www.ti.com

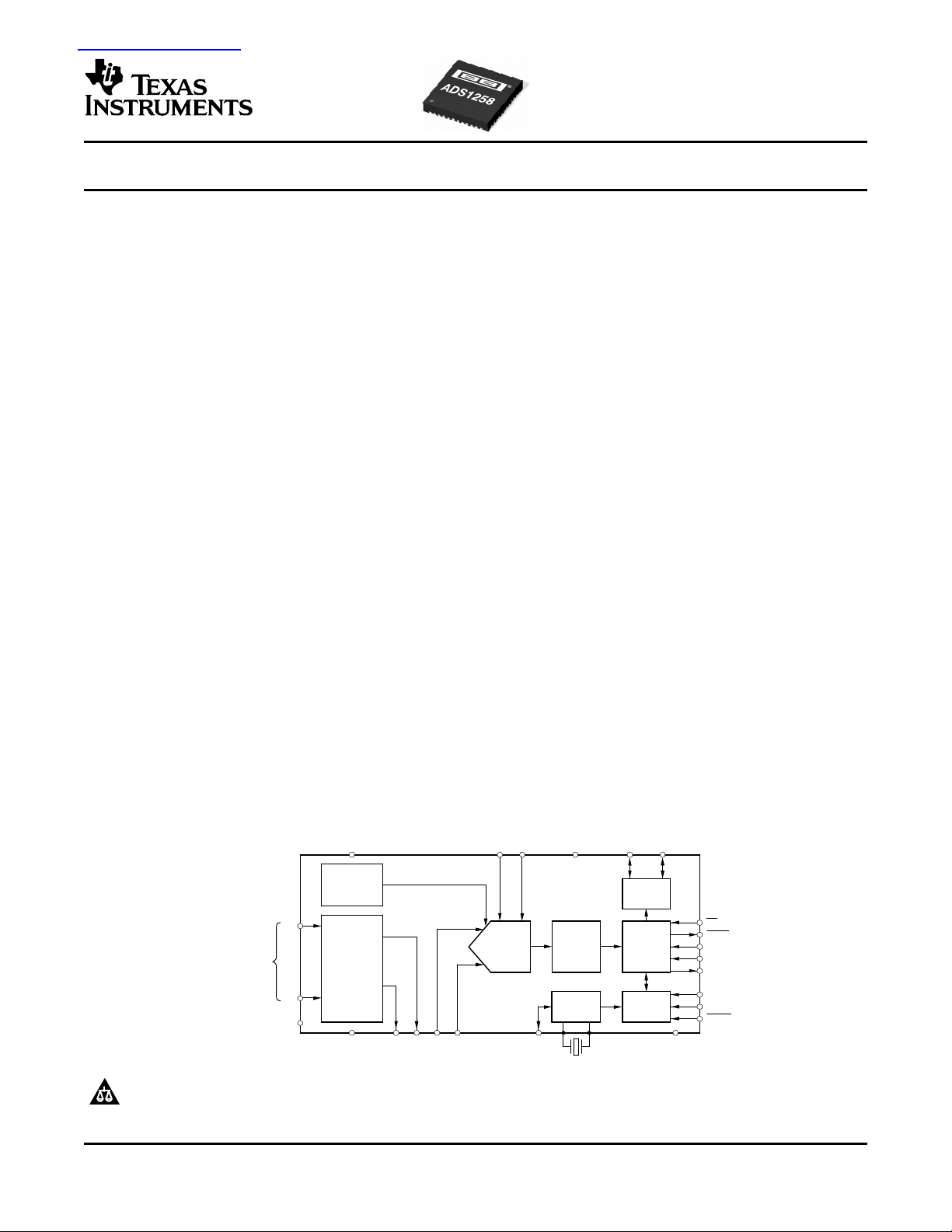

24−Bit

ADC

Digital

Filter

Internal

Monitoring

16:1

Analog

Input

MUX

1

16

AINCOM

…

ADC

In

Extclk

In/Out

AVSS DGND

AVDD DVDD

MUX

Out

SPI

Interface

CS

DRDY

SCLK

DIN

DOU T

ControlOscillator

GPIO

START

RESET

PWDN

GPIO[7:0]V

REF

ADS1258

Analog Inputs

查询ADS1258供应商查询ADS1258供应商

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

16-Channel, 24-Bit Analog-to-Digital Converter

FEATURES DESCRIPTION

• 24 Bits, No Missing Codes

• Fixed-Channel or Automatic Channel Scan

• Fixed-Channel Data Rate: 125kSPS

• Auto-Scan Data Rate: 23.7kSPS

• Single-Conversion Settled Data multiplexer accepts combinations of eight differential

• 16 Single-Ended or 8 Differential Inputs

• Unipolar (+5V) or Bipolar ( ± 2.5V) Operation

• Low Noise: 2.8µV

at 1.8kSPS

RMS

• 0.0003% Integral Nonlinearity

• DC Stability (typical): The differential output of the multiplexer is accessible

0.02µV/ ° C Offset Drift, 0.4ppm/ ° C Gain Drift

• Open-Sensor Detection

• Conversion Control (Pin and Commands)

• Multiplexer Output for External Signal

Conditioning

• On-Chip Temperature, Reference, Offset,

Gain, and Supply Voltage Readback

• 42mW Power Dissipation

• Standby, Sleep, and Power-Down Modes

• 8 General-Purpose Inputs/Outputs (GPIO)

• 32.768kHz Crystal Oscillator or External Clock

The ADS1258 is a 16-channel (multiplexed),

low-noise, 24-bit, delta-sigma ( ∆ Σ ) analog-to-digital

converter (ADC) that provides single-cycle settled

data at channel scan rates from 1.8k to 23.7k

samples per second (SPS). A flexible input

or 16 single-ended inputs with a full-scale differential

range of 5V or true bipolar range of ± 2.5V when

operating with a 5V reference. The fourth-order

delta-sigma modulator is followed by a fifth-order sinc

digital filter optimized for low-noise performance.

to allow signal conditioning prior to the input of the

ADC. Internal system monitor registers provide

supply voltage, temperature, reference voltage, gain,

and offset data.

An onboard PLL generates the system clock from a

32.768kHz crystal, or can be overridden by an

external clock source. A buffered system clock output

(15.7MHz) is provided to drive a microcontroller or

additional converters.

Serial digital communication is handled via an

SPI™-compatible interface. A simple command word

structure controls channel configuration, data rates,

digital I/O, monitor functions, etc.

ADS1258

APPLICATIONS

• Medical, Avionics, and Process Control

• Machine and System Monitoring

• Fast Scan Multi-Channel Instrumentation

• Industrial Process Controls

• Test and Measurement Systems

SPI is a trademark of Motorola, Inc.

All trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Programmable sensor bias current sources can be

used to bias sensors or verify sensor integrity.

The ADS1258 operates from a unipolar +5V or

bipolar ± 2.5V analog supply and a digital supply

compatible with interfaces ranging from 2.7V to

5.25V. The ADS1258 is available in a QFN-48

package.

Copyright © 2005, Texas Instruments Incorporated

www.ti.com

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated

circuits be handled with appropriate precautions. Failure to observe proper handling and installation

procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision

integrated circuits may be more susceptible to damage because very small parametric changes could

cause the device not to meet its published specifications.

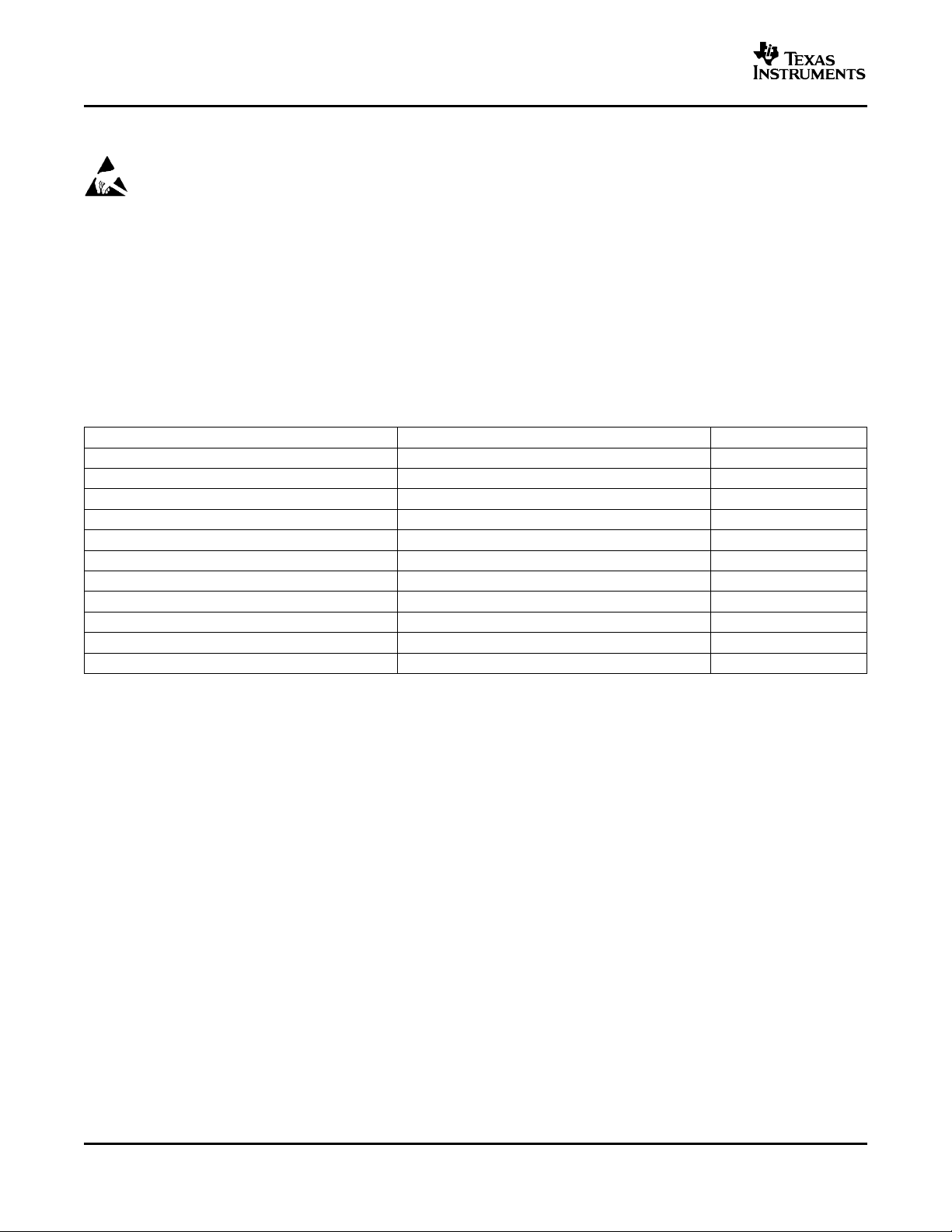

ORDERING INFORMATION

For the most current package and ordering information see the Package Option Addendum at the end of this

document, or see the TI web site at www.ti.com .

ABSOLUTE MAXIMUM RATINGS

Over operating free-air temperature range (unless otherwise noted).

AVDD to AVSS –0.3 to +5.5 V

AVSS to DGND –2.8 to +0.3 V

DVDD to DGND –0.3 to +5.5 V

Input Current 100, Momentary mA

Input Current 10, Continuous mA

Analog Input Voltage AVSS – 0.3 to AVDD + 0.3 V

Digital Input Voltage to DGND –0.3 to DVDD + 0.3 V

Maximum Junction Temperature +150 ° C

Operating Temperature Range –40 to +105 ° C

Storage Temperature Range –60 to +150 ° C

Lead Temperature (soldering, 10s) +300 ° C

(1) Stresses above these ratings may cause permanent damage. Exposure to absolute maximum conditions for extended periods may

degrade device reliability. These are stress ratings only, and functional operation of the device at these or any other conditions beyond

those specified is not implied.

(1)

ADS1258 UNIT

2

www.ti.com

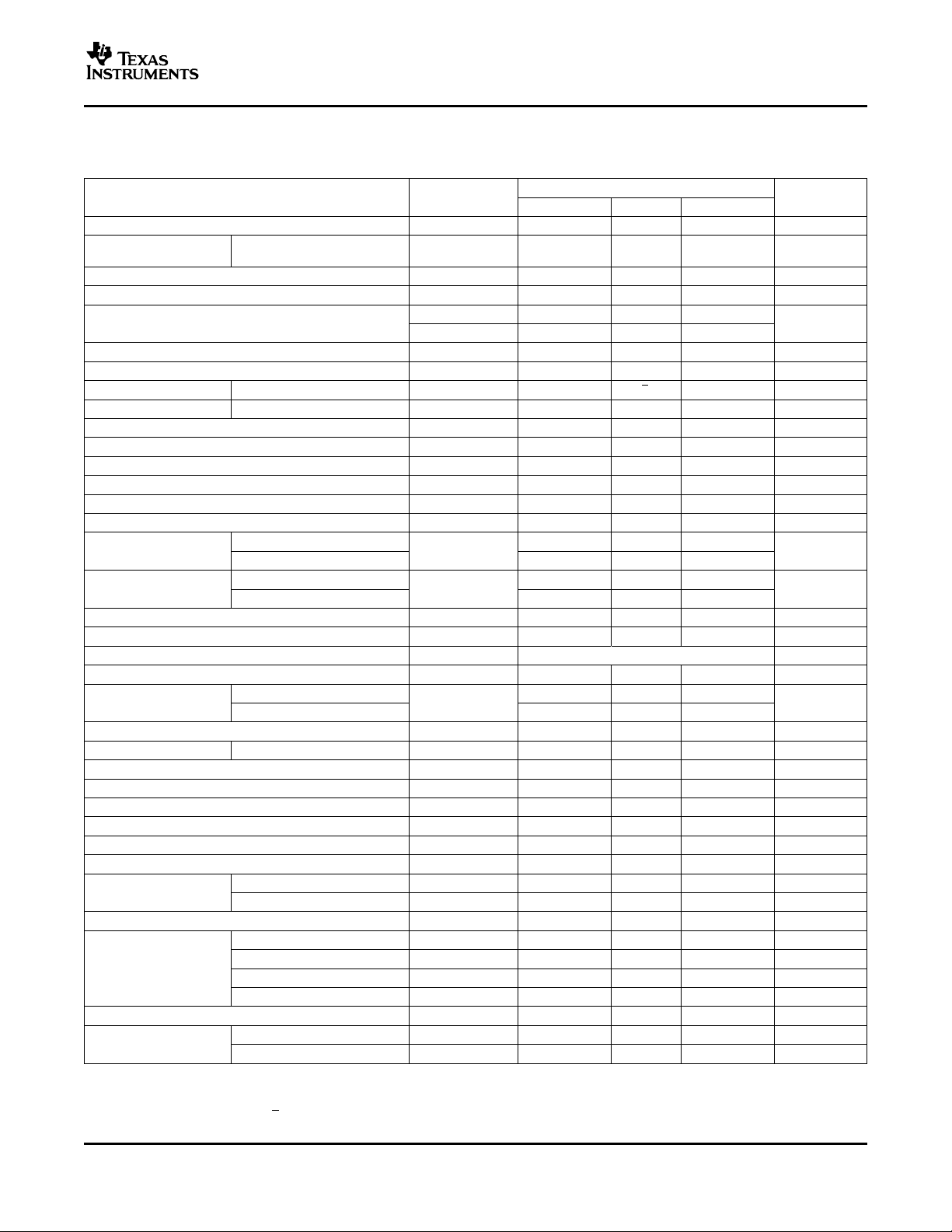

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

ELECTRICAL CHARACTERISTICS

All specifications at TA= –40 ° C to +105 ° C, AVDD = +2.5V, AVSS = –2.5V, DVDD = +3.3V, f

OPA227 buffer between MUX outputs and ADC inputs, V

PARAMETER CONDITIONS MIN TYP MAX UNIT

Analog Multiplexer Inputs

Absolute Input Voltage AVSS – 100mV AVDD + 100mV V

AINCOM with respect to DGND

On-Channel Resistance 80 Ω

Crosstalk fIN= 1kHz –110 dB

Sensor Bias (Current Source) µA

1.5 µ A:24 µ A Ratio Error 1 %

ADC Input

Full-Scale Input Voltage (V

IN

Absolute Input Voltage (ADCINP, ADCINN) AVSS – 100mV AVDD + 100mV V

Differential Input Impedance 65 k Ω

System Performance

Resolution No Missing Codes 24 Bits

Data Rate, Fixed-Channel Mode 1.953 125 kSPS

Data Rate, Auto-Scan Mode 1.805 23.739 kSPS

Integral Nonlinearity (INL)

(1)

Offset Error Shorted Inputs µ V

Offset Drift

(3)

Gain Error 0.1 0.5 %

Gain Drift

(3)

Noise (see Table 4 )

Common-Mode Rejection fCM= 60Hz 90 100 dB

Power-Supply Rejection fPS= 60Hz dB

Voltage Reference Input

Reference Input Voltage (V

REF

Negative Reference Input (VREFN) AVSS – 0.1V VREFP – 0.5 V

Positive Reference Input (VREFP) VREFN + 0.5 AVDD + 0.1V V

Reference Input Impedance 40 k Ω

System Parameters

External Reference Reading Error 1 3 %

Analog Supply Reading Error 1 3 %

Temperature Sensor Voltage TA= +25 ° C 168 mV

Reading

Digital Input/Output

Logic Levels: V

Input Leakage VIN= DVDD, GND 10 µA

Master Clock Input (CLKIO)

AIN0–AIN15,

= ADCINP – ADCINN) ± 1.0 6V

Chopping Off 20

Chopping On 1 10

Chopping Off 0.5

Chopping On 0.02 0.1

AVDD, AVSS 70 85

DVDD 80 95

= VREFP – VREFN) 0.5 4.096 AVDD – AVSS V

Coefficient 394 µ V/ ° C

IH

V

IL

V

OH

V

OL

Frequency 0.1 16 MHz

Duty Cycle 40 60 %

= +4.096V, and VREFN = –2.5V, unless otherwise noted.

REF

ADS1258

SBCS[1:0] = 01 1.5

SBCS[1:0] = 11 24

Differential Input 0.0003 0.0010 % of FSR

Shorted Inputs µ V/ ° C

0.7DVDD DVDD V

DGND 0.3DVDD V

IOH= 2mA 0.8DVDD DVDD V

IOL= 2mA DGND 0.2DVDD V

= 16MHz (external clock),

CLK

REF

0.4 2 ppm/ ° C

ADS1258

V

(2)

(1) Best straight line fit method.

(2) FSR = Full-scale range = 2.1 3V

(3) Ensured by characterization.

.

REF

3

www.ti.com

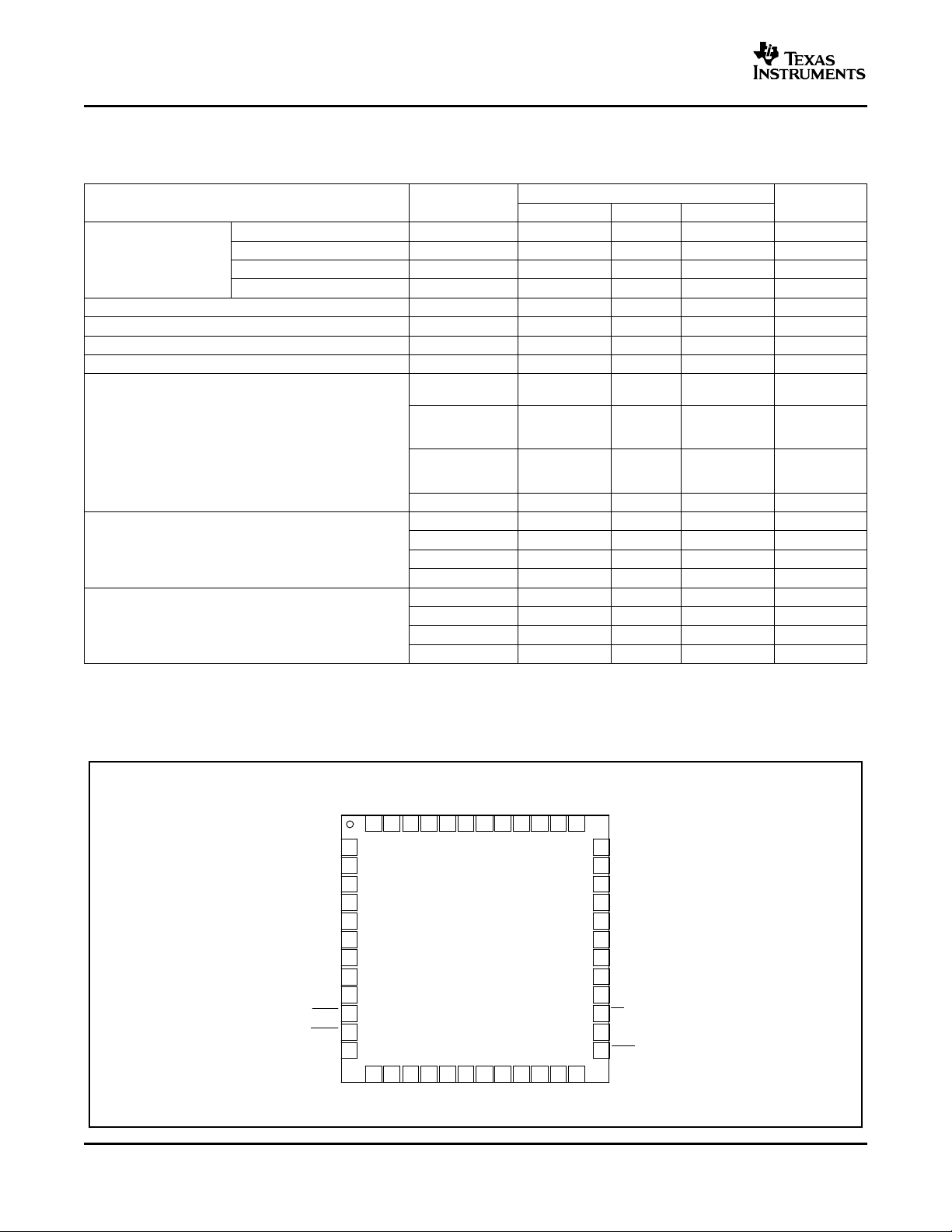

Top View QFN

36

35

34

33

32

31

30

29

28

27

26

25

AIN12

AIN13

AIN14

AIN15

AINCOM

VREFP

VREFN

DGND

DVDD

CS

START

DRDY

AIN4

AIN5

AIN6

AIN7

MUXOUTP

MUXOUTN

ADCINP

ADCINN

AIN8

AIN9

AIN10

AIN11

CLKIO

GPIO0

GPIO1

GPIO2

GPIO3

GPIO4

GPIO5

GPIO6

GPIO7

SCLK

DIN

DOUT

1

2

3

4

5

6

7

8

9

10

11

12

AIN3

AIN2

AIN1

AIN0

AVSS

AVDD

PLLCAP

XTAL1

XTAL2

PWDN

RESET

CLKSEL

48 47 46 45 44 43 42 41 40 39 38

13 14 15 16 17 18 19 20 21 22 233724

ADS1258

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

ELECTRICAL CHARACTERISTICS (continued)

All specifications at TA= –40 ° C to +105 ° C, AVDD = +2.5V, AVSS = –2.5V, DVDD = +3.3V, f

OPA227 buffer between MUX outputs and ADC inputs, V

PARAMETER CONDITIONS MIN TYP MAX UNIT

Crystal Frequency 32.768 kHz

Crystal Oscillator

(see Crystal Oscillator

section)

Start-Up Time (Clock Output Valid) 150 mS

Power Supply

DVDD 2.7 5.25 V

AVSS –2.6 0 V

AVDD AVSS + 4.75 AVSS + 5.25 V

DVDD Supply Current

AVDD, AVSS Supply Current

Power Dissipation

Clock Output Frequency 15.729 MHz

Clock Output Duty Cycle 40 60 %

= +4.096V, and VREFN = –2.5V, unless otherwise noted.

REF

ADS1258

External Clock

Operation

Internal Oscillator

Operation, Clock 0.04 mA

Output Disabled

Internal Oscillator

Operation, Clock 1.4 mA

Output Enabled

Power-Down

(4)

(5)

Converting 8.2 12 mA

Standby 5.6 mA

Sleep 2.1 mA

Power-Down 2 85 µA

Converting 42 62 mW

Standby 29 mW

Sleep 11 mW

Power-Down 14 µ W

= 16MHz (external clock),

CLK

0.25 0.6 mA

1 25 µA

(4) CLKIO load = 20pF.

(5) No clock applied to CLKIO.

PIN CONFIGURATION

4

www.ti.com

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

PIN ASSIGNMENTS

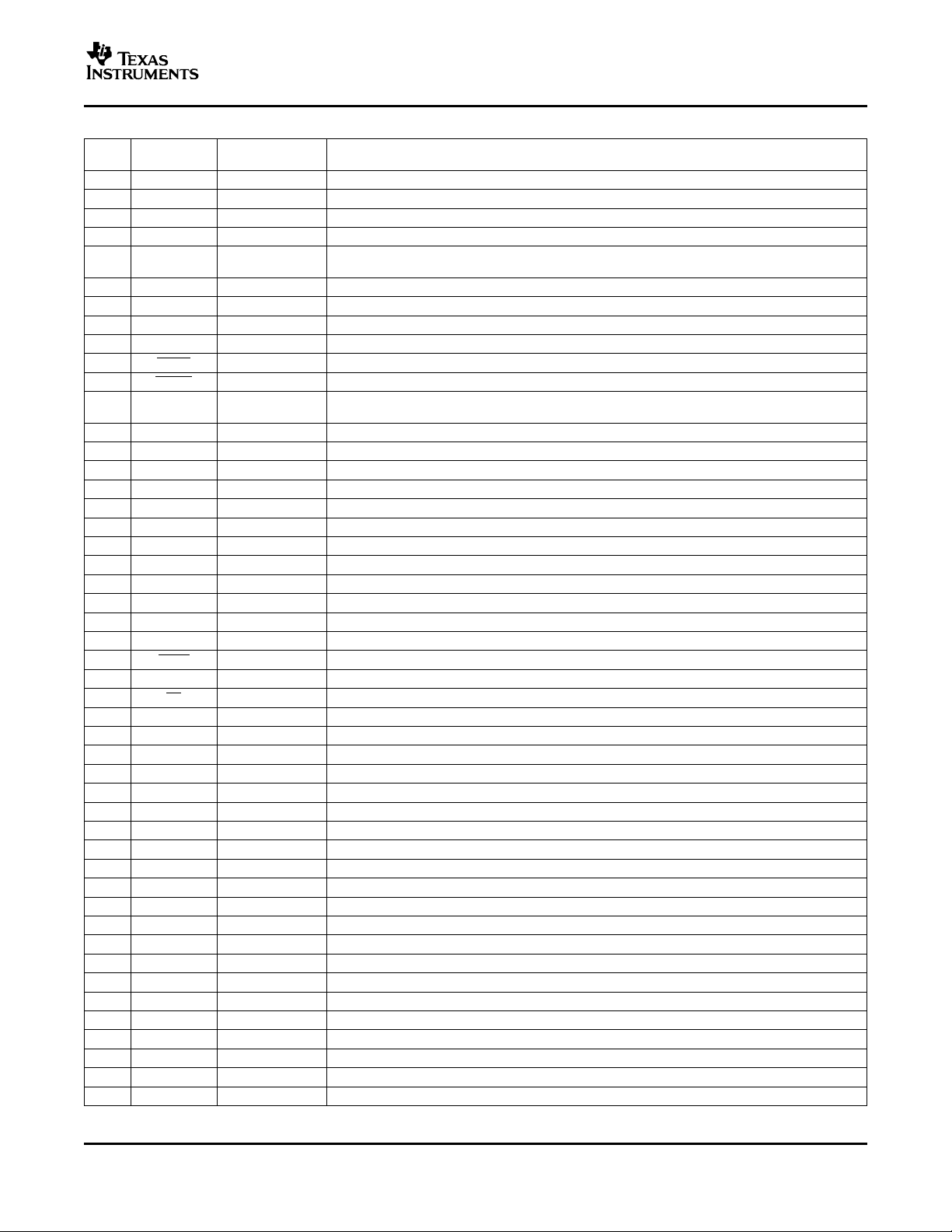

PIN # NAME INPUT/OUTPUT DESCRIPTION

1 AIN3 Analog Input Analog Input 3: Single-Ended Channel 3, Differential Channel 1 (–)

2 AIN2 Analog Input Analog Input 2: Single-Ended Channel 2, Differential Channel 1 (+)

3 AIN1 Analog Input Analog Input 1: Single-Ended Channel 1, Differential Channel 0 (–)

4 AIN0 Analog Input Analog Input 0: Single-Ended Channel 0, Differential Channel 0 (+)

5 AVSS Analog

6 AVDD Analog Positive Analog Power Supply: +5V for unipolar operation, +2.5V for bipolar operation.

7 PLLCAP Analog PLL Bypass Capacitor: Connect 22nF capacitor to AVSS when using crystal oscillator.

8 XTAL1 Analog 32.768kHz Crystal Oscillator Input 1; see Crystal Oscillator section.

9 XTAL2 Analog 32.768kHz Crystal Oscillator Input 2; see Crystal Oscillator section.

10 PWDN Digital Input Power-Down Input: Hold low for minimum of two f

11 RESET Digital Input Reset Input: Hold low for minimum of two f

12 CLKSEL Digital Input

13 CLKIO Digital I/O System Clock Input/Output (See CLKSEL pin.)

14 GPIO0 Digital I/O General-Purpose Digital Input/Output 0

15 GPIO1 Digital I/O General-Purpose Digital Input/Output 1

16 GPIO2 Digital I/O General-Purpose Digital Input/Output 2

17 GPIO3 Digital I/O General-Purpose Digital Input/Output 3

18 GPIO4 Digital I/O General-Purpose Digital Input/Output 4

19 GPIO5 Digital I/O General-Purpose Digital Input/Output 5

20 GPIO6 Digital I/O General-Purpose Digital Input/Output 6

21 GPIO7 Digital I/O General-Purpose Digital Input/Output 7

22 SCLK Digital Input SPI Interface Clock Input: Data clocked in on rising edge, clocked out on falling edge.

23 DIN Digital Input SPI Interface Data Input: Data is input to the device.

24 DOUT Digital Output SPI Interface Data Output: Data is output from the device.

25 DRDY Digital Output Data Ready Output: Active low.

26 START Digital Input Start Conversion Input: Active high.

27 CS Digital Input SPI Interface Chip Select Input: Active low.

28 DVDD Digital Digital Power Supply: 2.7V to 5.25V

29 DGND Digital Digital Ground

30 VREFN Analog Input Reference Input Negative

31 VREFP Analog Input Reference Input Positive

32 AINCOM Analog Input Analog Input Common: Common input pin to all single-ended inputs.

33 AIN15 Analog Input Analog Input 15: Single-Ended Channel 15, Differential Channel 7 (–)

34 AIN14 Analog Input Analog Input 14: Single-Ended Channel 14, Differential Channel 7 (+)

35 AIN13 Analog Input Analog Input 13: Single-Ended Channel 13, Differential Channel 6 (–)

36 AIN12 Analog Input Analog Input 12: Single-Ended Channel 12, Differential Channel 6 (+)

37 AIN11 Analog Input Analog Input 11: Single-Ended Channel 11, Differential Channel 5 (–)

38 AIN10 Analog Input Analog Input 10: Single-Ended Channel 10, Differential Channel 5 (+)

39 AIN9 Analog Input Analog Input 9: Single-Ended Channel 9, Differential Channel 4 (–)

40 AIN8 Analog Input Analog Input 8: Single-Ended Channel 8, Differential Channel 4 (+)

41 ADCINN Analog Input ADC Differential Input (–)

42 ADCINP Analog Input ADC Differential Input (+)

43 MUXOUTN Analog Output Multiplexer Differential Output (–)

44 MUXOUTP Analog Output Multiplexer Differential Output (+)

45 AIN7 Analog Input Analog Input 7: Single-Ended Channel 7, Differential Channel 3 (–)

46 AIN6 Analog Input Analog Input 6 : Single-Ended Channel 6, Differential Channel 3 (+)

47 AIN5 Analog Input Analog Input 5: Single-Ended Channel 5, Differential Channel 2 (–)

48 AIN4 Analog Input Analog Input 4: Single-Ended Channel 4, Differential Channel 2 (+)

ANALOG/DIGITAL

Negative Analog Power Supply: 0V for unipolar operation, –2.5V for bipolar operation.

(Internally connected to exposed thermal pad of QFN package.)

cycles to engage low-power mode.

CLK

cycles to reset the device.

CLK

Clock Select Input: Low = Activates Crystal Oscillator, f

High = Disables Crystal Oscillator, apply f

to CLKIO.

CLK

output on CLKIO.

CLK

ADS1258

5

www.ti.com

SCLK

CS

(1)

DIN

DOUT

t

SCLK

t

CSSC

t

SPW

t

DIST

t

DIHD

t

SPW

t

CSDO

t

DOPD

t

DOHD

NOTE: (1) CS can be tied low.

DRDY

DOUT

t

DRDY

t

DDO

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

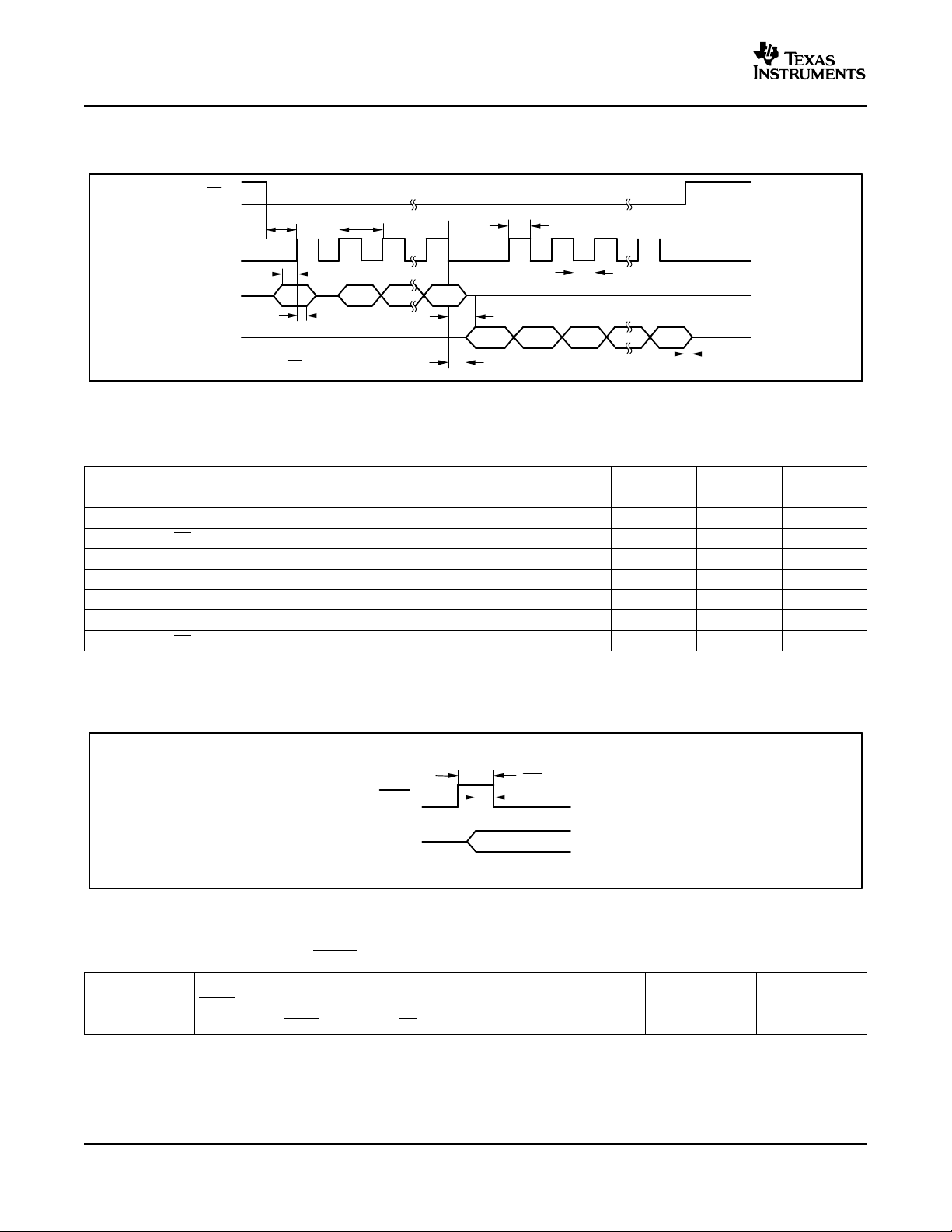

PARAMETER MEASUREMENT INFORMATION

Figure 1. Serial Interface Timing

SERIAL INTERFACE TIMING CHARACTERISTICS

SYMBOL DESCRIPTION MIN MAX UNITS

t

SCLK

t

SPW

t

CSSC

t

DIST

t

DIHD

t

DOPD

t

DOHD

t

CSDO

(1) τ

CLK

(2) Programmable to 256 τ

(3) CS can be tied low.

(4) DOUT load = 20 pF || 100k Ω to DGND.

SCLK Period 2 τ

SCLK High or Low Pulse Width (exceeding max resets SPI interface) 0.8 4096

CS Low to First SCLK: Setup Time

(3)

0.5 τ

Valid DIN to SCLK Rising Edge: Setup Time 10 ns

Valid DIN to SCLK Rising Edge: Hold Time 5 ns

SCLK Falling Edge to Valid New DOUT: Propagation Delay

(4)

SCLK Falling Edge to Old DOUT Invalid: Hold Time 0 ns

CS High to DOUT Invalid (tri-state) 5 τ

= master clock period = 1/f

CLK

.

CLK

.

(2)

5 ns

(1)

CLK

τ

CLK

CLK

CLK

Figure 2. DRDY Update Timing

DRDY UPDATE TIMING CHARACTERISTICS

SYMBOL DESCRIPTION TYP UNITS

t

DRDY

t

DDO

6

DRDY High Pulse Width Without Data Read 1 τ

Valid DOUT to DRDY Falling Edge ( CS = 0) 0.5 τ

CLK

CLK

www.ti.com

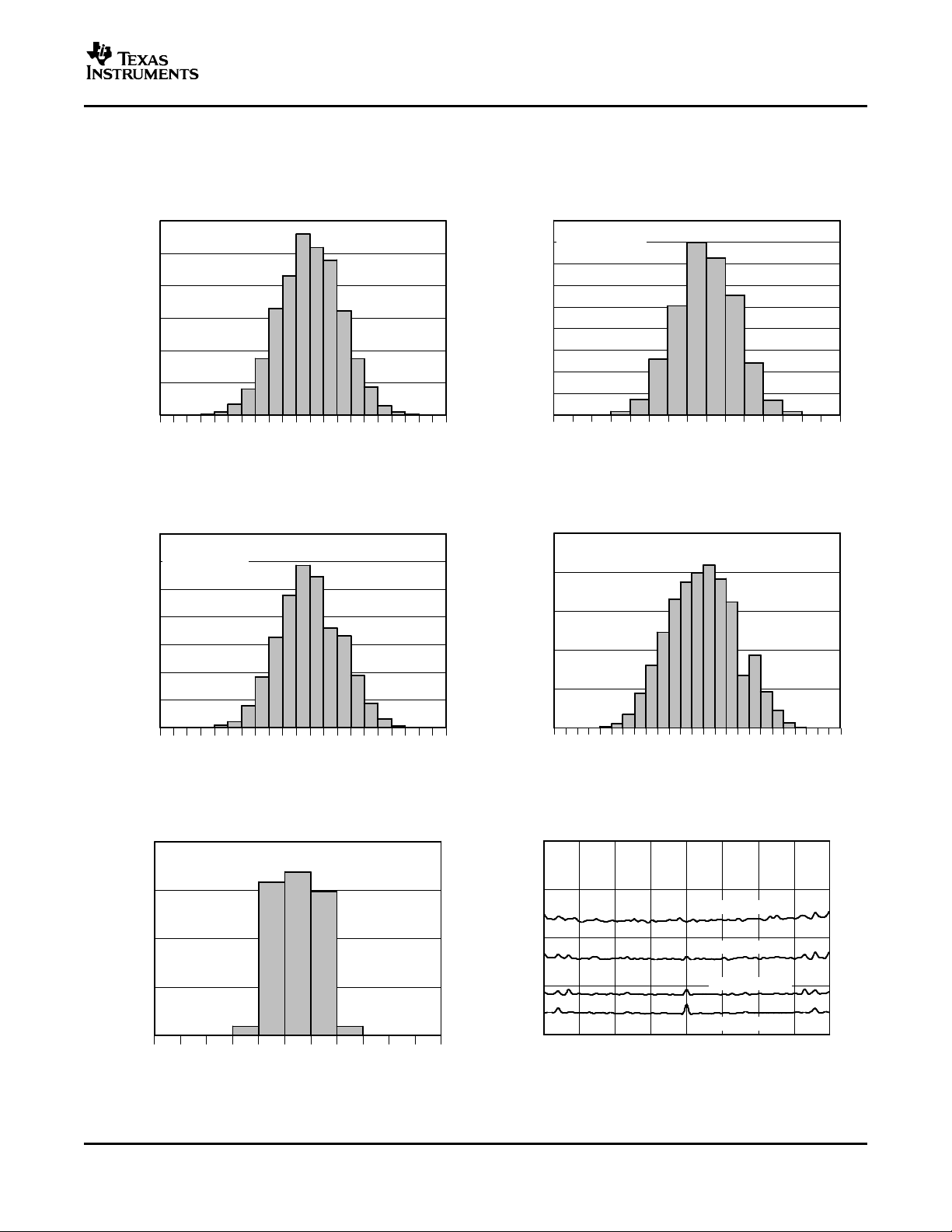

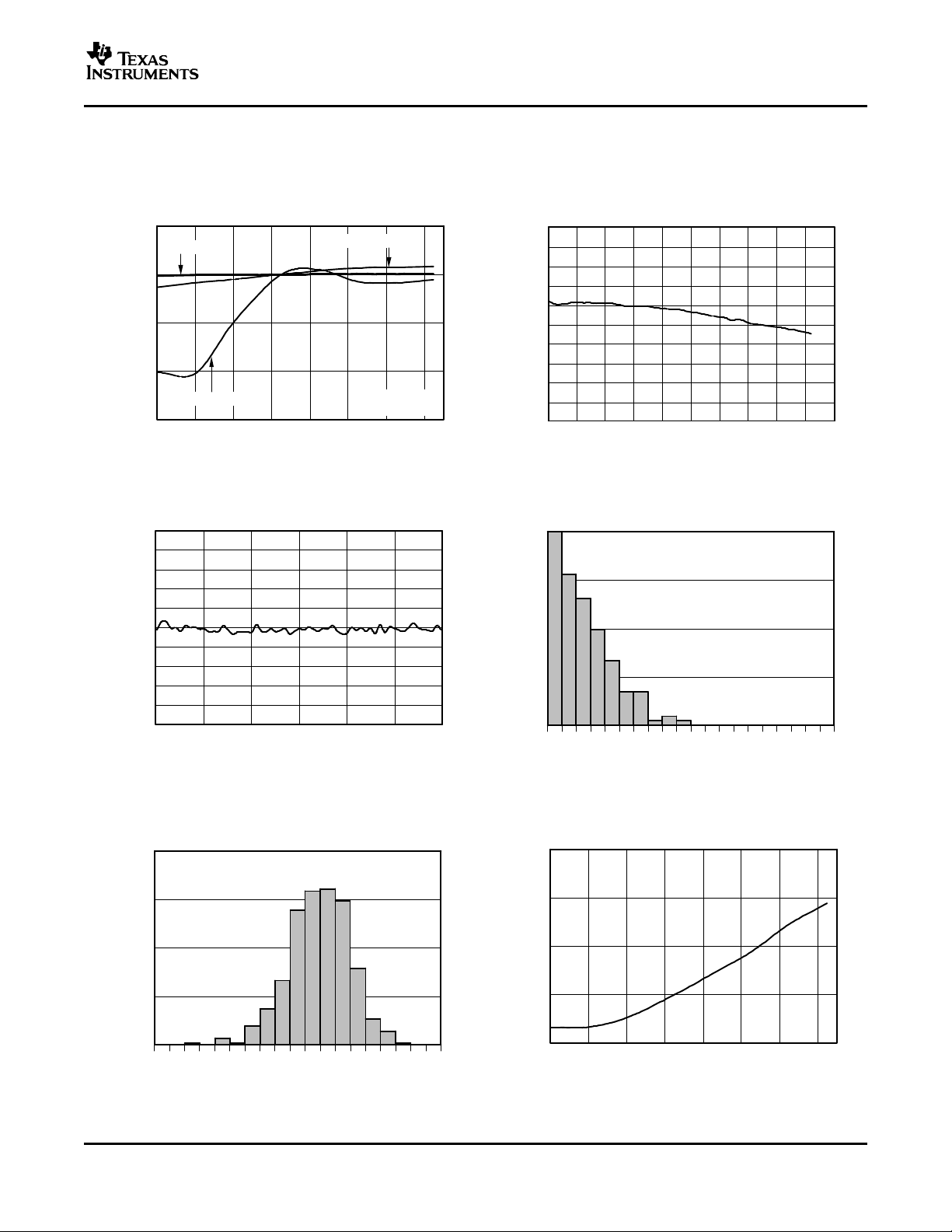

TYPICAL CHARACTERISTICS

Number of Occurences

Offset (µV)

3000

2500

2000

1500

1000

500

0

−

50

−

45

−

40

−

35

−

30

−

25

−

20

−

15

−

10

505

10

15

20

25

30

35

40

45

50

DRATE[1:0] = 11

16384 Points

Number of Occurences

Offset (µV)

4500

4000

3500

3000

2500

2000

1500

1000

500

0

−

35

−

30

−

25

−

20

−

15

−

10

−

5

0

5

10

15

20

25

30

35

DRATE[1:0] = 10

16384 Points

Number of Occurences

Offset (µV)

3500

3000

2500

2000

1500

1000

500

0

−

20

−

16

−

12

−

8

−

4

0

4

8

12

16

20

DRATE[1:0] = 01

16384 Points

Number of Occurences

Offset (µV)

2500

2000

1500

1000

500

0

−

12

−

10

−

8

−

6

−

4

−

2

0

2

4

6

8

10

12

DRATE[1:0] = 00

16384 Points

RMS Noise (

µ

V)

Input Voltage (%FS)

20

15

10

5

0

−

100−75 10075

−50−

25 50250

DRATE[1:0] = 11

DRATE[1:0] = 10

DRATE[1:0] = 01

DRATE[1:0] = 00

Number of Occurences

RMS Noise (µV)

20

15

10

5

0

10.0

10.5

11.0

11.5

12.0

12.5

13.0

13.5

14.0

14.5

15.0

50 units from twoproduction lots.

DRATE[1:0] = 11

At TA= +25 ° C, AVDD = +2.5V, AVSS = –2.5V, DVDD = +3.3V, f

outputs and ADC inputs, VREFP = +2.048V, and VREFN = –2.048V, unless otherwise noted.

READING HISTOGRAM READING HISTOGRAM

Figure 3. Figure 4.

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

= 16MHz (external), OPA227 buffer between MUX

CLK

ADS1258

READING HISTOGRAM READING HISTOGRAM

Figure 5. Figure 6.

NOISE HISTOGRAM NOISE vs INPUT VOLTAGE

Figure 7. Figure 8.

7

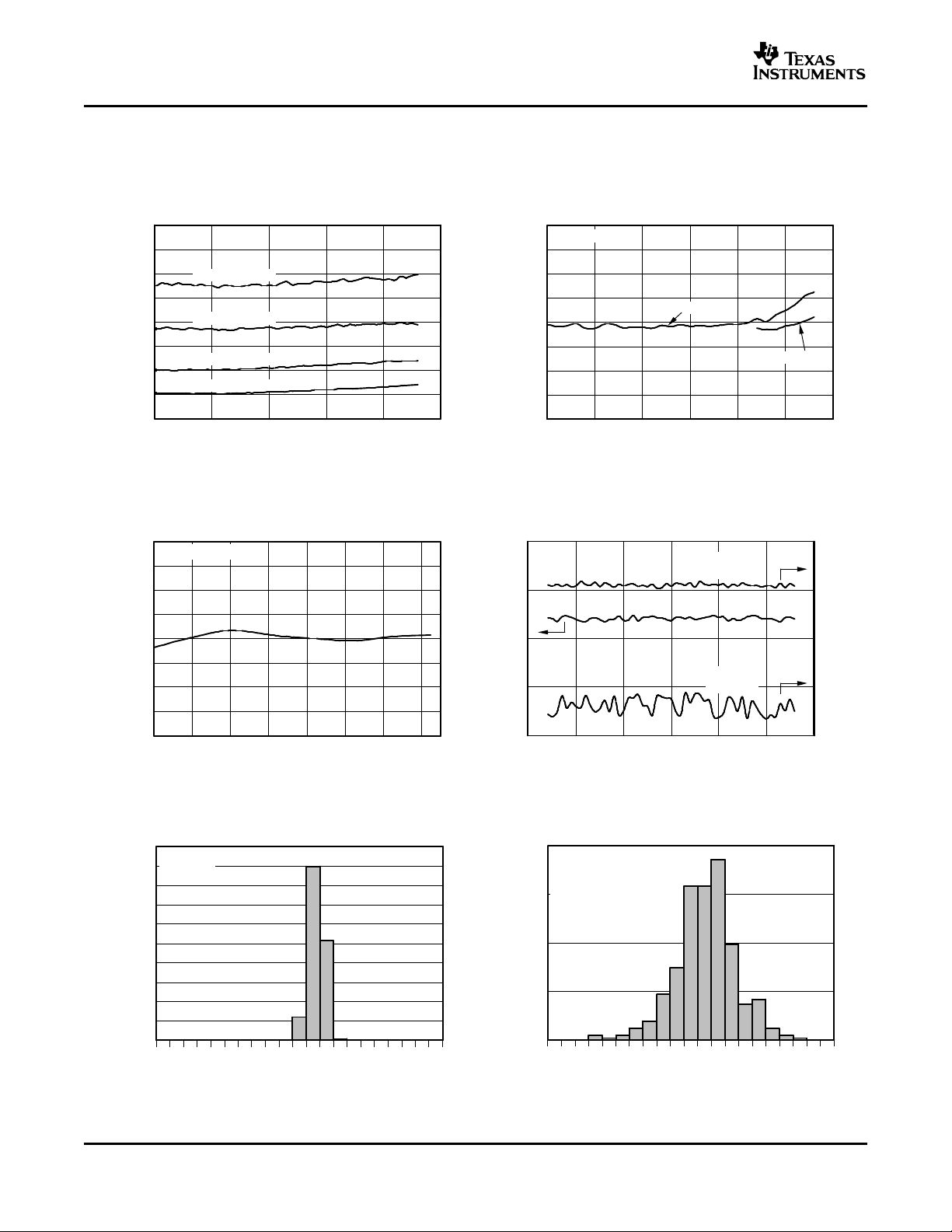

www.ti.com

RMS Noise (

µ

V)

V

REF

(V)

16

14

12

10

8

6

4

2

0

0.5 1.5 5.52.5 3.5 4.5

DRATE[1:0] = 11

DRATE[1:0] = 10

DRATE[1:0] = 01

DRATE[1:0] = 00

RMS Noise (

µ

V)

DVDD, AVDD−AVSS (V)

20

18

16

14

12

10

8

6

4

2.5 3.0 5.53.5 4.0 4.5 5.0

DRATE[1:0] = 11

from DVDD

from AVDD−AVSS

RMS Noise (

µ

V)

Temperature (C)

20

18

16

14

12

10

8

6

4

−40−

20 0

20 40 60 80 100

DRATE[1:0] = 11

RMS Noise (

µ

V)

Common−Mode Input Voltage(V)

20

15

10

5

0

Offset (

µ

V)

5

0

−

5

−

10

−

15

−

3

−

2 3

−

1 0 1 2

OFFSET

CHOP = 1

OFFSET

CHOP = 0

NOISE

Number of Occurences

Offset (µV)

200

180

160

140

120

100

80

60

40

20

0

−

10

−

8

−

6

−

4

−

2

0

2

4

6

8

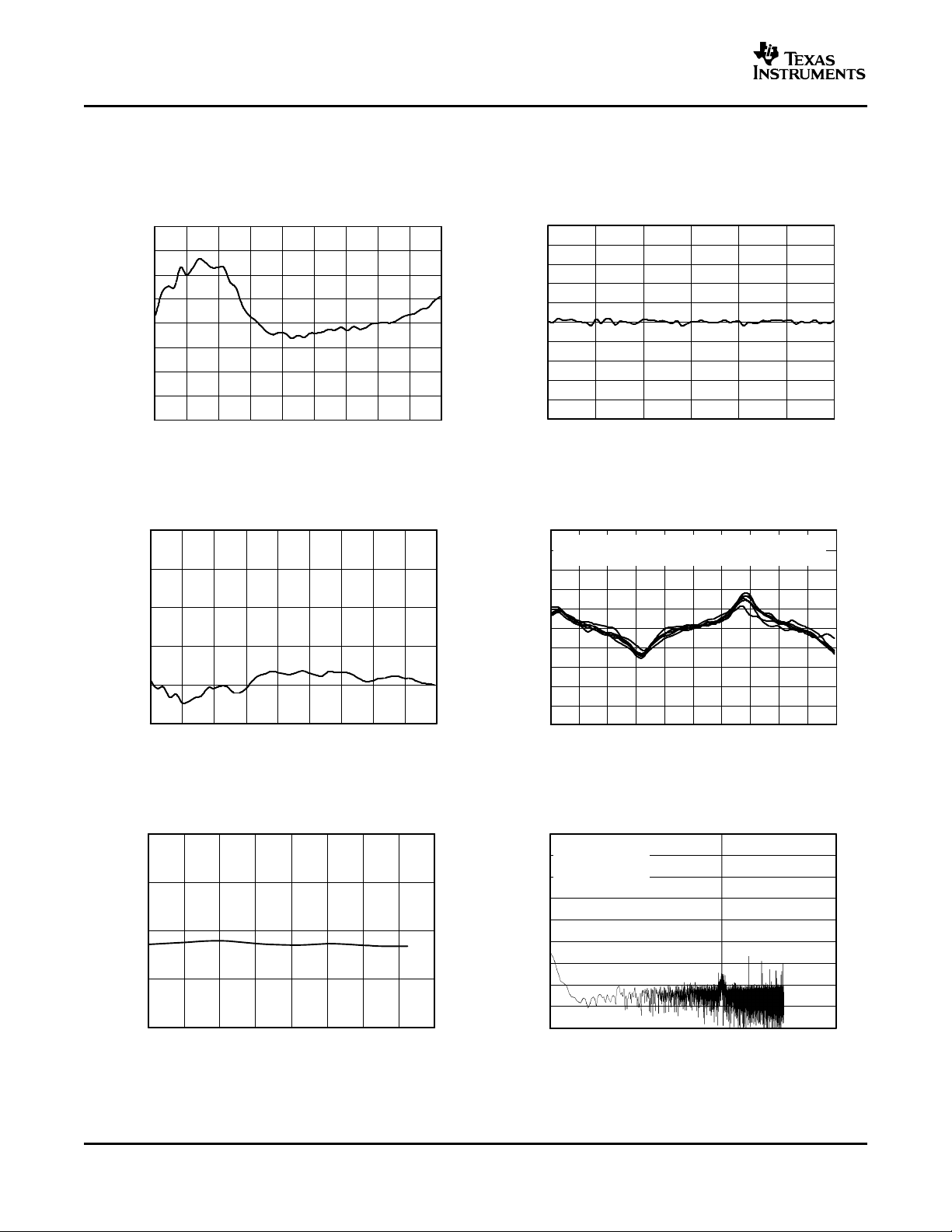

10

311 units fromone production lot.

CHOP = 1

Number of Occurences

Offset Drift (µV/C)

80

60

40

20

0

−

0.10

−

0.09

−

0.08

−

0.07

−

0.06

−

0.05

−

0.04

−

0.03

−

0.02

−

0.01

0

0.01

0.02

0.03

0.04

0.05

0.06

0.07

0.08

0.09

0.10

50 units from two

production lots.

Based on 20C intervals

over the range of

−

40C to +105C.

CHOP = 1

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

TYPICAL CHARACTERISTICS (continued)

At TA= +25 ° C, AVDD = +2.5V, AVSS = –2.5V, DVDD = +3.3V, f

outputs and ADC inputs, VREFP = +2.048V, and VREFN = –2.048V, unless otherwise noted.

= 16MHz (external), OPA227 buffer between MUX

CLK

NOISE vs V

REF

NOISE vs SUPPLY VOLTAGE

Figure 9. Figure 10.

NOISE AND OFFSET vs

NOISE vs TEMPERATURE COMMON-MODE INPUT VOLTAGE

8

Figure 11. Figure 12.

OFFSET HISTOGRAM OFFSET DRIFT HISTOGRAM

Figure 13. Figure 14.

www.ti.com

Normalized Offset (

µ

V)

Temperature (C)

20

0

−

20

−

40

−

60

−

40−20 100

0 20 806040

CHOP = 1

CHOP = 1, NoBuffer

CHOP = 0, No Buffer

50 Units from

2 Production Lots

Normalized Offset (

µ

V)

V

REF

(V)

0.5 1.0

10

8

6

4

2

0

−

2

−

4

−

6

−

8

−

10

5.51.5 2.0 2.5 3.0 3.5 4.0 4.5 5.0

Normalized Offset (

µ

V)

Time After Power−On (s)

10

8

6

4

2

0

−

2

−

4

−

6

−

8

−

10

0 10 6020 30 40 50

Free−Air

Number of Occurences

Absolute Gain Error (ppm)

80

60

40

20

0

100

300

500

700

900

1100

1300

1500

1700

1900

320 units from one production lot.

Normalized Gain Error (ppm)

Temperature (C)

30

20

10

0

−

10

−

40−20 100

0 20 806040

Number of Occurences

Gain Drift (ppm/C)

80

60

40

20

0

−

1.8

−

1.6

−

1.4

−

1.2

−

1.0

−

0.8

−

0.6

−

0.4

−

0.2

0

0.2

0.4

0.6

0.8

1.0

1.2

1.4

1.6

1.8

50 units from two production lots.

Based on 20C intervals over the

range of−40C to +105C.

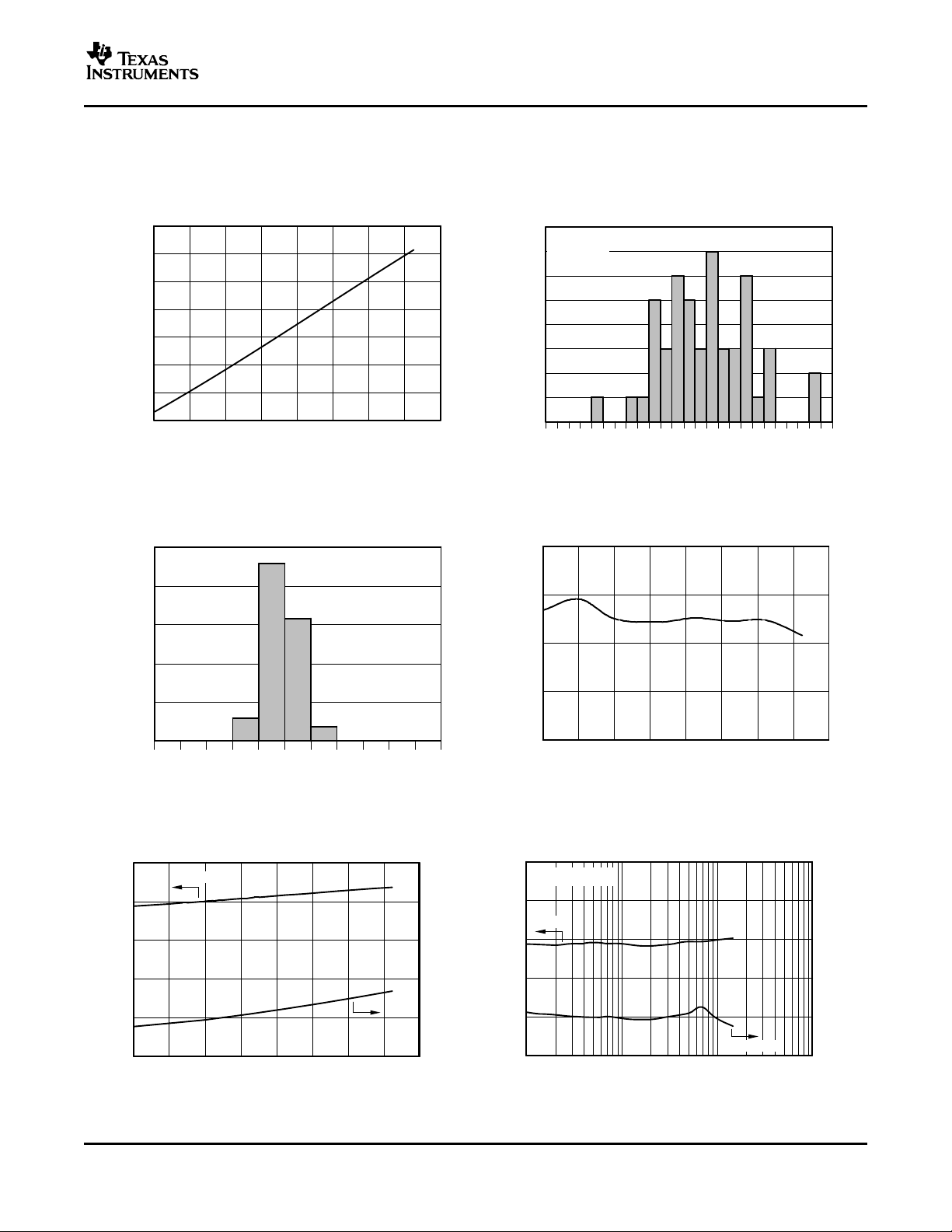

TYPICAL CHARACTERISTICS (continued)

At TA= +25 ° C, AVDD = +2.5V, AVSS = –2.5V, DVDD = +3.3V, f

outputs and ADC inputs, VREFP = +2.048V, and VREFN = –2.048V, unless otherwise noted.

= 16MHz (external), OPA227 buffer between MUX

CLK

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

OFFSET vs TEMPERATURE OFFSET vs V

Figure 15. Figure 16.

OFFSET POWER-ON WARMUP GAIN ERROR HISTOGRAM

REF

GAIN DRIFT HISTOGRAM GAIN ERROR vs TEMPERATURE

Figure 17. Figure 18.

Figure 19. Figure 20.

9

www.ti.com

Normalized Gain Error (ppm)

V

REF

(V)

20

15

10

5

0

−

5

−

10

−

15

−

20

0.5 1.0 5.01.5 2.0 2.5 3.0 3.5 4.0 4.5

Normalized Gain Error (ppm)

Time After Power−On (s)

10

8

6

4

2

0

−

2

−

4

−

6

−

8

−

10

0 10 6020 30 40 50

Free−Air

Linearity Error (ppm)

V

REF

(V)

10

8

6

4

2

0

0.5 1.0 5.01.5 2.0 2.5 3.0 3.5 4.0 4.5

Linearity Error (ppm)

VIN(V)

−5−

4

10

8

6

4

2

0

−

2

−

4

−

6

−

8

−

10

5

−3−2−

1 0 1 2 3 4

V

REF

= 5V

TA=−40C,−10C, +25C, +55C, +85C, +105C

INL (ppm)

Temperature (C)

8

6

4

2

0

−40−

20 120100

0 20 806040

Level (dBFS)

Frequency (Hz)

0

−

20

−

40

−

60

−

80

−

100

−

120

−

140

−

160

−

180

1 10 100k100 1k 10k

f = 1kHz,−0.5dBFs

DRATE[1:0] = 11

65536 Points

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

TYPICAL CHARACTERISTICS (continued)

At TA= +25 ° C, AVDD = +2.5V, AVSS = –2.5V, DVDD = +3.3V, f

outputs and ADC inputs, VREFP = +2.048V, and VREFN = –2.048V, unless otherwise noted.

= 16MHz (external), OPA227 buffer between MUX

CLK

GAIN ERROR vs V

REF

Figure 21. Figure 22.

INTEGRAL NONLINEARITY vs V

GAIN ERROR POWER-ON WARMUP

REF

INTEGRAL NONLINEARITY vs INPUT LEVEL

INTEGRAL NONLINEARITY vs TEMPERATURE OUTPUT SPECTRUM

10

Figure 23. Figure 24.

Figure 25. Figure 26.

www.ti.com

Temperature Sensor Voltage (mV)

Temperature (C)

210

200

190

180

170

160

150

140

−40−

20 12040

0 20 60 80 100

Number of Occurences

Temperature Reading (C)

8

7

6

5

4

3

2

1

0

12

13

14

15

16

17

18

19

20

21

22

23

24

25

26

27

28

29

30

31

32

33

34

35

36

50 units from two production lots.

TA= +25C

Ratio (

µ

A/

µ

A)

Temperature (C)

18

17

16

15

14

−40−

20 120100

0 20 806040

Number of Occurences

Ratio (µA/µA)

25

20

15

10

5

0

14.0

14.5

15.0

15.5

16.0

16.5

17.0

17.5

18.0

18.5

19.0

50 units from two production lots.

AVDD, AVSS Current (mA)

Temperature (C)

10

8

6

4

2

0

DVDD Current (mA)

1.0

0.8

0.6

0.4

0.2

0

−40−

20 1200 20 40 60 80 100

AVDD, AVSS

DVDD

RMS Noise (

µ

V)

Master Clock (MHz)

20

16

12

8

4

0

Linearity Error (ppm)

20

16

12

8

4

0

0.1 1 10010

DRATE[1:0] = 11

Noise

Linearity

TYPICAL CHARACTERISTICS (continued)

At TA= +25 ° C, AVDD = +2.5V, AVSS = –2.5V, DVDD = +3.3V, f

outputs and ADC inputs, VREFP = +2.048V, and VREFN = –2.048V, unless otherwise noted.

TEMPERATURE SENSOR VOLTAGE vs TEMPERATURE TEMPERATURE SENSOR READING HISTOGRAM

Figure 27. Figure 28.

= 16MHz (external), OPA227 buffer between MUX

CLK

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

SENSOR BIAS CURRENT SOURCE RATIO SENSOR BIAS CURRENT SOURCE RATIO

HISTOGRAM vs TEMPERATURE

Figure 29. Figure 30.

SUPPLY CURRENT vs TEMPERATURE NOISE AND INL vs MASTER CLOCK

Figure 31. Figure 32.

11

www.ti.com

AIN0

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

AIN7

AIN8

AIN9

AIN10

AIN11

AIN12

AIN13

AIN14

AIN15

AINCOM

Control

Logic

VREFPVREFN

AVSS

PLLCAP XTAL1XTAL2

DRDY

PWDN

RESET

START

SPI

Interface

CS

SCLK

DIN

DOUT

Digital Filter

Clock Control

16−Channel

MUX

AVDD

Sensor

Bias

M

UXOUTP

MUX

OUTN

ADCINP GND

AD

CINN

ADC Channel Control

Supply Monitor

GPIO

G

PIO[7:0]

DVDD

Temperature

Ext Ref Monitor

Internal Ref

ADC

CLKSELCLKIO

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

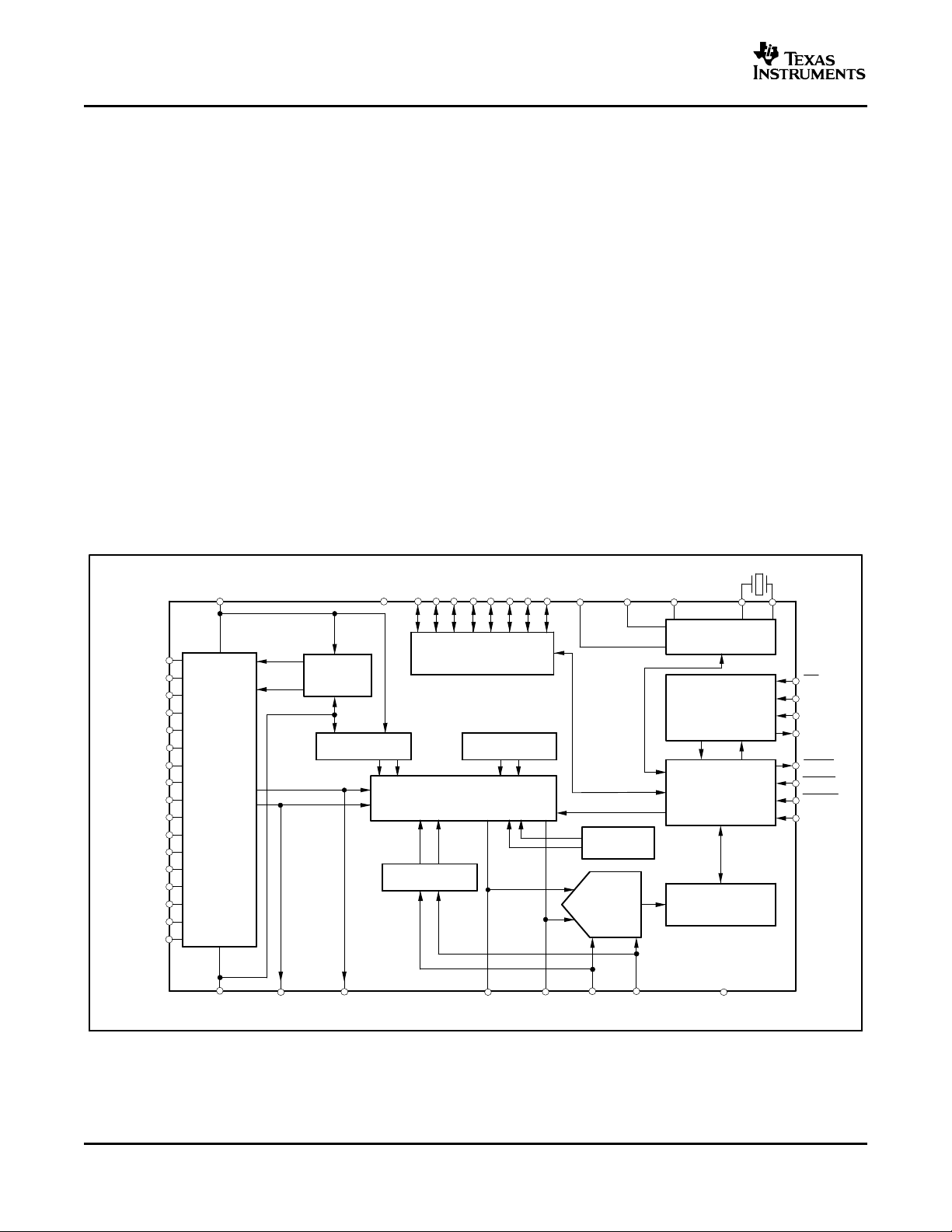

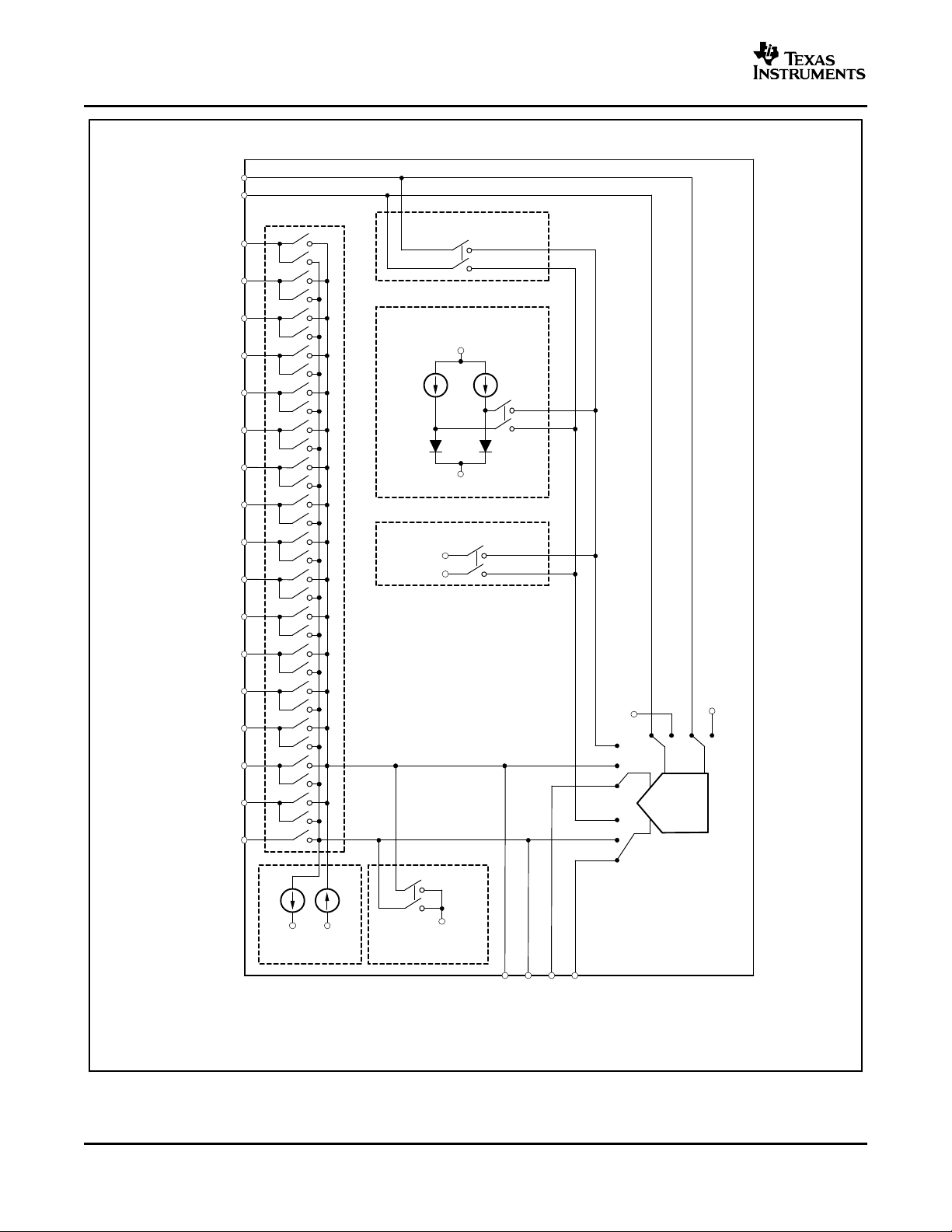

The ADS1258 is a flexible, 24-bit, low-noise ADC

optimized for fast multi-channel, high-resolution

measurement systems. The converter provides a

maximum channel scan rate of 23.7kSPS, providing a

complete 16-channel scan in less than 700µs.

Figure 33 shows the block diagram of the ADS1258.

The input multiplexer selects the analog input pins

connected to the multiplexer output pins

(MUXOUTP/MUXOUTN). External signal conditioning

can be used between the multiplexer output pins and

the ADC input pins (ADCINP/ADCINN) or the

multiplexer output can be routed internally to the ADC

inputs without external circuitry. Selectable current

sources within the input multiplexer can be used to

bias sensors or detect for a failed sensor. On-chip

system function readings provide readback of

temperature, supply voltage, gain, offset, and external

reference. The ADS1258 converter is comprised of a

fourth-order, delta-sigma modulator followed by a

programmable digital filter. The modulator measures

the differential input signal V

against the differential reference input V

IN

= (ADCINP – ADCINN)

REF

OVERVIEW

(VREFP – VREFN). The digital filter receives the

modulator signal and provides a low-noise digital

output. The ADC channel block controls the

multiplexer Auto-Scan feature. Channel Auto-Scan

occurs at a maximum rate of 23.7kSPS. Slower scan

rates can be used with corresponding increases in

resolution.

Communication is handled over an SPI-compatible

serial interface with a set of simple commands

providing control of the ADS1258. Onboard registers

store the various settings for the input multiplexer,

sensor detect bias, data rate selection, etc. Either an

external 32.768kHz crystal, connected to pins XTAL1

and XTAL2, or an external clock applied to pin CLKIO

can be used as the clock source. When using the

external crystal oscillator, the system clock is

available as an output for driving other devices or

controllers. General-purpose digital I/Os (GPIO)

provide input and output control of eight pins.

=

12

Figure 33. ADS1258 Block Diagram

www.ti.com

AVSS 100mV VREFP or VREFN AVDD 100mV

ESD

Diodes

ESD

Diodes

3pF

R

eff

= 40k

Ω

(f

CLK

= 16MHz)

AVDD

AVSS

VREFP

VREFN

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

MULTIPLEXER INPUTS

A simplified diagram of the input multiplexer is

illustrated in Figure 35 . The multiplexer connects one

of 16 single-ended external inputs, one of eight

differential external inputs, or one of the on-chip

internal variables to the ADC inputs. The output of the

channel multiplexer can be routed to external pins

and then to the input of the ADC. This flexibility

allows for use of external signal conditioning. See the

External Multiplexer Loop section.

ESD diodes protect the analog inputs. To keep these

diodes from turning on, make sure the voltages on

the input pins do not go below AVSS by more than

100mV, and likewise do not exceed AVDD by more

than 100mV:

AVSS – 100mV < (Analog Inputs) < AVDD + 100mV.

The converter supports two modes of channel access

through the multiplexer: the Auto-Scan mode and the

Fixed-Channel mode. These modes are selected by

the MUXMOD bit of register CONFIG0. The

Auto-Scan mode scans through the selected

channels automatically, with break-before-make

switching. The Fixed-Channel mode requires the user

to set the channel address for each channel

measured.

ESD diodes protect the reference inputs. To keep

these diodes from turning on, make sure the voltages

on the reference pins do not go below AVSS by more

than 100mV, and likewise do not exceed AVDD by

100mV, as described in Equation 1 :

(1)

A high-quality reference voltage is essential for

achieving the best performance from the ADS1258.

Noise and drift on the reference degrade overall

system performance. It is especially critical that

special care be given to the circuitry that generates

the reference voltages and the layout when operating

in the low-noise settings (that is, with low data rates)

to prevent the voltage reference from limiting

performance. See the Reference Inputs description in

the Hardware Considerations segment of the

Applications section.

VOLTAGE REFERENCE INPUTS

(VREFP, VREFN)

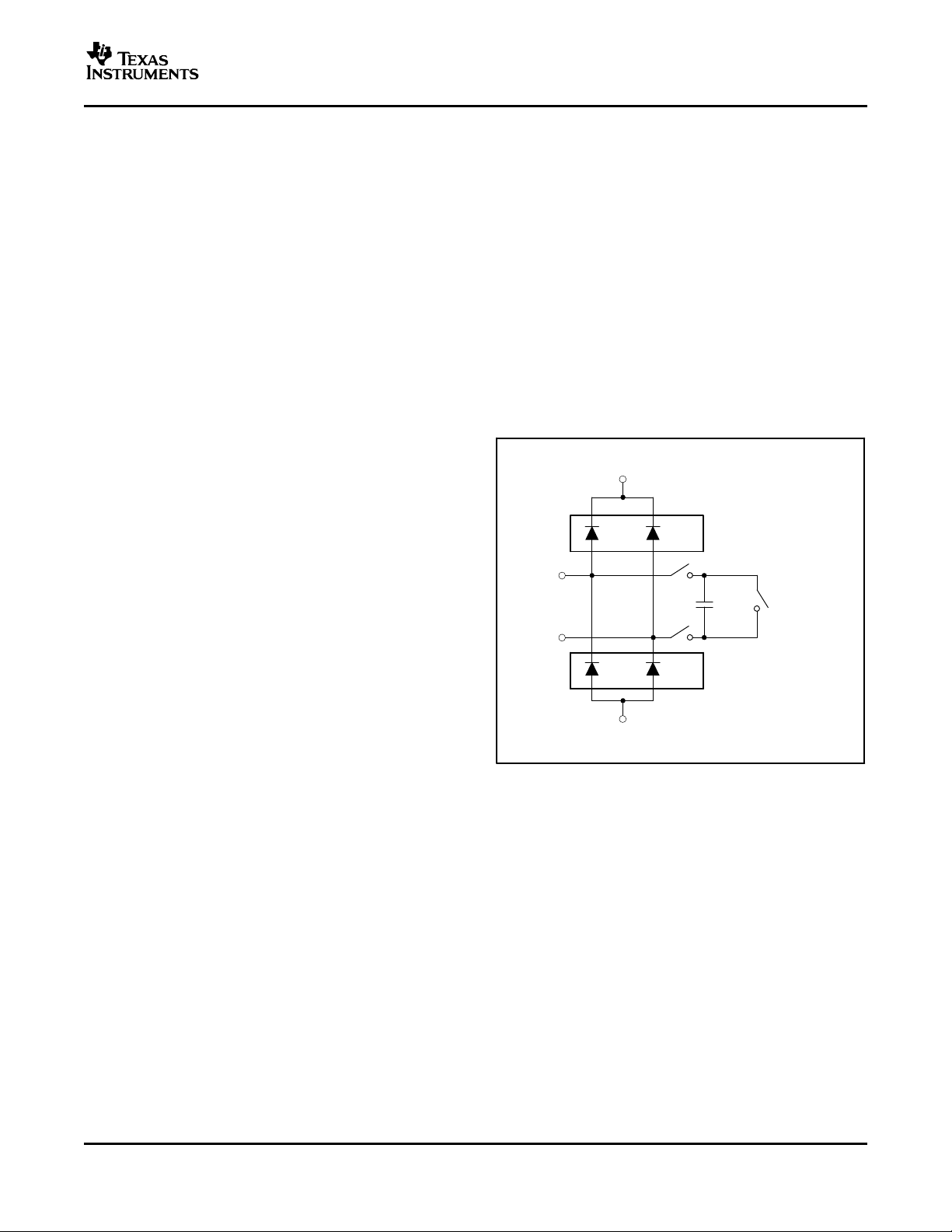

The voltage reference for the ADS1258 ADC is the

differential voltage between VREFP and VREFN:

V

= VREFP – VREFN. The reference inputs use a

REF

structure similar to that of the analog inputs with the

circuitry on the reference inputs shown in Figure 34 .

The load presented by the switched capacitor can be

modeled with an effective resistance (R

f

= 16MHz. Note that the effective impedance of

CLK

the reference inputs will load an external reference

with a non-zero source impedance.

) of 40k Ω for

eff

Figure 34. Simplified Reference Input Circuit

13

www.ti.com

ADC

AIN0

VREFN

VREFP

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

AIN7

AIN8

AIN9

AIN10

AIN11

AIN12

AIN13

AIN14

AIN15

AINCOM

Multiplexer

Reference/Gain Monitor

NOTE: ESD diodes not shown.

Supply Monitor

AVDD

AVSS

AVDD

AVSS

Temperature Sensor Monitor

1x 2x

8x 1x

AVDD

(AVDD−AVSS)/2

AVSS

Sensor Bias Offset Monitor

MUXOUTP

MUXOUTN

ADCINP

ADCINN

Internal

Reference

AVSS

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

Figure 35. Input Multiplexer

14

www.ti.com

t

SAMPLE

ON

OFF

S

1

S

2

OFF

ON

S

1

S

1

AVSS + 1.3V

R

AIN

= R

effB

|| 2R

effA

AVSS + 1.3V

R

effA

= 190k

Ω

R

effB

= 78kΩ(f

CLK

= 16MHz)

R

effA

= 190k

Ω

ADCINN

ADCINP

CA1= 0.65pF

CB= 1.6pF

C

A2

= 0.65pF

ADCINN

S

2

AVSS + 1.3V

S

2

AVSS + 1.3V

ADCINP

Equivalent

Circuit

R

eff

= t

SAMPLE/CX

NOTE: ESD input diodes not shown.

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

ADC INPUTS

The ADS1258 ADC inputs (ADCINP, ADCINN)

measure the input signal using internal capacitors

R

= V

eff

with f

IN/IAVERAGE

. For example, if f

CLK

two, the impedances will double.

. These impedances scale inversely

is reduced by a factor of

CLK

that are continuously charged and discharged. The As with the multiplexer and reference inputs, ESD

left side of Figure 37 shows a simplified schematic of diodes protect the ADC inputs. To keep these diodes

the ADC input circuitry; the right side of Figure 37 from turning on, make sure the voltages on the input

shows the input circuitry with the capacitors and pins do not go below AVSS by more than 100mV,

switches replaced by an equivalent circuit. Figure 36 and likewise do not exceed AVDD by more than

shows the ON/OFF timings of the switches shown in 100mV.

Figure 37 . S

sampling phase. With S

ADCINP, C

(ADCINP – ADCINN). For the discharge phase, S

opens first and then S

to approximately AVSS + 1.3V and C

switches close during the input

1

charges to ADCINN, and C

A2

2

1

closes. C

closed, C

charges to

A1

charges to

B

and C

A1

discharge

A2

discharges to

B

1

0V. This two-phase sample/discharge cycle repeats

with a period of t

SAMPLE

= 2/f

.

CLK

The charging of the input capacitors draws a transient

current from the source driving the ADS1258 ADC

inputs. The average value of this current can be used

to calculate an effective impedance (R

) where

eff

Figure 36. S1and S

Switch Timing for Figure 37

2

Figure 37. Simplified ADC Input Structure

15

www.ti.com

50

Ω

32.768kHz

(1)

4.7pF 4.7pF

22nF

CLKSEL XTAL1 XTAL2 PLLCAP

AVSS

CLKIO

ClockOutput

(15.729MHz)

0Vto−2.5V

NOTE:(1)Parallelresonant type, C

L

=12.5pF, ESR = 35kΩ(max).

Placethe crystalandloadcapacitorsas closeas possibleto thedevicepins.

32.768kHz

Crystal Oscillator

and PLL

MUX

CLKENB Bit

Internal Master Clock (f

CLK

)

CLKSEL

CLKIO

XTAL1 XTAL2 PLL

50

Ω

CLKSEL XTAL1 XTAL2 PLLCAP

DVDD

CLKIO

Clock Input

(16MHz)

2.7V

to 5V

No Connection

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

MASTER CLOCK (f

)

CLK

The ADS1258 oversamples the analog input at a high

rate. This requires a high-frequency master clock to

be supplied to the converter. As shown in Figure 38 ,

the clock comes from either a crystal oscillator or an

external clock source.

Figure 38. Clock Generation Block Diagram

Figure 39. Crystal Oscillator Connection

Table 1. System Clock Source

CLKSEL CLKENB

PIN CLOCK SOURCE BIT CLKIO FUNCTION

0 0

0 1 Output (15.729MHz)

1 External Clock Input X Input (16MHz)

32.768kHz Disabled

Crystal Oscillator (internally grounded)

32.768kHz

Crystal Oscillator

The CLKSEL pin determines the source of the

system clock, as shown in Table 1 . The CLKIO pin

functions as an input or as an output. When the

CLKSEL pin is set to '1', CLKIO is configured as an

input to receive the master clock. When the CLKSEL

pin is set to '0', the crystal oscillator generates the

clock. The CLKIO pin can then be configured to

output the master clock. When the clock output is not

needed, it can be disabled to reduce device power

consumption.

Crystal Oscillator

An on-chip oscillator and Phase-Locked Loop (PLL)

can be used to generate the system clock. For this

mode, tie the CLKSEL pin low. A 22nF PLL filter

capacitor, connected from the PLLCAP pin to the

AVSS pin, is required. The internal clock of the PLL

can be output to the CLKIO to drive other converters

or controllers. If not used, disable the clock output to

reduce device power consumption; see Table 1 for

settings. The clock output is enabled by a register bit

setting (default is ON). Figure 39 shows the oscillator

connections. Place these components as close to the

pins as possible to avoid interference and coupling.

Do not connect XTAL1 or XTAL2 to any other logic.

The oscillator start-up time may vary depending on

the crystal and ambient temperature. The user should

verify the oscillator start-up time.

16

Table 2. Approved Crystal Vendors

VENDOR CRYSTAL PRODUCT

Epson C-001R

External Clock Input

When using an external clock to operate the device,

apply the master clock to the CLKIO pin. For this

mode, the CLKSEL pin is tied high. CLKIO then

becomes an input, as shown in Figure 40 .

Make sure to use a clock source clean from jitter or

interference. Ringing or under/overshoot should be

avoided. A 50 Ω resistor in series with the CLKIO pin

(placed close to the source) can often help.

Figure 40. External Clock Connection

www.ti.com

f

CLK

128(4

11bDR

4.265625 TD) 2

CHOP

f

CLK

128(4

11bDR

CHOP(4.265625 TD)) 2

CHOP

Analog

Modulator

sinc

5

Filter

Programmable

Averager

Data Rate = f

CLK

/128Modulator Rate = f

CLK

/2

Num_Ave

Data Rate

(1)

= f

CLK

/(128×Num_Ave)

NOTE: (1) Data rate for Fixed−Channel Mode, Chop = 0, Delay = 0.

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

ADC

The ADC block of the ADS1258 is composed of two

blocks: a modulator and a digital filter.

Modulator

The modulator converts the analog input voltage into

a Pulse Code Modulated (PCM) data stream. When

the level of differential analog input (ADCINP –

ADCINN) is near the level of the reference voltage,

the '1' density of the PCM data stream is at its

highest. When the level of the differential analog input

is near zero, the PCM '0' and '1' densities are nearly Data Rate (Auto-Scan):

equal. The fourth-order modulator shifts the

quantization noise to a high frequency (out of the

passband) where the digital filter can easily remove it.

The modulator continuously chops the input, resulting

in excellent offset and offset drift performance. It is

important to note that offset or offset drift originating

from the external circuitry is not removed by the

modulator chopping. These errors can be effectively

removed by using the external chopping feature of

the ADS1258 (see the External Chopping section).

Digital Filter

The programmable low-pass digital filter receives the

modulator output and produces a high-resolution

digital output. By adjusting the amount of filtering,

tradeoffs can be made between resolution and data

rate: filter more for higher resolution, filter less for

higher data rate. The filter is comprised of two

sections, a fixed filter followed by a programmable

filter. Figure 41 shows the block diagram of the filter.

Data is supplied to the filter from the analog

modulator at a rate of f

/2. The fixed filter is a

CLK

fifth-order sinc filter with a decimation value of 64 that

outputs data at a rate of f

/128. The second stage

CLK

of the filter is a programmable averager (first-order

sinc filter) with the number of averages set by the

DRATE[1:0] bits.

The data rate depends upon the system clock

frequency (f

) and the converter configuration. The

CLK

data rate can be computed by Equation 2 or

Equation 3 :

Data Rate (Fixed-Channel Mode):

where:

• DR = DRATE[1:0] register bits (binary);

• CHOP = Chop register bit;

• and TD = time delay value given in Table 5 from

the DLY[2:0] register bits (128/f

periods).

CLK

(2)

(3)

Figure 41. Block Diagram of Digital Filter

17

www.ti.com

Hf

H

sinc

5

f

H

Averager

f

sin

128f

f

CLK

64 sin

2f

f

CLK

5

sin

128Num_Avef

f

CLK

Num_Ave sin

128f

f

CLK

0

−

20

−

40

−

60

−

80

−

100

−

120

−

140

Frequency (kHz)

Gain (dB)

125 2500 375 500 625

Data Rate

Auto−Scan Mode

(23.739kSPS)

Data Rate

Fixed−Channel Mode

(125kSPS)

0

−

20

−

40

−

60

−

80

−

100

−

120

−

140

Frequency (kHz)

Gain (dB)

125 2500 375 500 625

Data Rate

Auto−Scan Mode

(15.123kSPS)

Data Rate

Fixed−Channel Mode

(31.25kSPS)

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

Table 3 shows a listing of the averaging and data Figure 43 shows the response with averaging set to 4

rates for each of the four DRATE[1:0] register (DRATE[1:0] = 10). 4-reading, post-averaging

settings for the Auto-Scan and Fixed-Channel modes, produces three equally-spaced notches between

with CHOP, DLY = 0. Note that the data rate scales each main notch of the sinc

directly with f

reduces the maximum data rate by 2x. pattern, but with 15 and 63 equally-spaced notches

. For example, reducing f

CLK

by 2x response of DRATE[1:0] = 01 and 00 follow a similar

CLK

between the main sinc

5

FREQUENCY RESPONSE

The low-pass digital filter sets the overall frequency

response for the ADS1258. The filter response is the

product of the responses of the fixed and

programmable filter sections and is given by

Equation 4 :

(4)

The digital filter attenuates noise on the modulator

output including noise from within the ADS1258 and

external noise present within the ADS1258 input

signal. Adjusting the filtering by changing the number

of averages used in the programmable filter changes

the filter bandwidth. With a higher number of

averages, the bandwidth is reduced and more noise

is attenuated.

The low-pass filter has notches (or zeros) at the data

output rate and multiples thereof. The sinc

the filter produces wide notches at f

5

part of

/128 and

CLK

multiples thereof. At these frequencies, the filter has

zero gain. Figure 42 shows the response with no post

averaging. Note that in Auto-Scan mode, the data

rate is reduced while retaining the same frequency

response as in Fixed-Channel mode.

With programmable averaging, the wide notches

produced by the sinc

5

filter remain, but a number of

narrow notches are superimposed in the response.

The number of the superimposed notches is

determined by the number of readings

averaged (minus one).

Figure 42. Frequency Response, DRATE[1:0] = 11

Figure 43. Frequency Response, DRATE[1:0] = 10

5

filter. The frequency

notches, respectively.

Table 3. Data Rates

DATA RATE AUTO-SCAN DATA RATE FIXED-CHANNEL –3dB BANDWIDTH

MODE (SPS)

(3)

(2)

DRATE[1:0] Num_Ave

(1) f

(2) Num_Ave is the number of averages performed by the digital filter second stage.

(3) In Auto-Scan mode, the data rate listed is for a single channel; the effective data rate for multiple channels (on a per-channel basis) is

18

11 1 23739 125000 25390

10 4 15123 31250 12402

01 16 6168 7813 3418

00 64 1831 1953 869

= 16MHz, Chop = 0, and Delay = 0.

CLK

the value shown in Figure 43 and Figure 46 divided by the number of active channels in a scan loop.

(1)

MODE (SPS) (Hz)

www.ti.com

ALIASING

DRDY 1 2

Step Input

Data Not Settled Settled Data

DRDY 1 2 6

Step Input

Data Not Settled Settled Data

0

−

20

−

40

−

60

−

80

−

100

−

120

−

140

Frequency (MHz)

Gain (dB)

4 80 12 16

DRATE[1:0] = 11

125kSPS

Fixed−Channel Mode

ENOB

Ln

FSR

RMS

Noise

Ln2

FSR 2.13V

REF

The digital filter low-pass characteristic repeats at

multiples of the modulator rate of f

shows the response plotted out to 16MHz at the data

rate of 125kSPS (Fixed-Channel mode). Notice how

the responses near DC, 8MHz, and 16MHz are the

same. The digital filter will attenuate high-frequency

noise on the ADS1258 inputs up to the frequency

where the response repeats. However, noise or

frequency components present on the analog input

where the response repeats will alias into the

passband. For most applications, an anti-alias filter is

recommended to remove the noise. A simple

first-order input filter with a pole at 200kHz provides

–34dB rejection at the first image frequency.

Referring to Figure 42 and Figure 43 , frequencies

present on the analog input above the Nyquist rate

(sample rate/2) are first attenuated by the digital filter

and then will alias into the passband.

/2. Figure 44

CLK

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

input. For most modes of operation, the analog input

must be stable for one complete conversion cycle to

provide settled data. In Fixed-Channel mode

(DRATE[1:0] = 11), the input must be stable for five

complete conversion cycles.

Figure 45. Asynchronous Step-Input Settling Time

(DRATE[1:0] = 10, 01, 00)

Figure 44. Frequency Response Out to 16MHz

SETTLING TIME

The design of the ADS1258 provides fully-settled

data when scanning through the input channels in

Auto-Scan mode. The DRDY flag asserts low when

the data for each channel is ready. It may be

necessary to use the automatic switch time delay

feature to provide time for settling of the external

buffer and associated components after channel

switching. When the converter is started (START pin

transitions high or Start Command) with stable inputs,

the first converter output is fully settled. When

applying asynchronous step inputs, the settling time

is somewhat different. The step-input settling time

diagrams (Figure 45 and Figure 46 ) show the

converter step response with an asynchronous step

Figure 46. Asynchronous Step-Input Settling Time

(Fixed-Channel Mode, DRATE[1:0] = 11)

NOISE PERFORMANCE

The ADS1258 offers outstanding noise performance

that can be optimized by adjusting the data rate. As

the averaging is increased by reducing the data rate,

noise drops correspondingly. See Table 4 for

Input-Referred Noise, Noise-Free Resolution, and

Effective Number of Bits (ENOB). The noise

performance of low-level signals can be improved

substantially by using external gain. Note that when

Chop = 1, the data rate is reduced by 2x and the

noise is reduced by 1.4x.

ENOB is defined in Equation 5 :

The data for the Noise-Free Resolution (bits) is

calculated in the same way as ENOB, except

peak-to-peak noise is used.

As seen in the illustration of Noise vs V

the converter noise is relatively constant versus the

reference voltage. Optimum signal-to-noise ratio of

the converter is achieved by using higher reference

voltages (V

REF MAX

= AVDD – AVSS).

REF

(Figure 9 ),

(5)

19

www.ti.com

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

Table 4. Noise Performance

DATA RATE DATA RATE NOISE-FREE NUMBER

AUTO-SCAN MODE FIXED-CHANNEL MODE INPUT-REFERRED NOISE RESOLUTION OF BITS

(1) V

(SPS) (SPS) (µV

23739 125000 12 16.8 19.5

15123 31250 7.9 17.4 20.1

6168 7813 4.5 18.2 20.9

1831 1953 2.8 18.9 21.6

REF

= 4.096V, f

= 16MHz, Chop = 0, Delay = 0, Inputs shorted, and 2048 sample size.

CLK

) (Bits) (ENOB)

RMS

Table 5. Effective Data Rates with Switch-Time Delay (Auto-Scan Mode)

TIME DELAY

(1/f

× 128 TIME DELAY

DLY[2:0] periods) (µS) DRATE[1:0] = 11 DRATE[1:0] = 10 DRATE[1:0] = 01 DRATE[1:0] = 00

000 0 0 23739 15123 6168 1831

001 1 8 19950 13491 5878 1805

010 2 16 17204 12177 5614 1779

011 4 32 13491 10191 5151 1730

100 8 64 9423 7685 4422 1639

101 16 128 5878 5151 3447 1483

110 32 256 3354 3104 2392 1247

111 48 384 2347 2222 1831 1075

(1) Time delay and data rates scale with f

EXTERNAL MULTIPLEXER LOOP

The external multiplexer loop consists of two

differential multiplexer output pins and two differential

ADC input pins. The user may use external

components (buffering/filtering, single-ended to

differential conversion, etc), forming a signal

conditioning loop. For best performance, the ADC

input should be buffered and driven differentially.

To bypass the external multiplexer loop, connect the

ADC input pins directly to the multiplexer output pins,

or select internal bypass connection (BYPASS = 0 of

CONFIG0). Note that the multiplexer output pins are

active regardless of the bypass setting.

CLK

. If Chop = 1, the data rates are half those shown. f

CLK

Use of the switch time delay register reduces the

effective channel data rate. Table 5 shows the actual

data rates derived from Equation 2 , when using the

switch time delay feature.

When pulse converting, where one channel is

converted with each start pin pulse or each pulse

command, the application software may provide the

required time delay between pulses. However, with

Chop = 1, the switch time delay feature may still be

necessary to allow for settling.

In estimating the time delay that may be required,

Table 6 lists the time delay-to-time constant ratio (t/ τ )

and the corresponding final settled data in % and

number of bits.

(1)

(1)

= 16MHz, Auto-Scan Mode.

CLK

EFFECTIVE

SWITCH TIME DELAY

When using the ADS1258 in the Auto-Scan mode,

where the converter automatically switches from one

channel to the next, the settling time of the external

signal conditioning circuit becomes important. If the

channel does not fully settle after the multiplexer

channel is switched, the data may not be correct. The

ADS1258 provides a switch time delay feature which

automatically provides a delay after channel switching

to allow the channel to settle before taking a reading.

The amount of time delay required depends primarily

on the settling time of the external signal conditioning.

Additional consideration may be needed to account

for the settling of the input source arising from the

transient generated from channel switching.

20

Table 6. Settling Time

(1)

t/ τ

1 63 2

3 95 5

5 99.3 7

7 99.9 10

10 99.995 14

15 99.9999 20

17 99.999994 24

FINAL SETTLING FINAL SETTLING

(%) (Bits)

(1) Multiple time constants can be approximated by:

2

( τ

2

+ τ

2

+ … )½.

1

www.ti.com

dV

dt

I

SDC

C

80

Ω

AVDD

R

L

R

S

ADCINP

80

Ω

AVSS

ADCINN

MUXOUTP

MUXOUTN

I

SDC

I

SDC

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

SENSOR BIAS

An integrated current source provides a means to

bias an external sensor (for example, a diode

junction); or it verifies the integrity of a sensor or

sensor connection. When the sensor fails to an open

condition, the current sources drive the inputs of the

converter to positive full-scale. The biasing is in the

form of differential currents (programmable 1.5µA or

24µA), connected to the output of the multiplexer.

Figure 47 shows a simplified diagram of ADS1258

input structure with the external sensor modeled as a

resistance R

series resistors, R

resistances. R

resistance of the ADC input or external buffer. When

the sensor bias is enabled, they source I

selected input pin (connected to the MUXOUTP) and

sink I

SDC

to the MUXOUTN channel. The signal measured with

the biasing enabled equals the total IR drop:

I

[(2R

SDC

a direct short (that is, R

small signal measured by the ADS1258 when the

biasing is enabled: I

The current source is connected to the output of the

multiplexer. For unselected channels, the current

source is not connected. This configuration means

that when a new channel is selected, the current

source charges stray sensor capacitance, which may

slow the rise of the sensor voltage. The automatic

switch time delay feature can be used to apply an

appropriate time delay before a conversion is started

to provide fully settled data (see the Switch Time

Delay section).

between two input pins. The two 80 Ω

S

, model the ADS1258 internal

MUX

represents the effective input

L

from the other selected input pin connected

+ RS) ׀ ׀ RL]. Note that when the sensor is

MUX

SDC

= 0), there will still be a

S

[2R

׀ ׀ RL].

MUX

to one

SDC

The time to charge the external capacitance is given

in Equation 6 :

(6)

It is also important to note that the low impedance

(65k Ω ) of the direct ADC inputs or the impedance of

the external signal conditioning loads the current

sources. This low impedance limits the ability of the

current source to pull the inputs to positive full-scale

for open-channel detection.

OPEN-SENSOR DETECTION

For open-sensor detection, set the biasing to either

1.5µA or 24µA. Then select the channel and read the

output code. When a sensor opens, the positive input

is pulled to AVDD and the negative input is pulled to

AVSS. Because of this configuration, the output code

will be positive full-scale. Note that the interaction of

the multiplexer resistance with the current source

may lead to degradation in converter linearity. It is

recommended to enable the current source only

periodically to check for open inputs and discard the

associated data.

EXTERNAL DIODE BIASING

The current source can be used to bias external

diodes for temperature sensing. Scan the appropriate

channels with the current source set to 24µA.

Re-scan the same channels with the current source

set to 1.5µA. The difference in diode voltage readings

resulting from the two bias currents is directly

proportional to temperature.

Note that errors in current ratio, diode and cable

resistance, or the non-ideality factor of the diode can

lead to errors in temperature readings. These effects

can be compensated by characterization or by

calibrating the diode at known temperatures.

Figure 47. Sensor Bias Structure

21

www.ti.com

GPIO Pin

GPIO Data (read)

GPIO Data (write)

GPIO Control

ADC

Multiplexer

(chopping)

AINn

AINn

MUXOUTP

MUXOUTN

ADCINP

ADCINN

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

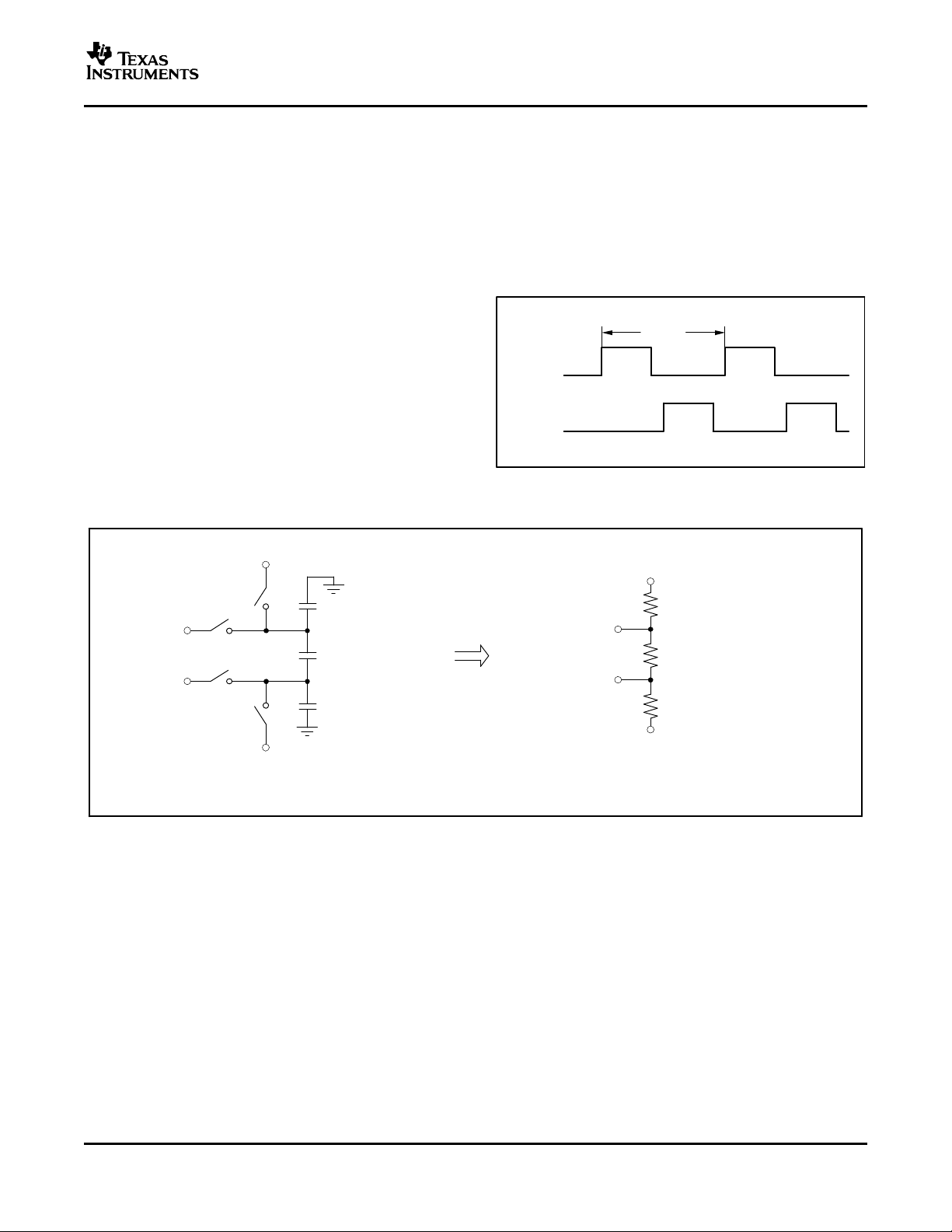

EXTERNAL CHOPPING

The modulator of the ADS1258 incorporates a

chopping front-end which removes offset errors,

providing excellent offset and offset drift performance.

However, offset and offset drift originating from

external signal conditioning are not removed by the

modulator. The ADS1258 has an additional chopping

feature that removes external offset errors (CHOP =

1).

With external chopping enabled, the converter takes

two readings in succession on the same channel. The

first reading is taken with one polarity and the second

reading is taken with the opposite polarity. The

converter averages the two readings, canceling the

offset, as shown in Figure 48 . With chopping enabled,

the effective reading is reduced to half of the nominal

reading rate.

Note that since the inputs are reversed under control

of the ADS1258, a delay time may be necessary to

provide time for external signal conditioning to fully

settle before the second phase of the reading

sequence starts (see the Switch Time Delay section).

Figure 48. External Chopping

External chopping can be used to significantly reduce

total offset errors (to less than 10 µ V) and offset drift

over temperature (to less than 0.2 µ V/ ° C). Note that

chopping must be disabled (CHOP = 0) to take the

internal monitor readings.

GPIO DIGITAL PORT (GPIOx)

The ADS1258 has eight dedicated pins for

General-Purpose Digital I/O (GPIO). The digital I/O

pins are individually configurable as either inputs or

as outputs through the GPIOC (GPIO-Configure)

register. The GPIOD (GPIO-Data) register controls

the level of the pins. When reading the GPIOD

register, the data returned is the level of the pins,

whether they are programmed as inputs or outputs.

As inputs, a write to the GPIOD has no effect. As

outputs, a write to the GPIOD sets the output value.

During Standby and Power-Down modes, the GPIO

remains active. If configured as inputs, they must be

driven (do not float). If configured as outputs, they

continue to drive the pins. The GPIO pins are set as

inputs after power-on or after a reset. Figure 49

shows the GPIO port structure.

Figure 49. GPIO Port Pin

POWER-DOWN INPUT ( PWDN)

The PWDN pin is used to control the power-down

mode of the converter. In power-down mode, all

internal circuitry is deactivated including the oscillator

and the clock output. Hold PWDN low for at least two

f

cycles to engage power-down. The register

CLK

settings are retained during power-down. When the

pin is returned high, the converter requires a wake-up

time before readings can be taken, as shown in the

Power-Up Timing section. Note that in power-down

mode, the inputs of the ADS1258 must still be driven

and the device continues to drive the outputs.

POWER-UP TIMING

When powering up the device or taking the PWDN

pin high to wake the device, a wake-up time is

required before readings can be taken. When using

the internal oscillator, the wake-up time is composed

of the oscillator start-up time and the PLL lock time,

and if the supplies are also being powering, there is a

reset interval time of 2

is not valid during the wake-up period, as shown in

Figure 50 .

18

f

cycles. Note that CLKIO

CLK

22

www.ti.com

CLKIO

Device Ready

t

WAKE

3.2V, typical

CLKSEL

or

AVDD−AVSS

(1)

or

PWDN

NOTE: (1) Shown with DVDD stable.

CLKIO

DeviceReady

t

WAKE

3.2V,typical

or

AVDD−AVSS

(1)

PWDN,

CLKSEL

NOTE:(1)ShownwithDVDDstable.

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

POWER-UP SEQUENCE

The analog and digital supplies should be applied

before any analog or digital input is driven. The power

supplies may be sequenced in any order. The internal

master reset signal is generated from the analog

power supply (AVDD – AVSS), when the level

reaches approximately 3.2V. The power-up master

reset signal is functionally the same as the Reset

Command and the RESET input pin.

Reset Input ( RESET)

When RESET is held low for at least two f

all registers are reset to their default values and the

digital filter is cleared. When RESET is released high,

the device is ready to convert data.

CLK

cycles,

Figure 50. Device Wake Time with

Internal Oscillator

When using the device with an external clock, the

wake-up time is 2/f

the PWDN pin and 218/f

cycles when waking up with

CLK

cycles when powering the

CLK

supplies, all after a valid CLKIO is applied, as shown

in Figure 51 .

Figure 51. Device Wake Time with External Clock

Table 7 summarizes the wake-up times using the

internal oscillator and the external clock operations.

Clock Select Input (CLKSEL)

This pin selects the source of the system clock: the

crystal oscillator or an external clock. Tie CLKSEL

low to select the crystal oscillator. When using an

external clock (applied to the CLKIO pin), tie CLKSEL

high.

Clock Input/Output (CLKIO)

This pin serves either as a clock output or clock input,

depending on the state of the CLKSEL pin. When

using an external clock, apply the clock to this pin

and set the CLKSEL pin high. When using the

internal oscillator, this pin has the option of providing

a clock output. The CLKENB bit of register CONFIG0

enables the clock output (default is enabled).

Start Input (START)

The START pin is an input which controls the ADC

process. When the START pin is taken high, the

converter starts converting the selected input

channels. When the START pin is taken low, the

conversion in progress runs to completion and the

converter is stopped. The device then enters one of

the two idle modes (see the Idle Modes section). This

pin may be tied low and conversions can be

controlled via commands sent through the SPI

interface (see the Operating Modes section).

Table 7. Wake-Up Times

t

WAKE

CONDITION OSCILLATOR

PWDN or CLKSEL t

AVDD – AVSS t

(1) Wake-up times for the internal oscillator operation are typical and may

vary depending on crystal characteristics and layout capacitance. The user

should verify the oscillator start-up times (t

INTERNAL t

+ 218/f

OSC

OSC

(1)

EXTERNAL CLOCK

CLK

= oscillator start-up time).

OSC

Data Ready Output ( DRDY)

The DRDY pin is an output that asserts low to

WAKE

indicate when new channel data is available to read

(the previous conversion data is lost). DRDY returns

2/f

CLK

218/f

CLK

high after the first falling edge of SCLK during a data

read operation. If the data is not read (no SCLK

pulses), DRDY remains low until new channel data is

available once again. DRDY then pulses high, then

low to indicate new data is available; see Figure 52 .

23

www.ti.com

Total Analog Supply Voltage(V

)

Code

786432

DRDY

DRDY

SCLK

SCLK

DRDY with SCLK

DRDY without SCLK

t

DRDYPLS

t

DRDYPLS

=

1

f

CLK

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

DRDY is usually connected to an interrupt of a and the output clips when:

controller, DSP, or connected to a controller port pin

for polling in a software loop. Channel data can be

read without the use of DRDY. Read the data using

the register format read and check the Status Byte

when the NEW bit = 1, which indicates new channel

data.

|V

| ≥ 1.0 6× V

IN

Table 8 summarizes the ideal output codes versus

input signals.

INTERNAL SYSTEM READINGS

Analog Power-Supply Reading (VCC)

The analog power-supply voltage of the ADS1258

can be monitored by reading the VCC register. The

supply voltage is routed internal to the ADS1258 and

is measured and scaled using an internal reference.

The supply readback channel outputs the difference

between AVDD and AVSS (AVDD – AVSS), for both

single and dual configurations. Note that it is required

to disable chopping (CHOP = 0) prior to taking this

reading.

The following scale factor of Equation 7 converts the

code value to volts:

.

REF

Figure 52. DRDY Timing

(See Figure 2 for the DRDY Pulse)

Output Data Scaling and Over-Range

The ADS1258 is scaled such that the output data

code resulting from an input voltage equal to ± V

has a margin of 6. 6% before clipping. This

architecture allows operation of applied input signals

at or near full-scale without overloading the converter.

Specifically, the device is calibrated so that:

1LSB = V

/780000h,

REF

Table 8. Ideal Output Code vs Input Signal

INPUT SIGNAL V

(ADCINP – ADCINN) IDEAL OUTPUT CODE

≥ +1.0 6 V

+V

REF

+1.0 6 V

REF

–1.0 6 V

≤ – 1.0 6 V

(1) Excludes effects of noise, linearity, offset, and gain errors.

0 000000h Bipolar Zero

REF

–V

REF

REF

IN

REF

23

/(2

– 1) 000001h +1LSB

23

/(2

– 1) FFFFFFh –1LSB

23

23

× (2

/2

– 1) 800000h Maximum Negative Full-Scale Before Output Clipping

When the power supply falls below the minimum

specified operating voltage, the full operation of the

ADS1258 cannot be ensured. Note that when the

total analog supply voltage falls to below

approximately 4.3V the returned data is set to zero.

The SUPPLY bit in the status byte is then set. The bit

is cleared when the total supply voltage rises

approximately 50mV.

REF

The digital supply (DVDD) may be monitored by

looping-back the supply voltage to an input channel.

A resistor divider may be required for bipolar supply

operation to reduce the DVDD level to within the

range of the analog supply.

(1)

DESCRIPTION

7FFFFFh Maximum Positive Full-Scale Before Output Clipping

780000h VIN= +V

87FFFFh VIN= –V

REF

REF

(7)

24

www.ti.com

Device GainVV

Code

7864320

External Reference(V

)

Code

786432

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

Gain Reading (GAIN)

In this configuration, the external reference is

connected both to the analog input and to the

reference input of the ADC. The data from this

register indicates the gain of the device.

The following scale factor of Equation 8 converts the

code value to device gain:

To correct the device gain error, the user software

can divide each converter data value by the device

gain. Note that this corrects only for gain errors

originating within the ADC; system gain errors

because of an external gain stage error or because of

reference errors are not compensated. Note that it is

required to disable chopping (CHOP = 0) prior to

taking this reading.

Reference Reading (REF)

In this configuration, the external reference is

connected to the analog input and an internal

reference is connected to the reference of the ADC.

The data from this register indicates the magnitude of

the external reference voltage.

The following scale factor of Equation 9 converts the

code value to external reference voltage:

This readback function can be used to check for

missing or an out-of-range reference. If the reference

input pins are floating (not connected), internal

biasing pulls them to the AVSS supply. This causes

the output code to tend toward '0'. Bypass capacitors

connected to the external reference pins may slow

the response of the pins when open. When reading

this register immediately after power-on, verify that

the reference has settled to ensure an accurate

reading. Note that it is required to disable chopping

(CHOP = 0) prior to taking this reading.

Temperature Reading (TEMP)

The ADS1258 contains an on-chip temperature

sensor. This sensor uses two internal diodes with one

diode having a current density of 16x of the other.

The difference in current densities of the diodes

yields a difference voltage that is proportional to

absolute temperature.

As a result of the low thermal resistance of the

package to the printed circuit board (PCB), the

internal device temperature tracks the PCB

temperature closely. Note also that self-heating of the

ADS1258 causes a higher reading than the

temperature of the surrounding PCB. Note that it is

required to disable chopping (CHOP = 0) prior to

taking this reading.

Offset Reading (OFFSET)

The differential output of the multiplexer is shorted

(8)

together and set to a common-mode voltage of

(AVDD – AVSS)/2. Ideally, the code from this register

function is 0h, but varies because of the noise of the

ADC and offsets stemming from the ADC and

external signal conditioning. This register can be used

to calibrate or track the offset of the ADS1258 and

external signal conditioning. The chop feature of the

ADC can automatically remove offset and offset drift

from the external signal conditioning loop; see the

External Chopping section.

CONVERSION PROCESS

The ADS1258 conversion process is controlled by

use of either the START pin or by commands sent

through the SPI interface. The START pin and start

commands are OR’d together. Tie the START pin low

if only commands control the converter. To have the

device convert continuously, tie the START pin high.

The following definitions relate the functions of the

START input pin and control commands.

(9)

1. The Pulse Convert Condition occurs when a

Pulse Start/Stop command is issued, or when the

START pin is toggled high and then returned low

before the current conversion cycle is completed.

In this mode, one conversion of one channel is

performed.

2. The Continuous Convert Condition occurs when a

Continuous Convert command is issued, or when

the START pin is held high. In this mode, multiple

conversions are performed until a Stop Convert

condition is received.

3. A Stop Convert Condition occurs when a Pulse

Start/Stop command is issued after a Continuous

Convert command (with the START pin low), or

when the START pin is taken from high to low. In

this mode, the current channel data is completed

and the device enters one of the Idle Modes.

Pulse Convert Condition

When the Pulse Convert condition occurs, the device

converts the current channel, after which it enters the

standby or sleep modes waiting for a new start

condition. As shown in Figure 53 , the START pin is

taken high to start a conversion. The START pin must

be taken low prior to DRDY low to avoid starting a

second conversion. If more than one channel is

enabled (Auto-Scan mode), the converter indexes to

the next selected channel after completing the

reading. With each Pulse Conversion condition, the

25

www.ti.com

DRDY

START Pin

Continuous

Convert

Command

Pulse

Start/Stop

Command

Data Ready, Index to Next Channel

IdleIdle Mode Converting

or

(START pin low)

DRDY

START Pin

Pulse Start

Command

Converting ConvertingIdle

Data Ready, Index to Next Channel

or

Initial Delay

Fully−Settled Data

DRDY

Start

Condition

ADS1258

SBAS297A – JUNE 2005 – REVISED SEPTEMBER 2005

converter indexes to the next programmed channel. If the START pin is high after a Pulse Start/Stop

When the last selected channel in the program list command, the device continues to convert. A channel

has been converted, the device starts a new under conversion during a Stop Convert will

conversion beginning at the highest priority channel. complete. After the Stop Convert is received, the

If there is only one channel selected in Auto-Scan device enters one of the Pause Modes (Standby or

mode, the converter remains fixed on one channel. A Sleep); refer to Figure 54 .

write operation to any of the multiplexer channel

registers resets the channel pointer to the highest

priority channel (see Table 10 ).