ADS1210

ADS1211

ADS1210

ADS1211

ADS1211

查询ADS1210供应商查询ADS1210供应商

®

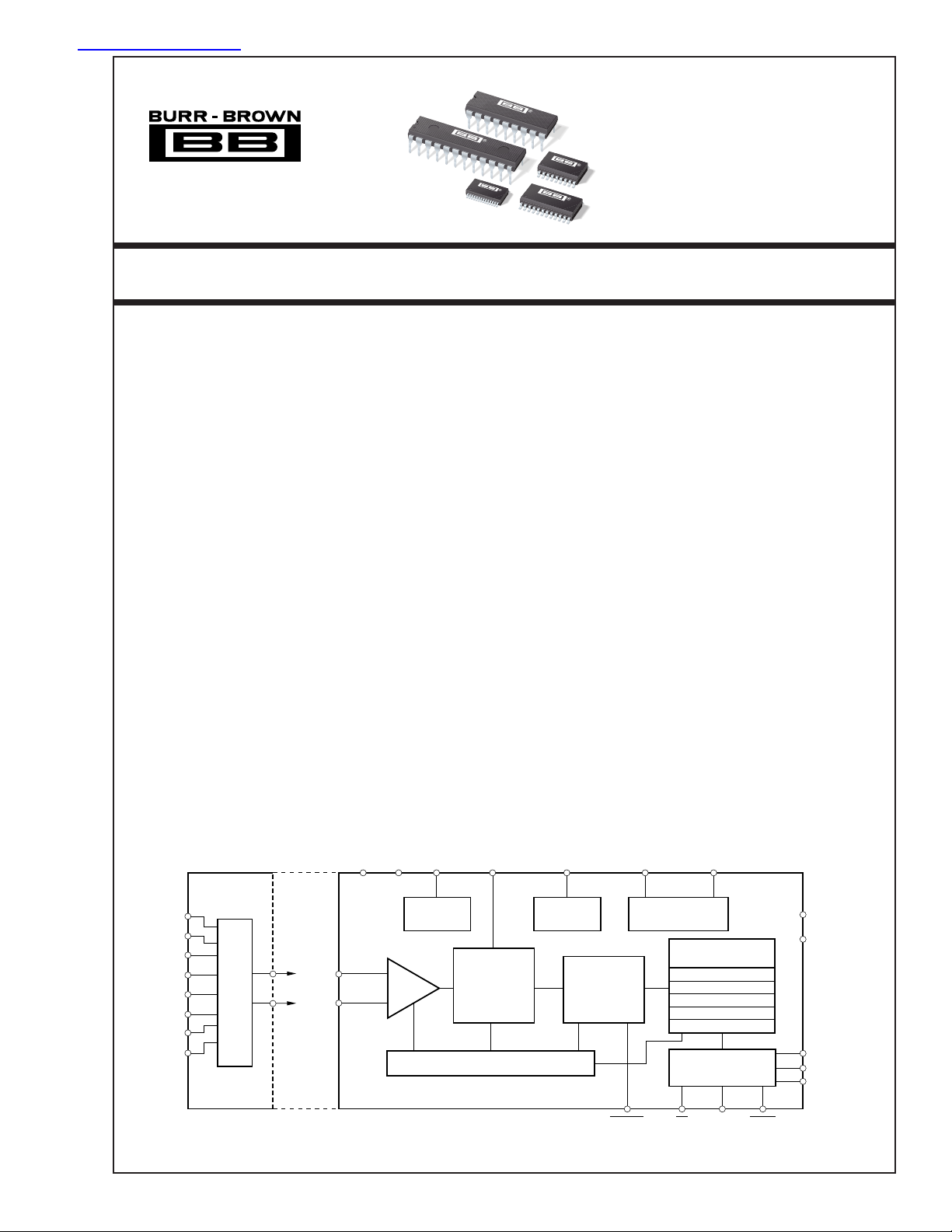

24-Bit ANALOG-TO-DIGITAL CONVERTER

FEA TURES

● DELTA-SIGMA A/D CONVERTER

● 23 BITS EFFECTIVE RESOLUTION AT 10Hz

AND 20 BITS AT 1000Hz

● DIFFERENTIAL INPUTS

● PROGRAMMABLE GAIN AMPLIFIER

● FLEXIBLE SPI COMPATIBLE SSI

INTERFACE WITH 2-WIRE MODE

● PROGRAMMABLE CUT-OFF FREQUENCY

UP TO 15.6kHz

● INTERNAL/EXTERNAL REFERENCE

● ON CHIP SELF-CALIBRATION

● ADS1211 INCLUDES 4 CHANNEL MUX

APPLICATIONS

● INDUSTRIAL PROCESS CONTROL

● INSTRUMENTATION

● BLOOD ANALYSIS

● SMART TRANSMITTERS

● PORTABLE INSTRUMENTS

● WEIGH SCALES

● PRESSURE TRANSDUCERS

AGND AVDDREF

OUT

ADS1210

ADS1211

DESCRIPTION

The ADS1210 and ADS1211 are precision, wide

dynamic range, delta-sigma analog-to-digital converters

with 24-bit resolution operating from a single +5V

supply. The differential inputs are ideal for direct

connection to transducers or low level voltage signals. The delta-sigma architecture is used for wide

dynamic range and to guarantee 22 bits of no missing

code performance. An effective resolution of 23 bits

is achieved through the use of a very low-noise input

amplifier at conversion rates up to 10Hz. Effective

resolutions of 20 bits can be maintained up to a

sample rate of 1kHz through the use of the unique

Turbo modulator mode of operation. The dynamic

range of the converters is further increased by providing a low-noise programmable gain amplifier with a

gain range of 1 to 16 in binary steps.

The ADS1210 and ADS1211 are designed for high

resolution measurement applications in smart transmitters, industrial process control, weigh scales, chromatography and portable instrumentation. Both converters include a flexible synchronous serial interface

which is SPI compatible and also offers a two-wire

control mode for low cost isolation.

The ADS1210 is a single channel converter and is

offered in both 18-pin DIP and 18-lead SOIC packages. The ADS1211 includes a 4 channel input multiplexer and is available in 24-pin DIP, 24-lead SOIC,

and 28-lead SSOP packages.

REF

IN

V

BIAS

X

IN

X

OUT

PGA

+2.5V

Reference

Second-Order

∆∑

Modulator

Modulator Control

1P

A

IN

AIN1N

A

2P

IN

AIN2N

A

3P

IN

AIN3N

A

4P

IN

AIN4N

International Airport Industrial Park • Mailing Address: PO Box 11400, Tucson, AZ 85734 • Street Address: 6730 S. Tucson Blvd., Tucson, AZ 85706 • Tel: (520) 746-1111

©

1996 Burr-Brown Corporation PDS-1284E Printed in U.S.A. May, 2000

MUX

ADS1211 Only ADS1210/11

Twx: 910-952-1111 • Internet: http://www.burr-brown.com/ • Cable: BBRCORP • Telex: 066-6491 • FAX: (520) 889-1510 • Immediate Product Info: (800) 548-6132

AINP

A

IN

N

+3.3V Bias

Generator

Third-Order

Digital Filter

Clock Generator

Micro Controller

Instruction Register

Command Register

Data Output Register

Offset Register

Full-Scale Register

Serial Interface

DSYNC CS DRDY

MODE

1 ADS1210, 1211

DGND

DV

DD

SCLK

SDIO

SDOUT

®

SPECIFICATIONS

All specifications T

and external 2.5V reference, unless otherwise specified.

PARAMETER CONDITIONS MIN TYP MAX UNITS

ANALOG INPUT

Input Voltage Range

Input Impedance G = Gain, TMR = Turbo Mode Rate 4/(G • TMR)

Programmable Gain Amplifier User Programmable: 1, 2, 4, 8, or 16 1 16

Input Capacitance 8pF

Input Leakage Current At +25°C550pA

SYSTEMS PERFORMANCE

Resolution 24 Bits

No Missing Codes f

Integral Linearity f

Unipolar Offset Error

Unipolar Offset Drift

Gain Error

Gain Error Drift

Common-Mode Rejection

Normal-Mode Rejection 50Hz, f

Output Noise See Typical Performance Curves

Power Supply Rejection DC, 50Hz, and 60Hz 65 dB

VOLTAGE REFERENCE

Internal Reference (REF

Drift 25 ppm/°C

Noise 50 µVp-p

Load Current Source or Sink 1 mA

Output Impedance 2 Ω

External Reference (REF

Load Current 2.5 µA

V

Output Using Internal Reference 3.15 3.3 3.45 V

BIAS

Drift 50 ppm/°C

Load Current Source or Sink 10mA

DIGITAL INPUT/OUTPUT

Logic Family TTL Compatible CMOS

Logic Level: (all except X

X

Input Levels: V

IN

X

Frequency Range (f

IN

Output Data Rate (f

Data Format User Programmable

SYSTEM CALIBRATION

Offset and Full-Scale Limits V

VFS – | VOS |V

to T

MIN

, AVDD = DVDD = +5V, f

MAX

= 10MHz, programmable gain amplifier setting of 1, Turbo Mode Rate of 1, REF

XIN

disabled,V

OUT

BIAS

disabled,

ADS1210U, P/ADS1211U, P, E

(1)

With V

At T

DATA

DATA

f

= 1000Hz, TMR of 16 ±0.0015 %FSR

(4)

(6)

(4)

(6)

(9)

DATA

At DC, +25°C 100 115 dB

At DC, T

50Hz, f

60Hz, f

60Hz, f

) 2.4 2.5 2.6 V

OUT

) 2.0 3.0 V

IN

)

V

IH

V

IL

V

OH

V

OL

IN

IOH = 2 TTL Loads 2.4 V

IOL = 2 TTL Loads 0.4 V

IH

V

IL

) 0.5 10 MHz

XIN

) User Programmable 2.4 15,625 Hz

DATA

f

XIN

(2)

BIAS

to T

MIN

MAX

= 60Hz 22 Bits

= 60Hz ±0.0015 %FSR

to T

MIN

MAX

(7)

= 50Hz

DATA

DATA

DATA

DATA

= 60Hz

= 50Hz

= 60Hz

(7)

(7)

(7)

IIH = +5µA 2.0 DV

IIL = +5µA –0.3 0.8 V

= 500kHz 0.12 781 Hz

0+5V

–10 +10 V

(3)

MΩ

1nA

See Note 5

1 µV/°C

See Note 5

1 µV/°C

90 115 dB

160 dB

160 dB

100 dB

100 dB

+0.3 V

DD

3.5 DV

–0.3 0.8 V

+0.3 V

DD

Two’s Complement

or Offset Binary

= Full-Scale Differential Voltage

FS

= Offset Differential Voltage

OS

(8)

0.7 • (2 • REFIN)/G

(8)

1.3 • (2 • REFIN)/G

The information provided herein is believed to be reliable; however, BURR-BROWN assumes no responsibility for inaccuracies or omissions. BURR-BROWN assumes

no responsibility for the use of this information, and all use of such information shall be entirely at the user’s own risk. Prices and specifications are subject to change

without notice. No patent rights or licenses to any of the circuits described herein are implied or granted to any third party. BURR-BROWN does not authorize or warrant

any BURR-BROWN product for use in life support devices and/or systems.

®

ADS1210, 1211

2

SPECIFICATIONS (CONT)

All specifications T

and external 2.5V reference, unless otherwise specified.

PARAMETER CONDITIONS MIN TYP MAX UNITS

POWER SUPPLY REQUIREMENTS

Power Supply Voltage 4.75 5.25 V

Power Supply Current:

Analog Current 2mA

Digital Current 3.5 mA

Additional Analog Current with

REF

V

BIAS

Power Dissipation 26 40 mW

TEMPERATURE RANGE

Specified –40 +85 °C

Storage –60 +125 °C

NOTES: (1) In order to achieve the converter’s full-scale range, the input must be fully differential (A

A

P is fixed), then the full scale range is one-half that of the differential range. (2) This range is set with external resistors and V

IN

Other ranges are possible. (3) Input impedance is higher with lower f

of the effective resolution of the converter. Refer to the Typical Performance Curves which apply to the desired mode of operation. (6) Recalibration can remove

these errors. (7) The specification also applies at f

mode rejection test is performed with a 100mV differential input.

to T

MIN

Enabled 1.6 mA

OUT

Enabled No Load 1 mA

, AVDD = DVDD = +5V, f

MAX

= 10MHz, programmable gain amplifier setting of 1, Turbo Mode Rate of 1, REF

XIN

ADS1210U, P/ADS1211U, P, E

TMR of 16 37 60 mW

f

= 2.5MHz 17 mW

XIN

f

= 2.5MHz, TMR of 16 27 mW

XIN

Sleep Mode 11 mW

N = 2 • REFIN – AINP). If the input is single-ended (AINN or

IN

. (4) Applies after calibration. (5) After system calibration, these errors will be of the order

XIN

/i, where i is 2, 3, 4, etc. (8) Voltages at the analog inputs must remain within AGND to AVDD. (9) The common-

DATA

disabled,V

OUT

(as described in the text).

BIAS

BIAS

disabled,

ABSOLUTE MAXIMUM RATINGS

Analog Input: Current................................................ ±100mA, Momentary

AV

DD

AV

DD

DV

DD

AGND to DGND ................................................................................ ±0.3V

REF

Digital Input Voltage to DGND ..................................–0.3V to DV

Digital Output Voltage to DGND ............................... –0.3V to DV

Lead Temperature (soldering, 10s) .............................................. +300°C

Power Dissipation (Any package) .................................................. 500mW

Voltage ................................... AGND –0.3V to AV

to DVDD...........................................................................–0.3V to 6V

to AGND .........................................................................–0.3V to 6V

to DGND.........................................................................–0.3V to 6V

Voltage to AGND............................................–0.3V to AVDD +0.3V

IN

±10mA, Continuous

DD

DD

DD

+0.3V

+0.3V

+0.3V

ELECTROSTATIC

DISCHARGE SENSITIVITY

This integrated circuit can be damaged by ESD. Burr-Brown

recommends that all integrated circuits be handled with appropriate precautions. Failure to observe proper handling and

installation procedures can cause damage.

Electrostatic discharge can cause damage ranging from

performance degradation to complete device failure. BurrBrown Corporation recommends that all integrated circuits be

handled and stored using appropriate ESD protection

methods.

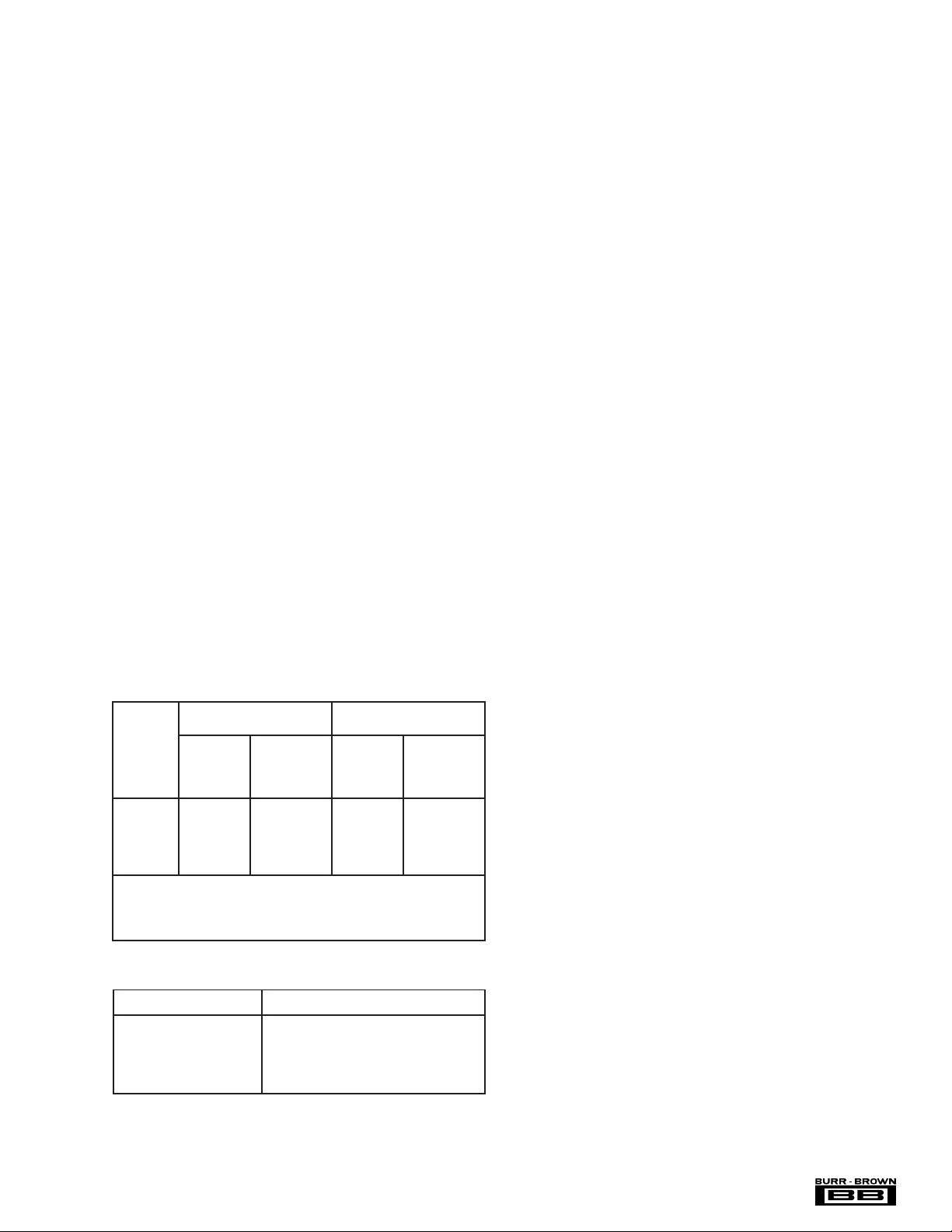

PACKAGE/ORDERING INFORMATION

PACKAGE

DRAWING TEMPERATURE

PRODUCT PACKAGE NUMBER

ADS1210P 18-Pin Plastic DIP 218 –40°C to +85°C

ADS1210U 18-Lead SOIC 219 –40°C to +85°C

ADS1211P 24-Pin Plastic DIP 243 –40°C to +85°C

ADS1211U 24-Lead SOIC 239 –40°C to +85°C

ADS1211E 28-Lead SSOP 324 –40°C to +85°C

NOTE: (1) For detailed drawing and dimension table, please see end of data

sheet, or Appendix C of Burr-Brown IC Data Book.

(1)

RANGE

3 ADS1210, 1211

®

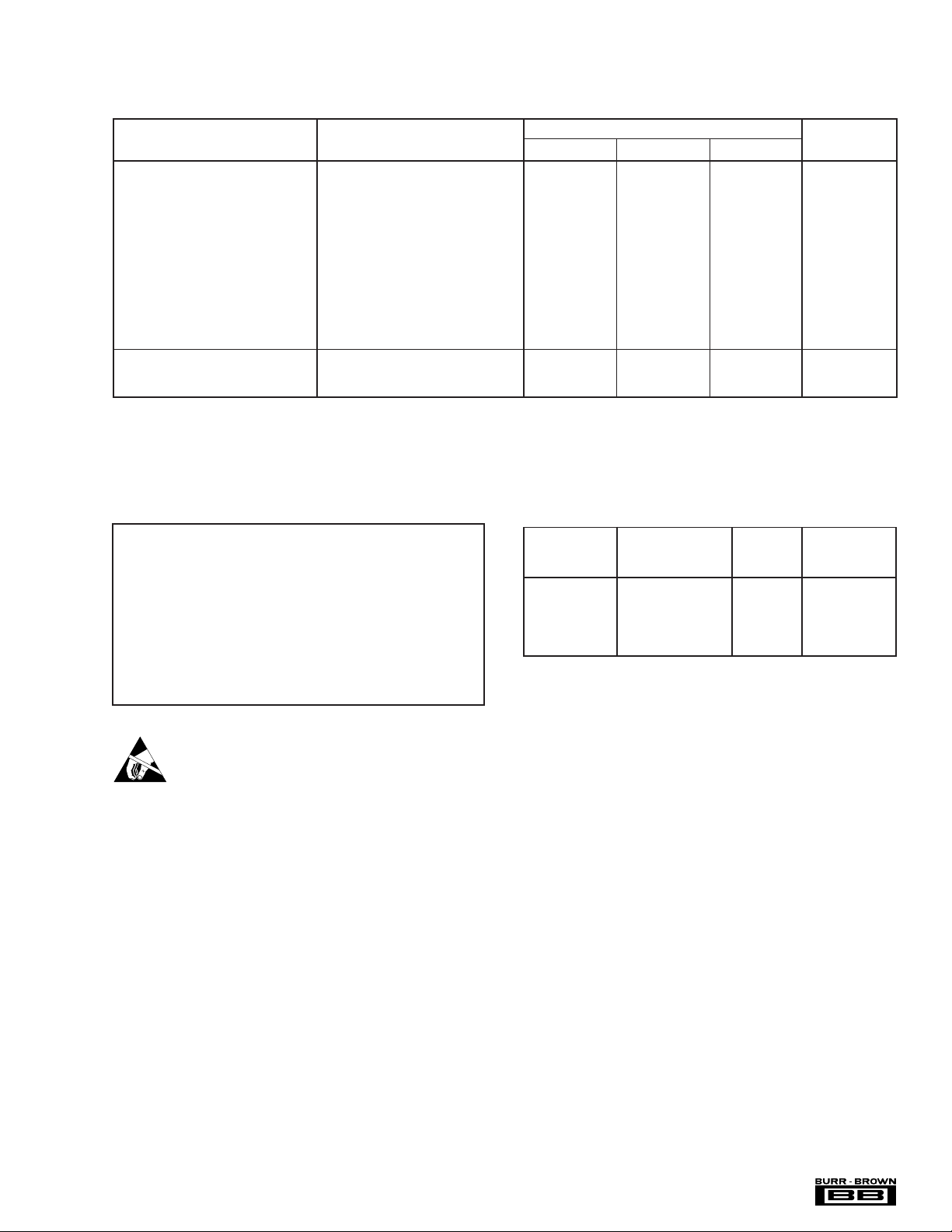

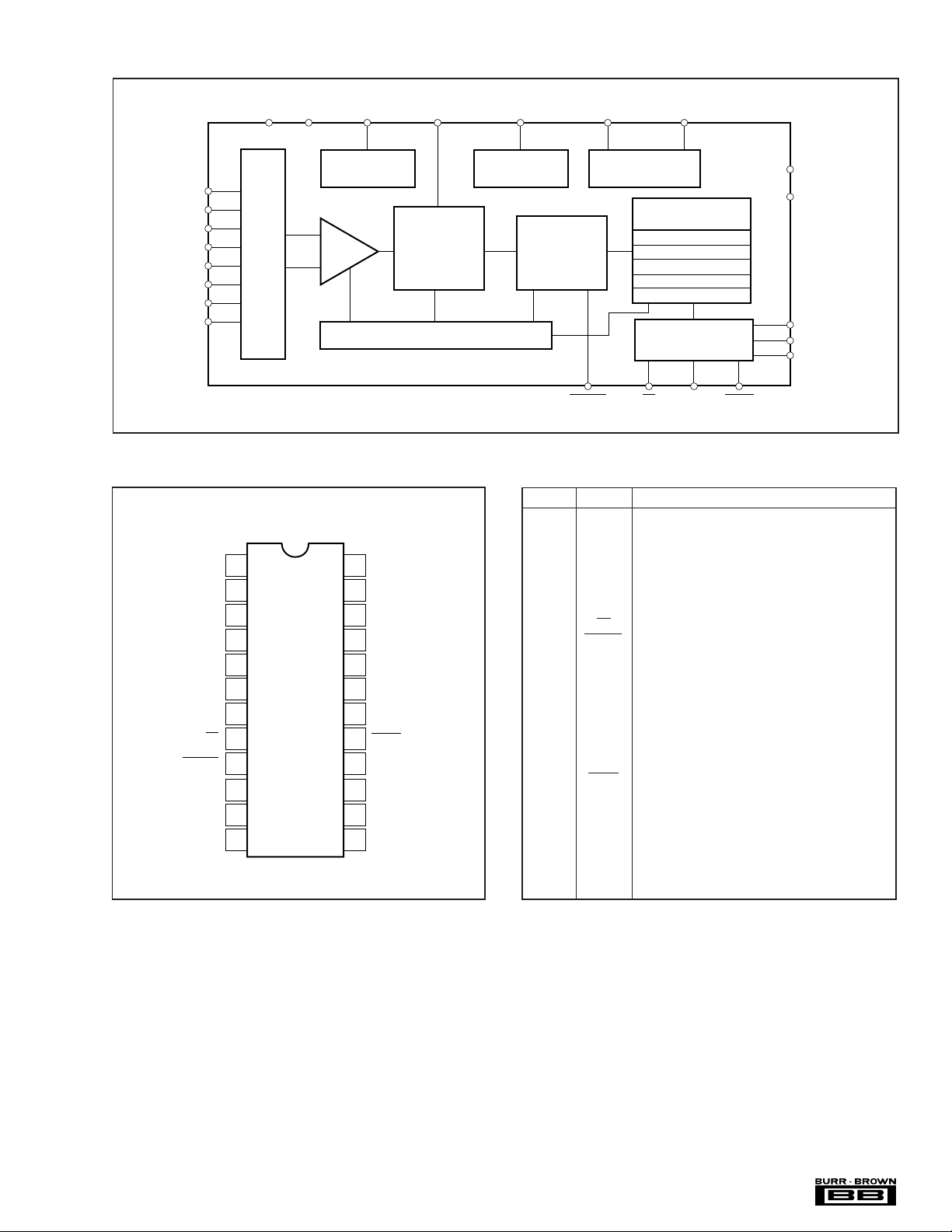

ADS1210 SIMPLIFIED BLOCK DIAGRAM

AGND AV

3

REF

DD

OUT

REF

IN

16 17 18 4 7 8

+2.5V

Reference

1

AINP

A

IN

2

N

PGA

Second-Order

∆Σ

Modulator

Modulator Control

ADS1210 PIN CONFIGURATION

TOP VIEW DIP/SOIC

A

IN

A

IN

AGND

V

BIAS

CS

DSYNC

X

X

OUT

DGND

1

P

2

N

3

4

ADS1210

5

6

7

IN

8

9

18

17

16

15

14

13

12

11

10

REF

IN

REF

OUT

AV

DD

MODE

DRDY

SDOUT

SDIO

SCLK

DV

DD

V

BIAS

+3.3V Bias

Generator

X

IN

Clock Generator

Third-Order

Digital Filter

65 1415

DSYNC CS DRDYMODE

ADS1210 PIN DEFINITIONS

PIN NO NAME DESCRIPTION

1A

2A

3 AGND Analog Ground.

4V

5 CS Chip Select Input.

6 DSYNC Control Input to Synchronize Serial Output Data.

7X

8X

9 DGND Digital Ground.

10 DV

11 SCLK Clock Input/Output for serial data transfer.

12 SDIO Serial Data Input (can also function as Serial Data

13 SDOUT Serial Data Output.

14 DRDY Data Ready.

15 MODE SCLK Control Input (Master = 1, Slave = 0).

16 AV

17 REF

18 REF

P Noninverting Input.

IN

N Inverting Input.

IN

BIAS

IN

OUT

DD

DD

OUT

IN

X

OUT

9

DGND

DV

10

DD

Micro Controller

Instruction Register

Command Register

Data Output Register

Offset Register

Full-Scale Register

11

SCLK

Serial Interface

12

SDIO

13

SDOUT

Bias Voltage Output, +3.3V nominal.

System Clock Input.

System Clock Output (for Crystal or Resonator).

Digital Supply, +5V nominal.

Output).

Analog Supply, +5V nominal.

Reference Output, +2.5V nominal.

Reference Input.

®

ADS1210, 1211

4

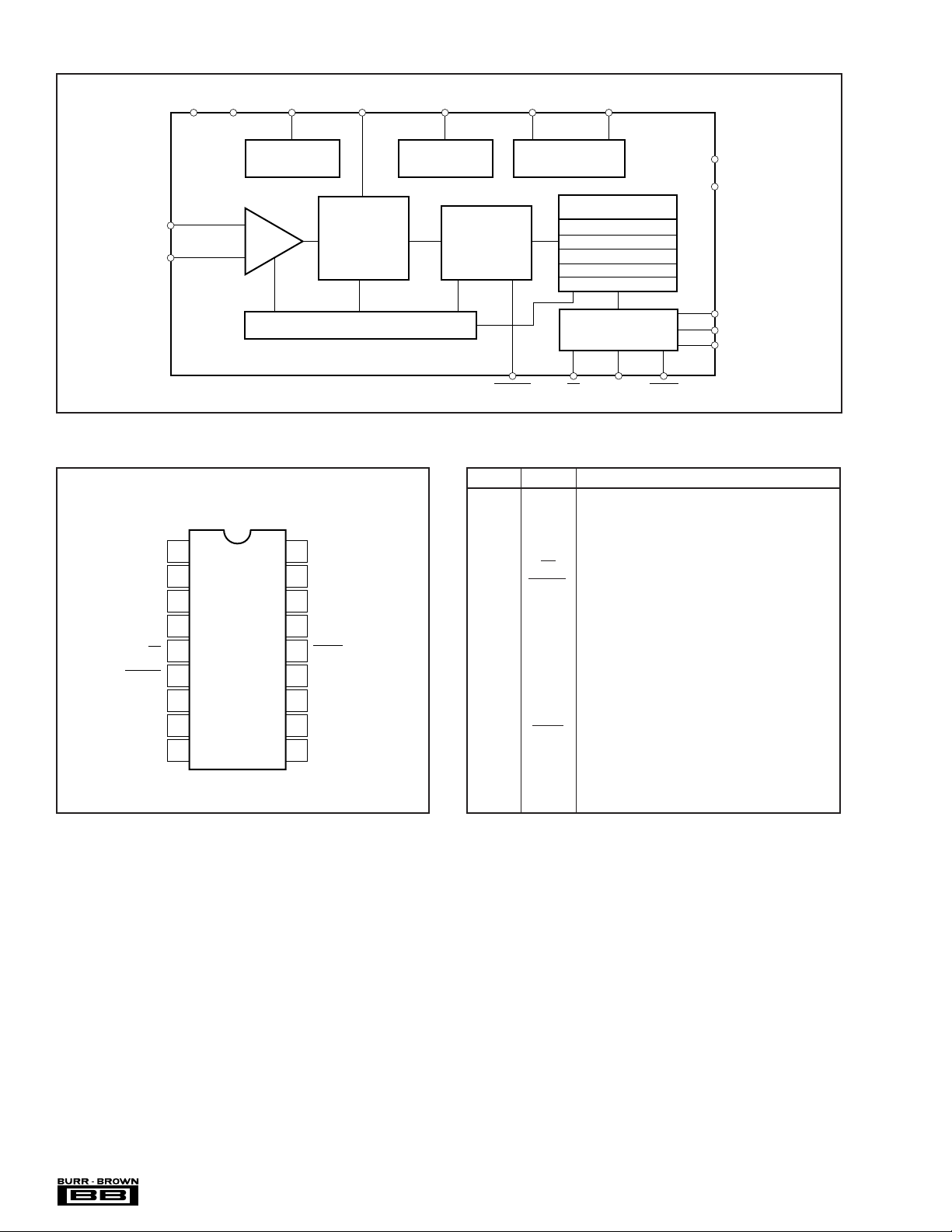

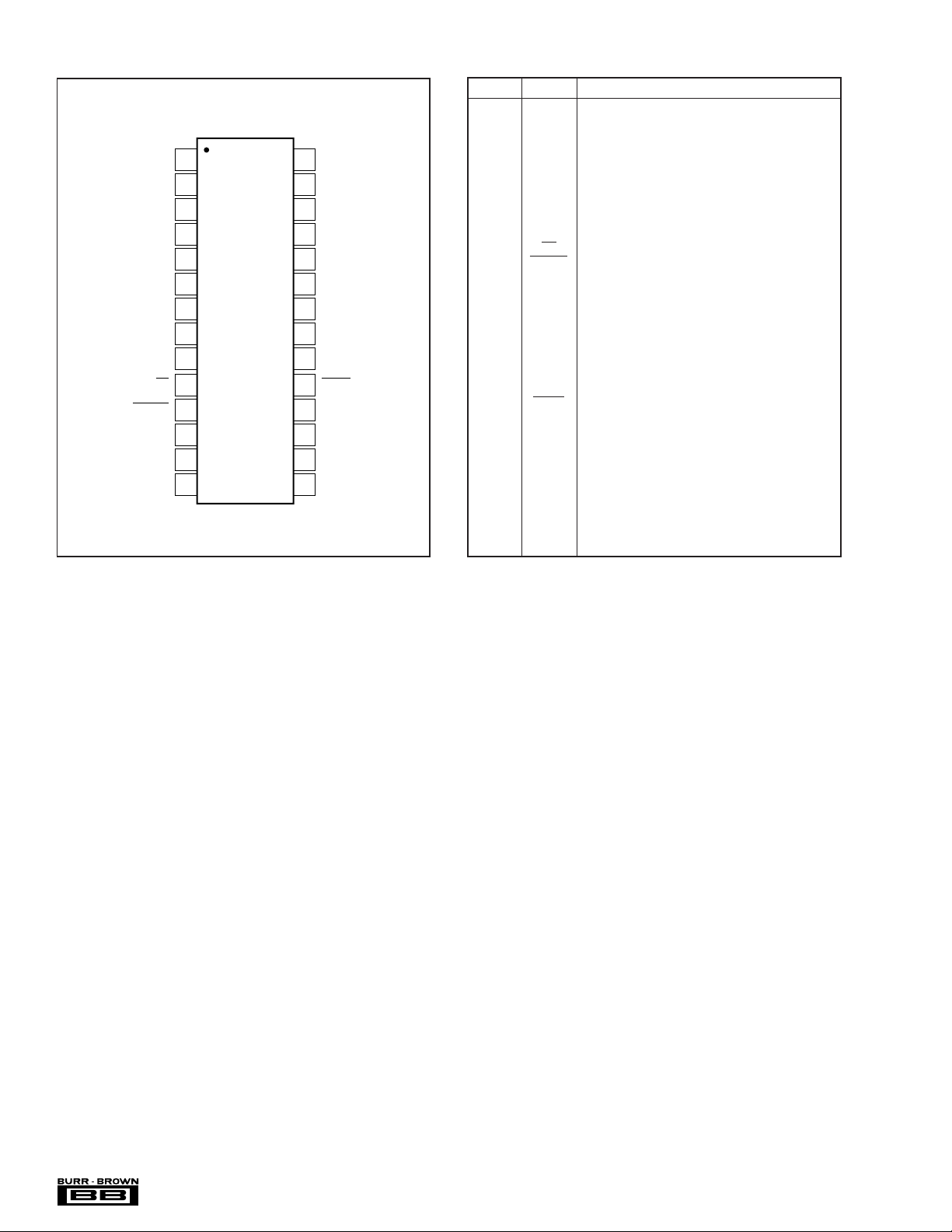

ADS1211 SIMPLIFIED BLOCK DIAGRAM

AGND AV

REF

DD

OUT

REF

IN

6 19 20 21 7 10 11

+2.5V

4

1P

A

IN

5

A

1N

IN

2

A

2P

IN

3

A

2N

IN

A

3P

IN

A

3N

IN

A

4P

IN

A

4N

IN

MUX

24

1

22

23

Reference

PGA

Second-Order

∆∑

Modulator

Modulator Control

ADS1211P AND ADS1211U PIN CONFIGURATION

TOP VIEW DIP/SOIC

A

3N

IN

2P

A

IN

A

2N

IN

A

1P

IN

A

1N

IN

AGND

V

BIAS

CS

DSYNC

X

X

OUT

DGND

1

2

3

4

5

6

ADS1211P

7

ADS1211U

8

9

10

IN

11

12

24

23

22

21

20

19

18

17

16

15

14

13

3P

A

IN

4N

A

IN

A

4P

IN

REF

IN

REF

OUT

AV

DD

MODE

DRDY

SDOUT

SDIO

SCLK

DV

DD

V

BIAS

+3.3V Bias

Generator

X

IN

Clock Generator

X

OUT

12

13

Micro Controller

Third-Order

Digital Filter

Instruction Register

Command Register

Data Output Register

Offset Register

Full-Scale Register

14

Serial Interface

15

16

98 1718

DSYNC CS DRDYMODE

ADS1211P AND ADS1211U PIN DEFINITIONS

PIN NO NAME DESCRIPTION

1AIN3N Inverting Input Channel 3.

2AIN2P Noninverting Input Channel 2.

3A

4A

5AIN1N Inverting Input Channel 1.

6 AGND Analog Ground.

7V

8 CS Chip Select Input.

9 DSYNC Control Input to Synchronize Serial Output Data.

10 X

11 X

12 DGND Digital Ground.

13 DV

14 SCLK Clock Input/Output for serial data transfer.

15 SDIO Serial Data Input (can also function as Serial Data

16 SDOUT Serial Data Output.

17 DRDY Data Ready.

18 MODE SCLK Control Input (Master = 1, Slave = 0).

19 AV

20 REF

21 REF

22 A

23 AIN4N Inverting Input Channel 4.

24 A

2N Inverting Input Channel 2.

IN

1P Noninverting Input Channel 1.

IN

BIAS

OUT

Bias Voltage Output, +3.3V nominal.

System Clock Input.

IN

System Clock Output (for Crystal or Resonator).

Digital Supply, +5V nominal.

DD

Output).

Analog Supply, +5V nominal.

DD

Reference Output: +2.5V nominal.

OUT

Reference Input.

IN

4P Noninverting Input Channel 4.

IN

3P Noninverting Input Channel 3.

IN

DGND

DV

DD

SCLK

SDIO

SDOUT

5 ADS1210, 1211

®

ADS1211E PIN CONFIGURATION

TOP VIEW SSOP

A

3N

IN

A

2P

IN

A

2N

IN

A

1P

IN

A

1N

IN

AGND

V

BIAS

NIC

NIC

CS

DSYNC

X

X

OUT

DGND

1

2

3

4

5

6

7

ADS1211E

8

9

10

11

12

IN

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

3P

A

IN

A

4N

IN

A

4P

IN

REF

IN

REF

OUT

AV

DD

MODE

NIC

NIC

DRDY

SDOUT

SDIO

SCLK

DV

DD

ADS1211E PIN DEFINITIONS

PIN NO NAME DESCRIPTION

1A

2A

3AIN2N Inverting Input Channel 2.

4A

5A

6 AGND Analog Ground.

7V

8 NIC Not Internally Connected.

9 NIC Not Internally Connected.

10 CS Chip Select Input.

11 DSYNC Control Input to Synchronize Serial Output Data.

12 X

13 X

14 DGND Digital Ground.

15 DV

16 SCLK Clock Input/Output for serial data transfer.

17 SDIO Serial Data Input (can also function as Serial Data

18 SDOUT Serial Data Output.

19 DRDY Data Ready.

20 NIC Not Internally Connected.

21 NIC Not Internally Connected.

22 MODE SCLK Control Input (Master = 1, Slave = 0).

23 AV

24 REF

25 REF

26 A

27 AIN4N Inverting Input Channel 4.

28 A

3N Inverting Input Channel 3.

IN

2P Noninverting Input Channel 2.

IN

1P Noninverting Input Channel 1.

IN

1N Inverting Input Channel 1.

IN

BIAS

Bias Voltage Output, +3.3V nominal.

System Clock Input.

IN

System Clock Output (for Crystal or Resonator).

OUT

Digital Supply, +5V nominal.

DD

Output).

Analog Supply, +5V nominal.

DD

Reference Output: +2.5V nominal.

OUT

Reference Input.

IN

4P Noninverting Input Channel 4.

IN

3P Noninverting Input Channel 3.

IN

®

ADS1210, 1211

6

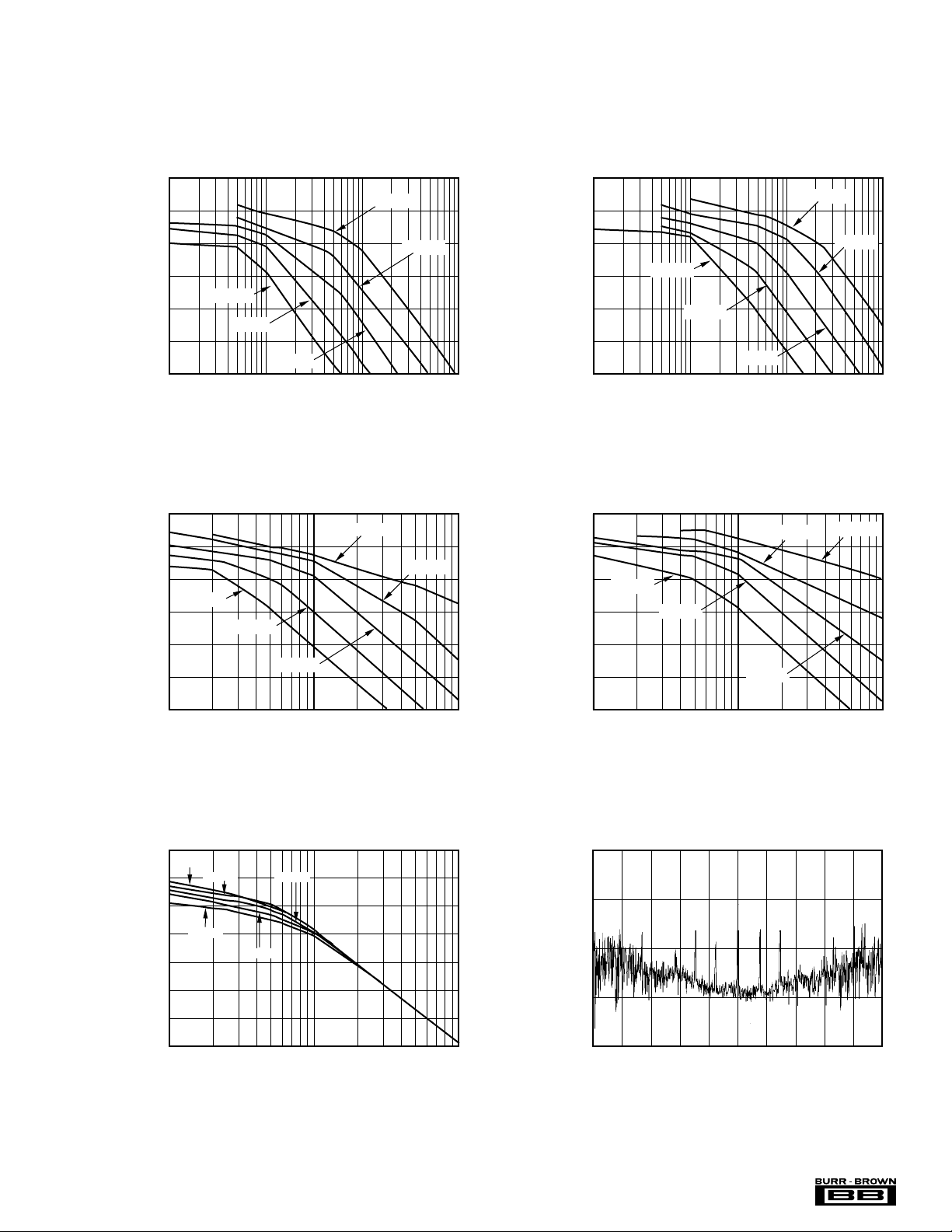

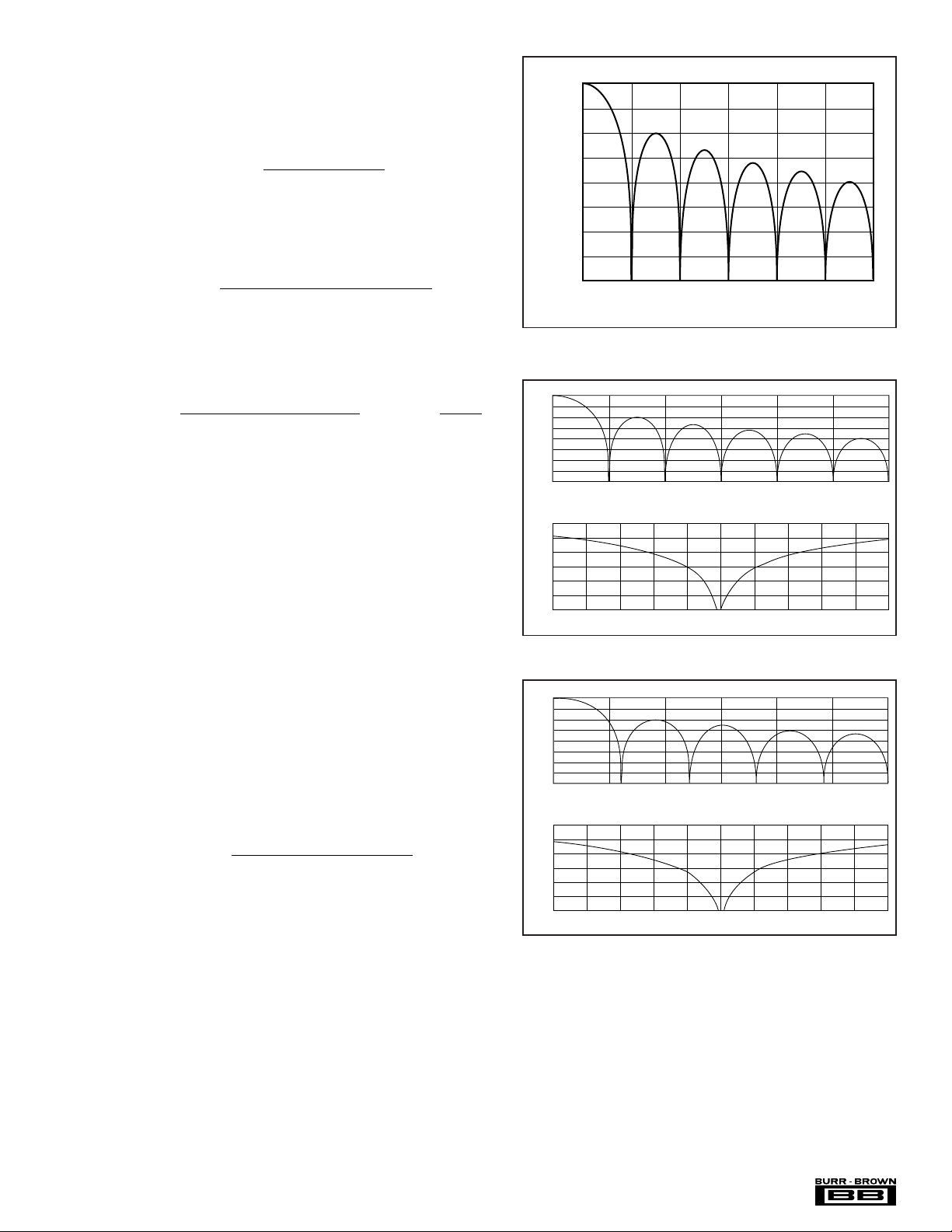

TYPICAL PERFORMANCE CURVES

At TA = +25°C, AVDD = DV

2.5V reference, unless otherwise noted.

DD =

+5V, f

= 10MHz, programmable gain amplifier setting of 1, Turbo Mode Rate of one, REF

XIN

disabled, V

OUT

disabled, and external

BIAS

EFFECTIVE RESOLUTION vs DATA RATE

24

22

20

18

16

14

Effective Resolution in Bits (rms)

12

24

22

20

18

16

14

Effective Resolution in Bits (rms)

12

10 100 1k

Turbo 1

Turbo 2

1 10 100 1k

EFFECTIVE RESOLUTION vs DATA RATE

Turbo 1

(1MHz Clock)

Turbo 16

Turbo 4

Data Rate (Hz)

(5MHz Clock)

Turbo 16

Turbo 2

Turbo 4

Data Rate (Hz)

Turbo 8

Turbo 8

EFFECTIVE RESOLUTION vs DATA RATE

24

22

20

18

16

14

Effective Resolution in Bits (rms)

12

1 10 100 1k

24

22

20

18

16

14

Effective Resolution in Bits (rms)

12

10 100 1k

Turbo 1

EFFECTIVE RESOLUTION vs DATA RATE

Turbo 1

(2.5MHz Clock)

Turbo 16

Turbo 2

Turbo 4

Data Rate (Hz)

(10MHz Clock)

Turbo 8

Turbo 2

Turbo 4

Data Rate (Hz)

Turbo 8

Turbo 16

24

22

20

18

16

14

12

Effective Resolution in Bits (rms)

10

EFFECTIVE RESOLUTION vs DATA RATE

PGA 1

PGA 2 PGA 4

PGA 16

PGA 8

10

Data Rate (Hz)

100 1k

RMS NOISE vs INPUT VOLTAGE LEVEL

2.5

2.0

1.5

RMS Noise (ppm)

1.0

0.5

–5.0 –4.0 –3.0 –2.0 –1.0 0 1.0 2.0 3.0 4.0 5.0

(60Hz Data Rate)

Analog Input Differential Voltage (V)

7 ADS1210, 1211

®

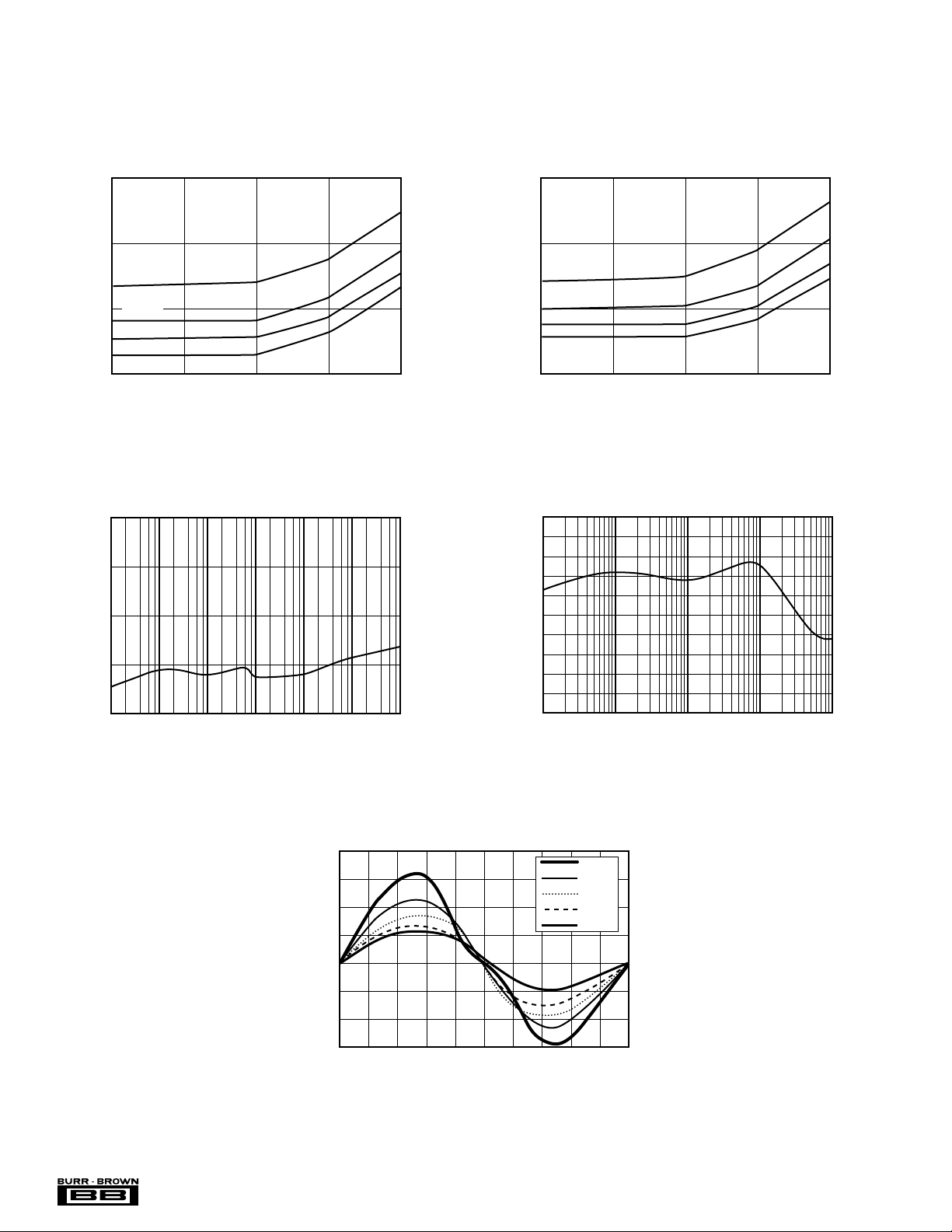

TYPICAL PERFORMANCE CURVES (CONT)

At TA = +25°C, AVDD = DV

2.5V reference, unless otherwise noted.

DD =

+5V, f

= 10MHz, programmable gain amplifier setting of 1, Turbo Mode Rate of 1, REF

XIN

disabled, V

OUT

disabled, and external

BIAS

POWER DISSIPATION vs TURBO MODE RATE

50.0

40.0

10MHz

30.0

Power Dissipation (mW)

20.0

85.0

80.0

5MHz

2.5MHz

1MHz

124816

(REF

Enabled)

OUT

Turbo Mode Rate

PSRR vs FREQUENCY

POWER DISSIPATION vs TURBO MODE RATE

40.0

30.0

10MHz

20.0

Power Dissipation (mW)

10.0

120.0

5MHz

2.5MHz

1MHz

124816

(External Reference; REF

Turbo Mode Rate

CMRR vs FREQUENCY

OUT

)

75.0

PSRR (dB)

70.0

65.0

0.1 1 10 100

Frequency (Hz)

115.0

CMRR (dB)

110.0

1k 10k 100k

LINEARITY vs TEMPERATURE

8

6

4

2

0

–2

Integral Nonlinearity (ppm)

–4

–6

–5 –4 –3 –2 –1 0 1 2 3 4 5

(60Hz Data Rate)

Analog Input Differential Voltage (V)

0.1 1 10

100 1k

Frequency (Hz)

–40°C

–5°C

+25°C

+55°C

+85°C

®

ADS1210, 1211

8

THEORY OF OPERATION

The ADS1210 and ADS1211 are precision, high dynamic

range, self-calibrating, 24-bit, delta-sigma A/D converters

capable of achieving very high resolution digital results.

Each contains a programmable gain amplifier (PGA); a

second-order delta-sigma modulator; a programmable digital filter; a microcontroller including the Instruction, Command and Calibration registers; a serial interface; a clock

generator circuit; and an internal 2.5V reference. The

ADS1211 includes a 4-channel input multiplexer.

In order to provide low system noise, common-mode rejection of 115dB and excellent power supply rejection, the

design topology is based on a fully differential switched

capacitor architecture. Turbo Mode, a unique feature of the

ADS1210/11, can be used to boost the sampling rate of the

input capacitor, which is normally 19.5kHz with a 10MHz

clock. By programming the Command Register, the sampling rate can be increased to 39kHz, 78kHz, 156kHz, or

312kHz. Each increase in sample rate results in an increase

in performance when maintaining the same output data rate.

The programmable gain amplifier (PGA) of the ADS1210/

11 can be set to a gain of 1, 2, 4, 8 or 16—substantially

increasing the dynamic range of the converter and simplifying the interface to the more common transducers (see Table

I). This gain is implemented by increasing the number of

samples taken by the input capacitor from 19.5kHz for a

gain of 1 to 312kHz for a gain of 16. Since the Turbo Mode

and PGA functions are both implemented by varying the

sampling frequency of the input capacitor, the combination

of PGA gain and Turbo Mode Rate is limited to 16 (see

Table II). For example, when using a Turbo Mode Rate of

8 (156kHz at 10MHz), the maximum PGA gain setting is 2.

ANALOG ANALOG INPUT

(1)

INPUT

FULL- EXAMPLE FULL- EXAMPLE

GAIN RANGE RANGE

SETTING (V) (V) (V) (V)

1 10 0 to 5 40 ±10

2 5 1.25 to 3.75 20 ±5

4 2.5 1.88 to 3.13 10 ±2.5

8 1.25 2.19 to 2.81 5 ±1.25

16 0.625 2.34 to 2.66 2.5 ±0.625

NOTE: (1) With a 2.5V reference, such as the internal reference. (2) This

example utilizes the circuit in Figure 12. Other input ranges are possible. (3)

The ADS1210/11 allows common-mode voltage as long as the absolute

input voltage on A

SCALE VOLTAGE SCALE VOLTAGE

P or AINN does not go below AGND or above AVDD.

IN

UTILIZING V

(3)

RANGE RANGE

BIAS

(1,2)

(3)

TABLE I. Full-Scale Range vs PGA Setting.

TURBO MODE RATE AVAILABLE PGA SETTINGS

1 1, 2, 4, 8, 16

2 1, 2, 4, 8

4 1, 2, 4

8 1, 2

16 1

The output data rate of the ADS1210/11 can be varied from

a few hertz to as much as 15,625kHz, trading off lower

resolution results for higher data rates. In addition, the data

rate determines the first null of the digital filter and sets the

–3dB point of the input bandwidth (see the Digital Filter

section). Changing the data rate of the ADS1210/11 does not

result in a change in the sampling rate of the input capacitor.

The data rate effectively sets the number of samples which

are used by the digital filter to obtain each conversion result.

A lower data rate results in higher resolution, lower input

bandwidth, and different notch frequencies than a higher

data rate. It does not result in any change in input impedance

or modulator frequency, or any appreciable change in power

consumption.

The ADS1210/11 also includes complete on-board calibration that can correct for internal offset and gain errors or

limited external system errors. Internal calibration can be

run when needed, or automatically and continuously in the

background. System calibration can be run as needed and the

appropriate input voltages must be provided to the ADS1210/

11. For this reason, there is no continuous System Calibration Mode. The calibration registers are fully readable and

writable. This feature allows for switching between various

configurations—different data rates, Turbo Mode Rates, and

gain settings—without re-calibrating.

The various settings, rates, modes, and registers of the

ADS1210/11 are read or written via a synchronous serial

interface. This interface can operate in either a self-clocked

mode (Master Mode) or an externally clocked mode (Slave

Mode). In the Master Mode, the serial clock (SCLK) frequency is one-half of the ADS1210/11 XIN clock frequency.

This is an important consideration for many systems and

may determine the maximum ADS1210/11 clock that can be

used.

The high resolution and flexibility of the ADS1210/11 allow

these converters to fill a wide variety of A/D conversion

tasks. In order to ensure that a particular configuration will

meet the design goals, there are several important items

which must be considered. These include (but are certainly

not limited to) the needed resolution, required linearity,

desired input bandwidth, power consumption goal, and sensor output voltage.

The remainder of this data sheet discusses the operation of

the ADS1210/11 in detail. In order to allow for easier

comparison of different configurations, “effective resolution” is used as the figure of merit for most tables and

graphs. For example, Table III shows a comparison between

data rate (and –3dB input bandwidth) versus PGA setting at

a Turbo Mode Rate of 1 and a clock rate of 10MHz. See the

Definition of Terms section for a definition of effective

resolution.

TABLE II. Available PGA Settings vs Turbo Mode Rate.

®

9 ADS1210, 1211

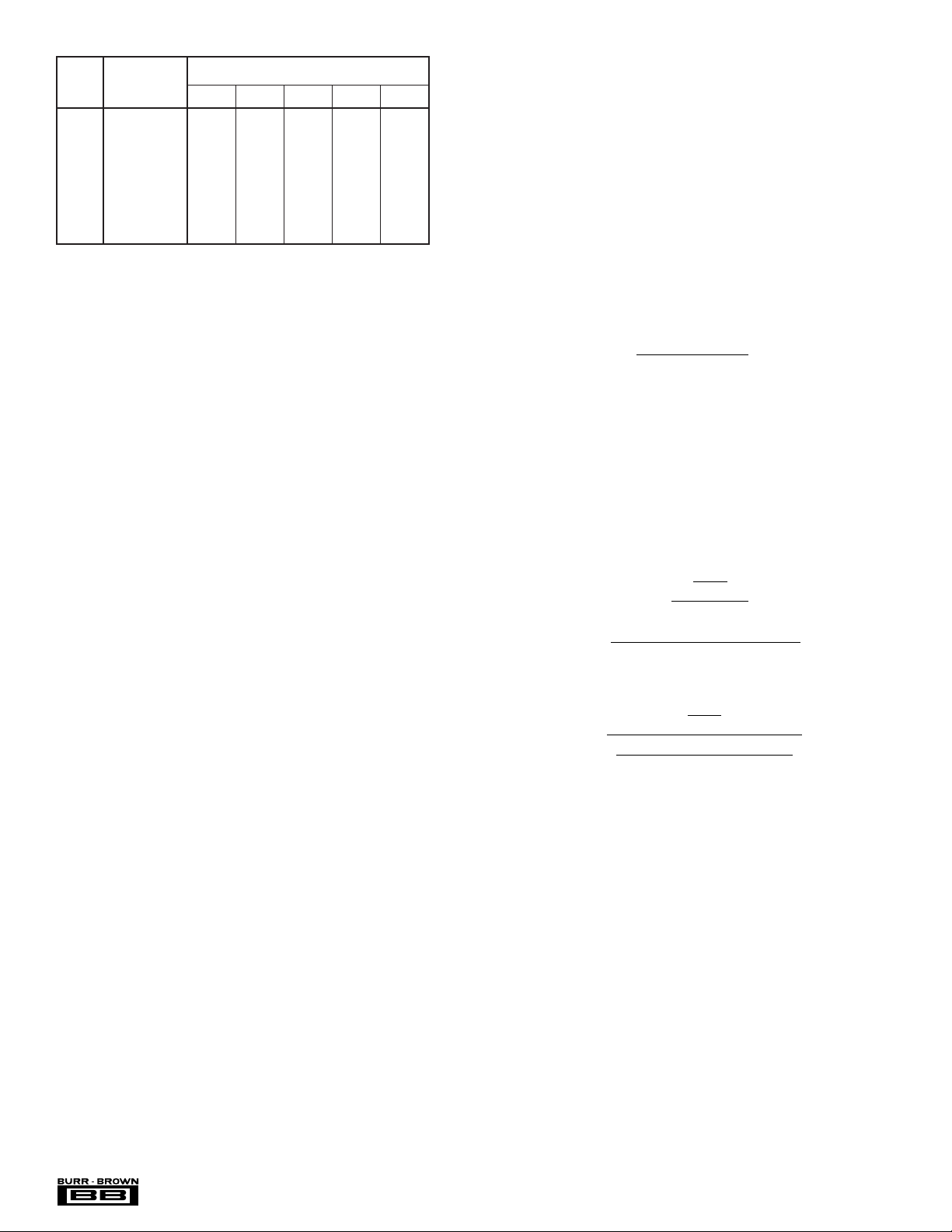

DATA -3DB

RATE FREQUENCY

(HZ) (HZ) G = 1 G = 2 G = 4 G = 8 G = 16

10 2.62 21.5 21.0 21.0 21.0 20.0

25 6.55 20.5 20.5 20.5 20.0 19.5

30 7.86 20.5 20.5 20.5 20.0 19.5

50 13.1 20.0 20.0 20.0 19.5 19.0

60 15.7 19.5 19.5 19.5 19.0 19.0

100 26.2 18.0 18.0 18.0 18.0 18.0

250 65.5 15.0 15.0 15.0 15.0 15.0

500 131 12.5 12.5 12.5 12.5 12.5

1000 262 10.0 10.5 10.0 10.0 10.0

EFFECTIVE RESOLUTION (BITS RMS)

TABLE III. Effective Resolution vs Data Rate and Gain

Setting. (Turbo Mode Rate of 1 and a 10MHz

clock.)

DEFINITION OF TERMS

An attempt has been made to be consistent with the terminology used in this data sheet. In that regard, the definition

of each term is given as follows:

Analog Input Differential Voltage—For an analog signal

that is fully differential, the voltage range can be compared

to that of an instrumentation amplifier. For example, if both

analog inputs of the ADS1210 are at 2.5V, then the differential voltage is 0V. If one is at 0V and the other at 5V, then

the differential voltage magnitude is 5V. But, this is the case

regardless of which input is at 0V and which is at 5V, while

the digital output result is quite different.

The analog input differential voltage is given by the following equation: AINP – AINN. Thus, a positive digital output is

produced whenever the analog input differential voltage is

positive, while a negative digital output is produced whenever the differential is negative.

For example, when the converter is configured with a 2.5V

reference and placed in a gain setting of 2, the positive fullscale output is produced when the analog input differential

is 2.5V. The negative full-scale output is produced when the

differential is –2.5V. In each case, the actual input voltages

must remain within the AGND to AVDD range (see Table I).

Actual Analog Input Voltage—The voltage at any one

analog input relative to AGND.

Full-Scale Range (FSR)—As with most A/D converters,

the full-scale range of the ADS1210/11 is defined as the

“input” which produces the positive full-scale digital output

minus the “input” which produces the negative full-scale

digital output.

For example, when the converter is configured with a 2.5V

reference and is placed in a gain setting of 2, the full-scale

range is: [2.5V (positive full scale) minus –2.5V (negative

full scale)] = 5V.

Typical Analog Input Voltage Range—This term describes the actual voltage range of the analog inputs which

will cover the converter’s full-scale range, assuming that

each input has a common-mode voltage that is greater than

REFIN/PGA and smaller than (AVDD – REFIN/PGA).

For example, when the converter is configured with a 2.5V

reference and placed in a gain setting of 2, the typical input

voltage range is 1.25V to 3.75V. However, an input range of

0V to 2.5V or 2.5V to 5V would also cover the converter’s

full-scale range.

Voltage Span—This is simply the magnitude of the typical

analog input voltage range. For example, when the converter

is configured with a 2.5V reference and placed in a gain

setting of 2, the input voltage span is 2.5V.

Least Significant Bit (LSB) Weight—This is the theoretical amount of voltage that the differential voltage at the

analog input would have to change in order to observe a

change in the output data of one least significant bit. It is

computed as follows:

LSB Weight =

Full−Scale Range

N

2

where N is the number of bits in the digital output.

Effective Resolution—The effective resolution of the

ADS1210/11 in a particular configuration can be expressed

in two different units: bits rms (referenced to output) and

microvolts rms (referenced to input). Computed directly

from the converter’s output data, each is a statistical calculation based on a given number of results. Knowing one, the

other can be computed as follows:

10V

ER in bits rms =

ER in Vrms =

20• log

PGA

ER in Vrms

6.02

10V

PGA

6.02•ER in bits rms +1.76

10

20

−1.76

The 10V figure in each calculation represents the full-scale

range of the ADS1210/11 in a gain setting of 1. This means

that both units are absolute expressions of resolution—the

performance in different configurations can be directly compared regardless of the units. Comparing the resolution of

different gain settings expressed in bits rms requires accounting for the PGA setting.

Main Controller—A generic term for the external

microcontroller, microprocessor, or digital signal processor

which is controlling the operation of the ADS1210/11 and

receiving the output data.

®

ADS1210, 1211

10

f

FILTER RESPONSE

Frequency (Hz)

–40

–60

–80

–100

–120

–140

–160

55 56 57 58 59 60 61 62 63 64 65

FILTER RESPONSE

Frequency (Hz)

0

–20

–40

–60

–80

–100

–120

–140

–160

0 50 100 150 200 250 300

Gain (dB) Gain (dB)

—The frequency of the crystal oscillator or CMOS

XIN

compatible input signal at the XIN input of the ADS1210/11.

f

—The frequency or speed at which the modulator of the

MOD

ADS1210/11 is running, given by the following equation:

•Turbo Mode

f

f

MOD

f

—The frequency or switching speed of the input

SAMP

XIN

=

512

sampling capacitor. The value is given by the following

equation:

•Turbo Mode• Gain Setting

f

XIN

=

512

—The frequency of the digital output data

f

DATA

, t

f

SAMP

DATA

produced by the ADS1210/11 or the inverse of this (the

period), respectively, f

f

f

DATA

=

XIN

512• DecimationRatio +1

()

is also referred to as the data rate.

DATA

•Turbo Mode

,t

DATA

1

=

f

DATA

Conversion Cycle—The term “conversion cycle” usually

refers to a discrete A/D conversion operation, such as that

performed by a successive approximation converter. As

used here, a conversion cycle refers to the t

time period.

DATA

However, each digital output is actually based on the modulator results from the last three t

time periods.

DATA

DIGITAL FILTER

The digital filter of the ADS1210/11 computes the output

result based on the most recent results from the delta-sigma

modulator. The number of modulator results that are used

depend on the decimation ratio set in the Command Register. At the most basic level, the digital filter can be thought

of as simply averaging the modulator results and presenting

this average as the digital output.

While the decimation ratio determines the number of modulator results to use, the modulator runs faster at higher Turbo

Modes. These two items, together with the ADS1210/11

clock frequency, determine the output data rate:

0

–20

–40

–60

–80

Gain (dB)

–100

–120

–140

–160

NORMALIZED DIGITAL FILTER RESPONSE

0123456

Frequency (Hz)

FIGURE 1. Normalized Digital Filter Response.

0

–20

–40

–60

–80

–100

Gain (dB)

–120

–140

–160

0 50 100 150 200 250 300

–40

–60

–80

–100

Gain (dB)

–120

–140

–160

45 46 47 48 49 50 51 52 53 54 55

FILTER RESPONSE

Frequency (Hz)

FILTER RESPONSE

Frequency (Hz)

FIGURE 2. Digital Filter Response at a Data Rate of 50Hz.

•Turbo Mode

f

f

DATA

=

XIN

512• Decimation Ratio +1

()

Also, since the conversion result is essentially an average,

the data rate determines where the resulting notches are in

the digital filter. For example, if the output data rate is 1kHz,

then a 1kHz input frequency will average to zero during the

1ms conversion cycle. Likewise, a 2kHz input frequency

will average to zero, etc.

In this manner, the data rate can be used to set specific notch

frequencies in the digital filter response (see Figure 1 for the

normalized response of the digital filter). For example, if the

rejection of power line frequencies is desired, then the data

rate can simply be set to the power line frequency. Figures

2 and 3 show the digital filter response for a data rate of

50Hz and 60Hz, respectively.

FIGURE 3. Digital Filter Response at a Data Rate of 60Hz.

If the effective resolution at a 50Hz or 60Hz data rate is not

adequate for the particular application, then power line frequencies could still be rejected by operating the ADS1210/11

at 25/30Hz, 16.7/20Hz, 12.5/15Hz, etc. If a higher data rate

is needed, then power line frequencies must either be rejected

before conversion (with an analog notch filter) or after

conversion (with a digital notch filter running on the main

controller).

®

11 ADS1210, 1211

Filter Equation

The digital filter is described by the following transfer

function:

3

|H(f)|=

sin

N •sin

π•f • N

f

MOD

π•f

f

MOD

where N is the Decimation Ratio.

This filter has a (sin(x)/x)3 response and is referred to a sinc

filter. For the ADS1210/11, this type of filter allows the data

rate to be changed over a very wide range (nearly four orders

of magnitude). However, the –3dB point of the filter is 0.262

times the data rate. And, as can be seen in Figures 1 and 2,

the rejection in the stopband (frequencies higher than the

first notch frequency) may only be –40dB.

These factors must be considered in the overall system

design. For example, with a 50Hz data rate, a significant

signal at 75Hz may alias back into the passband at 25Hz.

The analog front end can be designed to provide the needed

attenuation to prevent aliasing, or the system may simply

provide this inherently. Another possibility is increasing the

data rate and then post filtering with a digital filter on the

main controller.

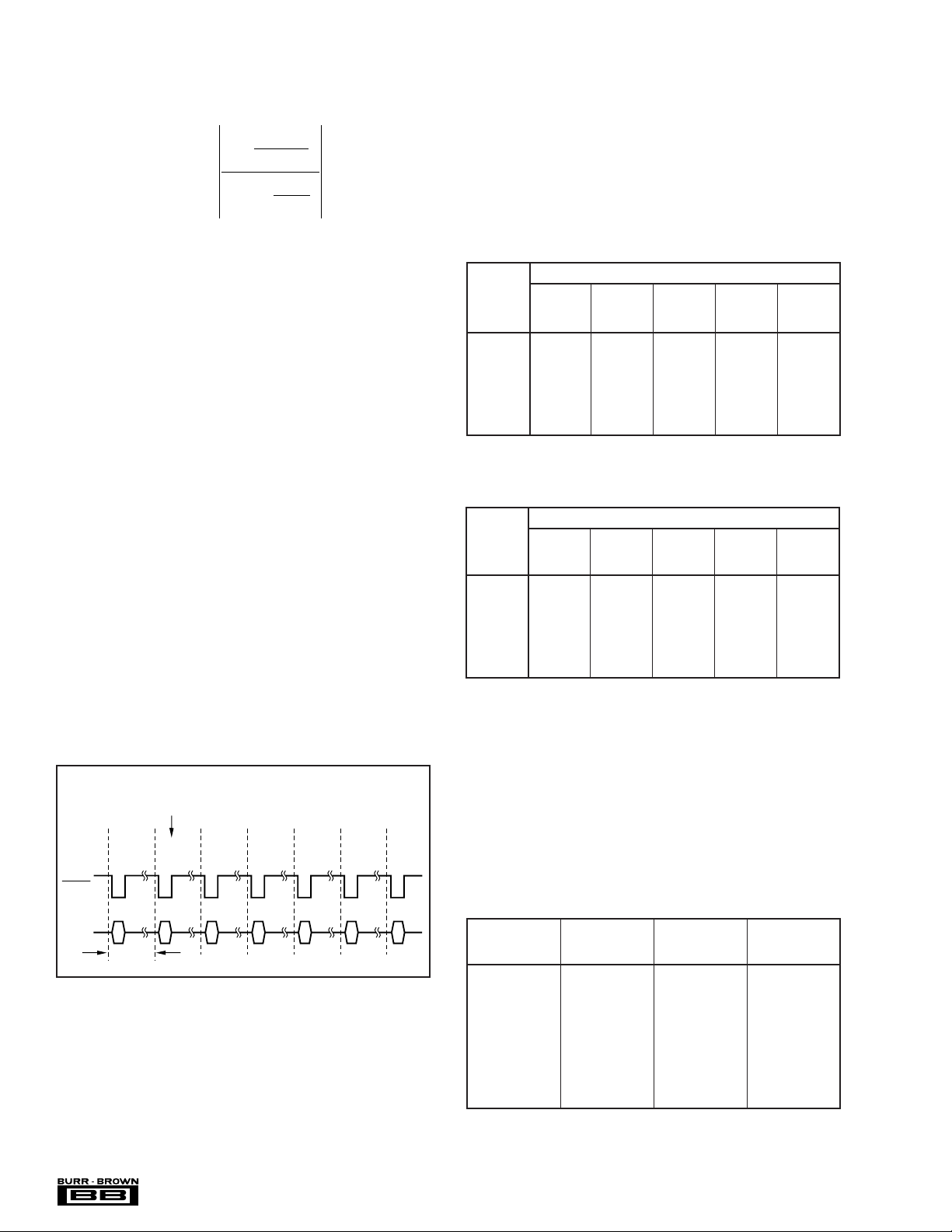

Filter Settling

The number of modulator results used to compute each

conversion result is three times the Decimation Ratio. This

means that any step change (or any channel change for the

ADS1211) will require at least three conversions to fully

settle. However, if the change occurs asynchronously, then at

least four conversions are required to ensure complete settling. For example, on the ADS1211, the fourth conversion

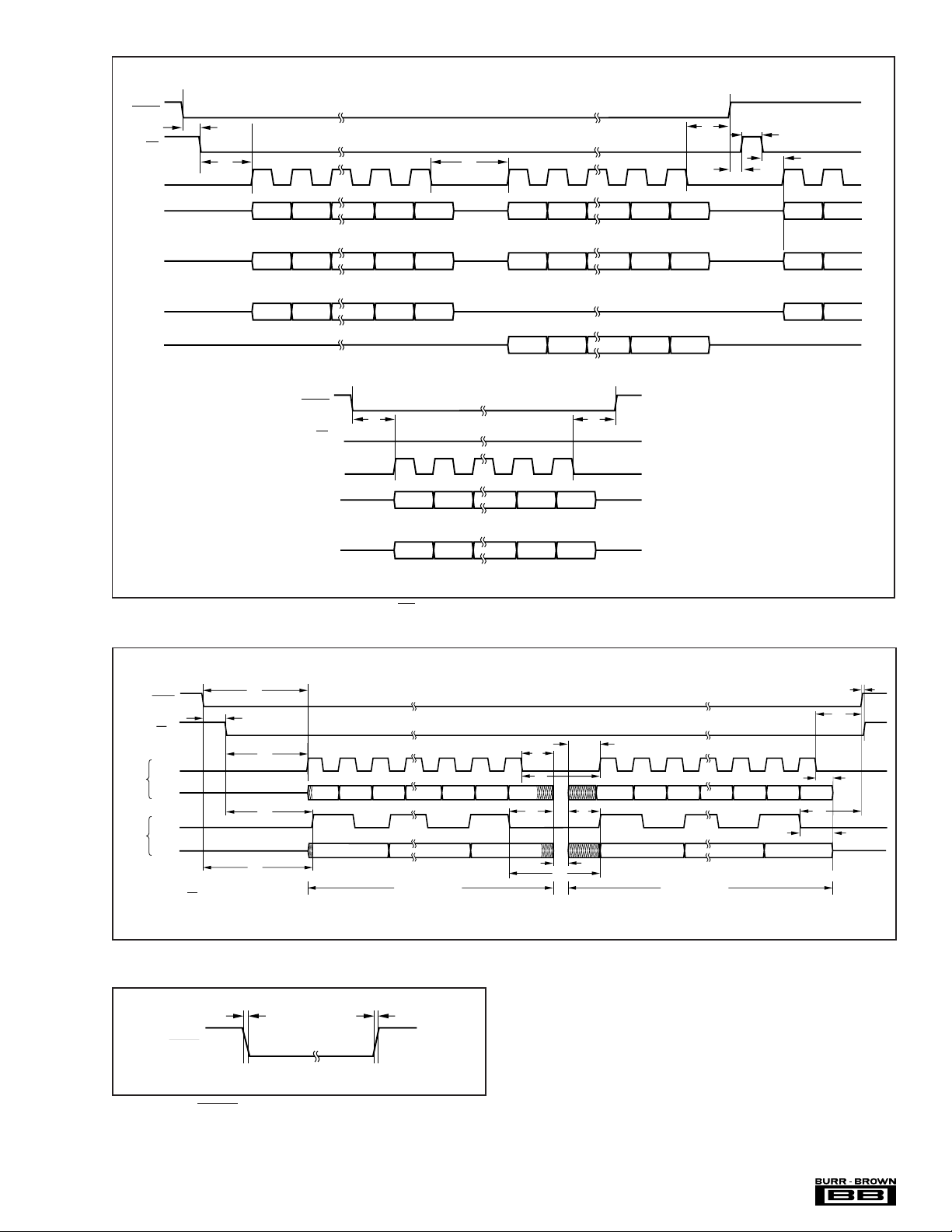

result after a channel change will be valid (see Figure 4).

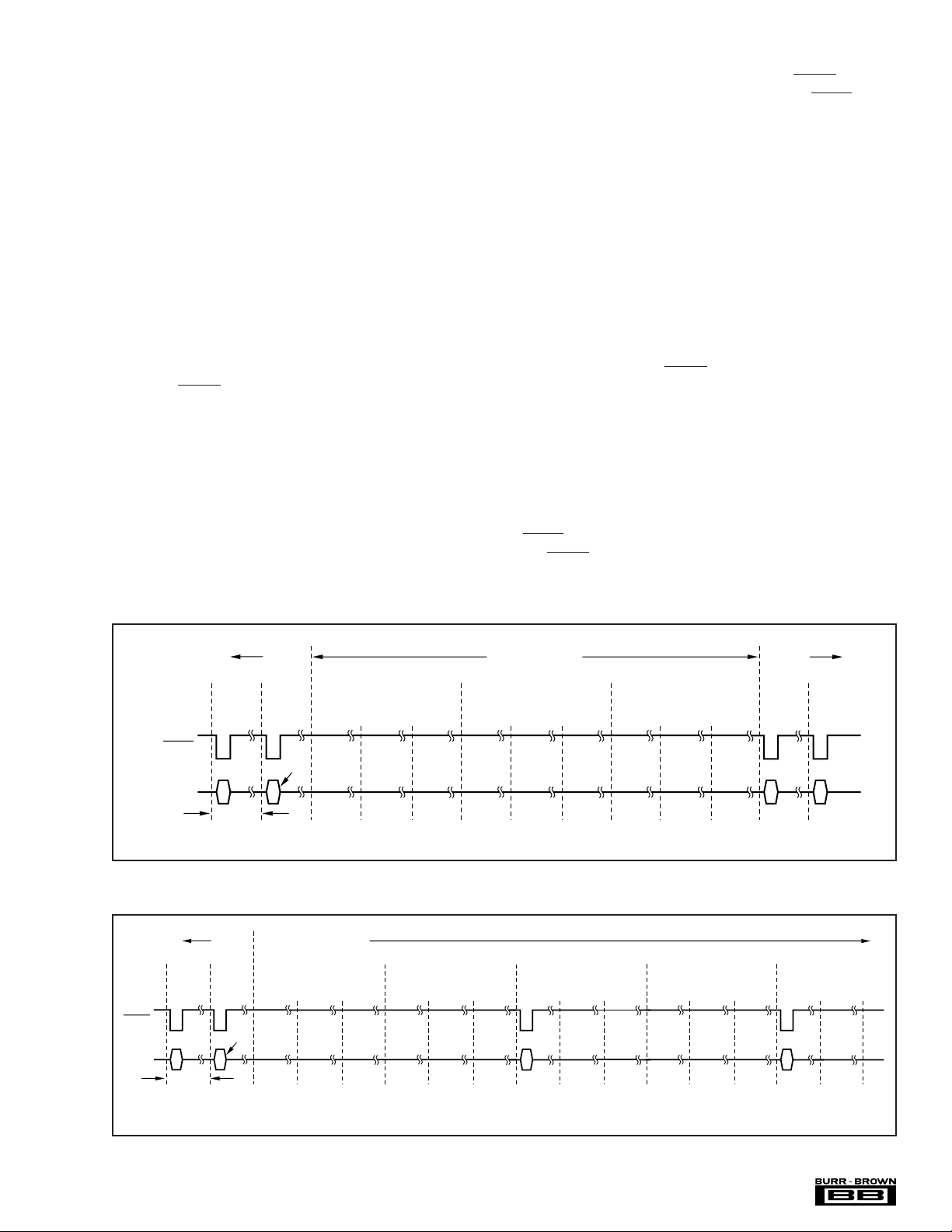

Significant Analog Input Change

ADS1211 Channel Change

Valid

Data

DRDY

or

Valid

Data

Data

not

Valid

Data

not

Valid

Data

not

Valid

Valid

Data

Valid

Data

the effective resolution of the output data at a given data rate,

but there is also an increase in power dissipation. For Turbo

Mode Rates 2 and 4, the increase is slight. For rates 8 and

16, the increase is more substantial. See the Typical Performance Curves for more information.

In a Turbo Mode Rate of 16, the ADS1210/11 can offer 20

bits of effective resolution at a 1kHz data rate. A comparison

of effective resolution versus Turbo Mode Rates and output

data rates is shown in Table IV while Table V shows the

corresponding noise level in µVrms.

3

Data Turbo Turbo Turbo Turbo Turbo

Rate Mode Mode Mode Mode Mode

(Hz) Rate 1 Rate 2 Rate 4 Rate 8 Rate 16

10 21.5 22.0 22.5

20 21.0 22.0 22.0 22.5

40 20.0 21.5 22.0 22.5 23.0

50 20.0 21.5 21.5 22.0 23.0

60 19.5 21.0 21.5 22.0 23.0

100 18.0 20.0 21.0 21.5 22.5

1000 10.0 12.5 15.0 17.5 20.0

Effective Resolution (Bits rms)

TABLE IV. Effective Resolution vs Data Rate and Turbo Mode

Rate. (Gain setting of 1 and 10MHz clock.)

NOISE LEVEL (µVrms)

DATA TURBO TURBO TURBO TURBO TURBO

RATE MODE MODE MODE MODE MODE

(Hz) RATE 1 RATE 2 RATE 4 RATE 8 RATE 16

10 2.9 1.7 1.3

20 4.3 2.1 1.7 1.3

40 6.9 3.0 2.3 1.6 1.0

50 8.1 3.2 2.4 1.8 1.0

60 10.5 3.9 2.6 1.9 1.0

100 26.9 6.9 3.5 2.7 1.4

1000 6909.7 1354.5 238.4 46.6 7.8

TABLE V. Noise Level vs Data Rate and Turbo Mode Rate.

(Gain setting of 1 and 10MHz clock.)

The Turbo Mode feature allows trade-offs to be made

between the ADS1210/11 XIN clock frequency, power dissipation, and effective resolution. If a 5MHz clock is available

but a 10MHz clock is needed to achieve the desired performance, a Turbo Mode Rate of 2X will result in the same

effective resolution. Table VI provides a comparison of

effective resolution at various clock frequencies, data rates,

and Turbo Mode Rates.

Serial

I/O

t

DATA

FIGURE 4. Asynchronous ADS1210/11 Analog Input Volt-

age Step or ADS1211 Channel Change to Fully

Settled Output Data.

TURBO MODE

The ADS1210/11 offers a unique Turbo Mode feature which

can be used to increase the modulator sampling rate by 2, 4,

8, or 16 times normal. With the increase of modulator

sampling frequency, there can be a substantial increase in

®

ADS1210, 1211

DATA XIN CLOCK TURBO EFFECTIVE

RATE FREQUENCY MODE RESOLUTION

(Hz) (MHz) RATE (Bits rms)

60 10 1 19.5

60 5 2 19.5

60 2.5 4 19.5

60 1.25 8 19.5

60 0.625 16 19.5

100 10 1 18.0

100 5 2 18.0

100 2.5 4 18.0

100 1.25 8 18.0

100 0.625 16 18.0

TABLE VI. Effective Resolution vs Data Rate, Clock

Frequency, and Turbo Mode Rate. (Gain setting of 1.)

12

The Turbo Mode Rate (TMR) is programmed via the Sampling Frequency bits of the Command Register. Due to the

increase in input capacitor sampling frequency, higher Turbo

Mode settings result in lower analog input impedance;

AIN Impedance (Ω) = (10MHz/f

)•4.3E6/(G•TMR)

XIN

where G is the gain setting. Because the modulator rate also

changes in direct relation to the Turbo Mode setting, higher

values result in a lower impedance for the REFIN input:

REFIN Impedance (Ω) = (10MHz/f

)•1E6/TMR

XIN

The Turbo Mode Rate can be set to 1, 2, 4, 8, or 16. Consult

the graphs shown in the Typical Performance Curves for full

details on the performance of the ADS1210/11 operating in

different Turbo Mode Rates. Keep in mind that higher Turbo

Mode Rates result in fewer available gain settings as shown

in Table II.

PROGRAMMABLE GAIN AMPLIFIER

The programmable gain amplifier gain setting is programmed

via the PGA Gain bits of the Command Register. Changes

in the gain setting (G) of the programmable gain amplifier

results in an increase in the input capacitor sampling frequency. Thus, higher gain settings result in a lower analog

input impedance:

AIN Impedance (Ω) = (10MHz/f

)•4.3E6/(G•TMR)

XIN

where TMR is the Turbo Mode Rate. Because the modulator

speed does not depend on the gain setting, the input impedance seen at REFIN does not change.

The PGA can be set to gains of 1, 2, 4, 8, or 16. These gain

settings with their resulting full-scale range and typical

voltage range are shown in Table I. Keep in mind that higher

Turbo Mode Rates result in fewer available gain settings as

shown in Table II.

SOFTWARE GAIN

The excellent performance, flexibility, and low cost of the

ADS1210/11 allow the converter to be considered for designs which would not normally need a 24-bit ADC. For

example, many designs utilize a 12-bit converter and a highgain INA or PGA for digitizing low amplitude signals. For

some of these cases, the ADS1210/11 by itself may be a

solution, even though the maximum gain is limited to 16.

To get around the gain limitation, the digital result can

simply be shifted up by “n” bits in the main controller—

resulting in a gain of “n” times G, where G is the gain

setting. While this type of manipulation of the output data

is obvious, it is easy to miss how much the gain can be

increased in this manner on a 24-bit converter.

For example, shifting the result up by three bits when the

ADS1210/11 is set to a gain of 16 results in an effective gain

of 128. At lower data rates, the converter can easily provide

more than 12 bits of resolution. Even higher gains are

possible. The limitation is a combination of the needed data

rate, desired noise performance, and desired linearity.

CALIBRATION

The ADS1210/11 offers several different types of calibration, and the particular calibration desired is programmed

via the Command Register. In the case of Background

Calibration, the calibration will repeat at regular intervals

indefinitely. For all others, the calibration is performed once

and then normal operation is resumed.

Each type of calibration is covered in detail in their respective section. In general, calibration is recommended immediately after power-on and whenever there is a “significant”

change in the operating environment. The amount of change

which should cause a re-calibration is dependent on the

application, effective resolution, etc. Where high accuracy is

important, re-calibration should be done on changes in

temperature and power supply. In all cases, re-calibration

should be done when the gain, Turbo Mode, or data rate is

changed.

After a calibration has been accomplished, the Offset Calibration Register and the Full-Scale Calibration Register

contain the results of the calibration. The data in these

registers are accurate to the effective resolution of the

ADS1210/11’s mode of operation during the calibration.

Thus, these values will show a variation (or noise) equivalent to a regular conversion result.

For those cases where this error must be reduced, it is

tempting to consider running the calibration at a slower data

rate and then increasing the converter’s data rate after the

calibration is complete. Unfortunately, this will not work as

expected. The reason is that the results calculated at the

slower data rate would not be valid for the higher data rate.

Instead, the calibration should be done repeatedly. After

each calibration, the results can be read and stored. After the

desired number of calibrations, the main controller can

compute an average and write this value into the calibration

registers. The resulting error in the calibration values will be

reduced by the square root of the number of calibrations

which were averaged.

The calibration registers can also be used to provide system

offset and gain corrections separate from those computed by

the ADS1210/11. For example, these might be burned into

E2PROM during final product testing. On power-on, the

main controller would load these values into the calibration

registers. A further possibility is a look-up table based on the

current temperature.

Note that the values in the calibration registers will vary from

configuration to configuration and from part to part. There is

no method of reliably computing what a particular calibration

register should be to correct for a given amount of system

error. It is possible to present the ADS1210/11 with a known

amount of error, perform a calibration, read the desired

calibration register, change the error value, perform another

calibration, read the new value and use these values to

interpolate an intermediate value.

13 ADS1210, 1211

®

Normal

Mode

Valid

Data

DRDY

Serial

I/O

t

DATA

Valid

Data

SC

(1)

NOTES: (1) SC = Self-Calibration instruction. (2) In Slave Mode, this function requires 4 cycles.

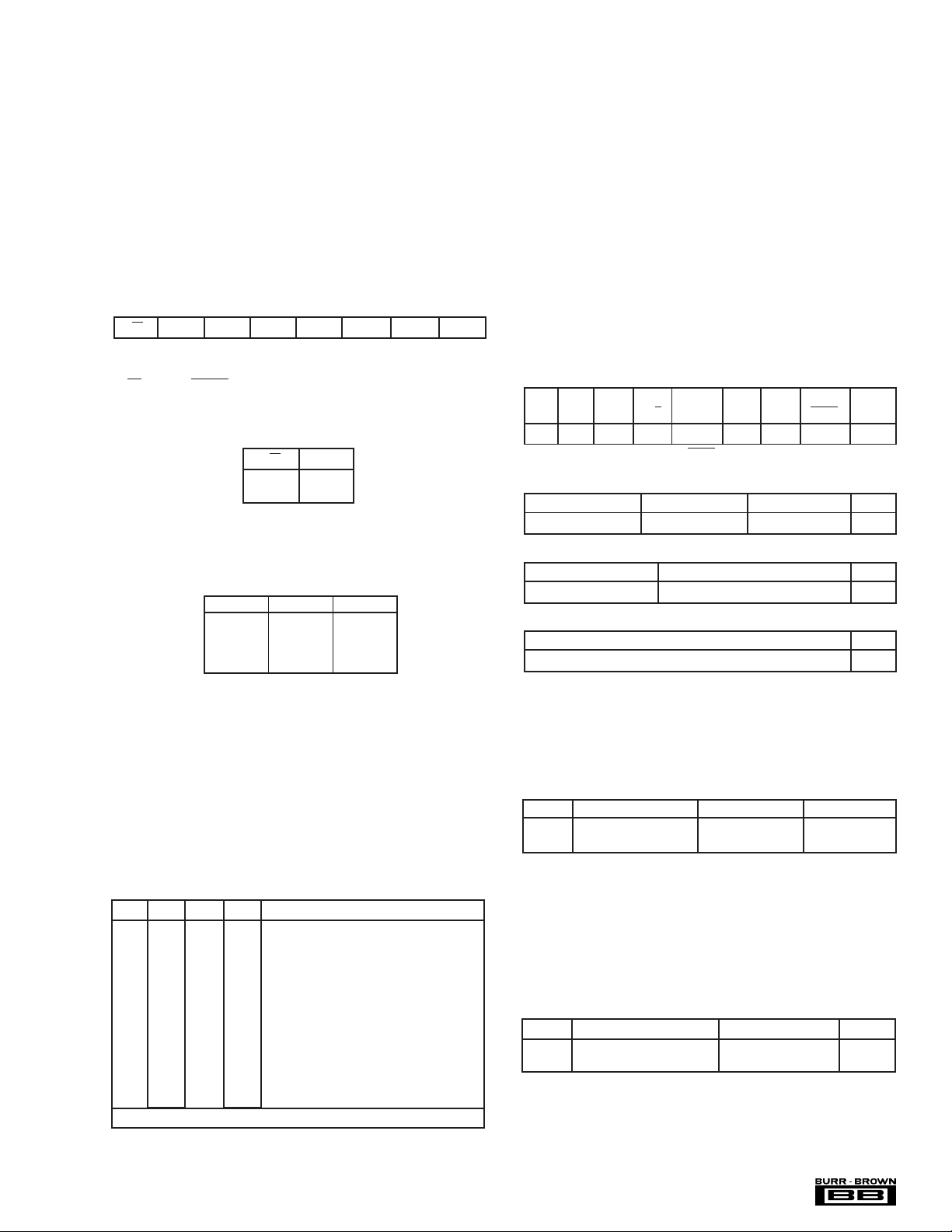

FIGURE 5. Self-Calibration Timing.

Offset

Calibration on

Internal Offset

Self-Calibration

Mode

Full-Scale

(2)

Calibration on

Internal Full-Scale

Analog

Input

Conversion

Normal

Mode

Valid

Data

Valid

Data

Self-Calibration

A self-calibration is performed after the bits 001 have been

written to the Command Register Operation Mode bits

(MD2 through MD0). This initiates the following sequence

at the start of the next conversion cycle (see Figure 5). The

DRDY signal will not go LOW but will remain HIGH and

will continue to remain HIGH throughout the calibration

sequence. The inputs to the sampling capacitor are disconnected from the converter’s analog inputs and are shorted

together. An offset calibration is performed over the next

three conversion periods (four in Slave Mode). Then, the

input to the sampling capacitor is connected across REFIN,

and a full-scale calibration is performed over the next three

conversions.

After this, the Operation Mode bits are reset to 000 (normal

mode) and the input capacitor is reconnected to the input.

Conversions proceed as usual over the next three cycles in

order to fill the digital filter. DRDY remains HIGH during

this time. On the start of the fourth cycle, DRDY goes LOW

indicating valid data and resumption of normal operation.

System Offset Calibration

A system offset calibration is performed after the bits 010

have been written to the Command Register Operation

Mode bits (MD2 through MD0). This initiates the following

sequence (see Figure 6). At the start of the next conversion

cycle, the DRDY signal will not go LOW but will remain

HIGH and will continue to remain HIGH throughout the

calibration sequence. The offset calibration will be performed on the differential input voltage present at the

converter’s input over the next three conversion periods

(four in Slave Mode). When this is done, the Operation

Mode bits are reset to 000 (Normal Mode). A single conversion is done with DRDY HIGH. After this conversion, the

DRDY signal goes LOW indicating resumption of normal

operation.

Normal operation returns within a single conversion cycle

because it is assumed that the input voltage at the converter’s

input is not removed immediately after the offset calibration

is performed. In this case, the digital filter already contains

a valid result.

For full system calibration, offset calibration must be performed first and then full-scale calibration. In addition, the

offset calibration error will be the rms sum of the conversion

error and the noise on the system offset voltage. See the

System Calibration Limits section for information regarding

the limits on the magnitude of the system offset voltage.

System Full-Scale Calibration

A system full-scale calibration is performed after the bits

011 have been written to the Command Register Operation

Mode bits (MD2 through MD0). This initiates the following

sequence (see Figure 7). At the start of the next conversion

cycle, the DRDY signal will not go LOW but will remain

HIGH and will continue to remain HIGH throughout the

calibration sequence. The full-scale calibration will be performed on the differential input voltage (2 • REFIN/G)

present at the converter’s input over the next three conversion periods (four in Slave Mode). When this is done, the

Operation Mode bits are reset to 000 (Normal Mode). A

single conversion is done with DRDY HIGH. After this

conversion, the DRDY signal goes LOW indicating resumption of normal operation.

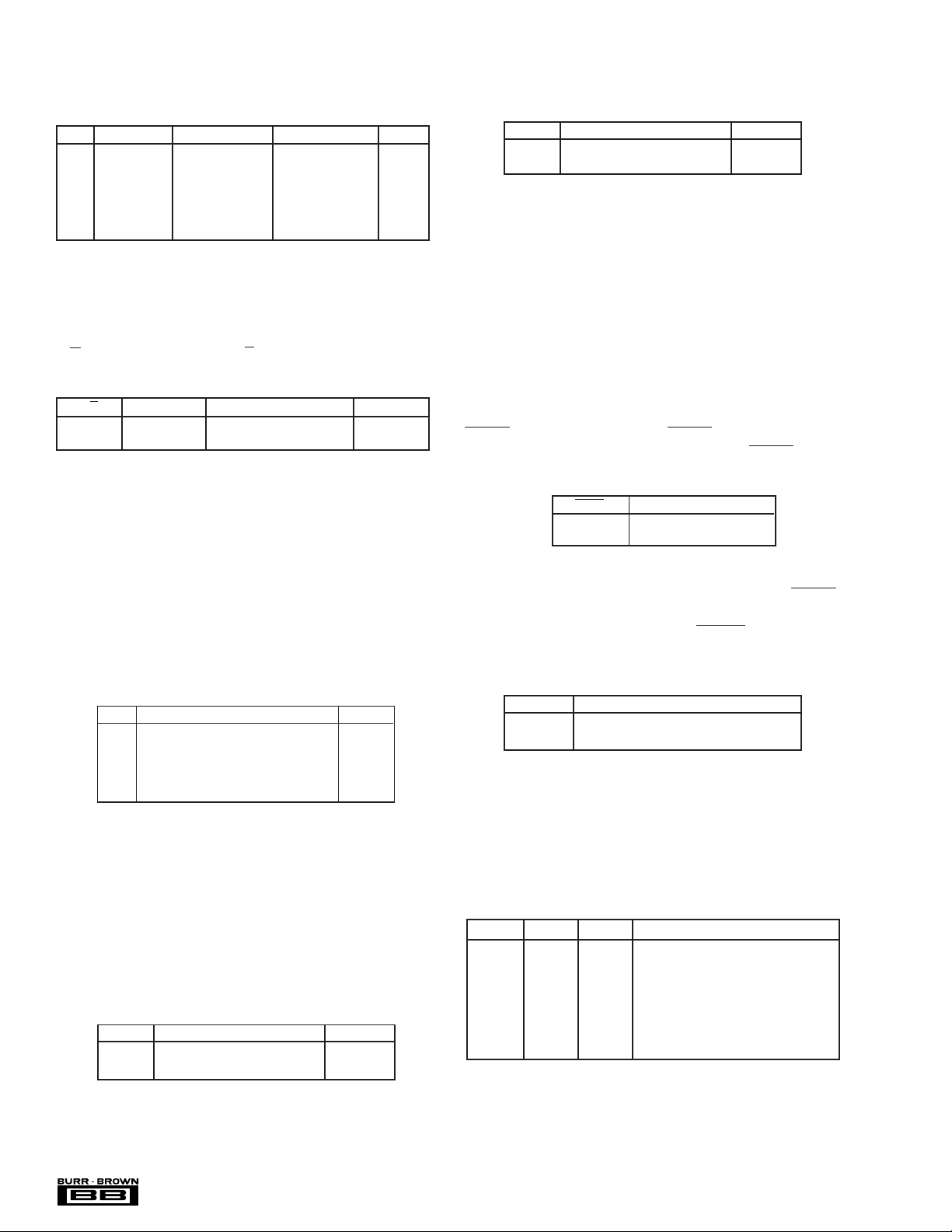

DRDY

Serial

I/O

Valid

Data

t

DATA

Normal

Mode

Valid

Data

(1)

SOC

NOTES: (1) SOC = System Offset Calibration instruction.

(2) In Slave Mode, this function requires 4 cycles.

System Offset

Calibration Mode

Offset

Calibration on

System Offset

Analog

Input

(2)

Conversion

FIGURE 6. System Offset Calibration Timing.

®

ADS1210, 1211

Normal

Mode

Possibly

Valid

Data

Possibly

Valid

Data

DRDY

Serial

I/O

Normal

Mode

Valid

Valid

Data

Data

(1)

SFSC

t

DATA

NOTES: (1) SFSC = System Full-Scale Calibration instruction.

(2) In Slave Mode, this function requires 4 cycles.

System Full-Scale

Calibration Mode

Full-Scale

Calibration on

System Full-Scale

(2)

Analog

Input

Conversion

FIGURE 7. System Full-Scale Calibration Timing.

14

Normal

Mode

Possibly

Valid

Data

Possibly

Valid

Data

Normal operation returns within a single conversion cycle

because it is assumed that the input voltage at the converter’s

input is not removed immediately after the full-scale calibration is performed. In this case, the digital filter already

contains a valid result.

For full system calibration, offset calibration must be performed first and then full-scale calibration. The calibration

error will be a sum of the rms noise on the conversion result

and the input signal noise. See the System Calibration Limits

section for information regarding the limits on the magnitude of the system full-scale voltage.

Pseudo System Calibration

The Pseudo System Calibration is performed after the bits

100 have been written to the Command Register Operation

Mode bits (MD2 through MD0). This initiates the following

sequence (see Figure 8). At the start of the next conversion

cycle, the DRDY signal will not go LOW but will remain

HIGH and will continue to remain HIGH throughout the

calibration sequence. The offset calibration will be performed

on the differential input voltage present at the converter’s

input over the next three conversion periods (four in Slave

Mode). Then, the input to the sampling capacitor is disconnected from the converter’s analog input and connected

across REFIN. A gain calibration is performed over the next

three conversions.

After this, the Operation Mode bits are reset to 000 (normal

mode) and the input capacitor is then reconnected to the

input. Conversions proceed as usual over the next three

cycles in order to fill the digital filter. DRDY remains

HIGH during this time. On the next cycle, the DRDY signal

goes LOW indicating valid data and resumption of normal

operation.

The system offset calibration range of the ADS1210/11

is limited and is listed in the Specifications Table. For

more information on how to use these specifications, see

the System Calibration Limits section. To calculate VOS,

use 2 • REFIN/ GAIN for VFS.

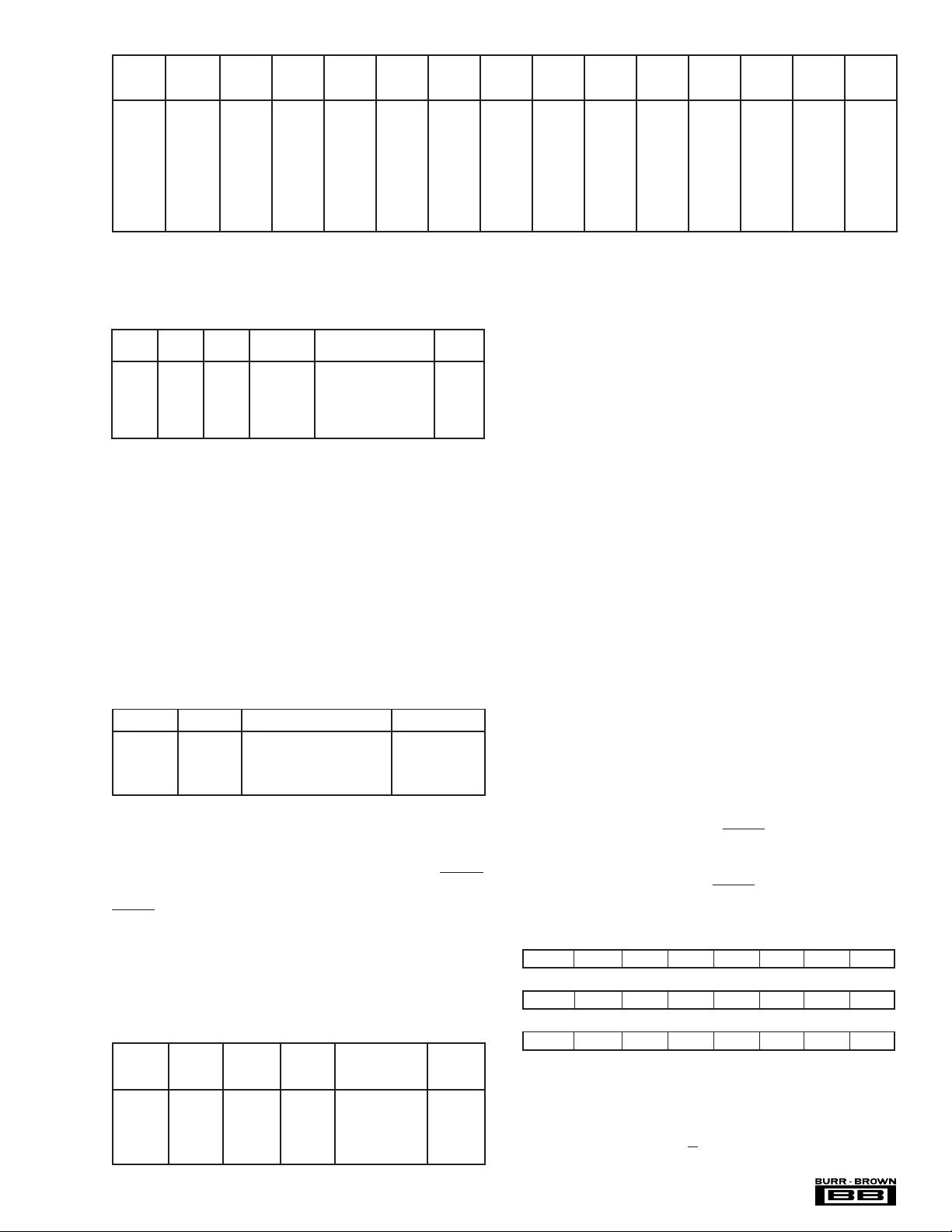

Background Calibration

The Background Calibration Mode is entered after the bits

101 have been written to the Command Register Operation

Mode bits (MD2 through MD0). This initiates the following

continuous sequence (see Figure 9). At the start of the next

conversion cycle, the DRDY signal will not go LOW but

will remain HIGH. The inputs to the sampling capacitor are

disconnected from the converter’s analog input and shorted

together. An offset calibration is performed over the next

three conversion periods (in Slave Mode, the very first offset

calibration requires four periods and all subsequent offset

calibrations require three periods). Then, the input capacitor

is reconnected to the input. Conversions proceed as usual

over the next three cycles in order to fill the digital filter.

DRDY remains HIGH during this time. On the next cycle,

the DRDY signal goes LOW indicating valid data.

Normal

Mode

Offset

Calibration on

System Offset

DRDY

Serial

I/O

Valid

Data

t

DATA

Valid

Data

(1)

PSC

NOTES: (1) PSC = Pseudo System Calibration instruction. (2) In Slave Mode, this function requires 4 cycles.

FIGURE 8. Pseudo System Calibration Timing.

DRDY

Serial

I/O

Valid

Data

t

DATA

Normal

Background Calibration

Mode

Mode

Valid

Data

(1)

BC

Offset

Calibration on

Internal Offset

(2)

NOTES: (1) BC = Background Calibration instruction. (2) In Slave Mode, the very first offset

calibration will require 4 cycles. All subsequent offset calibrations will require 3 cycles.

(2)

Analog

Input

Conversion

Pseudo System

Calibration Mode

Full-Scale

Calibration on

Internal Full-Scale

Full-Scale

Calibration on

Internal Full-Scale

Analog

Input

Conversion

Analog

Conversion

Input

Normal

Mode

Valid

Data

Valid

Data

Cycle Repeats

with Offset

Calibration

FIGURE 9. Background Calibration Timing.

®

15 ADS1210, 1211

Also, during this cycle, the sampling capacitor is disconnected from the converter’s analog input and is connected

across REFIN. A gain calibration is initiated and proceeds

over the next three conversions. After this, the input capacitor is once again connected to the analog input. Conversions

proceed as usual over the next three cycles in order to fill the

digital filter. DRDY remains HIGH during this time. On the

next cycle, the DRDY signal goes LOW indicating valid

data, the input to the sampling capacitor is shorted, and an

offset calibration is initiated. At this point, the Background

Calibration sequence repeats.

In essence, the Background Calibration Mode performs

continuous self-calibration where the offset and gain calibrations are interleaved with regular conversions. Thus, the

data rate is reduced by a factor of 6. The advantage is that

the converter is continuously adjusting to environmental

changes such as ambient or component temperature (due to

airflow variations).

The ADS1210/11 will remain in the Background Calibration Mode indefinitely. To move to any other mode, the

Command Register Operation Mode bits (MD2 through

MD0) must be set to the appropriate values.

System Calibration Offset and Full-Scale

Calibration Limits

The System Offset and Full-Scale Calibration range of the

ADS1210/11 is limited and is listed in the Specifications

Table. The range is specified as:

(VFS – | V

(VFS – | V

where VFS is the system full-scale voltage and | V

|) < 1.3 • (2 • REFIN)/GAIN

OS

|) > 0.7 • (2 • REFIN)/GAIN

OS

OS

| is the

absolute value of the system offset voltage. In the following

discussion, keep in mind that these voltages are differential

voltages.

For example, with the internal reference (2.5V) and a gain of

two, the previous equations become (after some manipulation):

VFS – 3.25 < VOS < VFS – 1.75

If VFS is perfect at 2.5V (positive full-scale), then VOS must

be greater than –0.75V and less than 0.75V. Thus, when offset

calibration is performed, the positive input can be no more

than 0.75V below or above the negative input. If this range is

exceeded, the ADS1210/11 may not calibrate properly.

This calculation method works for all gains other than one.

For a gain of one and the internal reference (2.5V), the

equation becomes:

VFS – 6.5 < VOS < VFS – 3.5

With a 5V positive full-scale input, VOS must be greater than

–1.5V and less than 1.5V. Since the offset represents a

common-mode voltage and the input voltage range in a gain

of one is 0V to 5V, a common-mode voltage will cause the

actual input voltage to possibly go below 0V or above 5V.

The specifications also show that for the specifications to be

valid, the input voltage must not go below AGND by more

than 30mV or above AVDD by more than 30mV.

This will be an important consideration in many systems

which use a 2.5V or greater reference, as the input range is

constrained by the expected power supply variations. In

addition, the expected full-scale voltage will impact the

allowable offset voltage (and vice-versa) as the combination

of the two must remain within the power supply and ground

potentials, regardless of the results obtained via the range

calculation shown previously.

There are only two solutions to this constraint: either the

system design must ensure that the full-scale and offset

voltage variations will remain within the power supply and

ground potentials, or the part must be used in a gain of 2 or

greater.

SLEEP MODE

The Sleep Mode is entered after the bits 110 have been

written to the Command Register Operation Mode bits

(MD2 through MD0). This mode is exited by entering a new

mode into the MD2-MD0 bits.

The Sleep Mode causes the analog section and a good deal

of the digital section to power down. For full analog power

down, the V

generator and the internal reference must

BIAS

also be powered down by setting the BIAS and REFO bits

in the Command Register accordingly. The power dissipation shown in the Specifications Table is with the internal

reference and the V

generator disabled.

BIAS

To initiate serial communication with the converter while it

is in Sleep Mode, one of the following procedures must be

used: If CS is being used, simply taking CS LOW will

enable serial communication to proceed normally. If CS is

not being used (tied LOW) and the ADS1210/11 is in the

Master Mode, then a falling edge must be produced on the

SDIO line. If SDIO is LOW, the SDIO line must be taken

HIGH for 2 • t

periods (minimum) and then taken LOW.

XIN

Alternatively, SDIO can be forced HIGH after putting the

ADS1210/11 to “sleep” and then taken LOW when the

Sleep Mode is to be exited. Finally, if CS is not being used

(tied LOW) and the ADS1210/11 is in the Slave Mode, then

simply sending a normal Instruction Register command will

re-establish communication.

Once serial communication is resumed, the Sleep Mode is

exited by changing the MD2-MD0 bits to any other mode.

When a new mode (other than Sleep) has been entered, the

ADS1210/11 will execute a very brief internal power-up

sequence of the analog and digital circuitry. Once this has

been done, one normal conversion cycle is performed before

the new mode is actually entered. At the end of this conversion

cycle, the new mode takes effect and the converter will

respond accordingly. The DRDY signal will remain HIGH

through the first conversion cycle. It will also remain HIGH

through the second, even if the new mode is the Normal Mode.

If the V

generator and/or the internal reference have

BIAS

been disabled, then they must be manually re-enabled via the

appropriate bits in the Command Register. In addition, the

internal reference will have to charge the external bypass

capacitor(s) and possibly other circuitry. There may also be

®

ADS1210, 1211

16

considerations associated with V

and the settling of

BIAS

external circuitry. All of these must be taken into account

when determining the amount of time required to resume

normal operation. The timing diagram shown in Figure 10

does not take into account the settling of external circuitry.

Sleep Mode

DRDY

Serial

I/O

NOTE: (1) Assuming that the external circuitry has

been stable for the previous three t

Change to Normal Mode Occurs Here

One

Normal

Conversion

t

DATA

(Other

Modes

Start Here)

Data

Not

Valid

DATA

Valid

Data

periods.

Valid

(1)

Data

(1)

FIGURE 10. Sleep Mode to Normal Mode Timing.

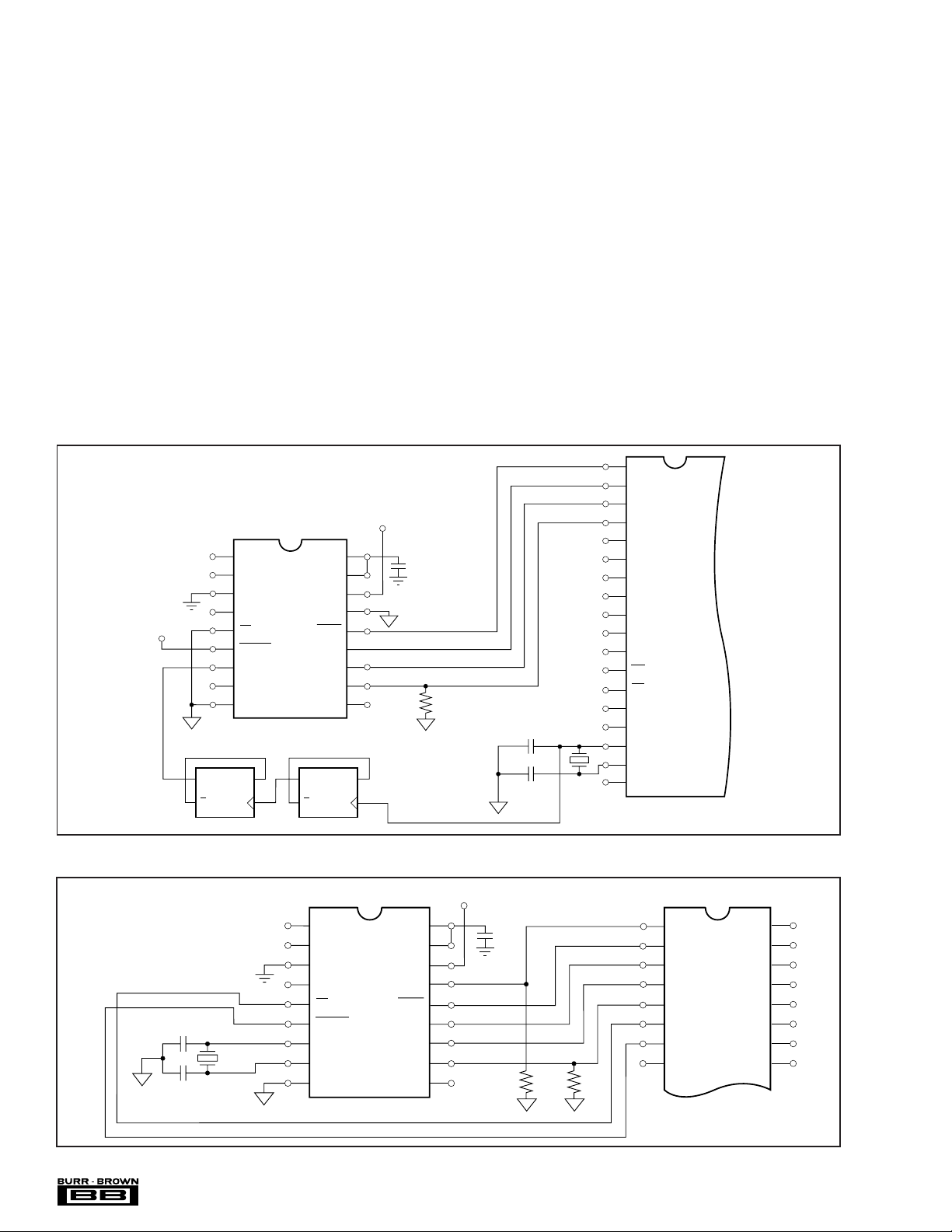

ANALOG OPERATION

ANALOG INPUT

The input impedance of the analog input changes with

ADS1210/11 clock frequency (f

Mode Rate (TMR). The relationship is:

AIN Impedance (Ω) = (10MHz/f

Figure 11 shows the basic input structure of the ADS1210.

The ADS1211 includes an input multiplexer, but this has

little impact on the analysis of the input structure. The

impedance is directly related to the sampling frequency of

the input capacitor. The XIN clock rate sets the basic sampling rate in a gain of 1 and Turbo Mode Rate of 1. Higher

gains and higher Turbo Mode Rates result in an increase of

the sampling rate, while slower clock (XIN) frequencies

result in a decrease.

R

SW

(8kΩ typical)

A

IN

Switching Frequency

= f

SAMP

), gain (G), and Turbo

XIN

)•4.3E6/(G•TMR)

XIN

High

Impedance

> 1GΩ

C

INT

8pF Typical

V

CM

the analog signal must reside within this range, the linearity

of the ADS1210/11 is only guaranteed when the actual

analog input voltage resides within a range defined by

AGND –30mV and AV

paths which occur within the part when AGND and AV

+30mV. This is due to leakage

DD

DD

are exceeded.

For this reason, the 0V to 5V input range (gain of 1 with a 2.5V

reference) must be used with caution. Should AVDD be 4.75V,

the analog input signal would swing outside of the guaranteed

specifications of the device. Designs utilizing this mode of

operation should consider limiting the span to a slightly smaller

range. Common-mode voltages are also a significant concern

in this mode and must be carefully analyzed.

An input voltage range of 0.75V to 4.25V is the smallest

span that is allowed if a full system calibration will be

performed (see the Calibration section for more details).

This also assumes an offset error of zero. A better choice

would be 0.5V to 4.5V (a full-scale range of 9V). This span

would allow some offset error, gain error, power supply

drift, and common-mode voltage while still providing full

system calibration over reasonable variation in each of these

parameters.

The actual input voltage exceeding AGND or AVDD should not

be a concern in higher gain settings as the input voltage range

will reside well within 0V to 5V. This is true unless the

common-mode voltage is large enough to place positive fullscale or negative full-scale outside of the AGND to AVDD range.

REFERENCE INPUT

The input impedance of the REFIN input changes with clock

frequency (f

) and Turbo Mode Rate (TMR). The relationship

XIN

is:

REFIN Impedance (Ω) = (10MHz/f

)•1E6/TMR

XIN

Unlike the analog input, the reference input impedance has

a negligible dependency on the PGA gain setting.

The reference input voltage can vary between 2V and 3V. A

nominal voltage of 2.5V appears at REF

, and this can be

OUT

directly connected to REFIN. Higher reference voltages will

cause the full-scale range to increase while the internal

circuit noise of the converter remains approximately the

same. This will increase the LSB weight but not the internal

noise, resulting in increased signal-to-noise ratio and effective resolution. Likewise, lower reference voltages will decrease the signal-to-noise ratio and effective resolution.

FIGURE 11. Analog Input Structure.

This input impedance can become a major point of consideration in some designs. If the source impedance of the input

signal is significant or if there is passive filtering prior to the

ADS1210/11, then a significant portion of the signal can be

lost across this external impedance. How significant this

effect is depends on the desired system performance.

There are two restrictions on the analog input signal to the

ADS1210/11. Under no conditions should the current into

or out of the analog inputs exceed 10mA. In addition, while

REFERENCE OUTPUT

The ADS1210/11 contains an internal +2.5V reference.

Tolerances, drift, noise, and other specifications for this

reference are given in the Specification Table. Note that it is

not designed to sink or to source more than 1mA of current.

In addition, loading the reference with a dynamic or variable

load is not recommended. This can result in small changes

in reference voltage as the load changes. Finally, for designs

approaching or exceeding 20 bits of effective resolution, a

low-noise external reference is recommended as the internal

reference may not provide adequate performance.

®

17 ADS1210, 1211

±10V

±10V

DGND

R

3kΩ

R

3kΩ

1

2

C

12pF

C

12pF

A

P

IN

N

A

3

GND

XTAL

DV

R

1kΩ

4

DD

DGND

R

1kΩ

1

2

IN

AGND

V

BIAS

CS

DSYNC

X

IN

X

OUT

DGND

ADS1210

REF

REF

OUT

AV

MODE

DRDY

SDOUT

SDIO

SCLK

DV

IN

DD

DD

AV

DGND

DV

1.0µF

AGND

DD

DD

FIGURE 12. ±10V Input Configuration Using V

BIAS

.

The circuitry which generates the +2.5V reference can be

disabled via the Command Register and will result in a lower

power dissipation. The reference circuitry consumes a little over

1.6mA of current with no external load. When the ADS1210/11

is in its default state, the internal reference is enabled.

V

BIAS

The V

output voltage is dependent on the reference input

BIAS

(REFIN) voltage and is approximately 1.33 times as great.

This output is used to bias input signals such that bipolar

signals with spans of greater than 5V can be scaled to match

the input range of the ADS1210/11. Figure 12 shows a

connection diagram which will allow the ADS1210/11 to

accept a ±10V input signal (40V full-scale range).

This method of scaling and offsetting the ±20V differential

input signal will be a concern for those requiring minimum

power dissipation. V

will supply 1.68mA for every chan-

BIAS

nel connected as shown. For the ADS1211, the current draw

is within the specifications for V

, but, at 12mW, the

BIAS

power dissipation is significant. If this is a concern, resistors

R1 and R2 can be set to 9kΩ and R3 and R4 to 3kΩ. This will

reduce power dissipation by one-third. In addition, these

resistors can also be set to values which will provide any

arbitrary input range. In all cases, the maximum current into

or out of V

should not exceed its specification of 10mA.

BIAS

Note that the connection diagram shown in Figure 12 causes

a constant amount of current to be sourced by V

BIAS

. This

will be very important in higher resolution designs as the

voltage at V

will not change with loading, as the load is

BIAS

constant. However, if the input signal is single-ended and one

side of the input is grounded, the load will not be constant and

V

will change slightly with the input signal. Also, in all

BIAS

cases, note that noise on V

introduces a common-mode

BIAS

error signal which is rejected by the converter.

The 3k resistors should not be used as part of an anti-alias

filter with a capacitor across the inputs. The ADS1210

samples charge from the capacitor which has the effect of

introducing an offset in the measurement. This might be

acceptable for relative differential measurements.

The circuitry to generate V

is disabled when the

BIAS

ADS1210/11 is in its default state, and it must be enabled,

via the Command Register, in order for the V

®

voltage to

BIAS

ADS1210, 1211

be present. When enabled, the V

circuitry consumes

BIAS

approximately 1mA with no external load.

On power-up, external signals may be present before V

is enabled. This can create a situation in which a negative

voltage is applied to the analog inputs (–2.5V for the circuit

shown in Figure 12), reverse biasing the negative input

protection diode. This situation should not be a problem as

long as the resistors R1 and R2 limit the current being

sourced by each analog input to under 10mA (a potential of

0V at the analog input pin should be used in the calculation).

DIGITAL OPERATION

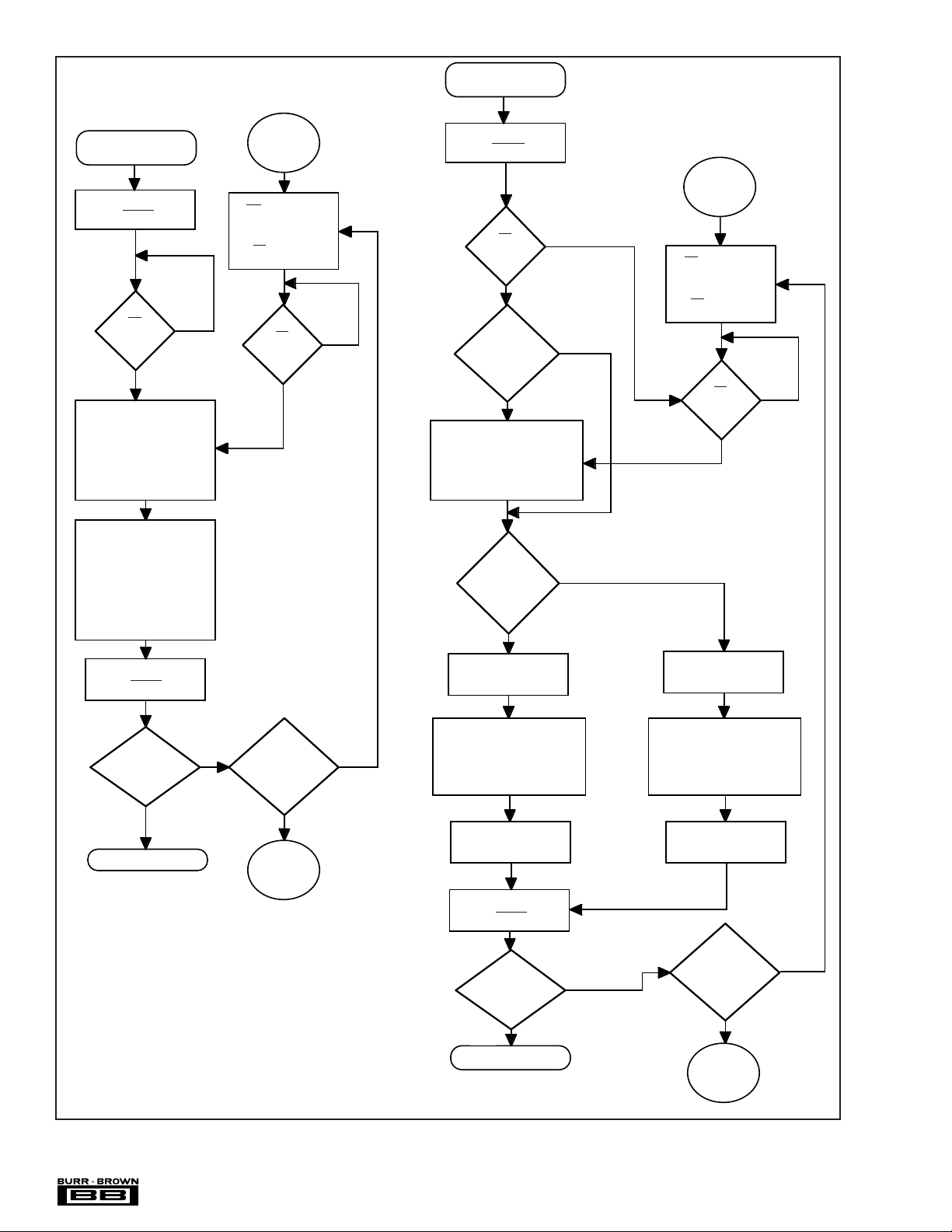

SYSTEM CONFIGURATION

The Micro Controller (MC) consists of an ALU and a

register bank. The MC has two states: power-on reset and

convert. In the power-on reset state, the MC resets all the

registers to their default state, sets up the modulator to a

stable state, and performs self-calibration at a 850Hz data

rate. After this, it enters the convert mode, which is the

normal mode of operation for the ADS1210/11.

The ADS1210/11 has 5 internal registers, as shown in Table

VII. Two of these, the Instruction Register and the Command Register, control the operation of the converter. The

Data Output Register (DOR) contains the result from the

most recent conversion. The Offset and Full-Scale Calibration Registers (OCR and FCR) contain data used for correcting the internal conversion result before it is placed into the

DOR. The data in these two registers may be the result of a

calibration routine, or they may be values which have been

written directly via the serial interface.

INSR Instruction Register 8 Bits

DOR Data Output Register 24 Bits

CMR Command Register 32 Bits

OCR Offset Calibration Register 24 Bits

FCR Full-Scale Calibration Register 24 Bits

TABLE VII. ADS1210/11 Registers.

Communication with the ADS1210/11 is controlled via the

Instruction Register (INSR). Under normal operation, the INSR

is written as the first part of each serial communication. The

instruction that is sent determines what type of communication

will occur next. It is not possible to read the INSR.

18

BIAS

The Command Register (CMR) controls all of the ADS1210/

11’s options and operating modes. These include the PGA

gain setting, the Turbo Mode Rate, the output data rate

(decimation ratio), etc. The CMR is the only 32-bit register

within the ADS1210/11. It, and all the remaining registers,

may be read from or written to.

Instruction Register (INSR)

The INSR is an 8-bit register which commands the serial

interface either to read or to write “n” bytes beginning at the

specified register location. Table VIII shows the format for

the INSR.

MSB LSB

R/W MB1 MB0 0 A3 A2 A1 A0

TABLE VIII. Instruction Register.

R/W (Read/Write) Bit—For a write operation to occur, this

bit of the INSR must be 0. For a read, this bit must be 1, as

follows:

R/W

0 Write

1 Read

MB1, MB0 (Multiple Bytes) Bits—These two bits are used

to control the word length (number of bytes) of the read or

write operation, as follows:

MB1 MB0

0 0 1 Byte

0 1 2 Bytes

1 0 3 Bytes

1 1 4 Bytes

A3-A0 (Address) Bits—These four bits select the beginning register location which will be read from or written to,

as shown in Table IX. Each subsequent byte will be read

from or written to the next higher location. (If the BD bit in

the Command Register is set, each subsequent byte will be

read from the next lower location. This bit does not affect the

write operation.) If the next location is not defined in Table

IX, then the results are unknown. Reading or writing continues until the number of bytes specified by MB1 and MB0

have been transferred.