Page 1

User's Guide

SBAU125A – August 2007 – Revised September 2007

ADS1230REF User's Guide

The ADS1230REF is a reference design for the ADS1230 20-bit, delta-sigma analog-to-digital converter

(ADC). It contains all the circuitry and user interface elements needed for a weigh-scale digitizer, and is

meant as an example of good design for a basic weigh-scale system. The ADS1230REF is also suitable

for general evaluation of the ADS1230 device.

The ADS1230REF hardware has the following features:

• ADS1230 ADC

• Connections for load cells or other voltage sources

• Low-side excitation switch on the load cell header connector

• Ample EMI/RFI suppression between the ADC and rest of design

• Eight-digit starburst LCD readout

• USB connection for firmware updates and remote control

• Designed for very low power consumption

• Battery (9V) or wall power

Version 1.1.0 of the firmware includes the following features:

• Weigh-scale mode with two-point calibration

• Complete configuration of the device

• Real-time peak-to-peak and RMS noise calculation

• Autoranging voltage display

• Noise displayed in volts, codes, and bits

• Voltage displayed in volts or codes

• Adjustable averaging mode

• Raw hexadecimal code display

• Simple and fast configuration

• Parameters saved to internal flash memory

• Computer link

Graphical PC software is also provided for histogram display, datalogging, and device control.

We welcome bug reports and suggestions for additional features; please contact the Texas Instruments

Precision Analog Applications Group.

Hyperterm is a trademark of Microsoft Corporation.

Windows is a registered trademark of Microsoft Corporation.

All other trademarks are the property of their respective owners.

SBAU125A – August 2007 – Revised September 2007 ADS1230REF User's Guide 1

Submit Documentation Feedback

Page 2

www.ti.com

Contents

1 Getting Started ............................................................................................................... 3

2 Weigh Scale Mode........................................................................................................... 7

3 Analysis Mode .............................................................................................................. 11

4 Using the PC Software .................................................................................................... 14

5 Serial Console .............................................................................................................. 18

6 Hardware .................................................................................................................... 20

Appendix A Schematic and Layout ........................................................................................... 24

List of Figures

1 ADS1230REF Controls and Connectors .................................................................................. 3

2 4-Wire Load Cell to Terminal Block ....................................................................................... 4

3 6-Wire Load Cell to Terminal Block ....................................................................................... 5

4 4-Wire Load Cell to Header ................................................................................................ 5

5 6-Wire Load Cell to Header ................................................................................................ 5

6 ADS1230REF PC Software Display ..................................................................................... 15

7 ADS1230REF Average Data ............................................................................................. 16

8 ADS1230REF Hardware Block Diagram ................................................................................ 20

A-1 ADS1230REF PCB—Top Side ........................................................................................... 26

A-2 ADS1230REF PCB—Bottom Side ....................................................................................... 26

A-3 ADS1230REF Schematic—ADC ......................................................................................... 27

A-4 ADS1230REF Schematic—MCU ......................................................................................... 28

A-5 ADS1230REF Schematic—USB ......................................................................................... 29

List of Tables

1 Unit Conversion Factors and Display Formats ........................................................................... 8

2 Parameters in Configuration Mode ........................................................................................ 9

3 Modes and Example Displays ............................................................................................ 11

4 Voltage Display Ranges ................................................................................................... 12

5 Parameters in Analysis Mode............................................................................................. 13

6 Console Mode Commands ................................................................................................ 19

7 Load Cell Header Pinout .................................................................................................. 21

8 Terminal Block Pinout ..................................................................................................... 22

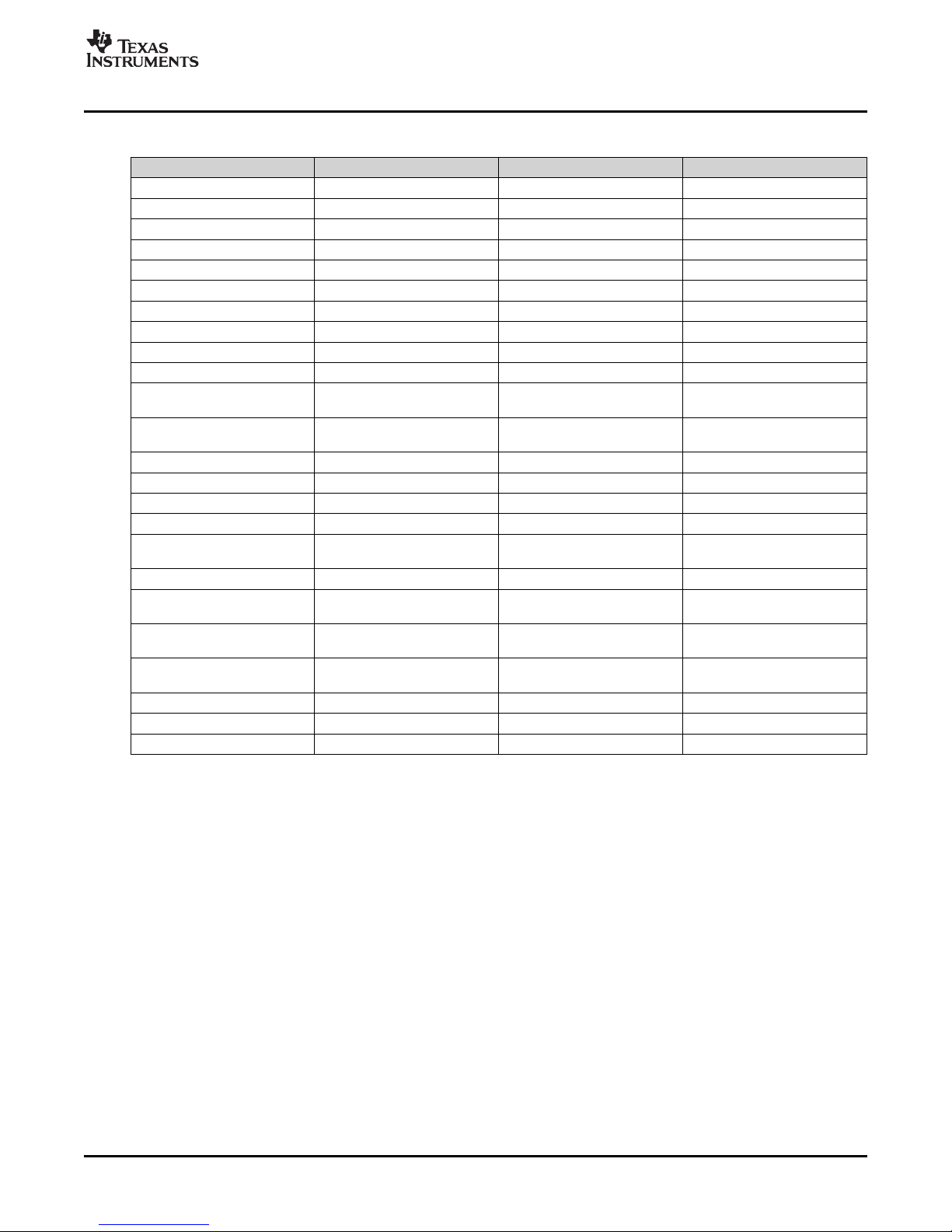

A-1 ADS1230REF Bill of Materials ............................................................................................ 24

2 ADS1230REF User's Guide SBAU125A – August 2007 – Revised September 2007

Submit Documentation Feedback

Page 3

www.ti.com

1 Getting Started

Getting Started

A diagram of the ADS1230REF is shown in Figure 1 .

1.1 Operating Modes

The ADS1230REF operates in one of three modes:

• Scale mode: When the mode select switch is in Scale position, the ADS1230REF acts as a basic

• Analysis mode: When the mode select switch is in Analysis position, codes are taken directly from the

• Configuration mode: Parameters governing the operation of the ADS1230REF can be viewed and

Figure 1. ADS1230REF Controls and Connectors

weigh scale. The scale has tare, range, and calibrate functions, and can display metric (SI) units. Other

parameters can be configured in configuration screens. Scale mode is described in detail in Section 2 .

ADS1230 device and various measurements are made upon them. Several measurements are

available, including raw display, voltage, RMS noise, and peak-to-peak measurements. The ADS1230

can also be configured directly from this mode. Analysis mode is described in detail in Section 3 .

altered in this mode. Scale and Analysis modes have different options in configuration mode:

configuration for Scale mode is described in Section 2.4 , and configuration for Analysis mode is

described in Section 3.4 .

SBAU125A – August 2007 – Revised September 2007 ADS1230REF User's Guide 3

Submit Documentation Feedback

Page 4

www.ti.com

EXCSNSSNS+

SIG+

SIGEXC+

OUT+

EXC-

OUT-

EXC+

Getting Started

1.2 Controls

The main controls for the ADS1230REF are the four buttons and the mode selection slide-switch (see

Figure 1 ).

The slide-switch selects between weigh-scale (Scale) and Analysis modes. The ADS1230REF switches

modes only when it is displaying data. If the switch is changed in a configuration mode, nothing happens

until the configuration mode is exited. At that time the ADS1230REF reads the switch and enters the

selected mode.

The four buttons have different functions, depending on the operating mode. In Scale mode, the switches

have the functions in the box labeled SCALE. In Analysis mode, the switches have the functions shown in

the box labeled ANALYSIS. In configuration mode, the switches have the functions shown in the box

labeled CONFIG.

The buttons also have different names in different modes. In this document, they are identifed by the

respective names they have in the mode under discussion.

1.2.1 Auxiliary Controls

The Reset switch resets the board, except for the USB interface.

The USB Reset switch resets the USB interface. If USB communication fails, pressing USB Reset may

solve the problem.

The Programming Mode switch is used to update the firmware. For normal operation, it should be set to

JTAG.

1.3 Power

To apply power to the ADS1230REF, connect a 9V battery or plug in a 6V–9V ac wall adapter.

AC adapters must be tip positive/sleeve negative. When an ac adapter is plugged in, the board always

takes power from it, and not from the battery.

The ADS1230REF is protected against polarity reversal. If a power source is connected in reverse by

mistake, the display remains blank. To prevent damage to the board, do not leave a reversed power

source connected for longer than a few seconds.

1.4 Connecting a Load Cell

The ADS1230REF is specifically designed for connection to load cells. Two connectors are provided for

this application. The terminal block is used for load cells having stripped wire connections; the load cell

header is for load cells having a header connector. The terminal block provides connections to the

reference input (or power supply) and the header has switched excitation.

1.4.1 Connecting a 4-Wire Load Cell to the Terminal Block

Figure 2 shows the connection of a 4-wire load cell to the terminal block. In this configuration, the load cell

is excited by the +5V power supply, and the ADC reference is taken from the power supply.

For this configuration, the reference select switch must be in the +5VA position.

ADS1230REF User's Guide4 SBAU125A – August 2007 – Revised September 2007

Figure 2. 4-Wire Load Cell to Terminal Block

Submit Documentation Feedback

Page 5

www.ti.com

1.4.2 Connecting a 6-Wire Load Cell to the Terminal Block

EXCSNSSNS+

SIG+

SIGEXC+

OUT+

EXCSENSE-

OUTSENSE+

EXC+

OUT+

EXC-

OUT-

EXC+

1

2

3

4

5

6

OUT-

EXC+

OUT+

EXC-

SENSE+

SENSE-

1

2

3

4

5

6

Figure 3 shows the connection of a 6-wire load cell to the terminal block. In this configuration, the load cell

is excited by the +5V power supply, and the ADC’s reference is taken from the sense wire returning from

the load cell. The sense wire connects to the excitation wire at the bridge sensor.

Figure 3. 6-Wire Load Cell to Terminal Block

1.4.3 Connecting a 4-Wire Load Cell to the Header

Figure 4 shows the connection of a 4-wire load cell to the header. In this configuration, the load cell is

excited by the +5V power supply, and the ADC reference is taken from the power supply.

Getting Started

For this configuration, the reference select switch must be in the +5VA position; the EXT position does not

work.

1.4.4 Connecting a 6-Wire Load Cell to the Header

Figure 5 shows the connection of a 6-wire load cell to the header. In this configuration, the load cell is

excited by the +5V power supply, and the ADC reference is taken from the sense wire returning from the

load cell. The sense wire connects to the excitation wire at the bridge sensor.

For this configuration, the reference select switch should be in the EXT position for best performance. The

+5V position also works, but the device may not perform as well.

SBAU125A – August 2007 – Revised September 2007 ADS1230REF User's Guide 5

Submit Documentation Feedback

Figure 4. 4-Wire Load Cell to Header

Figure 5. 6-Wire Load Cell to Header

Page 6

www.ti.com

Getting Started

1.5 Connecting Other Signal Sources

In general, the ADS1230REF can accurately measure any voltage in the input range of the ADS1230

ADC, as long as the following rules are observed:

• Never apply a negative voltage to the inputs of the ADS1230REF. The ADS1230 cannot accept

negative voltages at its input. Applying negative voltages may damage both the device and the

ADS1230REF. (The negative signs used in some signal names indicate inversion, not polarity.)

• For single-ended signals, ground the negative input or connect it to 2.5V. 2.5V is available from a

voltage divider by shorting J7; see Section 6.4.5 for details.

• The input range of the amplifier on the ADS1230 does not extend to the supplies. See the ADS1230

data sheet for details.

Note that Scale mode is designed only for use with load cells. Although it can be tested with a voltage

source or resistive divider, Scale mode does not, in general, display meaningful data unless a load cell is

connected and calibration is performed.

1.6 Connecting an External Clock

To connect an external clock, connect a clock oscillator to the EXTCLK test point. No settings need to be

changed; the ADS1230 will automatically use the attached clock.

The clock source must conform to 3.3V TTL or CMOS logic rules.

1.7 Common Tasks

1.7.1 Shorted-Input Noise Test

The noise measurements given in the product data sheet are taken with the inputs shorted to 2.5V. These

noise measurements can be replicated on the ADS1230REF with no external hardware. To set up these

measurements on the ADS1230REF, perform the following steps:

1. Move the mode switch to Analysis mode.

2. Short jumpers J8 and J7. (These jumpers are located very near the terminal block, and are marked

Input Shorting Jumpers in Figure 1 .)

3. Set up the ADS1230 as desired, as described in the previous sections.

4. Hold down the DISP button. The display shows the current display mode. While holding down DISP,

press the MODE button until the word on the left side is RMS.

5. While still holding down DISP, press the UNIT button until the word on the right side is VOLT.

6. Release the DISP button. The display shows the word GOT followed by an increasing number. Once

the appropriate number of points is collected, the calculated noise voltage is displayed. This value is

the shorted-input RMS noise voltage, input-referred.

The first RMS noise measurement may be incorrect as a result of device settling. The second

measurement is generally correct.

For a detailed description of Analysis mode, see Section 3 .

1.7.2 Measuring Mass

The following items are required to measure mass with the ADS1230REF:

• A load cell, connected as described in Section 1.4

• An object of known mass within the load cell range

To avoid performing calibration on each power-up, you can save the calibration settings to flash memory.

See Section 3.4.1 for details.

6 ADS1230REF User's Guide SBAU125A – August 2007 – Revised September 2007

Submit Documentation Feedback

Page 7

www.ti.com

Weigh Scale Mode

Obtaining a calibration weight:

Before the ADS1230REF can display the mass of an object, it must measure the output of the load cell for

a previously known mass. The known mass can be adjusted.

At power-up, the ADS1230REF expects a 5kg mass. If this mass is not available, or if the load cell range

is not compatible with this mass, the calibration mass can be changed in the following manner:

1. Determine the mass of the calibration weight. The most accurate way to determine the mass is to

weigh the calibration object on an accurately calibrated scale. If the weight is precalibrated, its given

mass can be used, although this approach is not generally as accurate. (Note that the accuracy of the

ADS1230REF as a scale directly depends on the accuracy to which the calibration weight can be

measured.)

2. Switch the mode switch to SCALE mode.

3. Press the ENT and SEL buttons simultaneously. The ADS1230REF enters configuration mode.

4. Use the PARM buttons to select the screen which shows UNIT =. This screen allows you to select the

units used for the calibration mass. If the units shown are not correct, adjust them using the VALUE

buttons.

5. Use the PARM buttons to select the screen that shows CW= followed by the calibration mass. On this

screen, you can adjust each digit of the calibration mass separately. Select the digit using the PARM

buttons. The currently-selected digit flashes, and can be adjusted using the VALUE buttons.

6. Adjust the calibration mass to match the mass of the calibration weight.

7. Press the VALUE buttons simultaneously to exit the configuration mode.

Preparing Scale mode:

Do the following steps to set up the scale mode:

1. Connect the load cell.

2. If the input shorting jumpers J8 and J7 are connected, disconnect them (see Figure 1 ).

3. Obtain a weight of known mass.

4. If the mass of the weight is not equal to the configured calibration mass, adjust the calibration mass as

described above.

5. Move the mode switch to SCALE position. If calibration has not been performed, the display reads

NO CAL.

6. Press the CAL button, and follow the calibration procedure given in Section 2.3 .

If the calibration is performed properly, and the load cell is connected correctly, the ADS1230REF will

measure the mass of an object placed on the load cell (provided that the mass of the object is within the

device range).

Weigh scale mode is described in detail in Section 2 .

2 Weigh Scale Mode

In weigh scale mode, the ADS1230REF displays mass.

units based on the voltage received from a load cell.

The ADS1230REF operates in Scale mode when the mode switch is set to the Scale position.

To accurately calculate mass, the ADS1230REF must have calibration information for the load cell. When

scale mode is first entered, the ADS1230REF displays NO CAL, because the ADS1230REF has no

calibration data when it is powered on.

By default, mass is calculated from the average of four successive readings from the ADC. The number of

points for averaging can be adjusted, and averaging can be turned off.

(1)

Load cells do not measure mass directly; they output a voltage proportional to the weight of an object. The mass of an object can be

accurately inferred from this voltage as long as a calibration is accurately performed, the downward force of gravity remains constant (as

it does if the load cell is not moved to a different altitude), and the tilt of the load cell does not change; if either of the latter conditions

change, a new calibration must be performed.

SBAU125A – August 2007 – Revised September 2007 ADS1230REF User's Guide 7

Submit Documentation Feedback

(1)

Mass is displayed in either SI or avoirdupois

Page 8

www.ti.com

m=

w

fs

c-c

fs zs

Weigh Scale Mode

2.1 Display

Weigh scale mode can display mass in these uints: μ g (displayed as ug), g, kg, pounds ( lb), stone ( st),

and ounces ( oz).

Internally, mass is measured in grams, and calibration factors are stored in grams. At display time, grams

are converted to the desired display unit using the conversion factors given in Table 1 .

xxx

(2)

The avoirdupois units used by the ADS1230REF are equal in the imperial and U. S. customary systems.

The display format for stone differs from the format used for the other units. One stone is equal to fourteen

pounds; weight in stone is commonly expressed as a number of stone followed by a number of pounds.

On the ADS1230REF, two digits are shown for stone, followed by st, followed by pounds displayed to two

decimal places.

(2)

Table 1. Unit Conversion Factors and Display Formats

Unit Multiplier Format

micrograms ( μ g) 10

milligrams (mg) 1000 nnn.nnnmg

grams (g) 1 nnn.nnng

kilograms (kg) 10

ounces (oz) 0.035274 nnn.nnnoz

pounds (lb) 0.0022046 nnn.nnnlb

stone (st) 157.473 × 10

6

–3

–6

nnn.nnnug

nnn.nnnkg

nnstnn.nn

2.1.1 Calculation of Mass

Mass is calculated from ADC code using the formula:

w = mc + w

where:

• w = mass

• c = the ADC code

• w

= t are weight

t

• m, w

, wt = values determined in the calibration process

zs

m is a calibration constant, and is calculated using Equation 1 :

where w

is the user-specified calibration mass, cfsis the ADC code taken with the calibration mass

fs

applied, and c

w

, the zero-scale mass, is calculated from m and c

zs

w

= –mc

zs

2.2 Button Functions

2.2.1 TARE

The tare function allows the mass of a substance to be measured separately from the mass of its

container. When the TARE button is pressed, the scale measures the mass and records it. This reading is

subtracted from each subsequent measurement.

The recorded tare value can be reset to zero by holding the TARE button down for at least one second.

When the tare value is to be reset, the display reads TARE OFF.

Tare is also reset following a calibration.

– w

zs

t

is the ADC measurement taken with no load.

zs

zs

using Equation 2 :

zs

(1)

(2)

ADS1230REF User's Guide8 SBAU125A – August 2007 – Revised September 2007

Submit Documentation Feedback

Page 9

www.ti.com

2.2.2 RANGE

2.2.3 CAL

2.3 Calibration

Weigh Scale Mode

The RANGE button changes the units or range of the display. RANGE cycles through all available units;

see Section 2.1 for details. When the RANGE button is depressed, it displays the selected unit.

Pressing CAL initiates the two-point calibration sequence. See Section 2.3 for details.

Two-point calibration is performed by pressing the CAL button. When this button is pressed, the board

executes the following command sequence:

1. The board scrolls the message, REMOVE WEIGHT.

2. The user removes all weight from the load cell and presses any button.

3. The board measures the load cell voltage and records it as the zero point.

4. The board scrolls the message PLACE CAL

WEIGHT.

5. The user places a weight on the load cell and presses any button. The weight should have the mass

that was selected in the configuration mode.

6. The board measures the load cell voltage and records it as the calibration weight.

New calibration data is lost when power is removed. To prevent this data loss, calibration data can be

saved, with other board settings, to flash memory. See Section 3.4.1 for details.

2.4 Configuration

The parameters for Scale mode can be adjusted in the configuration mode.

To enter configuration mode, press the VALUE buttons simultaneously. The four buttons then assume the

functions shown in the CONFIG box. To exit Configuration mode, press the VALUE buttons

simultaneously again. This function does not cause parameters to be adjusted, because only button

releases are detected in Configuration mode.

Configuration mode contains a number of adjustable parameters. To scroll through the available

parameters, use the PARM buttons. To change the parameter values, use the VALUE buttons.

Some items in configuration mode are not parameters, but commands or gateways to a submenu. These

items are labelled as words with a question mark. To enter these or to execute the command, press SEL

or ENT.

All parameters in the analysis and scale configuration menus are independent, including the parameters

found in both modes.

Table 2 summarizes the available parameters.

Table 2. Parameters in Configuration Mode

Parameter Display Value Range Description

Display units UNIT= μ g, mg, g, kg, lb, st, oz Display units

Averages AVGS= 2–128 Number of points to

ADC speed SPD= FAST, SLOW Acquisition rate

Calibration mass CW= 0–99.9 in various units Calibration mass and unit

Offset calibration OCAL? — Offset calibration; see text

Save parameters SAVE? — Save parameters; see text

Version number V1.1.0 — Firmware version number

average

display

SBAU125A – August 2007 – Revised September 2007 ADS1230REF User's Guide 9

Submit Documentation Feedback

Page 10

www.ti.com

Weigh Scale Mode

2.4.1 Parameters

Display units: The units to use when displaying mass. Available units are μ g (displayed as ug), mg, g, kg,

ounces (oz), pounds, (lb), and stone (st). See Section 2.1 for details.

Averages: Number of points to use when reading weight. The choices available are 2, 4, 8, 10, 16, 32,

50, 64, 100, and 128. The default is 50.

ADC speed: This parameter selects between the two data rates on the ADS1230, which are called

high-speed and low-speed. When high-speed mode is selected, FAST is shown; for low-speed mode,

SLOW is shown.

(1)

The actual data rate of the ADS1230 depends on the frequency of the master clock, f

data rate is f

/61440; in slow mode, the data rate is f

CLK

/491520. See the ADS1230 data sheet for

CLK

further information.

The default setting is low-speed mode.

Calibration weight: This parameter gives the expected mass of the calibration weight used in the

calibration procedure (Section 2.3 ). The calibration mass can be given in any of the available units, in

three significant figures. The unit is independent of the display unit.

Each digit in the mass is adjusted separately. The currently-selected digit flashes, and can be adjusted

with the VALUE buttons. The PARM buttons are used to select the digit. The unit is adjusted in the same

manner, and flashes when selected.

When the unit is changed, the value changes to the equivalent mass in the new unit.

Offset calibration: This screen has the same function as it does in Analysis mode. See Calibration

section 2.3 for information.

Save parameters: This screen allows the settings of the ADS1230REF to be stored in flash memory. It

functions the same as it does in Analysis mode. When ENT or SEL is pressed on this screen, the

ADS1230REF saves its settings to flash memory. These settings are loaded from flash memory when the

board is reset or powered on. All operating parameters are saved, including scale calibration settings,

voltage reference, display mode, and units.

Version number: This screen displays the version number of the ADS1230REF firmware.

(1)

The ADS1230REF cannot detect the frequency of the ADS1230 master clock, so it cannot display the actual data rate of the ADS1230

device.

. In fast mode, the

CLK

ADS1230REF User's Guide10 SBAU125A – August 2007 – Revised September 2007

Submit Documentation Feedback

Page 11

www.ti.com

3 Analysis Mode

v=

2 1-

24

x

v

REF

A

·

In Analysis mode, the ADS1230REF analyzes code output from the ADS1230 and displays it in different

ways. Table 3 summarizes the numerous display modes available, together with example displays.

Raw 1992E9H +1676001 +499.488M n/a

RMS n/a +5.789 +17.495N +23.18BIT

Peak-to-Peak n/a +31.256 +90.293N +21.92BIT

Averaged n/a +1676001 +499.488M n/a

The ADS1230REF operates in Analysis mode when the mode switch is set to the ANALYSIS position.

The default Analysis mode is RAW HEX.

To change measurement types, hold down DISP and press MODE. This function cycles through the four

available measurement types. When DISP is released, the newly selected measurement is made. To

change units, press UNIT. This option cycles through the available units for the active measurement type.

This procedure can also be done while DISP is depressed; in that case, the new unit is shown by name

on the display. The measurement modes are described in detail in Section 3.2 .

The ADS1230 itself can be configured directly from this mode, as described in Section 3.1 .

3.1 Switch Functions

NEW BLOCK: Pressing this switch resets the collection process for the RMS, peak-to-peak, and

averaged measurements.

UNIT: Cycles between available units. Not all units are available in all modes.

DISP: When this switch is pressed, the display shows the current measurement mode and unit. While

DISP is still pressed, pressing NEW BLOCK / MODE cycles through the available measurement modes.

CHIP: Holding this switch down allows the settings of the ADS1230 to be changed, using the PARM

(NEW BLOCK) and VAL (UNIT) buttons.

Pressing PARM while DISP is pressed down cycles through the available parameters—gain, data rate,

and active channel.

The gain setting is displayed as GAIN= followed by the gain setting. Gains of 64 and 128 are available.

Data rate is shown on the display as SPD=FAST or SPD=SLOW. See ADC speed in the Parameters section

for further information.

If any of these parameters are changed during a multisample measurement, the measurement is

restarted.

Analysis Mode

Table 3. Modes and Example Displays

Hex Code Dec Code Voltage ENOB

3.2 Measurement Modes

Raw: In this measurement, codes are read from the ADS1230 and displayed. No processing or analysis is

done on the sample stream. Data can be displayed as hexadecimal codes, decimal codes, or volts.

Voltage is calculated according to Equation 3 :

Where:

• A is the converter gain (64 or 128), determined from the programmed gain setting

• v

• x is the ADC decimal code

v

is adjustable from Configuration mode. By default, it is 5V.

REF

SBAU125A – August 2007 – Revised September 2007 ADS1230REF User's Guide 11

Submit Documentation Feedback

is the voltage at the converter reference input

REF

(3)

Page 12

www.ti.com

s =

N

(x )-ix

2

N

i =1

1

N

å

E=

24 log s :-

2 N0sN

¹

24:s 0N=

Analysis Mode

The voltage display is autoranging. All ranges are shown with six significant figures having three decimal

places. The ranges are given in Table 4 .

Table 4. Voltage Display Ranges

VOLTAGE RANGE DISPLAY SUFFIX

Nanovolts < 1 μ V n

Microvolts < 1mV u

Millivolts < 1V m

Volts ≥ 1V V

RMS noise: In this mode, a number of codes are read from the ADS1230, and an RMS noise calculation

is performed on them using the standard-deviation formula (given in Equation 4 ):

The result can be displayed as decimal codes, volts, or an effective number of bits (ENOB). For decimal

codes, sNis displayed directly. (Hexadecimal is not available because sNmay be fractional.) For volts, s

is converted to a voltage as in raw mode.

ENOB: E is calculated using Equation 5 :

(4)

N

The zero case is needed when a string of equal codes is read. This can happen when the converter is

clipping.

This measurement requires a number of codes to be read before a calculation can be made. Therefore,

during the first run, the display shows the word GOT followed by the number of samples collected. This

event happens when the mode is first entered, when the converter configuration changes, or when NEW

BLOCK is pressed.

The number of codes used in the calculation is selected in Configuration mode; 50 codes are used in

laboratory characterization, so this value is the default.

Peak-to-peak noise: In this mode, a number of codes are collected, and the absolute value of the

difference between the minimum and maximum is calculated. The result can be displayed in decimal or

hexadecimal codes, volts, or noise-free bits (ENOB). Volts are calculated as in raw mode; ENOB is

calculated in the same way as in RMS mode.

The number of codes used in the calculation is selectable in Configuration mode.

Averaged: In this mode, a number of codes are collected, and the average is calculated. The result can

be displayed in decimal codes or volts. (Hexadecimal is not available because the result may be

fractional.) Volts are calculated as in raw mode.

The number of codes used in the calculation is selectable in Configuration mode.

3.3 Progress Graph

The row of apostrophes at the top of the display are used to indicate measurement progress. In Raw

mode, the apostrophe moves across the display when data is being received from the converter. The

apostrophe moves once for every eight samples collected from the ADC.

In block collection modes, the apostrophes form a bar graph. As the collection of a block proceeds, the

bar graph increases. When the bar graph reaches all the way to the right, the new result is generated and

collection restarts.

(5)

ADS1230REF User's Guide12 SBAU125A – August 2007 – Revised September 2007

Submit Documentation Feedback

Page 13

www.ti.com

Analysis Mode

3.4 Configuration

To enter Configuration mode, press the VALUE buttons simultaneously. The four buttons then assume the

functions shown in the CONFIG box. To exit Configuration mode, press the VALUE buttons

simultaneously again. This operation does not cause parameters to be adjusted; only button releases are

detected in Configuration mode.

Configuration mode contains a number of adjustable parameters. To scroll through the available

parameters, use the PARM buttons. To change the parameter values, use the VALUE buttons.

Some items in configuration mode are not parameters, but commands or gateways to a submenu. These

items are labelled as words with a question mark. To enter these items or to execute the command, press

SEL or ENT.

Although a few of the parameters in the Analysis and Scale configuration menus are the same, the

settings are kept separate between the modes.

Table 5 summarizes the available parameters.

Table 5. Parameters in Analysis Mode

Parameter Display Value Range Description

Averages AVG= 2–128 Number of points for average,

Voltage Reference VREF= 0.5–5.0 Voltage used in various

Power-down mode PDWN? — Power-down mode; see text

Offset calibration OCAL? — Offset calibration; see text

Save parameters SAVE? — Save parameters; see text

Version number V1.0.0 — Firmware version number display

peak-to-peak, and RMS modes

calculations

3.4.1 Parameters

Averages: Number of points to use in Averaged, RMS noise, and Peak-Peak calculations. The choices

available are 2, 4, 8, 10, 16, 32, 50, 64, and 128. The default setting is 50.

Voltage reference: To convert voltages to codes, the ADS1230REF requires the voltage reference level.

Since this level cannot be measured, it must be selected manually. This parameter allows the reference

level to be set.

Each digit of the voltage reference is selected and adjusted separately. Use the PARM buttons to select a

digit, and the VALUE buttons to adjust it. The selected digit flashes.

This parameter does not affect the actual voltage reference used. If it is incorrect, voltage calculations will

be wrong. The voltage reference is typically the +5V rail; the default value for this parameter is 5.0V.

Power-down mode: When ENT or SEL is pressed on this screen, the ADS1230REF causes the

ADS1230 to enter power-down mode. This action occurs by pulling the PDWN line low. While the PDWN

line is low, the display reads POWER DN. When a button is pressed from this display, the ADS1230REF

powers the converter on and returns to the analysis display, exiting configuration mode.

This mode can be used to test the current consumption of the board when the ADS1230 is powered down.

Offset calibration: When ENT or SEL is pressed on this screen, the ADS1230REF initiates a hardware

offset calibration on the ADS1230 by providing two extra shift clock cycles on the next data read cycle, as

described in the ADS1230 data sheet .

When ENT or SEL is pressed, the display briefly shows OK, indicating that calibration was performed.

Offset calibration is performed when the ADS1230REF is powered on, but is not automatically performed

at any other time.

Version number: This screen displays the version number of the ADS1230REF firmware.

SBAU125A – August 2007 – Revised September 2007 ADS1230REF User's Guide 13

Submit Documentation Feedback

Page 14

www.ti.com

Using the PC Software

4 Using the PC Software

The ADS1230REF is supplied with software that performs various analyses on data received from the

board via the USB connection. It also provides a means of recording received data to a file.

The program currently runs only on a Microsoft Windows

communicates with the ADS1230REF using a virtual COM port driver that causes the USB connection to

appear to Windows as a normal serial port. The necessary driver is installed with the EVM software.

4.1 Installation and Setup

The ADS1230REF software is distributed in an installer program called

ADS123x-setup-withLVRT-1.1.1.exe (the version number in the file name may differ), distributed on

the CD-ROM or available from Texas Instruments. To install the software, execute this program. The

program guides you through the installation process.

Note the following points:

• The installer installs two packages: the ADS123xREF program itself, and the TI Virtual COM Port

driver.

• If any version of the ADS123xREF program is already installed, the installer uninstalls it and quits. You

must run the installer again to complete the installation.

• If the Virtual COM Port driver is already installed, the installer offers to uninstall it. Do not uninstall it;

cancel this part of the installation.

The installer displays messages reminding you of these points.

®

platform. In Windows, the program

4.1.1 First Time Connection of the ADS123xREF

If the ADS1230REF has never been connected to your computer before, Windows detects the device as

unknown hardware and takes you through a series of dialogs to install the correct driver. Accept the

default settings; the driver is present and only needs to be copied to the correct location. If the driver is

successfully installed, Windows does not issue this prompt again.

On some computers, if the board is connected to a different USB port, the operating system detects the

board as new hardware. If this action occurs, proceed through the new hardware dialogs as usual, and

allow Windows to reinstall the driver.

4.2 The Display

The ADS1230REF software has a single display; see Figure 6 for a typical display. The major elements of

the display discussed next.

Strip chart: This feature displays a scrolling graph of data received from the board.

Histogram: A sliding histogram of data received from the board is also displayed. The number of points

used in the analysis is adjustable.

14 ADS1230REF User's Guide SBAU125A – August 2007 – Revised September 2007

Submit Documentation Feedback

Page 15

www.ti.com

DC analysis section: The results of RMS noise analysis, peak-to-peak analysis, and a running voltage

number are shown in this section. The number of analysis points and the reference voltage used for

voltage calculations are also adjustable here.

Recording section: This feature controls recording of data to a file.

Device control section: This section allows device parameters to be adjusted.

Status display: This display shows messages indicating the current state of the program.

Acquire button: This button starts and stops the running acquisition of data.

4.3 Starting the Program

When the program launches, a screen similar to that shown in Figure 6 appears. Immediately after launch,

the program searches all available serial ports for the board. To do this step, it opens every available

serial port in turn, testing it to see if there is an ADS1230REF connected. The program uses the first

ADS1230REF it finds.

Using the PC Software

Figure 6. ADS1230REF PC Software Display

Although this procedure is conceptually simple, it may not go as smoothly as expected. The following

process ensures that the board is found correctly. Note that Steps 1–3 can be done in any order.

Step 1. Apply power to the ADS1230REF.

Step 2. Plug in the USB connector.

Step 3. Start the program.

Step 4. Watch the status display. It reads Scanning followed by the name of the serial port being

tested. When the board is found, the display reads Idle. Until a board is found, the display

cycles through every port, spending approximately one second on each port.

Once the board is detected, the program enters Idle mode and is ready for use.

Note: If the board is never detected, it is still possible (and safe) to exit the program during the

search process. If the board does not respond, pressing the USB Reset switch (SW1) may

help.

SBAU125A – August 2007 – Revised September 2007 ADS1230REF User's Guide 15

Submit Documentation Feedback

Page 16

www.ti.com

Histogram

StripChart

Using the PC Software

4.4 Analysis or Record Mode

The program will operate in analysis mode or record mode. Both modes acquire the data and update the

displays, but record mode also writes the result to the selected file.

4.5 Adjusting Device Parameters

To adjust device parameters, use the controls in the Device control box. Each control corresponds to a

setting that can also be made from the board itself.

4.6 Acquiring Data

To start receiving and analyzing data from the board, click the Acquire button, located in the lower

right-hand corner of the display. The program begins to receive data from the board, displaying the results

in near-real time.

It is not possible for the program to adjust board parameters in Analysis mode. For this reason, the board

controls are disabled and dimmed while Analysis occurs.

4.6.1 Averaging

The PC software can process data collected from the board using a sliding-window averager. The controls

for the averager are found in the Averager box.

To turn the averager on, use the Averaging switch. The number of points averaged is set by the Points

control, and the number of points currently collected is shown in the Collected box.

When the averager is turned on, it is cleared. To reset the averager, turn it off and then on again.

The histogram displays an integer representation of the averaged data. Note that when selecting a high

number of averages, the integer results might include only one code; the histogram for that case will be

blank. The strip chart display shows both the full precision result of the averages and the integer version,

as illustrated in Figure 7 .

ADS1230REF User's Guide16 SBAU125A – August 2007 – Revised September 2007

Figure 7. ADS1230REF Average Data

Submit Documentation Feedback

Page 17

www.ti.com

4.6.2 Block Analysis Length

The histogram, RMS, and peak-to-peak calculations require a set of samples. These calculations are

updated with every group of samples received, and are performed on a block of the most recently

acquired (or averaged) samples.

The number of samples used is set using the Analysis points control. By default, this number is 50, but

can be changed at any time. This value also controls the RMS and peak-to-peak noise analysis lengths.

If the number of samples collected is not yet equal to the number of samples specified by the Analysis

points control, 0s are substituted for the samples not yet received.

In Analysis mode, the analysis can be reset using the button marked Reset analysis. This function clears

the internal analysis buffer. This button cannot be used outside of Analysis and Recording modes.

Analysis is automatically reset when Analysis and Recording modes are entered.

4.6.3 RMS and Peak-to-Peak Noise Analysis

The RMS and peak-to-peak noise analysis calculations are performed in exactly the same way as they are

in the ADS1230REF firmware, as described in Section 3.2 . Each calculation can be displayed in units of

volts, codes, or bits, as on the board. See Section 3.2 for detailed descriptions of the calculations.

The number of samples used in each calculation is set using the Analysis points control. By default, this

number is 50, but can be changed at any time. This control also controls the histogram length.

4.6.4 Displaying Volts

When units of volts are displayed, the program must have a value for the reference voltage applied to the

ADS1230 to properly calculate the voltage. Because this voltage cannot be measured using the

ADS1230REF, it is set manually using the Vref control.

The value of Vref defaults to 5V, because the reference is normally taken from the 5V power supply. If a

different reference voltage level is used, the value of Vref should be changed to reflect the different level,

so that voltage calculations are performed correctly.

The Vref control also affects voltages recorded in Record mode.

Using the PC Software

4.6.5 Block Acquisition

To enable the program to run reliably on slower computers, results are not calculated each time a sample

is received. Instead, groups of samples are collected and added to an analysis buffer that is processed as

it becomes full. This processing delay is timed so that the display updates at least every 0.75 seconds.

4.7 Data Recording

The ADS1230REF software can record incoming samples to a text file. This file can be loaded into other

programs for analysis. Data recording is performed using the controls in the Recording box.

Follow these steps to record data to a file:

Step 1. Select or create a destination file. Either type the file path directly into the Destination file

control, or click the small open folder icon to the right of the control to open a dialog box from

which a file can be selected. If the selected file exists already, the program will display a

warning. Otherwise, type the name of the file that you wish to create.

Step 2. Select a data format. Samples can be recorded as raw (decimal) codes or as volts. In both

cases, the data are written to the file as ASCII data, and the file is a text file.

Step 3. Click the Record button. The program begins to collect and analyze data from the board, as

well as write it to the selected file. As recording proceeds, the recording time indicators are

updated.

Step 4. Click Record again to stop the recording when the desired amount of data has been

collected.

SBAU125A – August 2007 – Revised September 2007 ADS1230REF User's Guide 17

Submit Documentation Feedback

Page 18

www.ti.com

Serial Console

4.7.1 File Format

5 Serial Console

The selected file is not opened or created until recording begins. If an error occurs at that time, recording

stops and a message displays in the status box.

Recording time is not measured, but calculated from the number of samples collected. The speed is used

to determine the amount of time for each sample. If the data rate is changed at the board, the recording

time will be incorrect. This change does not affect the data file, except that samples continue to be

collected with the different settings.

In Recording mode, analysis proceeds as in Analysis mode; Recording mode is identical to Analysis

mode, except that data is written to a file. See the previous section for documentation on Analysis mode.

When Recording mode begins, if the selected file exists, it is erased and overwritten. The pre-existence of

the file is checked only when a new file is selected.

Data files begin with a header that contains the text collected from ADS1230REF, the time of recording,

and the speed and gain. Following this header, values are written in either volts or raw codes, with one

value per line. Line separators are in DOS format, consisting of a carriage return and a line feed. This

format can be examined in a text editor and loaded or imported into most other software, including

spreadsheets.

Voltages are calculated using the reference voltage given in the Vref control; it is therefore important that

this value be correct.

The ADS1230REF provides a console mode that can be used with any Windows terminal emulation

program, such as Hyperterm™. In Windows, this configuration is done through the Virtual COM Port driver

supplied with the EVM software, causing the ADS1230REF to appear in Windows as an extra serial port.

5.1 Using the Console

To use the console, load a terminal emulation program and connect to the EVM serial port using the

following parameters:

• Baud rate: 115200

• Data bits: 8

• Parity: none

• Stop bits: 1

• Flow control: none

• Local echo: off

• Terminal emulation: ANSI or VT100

Setting up the terminal program is beyond the scope of this document; see the specific terminal program

documentation for details.

To locate the serial port, try higher port numbers first. When the board first starts, it outputs the following

message:

ADS1230REF 1.1.0c

(c)2005-2007 Texas Instruments

1230>

Pressing Reset causes the board to output this message.

The command prompt is always 1230> . Commands are entered at this prompt. Commands consist of

one letter possibly followed by arguments. The format of the arguments depends on the command.

Commands are case insensitive. Upper-case characters are printed here, but lower-case characters also

work.

18 ADS1230REF User's Guide SBAU125A – August 2007 – Revised September 2007

Submit Documentation Feedback

Page 19

www.ti.com

5.2 Command Reference

Serial Console

The available commands are listed in Table 6 . In this table, values in brackets indicate a range or list of

possible characters. A dash ( –) indicates a range, and commas ( ,) indicate a list.

Table 6. Console Mode Commands

COMMAND FORMAT OPERATION

P Set PGA

R Set data rate

K

V

S Start streaming

D Read data once

Q Query parameters

P [0,1]

R [F,S]

K

V

S

D

Q

Perform offset

calibration

Show firmware

version

Console mode does not interrupt standalone operation. It is always available, even when the standalone

mode is in use. However, if parameters are changed using both the console and standalone modes,

parameters may become out of sync.

5.2.1 P—Set PGA

This command sets the gain of the ADS1230 PGA, according to these parameters:

• P0—sets gain to 64

• P1—sets gain to 128

• P—(with no argument) prints the current gain setting

5.2.2 R—Set Data Rate

This command sets the speed of the ADS1230 according to these parameters:

• RF—sets rate to fast

• RS—sets rate to slow

• R—(with no argument) prints the current data rate setting

Note that the actual data rate depends on the frequency of the device clock.

5.2.3 K—Perform Offset Calibration

Initiates an offset calibration on the ADS1230, using the method described in the datasheet.

5.2.4 V—Show Version

Displays a message containing the firmware version and copyright notice.

SBAU125A – August 2007 – Revised September 2007 ADS1230REF User's Guide 19

Submit Documentation Feedback

Page 20

www.ti.com

USB-SERIAL

INTERFACE

POWER

SUPPLY

LOADCELL

CONNECTORS

INPUT

FILTERING

MSP430F449

USBCONNECTOR

LCD

SWITCHES

ADS1230

+5V

+3.3V

CH1

SPI

GPIO

UART

Hardware

5.2.5 S—Start Streaming

When S is issued, the ADS1230REF begins printing raw output codes from the ADS1230 in hexadecimal

format, separated by new lines. The device iterates continuously until a character is received from the

serial port.

S is used primarily by the EVM software for data collection.

5.2.6 D—Collect One Sample

Issuing the D command causes the ADS1230REF to report the latest collected sample from the ADS1230.

The sample is displayed in raw hexadecimal.

5.2.7 C—Set Channel

This command has no effect on the ADS1230 since there is only one channel.

• C0—set to channel 0

• C—(with no arguments) prints the current channel, always CHAN=0

5.2.8 Q—Query Parameters

Q causes the ADS1230REF to issue a coded string summarizing the current settings. The format of the

string is:

P[0,1]R[F,S]OIC0

followed by a carriage-return and linefeed.

6 Hardware

A block diagram of the ADS1230REF is shown in Figure 8 . The schematic and layout drawings are given

in Appendix A .

Figure 8. ADS1230REF Hardware Block Diagram

ADS1230REF User's Guide20 SBAU125A – August 2007 – Revised September 2007

Submit Documentation Feedback

Page 21

www.ti.com

6.1 Microcontroller

6.2 Power Supply

6.3 User Interface

6.4 ADC Section

Hardware

The ADS1230REF uses the MSP430F449 microcontroller. This device provides an LCD controller,

hardware SPI and UART interfaces, and a multiplier. The latter is important because the firmware must

perform many multiplications.

The ADS1230REF operates from +5VDC and +3.3VDC. These supplies are generated by linear

regulators U1 and U2. Input power comes from either wall-adapter connector J2, or battery connector

BT1. J2 is switched; when a connector is plugged in, BT1 is disconnected.

Noise is important because the ADS1230 voltage reference is typically taken from the power supply. The

supplies are heavily bypassed to reduce noise.

The ADS1230REF user interface consists of the display and switches SW2–5 and SW8. Switches are

connected to interrupt-capable GPIOs on the microcontroller, allowing them to wake the microcontroller

from sleep mode.

The ADC section consists of the ADS1230 device itself and ancillary circuitry.

All signals on the ADS1230 are filtered by pass-through capacitors that help to reject electromagnetic

interference (EMI), radio frequency interference (RFI), and noise generated by the digital circuitry.

6.4.1 Input Circuitry

The ADS1230REF is designed to connect to resistive bridge sensors, particularly load cells. The input

channel is filtered by pass-through capacitors C46 and C47 and differential capacitor C7. Common-mode

capacitors C32 and C29 provide additional RF rejection.

6.4.2 Load Cell Header

The load cell header, J6, provides a convenient terminal for load cells having a properly fitted header

connector. It provides excitation and sense connections. The negative excitation line is connected to

ground through analog switch U7, which is controlled by the microcontroller. This arrangement allows for

sleep-and-convert control, which can reduce self-heating in the load cell and conserve power.

The load cell connector’s pinout is given in Table 7 . For connection examples, see Section 1.4.3 and

Section 1.4.4 .

Table 7. Load Cell Header Pinout

PIN NO. PIN NAME FUNCTION

1 EXC+ Positive excitation; connected to +5VA

2 EXCSNS+ Positive sense; connected to external positive reference input

3 SIG+ Input for positive load cell output

4 SIG– Input for negative load cell output

5 EXCSNS– Negative sense; connected to external negative reference input

6 EXC– Negative excitation; connected to ground through switch U7

SBAU125A – August 2007 – Revised September 2007 ADS1230REF User's Guide 21

Submit Documentation Feedback

Page 22

www.ti.com

Hardware

6.4.3 Input Terminal Block

The input terminal block consists of J4 and J5. It provides connections to all of the analog inputs on the

ADS1230, and connections to the ADS1230REF voltage reference network.

The terminal block pinout is given in Table 8 .

6.4.4 Voltage Reference

The ADS1230REF is designed to operate either ratiometrically or with an external reference. The two

modes are selected using switch SW7.

In the EXT position, the ADS1230 reference inputs are taken from the load cell connectors. In the +5VA

position, the ADS1230 positive reference input comes from the 5V analog supply, and the negative

reference input is connected to ground.

After the switch is placed a filtering network that consists of resistors R14 and R15, bulk capacitor C4,

pass-through capacitors C44 and C45, and filtering capacitors C28, C30, and C31.

Table 8. Terminal Block Pinout

TERMINAL NAME FUNCTION

EXC–

SNS– Inverting excitation sense input

SNS+ Noninverting excitation sense input

SIG+ Noninverting input

SIG– Inverting input

EXC+

Negative excitation connected to ground

through SW7

Positive excitation output (+5V) or positive

reference input

6.4.5 Input Shorting Jumpers

The shorted-input noise test for the ADS1230 is best performed with both inputs connected to 2.5V. To

make this test easy to perform, jumpers J7 and J8 are provided.

Jumper J8 shorts the inputs together. Jumper J7 connects the inverting input to a voltage divider made

from R25 and R26, dividing the power supply by 2. This voltage divider electrically resembles an ideal

bridge sensor.

6.5 USB Interface

The USB interface can be used for firmware download or data communications. Its role in firmware

download is discussed in Section 6.6 .

The USB interface consists of USB-to-serial converter U4, a Texas Instruments TUSB3410 . This device

incorporates a USB interface module, a microcontroller, and a 16550-type UART. Driver software is

available that causes the device to appear as a serial port on the host PC.

The USB interface is powered separately from the rest of the ADS1230REF; it takes power from the USB

line, through linear regulator U3.

The serial port side of U4 is connected to the microcontroller UART signals. To keep the power domains

separate, and to keep the USB and microcontroller sides from inadvertently powering each other, the

UART is connected through isolators U8 and U9.

ADS1230REF User's Guide22 SBAU125A – August 2007 – Revised September 2007

Submit Documentation Feedback

Page 23

www.ti.com

6.6 Programming Connections

The MSP430 can be programmed via the dedicated JTAG port or the serial bootstrap loader.

The JTAG connector is not factory-installed. The footprint is similar to an edge-card pattern, and accepts a

standard dual-row 0.100in header mounted on the side of the board. This header is compatible with

MSP430 parallel-port JTAG adaptors.

To allow firmware to be downloaded through USB, U4 is connected to the microcontroller bootstrap loader

pins. The DTR and RTS pins are connected to the RST and TCK inputs on the microcontroller to allow the

serial bootstrap loader to operate. These lines are not isolated; instead, they are switched through SW9,

which also connects USB ground and power to the microcontroller ground and power. Normally this switch

is open; it is only switched on when firmware is to be downloaded through USB. This feature also protects

the microcontroller from unknown states on these pins at power-up.

Hardware

SBAU125A – August 2007 – Revised September 2007 ADS1230REF User's Guide 23

Submit Documentation Feedback

Page 24

www.ti.com

Appendix A

Appendix A Schematic and Layout

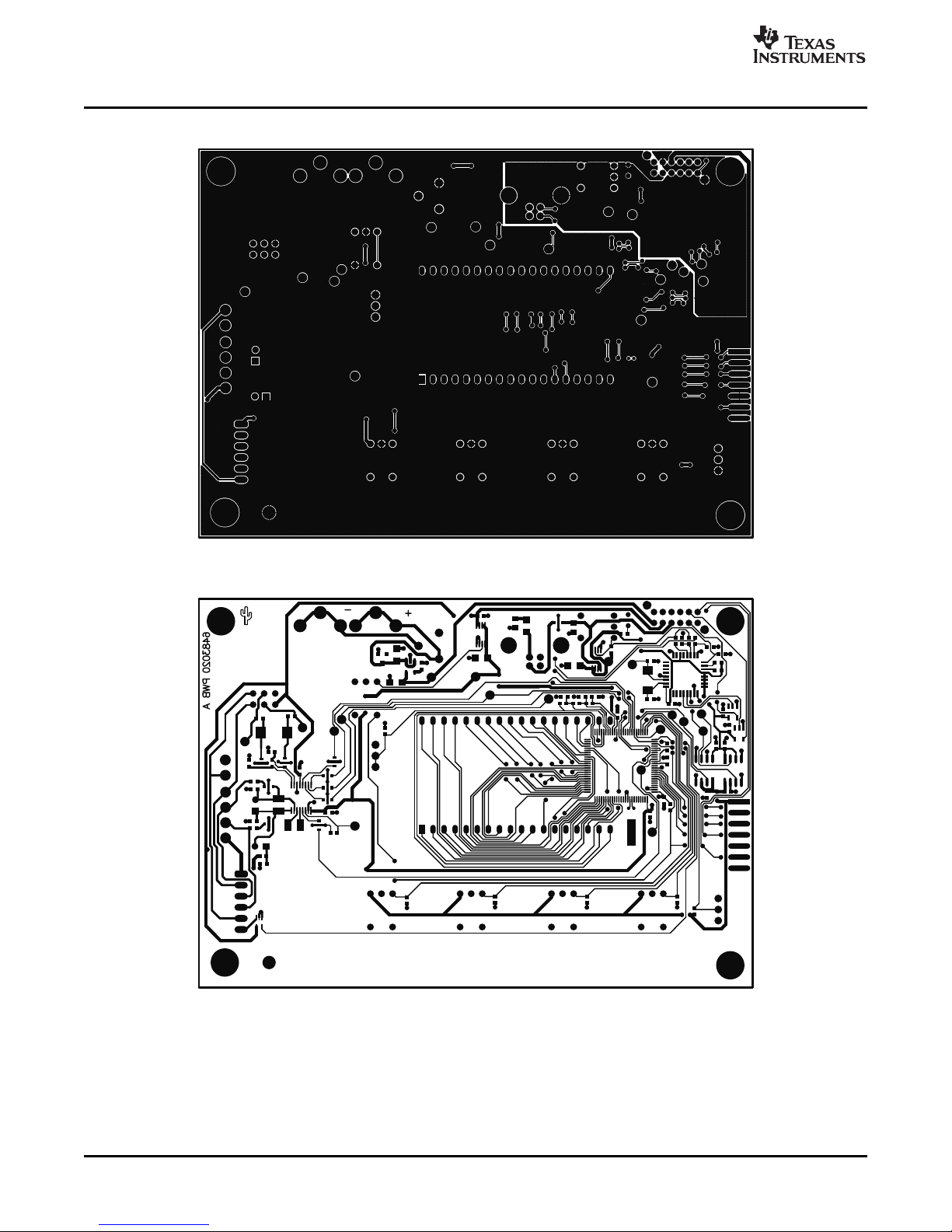

The printed circuit board (PCB) layouts for the top and bottom sides of the ADS1230REF are

shown in Figure A-1 and Figure A-2 , respectively. Schematics for the ADS1230REF are shown in

Section A.3 . The bill of materials is provided in Table A-1 .

A.1 Bill of Materials

Reference Designator Description Manufacturer Mfg. Part Number

R23, R24 0 1/16W 1% Chip Resistor Panasonic ERJ-3GEY0R00V

R17 20 1/4W 5% Chip Resistor Panasonic ERJ-8GEYJ200V

R2, R3 33 1/10W 5% Chip Resistor Panasonic ERJ-3GEYJ330V

R12–R15 100 1/10W 5% Chip Resistor Panasonic ERJ-3GEYJ101V

R11 220 1/10W 5% Chip Resistor Panasonic ERJ-3GEYJ221V

R1 1.5K 1/10W 5% Chip Resistor Panasonic ERJ-3GEYJ152V

R4–R10, R16 10K 1/10W 5% Chip Resistor Panasonic ERJ-3GEYJ103V

R25, R26 20K 1/16W 1% Chip Resistor Panasonic ERJ-3EKF2002V

R18, R30 47K 1/10W 5% Chip Resistor Panasonic ERJ-3GEYJ473V

R22 200k Potentiometer 200k Ω , Bourns 3362U-1-204LF

R19-R21 221k 1/16W 1% Chip Resistor Panasonic ERJ-3EKF2213V

C1, C2, C16, C17 22pF 50V Ceramic Chip TDK C1608C0G1H220J

C29, C30, C31, C32 100pF 16V PPS Film Chip Panasonic ECH-U1C101GX5

C38, C40–C43 100pF Filter High Frequency, Murata NFM21CC101U1H3D

C5, C11, C13–C15 0.01 μ F 50V Ceramic Chip TDK C1608X7R1H103K

C12, C21, C33–C36 0.1 μ F 50V Ceramic Chip TDK C1608X7R1H104K

C6, C7 0.1 μ F 16V PPS Film Chip Panasonic ECH-U1C104GX5

C9, C10, C22 1 μ F 16V Ceramic Chip TDK C1608X7R1C105K

C37, C44–C47 1 μ F Filter High-Frequency, Murata NFM21PC105B1C3D

C23–C28 2.2 μ F 6.3V Ceramic Chip TDK C1608X5R0J225M

C3 4.7 μ F 16V Ceramic Chip TDK C2012Y5V1C475Z

C8, C18–C20 10 μ F 16V Ceramic Chip TDK C3216X7R1C106M

C4 100 μ F 10V Tantalum Chip Kemet T494D107K010AT

U6 Analog-to-Digital Converter Texas Instruments ADS1230IPW

U5 Microcontroller Texas Instruments MSP430F449IPZ

U2, U3 Linear Voltage Regulator, Texas Instruments TPS77133DGKG4

U1 Linear Voltage Regulator, +5V Texas Instruments TPS76350DBVG4

Table A-1. ADS1230REF Bill of Materials

1/4in SQ

Capacitor, ± 0.5pF, NPO

Capacitor, 2%

100pF

Capacitor, ± 10%, X7R

Capacitor, ± 10%, X7R

Capacitor, 2%

Capacitor, ± 10%, X7R

1.0 μ F

Capacitor, ± 20%, X5R

Capacitor, +80/-20%, Y5V

Capacitor, ± 20%, X7R

Capacitor, ± 10%

+3.3V

24 Schematic and Layout SBAU125A – August 2007 – Revised September 2007

Submit Documentation Feedback

Page 25

www.ti.com

Table A-1. ADS1230REF Bill of Materials (continued)

Reference Designator Description Manufacturer Mfg. Part Number

U4 USB to Serial Converter Texas Instruments TUSB3410VFG4

U7 Analog Switch, SPST Texas Instruments TS5A3166DCKR

U8, U9 Digital Isolator Texas Instruments ISO721DG4

U10, U11 Inverter, Single Gate Texas Instruments SN74LVC1G04DBVRG4

BT1 (+) 9 Volt Battery Clip Female Keystone Electronics 594

BT1 (–) 9 Volt Battery Clip Male Keystone Electronics 593

J1 USB Type B Socket Mill-Max 897-43-004-90- 000000

J2 2.5mm Power Jack CUI PJ-102BH

J6 1 X 6 Header Samtec TSW-106-07-G-S

J7, J8 1 X 2 Header Samtec TSW-102-07-G-S

J4 3.5mm PCB Terminal Block, On Shore Technology ED555/4DS

4-position

J5 3.5mm PCB Terminal Block, On Shore Technology ED555/2DS

2-position

N/A ADS1230 REF PCB Texas Instruments 6483020

D1 30V, 200mA Schottky Diode Fairchild Semiconductor BAT54

D2 Green LED, SMD Lumex SSL-LX3052GD

L1 Ferrite Bead Core, 4A 100MHz Panasonic EXC-ML20A390U

LCD1 8-Character LCD Display, TN Varitronix VIM878-DP-RC-S-LV

Type

SW1–SW6 Push-button Switch ITT KSA1MZIILFT

SW7 DPDT Slide Switch, Top NKK SS22SDP2

Actuator

SW8 SPDT Slide Switch, Top NKK SS12SDP2

Actuator

SW9 4PDT Slide Switch, RA E-Switch EG4208

Actuator

TP15 Testpoint Keystone Electronics 5011

X1 12MHz Quartz Crystal Citizen CS10-12.000MABJUT

X2 32.678kHz Quartz Crystal Epson C-002RX 32.7680KE: PBFREE

Bill of Materials

SBAU125A – August 2007 – Revised September 2007 Schematic and Layout 25

Submit Documentation Feedback

Page 26

www.ti.com

PCB Layout

A.2 PCB Layout

Figure A-1. ADS1230REF PCB—Top Side

Figure A-2. ADS1230REF PCB—Bottom Side

Schematic and Layout26 SBAU125A – August 2007 – Revised September 2007

Submit Documentation Feedback

Page 27

www.ti.com

C26

2.2uF

+3.3VD

TP11

EXTCLK

C38

C43

C40

+5VA

C27

2.2uF

C6

0.1uF

C44

C45

R14

100

R15

100

C28

2.2uF

C31

100

p

F

C30

100pF

C46

MUR_NFM 21PC105F1C3D

C47

MUR_NFM 21PC105F1C3D

R23

0

R24

0

C7

0.1uF

C29

100pF

C32

100

p

F

SW7

SW-DPDT

+5VA

+5VA

DOUT

SCLK

SPEED

PDW N/RST

TP13

VREF+

TP14

VREF-

TP5

TEMP

TP9

SCLK

TP10

SPEED

TP12

PWDN/ RST

C41

C42

TP15

GND

J4

OST_ED555/4DS

1

2

345

6

J6

HEADER-6

+5VA

EXC+

EXCSNS+

SIG+

SIG-

EXCSNS-

EXC-

NO

1

GND

3

COM

2

V+

5

IN

4

U7

TS5A3166

DCK

+5VA

EXC

C4

100uF

1 2

J8

R26

20K

R25

20K

+5VA

1 2

J7

TP6

DOUT

TEMP

J2

CUI-STACK PJ-102BH

VIN

1

VOUT

5

GND

2

NR/ADJ UST

4

ENABLE

3

U1

TPS76350DBV

BT1

9V

C8

10uF

D1

C11

0.01uF

C19

10uF

C20

10uF

TP3

+5V

TP4

+3.3VD

+3.3VD

+5V

+5VA

C9

1uF

DVDD

1

DGND

2

CLKIN

3

TEMP

4

C1

5

C2

6

AIN P

7

AIN N

8

REFN

9

REFP

10

AGND

11

AVDD

12

SPEED

13

PDWN14SCLK

15

DRDY/DOUT

16

U6

ADS1230IPW

J5

OST_ED555/2DS

FB/SENSE

1

RESET

2

EN

3

GND

4

IN

5

IN

6

OUT7O

U

T

8

U2

TPS77

133

DGK

RST

R30

47K

Schematics

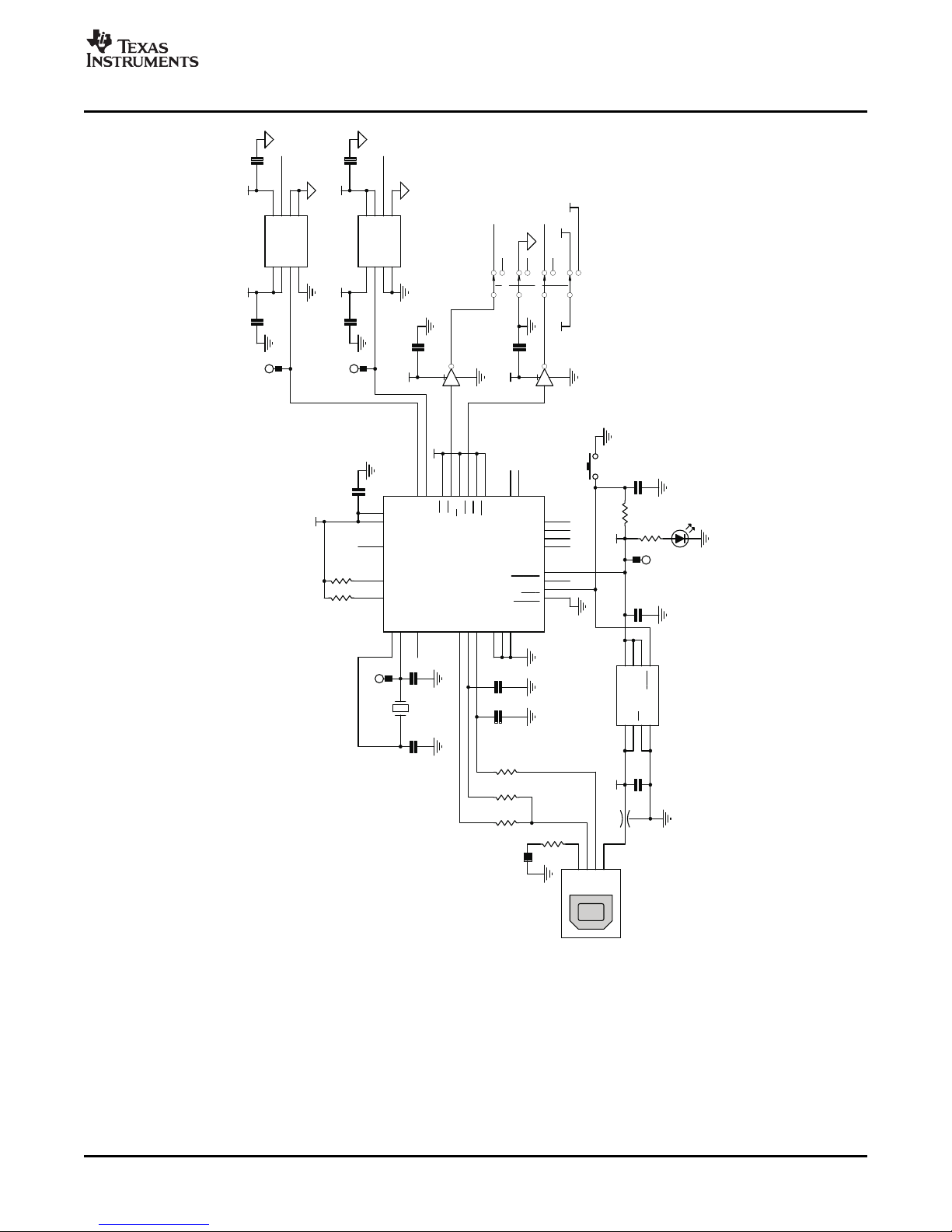

A.3 Schematics

Figure A-3. ADS1230REF Schematic—ADC

SBAU125A – August 2007 – Revised September 2007 Schematic and Layout 27

Submit Documentation Feedback

Page 28

www.ti.com

DVCC1

1

P6.3/A3

2

P6.4/A4

3

P6.5/A5

4

P6.6/A6

5

P6.7/A7/ SVSIN

6

VREF+

7

XIN

8

XOUT

9

VeREF+

10

VREF-/ VeREF-

11

P1.0/TA0

87

P1.1/TA0/M CLK

86

P1.2/TA1

85

P1.3/TBOU

TH/SVSOU

T

84

P1.4/TBCLK/SMCLK83P1.5/TACLK/ACLK

82

P1.6/CA0

81

P1.7/CA1

80

P2.0/TA2

79

P2.1/TB0

78

P2.2/TB1

77

P2.3/TB2

76

P2.4/UTXD0

75

P2.5/URXD0

74

P2.6/CAOUT

73

P2.7/ADC12CLK

72

P3.0/STE0

71

P3.1/SIM O0

70

P3.2/SOM I0

69

P3.3/UCLK0

68

P3.4/TB3

67

P3.5/TB4

66

P3.6/TB5

65

P3.7/TB6

64

P4.0/UTXD1

63

P4.1/URXD1

62

P4.2/STE1/S39

51

P4.3/SIM O1/S38

50

P4.4/SOMI1/ S37

49

P4.5/UCLK1/S36

48

P4.6/S35

47

P4.7/S34

46

P5.0/S1

13

P5.1/S0

12

P5.2/COM1

53

P5.3/COM2

54

P5.4/COM3

55

P5.5/R13

57

P5.6/R23

58

P5.7/R33

59

XT2O

U

T

88

XT2IN89TDO/TDI90TDI/TCLK

91

TMS

92

TCK93RST/NM I94P6.0/A0

95

P6.1/A1

96

P6.2/A2

97

AVSS

98

DVSS1

99

AVCC

100

S2

14

S3

15

S4

16

S5

17

S6

18

S7

19

S8

20

S9

21

S10

22

S11

23

S12

24

S13

25

S14

26

S15

27

S1628S1729S1830S19

31

S20

32

S21

33

S2234S2335S2436S2537S2638S2739S2840S2941S30

42

S31

43

S3244S33

45

COM0

52

R03

56

DVCC2

60

DVSS2

61

U5

MSP430F449IPZ

R19

221K

R20

2

21

K

R21

2

21

K

C13

0.01uF

C14

0.01uF

C15

0.01uF

+3.3VD

R22

200K

SW2

RA

NG

E

SW3

TARE

SW4

CAL

SW5

CONFIG

+3.3VD

R7

10K

R8

10K

R9

10K

R10

10K

R12 100

R13

100

C25

2.2uF

+3.3VD

246

135

7

8

9

10

111213

14

J3

HEADER-7X2

+3.3VD

SW6

RESET

+3.3VD

36

35

34

33

32

31

30

29

28

27

26

25

24

23

22

21

20

1918

17

16

15

14

13

12

11

10

9

8

7

6

5

4

3

2

1

LCD1

LCD_DISPLAY

TDO/TDI

TDI/CLK

TMS

TCK

RST

BSLRX

BSLTX

MCURX

MCUTX

TEMP

DOUT

SCLK

SPEED

PDWN /RST

COM(3)

COM(2)

COM(1)

COM(0)

S(39)

COM(3)

COM(2) COM (1)

COM(0)

S(38)

S(37)

S(36)

S(35)

S(34)

S(33)

S(32)

S(31)

S(30)

S(29)

S(28)

S(27)

S(26)

S(25)

S(24)

S(23)

S(22)

S(21)

S(20)

S(19)

S(18)

S(17)

S(16)

S(15)

S(14)

S(36)

S(35)

S(34)

S(33)

S(32)

S(31)

S(30)

S(29)

S(28)

S(27)

S(26)

S(25)

S(24)

S(23)

S(22)

S(21)

S(20)

S(19)

S(18)

S(17)

S(16)

S(15)

S(14)

S(5)

S(6)

S(7)

S(8)

S(9)

S(10)

S(11)

S(12)

S(13)

S(5)

S(6)

S(7)

S(8)

S(9)

S(10)

S(11)

S(12)

S(13)

C5

0.01uF

C23

2.2uF

C24

2.2

u

F

SW8

NKK_SS12SDP2

R16

10K

+3.3VD

EXC

R18

47K

DOUT

TP18

MCURX

TP8

MCUTX

SIM O0

TP7

DNP

RST

TCK

X2

EPS_C-002

RX32.7680

K-A:PBFREE

TP20

P1.4/SMCLK

Schematics

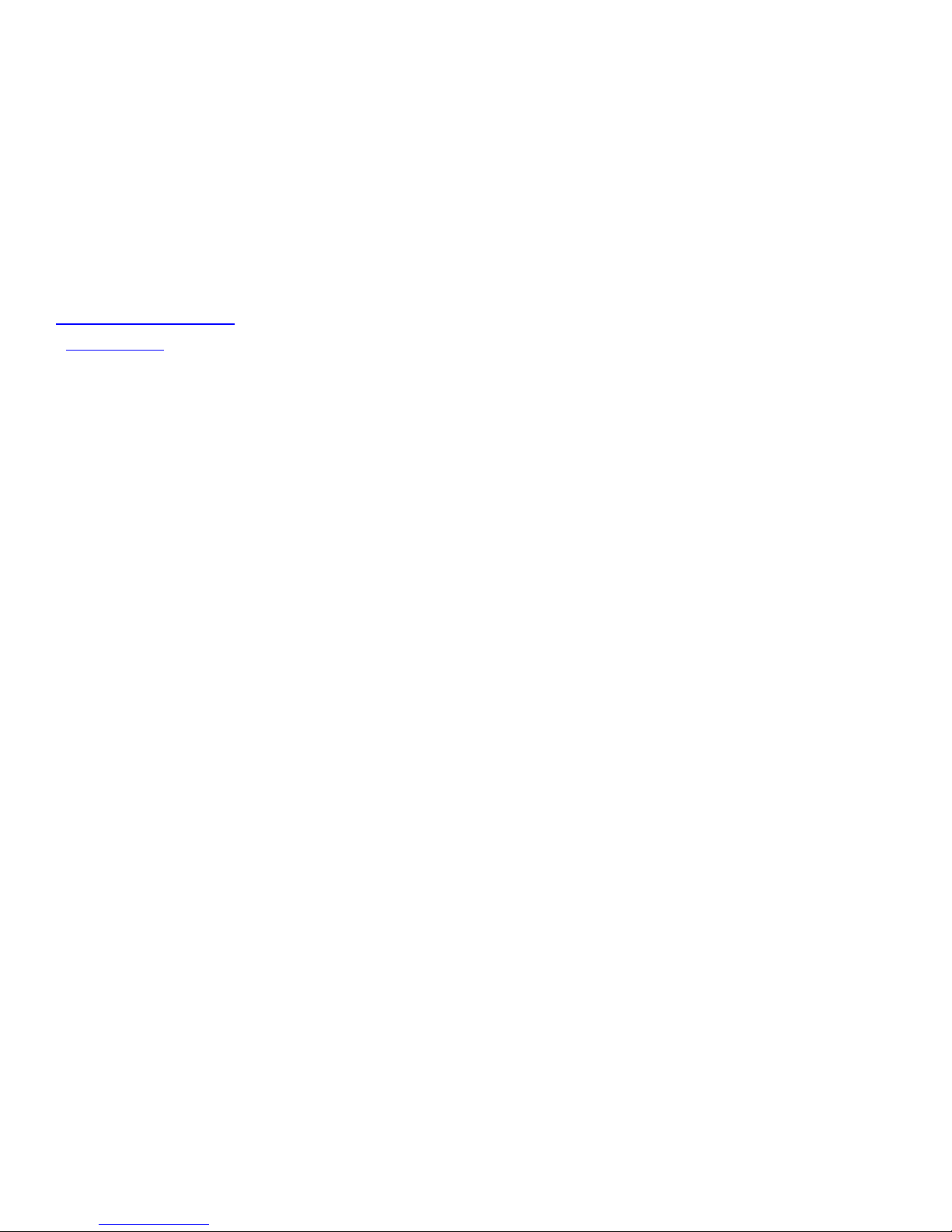

Figure A-4. ADS1230REF Schematic—MCU

28 Schematic and Layout SBAU125A – August 2007 – Revised September 2007

Submit Documentation Feedback

Page 29

www.ti.com

VCC

1

D-

2

D+

3

GND

4

J1

USB SLAVECONN

CTS

13

DCD

15

DSR14DTR

21

RTS

20

SIN/IR_SIN

17

SOUT/IR_SOUT

19

SDA

10

SCL

11

X2

26

X1/CLKI

27

CLKOUT

22

PUR

5

DP6DM

7

RESET

9

GND

8

G

N

D

18

GND

28

SUSPEND

2

VREGEN

1

RI/CP

16

WAK EUP

12

TEST124TEST0

23

P3.0

32

P3.1

31

P3.3

30

P3.4

29

VCC

25

VCC

3

VDD

4

U4

TUSB3410VF

R2

33

R3

33

R1

1.5K

C16

22pF

C17

22pF

X1

12MHz

C1

22pF

C2

22pF

C22

1uF

USB3.3V

USB3.3V

USB5V

R6

10K

C18

10uF

D2

GREEN

R11

220

L1

FERRITEB EAD

TP1

USB_CLK

R4

10K

R5

10K

C37

MUR_NFM 21PC105F1C3D

SW1

USB RESET

TP2

3.3V_USB

RX

TX

RTS

DTR

C3

4.7uF

R17

20

FB/SENSE

1

RESET

2

EN

3

GND4IN

5

IN

6

OUT

7

OUT

8

U3

TPS77133DGK

2

4

53

U10

SN74LVC1G04DBV

2

4

53

U11

SN74LVC1G04DBV

USB3.3V

USB3.3V

USB3.3V

USB3.3V

USB3.3V

+3.3VD

+3.3VD

MCURX

MCUTX

TP16

RX

TP17

TX

VCC11IN

2

VCC1

3

GND1

4

GND2

5

OUT

6

GND2

7

VCC2

8

U8

ISO721D

VCC1

1

IN

2

VCC1

3

GND1

4

GND25OUT

6

GND27VCC2

8

U9

ISO721D

C10

1uF

PROGRAMM ING M ODE

RST

TCK

+5V

USB5V

+5VA

C12

0.1uF

C21

0.1uF

C33

0.1uF

C34

0.1uF

C35

0.1uF

C36

0.1uF

SW9

ESW_EG4208

Schematics

Figure A-5. ADS1230REF Schematic—USB

SBAU125A – August 2007 – Revised September 2007 Schematic and Layout 29

Submit Documentation Feedback

Page 30

EVALUATION BOARD/KIT IMPORTANT NOTICE

Texas Instruments (TI) provides the enclosed product(s) under the following conditions:

This evaluation board/kit is intended for use for ENGINEERING DEVELOPMENT, DEMONSTRATION, OR EVALUATION PURPOSES

ONLY and is not considered by TI to be a finished end-product fit for general consumer use. Persons handling the product(s) must have

electronics training and observe good engineering practice standards. As such, the goods being provided are not intended to be complete

in terms of required design-, marketing-, and/or manufacturing-related protective considerations, including product safety and environmental

measures typically found in end products that incorporate such semiconductor components or circuit boards. This evaluation board/kit does

not fall within the scope of the European Union directives regarding electromagnetic compatibility, restricted substances (RoHS), recycling

(WEEE), FCC, CE or UL, and therefore may not meet the technical requirements of these directives or other related directives.

Should this evaluation board/kit not meet the specifications indicated in the User’s Guide, the board/kit may be returned within 30 days from

the date of delivery for a full refund. THE FOREGOING WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY SELLER TO BUYER

AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE.

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user indemnifies TI from all claims

arising from the handling or use of the goods. Due to the open construction of the product, it is the user’s responsibility to take any and all

appropriate precautions with regard to electrostatic discharge.

EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH ABOVE, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR ANY

INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL DAMAGES.

TI currently deals with a variety of customers for products, and therefore our arrangement with the user is not exclusive.

TI assumes no liability for applications assistance, customer product design, software performance, or infringement of patents or

services described herein.

Please read the User’s Guide and, specifically, the Warnings and Restrictions notice in the User’s Guide prior to handling the product. This

notice contains important safety information about temperatures and voltages. For additional information on TI’s environmental and/or