FEATURES DESCRIPTION

APPLICATIONS

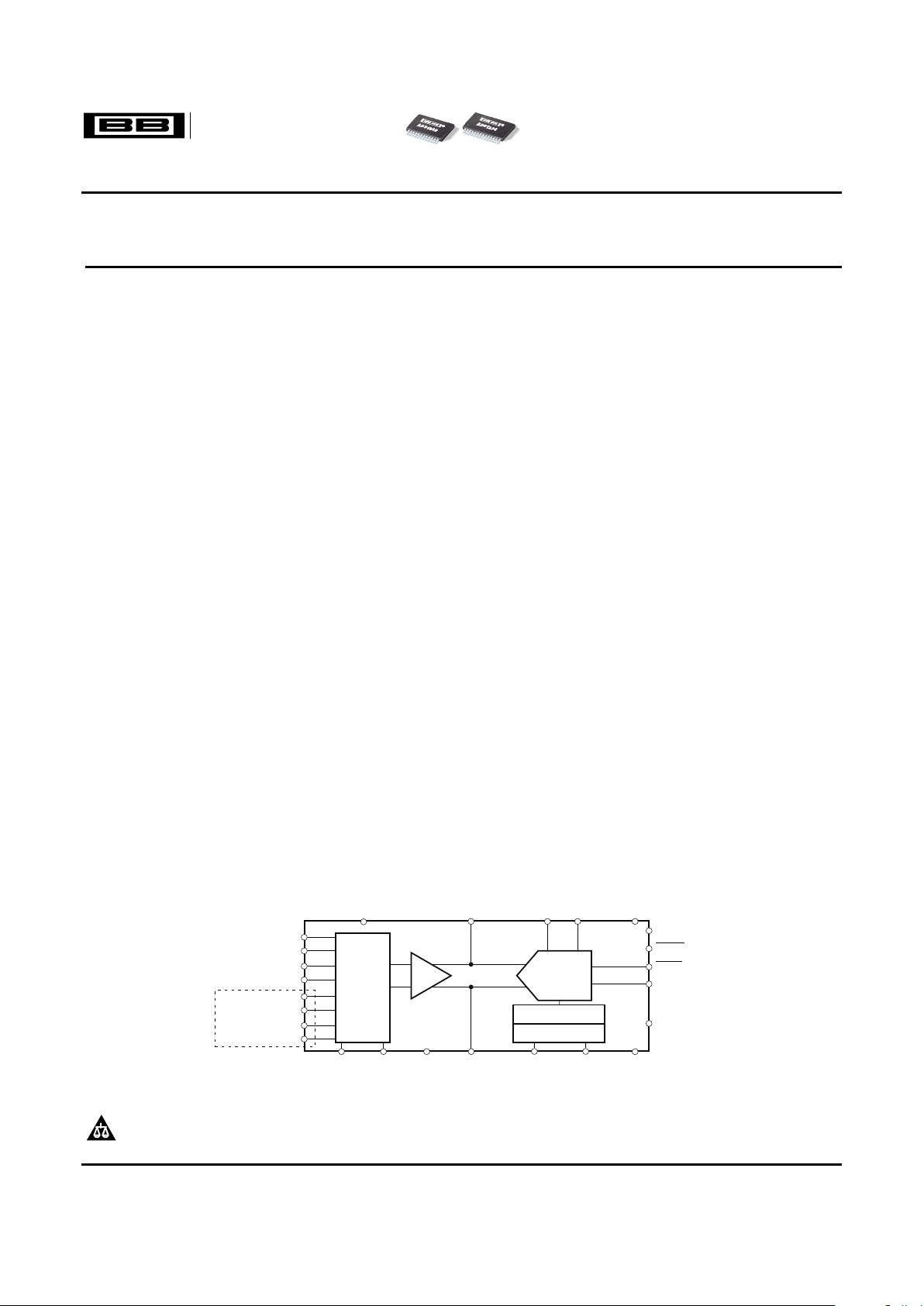

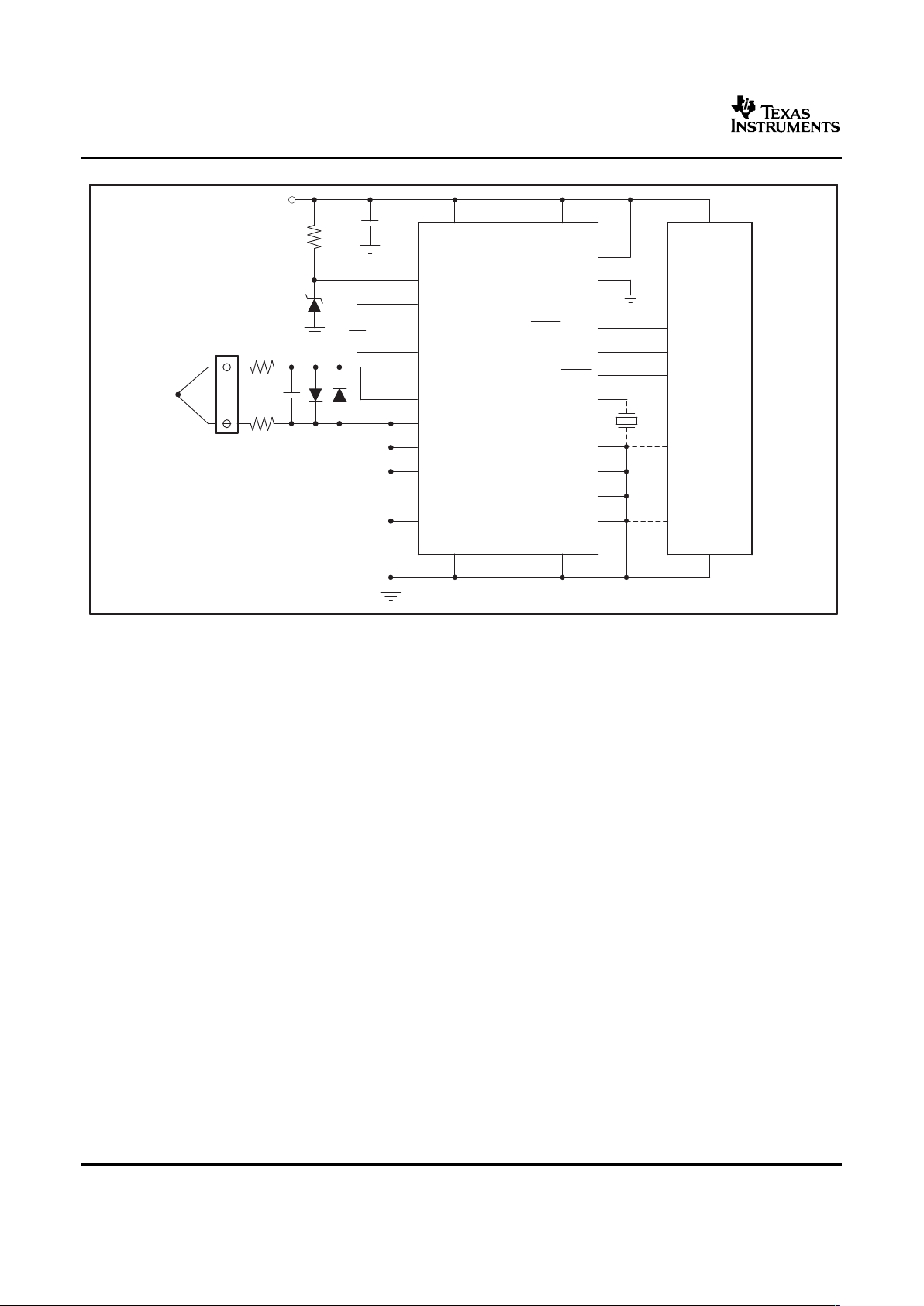

Input

Mux

DS ADC

REFP REFN

PGA

Gain=

1,2,64,or128

CAP DVDD

DGND

AGNDA1/TEMP

(1)

A0

NOTE:(1)A1forADS1234,TEMPforADS1232.

AINP1

AINN1

AINP2

AINN2

AINP3

AINN3

AINP4

AINN4

ADS1234

Only

SCLK

SPEED

DRDY/DOUT

PDWN

GAIN[1:0]

AVDD

CAP

ExternalOscillator

InternalOscillator

CLKIN/XTAL1

XTAL2

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

24-Bit Analog-to-Digital Converter

For Bridge Sensor

• Complete Front-End for Bridge Sensor

The ADS1232 and ADS1234 are precision 24-bit

analog-to-digital converters (ADCs). With an

• Up to 23.5 Effective Bits

onboard, low-noise programmable gain amplifier

• Onboard, Low-Noise PGA

(PGA), precision delta-sigma ADC and internal

• RMS Noise:

oscillator, the ADS1232/4 provide a complete

17nV at 10SPS (PGA = 128)

front-end solution for bridge sensor applications

44nV at 80SPS (PGA = 128)

including weigh scales, strain gauges and pressure

sensors.

• 19.2-Bit Noise-Free Resolution at Gain = 64

• Over 100dB Simultaneous 50Hz and 60Hz

The input multiplexer accepts either two (ADS1232)

or four (ADS1234) differential inputs. The ADS1232

Rejection

also includes an onboard temperature sensor to

• Flexible Clocking:

monitor ambient temperature. The onboard,

Low-Drift Onboard Oscillator ( ± 3%)

low-noise PGA has a selectable gain of 1, 2, 64, or

Optional External Crystal

128 supporting a full-scale differential input of ± 2.5V,

• Selectable Gains of 1, 2, 64, and 128

± 1.25V, ± 39mV, or ± 19.5mV. The delta-sigma ADC

has 23.5-bit effective resolution and is comprised of

• Easy Ratiometric Measurements–

a 3rd-order modulator and 4th-order digital filter. Two

External Voltage Reference up to 5V

data rates are supported: 10SPS (with both 50Hz

• Selectable 10SPS or 80SPS Data Rates

and 60Hz rejection) and 80SPS. The ADS1232/4 can

• Two-Channel Differential Input with Built-In

be clocked externally using an oscillator or a crystal.

Temperature Sensor (ADS1232)

There is also an internal oscillator available that

requires no external components. Offset calibration

• Four-Channel Differential Input (ADS1234)

is performed on-demand and the ADS1232/4 can be

• Simple Serial Digital Interface

put in a low-power standby mode or shut off

• Supply Range: 2.7V to 5.3V

completely in power-down mode. All of the features

of the ADS1232/4 are operated through simple

• –40 ° C to +105 ° C Temperature Range

pin-driven control. There are no digital registers to

program in order to simplify software development.

Data is output over an easily-isolated serial interface

• Weigh Scales

that connects directly to the MSP430 and other

• Strain Gauges

microcontrollers.

• Pressure Sensors

The ADS1232 is available in a TSSOP-24 package

• Industrial Process Control

and the ADS1234 is in a TSSOP-28. Both are fully

specified from -40 ° C to +105 ° C.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

All trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Copyright © 2005–2006, Texas Instruments Incorporated

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

www.ti.com

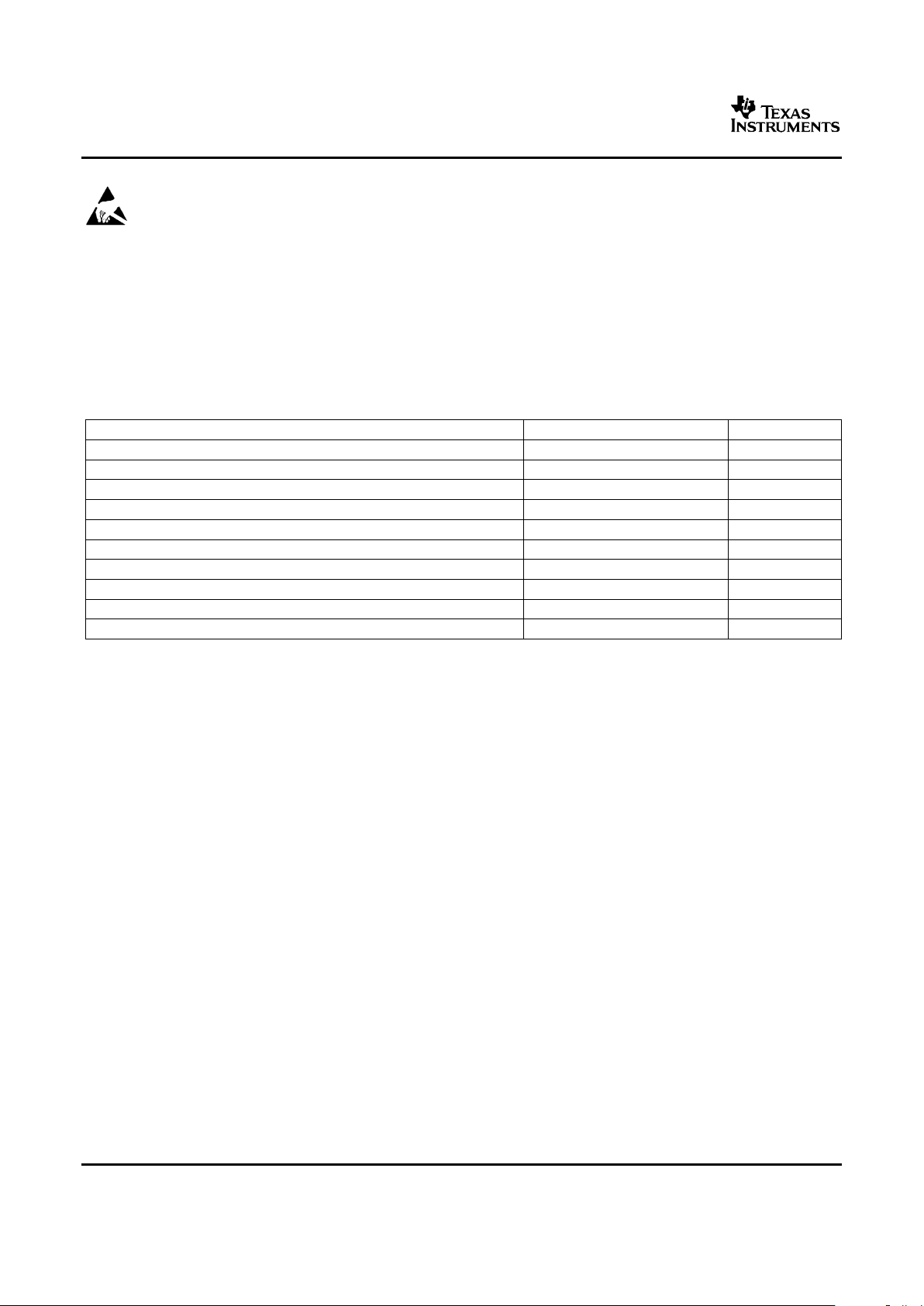

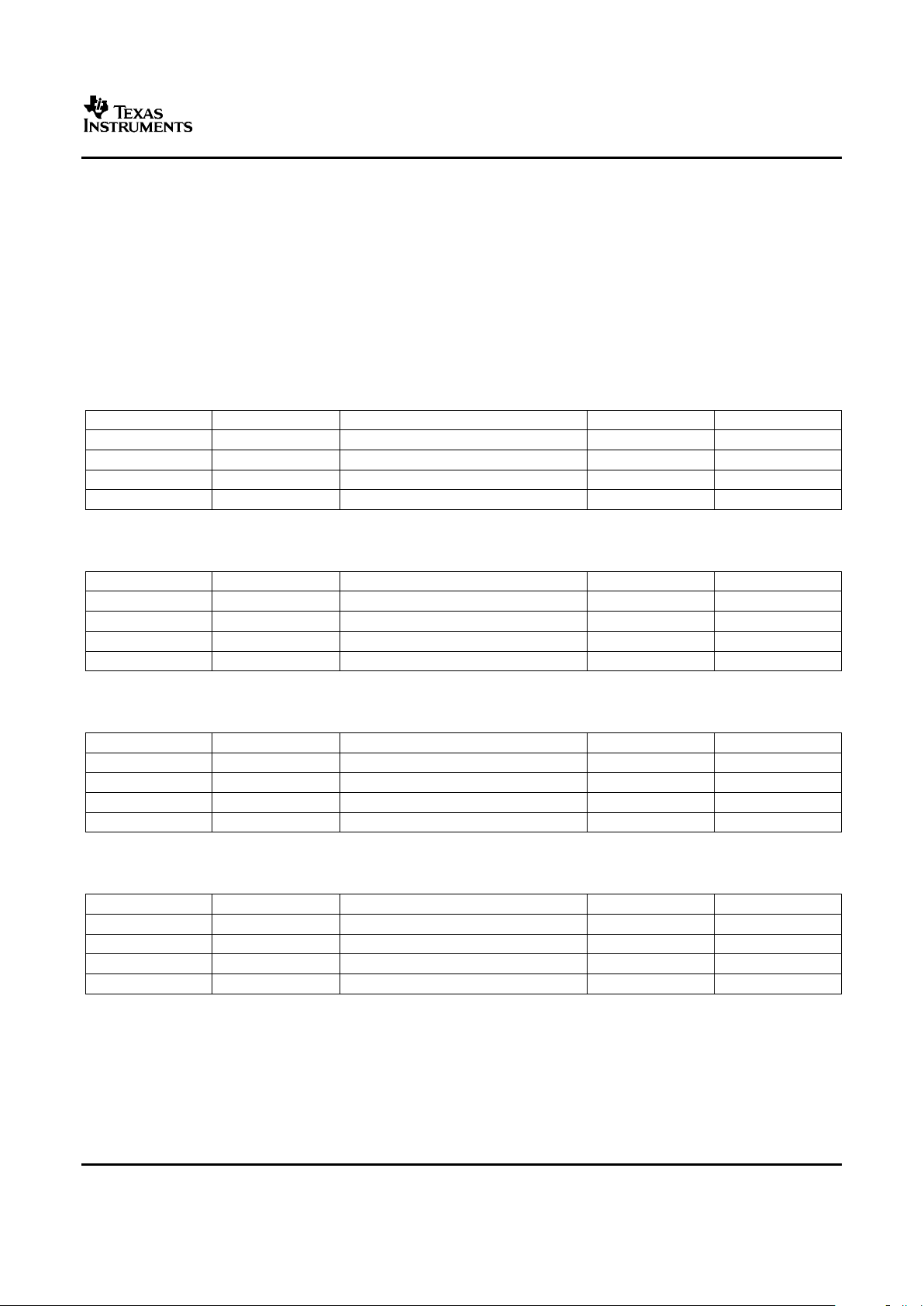

ORDERING INFORMATION

ABSOLUTE MAXIMUM RATINGS

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be

more susceptible to damage because very small parametric changes could cause the device not to meet its published

specifications.

For the most current package and ordering information, see the Package Option Addendum at the end of this

data sheet, or see the TI website at www.ti.com.

over operating free-air temperature range (unless otherwise noted)

(1)

ADS1232, ADS1234 UNIT

AVDD to AGND –0.3 to +6 V

DVDD to DGND –0.3 to +6 V

AGND to DGND –0.3 to +0.3 V

Input Current 100, Momentary mA

Input Current 10, Continuous mA

Analog Input Voltage to AGND –0.3 to AVDD + 0.3 V

Digital Input Voltage to DGND –0.3 to DVDD + 0.3 V

Maximum Junction Temperature +150 °C

Operating Temperature Range –40 to +105 °C

Storage Temperature Range –60 to +150 °C

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated under Recommended Operating

Conditions is not implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

2

www.ti.com

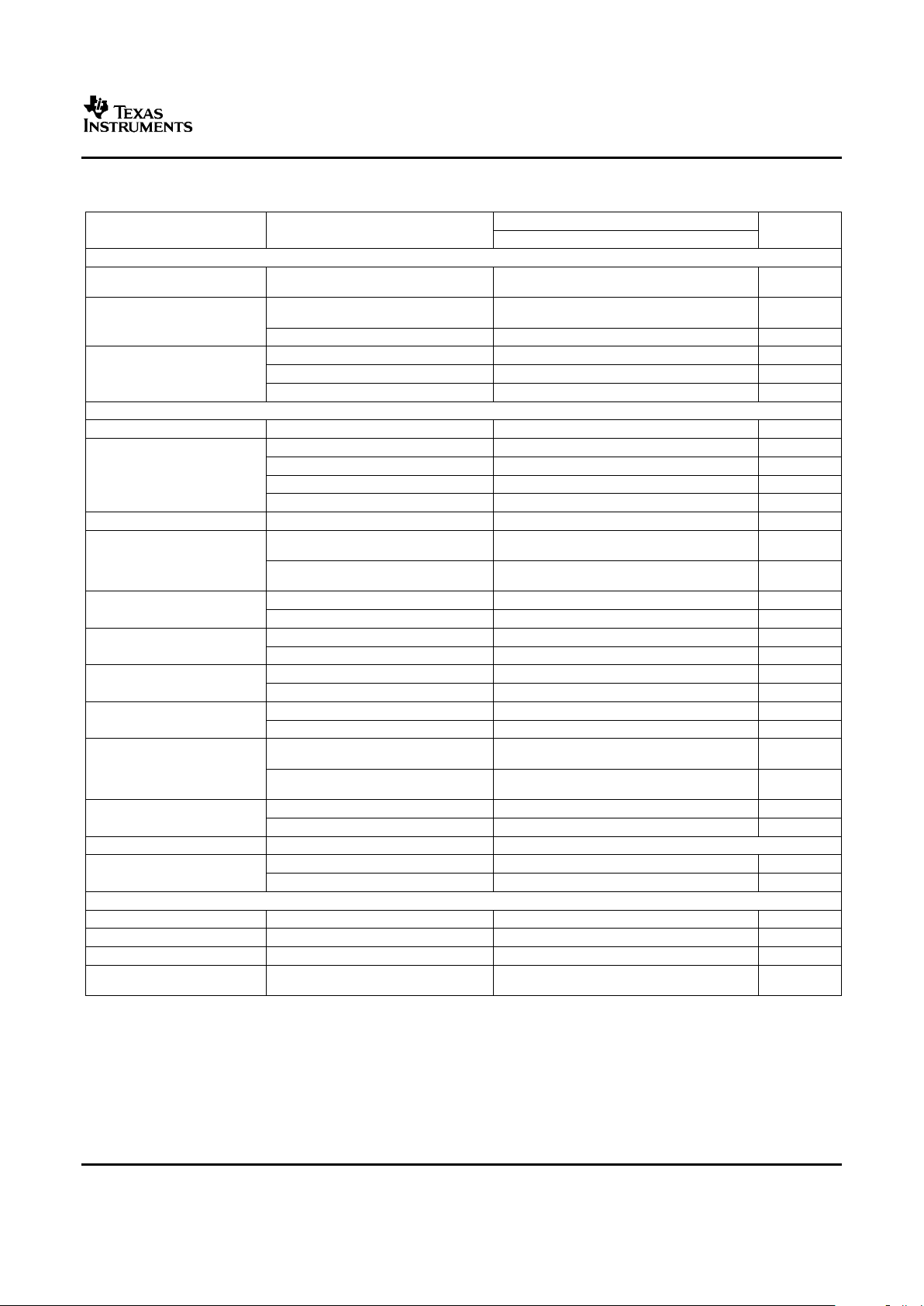

ELECTRICAL CHARACTERISTICS

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

All specifications at TA= –40°C to +105°C, AVDD = DVDD = VREFP = +5V, and VREFN = AGND, unless otherwise noted.

ADS1232, ADS1234

PARAMETER CONDITIONS MIN TYP MAX UNIT

Analog Inputs

Full-Scale Input Voltage

±0.5V

REF

/Gain V

(AINP – AINN)

AINxP or AINxN with respect to GND,

AGND – 0.1 AVDD + 0.1 V

Gain = 1, 2

Common-Mode Input Range

Gain = 64, 128 AGND + 1.5V AVDD – 1.5V V

Gain = 1 ± 3 nA

Differential Input Current Gain = 2 ± 6 nA

Gain = 64, 128 ± 3.5 nA

System Performance

Resolution No Missing Codes 24 Bits

Internal Oscillator, SPEED = High 78 80 82.4 SPS

Internal Oscillator, SPEED = Low 9.75 10 10.3 SPS

Data Rate

External Oscillator, SPEED = High f

CLK

/61,440 SPS

External Oscillator, SPEED = Low f

CLK

/491,520 SPS

Digital Filter Settling Time Full Settling 4 Conversions

Differential Input, End-Point Fit

± 0.0002 ± 0.001 % of FSR

(1)

Gain = 1, 2

Integral Nonlinearity (INL)

Differential Input, End-Point Fit

± 0.0004 % of FSR

Gain = 64, 128

Gain = 1 ± 0.2 ± 5 ppm of FS

Input Offset Error

(2)

Gain = 128 ± 0.02 ± 1 ppm of FS

Gain = 1 ± 0.3 µV/°C

Input Offset Drift

Gain = 128 ± 10 nV/°C

Gain = 1 ± 0.001 ± 0.02 %

Gain Error

(3)

Gain = 128 ± 0.01 ± 0.1 %

Gain = 1 ± 0.2 ppm/ ° C

Gain Drift

Gain = 128 ± 2.5 ppm/ ° C

Internal Oscillator, f

DATA

= 10SPS

100 110 dB

fIN= 50Hz or 60Hz, ± 1Hz

Normal-Mode Rejection

(4)

External Oscillator, f

DATA

= 10SPS

120 130 dB

fIN= 50Hz or 60Hz, ± 1Hz

at DC, Gain = 1, ∆ VDD = 1V 95 110 dB

Common-Mode Rejection

at DC, Gain = 128, ∆ VDD = 0.1V 95 110 dB

Input-Referred Noise See Noise Performance Tables

at DC, Gain = 1, ∆ VDD = 1V 100 120 dB

Power-Supply Rejection

at DC, Gain = 128, ∆ VDD = 0.1V 100 120 dB

Voltage Reference Input

Voltage Reference Input (V

REF

) V

REF

= VREFP – VREFN 1.5 AVDD AVDD + 0.1V V

Negative Reference Input (VREFN) AGND – 0.1 VREFP – 1.5 V

Positive Reference Input (VREFP) VREFN + 1.5 AVDD + 0.1 V

Voltage Reference

10 nA

Input Current

(1) FSR = full-scale range = V

REF

/Gain.

(2) Offset calibration can minimize these errors to the level of noise at any temperature.

(3) Gain errors are calibrated at the factory (AVDD = +5V, all gains, TA= +25 ° C).

(4) Specification is assured by the combination of design and final production test.

3

www.ti.com

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

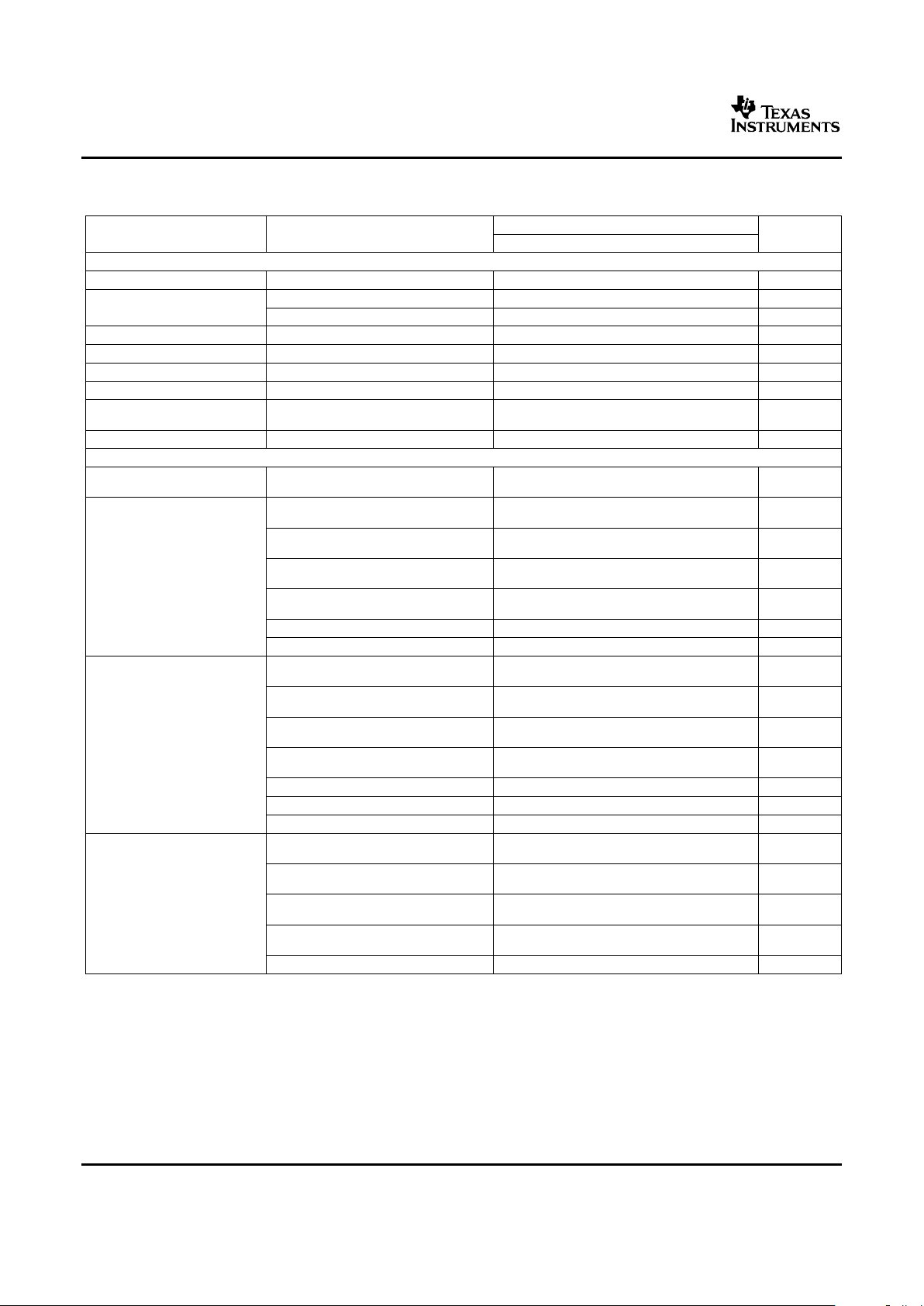

ELECTRICAL CHARACTERISTICS (continued)

All specifications at TA= –40°C to +105°C, AVDD = DVDD = VREFP = +5V, and VREFN = AGND, unless otherwise noted.

ADS1232, ADS1234

PARAMETER CONDITIONS MIN TYP MAX UNIT

Digital

Logic Levels

All digital inputs except CLKIN/XTAL1 0.7 DVDD DVDD + 0.1 V

V

IH

CLKIN/XTAL1 0.7 DVDD 5.1 V

V

IL

DGND 0.2 DVDD V

V

OH

IOH= 1mA DVDD – 0.4 V

V

OL

IOL= 1mA 0.2 DVDD V

Input Leakage 0 < VIN< DVDD ± 10 µA

External Clock Input Frequency

0.2 4.9152 8 MHz

(f

CLKIN

)

Serial Clock Input Frequency (f

SCLK

) 5 MHz

Power Supply

Power-Supply Voltage

2.7 5.3 V

(AVDD, DVDD)

Normal Mode, AVDD = 3V,

600 1300 µA

Gain = 1, 2

Normal Mode, AVDD = 3V,

1350 2500 µA

Gain = 64, 128

Normal Mode, AVDD = 5V,

650 1300 µA

Analog Supply Current

Gain = 1, 2

Normal Mode, AVDD = 5V,

1350 2500 µA

Gain = 64, 128

Standby Mode 0.1 1 µA

Power-Down 0.1 1 µA

Normal Mode, DVDD = 3V,

60 95 µA

Gain = 1, 2

Normal Mode, DVDD = 3V,

75 120 µA

Gain = 64, 128

Normal Mode, DVDD = 5V,

95 130 µA

Gain = 1, 2

Digital Supply Current

Normal mode, DVDD = 5V,

75 120 µA

Gain = 64, 128

Standby Mode, SCLK = High, DVDD = 3V 45 80 µA

Standby Mode, SCLK = High, DVDD = 5V 65 80 µ A

Power-Down 0.2 1.3 µA

Normal Mode, AVDD = DVDD = 3V,

2 4.2 mW

Gain = 1, 2

Normal Mode, AVDD = DVDD = 5V,

3.7 7.2 mW

Gain = 1, 2

Power Dissipation, Total Normal Mode, AVDD = DVDD = 3V,

4.3 7.9 mW

Gain = 64, 128

Normal Mode, AVDD = DVDD = 5V,

7.1 13.1 mW

Gain = 64, 128

Standby Mode, AVDD = DVDD = 5V 0.3 0.4 mW

4

www.ti.com

NOISE PERFORMANCE

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

The ADS1232/4 offer outstanding noise performance that can be optimized for a given full-scale range using the

on-chip programmable gain amplifier. Table 1 through Table 4 summarize the typical noise performance with

inputs shorted externally for different gains, data rates, and voltage reference values.

The RMS and Peak-to-Peak noise are referred to the input. The Effective Number of Bits (ENOB) is defined as:

• ENOB = ln (FSR/RMS noise)/ln(2)

The Noise-Free Bits are defined as:

• Noise-Free Bits = ln (FSR/Peak-to-Peak Noise)/ln(2)

Where FSR (Full-Scale Range) = V

REF

/Gain

Table 1. AVDD = 5V, V

REF

= 5V, Data Rate = 10SPS

GAIN RMS NOISE PEAK-TO-PEAK NOISE

(1)

ENOB (RMS) NOISE-FREE BITS

1 420nV 1.79µV 23.5 21.4

2 270nV 900nV 23.1 21.4

64 19nV 125nV 22.0 19.2

128 17nV 110nV 21.1 18.4

(1) Peak-to-peak noise data is based on direct measurement.

Table 2. AVDD = 5V, V

REF

= 5V, Data Rate = 80SPS

GAIN RMS NOISE PEAK-TO-PEAK NOISE

(1)

ENOB (RMS) NOISE-FREE BITS

1 1.36µV 8.3µV 21.8 19.2

2 850nV 5.5µV 21.5 18.8

64 48nV 307nV 20.6 18

128 44nV 247nV 19.7 17.2

(1) Peak-to-peak noise data is based on direct measurement.

Table 3. AVDD = 3V, V

REF

= 3V, Data Rate = 10SPS

GAIN RMS NOISE PEAK-TO-PEAK NOISE

(1)

ENOB (RMS) NOISE-FREE BITS

1 450nV 2.8µV 22.6 20

2 325nV 1.8µV 22.1 19.7

64 20nV 130nV 21.2 18.5

128 18nV 115nV 20.3 17.6

(1) Peak-to-peak noise data is based on direct measurement.

Table 4. AVDD = 3V, V

REF

= 3V, Data Rate = 80SPS

GAIN RMS NOISE PEAK-TO-PEAK NOISE

(1)

ENOB (RMS) NOISE-FREE BITS

1 2.2µV 12µV 20.4 17.9

2 1.2µV 6.8µV 20.2 17.8

64 54nV 340nV 19.7 17.1

128 48nV 254nV 18.9 16.5

(1) Peak-to-peak noise data is based on direct measurement of 1024 samples.

5

www.ti.com

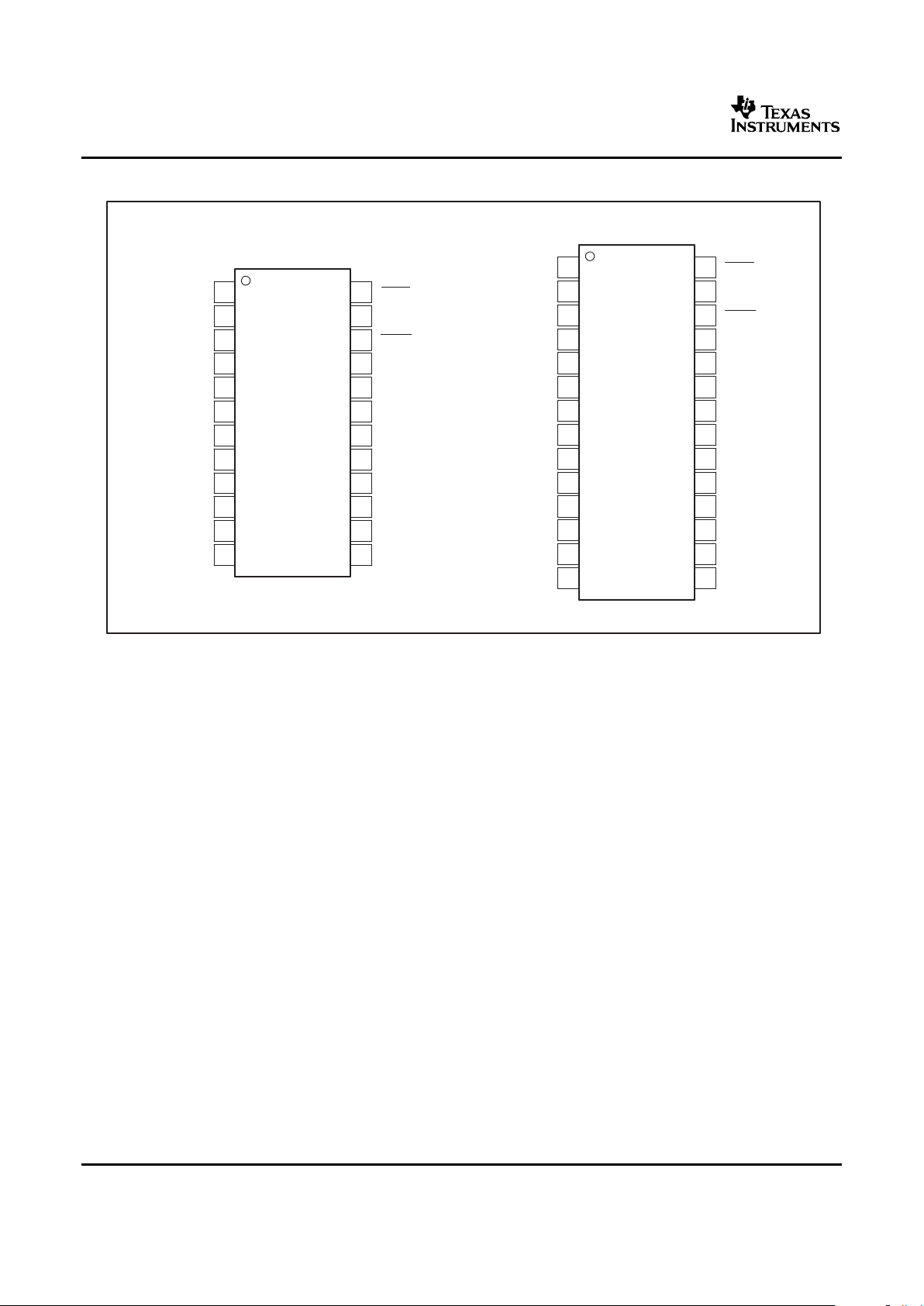

PIN CONFIGURATION

DVDD

DGND

CLKIN/XTAL1

XTAL2

DGND

DGND

A1

A0

CAP

CAP

AINP1

AINN1

AINP3

AINN3

DRDY/DOUT

SCLK

PDWN

SPEED

GAIN1

GAIN0

AVDD

AGND

REFP

REFN

AINP2

AINN2

AINP4

AINN4

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

ADS1234

DVDD

DGND

CLKIN/XTAL1

XTAL2

DGND

DGND

TEMP

A0

CAP

CAP

AINP1

AINN1

DRDY/DOUT

SCLK

PDWN

SPEED

GAIN1

GAIN0

AVDD

AGND

REFP

REFN

AINP2

AINN2

1

2

3

4

5

6

7

8

9

10

11

12

24

23

22

21

20

19

18

17

16

15

14

13

ADS1232

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

6

www.ti.com

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

PIN CONFIGURATION (continued)

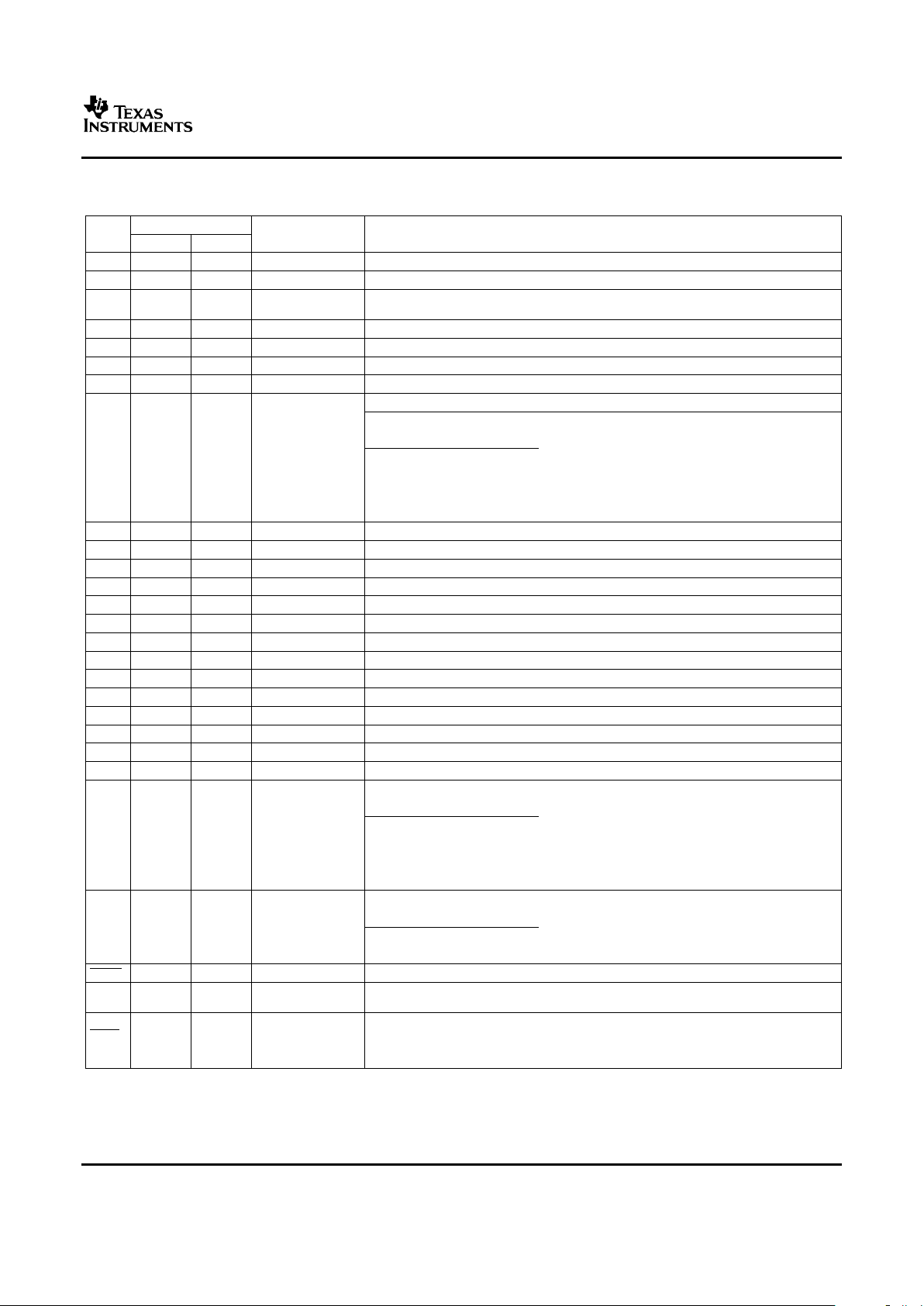

PIN DESCRIPTIONS

TERMINAL

ANALOG/DIGITAL

NAME ADS1232 ADS1234 INPUT/OUTPUT DESCRIPTION

DVDD 1 1 Digital Digital Power Supply: 2.7V to 5.3V

DGND 2 2 Digital Digital Ground

CLKIN/ External Clock Input: typically 4.9152MHz. Tie low to activate internal oscillator. Can also use

3 3 Digital/Digital Input

XTAL1 external crystal across CLKIN/XTAL1 and XTAL2 pins. See text for more details.

XTAL2 4 4 Digital External crystal connection

DGND 5 5 Digital Digital Ground

DGND 6 6 Digital Digital Ground

TEMP 7 – Digital Input Onboard Temperature Diode Enable

Input Mux Select Input pin (MSB)

Input Mux Select Input pin (LSB):

A1 A0 Channel

A1 – 7

Digital Input 0 0 AIN1

A0 8 8

0 1 AIN2

1 0 AIN3

1 1 AIN4

CAP 9 9 Analog Gain Amp Bypass Capacitor Connection

CAP 10 10 Analog Gain Amp Bypass Capacitor Connection

AINP1 11 11 Analog Input Positive Analog Input Channel 1

AINN1 12 12 Analog Input Negative Analog Input Channel 1

AINP3 – 13 Analog Input Positive Analog Input Channel 3

AINN3 – 14 Analog Input Negative Analog Input Channel 3

AINN4 – 15 Analog Input Negative Analog Input Channel 4

AINP4 – 16 Analog Input Positive Analog Input Channel 4

AINN2 13 17 Analog Input Negative Analog Input Channel 2

AINP2 14 18 Analog Input Positive Analog Input Channel 2

REFN 15 19 Analog Input Negative Reference Input

REFP 16 20 Analog Input Positive Reference Input

AGND 17 21 Analog Analog Ground

AVDD 18 22 Analog Analog Power Supply, 2.7V to 5.3V

Gain Select

GAIN1 GAIN0 GAIN

0 0 1

GAIN0 19 23

Digital Input

GAIN1 20 24

0 1 2

1 0 64

1 1 128

Data Rate Select:

SPEED DATA RATE

SPEED 21 25 Digital Input

0 10SPS

1 80SPS

PDWN 22 26 Digital Input Power-Down: Holding this pin low powers down the entire converter and resets the ADC.

Serial Clock: Clock out data on the rising edge. Also used to initiate Offset Calibration and Sleep

SCLK 23 27 Digital Input

modes. See text for more details.

Dual-Purpose Output:

DRDY/

24 28 Digital Output Data Ready: Indicates valid data by going low.

DOUT

Data Output: Outputs data, MSB first, on the first rising edge of SCLK.

7

www.ti.com

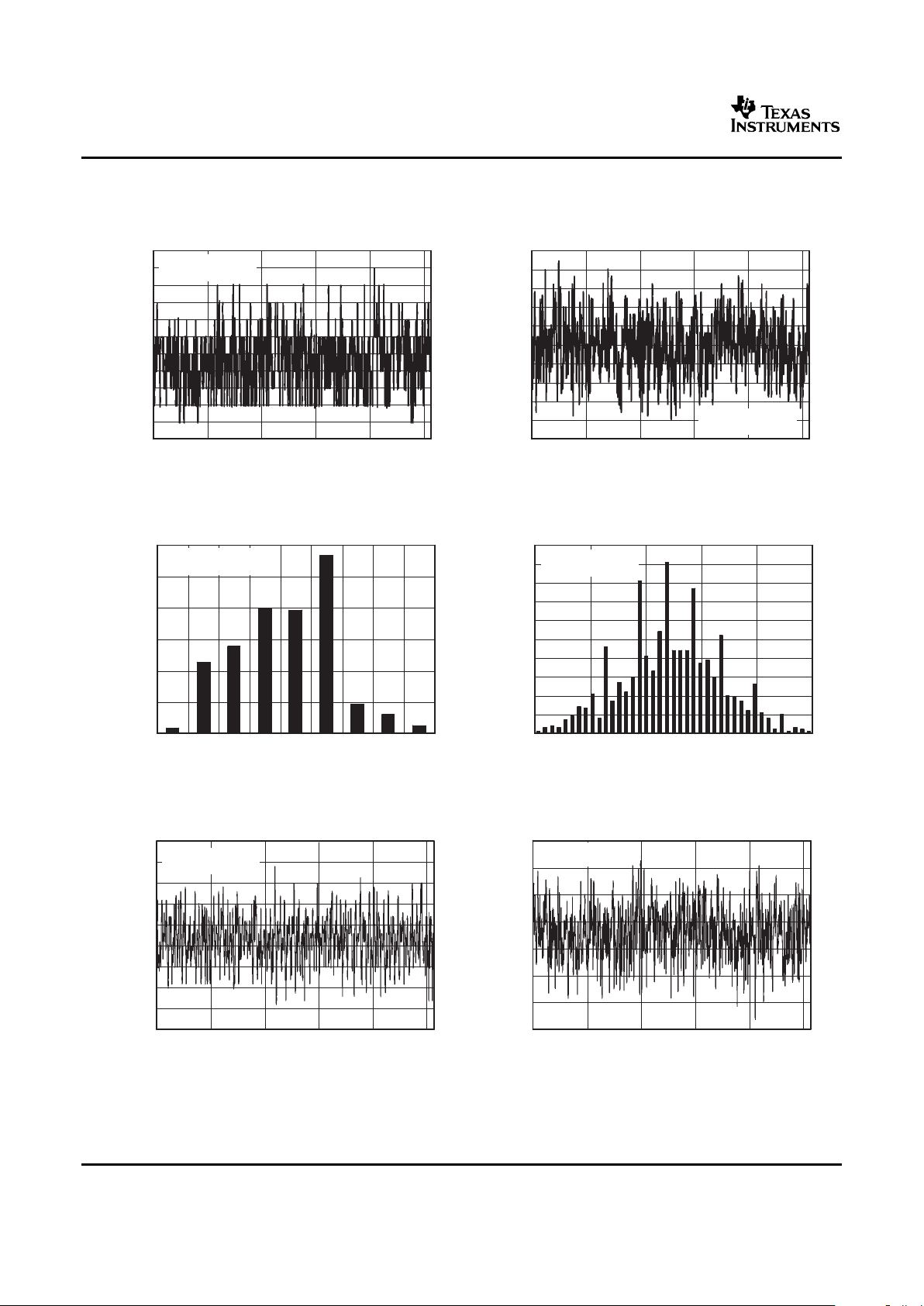

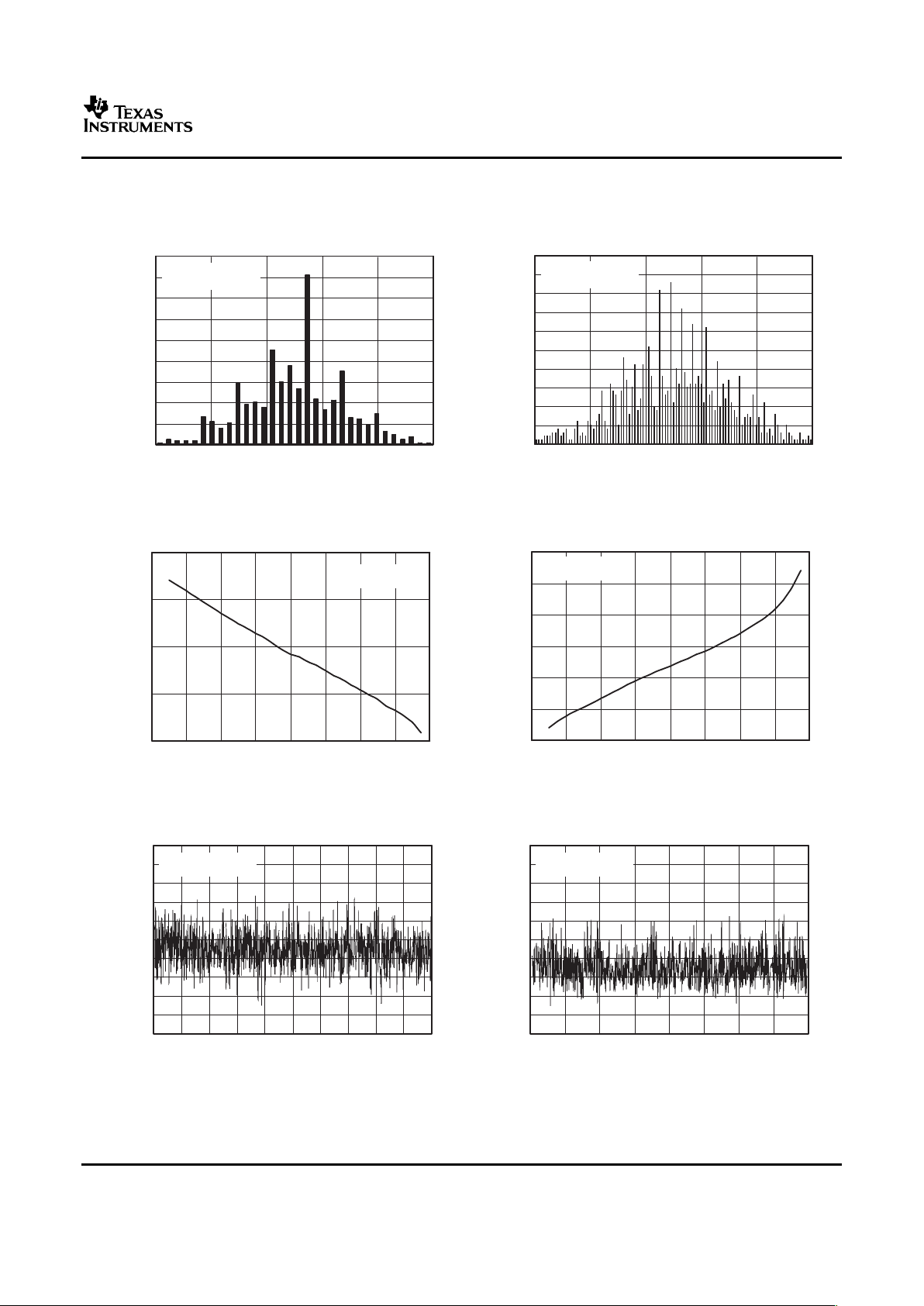

TYPICAL CHARACTERISTICS

Time (Reading Number)

Output Code (LSB)

6

5

4

3

2

1

−

1

−

2

−

3

−

4

−

5

−

6

200 400 600 800 1000

0

PGA = 1

Data Rate = 10SPS

Time (Reading Number)

Output Code (LSB)

25

20

15

10

5

0

−

5

−

10

−

15

−

20

−

25

200 400 600 800 1000

0

PGA = 128

Data Rate = 10SPS

Output Code (LSB)

Occurrence

300

250

200

150

100

50

0

−

4

−

2

0

2

4

PGA = 1

Data Rate = 10SPS

Output Code (LSB)

Occurrence

100

90

80

70

60

50

40

30

20

10

0

−

16

1680

−

8

PGA = 128

Data Rate = 10SPS

Time (Reading Number)

Output Code(LSB)

22.5

17.5

12.5

7.5

2.5

−

2.5

−

7.5

−

12.5

−

17.5

−

22.5

200 400 600 800 1000

0

PGA = 1

Data Rate = 80SPS

Time (Reading Number)

Output Code (LSB)

70

50

30

10

−

10

−

30

−

50

−

70

200 400 600 800 1000

0

PGA = 128

Data Rate = 80SPS

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

At TA= +25 ° C, AVDD = DVDD = VREFP = 5V, and VREFN = AGND, unless otherwise noted.

NOISE PLOT NOISE PLOT

Figure 1. Figure 2.

NOISE HISTOGRAM NOISE HISTOGRAM

Figure 3. Figure 4.

NOISE PLOT NOISE PLOT

Figure 5. Figure 6.

8

www.ti.com

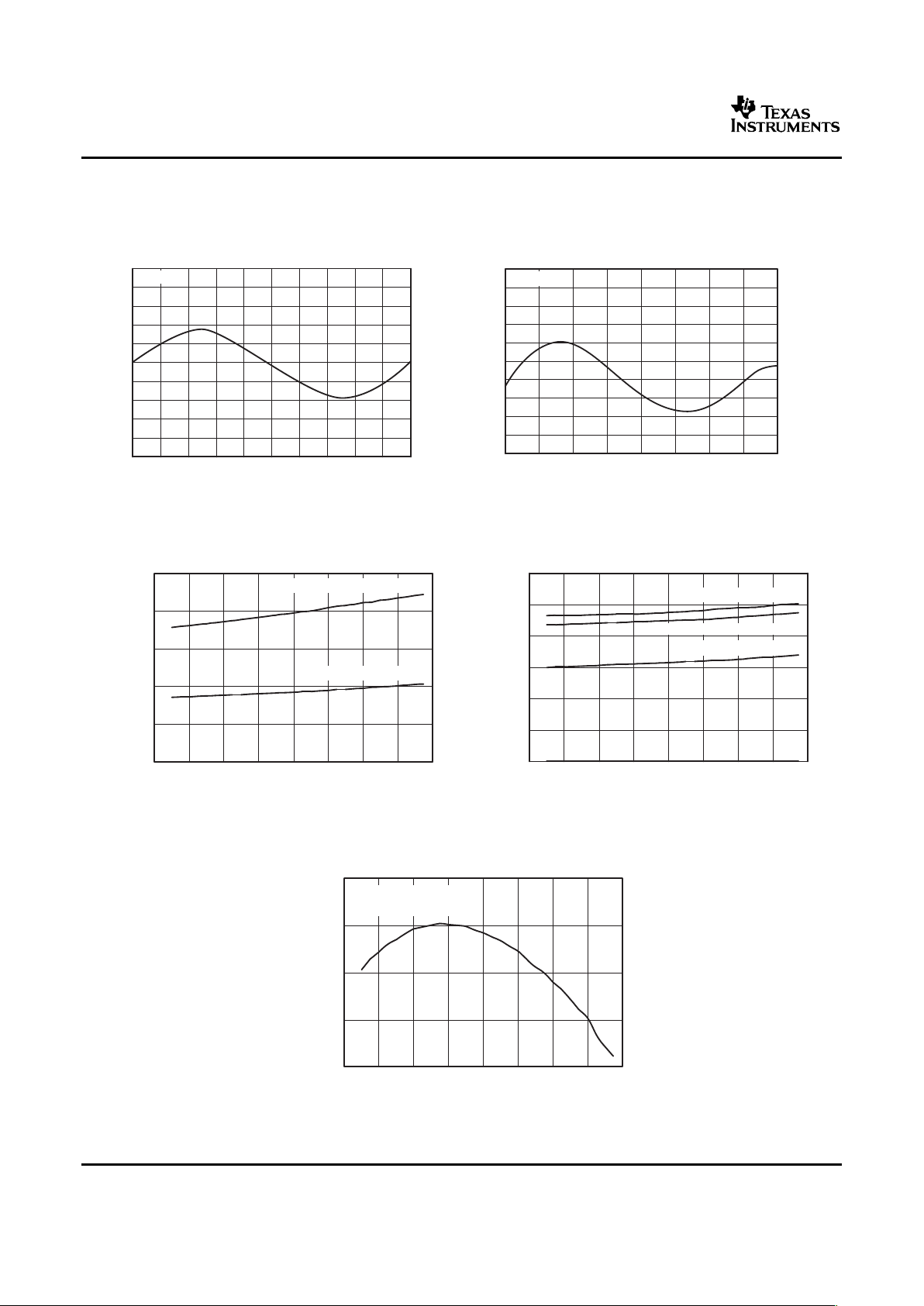

Output Code (LSB)

Occurance

180

160

140

120

100

80

60

40

20

0

−

12

−

6

1260

PGA = 1

Data Rate = 80SPS

Output Code (LSB)

Occurance

50

45

40

35

30

25

20

15

10

5

0

−

40

−

20 0 20

40

PGA = 128

Data Rate = 80SPS

Temperature (_C)

Offset (nV)

1000

500

0

−

500

−

1000

110

−50−30−

10 10 30 50 70 90

PGA = 128

Data Rate = 10SPS

Temperature (_C)

Gain Error (%)

0.04

0.03

0.02

0.01

0

−

0.01

−

0.02

110

−50−30−

10 10 30 50 70 90

PGA = 128

Data Rate = 10SPS

VIN(V)

RMS Noise (nV)

1000

900

800

700

600

500

400

300

200

100

0

2.5

−

2.5−2.0−1.5

−

0.5

−

1.0 1.00 0.5 1.5 2.0

PGA = 1

Data Rate = 10SPS

VIN(mV)

RMS Noise (nV)

50

45

40

35

30

25

20

15

10

5

0

19

−19−

14.25−9.5−4.75 4.750 9.5 14.25

PGA = 128

Data Rate = 10SPS

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

TYPICAL CHARACTERISTICS (continued)

At TA= +25 ° C, AVDD = DVDD = VREFP = 5V, and VREFN = AGND, unless otherwise noted.

NOISE HISTOGRAM NOISE HISTOGRAM

Figure 7. Figure 8.

OFFSET vs TEMPERATURE GAIN ERROR vs TEMPERATURE

Figure 9. Figure 10.

NOISE vs INPUT SIGNAL NOISE vs INPUT SIGNAL

Figure 11. Figure 12.

9

www.ti.com

VIN(mV)

INL (ppmof FSR)

INL (nV)

10

8

6

4

2

0

−

2

−

4

−

6

−

8

−

10

390.625

312.5

234.375

156.25

78.125

0

−

78.125

−

156.25

−

234.375

−

312.5

−

390.625

19

−19−

14.25−9.5−4.75 4.750 9.5 14.25

PGA = 128

VIN(V)

INL (ppm of FSR)

INL (

µ

V)

5

4

3

2

1

0

−

1

−

2

−

3

−

4

−

5

25

20

15

10

5

0

−

5

−

10

−

15

−

20

−

25

2.5

−

2.5−2.0−1.5

−

0.5

−

1.0 1.00 0.5 1.5 2.0

PGA = 1

Temperature (_C)

Analog Current (

µ

A)

2000

1600

1200

800

400

0

110

−50−30−

10 10 30 50 70 90

Normal Mode, PGA = 64, 128

Normal Mode, PGA = 1, 2

Temperature (_C)

Digital Current (

µ

A)

120

100

80

60

40

20

0

110

−50−30−

10 10 30 50 70 90

Normal Mode, PGA = 64, 128

Normal Mode, PGA = 1, 2

Sleep Mode, All PGAs

Temperature (_C)

Data Rate (SPS)

10.06

10.01

9.96

9.91

9.86

110

−50−30−

10 10 30 50 70 90

SPEED = LOW

CLKIN/XTAL1 = LOW (Internal Oscillator)

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

TYPICAL CHARACTERISTICS (continued)

At TA= +25 ° C, AVDD = DVDD = VREFP = 5V, and VREFN = AGND, unless otherwise noted.

INTEGRAL NONLINEARITY INTEGRAL NONLINEARITY

vs INPUT SIGNAL vs INPUT SIGNAL

Figure 13. Figure 14.

ANALOG CURRENT DIGITAL CURRENT

vs TEMPERATURE vs TEMPERATURE

Figure 15. Figure 16.

DATA RATE

vs TEMPERATURE

Figure 17.

10

www.ti.com

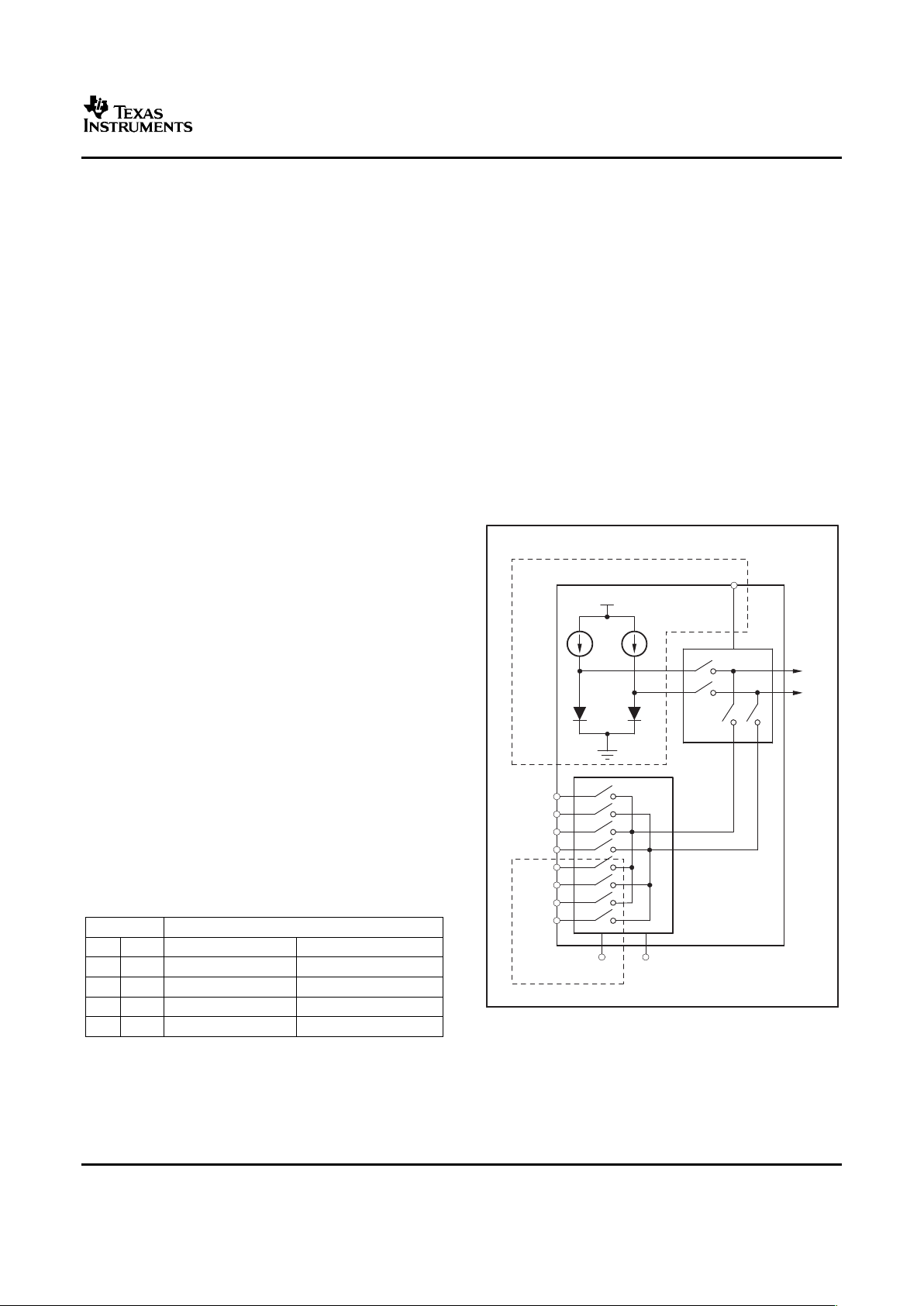

TEMPERATURE SENSOR (ADS1232 only)

OVERVIEW

ANALOG INPUTS (AINPx, AINNx)

A0A1

AINP

AINP1

AINN1

AINP2

AINN2

AINP3

AINN3

AINP4

AINN4

10I 1I

1X 8X

AINN

ADS1232 Only

AVDD

ADS1234 Only

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

On-chip diodes provide temperature-sensing

capability. By setting the TEMP pin high, the

The ADS1232 and ADS1234 are highly integrated,

selected analog inputs are disconnected and the

24-bit ADCs that include an input multiplexer,

inputs to the ADC are connected to the anodes of

low-noise PGA, third-order delta-sigma ( ∆ Σ )

two diodes scaled to 1x and 80x in current and size,

modulator, and fourth-order digital filter. With

as shown in Figure 18 . By measuring the difference

input-referred RMS noise down to 17nV, the

in voltage of these diodes, temperature changes can

ADS1232/4 are ideally suited for measuring the very

be inferred from a baseline temperature. Typically,

low signals produced by bridge sensors in

the difference in diode voltage is 111.7mV at 25 ° C

applications such as weigh scales, strain gauges,

with a temperature coefficient of 379 µ V/ ° C. With

and pressure sensors.

PGA = 1 and 2, the difference voltage output from

Clocking can be supplied by an external oscillator,

the PGA will be 111.7mV and 323.4mV, respectively.

an external crystal, or by a precision internal

With PGA = 64 and 128, it is impossible to use the

oscillator. Data can be output at 10SPS for excellent

temperature sensor function. A similar structure is

50Hz and 60Hz rejection, or at 80SPS when higher

used in the MSC1210 for temperature measurement.

speeds are needed. The ADS1232/4 are easy to

For more information, see TI application report

configure, and all digital control is accomplished

SBAA100 , Using the MSC121x as a High-Precision

through dedicated pins; there are no registers to

Intelligent Temperature Sensor, available for

program. A simple two-wire serial interface retrieves

download at www.ti.com .

the data.

The input signal to be measured is applied to the

input pins AINPx and AINNx. The positive internal

input is generalized as AINP, and the negative

internal input generalized as AINN. The signal is

selected through the input mux, which is controlled

by pins A0 and A1 (ADS1234 only), as shown in

Table 5 . For the ADS1232, the A1 pin is replaced by

the TEMP pin to activate the onboard diodes (see

the Temperature Sensor section for more details).

The ADS1232/4 accept differential input signals, but

can also measure unipolar signals. When measuring

unipolar (or single-ended signals) with respect to

ground, connect the negative input (AINNx) to

ground and connect the input signal to the positive

input (AINPx). Note that when the ADS1232/4 are

configured this way, only half of the converter

full-scale range is used, since only positive digital

output codes are produced.

Table 5. Input Channel Selection with A0 and A1

(ADS1234 only)

MUX PINS SELECTED ANALOG INPUTS

A1 A0 POSITIVE INPUT NEGATIVE INPUT

0 0 AINP1 AINN1

0 1 AINP2 AINN2

1 0 AINP3 AINN3

1 1 AINP4 AINN3

Figure 18. Measurement of the Temperature

Sensor in the Input Multiplexer

11

www.ti.com

LOW-NOISE PGA

VOLTAGE REFERENCE INPUTS

Z

EFF

+

1

2f

MOD

C

BUF

Z

EFF

+

1

(2)(76.8kHz)(32.5fF)

+ 200MW

R

INT

R

INT

R

F1

R

1

R

F2

ADC

A3

Gainof1or2

CAP

AINP

AINN

CAP

A2

A1

450W

18pF

450W

18pF

AVDD

(1) f

MOD

= 76.8kHz

Z

EFF

= 200M

Ω

(1)

VREFP VREFN

AVDD

ESD

Protection

C

BUF

Bypass Capacitor

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

attenuates the chopping residue from the PGA (for

gains of 64 and 128 only) to improve temperature

The ADS1232/4 features a low-drift, low-noise PGA

drift performance. It is not required to use high

that provides a complete front-end solution for bridge

quality capacitors (such as ceramic or tantalum

sensors. A simplified diagram of the PGA is shown in

capacitors) for a general application. However, high

Figure 19 . It consists of two chopper-stabilized

quality capacitors such as poly are recommended for

amplifiers (A1 and A2) and three accurately-matched

high linearity applications.

resistors (R

1

, R

F1

, and R

F2

), which construct a

differential front-end stage with a gain of 64, followed

by gain stage A3. The PGA inputs are equipped with

(REFP, REFN)

an EMI filter, as shown in Figure 19 . The cut-off

frequency of the EMI filter is 19.6MHz. If the PGA is

The voltage reference used by the modulator is

set to 1 or 2, the gain-of-64 stage is bypassed and

generated from the voltage difference between

shut down to save power. With the combination of

REFP and REFN: V

REF

= REFP – REFN. The

both gain stages, the PGA can be set to 64 or 128.

reference inputs use a structure similar to that of the

The PGA of the ADS1232/4 can be set to 1, 2, 64, or

analog inputs. In order to increase the reference

128 with pins GAIN1 (MSB) and GAIN0 (LSB). By

input impedance, a switching buffer circuitry is used

using AVDD as the reference input, the bipolar input

to reduce the input equivalent capacitance. A

ranges from ± 2.5V to ± 19.5mV, while the unipolar

simplified diagram of the circuitry on the reference

ranges from 2.5V to 19.5mV. When the PGA is set to

inputs is shown in Figure 20 . The switches and

1 or 2, the absolute inputs can go rail-to-rail without

capacitors can be modeled with an effective

significant performance degradation. However, the

impedance of:

inputs of the ADS1232/4 are protected with internal

diodes connected to the power-supply rails. These

diodes will clamp the applied signal to prevent it from

damaging the input circuitry. On the other hand,

Where:

when the PGA is set to 64 or 128, the operating

f

MOD

= modulator sampling frequency (76.8kHz)

input range is limited to (AGND + 1.5V) to (AVDD –

C

BUF

= input capacitance of the buffer

1.5V), in order to prevent saturating the differential

front-end circuitry and degrading performance.

For the ADS1232/4:

Figure 19. Simplified Diagram of the PGA

Figure 20. Simplified Reference Input Circuitry

ESD diodes protect the reference inputs. To prevent

By applying a 0.1µF external capacitor (C

EXT

) across

these diodes from turning on, make sure the

two capacitor pins and the combination of the

voltages on the reference pins do not go below GND

internal 2k Ω resistor R

INT

on-chip, a low-pass filter

by more than 100mV, and likewise, do not exceed

(with a corner frequency of 720Hz) is created to

AVDD by 100mV:

bandlimit the signal path prior to the modulator input.

This low-pass filter serves two purposes. First, the

GND – 100mV < (REFP or REFN) < AVDD + 100mV

input signal is bandlimited to prevent aliasing as well

as to filter out the high-frequency noise. Second, it

12

www.ti.com

CLOCK SOURCES

CLK_DETECT

Internal

Oscillator

MUX

To ADC

S

S0 S1

EN

Crystal

Oscillator

CLKIN/XTAL1

XTAL2

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

When the clock source is a crystal, simply connect

the 4.9152MHz crystal across the CLKIN/XTAL1 and

The ADS1232/4 can use an external clock source,

XTAL2 pins. Table 6 shows the recommended part

external crystal, or internal oscillator to

numbers. Due to the low-power design of the parallel

accommodate a wide variety of applications.

resonant driver circuitry onboard, both the

Figure 21 shows the equivalent circuitry of the clock

CLKIN/XTAL1 and XTAL2 pins are only for use with

source. The CLK_DETECT block determines

external crystals; they should not be used as clock

whether the crystal oscillator/external clock signal is

output drivers for external circuitry. No external

applied to the CLKIN/XTAL1 pin so that the internal

capacitors are used with the crystal; it is

oscillator is bypassed or activated. When the

recommended to place the crystal close to the part in

CLKIN/XTAL1 pin frequency is above ~200kHz, the

order to reduce board stray capacitance for both the

CLK_DETECT output goes low and shuts down the

CLKIN/XTAL1 and XTAL2 pins and to insure proper

internal oscillator. When the XIN pin frequency is

operation.

below ~200kHz, the CLK_DETECT output goes high

and activates the internal oscillator. It is highly

Table 6. Recommended Crystals

recommended to hard-wire the CLKIN/XTAL1 pin to

MANUFACTURER FREQUENCY PART NUMBER

ground when the internal oscillator is chosen.

ECS 4.9152MHz ECS-49-20-1

ECS 4.9152MHz ECS-49-20-4

An external oscillator may be used by driving the

CLKIN/XTAL1 pin directly. The Electrical

Characteristics table shows the allowable frequency

range. The clock input may be driven with 5V logic,

regardless of the DVDD or AVDD voltage.

Figure 21. Equivalent Circuitry of the Clock

Source

13

www.ti.com

FREQUENCY RESPONSE

Frequency (kHz)

Gain (dB)

0

−

20

−

40

−

60

−

80

−

100

−

120

−

140

−

160

−

180

−

200

38.4 76.8

0

f

CLK

= 4.9152MHz

Frequency (Hz)

Gain (dB)

0

−

50

−

100

−

150

0 10 20 30 40 50 60 70 80 90 100

(a)

Frequency (Hz)

(b)

Gain (dB)

−

50

−

100

−

150

494846 47 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64

Data Rate = 10SPS

Data Rate =10SPS

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

Figure 23 (b) shows the zoom in plot for both 50Hz

and 60Hz notches with the SPEED pin tied low

The ADS1232/4 use a sinc

4

digital filter with the

(10SPS data rate). With only a ± 3% variation of the

frequency response (f

CLK

= 4.9152MHz) shown in

internal oscillator, over 100dB of normal-mode

Figure 22 . The frequency response repeats at

rejection is achieved.

multiples of the modulator sampling frequency of

76.8kHz. The overall response is that of a low-pass

filter with a –3dB cutoff frequency of 3.32Hz with the

SPEED pin tied low (10SPS data rate) and 11.64Hz

with the SPEED pin tied high (80SPS data rate).

Figure 22. Frequency Response

To help see the response at lower frequencies,

Figure 23 (a) illustrates the response out to 100Hz,

when the data rate = 10SPS. Notice that signals at

multiples of 10Hz are rejected, and therefore

simultaneous rejection of 50Hz and 60Hz is

achieved.

Figure 23. Frequency Response Out To 100Hz

The benefit of using a sinc

4

filter is that every

frequency notch has four zeros on the same location.

This response, combined with the low drift internal

The ADS1232/4 data rate and frequency response

oscillator, provides an excellent normal-mode

scale directly with clock frequency. For example, if

rejection of line-cycle interference.

f

CLK

increases from 4.9152MHz to 6.144MHz when

the SPEED pin is tied high, the data rate increases

from 80SPS to 100SPS, while notches also increase

from 80Hz to 100Hz. Note that this is only possible

when the external clock source is applied.

14

www.ti.com

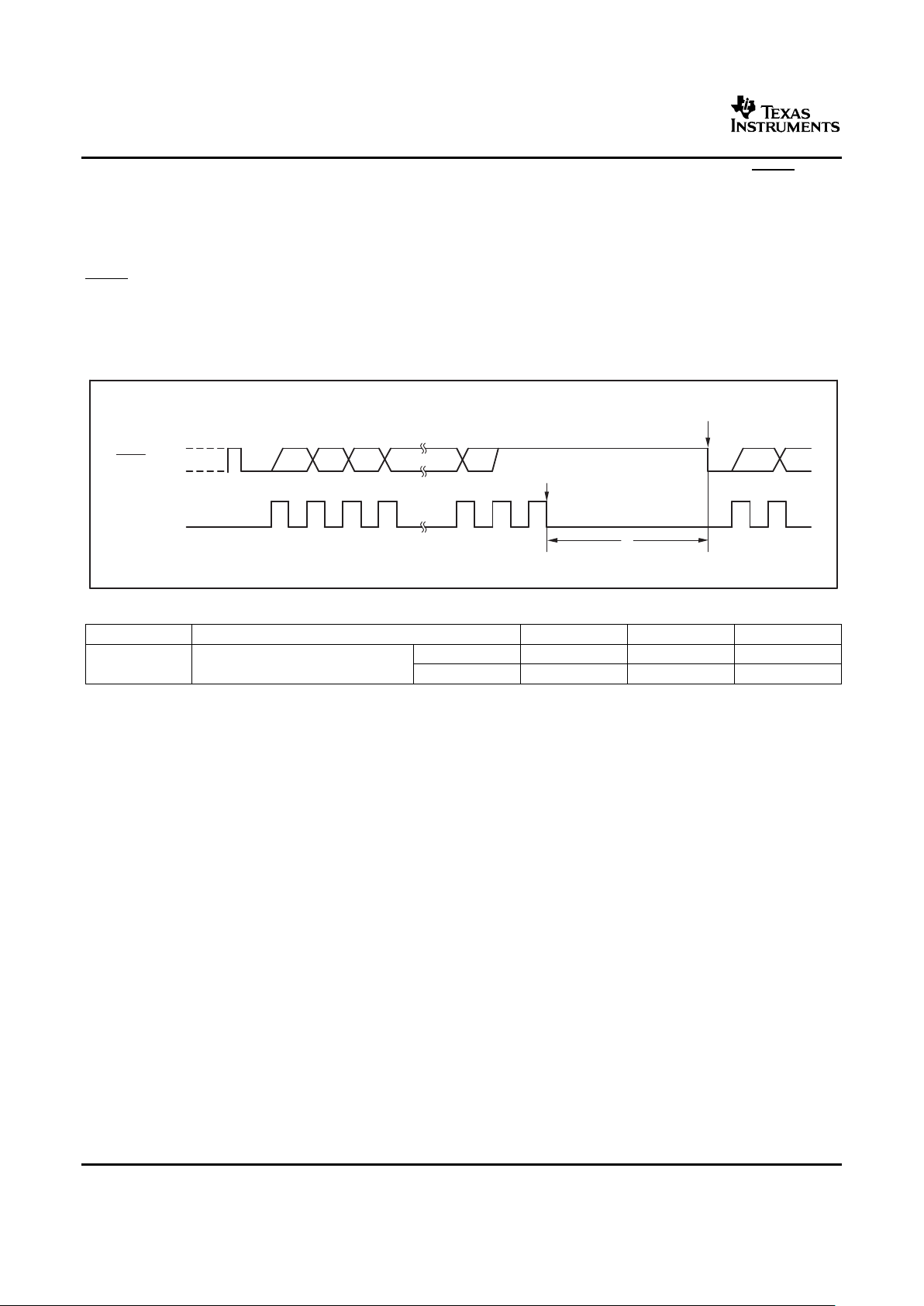

SETTLING TIME

A1, A0, or TEMP change

t

1

DRDY/DOUT

t

S

Abrupt Change in External V

IN

V

IN

DRDY/DOUT

Start of

Conversion

1st Conversion;

includes

unsettled VIN.

2nd Conversion;

VINsettled, but

digital filter

unsettled.

3rd Conversion;

VINsettled, but

digital filter

unsettled.

4th Conversion;

VINsettled, but

digital filter

unsettled.

5th Conversion;

VINand digital

filter both

settled.

Conversion

Time

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

In certain instances, large changes in input will

require settling time. For example, an external

After changing the input multiplexer, or selecting the

multiplexer in front of the ADS1232/4 can put large

onboard temperature sensor (ADS1232 only), the

changes in input voltage by simply switching input

first data is fully settled. In both the ADS1232/4, the

channels. Abrupt changes in the input will require

digital filter is allowed to settle after toggling any of

four data cycles to settle. When continuously

the A1, A0, or TEMP pins. Toggling any of these

converting, five readings may be necessary in order

digital pins will hold the DRDY/DOUT line high until

to settle the data. If the change in input occurs in the

the digital filter is fully settled. For example, if A0

middle of the first conversion, four more full

changes from low to high, selecting a different input

conversions of the fully-settled input will be required

channel, DRDY/DOUT immediately goes high, and

to get fully-settled data. Discard the first four

DRDY/DOUT goes low when fully-settled data is

readings because they will contain only

ready for retrieval. There is no need to discard any

partially-settled data. Figure 25 illustrates the settling

data. Figure 24 shows the timing of the DRDY/DOUT

time for the ADS1232/4 in Continuous Conversion

line as the input multiplexer changes.

Mode.

Figure 24. Example of Settling Time After Changing the Input Multiplexer

SYMBOL DESCRIPTION

(1)

MIN MAX UNITS

t

S

Setup time for changing any of the A1, A0, or TEMP pins 40 50 µ s

SPEED = 1 51 51 ms

Settling time ( DRDY/DOUT

t

1

held high)

SPEED = 0 401 401 ms

(1) Values given for f

CLK

= 4.9152MHz. For different f

CLK

frequencies, scale proportional to CLK period. Expect a ± 3% variation when an

internal oscillator is used.

Figure 25. Settling Time in Continuous Conversion Mode

15

www.ti.com

DATA RATE

DATA FORMAT

DATA READY/DATA OUTPUT ( DRDY/DOUT) SERIAL CLOCK INPUT (SCLK)

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

Table 7. Data Rate Settings

DATA RATE

The ADS1232/4 data rate is set by the SPEED pin,

SPEED

Internal Oscillator External

as shown in Table 7 . When SPEED is low, the data

PIN

or 4.9152MHz Crystal Oscillator

rate is nominally 10SPS. This data rate provides the

lowest noise, and also has excellent rejection of both 0 10SPS f

CLKIN

/ 491,520

50Hz and 60Hz line-cycle interference. For

1 80SPS f

CLKIN

/ 61,440

applications requiring fast data rates, setting SPEED

high selects a data rate of nominally 80SPS.

Table 8. Ideal Output Code vs Input Signal

(1)

The ADS1232/4 output 24 bits of data in binary two’s

INPUT SIGNAL V

IN

complement format. The least significant bit (LSB)

(AINP – AINN) IDEAL OUTPUT CODE

has a weight of 0.5V

REF

/(2

23

– 1). The positive

≥ +0.5V

REF

/Gain 7FFFFFh

full-scale input produces an output code of 7FFFFFh

and the negative full-scale input produces an output

(+0.5V

REF

/Gain)/(2

23

– 1) 000001h

code of 800000h. The output clips at these codes for

0 000000h

signals exceeding full-scale. Table 8 summarizes the

(–0.5V

REF

/Gain)/(2

23

– 1) FFFFFFh

ideal output codes for different input signals.

≤ – 0.5V

REF

/Gain 800000h

(1) Excludes effects of noise, INL, offset, and gain errors.

This digital output pin serves two purposes. First, it This digital input shifts serial data out with each

indicates when new data is ready by going low. rising edge. As with CLK, this input may be driven

Afterwards, on the first rising edge of SCLK, the with 5V logic regardless of the DVDD or AVDD

DRDY/DOUT pin changes function and begins voltage. This input has built-in hysteresis, but care

outputting the conversion data, most significant bit should still be taken to ensure a clean signal.

(MSB) first. Data is shifted out on each subsequent Glitches or slow-rising signals can cause unwanted

SCLK rising edge. After all 24 bits have been additional shifting. For this reason, it is best to make

retrieved, the pin can be forced high with an sure the rise-and-fall times of SCLK are less than

additional SCLK. It will then stay high until new data 50ns.

is ready. This configuration is useful when polling on

the status of DRDY/DOUT to determine when to

begin data retrieval.

16

www.ti.com

DATA RETRIEVAL

DRDY/DOUT 23 22 21

1 24

0

LSBMSB

Data

Data Ready

SCLK

t

2

t

7

t

3

t

3

t

6

New Data Ready

t

4

t

5

23

1 24 25

22 21 0

Data

25th SCLK to Force DRDY/DOUT High

Data Ready New Data Ready

DRDY/DOUT

SCLK

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

last bit shifted out until it is taken high (see t6),

indicating that new data is being updated. To avoid

The ADS1232/4 continuously convert the analog

having DRDY/DOUT remain in the state of the last

input signal. To retrieve data, wait until DRDY/DOUT

bit, the user can shift SCLK to force DRDY/DOUT

goes low, as shown in Figure 26 . After this occurs,

high, as shown in Figure 27 . This technique is useful

begin shifting out the data by applying SCLKs. Data

when a host controlling the device is polling

is shifted out MSB first. It is not required to shift out

DRDY/DOUT to determine when data is ready.

all 24 bits of data, but the data must be retrieved

before new data is updated (within t7) or else it will

be overwritten. Avoid data retrieval during the update

period (t6). DRDY/DOUT remains at the state of the

Figure 26. Data Retrieval Timing

SYMBOL DESCRIPTION MIN TYP MAX UNITS

t

2

DRDY/DOUT low to first SCLK rising edge 0 ns

t

3

SCLK positive or negative pulse width 100 ns

t

4

SCLK rising edge to new data bit valid: propagation 50 ns

delay

t

5

SCLK rising edge to old data bit valid: hold time 0 ns

t

6

(1)

Data updating: no readback allowed 39 µ s

SPEED = 1 12.5 ms

t

7

(1)

Conversion time (1/data rate)

SPEED = 0 100 ms

(1) Values given for f

CLK

= 4.9152MHz. For different f

CLK

frequencies, scale proportional to CLK period.

Figure 27. Data Retrieval with DRDY/DOUT Forced High Afterwards

17

www.ti.com

OFFSET CALIBRATION

23DRDY/DOUT

SCLK

1 24

t

8

25 26

2322 21 0

Data Ready AfterCalibration

Calibration Begins

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

When the calibration is completed, DRDY/DOUT

goes low, indicating that new data is ready. The

Offset calibration can be initiated at any time to

analog input pins are disconnected within the ADC

remove the ADS1232/4 inherited offset error. To

and the appropriate signal is applied internally to

initiate offset calibration, apply at least two additional

perform the calibration. The first conversion after a

SCLKs after retrieving 24 bits of data. Figure 28

calibration is fully settled and valid for use. The offset

shows the timing pattern. The 25th SCLK will send

calibration takes exactly the same time as specified

DRDY/DOUT high. The falling edge of the 26th

in (t8) right after the falling edge of the 26th SCLK.

SCLK will begin the calibration cycle. Additional

SCLK pulses may be sent after the 26th SCLK;

however, activity on SCLK should be minimized

during offset calibration for best results.

Figure 28. Offset-Calibration Timing

SYMBOL DESCRIPTION MIN MAX UNITS

SPEED = 1 101.28 101.29 ms

t

8

(1)

First data ready after calibration

SPEED = 0 801.02 801.03 ms

(1) Values given for f

CLK

= 4.9152MHz. For different f

CLK

frequencies, scale proportional to CLK period. Expect a ± 3% variation when an

internal oscillator is used.

18

www.ti.com

STANDBY MODE

DRDY/DOUT 23 22 21

1 24

0 23

SCLK

Standby Mode

Start Conversion

Data Ready

t

9

t

10

t

11

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

When t10has passed with SCLK held high, Standby

mode will activate. DRDY/DOUT stays high when

Standby mode dramatically reduces power

Standby mode begins. SCLK must remain high to

consumption by shutting down most of the circuitry.

stay in Standby mode. To exit Standby mode

In Standby mode, the entire analog circuitry is

(wakeup), set SCLK low. The first data after exiting

powered down and only the clock source circuitry is

Standby mode is valid.

awake to reduce the wake-up time from the Standby

mode. To enter Standby mode, simply hold SCLK

high after DRDY/DOUT goes low; see Figure 29 .

Standby mode can be initiated at any time during

readback; it is not necessary to retrieve all 24 bits of

data beforehand.

Figure 29. Standby Mode Timing (can be used for single conversions)

SYMBOL DESCRIPTION MIN MAX UNITS

SPEED = 1 0 12.44 ms

SCLK high after DRDY/DOUT goes

t

9

(1)

low to activate Standby mode

SPEED = 0 0 99.94 ms

SPEED = 1 12.46 ms

t

10

(1)

Standby mode activation time

SPEED = 0 99.96 ms

SPEED = 1 52.51 52.51 ms

t

11

(1)

Data ready after exiting Standby mode

SPEED = 0 401.8 401.8 ms

(1) Values given for f

CLK

= 4.9152MHz. For different f

CLK

frequencies, scale proportional to CLK period. Expect a ± 3% variation when an

internal oscillator is used.

19

www.ti.com

STANDBY MODE WITH

Standby Mode

Begin Calibration

Data Ready After Calibration

t

10

t

12

DRDY/DOUT 23

1 24 25

22 21 0 23

SCLK

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

To force an offset-calibration with Standby mode,

OFFSET-CALIBRATION shift 25 SCLKs and take the SCLK pin high to enter

Standby mode. Offset-calibration then begins after

Offset-calibration can be set to run immediately after

wake-up; see Figure 30 for the appropriate timing.

exiting Standby mode. This is useful when the

Note the extra time needed after wake-up for

ADS1232/4 is put in Standby mode for long periods

calibration before data is ready. The first data after

of time, and offset-calibration is desired afterwards to

Standby mode with offset-calibration is fully settled

compensate for temperature or supply voltage

and can be used right away.

changes.

Figure 30. Standby Mode with Offset-Calibration Timing (can be used for single conversions)

SYMBOL DESCRIPTION MIN MAX UNITS

t

12

(1)

SPEED = 1 103 103 ms

Data ready after exiting Standby mode

and calibration

SPEED = 0 803 803 ms

(1) Values given for f

CLK

= 4.9152MHz. For different f

CLK

frequencies, scale proportional to CLK period. Expect a ± 3% variation when an

internal oscillator is used.

20

www.ti.com

POWER-DOWN MODE

DataReady

Start

Conversion

DRDY/DOUT

SCLK

CLKSoure

WakeupPower-DownMode

PDWN

t

13

t

11

t

14

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

from locking up to an unknown state. Power-Down

mode can be initiated at any time during readback; it

Power-Down mode shuts down the entire ADC

is not necessary to retrieve all 24 bits of data

circuitry and reduces the total power consumption

beforehand. Figure 31 shows the wake-up timing

close to zero. To enter Power-Down mode, simply

from Power-Down mode.

hold the PDWN pin low. Power-Down mode also

resets the entire circuitry to free the ADC circuitry

Figure 31. Wake-Up Timing from Power-Down Mode

SYMBOL DESCRIPTION TYP UNITS

Internal clock 7.95 µ s

t

13

Wake-up time after Power-Down mode External clock 0.16 µ s

Crystal oscillator

(1)

5.6 ms

t

14

(2)

PDWN pulse width 26 (min) µ s

(1) No capacitors on CLKIN/XTAL1 or XTAL2 outputs.

(2) Value given for f

CLK

= 4.9152MHz. For different f

CLK

frequencies, the scale is proportional to the CLK period except for a ± 3% variation

when an internal oscillator is used.

21

www.ti.com

APPLICATION EXAMPLES

Weigh-Scale System

Noise−Free Counts +ǒ2

(18.4)1)

Ǔ

ǒ

10mV

39mV

Ǔ

+ 177,385

Thermocouple

Noise−Free Counts +ǒ2

BIT

Eff

Ǔ

ǒ

FS

LC

FS

AD

Ǔ

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

Therefore:

Figure 32 shows a typical ADS1232 hook-up as part

With +5V supply voltage, 177,385 noise-free counts

of a weigh-scale system. In this setup, the ADS1232

can be expected from the ADS1232/4 with the

is configured to channel one input with a gain of 128

onboard PGA set to 128.

at a 10SPS data rate. Note that the internal oscillator

is used by grounding the CLKIN/XTAL1 pin. The

user can also apply either a 4.9152MHz crystal

across the CLKIN/XTAL1 and XTAL2 pins, or simply

See Figure 33 for the ADS1232 in a thermocouple

apply a clock to the CLKIN/XTAL1 pin. For a typical

application. In this example, a type k thermocouple is

2mV/V load cell, the maximum output signal is

used; the temperature range is from –260 ° C to

approximately 10mV for a single +5V excitation

+900 ° C when the gain is set to 64 to maximize the

voltage. The ADS1232/4 can achieve 18.4 noise-free

full input range of the ADS1232. R

1

and a

bits at 10SPS when the PGA = 128 (refer to

REF1004-2.5V are used to set the common-mode

Table 1 ). With the extra software filtering/averaging

voltage to 2.5V for ungrounded junction

(typically done by a microprocessor), an extra bit can

thermocouples. With a gain of 128, the ADS1232

be expected.

input has a typical noise of 17nV

RMS

for extremely

high-resolution applications.

If either a wider temperature range application is

required (up to +1350 ° C, for example), or a

Where:

grounded junction thermocouple is used, pin 1 of the

thermocouple can be grounded (see Figure 34 ).

BIT

EFF

= effective noise-free bits (18.4 + 1 bit

When the gain is set to 2, the ADS1232 input has a

from software filtering/averaging)

typical 500nV offset error and a noise level of

FS

LC

= full-scale output of the load cell (10mV)

270nV

RMS

, which is good for all kinds of low-voltage

FS

AD

= full-scale input of the ADS1232/4 (39mV

output sensors. Note that to calculate the actual

when PGA = 128)

thermocouple temperature, the ADS1232 internal

temperature sensor can be accessed in order to

measure the cold junction temperature along with the

thermocouple reading.

22

www.ti.com

ADS1232

16

9

10

11

12

14

13

15

20

19

24

23

22

4

3

21

8

7

REFP

CAP

CAP

AINP1

AINN1

AINP2

AINN2

REFN

GAIN0

AVDD DVDD

AGND DGND

DRDY/DOUT

SCLK

PDWN

XTAL2

CLKIN/XTAL1

SPEED

A0

TEMP

0.1µF

0.1µF

2.7V to 5.3V

GAIN1

+

−

17 2, 5, 6

18 1

MSP430x4xx

or Other

Microprocessor

VDD

GND

Gain = 128

ADS1232

16

9

10

11

12

14

13

15

20

19

24

23

22

4

3

21

8

7

REFP

CAP

CAP

AINP1

AINN1

AINP2

AINN2

REFN

GAIN0

AVDD DVDD

AGND DGND

DRDY/DOUT

SCLK

PDWN

XTAL2

CLKIN/XTAL1

SPEED

A0

TEMP

0.1µF

0.1µF

2.7V to 5.3V

GAIN1

17 2, 5, 6

18 1

MSP430x4xx

or Other

Microprocessor

VDD

GND

Gain = 128

R

1

50k

Ω

REF1004−2.5V

2

1

Thermocouple Type k

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

Figure 32. Weigh Scale Application

Figure 33. Ungrounded Junction Thermocouple Application

23

www.ti.com

ADS1232

16

9

10

11

12

14

13

15

19

20

24

23

22

4

3

21

8

7

REFP

CAP

CAP

AINP1

AINN1

AINP2

AINN2

REFN

GAIN1

AVDD DVDD

AGND DGND

DRDY/DOUT

SCLK

PDWN

XTAL2

CLKIN/XTAL1

SPEED

A0

TEMP

0.1µF

0.1µF

2.7V to 5.3V

GAIN0

17 2, 5, 6

18 1

MSP430x4xx

or Other

Microprocessor

VDD

GND

Gain = 2

R

1

50k

Ω

REF1004−2.5V

2

1

Thermocouple Type k

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

Figure 34. Grounded Junction Thermocouple Application

24

www.ti.com

RTDs and Thermistors

ADS1232

16

9

10

14

11

13

12

15

20

19

24

23

22

4

3

21

8

7

REFP

CAP

CAP

AINP2

AINP1

AINN2

AINN1

REFN

GAIN0

AVDD DVDD

AGND DGND

DRDY/DOUT

SCLK

PDWN

XTAL2

CLKIN/XTAL1

SPEED

A0

TEMP

0.1µF

0.1µF

2.7V to 5.3V

GAIN1

17 2, 5, 6

18 1

MSP430x4xx

or Other

Microprocessor

VDD

GND

Gain = 128

R

1

33k

Ω

R

2

33k

Ω

R

L

R

L

R

L

RTD

NOTE: RLis lead resistance.

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

common-mode voltage of the ADS1232 PGA. By

using both differential channels of the ADS1232, the

Figure 35 shows a typical schematic for a style 2

temperature change in lead resistance, RL, can be

(three-wire) RTD application. R

1

and R

2

are used to

eliminated. This condition is accomplished by using

excite the RTD as well as establish the

the following formula:

(AINP1 – AINN1) – 2(AINP2 – AINN2).

Figure 35. Style 2 (Three-Wire) RTD Schematic

25

www.ti.com

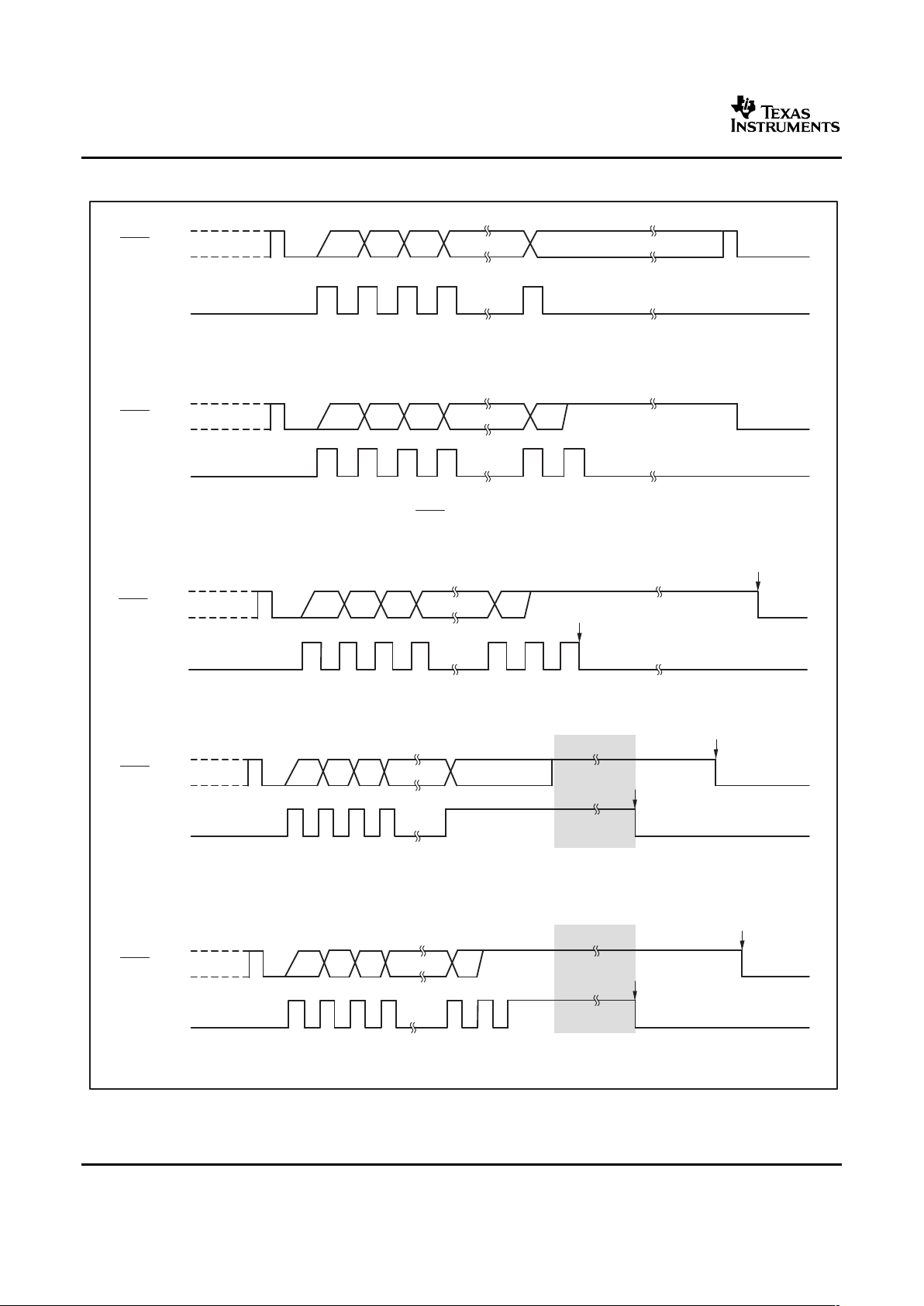

SUMMARY OF SERIAL INTERFACE WAVEFORMS

DRDY/DOUT

SCLK

23 22 21 0

MSB LSB

1 24

DRDY/DOUT

SCLK

23 22 21 0

1 24 25

DRDY/DOUT

SCLK

23 22 21 0

1 24 25 26

Calibration Begins

Data Ready

After Calibration

DRDY/DOUT

SCLK

Data Ready

Start

Conversion

Standby Mode

23 22 21 0

1 24

DRDY/DOUT

SCLK

23 22 21 0

1 24 25

Data Ready

After Calibration

Calibration Begins

(a) Data Retrieval

(b) Data Retrieval with DRDY/DOUT Forced High Afterwards

(c) Offset−Calibration Timing

(d) Standby Mode/Single Conversions

(e) Standby Mode/Single Conversions with Offset Calibration

Standby Mode

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

Figure 36. Summary of Serial Interface Waveforms

26

www.ti.com

ADS1232

ADS1234

SBAS350C – JUNE 2005 – REVISED JUNE 2006

Changes from B Revision (September 2005) to C Revision ......................................................................................... Page

• Deleted last row from Absolute Maximum Ratings table. ..................................................................................................... 2

• Changed Analog Inputs section of Electrical Characteristics table. ..................................................................................... 3

• Changed the typical value in last row of Voltage Reference Input section of Electrical Characteristics table. .................... 3

• Added footnote 1 to Table 1 , Table 2 , Table 3 , and Table 4 . ............................................................................................... 5

• Changed fourth sentence in Temperature Sensor section of Overview . ............................................................................ 11

• Added fifth and sixth sentences to Temperature Sensor section of Overview . .................................................................. 11

• Added fourth and fifth sentences to Low-Noise PGA section of Overview ......................................................................... 12

• Changed Figure 19 . ............................................................................................................................................................ 12

• Changed t11to t10in third paragraph of Standby Mode section of Overview . .................................................................... 19

• Changed min and max variables of t10row in table below Figure 29 . ................................................................................ 19

• Changed Figure 31 . ............................................................................................................................................................ 21

• Added last row and second footnote to table below Figure 31 . ......................................................................................... 21

27

PACKAGING INFORMATION

Orderable Device Status

(1)

Package

Type

Package

Drawing

Pins Package

Qty

Eco Plan

(2)

Lead/Ball Finish MSL Peak Temp

(3)

ADS1232IPW ACTIVE TSSOP PW 24 60 Green (RoHS &

no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR

ADS1232IPWG4 ACTIVE TSSOP PW 24 60 Green (RoHS &

no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR

ADS1232IPWR ACTIVE TSSOP PW 24 2000 Green (RoHS &

no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR

ADS1232IPWRG4 ACTIVE TSSOP PW 24 2000 Green (RoHS &

no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR

ADS1234IPW ACTIVE TSSOP PW 28 50 Green (RoHS &

no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR

ADS1234IPWG4 ACTIVE TSSOP PW 28 50 Green (RoHS &

no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR

ADS1234IPWR ACTIVE TSSOP PW 28 2000 Green (RoHS &

no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR

ADS1234IPWRG4 ACTIVE TSSOP PW 28 2000 Green (RoHS &

no Sb/Br)

CU NIPDAU Level-2-260C-1 YEAR

(1)

The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

(2)

Eco Plan - The planned eco-friendly classification: Pb-Free (RoHS), Pb-Free (RoHS Exempt), or Green (RoHS & no Sb/Br) - please check

http://www.ti.com/productcontent for the latest availability information and additional product content details.

TBD: The Pb-Free/Green conversion plan has not been defined.

Pb-Free (RoHS): TI's terms "Lead-Free" or "Pb-Free" mean semiconductor products that are compatible with the current RoHS requirements

for all 6 substances, including the requirement that lead not exceed 0.1% by weight in homogeneous materials. Where designed to be soldered

at high temperatures, TI Pb-Free products are suitable for use in specified lead-free processes.

Pb-Free (RoHS Exempt): This component has a RoHS exemption for either 1) lead-based flip-chip solder bumps used between the die and

package, or 2) lead-based die adhesive used between the die and leadframe. The component is otherwise considered Pb-Free (RoHS

compatible) as defined above.

Green (RoHS & no Sb/Br): TI defines "Green" to mean Pb-Free (RoHS compatible), and free of Bromine (Br) and Antimony (Sb) based flame

retardants (Br or Sb do not exceed 0.1% by weight in homogeneous material)

(3)

MSL, Peak Temp. -- The Moisture Sensitivity Level rating according to the JEDEC industry standard classifications, and peak solder

temperature.

Important Information and Disclaimer:The information provided on this page represents TI's knowledge and belief as of the date that it is

provided. TI bases its knowledge and belief on information provided by third parties, and makes no representation or warranty as to the

accuracy of such information. Efforts are underway to better integrate information from third parties. TI has taken and continues to take

reasonable steps to provide representative and accurate information but may not have conducted destructive testing or chemical analysis on

incoming materials and chemicals. TI and TI suppliers consider certain information to be proprietary, and thus CAS numbers and other limited

information may not be available for release.

In no event shall TI's liability arising out of such information exceed the total purchase price of the TI part(s) at issue in this document sold by TI

to Customer on an annual basis.

PACKAGE OPTION ADDENDUM

www.ti.com

6-Dec-2006

Addendum-Page 1

MECHANICAL DATA

MTSS001C – JANUARY 1995 – REVISED FEBRUARY 1999

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

PW (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PINS SHOWN

0,65

M

0,10

0,10

0,25

0,50

0,75

0,15 NOM

Gage Plane

28

9,80

9,60

24

7,90

7,70

2016

6,60

6,40

4040064/F 01/97

0,30

6,60

6,20

8

0,19

4,30

4,50

7

0,15

14

A

1

1,20 MAX

14

5,10

4,90

8

3,10

2,90

A MAX

A MIN

DIM

PINS **

0,05

4,90

5,10

Seating Plane

0°–8°

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0,15.

D. Falls within JEDEC MO-153

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements,

improvements, and other changes to its products and services at any time and to discontinue any product or service without notice.

Customers should obtain the latest relevant information before placing orders and should verify that such information is current and

complete. All products are sold subject to TI’s terms and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in accordance with TI’s

standard warranty. Testing and other quality control techniques are used to the extent TI deems necessary to support this

warranty. Except where mandated by government requirements, testing of all parameters of each product is not necessarily

performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for their products and

applications using TI components. To minimize the risks associated with customer products and applications, customers should

provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right, copyright, mask

work right, or other TI intellectual property right relating to any combination, machine, or process in which TI products or services

are used. Information published by TI regarding third-party products or services does not constitute a license from TI to use such

products or services or a warranty or endorsement thereof. Use of such information may require a license from a third party under

the patents or other intellectual property of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of TI information in TI data books or data sheets is permissible only if reproduction is without alteration and is

accompanied by all associated warranties, conditions, limitations, and notices. Reproduction of this information with alteration is an

unfair and deceptive business practice. TI is not responsible or liable for such altered documentation. Information of third parties

may be subject to additional restrictions.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that product or service

voids all express and any implied warranties for the associated TI product or service and is an unfair and deceptive business

practice. TI is not responsible or liable for any such statements.

TI products are not authorized for use in safety-critical applications (such as life support) where a failure of the TI product would

reasonably be expected to cause severe personal injury or death, unless officers of the parties have executed an agreement

specifically governing such use. Buyers represent that they have all necessary expertise in the safety and regulatory ramifications

of their applications, and acknowledge and agree that they are solely responsible for all legal, regulatory and safety-related

requirements concerning their products and any use of TI products in such safety-critical applications, notwithstanding any

applications-related information or support that may be provided by TI. Further, Buyers must fully indemnify TI and its

representatives against any damages arising out of the use of TI products in such safety-critical applications.

TI products are neither designed nor intended for use in military/aerospace applications or environments unless the TI products are

specifically designated by TI as military-grade or "enhanced plastic." Only products designated by TI as military-grade meet military

specifications. Buyers acknowledge and agree that any such use of TI products which TI has not designated as military-grade is

solely at the Buyer's risk, and that they are solely responsible for compliance with all legal and regulatory requirements in

connection with such use.

TI products are neither designed nor intended for use in automotive applications or environments unless the specific TI products

are designated by TI as compliant with ISO/TS 16949 requirements. Buyers acknowledge and agree that, if they use any

non-designated products in automotive applications, TI will not be responsible for any failure to meet such requirements.

Following are URLs where you can obtain information on other Texas Instruments products and application solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

RFID www.ti-rfid.com Telephony www.ti.com/telephony

Low Power www.ti.com/lpw Video & Imaging www.ti.com/video

Wireless

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2007, Texas Instruments Incorporated

Loading...

Loading...