Page 1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments

查询ADS1255供应商查询ADS1255供应商

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

FEATURES

D 24 Bits, No Missing Codes

− All Data Rates and PGA Settings

D Up to 23 Bits Noise-Free Resolution

D ±0.0010% Nonlinearity (max)

D Data Output Rates to 30kSPS

D Fast Channel Cycling

− 18.6 Bits Noise-Free (21.3 Effective Bits)

at 1.45kHz

D One-Shot Conversions with Single-Cycle

Settling

D Flexible Input Multiplexer with Sensor Detect

− Four Differential Inputs (ADS1256 only)

− Eight Single-Ended Inputs (ADS1256 only)

D Chopper-Stabilized Input Buffer

D Low-Noise PGA: 27nV Input-Referred Noise

D Self and System Calibration for All PGA

Settings

D 5V Tolerant SPI-Compatible Serial Interface

D Analog Supply: 5V

D Digital Supply: 1.8V to 3.6V

D Power Dissipation

− As Low as 38mW in Normal Mode

− 0.4mW in Standby Mode

AVDD DVDD

APPLICATIONS

D Weigh Scales

D Scientific Instrumentation

D Industrial Process Control

D Medical Equipment

D Test and Measurement

AIN0

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

ADS1256 Only

AIN7

AINCOM

Mux

and

Sensor

Detect

DESCRIPTION

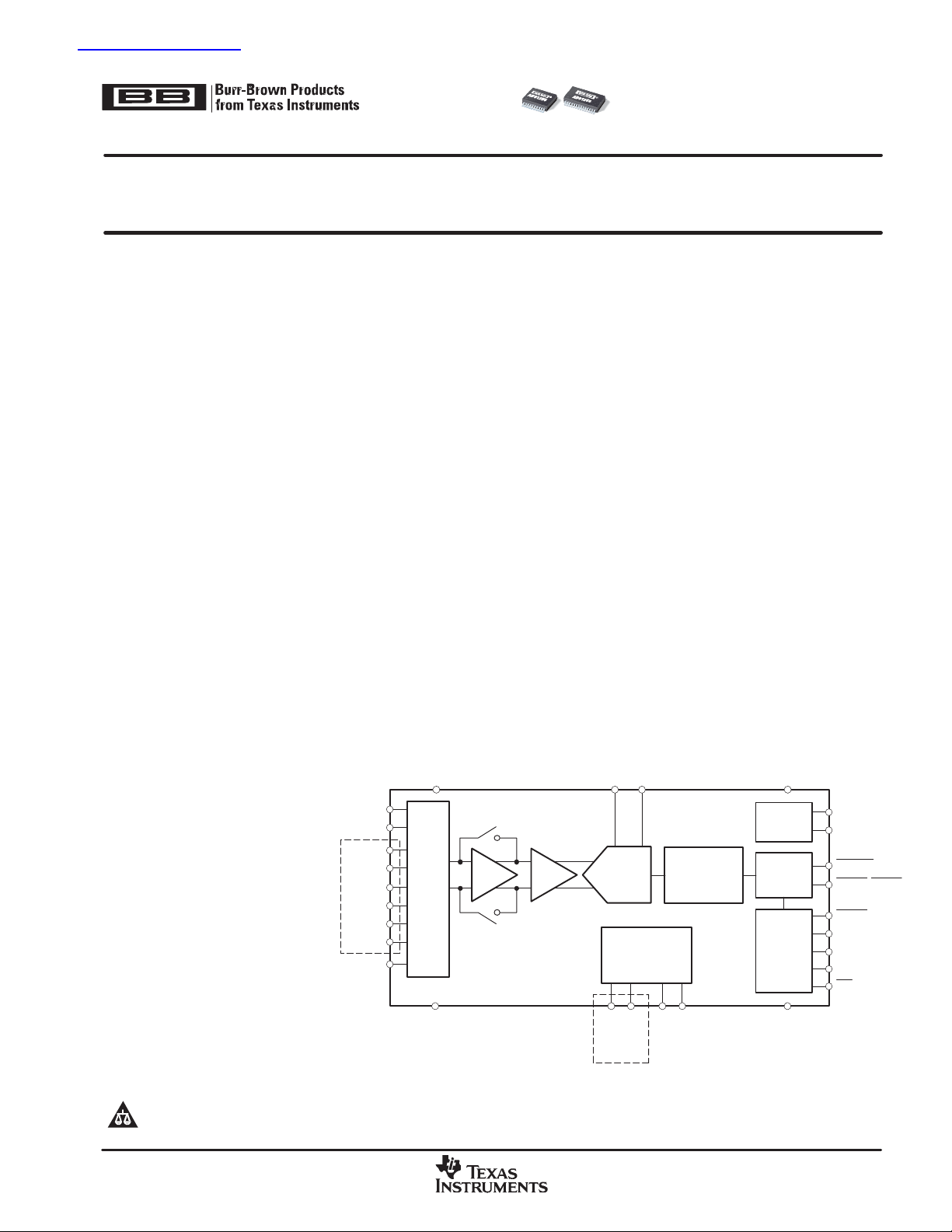

The ADS1255 and ADS1256 are extremely low-noise,

24-bit analog-to-digital (A/D) converters. They provide

complete high-resolution measurement solutions for the

most demanding applications.

The converter is comprised of a 4th-order, delta-sigma

(∆Σ) modulator followed by a programmable digital filter. A

flexible input multiplexer handles differential or

single-ended signals and includes circuitry to verify the

integrity of the external sensor connected to the inputs.

The selectable input buffer greatly increases the input

impedance and the low-noise programmable gain

amplifier (PGA) provides gains from 1 to 64 in binary steps.

The programmable filter allows the user to optimize

between a resolution of up to 23 bits noise-free and a data

rate of up to 30k samples per second (SPS). The

converters offer fast channel cycling for measuring

multiplexed inputs and can also perform one-shot

conversions that settle in just a single cycle.

Communication is handled over an SPI-compatible serial

interface that can operate with a 2-wire connection.

Onboard calibration supports both self and system

correction of o ffset and gain errors for all the PGA settings.

Bidirectional digital I/Os and a programmable clock output

driver are provided for general use. The ADS1255 is

packaged in an SSOP-20, and the ADS1256 in an

SSOP-28.

VREFP VREFN

Clock

Generator

1:64

Buffer

PGA

4th−Order

Modulator

General

Purpose

Digital I/O

Programmable

Digital Filter

Control

Serial

Interface

XTAL1/CLKIN

XTAL2

RESET

SYNC/PDWN

DRDY

SCLK

DIN

DOUT

CS

D3 D2 D1 D0/CLKOUTAGND

ADS1256

Only

semiconductor products and disclaimers thereto appears at the end of this data sheet.

All trademarks are the property of their respective owners.

!"#$! # %& '( % )(*' +, +('

'%& )'%' ) - & % #. $(& ++ ,

+(' )' + ' '(+ % )&,

www.ti.com

Copyright 2003−2004, Texas Instruments Incorporated

DGND

Page 2

ADS1255

SSOP-20

DB

ADS1255IDB

ADS1256

SSOP-28

DB

ADS1256IDB

Input Current

l

inputs

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

www.ti.com

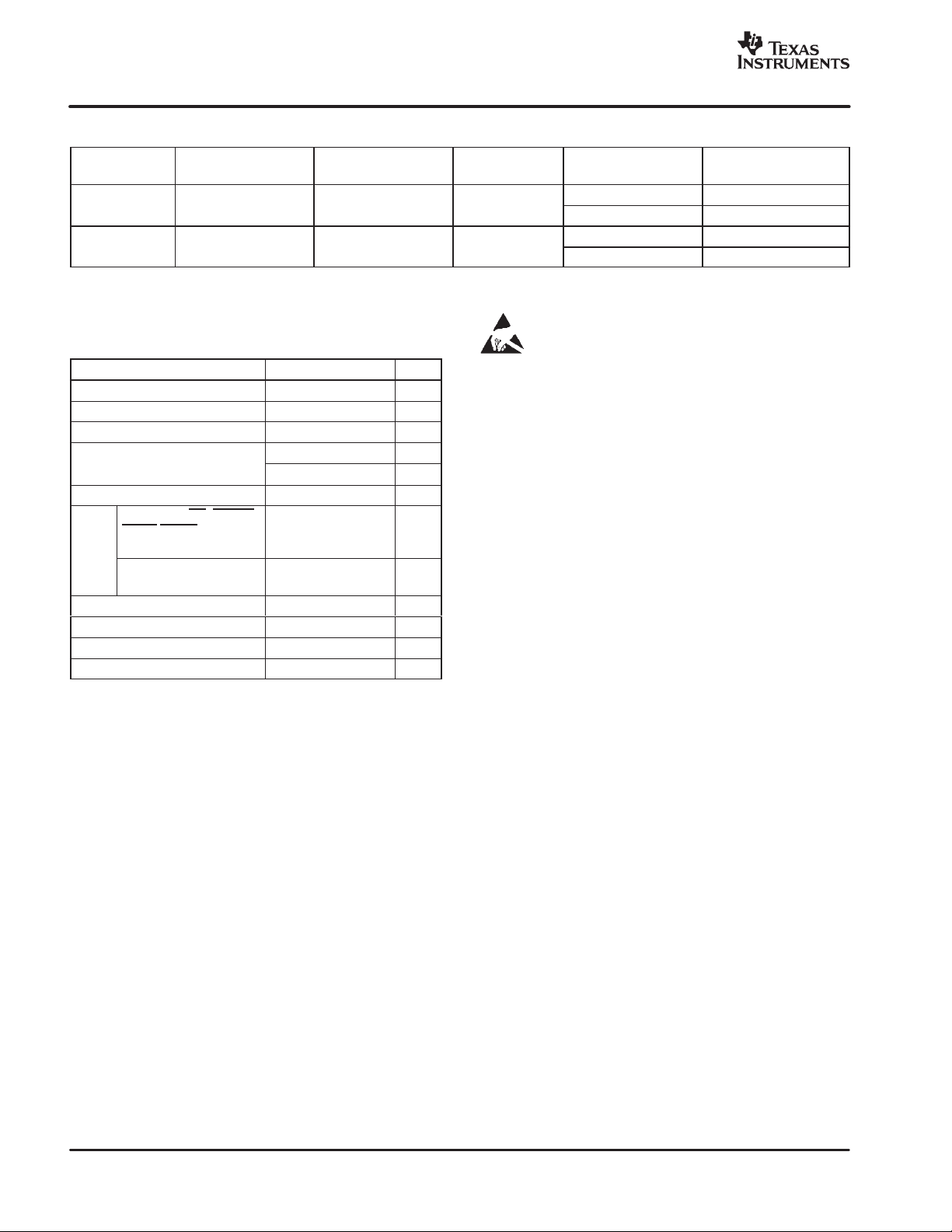

ORDERING INFORMATION

PRODUCT PACKAGE-LEAD

(1)

For the most current package and ordering information, refer to our web site at www.ti.com.

(1)

PACKAGE

DESIGNATOR

PACKAGE

MARKING

ABSOLUTE MAXIMUM RATINGS

over operat i n g f ree-air temperature range unless otherwise noted

ADS1255, ADS1256 UNIT

AVDD to AGND −0.3 to +6 V

DVDD to DGND −0.3 to +3.6 V

AGND to DGND −0.3 to +0.3 V

100, Momentary mA

10, Continuous mA

Analog inputs to AGND −0.3 to AVDD + 0.3 V

DIN, SCLK, CS, RESET,

SYNC/PDWN,

Digita

XTAL1/CLKIN to DGND

D0/CLKOUT, D1, D2, D3

to DGND

Maximum Junction Temperature +150 °C

Operating Temperature Range −40 to +105 °C

Storage Temperature Range −60 to +150 °C

Lead Tem perature (soldering, 10s) +300 °C

(1)

Stresses above those listed under Absolute Maximum Ratings

may cause permanent damage to the device. Exposure to

absolute maximum conditions for extended periods may degrade

device reliability. These are stress ratings only, and functional

operation of the device at these or any other conditions beyond

those specified is not implied.

−0.3 to +6 V

−0.3 to DVDD + 0.3 V

(1)

proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to

complete device failure. Precision integrated circuits may be more

susceptible t o damage because very small parametric changes could

cause the device not to meet its published specifications.

ORDERING NUMBER

ADS1255IDBT Tape and Reel, 250

ADS1255IDBR Tape and Reel, 1000

ADS1256IDBT Tape and Reel, 250

ADS1256IDBR Tape and Reel, 1000

This integrated circuit can be damaged by ESD. Texas

Instruments recommends that all integrated circuits be

handled with appropriate precautions. Failure to observe

TRANSPORT MEDIA,

QUANTITY

2

Page 3

Absolute input voltage

Differential input impedance

Sensor detect current sources

Integral nonlinearity

Offset drift

Gain error

Gain drift

Negative reference input (VREFN)

Positive reference input (VREFP)

IH

V

IH

Master clock rate

www.ti.com

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

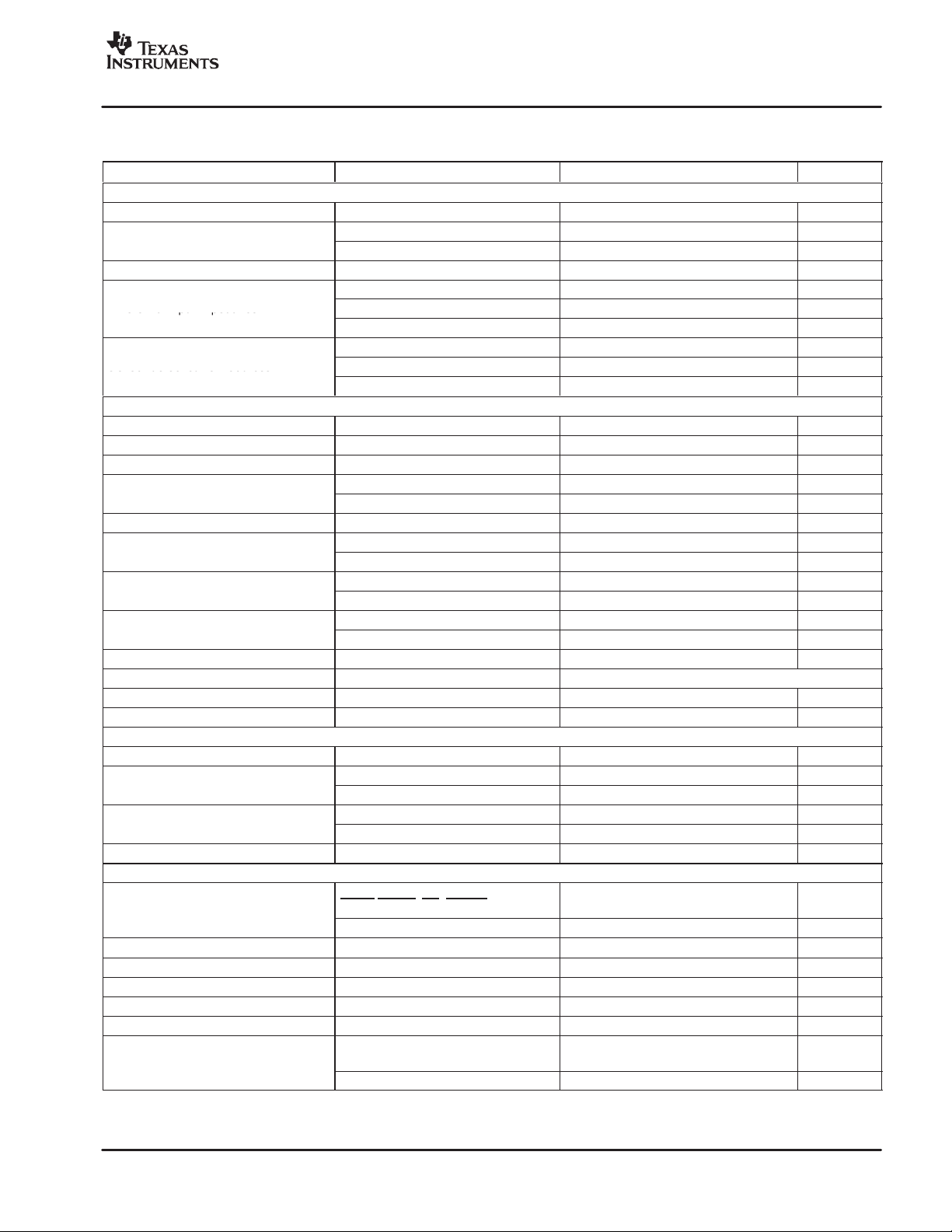

ELECTRICAL CHARACTERISTICS

All specifications at −40°C to +85°C, AVDD = +5V, DVDD = +1.8V, f

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Analog Inputs

Full-scale input voltage (AINP − AINN) ±2V

Absolute input voltage

(AIN0-7, AINCOM to AGND)

Programmable gain amplifier 1 64

Differential input impedance

Sensor detect current sources

System Performance

Resolution 24 Bit

No missing codes All data rates and PGA settings 24 Bit

Data rate (f

Offset error After calibration On the level of the noise

Common-mode rejection f

Noise See Noise Performance Tables

AVDD power-supply rejection ±5% ∆ in AVDD 60 70 dB

DVDD power-supply rejection ±10% ∆ in DVDD 100 dB

Voltage Reference Inputs

Reference input voltage (V

Voltage reference impedance f

Digital Input/Output

V

V

IL

V

OH

V

OL

Input hysteresis 0.5 V

Input leakage 0 < V

Master clock rate

) f

DATA

REF

) V

Buffer off AGND − 0.1 AVDD + 0.1 V

Buffer on AGND AVDD − 2.0 V

Buffer off, PGA = 1, 2, 4, 8, 16 150/PGA kΩ

Buffer off, PGA = 32, 64 4.7 kΩ

Buffer on, f

SDCS[1:0] = 01 0.5 µA

SDCS[1:0] = 10 2 µA

SDCS[1:0] = 11 10 µA

= 7.68MHz 2.5 30,000 SPS

CLKIN

Differential input, PGA = 1 ±0.0003 ±0.0010 %FSR

Differential input, PGA = 64 ±0.0007 %FSR

PGA = 1 ±100 nV/°C

PGA = 64 ±4 nV/°C

After calibration, PGA = 1, Buffer on ±0.005 %

After calibration, PGA = 64, Buffer on ±0.03 %

PGA = 1 ±0.8 ppm/°C

PGA = 64 ±0.8 ppm/°C

(4)

= 60Hz, f

CM

≡ VREFP − VREFN 0.5 2.5 2.6 V

REF

Buffer off AGND − 0.1 VREFP − 0.5 V

Buffer on

Buffer off VREFN + 0.5 AVDD + 0.1 V

Buffer on

= 7.68MHz 18.5 kΩ

CLKIN

DIN, SCLK, XTAL1/CLKIN,

SYNC/PDWN, CS, RESET

D0/CLKOUT, D1, D2, D3 0.8 DVDD DVDD V

IOH = 5mA 0.8 DVDD V

IOL = 5mA 0.2 DVDD V

DIGITAL INPUT

External crystal between XTAL1 and

XTAL2

External oscillator driving CLKIN 0.1 7.68 10 MHz

(6)

(6)

DATA

≤ 50Hz

DATA

< DVDD ±10 µA

= 7.68MHz, PGA = 1, and V

CLKIN

(1)

= 30kSPS

(5)

= +2.5V , unless otherwise noted.

REF

/PGA V

REF

80 MΩ

95 110 dB

AGND VREFP − 0.5 V

VREFN + 0.5 AVDD − 2.0 V

0.8 DVDD 5.25 V

DGND 0.2 DVDD V

2 7.68 10 MHz

(2)

(3)

3

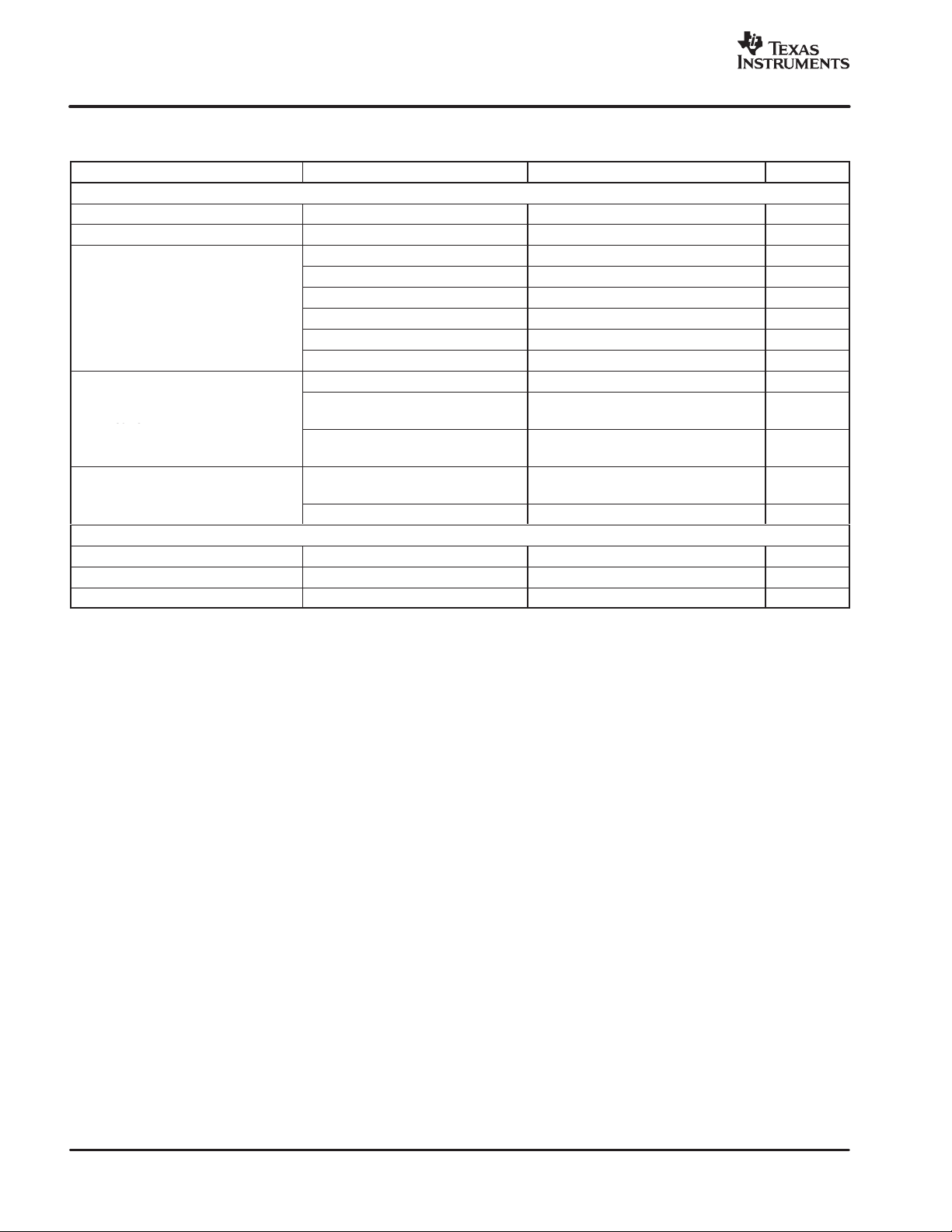

Page 4

AVDD current

DVDD current

Power dissipation

www.ti.com

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

ELECTRICAL CHARACTERISTICS (continued)

All specifications at −40°C to +85°C, AVDD = +5V, DVDD = +1.8V, f

PARAMETER UNITMAXTYPMINTEST CONDITIONS

Power-Supply

AVDD 4.75 5.25 V

DVDD 1.8 3.6 V

Power-down mode 2 µA

Standby mode 20 µA

Normal mode, PGA = 1, Buffer off 7 10 mA

Normal mode, PGA = 64, Buffer off 16 22 mA

Normal mode, PGA = 1, Buffer on 13 19 mA

Normal mode, PGA = 64, Buffer on 36 50 mA

Power-down mode 2 µA

Standby mode, CLKOUT off,

DVDD current

Power dissipation

Temperature Range

Specified −40 +85 °C

Operating −40 +105 °C

Storage −60 +150 °C

(1)

See text for more information on input impedance.

(2)

SPS = samples per second.

(3)

FSR = full-scale range = 4V

(4)

fCM is the frequency of the common-mode input signal.

(5)

Placing a notch of the digital filter at 60Hz (setting f

common-mode rejection of this frequency.

(6)

The reference input range with Buffer on is restricted only if self-calibration or gain self-calibration is to be used. If using system calibration or

writing calibration values directly to the registers, the entire Buffer off range can be used.

REF

DVDD = 3.3V

Normal mode, CLKOUT off,

DVDD = 3.3V

Normal mode, PGA = 1, Buffer off,

DVDD = 3.3V

Standby mode, DVDD = 3.3V 0.4 mW

/PGA.

= 60SPS, 30SPS, 15SPS, 10SPS, 5SPS, or 2.5SPS) will further improve the

DATA

= 7.68MHz, PGA = 1, and V

CLKIN

= +2.5V , unless otherwise noted.

REF

95 µA

0.9 2 mA

38 57 mW

4

Page 5

www.ti.com

ANALOG/DIGITAL

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

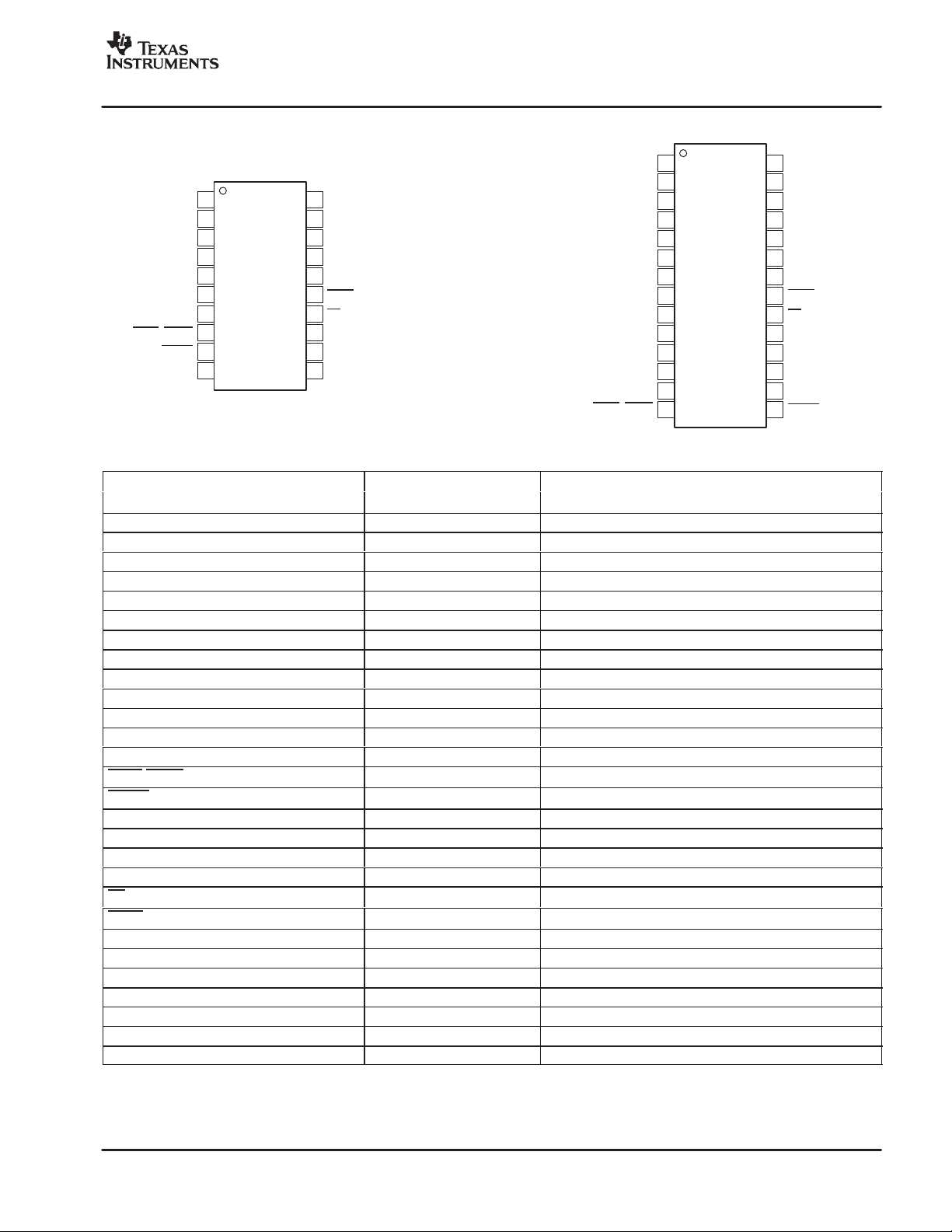

PIN ASSIGNMENTS

AVDD

AGND

VREFN

VREFP

AINCOM

AIN0

AIN1

SYNC, PDWN

RESET

DVDD

SSOP P ACKAGE

(TOP VIEW)

1

2

3

4

5

ADS1255 ADS1256

6

7

8

9

10 11

D1

20

D0/CLKOUT

19

SCLK

18

DIN

17

DOUT

16

15

DRDY

CS

14

XTAL1/CLKIN

13

XTAL2

12

DGND

AVDD

AGND

VREFN

VREFP

AINCOM

AIN0

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

AIN7

SYNC, PDWN

1

2

3

4

5

6

7

8

9

10

11

12

13

14

Terminal Functions

TERMINAL NO.

NAME ADS1255 ADS1256

AVDD 1 1 Analog Analog power supply

AGND 2 2 Analog Analog ground

VREFN 3 3 Analog input Negative reference input

VREFP 4 4 Analog input Positive reference input

AINCOM 5 5 Analog input Analog input common

AIN0 6 6 Analog input Analog input 0

AIN1 7 7 Analog input Analog input 1

AIN2 — 8 Analog input Analog input 2

AIN3 — 9 Analog input Analog input 3

AIN4 — 10 Analog input Analog input 4

AIN5 — 11 Analog input Analog input 5

AIN6 — 12 Analog input Analog input 6

AIN7 — 13 Analog input Analog input 7

SYNC/PDWN 8 14 Digital input

RESET 9 15 Digital input

DVDD 10 16 Digital Digital power supply

DGND 11 17 Digital Digital ground

XTAL2 12 18 Digital

XTAL1/CLKIN 13 19 Digital/Digital input

CS 14 20 Digital input

DRDY 15 21 Digital output: active low Data ready output

DOUT 16 22 Digital output Serial data output

DIN 17 23 Digital input

SCLK 18 24 Digital input

D0/CLKOUT 19 25 Digital IO

D1 20 26 Digital IO

D2 — 27 Digita l IO

D3 — 28 Digita l IO

(1)

Schmitt-Trigger digital input.

(2)

5V tolerant digital input.

(3)

Leave disconnected if external clock input is applied to XTAL1/CLKIN.

(4)

Schmitt-Trigger digital input when the digital I/O is configured as an input.

INPUT/OUTPUT

(1)(2)

: active low Synchronization / power down input

(1)(2)

: active low Reset input

(3)

(1)(2)

: active low Chip select

(1)(2)

(1)(2)

(4)

(4)

(4)

(4)

(2)

Crystal oscillator connection

Crystal oscillator connection / external clock input

Serial data input

Serial clock input

Digital I/O 0 / clock output

Digital I/O 1

Digital I/O 2

Digital I/O 3

DESCRIPTION

D3

28

D2

27

D1

26

D0/CLKOUT

25

SCLK

24

DIN

23

DOUT

22

DRDY

21

20

CS

XTAL1/CLKIN

19

XTAL2

18

DGND

17

DVDD

16

RESET

15

5

Page 6

t

SCLK period

t

SCLK pulse width: high

Final SCLK falling edge of command to first SCLK

www.ti.com

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

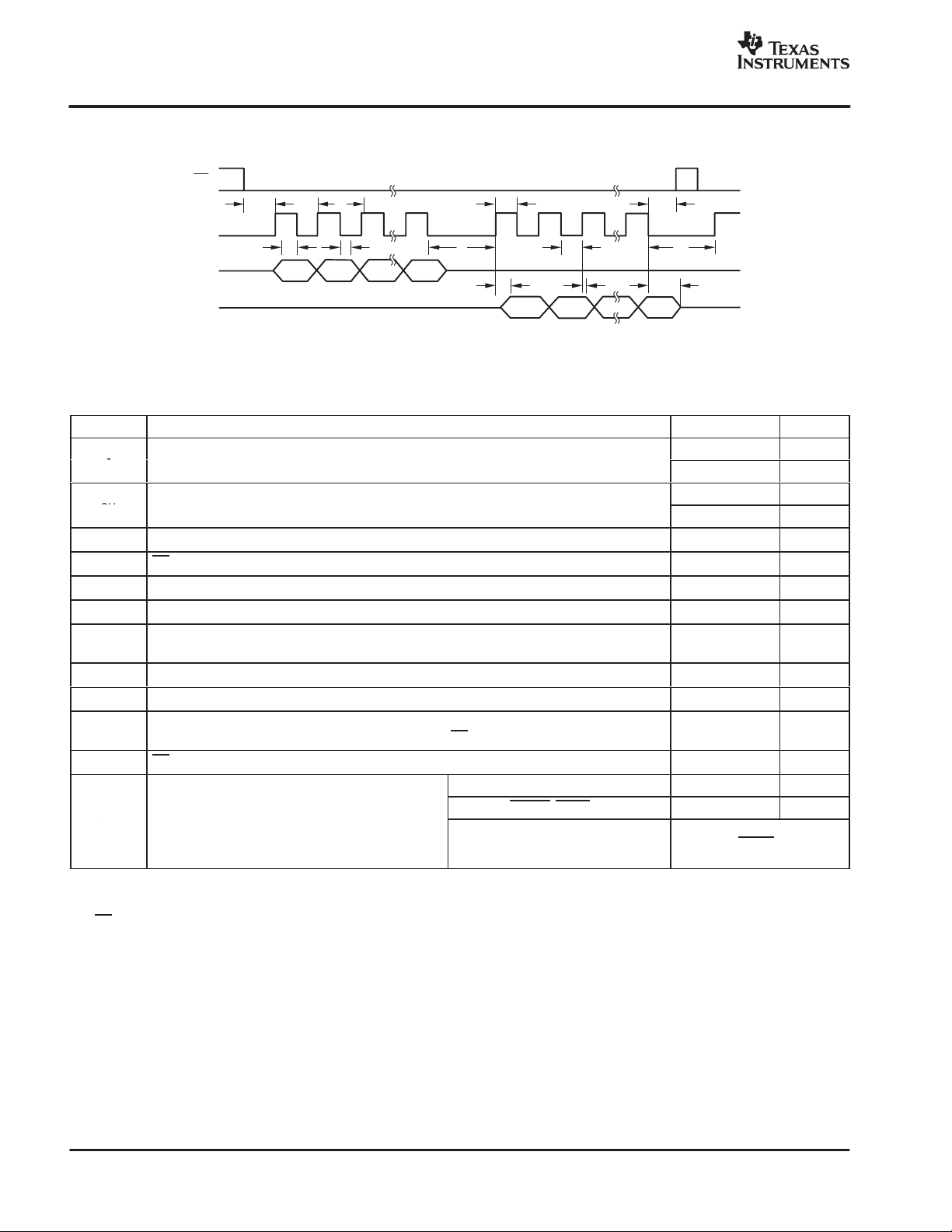

PARAMETER MEASUREMENT INFORMATION

CS

SCLK

DIN

DOUT

t

3

t

4

t

1

t

5

Figure 1. Serial Interface Timing

TIMING CHARACTERISTICS FOR FIGURE 1

SYMBOL DESCRIPTION MIN MAX UNIT

1

2H

t

2L

t

t

t

t

t

t

t

t

10

t

11

(1)

τ

CLKIN

(2)

τ

DATA

(3)

CS can be tied low.

(4)

DOUT load = 20pF 100kΩ to DGND.

SCLK pulse width: low

CS low to first SCLK: setup time

3

Valid DIN to SCLK falling edge: setup time

4

Valid DIN to SCLK falling edge: hold time

5

Delay from last SCLK edge for DIN to first SCLK rising edge for DOUT: RDATA, RDATAC,

6

RREG Commands

SCLK rising edge to valid new DOUT: propagation delay

7

SCLK rising edge to DOUT invalid: hold time

8

Last SCLK falling edge to DOUT high impedance

9

NOTE: DOUT goes high impedance immediately when CS goes high

(3)

CS low after final SCLK falling edge

RREG, WREG, RDATA

RDATAC, RESET, SYNC

rising edge of next command.

RDATAC, STANDBY, SELFOCAL, SYSOCAL, SELFGCAL,

SYSGCAL, SELFCAL

= master clock period = 1/f

= output data period 1/f

DATA

CLKIN

.

.

(4)

t

2H

t

6

t

7

t

2L

t

8

t

10

t

11

t

9

4 τ

10 τ

CLKIN

DATA

200 ns

9 τ

200 ns

0 ns

50 ns

50 ns

50 τ

50 ns

0 ns

6 10 τ

0 ns

4 τ

24 τ

Wait for DRDY to go low

(1)

(2)

DATA

CLKIN

CLKIN

CLKIN

CLKIN

6

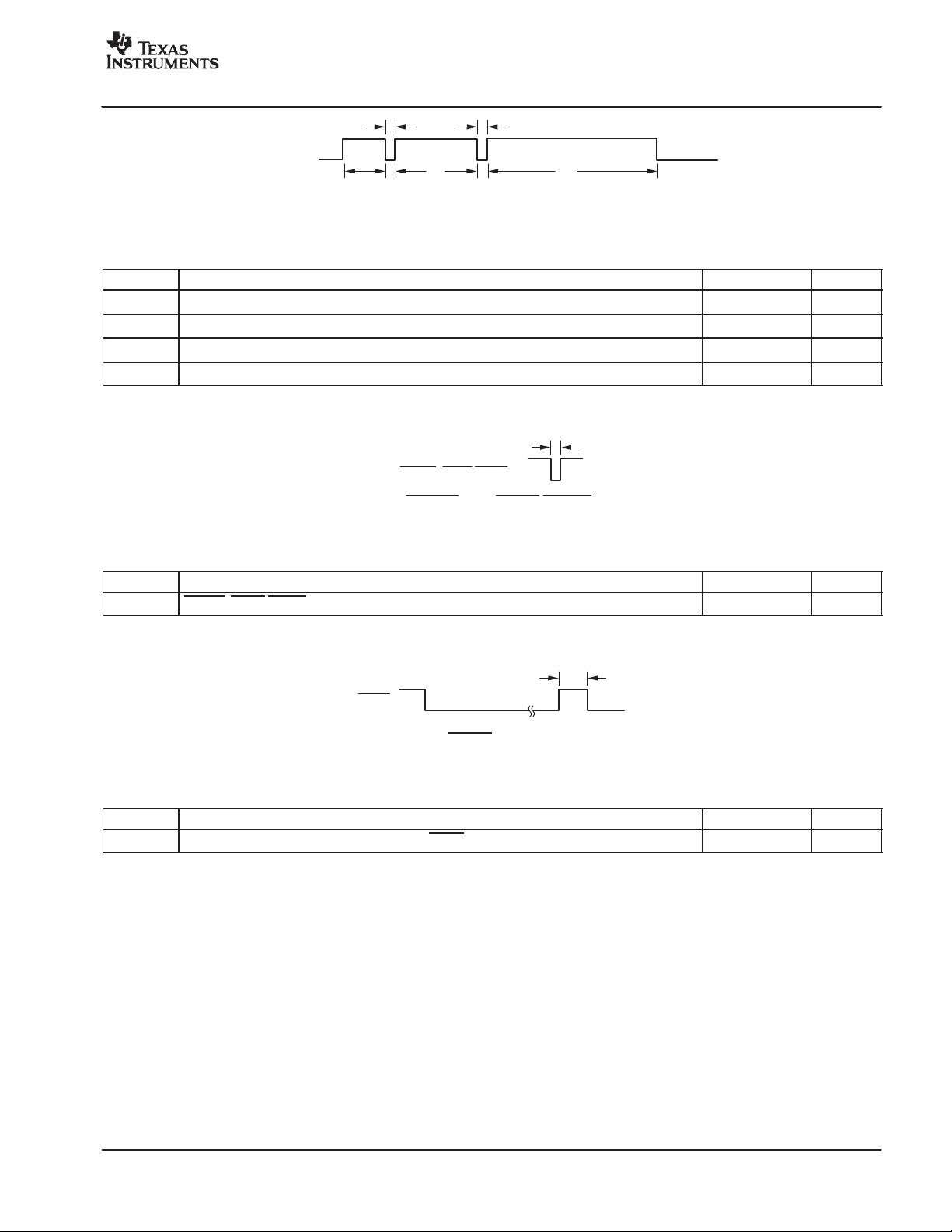

Page 7

www.ti.com

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

SCLK

t

13

t

12

t

13

t

14

t

15

Figure 2. SCLK Reset Timing

TIMING CHARACTERISTICS FOR FIGURE 2

SYMBOL DESCRIPTION MIN MAX UNIT

(1)

t

12

t

13

t

14

t

15

τ

CLKIN

SCLK reset pattern, first high pulse

SCLK reset pattern, low pulse

SCLK reset pattern, second high pulse

SCLK reset pattern, third high pulse

= master clock period = 1/f

CLKIN

.

t

16

RESET, SYNC/PDWN

300 500 τ

5 τ

550 750 τ

1050 1250 τ

CLKIN

Figure 3. RESET and SYNC/PDWN Timing

TIMING CHARACTERISTICS FOR FIGURE 3

SYMBOL DESCRIPTION MIN MAX UNIT

(1)

t

16

τ

CLKIN

RESET, SYNC/PDWN, pulse width

= master clock period = 1/f

CLKIN

.

4 τ

CLKIN

(1)

CLKIN

CLKIN

CLKIN

(1)

t

17

DRDY

Figure 4. DRDY Update Timing

TIMING CHARACTERISTICS FOR FIGURE 4

SYMBOL DESCRIPTION MIN MAX UNIT

(1)

t

17

τ

CLKIN

Conversion data invalid while being updated (DRDY shown with no data retrieval)

= master clock period = 1/f

CLKIN

.

16 τ

CLKIN

(1)

7

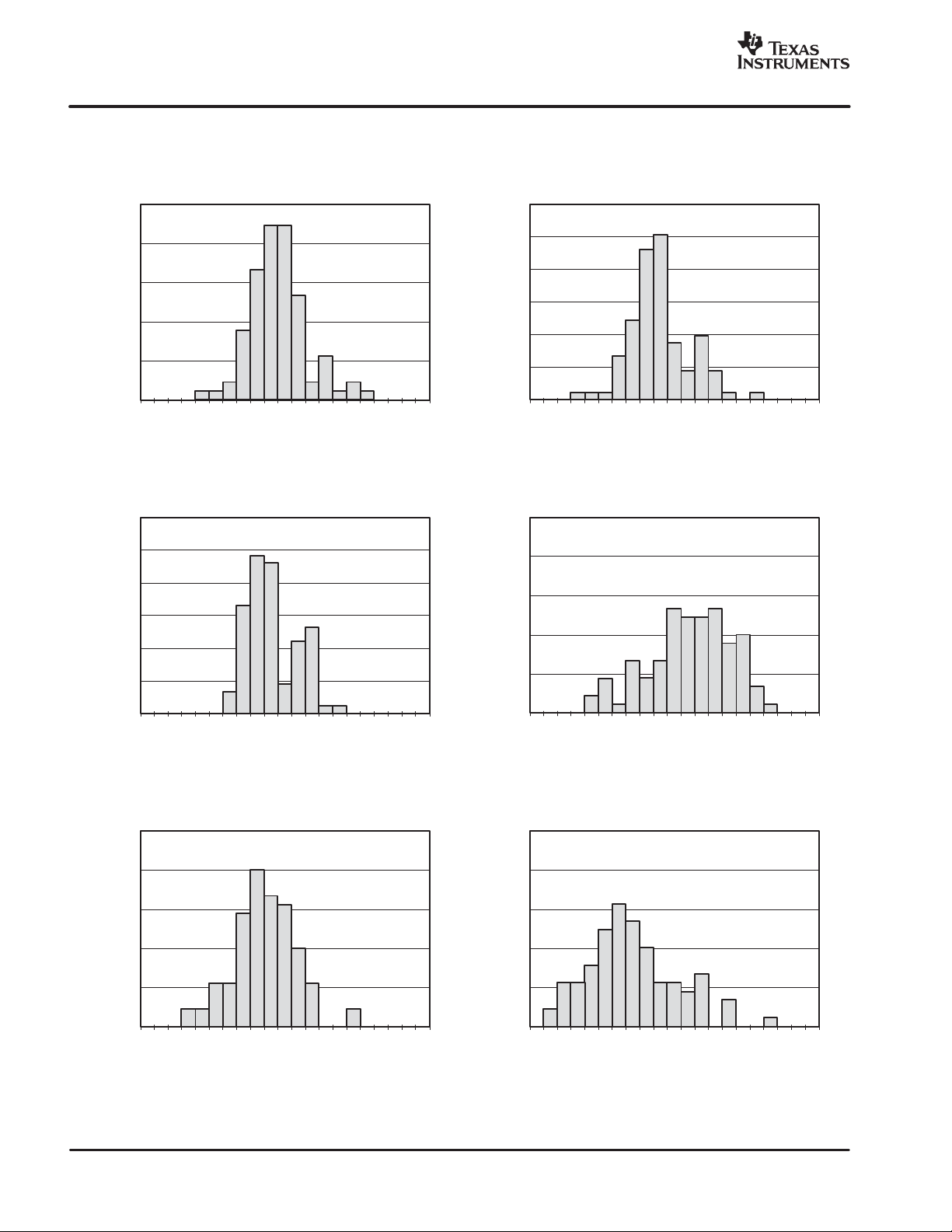

Page 8

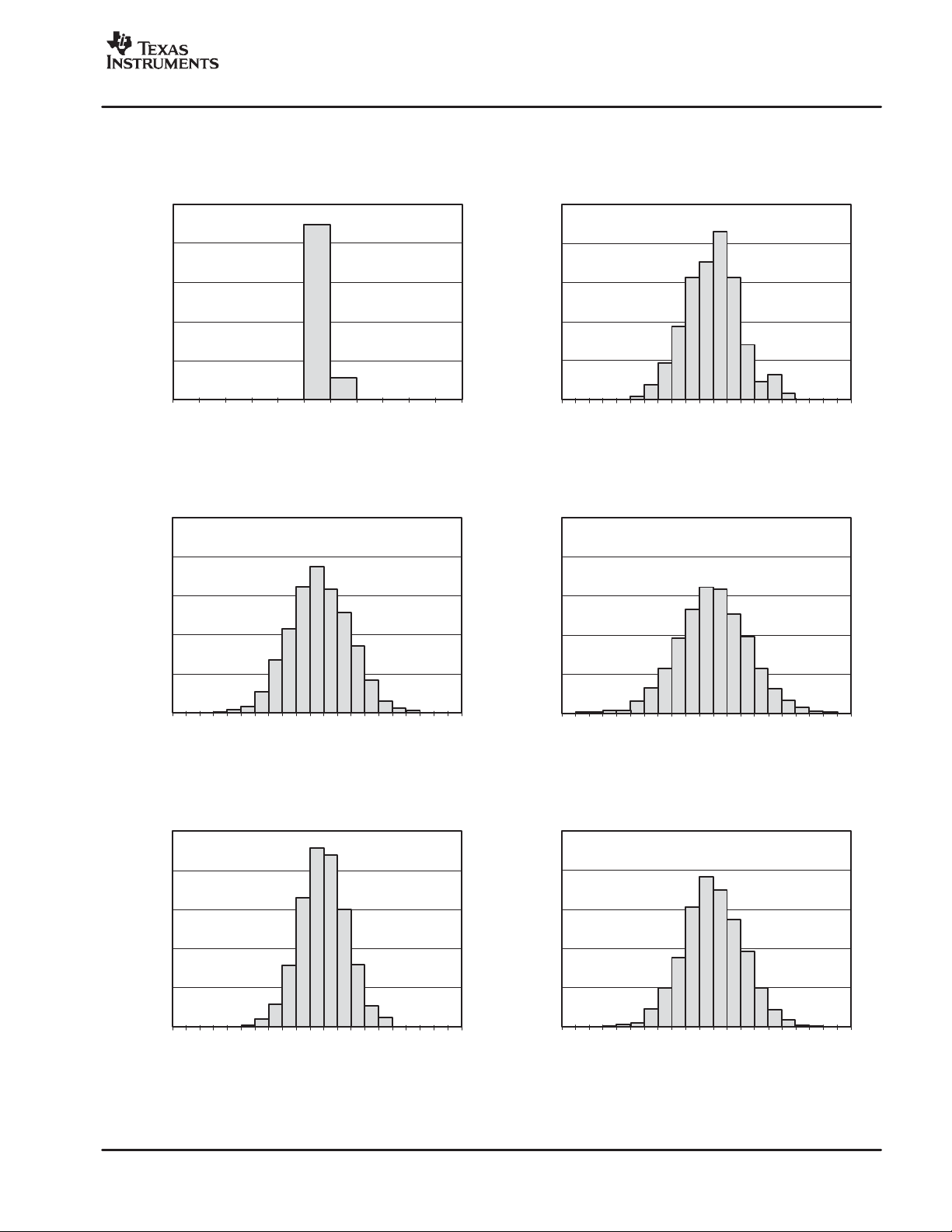

OFFSET DRIFT HISTOGRAM

OFFSET DRIFT HISTOGRAM

GAIN ERROR HISTOGRAM

GAIN ERROR HISTOGRAM

GAIN DRIFT HISTOGRAM

GAIN DRIFT HISTOGRAM

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

TYPICAL CHARACTERISTICS

TA = +25°C, AVDD = 5V, DVDD = 1.8V, f

CLKIN

= 7.68MHz, PGA = 1, and V

= 2.5V , unless otherwise noted.

REF

www.ti.com

25

PGA = 1 90 Units from 3 Production Lots

20

15

10

Percent of Population

5

0

500−450−400−350−300−250−200−150−100

−

30

PGA = 1

25

20

15

10

Percent of Population

5

Offset Drift (nV/_C)

0

50

50

−

100

150

200

90 Units from 3 Production Lots

30

PGA = 64

25

20

15

10

Percent of Population

5

0

10

25

20

15

10

Percent of Population

5

−20−18−16−14−12−

PGA = 64

250

300

350

400

450

500

90 Units from 3 Production Lots

2

−8−6−4−

Offset Drift (nV/_C)

02468

90 Units from 3 Production Lots

1012141618

20

0

0.0100−0.0095−0.0090−0.0085−0.0080−0.0075−0.0070−0.0065−0.0060−0.0055−0.0050−0.0045−0.0040−0.0035−0.0030−0.0025−0.0020−0.0015−0.0010−0.0005

−

25

PGA = 1

20

15

10

Percent of Population

5

0

0

0.1

0.2

0.3

Gain Error (%)

0.4

0.5

0.6

0.7

GainDrift (ppm/_C)

90 Units from 3 Production Lots

0.8

0.9

1.0

1.1

1.2

0

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2.0

0

0.060−0.057−0.054−0.051−0.048−0.045−0.042−0.039−0.036−0.033−0.030−0.027−0.024−0.021−0.018−0.015−0.012−0.009−0.006−0.003

Percent of Population

25

20

15

10

5

0

−

PGA = 64

0

0.1

0.2

0.3

Gain Error (%)

0.4

0.5

0.6

0.7

GainDrift (ppm/_C)

90 Units from 3 Production Lots

0.8

0.9

1.0

1.1

1.2

0

1.3

1.4

1.5

1.6

1.7

1.8

1.9

2.0

8

Page 9

www.ti.com

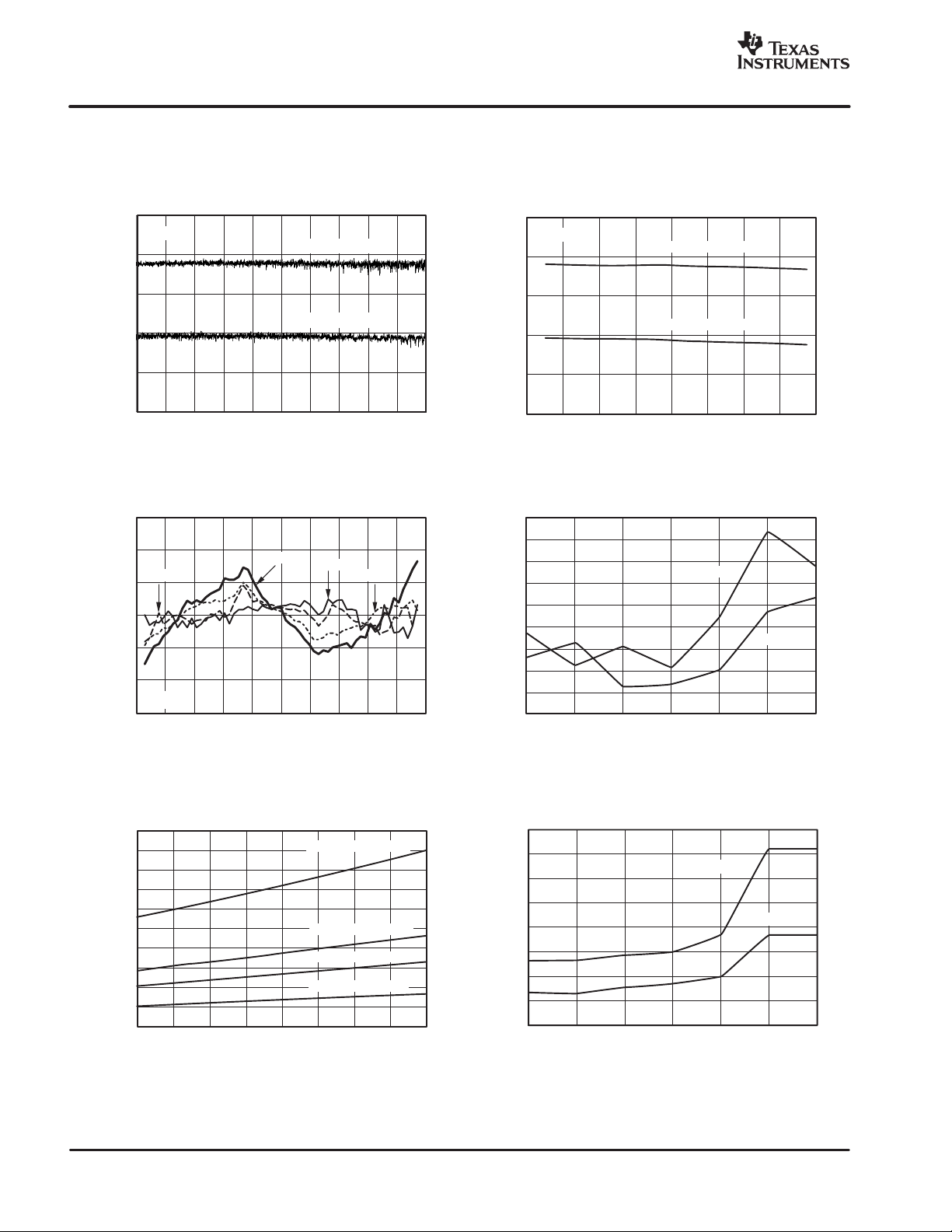

NOISE HISTOGRAM

NOISE HISTOGRAM

NOISE HISTOGRAM

NOISE HISTOGRAM

NOISE HISTOGRAM

NOISE HISTOGRAM

TYPICAL CHARACTERISTICS (continued)

TA = +25°C, AVDD = 5V, DVDD = 1.8V, f

= 7.68MHz, PGA = 1, and V

CLKIN

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

= 2.5V , unless otherwise noted.

REF

100

PGA = 1

Data Rate = 2.5SPS

80

60

40

Percent of Population

20

0

−5−4−3−2−

25

PGA = 1

Data Rate = 1kSPS

20

15

10

Buffer= Off

256 Readings

10 1 2 3 4 5

Output Code (LSB)

Buffer = Off

4096 Readings

25

PGA = 64

Data Rate = 2.5SPS

20

15

10

Percent of Population

5

0

−20−18−16−14−12−

25

PGA = 64

Data Rate = 1kSPS

20

15

10

10

2

−8−6−4−

Output Code(LSB)

02468

Buffer = Off

256 Readings

1012141618

Buffer = Off

4096Readings

20

Percent of Population

5

0

−20−18−16−14−12−

25

PGA = 1

DataRate= 30kSPS

20

15

10

Percent of Population

5

0

100

−90−80−70−60−50−40−30−20−

−

10

2

−8−6−4−

Output Code(LSB)

10

Output Code(LSB)

02468

0

102030405060708090

1012141618

Buffer = Off

4096 Readings

20

100

Percent of Population

5

0

150−135−120−105

−

25

PGA = 64

Data Rate = 30kSPS

20

15

10

Percent of Population

5

0

600−540−480−420−360−300−240−180−120

−

−90−75−60−45−30−

Output Code(LSB)

Output Code(LSB)

15

60

−

0

0

1530456075

4096 Readings

60

120

180

240

90

105

Buffer = Off

300

360

420

120

480

135

540

150

600

9

Page 10

EFFECTIVE NUMBER OF BITS

EFFECTIVE NUMBEROF BITS

INTEGRAL NONLINEARITY vs INPUT SIGNAL

INL (% of FSR)

INTEGRAL NONLINEARITY vs PGA

ANALOG SUPPLY CURRENT vs TEMPERATURE

ANALOG SUPPLY CURRENT vs PGA

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

TYPICAL CHARACTERISTICS (continued)

TA = +25°C, AVDD = 5V, DVDD = 1.8V, f

= 7.68MHz, PGA = 1, and V

CLKIN

= 2.5V , unless otherwise noted.

REF

www.ti.com

0.0006

0.0004

0.0002

−

0.0002

−

0.0004

−

0.0006

23

PGA = 1

22

21

20

ENOB(rms)

19

18

0

PGA = 1

−4−

−

5

vs INPUT VOLTAGE

Input Voltage, V

−2−

3

Input Voltage, VIN(V)

Data Rate = 1kSPS

Data Rate = 30kSPS

2.50 0.5 1.0 1.5 2.0 3.0 3.5 4.0 4.5 5.0

(V)

IN

−40_

C

+125_C

+25_C+85_C

1345210

0.0009

0.0008

0.0007

0.0006

0.0005

(% of FSR)

0.0004

INL

0.0003

0.0002

0.0001

23

PGA = 1

22

21

20

ENOB (rms)

19

18

−

−

30

50

0

2148 643216

vs TEMPERATURE

Data Rate = 1kSPS

Data Rate = 30kSPS

−

10 10 30 90 1107050

Temperature(_C)

PGA Setting

Buffer Off

Buffer On

50

45

40

35

30

25

20

15

Analog Current (mA)

10

5

0

−

−

50

−

30

10 10 30 90 1107050

Temperature(_C)

PGA = 64, Buffer On

PGA = 64, Buffer Off

PGA = 1, Buffer On

PGA = 1, Buffer Off

40

35

30

25

20

15

Analog Current (mA)

10

5

0

2148 643216

PGA Setting

Buffer On

Buffer Off

10

Page 11

www.ti.com

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

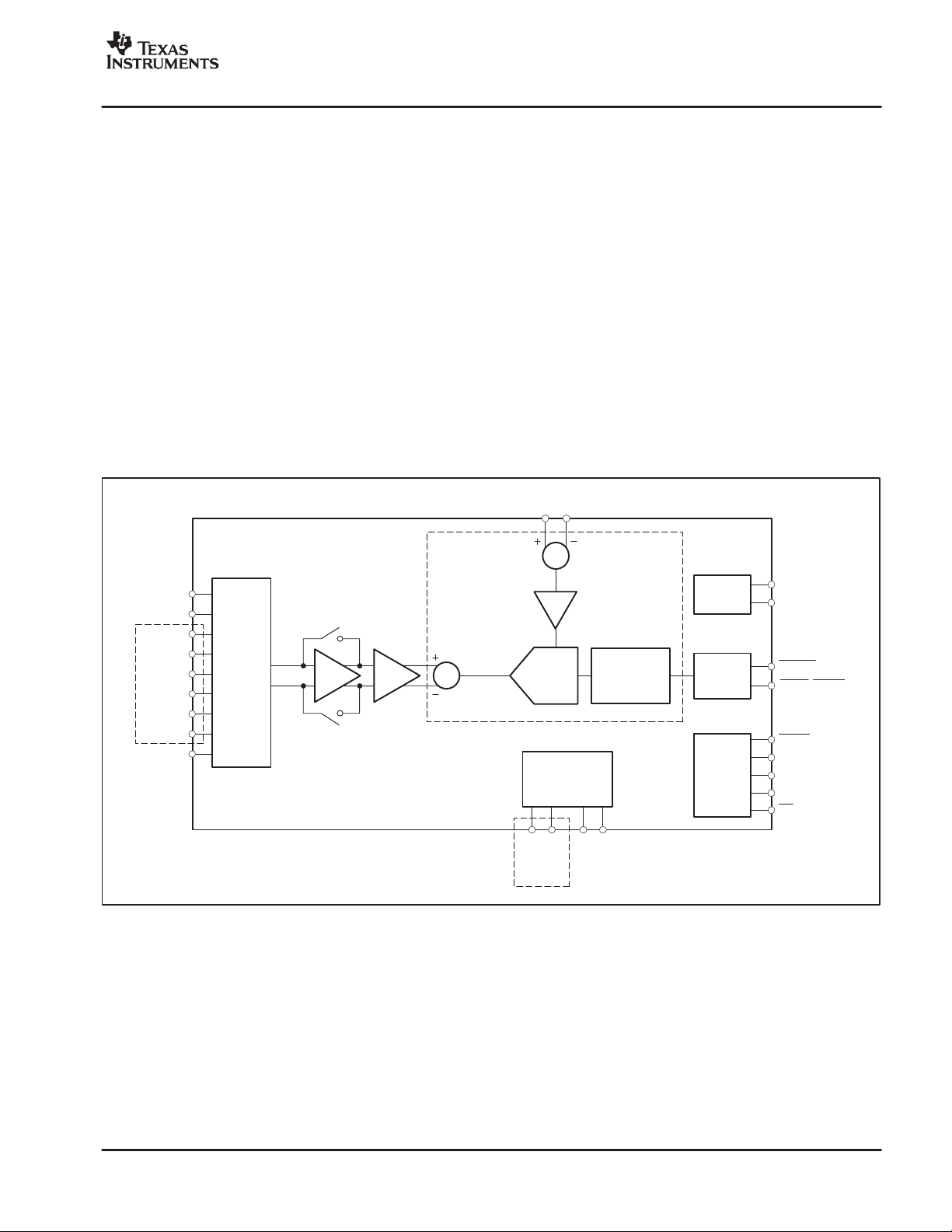

OVERVIEW

The ADS1255 and ADS1256 are very low-noise A/D

converters. The ADS1255 supports one differential or two

single-ended inputs and has two general-purpose digital

I/Os. The ADS1256 supports four differential or eight

single-ended inputs and has four general-purpose digital

I/Os. Otherwise, the two units are identical and are

referred to together in this data sheet as the ADS1255/6.

Figure 5 shows a block diagram of the ADS1256. The

input multiplexer selects which input pins are connected to

the A/D converter. Selectable current sources within the

input multiplexer can check for open- or short-circuit

conditions on the external sensor. A selectable onboard

input buffer greatly reduces the input circuitry loading by

providing up to 80MΩ of impedance. A low-noise PGA

provides a gain of 1, 2, 4, 8, 16, 32, or 64. The ADS1255/6

converter is comprised of a 4th-order, delta-sigma

modulator followed by a programmable digital filter.

AIN0

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

ADS1256 Only

AIN7

AINCOM

Input

Multiplexer

and

Sensor

Detect

AIN

AIN

P

Buffer

N

PGA

1:64

Σ

The modulator measures the amplified differential input

signal, V

reference, V

= (AINP – AINN), against the differential

IN

= (VREFP − VREFN). The differential

REF

reference is scaled internally by a factor of two so that the

full-scale input range is ±2V

(for PGA = 1).

REF

The digital filter receives the modulator signal and

provides a low-noise digital output. The data rate of the

filter is programmable from 2.5SPS to 30kSPS and allows

tradeoffs between resolution and speed.

Communication is done over an SPI-compatible serial

interface with a set of simple commands providing control of

the ADS1255/6. Onboard registers store t he v arious settings

for the input m ultiplexer , s ensor detect current sources, input

buffer enable, PGA setting, data rate, etc. Either an external

crystal or clock oscillator can be used to provide the clock

source. General-purpose digital I /Os p rovide static r ead/write

control of up to four pins. One of the pins can also be used

to supply a programmable clock output.

VREFP VREFN

Σ

V

REF

2

2V

REF

•

V

PGA

IN

4th−Order

Modulator

General

Purpose

Digital I/O

A/D

Converter

Programmable

Digital Filter

Clock

Generator

Control

SPI

Serial

Interface

XTAL1/CLKIN

XTAL2

RESET

SYNC/PDWN

DRDY

SCLK

DIN

DOUT

CS

D3 D2 D1 D0/CLKOUT

ADS1256

Only

Figure 5. Block Diagram

11

Page 12

RATE

RATE

RATE

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

www.ti.com

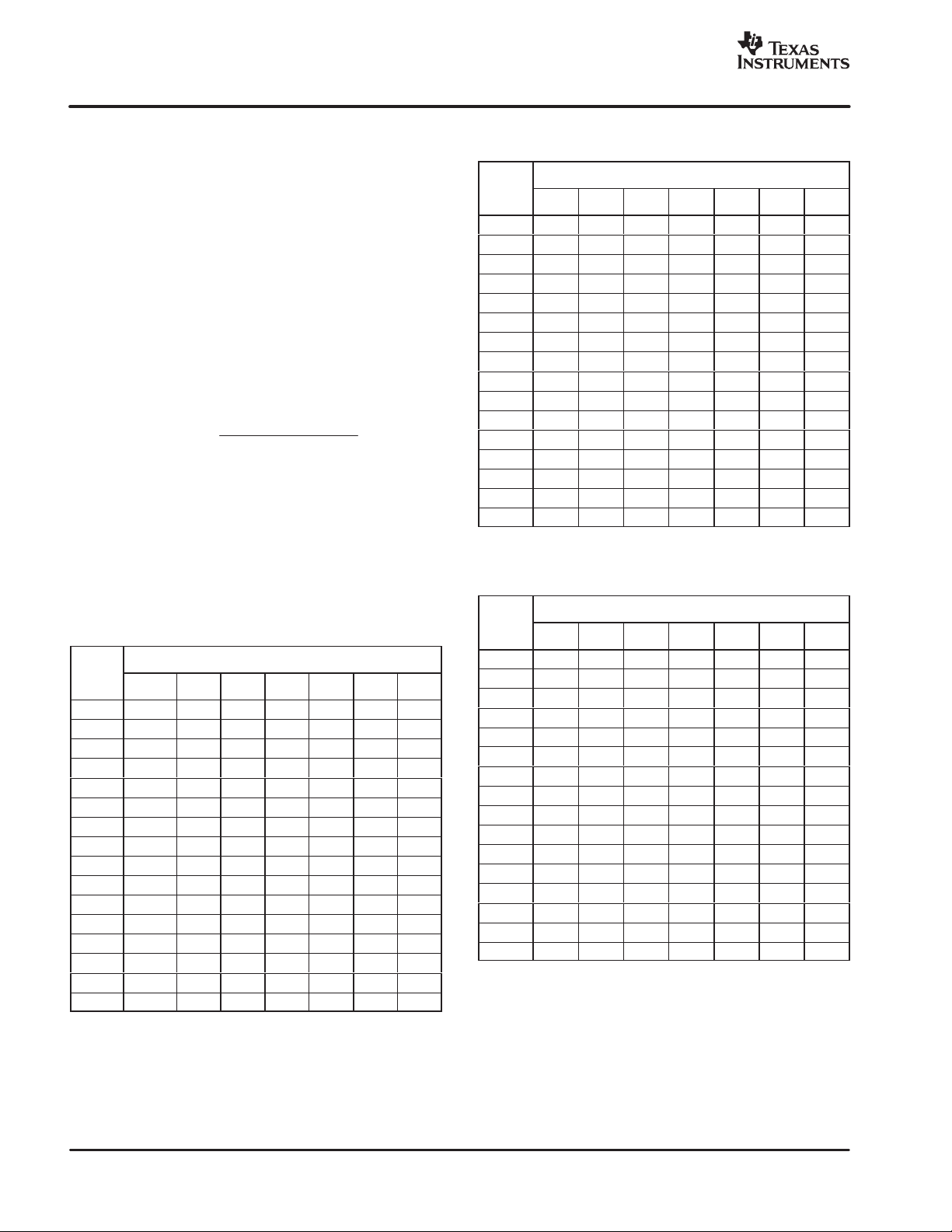

NOISE PERFORMANCE

The ADS1255/6 offer outstanding noise performance that

can be optimized by adjusting the data rate or PGA setting.

As the averaging is increased by reducing the data rate,

the noise drops correspondingly. The PGA reduces the

input-referred noise when measuring lower level signals.

Table 1 through Table 6 summarize the typical noise

performance with the inputs shorted externally. In all six

tables, the following conditions apply: T = +25°C,

AVDD = 5V, DVDD = 1.8V, V

7.68MHz. Table 1 to Table 3 reflect the device input bu ffer

enabled. Table 1 shows the rms value of the input-referred

noise in volts. Table 2 shows the effective number of bits

of resolution (ENOB), using the noise data from Table 1.

ENOB is defined as:

ENOB +

lnǒFSRńRMS Noise

where FSR is the full-scale range. Table 3 shows the

noise-free bits of resolution. It is calculated with the same

formula as ENOB except the peak-to-peak noise value is

used instead of rms noise. Table 4 through Table 6 show

the same noise data, but with the input buffer disabled.

= 2.5V, and f

REF

)

ln(2

=

CLKIN

Ǔ

Table 2. Effective Number of Bits (ENOB, rms)

with Buffer On

DATA

(SPS)

2.5 25.3 24.9 24.9 24.4 23.8 23.0 22.2

5 25.0 24.8 24.5 24.0 23.3 22.7 21.8

10 24.8 24.5 24.1 23.5 22.9 22.3 21.3

15 24.6 24.2 23.8 23.2 22.5 21.8 21.0

25 24.3 24.0 23.4 23.0 22.2 21.5 20.7

30 24.2 23.8 23.3 22.8 22.1 21.5 20.5

50 23.9 23.6 23.0 22.5 21.8 21.1 20.3

60 23.8 23.4 22.9 22.4 21.7 21.0 20.2

100 23.4 23.0 22.5 22.0 21.4 20.8 19.8

500 22.3 21.9 21.5 20.9 20.3 19.6 18.7

1000 21.7 21.3 20.8 20.2 19.8 19.2 18.3

2000 21.2 20.9 20.4 19.7 19.3 18.8 17.9

3750 20.8 20.5 20.0 19.4 19.0 18.4 17.4

7500 20.4 20.1 19.6 19.0 18.5 17.9 17.0

15,000 20.1 19.7 19.3 18.7 18.2 17.7 16.7

30,000 19.8 19.5 19.1 18.5 18.0 17.4 16.5

1 2 4 8 16 32 64

PGA

Table 3. Noise-Free Resolution (bits)

with Buffer On

Table 1. Input Referred Noise (µV, rms)

with Buffer On

DATA

(SPS)

2.5 0.247 0.156 0.080 0.056 0.043 0.037 0.033

5 0.301 0.175 0.102 0.076 0.061 0.045 0.044

10 0.339 0.214 0.138 0.106 0.082 0.061 0.061

15 0.401 0.264 0.169 0.126 0.107 0.085 0.073

25 0.494 0.305 0.224 0.149 0.134 0.102 0.093

30 0.533 0.335 0.245 0.176 0.138 0.104 0.106

50 0.629 0.393 0.292 0.216 0.168 0.136 0.122

60 0.692 0.438 0.321 0.233 0.184 0.146 0.131

100 0.875 0.589 0.409 0.305 0.229 0.170 0.169

500 1.946 1.250 0.630 0.648 0.497 0.390 0.367

1000 2.931 1.891 1.325 1.070 0.689 0.512 0.486

2000 4.173 2.589 1.827 1.492 0.943 0.692 0.654

3750 5.394 3.460 2.376 1.865 1.224 0.912 0.906

7500 7.249 4.593 3.149 2.436 1.691 1.234 1.187

15,000 9.074 5.921 3.961 2.984 2.125 1.517 1.515

30,000 10.728 6.705 4.446 3.280 2.416 1.785 1.742

1 2 4 8 16 32 64

PGA

DATA

(SPS)

2.5 23.0 22.6 22.1 21.7 21.3 20.8 19.7

5 22.3 22.4 21.9 21.3 20.7 20.3 19.3

10 22.3 22.0 21.6 21.0 20.4 19.9 18.9

15 22.0 21.7 21.3 20.7 20.1 19.3 18.7

25 21.7 21.4 21.1 20.5 19.7 19.2 18.5

30 21.8 21.3 20.8 20.4 19.8 19.0 18.1

50 21.3 21.1 20.4 19.9 19.4 18.8 17.9

60 21.3 20.9 20.5 19.8 19.3 18.8 17.8

100 20.9 20.7 20.2 19.6 19.1 18.5 17.4

500 20.1 19.6 19.1 18.6 18.0 17.3 16.3

1000 19.0 18.6 18.1 17.5 17.2 16.5 15.6

2000 18.5 18.1 17.8 17.0 16.6 16.1 15.3

3750 18.1 17.8 17.3 16.6 16.2 15.7 14.7

7500 17.7 17.3 16.9 16.2 15.8 15.3 14.4

15,000 17.3 17.0 16.5 15.9 15.5 14.9 13.9

30,000 17.1 16.7 16.4 15.9 15.4 14.6 13.8

1 2 4 8 16 32 64

PGA

12

Page 13

www.ti.com

RATE

RATE

RATE

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

Table 4. Input Referred Noise (µV, rms)

with Buffer Off

DATA

(SPS)

2.5 0.247 0.149 0.097 0.058 0.036 0.031 0.027

5 0.275 0.176 0.109 0.070 0.046 0.039 0.038

10 0.338 0.201 0.129 0.084 0.063 0.048 0.047

15 0.401 0.221 0.150 0.109 0.070 0.063 0.057

25 0.485 0.279 0.177 0.136 0.093 0.076 0.076

30 0.559 0.315 0.202 0.142 0.107 0.093 0.082

50 0.644 0.390 0.238 0.187 0.129 0.108 0.103

60 0.688 0.417 0.281 0.204 0.134 0.109 0.111

100 0.815 0.530 0.360 0.233 0.169 0.123 0.122

500 1.957 1.148 0.772 0.531 0.375 0.276 0.259

1000 2.803 1.797 1.191 0.940 0.518 0.392 0.365

2000 4.025 2.444 1.615 1.310 0.700 0.526 0.461

3750 5.413 3.250 2.061 1.578 0.914 0.693 0.625

7500 7.017 4.143 2.722 1.998 1.241 0.914 0.857

15,000 8.862 5.432 3.378 2.411 1.569 1.149 1.051

30,000 10.341 6.137 3.873 2.775 1.805 1.313 1.211

1 2 4 8 16 32 64

PGA

Table 5. Effective Number of Bits (ENOB, rms)

with Buffer Off

Table 6. Noise-Free Resolution (bits)

with Buffer Off

DATA

(SPS)

2.5 23.0 22.4 22.0 21.9 21.3 21.1 20.0

5 22.4 22.1 21.9 21.5 21.2 20.4 19.4

10 22.3 22.1 21.7 21.5 20.8 20.3 19.2

15 22.0 21.8 21.4 20.8 20.6 19.9 19.0

25 21.8 21.7 21.1 20.7 20.3 19.5 18.6

30 21.6 21.4 21.1 20.4 20.0 16.4 18.5

50 21.3 21.3 20.7 20.1 19.8 19.1 18.2

60 21.2 21.0 20.6 20.1 19.8 19.1 18.1

100 21.1 20.5 20.3 19.9 19.5 19.0 17.9

500 20.0 19.7 19.3 18.9 18.3 17.8 16.9

1000 19.0 18.7 18.4 17.7 17.5 16.9 15.9

2000 18.5 18.3 17.9 17.4 17.0 16.4 15.6

3750 18.1 17.8 17.5 17.0 16.7 16.1 15.2

7500 17.7 17.6 17.0 16.6 16.2 15.7 14.8

15,000 17.4 17.1 16.8 16.3 15.9 15.3 14.4

30,000 17.1 17.0 16.6 16.0 15.6 15.0 14.4

1 2 4 8 16 32 64

PGA

DATA

(SPS)

2.5 25.3 25.0 24.6 24.4 24.0 23.2 22.5

5 25.1 24.8 24.5 24.1 23.7 22.9 22.0

10 24.8 24.6 24.2 23.8 23.2 22.6 21.7

15 24.6 24.4 24.0 23.4 23.1 22.2 21.4

25 24.3 24.1 23.8 23.1 22.7 22.0 21.0

30 24.1 23.9 23.6 23.1 22.5 21.7 20.9

50 23.9 23.6 23.3 22.7 22.2 21.5 20.5

60 23.8 23.5 23.1 22.5 22.1 21.5 20.4

100 23.5 23.2 22.7 22.4 21.8 21.3 20.3

500 22.3 22.1 21.6 21.2 20.7 20.1 19.2

1000 21.8 21.4 21.0 20.3 20.2 19.6 18.7

2000 21.2 21.0 20.6 19.9 19.8 19.2 18.4

3750 20.8 20.6 20.2 19.6 19.4 18.8 17.9

7500 20.4 20.2 19.8 19.3 18.9 18.4 17.5

15,000 20.1 19.8 19.5 19.0 18.6 18.1 17.2

30,000 19.9 19.6 19.3 18.8 18.4 17.9 17.0

1 2 4 8 16 32 64

PGA

13

Page 14

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

www.ti.com

INPUT MULTIPLEXER

Figure 6 shows a simplified diagram of the input

multiplexer. This flexible block allows any analog input pin

to be connected to either of the converter differential

inputs. That is, any pin can be selected as the positive

input (AIN

negative input (AIN

); likewise, any pin can be selected as the

P

). The pin selection is controlled by

N

the multiplexer register.

The ADS1256 offers nine analog inputs, which can be

configured as four independent differential inputs, eight

single-ended inputs, or a combination of differential and

single-ended inputs.

The ADS1255 offers three analog inputs, which can be

configured as one differential input or two single-ended

inputs. When using the ADS1255 and programming the

input, make sure to select only the available inputs when

programming the input multiplexer register.

In general, there are no restrictions on input pin selection.

AVDD

AIN0

AVDD

However, for optimum analog performance, the following

recommendations are made:

1. For differential measurements use AIN0 through

AIN7, preferably adjacent inputs. For example, use

AIN0 and AIN1. Do not use AINCOM.

2. For single-ended measurements use AINCOM as

common input and AIN0 through AIN7 as

single-ended inputs.

3. Leave any unused analog inputs floating. This

minimizes the input leakage current.

ESD diodes protect the analog inputs. To keep these

diodes from turning on, make sure the voltages on the

input pins do not go below AGND by more than 100mV,

and likewise do not exceed AVDD by more than 100mV:

−100mV < (AIN0 − 7 and AINCOM) < AVDD + 100mV.

When using ADS1255/6 for single-ended measurements,

it is important to note that common input AINCOM does not

need to be tied to ground. For example, AINCOM can be

tied to a midpoint reference such as +2.5V or even AVDD.

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

AIN7

AINCOM

AVDD

AVDD

AVDD

AVDD

AVDD

AVDD

ADS1256 Only

AVDD AGND

InputMultiplexer

AVDD

AIN

AIN

AGND

Sensor Detect

Current

Source

P

Input

Buffer

N

Sensor Detect

Current

Source

14

Figure 6. Simplified Diagram of the Input Multiplexer

Page 15

www.ti.com

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

OPEN/SHORT SENSOR DETECTION

The sensor detect current sources (SDCS) provide a

means to verify the integrity of the external sensor

connected to the ADS1255/6. When enabled, the SDCS

supply a current (I

) of approximately 0.5µA, 2µA, or

SDC

10µA to the sensor through the input multiplexer. The

SDCS bits in the ADCON register enable the SDCS and

set the value of I

SDC

.

When the SDCS are enabled, the ADS1255/6

automatically turns on the analog input buffer regardless

of the BUFEN bit setting. This is done to prevent the input

circuitry from loading the SDCS. AIN

must stay below 3V

P

to be within the absolute input range of the buffer. To

ensure this condition is met, a 3V clamp will start sinking

current from AIN

to AGND if AINP exceeds 3V. Note that

P

this clamp is activated only when the SDCS are enabled.

Figure 7 shows a simplified diagram of ADS1255/6 input

structure with the external sensor modeled as resistance

R

between two input pins. When the SDCS are

SENS

enabled, they source I

AIN

and sink I

P

SDC

The two 25Ω series resistors, R

to the input pin connected to

SDC

from the input pin connected to AINN.

model the

MUX,

ADS1255/6 internal resistances. The signal measured

with the SDCS enabled equals the total IR drop:

I

× (2R

SDC

direct short (that is, R

MUX

+ R

). Note that when the sensor is a

SENS

= 0), there will still be a small

SENS

signal measured by the ADS1255/6 when the SDCS are

enabled: I

SDC

× 2R

MUX

.

ANALOG INPUT BUFFER

To dramatically increase the input impedance presented

by the ADS1255/6, the low-drift chopper-stabilized buffer

can be enabled via the BUFEN bit in the STA TUS register.

The input impedance with the buffer enabled can be

modeled by a resistor, as shown in Figure 8. Table 7 lists

the values of Z

for the different data rate settings. The

EFF

input impedance scales inversely with the frequency of

CLKIN. For example, if f

3.84MHz, Z

for a data rate of 50SPS will double from

EFF

is reduced by half to

CLKIN

80MΩ to 160MΩ.

AIN0

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

ADS1256 Only

AIN7

AINCOM

Input

Multiplexer

AIN

AIN

P

Z

EFF

N

Figure 8. Effective Impedance with Buffer On

AVDD

Sensor Detect

Current Source

R

MUX

Ω

25

AIN

P

3V

R

SENS

R

MUX

25

NOTE: Arrows indicate switch positions when the SDCS are enabled.

Clamp

Ω

AIN

N

Sensor Detect

Current Source

Input

Buffer

Figure 7. Sensor Detect Circuitry

Table 7. Input Impedance with Buffer On

NOTE: f

DATA RATE

(SPS)

30,000 10

15,000 10

7,500 10

3,750 10

2,000 10

1,000 20

500 40

100 40

60 40

≤ 50 80

= 7.68MHz.

CLKIN

Z

EFF

(MΩ)

With the buffer enabled, the voltage on the analog inputs

with respect to ground (listed in the Electrical

Characteristics as Absolute Input Voltage) must remain

between AGND and AVDD − 2.0V. Exceeding this range

reduces performance, in particular the linearity of the

ADS1255/6. This same voltage range, AGND to

AVDD − 2.0V, applies to the reference inputs when

performing a self gain calibration with the buffer enabled.

15

Page 16

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

www.ti.com

PROGRAMMABLE GAIN AMPLIFIER (PGA)

The ADS1255/6 is a very high resolution converter. To

further complement its performance, the low-noise PGA

provides even more resolution when measuring smaller

input signals. For the best resolution, set the PGA to the

highest possible setting. This will depend on the largest

input signal to be measured. The ADS1255/6 full-scale

input voltage equals ±2V

/PGA. Table 8 shows the

REF

full-scale input voltage for the different PGA settings for

V

= 2.5V. For example, if the largest signal to be

REF

measured is 1.0V, the optimum PGA setting would be 4,

which gives a full-scale input voltage of 1.25V. Higher

PGAs cannot be used since they cannot handle a 1.0V

input signal.

Table 8. Full-Scale Input Voltage vs

PGA Setting

PGA SETTING FULL-SCALE INPUT VOLTAGE (V

1 ±5V

2 ±2.5V

4 ±1.25V

8 ±0.625V

16 ±312.5mV

32 ±156.25mV

64 ±78.125mV

REF

= 2.5V)

The PGA is controlled by the ADCON register.

Recalibrating the A/D converter after changing the PGA

setting is recommended. The time required for

self-calibration is dependent on the PGA setting. See the

Calibration section for more details. The analog current

and input impedance (when the buffer is disabled) vary as

a function of PGA setting.

MODULATOR INPUT CIRCUITRY

The ADS1255/6 modulator measures the input signal

using internal capacitors that are continuously charged

and discharged. Figure 9 shows a simplified schematic of

the ADS1255/6 input circuitry with the input buffer

disabled. Figure 10 shows the on/off timings of the

switches of Figure 9. S1 switches close during the input

sampling phase. With S1 closed, C

charges to AINP, C

A1

A2

charges to A I NN, and CB charges to (AINP – AINN). For the

discharge phase, S1 opens first and then S2 closes. C

A1

and CA2 discharge to approximately AVDD/2 and C

discharges to 0V. This two-phase sample/discharge cycle

repeats with a period of τ

SAMPLE

. This time is a function of

the PGA setting as shown in Table 9 along with the values

of the capacitor CA1 = C

AIN0

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

ADS1256 Only

AIN7

AINCOM

A2

Input

Multiplexer

= C

and CB.

A

AIN

P

AIN

N

AVDD/2

S2

S1

S1

S2

AVDD/2

Figure 9. Simplified Input Structure

with Buffer Off

τ

SAMPLE

ON

S

1

OFF

ON

S

2

OFF

Figure 10. S1 and S2 Switch Timing for Figure 9

Table 9. Input Sampling Time, τ

CA and CB vs PGA

PGA

SETTING

1 f

2 f

4 f

8 f

16 f

32 f

B

64 f

(1)

τ

SAMPLE

for f

τ

SAMPLE

CLKIN

CLKIN

CLKIN

CLKIN

CLKIN

CLKIN

CLKIN

CLKIN

(1)

/4 (521ns) 2.1pF 2.4pF

/4 (521ns) 4.2pF 4.9pF

/4 (521ns) 8.3pF 9.7pF

/4 (521ns) 17pF 19pF

/4 (521ns) 33pF 39pF

/2 (260ns) 33pF 39pF

/2 (260ns) 33pF 39pF

= 7.68MHz.

SAMPLE

C

A

C

A1

C

C

A2

B

, and

C

B

16

Page 17

www.ti.com

The charging of the input capacitors draws a transient

current from the sensor driving the ADS1255/6 inputs. The

average value of this current can be used to calculate an

effective impedance Z

where Z

EFF

EFF=VIN

/ I

AVERAGE

Figure 11 shows the input circuitry with the capacitors and

switches of Figure 9 replaced by their effective

impedances. These impedances scale inversely with the

CLKIN frequency. For example, if f

is reduced by a

CLKIN

factor of two, the impedances will double. They also

change with the PGA setting. Table 10 lists the effective

impedances with the buffer off for f

AIN

AIN

AVDD/2

P

N

AVDD/2

AIN0

AIN1

AIN2

AIN3

AIN4

AIN5

AIN6

ADS1256 Only

AIN7

AINCOM

Input

Multiplexer

CLKIN

ZeffA=

ZeffB=

ZeffA=

= 7.68MHz.

τ

SAMPLE/CA

τ

SAMPLE/CB

τ

SAMPLE/CA

Figure 11. Analog Input Effective Impedances

with Buffer Off

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

VREFP VREFN

.

AVDD

Self Gain

Calibration

Z

=18.5k

EFF

AIN

AIN

P

N

(1) f

=7.68MHz

CLKIN

Figure 12. Simplified Reference Input Circuitry

ESD diodes protect the reference inputs. To keep these

diodes from turning on, make sure the voltages on the

reference pins do not go below AGND by more than

100mV, and likewise do not exceed AVDD by 100mV:

AVDD

ESD

Protection

(1)

Ω

Table 10. Analog Input Impedances with Buffer Off

PGA

SETTING

1 260 220

2 130 110

4 65 55

8 33 28

16 16 14

32 8 7

64 8 7

NOTE: f

CLKIN

= 7.68MHz.

Zeff

(kΩ)

A

Zeff

(kΩ)

B

VOLTAGE REFERENCE INPUTS (VREFP, VREFN)

The voltage reference for the ADS1255/6 A/D converter is

the differential voltage between VREFP and VREFN:

V

= VREFP − VREFN. The reference inputs use a

REF

structure similar to that of the analog inputs with the

circuitry on the reference inputs of Figure 12. The load

presented by the switched capacitor can be modeled with

an effective impedance (Z

f

= 7.68MHz. The temperature coefficient of the

CLKIN

) of 18.5kΩ for

EFF

effective impedance of the voltage reference inputs is

approximately 35ppm/°C.

−100mV < (VREFP or VREFN) < AVDD + 100mV

During self gain calibration, all the switches in the input

multiplexer are opened, VREFN is internally connected to

AIN

, and VREFP is connected to AINP. The input buffer

N

may be disabled or enabled during calibration. When the

buffer is disabled, the reference pins will be driving the

circuitry shown in Figure 9 during self gain calibration,

resulting in increased loading. To prevent this additional

loading from introducing gain errors, make sure the

circuitry driving the reference pins has adequate drive

capability. When the buffer is enabled, the loading on the

reference pins will be much less, but the buffer will limit the

allowable voltage range on VREFP and VREFN during

self or self gain calibration as the reference pins must

remain within the specified input range of the buffer in

order to establish proper gain calibration.

A high-quality reference voltage is essential for achieving

the best performance from the ADS1255/6. Noise and drift

on the reference degrade overall system performance. It

is especially critical that special care be given to the

circuitry generating the reference voltages and their layout

when operating in the low-noise settings (that is, with low

data rates) to prevent the voltage reference from limiting

performance.

17

Page 18

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

www.ti.com

DIGITAL FILTER

The programmable low-pass digital filter receives the

modulator output and produces a high-resolution digital

output. By adjusting the amount of filtering, tradeoffs can

be made between resolution and data rate: filter more for

higher resolution, filter less for higher data rate. The filter

is comprised of two sections, a fixed filter followed by a

programmable filter. Figure 13 shows the block diagram of

the analog modulator and digital filter. Data is supplied to

the filter from the analog modulator at a rate of f

CLKIN

/4.

The fixed filter is a 5th-order sinc filter with a decimation

value of 64 that outputs data at a rate of f

CLKIN

/256. The

second stage of the filter is a programmable averager

(1st-order sinc filter) with the number of averages set by

the DRATE register. The data rate is a function of the

number of averages (Num_Ave) and is given by

Equation 1.

f

Data Rate +

Modulator Rate =

f

/4

CLKIN

Analog

Modulator

DataRate +

sinc

Filter

ǒ

f

5

CLKIN

256

CLKIN

256

Programmable

(set by DRATE)

Digital Filter

Ǔǒ

Num_Ave

DataRate +

Averager

Num_Ave

1

Ǔ

(1)

f

CLKIN

1

ǒ

Ǔ

Num_Ave

Ǔ

ǒ

256

Table 11 shows the averaging and corresponding data rate

for each of the 16 valid DRATE register settings when

f

with the CLKIN frequency. For example, reducing f

= 7.68MHz. Note that the data rate scales directly

CLKIN

CLKIN

from 7.68MHz to 3.84MHz reduces the data rate for

DR[7:0] = 11110000 from 30,000SPS to 15,000SPS.

Table 11. Number of Averages and Data Rate for

Each Valid DRATE Register Setting

DRATE

DR[7:0]

11110000 1 (averager bypassed) 30,000

11100000 2 15,000

11010000 4 7500

11000000 8 3750

10110000 15 2000

10100001 30 1000

10010010 60 500

10000010 300 100

01110010 500 60

01100011 600 50

01010011 1000 30

01000011 1200 25

00110011 2000 15

00100011 3000 10

00010011 6000 5

00000011 12,000 2.5

(1)

for f

NUMBER OF AVERAGES FOR

PROGRAMMABLE FILTER

(Num_Ave)

= 7.68MHz.

CLKIN

DAT A R ATE

(1)

(SPS)

Figure 13. Block Diagram of the Analog

Modulator and Digital Filter

18

Page 19

www.ti.com

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

FREQUENCY RESPONSE

The low-pass digital filter sets the overall frequency

response for the ADS1255/6. The filter response is the

product of the responses of the fixed and programmable

filter sections and is given by Equation 2.

256p · f

f

CLKIN

ǒ

f

+

Ǔ

4p ·f

CLKIN

Ť

H

ȧ

ȧ

ȧ

Ǔ

ȧ

sin

ȧ

ȧ

ȧ

64 · sin

ȧ

|H(f)|

ǒ

The digital filter attenuates noise on the modulator output,

including noise from within the ADS1255/6 and external

noise present on the ADS1255/6 input signal. Adjusting

the filtering by changing the number of averages used in

the programmable filter changes the filter bandwidth. With

a higher number of averages, bandwidth is reduced and

more noise is attenuated.

The low-pass filter has notches (or zeros) at the data

output rate and multiples thereof. At these frequencies, the

filter has zero gain. This feature can be useful when trying

to eliminate a particular interference signal. For example,

to eliminate 60Hz (and the harmonics) pickup, set the data

rate equal to 2.5SPS, 5SPS, 10SPS, 15SPS, 30SPS, or

60SPS. To help illustrate the filter characteristics,

Figure 14 and Figure 15 show the responses at the data

rate extremes of 30kSPS and 2.5SPS respectively.

Table 12 summarizes the first-notch frequency and −3dB

bandwidth for the different data rate settings.

0

−

20

−

40

−

60

−

80

Gain (dB)

−

100

−

120

−

140

0 153045607590105120

Figure 14. Frequency Response for

Ť

Ť

(f)

·

H

5

sinc

5

ǒ

sin

ȧ

ȧ

·

ȧ

Num_Ave · sin

ȧ

Frequency (kHz)

Averager

256p · Num_Ave f

f

CLKIN

(f)

Ť

Data Rate = 30kSPS

+

256p · f

ǒ

f

CLKIN

Ǔ

f

DATA

ȧ

ȧ

ȧ

Ǔ

ȧ

=30kSPS

(2)

0

−

6

−

12

−

18

−

24

−

30

Gain (dB)

−

36

−

42

−

48

−

54

−

60

01520105 253035404550 6055

Frequency (Hz)

f

DATA

=2.5SPS

Figure 15. Frequency Response for

Data Rate = 2.5SPS

Table 12. First Notch Frequency and

−3dB Filter Bandwidth

DATA RATE

(SPS)

30,000 30,000 6106

15,000 15,000 4807

7500 7500 3003

3750 3750 1615

2000 2000 878

1000 1000 441

500 500 221

100 100 44.2

(1)

60

(2)

50

(1)

30

(2)

25

(1)

15

(3)

10

(3)

5

(3)

2.5

NOTE: f

(1)

Notch at 60Hz.

(2)

Notch at 50Hz.

(3)

Notch at 50Hz and 60Hz.

CLKIN

= 7.68MHz.

FIRST NOTCH

(Hz)

60 26.5

50 22.1

30 13.3

25 11.1

15 6.63

10 4.42

5 2.21

2.5 1.1

−3dB BANDWIDTH

(Hz)

The digital filter low-pass characteristic repeats at

multiples of the modulator rate of f

/4. Figure 16 and

CLKIN

Figure 17 show the responses plotted out to 7.68MHz at

the data rate extremes of 30kSPS and 2.5SPS. Notice

how the responses near DC, 1.92MHz, 3.84MHz,

19

Page 20

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

www.ti.com

5.76MHz, 7.68MHz, are the same. The digital filter will

attenuate high-frequency noise on the ADS1255/6 inputs

up to the frequency where the response repeats. If

significant noise on the inputs is present above this

frequency, make sure to remove with external filtering.

Fortunately, this can be done on the ADS1255/6 with a

simple RC filter, as shown in the Applications Section (see

Figure 25).

0

−

20

−

40

−

60

−

80

Gain (dB)

−

100

−

120

−

140

0 1.92 3.84 5.76 7.68

Frequency(MHz)

f

DATA

f

CLKIN

= 30k SPS

=7.68MHz

Table 13. Settling Time vs Data Rate

DATA RATE

(SPS)

30,000 0.21

15,000 0.25

7500 0.31

3750 0.44

2000 0.68

1000 1.18

500 2.18

100 10.18

60 16.84

50 20.18

30 33.51

25 40.18

15 66.84

10 100.18

5 200.18

2.5 400.18

NOTE: f

CLKIN

= 7.68MHz.

SETTLING TIME (t18)

(ms)

Figure 16. Frequency Response Out to 7.68MHz

for Data Rate = 30kSPS

0

−

20

−

40

−

60

−

80

Gain (dB)

−

100

−

120

−

140

0 1.92 3.84 5.76 7.68

Frequency (MHz)

f

DATA

f

CLKIN

=2.5SPS

= 7.68M H z

Figure 17. Frequency Response Out to 7.68MHz

for Data Rate = 2.5SPS

SETTLING TIME

The ADS1255/6 features a digital filter optimized for fast

settling. The settling time (time required for a step change

on the analog inputs to propagate through the filter) for the

different data rates is shown in Table 13. The following

sections highlight the single-cycle settling ability of the

filter and show various ways to control the conversion

process.

Settling Time Using Synchronization

The SYNC/PDWN pin allows direct control of conversion

timing. Simply issue a Sync command or strobe the

SYNC

/PDWN pin after changing the analog inputs (see

the Synchronization section for more information). The

conversion begins when SYNC/PDWN is taken high,

stopping the current conversion and restarting the digital

filter. As soon as SYNC

/PDWN goes low, the DRDY

output goes high and remains high during the conversion.

After the settling time (t

), DRDY goes low, indicating that

18

data is available. The ADS1255/6 settles in a single

cycle—there is no need to ignore or discard data after

synchronization. Figure 18 shows the data retrieval

sequence following synchronization.

−AIN

AIN

P

N

SYNC/PDWN

t

18

DRDY

DIN

DOUT

RDATA

Settled

Data

Figure 18. Data Retrieval After Synchronization

20

Page 21

www.ti.com

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

Settling Time Using the Input Multiplexer

The most efficient way to cycle through the inputs is to

change the multiplexer setting (using a WREG command

to the multiplexer register MUX) immediately after DRDY

goes low. Then, after changing the multiplexer, restart the

conversion process by issuing the SYNC and WAKEUP

commands, and retrieve the data with the RDATA

command. Changing the multiplexer before reading the

data allows the ADS1256 to start measuring the new input

channel sooner. Figure 19 demonstrates efficient input

cycling. There is no need to ignore or discard data while

cycling through the channels of the input multiplexer

because the ADS1256 fully settles before DRDY

goes low,

indicating data is ready.

Step 1: When DRDY

goes low, indicating that data is ready

for retrieval, update the multiplexer register MUX using the

WREG command. For example, setting MUX to 23h gives

AIN

= AIN2, AINN = AIN3.

P

Step 2: Restart the conversion process by issuing a SYNC

command immediately followed by a WAKEUP command.

Make sure to follow timing specification t

between

11

commands.

Step 3: Read the data from the previous conversion using

the RDATA command.

Step 4: When DRDY

goes low again, repeat the cycle by

first updating the multiplexer register, then reading the

previous data.

Table 14

g iv es th e effective overall throughput (1/t

) when

19

cycling the input multiplexer. The values for throughput

(1/t19) assume the multiplexer was changed with a 3-byte

WREG command and f

SCLK

= f

CLKIN

/4.

Table 14. Multiplexer Cycling Throughput

NOTE: f

DATA RATE

(SPS)

30,000 4374

15,000 3817

7500 3043

3750 2165

2000 1438

1000 837

500 456

100 98

60 59

50 50

30 30

25 25

15 15

10 10

5 5

2.5 2.5

= 7.68MHz.

CLKIN

CYCLING THROUGHPUT (1/t19)

(Hz)

DRDY

DIN

DOUT

MUX

Register

WREG 23h

to MUX reg

01h

AINP=AIN0,AINN=AIN

t

18

RDATASYNC WAKEUP SYNC WAKEUP

Data from

MUX = 01h

1

AINP=AIN2,AINN=AIN3

23h

WREG 45h

to MUX reg

t

19

RDATA

AINP=AIN4,AINN=AIN5

45h

Data from

MUX = 2 3h

Figure 19. Cycling the ADS1256 Input Multiplexer

21

Page 22

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

www.ti.com

Settling Time Using One-Shot Mode

A dramatic reduction in power consumption can b e achieved

in the ADS1255/6 by performing o ne-shot c onversions u sing

the STANDBY command; the sequence for this is shown in

Figure 20. Issue the WAKEUP command from Standby

mode to begin a one-shot conversion. Following the settling

time (t

), DRDY will go low, indicating that the conversion i s

18

complete and data can b e r ead u sing t he RDAT A command.

The ADs1255/6 settles in a s ingle c ycle—there is no n eed t o

ignore or discard data. Following the data read cycle, issue

another ST ANDBY command to reduce power consumption.

When ready for the next measurement, repeat the cycle

starting with another WAKEUP command.

Settling Time while Continuously Converting

After a synchronization, input multiplexer change, or

wakeup from Standby mode, the ADS1255/6 will

continuously convert the analog input. The conversions

coincide with the falling edge of DRDY

. While continuously

converting, it is often more convenient to consider settling

times in terms of DRDY periods, as shown in Table 15.

The DRDY

period equals the inverse of the data rate.

If there is a step change on the input signal while

continuously converting, performing a synchronization

operation to start a new conversion is recommended.

Otherwise, the next data will represent a combination of

the previous and current input signal and should therefore

be discarded. Figure 21 shows an example of readback in

this situation.

Table 15. Data Settling Delay vs Data Rate

DATA RATE

(SPS)

30,000 5

15,000 3

7500 2

3750 1

2000 1

1000 1

500 1

100 1

60 1

50 1

30 1

25 1

15 1

10 1

5 1

2.5 1

SETTLING TIME

(DRDY Periods)

ADS1255/6

Status

DRDY

DIN

DOUT

STANDBY

Standby

Mode

WAKEUP

t

18

Performing One−Shot Conversion

RDATA

Settled

Data

STANDBY

Figure 20. One-Shot Conversions Using the STANDBY Command

New V

IN

IN

=AIN

−

P

AIN

DRDY

DIN

DOUT

N

Old V

IN

OldVINData

Mix of

Old and New

Data

V

IN

Fully Settled

New V

RDATA

IN

Data

Settled

Data

V

Figure 21. Step Change on VIN while Continuously Converting for Data Rates ≤ 3750SPS

Standby

Mode

22

Page 23

www.ti.com

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

DATA FORMAT

The ADS1255/6 output 24 bits of data in Binary Two’s

Complement format. The LSB has a weight of

2V

/(PGA(223 − 1)). A positive full-scale input produces

REF

an output code of 7FFFFFh and the negative full-scale

input produces an output code of 800000h. The output

clips at these codes for signals exceeding full-scale.

Table 16 summarizes the ideal output codes for different

input signals.

Table 16. Ideal Output Code vs Input Signal

INPUT SIGNAL V

(AINP − AINN)

) 2V

w

PGA

) 2V

PGA(223* 1

* 2V

PGA(223* 1

* 2V

v

(1)

Excludes effects of noise, INL, offset, and gain errors.

REF

PGA

IN

REF

REF

IDEAL OUTPUT CODE

7FFFFFh

000001h

)

0 000000h

REF

2

ǒ

223* 1

)

23

Ǔ

FFFFFFh

800000h

(1)

CLOCK OUTPUT (D0/CLKOUT)

The clock output pin can be used to clock another device,

such as a microcontroller. This clock can be configured to

operate at frequencies of f

CLKIN

, f

CLKIN

/2, or f

CLKIN

/4 using

CLK1 and CLK0 in the ADCON register. Note that enabling

the output clock and driving an external load will increase

the digital power dissipation. Standby mode does not

affect the clock output status. That is, if Standby is

enabled, the clock output will continue to run during

Standby mode. If the clock output function is not needed,

it should be disabled by writing to the ADCON register after

power-up or reset.

CLOCK GENERATION

The master clock source for the ADS1255/6 can be

provided using an external crystal or clock generator.

When the clock is generated using a crystal, external

capacitors must be provided to ensure start-up and a

stable clock frequency, as shown in Figure 22. Table 17

lists two recommended crystals. Long leads should be

minimized with the crystal placed close to the ADS1255/6

pins. For information on ceramic resonators, see

application note SBAA104, Using Ceramic Resonators

with the ADS1255/6, available for download at

www.ti.com.

GENERAL-PURPOSE DIGITAL I/O (D0-D3)

The ADS1256 has 4 pins dedicated for digital I/O and the

ADS1255 has 2 digital I/O pins. All of the digital I/O pins are

individually configurable as either inputs or outputs

through the IO register. The DIR bits of the IO register

define whether each pin is an input or output, and the DIO

bits control the status of the pins. Reading back the DIO

register shows the state of the digital I/O pins, whether they

are configured as inputs or outputs by the DIR bits. When

digital I/O pins are configured as inputs, the DIO register

is used to read the state of these pins. When configured as

outputs, DIO sets the output value. On the ADS1255, the

digital I/O pins D2 and D3 do not exist and the settings of

the IO register bits that control operation of D2 and D3

have no effect on that device.

During Standby and Power-Down modes, the GPIO

remain active. If configured as outputs, they continue to

drive the pins. If configured as inputs, they must be driven

(not left floating) to prevent excess power dissipation.

The digital I/O pins are set as inputs after power-up or a

reset, except for D0/CLKOUT, which is enabled as a clock

output. If the digital I/O pins are not used, either leave them

as inputs tied to ground or configure them as outputs. This

prevents excess power dissipation.

XTAL1/CLKIN

C

Crystal

1

XTAL2

C

2

C

: 5pF to 20pF

1,C2

Figure 22. Crystal Connection

Table 17. Recommended Crystals

MANUFACTURER FREQUENCY

Citizen 7.68MHz CIA/53383

ECS 8.0MHz ECS-80-5-4

PART

NUMBER

When using a crystal, neither the XTAL1/CLKIN nor

XTAL2 pins can be used to drive any other logic. If other

devices need a clock source, the D0/CLKOUT pin is

available for this function. When using an external clock

generator, supply the clock signal to XTAL1/CLKIN and

leave XTAL2 floating. Make sure the external clock

generator supplies a clean clock waveform. Overshoot

and glitches on the clock will degrade overall performance.

23

Page 24

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

www.ti.com

CALIBRATION

Offset and gain errors can be minimized using the

ADS1255/6 onboard calibration circuitry. Figure 23 shows

the calibration block diagram. Offset errors are corrected

with the Offset Calibration (OFC) register and, likewise,

full-scale errors are corrected with the Full-Scale

Calibration (FSC) register. Each of these registers is

24-bits and can be read from or written to.

VREFNVREFP

AIN

P

AIN

PGA

N

Figure 23. Calibration Block Diagram

The output of the ADS1255/6 after calibration is shown in

Equation 3.

Analog

Modulator

Digital

Filter

Σ

OFC

Register

X

FSC

Register

Output

Output +

PGA · V

ǒ

2V

REF

OFC

IN

*

a

Ǔ

FSC ·b

(3)

where α and β vary with data rate settings shown in

Table 18 along with the ideal values (assumes perfect

analog performance) for OFC and FSC. OFC is a Binary

Two’s Complement number that can range from

−8,388,608 to 8,388,607, while FSC is unipolar ranging

from 0 to 16,777,215.

The ADS1255/6 supports both self-calibration and system

calibration for any PGA setting using a set of five

commands: SELFOCAL, SELFGCAL, SELFCAL,

SYSOCAL, and SYSGCAL. Calibration can be done at

any time, though in many applications the ADS1255/6 drift

performance is low enough that a single calibration is all

that is needed. DRDY

goes high when calibration begins

and remains so until settled data is ready afterwards.

There is no need to discard data after a calibration. It is

strongly recommended to issue a self-calibration

command after power-up when the reference has

stabilized. After a reset, the ADS1255/6 performs

self-calibration. Calibration must be performed whenever

the data rate changes and should be performed when the

buffer configuration or PGA changes.

Table 18. Calibration Values for Different Data Rate Settings

DATA RATE

(SPS)

30,000 400000

15,000 400000

7500 400000

3750 400000

2000 3C0000

1000 3C0000

500 3C0000

100 4B0000

60 3E8000

50 4B0000

30 3E8000

25 4B0000

15 3E8000

10 5DC000

5 5DC000

2.5 5DC000

α β IDEAL OFC IDEAL FSC

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

1.8639 000000

1.8639 000000

1.8639 000000

1.8639 000000

1.7474 000000

1.7474 000000

1.7474 000000

2.1843 000000

1.8202 000000

2.1843 000000

1.8202 000000

2.1843 000000

1.8202 000000

2.7304 000000

2.7304 000000

2.7304 000000

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

44AC08

44AC08

44AC08

44AC08

494008

494008

494008

3A99A0

4651F3

3A99A0

4651F3

3A99A0

4651F3

2EE14C

2EE14C

2EE14C

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

H

24

Page 25

www.ti.com

DATA RATE

DATA RATE

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

Self-Calibration

Self-calibration corrects internal offset and gain errors.

During self-calibration, the appropriate calibration signals

are applied internally to the analog inputs.

SELFOCAL performs a self offset calibration. The analog

inputs AIN

and AINN are disconnected from the signal

P

source and connected to AVDD/2. See Table 19 for the

time required for self offset calibration for the dif ferent data

rate settings. As with most of the ADS1255/6 timings, the

calibration time scales directly with f

. Self offset

CLKIN

calibration updates the OFC register.

Table 19. Self Offset and System Offset

Calibration Timing

DATA RATE

(SPS)

30,000 387µs

15,000 453µs

7500 587µs

3750 853µs

2000 1.3ms

1000 2.3ms

500 4.3ms

100 20.3ms

60 33.7ms

50 40.3ms

30 67.0ms

25 80.3ms

15 133.7ms

10 200.3ms

5 400.3ms

2.5 800.3ms

NOTE: For f

CLKIN

SELF OFFSET CALIBRATION AND

SYSTEM OFFSET CALIBRATION TIME

= 7.68MHz.

SELFGCAL performs a self gain calibration. The analog

inputs AIN

source and AIN

AIN

N

and AINN are disconnected from the signal

P

is connected internally to VREFP while

P

is connected to VREFN. Self gain calibration can be

used with any PGA setting, and the ADS1255/6 has

excellent gain calibration even for the higher PGA settings,

as shown in the Typical Characteristics section. Using the

buffer will limit the common-mode range of the reference

inputs during self gain calibration since they will be

connected to the buffer inputs and must be within the

specified analog input range. When the voltage on VREFP

or VREFN exceeds the buffer analog input range

(AVDD – 2.0V), the buffer must be turned off during self

gain calibration. Otherwise, use system gain calibration or

write the gain coefficients directly to the FSC register.

Table 20 shows the time required for self gain calibration

for the different data rate and PGA settings. Self gain

calibration updates the FSC register.

Table 20. Self Gain Calibration Timing

DATA RATE

(SPS)

30,000 417µs 417µs 451µs 517µs 651µs

15,000 484µs 484µs 484µs 551µs 551µs

7500 617µs 617µs 617µs 617µs 751µs

3750 884

2000 1.4ms

1000 2.4ms

500 4.5ms

100 21.0ms

60 34.1ms

50 41.7ms

30 67.8ms

25 83.0ms

15 135.3ms

10 207.0ms

5 413.7ms

2.5 827.0ms

NOTE: For f

1 2 4 8 16, 32, 64

= 7.68MHz.

CLKIN

PGA SETTING

SELFCAL performs first a self offset and then a self gain

calibration. The analog inputs are disconnected from the

from the signal source during self-calibration. When using

the input buffer with self-calibration, make sure to observe

the common-mode range of the reference inputs as

described above. Table 21 shows the time required for

self-calibration for the different data rate settings.

Self-calibration updates both the OFC and FSC registers.

Table 21. Self-Calibration Timing

DATA RATE

(SPS)

30,000 596µs 596µs 692µs 696µs 892µs

15,000 696µs 696µs 696µs 762µs 896µs

7500 896µs 896µs 896µs 896µs 1029µs

3750 1.3ms

2000 2.0ms

1000 3.6ms

500 6.6ms

100 31.2ms

60 50.9ms

50 61.8ms

30 101.3ms

25 123.2ms

15 202.1ms

10 307.2ms

5 613.8ms

2.5 1227.2ms

NOTE: For f

1 2 4 8 16, 32, 64

= 7.68MHz.

CLKIN

PGA SETTING

25

Page 26

SBAS288D − JUNE 2003 − REVISED AUGUST 2004

www.ti.com

System Calibration

System calibration corrects both internal and external

offset and gain errors using the SYSOCAL and SYSGCAL

commands. During system calibration, the appropriate

calibration signals must be applied by the user to the

inputs.

SYSOCAL performs a system offset calibration. The user

must supply a zero input differential signal. The

ADS1255/6 then computes a value that will nullify the

offset in the system. Table 22 shows the time required for

system of fset calibration for the different data rate settings.

Note this timing is the same for the self offset calibration.

System offset calibration updates the OFC register.

SYSGCAL performs a system gain calibration. The user

must supply a full-scale input signal to the ADS1255/6.

The ADS1255/6 then computes a value to nullify the gain

error in the system. System gain calibration can correct

inputs that are 80% of the full-scale input voltage and

larger. Make sure not to exceed the full-scale input voltage

when using system gain calibration. Table 22 shows the

time required for system gain calibration for the different

data rate settings. System gain calibration updates the

FSC register.

Table 22. System Gain Calibration Timing

DATA RATE

(SPS)

30,000 417µs

15,000 484µs

7500 617µs

3750 884µs

2000 1.4ms

1000 2.4ms

500 4.4ms

100 20.4ms

60 33.7ms

50 40.4ms

30 67.0ms

25 80.4ms

15 133.7ms

10 200.4ms

5 400.4ms

2.5 800.4ms

NOTE: For f

SYSTEM GAIN CALIBRATION TIME

= 7.68MHz.

CLKIN

SERIAL INTERFACE

The SPI-compatible serial interface consists of four

signals: CS

controller to communicate with the ADS1255/6. The

programmable functions are controlled using a set of

on-chip registers. Data is written to and read from these

registers via the serial interface

The DRDY

when a conversion has been completed. DRDY

when new data is available. The Timing Specification

shows the timing diagram for interfacing to the

ADS1255/6.

CHIP SELECT (CS)

The chip select (CS) input allows individual selection of a

ADS1255/6 device when multiple devices share the serial

bus. CS must remain low for the duration of the serial

communication. When CS

interface is reset and DOUT enters a high impedance

state. CS may be permanently tied low.

SERIAL CLOCK (SCLK)

The serial clock (SCLK) features a Schmitt-triggered input

and is used to clock data on the DIN and DOUT pins into

and out of the ADS1255/6. Even though the input has

hysteresis, it is recommended to keep SCLK as clean as

possible to prevent glitches from accidentally shifting the