Page 1

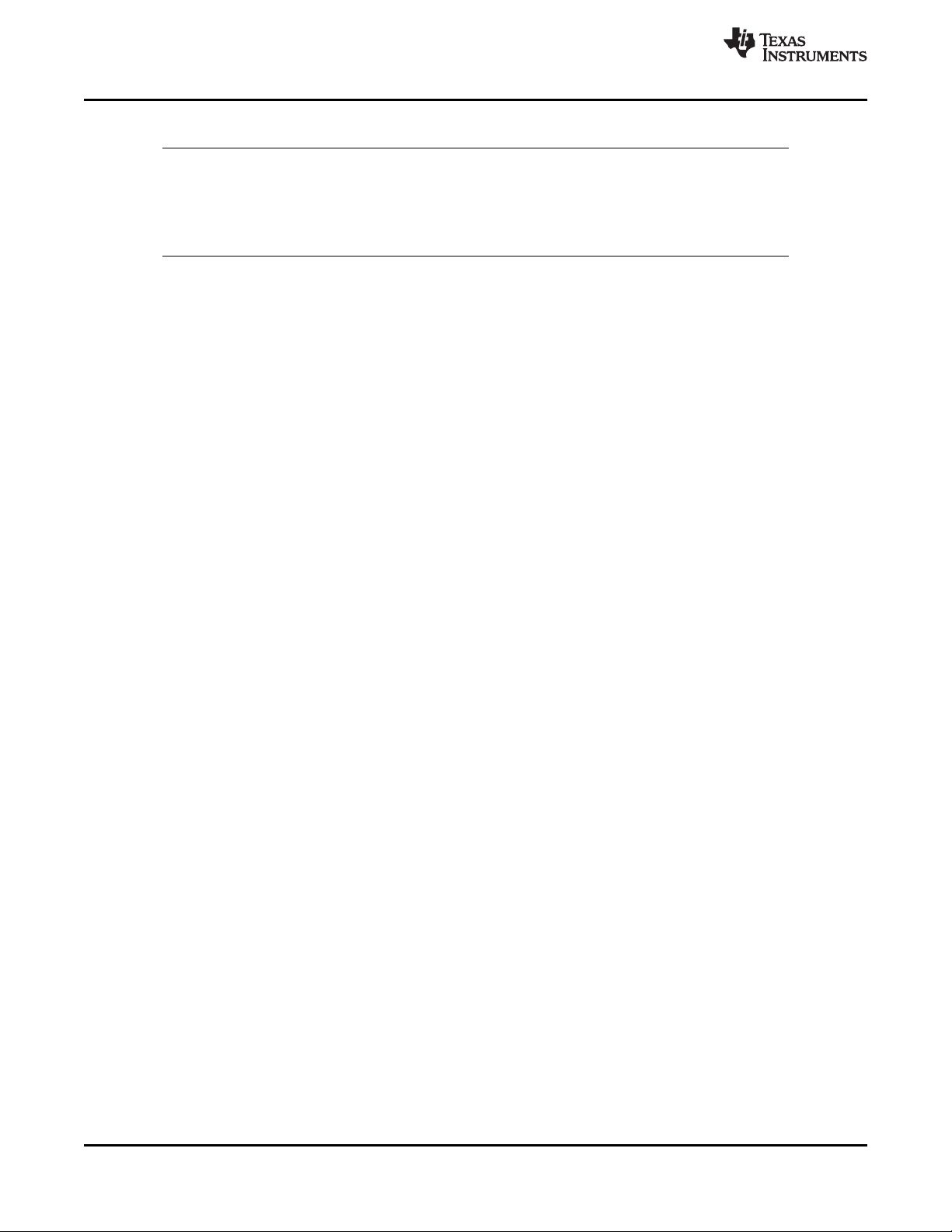

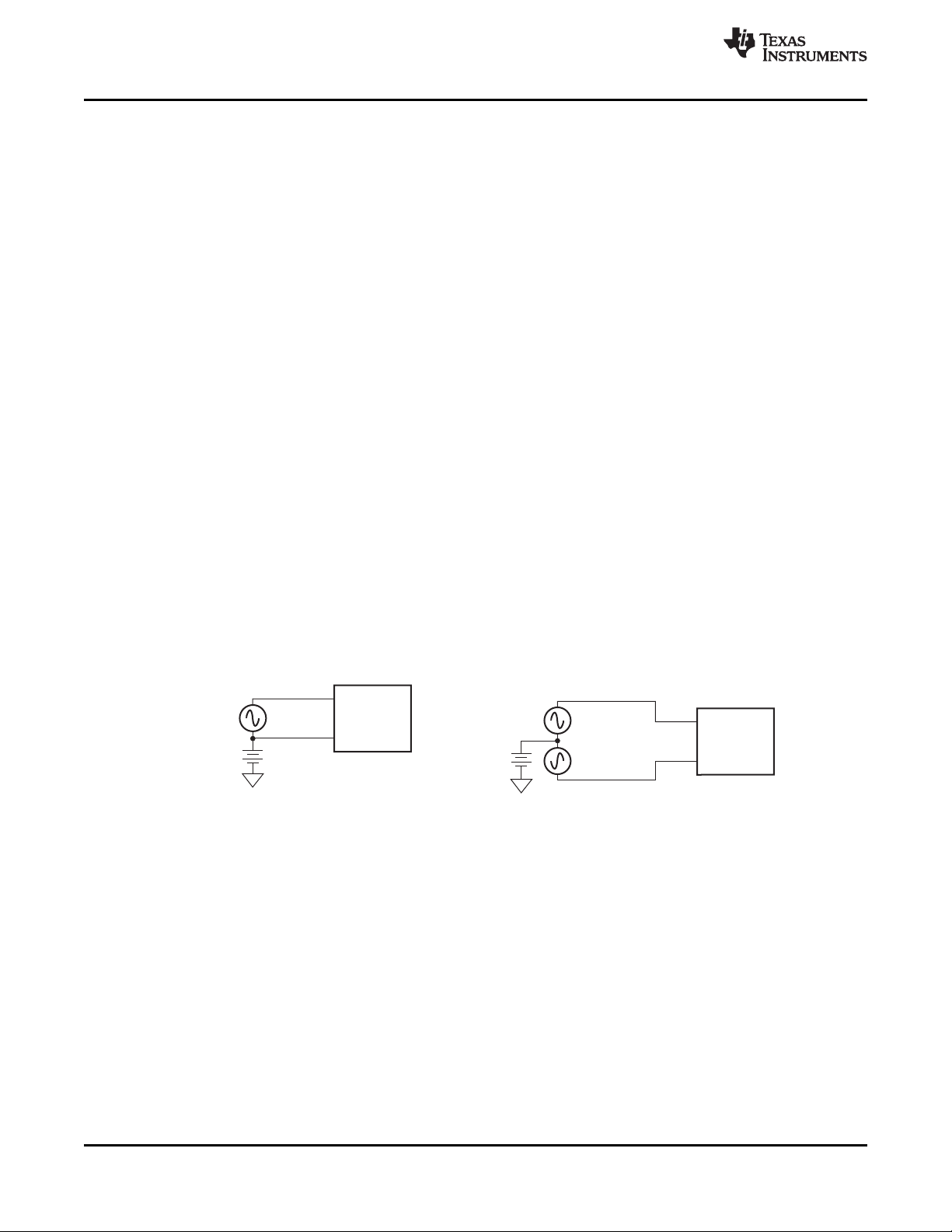

Control

CLK

GPIOANDCONTROL

Oscillator

SPI

TestSignalsand

Monitors

PACE

SPI

RLD

Wilson

Terminal

WCT

Reference

REF

ADC7

ADC8

ADC1

ADC2

ADC3

ADC4

ADC5

ADC6

A7

A8

A1

A2

A3

A4

A5

A6

MUX

INPUTS

¼ ¼

¼

ToChannel

RESP

Resp

RESP

DEMOD

ADS129xR

ADS129xR

www.ti.com.cn

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

用于生物电位测量的低功率,

查询样品

1

特性

23

• 8个低噪音PGA和8个高分辨率ADC(ADS1298,

ADS1298R)

• 低功耗:每通道 0.75 mW

• 输入参考噪声:4μVPP(150Hz BW, G = 6)

• 输入偏置电流:200pA

• 数据速率:250SPS至32kSPS

• CMRR:–115dB

• 可编程增益:1,2,3,4,6,8或者12

• 支持AAMI

EC11,EC13,IEC60601-1,IEC60601-2-27,

和IEC60601-2-51标准

• 单极或双极电源:

AVDD = 2.7V至5.25V,DVDD = 1.65V至3.6V

• 内置右腿驱动放大器,检测,WCT,PACE检测,

测试信号

• 集成的呼吸阻抗测量(只适用

于ADS1294R/6R/8R)

• 数字PACE检测功能

• 内置振荡器与参考

• 灵活的断电,待机模式

• 串行外设接口(SPI)™- 兼容串口

• 运行温度范围:

–40°C至+85°C

: ADS1294, ADS1294R, ADS1296, ADS1296R, ADS1298, ADS1298R

8通道,24位模拟前端

借助于其高水平的集成和出色的性

能,ADS1294/6/8/4R/6R/8R系列产品可以用大大减小

的尺寸,功率,和总体成本来开发可扩展的医疗仪器。

ADS1294/6/8/4R/6R/8R在每通道上有一个灵活输入复

用器,此复用器可独立连接至用于测试,温度,和持续

断线检测的内部生成信号。 此外,可选择输入通道的

各种配置生成右腿驱动器 (RLD) 输出信号。

ADS1294/6/8/4R/6R/8R运行数据速率最高可

达32KSPS,因此可实现软件PACE检测。 可通过上

拉/下拉电阻器或激磁电流源极/汲极为该器件内部实

施持续断线检测。 3个集成的放大器生成标准12引

线ECG所需的威尔逊(Wilson)中心终端(WCT)和高德伯

格(Goldberger)中心终端(GCT)。 ADS1294R/6R/8R版

本包括一个完全集成的,呼吸阻抗测量功能。

多个ADS1294/6/8/4R/6R/8R器件可使用菊花链配置级

联在高通道数量系统中。

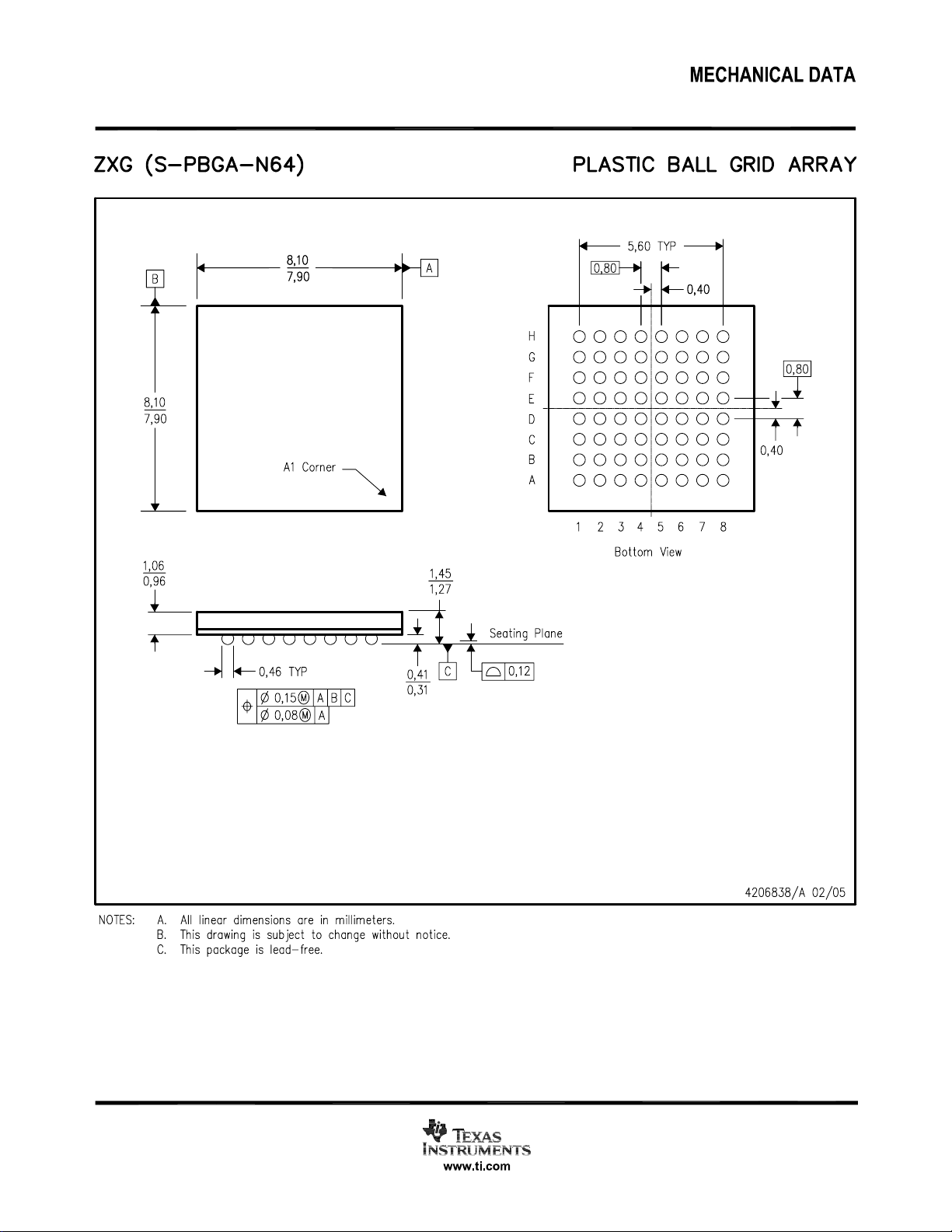

封装选项包括微小型 8mm × 8mm ,64焊球 BGA

与TQFP-64封装。 ADS1294/6/8 BGA版本商用额定温

度范围为0°C至+70°C。 ADS1294R/6R/8R BGA

和ADS1294/6/8 TQFP版本工业用额定温度范围

是–40°C至+85°C。

应用范围

• 医疗仪器(ECG,EMG和EEG)

病人监护:动态心电图,事件,压力,和包

括ECG,AED在内的重要生命体征信号,远程医疗

双谱指数(BIS),诱发音频电位(EAP),睡眠监护仪

• 高精度,同步,多通道信号采集

说明

ADS1294/6/8/4R/6R/8R是多通道,同步采样,24位,

三角积分(ΔΣ)模数转换器(ADC)系列产品,此产品具有

内置的可编程增益放大器(PGA),内部基准,和一个板

载振荡器。 ADS1294/6/8/4R/6R/8R包含了所有医疗心

电图(ECG)和脑电图(EEG)应用所通常要求的所有特

性。

1

2串行外设接口(SPI) is a trademark of Motorola.

3All other trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not English Data Sheet: SBAS459

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Copyright © 2010–2012, Texas Instruments Incorporated

Page 2

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

www.ti.com.cn

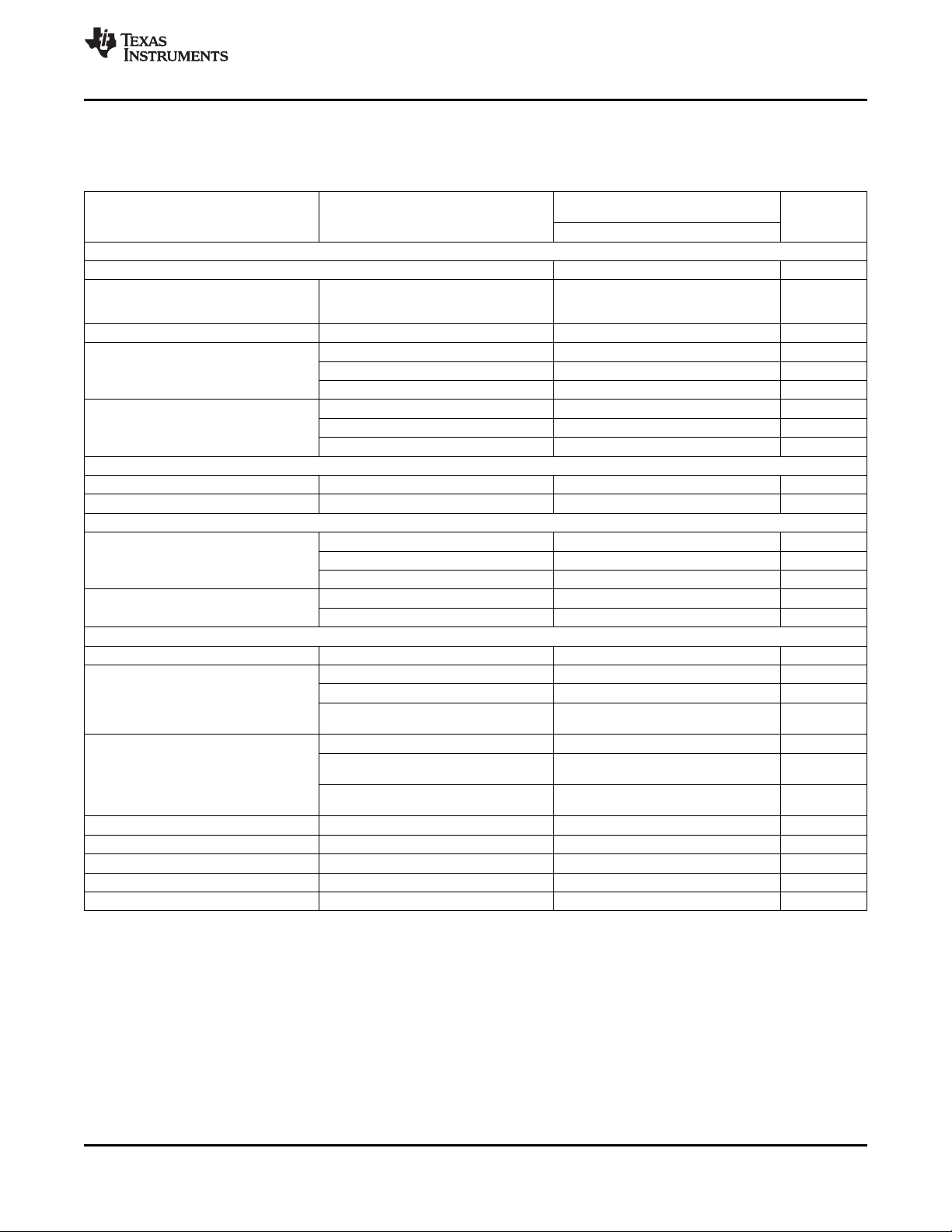

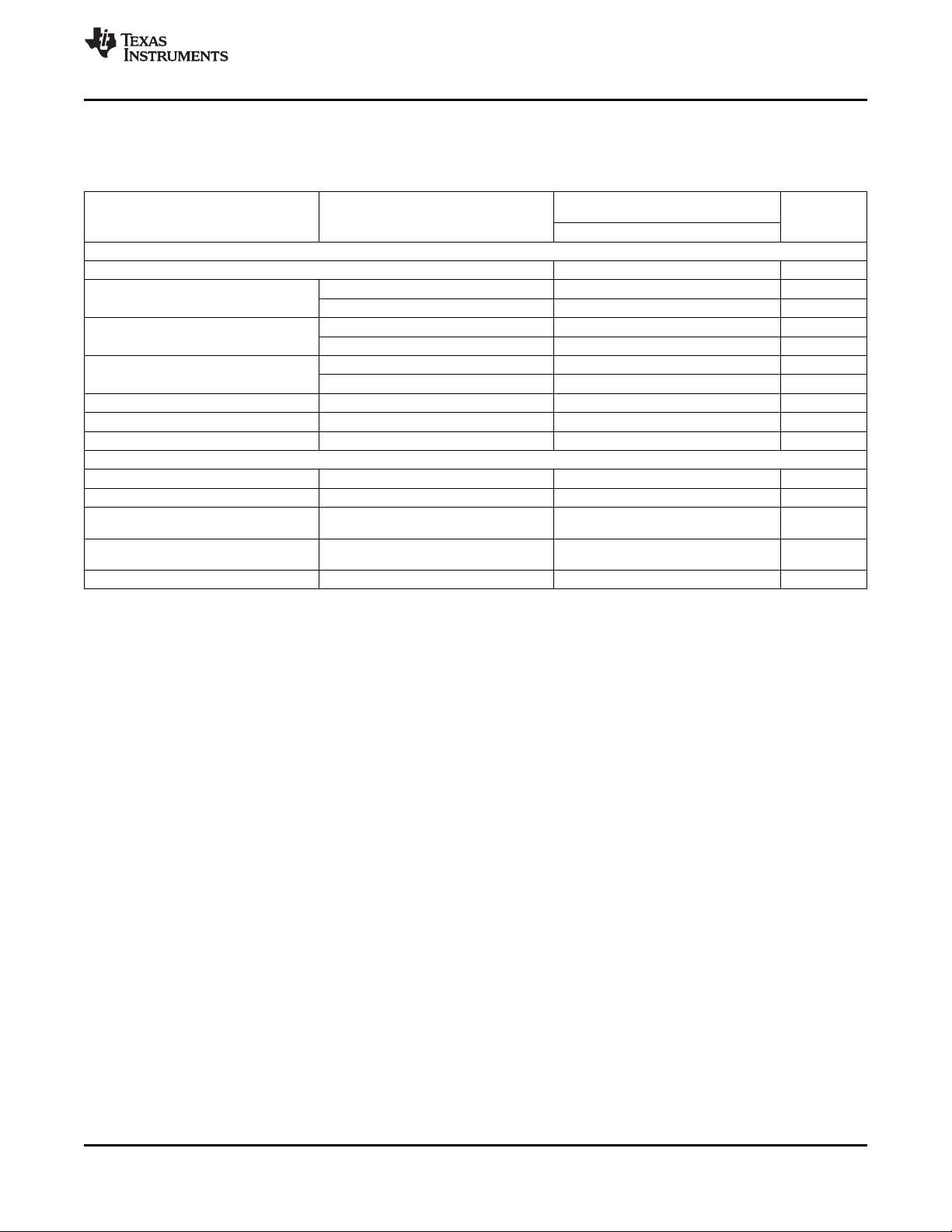

FAMILY AND ORDERING INFORMATION

PRODUCT OPTION CHANNELS RESOLUTION (kSPS) RANGE CIRCUITRY

ADS1194

ADS1196

ADS1198

ADS1294 BGA 4 24 32 0°C to +70°C External

ADS1294R BGA 4 24 32 –40°C to +85°C Yes

ADS1294 TQFP 4 24 32 –40°C to +85°C External

ADS1296 BGA 6 24 32 0°C to +70°C External

ADS1296R BGA 6 24 32 –40°C to +85°C Yes

ADS1296 TQFP 6 24 32 –40°C to +85°C External

ADS1298 BGA 8 24 32 0°C to +70°C External

ADS1298R BGA 8 24 32 –40°C to +85°C Yes

ADS1298 TQFP 8 24 32 –40°C to +85°C External

(1) For the most current package and ordering information, see the Package Option Addendum at the end of this document, or visit the

device product folder at www.ti.com.

ABSOLUTE MAXIMUM RATINGS

PACKAGE NUMBER OF ADC SAMPLE RATE TEMPERATURE RESPIRATION

BGA 4 16 8 0°C to +70°C No

TQFP 4 16 8 0°C to +70°C No

BGA 6 16 8 0°C to +70°C No

TQFP 6 16 8 0°C to +70°C No

BGA 8 16 8 0°C to +70°C No

TQFP 8 16 8 0°C to +70°C No

(1)

MAXIMUM OPERATING

(1)

Over operating free-air temperature range, unless otherwise noted.

ADS1294, ADS1296, ADS1298

ADS1294R, ADS1296R, ADS1298R

AVDD to AVSS –0.3 to +5.5 V

DVDD to DGND –0.3 to +3.9 V

AVSS to DGND –3 to +0.2 V

V

input to AVSS AVSS – 0.3 to AVDD + 0.3 V

REF

Analog input to AVSS AVSS – 0.3 to AVDD + 0.3 V

Digital input voltage to DGND –0.3 to DVDD + 0.3 V

Digital output voltage to DGND –0.3 to DVDD + 0.3 V

Input current (momentary) 100 mA

Input current (continuous) 10 mA

Operating

temperature

range

ESD ratings

Storage temperature range –60 to +150 °C

Maximum junction temperature (TJ) +150 °C

(1) Stresses above these ratings may cause permanent damage. Exposure to absolute maximum conditions for extended periods may

degrade device reliability. These are stress ratings only, and functional operation of the device at these or any other conditions beyond

those specified is not implied.

Commerical Grade: ADS1294, ADS1296, ADS1298 0 to +70 °C

Industrial grade: ADS1294I, ADS1296I, ADS1298I,

ADS1294RI, ADS1296RI, ADS1298RI

Human body model (HBM)

JEDEC standard 22, test method A114-C.01, all pins

Charged device model (CDM)

JEDEC standard 22, test method C101, all pins

–40 to +85 °C

±2000 V

±500 V

UNIT

2 Copyright © 2010–2012, Texas Instruments Incorporated

Page 3

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

www.ti.com.cn

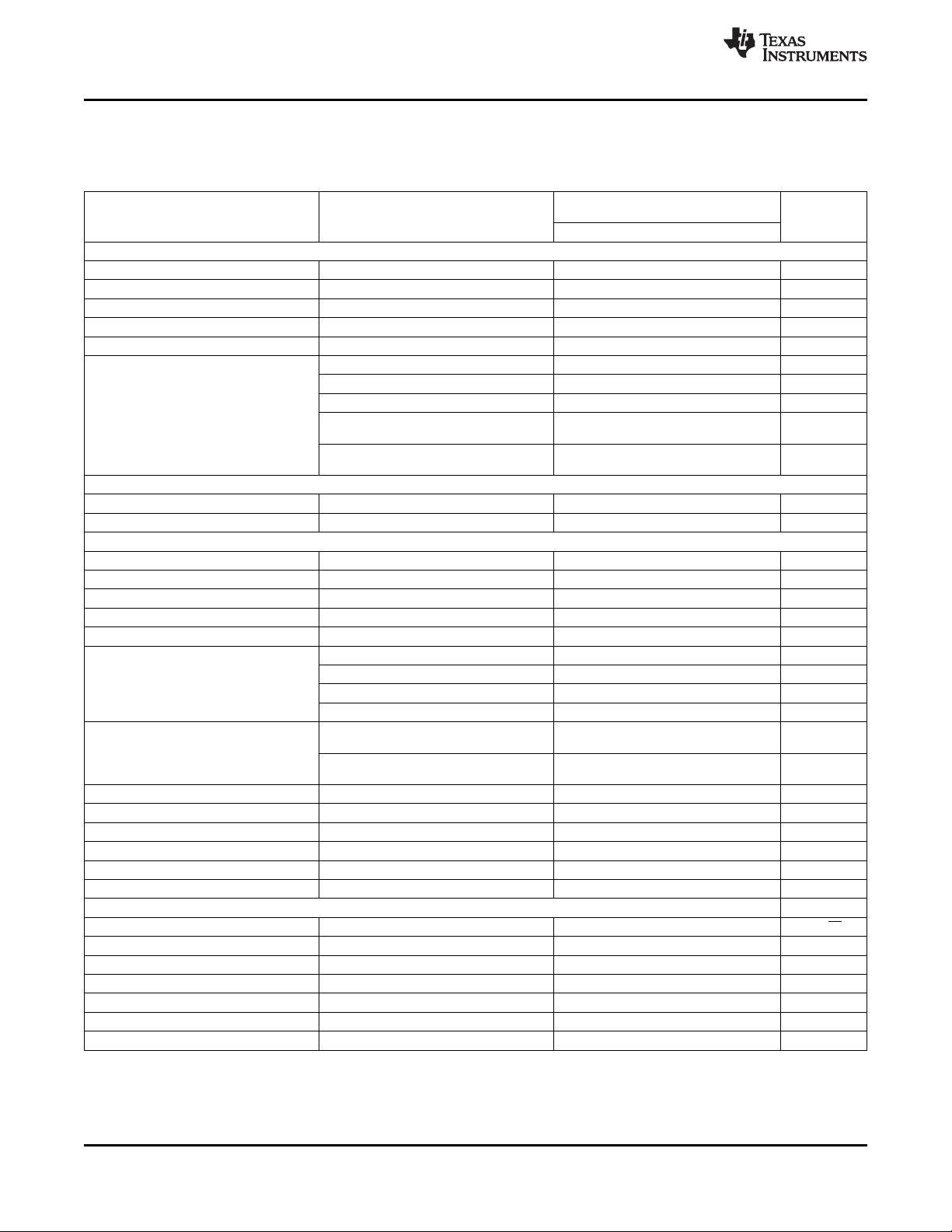

ELECTRICAL CHARACTERISTICS

Minimum/maximum specifications apply for all commercial grade (0°C to +70°C) devices and from –40°C to +85°C for

industrial grades devices. Typical specifications are at +25°C. All specifications at DVDD = 1.8V, AVDD – AVSS = 3V

V

= 2.4V, external f

REF

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

ANALOG INPUTS

Full-scale differential input voltage (AINP – AINN) ±V

Input common-mode range subsection of the PGA Settings and Input

Input capacitance 20 pF

Input bias current TA= 0°C to +70°C, input = 1.5V ±1 nA

DC input impedance Current source lead-off detection 500 MΩ

PGA PERFORMANCE

Gain settings 1, 2, 3, 4, 6, 8, 12

Bandwidth See Table 6

ADC PERFORMANCE

Resolution 16kSPS data rate 19 Bits

Data rate

CHANNEL PERFORMANCE

DC Performance

Input-referred noise

Integral nonlinearity ADS1294R/6R/8R channel 1

Offset error ±500 µV

Offset error drift 2 µV/°C

Gain error Excluding voltage reference error ±0.2 ±0.5 % of FS

Gain drift Excluding voltage reference drift 5 ppm/°C

Gain match between channels 0.3 % of FS

(1) Performance is applicable for 5V operation as well. Production testing for limits is performed at 3V.

(2) Noise data measured in a 10-second interval. Test not performed in production. Input-referred noise is calculated with input shorted

(without electrode resistance) over a 10-second interval.

= 2.048MHz, data rate = 500SPS, High-Resolution mode, and gain = 6, unless otherwise noted.

CLK

TA= +25°C, input = 1.5V ±200 pA

TA= –40°C to +85°C, input = 1.5V ±1.2 nA

No lead-off 1000 MΩ

Pull-up resistor lead-off detection 10 MΩ

Data rates up to 8kSPS, no missing codes 24 Bits

32kSPS data rate 17 Bits

f

= 2.048MHz, High-Resolution mode 500 32000 SPS

CLK

f

= 2.048MHz, Low-Power mode 250 16000 SPS

CLK

(2)

Gain = 6

Gain = 6, 256 points, 0.5 seconds of data 4 7 μV

Gain settings other than 6, data rates other

than 500SPS

Full-scale with gain = 6, best fit 8 ppm

Full-scale with gain = 6, best fit,

–20dBFS with gain = 6, best fit,

ADS1294R/6R/8R channel 1

, 10 seconds of data 5 μV

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

(1)

ADS1294, ADS1296, ADS1298

ADS1294R, ADS1296R, ADS1298R

/GAIN V

REF

See the Input Common-Mode Range

Range section

See Noise Measurements section

40 ppm

8 ppm

,

PP

PP

Copyright © 2010–2012, Texas Instruments Incorporated 3

Page 4

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

ELECTRICAL CHARACTERISTICS (continued)

Minimum/maximum specifications apply for all commercial grade (0°C to +70°C) devices and from –40°C to +85°C for

industrial grades devices. Typical specifications are at +25°C. All specifications at DVDD = 1.8V, AVDD – AVSS = 3V

V

= 2.4V, external f

REF

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

CHANNEL PERFORMANCE (continued)

AC Performance

Common-mode rejection ratio (CMRR) fCM= 50Hz, 60Hz

Power-supply rejection ratio (PSRR) fPS= 50Hz, 60Hz 90 dB

Crosstalk fIN= 50Hz, 60Hz –126 dB

Signal-to-noise ratio (SNR) fIN= 10Hz input, gain = 6 112 dB

Total harmonic distortion (THD)

DIGITAL FILTER

–3dB bandwidth 0.262f

Digital filter settling Full setting 4 Conversions

RIGHT LEG DRIVE (RLD) AMPLIFIER AND PACE AMPLIFIERS

RLD integrated noise BW = 150Hz 7 μV

PACE integrated noise BW = 8kHz 20 µV

PACE amplifier crosstalk Crosstalk between PACE amplifiers 60 dB

Gain bandwidth product 50kΩ || 10pF load, gain = 1 100 kHz

Slew rate 50kΩ || 10pF load, gain = 1 0.25 V/μs

PACE and RLD amplifier drive strength

PACE and RLD current

PACE amplifier output resistance 100 Ω

Total harmonic distortion fIN= 100Hz, gain = 1 –70 dB

Common-mode input range AVSS + 0.7 AVDD – 0.3 V

Common-mode resistor matching Internal 200kΩ resistor matching 0.1 %

Short-circuit current ±0.25 mA

Quiescent power consumption Either RLD or PACE amplifier 20 μA

WILSON CENTRAL TERMINAL (WCT) AMPLIFIER

Integrated noise BW = 150Hz See Table 5 nV/√Hz

Gain bandwidth product See Table 5 kHz

Slew rate See Table 5 V/s

Total harmonic distortion fIN= 100Hz 90 dB

Common-mode input range AVSS + 0.3 AVDD – 0.3 V

Short-circuit current Through internal 30kΩ resistor ±0.25 mA

Quiescent power consumption See Table 5 μA

(3) CMRR is measured with a common-mode signal of AVSS + 0.3V to AVDD – 0.3V. The values indicated are the maximum of the eight

channels.

(4) Harmonics above the second harmonic are attenuated by the digital filter.

= 2.048MHz, data rate = 500SPS, High-Resolution mode, and gain = 6, unless otherwise noted.

CLK

ADS1294, ADS1296, ADS1298

ADS1294R, ADS1296R, ADS1298R

(3)

10Hz, –0.5dBFs –98 dB

ADS1294R/6R/8R channel 1, 10Hz, –0.5dBFs –70 dB

100Hz, –0.5dBFs

ADS1294R/6R/8R channel 1,

100Hz, –0.5dBFs

ADS1294R/6R/8R channel 1,

100Hz, –20dBFs

Short-circuit to GND (AVDD = 3V) 270 μA

Short-circuit to supply (AVDD = 3V) 550 μA

Short-circuit to GND (AVDD = 5V) 490 μA

Short-circuit to supply (AVDD = 5V) 810 μA

Peak swing (AVSS + 0.3V to AVDD + 0.3V)

at AVDD = 3V

Peak swing (AVSS + 0.3V to AVDD + 0.3V)

at AVDD = 5V

(4)

(4)

(4)

–105 –115 dB

–100 dB

–68 dB

–86 dB

DR

50 μA

75 μA

www.ti.com.cn

(1)

,

Hz

RMS

RMS

4 Copyright © 2010–2012, Texas Instruments Incorporated

Page 5

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

www.ti.com.cn

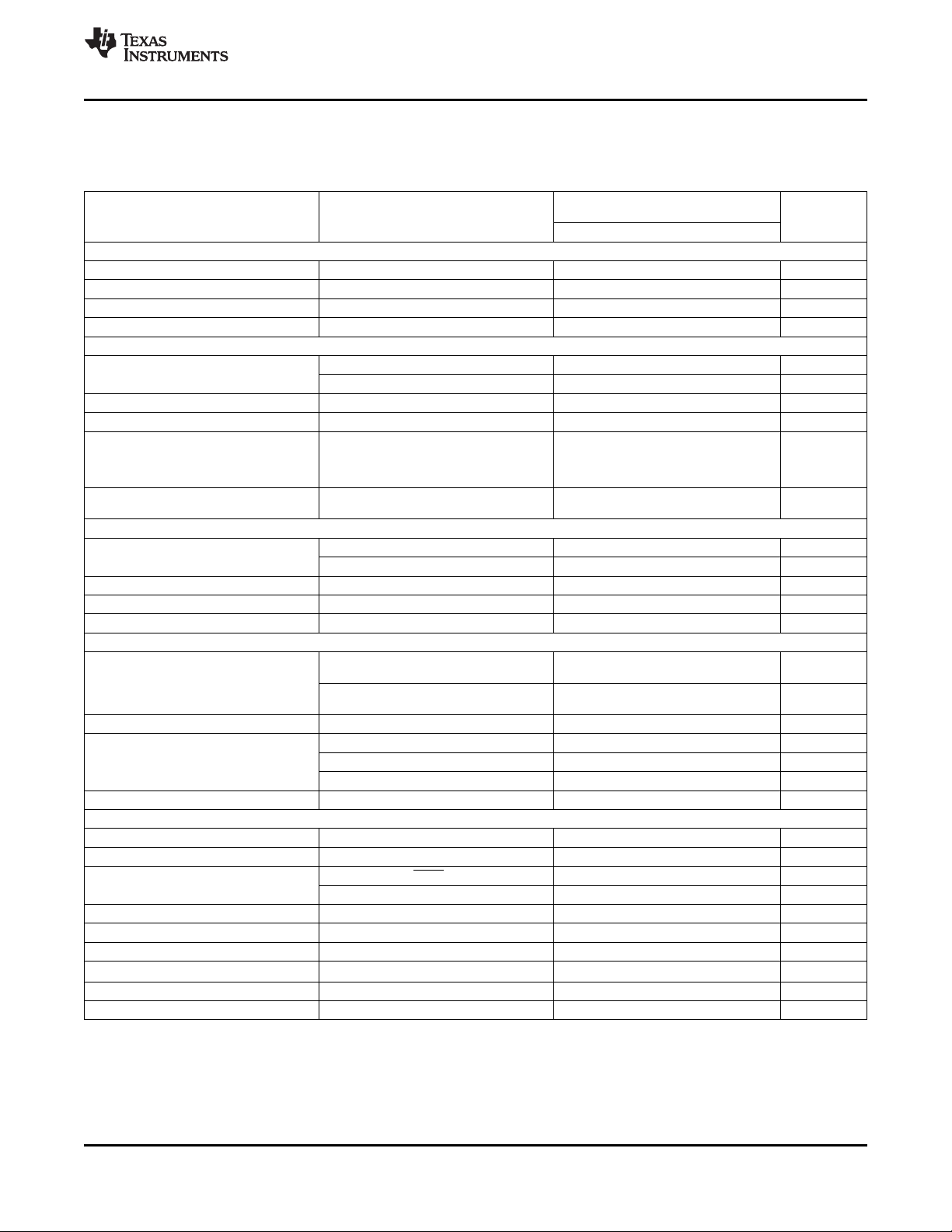

ELECTRICAL CHARACTERISTICS (continued)

Minimum/maximum specifications apply for all commercial grade (0°C to +70°C) devices and from –40°C to +85°C for

industrial grades devices. Typical specifications are at +25°C. All specifications at DVDD = 1.8V, AVDD – AVSS = 3V

V

= 2.4V, external f

REF

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

LEAD-OFF DETECT

Frequency See the Register Map section for settings 0, fDR/4 kHz

Current See the Register Map section for settings 6, 12, 18, 24 nA

Current accuracy ±20 %

Comparator threshold accuracy ±30 mV

RESPIRATION (ADS1294R/6R/8R Only)

Frequency

Phase shift See the Register Map section for settings 22.5 90 157.5 Degrees

Impedance range I

Impedance measurement noise 20 mΩ

Modulator current 29 µA

EXTERNAL REFERENCE

Reference input voltage

Negative input (VREFN) AVSS V

Positive input (VREFP) AVSS + 2.5 V

Input impedance 10 kΩ

INTERNAL REFERENCE

Output voltage

V

accuracy ±0.2 %

REF

Internal reference drift Commerical grade, 0°C to +70°C 35 ppm

Start-up time 150 ms

SYSTEM MONITORS

Analog supply reading error 2 %

Digital supply reading error 2 %

Device wake up

Temperature sensor reading, voltage TA= +25°C 145 mV

Temperature sensor reading, coefficient 490 μV/°C

Test Signal

Signal frequency See Register Map section for settings Hz

Signal voltage See Register Map section for settings ±1, ±2 mV

Accuracy ±2 %

= 2.048MHz, data rate = 500SPS, High-Resolution mode, and gain = 6, unless otherwise noted.

CLK

Internal source 32, 64 kHz

External source 32 64 kHz

= 30μA 10 kΩ

RESP

0.05Hz to 2Hz brick wall filter, 32kHz

modulation clock, phase = 112.5,

using I

gain = 4 test condition

internal reference, signal path = 82kΩ,

baseline = 2.21kΩ

3V supply V

5V supply V

Register bit CONFIG3.VREF_4V = 0,

AVDD ≥ 2.7V

Register bit CONFIG3.VREF_4V = 1,

AVDD ≥ 4.4V

TA= +25°C 35 ppm/°C

Industrial grade, –40°C to +85°C 45 ppm

From power-up to DRDY low 150 ms

STANDBY mode 9 ms

= 30μA with 2kΩ baseline load,

RESP

= (VREFP – VREFN) 2.5 V

REF

= (VREFP – VREFN) 4.0 V

REF

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

ADS1294, ADS1296, ADS1298

ADS1294R, ADS1296R, ADS1298R

2.4 V

4.0 V

CLK

20

/2

f

/221, f

CLK

(1)

,

PP

Copyright © 2010–2012, Texas Instruments Incorporated 5

Page 6

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

ELECTRICAL CHARACTERISTICS (continued)

Minimum/maximum specifications apply for all commercial grade (0°C to +70°C) devices and from –40°C to +85°C for

industrial grades devices. Typical specifications are at +25°C. All specifications at DVDD = 1.8V, AVDD – AVSS = 3V

V

= 2.4V, external f

REF

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

CLOCK

Internal oscillator clock frequency Nominal frequency 2.048 MHz

Internal clock accuracy

Internal oscillator start-up time 20 μs

Internal oscillator power consumption 120 μW

External clock input frequency CLKSEL pin = 0 1.94 2.048 2.25 MHz

DIGITAL INPUT/OUTPUT (DVDD = 1.65V to 3.6V)

Logic level

V

IH

V

IL

V

OH

V

OL

Input current (IIN) 0V < V

POWER-SUPPLY REQUIREMENTS

Analog supply (AVDD – AVSS) 2.7 3.0 5.25 V

Digital supply (DVDD) 1.65 1.8 3.6 V

AVDD – DVDD –2.1 3.6 V

SUPPLY CURRENT (RLD, WCT, and PACE Amplifiers Turned Off)

High-Resolution mode (ADS1298)

I

AVDD

I

DVDD

Low-Power mode (ADS1298)

I

AVDD

I

DVDD

POWER DISSIPATION (Analog Supply = 3V, RLD, WCT, and PACE Amplifiers Turned Off)

Quiescent power dissipation

ADS1298/8R

ADS1296/6R

ADS1294/4R

Power-down 10 μW

Standby mode 2 mW

Quiescent channel power PGA + ADC 818 μW

= 2.048MHz, data rate = 500SPS, High-Resolution mode, and gain = 6, unless otherwise noted.

CLK

ADS1294, ADS1296, ADS1298

ADS1294R, ADS1296R, ADS1298R

TA= +25°C ±0.5 %

0°C ≤ TA≤ +70°C ±2 %

–40°C ≤ TA≤ +85°C,

ADS1298I industrial grade version only

0.8DVDD DVDD + 0.1 V

–0.1 0.2DVDD V

IOH= –500μA DVDD – 0.4 V

IOL= +500μA 0.4 V

< DVDD –10 +10 μA

DigitalInput

AVDD – AVSS = 3V 2.75 mA

AVDD – AVSS = 5V 3.1 mA

DVDD = 3.0V 0.5 mA

DVDD = 1.8V 0.3 mA

AVDD – AVSS = 3V 1.8 mA

AVDD – AVSS = 5V 2.1 mA

DVDD = 3.0V 0.5 mA

DVDD = 1.8V 0.3 mA

High-Resolution mode 8.8 9.5 mW

Low-Power mode (250SPS) 6.0 7.0 mW

High-Resolution mode 7.2 7.9 mW

Low-Power mode 5.3 6.6 mW

High-Resolution mode 5.4 6 mW

Low-Power mode 4.1 4.4 mW

www.ti.com.cn

±2.5 %

(1)

,

6 Copyright © 2010–2012, Texas Instruments Incorporated

Page 7

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

www.ti.com.cn

ELECTRICAL CHARACTERISTICS (continued)

Minimum/maximum specifications apply for all commercial grade (0°C to +70°C) devices and from –40°C to +85°C for

industrial grades devices. Typical specifications are at +25°C. All specifications at DVDD = 1.8V, AVDD – AVSS = 3V

V

= 2.4V, external f

REF

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

POWER DISSIPATION (Analog Supply = 5V, RLD, WCT, and PACE Amplifiers Turned Off)

Quiescent power dissipation

ADS1298/8R

ADS1296/6R

ADS1294/4R

Power-down 20 μW

Standby mode 4 mW

Quiescent channel power PGA + ADC 1.5 mW

TEMPERATURE

Specified temperature range 0 +70 °C

Operating temperature range 0 +70 °C

Specified temperature range

(industrial grade only)

Operating temperature range

(industrial grade only)

Storage temperature range –60 +150 °C

= 2.048MHz, data rate = 500SPS, High-Resolution mode, and gain = 6, unless otherwise noted.

CLK

High-Resolution mode 17.5 mW

Low-Power mode 12.5 mW

High-Resolution mode 14.1 mW

Low-Power mode 10 mW

High-Resolution mode 10.1 mW

Low-Power mode 8.3 mW

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

ADS1294, ADS1296, ADS1298

ADS1294R, ADS1296R, ADS1298R

–40 +85 °C

–40 +85 °C

(1)

,

Copyright © 2010–2012, Texas Instruments Incorporated 7

Page 8

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

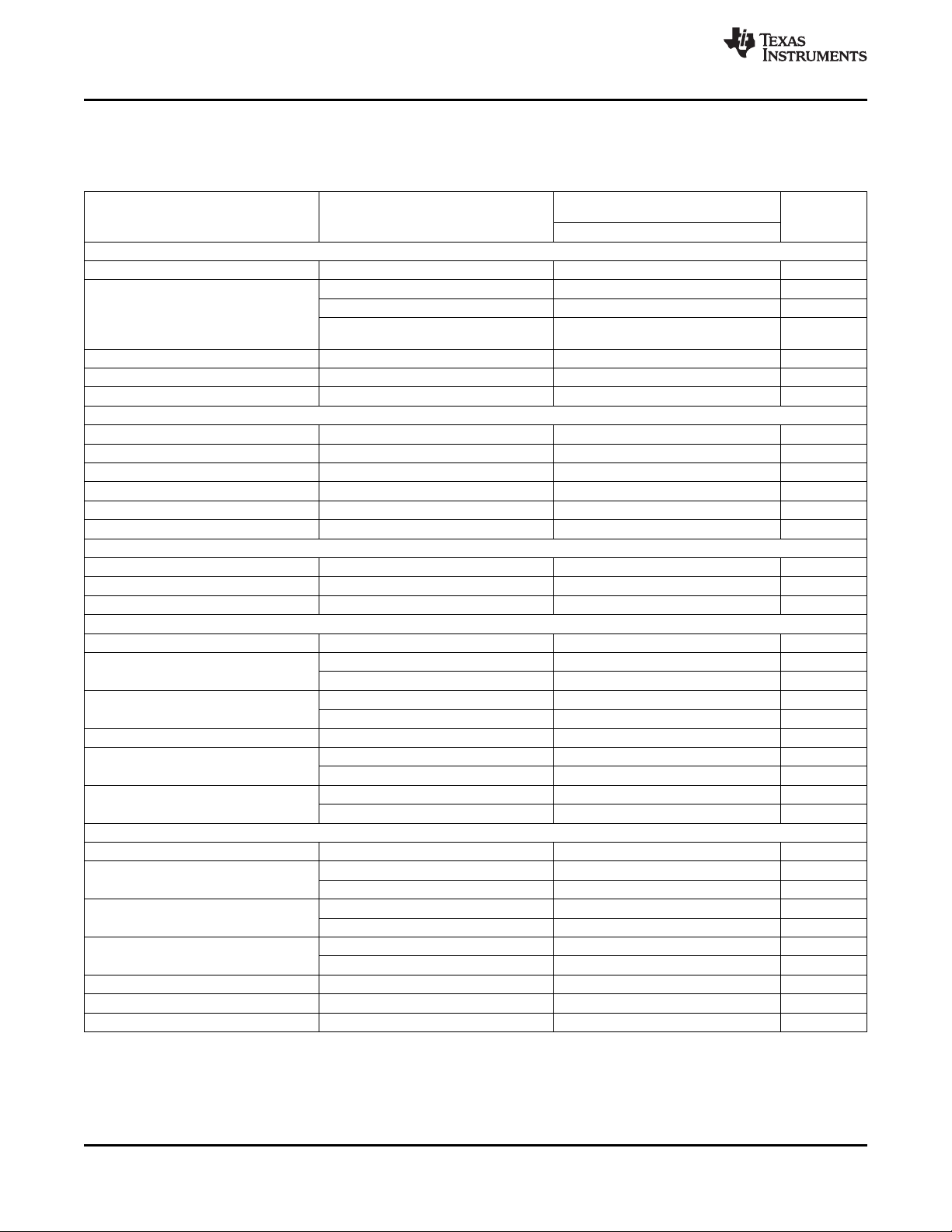

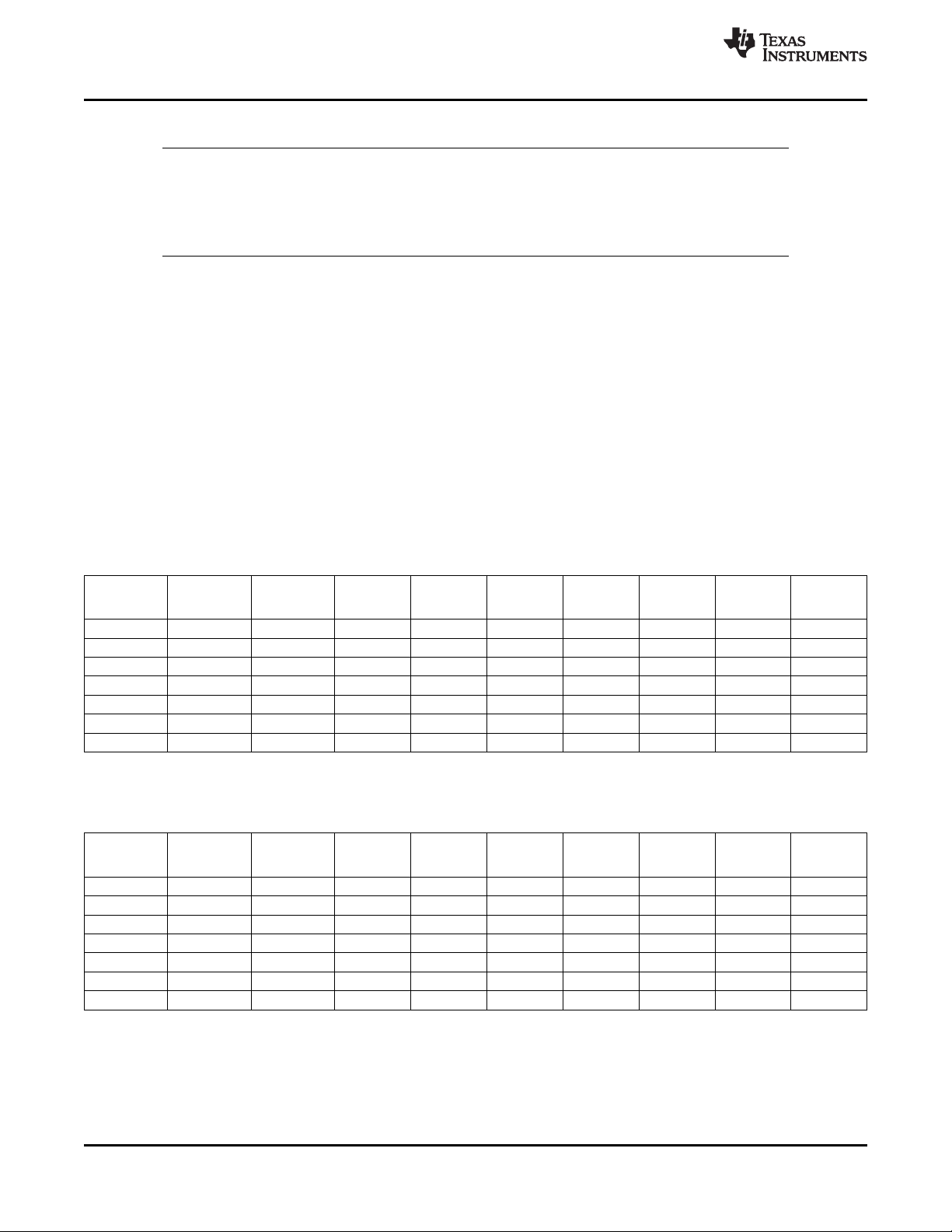

NOISE MEASUREMENTS

NOTE

The ADS1294R/6R/8R channel performance differs from the ADS1294/6/8 in regards to

respiration circuitry found on channel one. Unless otherwise noted, ADS129x refers to all

specifications and functional descriptions of the ADS1294, ADS1296, ADS1298,

ADS1294R, ADS1296R, and ADS1298R.

The ADS129x noise performance can be optimized by adjusting the data rate and PGA setting. As the averaging

is increased by reducing the data rate, the noise drops correspondingly. Increasing the PGA value reduces the

input-referred noise, which is particularly useful when measuring low-level biopotential signals. Table 1 and

Table 2 summarize the noise performance of the ADS129x in the High-Resolution (HR) mode and Low-Power

(LP) mode, respectively, with a 3V analog power supply. Table 3 and Table 4 summarize the noise performance

of the ADS129x in the HR mode and LP mode, respectively, with a 5V analog power supply. The data are

representative of typical noise performance at TA= +25°C. The data shown are the result of averaging the

readings from multiple devices and are measured with the inputs shorted together. A minimum of 1000

consecutive readings are used to calculate the RMS and peak-to-peak noise for each reading. For the two

highest data rates, the noise is limited by quantization noise of the ADC and does not have a gaussian

distribution. Thus, the ratio between rms noise and peak-to-peak noise is approximately 10. For the lower data

rates, the ratio is approximately 6.6.

Table 1 to Table 4 show measurements taken with an internal reference. The data are also representative of the

ADS129x noise performance when using a low-noise external reference such as the REF5025.

www.ti.com.cn

Table 1. Input-Referred Noise (μV

3V Analog Supply and 2.4V Reference

DR BITS OF OUTPUT –3dB

CONFIG1 DATA RATE BANDWIDTH PGA PGA PGA PGA PGA PGA PGA

REGISTER (SPS) (Hz) GAIN = 1 GAIN = 2 GAIN = 3 GAIN = 4 GAIN = 6 GAIN = 8 GAIN = 12

000 32000 8398 335/3553 168/1701 112/1100 85/823 58/529 42.5/378 28.6/248

001 16000 4193 56/613 28/295 18.8/188 14.3/143 9.7/94 7.4/69 5.2/44.3

010 8000 2096 12.4/111 6.5/54 4.5/37.9 3.5/29.7 2.6/21.7 2.2/17.8 1.8/13.8

011 4000 1048 6.1/44.8 3.2/23.3 2.4/17.1 1.9/14.0 1.5/11.1 1.3/9.7 1.2/8.5

100 2000 524 4.1/27.8 2.2/15.4 1.6/11.0 1.3/9.1 1.1/7.3 1.0/6.5 0.9/6.0

101 1000 262 2.9/19.0 1.6/10.1 1.2/7.5 1.0/6.2 0.8/5.0 0.7/4.6 0.6/4.1

110 500 131 2.1/12.5 1.1/6.8 0.9/5.1 0.7/4.3 0.6/3.5 0.5/3.1 0.5/2.9

(1) At least 1000 consecutive readings were used to calculate the RMS and peak-to-peak noise values in this table.

Table 2. Input-Referred Noise (μV

3V Analog Supply and 2.4V Reference

DR BITS OF OUTPUT –3dB

CONFIG1 DATA RATE BANDWIDTH PGA PGA PGA PGA PGA PGA PGA

REGISTER (SPS) (Hz) GAIN = 1 GAIN = 2 GAIN = 3 GAIN = 4 GAIN = 6 GAIN = 8 GAIN = 12

000 16000 4193 333/3481 166/1836 111/1168 84/834 56/576 42/450 28/284

001 8000 2096 56/554 28/272 19/177 14.3/133 9.7/85 7.4/64 5.0/42.4

010 4000 1048 12.5/99 6.5/51 4.5/35.0 3.4/25.9 2.4/18.8 2.0/14.5 1.5/11.3

011 2000 524 6.1/41.8 3.2/22.2 2.3/15.9 1.8/12.1 1.4/9.3 1.2/7.8 1.0/6.7

100 1000 262 4.1/26.3 2.2/14.6 1.6/9.9 1.3/8.1 1.0/6.2 0.8/5.4 0.7/4.7

101 500 131 3.0/17.9 1.6/9.8 1.1/6.8 0.9/5.7 0.7/4.2 0.6/3.6 0.5/3.4

110 250 65 2.1/11.9 1.1/6.3 0.8/4.6 0.7/4.0 0.5/3.0 0.5/2.6 0.4/2.4

(1) At least 1000 consecutive readings were used to calculate the RMS and peak-to-peak noise values in this table.

/μVPP) in High-Resolution Mode

RMS

/μVPP) in Low-Power Mode

RMS

(1)

(1)

8 Copyright © 2010–2012, Texas Instruments Incorporated

Page 9

www.ti.com.cn

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

Table 3. Input-Referred Noise (μV

5V Analog Supply and 4V Reference

DR BITS OF OUTPUT –3dB

CONFIG1 DATA RATE BANDWIDTH PGA PGA PGA PGA PGA PGA PGA

REGISTER (SPS) (Hz) GAIN = 1 GAIN = 2 GAIN = 3 GAIN = 4 GAIN = 6 GAIN = 8 GAIN = 12

000 32000 8398 521/5388 260/2900 173/1946 130/1403 87/917 65/692 44/483

001 16000 4193 86/1252 43/633 29/402 22/298 15/206 11/141 7/91

010 8000 2096 17/207 9/112 6/71 4/57 3/36 3/29 2/18

011 4000 1048 6.4/48.2 3.4/25.9 2.417.7 1.9/15.4 1.5/11.2 1.3/9.6 1.1/8.2

100 2000 524 4.2/29.9 2.3/15.9 1.6/11.1 1.3/9.3 1.0/7.5 0.9/6.6 0.8/5.8

101 1000 262 2.9/18.8 1.6/10.4 1.1/7.8 0.9/6.1 0.7/4.9 0.6/4.7 0.6/3.9

110 500 131 2.0/12.8 1.1/7.2 0.8/5.2 0.7/4.0 0.5/3.3 0.5/3.3 0.4/2.7

(1) At least 1000 consecutive readings were used to calculate the RMS and peak-to-peak noise values in this table.

Table 4. Input-Referred Noise (μV

5V Analog Supply and 4V Reference

DR BITS OF OUTPUT –3dB

CONFIG1 DATA RATE BANDWIDTH PGA PGA PGA PGA PGA PGA PGA

REGISTER (SPS) (Hz) GAIN = 1 GAIN = 2 GAIN = 3 GAIN = 4 GAIN = 6 GAIN = 8 GAIN = 12

000 16000 4193 526/5985 263/2953 175/1918 132/1410 88/896 66/681 44/458

001 8000 2096 88/1201 44/619 29/411 22/280 15/191 11/139 7/83

010 4000 1048 17/208 9/103 6/62 4/52 3/37 2/25 2/16

011 2000 524 6.0/41.1 3.3/23.3 2.2/15.5 1.8/12.3 1.3/9.8 1.1/7.8 0.9/6.5

100 1000 262 4.1/27.1 2.3/14.8 1.5/10.1 1.2/8.1 0.9/6.0 0.8/5.4 0.7/4.4

101 500 131 2.9/17.4 1.6/9.6 1.1/6.6 0.9/5.9 0.7/4.3 0.6/3.4 0.5/3.2

110 250 65 2.1/11.9 1.1/6.6 0.8/4.6 0.6/3.7 0.5/3.0 0.4/2.5 0.4/2.2

(1) At least 1000 consecutive readings were used to calculate the RMS and peak-to-peak noise values in this table.

/μVPP) in High-Resolution Mode

RMS

/μVPP) in Low-Power Mode

RMS

(1)

(1)

Table 5. Typical WCT Performance

ANY ONE ANY TWO ALL THREE

PARAMETER (A, B, or C) (A+B, A+C, or B+C) (A+B+C) UNIT

Integrated noise 540 382 312 nV

Power 53 59 65 μW

–3dB BW 30 59 89 kHz

Slew rate BW limited BW limited BW limited —

RMS

Copyright © 2010–2012, Texas Instruments Incorporated 9

Page 10

1

2

3

4

5

6

7

8

H

G

F

E

D

C

B

A

IN8P

IN7P

IN6PIN5P

IN4P

IN3P

IN2PIN1P

IN8N

IN7N

IN6NIN5N

IN4N

IN3N

IN2NIN1N

RLDIN

RLDOUT

RLDINV

WCT

TESTP_

PACE_OUT1

TESTN_

PACE_OUT2

VCAP4

VREFP

AVDDAVDDRLDREF

AVSSRESV1

RESP_

MODN

RESP_

MODP

VREFN

AVSSAVSSAVSSAVSS

GPIO4GPIO1

PWDN

VCAP1

AVDDAVDDAVDD

DRDY

GPIO3

DAISY_IN

RESET

VCAP2

AVDD1

VCAP3DGNDDGNDGPIO2

CS

START

DGND

AVSS1

CLKSEL

DVDD

DVDDDOUTSCLKCLK

DIN

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

(TOP VIEW, SOLDER BUMPS ON BOTTOM SIDE)

www.ti.com.cn

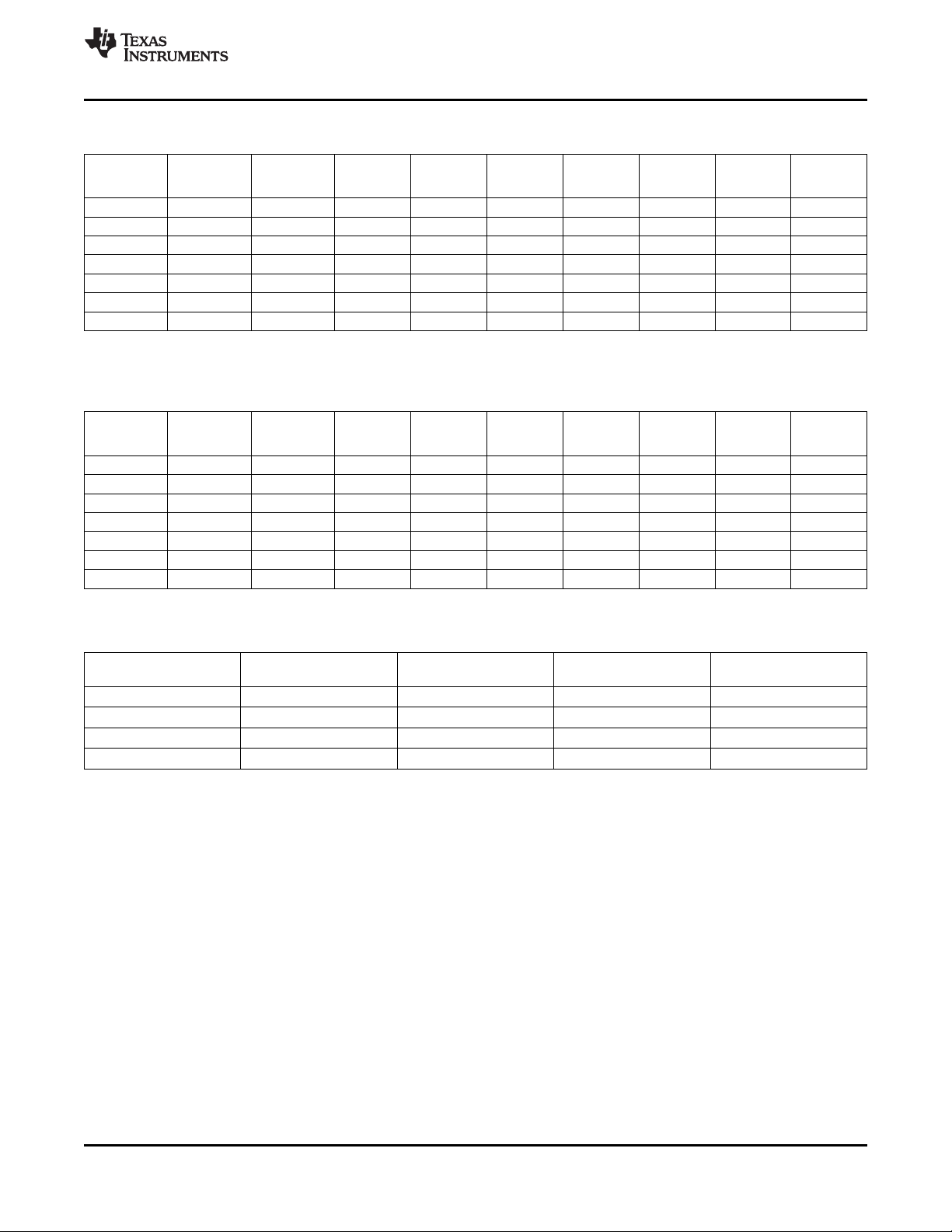

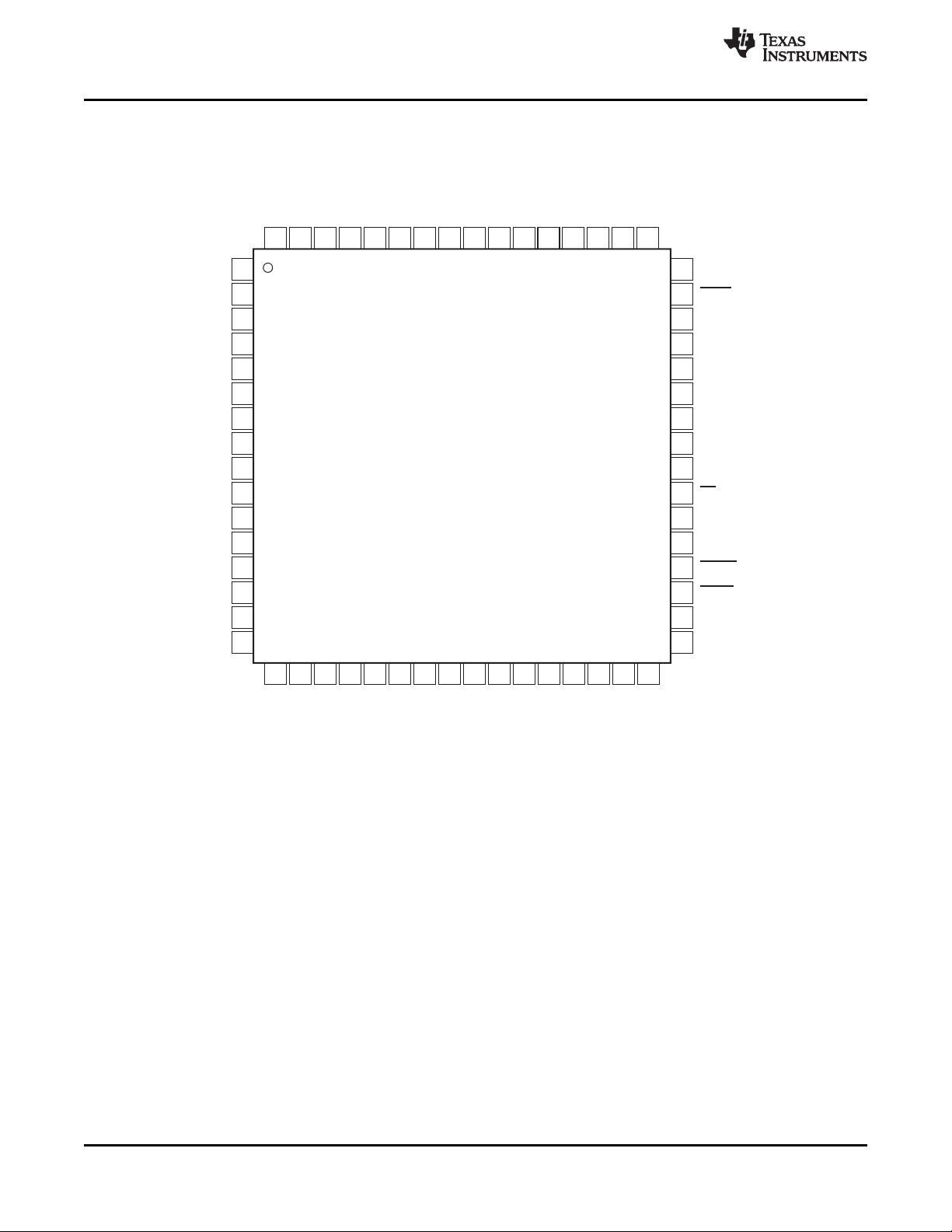

PIN CONFIGURATIONS

ZXG PACKAGE

BGA-64

(1) Connect unused terminals to AVDD.

10 Copyright © 2010–2012, Texas Instruments Incorporated

NAME TERMINAL FUNCTION DESCRIPTION

(1)

IN8P

(1)

IN7P

(1)

IN6P

(1)

IN5P

(1)

IN4P

(1)

IN3P

(1)

IN2P

(1)

IN1P

(1)

IN8N

(1)

IN7N

(1)

IN6N

(1)

IN5N

(1)

IN4N

(1)

IN3N

(1)

IN2N

(1)

IN1N

BGA PIN ASSIGNMENTS

1A Analog input Differential analog positive input 8 (ADS1298/8R)

1B Analog input Differential analog positive input 7 (ADS1298/8R)

1C Analog input Differential analog positive input 6 (ADS1296/8/6R/8R)

1D Analog input Differential analog positive input 5 (ADS1296/8/6R/8R)

1E Analog input Differential analog positive input 4

1F Analog input Differential analog positive input 3

1G Analog input Differential analog positive input 2

1H Analog input Differential analog positive input 1

2A Analog input Differential analog negative input 8 (ADS1298/8R)

2B Analog input Differential analog negative input 7 (ADS1298/8R)

2C Analog input Differential analog negative input 6 (ADS1296/8/6R/8R)

2D Analog input Differential analog negative input 5 (ADS1296/8/6R/8R)

2E Analog input Differential analog negative input 4

2F Analog input Differential analog negative input 3

2G Analog input Differential analog negative input 2

2H Analog input Differential analog negative input 1

Page 11

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

www.ti.com.cn

BGA PIN ASSIGNMENTS (continued)

NAME TERMINAL FUNCTION DESCRIPTION

(2)

RLDIN

RLDOUT 3B Analog output Right leg drive output

RLDINV 3C Analog input/output Right leg drive inverting input

WCT 3D Analog output Wilson Central Terminal output

TESTP_PACE_OUT1

TESTN_PACE_OUT2

VCAP4 3G Analog output Analog bypass capacitor

VREFP 3H Analog input/output Positivereference voltage

AVDD 4A Supply Analog supply

AVDD 4B Supply Analog supply

RLDREF 4C Analog input Right leg drive noninverting input

AVSS 4D Supply Analog ground

RESV1 4E Digital input Reserved for future use; must tie to logic low (DGND).

RESP_MODN 4F Analog output side.

RESP_MODP 4G Analog output side.

VREFN 4H Analog input Negative reference voltage

AVSS 5A Supply Analog ground

AVSS 5B Supply Analog ground

AVSS 5C Supply Analog ground

AVSS 5D Supply Analog ground

GPIO4 5E Digital input/output GPIO4 in normal mode

GPIO1 5F Digital input/output General purpose input/output pin

PWDN 5G Digital input Power-down; active low

VCAP1 5H Analog input/output Analog bypass capacitor

AVDD 6A Supply Analog supply

AVDD 6B Supply Analog supply

AVDD 6C Supply Analog supply

DRDY 6D Digital output Data ready; active low

GPIO3 6E Digital input/output GPIO3 in normal mode

DAISY_IN 6F Digital input Daisy-chain input; if not used, short to DGND.

RESET 6G Digital input System reset; active low

VCAP2 6H — Analog bypass capacitor

AVDD1 7A Supply Analog supply for charge pump

VCAP3 7B — Analog bypass capacitor; internally generated AVDD + 1.9V.

DGND 7C Supply Digital ground

DGND 7D Supply Digital ground

GPIO2 7E Digital input/output General-purpose input/output pin

CS 7F Digital input SPI chip select; active low

START 7G Digital input Start conversion

DGND 7H Supply Digital ground

AVSS1 8A Supply Analog ground for charge pump

CLKSEL 8B Digital input Master clock select

DVDD 8C Supply Digital power supply

DVDD 8D Supply Digital power supply

DOUT 8E Digital output SPI data out

SCLK 8F Digital input SPI clock

CLK 8G Digital input/output External Master clock input or internal clock output.

DIN 8H Digital input SPI data in

(2)

(2)

(2) Connect unused terminals to AVDD.

Copyright © 2010–2012, Texas Instruments Incorporated 11

3A Analog input Right leg drive input to MUX

3E Analog input/buffer output Internal test signal/single-ended buffer output based on register settings

3F Analog input/output Internal test signal/single-ended buffer output based on register settings

ADS1294R/6R/8R: modulation clock for respiration measurement, negative

ADS1294/6/8: leave floating.

ADS1294R/6R/8R: modulation clock for respiration measurement, positive

ADS1294/6/8: leave floating.

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

Page 12

48

47

46

45

44

43

42

41

40

39

38

37

36

35

34

33

DVDD

GPIO4

GPIO3

GPIO2

DOUT

GPIO1

DAISY_IN

SCLK

START

CLK

DIN

DGND

DRDY

CS

RESET

PWDN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

15

16

IN8N

IN8P

IN7N

IN7P

IN6N

IN6P

IN5N

IN5P

IN4N

IN4P

IN3N

IN3P

IN2N

IN2P

IN1N

IN1P

WCT

RLDOUT

RLDIN

RLDINV

RLDREF

AVDD

AVSS

AVSS

AVDD

VCAP3

AVDD1

AVSS1

CLKSEL

DGND

DVDD

DGND

TESTP_PACE_OUT1

TESTN_PACE_OUT2

AVDD

AVSS

AVDD

AVDD

AVSS

VREFP

VREFN

VCAP4

NC

VCAP1

NC

VCAP2

RESV1

AVSS

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

64

63

62

61

60

59

58

57

56

55

54

53

52

51

50

49

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

www.ti.com.cn

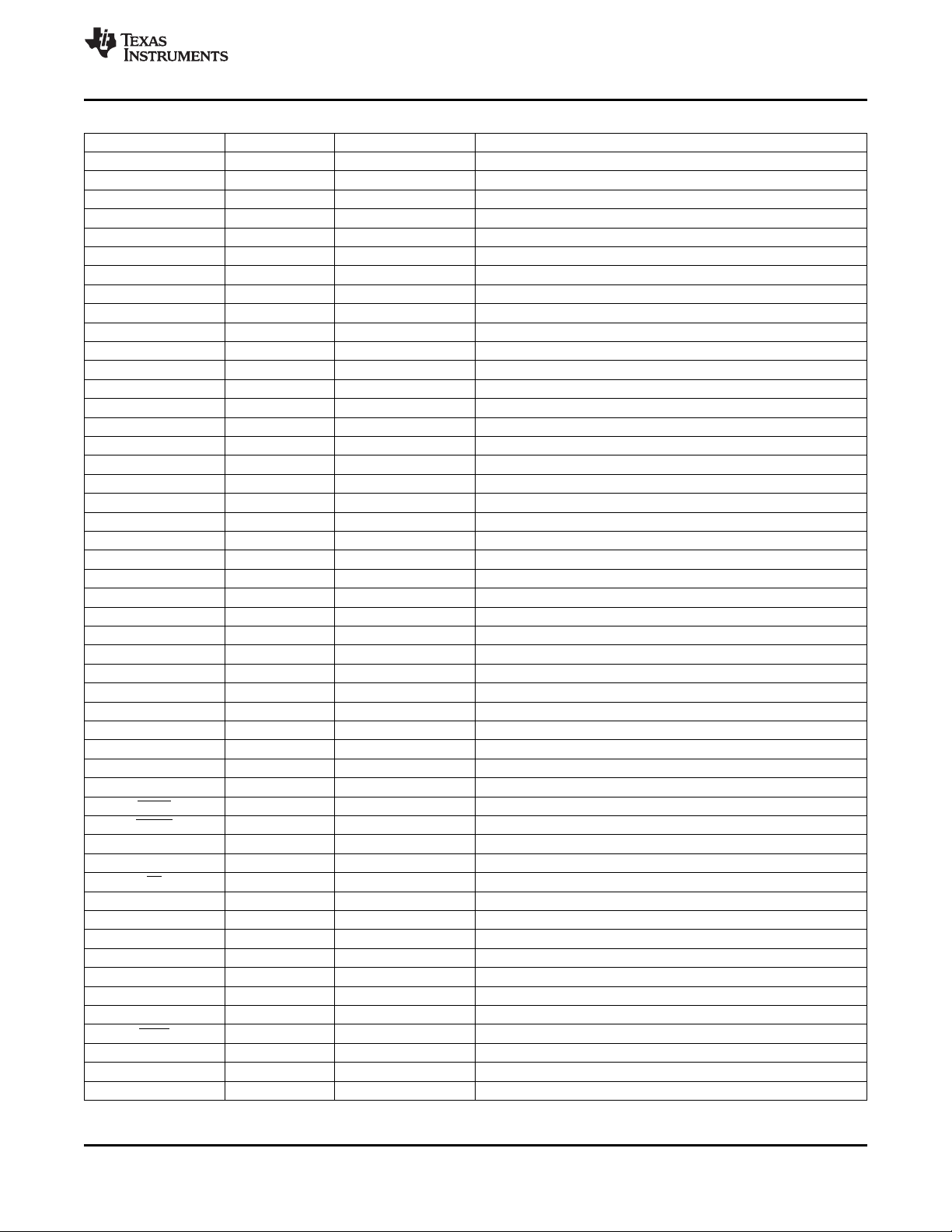

PAG PACKAGE

TQFP-64

(TOP VIEW)

12 Copyright © 2010–2012, Texas Instruments Incorporated

Page 13

www.ti.com.cn

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

PAG PIN ASSIGNMENTS

NAME PIN FUNCTION DESCRIPTION

(1)

IN8N

(1)

IN8P

(1)

IN7N

(1)

IN7P

(1)

IN6N

(1)

IN6P

(1)

IN5N

(1)

IN5P

(1)

IN4N

(1)

IN4P

(1)

IN3N

(1)

IN3P

(1)

IN2N

(1)

IN2P

(1)

IN1N

(1)

IN1P

TESTP_PACE_OUT1

TESTN_PACE_OUT2

(1)

(1)

AVDD 19 Supply Analog supply

AVSS 20 Supply Analog ground

AVDD 21 Supply Analog supply

AVDD 22 Supply Analog supply

AVSS 23 Supply Analog ground

VREFP 24 Analog input/output Positive reference voltage

VREFN 25 Analog input Negative reference voltage

VCAP4 26 Analog output Analog bypass capacitor

NC 27 — No connection

VCAP1 28 — Analog bypass capacitor

NC 29 — No connection

VCAP2 30 — Analog bypass capacitor

RESV1 31 Digital input Reserved for future use; must tie to logic low (DGND).

AVSS 32 Supply Analog ground

DGND 33 Supply Digital ground

DIN 34 Digital input SPI data in

PWDN 35 Digital input Power-down; active low

RESET 36 Digital input System reset; active low

CLK 37 Digital input/output External Master clock input or internal clock output.

START 38 Digital input Start conversion

CS 39 Digital input SPI chip select; active low

SCLK 40 Digital input SPI clock

DAISY_IN 41 Digital input Daisy-chain input; if not used, short to DGND.

GPIO1 42 Digital input/output General-purpose input/output pin

DOUT 43 Digital output SPI data out

GPIO2 44 Digital input/output General-purpose input/output pin

GPIO3 45 Digital input/output General-purpose input/output pin

GPIO4 46 Digital input/output General-purpose input/output pin

DRDY 47 Digital output Data ready; active low

DVDD 48 Supply Digital power supply

DGND 49 Supply Digital ground

DVDD 50 Supply Digital power supply

1 Analog input Differential analog negative input 8 (ADS1298)

2 Analog input Differential analog positive input 8 (ADS1298)

3 Analog input Differential analog negative input 7 (ADS1298)

4 Analog input Differential analog positive input 7 (ADS1298)

5 Analog input Differential analog negative input 6 (ADS1296/8)

6 Analog input Differential analog positive input 6 (ADS1296/8)

7 Analog input Differential analog negative input 5 (ADS1296/8)

8 Analog input Differential analog positive input 5 (ADS1296/8)

9 Analog input Differential analog negative input 4

10 Analog input Differential analog positive input 4

11 Analog input Differential analog negative input 3

12 Analog input Differential analog positive input 3

13 Analog input Differential analog negative input 2

14 Analog input Differential analog positive input 2

15 Analog input Differential analog negative input 1

16 Analog input Differential analog positive input 1

17 Analog input/buffer output Internal test signal/single-ended buffer output based on register settings

18 Analog input/output Internal test signal/single-ended buffer output based on register settings

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

(1) Connect unused terminals to AVDD.

Copyright © 2010–2012, Texas Instruments Incorporated 13

Page 14

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

PAG PIN ASSIGNMENTS (continued)

NAME PIN FUNCTION DESCRIPTION

DGND 51 Supply Digital ground

CLKSEL 52 Digital input Master clock select

AVSS1 53 Supply Analog ground

AVDD1 54 Supply Analog supply

VCAP3 55 Analog Analog bypass capacitor; internally generated AVDD + 1.9V.

AVDD 56 Supply Analog supply

AVSS 57 Supply Analog ground

AVSS 58 Supply Analog ground

AVDD 59 Supply Analog supply

RLDREF 60 Analog input Right leg drive noninverting input

RLDINV 61 Analog input/output Right leg drive inverting input

(1)

RLDIN

RLDOUT 63 Analog output Right leg drive output

WCT 64 Analog output Wilson Central Terminal output

62 Analog input Right leg drive input to MUX

www.ti.com.cn

14 Copyright © 2010–2012, Texas Instruments Incorporated

Page 15

1

CS

SCLK

DIN

DOUT

2

3 8

1 2

83

t

CSSC

t

DIST

t

DIHD

t

DOHD

t

CSH

t

DOPD

t

SPWH

t

SPWL

t

SCCS

Hi-Z

t

CSDOZ

t

CSDOD

Hi-Z

t

SCLK

t

SDECODE

CLK

t

CLK

D ISY_INA

DOUT

SCLK

MSB

D1

t

DISCK2ST

MSB

21

3 216

217

218

MSB

D1

LSB

t

DISCK2HT

t

DOPD

Don’tCare

LSB

D1

219

www.ti.com.cn

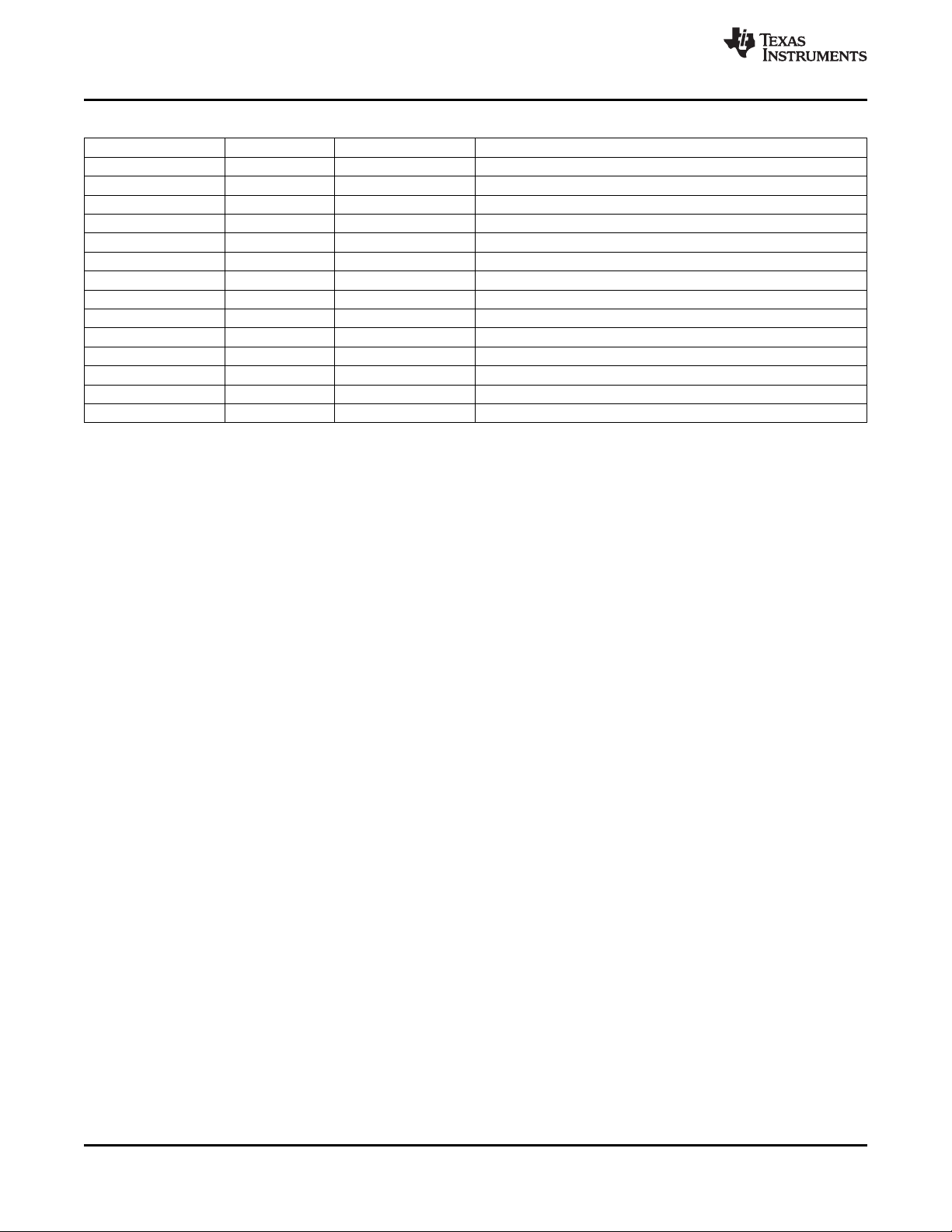

TIMING CHARACTERISTICS

NOTE: SPI settings are CPOL = 0 and CPHA = 1.

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

Figure 1. Serial Interface Timing

NOTE: Daisy-chain timing shown for eight-channel ADS1298, ADS1298R, and ADS1298I.

Figure 2. Daisy-Chain Interface Timing

Timing Requirements For Figure 1 and Figure 2

Specifications apply from –40°C to +85°C, unless otherwise noted. Load on D

PARAMETER DESCRIPTION MIN TYP MAX MIN TYP MAX UNIT

t

CLK

t

CSSC

t

SCLK

t

SPWH, L

t

DIST

t

DIHD

t

DOHD

t

DOPD

t

CSH

t

CSDOD

t

SCCS

t

SDECODE

t

CSDOZ

t

DISCK2ST

t

DISCK2HT

Copyright © 2010–2012, Texas Instruments Incorporated 15

Master clock period 414 514 414 514 ns

CS low to first SCLK, setup time 6 17 ns

SCLK period 50 66.6 ns

SCLK pulse width, high and low 15 25 ns

DIN valid to SCLK falling edge: setup time 10 10 ns

Valid DIN after SCLK falling edge: hold time 10 11 ns

SCLK falling edge to invalid DOUT: hold time 10 10 ns

SCLK rising edge to DOUT valid: setup time 17 32 ns

CS high pulse 2 2 t

CS low to DOUT driven 10 20 ns

Eighth SCLK falling edge to CS high 4 4 t

Command decode time 4 4 t

CS high to DOUT Hi-Z 10 20 ns

DAISY_IN valid to SCLK rising edge: setup time 10 10 ns

DAISY_IN valid after SCLK rising edge: hold time 10 10 ns

= 20pF || 100kΩ.

OUT

2.7V ≤ DVDD ≤ 3.6V 1.65V ≤ DVDD ≤ 2V

CLKs

CLKs

CLKs

Page 16

3

2

1

0

1

2

3

-

-

-

Time(sec)

Input-ReferredNoise( V)m

1 20 103 4 5 6 7 8 9

Peak-to-PeakOver10sec=5 Vm

1600

1400

1200

1000

800

600

400

200

0

Input-ReferredNoise( V)m

Occurrences

-2.88

-2.35

-1.85

-1.35

-0.84

-0.34

0.17

1.17

2.18

0.67

1.68

2.408

2.406

2.404

2.402

2.4

2.398

2.396

-40

85

Temperature( C)°

InternalReference(V)

-15 10

6035

-130

125

120

115

110

105

100

95

90

85

-

-

-

-

-

-

-

-

-

10

1k

Frequency(Hz)

Common-ModeRejectionRatio(dB)

100

Gain=1

DataRate=4kSPS

AIN=AVDD 0.3VtoAVSS+0.3V-

Gain=2

Gain=3

Gain=4

Gain=6

Gain=8

Gain=12

0.18

0.16

0.14

0.12

0.10

0.08

0.06

0.04

0.02

0

0.3

4.8

InputVoltage(V)

InputLeakageCurrent(nA)

2.3

AVDD AVSS=5V

PGA=1

-

1.81.30.8 2.8 3.3 3.8 4.3

1200

1000

800

600

400

200

0

-40

85

Temperature( C)°

LeakageCurrent(pA)

3510-15 60

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

TYPICAL CHARACTERISTICS

All plots at TA= +25°C, AVDD = 3V, AVSS = 0V, DVDD = 1.8V, internal VREFP = 2.4V, VREFN = AVSS, external clock =

2.048MHz, data rate = 500SPS, High-Resolution mode, and gain = 6, unless otherwise noted.

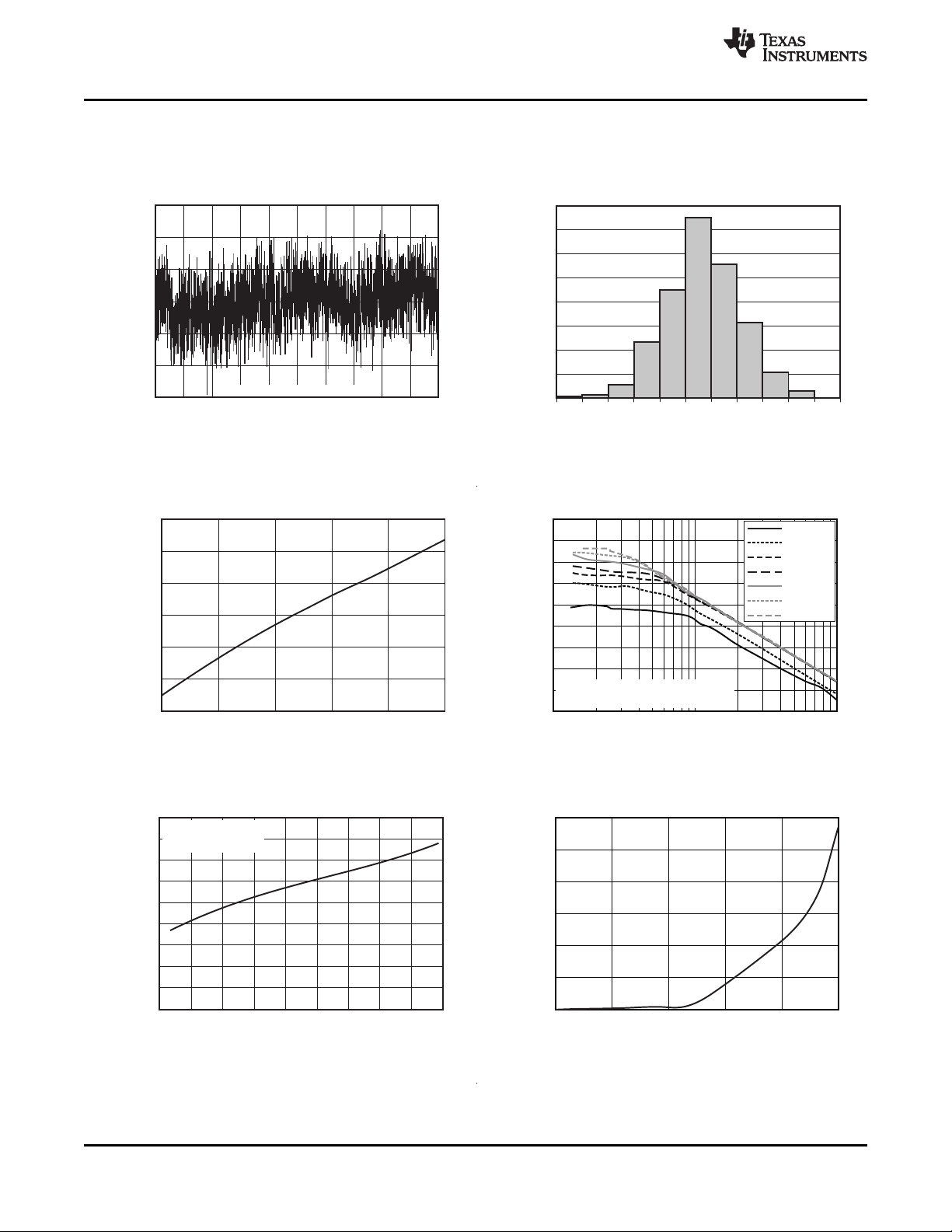

INPUT-REFERRED NOISE NOISE HISTOGRAM

Figure 3. Figure 4.

www.ti.com.cn

INTERNAL REFERENCE vs TEMPERATURE CMRR vs FREQUENCY

Figure 5. Figure 6.

LEAKAGE CURRENT vs INPUT VOLTAGE LEAKAGE CURRENT vs TEMPERATURE

16 Copyright © 2010–2012, Texas Instruments Incorporated

Figure 7. Figure 8.

Page 17

110

105

100

95

90

85

80

75

70

10

1k

Frequency(Hz)

Power-SupplyRejectionRatio(dB)

100

DataRate=4kSPS

Gain=2

Gain=4

Gain=1

Gain=12

Gain=3

Gain=8

Gain=6

-105

100

95

90

85

80

75

70

-

-

-

-

-

-

-

10

1k

Frequency(Hz)

TotalHarmonicDistortion(dB)

100

DataRate=4kSPS

AIN=0.5dBFS

Gain=1

Gain=2

Gain=4

Gain=12

Gain=3

Gain=8

Gain=6

8

6

4

2

0

2

4

6

8

-

-

-

-

-1

1

InputRange(NormalizedtoFull-Scale)

IntegralNonlinearity(ppm)

-0.5

0.50

-40 C°

-20 C°

0 C°

+25 C°

+40 C°

+60 C°

+70 C°

+85 C°

10

8

6

4

2

0

2

4

6

8

10

-

-

-

-

-

Input(NormalizedtoFull-Scale)

IntegralNonlinearity(ppm)

-0.8-1.0 1.0-0.2 0.2 0.6-0.6 0.8-0.4 0 0.4

Gain=6

Gain=8

Gain=12

Gain=1

Gain=2

Gain=3

Gain=4

0

20

40

60

80

100

120

140

160

180

-

-

-

-

-

-

-

-

-

Frequency(Hz)

Amplitude(dBFS)

500 250100 150 200

PGAGain=1

THD= 102dB

SNR=115dB

f =500SPS

f =ExternalClock

-

DR

CLK

0

20

40

60

80

100

120

140

160

180

-

-

-

-

-

-

-

-

-

Frequency(kHz)

Amplitude(dBFS)

20 164 6 8

PGAGain=6

THD= 104dB

SNR=74.5dB

-

f =32kSPS

DR

10 12 14

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

www.ti.com.cn

TYPICAL CHARACTERISTICS (continued)

All plots at TA= +25°C, AVDD = 3V, AVSS = 0V, DVDD = 1.8V, internal VREFP = 2.4V, VREFN = AVSS, external clock =

2.048MHz, data rate = 500SPS, High-Resolution mode, and gain = 6, unless otherwise noted.

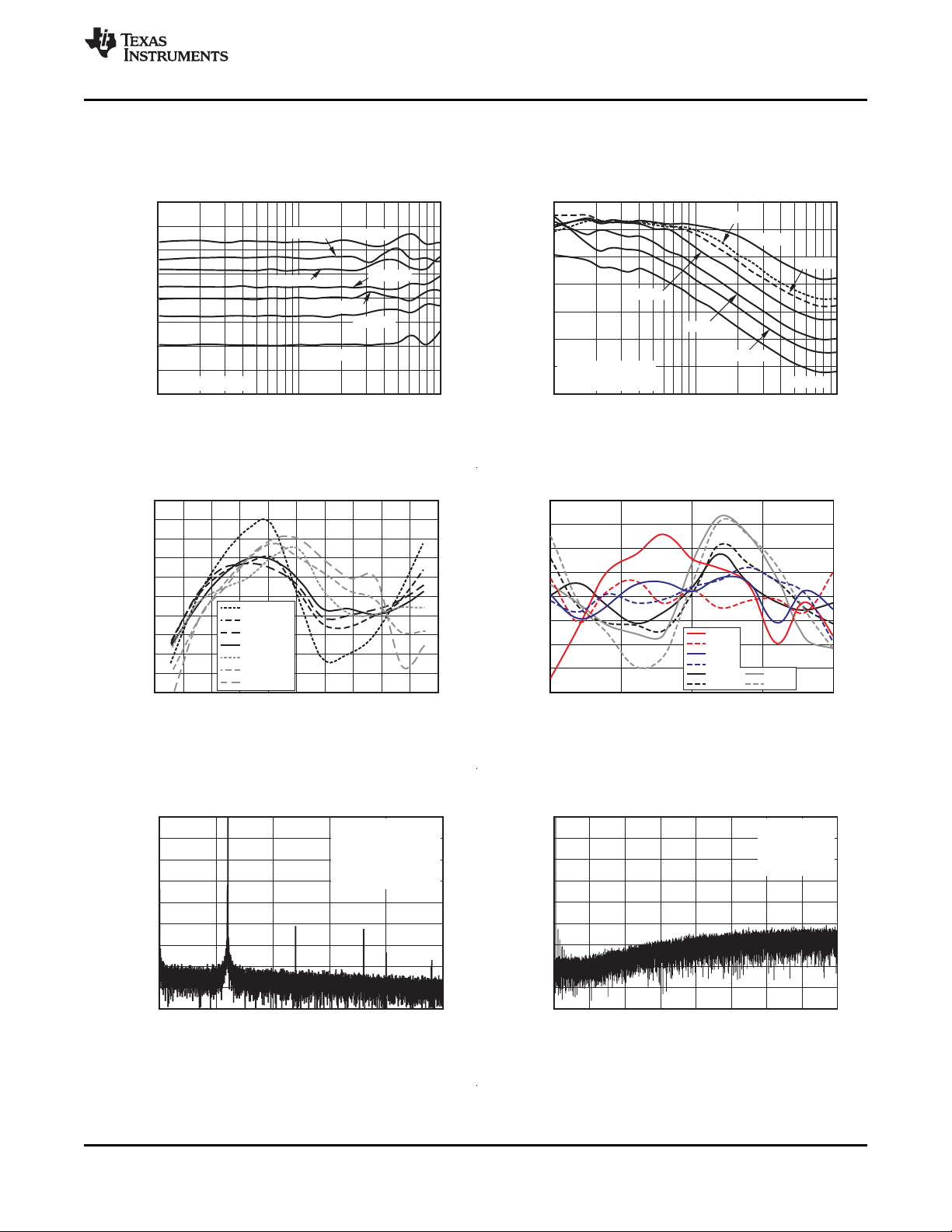

PSRR vs FREQUENCY THD vs FREQUENCY

Figure 9. Figure 10.

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

INL vs PGA GAIN INL vs TEMPERATURE

Figure 11. Figure 12.

THD FFT PLOT FFT PLOT

(60Hz Signal) (60Hz Signal)

Copyright © 2010–2012, Texas Instruments Incorporated 17

Figure 13. Figure 14.

Page 18

800

700

600

500

400

300

200

100

0

1

12

PGAGain

Offset( V)m

8642 109753 11

70

60

50

40

30

20

10

0

-0.53

Error(%)

NumberofBins

-0.41

-0.18

0.06

0.30

0.54

0.66

0.42

0.18

-0.06

-0.29

DataFrom31Devices,TwoLots

80

70

60

50

40

30

20

10

0

-20

ThresholdError(mV)

NumberofBins

-15

0

10

20

30

35

25

15

5

-10

DataFrom31Devices,TwoLots

120

100

80

60

40

20

0

-2.70

ErrorinCurrentMagnitude(nA)

NumberofBins

-2.14

-1.01

0.12

1.24

2.37

2.93

1.80

0.68

-0.45

-1.57

DataFrom31Devices,TwoLots

CurrentSetting=24nA

17.5

15.5

13.5

11.5

9.5

7.5

5.5

3.5

1.5

Number of Channels Disabled

Power (mW)

10 84 62 3 5 7

AVDD = 3V

AVDD = 5V

40

30

20

10

0

10

20

30

40

50

-

-

-

-

-

InputRange(NormalizedtoFull-Scale)

IntegralNonlinearity(ppm)

-0.8-1 1-0.2 0.2-0.6 -0.4 0 0.4 0.80.6

Channel1

Channel2

Channel3

Channel4

Channel5

Channel6

Channel7

Channel8

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

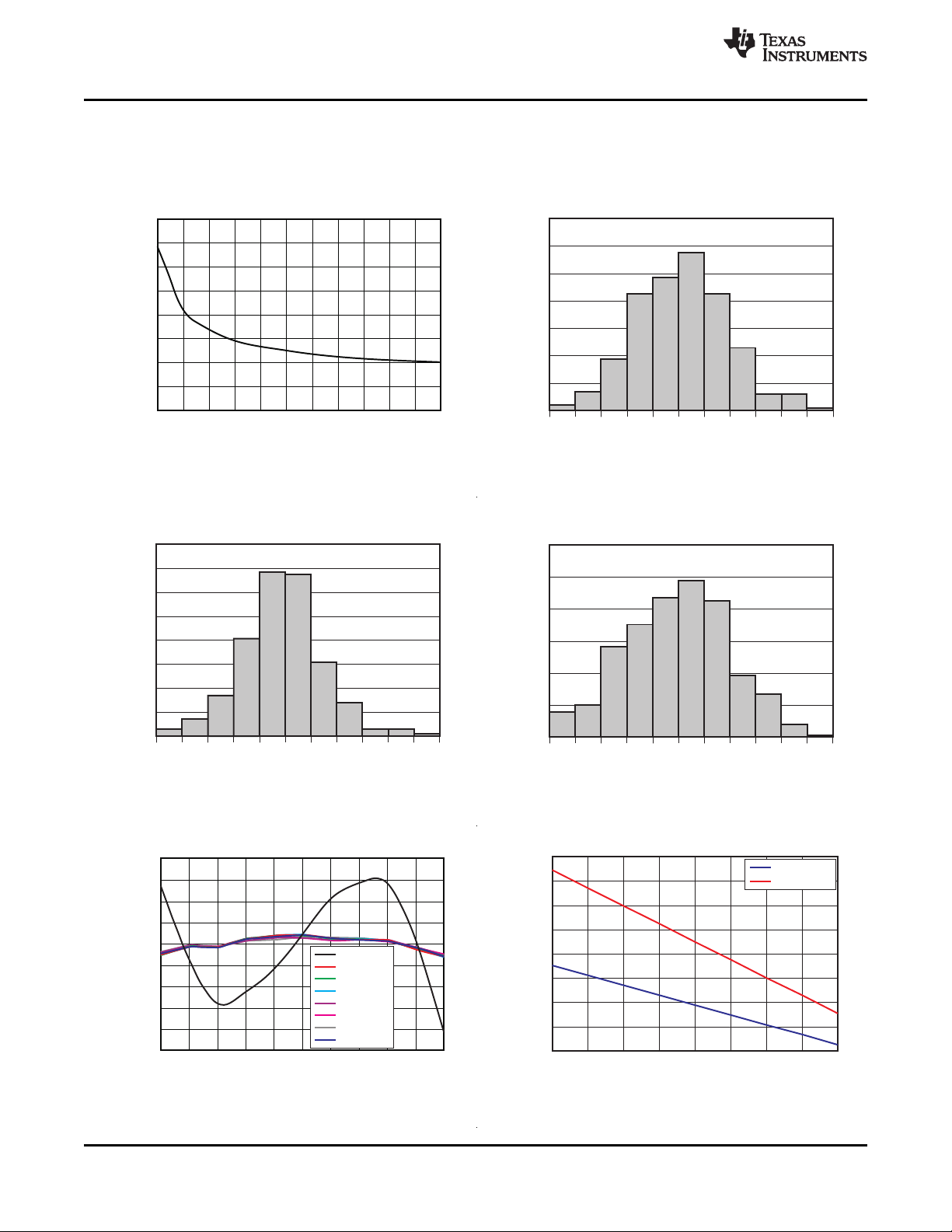

TYPICAL CHARACTERISTICS (continued)

All plots at TA= +25°C, AVDD = 3V, AVSS = 0V, DVDD = 1.8V, internal VREFP = 2.4V, VREFN = AVSS, external clock =

2.048MHz, data rate = 500SPS, High-Resolution mode, and gain = 6, unless otherwise noted.

OFFSET vs PGA GAIN

(ABSOLUTE VALUE) TEST SIGNAL AMPLITUDE ACCURACY

Figure 15. Figure 16.

www.ti.com.cn

LEAD-OFF COMPARATOR THRESHOLD ACCURACY DISTRIBUTION

LEAD-OFF CURRENT SOURCE ACCURACY

Figure 17. Figure 18.

ADS1294R/6R/8R NONLINEARITY ADS1298/8R CHANNEL POWER

18 Copyright © 2010–2012, Texas Instruments Incorporated

Figure 19. Figure 20.

Page 19

110

105

100

95

90

85

80

75

70

65

60

Channel

TotalHarmonicDistortion(dBc)

1 84 62 3 5 7

f =10Hz, 0.5dBFS-

IN

120

110

100

90

80

70

60

50

InputAmplitude(dBFS)

Signal-to-NoiseRatio(dB)

-50

-60 -0.5-20 -5-40 -30 -12 -2

InternalMasterClock,AVDD=3V

ExternalMasterClock,AVDD=3V

ExternalMasterClock,AVDD=5V

InternalMasterClock,AVDD=5V

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

www.ti.com.cn

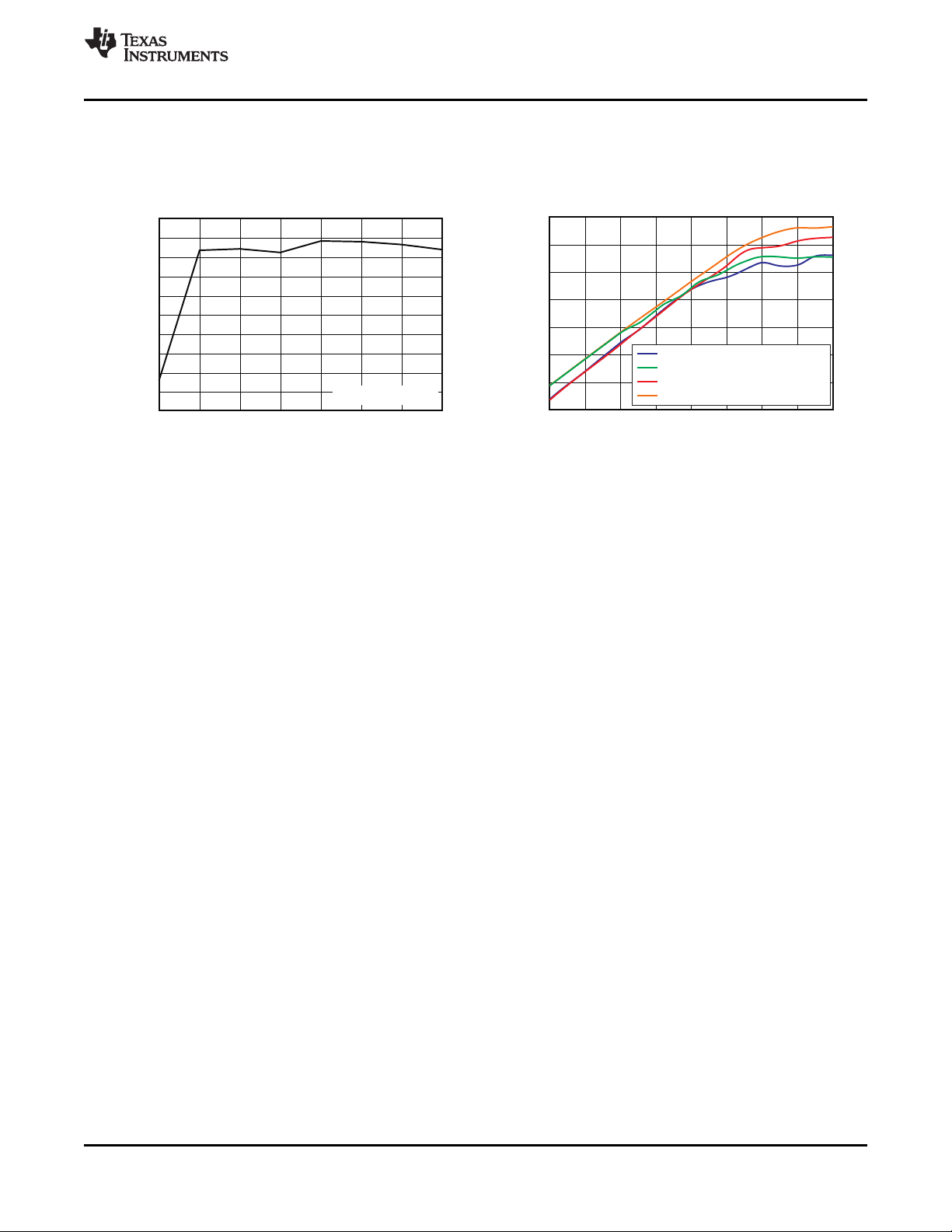

TYPICAL CHARACTERISTICS (continued)

All plots at TA= +25°C, AVDD = 3V, AVSS = 0V, DVDD = 1.8V, internal VREFP = 2.4V, VREFN = AVSS, external clock =

2.048MHz, data rate = 500SPS, High-Resolution mode, and gain = 6, unless otherwise noted.

ADS129xR THD (10Hz Sine Wave)

Figure 21. Figure 22.

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

SNR vs INPUT AMPLITUDE

Copyright © 2010–2012, Texas Instruments Incorporated 19

Page 20

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

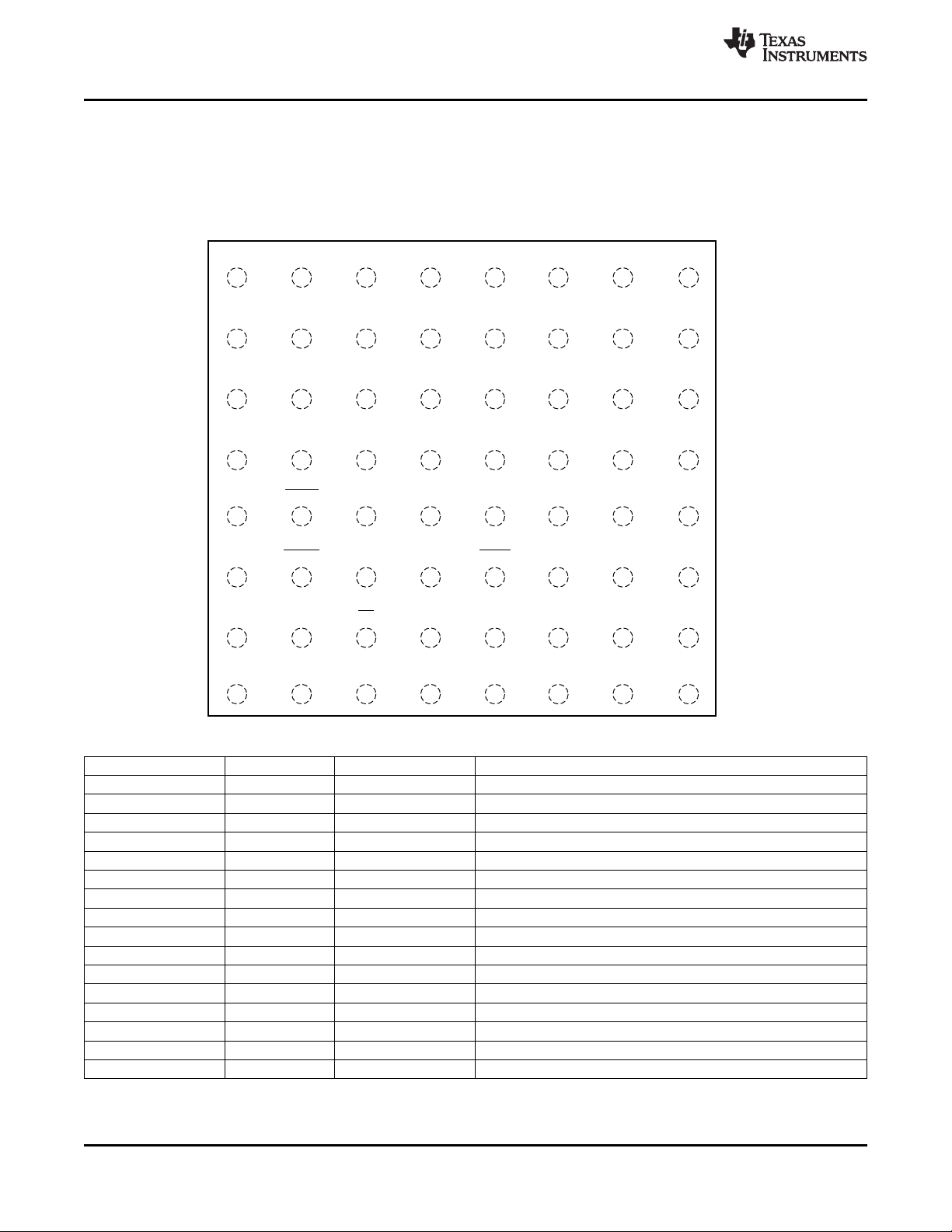

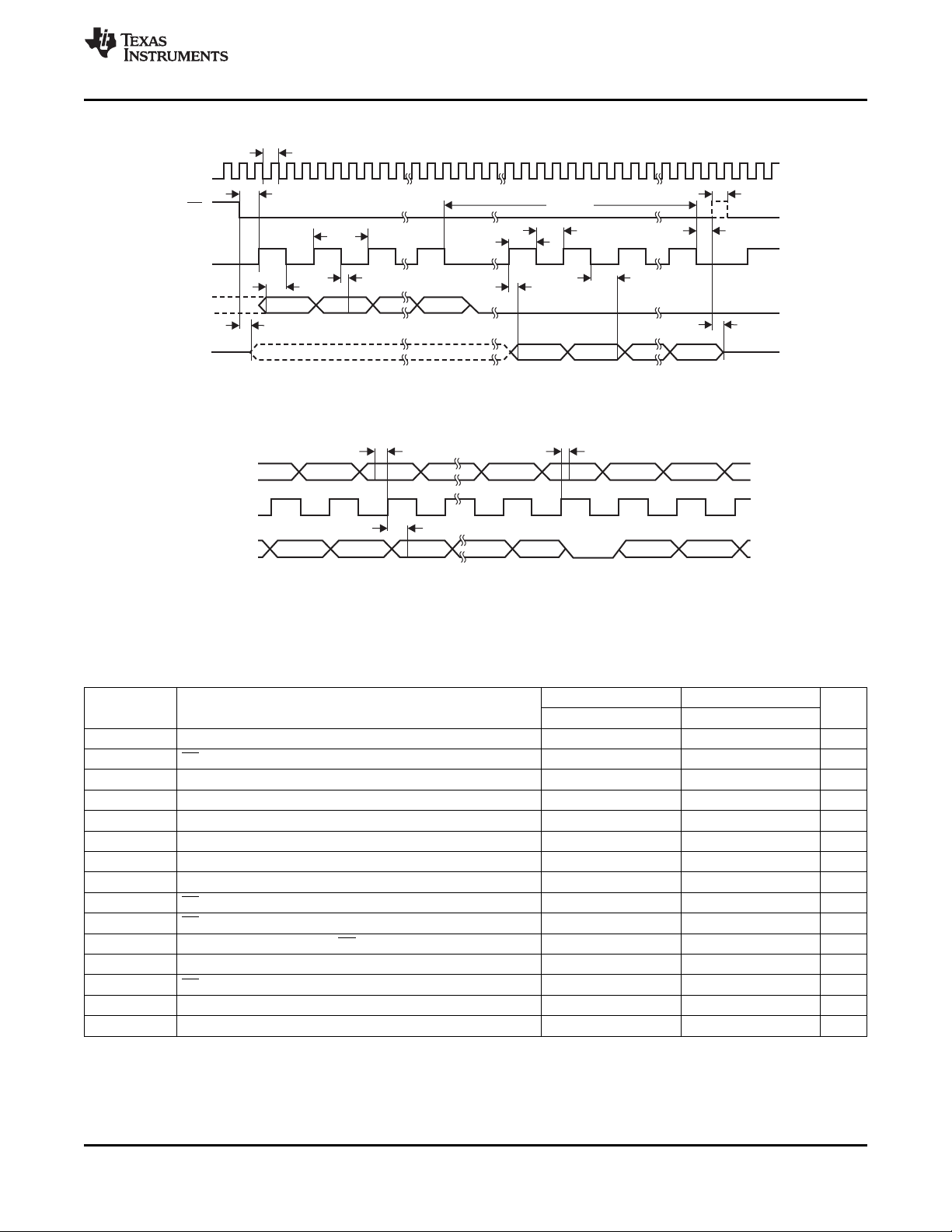

OVERVIEW

NOTE

The ADS1294R/6R/8R channel performance differs from the ADS1294/6/8 in regards to

respiration circuitry found on channel one. Unless otherwise noted, ADS129x refers to all

specifications and functional descriptions of the ADS1294, ADS1296, ADS1298,

ADS1294R, ADS1296R, and ADS1298R.

The ADS129x are low-power, multichannel, simultaneously-sampling, 24-bit delta-sigma (ΔΣ) analog-to-digital

converters (ADCs) with integrated programmable gain amplifiers (PGAs). These devices integrate various

ECG-specific functions that make them well-suited for scalable electrocardiogram (ECG),

electroencephalography (EEG), and electromyography (EMG) applications. The devices can also be used in

high-performance, multichannel data acquisition systems by powering down the ECG-specific circuitry.

The ADS129x have a highly programmable multiplexer that allows for temperature, supply, input short, and RLD

measurements. Additionally, the multiplexer allows any of the input electrodes to be programmed as the patient

reference drive. The PGA gain can be chosen from one of seven settings (1, 2, 3, 4, 6, 8, and 12). The ADCs in

the device offer data rates from 250SPS to 32kSPS. Communication to the device is accomplished using an

SPI-compatible interface. The device provides four GPIO pins for general use. Multiple devices can be

synchronized using the START pin.

The internal reference can be programmed to either 2.4V or 4V. The internal oscillator generates a 2.048MHz

clock. The versatile right leg drive (RLD) block allows the user to choose the average of any combination of

electrodes to generate the patient drive signal. Lead-off detection can be accomplished either by using a

pull-up/pull-down resistor or a current source/sink. An internal ac lead-off detection feature is also available. The

device supports both hardware PACE detection and software PACE detection. The Wilson Central Terminal

(WCT) block can be used to generate the WCT point of the standard 12-lead ECG.

Additionally, the ADS1294R, ADS1296R, and ADS1298R provide options for an internal respiration modulator

and a demodulator circuit in the signal path of channel 1.

www.ti.com.cn

20 Copyright © 2010–2012, Texas Instruments Incorporated

Page 21

DRDY

CLK

CLKSEL

START

MUX

Oscillator

Power-Supply Signal

SPI

DVDD

DGND

RLD

INV

RLD

OUT

RLD

REF

Lead-Off Excitation Source

PACE

OUT2

GPIO1

GPIO4/RCLKO

GPIO3/RCLKO

RESP

CLK

PACE

OUT1

CS

SCLK

DIN

DOUT

RLD

IN

ADS1298/8R

ADS1296/6R/8/8R

GPIO2

AVDD

AVSS

IN8P

IN8N

IN7P

IN7N

IN6P

IN6N

IN5P

IN5N

IN4P

IN4N

IN3P

IN3N

IN2P

IN2N

IN1P

IN1N

PGA1

DS

ADC1

PGA2

PGA3

PGA4

PGA5

PGA6

PGA7

PGA8

EMI

Filter

EMI

Filter

EMI

Filter

EMI

Filter

EMI

Filter

EMI

Filter

EMI

Filter

EMI

Filter

Temperature Sensor Input

RLD

Amplifier

PACE

Amplifier 2

PACE

Amplifier 1

WCT

B

C

A

From

Wmuxc

From

Wmuxa

From

Wmuxb

WCT

Reference

VREFP

VREFN

Control

PWDN

RESET

DS

ADC2

DS

ADC3

DS

ADC4

DS

ADC5

DS

ADC6

DS

ADC7

DS

ADC8

AVDD1

AVSS1

Test Signal

Internal Respiration

Modulator

( )ADS129xR

RESP

DEMOD

RESP_DEMOD_EN

ADS129xR

ADS129xR

RESP_MODP

RESP_MODN

G = 0.4

G = 0.4

www.ti.com.cn

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

Figure 23. Functional Block Diagram

Copyright © 2010–2012, Texas Instruments Incorporated 21

Page 22

MUX[2:0]=101

TempP

MUX[2:0]= 100

MvddP

(1)

MUX[2:0]= 011

FromLoffP

MUX[2:0]= 000

MUX[2:0]= 110

MUX[2:0]= 001

ToPgaP

ToPgaN

MUX[2:0]= 001

RLDIN

MUX[2:0]= 010

RLD_MEAS

AND

MUX[2:0]= 111

VINP

VINN

MUX[2:0]= 000

FromLoffN

RLD_REF

MUX[2:0]= 010

RLD_MEAS

AND

MvddN

(1)

TempN

MUX[2:0]= 100

MUX[2:0]= 101

ADS129x

MUX

TestP

TestN

TESTP_PACE_OUT1

INT_TEST

INT_TEST

TESTN_PACE_OUT2

INT_TEST

INT_TEST

MUX[2:0]= 011

EMI

Filter

(AVDD+AVSS)

2

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

THEORY OF OPERATION

This section discusses the details of the ADS129x internal functional elements. The analog blocks are reviewed

first, followed by the digital interface. Blocks implementing ECG-specific functions are covered in the end.

Throughout this document, f

denotes the frequency of the signal at the CLK pin, t

CLK

denotes the period of the

CLK

signal at the CLK pin, fDRdenotes the output data rate, tDRdenotes the time period of the output data, and f

denotes the frequency at which the modulator samples the input.

EMI FILTER

An RC filter at the input acts as an EMI filter on all of the channels. The –3dB filter bandwidth is approximately

3MHz.

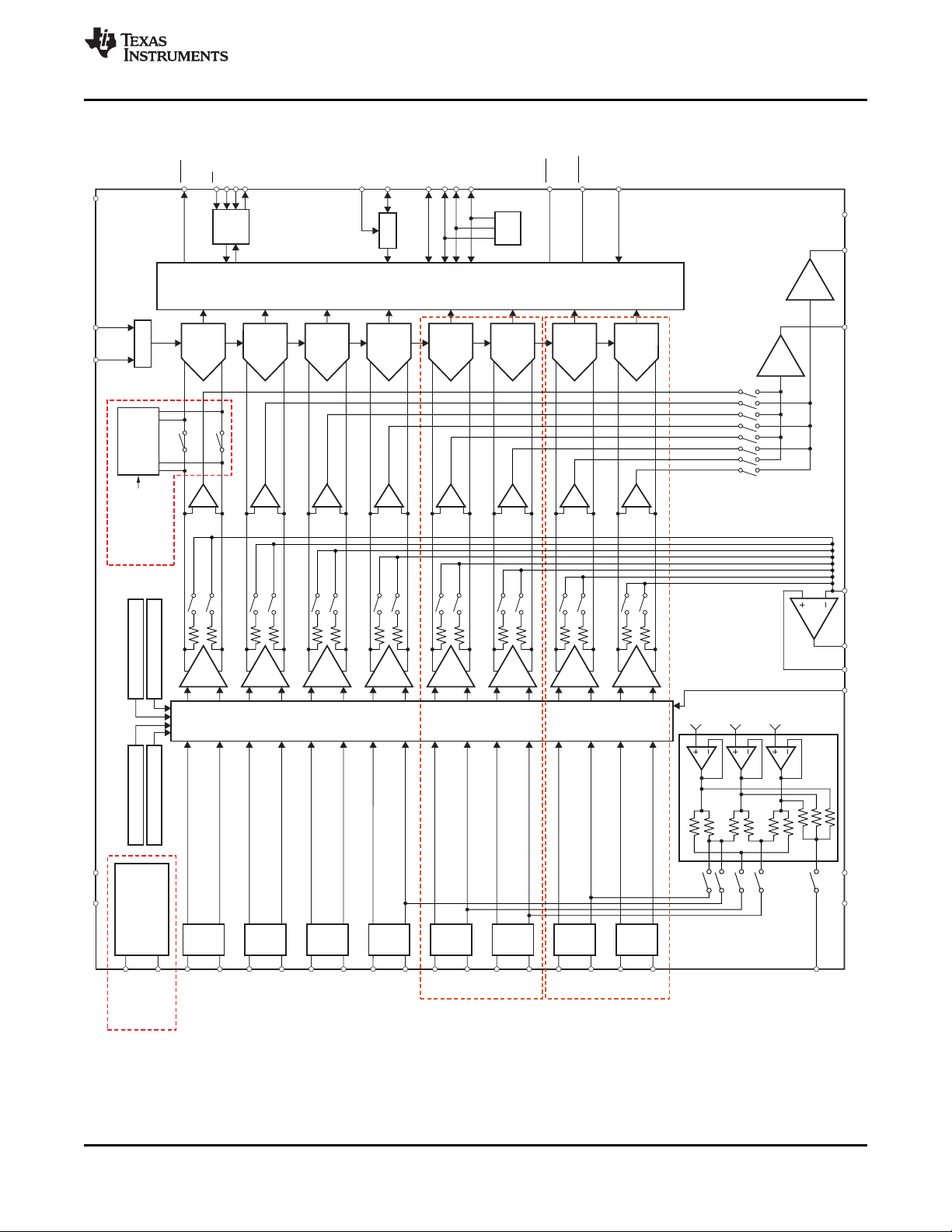

INPUT MULTIPLEXER

The ADS129x input multiplexers are very flexible and provide many configurable signal switching options.

Figure 24 shows the multiplexer on a single channel of the device. Note that the device has eight such blocks,

one for each channel. TEST_PACE_OUT1, TEST_PACE_OUT2, and RLD_IN are common to all eight blocks.

VINP and VINN are separate for each of the eight blocks. This flexibility allows for significant device and

sub-system diagnostics, calibration, and configuration. Selection of switch settings for each channel is made by

writing the appropriate values to the CHnSET[2:0] register (see the CHnSET: Individual Channel Settings section

for details) and by writing the RLD_MEAS bit in the CONFIG3 register (see the CONFIG3: Configuration Register

3 subsection of the Register Map section for details). More details of the ECG-specific features of the multiplexer

are presented in the Input Multiplexer subsection of the ECG-Specifc Functions section.

www.ti.com.cn

MOD

22 Copyright © 2010–2012, Texas Instruments Incorporated

(1) MVDD monitor voltage supply depends on channel number; see the Supply Measurements (MVDDP, MVDDN)

section.

Figure 24. Input Multiplexer Block for One Channel

Page 23

Temperature( C)=°

TemperatureReading( V) 145,300 Vm - m

490 V/ Cm °

+25 C°

2x

1x

1x

8x

AVDD

AVSS

TemperatureSensorMonitor

ToMUXTempP

ToMUXTempN

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

www.ti.com.cn

Device Noise Measurements

Setting CHnSET[2:0] = 001 sets the common-mode voltage of (AVDD – AVSS)/2 to both inputs of the channel.

This setting can be used to test the inherent noise of the device in the user system.

Test Signals (TestP and TestN)

Setting CHnSET[2:0] = 101 provides internally-generated test signals for use in sub-system verification at

power-up. This functionality allows the entire signal chain to be tested out. Although the test signals are similar to

the CAL signals described in the IEC60601-2-51 specification, this feature is not intended for use in compliance

testing.

Control of the test signals is accomplished through register settings (see the CONFIG2: Configuration Register 2

subsection in the Register Map section for details). TEST_AMP controls the signal amplitude and TEST_FREQ

controls switching at the required frequency.

The test signals are multiplexed and transmitted out of the device at the TESTP_PACE_OUT1 and

TESTN_PACE_OUT2 pins. A bit register (CONFIG2.INT_TEST = 0) deactivates the internal test signals so that

the test signal can be driven externally. This feature allows the calibration of multiple devices with the same

signal. The test signal feature cannot be used in conjunction with the external hardware PACE feature (see the

External Hardware Approach subsection of the ECG-Specific Functions section for details).

Auxiliary Differential Input (TESTP_PACE_OUT1, TESTN_PACE_OUT2)

When hardware PACE detect is not used, the TESTP_PACE_OUT1 and TESPN_PACE_OUT2 signals can be

used as a multiplexed differential input channel. These inputs can be multiplexed to any of the eight channels.

The performance of the differential input signal fed through these pins is identical to the normal channel

performance.

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

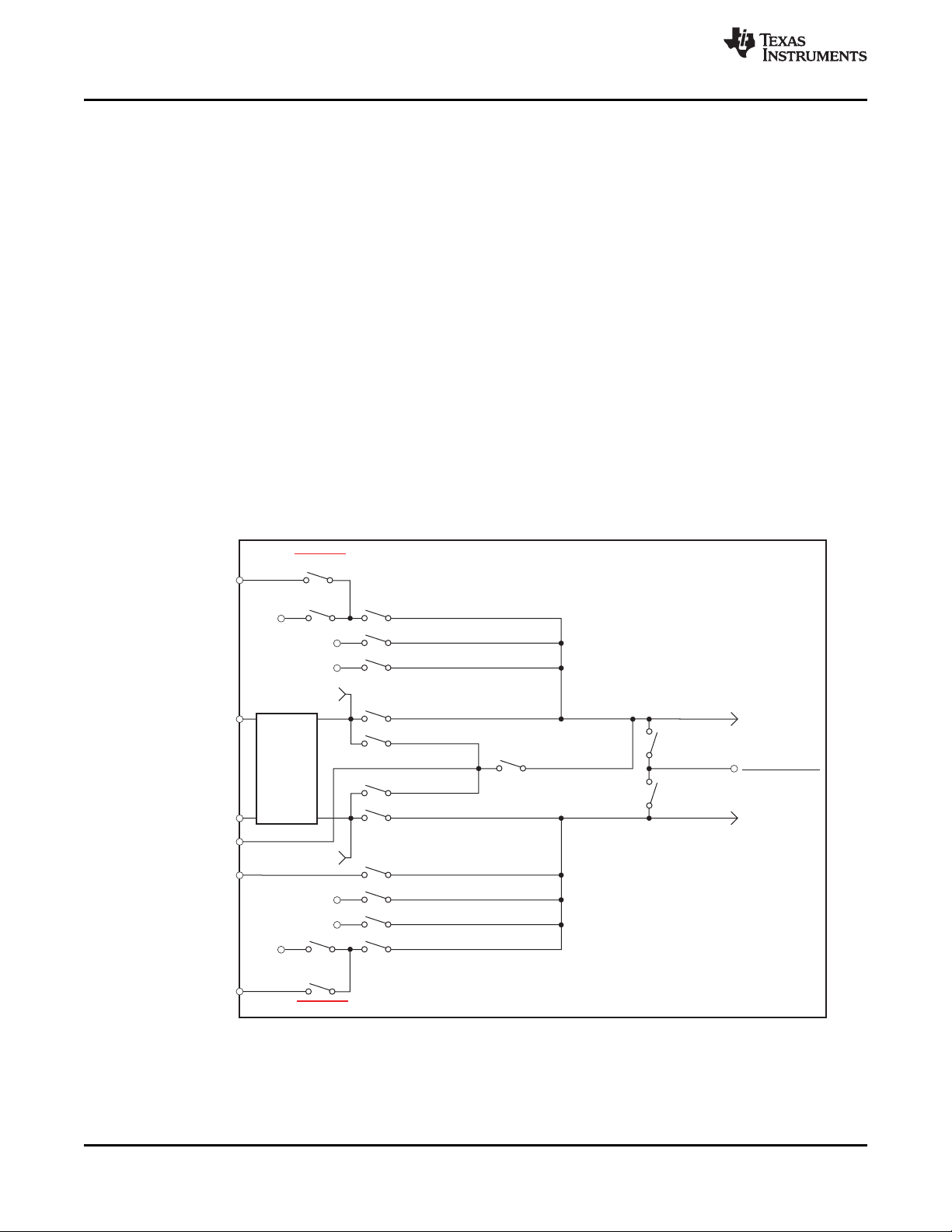

Temperature Sensor (TempP, TempN)

The ADS129x contain an on-chip temperature sensor. This sensor uses two internal diodes with one diode

having a current density 16x that of the other, as shown in Figure 25. The difference in current densities of the

diodes yields a difference in voltage that is proportional to absolute temperature.

As a result of the low thermal resistance of the package to the printed circuit board (PCB), the internal device

temperature tracks the PCB temperature closely. Note that self-heating of the ADS129x causes a higher reading

than the temperature of the surrounding PCB.

The scale factor of Equation 1 converts the temperature reading to °C. Before using this equation, the

temperature reading code must first be scaled to μV.

(1)

Copyright © 2010–2012, Texas Instruments Incorporated 23

Figure 25. Measurement of the Temperature Sensor in the Input

Page 24

ADS1298

- V to

+1/2V

REF

REF

1/2

Common

Voltage

Single-EndedInput

ADS1298

V

peak-to-peak

REF

V

peak-to-peak

REF

Common

Voltage

DifferentialInput

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

Supply Measurements (MVDDP, MVDDN)

Setting CHnSET[2:0] = 011 sets the channel inputs to different supply voltages of the device. For channels 1, 2,

5, 6, 7, and 8, (MVDDP – MVDDN) is [0.5 × (AVDD – AVSS)]; for channel 3 and for channel 4, (MVDDP –

MVDDN) is DVDD/4. Note that to avoid saturating the PGA while measuring power supplies, the gain must be

set to '1'. For example, if AVDD = 2.5V and AVSS = –2.5V, then the measurement result would be 2.5V.

Lead-Off Excitation Signals (LoffP, LoffN)

The lead-off excitation signals are fed into the multiplexer before the switches. The comparators that detect the

lead-off condition are also connected to the multiplexer block before the switches. For a detailed description of

the lead-off block, refer to the Lead-Off Detection subsection in the ECG-Specific Functions section.

Auxiliary Single-Ended Input

The RLD_IN pin is primarily used for routing the right leg drive signal to any of the electrodes in case the right leg

drive electrode falls off. However, the RLD_IN pin can be used as a multiple single-ended input channel. The

signal at the RLD_IN pin can be measured with respect to the voltage at the RLD_REF pin using any of the eight

channels. This measurement is done by setting the channel multiplexer setting to '010' and the RLD_MEAS bit of

the CONFIG3 register to '1'.

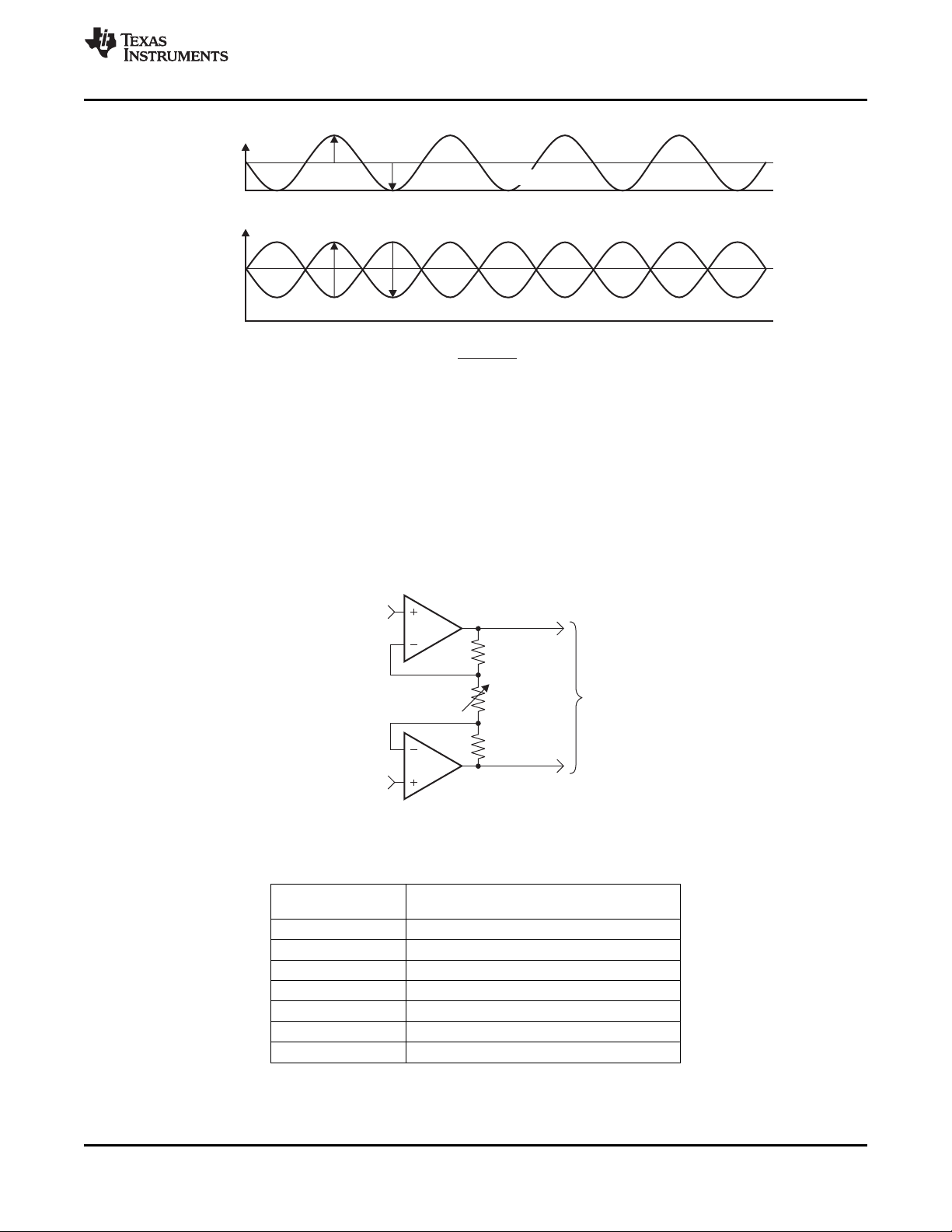

ANALOG INPUT

The analog input to the ADS1298 is fully differential. Assuming PGA = 1, the differential input (INP – INN) can

span between –V

and AVDD + 0.3V. Refer to Table 8 for an explanation of the correlation between the analog input and the digital

codes. There are two general methods of driving the analog input of the ADS1298: single-ended or differential,

as shown in Figure 26 and Figure 27. Note that INP and INN are 180°C out-of-phase in the differential input

method. When the input is single-ended, the INN input is held at the common-mode voltage, preferably at

mid-supply. The INP input swings around the same common voltage and the peak-to-peak amplitude is the

(common-mode + 1/2V

is given by (INP + INN)/2. Both the INP and INN inputs swing from (common-mode + 1/2V

common-mode – 1/2V

differential configuration.

REF

to +V

REF

REF

. Note that the the absolute range for INP and INN must be between AVSS – 0.3V

REF

) and the (common-mode – 1/2V

). When the input is differential, the common-mode

REF

). For optimal performance, it is recommended that the ADS1298 devices be used in a

www.ti.com.cn

REF

to

Figure 26. Methods of Driving the ADS1298: Single-Ended or Differential

24 Copyright © 2010–2012, Texas Instruments Incorporated

Page 25

CM+1/2V

REF

+1/2V

REF

- V

REF

1/2

Single-EndedInputs

t

INP

CMVoltage

CM V-

REF

1/2

CM+1/2V

REF

DifferentialInputs

t

INP

INN

CMVoltage

CM 1/2V

REF

-

+V

REF

-V

REF

Common-ModeVoltage(DifferentialMode)=

(INP)+(INN)

2

,Common-ModeVoltage(Single-EndedMode)= INN.

INN=CMVoltage

InputRange(DifferentialMode)=(AINP AINN)=V ( V )=2V .-

REF REF

- -

REF

PgaP

R

50kW

2

R

20k

(forGain=6)

W

1

R

50kW

2

FromMuxP

PgaN

FromMuxN

ToADC

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

www.ti.com.cn

Figure 27. Using the ADS1298 in the Single-Ended and Differential Input Modes

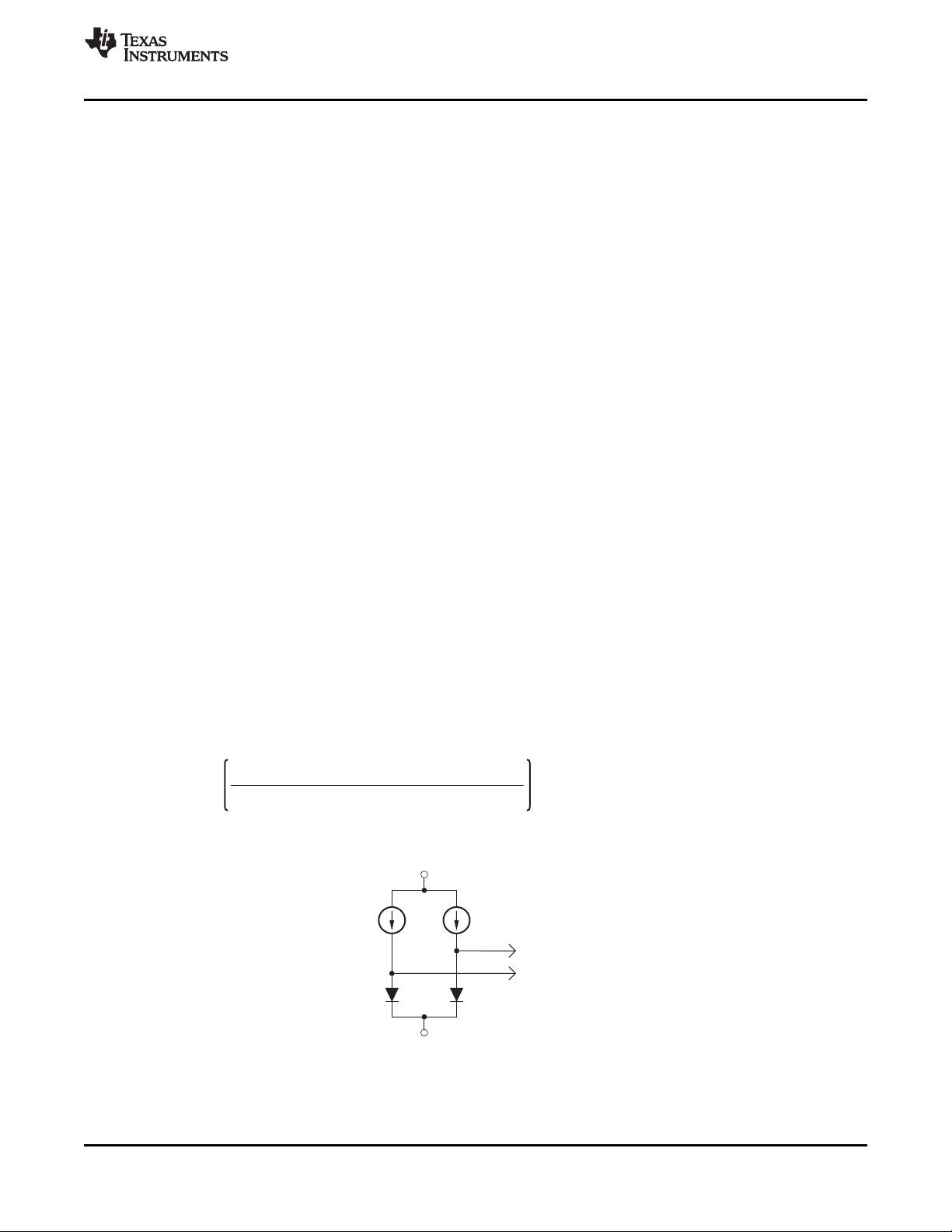

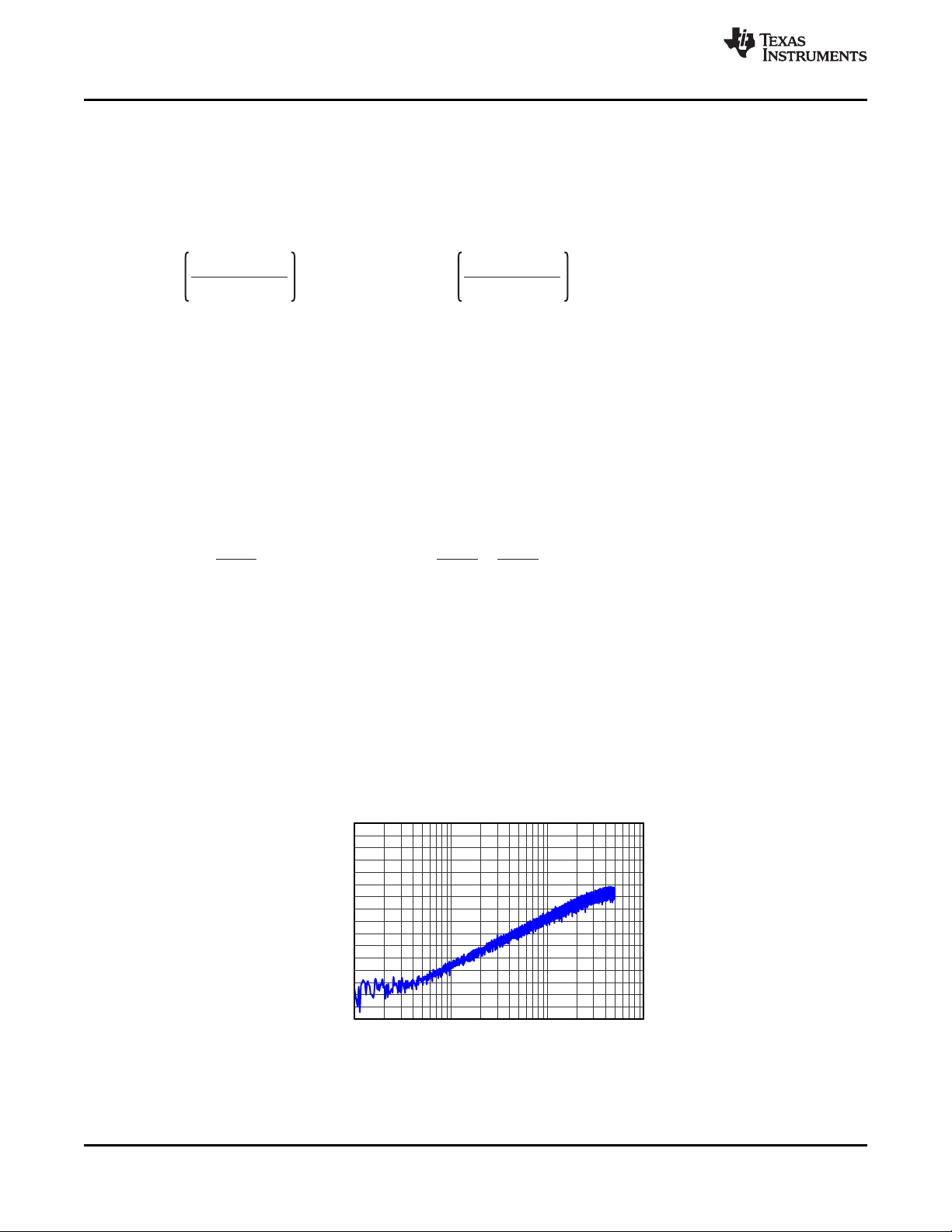

PGA SETTINGS AND INPUT RANGE

The PGA is a differential input/differential output amplifier, as shown in Figure 28. It has seven gain settings (1,

2, 3, 4, 6, 8, and 12) that can be set by writing to the CHnSET register (see the CHnSET: Individual Channel

Settings subsection of the Register Map section for details). The ADS129x have CMOS inputs and hence have

negligible current noise. Table 6 shows the typical values of bandwidths for various gain settings. Note that

Table 6 shows the small-signal bandwidth. For large signals, the performance is limited by the slew rate of the

PGA.

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

Figure 28. PGA Implementation

Table 6. PGA Gain versus Small-Signal Bandwidth

GAIN TEMPERATURE (kHz)

1 237

2 146

Copyright © 2010–2012, Texas Instruments Incorporated 25

3 127

4 96

6 64

8 48

12 32

NOMINAL BANDWIDTH AT ROOM

Page 26

AVDD 0.2- -

GainV

MAX_DIFF

2

>CM>AVSS+0.2+

GainV

MAX_DIFF

2

Max(INP INN)<-

V

REF

Gain

Full-ScaleRange=

±V

REF

Gain

; =

2V

REF

Gain

−160

−150

−140

−130

−120

−110

−100

−90

−80

−70

−60

−50

−40

−30

−20

−10

0

0.001 0.01 0.1 1

Normalized Frequency (fIN/f

MOD

)

Power Spectral Density (dB)

G001

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

The resistor string of the PGA that implements the gain has 120kΩ of resistance for a gain of 6. This resistance

provides a current path across the outputs of the PGA in the presence of a differential input signal. This current

is in addition to the quiescent current specified for the device in the presence of a differential signal at the input.

Input Common-Mode Range

The usable input common-mode range of the front end depends on various parameters, including the maximum

differential input signal, supply voltage, PGA gain, etc. This range is described in Equation 2:

where:

V

MAX_DIFF

= maximum differential signal at the input of the PGA

CM = common-mode range (2)

For example:

If VDD= 3V, gain = 6, and V

MAX_DIFF

= 350mV

Then 1.25V < CM < 1.75V

www.ti.com.cn

Input Differential Dynamic Range

The differential (INP – INN) signal range depends on the analog supply and reference used in the system. This

range is shown in Equation 3.

(3)

The 3V supply, with a reference of 2.4V and a gain of 6 for ECGs, is optimized for power with a differential input

signal of approximately 300mV. For higher dynamic range, a 5V supply with a reference of 4V (set by the

VREF_4V bit of the CONFIG3 register) can be used to increase the differential dynamic range.

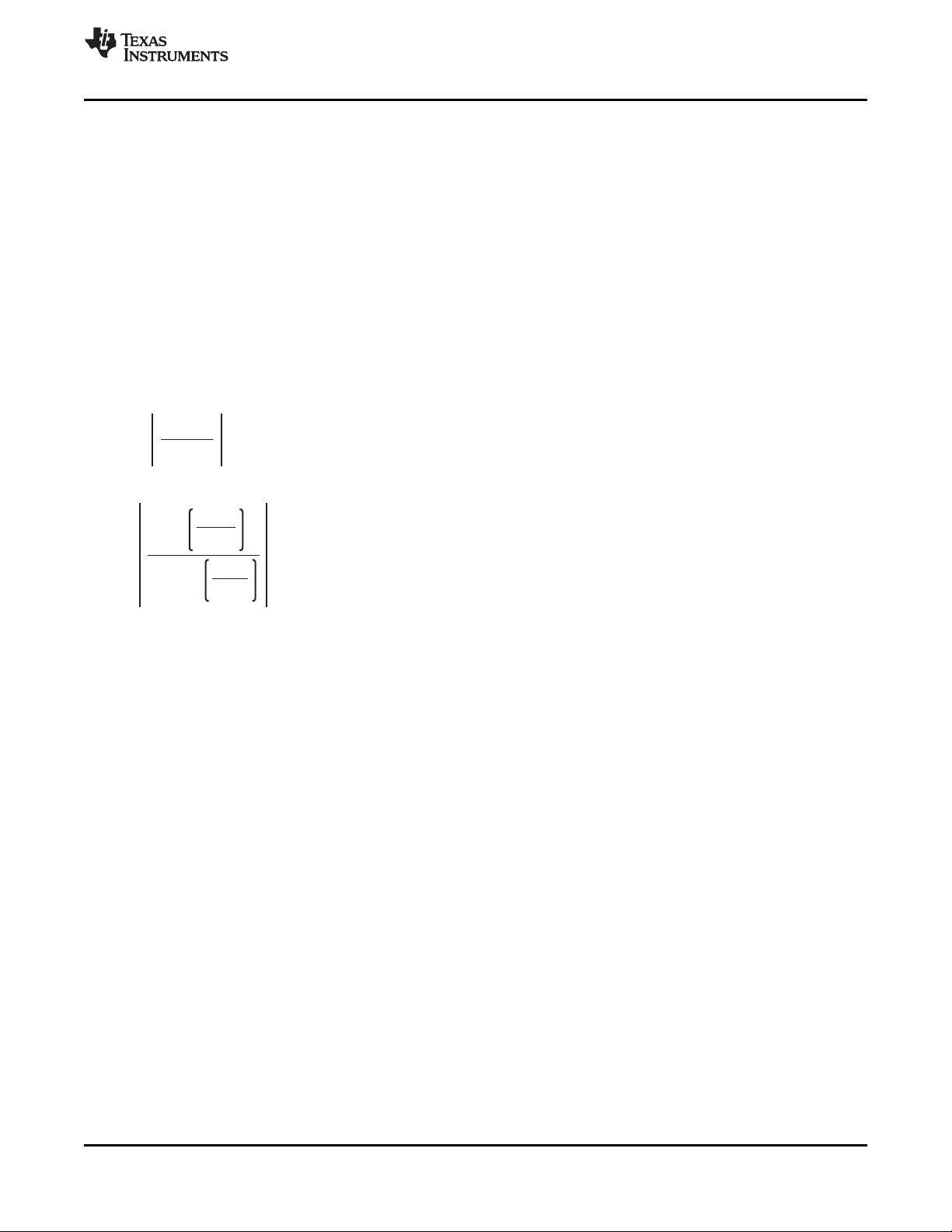

ADC ΔΣ Modulator

Each channel of the ADS129x has a 24-bit ΔΣ ADC. This converter uses a second-order modulator optimized for

low-power applications. The modulator samples the input signal at the rate of f

mode and f

shaped until f

= f

MOD

MOD

/8 for Low-Power mode. As in the case of any ΔΣ modulator, the noise of the ADS129x is

CLK

/2, as shown in Figure 29. The on-chip digital decimation filters explained in the next section

MOD

= f

/4 for High-Resolution

CLK

can be used to filter out the noise at higher frequencies. These on-chip decimation filters also provide antialias

filtering. This feature of the ΔΣ converters drastically reduces the complexity of the analog antialiasing filters that

are typically needed with Nyquist ADCs.

26 Copyright © 2010–2012, Texas Instruments Incorporated

Figure 29. Modulator Noise Spectrum Up To 0.5 × f

MOD

Page 27

½H(z) =½

3

1 Z-

- N

1 Z-

- 1

3

sin

N fp

f

MOD

N sin´

pf

f

MOD

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

www.ti.com.cn

DIGITAL DECIMATION FILTER

The digital filter receives the modulator output and decimates the data stream. By adjusting the amount of

filtering, tradeoffs can be made between resolution and data rate: filter more for higher resolution, filter less for

higher data rates. Higher data rates are typically used in ECG applications for implement software PACE

detection and ac lead-off detection.

The digital filter on each channel consists of a third-order sinc filter. The decimation ratio on the sinc filters can

be adjusted by the DR bits in the CONFIG1 register (see the Register Map section for details). This setting is a

global setting that affects all channels and, therefore, in a device all channels operate at the same data rate.

Sinc Filter Stage (sinx/x)

The sinc filter is a variable decimation rate, third-order, low-pass filter. Data are supplied to this section of the

filter from the modulator at the rate of f

then decimates the data stream into parallel data. The decimation rate affects the overall data rate of the

converter.

Equation 4 shows the scaled Z-domain transfer function of the sinc filter.

The frequency domain transfer function of the sinc filter is shown in Equation 5.

. The sinc filter attenuates the high-frequency noise of the modulator,

MOD

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

(4)

where:

N = decimation ratio (5)

Copyright © 2010–2012, Texas Instruments Incorporated 27

Page 28

0

-20

-40

-60

-80

-100

-120

-140

NormalizedFrequency(f /f )

IN DR

Gain(dB)

1.0 2.00 3.0 4.0 5.00.5 4.53.52.51.5

0

0.5

1.0

1.5

2.0

2.5

3.0

-

-

-

-

-

-

NormalizedFrequency(f /f )

IN DR

Gain(dB)

0.05 0.100 0.15 0.350.20 0.25 0.30

0

20

40

60

80

100

120

140

-

-

-

-

-

-

-

NormalizedFrequency(f /f )

IN MOD

Gain(dB)

0.05 0.100 0.500.15 0.20 0.25 0.30 0.35 0.40 0.45

DR[2:0]=110

DR[2:0]=000

0

20

40

60

80

100

120

140

-

-

-

-

-

-

-

NormalizedFrequency(f /f )

IN MOD

Gain(dB)

0.010 0.070.02 0.03 0.04 0.05 0.06

DR[2:0]=000

DR[2:0]=110

10

10

30

50

70

90

110

130

-

-

-

-

-

-

-

NormalizedFrequency(f /f )

IN MOD

Gain(dB)

0.50 4.01.0 1.5 2.0 2.5 3.0 3.5

DR[2:0]=110DR[2:0]=000

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

The sinc filter has notches (or zeroes) that occur at the output data rate and multiples thereof. At these

frequencies, the filter has infinite attenuation. Figure 30 shows the frequency response of the sinc filter and

Figure 31 shows the roll-off of the sinc filter. With a step change at input, the filter takes 3 × tDRto settle. After a

rising edge of the START signal, the filter takes t

time to give the first data output. The settling time of the

SETTLE

filters at various data rates are discussed in the START subsection of the SPI Interface section. Figure 32 and

Figure 33 show the filter transfer function until f

shows the transfer function extended until 4 × f

itself at every f

in frequencies around multiples of f

. The input R-C anti-aliasing filters in the system should be chosen such that any interference

MOD

are attenuated sufficiently.

MOD

/2 and f

MOD

. It can be seen that the passband of the ADS129x repeats

MOD

/16, respectively, at different data rates. Figure 34

MOD

www.ti.com.cn

Figure 30. Sinc Filter Frequency Response Figure 31. Sinc Filter Roll-Off

Figure 32. Transfer Function of On-Chip Figure 33. Transfer Function of On-Chip

Decimation Filters Until f

/2 Decimation Filters Until f

MOD

MOD

/16

Figure 34. Transfer Function of On-Chip Decimation Filters

Until 4f

28 Copyright © 2010–2012, Texas Instruments Incorporated

for DR[2:0] = 000 and DR[2:0] = 110

MOD

Page 29

22 Fm

ToADCReferenceInputs

VCAP1

10 Fm

VREFP

VREFN

Bandgap

2.4Vor4V

AVSS

R1

(1)

R3

(1)

R2

(1)

100W

100kW

100W

OPA211

10pF

0.1 Fm

+5V

0.1 Fm10 Fm

100 Fm22 Fm

OUTVIN+5V

TRIM

22 Fm

REF5025

ToVREFPPin

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

www.ti.com.cn

REFERENCE

Figure 35 shows a simplified block diagram of the internal reference of the ADS129x. The reference voltage is

generated with respect to AVSS. When using the internal voltage reference, connect VREFN to AVSS.

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

(1) For V

= 2.4V: R1 = 12.5kΩ, R2 = 25kΩ, and R3 = 25kΩ. For V

REF

= 4V: R1 = 10.5kΩ, R2 = 15kΩ, and R3 = 35kΩ.

REF

Figure 35. Internal Reference

The external band-limiting capacitors determine the amount of reference noise contribution. For high-end ECG

systems, the capacitor values should be chosen such that the bandwidth is limited to less than 10Hz, so that the

reference noise does not dominate the system noise. When using a 3V analog supply, the internal reference

must be set to 2.4V. In case of a 5V analog supply, the internal reference can be set to 4V by setting the

VREF_4V bit in the CONFIG2 register.

Alternatively, the internal reference buffer can be powered down and VREFP can be applied externally. Figure 36

shows a typical external reference drive circuitry. Power-down is controlled by the PD_REFBUF bit in the

CONFIG3 register. By default the device wakes up in external reference mode.

Copyright © 2010–2012, Texas Instruments Incorporated 29

Figure 36. External Reference Driver

Page 30

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

ZHCS313I –JANUARY 2010– REVISED JANUARY 2012

CLOCK

The ADS129x provide two different methods for device clocking: internal and external. Internal clocking is ideally

suited for low-power, battery-powered systems. The internal oscillator is trimmed for accuracy at room

temperature. Over the specified temperature range the accuracy varies; see the Electrical Characteristics. Clock

selection is controlled by the CLKSEL pin and the CLK_EN register bit.

The CLKSEL pin selects either the internal or external clock. The CLK_EN bit in the CONFIG1 register enables

and disables the oscillator clock to be output in the CLK pin. A truth table for these two pins is shown in Table 7.

The CLK_EN bit is useful when multiple devices are used in a daisy-chain configuration. It is recommended that

during power-down the external clock be shut down to save power.

Table 7. CLKSEL Pin and CLK_EN Bit

CLKSEL PIN BIT CLOCK SOURCE CLK PIN STATUS

0 X External clock Input: external clock

1 0 Internal clock oscillator 3-state

1 1 Internal clock oscillator Output: internal clock oscillator

CONFIG1.CLK_EN

DATA FORMAT

The ADS129x output 24 bits of data per channel in binary twos complement format, MSB first. The LSB has a

weight of V

full-scale input produces an output code of 800000h. The output clips at these codes for signals exceeding

full-scale. Table 8 summarizes the ideal output codes for different input signals. Note that for DR[2:0] = 000 and

001, the device has only 17 and 19 bits of resolution, respectively. The last seven (in 17-bit mode) or five (in

19-bit mode) bits can be ignored.

/(223– 1). A positive full-scale input produces an output code of 7FFFFFh and the negative

REF

www.ti.com.cn

Table 8. Ideal Output Code versus Input Signal

INPUT SIGNAL, V

(AINP – AINN) IDEAL OUTPUT CODE

≥ V

REF

+V

/(223– 1) 000001h

REF

0 000000h

–V

/(223– 1) FFFFFFh

REF

≤ –V

(1) Only valid for 24-bit resolution data rates.

(2) Assumes gain = 1.

(3) Excludes effects of noise, linearity, offset, and gain error.

(223/223– 1) 800000h

REF

IN

7FFFFFh

(1)(2)

(3)

30 Copyright © 2010–2012, Texas Instruments Incorporated

Page 31

ADS1294, ADS1294R

ADS1296, ADS1296R

ADS1298, ADS1298R

www.ti.com.cn

SPI INTERFACE

The SPI-compatible serial interface consists of four signals: CS, SCLK, DIN, and DOUT. The interface reads

conversion data, reads and writes registers, and controls the ADS129x operation. The DRDY output is used as a

status signal to indicate when data are ready. DRDY goes low when new data are available.

Chip Select (CS)

Chip select (CS) selects the ADS129x devices for SPI communication. While CS is low the serial interface is

active CS must remain low for the entire duration of the serial communication. After the serial communication is

finished, always wait four or more t

is reset, SCLK and DIN are ignored, and DOUT enters a high-impedance state. DRDY asserts when data

conversion is complete, regardless of whether CS is high or low.

While ADS129x is selected the device will attempt to decode and execute commands every eight serial clocks. If

the devices ceases to execute serial commands, it is possible extra clock pulses were presented and placed the

serial interface in an unknown state. Take CS high and back low to reset the serial interface to a known state.

Serial Clock (SCLK)

SCLK is the serial peripheral interface (SPI) serial clock. It is used to shift in commands and shift out data from

the device. The serial clock (SCLK) features a Schmitt-triggered input and clocks data on the DIN and DOUT

pins into and out of the ADS129x. Even though the input has hysteresis, it is recommended to keep SCLK as

clean as possible to prevent glitches from accidentally forcing a clock event. The absolute maximum limit for

SCLK is specified in the Serial Interface Timing table.

While ADS129x is selected(CS = LOW), the device attempts to decode and execute commands every eight

serial clocks. It is therefore recommended that multiples of 8 SCLKs be presented every serial transfer to keep

the interface in a normal operating mode. If the interface ceases to function because of extra serial clocks, it can

be reset by toggling CS high and back to low.

cycles before taking CS high. When CS is taken high, the serial interface

CLK