Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments

查询ADS1271供应商查询ADS1271供应商

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

FEATURES

D 105kSPS Data Rate

D AC Performance:

51kHz Bandwidth

109dB SNR (High-Resolution Mode)

−105dB THD

D DC Accuracy:

1.8µV/°C Offset Drift

2ppm/°C Gain Drift

D Selectable Operating Modes:

High-Speed: 105kSPS Data Rate

High-Resolution: 109dB SNR

Low-Power: 35mW Dissipation

D Power-Down Control

D Digital Filter:

Linear Phase Response

Passband Ripple: ±0.005dB

Stop Band Attenuation: 100dB

D Internal Offset Calibration On Command

D Selectable SPIt or Frame Sync Serial In terface

D Designed for Multichannel Systems:

Daisy-Chainable Serial Interface

Easy Synchronization

D Simple Pin-Driven Control

D Specified fro m −40°C to +105°C

D Analog Supply: 5V

D Digital Supply: 1.8V to 3.3V

APPLICATIONS

D Vibration/Modal Analysis

D Acoustics

D Dynamic Strain Gauges

D Pressure Sensors

D Test and Measurement

DESCRIPTION

The ADS1271 is a 24-bit, delta-sigma analog-to-digital

converter (ADC) with a data rate up to 105kSPS. It offers

a unique combination of excellent DC accuracy and

outstanding AC performance. The high-order,

chopper-stabilized modulator achieves very low drift with

low in-band noise. The onboard decimation filter

suppresses modulator and signal out-of-band noise. The

ADS1271 provides a usable signal bandwidth up to 90%

of the Nyquist rate with less than 0.005dB of ripple.

Traditionally, industrial delta-sigma ADCs offering good

drift performance use digital filters with large passband

droop. As a result, they have limited signal bandwidth and

are mostly suited for DC measurements. High-resolution

ADCs in audio applications offer larger usable bandwidths,

but the offset and drift specification are significantly

weaker than their industrial counterparts. The ADS1271

combines these converters, allowing high-precision

industrial measurement with excellent DC and AC

specifications ensured over an extended industrial

temperature range.

Three operating modes allow for optimization of speed,

resolution, and power. A selectable SPI or a frame-sync

serial interface provides for convenient interfacing to

microcontrollers or DSPs. All operations, including internal

offset calibration, are controlled directly by pins; there are

no registers to program.

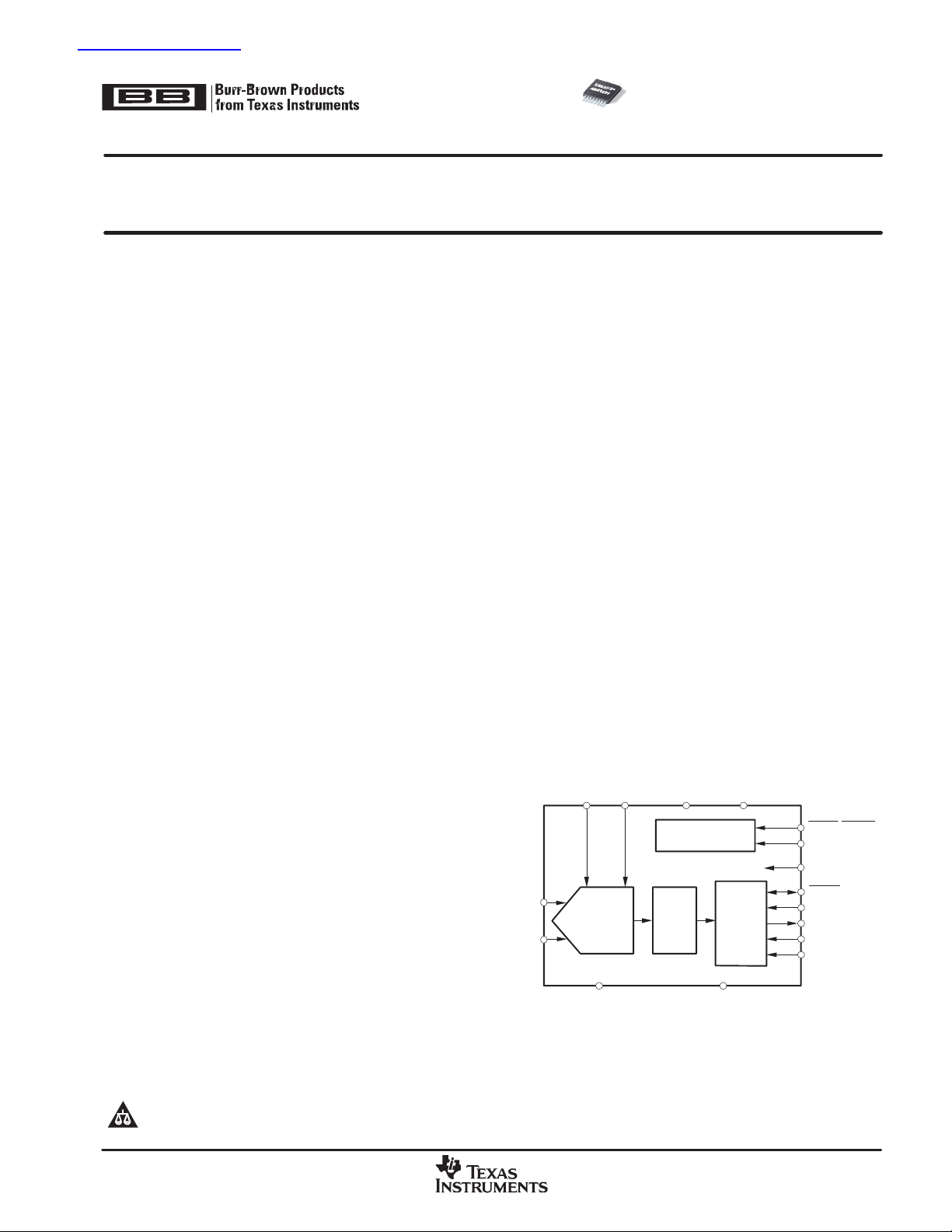

VREFP VREFN AVDD DVDD

SYNC/PDWN

MODE

CLK

DRDY/FSYNC

SCLK

DOUT

DIN

FORMAT

AINP

AINN

∆Σ

Modulator

Digital

Filter

Control

Logic

Serial

Interface

DGNDAGND

semiconductor products and disclaimers thereto appears at the end of this data sheet.

All trademarks are the property of their respective owners.

! "# $ %& $ " '&(% ) &%$

%"# $'%"%$ ' #$ " *$ $&#$ $ +)

&% '%$$ $ %$$+ %& $ " '#$)

www.ti.com

Copyright 2004, Texas Instruments Incorporated

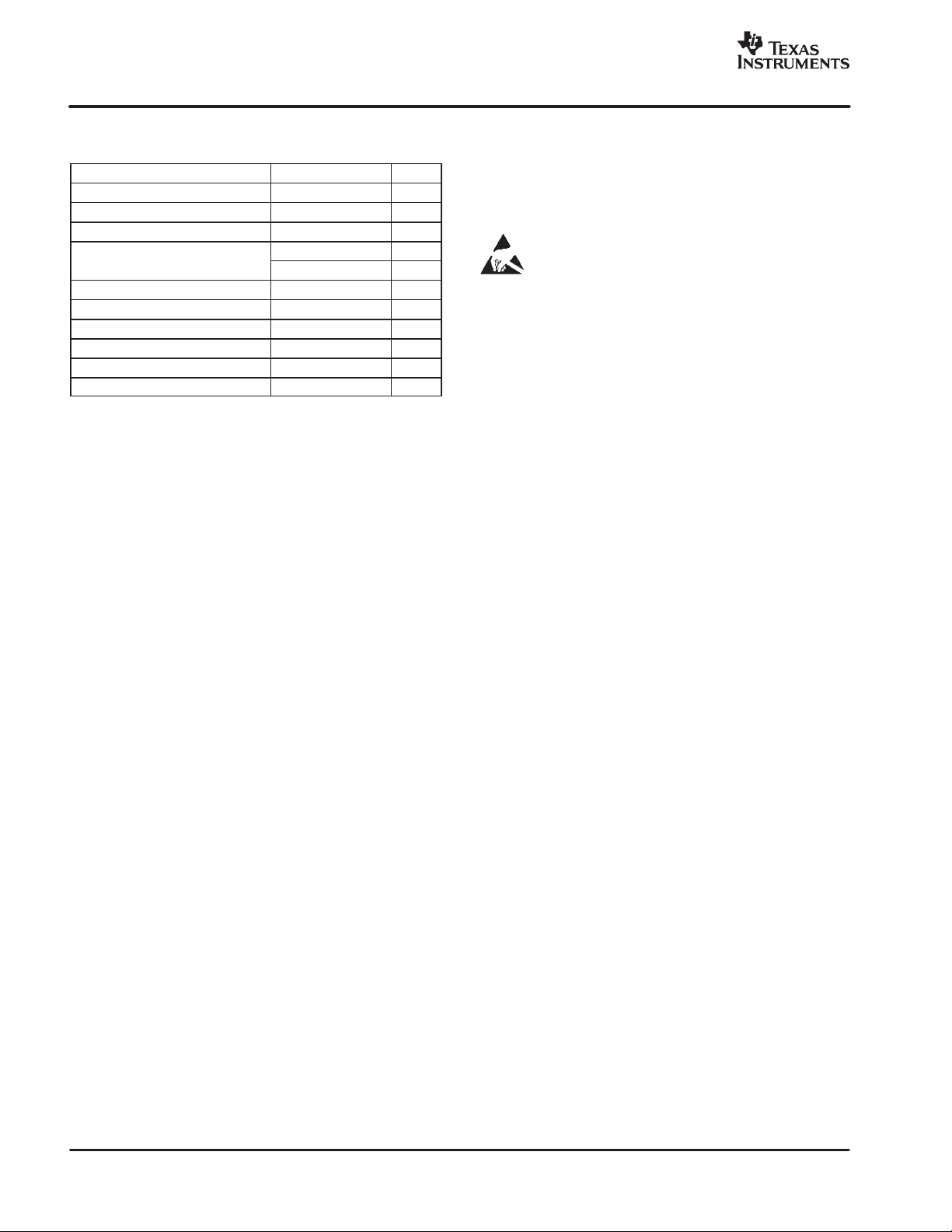

Input Current

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

www.ti.com

ABSOLUTE MAXIMUM RATINGS

over opera t i n g f r e e - a i r t e m p e r a t ure range u n l e s s o t h e r w i s e n o t e d

ADS1271 UNIT

AVDD to AGND −0.3 to +6.0 V

DVDD to DGND −0.3 to +3.6 V

AGND to DGND −0.3 to +0.3 V

100, Momentary mA

10, Continuous mA

Analog Input to AGND −0.3 to AVDD + 0 .3 V

Digital Input or Output to DGND −0.3 to DVDD + 0.3 V

Maximum Junction Tem perature +150 °C

Operating Temperature Range −40 to +105 °C

Storage Temperature Range −60 to +150 °C

Lead Temperature (soldering, 10s) +300 °C

(1)

Stresses above these ratings may cause permanent damage.

Exposure to absolute maximum conditions for extended periods

may degrade device reliability. These are stress ratings only , an d

functional operation of the device at these or any other conditions

beyond those specified is not implied.

(1)

ORDERING INFORMATION

For the most current package and ordering information,

see the Package Option Addendum located at the end of

this data sheet, or refer to our web site at www.ti.com.

This integrated circuit can be damaged by ESD. Texas

Instruments recommends that all integrated circuits be

handled with appropriate precautions. Failure to observe

proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to

complete device failure. Precision integrated circuits may be more

susceptible t o damage because very small parametric changes could

cause the device not to meet its published specifications.

2

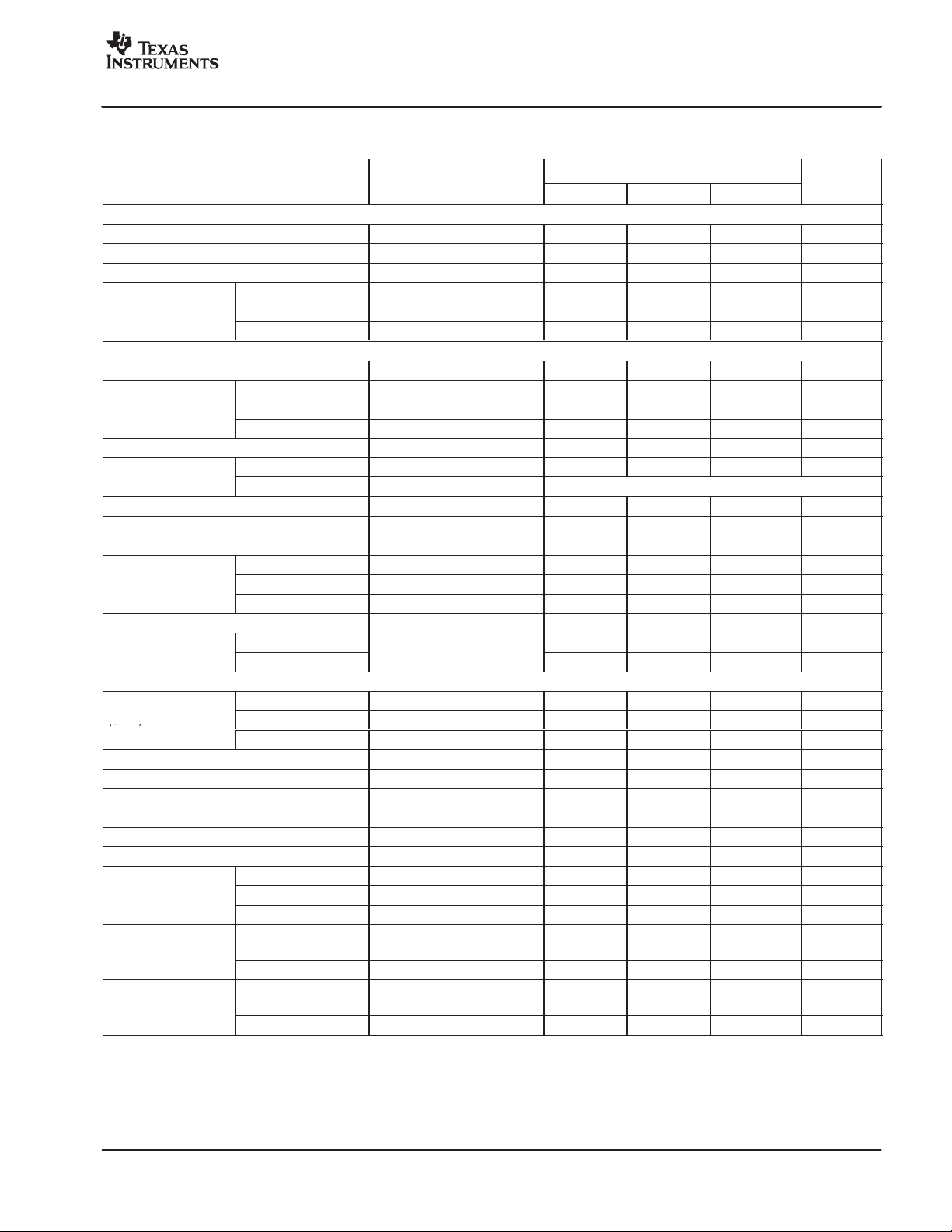

Differential input

impedance

DATA

Data rate (f

DATA

)

Offset error

Noise

Power-supply

Power-supply

f = 60Hz

Signal-to-noise ratio

Signal-to-noise ratio

(SNR)

(2)

Stop band

Group delay

Group delay

Settling time (latency)

Settling time (latency)

www.ti.com

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

ELECTRICAL CHARACTERISTICS

All specifications at TA = −40°C to +105°C, AVDD = +5V, DVDD = +1.8V, f

PARAMETER TEST CONDITIONS MIN TYP MAX

Analog Inputs

Full-scale input voltage (FSR)

Absolute input voltage AINP or AINN to AGND AGND – 0.1 AVDD + 0.1 V

Common-mode input voltage VCM = (AINP + AINN)/2 2.5 V

DC Performance

Resolution No missing codes 24 Bits

Data rate (f

Integral nonlinearity (INL) Differential input, VCM = 2.5V ± 0.0006 ± 0.0015 % of FSR

Offset drift 1.8 µV/_C

Gain error 0.1 0.5 %

Gain error drift 2 ppm/°C

Noise

Common-mode rejection fCM = 60Hz 90 100 dB

rejection

AC Performance

(2)

(SNR)

(unweighted)

Total harmonic distortion (THD)

Spurious free dynamic range −108 dB

Passband ripple ±0.005 dB

Passband 0.453 f

−3dB Bandwidth 0.49 f

Stop band attenuation 100 dB

Stop band

(1)

FSR = full-scale range = 2V

(2)

Minimum SNR is ensured by the limit of the DC noise specification.

(3)

THD includes the first nine harmonics of the input signals.

(4)

MODE and FORMAT pins excluded.

(5)

See the text for more details on SCLK.

)

(1)

High-Speed mode 16.4 kΩ

High-Resolution mode 16.4 kΩ

Low-Power mode 32.8 kΩ

High-Speed mode 105,469 SPS

High-Resolution mode 52,734 SPS

Low-Power mode 52,734 SPS

High-Speed mode Without calibration 0.150 1 mV

High-Speed mode Shorted input 9.0 20 µV, rms

High-Resolution mode 6.5 µV, rms

Low-Power mode 9.0 µV, rms

AVDD

DVDD

High-Speed mode 99 106 dB

High-Resolution mode 109 dB

Low-Power mode 106 dB

(3)

High-Speed mode 0.547 f

High-Resolution mode 0.547 f

Low-Power mode 0.547 f

High-Speed and

Low-Power modes

High-Resolution mode 39/f

High-Speed and

Low-Power modes

High-Resolution mode Complete settling 78/f

.

REF

VIN = (AINP – AINN) ±V

With calibration On the level of the noise

VIN = 1kHz, −0.5dBFS −105 −95 dB

Complete settling 76/f

= 27MHz, and V

CLK

DATA

DATA

DATA

= +2.5V , unless otherwise noted.

REF

ADS1271

REF

80 dB

80 dB

DATA

DATA

63.453 f

127.453 f

63.453 f

38/f

DATA

DATA

DATA

DATA

DATA

DATA

DATA

UNITS

V

Hz

Hz

Hz

Hz

Hz

s

s

s

s

(1)

3

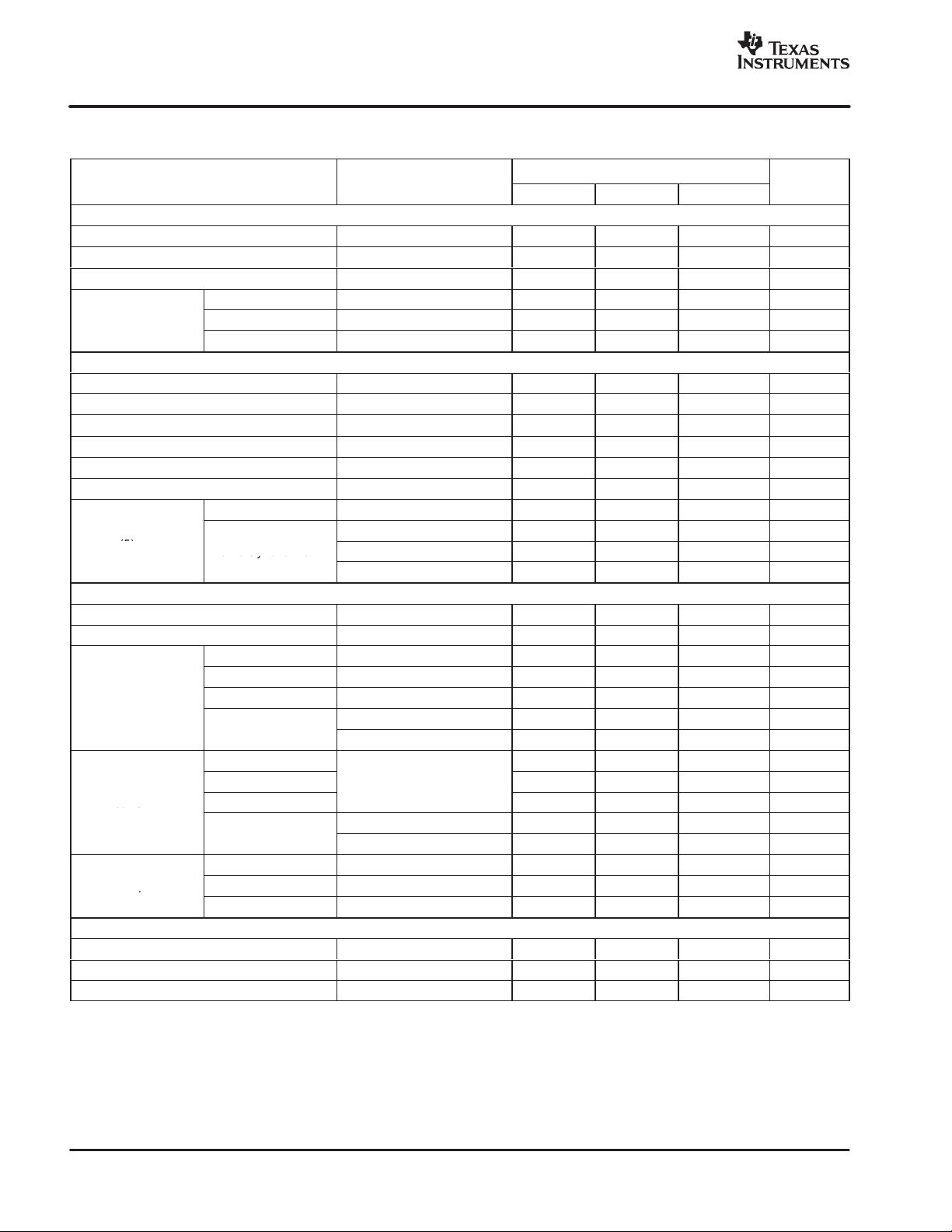

Reference Input

impedance

Serial clock rate

SCLK

Frame-Sync format

AVDD current

Power-Down mode

DVDD current

Power-Down mode

Power dissipation

www.ti.com

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

ELECTRICAL CHARACTERISTICS (continued)

All specifications at TA = −40°C to +105°C, AVDD = +5V, DVDD = +1.8V, f

PARAMETER

Voltage Reference Inputs

Reference input Voltage (V

Negative reference input (VREFN) AGND − 0.1 VREFP − 0.5 V

Positive reference input (VREFP) VREFN + 0.5 AVDD + 0.1 V

Digital Input/Output

V

IH

V

IL

V

OH

V

OL

Input leakage

Master clock rate (f

Serial clock rate

(f

SCLK

Power Supply

AVDD 4.75 5 5.25 V

DVDD 1.65 3.6 V

AVDD current

DVDD current

Power dissipation

Temperature Range

Specified −40 +105 _C

Operating −40 +105 _C

Storage −60 +150 _C

(1)

FSR = full-scale range = 2V

(2)

Minimum SNR is ensured by the limit of the DC noise specification.

(3)

THD includes the first nine harmonics of the input signals.

(4)

MODE and FORMAT pins excluded.

(5)

See the text for more details on SCLK.

(4)

CLK

(5)

)

) V

REF

High-Speed mode 4.2 kΩ

High-Resolution mode 4.2 kΩ

Low-Power mode 8.4 kΩ

) 1 27 MHz

SPI format 24 f

Frame-Sync format

High-Speed mode 17 25 mA

High-Resolution mode 17 25 mA

Low-Power mode 6.3 9.5 mA

High-Speed mode 3.5 6 mA

High-Resolution mode 2.5 5 mA

Low-Power mode 1.8 3.5 mA

High-Speed mode 92 136 mW

High-Resolution mode 90 134 mW

Low-Power mode 35 54 mW

.

REF

= VREFP – VREFN 0.5 2.5 2.65 V

REF

IOH = 5mA 0.8 DVDD DVDD V

IOL = 5mA DGND 0.2 DVDD V

0 < VIN

DIGITAL

High-Speed mode 64 f

High-Resolution mode 128 f

Low-Power mode 64 f

T ≤ 105°C 1 70 µA

T ≤ 85°C 1 10 µA

T ≤ 105°C, DVDD = 3.3V 1 70 µA

T ≤ 85°C, DVDD = 3.3V 1 20 µA

< DVDD ±10 µA

= 27MHz, and V

CLK

= +2.5V , unless otherwise noted.

REF

ADS1271

MAXTYPMINTEST CONDITIONS

0.7 DVDD DVDD V

DGND 0.3 DVDD V

64 f

128 f

64 f

f

CLK

DATA

DATA

DATA

DATA

DATA

DATA

DATA

UNITS

UNITS

MHz

MHz

MHz

MHz

4

www.ti.com

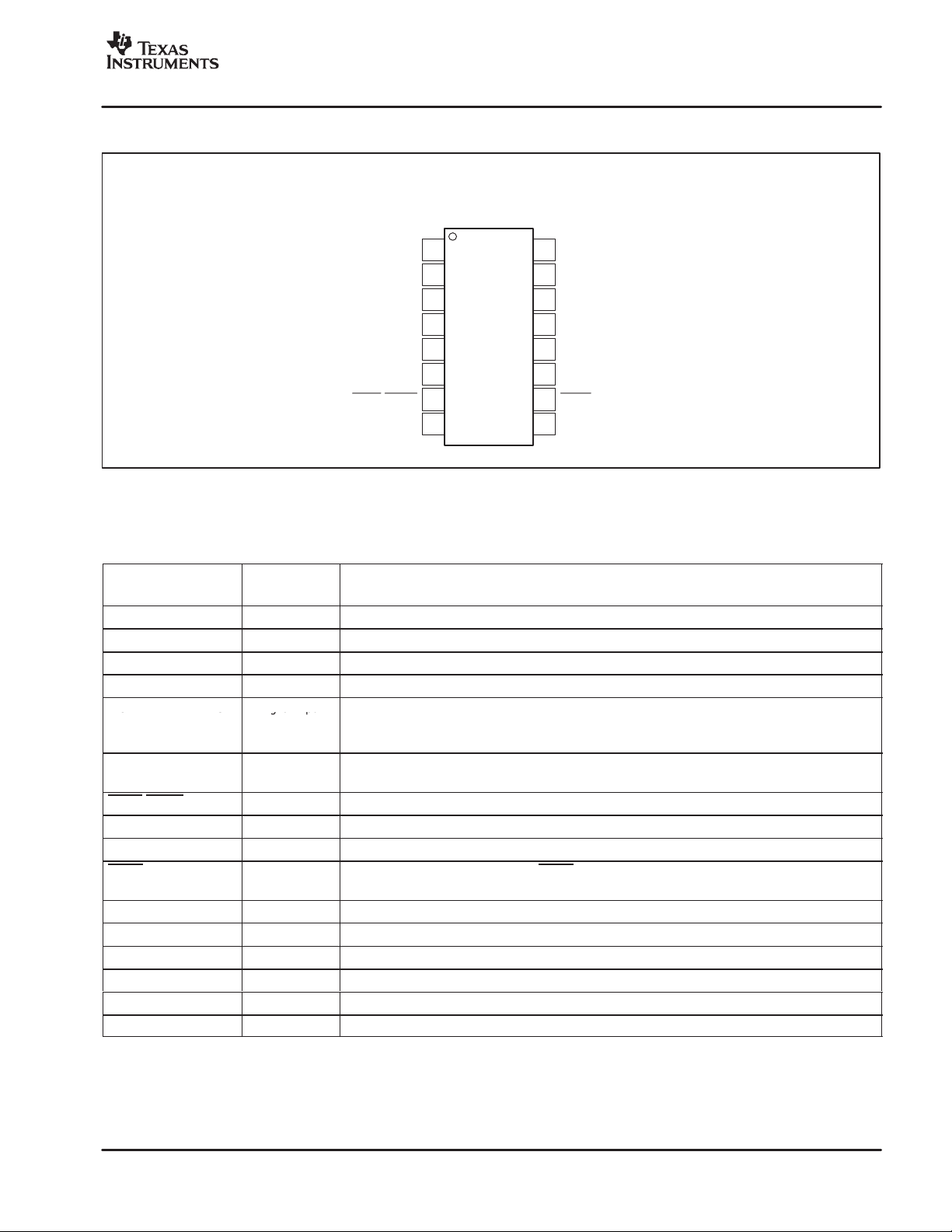

MODE5Digital Input

PIN ASSIGNMENTS

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

TSSOP (PW) PACKAGE

(TOP VIEW)

AINP

AINN

AGND

AVDD

MODE

FORMAT

SYNC/PDWN

DIN

1

2

3

4

ADS1271

5

6

7

8

16

VREFP

15

VREFN

14

DGND

13

DVDD

12

CLK

11

SCLK

10

DRDY/FSYNC

9

DOUT

Terminal Functions

PIN

NAME NO. FUNCTION DESCRIPTION

AINP 1 Analog Input Positive analog input

AINN 2 Analog Input Negative analog input

AGND 3 Analog Input Analog ground

AVDD 4 Analog Input Analog supply

MODE 5 Digital Input MODE = 0: High-Speed mode

MODE = float: High-Resolution mode

MODE = 1: Low-Power mode

FORMAT 6 Digital Input FORMAT = 0: SPI

FORMAT = 1: Frame-Sync

SYNC/PDWN 7 Digital Input Synchronize/Power-down input, active low

DIN 8 Digital Input Data input for daisy-chain operation

DOUT 9 Digital Output Data output

DRDY/FSYNC 10 Digital

Input/Output

SCLK 11 Digital Input Serial clock for data retrieval

CLK 12 Digital Input Master clock

DVDD 13 Digital Input Digital supply

DGND 14 Digital Input Digital ground

VREFN 15 Analog Input Negative reference input

VREFP 16 Analog Input Positive reference input

If FORMAT = 0 (SPI), then pin 10 = DRDY output

If FORMAT = 1 (Frame-Sync), then pin 10 = FSYNC input

5

CONV

DATA

t

CONV

Conversion period (1/f

DATA

)

www.ti.com

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

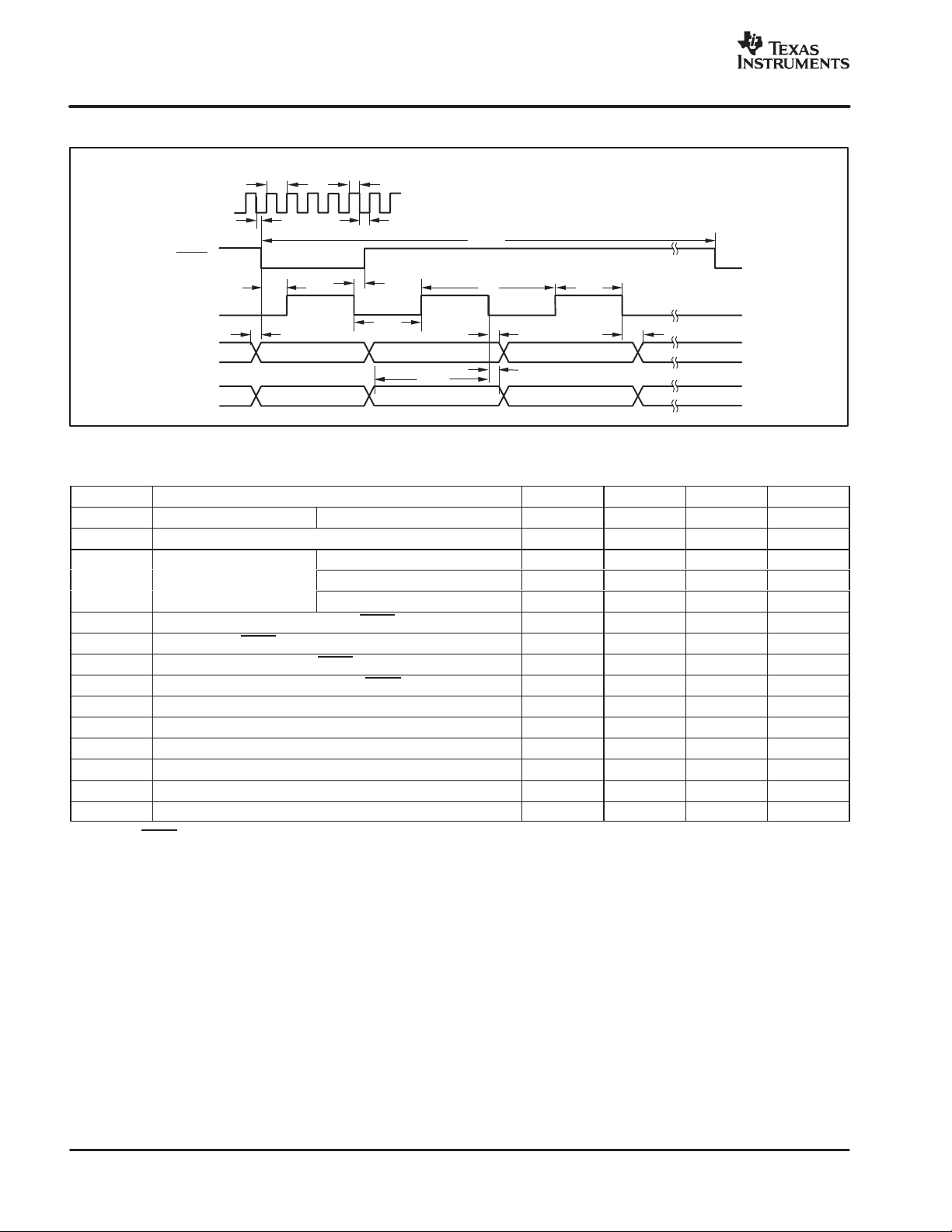

TIMING CHARACTERISTICS: SPI FORMAT

t

CLK

CLK

t

CD

DRDY

t

DS

SCLK

t

DDO

DOUT

DIN

Bit 23 (MSB) Bit 22 Bit 21

TIMING REQUIREMENTS: SPI FORMAT

For TA = −40°C to +105°C and DVDD = 1.65V to 3.6V.

SYMBOL PARAMETER MIN TYP MAX UNIT

t

CLK

t

CPW

t

(1)

t

CD

(1)

t

DS

(1)

t

DDO

(1)

t

SD

t

S

t

SPW

t

DOHD

t

DOPD

t

DIST

t

DIHD

(1)

Load on DRDY and DOUT = 20pF.

CLK period (1/f

) 37 1000 ns

CLK

CLK positive or negative pulse width 15 ns

High-Speed mode 256 CLK periods

Conversion period (1/f

High-Resolution mode 512 CLK periods

)

Low-Power mode 512 CLK periods

Falling edge of CLK to falling edge of DRDY 8 ns

Falling edge of DRDY to rising edge of first SCLK to retrieve data 5 ns

Valid DOUT to falling edge of DRDY 0 ns

Falling edge of SCLK to rising edge of DRDY 8 ns

SCLK period t

SCLK positive or negative pulse width 12 ns

(1)

SCLK falling edge to old DOUT invalid (hold time) 5 ns

(1)

SCLK falling edge to new DOUT valid (propagation delay) 12 ns

New DIN valid to falling edge of SCLK (setup time) 6 ns

Old DIN valid to falling edge of SCLK (hold time) 6 ns

t

t

SPW

CPW

t

SD

t

•••

CPW

t

DIST

t

CONV

t

S

t

DOHD

t

DIHD

t

SPW

t

DOPD

CLK

ns

6

www.ti.com

FRAME

DATA

t

FRAME

Frame period (1/f

DATA

)

S

τ

S

be continuously running)

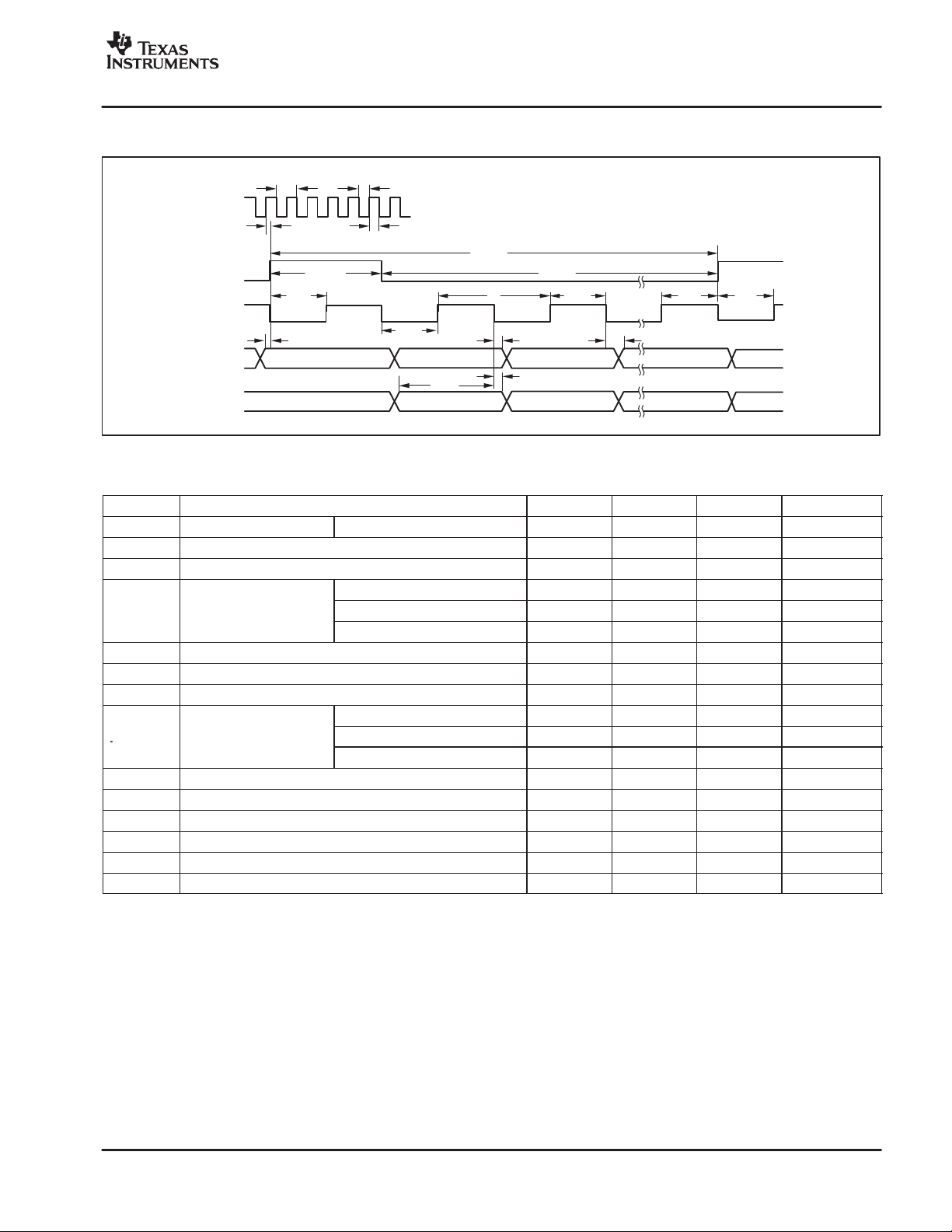

TIMING CHARACTERISTICS: FRAME-SYNC FORMAT

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

t

CPW

•••

t

CPW

t

SPW

t

DIST

t

FRAME

t

FPW

t

S

t

DOHD

t

DIHD

t

SPW

t

DOPD

t

SF

t

FS

CLK

FSYNC

SCLK

DOUT

DIN

τ

C

t

CF

t

FPW

t

SPW

t

DDO

Bit 23(MSB) Bit 22 Bit 21

TIMING REQUIREMENTS: FRAME-SYNC FORMAT

for TA = −40°C to +105°C and DVDD = 1.65V to 3.6V.

SYMBOL PARAMETER MIN TYP MAX UNIT

t

CLK

t

CPW

t

CS

t

t

FPW

t

FS

t

SF

τ

t

SPW

t

DOHD

t

DOPD

t

DDO

t

DIST

t

DIHD

(1)

The ADS1271 automatically detects either frame period.

(2)

Load on DOUT = 20pF.

CLK period (1/f

) 37 1000 ns

CLK

CLK positive or negative pulse width 15 ns

Rising edge of CLK to falling edge of SCLK −2 8 ns

High-Speed mode 256 CLK periods

Frame period (1/f

High-Resolution mode 256 or 512

)

Low-Power mode 256 or 512

(1)

(1)

FSYNC positive or negative pulse width 1 SCLK periods

Rising edge of FSYNC to rising edge of SCLK 5 ns

Rising edge of SCLK to rising edge of FSYNC 5 ns

SCLK period (SCLK must

High-Resolution mode τ

FRAME

Low-Power mode τ

High-Speed mode τ

SCLK positive or negative pulse width 0.4τ

(2)

SCLK falling edge to old DOUT invalid (hold time) 5 ns

(2)

SCLK falling edge to new DOUT valid (propagation delay) 12 ns

(2)

Valid DOUT to falling edge of FSYNC 0 ns

SCLK

/64 τ

FRAME

/128 τ

/64 τ

FRAME

0.6τ

SCLK

New DIN valid to falling edge of SCLK (setup time) 6 ns

Old DIN valid to falling edge of SCLK (hold time) 6 ns

CLK periods

CLK periods

FRAME

FRAME

FRAME

periods

periods

periods

ns

7

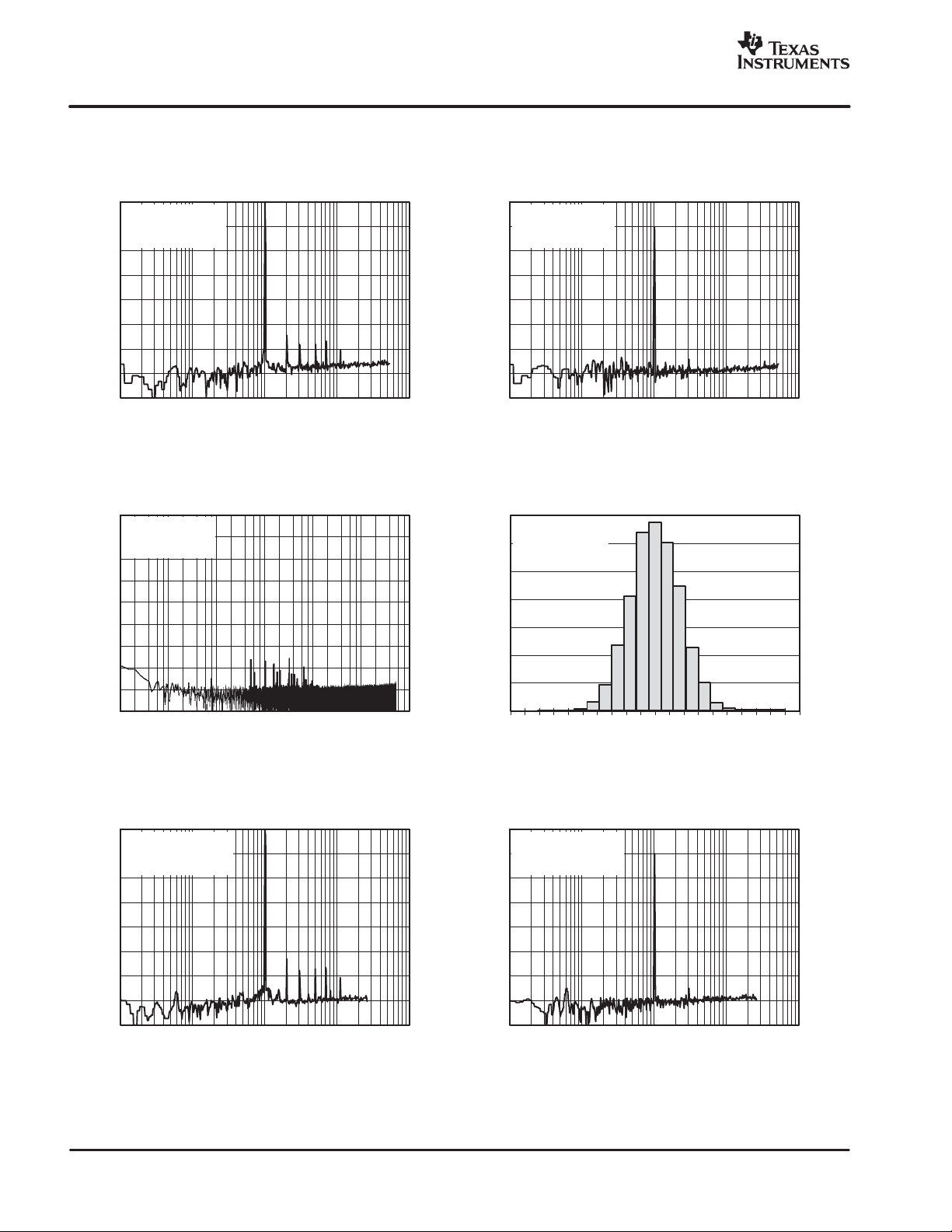

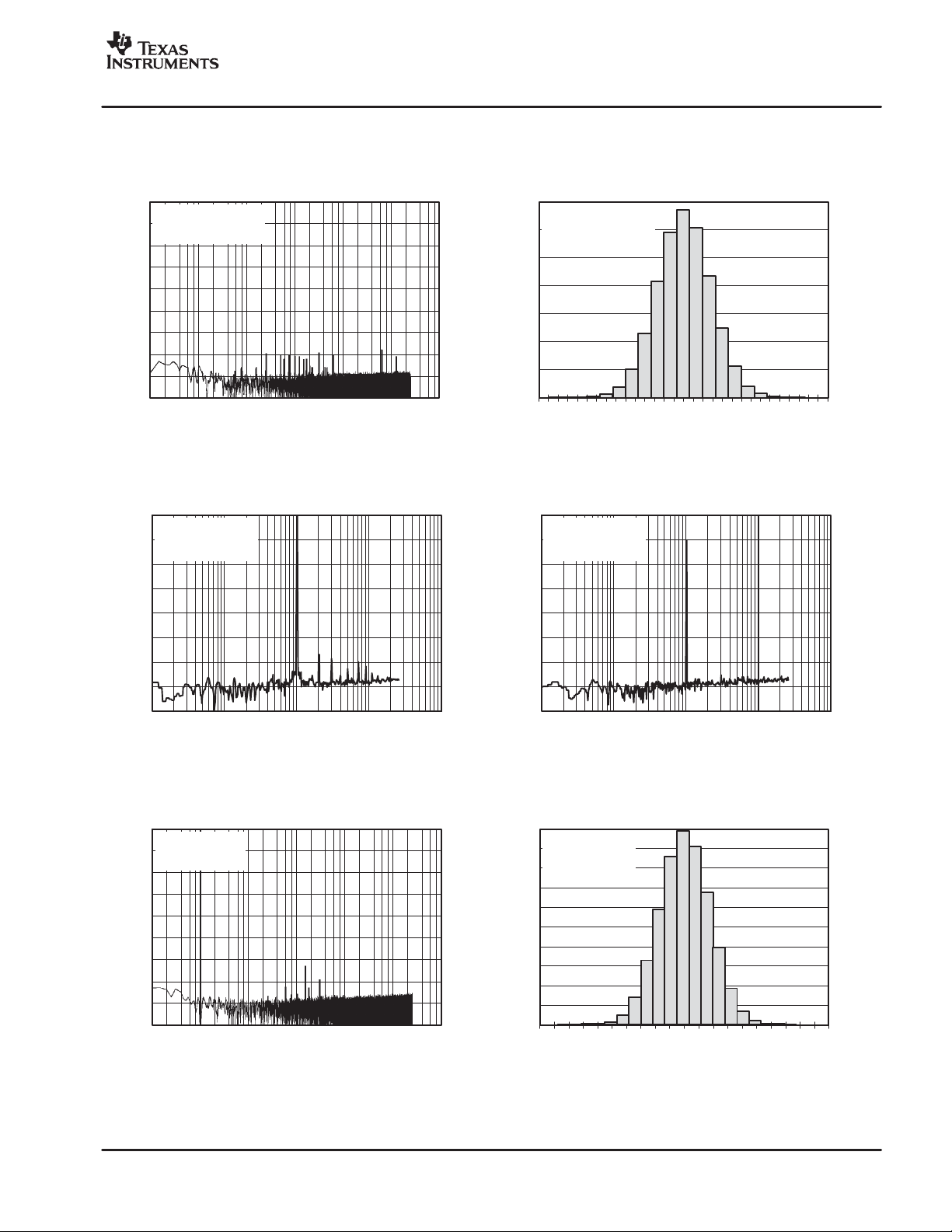

OUTPUT SPECTRUM

Amplitude (dB)

OUTPUT SPECTRUM

Amplitude (dB)

OUTPUT SPECTRUM

Amplitude (dB)

NOISE HISTOGRAM

OUTPUT SPECTRUM

Amplitude (dB)

OUTPUT SPECTRUM

Amplitude (dB)

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

TYPICAL CHARACTERISTICS

TA = 25°C, AVDD = 5V, DVDD = 1.8V, f

= 27MHz, and V

CLK

= 2.5V , unless otherwise noted.

REF

www.ti.com

0

High−Speed Mode

= 1kHz,−0.5dBFS

f

−

20

IN

32,768 Points

−

40

−

60

−

80

−

100

−

120

−

140

−

160

10 100 1k

Frequency (Hz)

Figure 1

0

High−Speed Mode

−

Shorted Input

20

2,097,152 Points

−

40

−

60

−

80

−

100

−

120

−

140

−

160

−

180

0.1 1 10 100 1k

Frequency (Hz)

10k 100k

10k 100k

0

High−Speed Mode

=1kHz,−20dBFS

f

−

20

IN

32,768 Points

−

40

−

60

−

80

−

100

−

120

−

140

−

160

10 100 1k

420k

High−Speed Mode

Shorted Input

360k

2,097,152 Points

300k

240k

180k

120k

Number of Occurrences

60k

0

−50−45−40−35−30−25−20−15−

Frequency (Hz)

Figure 2

5

0

5

10

−

Output (µV)

10k 100k

101520253035404550

Figure 3

0

High−Resolution Mode

=1kHz,−0.5dBFS

f

−

20

IN

32,768 Points

−

40

−

60

−

80

−

100

−

120

−

140

−

160

10 100 1k

Frequency (Hz)

Figure 5

10k 100k

0

High−Resolution Mode

= 1kHz,−20dBFS

f

−

20

IN

32,768 Points

−

40

−

60

−

80

−

100

−

120

−

140

−

160

10 100 1k

Figure 4

10k 100k

Frequency (Hz)

Figure 6

8

www.ti.com

OUTPUT SPECTRUM

Amplitude (dB)

NOISE HISTOGRAM

OUTPUT SPECTRUM

Amplitude (dB)

OUTPUT SPECTRUM

Amplitude (dB)

OUTPUT SPECTRUM

Amplitude (dB)

NOISEH ISTOGRAM

TYPICAL CHARACTERISTICS (continued)

TA = 25°C, AVDD = 5V, DVDD = 1.8V, f

= 27MHz, and V

CLK

REF

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

= 2.5V , unless otherwise noted.

0

High−Resolution Mode

−

20

Shorted Input

1,048,576 Points

−

40

−

60

−

80

−

100

−

120

−

140

−

160

−

180

0.1 1 10 100 1k

Frequency (Hz)

Figure 7

0

Low−Power Mode

=1kHz,−0.5dBFS

f

−

20

IN

32,768 Points

−

40

−

60

−

80

−

100

−

120

−

140

−

160

10 100 1k

Frequency (Hz)

10k 100k

10k 100k

210k

High−ResolutionMode

Shorted Input

180k

1,048,576 Points

150k

120k

90k

60k

Number ofOccurrences

30k

0

−30−28−26−24−22−20−18−16−14−12−

0

Low−Power Mode

=1kHz,−20dBFS

f

−

20

IN

32,768 Points

−

40

−

60

−

80

−

100

−

120

−

140

−

160

10 100 1k

2

−8−6−4−

Output (µV)

02468

10

Figure 8

Frequency (Hz)

1012141618202224262830

10k 100k

Figure 9

0

Low−Power Mode

−

Shorted Input

20

1,048,576 Points

−

40

−

60

−

80

−

100

−

120

−

140

−

160

−

180

0.1 1 10 100 1k

Frequency (Hz)

Figure 11

10k 100k

200k

Low−Power Mode

180k

Shorted Input

1,048,576 Points

160k

140k

120k

100k

80k

60k

Number of Occurrences

40k

20k

0

−50−45−40−35−30−25−20−15−

Figure 10

5

0

5

10

−

Output (µV)

Figure 12

101520253035404550

9

TOTAL HARMONIC DISTORTION

THD, THD+NAmplitude (dB)

TOTAL HARMONIC DISTORTION

THD, THD+NAmplitude (dB)

TOTAL HARMONIC DISTORTION

THD, THD+NAmplitude (dB)

TOTAL HARMONIC DISTORTION

THD, THD+NAmplitude (dB)

TOTAL HARMONIC DISTORTION

THD, THD+NAmplitude (dB)

TOTAL HARMONIC DISTORTION

THD, THD+NAmplitude (dB)

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

TYPICAL CHARACTERISTICS (continued)

TA = 25°C, AVDD = 5V, DVDD = 1.8V, f

= 27MHz, and V

CLK

= 2.5V , unless otherwise noted.

REF

www.ti.com

0

High−Speed Mode

=−0.5dBFS

V

IN

−

20

−

40

−

60

−

80

−

100

−

120

10 100 1k

0

High−Resolution Mode

=−0.5dBFS

V

IN

−

20

−

40

−

60

−

80

−

100

−

120

10 100 1k

vs FREQUENCY

THD+N

THD

Frequency (Hz)

Figure 13

vs FREQUENCY

THD+N

THD

Frequency (Hz)

Figure 15

10k 100k

10k 100k

0

High−Speed Mode

=1kHz

f

IN

−

20

−

40

−

60

−

80

−

100

−

120

−

140

−

120−100

0

High−Resolution Mode

=1kHz

f

IN

−

20

−

40

−

60

−

80

−

100

−

120

−

140

−

120−100

vs INPUT LEVEL

THD+N

THD

−

−

80

Input Amplitude (dBFS)

−

60

Figure 14

vs INPUT LEVEL

THD+N

THD

−

−

80

Input Amplitude (dBFS)

−

60

Figure 16

−

40

40

20 0

−

20 0

0

Low−Power Mode

=−0.5dBFS

V

IN

−

20

−

40

−

60

−

80

−

100

−

120

10 100 1k

vs FREQUENCY

THD+N

THD

Frequency (Hz)

10k 100k

0

−

20

−

40

−

60

−

80

−

100

−

120

−

140

−

120−100

Low−Power Mode

=1kHz

f

IN

Figure 17

vs INPUT LEVEL

THD+N

THD

−

−

80

Input Amplitude (dBFS)

−

60

Figure 18

−

40

20 0

10

www.ti.com

ABSOLUTE OFFSET DRIFT HISTOGRAM

GAIN DRIFT HISTOGRAM

OFFSETPOWER−ON WARMUP

GAIN ERROR POWER−ON WARMUP

UNCALIBRATED OFFSET HISTOGRAM

GAIN ERRORHISTOGRAM

TYPICAL CHARACTERISTICS (continued)

TA = 25°C, AVDD = 5V, DVDD = 1.8V, f

= 27MHz, and V

CLK

REF

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

= 2.5V , unless otherwise noted.

60

30 Units, Basedon

20_CIntervals

50

40

30

20

Occurrences (%)

10

0

1 3 5 7 9 111315171921

Absolute Offset Drift (µV/_C)

Figure 19

40

30

V)

20

µ

10

0

−

10

−

20

Normalized Offset (

−

30

−

40

0102030405060

Response

Band

Time After Power−On (s)

High−SpeedMode

DVDD = 3.3V

15

30 Units, Based on

20_C Intervals

10

5

Occurrences (%)

0

6.0−5.5−5.0−4.5−4.0−3.5−3.0−2.5−2.0−1.5−1.0−0.5

−

Gain Drift (ppm/_C)

0

0.5

1.0

1.5

2.0

2.5

3.0

Figure 20

10

8

6

4

2

0

−

2

−

4

−

6

Normalized Gain Error (ppm)

−

8

−

10

0102030405060

Response

Band

Time AfterPower−On (s)

High−Speed Mode

DVDD = 3.3V

3.5

4.0

Figure 21

30

High−Speed Mode

30 Units

20

Units (%)

10

0

500−450−400−350−300−250−200−150−100

−

Uncalibrated Offset (µV)

Figure 23

50

−

Figure 22

50

High− Speed Mode

30 Units

40

30

Units (%)

20

10

0

50

100

150

200

250

300

0

2350−2300−2250−2200−2150−2100−2050−2000−1950−1900−1850−1800−1750−1700−1650−1600

−

Gain Error(ppm)

Figure 24

11

REFERENCE INPUT DIFFERENTIAL IMPEDANCE

Reference Input Impedance (

)

REFERENCE INPUT DIFFERENTIAL IMPEDANCE

ANALOG INPUT DIFFERENTIAL IMPEDANCE

Analog Input Impedance (

)

ANALOG INPUT DIFFERENTIAL IMPEDANCE

Analog InputImpedance (

)

INTEGRAL NONLINEARITY vs TEMPERATURE

LINEARITY ERROR vs INPUT LEVEL

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

TYPICAL CHARACTERISTICS (continued)

TA = 25°C, AVDD = 5V, DVDD = 1.8V, f

= 27MHz, and V

CLK

= 2.5V , unless otherwise noted.

REF

www.ti.com

Ω

Ω

4280

High−Speed and

4260

High−Resolution Modes

4240

4220

4200

4180

4160

4140

4120

4100

−40−

16550

16500

16450

16400

16350

16300

16250

16200

16150

−40−

vs TEMPERATURE

20 0 20 40 60 80 100

Temperature (_C)

Figure 25

vs TEMPERATURE

High−Speed and

High−Resolution Modes

20 0 20 40 60 80 100

Temperature (_C)

Figure 27

120 125

120 125

)

Ω

Reference Input Impedance (

Ω

8900

8800

8700

8600

8500

8400

8300

8200

−40−

33200

33000

32800

32600

32400

32200

32000

−40−

vs TEMPERATURE

Low−Power Mode

20 0 20 40 60 80 100

Temperature (_C)

Figure 26

vs TEMPERATURE

Low−Power Mode

20 0 20 40 60 80 100

Temperature (_C)

Figure 28

120125

120 125

14

12

10

8

6

INL (ppm)

4

2

0

−40−

High−Resolution

High−Speed

Low−Power

20 0 20 40 60 80 100

Temperature (_C)

120125

Figure 29

10

High−Speed Mode

8

6

4

2

0

−

2

−

4

Linearity Error (ppm)

−

6

−

8

−

10

−

2.5−2.0 2.0

T=+105_C

T=+25_C

T=−40_C

−

−

1.5 1.5

−

1.0 1.0

0.5 0.50

(V)

V

IN

Figure 30

T=+125_C

2.5

12

www.ti.com

NOISE vs AVDD

NOISE vs DVDD

NOISE vs TEMPERATURE

NOISE vs INPUT LEVEL

AVDD CURRENTvs TEMPERATURE

DVDD CURRENT vs TEMPERATURE

TYPICAL CHARACTERISTICS (continued)

TA = 25°C, AVDD = 5V, DVDD = 1.8V, f

= 27MHz, and V

CLK

REF

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

= 2.5V , unless otherwise noted.

20

18

16

14

V)

µ

12

10

8

RMS Noise (

6

4

2

0

4.75 4.85 5.154.95 5.05

AVDD (V)

Figure 31

12

10

V)

µ

RMS Noise (

8

6

4

2

0

−40−

High−Speed

20 0 20 40 60 80 100

Temperature (_C)

High−Speed

Low−Power

High−Resolution

Low−Power

High−Resolution

5.25

120 125

20

18

16

14

V)

µ

12

10

8

RMS Noise (

6

4

2

0

1.6 2.0 2.21.8 3.2 3.42.4 2.6 2.8 3.0

High−Speed

Low−Power

DVDD (V)

Figure 32

20

18

16

14

V)

High−Speed

µ

12

10

8

RMS Noise (

6

4

2

0

−

2.5−2.0−1.5−1.0 1.51.0

−

0.5 0.50

(V)

V

IN

High−Resolution

3.6

Low−Power

High−Resolution

2.52.0

Figure 33

22

20

High−Speed and

18

High−Resolution

16

14

12

10

8

Low−Power

AVDD Current(mA)

6

4

2

0

−40−

20 0 20 40 60 80 100

Temperature (_C)

Figure 35

120 125

DVDD Current (mA)

4.0

3.5

3.0

2.5

2.0

1.5

1.0

0.5

0

Figure 34

−40−

20 0 20 40 60 80 100

Temperature (_C)

Figure 36

High−Speed

High−Resolution

Low−Power

120125

13

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

OVERVIEW

The ADS1271 is a 24-bit, delta-sigma ADC. It offers the

combination of outstanding DC accuracy and superior AC

performance. Figure 37 shows the block diagram for the

ADS1271. The ADS1271 converter is comprised of an

advanced, 6th-order, chopper-stabilized, delta-sigma

modulator followed by a low-ripple, linear phase FIR filter.

The modulator measures the differential input signal,

V

= (AINP – AINN), against the differential reference,

IN

= (VREFP – VREFN). The digital filter receives the

V

REF

modulator signal and provides a low-noise digital output.

To allow tradeoffs among speed, resolution, and power,

three modes of operation are supported on the ADS1271:

High-Speed, High-Resolution, and Low-Power. Table 1

VREFP

VREFN

Σ

V

REF

AINP

AINN

V

Σ

IN

∆Σ

Modulator

www.ti.com

summarizes the performance of each mode.

In High-Speed mode, the data rate is 105kSPS; in

High-Resolution mode, the SNR = 109dB; and in

Low-Power mode, the power dissipation is only 35mW.

The ADS1271 is configured by simply setting the

appropriate IO pins—there are no registers to program.

Data is retrieved over a serial interface that supports both

SPI and Frame-Sync formats. The ADS1271 has a

daisy-chainable output and the ability to synchronize

externally, so it can be used conveniently in multichannel

systems.

SYNC/PDWN

MODE

CLK

Digital

Filter

SPI

or

Frame−

Sync

Serial

Interface

DRDY/FSYNC

SCLK

DOUT

DIN

FORMAT

Figure 37. Block Diagram

Table 1. Operating Mode Performance Summary

MODE DATA RATE (SPS) PASSBAND (Hz) SNR (dB) NOISE (µV

High-Speed 105,469 47,777 106 9.0 92

High-Resolution 52,734 23,889 109 6.5 90

Low-Power 52,734 23,889 106 9.0 35

) POWER (mW)

RMS

14

www.ti.com

High-Resolution

Low-Power

ANALOG INPUTS (AINP, AINN)

The ADS1271 measures the differential input signal

V

= (AINP – AINN) against the differential reference

IN

= (VREFP – VREFN). The most positive measurable

V

REF

differential input is +V

positive digital output code of 7FFFFFh. Likewise, the

most negative measurable differential input is −V

which produces the most negative digital output code of

800000h.

While the ADS1271 measures the differential input signal,

the absolute input voltage is also important. This is the

voltage on either input (AINP or AINN) with respect to

AGND. The range for this voltage is:

−0.1V < (AINN or AINP) < AVDD +0.1V

, which produces the most

REF

REF

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

t

=1/f

ON

S1

OFF

ON

,

S2

OFF

SAMPLE

MOD

Figure 39. S1 and S2 Switch Timing for Figure 38

Table 2. Modulator Frequency for the Different

Mode and Format Settings

If either input is taken below –0.1V or above (AVDD + 0.1),

ESD protection diodes on the inputs may turn on.

The ADS1271 uses switched-capacitor circuitry to

measure the input voltage. Internal capacitors are charged

by the inputs and then discharged. Figure 38 shows a

conceptual diagram of these circuits. Switch S2

represents the net effect of the modulator circuitry in

discharging the sampling capacitor; the actual

implementation is di fferent. The timing for switches S1 and

S2 is shown in Figure 39. The sampling time (t

the inverse of modulator sampling frequency (f

SAMPLE

MOD

) is

) and is

a function of the mode, format, and frequency of CLK, as

shown in Table 2. When using the Frame-Sync format with

High-Resolution or Low-Power modes, the ratio between

f

MOD

and f

depends on the frame period that is set by

CLK

the FSYNC input.

AGND

AVDD

S

AINP

1

S

9pF

2

INTERFACE

MODE

High-Speed SPI or Frame-Sync f

FORMAT

SPI f

Frame-Sync f

SPI f

Frame-Sync f

CLK

CLK

f

MOD

CLK

CLK

/4 or f

CLK

/8 or f

/4

/4

CLK

/8

CLK

/2

/4

The average load presented by the switched capacitor

input can be modeled with an effective differential

impedance, as shown in Figure 40. Note that the effective

impedance is a function of f

AINP

Zeff = 16.4kΩ×(6.75MHz/f

AINN

MOD

.

)

MOD

AINN

AVDDAGND

ESD Protection

S

1

Figure 38. Equivalent Analog Input Circuitry

Figure 40. Effective Input Impedances

The ADS1271 is a very high-performance ADC. For

optimum performance, it is critical that the appropriate

circuitry be used to drive the ADS1271 inputs. See the

Application Information section for the recommended

circuits.

15

High-Resolution

Low-Power

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

www.ti.com

VOLTAGE REFERENCE INPUTS (VREFP,

VREFN)

The voltage reference for the ADS1271 ADC is the

differential voltage between VREFP and VREFN:

V

= (VREFP−VREFN). The reference inputs use a

REF

structure similar to that of the analog inputs with the

equivalent circuitry on the reference inputs shown in

Figure 41. As with the analog inputs, the load presented by

the switched capacitor can be modeled with an effective

impedance, as shown in Figure 42.

VREFP

Figure 41. Equivalent Reference Input Circuitry

VREFP VREFN

Zeff = 4.2kΩ×(6.75MHz/f

Figure 42. Effective Reference Impedance

VREFN

Protection

)

MOD

AVDDAVDD

ESD

ESD diodes protect the reference inputs. To keep these

diodes from turning on, make sure the voltages on the

reference pins do not go below AGND by more than 0.1V,

and likewise do not exceed AVDD by 0.1V:

−0.1V < (VREFP or VREFN) < AVDD + 0.1V

A high-quality reference voltage wi th the appropriate drive

strength is essential for achieving the b est p erformance f rom

the ADS1271. Noise and drift on the reference degrade

overall system performance. See the Application

Information section for example reference circuits.

CLOCK INPUT (CLK)

The ADS1271 requires an external clock signal to be

applied to the CLK input pin. As with any high-speed data

converter, a high-quality, low-jitter clock is essential for

optimum performance. Crystal clock oscillators are the

recommended clock source. Make sure to avoid excess

ringing on the clock input; keeping the clock trace as short

as possible using a 47Ω series resistor will help.

The ratio between the clock frequency and output data rate

is a function of the mode and format. Table 3 shows the

ratios when the SPI format is selected. Also included in this

table is the typical CLK frequency and the corresponding

data rate. When High-Speed mode is used, each

conversion takes 256 CLK periods. When

High-Resolution or Low-Power modes are selected, the

conversions take 512 CLK periods.

Table 4 shows the ratios when the Frame-Sync format is

selected. When using the Frame-Sync format in either

High-Resolution or Low-Power mode, the f

CLK/fDATA

can be 256 or 512. The ADS1271 automatically detects

which ratio is being used. Using a ratio of 512 allows the

CLK frequency to be reduced by a factor of two while

maintaining the same data rate. The output data rate

scales with the clock frequency. See the Serial Interface

section for more details on the Frame-Sync operation.

ratio

MODE SELECTION f

High-Resolution 512 27 " 52,734

MODE SELECTION f

16

Table 3. Clock Ratios for SPI Format

CLK/fDATA

High-Speed 256 27 " 105,469

Low-Power 512 27 " 52,734

TYPICAL f

(MHz) " CORRESPONDING DA TA RATE (SPS)

CLK

Table 4. Clock Ratios for Frame-Sync Format

CLK/fFRAME

High-Speed 256 27 " 105,469

256 13.5 " 52,734

512 27 " 52,734

256 13.5 " 52,734

512 27 " 52,734

TYPICAL f

(MHz) " CORRESPONDING DA TA RATE (SPS)

CLK

www.ti.com

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

MODE SELECTION (MODE)

The ADS1271 supports three modes of operation:

High-Speed, High-Resolution, and Low-Power. The mode

selection is determined by the status of the digital input

MODE pin, as shown in Table 5. A high impedance, or

floating, condition allows the MODE pin to support a third

state. The ADS1271 constantly monitors the status of the

MODE pin during operation and responds to a change in

status after 12,288 CLK periods. When floating the MODE

pin, keep the total capacitance on the pin less than 100pF

and the resistive loading greater than 10MΩ to ensure

proper operation. Changing the mode clears the internal

offset calibration value. If onboard offset calibration is

being used, be sure to recalibrate after a mode change.

When daisy-chaining multiple ADS1271s together and

operating in High-Resolution mode (MODE pin floating), the

MODE pin of e ach d evice m ust be isolated from o ne another;

this ensures p roper d evice operation. T he MODE p ins can b e

tied together for High-Speed and Low-Power modes.

Table 5. Mode Selection

MODE PIN ST ATUS MODE SELECTION

Logic Low (DGND) High-Speed

(1)

Floating

Logic High (DVDD) Low-Power

(1)

Load on MODE: C < 100pF, R > 10MΩ

High-Resolution

When using the SPI format, DRDY is held high after a

mode change occurs until settled (or valid) data is ready,

as shown in Figure 43.

In Frame-Sync format, the DOUT pin is held low after a

mode change occurs until settled data is ready, as shown

in Figure 43. Data can be read from the device to detect

when DOUT changes to logic 1, indicating valid data.

FORMAT SELECTION (FORMAT)

To help connect easily to either microcontrollers or DSPs,

the ADS1271 supports two formats for the serial interface:

an SPI-compatible interface and a Frame-Sync interface.

The format is selected by the FORMAT pin, as shown in

Table 6. It is recommended that the FORMAT pin be

directly tied to the appropriate voltage. If the status of this

pin changes, perform a Sync operation afterwards to

ensure proper operation.

Table 6. Format Selection

FORMAT PIN STATUS SERIAL INTERFACE FORMAT

Logic Low (DGND) SPI

Logic High (DVDD) Frame-Sync

SPI

Format

Frame−Sync

Format

SYMBOL

MODE

Pin

CLK

ADS1271

Mode

DRDY

DOUT

t

MD

t

NDR

High−Speed

t

MD

Time to register MODE changes

Time for new data to be ready

Figure 43. Mode Change Timing

MIN TYP MAX UNITSDESCRIPTION

12,288

Low−Power

t

NDR

Low−Power Mode

ValidData Ready

t

NDR

Low−Power Mode

ValidDataonDOUT

128

CLK periods

Conversions

)

(1/f

DATA

17

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

www.ti.com

SYNCHRONIZATION

The SYNC/PDWN pin has two functions. When pulsed, it

synchronizes the start of conversions and, if held low for

more than 219 CLK cycles (t

Power-Down mode. See the Power-Down and Offset

Calibration section for more details.

The ADS1271 can be synchronized by taking

SYNC

/PDWN low. This stops the conversion process and

resets the internal counters used by the digital filter. Return

SYNC

/PDWN high on the rising edge of CLK to begin the

conversion process. Synchronization allows the

conversions to be aligned with an external event; for

example, the changing of an external multiplexer on the

analog inputs. It can also be used to synchronize the

conversions of multiple ADS1271s.

), places the ADS1271 in

SYN

CLK

t

SYNC/PDWN

DRDY

SYN

••••••

In the SPI format, DRDY goes high as soon as

/PDWN is taken low, as shown in Figure 44. After

SYNC

SYNC

/PDWN is returned high, DRDY stays high while the

digital filter is settling. Once valid data is ready for retrieval,

DRDY

goes low.

In the Frame-Sync format, DOUT goes low as soon as

SYNC

/PDWN is taken low, as shown in Figure 45. After

SYNC

/PDWN is returned high, DOUT stays low while the

digital filter is settling. Once valid data is ready for retrieval,

DOUT begins to output valid data. The device detects the

state of the SYNC

synchronizing multiple devices, set the SYNC

/PDWN pin on the falling edge. When

/PDWN pin

high on the rising edge of SCLK to ensure all devices are

restarted on the same S C L K p e r i o d . I t is recommended to

leave FSYNC and SCLK running during a

synchronization.

t

NDR

SYMBOL

t

SYN

t

NDR

SYMBOL

t

SYN

t

NDR

MIN TYP MAX UNITSDESCRIPTION

Synchronize pulse width

Time for new data to be ready

1 CLK periods

128

Figure 44. Synchronization Timing for SPI format

CLK

SYNC/PDWN

FSYNC

DOUT

Synchronize pulse width

Time for new data to be ready

••••••

t

SYN

t

NDR

MIN TYP MAX UNITSDESCRIPTION

1 CLK periods

128

18

2

Valid Data

18

2

129

Conversions

)

(1/f

DATA

Conversions

)

(1/f

DATA

18

Figure 45. Synchronization Timing for Frame-Sync Format

www.ti.com

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

POWER-DOWN AND OFFSET CALIBRATION

In addition to controlling synchronization, the

SYNC

/PDWN pin also serves as the control for

Power-Down mode and offset calibration. To enter this

mode, hold the SYNC/PDWN pin low for at least 219 CLK

periods. While in Power-Down mode, both the analog and

digital circuitry are completely deactivated. The digital

inputs are internally disabled so that is not necessary to

shut down CLK and SCLK. To exit Power-Down mode,

return SYNC

The ADS1271 uses a chopper-stabilized modulator to

provide inherently very low offset drift. To further minimize

offset, the ADS1271 automatically performs an offset

self-calibration when exiting Power-Down mode. When

power down completes, the offset self-calibration begins

with the inputs AINP and AINN automatically

disconnected from the signal source and internally shorted

together. There is no need to modify the signal source

applied to the analog inputs during this calibration.

/PDWN high on the rising edge of CLK.

CLK

t

SYNC/PDWN

DRDY

PDWN

It is critical for the reference voltage to be stable when

exiting Power-Down mode; otherwise, the calibration will

be corrupted.

The offset self- calib r at ion on ly removes offset errors internal

to the device, not offset errors due to external sources.

NOTE: When an offset self-calibration is performed, the

resulting offset value will vary each time within the

peak-to-peak noise range of the converter. In High-Speed

mode, this is typically 178 LSBs.

The offset calibration value is cleared whenever the device

mode is changed (for example, from High-Speed mode to

High-Resolution mode).

When using the SPI format, DRDY

will stay high after

exiting Power-Down mode while the digital filter settles, as

shown in Figure 46.

When using the Frame-Sync format, DOUT will stay low

after exiting Power-Down mode while the digital filter

settles, as shown in Figure 47.

••••••

t

OFS

Post−Calibration

Data Ready

Status

Converting Sync Power Down Converting

SYMBOL

t

SYNC/PDWN

PDWN pulse width to enter Power−Down mode

t

Time for offset calibrationand filtersettling

OFS

Figure 46. Power-Down Timing for SPI format

CLK

t

SYNC/PDWN

FSYNC

DOUT

Status

SYMBOL

t

PDWN

t

OFS

Converting Sync Power Down Converting

SYNC/PDWN

Time for offset calibration and filter settling

PDWN

pulse width to enter Power−Down mode

Offset Cal and Filter Settling

MIN TYP MAX UNITSDESCRIPTION

19

2

256

••••••

t

OFS

Offset Cal and Filter Settling

MIN TYP MAX UNITSDESCRIPTION

19

2

CLK periods

Conversions

)

(1/f

DATA

Post−Calibration Data

CLK periods

Conversions

257256

(1/f

DATA

)

Figure 47. Power-Down Timing for Frame-Sync Format

19

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

www.ti.com

POWER-UP SEQUENCE

The analog and digital supplies should be applied before

any analog or digital input is driven. The power supplies

may be sequenced in any order. Once the supplies and the

voltage reference inputs have stabilized, data can be read

from the device.

FREQUENCY RESPONSE

The digital f ilter s ets t he o verall f requency r esponse. T he f ilter

uses a multi-stage FIR topology to provide linear phase with

minimal passband ripple a nd h igh stopband attenuation. T he

oversampling ratio of the digital filter (that is, the ratio of the

modulator sampling to the output data rate: f

MOD/fDATA

function of the selected mode, as shown in Table 7. f

CLK/2 or CLK/4, depending on the mode.

Table 7. Oversampling Ratio versus Mode

MODE OVERSAMPLING RATIO (f

High-Speed 64

High-Resolution 128

Low-Power 64

MOD/fDATA

High-Speed and Low-Power Modes

The digital filter configuration is the same in both

High-Speed and Low-Power modes with the oversampling

ratio set to 64. Figure 48 shows the frequency response in

High-Speed and Low-Power modes

normalized to f

Figure 49 shows the passband ripple. The transition from

passband to stop band is illustrated in Figure 50. The

overall frequency response repeats at 64x multiples of the

modulator frequency f

, as shown in Figure 51. These

MOD

image frequencies, if present in the signal and not

externally filtered, will fold back (or alias) into the

passband, causing errors. However, with such a wide

stopband, only a simple low-order, antialias filter is

typically required in front of the ADS1271 inputs to limit

out-of-band noise. See Table 8 for more detail.

0

−

20

−

40

−

60

−

80

Amplitude (dB)

−

100

−

120

−

140

0 0.2 0.6 0.8 1.0

Normalized Input Frequency (f

0.4

IN/fDATA

)

Figure 48. Frequency Response for High-Speed

and Low-Power Modes

) is a

MOD

)

DATA

is

0.02

0

−

0.02

−

0.04

−

Amplitude (dB)

0.06

−

0.08

−

0.10

0 0.1 0.3 0.4 0.5 0.6

0.2

Normalized Input Frequency (f

IN/fDATA

)

Figure 49. Passband Response for High-Speed

and Low-Power Modes

0

−

1

−

2

−

3

−

4

−

5

−

6

Amplitude (dB)

−

7

.

−

8

−

9

−

10

0.45 0.47 0.49 0.51 0.53 0.55

Normalized Input Frequency (f

IN/fDATA

)

Figure 50. Transition Band Response for

High-Speed and Low-Power Modes

20

0

−

20

−

40

−

60

−

80

Gain (dB)

−

100

−

120

−

140

−

160

016324864

Input Frequency (f

Figure 51. Frequency Response Out to f

High-Speed and Low-Power Modes

IN/fDATA

)

for

MOD

20

www.ti.com

ANTIALIAS

High-Resolution Mode

The oversampling ratio is 128 in High-Resolution mode.

Figure 52 shows the frequency response in

High-Resolution mode normalized to f

. Figure 53

DATA

shows the passband ripple, and the transition from

passband to stop band is illustrated in Figure 54. The

overall frequency response repeats at multiples of the

modulator frequency f

, (128 × f

MOD

), as shown in

DATA

Figure 55. With such an extremely wide stop band, only a

simple antialias filter is typically required in front of the

ADS1271 inputs to limit out-of-band noise. See T able 8 for

more detail.

0

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

0

−

1

−

2

−

3

−

4

−

5

−

6

Amplitude (dB)

−

7

−

8

−

9

−

10

0.45 0.47 0.49 0.51 0.53 0.55

Normalized Input Frequency (f

IN/fDATA

)

−

20

−

40

−

60

−

80

Amplitude (dB)

−

100

−

120

−

140

00.25 0.751

Normalized Input Frequency (f

0.50

IN/fDATA

)

Figure 52. Frequency Response for

High-Resolution Mode

0.02

0

−

0.02

−

0.04

Figure 54. Transition Band Response for

High-Resolution Mode

20

0

−

20

−

40

−

60

−

80

Gain (dB)

−

100

−

120

−

140

−

160

0 32 64 96 128

Normalized Input Frequency (fIN/f

Figure 55. Frequency Response out to f

High-Resolution Mode

DATA

)

MOD

Table 8. Antialias Filter Order Image Rejection

for

−

Amplitude (dB)

0.06

−

0.08

−

0.10

0 0.1 0.3 0.4 0.5 0.6

0.2

Normalized Input Frequency (f

Figure 53. Passband Response for

High-Resolution Mode

IN/fDATA

IMAGE REJECTION (dB)

(f

FIL TER ORDER

at f

−3dB

HS, LP HR

DATA

)

1 39 45

)

2 75 87

3 111 129

21

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

www.ti.com

PHASE RESPONSE

The ADS1271 incorporates a multiple stage, linear phase

digital filter. Linear phase filters exhibit constant delay time

versus input frequency (constant group delay). This

means the time delay from any instant of the input signal

to the same instant of the output data is constant and is

independent of input signal frequency. This behavior

results in essentially zero phase errors when analyzing

multi-tone signals.

SETTLING TIME

As with frequency and phase response, the digital filter

also determines settling time. Figure 56 shows the output

settling behavior after a step change on the analog inputs

normalized to conversion periods. The X axis is given in

units of conversion. Note that after the step change on the

input occurs, the output data changes very little prior to 30

conversion periods. The output data is fully settled after 76

conversion periods for High-Speed and Low-Power

modes, and 78 conversions for High-Resolution mode.

100

% Settling

Initial Value

0

Final Value

Fully Settled Data

at 76 Conversions

(78 Conversions for

High−Resolution mode)

Table 9. Ideal Output Code versus Input Signal

INPUT SIGNAL V

(AINP − AINN)

w +V

+V

223* 1

−V

223* 1

v −V

REF

(1)

Excludes effects of noise, INL, offset and gain errors.

IN

REF

REF

0 000000h

REF

23

2

ǒ

223* 1

Ǔ

IDEAL OUTPUT CODE

7FFFFFh

000001h

FFFFFFh

800000h

(1)

SERIAL INTERFACE

Data is retrieved from the ADS1271 using the serial

interface. To provide easy connection to either

microcontrollers or DSPs, two formats are available for the

interface: SPI and Frame-Sync. The FORMA T pin selects

the interface. The same pins are used for both interfaces

(SCLK, DRDY

/FSYNC, DOUT and DIN), though their

respective functionality depends on the particular interface

selected.

SPI SERIAL INTERFACE

The SPI-compatible format is a simple read-only interface.

Data ready for retrieval is indicated by the DRDY

and is shifted out on the falling edge of SCLK, MSB first.

The interface can be daisy-chained using the DIN input

when using multiple ADS1271s. See the Daisy-Chaining

section for more information.

output

02010 4030 6050 8070

Conversions (1/f

DATA

)

Figure 56. Settling Time for All Power Modes

DATA FORMAT

The ADS1271 outputs 24 bits of data in two’s complement

format.

A positive full-scale input produces an output code of

7FFFFFh, and the negative full-scale input produces an

output code of 800000h. The output clips at these codes

for signals exceeding full-scale. Table 9 summarizes the

ideal output codes for different input signals.

22

SCLK (SPI Format)

The serial clock (SCLK) features a Schmitt-triggered input

and shifts out data on DOUT on the falling edge. It also

shifts in data on the falling edge on DIN when this pin is

being used for daisy-chaining. The device shifts data out

on the falling edge and the user shifts this data in on the

rising edge. Even though the SCLK input has hysteresis,

it is recommended to keep SCLK as clean as possible to

prevent glitches from accidentally shifting the data. SCLK

should be held low after data retrieval. SCLK may be run

as fast as the CLK frequency. SCLK may be either in

free-running or stop-clock operation between

conversions. To maximize the converter performance, the

ratio of CLK to SCLK should be held to:

CLK

SCLK +

(

N

2

N + 0, 1,2AAA

)

.

www.ti.com

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

DRDY/FSYNC

In the SPI format, this pin functions as the DRDY output.

It goes low when data is ready for retrieval and then returns

high on the rising edge of the first subsequent SCLK. If

data is not retrieved (that is, SCLK is held low), DRDY

will

pulse high just before the next conversion data is ready , a s

shown in Figure 57. The new data is loaded within the

ADS1271 one CLK cycle before DRDY

goes low. All data

must be shifted out before this time to avoid being

overwritten.

1/f

CLK

DRDY

SCLK

1/f

DATA

Figure 57. DRDY Timing with No Readback

DOUT

The conversion data is shifted out on DOUT. The MSB

data is valid on DOUT when DRDY

goes low. The

subsequent bits are shifted out with each falling edge of

SCLK. If daisy-chaining, the data shifted in using DIN will

appear on DOUT after all 24 bits have been shifted out.

DIN

This input is used when multiple ADS1271s are to be

daisy-chained together. The DOUT pin of the first device

connects to the DIN pin of the next, etc. It can be used with

either the SPI or Frame-Sync formats. Data is shifted in on

the falling edge of SCLK. When using only one ADS1271,

tie DIN low. See the Daisy-Chaining section for more

information.

being used for daisy-chaining. Even though SCLK has

hysteresis, it is recommended to keep SCLK as clean as

possible to prevent glitches from accidentally shifting the

data. When using Frame-Sync format, SCLK must run

continuously. If it is shut down, the data readback will be

corrupted. Frame-Sync format requires a specific

relationship between SCLK and FSYNC, determined by

the mode shown in Table 10.

Table 10. SCLK Period When Using Frame-Sync

Format

MODE REQUIRED SCLK PERIOD

High-Speed τ

High-Resolution τ

Low-Power τ

FRAME

FRAME

FRAME

/64

/128

/64

DRDY/FSYNC

In Frame-Sync format, this pin is used as the FSYNC input.

The frame-sync input (FSYNC) sets the frame period. The

required FSYNC periods are shown in Table 11. For

High-Speed mode, the FSYNC period must be 256 CLK

periods. For both High-Resolution and Low-Power modes,

the FSYNC period can be either 512 or 256 CLK periods;

the ADS1271 will automatically detect which is being

used. If the FSYNC period is not the proper value, data

readback will be corrupted. It is recommended that

FSYNC be aligned with the falling edge of SCLK.

Table 11. FSYNC Period

MODE REQUIRED FSYNC PERIOD

High-Speed 256 CLK Periods

High-Resolution 256 or 512 CLK periods

Low-Power 256 or 512 CLK periods

FRAME-SYNC SERIAL INTERFACE

Frame-Sync format is similar to the interface often used on

audio ADCs. It operates in slave fashion—the user must

supply framing signal FSYNC (similar to the left/right clock

on stereo audio ADCs) and the serial clock SCLK (similar

to the bit clock on audio ADCs). The data is output MSB

first or left-justified. When using Frame-Sync format, the

CLK, FSYNC and SCLK inputs must be synchronized

together, as described in the following sub-sections.

SCLK (Frame-Sync Format)

The serial clock (SCLK) features a Schmitt-triggered input

and shifts out data on DOUT on the falling edge. It also

shifts in data on the falling edge on DIN when this pin is

DOUT

The conversion data is shifted out on DOUT. The MSB

data becomes valid on DOUT on the SCLK rising edge

prior to FSYNC going high. The subsequent bits are

shifted out with each falling edge of SCLK. If

daisy-chaining, the data shifted in using DIN will appear on

DOUT after all 24 bits have been shifted out.

DIN

This input is used when multiple ADS1271s are to be

daisy-chained together. It can be used with either SPI or

Frame-Sync formats. Data is shifted in on the falling edge

of SCLK. When using only one ADS1271, tie DIN low.See

the Daisy-Chaining section for more information.

23

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

www.ti.com

DAISY-CHAINING

Multiple ADS1271s can be daisy-chained together to

simplify the serial interface connections. The DOUT of one

ADS1271 is connected to the DIN of the next ADS1271.

The first DOUT provides the output data and the last DIN

in the chain is connected to ground. A common SCLK is

used for all the devices in the daisy chain. Figure 58 shows

an example of a daisy chain with four ADS1271s.

Figure 59 shows the timing diagram when reading back in

the SPI format. It takes 96 SCLKs to shift out all the data.

In SPI format, it is recommended to tie all the

SYNC

/PDWN inputs together, which forces

synchronization of all the devices. It is only necessary to

monitor the DRDY output of one device when multiple

devices are configured this way.

In Frame-Sync format, all of the devices are driven to

synchronization by the FSYNC and SCLK inputs. However,

to ensure synchronization to the same f

recommended to tie all SYNC

The device clocks the SYNC

. To ensure exact synchronization, the SYNC/PDWN

of f

CLK

/PDWN inputs together.

/PDWN pin on the falling edge

pin should transition on the rising edge of f

cycle, it is

CLK

CLK

Since DOUT and DIN are both shifted on the falling edge

of SCLK, the propagation delay on DOUT creates the

setup time on DIN. Minimize the skew in SCLK to avoid

timing violations. See Mode Selection section for MODE

pin use when daisy-chaining.

The SPI format offers the most flexibility when

daisy-chaining because there is more freedom in setting

the SCLK frequency. The maximum number of ADS1271s

that can be daisy-chained is determined by dividing the

conversion time (1/f

all 24 bits (24 × 1/f

) by the time needed to read back

DATA

).

SCLK

Consider the case where:

f

= 27MHz

CLK

mode = High-Resolution (52,734SPS)

format = SPI

f

= 27MHz

SCLK

The maximum length of the daisy-chain is:

27MHz/(24 × 52,734SPS) = 21.3

Rounding down gives 21 as the maximum number of

ADS1271s that can be daisy-chained.

Daisy-chaining also works in Frame-Sync format, but the

maximum number of devices that can be daisy-chained is

less than when using the SPI format. The ratio between the

frame period and SCLK period is fixed, as shown in

Table 10. Using these values, the maximum number of

devices is two for High-Speed and Low-Power modes, and

four for High-Resolution mode.

24

SYNC

SCLK

ADS1271

SYNC

DIN

SCLK

4

DOUT

ADS1271

SYNC

DIN

SCLK

3

DOUT

ADS1271

SYNC

DIN

SCLK

2

DOUT

ADS1271

SYNC

DIN

SCLK

1

DRDY

DOUT

Figure 58. Example of SPI-Format, Daisy-Chain Connection for Multiple ADS1271s

DRDY

SCLK 1

DOUT

ADS1271

Bit 23 (MSB)

1

24 25 73 96

ADS1271

Bit 0 (LSB)

1

Bit 23 (MSB)

ADS1271

2

ADS1271

Bit 2 3 (MSB)

4

ADS1271

Bit 0(LSB)

4

Figure 59. Timing Diagram for Example in Figure 58 (SPI Format)

www.ti.com

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

APPLICATION INFORMATION

To obtain the specified performance from the ADS1271,

the following layout and component guidelines should be

considered.

1. Power Supplies: The device requires two power

supplies for operation: DVDD and A VDD. The allowed

range for DVDD is 1.65V to 3.6V, and AVDD is

restricted to 4.75V to 5.25V. Best performance is

achieved when DVDD = 1.8V. For both supplies, use

a 10µF tantalum capacitor, bypassed with a 0.1µF

ceramic capacitor, placed close to the device pins.

Alternatively, a single 10µF ceramic capacitor can be

used. The supplies should be relatively free of noise

and should not be shared with devices that produce

voltage spikes (such as relays, LED display drivers,

etc.). If a switching power supply source is used, the

voltage ripple should be low (< 2mV). The power

supplies may be sequenced in any order.

2. Ground Plane: A single ground plane connecting both

AGND and DGND pins can be used. If separate digital

and analog grounds are used, connect the grounds

together at the converter.

3. Digital Inputs: It is recommended to source terminate

the digital inputs to the device with 50Ω series

resistors. The resistors should be placed close to the

driving end of digital source (oscillator, logic gates,

DSP, etc.) This helps to reduce ringing on the digital

lines, which may lead to degraded ADC performance.

4. Analog/Digital Circuits: Place analog circuitry (input

buffer, reference) and associated tracks together,

keeping them away from digital circuitry (DSP,

microcontroller, logic). Avoid crossing digital tracks

across analog tracks to reduce noise coupling and

crosstalk.

5. Reference Inputs: It is recommended to use a

minimum 10µF tantalum with a 0.1µF ceramic

capacitor directly across the reference inputs, REFP

and REFN. The reference input should be driven by a

low-impedance source. For best performance, the

reference should have less than 3µV

broadband

RMS

noise. For references with noise higher than this,

external reference filtering may be necessary.

6. Analog Inputs: The analog input pins must be driven

differentially to achieve specified performance. A true

differential driver or transformer (AC applications) can

be used for this purpose. Route the analog inputs

tracks (AINP, AINN) as a pair from the buffer to the

converter using short, direct tracks and away from

digital tracks.

A 1nF to 10nF capacitor should be used directly

across the analog input pins, AINP and AINN. A low-k

dielectric (such as COG or film type) should be used to

maintain low THD. Capacitors from each analog input

to ground should be used. They should be no larger

than 1/10 the size of the difference capacitor (typically

100pF) to preserve the AC common-mode

performance.

7. Component Placement: Place the power supply,

analog input, and reference input bypass capacitors

as close as possible to the device pins. This is

particularly important for the small-value ceramic

capacitors. Surface-mount components are

recommended to avoid the higher inductance of

leaded components.

Figure 60 to Figure 62 illustrate basic connections and

interfaces that can be used with the ADS1271.

25

SBAS306A − NOVEMBER 2004 − REVISED DECEMBER 2004

www.ti.com

Ω

1k

10nF

+5V

Differential

Inputs

+5V

Tie to

Either

DVDD

or GND

100pF

0.1µF

50

50

100pF

Ω

Ω

+

1nF

10µF

1

2

3

4

5

6

7

8

ADS1271

AINP

AINN

AGND

AVDD

MODE

FORMAT

SYNC/

PDWN

DIN

0.1µF

OPA350

1.8V to 3.3V

Ω

50

(1)

27MHz

VREFP

VREFN

DGND

DVDD

CLK

16

15

14

13

+

12

+

10µF0.1µF

10µF

100

0.1µF

Ω

Source

Ω

SCLK

DRDY/

FSYNC

DOUT

11

10

9

50

Ω

50

Ω

50

Figure 60. Basic Connection Drawing

100

Clock

+5V

Ω

Ω

1k

0.1µF

REF3125

100µF

0.1µF

NOTE: (1) 1.8V recommended.

Ω

1k

Ω

1k

1000pF

(1)

+15V

V

REF

V

V

IN

OCM

OPA1632

0.1µF

(1)

−

15V

49.9

49.9

Ω

AINP

Ω

AINN

1000pF

Ω

1k

Ω

1k

NOTE: (1) Bypass with 10µF and 0.1µF capacitors.

Figure 61. Basic Differential Signal Interface

Ω

V

1k

IN

10k

Ω

1000pF

(1)

+15V

V

REF

V

OCM

OPA1632

0.1µF

(1)

−

15V

1000pF

Ω

1k

10k

Ω

49.9

AINP

Ω

49.9

AINN

=10×V

V

ODIFF

V

OCOMM=VREF

Ω

NOTE: (1) Bypass with 10µFand0.1µF capacitors.

Figure 62. Basic Single-Ended Signal Interface

IN

26

PACKAGE OPTION ADDENDUM

www.ti.com

27-Dec-2004

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

ADS1271IPW ACTIVE TSSOP PW 16 94 None CU Level-2-240C-1 YEAR

ADS1271IPWR ACTIVE TSSOP PW 16 2500 None CU Level-2-240C-1 YEAR

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - May not be currently available - please check http://www.ti.com/productcontent for the latest availability information and additional

product content details.

None: Not yet available Lead (Pb-Free).

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Green (RoHS & no Sb/Br): TI defines "Green" to mean "Pb-Free" and in addition, uses package materials that do not contain halogens,

including bromine (Br) or antimony (Sb) above 0.1% of total product weight.

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDECindustry standard classifications, and peak solder

temperature.

(2)

Lead/Ball Finish MSL Peak Temp

(3)

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

Addendum-Page 1

MECHANICAL DATA

MTSS001C – JANUARY 1995 – REVISED FEBRUARY 1999

PW (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PINS SHOWN

0,65

1,20 MAX

14

0,30

0,19

8

4,50

4,30

PINS **

7

Seating Plane

0,15

0,05

8

1

A

DIM

6,60

6,20

14

0,10

M

0,10

0,15 NOM

0°–8°

2016

Gage Plane

24

0,25

0,75

0,50

28

A MAX

A MIN

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0,15.

D. Falls within JEDEC MO-153

3,10

2,90

5,10

4,90

5,10

4,90

6,60

6,40

7,90

7,70

9,80

9,60

4040064/F 01/97

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio