Page 1

ADS61xx and ADS61B23EVM

User's Guide

Literature Number: SLAU206B

September 2007 – Revised April 2008

Page 2

2 SLAU206B – September 2007 – Revised April 2008

Submit Documentation Feedback

Page 3

Contents

1 Overview ............................................................................................................................. 5

1.1 ADS61xx/ADS61B23 EVM Quick-Start Procedure ................................................................... 5

2 Circuit Description ............................................................................................................... 6

2.1 Schematic Diagram ....................................................................................................... 6

2.2 ADC Circuit Function ..................................................................................................... 6

3 TI ADC SPI Control Interface ................................................................................................ 10

3.1 Installing the ADC SPI Control Software ............................................................................. 10

3.2 Setting Up the EVM for ADC SPI Control ............................................................................ 11

3.3 Using the TI ADC SPI Interface Software ............................................................................ 11

4 Connecting to FPGA Platforms ............................................................................................ 13

4.1 TSW1100 ................................................................................................................. 13

4.2 TSW1200 ................................................................................................................. 13

5 ADC Evaluation .................................................................................................................. 14

5.1 Hardware Selection ..................................................................................................... 14

5.2 Coherent Input Frequency Selection .................................................................................. 15

6 Physical Description ........................................................................................................... 16

6.1 PCB Layout ............................................................................................................... 16

6.2 Bill of Materials ........................................................................................................... 21

6.3 EVM Schematics ........................................................................................................ 23

Important Notices ............................................................................................................... 29

SLAU206B – September 2007 – Revised April 2008 Table of Contents 3

Submit Documentation Feedback

Page 4

www.ti.com

List of Figures

1 TI ADC SPC Interface Screen ........................................................................................... 10

2 Top Silkscreen .............................................................................................................. 16

3 Component Side ............................................................................................................ 17

4 Ground Plane 1 ............................................................................................................. 18

5 Power Plane 1 .............................................................................................................. 19

6 Bottom Side ................................................................................................................. 20

7 EVM Schematic, Sheet 1 .................................................................................................. 23

8 EVM Schematic, Sheet 2 .................................................................................................. 24

9 EVM Schematic, Sheet 3 .................................................................................................. 25

10 EVM Schematic, Sheet 4 .................................................................................................. 26

11 EVM Schematic, Sheet 5 .................................................................................................. 27

12 Breakout Board Schematic, Sheet 6 ..................................................................................... 28

List of Tables

1 Breakout Board Pin Assignments.......................................................................................... 8

2 Jumpers ....................................................................................................................... 9

3 Surface-Mount Jumpers .................................................................................................... 9

4 ADS61xx Frequently Used Registers .................................................................................... 12

5 Bill of Materials ............................................................................................................. 21

4 List of Figures SLAU206B – September 2007 – Revised April 2008

Submit Documentation Feedback

Page 5

1 Overview

This user's guide gives a general overview of the evaluation module (EVM) and provides a general

description of the features and functions to be considered while using this module. This manual is

applicable to the ADS6122, ADS6123, ADS6124, ADS6125, ADS6142, ADS6143, ADS6144, ADS6145,

and ADS61B23, which collectively are referred to as ADS61xx and ADS61B23. The ADS61xx/ADS61B23

EVM provides a platform for evaluating the low-power, single-channel ADS61xx/ADS61B23 12- and 14-bit

analog-to-digital converters (ADC), and the ADS61B23 12-bit ADC with buffered analog input under

various signal, reference, and supply conditions.

This document should be used in combination with the respective ADC data sheet.

1.1 ADS61xx/ADS61B23 EVM Quick-Start Procedure

Using the quick-start procedure, many users can begin evaluating the ADC in a short time. The quick-start

procedure uses the default conditions of the EVM as shipped from the factory. In addition, the quick-start

guide configures the ADC in a CMOS offset binary data format. Users who have modified the board may

find the quick-start procedure to be ineffective.

1. Supply 3.3 V to J11 while connecting the return to a shorted J11 and J14. Power on the device.

2. Confirm jumper J6 is shorted 1–2 and jumpers J2, J3, and J7 have positions 2–3 shorted.

3. Use the silkscreen to confirm jumper J1 is set to Offset Binary, CMOS output.

4. Use the silkscreen to confirm jumper J4 is set to 0dB Gain, Int Ref.

5. Supply a –1-dBFS filtered, low-phase-noise, 10-MHz CW tone into J8.

6. Supply a filtered, low-phase-noise clock to J9.

7. Use the accompanying breakout board and monitor the digital output (see Table 1 ).

User's Guide

SLAU206B – September 2007 – Revised April 2008

Windows is a registered trademark of Microsoft Corporation.

Samtec is a trademark of Samtec, Inc.

Xilinx, Virtex are trademarks of Xilinx, Inc.

All other trademarks are the property of their respective owners.

SLAU206B – September 2007 – Revised April 2008 5

Submit Documentation Feedback

Page 6

Circuit Description

2 Circuit Description

2.1 Schematic Diagram

The schematic diagram for the EVM is in Section 6.3 .

2.2 ADC Circuit Function

The following sections describe the function of individual circuits. See the relevant data sheet for device

operating characteristics.

2.2.1 ADC Operational Mode

By default, the ADC is configured to operate in parallel-mode operation, because jumper (J3) asserts a

3.3-V state to the ADC reset pin. Consequently, the SW1 reset pushbutton must be pressed only when the

device is configured in serial operation mode. Because the ADC is in parallel operation mode, voltages

are used to set the ADC configuration modes. Users can use the EVM silkscreen to set the operation

modes.

2.2.2 EVM Power Connections

Power is supplied to the EVM by banana jack sockets. Separate connections are provided for a 3.3-V

digital buffer supply (J11) and 3.3-V analog supply (J13); however, by default these are shorted together

using R65, a 0- Ω resistor. Consequently, users can supply power to either J11 or J13 to power the ADC.

The separate connections allow users to separate analog and digital supplies by removing R65. When

using the amplifier evaluation path, connect the positive rail to J20 and the negative rail to J16. The

voltages depend on the coupling method and connection to the ADC. If the ADC VCM is not supplied to

the amplifier and the amplifier is connected to the ADC in a dc-coupled fashion, set J20 to 4 V and J16 to

–1 V. In ac-coupled configurations where the ADC VCM biases the ADC inputs, connect J20 to 5 V and

J16 to GND. The ADC SPI interface and CDCP1803 also are powered through J20, which should be set

to 5 V for operation of those circuits.

www.ti.com

2.2.3 ADC Analog Inputs

The EVM is configured to accept a single-ended input source and convert it to an ac-coupled differential

signal using a transformer. The inputs to the ADC must be dc-biased, which is accomplished by using the

ADC VCM output. The input is provided by the SMA connector J8.

Using SMA input J10, users can evaluate the ADC using a THS4509 amplifier, which converts a

single-ended input into a differential signal while providing 10 dB of signal gain. Users should enable the

amplifier path by connecting JP7 1–2 and by shorting positions 2–3 on both surface-mount jumpers JP5

and JP6. At low input frequencies, the ADC represents a high-input impedance and R38, R46, and C76

form a low-pass filter with a 3-db cutoff frequency of 70 MHz. Users can change these component values

depending on the bandwidth of the signal they are digitizing to band-limit the input noise into the ADC.

Using an excessively high cutoff frequency degrades the SNR of the system. Before beginning evaluation

of the amplifier path, a user must choose whether to dc-couple or ac-couple the amplifier path.

In a dc-coupled system, replace C75 and C77 with 0- Ω resistors and remove R37 and R45. Use the ADC

VCM to set the CM input of the amplifier by ensuring that R21 is populated with a 0- Ω resistor. Because

the ADC has a common-mode voltage of 1.5 V and because the THS4509 is not a rail-to-rail amplifier,

adjust VCC to 4 V and –VCC to –1 V, which can be done by applying the respective voltages to J20 and

J16.

For an ac-coupled system, use the voltage divider R37 and R45 to set the common-mode input of the

amplifier, which should be set to the midpoint of the amplifier supply. Alternatively, users can leave R37

and R45 unpopulated and the amplifier sets its own common voltage to (VCC – VEE)/2. Capacitors C75

and C77 provide ac-coupling of the system, and the ADC inputs then can be biased by the R41 and R42

combination. Another ac-coupled approach, not supported on this EVM, is to use a transformer at the

outputs of the THS4509. In this case, the transformer provides for ac-coupling, and the inputs of the ADC

can be biased by feeding the ADC VCM to the transformer center tap on the secondary.

6 SLAU206B – September 2007 – Revised April 2008

Submit Documentation Feedback

Page 7

www.ti.com

Note that the THS4509 used on this EVM is pinout compatible with the THS4508 , THS4511 , THS4513 ,

and THS4520 . Users can easily interchange the amplifier on this EVM and pick the appropriate amplifier

based on common-mode range, power supplies, and frequency of operation. Contact your local Texas

Instruments (TI) sales representative for assistance in selection of these amplifiers.

2.2.4 ADC Clock Input

Connect a filtered, low-phase-noise clock input to J9. A transformer, T3, provides the conversion from a

single-ended clock signal into a differential clock signal.

The EVM also provides a clock distribution path using the CDCP1803. The CDCP1803 provides for a 1:3

LVDS fanout helpful when clocking multiple ADCs from the same clocking source. Users selecting this

input path should use a low-jitter square-wave input. In addition, the CDCP1803 jitter performance makes

this a valid clocking solution only for input frequencies in the first Nyquist zone, as jitter degrades SNR for

frequencies much above the first Nyquist zone. To use this path, change jumper JP8 to short 1–2, and

JP2, JP3, and JP4 to short pins 2–3.

2.2.5 ADC Digital Outputs

The ADS61xx/ADS61B23 ADC parallel digital outputs are brought to J10, a high-density Samtec™

connector. Several options are available in processing the ADC data.

1. The mating logic analyzer breakout board can capture the ADC data using a logic analyzer. Users who

choose this option should use the companion breakout board and Table 1 for the connection details.

Users lacking access to a logic analyzer can use the TSW1100 to capture the digital data. See the

connection guidelines in Section 4.1 .

2. Users can create their own digital interface board which directly interfaces to the ADC. In this case,

they design their mating digital interface board with the Samtec part number QSO-060-01-F-D-A, which

is the companion part number to the EVM connector.

Circuit Description

SLAU206B – September 2007 – Revised April 2008 7

Submit Documentation Feedback

Page 8

Circuit Description

www.ti.com

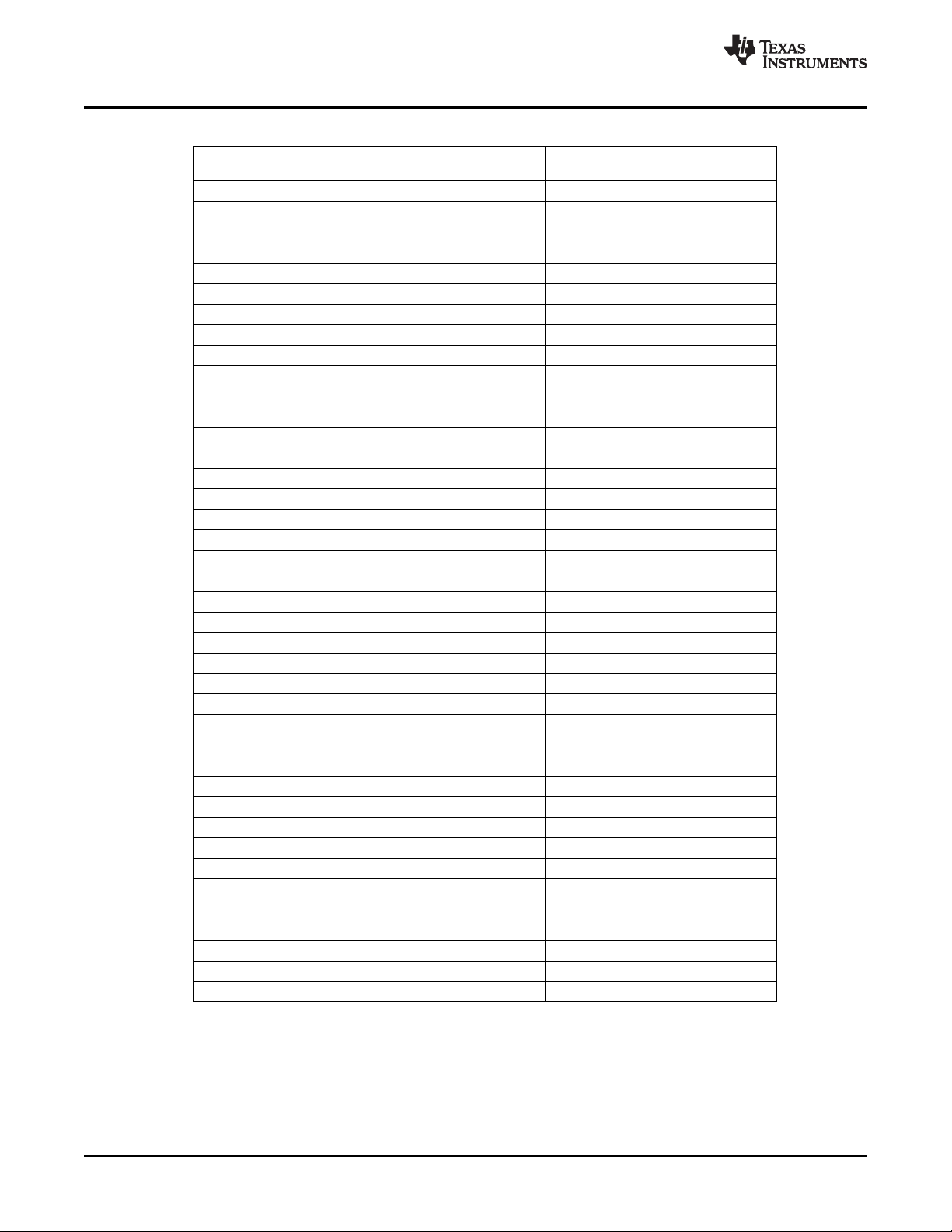

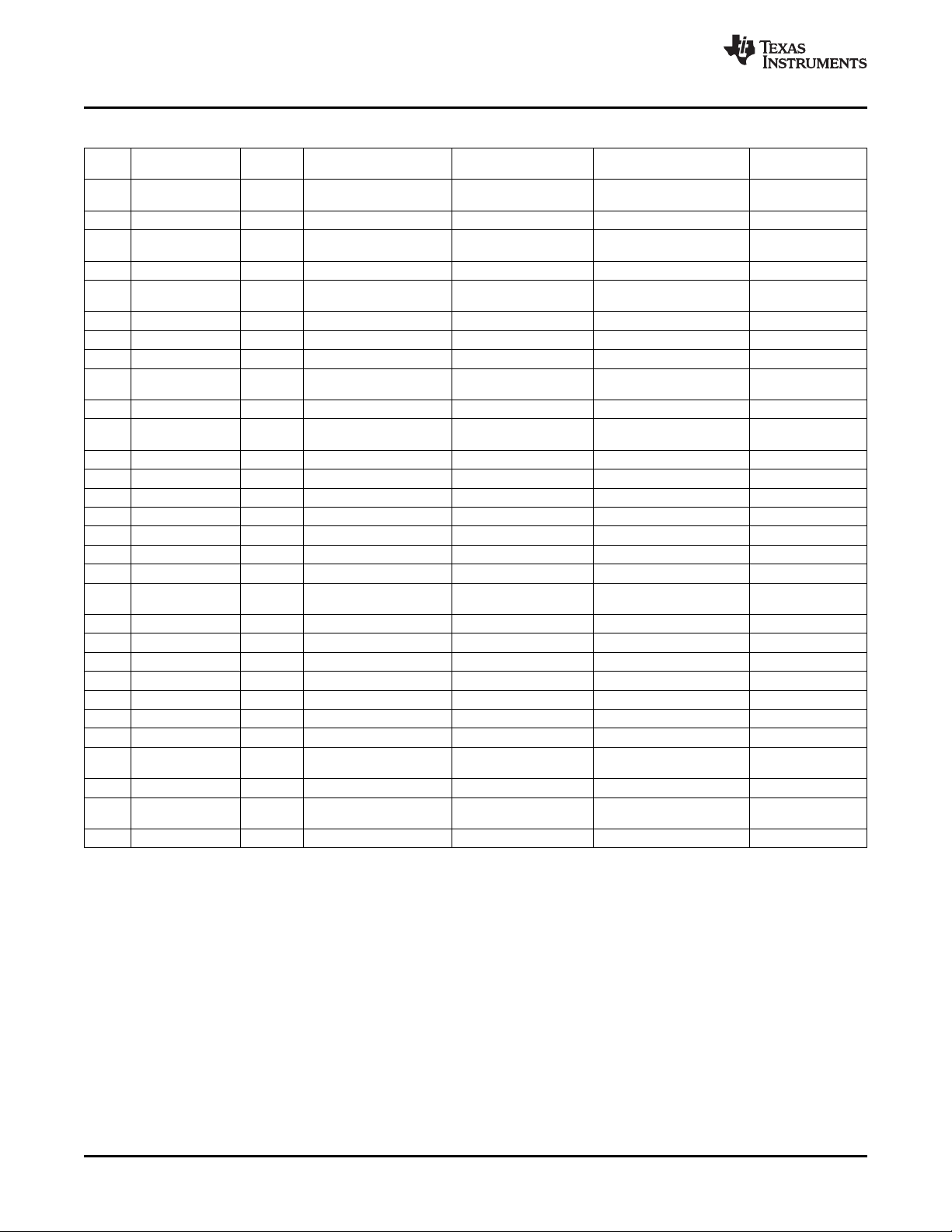

Table 1. Breakout Board Pin Assignments

J4 PIN ADS6142/43/44/45 DESCRIPTION

1 GND GND

2 CLK CLK

3 GND GND

4 NC NC

5 GND GND

6 NC Data bit 0 (LSB)

7 GND GND

8 NC Data bit 1

9 GND GND

10 Data bit 0 (LSB) Data bit 2

11 GND GND

12 Data bit 1 Data bit 3

13 GND GND

14 Data bit 2 Data bit 4

15 GND GND

16 Data bit 3 Data bit 5

17 GND GND

18 Data bit 4 Data bit 6

19 GND GND

20 Data bit 5 Data bit 7

21 GND GND

22 Data bit 6 Data bit 8

23 GND GND

24 Data bit 7 Data bit 9

25 GND GND

26 Data bit 8 Data bit 10

27 GND GND

28 Data bit 9 Data bit 11

29 GND GND

30 Data bit 10 Data bit 12

31 GND GND

32 Data bit 11 (MSB) Data bit 13 (MSB)

33 GND GND

34 NC NC

35 GND GND

36 NC NC

37 GND GND

38 NC NC

39 GND GND

40 NC NC

ADS6122/23/B23/24/25

DESCRIPTION

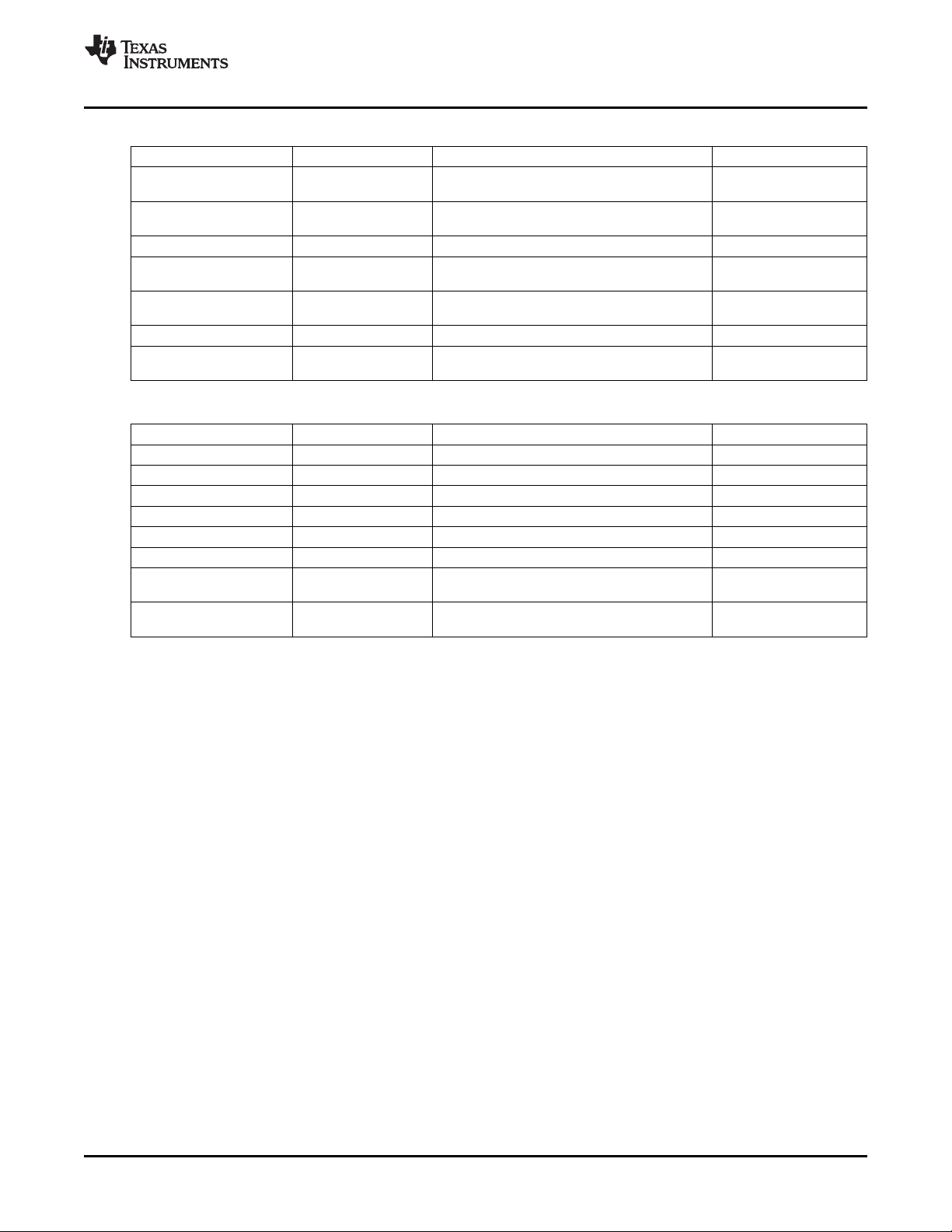

2.2.6 Jumper Selections

The EVM features several jumpers whose functions are described in Table 2 . The EVM also features

surface-mount jumpers in cases where either the signal integrity is important or the functions are rarely

used. Table 3 summarizes these options.

8 SLAU206B – September 2007 – Revised April 2008

Submit Documentation Feedback

Page 9

www.ti.com

Circuit Description

Table 2. Jumpers

Description Reference Designator Default Selection Optional Selection

Parallel mode: SEN pin J1 5–6, Offset binary, CMOS output Multiple choices

voltage bias

SEN control J2 2–3, EVM controlled 1–2, USB or FPGA

ADC control mode J3 2–3, Parallel mode 1–2, serial mode

Parallel mode: SCLK pin J4 1–2, 0-dB Gain, Int Ref Multiple choices

voltage bias

ADS61xx/ADS61B23 J5 1–2, ADS61xx/ADS61B23 powered on 2–3, ADS61xx/ADS61B23

power down powered off

SDATA control J6 1–2, USB or FPGA controlled 2–3, EVM controlled

SCLK control J7 2–3, EVM controlled 2–3, USB or FPGA

controlled

controlled

Table 3. Surface-Mount Jumpers

Description Reference Designator Default Selection Optional Selection

JP1 Probe point for CDCP1803 output

Clock input path selection JP2 1–2, transformer coupled path 2–3, CDCP1803 path

Clock input path selection JP3 1–2, transformer coupled path 2–3, CDCP1803 path

Clock input path selection JP4 1–2, transformer coupled path 2–3, CDCP1803 path

Analog input path JP5 1–2, transformer coupled input path 2–3, THS4509 path

Analog input path JP6 1–2, transformer coupled input path 2–3, THS4509 path

THS4509 power down JP7 2–3, THS4509 powered down 1–2, THS4509 powered

CDCP1803 power down JP8 2–3, CDCP1803 powered down 1–2, CDCP1803 powered

on

on

SLAU206B – September 2007 – Revised April 2008 9

Submit Documentation Feedback

Page 10

TI ADC SPI Control Interface

3 TI ADC SPI Control Interface

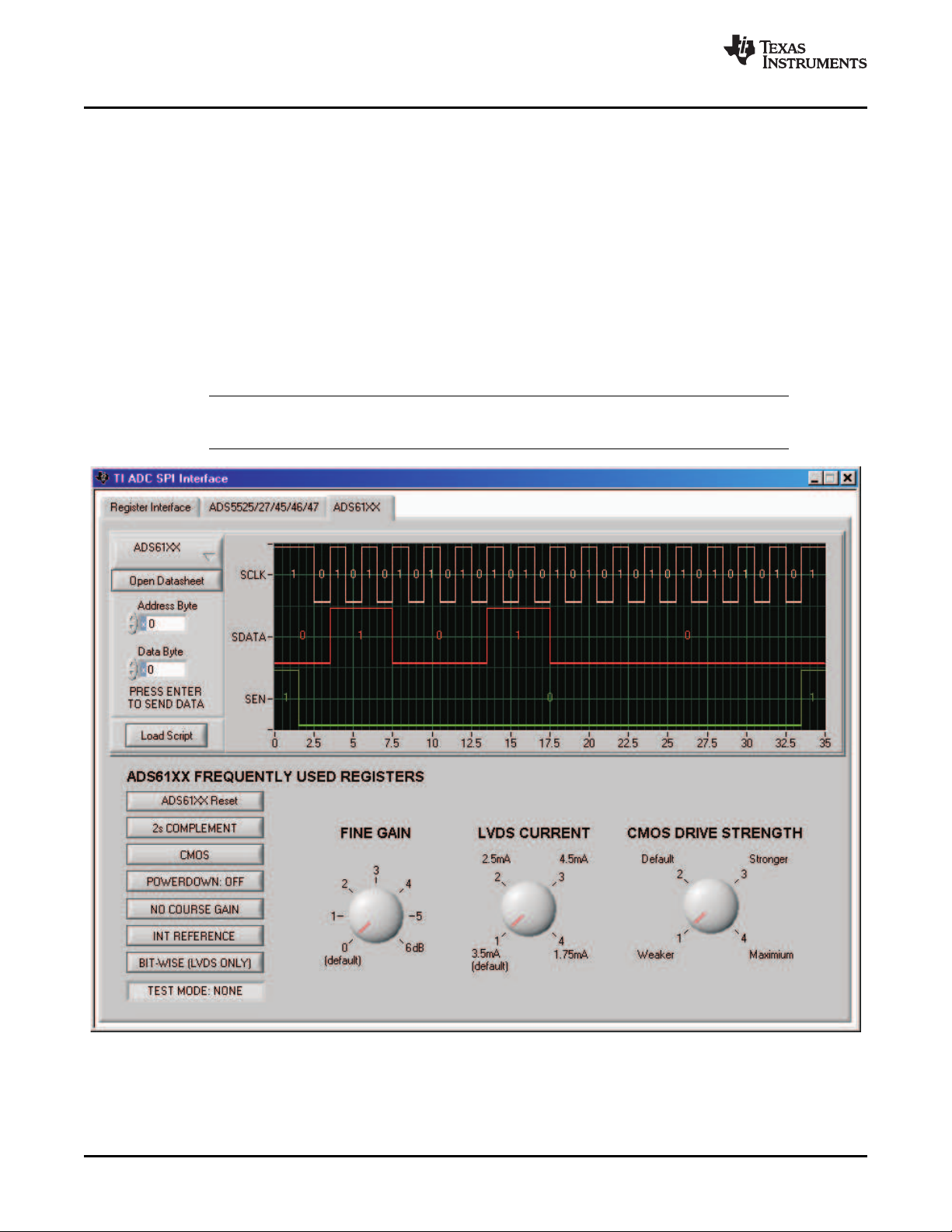

This section describes the software features accompanying the EVM kit. The TI ADC SPI control software

provides full control of the SPI interface, allowing users to write to any of the ADC registers found in the

ADC data sheet. For most ADS61xx/ADS61B23 performance evaluations, users do not need to use the TI

SPI control software to get evaluation results. Users only need to use the ADC SPI control software when

the desired feature is inaccessible because the ADC is in parallel interface mode.

3.1 Installing the ADC SPI Control Software

The ADC SPI control software can be installed on a personal computer by running the setup.exe file

located on the CD. This file installs the graphical user interface (GUI) along with the USB drivers needed

to communicate to the USB port that resides on the EVM. After the software is installed and the USB

cable has been plugged in for the first time, the user is prompted to complete the installation of the USB

drivers. When prompted, users should allow the Windows

and it should automatically find the TI ADC SPI interface drivers. See Figure 1 .

Note: Before plugging in the USB cable for the first time, install the TI ADC SPI software. The

software installs the drivers necessary for USB communication.

®

operating system to search for device drivers,

www.ti.com

Figure 1. TI ADC SPC Interface Screen

10 SLAU206B – September 2007 – Revised April 2008

Submit Documentation Feedback

Page 11

www.ti.com

3.2 Setting Up the EVM for ADC SPI Control

Users who wish to use the ADC SPI interface must supply 5 VDC to J20, which provides power to the

USB circuit. By default, the EVM comes with the ADC configured in parallel mode. In order to use the SPI

interface to control the ADC modes of operation, users must move several jumpers.

• Move jumper J3 to short positions 1–2, which places the ADC into serial operation mode.

• Move jumper J7 to short positions 1–2, which allows the USB circuit to control SCLK.

• Move jumper J6 to short positions 1–2, which allows the USB circuit to control SDATA.

• Move jumper J2 to short positions 1–2, which allows the USB circuit to control SEN.

3.3 Using the TI ADC SPI Interface Software

Once the software is installed and the USB cable is connected, three primary modes of operating the

software are available: SPI Register Writes, SPI Register Write Using a Script File, and

ADS61xx/ADS61B23 Frequently Used Registers.

3.3.1 SPI Register Writes

The most basic mode of operation allows full control of writing to individual register addresses. In the top

left corner of the interface screen (Figure 1 ), select the ADS61xx ADC from the ADC SPI Protocol

drop-down list. Next, type the Address Bytes(s) in hexadecimal (hex) and Data Byte(s) in hex, which can

be found in the device data sheet. When you are ready to send this command to the ADC, press "Enter"

on your keyboard. The graph indicator is updated with the patterns sent to the ADC. The default inputs to

both the Address Byte(s) and Data Byte(s) fields are hex inputs as designated by the small x in the

control. Users can change the default input style by clicking on the "x" to binary, decimal, octal, or hex.

Multiple register writes can be written simply by changing the contents of the Address Byte(s) and Data

Byte(s) field and pressing Enter again.

TI ADC SPI Control Interface

3.3.2 SPI Register Write Using a Script File

For situations where the same multiple registers must be written on a frequent basis, users can easily use

a text editor to create a script file containing all ADC register writes. An example script file is located in the

\\Install Directory\Script Files\ADS6145_LVDS_CourseGain.txt. Users who wish to take advantage of

writing their own script files should start by using the ADS6145_LVDS_CourseGain.txt as a template file.

When ready to write the contents of the script file to the ADC, users can press the Load Script button and

they will be prompted for the file location of their script file. The commands are sent to the ADC when the

user acknowledges the selection of the file.

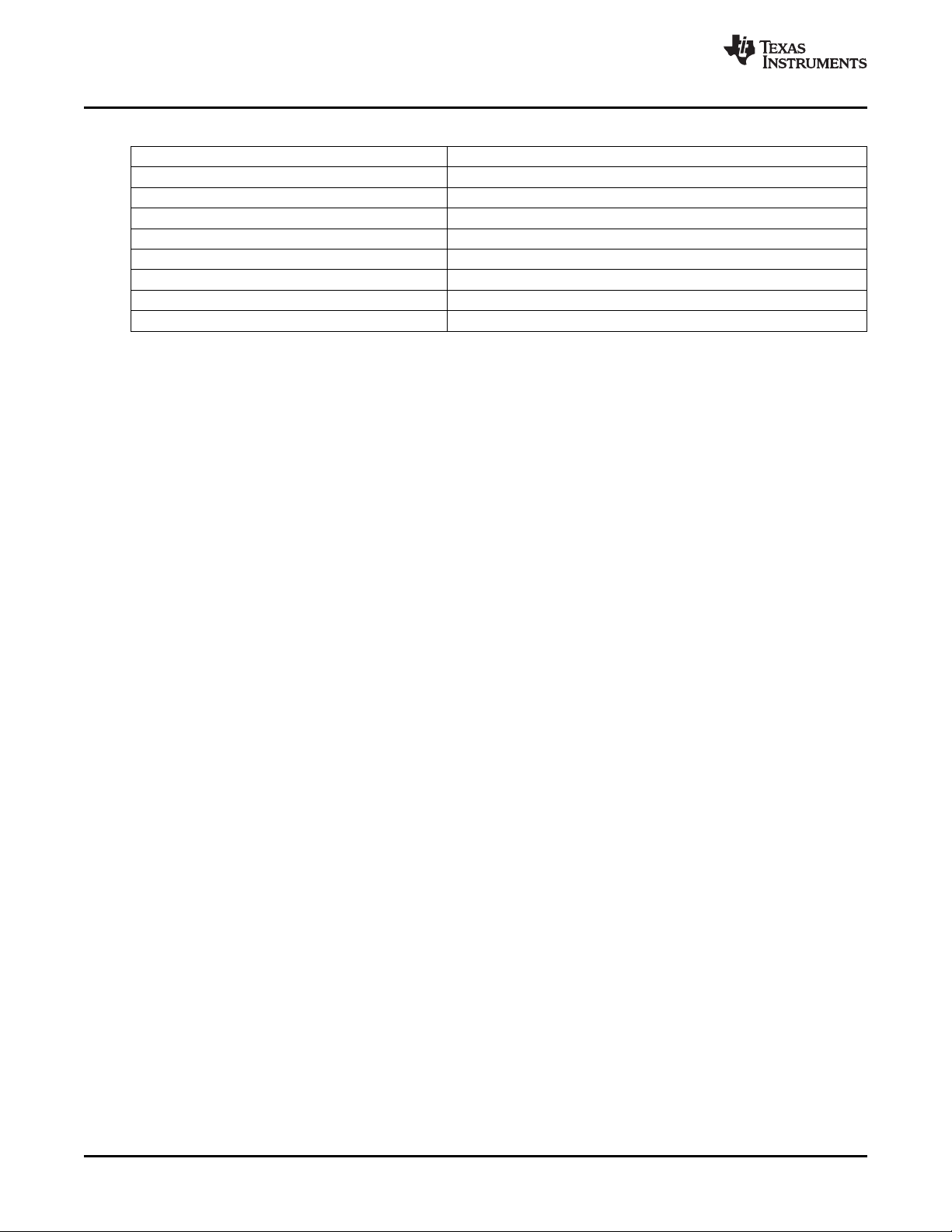

3.3.2.1 ADS61xx Frequently Used Registers

For ease of use, several buttons have been added that allow one-click register writes of commonly used

features found in Table 4 . These are found in the ADS61xx tab, as these commands are specific to the

ADS61xx ADC only. The software writes to the ADC both the contents of the associated address and data

when the button is clicked. When the ADS61xx Reset button is pressed, it issues a software reset to the

ADC, and it resets the button values to match the contents inside of the ADC. The graph indicator plots

the SPI commands written to the ADC when a button has been depressed.

SLAU206B – September 2007 – Revised April 2008 11

Submit Documentation Feedback

Page 12

TI ADC SPI Control Interface

ADS61xx Reset

2s Complement Straight Binary

CMOS DDR LVDS

Powerdown: OFF Powerdown On

No Course Gain 3.5-dB Course Gain

INT Reference EXT Reference

Bit-Wise (LVDS Only) Byte-Wise

Test Mode: None Multiple Options

www.ti.com

Table 4. ADS61xx Frequently Used Registers

Default Value Alternate Value

12 SLAU206B – September 2007 – Revised April 2008

Submit Documentation Feedback

Page 13

www.ti.com

4 Connecting to FPGA Platforms

The ADS61xx/ADS61B23 EVM provides several connection options to mate the EVM to various FPGA

development platforms and FPGA-based capture boards.

4.1 TSW1100

Using the accompanying CMOS breakout board, users can easily mate TI's TSW1100 capture board to

the ADS61xx/ADS61B23 EVM. Simply connect the breakout board to the J2 (Channel 2) connector on the

TSW1100. From an orientation standpoint, the Xilinx™ FPGA faces the ADC when correctly configured.

Before using the TSW1100 to capture ADC data for the first time, users should update the TSW1100

Supported_ADCs.txt file. They should explore the accompanying ADS61xx/ADS61B23 software CD and

replace the installed TSW1100 Supported_ADC.txt file with the one found on the CD; this file adds

TSW1100 support for both the ADS612x and ADS614x.

Finally, users should ensure that the ADC61xxEVM is configured in CMOS output mode. In addition, the

TSW1100 represents a load greater than 5 pF and as such, users should consider boosting the CMOS

drive strength by using the TI SPI Control software. In many cases, the boosting of the drive strength is

not required to perform valid data captures when using the TSW1100; this is an optional step.

4.2 TSW1200

The ADS61xx/ADS61B23 natively plugs into the TSW1200 FPGA platform. In most circumstances, the

TSW1200 functions as a deserializer. However, the Virtex™-4 FPGA can be reprogrammed to allow the

ultimate in flexible solution prototyping. For users wishing to apply FPGA control over the

ADS61xx/ADS61B23 SPI interface, move the surface-mount jumpers into the following positions.

• Move the jumper on J2 (SEN) to the 1–2 position, and remove R7 and populate R62 with a 0- Ω

resistor.

• Move the jumper on J7 (SCLK) to the 1–2 position, and remove R20 while installing the 0- Ω resistor to

R63.

• Move the jumper on J6 (SDATA) to the 1–2 position, and remove R19 while installing the 0- Ω resistor

to R64.

• Remove R18.

• Move the jumper on J3 to position 1–2 to configure the ADC into the SPI operation mode (serial

interface mode).

Connecting to FPGA Platforms

SLAU206B – September 2007 – Revised April 2008 13

Submit Documentation Feedback

Page 14

ADC Evaluation

5 ADC Evaluation

This section describes how to set up a typical ADC evaluation system that is similar to what TI uses to

perform testing for data-sheet generation. Consequently, the information in this section is generic in nature

and is applicable to all high-speed, high-resolution ADC evaluations. This section covers signal tone

analysis, which yields ADC data-sheet figures of merit such as signal-to-noise ratio (SNR) and spurious

free dynamic range (SFDR).

5.1 Hardware Selection

To reveal the true performance of the ADC under evaluation, great care should be taken in selecting both

the ADC signal source and ADC clocking source.

5.1.1 Analog Input Signal Generator

When choosing the quality of the ADC analog input source, consider both harmonic distortion performance

of the signal generator and the noise performance of the source.

In many cases, the harmonic distortion performance of the signal generator is inferior to that of the ADC,

and additional filtering is needed if users expect to reproduce the ADC SFDR numbers found in the data

sheet. Users can easily evaluate the harmonic distortion of the signal generator by hooking it directly to a

spectrum analyzer, measuring the power of the output signal, and comparing that to the power of the

integer multiples of the output signal frequency. If the harmonic distortion is worse than the ADC under

evaluation, the ADC digitizes the performance of the signal generator and the true SFDR of the ADC is

masked. To alleviate this, it is recommended that users provide additional LC filtering after the signal

generator output.

Another important metric when deciding on a signal generator is its noise performance. As with the

distortion performance, if the noise performance is worse than that of the ADC under evaluation, the ADC

digitizes the performance of the source. Noise can be broken into two components, broadband noise and

close-in phase noise. Broadband noise can be improved by the LC filter added to improve distortion

performance; however, the close-in phase noise typically cannot be improved by additional filtering.

Therefore, when selecting an analog signal source, it is important to review the manufacturer's phase

noise plots and take care to choose a signal generator with the best phase-noise performance.

www.ti.com

5.1.2 Clock Signal Generator

Equally important in the high-performance ADC evaluation setup is the selection of the clocking source.

Most modern ADCs, the ADS61xx/ADS61B23 included, accept either a sinusoidal or a square-wave clock

input. The key metric in selecting a clocking source is selecting a source with the lowest jitter. This

becomes increasingly important as the ADC input frequency (fin) increases, because the ADC SNR

evaluation setups can become jitter-limited (tj) as shown by the following equation.

In theory, a square-wave source with femtosecond jitter would be ideal for an ADC evaluation setup.

However, in practical terms, most commercially available square-wave generators offer jitter measured in

picoseconds, which is too great for high-resolution ADC evaluation setups. Therefore, most evaluation

setups rely on the ADC internal clock buffer to convert a sinusoidal input signal into a ultralow-jitter square

wave. When selecting a sinusoidal clocking source, it has been shown that phase noise has a direct

impact on jitter performance. Consequently, great scrutiny should be applied to the phase-noise

performance of the clocking signal generator. TI has found that high-Q monolithic crystal filters can

improve the phase noise of the signal generator, and these filters become essential elements of the

evaluation setup when high ADC input frequencies are being evaluated.

SNR (dBc) = 20 log (2 π × fin× tj(rms))

14 SLAU206B – September 2007 – Revised April 2008

Submit Documentation Feedback

Page 15

www.ti.com

5.2 Coherent Input Frequency Selection

Typical ADC analysis requires users to collect the resulting time-domain data and perform a Fourier

transform to analyze the data in the frequency domain. A stipulation of the Fourier transform is that the

signal must be continuous-time; however, this is impractical when looking at a finite set of ADC samples,

usually collected from a logic analyzer. Consequently, users typically apply a window function to minimize

the time-domain discontinuities that arise when analyzing a finite set of samples. For ADC analysis,

window functions have their own frequency signatures or lobes that distort both SNR and SFDR

measurements of the ADC.

TI uses the concept of coherent sampling to work around the use of a window function. The central

premise of coherent sampling entails that the input signal into the ADC is carefully chosen such that when

a continuous-time signal is reconstructed from a finite sample set, no time-domain discontinuities exist. To

achieve this, the input frequency must be an integer multiple of the ratio of the ADC sample rate (fs) and

the number of samples collected from the logic analyzer (N

the fundamental frequency (ff). Determining the ADC input frequency is a two-step process. First, the

users select the frequency of interest for evaluating the ADC; then, they divide this by the fundamental

frequency. This typically yields a non-integer value, which should be rounded to the nearest odd,

preferably prime, integer. Once that integer, or frequency bin (f

this with the fundamental frequency to obtain a coherent frequency to program into their ADC input signal

generator. The procedure is summarized as follows.

ff= fs/N

f

Coherent frequency = ff× f

s

= Odd_round(f

bin

ADC Evaluation

). The ratio of fsto N

s

), has been determined, users multiply

bin

/ff)

desired

bin

is typically referred to as

s

SLAU206B – September 2007 – Revised April 2008 15

Submit Documentation Feedback

Page 16

Physical Description

6 Physical Description

6.1 PCB Layout

www.ti.com

This section describes the physical characteristics and PCB layout of the EVM.

The EVM is constructed on a four-layer, 0.062-inch thick PCB using FR-4 material. The individual layers

are shown in Figure 2 through Figure 6 . The layout features a split ground plane; however, similar

performance can be obtained with careful layout using a common ground plane.

Figure 2. Top Silkscreen

16 SLAU206B – September 2007 – Revised April 2008

Submit Documentation Feedback

Page 17

www.ti.com

Physical Description

Figure 3. Component Side

SLAU206B – September 2007 – Revised April 2008 17

Submit Documentation Feedback

Page 18

Physical Description

www.ti.com

Figure 4. Ground Plane 1

18 SLAU206B – September 2007 – Revised April 2008

Submit Documentation Feedback

Page 19

www.ti.com

Physical Description

Figure 5. Power Plane 1

SLAU206B – September 2007 – Revised April 2008 19

Submit Documentation Feedback

Page 20

Physical Description

www.ti.com

Figure 6. Bottom Side

20 SLAU206B – September 2007 – Revised April 2008

Submit Documentation Feedback

Page 21

www.ti.com

6.2 Bill of Materials

Table 5. Bill of Materials

Qty Reference Not Part Foot Print Part Number Manufacturer

5 C1, C5, C8, C52, 33 µ F TANT_B B45196H2336M209 Kemet

C54

5 C2, C9, C30, C56, 10 µ F 805 ECJ-2FB0J106K Panasonic

C57

3 C3, C6, C31 1 µ F 603 ECJ-1VB1A105K Panasonic

43 C4, C7, 0.1 µ F 603 ECJ-1VB1C104K Panasonic

C11–C29,C32–C35,

C53, C55, C66,

C67, C70, C72,C74,

C75, C77–C79,C81,

C83, C85,

C87–C89, C92

4 C71, C73, C82, C84 10 µ F 805 ECJ-2FB1A106K Panasonic

1 C76 18 pF 603 ECJ-1VC1H180J Panasonic

1 C80 0.22 µ F 603 ECJ-1VB1A224K Panasonic

1 C86 10 µ F TANT_A T491A106M010AT Kemet

2 C90,C91 27 pF 603 GRM1885C2A270JA01D Murata

1 C93 0.01 µ F 603 C0603C103K1RACTU Kemet

0 JP1 Not HEADER 2/SM JUMPER2 NO PART

5 JP2–JP6 Jumper_1x3_SMT, Short pin SJP3_JUMPER NO PART

1 JP8 Jumper_1x3_SMT, Short pin SJP3_JUMPER NO PART

2 J1, J4 HEADER 4x2 hdr4X2_100ctr 90131-0124 Molex

4 J2, J3, J7, JP7 HMTSW-103-07-G-S-.240 HDR_THVT_1x3_100_M HMTSW-103-07-G-S-.240 Samtec

1 J6 HMTSW-103-07-G-S-.240 HDR_THVT_1x3_100_M HMTSW-103-07-G-S-.240 Samtec

1 J5 SMD3P_BRIDGE, Short pin smd_bridge_0603 NO PART

3 J8, J9, J15 SMA SMA_THVT_320x320 142-0701-201 Johnson Components

1 J10 CONN_QTH_30X2-D-A conn_QTH_30X2-D-A QTH-060-02-F-D-A Samtec

4 J11, J13, J16, J20 RED Banana Jack ST-351A ALLIED

2 J12, J14 BLK Banana Jack ST-351B ALLIED

1 J17 CONN USB TYP B FEM conn_usb_typb_fem 897-30-004-90-000 Milmax

5 L1–L3, L8, L9 68 603 MI0603J680R-10 Steward

1 L10 1 k at 100 MHz 805 BLM21AG102SN1D Murata

6 R3–R5, R9, R11, 1 k Ω 603 ERJ-3EKF1001V Panasonic

R14

5 R6, R10, R15, R18, 10 k Ω 603 ERJ-3EKF1002V Panasonic

R35

4 R7, R26, R57, 0 Ω 603 ERJ-3GEY0R00V Panasonic

8 R8, R12, R13, R17, 100 Ω 603 ERJ-3EKF1000V Panasonic

1 R16 10 Ω 603 ERJ-3EKF10R0V Panasonic

2 R22, R25 200 Ω 603 ERJ-3EKF2000V Panasonic

2 R23, R24 39 Ω 603 RC0603FR-0739RL Panasonic

0 R27, R28 Not 121 Ω 603 ERJ-3EKF1210V Panasonic

5 R29, R31, R38, 49.9 Ω 603 ERJ-3EKF49R9V Panasonic

1 R30 60.4 k Ω 603 ERJ-3EKF6042V Panasonic

2 R32, R34 10 Ω 603 ERJ-3EKF10R0V Panasonic

(1)

(1)

R66

R19, R20, R40, R44

R46, R47

Remove R66 for the ADS61B23 EVM.

Installed

installed

1 and 2 with 0 Ω

2 and 3 with 0 Ω

1 and 2 with 0 Ω

installed

Physical Description

ELECTRONICS

ELECTRONICS

SLAU206B – September 2007 – Revised April 2008 21

Submit Documentation Feedback

Page 22

Physical Description

Table 5. Bill of Materials (continued)

Qty Reference Not Part Foot Print Part Number Manufacturer

0 R33 Not 200 Ω 402 ERJ-2RKF2000X Panasonic

2 R36, R48 348 Ω 603 ERJ-3EKF3480V Panasonic

0 R37, R45 Not 499 Ω 603 ERJ-3EKF4990V Panasonic

2 R39, R43 69.8 Ω 603 ERJ-3EKF69R8V Panasonic

0 R41, R42 Not 200 Ω 603 ERJ-3EKF2000V Panasonic

1 R49 10 k Ω 603 ERJ-3GEYJ103V Panasonic

1 R50 2.21 k Ω 603 ERJ-3EKF2211V Panasonic

1 R51 4.7 k Ω 603 ERJ-3EKF4R71V Panasonic

0 R52 Not 10 k Ω 603 ERJ-3EKF1002V Panasonic

1 R53 1.5 k Ω 603 ERJ-3EKF1501V Panasonic

0 R21, R54, R62–R64 Not 0 Ω 603 ERJ-3GEY0R00V Panasonic

2 R55, R56 26.7 Ω 603 ERJ-3EKF26R7V Panasonic

2 R58, R60 130 Ω 603 ERJ-3EKF1300V Panasonic

2 R59, R61 82.5 Ω 603 ERJ-3EKF82R5V Panasonic

1 R65 0 Ω 1206 ERJ-S080R00V Panasonic

1 SW1 SW PUSHBUTTON SW_RESET_PTS635 PTS635SL43 C & K Switch

3 TP1, TP3, TP6 Test Point Black testpoint 5001 Keystone

3 TP2, TP4, TP5 Test Point White testpoint 5002 Keystone

0 TP7–TP9 Not T POINT R TESTPOINT 5002 Keystone

2 T1, T2 TC4-1W XFMR_TC4-1W TC4-1W Mini Circuits

1 T3 TC1-1T XFMR_TC4-1W TC1-1T Mini Circuits

1 U1 ADS614X QFN32 TI

1 U2 CDCP1803 mlf_qfn_24 CDCP1803RGET TI

1 U10 TPS73233 DBV5 TPS73233DBVT TI

1 U11 THS4509 QFN16 THS4509RGTT TI

1 U13 93C66B TSSOP8 93C66B Microchip

1 U14 FT245BM PQFP32 FT245BM Future Technology

1 Y1 6.0000MHz smd_csm-7_xtal ECS-60-32-5PDN-TR ECS

4 MP2 Screw machine, ph 4-40 × PMS 440 0038 PH Building Fasteners

4 MP3 Stand-off hex .5/4-40THR 1902C Keystone Electronic

Installed

installed

installed

installed

installed

installed

installed

3/8

www.ti.com

Devices

22 SLAU206B – September 2007 – Revised April 2008

Submit Documentation Feedback

Page 23

PD

VREF1

SIGNAL_IN

+5V_AMP

-VSS_AMP

+5V_AMP

AGND

AMP+

AMP-

AMP+

AMP-

VREF

SH2

IN_M

SH2

IN_P SH2

VREF

SH2

Default:Short2-3

Default:Short1-2

Default:Short1-2

R26

0OHM

R26

0OHM

R44

100

R44

100

C76

18pF

C76

18pF

T1

TC4-1WT1TC4-1W

3

2

1

6

5

4

C34

.1uF

C34

.1uF

1

2

R43

69.8

R43

69.8

R37

499

DoNotInstall

R37

499

DoNotInstall

R46

49.9

R46

49.9

C71

10uF

10V

C71

10uF

10V

12

C70

.1uF

16V

C70

.1uF

16V

C35

.1uF

C35

.1uF

1

2

R35

10K

1/10W

1%

R35

10K

1/10W

1%

C79

.1uF

16V

C79

.1uF

16V

C77

.1uF

C77

.1uF

R45

499

DoNotInstall

R45

499

DoNotInstall

R66

0OHM

R66

0OHM

C14

.1uF

C14

.1uF

1

2

R36

348

R36

348

C80

.22uF

C80

.22uF

R33

200

DoNotInstall

R33

200

DoNotInstall

C75

.1uF

C75

.1uF

MS A

DEN

J8

AIN

MS A

DEN

J8

AIN

1

5234

C74

.1uF

16V

C74

.1uF

16V

R47

49.9

R47

49.9

R57

0OHM

R57

0OHM

R39

69.8

R39

69.8

R32

10

1/16W

1%

R32

10

1/16W

1%

JP7JP7

1

3

2

U11

THS4509

U11

THS4509

NC1VIN-2CM1

4

VS+

5

VS+

6

VOUT+

3

VS+

7

VS+

8

CM2

9

VOUT-

10

VIN+

11

PD

12

VS-

13

VS-

14

VS-

15

VS-

16

PAD

17

R24

39

1/10W

1%

R24

39

1/10W

1%

R40

100

R40

100

T2

TC4-1WT2TC4-1W

3

2

1

6

5

4

MS A

DEN

J15

AMP

MS A

DEN

J15

AMP

1

5234

C15

.1uF

16V

C15

.1uF

16V

C72

.1uF

16V

C72

.1uF

16V

C82

10uF

10V

C82

10uF

10V

12

R25

200

R25

200

C73

10uF

10V

C73

10uF

10V

12

R48

348

R48

348

R22

200

R22

200

C78

.1uF

16V

C78

.1uF

16V

R38

49.9

R38

49.9

R42

200

DoNotInstall

R42

200

DoNotInstall

R34

10

1/16W 1%

R34

10

1/16W 1%

C81

.1uF

16V

C81

.1uF

16V

JP6JP6

1

3

2

JP5JP5

1

3

2

R21

0OHM

DoNotInstall

R21

0OHM

DoNotInstall

R41

200

DoNotInstall

R41

200

DoNotInstall

C84

10uF

10V

C84

10uF

10V

12

C83

.1uF

16V

C83

.1uF

16V

R23

39

1/10W

1%

R23

39

1/10W

1%

RemoveR66

for ADS61B23

www.ti.com

Physical Description

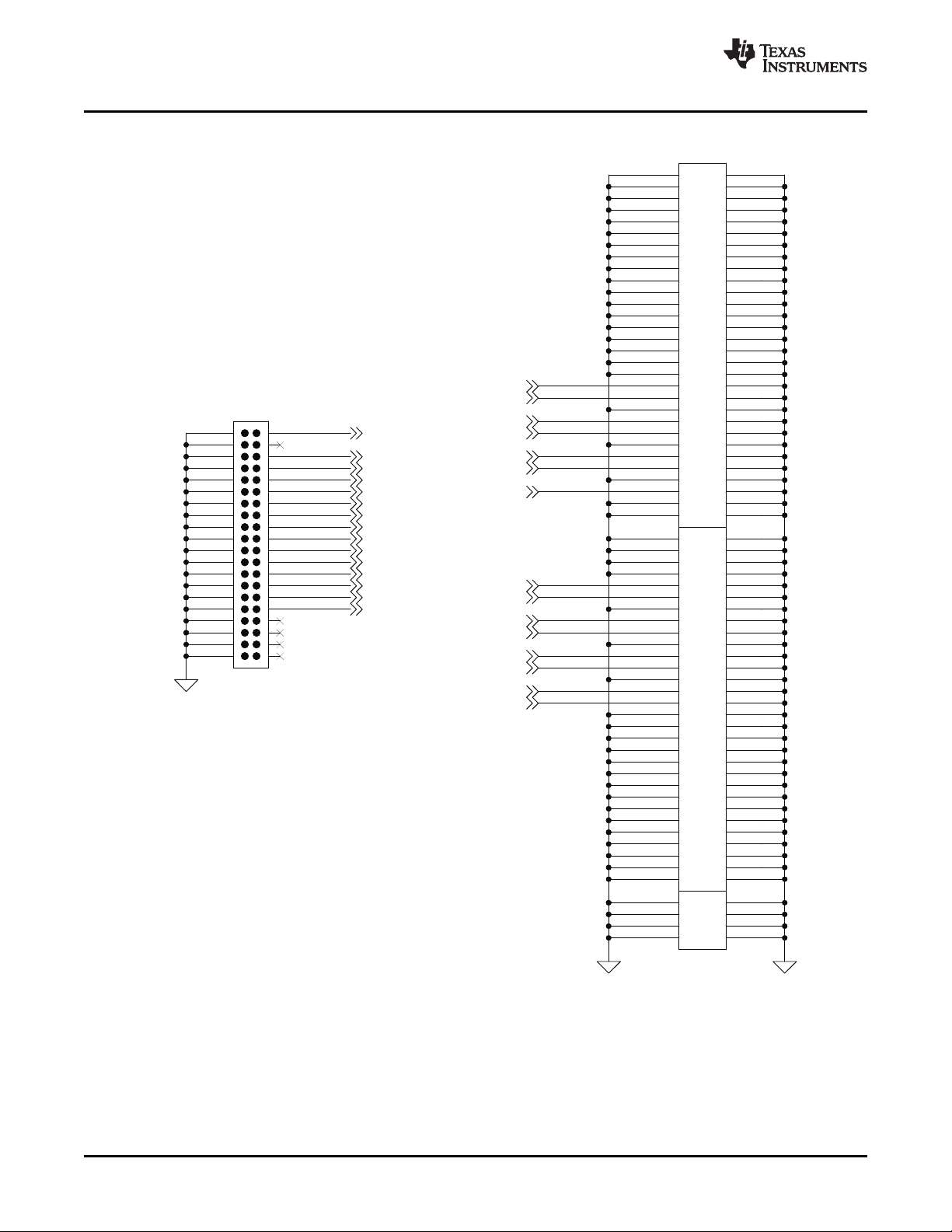

6.3 EVM Schematics

Figure 7. EVM Schematic, Sheet 1

SLAU206B – September 2007 – Revised April 2008 23

Submit Documentation Feedback

Page 24

ICLKP

ICLKM

SEN

SDA

SCLOCK

PDWN

SEN

RESET

SCLOCK

+3.3VD

+3.3VA

+3.3VD

+3.3VD

+3.3VD

+3.3VD

+3.3VD

+3.3VD

IN_M

SH1

IN_P

SH1

D2_D3_P SH4

D0_D1_P SH4

D0_D1_M SH4

D2_D3_M SH4

D4_D5_P SH4

D4_D5_M

SH4

D6_D7_P SH4

D6_D7_M

SH4

ICLKP

SH3

ICLKM

SH3

ADCRESETSH5

SDATASH5

VREF

SH1

PDN SH5

CS SH5

SCLK SH5

FPGA_SEN SH4

FPGA_SCLK SH4

FPGA_SDATASH4

CLKOUTP

SH4

CLKOUTM

SH4

D8_D9_P

SH4

D8_D9_M

SH4

D10_D11_P

SH4

D10_D1

1_M

SH4

D12_D13_P

SH4

D12_D13_M

SH4

PARALLELINTERFACE

SERIALINTERFACE

Default:Shunt2-3

Default:Shunt1-2

Default:Shunt2-3

Default:Shunt2-3

R17

100

R17

100

1

2

R111KR11

1K

12

R10

10K

R10

10K

12

TP5TP5

R6

10KR610K

12

R20

100

R20

100

1

2

SW1SW1

C13

.1uF

C13

.1uF

12

J4J4

246

8

135

7

R141KR14

1K

12

R8

100R8100

1

2

J2J2

123

U1

ADS614XU1ADS614X

DRVDD1RESET2SCLK3SDATA4SEN5AGND6CLKP7CLKM

8

AGND

9

INP

10

INM

11

AGND

12

AVDD

13

CM_REFIN

14

AVDD_FVDD

15

PDN

16

D0_D1_M

17

D0_D1_P

18

D2_D3_M

19

D2_D3_P

20

D4_D5_M

21

D4_D5_P

22

D6_D7_M

23

D6_D7_P

24

CLKOUTM

25

CLKOUTP

26

D8_D9_M

27

D8_D9_P

28

D10_D11_M

29

D10_D11_P

30

D12_D13_M

31

D12_D13_P

32

DRVSS(GNDPAD)

33

R64

0OHM

DoNotInstall

R64

0OHM

DoNotInstall

J7J7

123

TP6TP6

R7

0OHMR70OHM

R91KR9

1K

12

R18

10K

R18

10K

12

C12

.1uF

C12

.1uF

12

TP1TP1

R19

100

R19

100

1

2

R13

100

R13

100

1 2

TP3TP3

TP2TP2

R15

10K

R15

10K

12

C85

.1uF

C85

.1uF

12

R62

0OHM

DoNotInstall

R62

0OHM

DoNotInstall

J1J1

246

8

135

7

J3J3

123

TP4TP4

C11

.1uF

C11

.1uF

12

J6J6

123

R31KR3

1K

12

R12

100

R12

100

1

2

R51KR5

1K

12

J5J5

123

R63

0OHM

DoNotInstall

R63

0OHM

DoNotInstall

R41KR4

1K

12

R1610R16

10

Physical Description

www.ti.com

Figure 8. EVM Schematic, Sheet 2

24 SLAU206B – September 2007 – Revised April 2008

Submit Documentation Feedback

Page 25

ADCCLK-

CLKOUT\

CLKOUT

ADCCLK+

CLK-

CLK+

+3.3V_AUX

+3.3V_AUX

+3.3V_AUX

CDC_CLKM SH4

CDC_CLKP SH4

ICLKP

SH2

ICLKM SH2

Default:Short2-3

Default:Short1-2

Default:Short1-2

Default:Short1-2

R29

49.9

1/10W

1%

R29

49.9

1/10W

1%

C16

.1uF

16V

C16

.1uF

16V

1

2

R60

130

R60

130

1 2

C32

.1uF

16V

C32

.1uF

16V

1

2

R31

49.9

R31

49.9

JP8JP8

123

R28

121

1/10W

DoNotInstall

1%

R28

121

1/10W

DoNotInstall

1%

R58

130

R58

130

1 2

MSA

D EN

J9

CLK

MSA

D EN

J9

CLK

1

5234

C19

.1uF

16V

C19

.1uF

16V

C29

.1uF

C29

.1uF

1 2

C28

.1uF

C28

.1uF

1 2

C27

.1uF

C27

.1uF

1 2

C20

.1uF

C20

.1uF

1

2

C26

.1uF

C26

.1uF

1 2

C25

.1uF

C25

.1uF

1 2

JP4JP4

123

R27

121

1/10W

DoNotInstall

1%

R27

121

1/10W

DoNotInstall

1%

C24

.1uF

C24

.1uF

1 2

R59

82.5

R59

82.5

U2

CDCM1803

U2

CDCM1803

IN

4

VSS

7

VDDPECL

5

Y115Y1

16

VDD117VDD1

14

EN1VDDPECL2IN

3

VSS

13

VBB

6

VDD2

8

Y2

9

Y2

10

VDD2

11

NC

12

S0

18

S1

19

VDD0

20

Y0

21

Y0

22

VDD0

23

S2

24

GND

25

C23

.1uF

C23

.1uF

1 2

T3

TC1-1TT3TC1-1T

3

2

1

6

5

4

C18

.1uF

16V

C18

.1uF

16V

1

2

C33

.1uF

16V

C33

.1uF

16V

1

2

C22

.1uF

C22

.1uF

1 2

C21

.1uF

C21

.1uF

1 2

JP3JP3

123

R30

60.4K

R30

60.4K

JP2JP2

123

R61

82.5

R61

82.5

C17

.1uF

16V

C17

.1uF

16V

JP1

DoNotInstall

JP1

DoNotInstall

1

2

www.ti.com

Physical Description

Figure 9. EVM Schematic, Sheet 3

SLAU206B – September 2007 – Revised April 2008 25

Submit Documentation Feedback

Page 26

D12_D13_PSH2

D12_D13_MSH2

D10_D11_PSH2

D10_D11_MSH2

D8_D9_PSH2

D8_D9_MSH2

CLKOUTPSH2

CLKOUTMSH2

D6_D7_PSH2

D6_D7_MSH2

D4_D5_PSH2

D4_D5_MSH2

D2_D3_PSH2

D2_D3_MSH2

D0_D1_PSH2

D0_D1_MSH2

CDC_CLKPSH3

CDC_CLKMSH3

FPGA_SCLK SH2

FPGA_SEN SH2

FPGA_SDATA SH2

J10

CONN_QTH_30X2-D-A

J10

CONN_QTH_30X2-D-A

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

G1G2

G3G4

G5G6

G7G8

4142

4344

4546

4748

4950

5152

5354

5556

5758

5960

6162

6364

6566

6768

6970

7172

7374

7576

7778

7980

8182

8384

8586

8788

8990

9192

9394

9596

9798

99100

101102

103104

105106

107108

109110

111112

113114

115116

117118

119120

Physical Description

26 SLAU206B – September 2007 – Revised April 2008

Figure 10. EVM Schematic, Sheet 4

Submit Documentation Feedback

www.ti.com

Page 27

+3.3VD_IN

5V_IN

+3.3VA_IN

+3.3V

A

+3.3VD

5V

+5V_AMP

C3

1uFC31uF

12

C4

.1uFC4.1uF

12

J13

RED

+3.3VA_IN

J13

RED

+3.3VA_IN

C30

10uF

6.3V

C30

10uF

6.3V

12

L168L1

68

1

2

+

C8

33uF+C8

33uF

12

+

C52

33UF

10V

+

C52

33UF

10V

12

+

C1

33uF+C1

33uF

12

L268L2

68

1

2

C53

.1uF

16V

C53

.1uF

16V

+

C5

33uF+C5

33uF

12

J20

RED

+5V_IN

J20

RED

+5V_IN

C31

1uF

10V

C31

1uF

10V

12

C6

1uFC61uF

12

J11

RED

+3.3VD_IN

J11

RED

+3.3VD_IN

R65

0OHM

R65

0OHM

J14

BLK

GND

J14

BLK

GND

C7

.1uFC7.1uF

12

C9

10uF

6.3V

C9

10uF

6.3V

12

L868L8

68

1

2

C57

10uF

6.3V

C57

10uF

6.3V

12

L368L3

68

1

2

J12

BLK

GND

J12

BLK

GND

C2

10uF

6.3V

C2

10uF

6.3V

12

-5V_IN

+3.3V_AUX

5V

-VSS_AMP

C67

.1uF

16V

C67

.1uF

16V

C55

.1uF

16V

C55

.1uF

16V

C66

.1uF

16V

C66

.1uF

16V

J16

RED

-VSS_AMP

J16

RED

-VSS_AMP

L968L9

68

1

2

U10

TPS73233

U10

TPS73233

EN

3

IN1GND

2

OUT

5

NC/FB

4

C56

10uF

6.3V

C56

10uF

6.3V

1 2

+

C54

33UF

10V

+

C54

33UF

10V

12

www.ti.com

Physical Description

Figure 11. EVM Schematic, Sheet 5

SLAU206B – September 2007 – Revised April 2008 27

Submit Documentation Feedback

Page 28

GND

D6

D9

D1

D3

D7

D5

CLK

D13

D0

D2

D8

D10

D12

D11

D4

D7

D6

D5

D4

D3

D2

D1

D0

D13

D12

D11

D10

D9

D8

CLK

J1

CONN_QSH_30X2-D-A

J1

CONN_QSH_30X2-D-A

2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

34

36

38

40

1

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33

35

37

39

G1G2

G3G4

G5G6

G7G8

4142

4344

4546

4748

4950

5152

5354

5556

5758

5960

6162

6364

6566

6768

6970

7172

7374

7576

7778

7980

8182

8384

8586

8788

8990

9192

9394

9596

9798

99100

101102

103104

105106

107108

109110

111112

113114

115116

117118

119120

J2

40PINIDC

DATA_OUT

J2

40PINIDC

DATA_OUT

1 2

4

6

8

10

12

14

16

18

20

22

24

26

28

30

32

3

5

7

9

11

13

15

17

19

21

23

25

27

29

31

33 34

35 36

37 38

39 40

Physical Description

Figure 12. Breakout Board Schematic, Sheet 6

28 SLAU206B – September 2007 – Revised April 2008

Submit Documentation Feedback

www.ti.com

Page 29

EVALUATION BOARD/KIT IMPORTANT NOTICE

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION PURPOSES

ONLY and is not considered by TI to be a finished end-product fit for general consumer use. Persons handling the product(s) must have

electronics training and observe good engineering practice standards. As such, the goods being provided are not intended to be complete

in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including product safety and environmental

measures typically found in end products that incorporate such semiconductor components or circuit boards. This evaluation board/kit does

not fall within the scope of the European Union directives regarding electromagnetic compatibility, restricted substances (RoHS), recycling

(WEEE), FCC, CE or UL, and therefore may not meet the technical requirements of these directives or other related directives.

Should this evaluation board/kit not meet the specifications indicated in the User’s Guide, the board/kit may be returned within 30 days from

the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY SELLER TO BUYER

AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user indemnifies TI from all claims

arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to take any and all

appropriate precautions with regard to electrostatic discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or infringement of patents or

services described herein.

Please read the User’s Guide and, specifically, the Warnings and Restrictions notice in the User’s Guide prior to handling the product. This

notice contains important safety information about temperatures and voltages. For additional information on TI’s environmental and/or

safety programs, please contact the TI application engineer or visit www.ti.com/esh .

No license is granted under any patent right or other intellectual property right of TI covering or relating to any machine, process, or

combination in which such TI products or services might be or are used.

FCC Warning

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION PURPOSES

ONLY and is not considered by TI to be a finished end-product fit for general consumer use. It generates, uses, and can radiate radio

frequency energy and has not been tested for compliance with the limits of computing devices pursuant to part 15 of FCC rules, which are

designed to provide reasonable protection against radio frequency interference. Operation of this equipment in other environments may

cause interference with radio communications, in which case the user at his own expense will be required to take whatever measures may

be required to correct this interference.

EVM WARNINGS AND RESTRICTIONS

It is important to operate this EVM within the input voltage range of–0.3 V to 3.6 V and the output voltage range of –0.3 V to 3.6 V.

Exceeding the specified input range may cause unexpected operation and/or irreversible damage to the EVM. If there are questions

concerning the input range, please contact a TI field representative prior to connecting the input power.

Applying loads outside of the specified output range may result in unintended operation and/or possible permanent damage to the EVM.

Please consult the EVM User's Guide prior to connecting any load to the EVM output. If there is uncertainty as to the load specification,

please contact a TI field representative.

During normal operation, some circuit components may have case temperatures greater than 50 ° C. The EVM is designed to operate

properly with certain components above 25 ° C as long as the input and output ranges are maintained. These components include but are

not limited to linear regulators, switching transistors, pass transistors, and current sense resistors. These types of devices can be identified

using the EVM schematic located in the EVM User's Guide. When placing measurement probes near these devices during operation,

please be aware that these devices may be very warm to the touch.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright 2007-2008, Texas Instruments Incorporated

Page 30

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements,

and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should

obtain the latest relevant information before placing orders and should verify that such information is current and complete. All products are

sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s standard

warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this warranty. Except where

mandated by government requirements, testing of all parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should provide

adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask work right,

or other TI intellectual property right relating to any combination, machine, or process in which TI products or services are used. Information

published by TI regarding third-party products or services does not constitute a license from TI to use such products or services or a

warranty or endorsement thereof. Use of such information may require a license from a third party under the patents or other intellectual

property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is accompanied

by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an unfair and deceptive

business practice. TI is not responsible or liable for such altered documentation. Information of third parties may be subject to additional

restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service voids all

express and any implied warranties for the associated TI product or service and is an unfair and deceptive business practice. TI is not

responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would reasonably

be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement specifically governing

such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications of their applications, and

acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related requirements concerning their products

and any use of TI products in such safety-critical applications, notwithstanding any applications-related information or support that may be

provided by TI. Further, Buyers must fully indemnify TI and its representatives against any damages arising out of the use of TI products in

such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is solely at

the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products are

designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any non-designated

products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Clocks and Timers www.ti.com/clocks Digital Control www.ti.com/digitalcontrol

Interface interface.ti.com Medical www.ti.com/medical

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Telephony www.ti.com/telephony

RF/IF and ZigBee® Solutions www.ti.com/lprf Video & Imaging www.ti.com/video

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2008, Texas Instruments Incorporated

Wireless www.ti.com/wireless

Loading...

Loading...