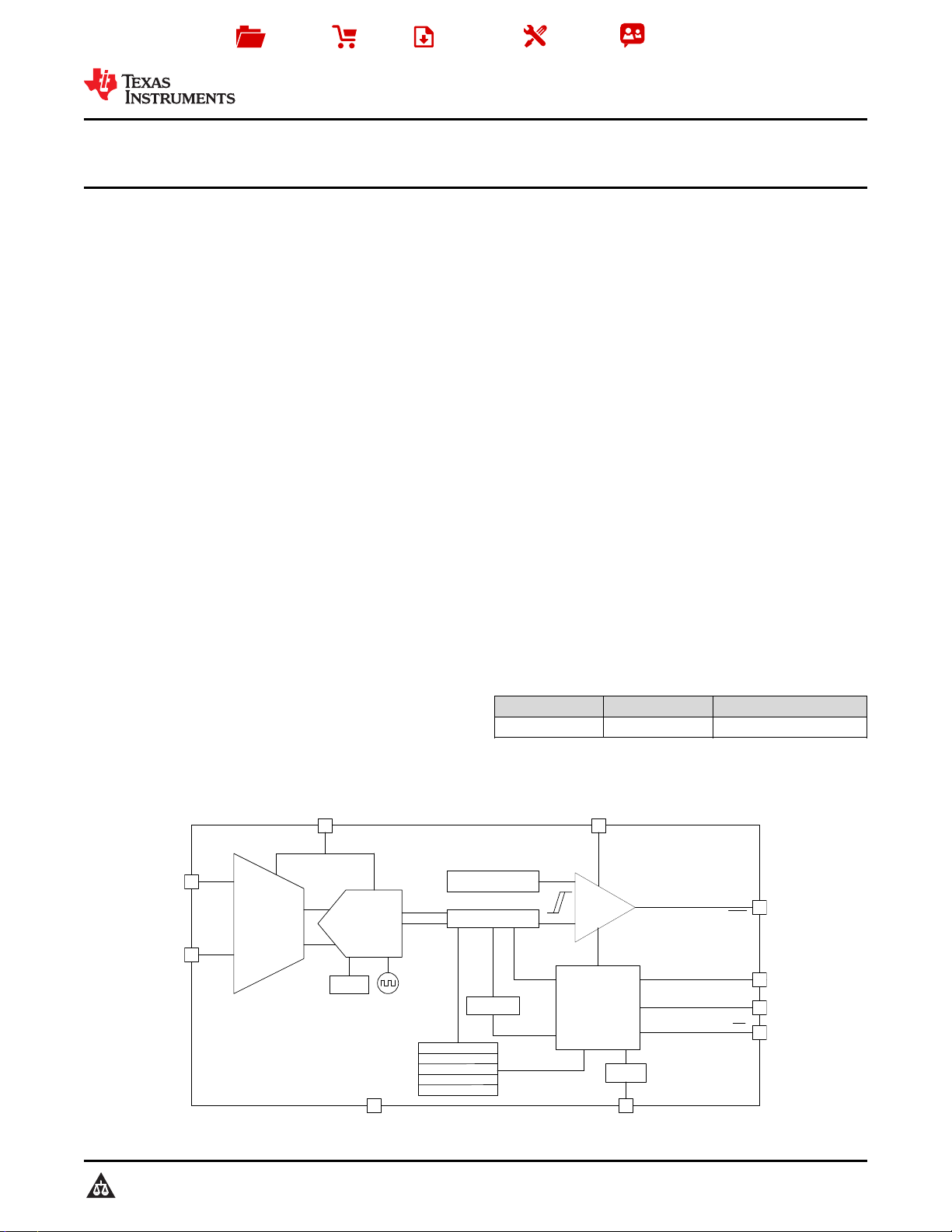

The ADS7142-Q1 is 12-bit, 140-kSPS successiveapproximation register (SAR) analog-to-digital

converter (ADC) that can autonomously monitor

signals while maximizing system power, reliability,

and performance. The device implements eventtriggered interrupts per channel using a digital

window comparator with programmable high and low

thresholds, hysteresis, and event counter. The device

includes a dual-channel analog multiplexer in front of

a SAR ADC followed by an internal data buffer for

converting and capturing data from sensors.

The ADS7142-Q1 is available in a 10-pin WSON

package and can achieve low power consumption of

only 900 nW. The small form-factor and low-power

consumption make this device suitable for spaceconstrained applications.

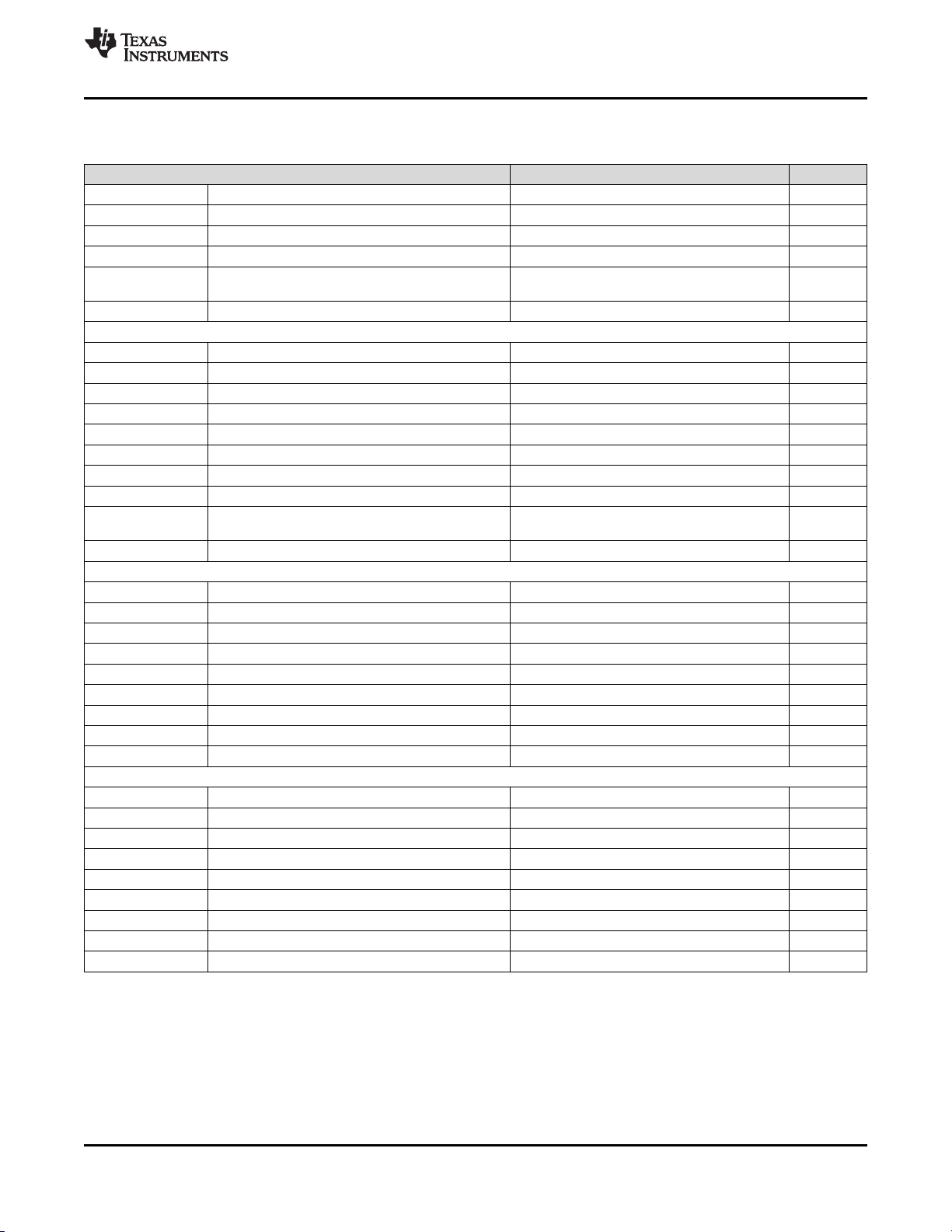

Device Information

PART NAME PACKAGE BODY SIZE (NOM)

ADS7142-Q1 WSON (10) 3.00 mm × 2.00 mm

(1) For all available packages, see the orderable addendum at

the end of the datasheet.

(1)

1

Block Diagram

An IMPORTANT NOTICE at the end of this data sheet addresses availability, warranty, changes, use in safety-critical applications,

intellectual property matters and other important disclaimers. PRODUCTION DATA.

ADS7142-Q1

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

www.ti.com

Table of Contents

1 Features.................................................................. 1

2 Applications ........................................................... 1

3 Description ............................................................. 1

4 Revision History..................................................... 2

5 Pin Configuration and Functions......................... 3

6 Specifications......................................................... 4

6.1 Absolute Maximum Ratings ...................................... 4

6.2 ESD Ratings.............................................................. 4

6.3 Recommended Operating Conditions....................... 4

6.4 Thermal Information.................................................. 4

6.5 Electrical Characteristics: All Modes......................... 5

6.6 Electrical Characteristics: Manual Mode................... 6

6.7 Electrical Characteristics: Autonomous Modes......... 7

6.8 Electrical Characteristics: High Precision Mode ....... 8

6.9 Timing Requirements................................................ 8

6.10 Switching Characteristics...................................... 10

6.11 Typical Characteristics: All Modes........................ 12

6.12 Typical Characteristics: Manual Mode.................. 13

6.13 Typical Characteristics: Autonomous Modes........ 17

6.14 Typical Characteristics: High-Precision Mode ...... 18

7 Detailed Description............................................ 19

4 Revision History

7.1 Overview................................................................. 19

7.2 Functional Block Diagram....................................... 19

7.3 Feature Description................................................. 20

7.4 Device Functional Modes........................................ 28

7.5 Programming........................................................... 39

7.6 Register Map........................................................... 42

8 Application and Implementation ........................ 59

8.1 Application Information............................................ 59

8.2 Typical Applications ................................................ 59

9 Power Supply Recommendations...................... 65

9.1 AVDD and DVDD Supply Recommendations......... 65

10 Layout................................................................... 66

10.1 Layout Guidelines ................................................. 66

10.2 Layout Example .................................................... 67

11 Device and Documentation Support................. 68

11.1 Receiving Notification of Documentation Updates 68

11.2 Community Resources.......................................... 68

11.3 Trademarks........................................................... 68

11.4 Electrostatic Discharge Caution............................ 68

11.5 Glossary................................................................ 68

12 Mechanical, Packaging, and Orderable

Information........................................................... 68

Changes from Original (November 2018) to Revision A Page

• Changed document status from advance information to production data.............................................................................. 1

2

Submit Documentation Feedback Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: ADS7142-Q1

1GND 10 DVDD

2AVDD 9 SCL

3AINP/AIN0 8 SDA

4AINM/AIN1 7 ALERT

5ADDR 6 BUSY/RDY

Not to scale

Thermal

Pad

ADS7142-Q1

www.ti.com

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

5 Pin Configuration and Functions

DQC Package

10-Pin WSON

Top View

Pin Functions

PIN

NO. NAME

1 GND Supply Ground for power supply, all analog and digital signals are referred to this pin.

2 AVDD Supply Analog supply input, also used as the reference voltage for analog-to-digital conversion.

3 AINP/AIN0 Analog input

4 AINM/AIN1 Analog input

5 ADDR Analog Input

6 BUSY/RDY Digital output

7 ALERT Digital output

8 SDA Digital input/output Serial data input/output for the I2C interface. Connect a pullup resistor from DVDD to this pin.

9 SCL Digital input Serial clock for the I2C interface. Connect a pullup resistor from DVDD to this pin.

10 DVDD Supply Digital I/O supply voltage.

I/O DESCRIPTION

Single-channel operation: positive analog signal input.

Two-channel operation: analog signal input, channel 0.

Single-channel operation: negative analog signal input.

Two-channel operation: analog signal input, channel 1.

Input for selecting the I2C address of the device.

See the I2C Address Selection section for details.

The device pulls this pin high when scanning through channels in a sequence and brings this pin

low when the sequence is completed or aborted.

Active low, open-drain output. The status of this pin is controlled by the digital window

comparator block. Connect a pullup resistor from DVDD to this pin.

Product Folder Links: ADS7142-Q1

Submit Documentation FeedbackCopyright © 2018–2019, Texas Instruments Incorporated

3

ADS7142-Q1

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

www.ti.com

6 Specifications

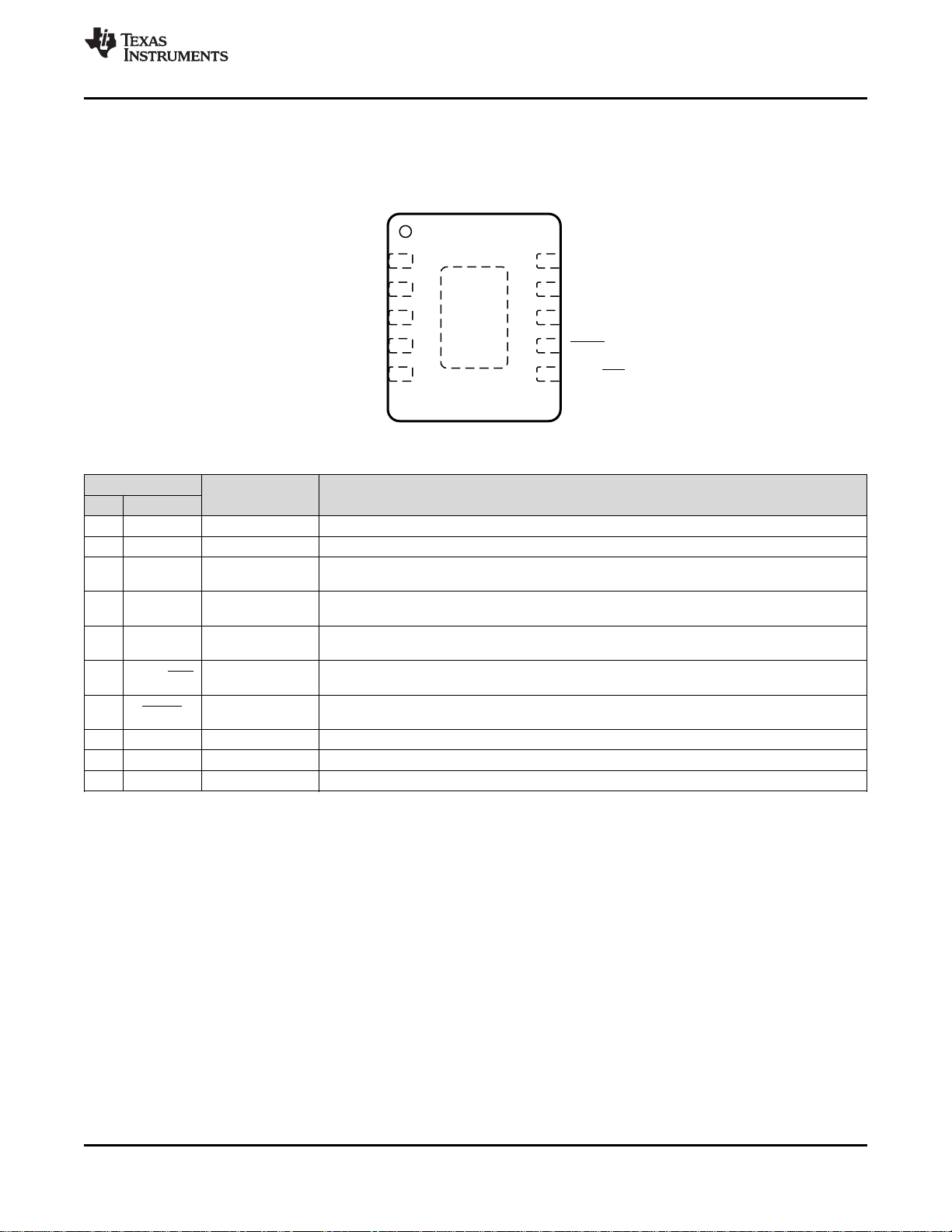

6.1 Absolute Maximum Ratings

over operating free-air temperature range (unless otherwise noted)

ADDR to GND –0.3 AVDD + 0.3 V

AVDD to GND –0.3 3.9 V

DVDD to GND –0.3 3.9 V

AINP/AIN0 to GND –0.3 AVDD + 0.3 V

AINM/AIN1 to GND –0.3 AVDD + 0.3 V

Input current on any pin except supply pins –10 10 mA

Digital input to GND –0.3 DVDD + 0.3 V

Junction temperature, T

Storage temperature, T

J

stg

(1) Stresses beyond those listed under Absolute Maximum Rating may cause permanent damage to the device. These are stress ratings

only, which do not imply functional operation of the device at these or any other conditions beyond those indicated under Recommended

Operating Condition. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

6.2 ESD Ratings

Human-body model (HBM), per AEC Q100-002

V

(ESD)

(1) AEC Q100-002 indicates that HBM stressing shall be in accordance with the ANSI/ESDA/JEDEC JS-001 specification.

Electrostatic discharge

Charged-device model (CDM), per AEC

Q100-011

(1)

MIN MAX UNIT

–40 150 °C

–60 150 °C

VALUE UNIT

(1)

Corner pins (1, 5, 6, and

10)

±2000

±750

V

All other pins ±500

6.3 Recommended Operating Conditions

over operating free-air temperature range (unless otherwise noted)

MIN NOM MAX UNIT

AVDD Analog supply voltage range 1.65 3.6 V

DVDD Digital supply voltage range 1.65 3.6 V

T

A

Ambient temperature –40 125 °C

6.4 Thermal Information

ADS7142-Q1

THERMAL METRIC

R

θJA

R

θJC(top)

R

θJB

Ψ

JT

Ψ

JB

R

θJC(bot)

Junction-to-ambient thermal resistance 61.8 °C/W

Junction-to-case (top) thermal resistance 66.3 °C/W

Junction-to-board thermal resistance 29.8 °C/W

Junction-to-top characterization parameter 2.1 °C/W

Junction-to-board characterization parameter 29.7 °C/W

Junction-to-case (bottom) thermal resistance 6.1 °C/W

(1) For more information about traditional and new thermal metrics, see the Semiconductor and IC Package Thermal Metrics application

report.

(1)

UNITDQC (WSON)

10 PINS

4

Submit Documentation Feedback Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: ADS7142-Q1

ADS7142-Q1

www.ti.com

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

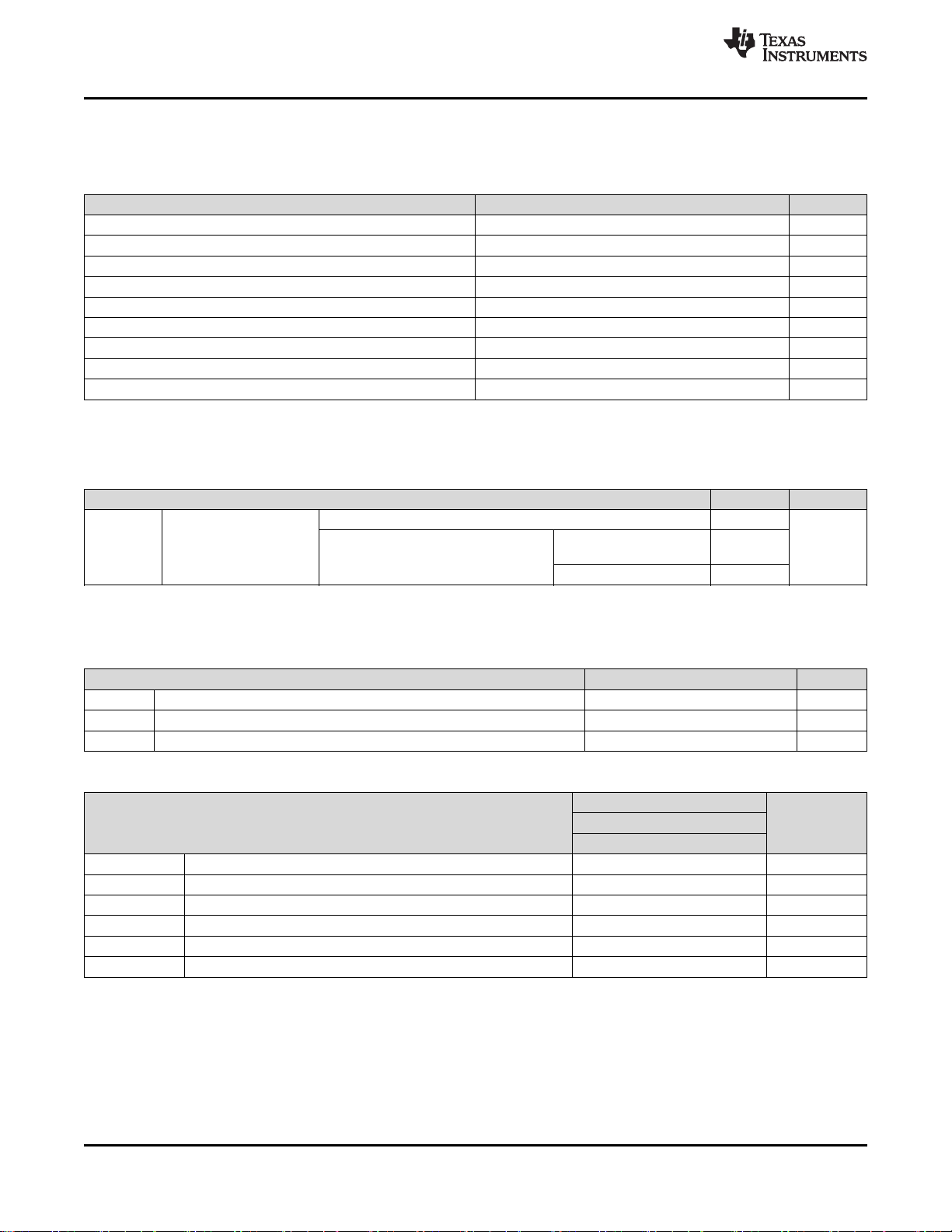

6.5 Electrical Characteristics: All Modes

at TA= -40°C to 125°C, AVDD = 3 V, DVDD = 1.65 V to 3.6 V, All Channel Configurations (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

ANALOG INPUT (Two-Channel Single-Ended Configuration)

Full-scale input voltage

(1)

span

Absolute input voltage

range

ANALOG INPUT (Single-Channel Single-Ended Configuration with Remote Ground Sense)

Full-scale input voltage

(1)

span

Absolute input voltage

range

ANALOG INPUT (Single-Channel Pseudo-Differential Configuration with Remote Ground Sense)

Full-scale input voltage

(1)

span

Absolute input voltage

range

INTERNAL OSCILLATOR

t

HSO

t

LPO

Time period for highspeed oscillator

Time period for low-power

oscillator

DIGITAL INPUT/OUTPUT (SCL, SDA)

V

V

V

I

OL

I

OL

I

I

C

High-level input voltage 0.7 × DVDD DVDD V

IH

Low-level input voltage 0 0.3 × DVDD V

IL

Low-level output voltage

OL

Low-level output current

(sink)

Low-level output current

(sink)

Input current on pin 10 µA

Input capacitance on pin 10 pF

I

DIGITAL OUTPUT (BUSY/RDY)

V

V

High-level output voltage I

OH

Low-level output voltage I

OL

DIGITAL OUTPUT (ALERT)

I

OL

V

Low-level output current VOL< 0.25 V 5 mA

Low-level output voltage I

OL

POWER-SUPPLY REQUIREMENTS

AVDD Analog supply voltage 1.65 3.6 V

DVDD Digital I/O supply voltage 1.65 3.6 V

(1) Ideal Input span, does not include gain or offset error.

AINP/AIN0 to GND or AINM/AIN1 to GND 0 AVDD V

AINP/AIN0 to GND or AINM/AIN1 to GND –0.1 AVDD + 0.1 V

AINP/AIN0 to AINM/AIN1 0 AVDD V

AINP/AIN0 to GND –0.1 AVDD + 0.1

AINM/AIN1 to GND –0.1 0.1

AINP/AIN0 to AINM/AIN1 –AVDD/2 AVDD/2 V

AINP/AIN0 to GND –0.1 AVDD + 0.1

AINM/AIN1 to GND AVDD/2–0.1 AVDD/2+0.1

50 110 ns

95.2 300 µs

With 3 mA sink current and DVDD > 2 V 0 0.4

With 3 mA sink current and 1.65 V < DVDD <

2 V

VOL= 0.4 V for standard and fast mode (100,

400 kHz)

0 0.2 × DVDD

3

VOL= 0.6 V for fast mode (400 kHz) 6

VOL= 0.4 V fast mode Plus (1 MHz) 20

VOL= 0.4 V high speed (1.7 MHz, 3.4 MHz) 25 mA

= 2 mA 0.7 × DVDD DVDD V

source

= 2 mA 0 0.3 × DVDD V

sink

= 5 mA 0 0.25 V

sink

(1)

V

V

V

mA

Product Folder Links: ADS7142-Q1

Submit Documentation FeedbackCopyright © 2018–2019, Texas Instruments Incorporated

5

ADS7142-Q1

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

www.ti.com

6.6 Electrical Characteristics: Manual Mode

at TA= -40°C to 125°C, AVDD = 3 V, DVDD = 1.65 V to 3.6 V, All Channel Configurations (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

SAMPLING DYNAMICS

t

conv

t

acq

t

cycle

DC SPECIFICATIONS

NMC No missing codes AVDD = 1.65 V to 3.6 V 12 Bits

DNL Differential nonlinearity AVDD = 1.65 V to 3.6 V –0.99 ±0.3 1 LSB

INL Integral nonlinearity –2.75 ±0.5 2.75 LSB

E

O

dVOS/dT Offset drift with temperature Post offset calibration 5 ppm/°C

E

G

AC SPECIFICATIONS

(2)

SNR

(2)(3)

THD

SINAD

SFDR

BW –3-dB small-signal bandwidth 25 MHz

POWER CONSUMPTION

I

AVDD

I

DVDD

I

AVDD

I

DVDD

(1) LSB means least significant byte. See the ADC Transfer Function for details.

(2) All specifications expressed in decibels (dB) refer to the full-scale input (FSR) and are tested with an input signal 0.5 dB below full-scale,

unless otherwise specified.

(3) Calculated on the first nine harmonics of the input frequency.

Conversion time AVDD = 1.65 V to 3.6 V 1.8 µs

Acquisition time AVDD = 1.65 V to 3.6 V 18 T

Cycle time AVDD = 1.65 V to 3.6 V, SCL = 3.4 MHz 7.1 µs

Resolution 12 Bits

Offset error Post offset calibration –4 ±0.5 4 LSB

Gain error –0.1 ±0.03 0.1 %FSR

Gain error drift with

temperature

Signal-to-noise ratio

Total harmonic distortion

(2)

Signal-to-noise and distortion

(2)

Spurious-free dynamic range

Analog supply current

Digital supply current

fIN= 2 kHz, AVDD = 3 V,

f

= 140 kSPS

SAMPLE

68.75 70

fIN= 2 kHz, AVDD = 1.8 V,

f

= 140 kSPS

SAMPLE

fIN= 2 kHz, AVDD = 3 V,

f

= 140 kSPS

SAMPLE

fIN= 2 kHz, AVDD = 1.8 V,

f

= 140 kSPS

SAMPLE

fIN= 2 kHz, AVDD = 3 V,

f

= 140 kSPS

SAMPLE

68.5 69.5

fIN= 2 kHz, AVDD = 1.8 V,

f

= 140 kSPS

SAMPLE

fIN= 2 kHz, AVDD = 3 V,

f

= 140 kSPS

SAMPLE

f

= 140 kSPS, SCL = 3.4 MHz 265 300

SAMPLE

f

= 5.5 kSPS, SCL = 100 kHz 8

SAMPLE

f

= 140 kSPS, SCL = 3.4 MHz, AVDD

SAMPLE

= 1.8 V

f

= 5.5 kSPS, SCL = 100 kHz, AVDD

SAMPLE

= 1.8 V

f

= 140 kSPS, SCL = 3.4 MHz, SDA =

SAMPLE

AAA0h

f

= 5.5 kSPS, SCL = 100 kHz, SDA =

SAMPLE

AAA0h

f

= 140 kSPS, SCL = 3.4 MHz, AVDD

SAMPLE

= 1.8 V, SDA = AAA0h

5 ppm/°C

68

–85

–80

67.5

90 dB

160

5

25

2

15

Static analog supply current No activity on SCL and SDA 6 nA

Static digital supply current No activity on SCL and SDA 2 nA

(1)

SCL

(1)

dB

dB

dB

µA

µA

6

Submit Documentation Feedback Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: ADS7142-Q1

ADS7142-Q1

www.ti.com

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

6.7 Electrical Characteristics: Autonomous Modes

at TA= -40°C to 125°C, AVDD = 3 V, DVDD = 1.65 V to 3.6 V, All Channel Configurations (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

SAMPLING DYNAMICS

t

conv

t

acq

t

cycle

Conversion time

Acquisition time

Cycle time

DC SPECIFICATIONS

Resolution 12 Bits

E

E

Offset error Post offset calibration ±0.5 LSB

O

Gain error ±0.03 %FSR

G

POWER CONSUMPTION

I

AVDD

I

DVDD

I

AVDD

I

DVDD

Analog supply current

Digital supply current

Static analog supply current No activity on SCL and SDA 5 nA

Static digital supply current No activity on SCL and SDA 0.6 nA

High-speed oscillator 14 t

Low-power oscillator 14 t

High-speed oscillator 7 t

Low-power oscillator 4 t

High-speed oscillator nCLK t

Low-power oscillator nCLK t

With low-power oscillator, nCLK = 18 0.75

With low-power oscillator, AVDD = 1.8 V,

nCLK = 18

0.45

With low-power oscillator, nCLK = 250 0.5

With low-power oscillator, nCLK = 21 940

With low-power oscillator, nCLK = 18, DVDD

= 3.3 V

With low-power oscillator, DVDD = 1.8 V,

nCLK = 18

With low-power oscillator, nCLK = 250,

DVDD = 3.3 V

With high-power oscillator, nCLK = 21,

DVDD = 3.3 V

0.15

0.25

0.15

0.15

HSO

LPO

HSO

LPO

HSO

LPO

µA

µA

Product Folder Links: ADS7142-Q1

Submit Documentation FeedbackCopyright © 2018–2019, Texas Instruments Incorporated

7

ADS7142-Q1

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

6.8 Electrical Characteristics: High Precision Mode

at TA= -40°C to 125°C, AVDD = 3 V, DVDD = 1.65 V to 3.6 V, All Channel Configurations (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

DC SPECIFICATIONS

Resolution

ENOB Effective number of bits With DC input of AVDD / 2

E

E

Offset error Post offset calibration ±10 LSB

O

Gain error ±0.03 %FSR

G

POWER CONSUMPTION

I

AVDD

I

DVDD

I

AVDD

I

DVDD

Analog supply current

Digital supply current

Static analog supply current No activity on SCL and SDA 5 nA

Static analog supply current No activity on SCL and SDA 0.7 nA

(1) Sampling dynamics for high precision mode are same as for autonomous modes.

(2) See Equation 5

(3) For DC input, ENOB = Ln[FSR/Standard deviation of Codes]/Ln[2]. See

(2)

(3)

16

15.4

With low-power oscillator, nCLK = 18 0.6

With low-power oscillator, AVDD = 1.8 V,

nCLK = 18

0.3

With low-power oscillator, nCLK = 250 0.5

With high-speed oscillator, nCLK = 21 980

With low-power oscillator, nCLK = 21, DVDD

= 3.3 V

With low-power oscillator, DVDD = 1.8 V,

nCLK = 21

With low-power oscillator, nCLK = 250,

DVDD = 3.3 V

With high-speed oscillator, nCLK = 21,

DVDD = 3.3 V

0.2

0.25

0.2

0.2

www.ti.com

(1)

Bits

µA

µA

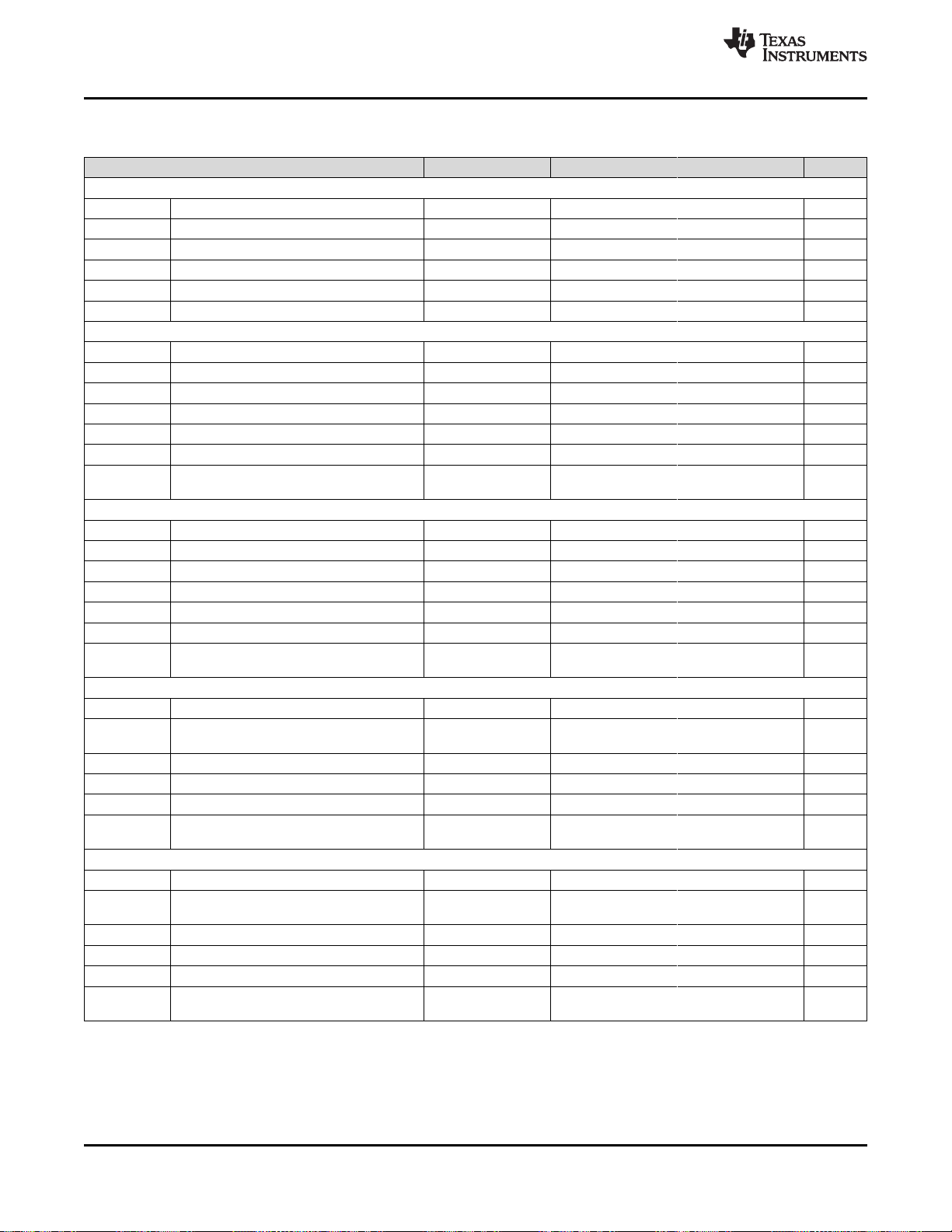

6.9 Timing Requirements

at TA= -40°C to 125°C, AVDD = 3 V, DVDD = 1.65 V to 3.6 V, All Channel Configurations (unless otherwise noted)

PARAMETER MIN MAX UNIT

STANDARD MODE (100 kHz)

f

SCL

t

HD-STA

t

LOW

t

HIGH

t

SU-STA

(2)(3)

t

HD-DAT

t

SU-DAT

t

SU-STO

t

BUF

C

b

FAST MODE (400 kHz)

f

SCL

t

HD-STA

t

LOW

t

HIGH

(1) All values referred to V

(2) t

(3) The maximum t

8

is the data hold time that is measured from the falling edge of SCL and applies to data in transmission and the acknowledge.

HD-DAT

t

by a transition time. This maximum must only be met if the device does not stretch the LOW period (t

VD-ACK

the clock is streched, the data must be valid by the setup time before being released.

Submit Documentation Feedback Copyright © 2018–2019, Texas Instruments Incorporated

SCL clock frequency 0 100 kHz

Hold time (repeated) START condition 4 µs

Low period of SCL 4.7 µs

High period of SCL 4 µs

Setup time for a repeated start condition 4.7 µs

Data hold time 0 µs

Data setup time 250 ns

Data setup time 4 µs

Bus free time between a STOP and START

condition

4.7 µs

Capacitive load on each line 400 pF

SCL clock frequency 0 400 kHz

Hold time (repeated) START condition 0.6 µs

Low period of SCL 1.3 µs

High period of SCL 0.6 µs

(0.7 DVDD) and V

IH(min)

can be 3.45 µs and 0.9 µs for standard-mode and fast-mode, but must be less than the maximum of t

HD-DAT

IL(max)

(0.3 DVDD).

) of the SCL signal. If

LOW

Product Folder Links: ADS7142-Q1

(1)

VD-DAT

or

ADS7142-Q1

www.ti.com

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

Timing Requirements (continued)

at TA= -40°C to 125°C, AVDD = 3 V, DVDD = 1.65 V to 3.6 V, All Channel Configurations (unless otherwise noted)

PARAMETER MIN MAX UNIT

t

SU-STA

t

HD-DAT

t

SU-DAT

t

SU-STO

t

BUF

C

b

FAST MODE PLUS (1000 kHz)

f

SCL

t

HD-STA

t

LOW

t

HIGH

t

SU-STA

t

HD-DAT

t

SU-DAT

t

SU-STO

t

BUF

C

b

HIGH SPEED MODE (1.7 MHz, Cb= 400 pF max)

f

SCLH

t

HD-STA

t

LOW

t

HIGH

t

SU-STA

t

HD-DAT

t

SU-DAT

t

SU-STO

C

b

HIGH SPEED MODE (3.4 MHz, Cb= 100 pF max)

f

SCLH

t

HD-STA

t

LOW

t

HIGH

t

SU-STA

t

HD-DAT

t

SU-DAT

t

SU-STO

C

b

Setup time for a repeated start condition 0.6 µs

Data hold time 0 µs

Data setup time 100 ns

Data setup time 0.6 µs

Bus free time between a STOP and START

condition

1.3 µs

Capacitive load on each line 400 pF

SCL clock frequency 0 1000 kHz

Hold time (repeated) START condition 0.26 µs

Low period of SCL 0.5 µs

High period of SCL 0.26 µs

Setup time for a repeated start condition 0.26 µs

Data hold time 0 µs

Data setup time 50 ns

Data setup time 0.26 µs

Bus free time between a STOP and START

condition

0.5 µs

Capacitive load on each line 550 pF

SCLH clock frequency 0 1.7 MHz

Hold time (repeated) START condition 160 ns

Low period of SCL 320 ns

High period of SCL 120 ns

Setup time for a repeated start condition 160 ns

Data hold time 0 150 ns

Data setup time 10 ns

Data setup time 160 ns

Capacitive load on each line 100 pF

SCLH clock frequency 0 3.4 MHz

Hold time (repeated) START condition 160 ns

Low period of SCL 160 ns

High period of SCL 60 ns

Setup time for a repeated start condition 160 ns

Data hold time 0 70 ns

Data setup time 10 ns

Data setup time 160 ns

Capacitive load on each line 100 pF

(1)

Product Folder Links: ADS7142-Q1

Submit Documentation FeedbackCopyright © 2018–2019, Texas Instruments Incorporated

9

ADS7142-Q1

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

6.10 Switching Characteristics

at TA= -40°C to 125°C, AVDD = 3 V, DVDD = 1.65 V to 3.6 V, All Channel Configurations (unless otherwise noted)

PARAMETER TEST CONDITIONS MIN MAX UNIT

STANDARD MODE (100 kHz)

t

rCL

t

rDA

t

fCL

t

fDA

(2)

t

VD-DAT

(2)

t

VD-ACK

FAST MODE (400 kHz)

t

rCL

t

rDA

t

fCL

t

fDA

t

VD-DAT

t

VD-ACK

(3)

t

SP

FAST MODE PLUS (1000 kHz)

t

rCL

t

rDA

t

fCL

t

fDA

t

VD-DAT

t

VD-ACK

t

SP

HIGH SPEED MODE (1.7 MHz, Cb= 400 pF max)

t

rCL

t

rCL1

t

rDA

t

fCL

t

fDA

t

SP

HIGH SPEED MODE (3.4 MHz, Cb= 100 pF max)

t

rCL

t

rCL1

t

rDA

t

fCL

t

fDA

t

SP

Rise time of SCL 1000 ns

Rise time of SDA 1000 ns

Fall time of SCL 300 ns

Fall time of SDA 300 ns

Data valid time 3.45 µs

Data hold time 3.45 µs

Rise time of SCL 20 300 ns

Rise time of SDA 20 300 ns

Fall time of SCL 20 × DVDD/3.6 300 ns

Fall time of SDA 20 × DVDD/3.6 300 ns

Data valid time 0.9 µs

Data hold time 0.9 µs

Pulse duration of spikes suppressed by the

input filter

0 50 ns

Rise time of SCL 120 ns

Rise time of SDA 120 ns

Fall time of SCL 20 × DVDD/3.6 120 ns

Fall time of SDA 20 × DVDD/3.6 120 ns

Data valid time 0.45 µs

Data hold time 0.45 µs

Pulse duration of spikes suppressed by the

input filter

0 50 ns

Rise time of SCLH 20 80 ns

Rise time of SCLH after a repeated start

condition and after an acknowledge bit

20 160 ns

Rise time of SDAH 20 160 ns

Fall time of SCLH 20 80 ns

Fall time of SDAH 20 160 ns

Pulse duration of spikes suppressed by the

input filter

0 10 ns

Rise time of SCLH 10 40 ns

Rise time of SCLH after a repeated start

condition and after an acknowledge bit

10 80 ns

Rise time of SDAH 10 80 ns

Fall time of SCLH 10 40 ns

Fall time of SDAH 10 80 ns

Pulse duration of spikes suppressed by the

input filter

0 10 ns

www.ti.com

(1)

(1) All values referred to V

(2) t

(3) Input filters on the SDA and SCL inputs suppress noise spikes of less than 50 ns.

10

= time for data signal from SCL LOW to SDA output.

VD-DAT

Submit Documentation Feedback Copyright © 2018–2019, Texas Instruments Incorporated

( 0.7 DVDD ) and V

IH(min)

IL(max)

( 0.3 DVDD ).

Product Folder Links: ADS7142-Q1

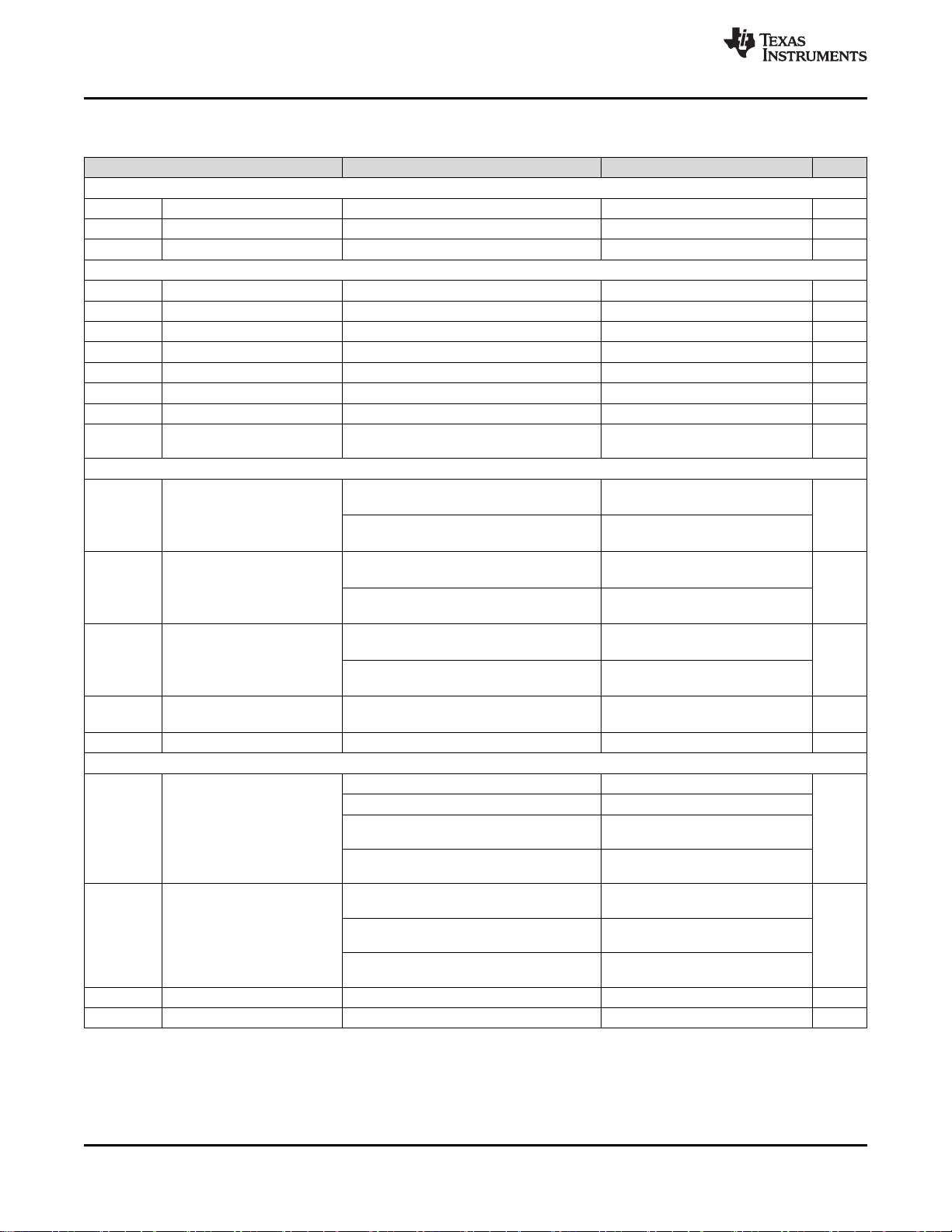

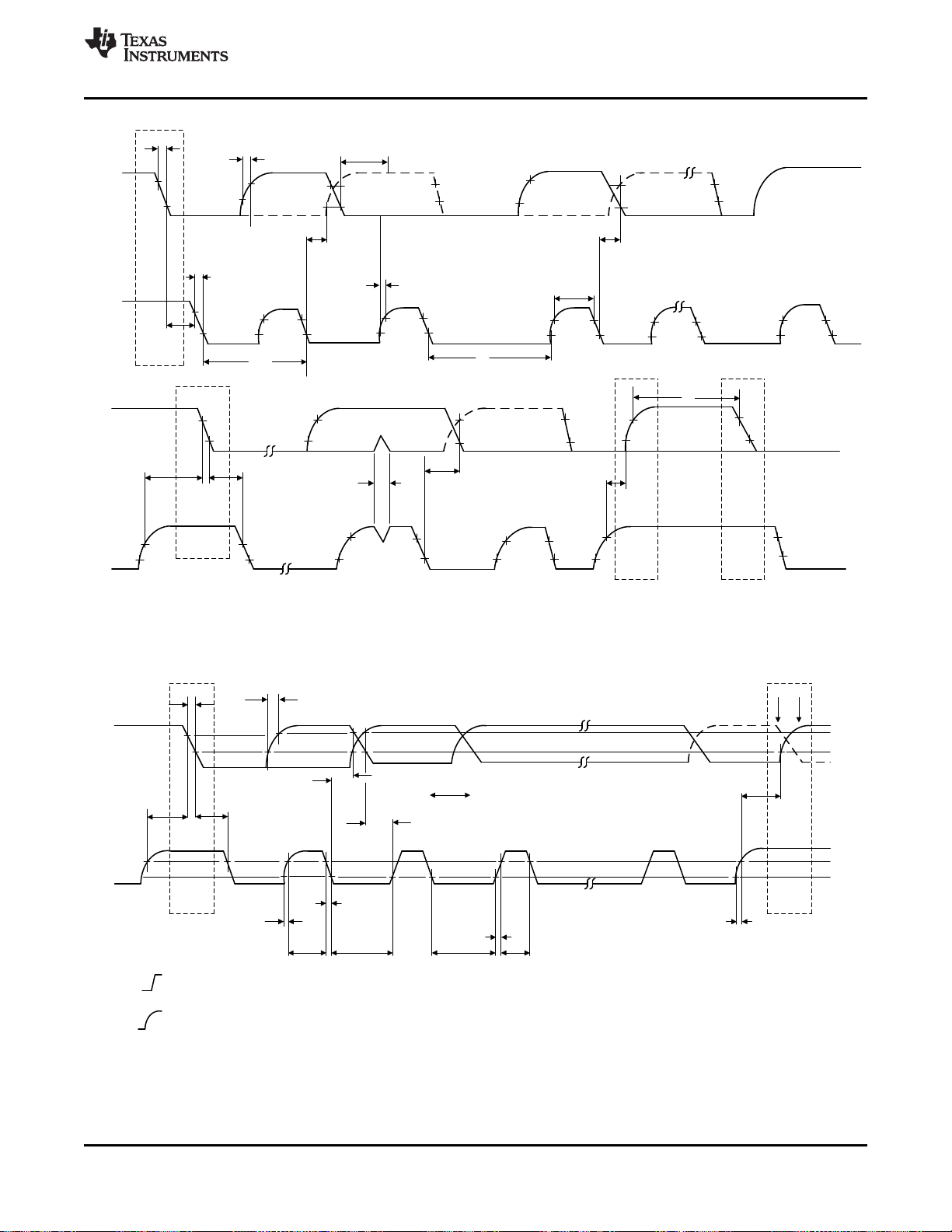

Sr

t

fDA

t

rDA

t

HD-DAT

t

SU-DAT

SDAH or SDA

t

SU-STA

t

HD-STA

SCLH or SCL

t

rCL1

t

HIGH

t

LOW

t

FCL

t

rCL

t

LOW

t

HIGH

t

rCL1

t

SU-STO

Sr P

0.7 x V

DD

0.3 x V

DD

0.7 x V

DD

0.3 x V

DD

= MCS current source pull-up

= Rp resistor pull-up

(1)

(1)

t

f

t

r

t

SU-DAT

t

HD-DAT

t

VD-DAT

«

cont.

«

cont.

9th clock

SDA

SCL

70%

30%

70%

30%

70%

30% 30%

70%

70%

30%

70%

30%

t

HIGH

t

LOW

t

HD-STA

S

1/f

SCL

1st clock cycle

. . . SDA

. . . SCL

t

r

t

SU-STA

t

HD-STA

Sr

t

SP

t

VD-ACK

70%

30%

9th clock

t

BUF

S

P

t

SU-STO

VIL = 0.3V

DD

VIH = 0.7V

DD

t

f

www.ti.com

ADS7142-Q1

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

Figure 1. Timing Diagram for Standard Mode, Fast Mode, and Fast Mode Plus

(1) First rising edge of the SCLH signal after Sr and after each acknowledge bit.

Figure 2. Timing Diagram for High-Speed Mode

Product Folder Links: ADS7142-Q1

11

Submit Documentation FeedbackCopyright © 2018–2019, Texas Instruments Incorporated

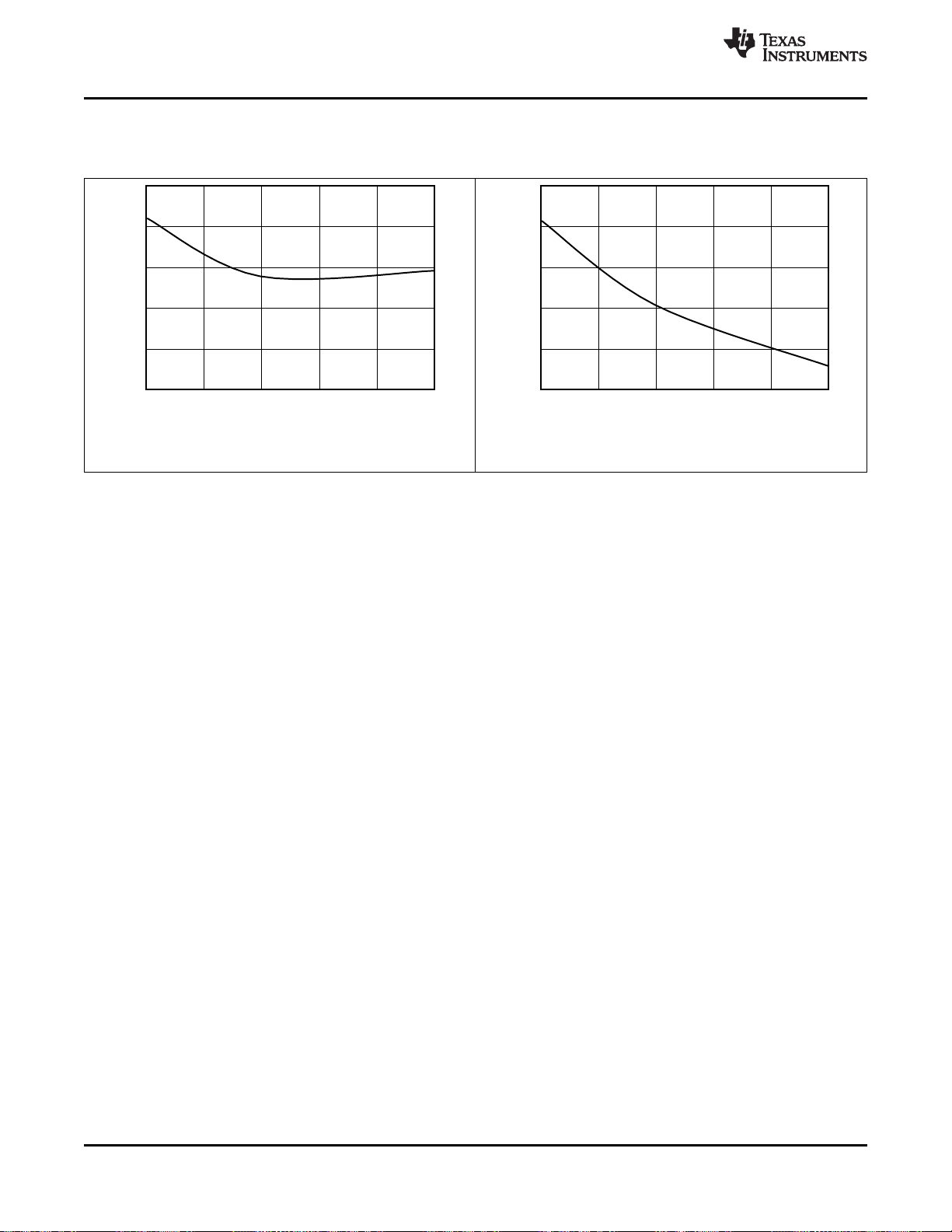

Free-Air Temperature (qC)

Time Period (ns)

-40 -7 26 59 92 125

40

44

48

52

56

60

ADS7

Free-Air Temperature (qC)

Time Period (Ps)

-40 -7 26 59 92 125

60

80

100

120

140

160

ADS7

ADS7142-Q1

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

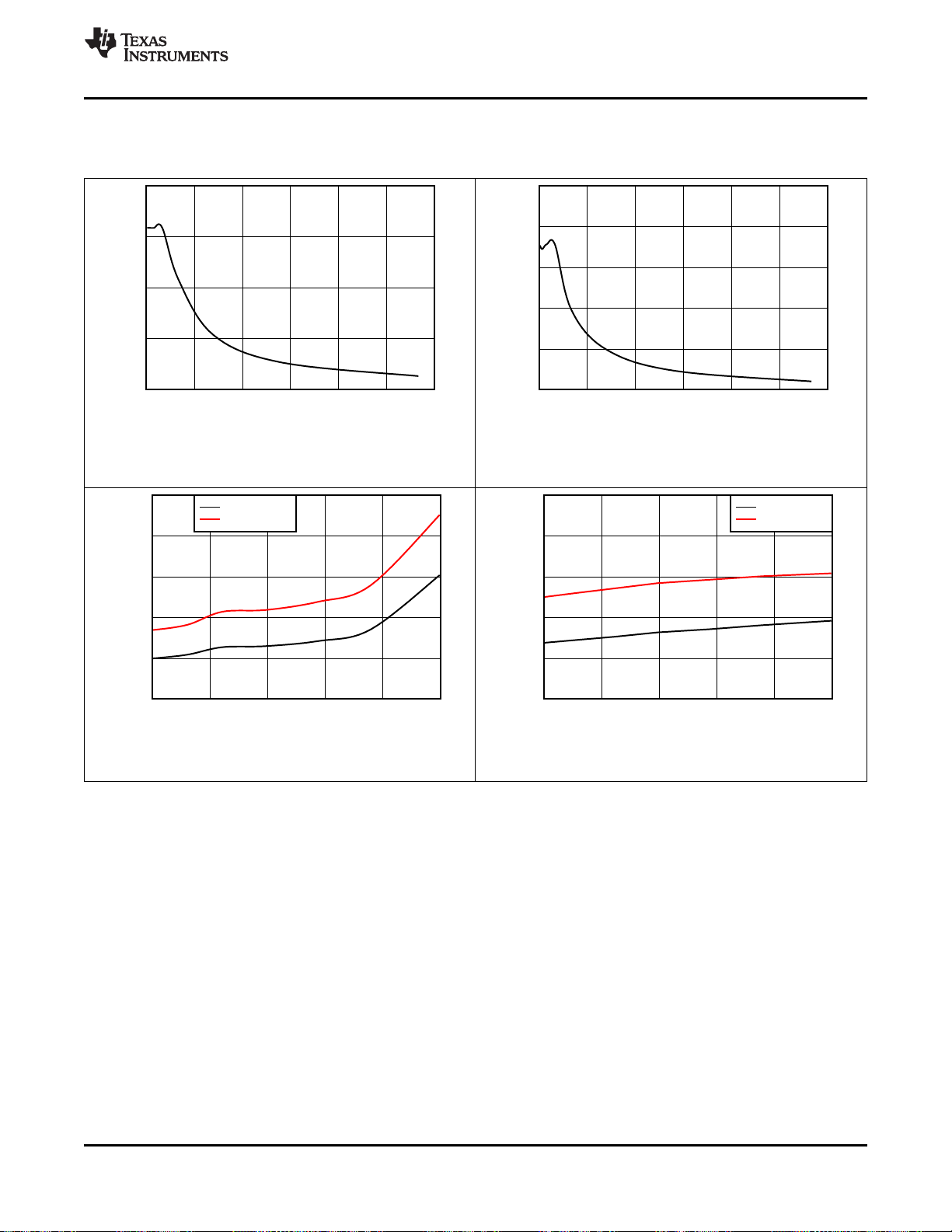

6.11 Typical Characteristics: All Modes

at TA= 25°C, AVDD = 3 V, DVDD = 3.3 V, and two-channel single-ended configuration (unless otherwise noted)

Figure 3. High-Speed Oscillator Time Period vs Temperature Figure 4. Low-Power Oscillator Time Period vs Temperature

www.ti.com

12

Submit Documentation Feedback Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: ADS7142-Q1

Free-Air Temperature (qC)

THD (dB)

-40 -7 26 59 92 125

-90

-88.4

-86.8

-85.2

-83.6

-82

ADS7

Free-Air Temperature (qC)

SFDR (dB)

-40 -7 26 59 92 125

88

88.6

89.2

89.8

90.4

91

ADS7

Free-Air Temperature (qC)

Amplitude (dB)

-40 -7 26 59 92 125

68

69

70

71

72

73

ADS7

SNR

SINAD

Free-Air Temperature (qC)

Amplitude (dB)

1.8 2.16 2.52 2.88 3.24 3.6

67

68

69

70

71

72

ADS7

SNR

SINAD

fIN, Input Frequency (Hz)

Amplitude (dB)

0 10000 20000 30000 40000 50000

-160

-140

-120

-100

-80

-60

-40

-20

0

ADS7

fIN, Input Frequency (Hz)

Amplitude (dB)

0 10000 20000 30000 40000 50000

-180

-160

-140

-120

-100

-80

-60

-40

-20

0

ADS7

www.ti.com

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

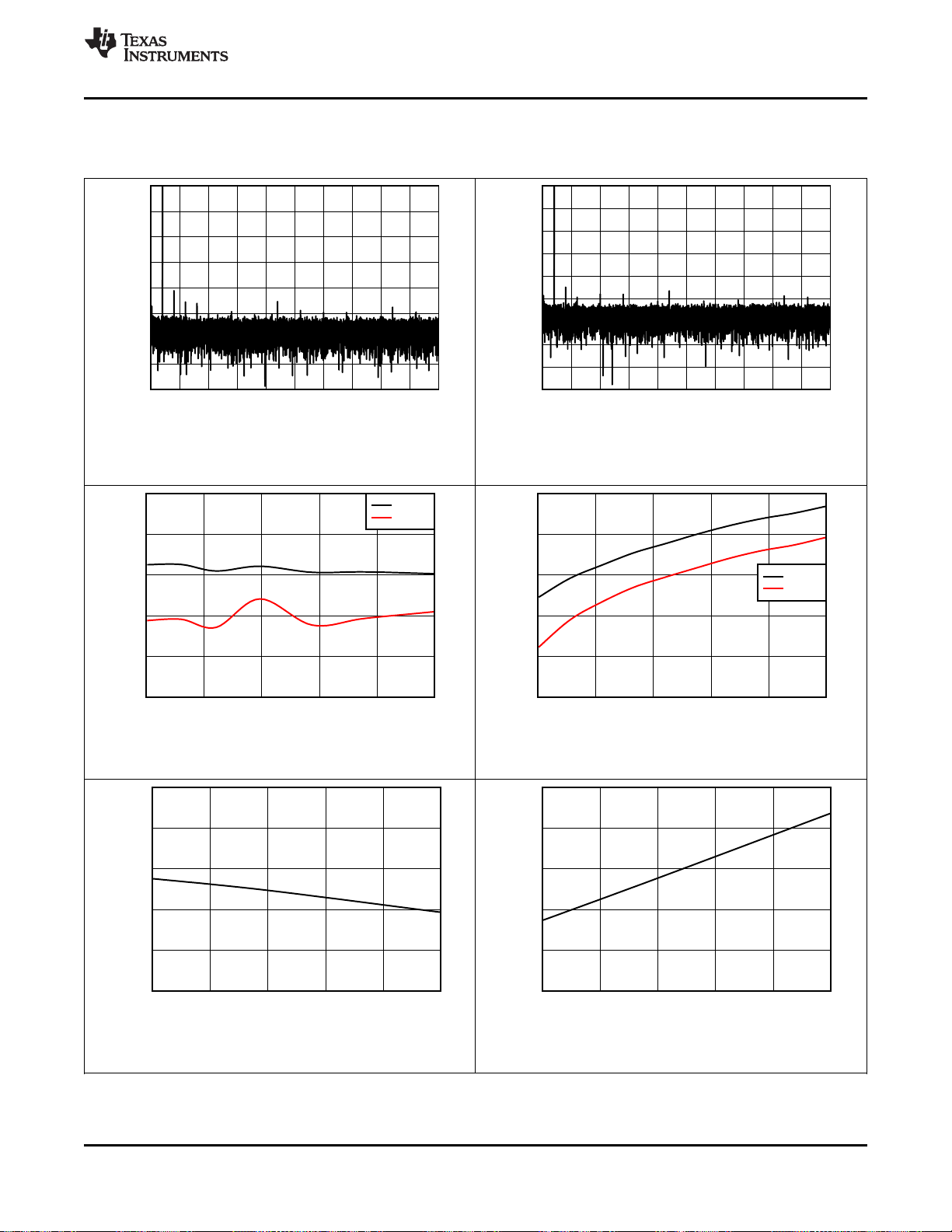

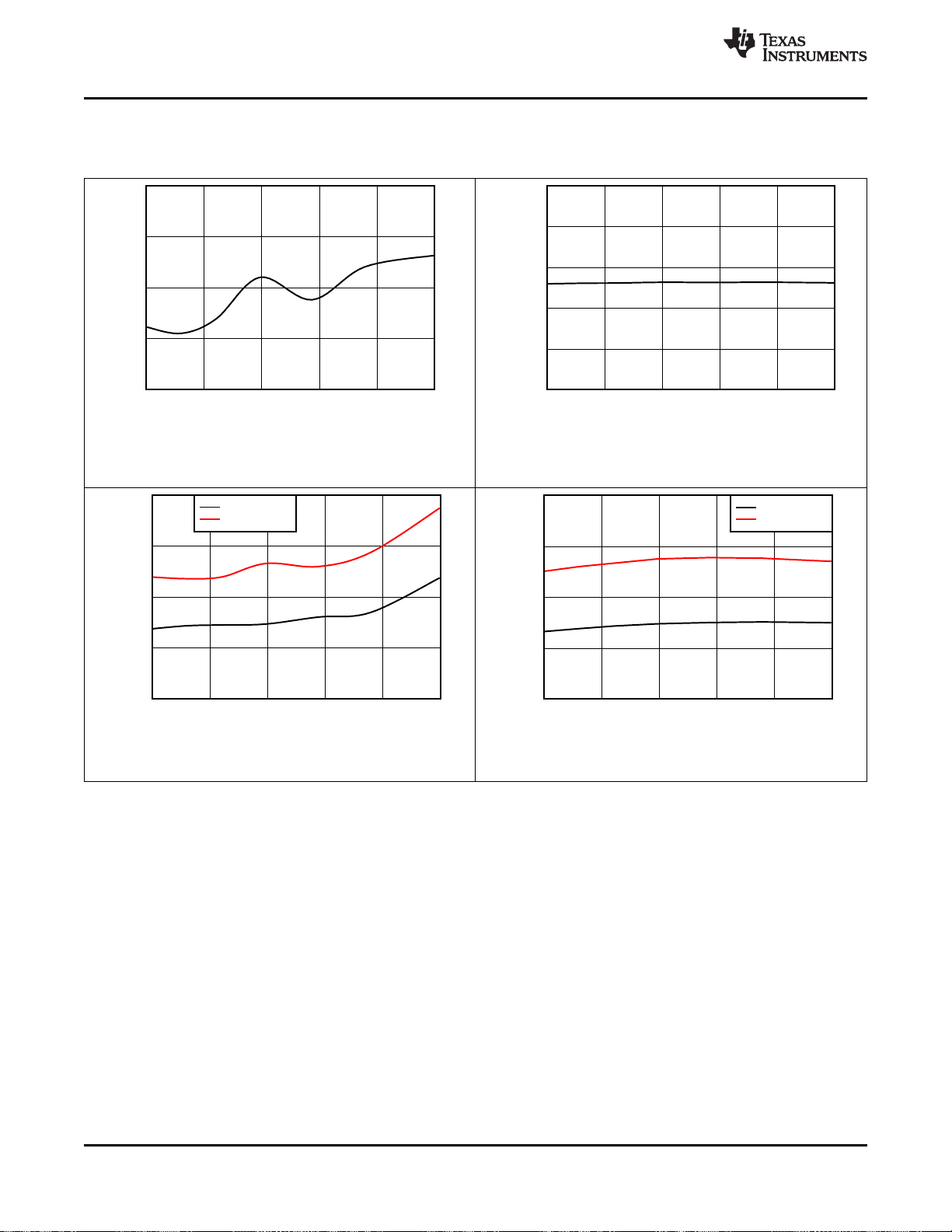

6.12 Typical Characteristics: Manual Mode

at TA= 25°C, AVDD = 3 V, DVDD = 3.3 V, and two-channel single-ended configuration (unless otherwise noted)

ADS7142-Q1

SNR = 69.6 dB, THD = –84 dB, ENOB = 11.2,

f

= 140 kSPS, SFDR = 87 dB, AVDD = 1.8 V

sample

Figure 5. Typical FFT in Manual Mode

f

= 140 kSPS

sample

Figure 7. SNR and SINAD in Manual Mode vs Temperature

SNR = 71.3 dB, THD = –87 dB, ENOB = 11.5,

f

= 140 kSPS, SFDR = 89.3 dB, AVDD = 3 V

sample

Figure 6. Typical FFT in Manual Mode

f

= 140 kSPS

sample

Figure 8. SNR and SINAD in Manual Mode vs AVDD

Figure 9. THD in Manual Mode vs Temperature

f

sample

= 140 kSPS

Figure 10. SFDR in Manual Mode vs Temperature

Product Folder Links: ADS7142-Q1

f

sample

Submit Documentation FeedbackCopyright © 2018–2019, Texas Instruments Incorporated

= 140 kSPS

13

Free-Air Temperature (qC)

Gain Error (FSR)

-40 -7 26 59 92 125

-0.05

-0.03

-0.01

0.01

0.03

0.05

ADS7

AVDD (V)

Gain Error (FSR)

1.8 2.16 2.52 2.88 3.24 3.6

-0.02

-0.002

0.016

0.034

0.052

0.07

ADS7

Free-Air Temperature (qC)

Offset Error (LSB)

-40 -7 26 59 92 125

1

1.4

1.8

2.2

2.6

3

ADS7

AVDD (V)

Offset Error (LSB)

1.8 2.16 2.52 2.88 3.24 3.6

0.5

0.9

1.3

1.7

2.1

2.5

ADS7

AVDD (V)

THD (dB)

1.8 2.16 2.52 2.88 3.24 3.6

-93

-90

-87

-84

-81

-78

ADS7

Output Code

Number of Hits

0

20000

40000

60000

2047 2048 2049

3790

3046

ADS7

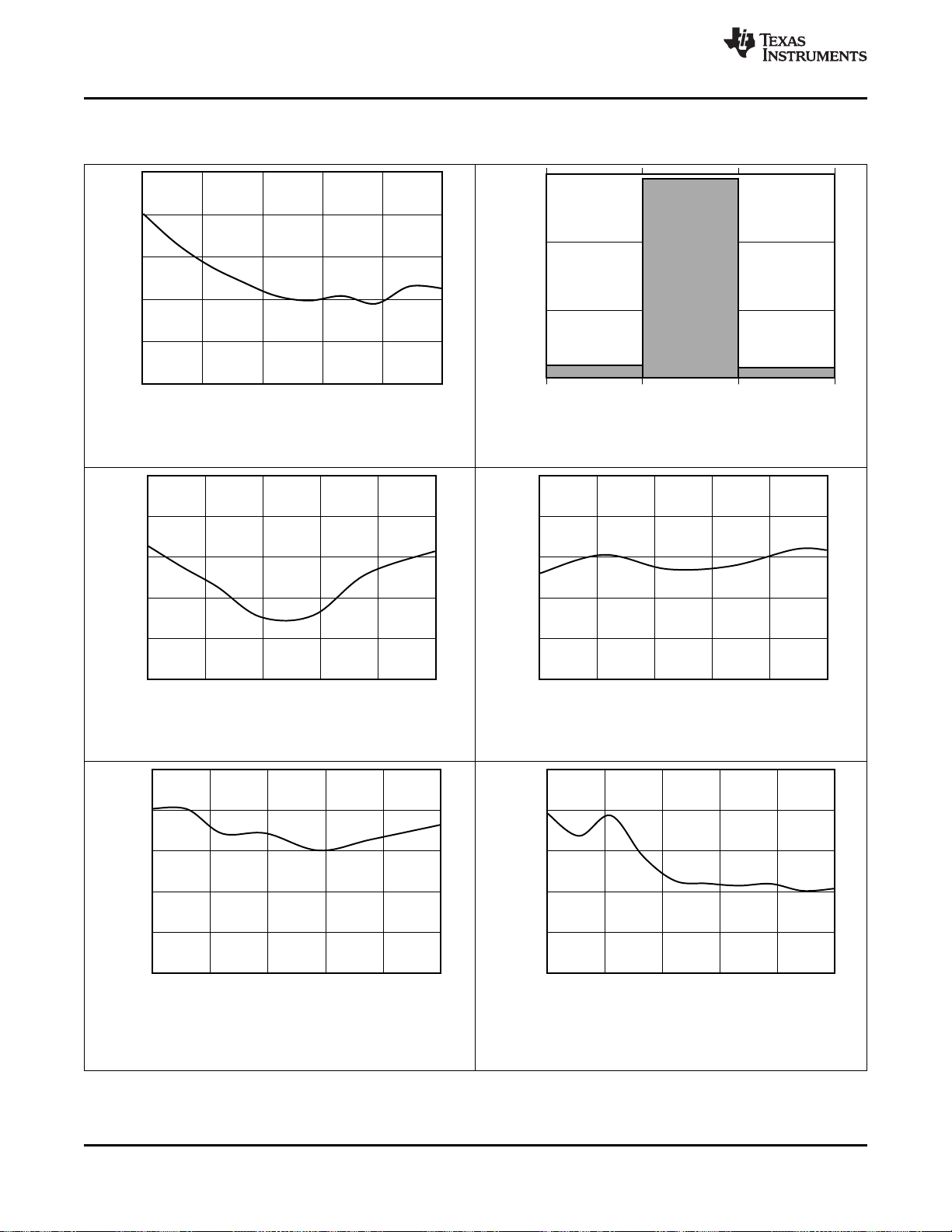

ADS7142-Q1

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

Typical Characteristics: Manual Mode (continued)

at TA= 25°C, AVDD = 3 V, DVDD = 3.3 V, and two-channel single-ended configuration (unless otherwise noted)

www.ti.com

f

= 140 kSPS

sample

Figure 11. THD in Manual Mode vs AVDD

Mean code = 2047.9, standard deviation = 0.32

Figure 12. Typical DC Code Spread in Manual Mode

Figure 13. Offset Error in Manual Mode vs Temperature Figure 14. Offset Error in Manual Mode vs AVDD

14

Figure 15. Gain Error in Manual Mode vs Free-Air

Temperature

Submit Documentation Feedback Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: ADS7142-Q1

Figure 16. Gain Error in Manual Mode vs AVDD

Free-Air Temperature (qC)

Differential Nonlinearity (LSB)

-40 -7 26 59 92 125

-1

-0.6

-0.2

0.2

0.6

1

ADS7

Maximum

Minimum

AVDD (V)

Differential Nonlinearity (LSB)

1.8 2.16 2.52 2.88 3.24 3.6

-1

-0.6

-0.2

0.2

0.6

1

ADS7

Maximum

Minimum

Output Code

Integral Nonlinearity (LSB)

0 819 1638 2457 3276 4095

-1.2

-0.6

0

0.6

1.2

ADS7

Output Code

Integral Nonlinearity (LSB)

0 819 1638 2457 3276 4095

-1

-0.6

-0.2

0.2

0.6

1

ADS7

Output Code

Differential Nonlinearity (LSB)

0 819 1638 2457 3276 4095

-0.5

-0.3

-0.1

0.1

0.3

0.5

ADS7

Output Code

Differential Nonlinearity (LSB)

0 819 1638 2457 3276 4095

-0.5

-0.3

-0.1

0.1

0.3

0.5

ADS7

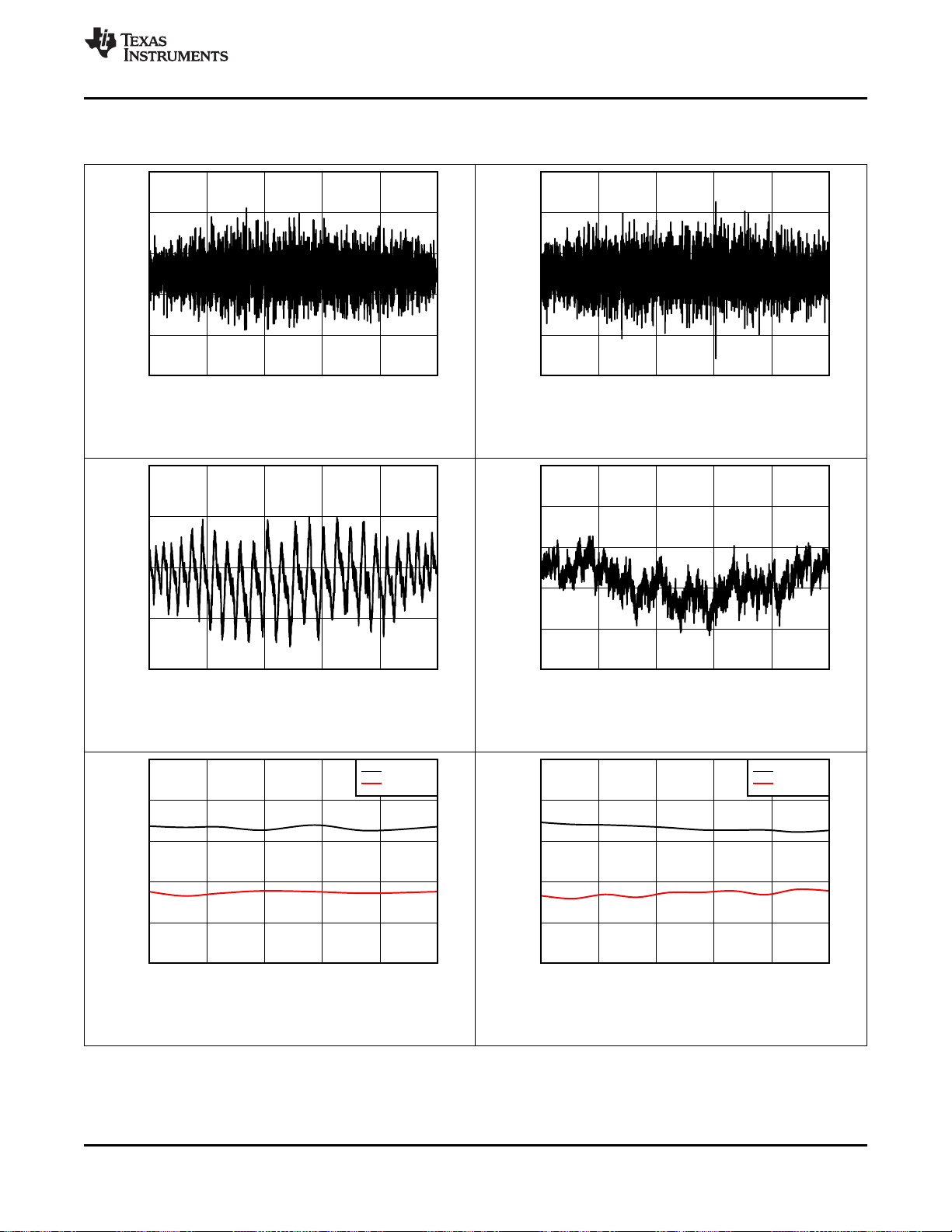

www.ti.com

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

Typical Characteristics: Manual Mode (continued)

at TA= 25°C, AVDD = 3 V, DVDD = 3.3 V, and two-channel single-ended configuration (unless otherwise noted)

ADS7142-Q1

AVDD = 3 V

Figure 17. Typical DNL in Manual Mode

AVDD = 3 V

Figure 19. Typical INL in Manual Mode

AVDD = 1.8 V

Figure 18. Typical DNL in Manual Mode

AVDD = 1.8 V

Figure 20. Typical INL in Manual Mode

Figure 21. DNL in Manual Mode vs Temperature Figure 22. DNL in Manual Mode vs AVDD

Product Folder Links: ADS7142-Q1

Submit Documentation FeedbackCopyright © 2018–2019, Texas Instruments Incorporated

15

SCL (kHz)

I

DVDD

(PA)

0 500 1000 1500 2000 2500 3000 3500

0

2.5

5

7.5

10

12.5

15

17.5

20

ADS7

Free-Air Temperature (qC)

I

AVDD

(PA)

-40 -7 26 59 92 125

-0.2

0

0.2

0.4

0.6

0.8

ADS7

AVDD = 1.8 V

AVDD = 3 V

AVDD (V)

I

AVDD

(PA)

1.8 2.16 2.52 2.88 3.24 3.6

100

150

200

250

300

350

ADS7

Free-Air Temperature (qC)

I

AVDD

(PA)

-40 -7 26 59 92 125

230

236

242

248

254

260

ADS7

Free-Air Temperature (qC)

Integral Nonlinearity (LSB)

-40 -7 26 59 92 125

-1.5

-1

-0.5

0

0.5

1

ADS7

Maximum

Minimum

AVDD (V)

Integral Nonlinearity (LSB)

1.8 2.16 2.52 2.88 3.24 3.6

-2

-1.4

-0.8

-0.2

0.4

1

ADS7

Maximum

Minimum

ADS7142-Q1

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

Typical Characteristics: Manual Mode (continued)

at TA= 25°C, AVDD = 3 V, DVDD = 3.3 V, and two-channel single-ended configuration (unless otherwise noted)

Figure 23. INL in Manual Mode vs Temperature Figure 24. INL in Manual Mode vs AVDD

www.ti.com

f

= 140 kSPS, SCL = 3.4 MHz

Sample

Figure 25. I

16

Figure 27. I

Submit Documentation Feedback Copyright © 2018–2019, Texas Instruments Incorporated

in Manual Mode vs AVDD Figure 26. I

AVDD

DVDD = 1.8 V

in Manual Mode vs SCL

DVDD

Figure 28. Static I

Product Folder Links: ADS7142-Q1

in Manual Mode vs Temperature

AVDD

No activity on SCL and SDA

in Manual Mode vs Temperature

AVDD

Free-Air Temperature (qC)

I

AVDD

(nA)

-40 -7 26 59 92 125

0

300

600

900

1200

1500

ADS7

AVDD = 1.8 V

AVDD = 3 V

Free-Air Temperature (qC)

I

AVDD

(PA)

-40 -7 26 59 92 125

0

300

600

900

1200

1500

Auto

AVDD = 1.8 V

AVDD = 3 V

nCLK

Analog Input Current (PA)

0 45 90 135 180 225 270

0

3

6

9

12

ADS7

nCLK

Analog Input Current (nA)

0 45 90 135 180 225 270

0

1.6

3.2

4.8

6.4

8

AINC

www.ti.com

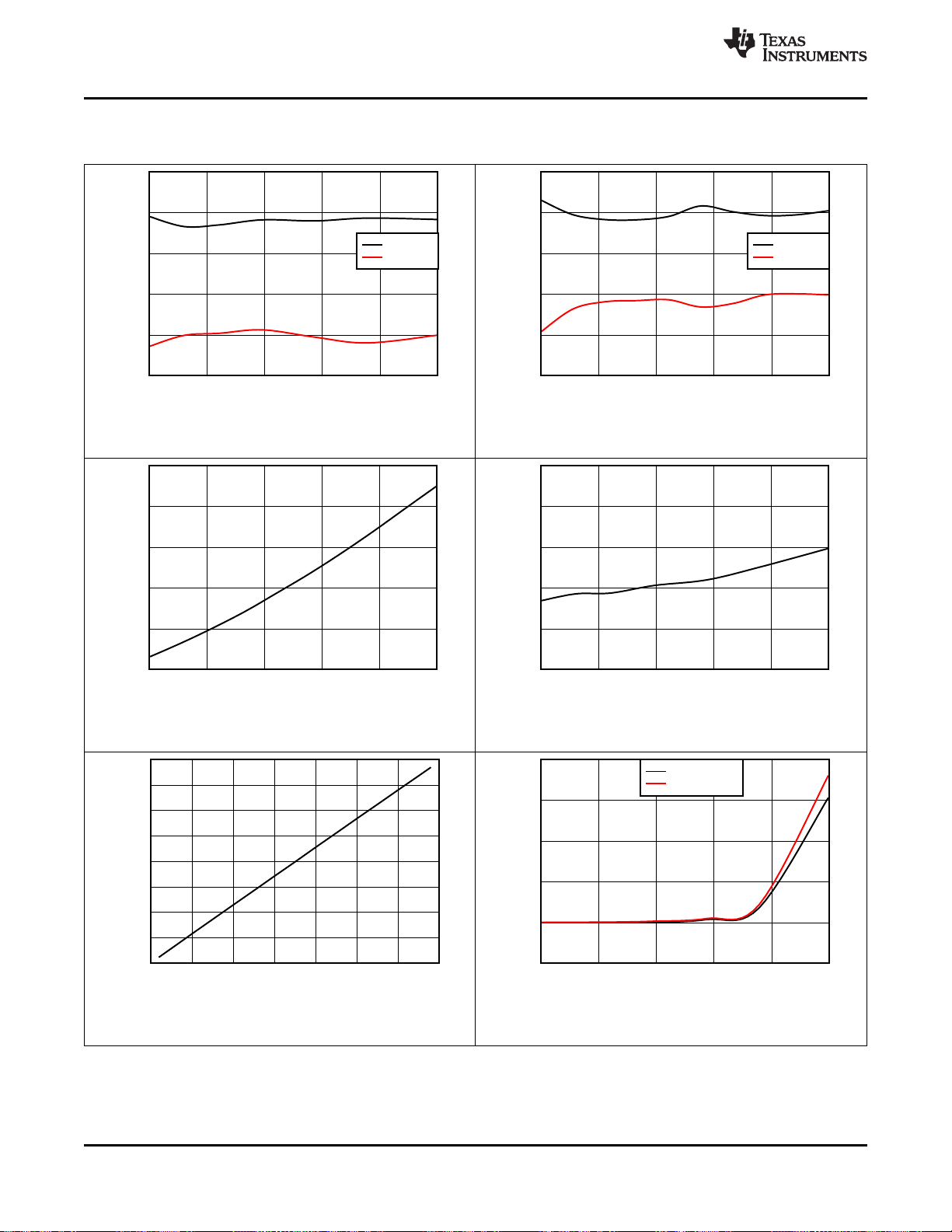

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

6.13 Typical Characteristics: Autonomous Modes

at TA= 25°C, AVDD = 3 V, DVDD = 3.3 V, and two-channel single-ended configuration (unless otherwise noted)

ADS7142-Q1

Input voltage = 1.5 V, CH0, high-speed oscillator, stop burst mode

Figure 29. Analog Input Current in Autonomous Modes vs

nCLK

Stop burst mode, low-power oscillator, nCLK = 25

Figure 31. I

in Autonomous Modes vs Temperature

AVDD

Input voltage = 1.5 V, CH0, low-power oscillator, stop burst mode

Figure 30. Analog Input Current in Autonomous Modes vs

nCLK

Stop burst mode, high-speed oscillator, nCLK = 25

Figure 32. I

in Autonomous Modes vs Temperature

AVDD

Product Folder Links: ADS7142-Q1

Submit Documentation FeedbackCopyright © 2018–2019, Texas Instruments Incorporated

17

Free-Air Temperature (qC)

I

AVDD

(nA)

-40 -7 26 59 92 125

0

300

600

900

1200

ADS7

AVDD = 1.8 V

AVDD = 3 V

Free-Air Temperature (qC)

I

AVDD

(PA)

-40 -7 26 59 92 125

0

300

600

900

1200

AVDD = 1.8 V

AVDD = 3 V

Free-Air Temperature (qC)

Offset Error (LSB)

-40 -7 26 59 92 125

-2

1

4

7

10

Offs

Free-Air Temperature(qC)

Gain Error (FSR)

-40 -7 26 59 92 125

-0.03

-0.018

-0.006

0.006

0.018

0.03

Gain

ADS7142-Q1

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

6.14 Typical Characteristics: High-Precision Mode

at TA= 25°C, AVDD = 3 V, DVDD = 3.3 V, and two-channel single-ended configuration (unless otherwise noted)

www.ti.com

Figure 33. Offset Error in High-Precision Mode vs

Temperature

Low-power oscillator, nCLK = 25

Figure 35. I

in High-Precision Mode vs Temperature

AVDD

Figure 34. Gain Error in High-Precision Mode vs

Temperature

High-speed oscillator, nCLK = 25

Figure 36. I

in High-Precision Mode vs Temperature

AVDD

18

Submit Documentation Feedback Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: ADS7142-Q1

SAR-ADC

Oscillator and

Timing Control

I2C Interface

Conversion Result

ALERT

ADDR

SCL

SDA

AINP/AIN0

AINM/AIN1

AVDD

DVDD

GND

BUSY/RDY

Accumulator

Conversion Result [0]

«««.

Conversion Result [15]

Data Buffer

Analog Input and

Multiplexer

«««.

«««.

High/Low Threshold

± Hysteresis

Digital

Window

Comparator

I2C Address

Selector

Offset

Calibration

ADS7142-Q1

www.ti.com

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

7 Detailed Description

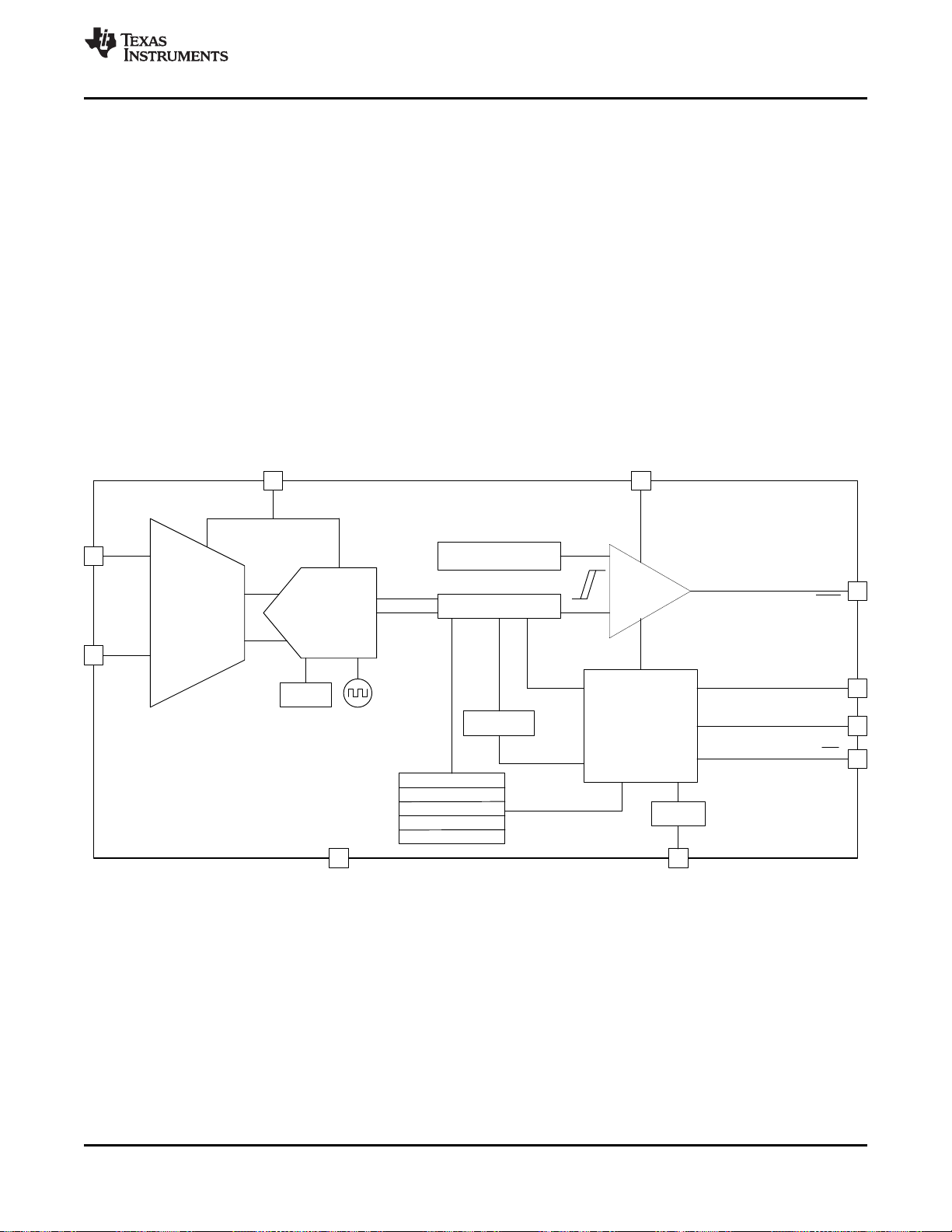

7.1 Overview

The ADS7142-Q1 is a small size, dual-channel, 12-bit programmable sensor monitor with an integrated analogto-digital converter (ADC), input multiplexer, digital comparator, data buffer, accumulator and internal oscillator.

The input multiplexer can be either configured as two single-ended channels, one single-ended channel with

remote ground sensing, or one pseudo-differential channel where the input can swing to approximately AVDD /

2. The device includes a digital window comparator with a dedicated output pin, which can be used to alert the

host when a programmed high or low threshold is crossed. The device address is configured by the I2C address

selector block. The device uses internal oscillators (high speed or low power) for conversion. The start of

conversion is controlled by the host in manual mode and by the device in the autonomous modes.

The device also features a data buffer and an accumulator. The data buffer can store up to 16 conversion results

of the ADC in the autonomous modes and the accumulator can accumulate up to 16 conversion results of the

ADC in high-precision mode.

The device includes an offset calibration to calibration its own offset.

7.2 Functional Block Diagram

Product Folder Links: ADS7142-Q1

Submit Documentation FeedbackCopyright © 2018–2019, Texas Instruments Incorporated

19

AINP/AIN0

AINM/AIN1

AVDD

GND

GND + 100mV

GND -100mV

GND

C

s1

C

s

2

V_BIAS

SW

1

R

s1

R

s2

GND

SW

2

MUX

CHANNEL_INPUT_CFG_REG

AINP/AIN0

AINM/AIN1

AVDD

GND

AVDD/2 + 100mV

AVDD/2-100mV

AVDD/2

C

s1

C

s

2

V_BIAS

SW

1

R

s1

R

s2

GND

SW

2

MUX

CHANNEL_INPUT_CFG_REG

AVDD/2

C

s1

C

s

2

AVDD

AVDD

V_BIAS

AINP/AIN0

AINM/AIN1

SW

1

R

s1

R

s2

GND

SW

2

MUX

CHANNEL_INPUT_CFG_REG

AVDD

GND

AVDD

GND

CH0

CH1

C

s1

C

s

2

V_BIAS

AINP/AIN0

AINM/AIN1

SW

1

R

s

1

R

s2

GND

SW

2

MUX

CHANNEL_INPUT_CFG_REG

CH0

CH1

ADS7142-Q1

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

www.ti.com

7.3 Feature Description

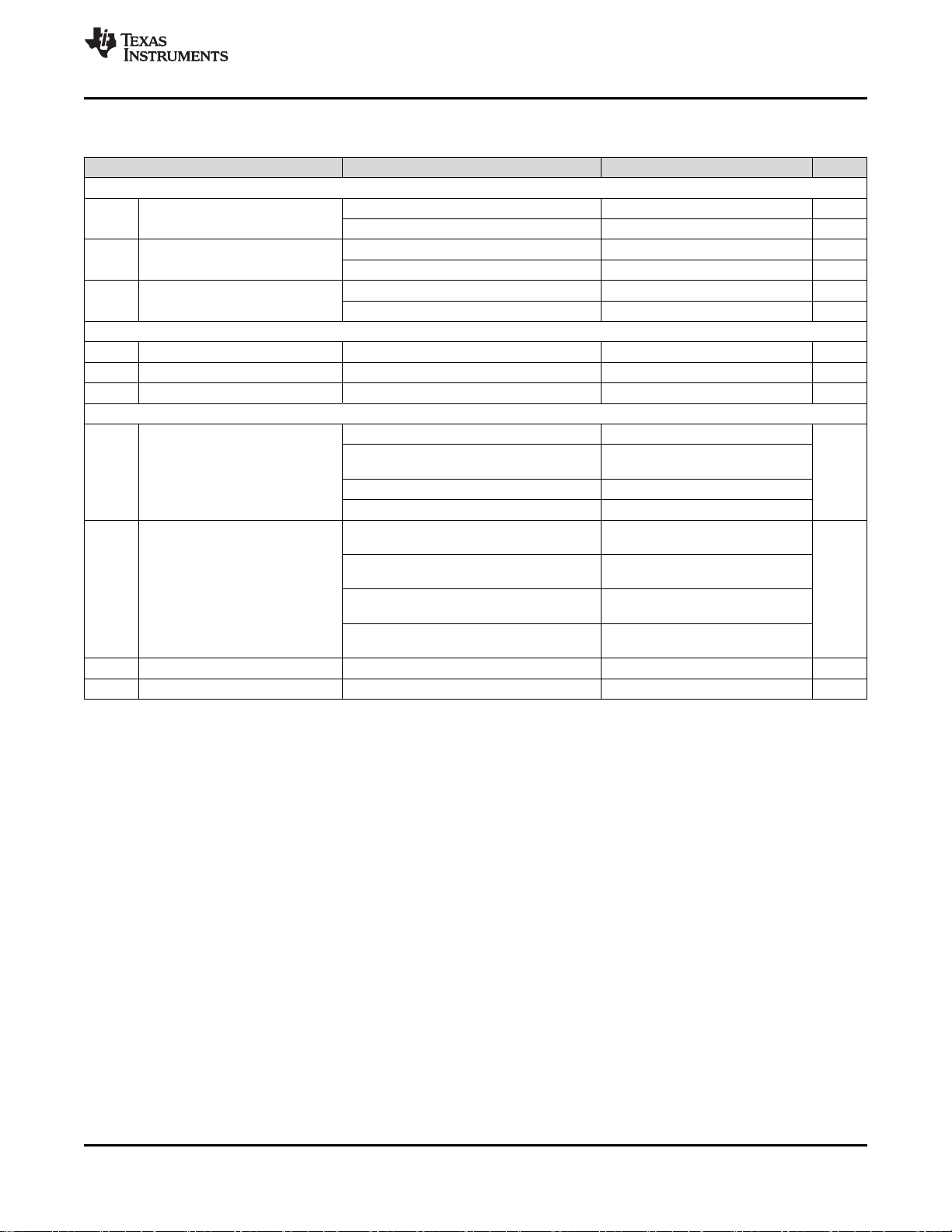

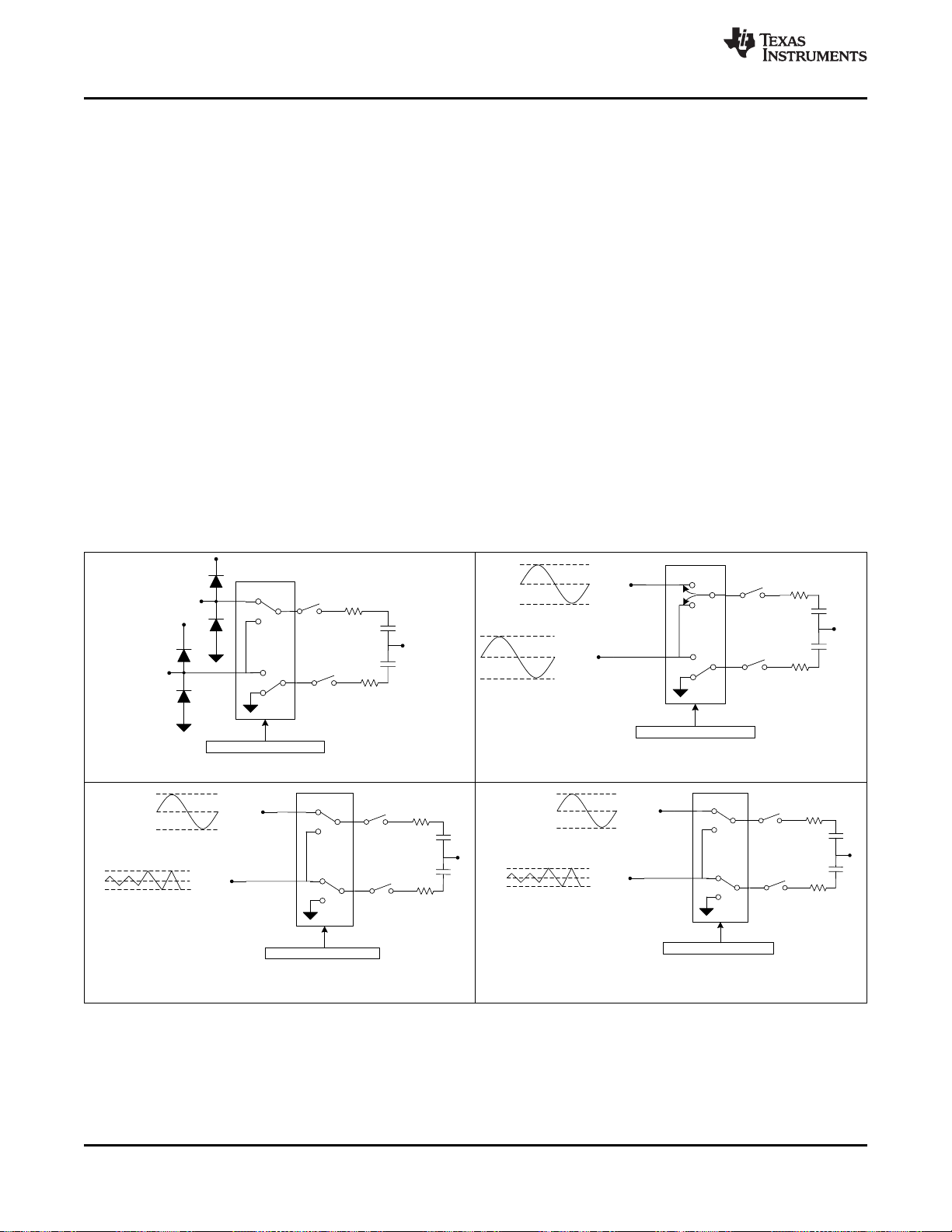

7.3.1 Analog Input and Multiplexer

Figure 37 shows a small-signal equivalent circuit for the analog input pins. The device includes a two-channel

analog multiplexer with each input pin having ESD protection diodes to AVDD and GND. The sampling switches

are represented by ideal switches SW1and SW2in series with resistors Rs1and Rs2(typically 150 Ω). The

sampling capacitors, Cs1and Cs2, are typically 15 pF. The multiplexer configuration is set by the

CH_INPUT_CFG register.

During acquisition, switches SW1and SW2are closed to allow the input signal to charge the internal sampling

capacitors.

During conversion, switches SW1and SW2are opened to disconnect the input signal from the sampling

capacitors.

The analog input of the device are optimized to be driven by high impedance source (up-to 100 kΩ) in

Autonomous Modes or in High Precision Mode mode with low power oscillator. It is recommended to drive the

analog input of the device with an external amplifier when in Autonomous Modes or in High Precision Mode

mode with a high-speed oscillator. Figure 29 and Figure 30 provide the analog input current for CH0 and CH1 of

the device.

Figure 38, Figure 39 and Figure 40 provide a simplified circuit for analog input for input configurations described

in Two-Channel, Single-Ended Configuration, Single-Channel, Single-Ended Configuration and Single-Channel,

Pseudo-Differential Configuration respectively. The analog multiplexer supports following input configurations (set

by writing into the CH_INPUT_CFG register).

Figure 37. Equivalent Circuit for Analog Input

Figure 38. Two-Channel, Single-Ended Configuration

Figure 39. Single-Channel, Single-Ended Configuration

With Remote Ground Sensing

7.3.1.1 Two-Channel, Single-Ended Configuration

Figure 38 shows a simplified block diagram showing a two-channel, single-ended configuration. Set the

CH0_CH1_IP_CFG bits = 00b or 11b to select this configuration. This configuration is also the default for the

device after power up. In this configuration, CS2always samples the GND pin and CS1samples the input signal

provided on channel 0 (AINP/AIN0) or channel 1 (AINM/AIN1) based on the channel selection. Each analog input

channel can accept input signals in the range 0 V to AVDD V.

20

Submit Documentation Feedback Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: ADS7142-Q1

Figure 40. Single-Channel, Pseudo-Differential

Configuration

ADS7142-Q1

www.ti.com

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

Feature Description (continued)

On power-up, the device wakes up in manual mode with two-channel, single-ended configuration and samples

CH0 only. This configuration can also be set by setting OPMODE_SEL to 000b or 001b,

The device can be configured to sample either CH0 or CH1 or both channels by setting bits in the

AUTO_SEQ_CHEN register to select the channels.

• To select a channel in AUTO sequence, set AUTO_SEQ_CHx bit in the AUTO_SEQ_CHEN register to 1.

• Set the bits in the OPMODE_SEL register to 100b or 101b for manual mode with AUTO sequence.

• Set the bits in the OPMODE_SEL register to 110b for Autonomous Modes with AUTO sequence.

• Set the bits in the OPMODE_SEL register to 111b for High Precision Mode with AUTO sequence.

7.3.1.2 Single-Channel, Single-Ended Configuration

See Figure 39 for a simplified block diagram showing a single-channel, single ended configuration. Set

CH0_CH1_IP_CFG bits = 01b to select this configuration. In this configuration, CS1samples the input signal

provided on the AINP/AIN0 pin whereas CS2samples input signal provided on the AINM/AIN1 pin. AINP/AIN0 pin

can accept input signals in the range 0 V to AVDD V and AINM/AIN1 pin can accept input signals in the range

–100 mV to +100 mV. This input configuration is useful in systems where the sensor and/or the signal

conditioning block is placed far from the device and there could be a small difference between the ground

potentials. In this channel configuration, remove channel 1 from AUTO sequence by setting the

AUTO_SEQ_CH1 bit to 0. Selecting channel 1 in AUTO sequence leads to an error condition and the device

sets an error flag in the SEQUENCE_STATUS register.

7.3.1.3 Single-Channel, Pseudo-Differential Configuration

See Figure 40 for a simplified block diagram showing a single-channel, pseudo-differential configuration. Set

CH0_CH1_IP_CFG bits = 10b to select this configuration. In this configuration, CS1samples the input signal

provided on the AINP/AIN0 pin whereas CS2samples input signal provided on the AINM/AIN1 pin. AINP/AIN0 pin

can accept input signals in the range 0 V to AVDD V and AINM/AIN1 pin can accept input signals in the range

(AVDD/2) - 100 mV to (AVDD/2) + 100 mV. This input configuration is useful to interface with sensors that

provide pseudo-differential signal with negative output as AVDD/2 like an electrochemical gas sensor. In this

channel configuration, remove channel 1 from AUTO sequence by setting the AUTO_SEQ_CH1 bit to 0.

Selecting channel 1 in AUTO sequence leads to an error condition and the device sets an error flag in

SEQUENCE_STATUS register.

7.3.2 OFFSET Calibration

The offset can be calibrated by setting the TRIG_OFFCAL bit in the OFFSET_CAL register. During offset

calibration, the sampling switches are open (Figure 37) and the device keeps BUSY/RDY pin high. The device

calculates its offset error and corrects for this error for subsequent conversions. The device calibrates the offset

on power up. To nullify the change in offset due to change in temperature or in AVDD voltage, it is recommended

to perform this calibration periodically.

7.3.3 Reference

The device uses the analog supply voltage (AVDD) as a reference for the analog-to-digital conversion process. It

is recommended to place a 220-nF, low-ESR ceramic decoupling capacitor between the AVDD pin and the GND

pin, close to the AVDD Pin. See Power Supply Recommendations section.

7.3.4 ADC Transfer Function

The ADC provides data in straight binary format. The ADC resolution can be computed by Equation 1:

1 LSB = V

REF

/ 2

N

where:

• V

• N = 12 for Autonomous Monitoring Modes and Manual Mode (1)

REF

= AVDD

Product Folder Links: ADS7142-Q1

Submit Documentation FeedbackCopyright © 2018–2019, Texas Instruments Incorporated

21

nCLK

frequencyOscillator

f

S

NFSC+1

PFSC

MC + 1

MC

ADC Code (Hex)

V

IN

NFSC

(V

REF

/2 ± 1 LSB)

1 LSB0(-V

REF

/2 + 1 LSB)

NFSC+1

PFSC

MC + 1

MC

ADC Code (Hex)

V

IN

NFSC

1 LSB

(V

REF

± 1 LSB)

(V

REF

/2 + 1 LSB)V

REF

/2

ADS7142-Q1

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

www.ti.com

Feature Description (continued)

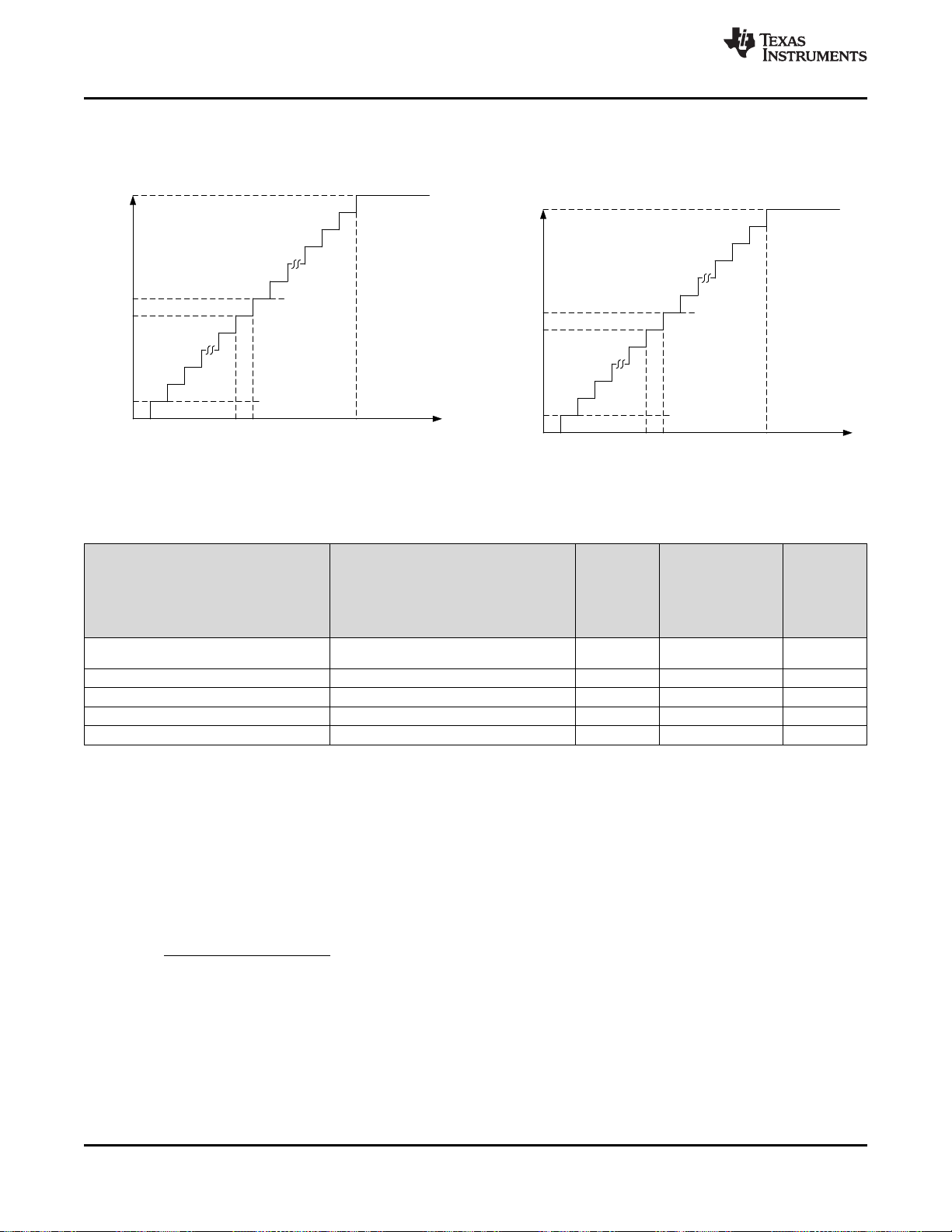

Figure 41 and Figure 42 show the ideal transfer characteristics for single-ended input and pseudo-differential

input, respectively. Table 1 show the digital output codes for the transfer functions.

Figure 41. Ideal Transfer Characteristics for

Single-Ended Configurations

Figure 42. Ideal Transfer Characteristics for

Pseudo-Differential Configuration

Table 1. Transfer Characteristics

IDEAL

OUTPUT

INPUT VOLTAGE FOR SINGLE-ENDED INPUT

INPUT VOLTAGE FOR PSEUDO

DIFFERENTIAL INPUT

CODE DESCRIPTION

CODE

(Autonomous

Monitoring

Mode or

Manual Mode)

Negative full-scale

code

000

(V

REF

(V

/ 2) + 1 LSB to (V

REF

≤1 LSB ≤ (–V

1 LSB to 2 LSBs (–V

/ 2) to (V

≥ V

/ 2) + 1 LSB 0 LSB to 1 LSB MC Mid code 800

REF

/ 2) + 2 LSBs 1 LSB to 2 LSB MC + 1 — 801

REF

– 1 LSB ≥ V

REF

/ 2 + 1) to (–V

REF

/ 2 + 1) LSB NFSC

REF

/ 2 + 2) LSB NFSC + 1 — 001

REF

/ 2 – 1 LSB PFSC Positive full-scale code FFF

REF

7.3.5 Oscillator and Timing Control

The device uses one of the two internal oscillators (low power oscillator or high speed oscillator) for converting

the analog input voltage into a digital output code.

The steps for selecting the oscillator and setting the sampling speed are listed below:

1. Select the low power oscillator (OSC_SEL = 1b) to monitor slow moving signals (< 300 Hz) at extremely low

power consumption and sampling speeds (< 600 SPS). Select the high speed oscillator (OSC_SEL = 0b) to

scan the sensor signals with faster sampling speed (> 50 kHz).

2. Set sampling speed by programming the NCLK_SEL register:

22

• fs= Sampling speed

• Oscillator frequency = 1 / t

1 / t

HSO

or 1 / t

LPO

HSO

or 1 / t

depending on the OSC_SEL bit; see the Specifications section for

LPO

• nCLK is number of clocks in one conversion cycle (see the NCLK_SEL register) (2)

Submit Documentation Feedback Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: ADS7142-Q1

Copyright © 2017, Texas Instruments Incorporated

R1

R2

AVDD

ADDR

ADS7142-Q1

www.ti.com

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

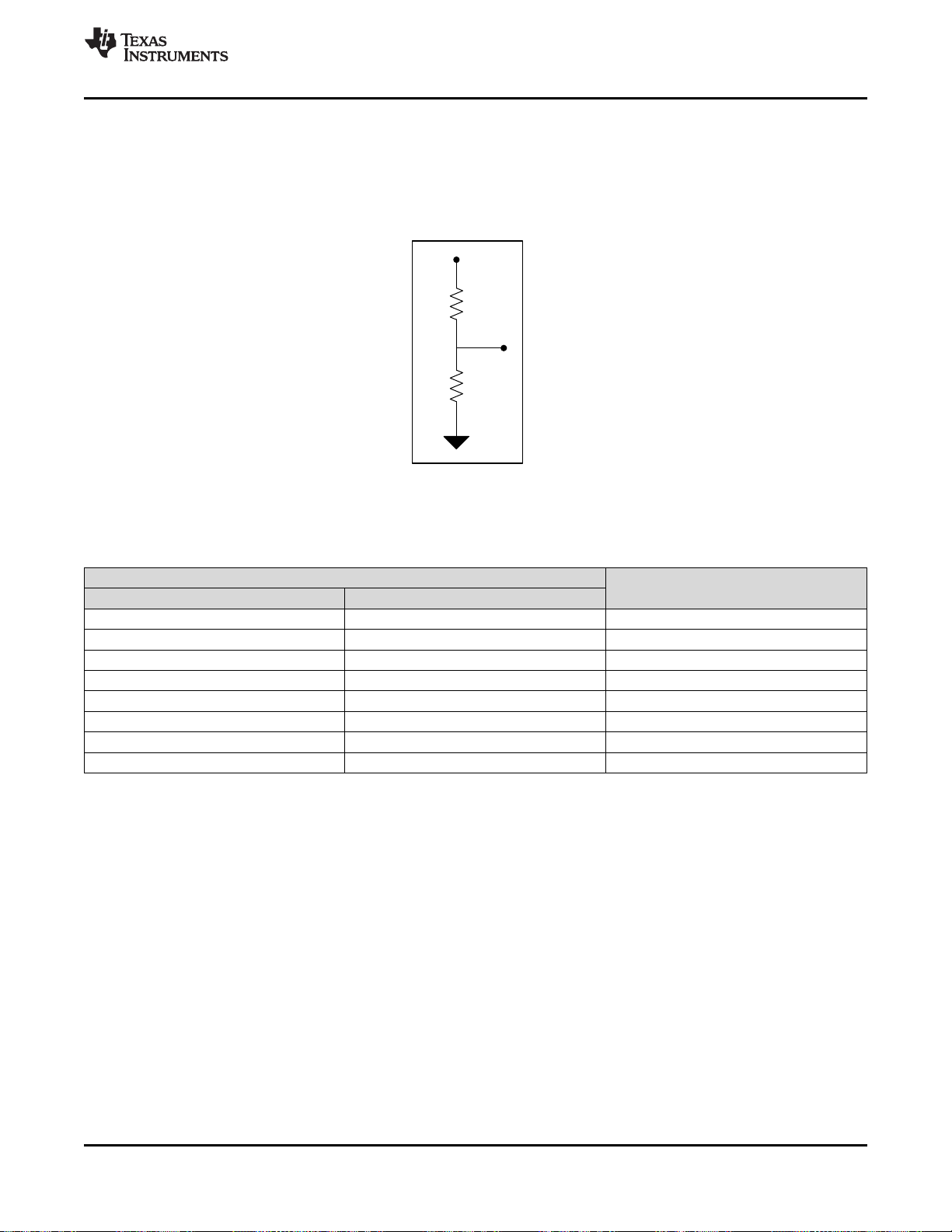

7.3.6 I2C Address Selector

The I2C address for the device is determined by connecting external resistors on ADDR pin. The device address

are selected on power-up based on the resistor values. The device retains this address until the next power up,

or until next device reset, or until the device receives a command to program its own address (General Call With

Write Software Programmable Part of Slave Address). Figure 43 provides the connection diagram for the ADDR

pin and Table 2 provides the resistor values for selecting different addresses of the device.

Figure 43. External Resistor Connection Diagram for ADDR Pin

Table 2. I2C Address Selection

(1)

R1

0 Ω DNP

11 kΩ DNP

33 kΩ DNP

100 kΩ DNP

(2)

DNP

(2)

DNP

(2)

DNP

(2)

DNP

(1) Tolerance for R1, R2 < ±5%.

(2) DNP = Do not populate.

RESISTORS

(1)

R2

(2)

(2)

(2)

(2)

0Ω or DNP

(2)

11 kΩ 0011001b (19h)

33 kΩ 0011010b (1Ah)

100 kΩ 0011011b (1Bh)

ADDRESS

0011111b (1Fh)

0011110b (1Eh)

0011101b (1Dh)

0011100b (1Ch)

0011000b (18h)

7.3.7 Data Buffer

When operating in autonomous monitoring mode, the device can use the internal data buffer for data storage.

The internal data buffer is 16-bit wide and 16-word deep and follows the first-in, first-out (FIFO) approach.

Product Folder Links: ADS7142-Q1

Submit Documentation FeedbackCopyright © 2018–2019, Texas Instruments Incorporated

23

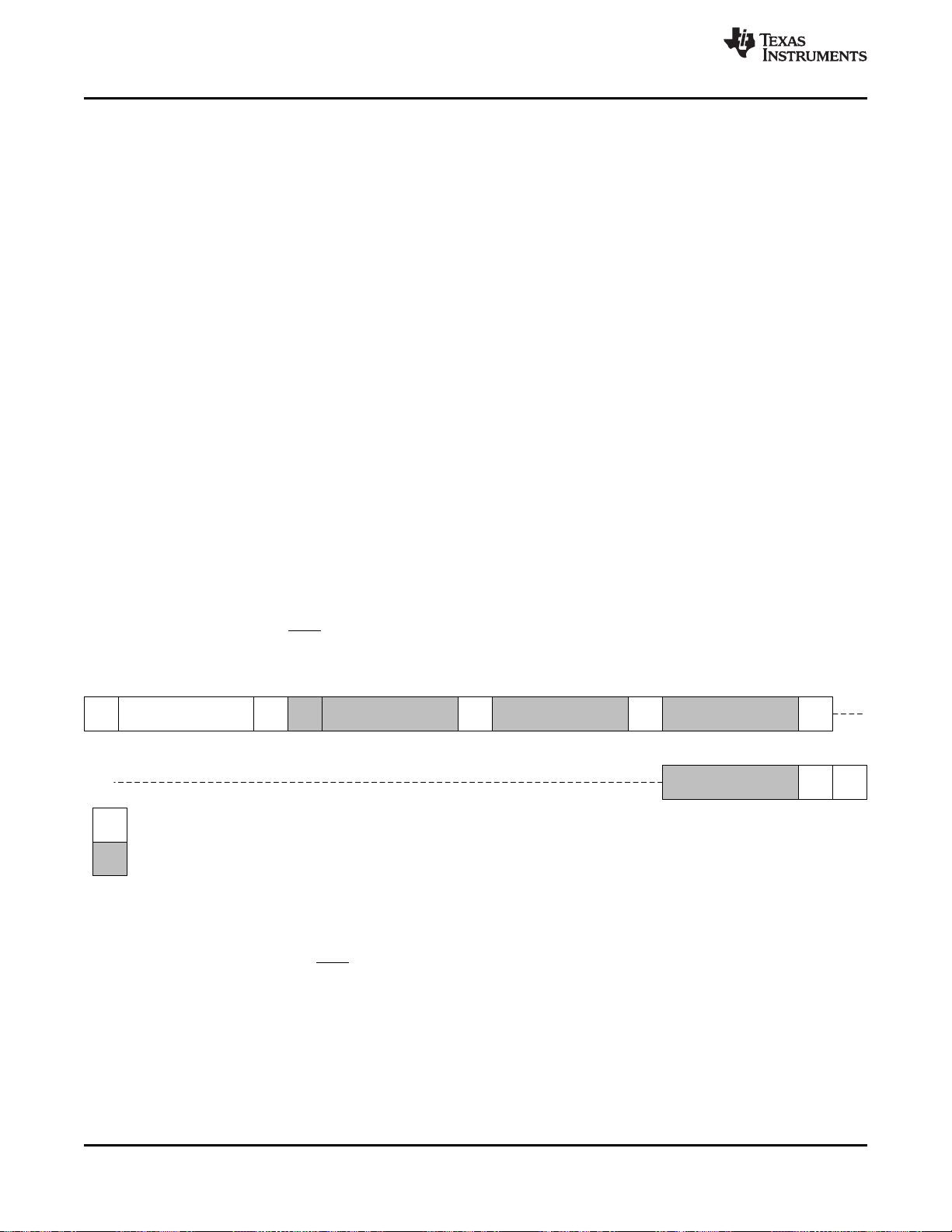

Device Address (7 Bits) MSB for Data Buffer Entry 0 A LSB for Data Buffer Entry 0

LSB for Data Buffer Entry 15

R A A

P/Sr

Data from Host to Device

Data from Device to Host

S

N

MSB for Data Buffer Entry 1 A

ADS7142-Q1

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

www.ti.com

7.3.7.1 Filling of the Data Buffer

The write operation to the data buffer starts and stops as per the settings in the DATA_BUFFER_OPMODE

register. The DATA_BUFFER_STATUS register provides the number of entries filled in the data buffer and this

register can be read during an active sequence to get the current status of the data buffer.

The time between two consecutive conversions is set by the NCLK_SEL register and Equation 3 provides the

relationship for time between two consecutive conversions of the same channel and nCLK parameter.

tcc= k x nCLK x OscillatorTimePeriod

where

• tcc= Time between two consecutive conversions of same channel, tcc= k × t

• k = Number of channels enabled in the device sequence

• nCLK = Number of clocks used by device for one conversion cycle

• Oscillator timer period = t

or t

HSO

LPO

or t

depending on the OSC_SEL value; see the Specifications section for t

HSO

cycle

LPO

(3)

The format of the 16-bit contents of each entry in the data buffer are set by programming the

DOUT_FORMAT_CFG register. The DATA_OUT_CFG register enables the channel ID and DATA_VALID flag in

data buffer. Channel ID represents the channel number for the data entry in the data buffer. DATA_VALID is set

to zero in either of the following conditions:

• If the entry in the data buffer is not filled after the last start of sequence.

• If the I2C master tries to read more than 16 entries from the data buffer, the device provides zeros with

DATA_VALID set to zero

At the end of the write operation, the data buffer always has results of 16 (or lesser) consecutive conversions.

The data buffer is filled in the order that the data is converted by the ADC. The channels converted by the ADC

are controlled by the AUTO_SEQ_CHEN register. The entries that are not filled during an active sequence are

filled with zeros.

7.3.7.2 Reading Data From the Data Buffer

The device brings the BUSY/RDY pin low after completion of the sequence or after the SEQ_ABORT bit is set.

As illustrated in Figure 44, the device provides the contents of the data buffer (in FIFO fashion) on receiving I2C

read frame, which consists of the device address and the read bit set to 1.

Figure 44. Reading Data Buffer (16 Bit Words × 16 Words)

The device returns zeroes with DATA VALID flag set to zero for all I2C read frames received after all the valid

data words from the data buffer are read or when a I2C read frame is issued during an active sequence

(indicated by high on the BUSY/RDY pin). The I2C master needs to provide a NACK followed by a STOP or

RESTART condition in an I2C frame to finish the reading process. The data buffer is reset by setting the

SEQ_START bit or after resetting the device.

24

Submit Documentation Feedback Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: ADS7142-Q1

Conversion Result for CH0

(High Side Threshold, Hysteresis)

for CH0

(Low Side Threshold, Hysteresis)

for CH0

High Latched Flag for CH0

Low Latched Flag for CH0

High Side

Counter

Low Side

Counter

High Side Comparator

Low Side Comaparator

ADC

S

R

Q

R

S

Q

Write Bit to

Reset

OR

ALERT_EN_CH0

ALERT

End of

Conversion

OR

Channel 1

Channel 0

DWC_BLOCK_EN

ALERT_EN_CH1

16

2

AVDD

LSB

¦

16

1k

CHxfor Result[k]ConversionCHxfor DataPrecision High

ADS7142-Q1

www.ti.com

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

7.3.8 Accumulator

When operating in High Precision Mode, the device offers a 16-bit internal accumulator per channel. The

Accumulator for a channel is enabled only if that channel is selected in the channel scanning sequence. The

accumulator adds sixteen 12-bit conversion results. The result of adding 16 twelve bit words is one 16 bit word

that has an effective resolution of an 16-bit ADC. The time between two consecutive conversions for

accumulation is controlled by the NCLK_SEL register and Equation 3 provides the relationship for time between

two consecutive conversions of same channel and nCLK parameter.

The accumulated data can be read from the ACC_CHx_MSB and ACC_CHx_LSB registers in the device. The

ACCUMULATOR_STATUS register provides the number of accumulations done in the accumulator since last

conversion. This register can be read during an active sequence to get the current status of the accumulator.

The accumulator is reset on setting the SEQ_START bit and on resetting the device.

Equation 4 provides the relationship between high precision data and ADC conversion results.

(4)

Equation 5 provides the value of LSB in high precision mode for the accumulated result.

(5)

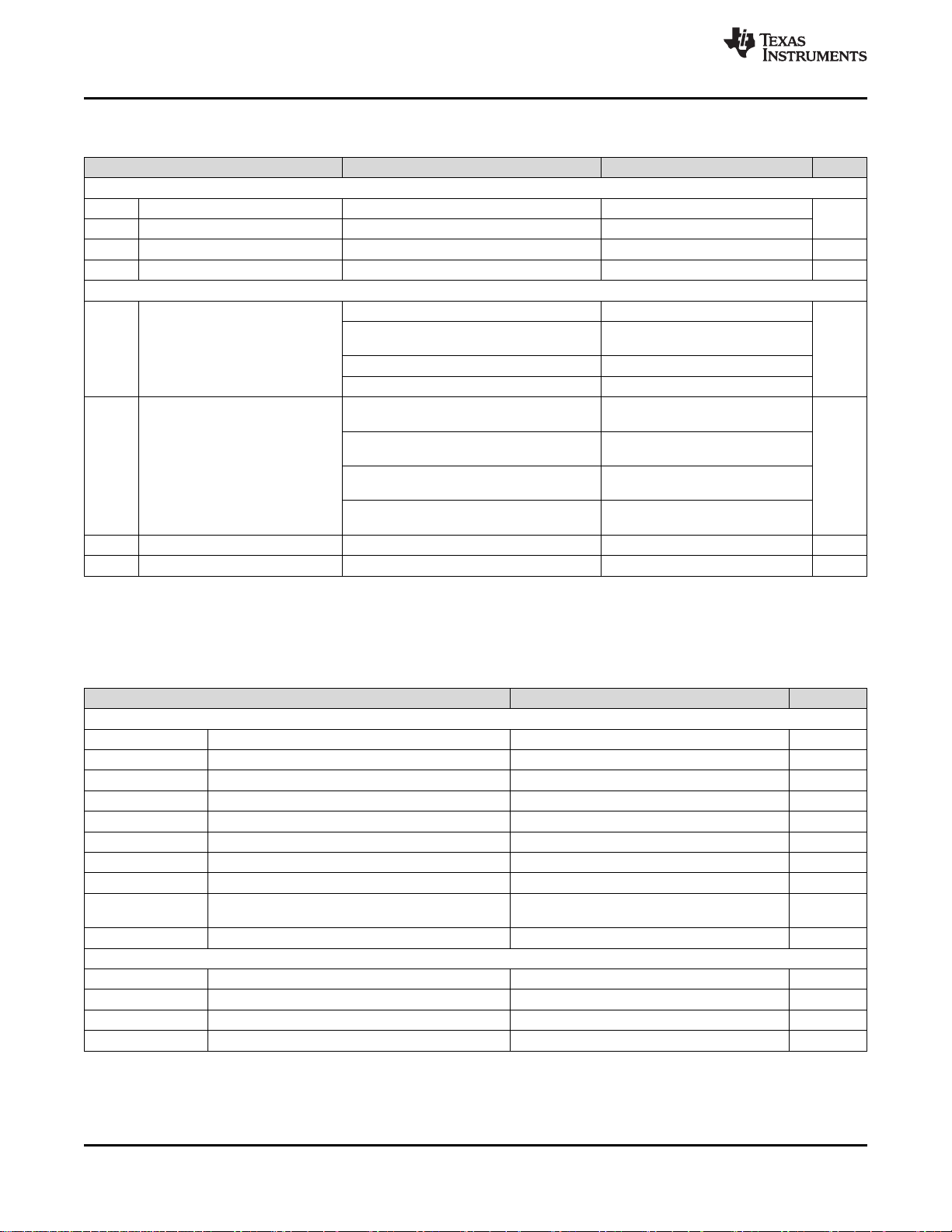

7.3.9 Digital Window Comparator

The internal digital window comparator is available in all modes. In Autonomous Modes with Thresholds

monitoring and Diagnostics, the digital window comparator controls the filling of the data and the output of the

alert pin and in other modes, it only controls the output of the ALERT pin. Figure 45 provides the block diagram

for digital window comparator.

Figure 45. Digital Comparator Block Diagram

The low side threshold, high side threshold, and hysteresis parameters are independently programmable for

each input channel. Figure 46 shows the comparison thresholds and hysteresis for the two comparators. A prealert event counter after each comparator counts the output of the comparator and sets the latched flags. The

pre-alert event counter settings are common to the two channels.

Submit Documentation FeedbackCopyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: ADS7142-Q1

25

NOTE: PRE_ALT_MAX_EVENT_COUNT = 70h

(waits for 8 counts to set alert)

1

2

1

2

3

4

5

6

7

8

Counter Reset because the high-side-comparator reset

before 8.

ALERT

High Side Comparator

(Internal Only Signal)

Low Side Comparator

(Internal Only Signal)

3

4

5

6

1

2

3

4

5

6

7

Low Threshold

Low Threshold + Hysteresis

High Threshold

High Threshold - Hysteresis

Counter Reset because the high-side-comparator reset

before 8.

ADS7142-Q1

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

www.ti.com

The DWC_BLOCK_EN bit in ALERT_DWC_EN register enables/disables the complete digital window

comparator block (disabled at power-up) and ALERT_EN_CHx bits in the ALERT_CHEN register enables digital

window comparator for individual channels. When enabled, whenever a new conversion result is available:

1. The output of the high side comparator transitions to logic high when the conversion result is greater than the

26

Figure 46. Thresholds, Hysteresis and Event Counter for Digital Window Comparator

high threshold. This comparator resets when the conversion result is less than the high threshold –

hysteresis.

Submit Documentation Feedback Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: ADS7142-Q1

ADS7142-Q1

www.ti.com

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

2. The output of the low side comparator transitions to logic high when the conversion result is less than the low

threshold. This comparator resets when the conversion result is greater than the low threshold + hysteresis.

3. A different threshold and hysteresis can be used for each channel.

4. When the output of either the high side or low side comparator transitions high the pre-alert event counter

begins to increment for each subsequent conversion. This counter continues to increment until it reaches the

value stored in the PRE_ALT_MAX_EVENT_COUNT register. When it reaches

PRE_ALT_MAX_EVENT_COUNT, the alert becomes active and sets the latched flags. If the comparator

output becomes zero before counter reaches PRE_ALT_MAX_EVENT_COUNT, then the event counter is

reset to zero, Alert does not be set and latched flag is not set.

Therefore, the latched flags (high and low) for the channel are updated only if the respective comparator output

remains 1 for the specified number of consecutive conversions (set by PRE_ALT_MAX_EVENT_COUNT).

The latched flags can be read from the ALERT_LOW_FLAGS and ALERT_HIGH_FLAGS registers. To clear a

latched flag, write 1 to the applicable bit location. The ALERT pin status is re-evaluated whenever an applicable

latched flag gets set or is cleared.

The response time for ALERT pin can be estimated by Equation 6

t

= [1 + k x (PRE_ALT_MAX_EVENT_COUNT + 1) ] x nCLK x Oscillator TimePeriod

response

where

• k = Number of channels enabled in device sequence

• nCLK = Number of clocks used by device for one conversion cycle

• Oscillator timer period = t

or t

HSO

LPO

or t

depending on the OSC_SEL value; see the Specifications section for t

HSO

LPO

(6)

7.3.10 I2C Protocol Features

7.3.10.1 General Call

On receiving a general call (00h), the device provides an ACK.

7.3.10.2 General Call With Software Reset

On receiving a general call (00h) followed with Software Reset (06h), the device resets itself.

7.3.10.3 General Call With Write Software Programmable Part of Slave Address

On receiving a general call (00h) followed by 04h, the device configures its own I2C address configured by the

ADDR pin. During this operation, the device keeps BUSY/RDY Pin high and does not respond to other I2C

commands except general call.

7.3.10.4 Configuring the Device Into High-Speed I2C Mode

The device can be configured in high-speed I2C mode by providing an I2C frame with one of the HS-mode

master codes (08h to 0Fh).

After receiving one of the HS-mode master codes, the device sets the HS_MODE bit in the

OPMODE_I2CMODE_STATUS register and remains in high-speed I2C mode until a STOP condition is received

in an I2C frame.

7.3.10.5 Bus Clear

If the SDA line is stuck low because of an incomplete I2C frame, providing nine clocks on SCL is recommended.

The device releases the SDA line within these nine clocks, and then the next I2C frame can be started.

Product Folder Links: ADS7142-Q1

Submit Documentation FeedbackCopyright © 2018–2019, Texas Instruments Incorporated

27

Device Power Up or

Reset

OFFSET Calibration

on Power Up

(1)

Select the Channel

Input

Configurations

(2)

Select the Operation

Mode of the device

(3)

Autonomous Modes

(5)

High Precision

Mode

(5)

Manual Mode

(5)

Set the I2C Mode to

High Speed

(Optional)

(4)

ADS7142-Q1

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

www.ti.com

7.4 Device Functional Modes

The device has below functional modes:

• Manual mode

• Autonomous modes:

– Autonomous mode with threshold monitoring and diagnostics

– Autonomous mode with burst data

• High-precision mode

Device powers up in manual mode and can be configured into one of the other modes of these modes by writing

the configuration registers for the desired mode. Steps for configuring device into different modes are illustrated

in Figure 47

(1) Offset can also be calibrated anytime during normal operation by setting the bit in the OFFSET_CAL register.

(2) Configure the CH_INPUT_CFG register.

(3) Configure the OPMODE_SEL register for the desired operation mode.

(4) See the Configuring the Device Into High-Speed I2C Mode section.

(5) Operating mode is selected by configuring the OPMODE_SEL register in step 3.

(6) For reading and writing registers, see the Programming section.

Figure 47. Configuring Device Into Different Modes

7.4.1 Device Power Up and Reset

On power up, the device calibrates its own offset and calculates the address from the resistors connected on

ADDR pin. During this time, the device keeps BUSY/RDY high.

The device can be reset by recycling power on AVDD pin, by general call (00h) followed by software reset (06h),

or by writing the WKEY register followed by setting the bit in the DEVICE_RESET register.

Recycling power on the AVDD pin and on general call (00h) followed by software reset (06h), all the device

configurations are reset, and the device initiates offset calibration and re-evaluates its I2C address.

When setting the bit in DEVICE_RESET register, all the device configurations except latched flags for the digital

window comparator and the WKEY register are reset, The device does not initiate offset calibration and does not

re-evaluate its I2C address.

28

Submit Documentation Feedback Copyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: ADS7142-Q1

> @

kT

f

SCL

S

u 18

1000

ADS7142-Q1

www.ti.com

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

Device Functional Modes (continued)

7.4.2 Manual Mode

On power-up, the device is in Manual Mode using the single ended and dual channel configuration and starts by

sampling the analog input applied on channel 0. In this mode, the device uses the high frequency oscillator for

conversions. Manual mode allows the external host processor to directly request and control when the data is

sampled. The data capture is initiated by an I2C command from the host processor and the data is then returned

over the I2C bus at a throughput rate of up to 140-kSPS. Applications that can take advantage of this type of

functionality include traditional ADC applications that require 1 or 2 channels of continuous data output.

After setting the operation mode to manual mode as illustrated in Figure 47, steps for operating the device to be

in manual mode and reading data are illustrated in Figure 48. The host can either configure the device to scan

through one channel or both channels by configuring the CH_INPUT_CFG register and AUTO_SEQ_CHEN

register.

7.4.2.1 Manual Mode With CH0 Only

Set the OPMODE_SEL register to 000b or 001b for manual mode with channel 0 only. The host must provide the

device address and read bit to start the conversions. To continue with conversions and reading data to the host

must provide continuous SCL (Figure 49). In this mode, a NACK followed by a STOP condition in I2C frame is

required to abort the operation. Then the device operation mode can be changed to another operation mode.

7.4.2.2 Manual Mode With AUTO Sequence

Set the OPMODE_SEL register to 100b or 101b for manual mode with AUTO Sequence. The host must set the

SEQ_START bit in the START_SEQUENCE register and provide the device address and read bit to start the

conversions. To continue with conversions and reading data, the host must provide continuous SCL (Figure 49).

In this mode, the SEQ_ABORT bit in the ABORT_SEQUENCE register must be set to abort the operation. Then

the device operation mode can be changed to another operation mode. In this mode, a register read aborts the

AUTO sequence.

In manual mode, the device always uses the high-speed oscillator and the nCLK parameter has no effect. The

maximum scan rate is given by Equation 7:

• fs= Maximum sampling speed in kSPS

• T

• if T

• if T

= Time period of SCL clock (in µs)

SCL

SCL-LOW

not applicable for standard I2C mode (100 kHz)

SCL-LOW

(Low period of SCL) < 1.8.µs, k = (1.8 - T

(low period of SCL) ≥ 1.8.µsec, k = 0 and the device does not stretch clock in manual mode (7)

Product Folder Links: ADS7142-Q1

) and the device stretches clock in manual mode;

SCL-LOW

Submit Documentation FeedbackCopyright © 2018–2019, Texas Instruments Incorporated

29

No

Manual Mode

(1)

Yes

Provide Device Address

and Read Bit to Start

Conversions

(4)

Continue with

conversions and

reading data

Scan CH0

Only

Set SEQ_START Bit

(3)

No

CH0 Only (Default)

Provide Device Address

and Read Bit to Start

Conversions

(4)

Continue with

conversions and

reading data

Exit to another Operation Mode

(6)

Yes

No

Set SEQ_ABORT Bit

(5)

Continue in

same Operation

Mode

Provide STOP

Condition on I2C Bus

(4)

Yes

Continue in

same Operation

Mode

Yes

No

No

No

Provide Continuous

SCL to the device

(4)

Provide Continuous

SCL to the device

(4)

Yes

Select Manual Mode

with AUTO Sequence

and Select Channels

in AUTO Sequence

(2)

AUTO

Sequence

ADS7142-Q1

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

Device Functional Modes (continued)

www.ti.com

30

(1) For setting the operation mode to manual mode, see Figure 47.

(2) Select manual mode with AUTO sequence in OPMODE_SEL register. Select channels in the AUTO_SEQ_CHEN

register.

(3) Set the bit SEQ_START bit in the START_SEQUENCE register.

(4) See Figure 49.

(5) Set the bit SEQ_ABORT bit in the ABORT_SEQUENCE register.

(6) Select another operation mode in the OPMODE_SEL register.

(7) For reading and writing registers, see the Programming section.

Submit Documentation Feedback Copyright © 2018–2019, Texas Instruments Incorporated

Figure 48. Device Operation in Manual Mode

Product Folder Links: ADS7142-Q1

S

A

6

SDA

A5A4A3A2A1A0R

ACK

1 2 3 4 5 6 7 8 9

SCL

1 2 3 4 5 6 7 8 9

D11D10D9D8D7D6D5D

4

ACK

10 11 12 13 14 15 16 17 18

D3D2D1D00 0 0 0

ACK

1 2 17 18

D11D

10

0

NA

CK

Device in Acquisition

Optional

Clock

Stretch

Device in Acquisition

Optional

Clock

Stretch

Device in Acquisition

Device I2C Address from Host

ADC Data for Sample A ADC Data for Sample A ADC Data for Sample A+1

Sample A

Sample A+1 Sample A+2

Data from Host to Device

Data from Device to Host

ADS7142-Q1

www.ti.com

SBAS891A –NOVEMBER 2018–REVISED OCTOBER 2019

Device Functional Modes (continued)

Data can be read from the device by providing a device address and read bit followed by continuous SCL as

shown in Figure 49.

(1) See Equation 7 for sampling speed in manual mode.

(2) If the device scans both channels in AUTO sequence, first data (for sample A) is from channel 0 and second data (for

sample A +1) is from channel 1.

Figure 49. Starting Conversion and Reading Data in Manual Mode

7.4.3 Autonomous Modes

In autonomous mode, the device can be programmed to monitor the voltage applied on the analog input pins of

the device and generate a signal on the ALERT pin when the programmable high or low threshold values are

crossed and store the conversion results in the data buffer before or after the crossing a threshold or before

setting the SEQ_ABORT bit (start burst) in the ABORT_SEQUENCE register or after setting the

START_SEQUENCE bit in the START_SEQUENCE register.

In autonomous mode, the device generates the start of conversion using the internal oscillator. The first start of

conversion must be provided by the host and the device generates the subsequent start of conversions.

After configuring the operation mode to autonomous mode (set the OPMODE_SEL register to 110b) as

illustrated in Figure 47, steps for operating the device to be in different autonomous modes are illustrated in

Figure 50.

Submit Documentation FeedbackCopyright © 2018–2019, Texas Instruments Incorporated

Product Folder Links: ADS7142-Q1

31

Autonomous Modes

(1)

Select the Oscillator

& Set the nCLK value

(3)

Select the Data Buffer Configuration

(4)

Set the

Thresholds,

Hysteresis and

Enable Alert

(5)

Set the

Thresholds,

Hysteresis and

Enable Alert

(5)

Set the

SEQ_START Bit

(6)

Set the

SEQ_START Bit

(6)

Pre Alert Post Alert Start Burst

Stop Burst

Set the

SEQ_START Bit

(6)

Device Starts

conversions and

starts Filling Data

Buffer

No

Yes

Is Alert Set or

SEQ_ABORT bit

set ?

Device Stops

Conversions &

Stops Filling Data

Buffers

Set the SEQ_Start

Bit

(6)

Device Starts

Conversions

No

Yes

Is Alert Set?

Device Starts

Filling Data Buffer

No

Yes

Is Data Buffer

Filled or

SEQ_ABORT

bit Set?

Device Stops

Conversions &