Page 1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas Instruments

查询ADS1224供应商查询ADS1224供应商

SBAS286A − JUNE 2003 − REVISED MARCH 2004

FEATURES

D 240SPS Data Rate with 4MHz Clock

D 20-Bit Effective Resolution

D Input Multiplexer with Four Differential

Channels

D Pin-Selectable, High-Impedance Input Buffer

D ±5V Differential Input Range

D 0.0003% INL (typ), 0.0015% INL (max)

D Self-Calibrating

D Simple 2-Wire Serial Interface

D On-Chip Temperature Sensor

D Single Conversions with Standby Mode

D Low Current Consumption: 300µA

D Analog Supply: 2.7V to 5.5V

D Digital Supply: 2.7V to 5.5V

APPLICATIONS

D Hand-Held Instrumentation

D Portable Medical Equipment

D Industrial Process Control

D Weigh Scales

DESCRIPTION

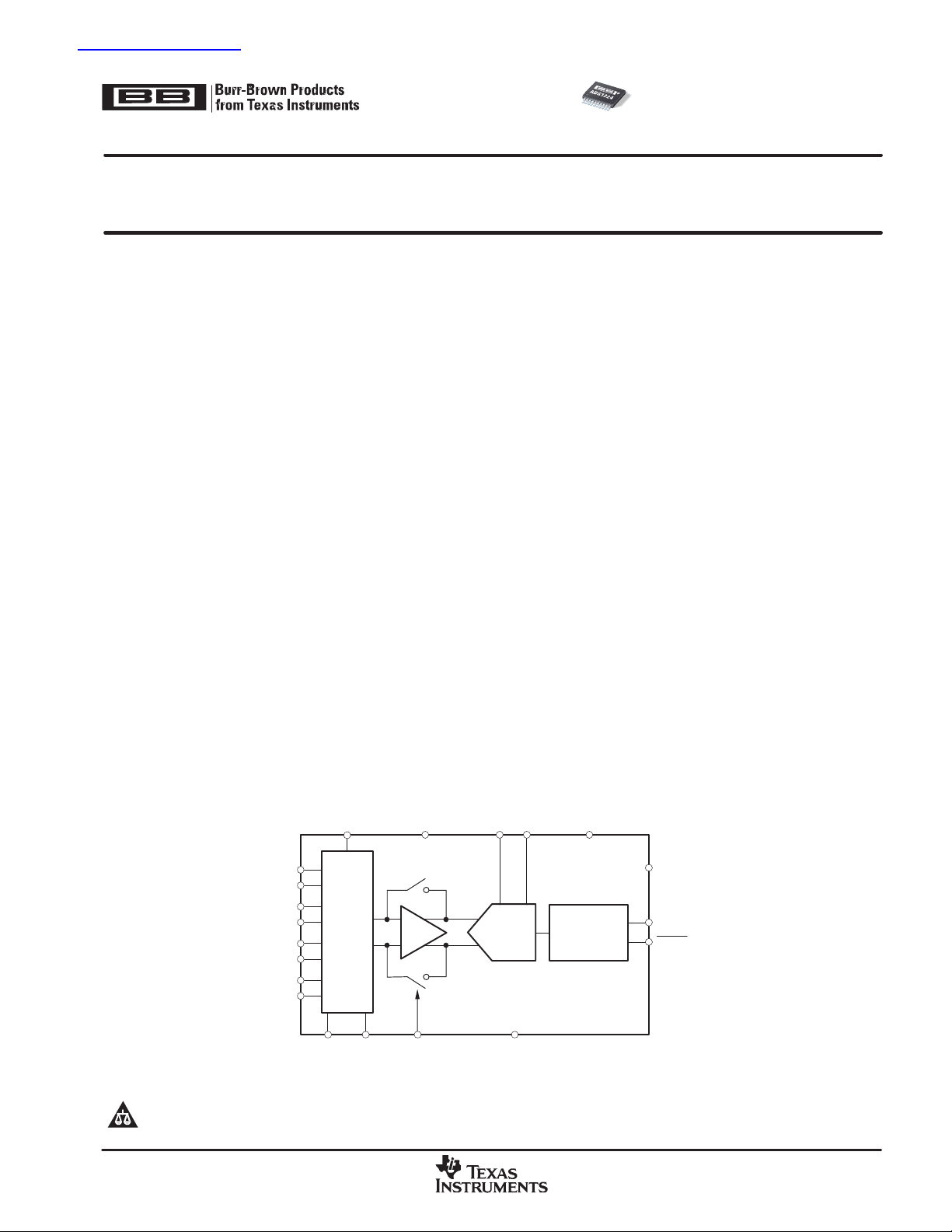

The ADS1224 is a 4-channel, 24-bit, delta-sigma analog-to-digital (A/D) converter. It offers excellent performance and low power in a TSSOP-20 package. The

ADS1224 is well-suited for demanding, high-resolution

measurements, especially in portable systems and other space-saving and power-constrained applications.

A delta-sigma modulator and digital filter form the basis

of the A/D converter. The analog modulator has a ±5V

differential input range. An input multiplexer (mux) is

used to select between four separate differential input

channels. A bu ffer can be selected to increase the input

impedance of the measurement.

A simple, 2-wire serial interface provides all the

necessary control. Data retrieval, self-calibration, and

Standby mode are handled with a few simple

waveforms. When only single conversions are needed,

the ADS1224 can be quickly shut down (Standby mode)

while idle between measurements to dramatically

reduce the overall power consumption. Multiple

ADS1224s can be connected together to create a

synchronously sampling multichannel measurement

system. The ADS1224 is designed to easily connect to

microcontrollers, such as the MSP430.

The ADS1224 supports 2.7V to 5.5V analog supplies

and 2.7V to 5.5V digital supplies. Power is typically less

than 1mW in 3V operation and less than 1µW during

Standby mode.

TEMPEN

AINP1

AINN1

AINP2

AINN2

AINP3

AINN3

AINP4

AINN4

semiconductor products and disclaimers thereto appears at the end of this data sheet.

All trademarks are the property of their respective owners.

!"# " $ % & % '& () (&%

&$ %&&% $% "% %$% %(( *)

(& &%% (% &%%* &( % $%)

Mux

MUX1 BUFEN

AVDD DVDD

Buffer

VREFP VREFN

∆Σ

Modulator

GNDMUX0

www.ti.com

Digital Filter

and

SerialInterface

Copyright 2003−2004, Texas Instruments Incorporated

CLK

SCLK

DRDY/DOUT

Page 2

ADS1224

TSSOP-20

PW

−40°C to +85°C

ADS1224

Input current

SBAS286A − JUNE 2003 − REVISED MARCH 2004

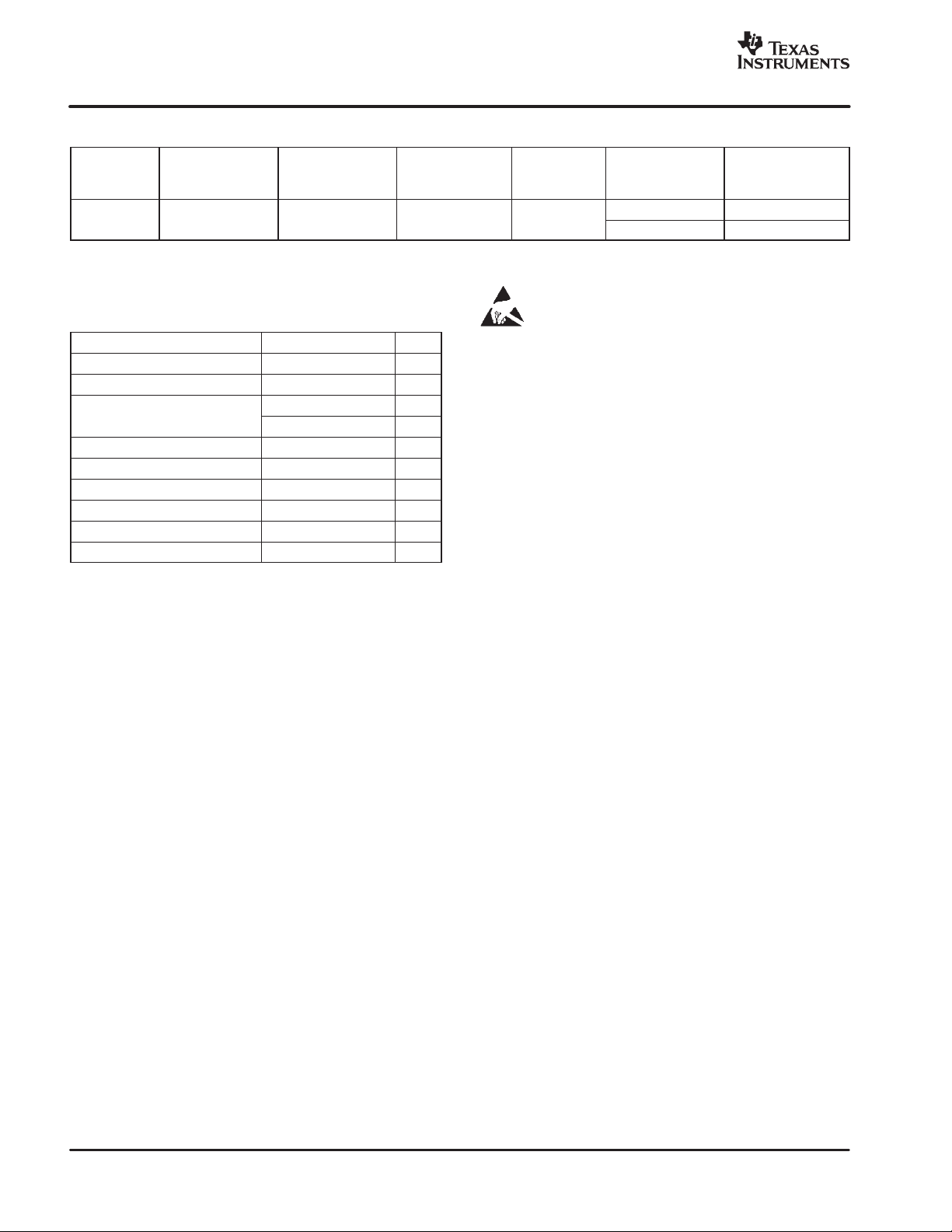

ORDERING INFORMATION

PRODUCT PACKAGE−LEAD

(1)

For the most current specification and package information, refer to our web site at www.ti.com.

PACKAGE

DESIGNATOR

(1)

SPECIFIED

TEMPERATURE

RANGE

PACKAGE

MARKING

www.ti.com

ORDERING

NUMBER

ADS1224IPWT Tape and Reel, 250

ADS1224IPWR Tape and Reel, 2500

TRANSPORT

MEDIA, QUANTITY

ABSOLUTE MAXIMUM RATINGS

over operat i n g f ree-air temperature range unless otherwise noted

ADS1224 UNIT

AVDD to GND −0.3 to +6 V

DVDD to GND −0.3 to +6 V

100, momentary mA

10, continuous mA

Analog input voltage to GND −0.3 to AVDD + 0.3 V

Digital input voltage to GND −0.3 to DVDD + 0.3 V

Maximum Junction Temperature +150 °C

Operating Temperature Range −55 to +125 °C

Storage Temperature Range −60 to +150 °C

Lead Tem perature (soldering, 10s) +300 °C

(1)

Stresses above these ratings may cause permanent damage.

Exposure to absolute maximum conditions for extended periods

may degrade device reliability. These are stress ratings only , an d

functional operation of the device at these or any other conditions

beyond those specified is not implied.

(1)

This integrated circuit can be damaged by ESD. Texas

Instruments recommends that all integrated circuits be

handled with appropriate precautions. Failure to observe

proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to

complete device failure. Precision integrated circuits may be more

susceptible t o damage because very small parametric changes could

cause the device not to meet its published specifications.

2

Page 3

Absolute input voltage

Differential input impedance

Integral nonlinearity (INL)

Offset error

Offset error drift

Gain error

Gain error drift

Common-mode rejection

Analog power-supply rejection

Digital power-supply rejection

www.ti.com

SBAS286A − JUNE 2003 − REVISED MARCH 2004

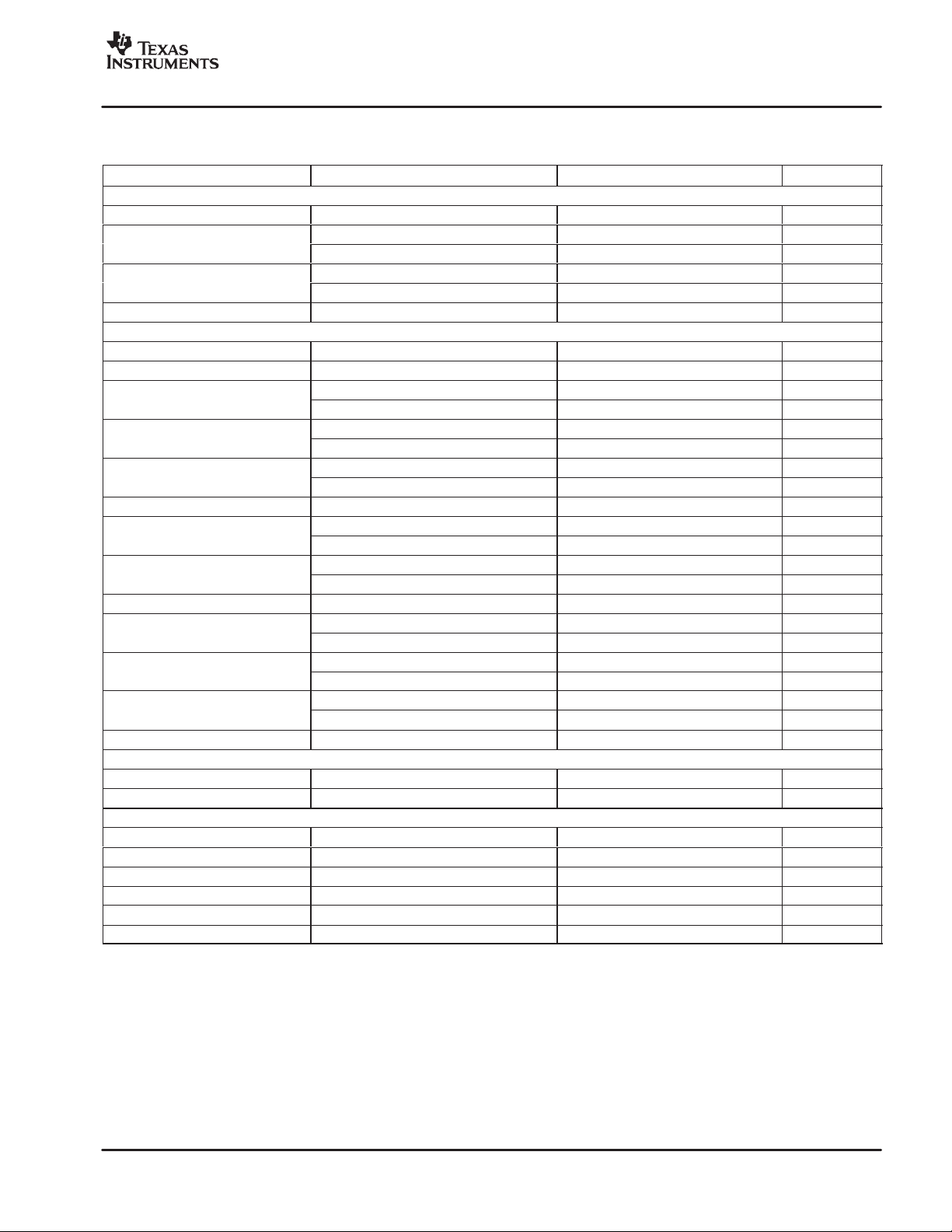

ELECTRICAL CHARACTERISTICS

All specifications at TA = −40°C to +85°C, AVDD = +5V, DVDD = +5V, f

PARAMETER TEST CONDITIONS MIN TYP MAX UNIT

Analog Input

Full-scale input voltage AINP − AINN ±2V

Buffer off; AINP, AINN with respect to GND GND − 0.1 A VDD + 0.1 V

Buffer on; AINP, AINN with respect to GND GND + 0.05 AVDD − 1.5 V

Buffer off; f

Buffer on; f

Common-mode input impedance Buffer off; f

System Performance

Resolution No missing codes 24 Bits

Data rate 120 (f

Buffer off, Differential input signal, end point fit 0.0003 0.0015 % of FSR

Buffer on, Differential input signal, end point fit 0.0006 % of FSR

Buffer off 20 100 µV

Buffer on 20 µV

Buffer off 0.2 µV/°C

Buffer on 0.2 µV/°C

Offset error match Between channels 20 100 µV

Buffer off 0.004 0.025 %

Buffer on 0.008 %

Buffer off 0.00003 % of FSR/°C

Buffer on 0.00006 % of FSR/°C

Gain error match Between channels 0.0005 %

Buffer off, at DC 90 110 dB

Buffer on, at DC 90 110 dB

Buffer off, at DC, ± 10% ∆ in AVDD 95 dB

Buffer on, at DC, ± 10% ∆ in AVDD 95 dB

Buffer off, at DC, DVDD = 2.7V to 5.5V 85 dB

Buffer on, at DC, DVDD = 2.7V to 5.5V 85 dB

Noise 0.8 ppm of FSR, rms

Temperature Sensor

Temperature sensor voltage TA = 25°C 106 mV

Temperature sensor coefficient 360 µV/°C

Voltage Reference Input

Reference input voltage V

Negative reference input Buffer off GND − 0.1 VREFP − 0.5 V

Positive reference input Buffer off VREFN + 0.5 AV DD + 0.1 V

Negative reference input Buffer on GND + 0.05 VREFP − 0.5 V

Positive reference input Buffer on VREFN + 0.5 AVD D − 1.5 V

Voltage reference impedance f

(1)

SPS = samples per second.

(2)

FSR = full-scale range = 4V

(3)

It will not be possible to reach the digital output full-scale code when V

REF

.

= VREFP − VREFN 0.5 2.5 AVDD

REF

= 2MHz 500 kΩ

CLK

= 2MHz 2.7 MΩ

CLK

= 2MHz 1.2 GΩ

CLK

= 2MHz 5.4 MΩ

CLK

= 2MHz, and V

CLK

> AVDD/2.

REF

= +2.5V , unless otherwise noted.

REF

REF

/2MHz) SPS

CLK

(3)

V

(1)

(2)

V

3

Page 4

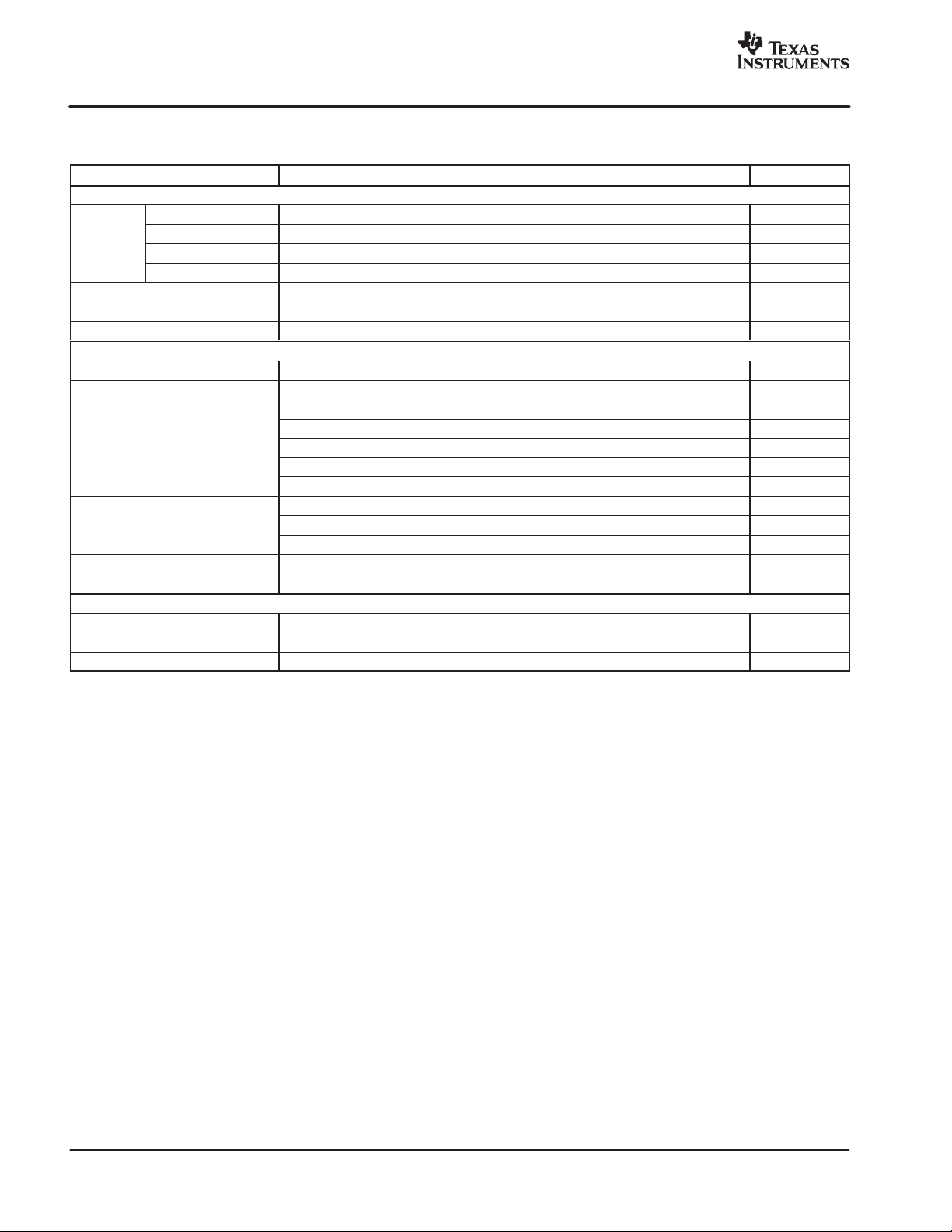

Logic

Logic

levels

AVDD current

DVDD current

Total power dissipation

www.ti.com

SBAS286A − JUNE 2003 − REVISED MARCH 2004

ELECTRICAL CHARACTERISTICS (continued)

All specifications at TA = −40°C to +85°C, AVDD = +5V, DVDD = +5V, f

PARAMETER UNITMAXTYPMINTEST CONDITIONS

Digital Input/Output

V

IH

V

IL

levels

Input leakage ±10 µA

CLK frequency (f

CLK duty cycle 30 70 %

Power Supply

AVDD 2.7 5.5 V

DVDD 2.7 5.5 V

AVDD current

DVDD current

Temperature Range

Specified −40 +85 °C

Operating −55 +125 °C

Storage −60 +150 °C

(1)

SPS = samples per second.

(2)

FSR = full-scale range = 4V

(3)

It will not be possible to reach the digital output full-scale code when V

V

OH

V

OL

) 8 MHz

CLK

IOH = 1mA 0.8 DVDD V

IOL = 1mA 0.2 DVDD V

Standby mode < 1 µA

AVDD = 5V, normal mode, buffer off 285 µA

AVDD = 5V, normal mode, buffer on 405 µA

AVDD = 3V, normal mode, buffer off 265 µA

AVDD = 3V, normal mode, buffer on 385 µA

Standby mode < 1 µA

DVDD = 5V , normal mode 20 µA

DVDD = 3V , normal mode 10 µA

AVDD = DVDD = 5V, buffer of f 1.5 2.25 mW

AVDD = DVDD = 3V, buffer of f 0.8 mW

.

REF

= 2MHz, and V

CLK

> AVDD/2.

REF

= +2.5V , unless otherwise noted.

REF

0.8 DVDD DVDD + 0.1 V

GND − 0.1 0.2 DVDD V

4

Page 5

www.ti.com

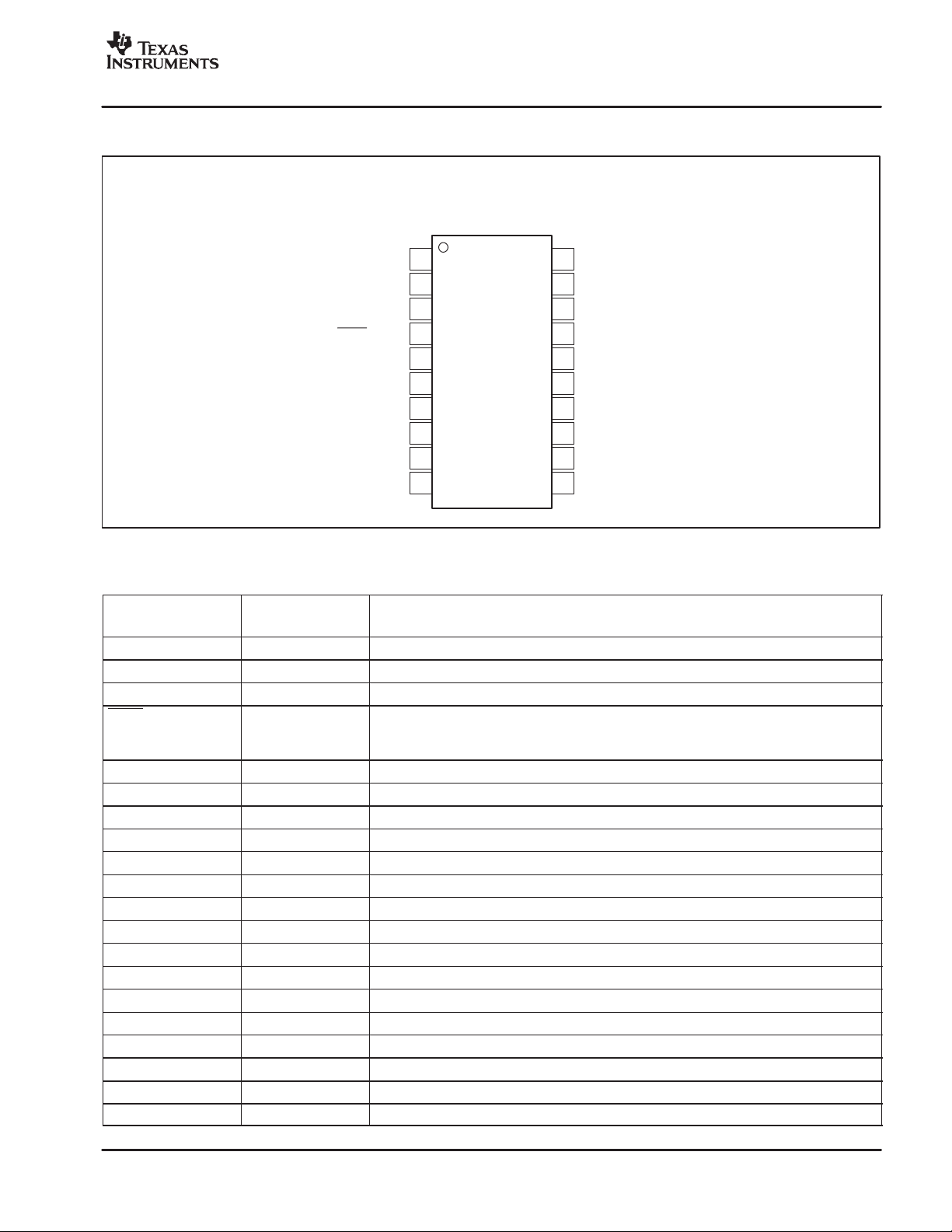

PIN ASSIGNMENTS

SBAS286A − JUNE 2003 − REVISED MARCH 2004

PW PACKAGE

TSSOP

(TOP VIEW)

DVDD

SCLK

CLK

DRDY/DOUT

MUX0

MUX1

TEMPEN

BUFEN

AINP4

AINN4

10

1

2

3

4

5

6

7

8

9

ADS1224

20

19

18

17

16

15

14

13

12

11

AVDD

VREFP

VREFN

GND

AINN1

AINP1

AINN2

AINP2

AINN3

AINP3

Terminal Functions

TERMINAL

NAME NO. I/O DESCRIPTION

DVDD 1 Digital Digital power supply

SCLK 2 Digital input Serial clock input

CLK 3 Digital input System clock input

DRDY/DOUT 4 Digital Ouput Dual-purpose output:

Data Ready: indicates valid data by going low.

Data Output: outputs data, MSB first, on the rising edge of SCLK.

MUX0 5 Digital input Selects analog input of mux, bit 0

MUX1 6 Digital input Selects analog input of mux, bit 1

TEMPEN 7 Digital input Selects temperature sensor input from mux

BUFEN 8 Digital input Enables input buffer

AINP4 9 Analog input Analog channel 4 positive input

AINN4 10 Analog input Analog channel 4 negative input

AINP3 11 Analog input Analog channel 3 positive input

AINN3 12 Analog input Analog channel 3 negative input

AINP2 13 Analog input Analog channel 2 positive input

AINN2 14 Analog input Analog channel 2 negative input

AINP1 15 Analog input Analog channel 1 positive input

AINN1 16 Analog input Analog channel 1 negative input

GND 17 Analog/Digital Analog and digital ground

VREFN 18 Analog input Negative reference input

VREFP 19 Analog input Positive reference input

AVDD 20 Analog Analog power supply

5

Page 6

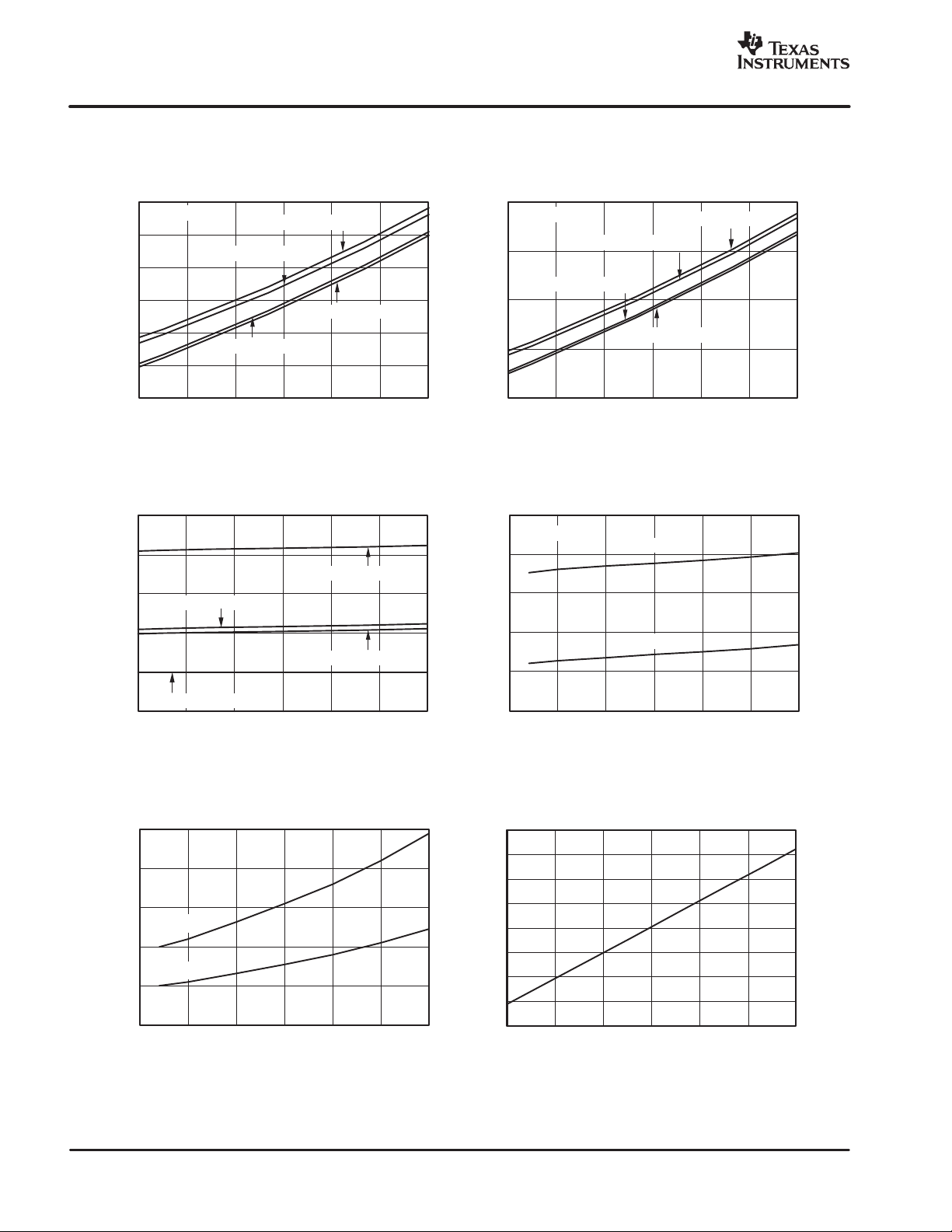

ANALOG CURRENT vs TEMPERATURE

ANALOG CURRENT vs TEMPERATURE

DIGITALCURRENT vs TEMPERATURE

ANALOG CURRENT vs SUPPLY VOLTAGE

DIGITALCURRENT vs SUPPLY VOLTAGE

TEMPERATURE SENSOR VOLTAGE vs TEMPERATURE

SBAS286A − JUNE 2003 − REVISED MARCH 2004

TYPICAL CHARACTERISTICS

At TA = −40°C to +85°C, AVDD = +5V, DVDD = +5V, f

= 2MHz, and V

CLK

= +2.5V , unless otherwise noted.

REF

www.ti.com

350

Buffer Off

325

f

300

A)

µ

275

Current (

250

225

200

−

55

CLK

f

−

25 35 65 95 125

f

=4MHz,AVDD=5V

CLK

=2MHz,AVDD=5V

=4MHz,AVDD=3V

CLK

5

Temperature (_C)

f

=2MHz,AVDD=3V

CLK

Figure 1

50

40

f

=4MHz,AVDD=5V

A)

30

µ

Current(

20

10

f

=2MHz,AVDD=5V

CLK

CLK

f

=4MHz,AVDD=3V

CLK

500

Buffer On

f

=2MHz,AVDD=5V

450

A)

µ

400

Current (

350

300

f

CLK

−

55

CLK

=4MHz,AVDD=3V

−

25 35 65 95 125

5

f

= 4MHz, AVDD = 5V

CLK

f

=2MHz,AVDD=3V

CLK

Temperature (_C)

Figure 2

450

f

=2MHz

CLK

400

A)

350

µ

300

Current (

250

Buffer On

Buffer Off

f

=2MHz,AVDD=3V

CLK

0

−

−

55

25 35 65 95 125

5

Temperature (_C)

Figure 3

50

40

A)

30

µ

Current(

f

=4MHz

CLK

20

f

=2MHz

CLK

10

0

3.53.0 4.0 4.5 5.0 5.52.5

Supply Voltage (V)

Figure 5

200

3.53.0 4.0 4.5 5.0 5.52.5

Supply Voltage (V)

Figure 4

150

140

130

120

110

100

90

80

Temperature Sensor Voltage (mV)

70

−

−

25 35 65 95 125

55

5

Temperature (_C)

Figure 6

6

Page 7

www.ti.com

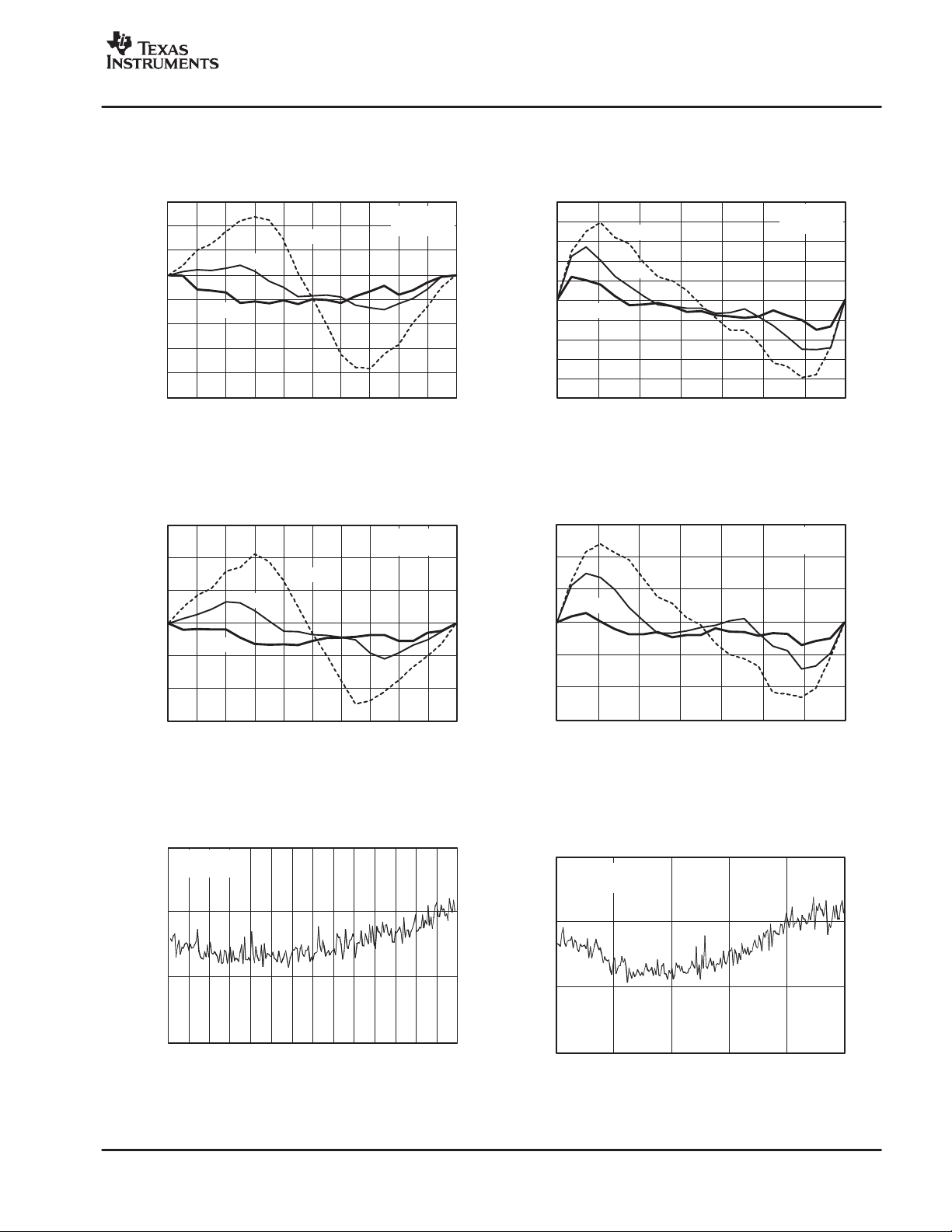

INTEGRAL NONLINEARITY vs INPUT VOLTAGE

INL (% of FSR)

INTEGRAL NONLINEARITY vs INPUT VOLTAGE

INL (% of FS R )

INTEGRAL NONLINEARITY vs INPUT VOLTAGE

INL (% o f FSR )

INTEGRAL NONLINEARITY vs INPUT VOLTAGE

INL (% o f F S R)

NOISE vs INPUT VOLTAGE

NOISE vs INPUT VOLTAGE

TYPICAL CHARACTERISTICS (CONTINUED)

At TA = −40°C to +85°C, AVDD = +5V, DVDD = +5V, f

= 2MHz, and V

CLK

SBAS286A − JUNE 2003 − REVISED MARCH 2004

= +2.5V , unless otherwise noted.

REF

0.0006

0.0004

0.0002

−

0.0002

−

0.0004

−

0.0006

−

0.0008

−

0.0010

0.0015

0.0010

0.0005

−

0.0005

f

=2MHz

CLK

−40_

C

+85_C

−

3

+25_C

−2−

1012345

Input Voltage, VIN(V)

0

−

−

4

5

Buffer Off

Figure 7

f

=4MHz

CLK

Buffer Off

−40_

C

+25_C

0

+85_C

0.0010

0.0008

0.0006

0.0004

0.0002

−

0.0002

−

0.0004

−

0.0006

−

0.0008

−

0.0010

0.0015

0.0010

0.0005

−

0.0005

−40_

C

+25_C

0

+85_C

−

−

−

3.5

2.5

−

1.5

0.5 0.5 1.5 2.5 3.5

Input Voltage, V

IN

Figure 8

−40_

C

+25_C

+85_C

0

(V)

f

CLK

Buffer On

f

CLK

Buffer On

=2MHz

=4MHz

−

−

0.0010

−

0.0015

−

5

−

−

4

3

−2−

10 1 2 3 4 5

Input Voltage, V

(V)

IN

Figure 9

1.5

f

=2MHz

CLK

Buffer On

1.0

0.5

Noise (ppm of FSR, rms)

0

3.5−3.0−2.5−2.0−1.5−1.0−0.5

−

0

0.5

Input Voltage, VIN(V)

1.0

1.5

2.0

2.5

3.0

3.5

Figure 11

0.0010

−

0.0015

Noise (ppm of FSR, rms)

1.5

1.0

0.5

−

3.5

0

−

f

=2MHz

CLK

Buffer Off

5

−

−

2.5

−

1.5

0.5 0.5 1.5 2.5 3.5

Input Voltage, V

(V)

IN

Figure 10

−

3

−

1135

Input Voltage, VIN(V)

Figure 12

7

Page 8

SBAS286A − JUNE 2003 − REVISED MARCH 2004

www.ti.com

OVERVIEW

The ADS1224 is an A/D converter comprised of a

delta-sigma modulator followed by a digital filter. A m u x

allows for one of four input channels to be selected. A

buffer can also be selected to increase the input

impedance. The modulator measures the differential

input signal VIN = (AINP – AINN) against the differential

reference V

= (VREFP – VREFN). Figure 13 shows

REF

a conceptual diagram of the device. The differential

reference is scaled internally so that the full-scale input

range i s ±2V

. The digital filter receives the modulator

REF

signal and provides a low-noise digital output. A 2-wire

serial interface indicates conversion completion and

provides the user with the output data.

ANALOG INPUTS (AINPx, AINNx)

The input signal to be measured is applied to the input

pins AINPx and AINNx. The positive internal input is

generalized as AINP, and the negative internal input is

generalized as AINN. The signal is selected though the

input mux, which is controlled by pins MUX0 and MUX1,

as shown in Table 1. The ADS1224 accepts differential

input signals, but can also measure unipolar signals.

When measuring unipolar (or single-ended signals)

with respect to ground, connect the negative input

(AINNx) to ground and connect the input signal to the

positive input (AINPx). Note that when the ADS1224 is

configured this way , only half of the converter full-scale

range is used since only positive digital output codes

are produced. An input buffer can be selected to

increase the input impedance of the A/D converter with

the BUFEN pin.

Table 1. Input Channel selection with MUX0 and

MUX1

DIGIT AL PINS SELECTED ANALOG INPUTS

MUX0 MUX1 POSITIVE INPUT NEGATIVE INPUT

0 0 AINP1 AINN1

0 1 AINP2 AINN2

1 0 AINP3 AINN3

1 1 AINP4 AINN4

AINP1

AINN1

AINP2

AINN2

AINP3

AINN3

AINP4

AINN4

TEMPEN

Temp

Sensor

AINP

Mux

AINN

MUX0

MUX1 BUFEN

Buffer

Σ

VREFPΣVREFN

+

V

IN

Modulator

2

∆Σ

Figure 13. Conceptual Diagram of the ADS1224

2V

−

V

REF

REF

Digital

Filter

and

Serial

Interface

CLK

SCLK

DRDY/DOUT

8

Page 9

www.ti.com

SBAS286A − JUNE 2003 − REVISED MARCH 2004

Analog Input Measurement without the Input Buffer

With the buffer disabled by setting the B UFEN pin l ow, the

ADS1224 measures the input signal using internal

capacitors that are continuously charged and discharged.

Figure 14 shows a sim plif ied schematic of the ADS1224

input circuitry, with F igure 15 showing t he on/off t imings of

the switches. The S

switches close during the input

1

sampling phase. With S1 closed, CA1 charges to AI NP,

CA2 charges to AINN, and CB charges to (AINP – AINN).

For the discharge phase, S1 opens first and then S

closes. CA1 and CA2 discharge to approximately A VDD/2

and CB discharges to 0V. This two-phase

sample/discharge cycle repeats with a frequency of

f

/32 (62.5kHz for f

CLK

ESD Protection

AVDD

AINPx

AINNx

AVDD

= 2MHz).

CLK

Mux

AINP

AINN

S

S

1

1

AVDD/2

S

S

AVDD/2

C

A1

3pF

2

C

B

6pF

2

C

A2

3pF

Figure 14. Simplified Input Structure with the

Buffer Turned Off

t

= 32/f

SAMPLE

ON

S

1

OFF

ON

S

2

OFF

CLK

AVDD/2

ZeffA=t

SAMPLE/CA1

AINPx

ZeffB=t

SAMPLE/CB

AINNx

ZeffA=t

SAMPLE/CA2

2

AVDD/2

NOTE: (1) f

CLK

=2MHz.

=6M

=3M

=6M

Ω

Ω

Ω

Figure 16. Effective Analog Input Impedances

with the Buffer Off

ESD diodes protect the inputs. To keep these diodes

from turning on, make sure the voltages on the input

pins do not go below GND by more than 100mV, and

likewise do not exceed AVDD by 100mV:

GND – 100mV < (AINP, AINN) < AVDD + 100mV

Analog Input Measurement with the Input Buffer

When the buffer is enabled by setting the BUFEN pin

high, a low-drift, chopper-stabilized input buffer is used

to achieve very high input impedance. The buffer

charges the input sampling capacitors, thus removing

the load from the measurement. Because the input

buffer is chopper-stabilized, the charging of parasitic

capacitances causes the charge to be carried away , as

if by resistance. The input impedance can be modeled

by a single resistor, as shown in Figure 17. The

impedance scales inversely with f

frequency, as in

CLK

the nonbuffered case.

AINP

(1)

Ω

1.2G

AINN

(1)

(1)

(1)

Figure 15. S1 and S2 Switch Timing for Figure 14

The constant charging of the input capacitors presents

a load on the inputs that can be represented by effective

impedances. Figure 16 shows the input circuitry with

the capacitors and switches of Figure 14 replaced by

their effective impedances. These impedances scale

inversely with f

frequency. For example, if f

CLK

CLK

frequency is reduced by a factor of 2, the impedances

will double.

NOTE: (1) f

CLK

=2MHz.

Figure 17. Effective Analog Input Impedances

with the Buffer On

Note that the analog inputs (listed in the Electrical

Characteristics table as Absolute Input Range) must

remain between GND + 0.05V to AVDD − 1.5V.

Exceeding this range degrades linearity and results in

performance outside the specified limits.

9

Page 10

SBAS286A − JUNE 2003 − REVISED MARCH 2004

www.ti.com

TEMPERATURE SENSOR

On-chip diodes provide temperature-sensing capability. By setting the TEMPEN pin high, the selected analog

inputs are disconnected and the inputs to the A/D

converter are connected to the anodes of two diodes

scaled to 1x and 64x in current and size inside the mux,

as shown in Figure 18. By measuring the difference in

voltage of these diodes, temperature changes can be

inferred from a baseline temperature. Typically, the

difference in diode voltages is 106mV at 25°C, with a

temperature coefficient of 360µV/°C. A similar structure

is used in the MSC1210 for temperature measurement.

For more information, see TI application report

SBAA100, Using the MSC121x as a High-Precision

Intelligent Temperature Sensor, available for download

at www.ti.com.

TEMPEN

AVDD

8I 1I

VOLTAGE REFERENCE INPUTS

(VREFP, VREFN)

The voltage reference used by the modulator is

generated from the voltage difference between VREFP

and VREFN: V

inputs use a structure similar to that of the analog

inputs. A simplified diagram of the circuitry on the

reference inputs is shown in Figure 19. The switches

and capacitors can be modeled with an effective

impedance of:

where f

Self Gain Cal

CLK

AVDD

= 2MHz.

= VREFP – VREFN. The reference

REF

t

sample

ǒ

Ǔ

ń16pF + 500kW

2

VREFP VREFN

AVDD

ESD

Protection

1X 8X

AINP1

AINN1

AINP2

AINN2

AINP3

AINN3

AINP4

AINN4

MUX0 MUX1

Figure 18. Measurement of the Temperature

Sensor in the Input Multiplexer

AINP

AINN

(1) f

CLK

AINP

=2MHz

AINN

16pF

Zeff= 500k

(1)

Ω

Figure 19. Simplified Reference input Circuitry

ESD diodes protect the reference inputs. To prevent

these diodes from turning on, make sure the voltages

on the reference pins do not go below GND by more

than 100mV, and likewise, do not exceed AVDD by

100mV:

GND – 100mV < (VREFP, VREFN) < AVDD + 100mV

During self gain calibration, all the switches in the input

multiplexer are opened, VREFN is internally connected to

AINN, and VREFP is connected to AINP. The input buffer

may be disabled or enabled during calibration. When the

buffer is dis abled, the reference pins will be driving the

circuitry shown in Figure 9 during self gain calibration,

resulting in increased loading. To prevent this additional

loading from introducing gain errors, make sure the

circuitry driving the reference pins has adequate drive

capability. When the buffer is enabled, the loading on the

reference p ins w ill b e m uch l ess, but the buffer w ill li mit the

10

Page 11

www.ti.com

SBAS286A − JUNE 2003 − REVISED MARCH 2004

allowable voltage range on VREFP and VREFN during

self or self gain calibrat ion as the ref erence pins must

remain within the specified input range of the buffer in

order to establish proper gain calibration.

For best performance, V

be raised as high as AVDD. When V

should b e A VDD/2, but it can

REF

REF

exceeds

AVDD/2, it is not possible to reach the full-scale digital

output value corresponding to ±2V

, since this r equires

REF

the analog inputs to exceed the power supplies. For

example, if V

= AVDD = 5V, the positive full-scale

REF

signal is 10V. The maximum positive input signal that can

be supplied before the ESD diodes turn on is when AINP

= 5.1V and AINN = –0.1V, resulting in VIN = 5.2V.

Therefore, it is not possible to reach the positive (or

negative) full-scale readings in this configuration. The

digital output codes are limited to approximately one half

of the entire range. For best performance, bypass the

voltage reference inputs with a 0.1µF capac itor between

VREFP and VREFN. Place the capacitor as close as

possible to the pins.

CLOCK INPUT (CLK)

This digital input supplies the system clock to the

ADS1224. The CLK frequency can be increased to

speed up the data rate. CLK must be left running during

normal operation. It may be turned off during Standby

mode to save power, but this is not required. The CLK

input may be driven with 5V logic, regardless of the

DVDD or AVDD voltage.

Minimize the overshoot and undershoot on CLK for the

best analog performance. A small resistor in series with

CLK (10Ω to 100Ω) can often help. CLK can be

generated from a number of sources including

standalone crystal oscillators and microcontrollers.

the pin can be forced high with an additional SCLK. It will

then stay high until new data is ready. This is useful

when polling on the status of DRDY/DOUT to determine

when to begin data retrieval.

SERIAL CLOCK INPUT (SCLK)

This digital input shifts serial data out with each rising

edge. As with CLK, this input may be driven with 5V

logic regardless of the DVDD or AVDD voltage. There

is hysteresis built into this input, but care should still be

taken to ensure a clean signal. Glitches or slow-rising

signals can cause unwanted additional shifting. For this

reason, it is best to make sure the rise-and-fall times of

SCLK are less than 50ns.

FREQUENCY RESPONSE

The ADS1224 frequency response for f

shown in Figure 20. The frequency response repeats at

multiples of the modulator sampling frequency of

62.5kHz. The overall response is that of a low-pass filter

with a −3db cutoff frequency of 31.5Hz. As shown, the

ADS1224 does a good job attenuating out to 60kHz. For

the best resolution, limit the input bandwidth to less than

this value to keep higher frequency noise from affecting

performance. Often, a simple RC filter on the ADS1224

analog inputs is all that is needed.

0

−

20

−

40

= 2MHz is

CLK

DATA READY/DATA OUTPUT (DRDY/DOUT)

This digital output pin serves two purposes. First, it

indicates when new data is ready by going LOW.

Afterwards, on the first rising edge of SCLK, the

DRDY/DOUT pin changes function and begins

outputting the conversion data, most significant bit

(MSB) first. Data is shifted out on each subsequent

SCLK rising edge. After all 24 bits have been retrieved,

Gain (dB)

−

60

−

80

−

100

31250 625000

Input Frequency (Hz)

Figure 20. Frequency Response

11

Page 12

SBAS286A − JUNE 2003 − REVISED MARCH 2004

www.ti.com

To help see the response at lower frequencies,

Figure 21 illustrates the response out to 1kHz. Notice

that signals at multiples of 120Hz are rejected. The

ADS1224 data rate and frequency response scale

directly with CLK frequency. For example, if f

CLK

increases from 2MHz to 4MHz, the data rate increases

from 120SPS to 240SPS, while the notches increase

from 120Hz to 240Hz.

0

−

20

−

40

Gain (dB)

−

60

−

80

−

100

500 600 700 800 900100 200 300 400 1k0

Input Frequency (Hz)

Figure 21. Frequency Response to 1kHz

Rejecting 50Hz or 60Hz noise is as simple as choosing

the clock frequency. If simultaneous rejection of 50Hz

and 60Hz noise is desired, f

= 910kHz can be

CLK

chosen. The data rate becomes 54.7sps and the

frequency response of the ADS1224 rejects the 50Hz

and 60Hz noise to below 60dB. The frequency

response of the ADS1224 near 50Hz and 60Hz with

f

= 910kHz is shown in Figure 22.

CLK

0

−

20

−

40

Gain (dB)

−

60

−

80

−

100

Input Frequency (Hz)

8030 40 50 60 70

Figure 22. Frequency Response Near 50Hz and

60Hz with f

CLK

= 910kHz

SETTLING TIME

After changing the input multiplexer, selecting the input

buffer, or using temperature sensor, the first data is fully

settled. In the ADS1224, the digital filter is allowed to

settle after toggling any of the MUX0, MUX1, BUFEN,

or TEMPEN pins. Toggling of any of these digital pins

will cause the input to switch to the proper channel, start

conversions, and hold the DRDY/DOUT line high until

the digital filter is fully settled. For example, if MUX0

changes from low to high, selecting a different input

channel, DRDY/DOUT immediately goes high and the

conversion process restarts. DRDY/DOUT goes low

when fully settled data is ready for retrieval. There is no

need to discard any data. Figure 23 shows the timing of

the DRDY/DOUT line as the input multiplexer changes.

12

MUX0

V

DRDY/DOUT

SYMBOL DESCRIPTION MIN MAX UNITS

(1)

Abrupt change in internal VINdue to status change (for example, switch channels, temp sensor, buffer enable)

IN

t

1

ADS1224 holds DRDY/DOUT

until digital filter settles

DRDY/DOUT suppressed after status change

(1)

t

1

Values given for f

Settling time (DRDY/DOUT held high) after a change in any of the 25.9 26.4 ms

MUX0, MUX1, BUFEN, or TEMPEN pins

= 2MHz. For different f

CLK

frequencies, scale proportional to CLK period.

CLK

Figure 23. Example of Settling Time After Changing the Input Multiplexer

Fully settled

data ready

Page 13

www.ti.com

SBAS286A − JUNE 2003 − REVISED MARCH 2004

The ADS1224 uses a Sinc3 digital filter to improve noise

performance. Therefore, in certain instances, large

changes in input will require settling time. For example,

an external multiplexer in front of the ADS1224 can put

large changes in input voltage by simply switching input

channels. Abrupt changes in the input will require three

data cycles to settle. When continuously converting,

four readings may be necessary to settle the data. If the

change in input occurs in the middle of the first conversion, three more full conversions of the fully settled input

will be required to get fully settled data. Discard the first

three readings because they will contain only partially−

settled data. Figure 24 illustrates the settling time for

the ADS1224 in Continuous Conversion mode.

If the input is known to change abruptly, the mux can be

quickly switched to an alternate channel and quickly

switched back to the original channel. By toggling the

mux, the ADS1224 resets the digital filter and initiates a

new conversion. During this time, the DRDY

/DOUT line

is held high until fully-settled data is available.

DATA FORMAT

The ADS1224 outputs 24 bits of data in binary two’s

complement format. The least significant bit (LSB) has

a weight of (2VREF)/(223 – 1). The positive full-scale

input produces an output code of 7FFFFFh and the

negative full-scale input produces an output code of

800000h. The output clips at these codes for signals

exceeding full-scale. Table 2 summarizes the ideal

output codes for different input signals.

Table 2. Ideal Output Code vs Input Signal

INPUT SIGNAL V

(AINP − AINN)

w +2V

+2V

223* 1

−2V

223* 1

v −2V

REF

(1)

Excludes effects of noise, INL, offset, and gain errors.

IN

REF

REF

0 000000h

REF

23

2

ǒ

223* 1

Ǔ

IDEAL OUTPUT CODE

7FFFFFh

000001h

FFFFFFh

800000h

(1)

DATA RETRIEVAL

The ADS1224 continuously converts the analog input

signal. To retrieve data, wait until DRDY/DOUT goes

low, as shown in Figure 25. After this occurs, begin

shifting out the data by applying SCLKs. Data is shifted

out MSB first. It is not required to shift out all 24 bits of

data, but the data must be retrieved before the new data

is updated (see t2) or else it will be overwritten. Avoid

data retrieval during the update period. DRDY/DOUT

remain at the state of the last bit shifted out until it is

taken high (see t6), indicating that new data is being

updated. To avoid having DRDY/DOUT remain in the

state of the last bit, shift a 25th SCLK to force

DRDY/DOUT high (see Figure 26). This technique is

useful when a host controlling the ADS1224 is polling

DRDY/DOUT to determine when data is ready.

V

DRDY/DOUT

Abrupt change in external V

IN

Starto f

conversion

Conversion

time

First Conversion;

includes

unsettled V

IN

Second Conversion;

settled, but

V

IN

digital filter

IN

unsettled

Third Conversion;

settled, but

V

IN

digital filter

unsettled

Fourth Conversion;

anddigital filter

V

IN

bothsettled

Figure 24. Settling Time in Continuous Conversion Mode

13

Page 14

SBAS286A − JUNE 2003 − REVISED MARCH 2004

Data Ready

DRDY/DOUT 23 22 21

www.ti.com

Data

NewData Ready

LSBMSB

0

SCLK

t

4

t

2

124

t

3

t

3

t

7

t

5

SYMBOL DESCRIPTION MIN MAX UNITS

t

DRDY/DOUT low to first SCLK rising edge 0 ns

2

t

SCLK positive or negative pulse width 100 ns

3

(1)

t

4

t

6

t

7

(1)

Values given for f

SCLK rising edge to new data bit valid: propogation delay 50 ns

t

SCLK rising edge to old data bit valid: hold time 0 ns

5

(1)

Data updating; no readback allowed 48 µs

(1)

Conversion time (1/data rate) 8.32 8.32 ms

= 2MHz. For different f

CLK

frequencies, scale proportional to CLK period.

CLK

Figure 25. Data Retrieval Timing

Data

Data Ready

t

6

New Data Ready

14

DRDY/DOUT

SCLK

23

22 21 0

12425

25th SCLK to Force DRDY/DOUT High

Figure 26. Data Retrieval with DRDY/DOUT Forced High Afterwards

Page 15

www.ti.com

SBAS286A − JUNE 2003 − REVISED MARCH 2004

SELF-CALIBRATION

Self-calibration can be initiated at any time, although in

many applications the ADS1224 drift performance is so

good that the self-calibration performed automatically

at power-up is all that is needed. To initiate

self-calibration, apply at least two additional SCLKs

after retrieving 24 bits of data. Figure 27 shows the

timing pattern. The 25th SCLK will send DRDY/DOUT

high. The falling edge of the 26th SCLK will begin the

calibration cycle. Additional SCLK pulses may be sent

after the 26th SCLK; however, activity on SCLK should

be minimized during calibration for best results.

When the calibration is complete, DRDY/DOUT goes

low, indicating that new data is ready. There is no need

to alter the analog input signal applied to the ADS1224

during calibration; the input pins are disconnected

within the A/D converter and the appropriate signals are

applied internally and automatically. The first

conversion after a calibration is fully settled and valid for

use. The time required for a calibration depends on two

independent signals: the falling edge of SCLK and an

internal clock derived from CLK. Variations in the

internal calibration values will change the time required

for calibration (t8) within the range given by the min/max

specs. t11 and t12 described in the next section are

affected likewise.

STANDBY MODE

Standby mode dramatically reduces power

consumption (typically < 1µW with CLK stopped) by

shutting down all of the active circuitry. To enter Standby

mode, simply hold SCLK high after DRDY/DOUT goes

low, as shown in Figure 28. Standby mode can be

initiated at any time during readback; it is not necessary

to retrieve all 24 bits of data beforehand.

When t11 has p assed with S CLK held h igh, Standby mode

will activate. DRDY/DOUT stays high when Standby

mode begins. SCLK must remain high to stay in Standby

mode. To exit St andby mode (wakeup), set SCLK low.

The first data after exiting Standby mode is valid. It is not

necessary to stop CLK during Standby mode, but doing

so will furt her reduc e the digital supply curr ent.

Standby Mode With Self-Calibration

Self-calibration can be set to run immediately after

exiting Standby mode. This is useful when the

ADS1224 is put in Standby mode for long periods of

time and self-calibration is desired afterwards to

compensate for temperature or supply voltage

changes.

To force a self-calibration with Standby mode, shift 25

bits out before taking SCLK high to enter Standby

mode. Self-calibration then begins after wakeup.

Figure 29 shows the appropriate timing. Note the extra

time needed after wakeup for calibration before data is

ready. The first data after Standby mode with

self-calibration is fully settled and can be used.

23DRDY/DOUT

SCLK 1 24

SYMBOL DESCRIPTION MIN MAX UNITS

(1)

t

8

(1)

Values given for f

First data ready after calibration 77.1 77.9 ms

= 2MHz. For different f

CLK

Figure 27. Self-Calibration Timing

Data Ready After Calibration

Calibration Begins

25 26

t

8

frequencies, scale proportional to CLK period.

CLK

2322 21 0

15

Page 16

SBAS286A − JUNE 2003 − REVISED MARCH 2004

www.ti.com

DRDY/DOUT 23 22 21

SCLK

SYMBOL DESCRIPTION MIN MAX UNITS

(2)

124

t

9

(1)

t

9

t

10

t

11

Values given for f

SCLK high after DRDY/DOUT goes low to activate Standby mode 0 8.272 ms

(1)

Standby mode activation time 8.272 8.304 ms

(1)

Data ready after exiting Standby mode 27.7 28.1 ms

= 2MHz. For different f

CLK

Figure 28. Standby Mode Timing (can be used for single conversions)

DRDY/DOUT 23

22 21 0 23

Standby Mode

023

t

10

frequencies, scale proportional to CLK period.

CLK

Standby Mode

Start Conversion

Begin Calibration

Data Ready

t

11

Data Ready After Calibration

SCLK

(1)

12425

t

10

SYMBOL DESCRIPTION MIN MAX UNITS

(1)

t

12

Values given for f

Data ready after exiting Standby mode and calibration 78.8 79.7 ms

= 2MHz. For different f

CLK

Figure 29. Standby Mode with Self-Calibration Timing (can be used for single conversions)

SINGLE CONVERSIONS

When only single conversions are needed, Standby

mode can be used to start and stop the ADS1224. To

make a single conversion, first enter the Standby mode

holding SCLK high. Now, when ready to start the

conversion, take SCLK low. The ADS1224 wakes up

and begins the conversion. Wait for DRDY/DOUT to go

low, and then retrieve the data. Afterwards, take SCLK

t

12

frequencies, scale proportional to CLK period.

CLK

high to stop the ADS1224 from converting and re-enter

Standby mode. Continue to hold SCLK high until ready

to start the next conversion. Operating in this fashion

greatly reduces power consumption since the

ADS1224 is shut down while idle between conversions.

Self-calibrations can be performed prior to the start of

the single conversions by using the waveform shown in

Figure 29.

16

Page 17

www.ti.com

SBAS286A − JUNE 2003 − REVISED MARCH 2004

APPLICATIONS INFORMATION

GENERAL RECOMMENDATIONS

The ADS1224 is a high-resolution A/D converter.

Achieving optimal device performance requires careful

attention to the support circuitry and printed circuit

board (PCB) design. Figure 30 shows the basic

connections for the ADS1224. As with any precision

circuit, be sure to use good supply bypassing capacitor

techniques. A smaller value ceramic capacitor in

parallel with a larger value tantulum capacitor works

well. Place the capacitors, in particular the ceramic

ones, close to the supply pins. Use a ground plane and

tie the ADS1224 GND pin and bypass capacitors

directly to it. Avoid ringing on the digital inputs. Small

resistors (≈100Ω) in series with the digital pins can help

by controlling the trace impedance. Place these

resistors at the source end.

+5V

VIN

VIN

Ω

301

P

301

N

0.1µF10µF

1

Ω

100

Ω

100

Ω

100

Ω

100

220pF

0.1µF

Ω

220pF

100

100

100

2

Ω

3

4

Ω

5

6

Ω

7

8

9

10

ADS1224

DVDD

SCLK

CLK

DRDY/DOUT

MUX0

MUX1

TEMPEN

BUFEN

AINP4

AINN4

Pay special attention to the reference and analog

inputs. These are the most critical circuits. Bypass the

voltage reference using similar techniques to the supply

voltages. The quality of the reference directly affects

the overall accuracy of the device. Make sure to use a

low noise and low drift reference such as the REF1004.

Often, only a simple RC filter is needed on the inputs.

This circuits limits the higher frequency noise. Avoid

low-grade dielectrics for the capacitors and place them

as close as possible to the input pins. Keep the traces

to the input pins short, and carefully watch how they are

routed on the PCB.

After the power supplies and reference voltage have

stabilized, issue a self-calibration command to

minimize offset and gain errors.

+5V

+2.5V Reference

AVDD

VREFP

VREFN

GND

AINN1

AINP1

AINN2

AINP2

AINN3

AINP3

0.1µF 10µF

20

19

18

17

16

15

14

13

12

11

0.1µF 10µF

Same as shown for AINP4 and AINN4.

Figure 30. Basic Connections

17

Page 18

SBAS286A − JUNE 2003 − REVISED MARCH 2004

www.ti.com

MULTICHANNEL SYSTEMS

Multiple ADS1224s can be operated in parallel to

measure multiple input signals. Figure 31 shows an

example of an eight-channel system. For simplicity, the

supplies and reference circuitry are not shown. The

same CLK signal should be applied to all devices. To

synchronize the ADS1224s, connect the same SCLK

signal to all devices. Then place all the devices in

Standby mode. Afterwards, starting a conversion will

synchronize all the ADS1224s; that is, they will sample

the input signals simultaneously. The DRDY/DOUT

outputs will go low at approximately the same time after

synchronization. When reading data from the devices,

the data appears in parallel on DRDY/DOUT as a result

of the common SCLK connection.

ADS1224

AINP1

CLK

SCLK

DRDY/DOUT

OUT1

Inputs

MUX Select

AINN1

…

AINP4

AINN4

MUX0

MUX1

The falling edges of DRDY

/DOUT, indicating that new

data is ready, will vary with respect to each other no

more than time t

. This variation is due to possible

13

differences in the ADS1224 internal calibration settings.

To account for this, when using multiple devices, either

wait for t13 to pass after seeing one DRDY/DOUT go

low, or wait until all DRDY/DOUTs have gone low before

retrieving data.

Note that changing channels (using the MUX0 and

MUX1 pins), or using the input buffer (BUFEN) or the

temperature sensor (TEMPEN), may require more care

to settle the digital filter. For example, if the MUX0 pin

is toggled on one device and not the other, the

DRDY/DOUT line will be held high until the conversion

settles on the first device. The latter device will continue

conversions through this time. See the Settling Time

section of this datasheet for further details.

ADS1224

AINP1

AINN1

Inputs

MUX Select

SYMBOL DESCRIPTION MIN MAX UNITS

(1)

t

13

(1)

Values given for f

…

AINP4

AINN4

MUX0

MUX1

Difference between DRDY/DOUTs going low in multichannel ±0.8 ms

systems

CLK

CLK

SCLK

DRDY/DOUT

CLK and SCLK

Sources

= 2MHz. For different f

OUT2

frequencies, scale proportional to CLK period.

CLK

OUT1

OUT2

t

13

Figure 31. Example of Using Multiple ADS1224s in Parallel

18

Page 19

www.ti.com

SBAS286A − JUNE 2003 − REVISED MARCH 2004

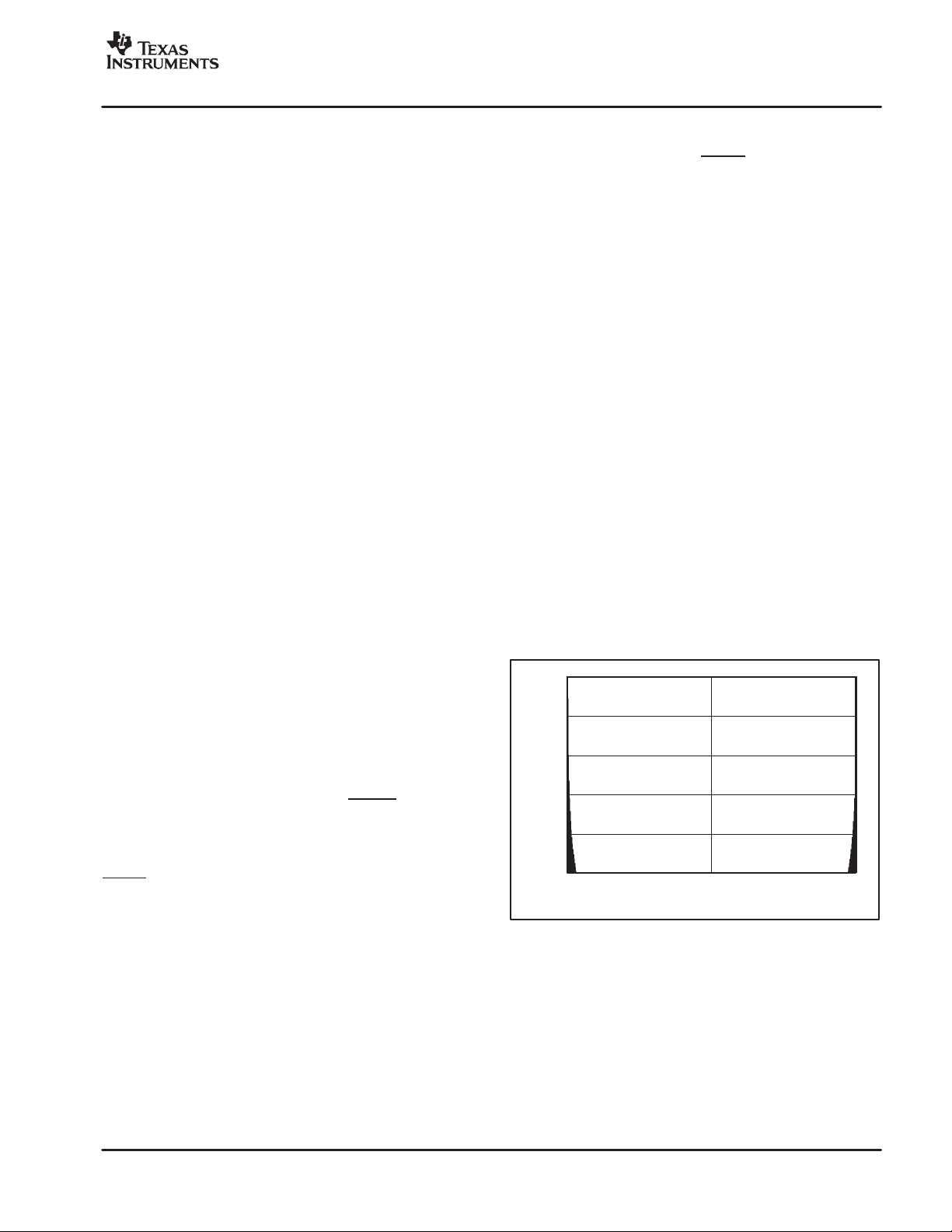

VESSEL WEIGHING WITH FOUR LOAD

CELLS

In vessel weighing systems, four load cells are

frequently employed to measure the weight of the

vessel and its contents. The output of the load cells are

usually combined in an external summing junction box

that balances the load cells’ sensitivities for accuracy.

The four differential inputs of the ADS1224 allow for

direct measurement of the four load cells individually. In

this way , the mechanical adjustments performed inside

the summing junction box are eliminated and are

replaced by digital summing of the load cells in

software. Figure 32 shows an example of such a

system.

The reference voltage of the ADS1224 is derived by

dividing down the AVDD supply voltage to 2.5V, while

the load cell has a positive full-scale output of 10mV . In

the figure, a low drift, dual op amp (OP A2335) provides

a differential in/differential out amplifier with a gain of

499V/V (G = 1 + 2RF/RG). Gain on the load cell gives

the amplifier a full-scale output of 5V.

Each load cell input uses an external amplifier. The

outputs of the amplifiers connect to the analog inputs of

the ADS1224 through a low-pass filter. The cut-off

frequency is set to 360Hz, allowing full settling in a

single measurement cycle. A lower cut-off frequency

can be used to reduce noise from mechanical

vibrations, but at the expense of filter settling time.

The internal buffer of the ADS1224 is disabled, allowing

the VREFN pin to be grounded. Note that the loading

from the reference inputs will change the effective

reference voltage. The effective input impedance into

the VREFP and VREFN pins will lower the reference

voltage seen at these pins. At 2MHz, input impedance

is approximately 500kΩ. For the reference circuit shown

in Figure 32, this lowers the effective reference voltage

by approximately 0.1%.

5V

+3V

Ω

350

Load Cell

NOTE: (1) Low−drift resistors.

Shield ed

Replicate for Chann e ls 2, 3 and 4

Cable

RFI

Filt er

RFI

Filt er

G=1+

RFI

Filt er

RFI

Filt er

100

2R

R

10

R

G

100

(1)

Ω

1k

VREFP

(1)

Ω

1k

VREFN

Ω

Ω

AINP1

0.22µF

AINN1

AINP2

AINN2

AINP3

AINN3

AINP4

AINN4

1/2

OPA2335

(1)

F

Ω

(1)

F

Ω

1/2

OPA2335

0.1µF

1k

1k

5V

Ω

R

F

2.49k

G

(1)

R

Ω

2.49k

Ω

0.1µF 0.1µF 0.1µF1µF

AVDD

DVDD

BUFEN

TEMPEN

ADS1224

CLK

SCLK

DRDY/DOUT

MUX0

MUX1

GND

Figure 32. Vessel Weighing System with Four Load Cells

DVCC

MSP 430 F 4 1x

P1.1/TA0/MCLK

P1.2/TA1

P1.0/TA0

P1.6/CA0

P1.7/CA1

XOUT/TCLK

GND

AVCC

XIN

19

Page 20

SBAS286A − JUNE 2003 − REVISED MARCH 2004

SUMMARY OF SERIAL INTERFACE WAVEFORMS

www.ti.com

DRDY/DOUT

SCLK

DRDY/DOUT

SCLK

DRDY/DOUT

SCLK

23 22 21 0

MSB LSB

124

(a) Data Retrieval

23 22 21 0

12425

(b) Data Retrieval with DRDY/DOUT Forced High Afterwards

Data Ready

After Calibration

23 22 21 0

1242526

Begin Calibration

DRDY/DOUT

SCLK

DRDY/DOUT

SCLK

(c) Self−Calibration

Standby Mode

23 22 21 0

124

(d) Standby Mode/Single Conversions

Standby Mode

23 22 21 0

12425

(e) Standby Mode/Single Conversions with Self−Calibration

Figure 33. Summary of Serial Interface Waveforms

Data Ready

Start

Conversion

Data Ready

AfterCalibration

Begin Calibration

20

Page 21

PACKAGE OPTION ADDENDUM

www.ti.com

29-Mar-2004

PACKAGING INFORMATION

ORDERABLE DEVICE STATUS(1) PACKAGE TYPE PACKAGE DRAWING PINS PACKAGE QTY

ADS1224IPWR ACTIVE TSSOP PW 20 2500

ADS1224IPWT ACTIVE TSSOP PW 20 250

(1) The marketing status values are defined as follows:

ACTIVE: Product device recommended for new designs.

LIFEBUY: TI has announced that the device will be discontinued, and a lifetime-buy period is in effect.

NRND: Not recommended for new designs. Device is in production to support existing customers, but TI does not recommend using this part in

a new design.

PREVIEW: Device has been announced but is not in production. Samples may or may not be available.

OBSOLETE: TI has discontinued the production of the device.

Page 22

MECHANICAL DATA

MTSS001C – JANUARY 1995 – REVISED FEBRUARY 1999

PW (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PINS SHOWN

0,65

1,20 MAX

14

0,30

0,19

8

4,50

4,30

PINS **

7

Seating Plane

0,15

0,05

8

1

A

DIM

14

0,10

6,60

6,20

M

0,10

0,15 NOM

0°–8°

2016

Gage Plane

24

0,25

0,75

0,50

28

A MAX

A MIN

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0,15.

D. Falls within JEDEC MO-153

3,10

2,90

5,10

4,90

5,10

4,90

6,60

6,40

7,90

7,70

9,80

9,60

4040064/F 01/97

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

Page 23

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. To minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third-party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party, or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Following are URLs where you can obtain information on other Texas Instruments products and application

solutions:

Products Applications

Amplifiers amplifier.ti.com Audio www.ti.com/audio

Data Converters dataconverter.ti.com Automotive www.ti.com/automotive

DSP dsp.ti.com Broadband www.ti.com/broadband

Interface interface.ti.com Digital Control www.ti.com/digitalcontrol

Logic logic.ti.com Military www.ti.com/military

Power Mgmt power.ti.com Optical Networking www.ti.com/opticalnetwork

Microcontrollers microcontroller.ti.com Security www.ti.com/security

Telephony www.ti.com/telephony

Video & Imaging www.ti.com/video

Wireless www.ti.com/wireless

Mailing Address: Texas Instruments

Post Office Box 655303 Dallas, Texas 75265

Copyright 2004, Texas Instruments Incorporated

Loading...

Loading...