Page 1

查询ADS1202供应商查询ADS1202供应商

1-Bit, 10MHz, 2nd-Order, Delta-Sigma Modulator

ADS1202

SBAS275 – DECEMBER 2002

Motor Control Current Shunt

FEATURES

● 16-BIT RESOLUTION

● 13-BIT LINEARITY

● RESOLUTION/SPEED TRADE-OFF:

10-Bit Effective Resolution with 20µs Signal

Delay (12-bit with 77µs)

●±250mV INPUT RANGE WITH SINGLE 5V SUPPLY

● 2% INTERNAL REFERENCE VOLTAGE

● 2% GAIN ERROR

● FLEXIBLE SERIAL INTERFACE WITH FOUR

DIFFERENT MODES

● IMPLEMENTED TWINNED BINARY CODING AS

SPLIT PHASE OR MANCHESTER CODING FOR

ONE LINE INTERFACING

● OPERATING TEMPERATURE RANGE:

–40°C to +85°C

APPLICATIONS

● MOTOR CONTROL

● CURRENT MEASUREMENT

● INDUSTRIAL PROCESS CONTROL

● INSTRUMENTATION

● SMART TRANSMITTERS

● PORTABLE INSTRUMENTS

● WEIGHT SCALES

● PRESSURE TRANSDUCERS

V

V

V

GND

DESCRIPTION

The ADS1202 is a precision, 80dB dynamic range, deltasigma (∆∑) modulator operating from a single +5V supply.

The differential inputs are ideal for direct connections to

transducers or low-level signals. With the appropriate digital

filter and modulator rate, the device can be used to achieve

16-bit Analog-to-Digital (A/D) conversion with no missing

codes. Effective resolution of 12 bits can be maintained with

a digital filter bandwidth of 10kHz at a modulator rate of

10MHz. The ADS1202 is designed for use in medium resolution measurement applications including current measurements, smart transmitters, industrial process control, weigh

scales, chromatography, and portable instrumentation. It is

available in a TSSOP-8 package.

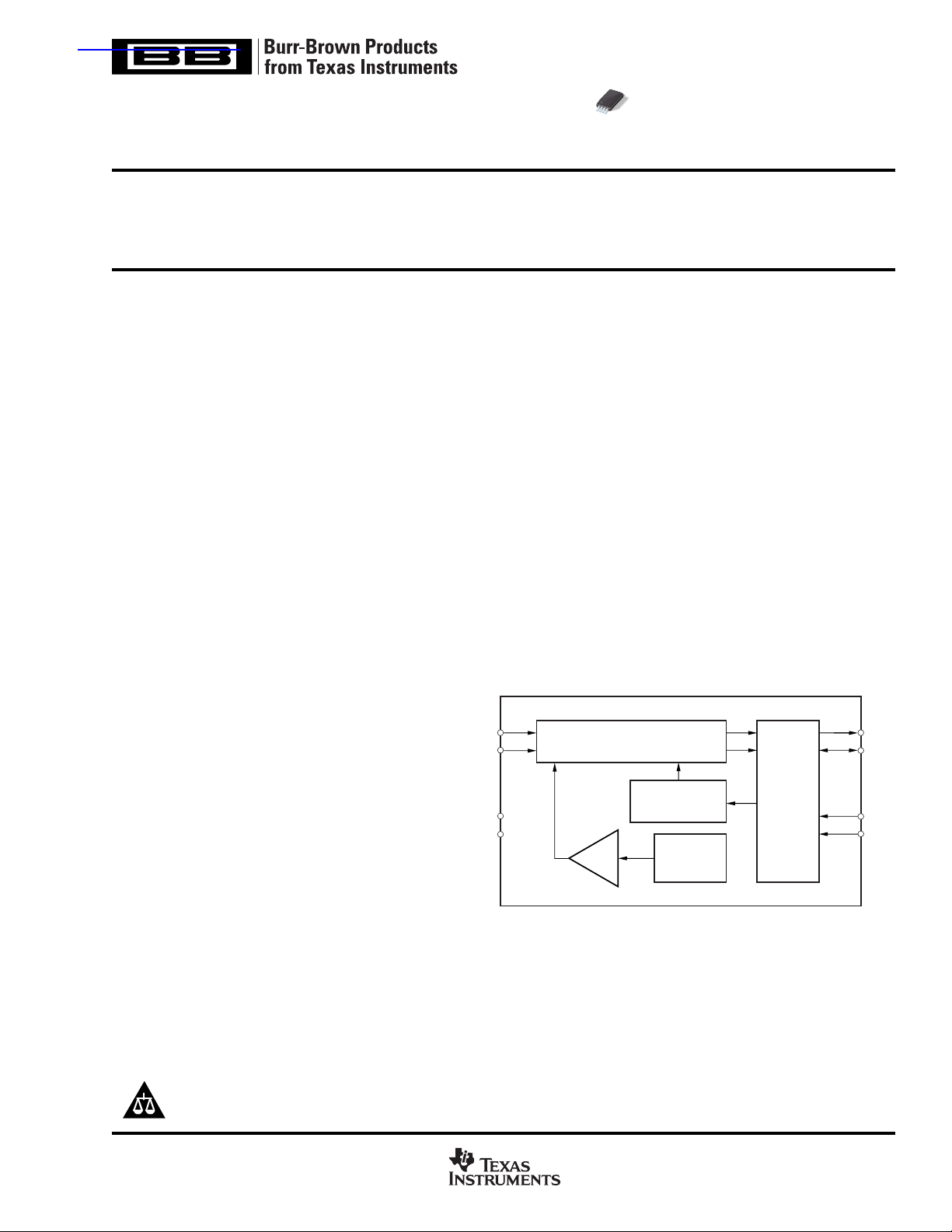

IN+

IN–

DD

2nd-Order

∆∑ Modulator

Buffer

RC Oscillator

20MHz

Reference

Voltage

2.5V

Interface

Circuit

MDAT

MCLK

M0

M1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Copyright © 2002, Texas Instruments Incorporated

www.ti.com

Page 2

ABSOLUTE MAXIMUM RATINGS

Over operating free-air temperature (unless otherwise noted)

(1)

ELECTROSTATIC

DISCHARGE SENSITIVITY

Supply Voltage, GND to VDD................................................. –0.3V to 6V

Analog Input Voltage Range ......................... GND – 0.4V to VDD + 0.3V

Digital Input Voltage Range .......................... GND – 0.3V to V

Power Dissipation ............................................................................ 0.25W

Operating Virtual Junction Temperature Range, T

Operating Free-Air Temperature Range, T

Storage Temperature Range, T

Lead Temperature 1.6mm (1/16") from Case for 10s .................. +260°C

NOTE: (1) Stresses beyond those listed under the Absolute Maximum Ratings

may cause permanent damage to the device. These are stress ratings only,

and functional operation of the device at these or any other conditions beyond

those indicated under the Recommended Operating Conditions is not implied.

Exposure to absolute-maximum-rated conditions for extended periods may

affect device reliability.

................................–65°C to +150°C

STG

........ –40°C to +150°C

J

....................–40°C to +85°C

A

+ 0.3V

DD

PACKAGE/ORDERING INFORMATION

MAXIMUM

INTEGRAL SPECIFIED

PRODUCT ERROR (LSB) GAIN ERROR (%) PACKAGE-LEAD DESIGNATOR

ADS1202 12 ±2 TSSOP-8 PW –40°C to +85°C ADS1202I ADS1202IPWT Tape and Reel, 250

ADS1202

NOTE: (1) For the most current specifications and package information, refer to our web site at www.ti.com.

LINEARITY MAXIMUM PACKAGE TEMPERATURE PACKAGE ORDERING TRANSPORT

"" """"

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling

and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits

may be more susceptible to damage because very small

parametric changes could cause the device not to meet its

published specifications.

(1)

RANGE MARKING NUMBER MEDIA, QUANTITY

ADS1202IPWR Tape and Reel, 2000

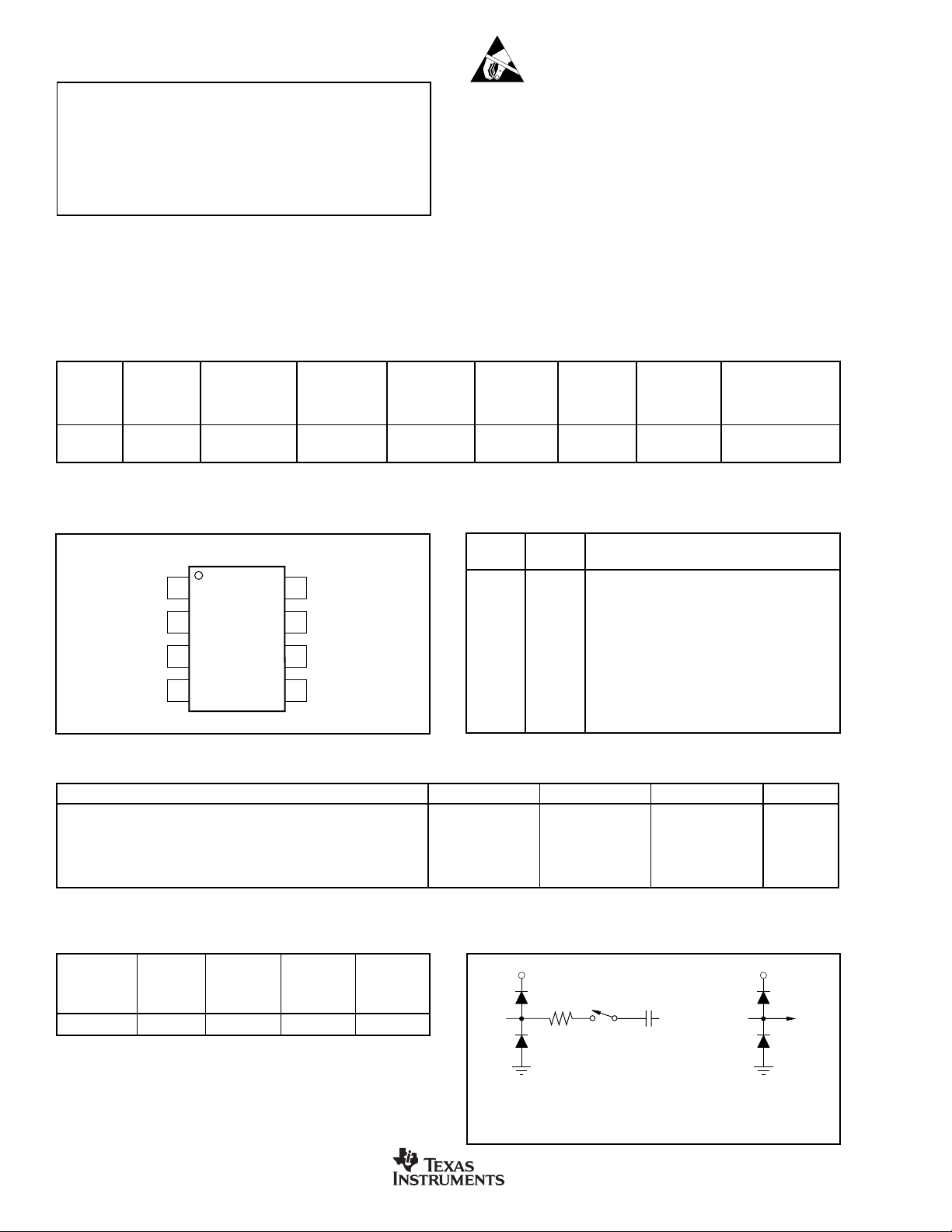

PIN CONFIGURATION

Top View TSSOP

1

M0

2

V

IN+

V

IN–

M1

ADS1202

3

4

8

V

DD

7

MCLK

6

MDAT

5

GND

PIN DESCRIPTIONS

PIN

NUMBER NAME DESCRIPTION

1 MO Mode Input

2V

3V

4 M1 Mode Input

5 GND Power Supply Ground

6 MDAT Modulator Data Output

7 MCLK Modulator Clock Input or Output

8VDDPower Supply, +5V Nominal

+ Analog Input: Noninverting Input

IN

– Analog Input: Inverting Input

IN

RECOMMENDED OPERATING CONDITIONS

PARAMETER MIN NOM MAX UNIT

Supply Voltage, V

Analog Input Voltage, V

Operating Common-Mode Signal, V

External Clock

Operating Junction Temperature Range –40 105 °C

NOTE: (1) With reduced accuracy, minimum clock can go up to 500kHz.

DD

IN

(1)

CM

DISSIPATION RATING

T

< 25°C FACTOR TA = 70°CTA = 85°C

A

PACKAGE RATING T

TSSOP-8 483.6mW 3.868mW/°C 309.5mW 251.4mW

NOTE: (1) This is the inverse of the traditional junction-to-ambient thermal

resistance (R

informational purposes only.

POWER ABOVE POWER POWER

). Thermal resistances are not production tested and are for

θ

JA

DERATING

= 25°C

A

(1)

RATING RATING

4.75 5.0 5.25 V

–250 +250 mV

05V

81012MHz

EQUIVALENT INPUT CIRCUIT

AV

DD

RON = 350Ω

A

IN

AGND

Diode Turn on Voltage: 0.35V

Equivalent Analog Input Circuit

C

(SAMPLE)

= 5pF

BV

DD

D

IN

BGND

Equivalent Digital Input Circuit

2

www.ti.com

ADS1202

SBAS275

Page 3

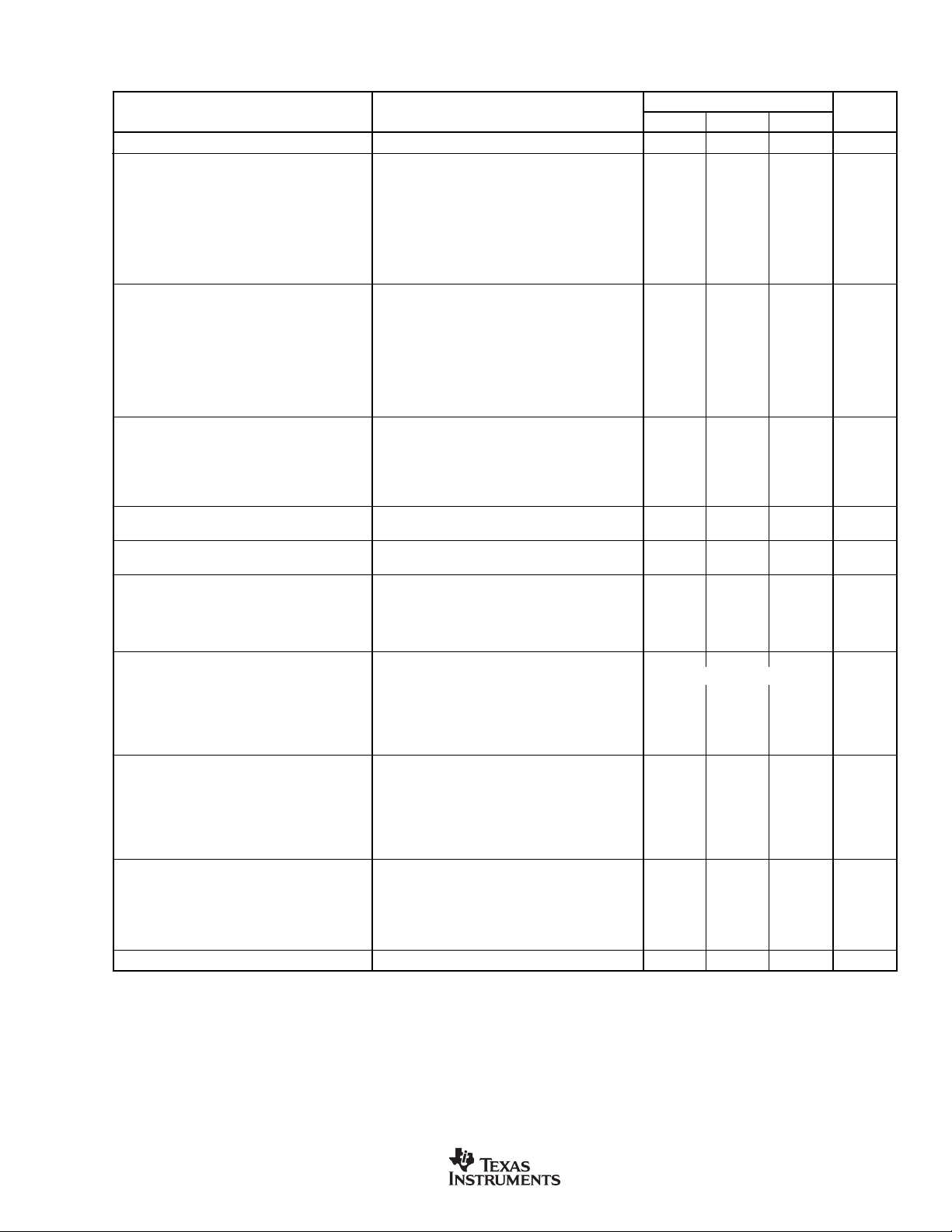

ELECTRICAL CHARACTERISTICS

Over recommended operating free-air temperature range at –40°C to +85°C, VDD = 5V, +In = –250mV to 250mV, –In = 0V, and MCLK = 10MHz, unless otherwise noted.

ADS1202IPW

PARAMETER CONDITIONS MIN TYP

(1)

RESOLUTION 16 Bits

DC ACCURACY

Integral Nonlinearity INL ±3 ±12 LSB

Differential Linearity

Input Offset V

Input Offset Drift TCV

Gain Error G

Gain Error Drift TCG

Power-Supply Rejection Ratio PSRR 4.75V < V

(1)

DNL ±1 LSB

OS

OS

ERR

ERR

< 5.25V 80 dB

DD

0.005 0.018 %

±300 ±1000 µV

28µV/°C

±0.25 ±2%

20 ppm/°C

ANALOG INPUT

Full-Scale Range FSR +In – (–In) ±320 mV

Operating Common-Mode Signal

(2)

–0.1 5 V

Input Capacitance Common-Mode 3 pF

Input Leakage Current ±1nA

Differential Input Resistance Equivalent 28 kΩ

Differential Input Capacitance 5pF

Common-Mode Rejection Ratio

(2)

CMRR At DC 90 dB

V

= ±1.25Vp-p at 50kHz 85 dB

IN

INTERNAL VOLTAGE REFERENCE

Reference Voltage V

Initial Accuracy Scale to 320mV ±2+-+ %

Reference Temperature Drift dV

PSRR 80 dB

OUT

/dT ±20 ppm/°C

OUT

Scale to 320mV 2.450 2.5 2.550 V

Startup Time 0.1 ms

INTERNAL CLOCK FOR MODES, 0, 1, AND 2

Clock Frequency 8 10 12 MHz

EXTERNAL CLOCK FOR MODE 3

Clock Frequency 16 20 24 MHz

AC ACCURACY

Signal-to-Noise Ratio + Distortion SINAD V

Signal-to-Noise Ratio SNR V

Total Harmonic Distortion THD V

Spurious Free Dynamic Range SFDR V

= ±250mVp-p at 5kHz 70 dB

IN

= ±250mVp-p at 5kHz 67 70.5 dB

IN

= ±250mVp-p at 5kHz –84 dB

IN

= ±250mVp-p at 5kHz 84 dB

IN

DIGITAL INPUT

Logic Family TTL with Schmitt Trigger

High-Level Input Voltage V

Low-Level Input Voltage V

High-Level Input Current I

Low-Level Input Current I

Input Capacitance C

IH

IL

IH

IL

J

VI = V

DD

VI = GND –2.5 0.005 µA

2.6 VDD + 0.3 V

–0.3 0.8 V

0.005 2.5 µA

5pF

DIGITAL OUTPUT

High-Level Digital Output V

Low-Level Digital Output V

Output Capacitance C

Load Capacitance C

OH

OL

O

L

VDD = 4.5V, IO = –5mA 4.6 V

V

= 4.5V, IO = –15mA 3.9 V

DD

VDD = 4.5V, IO = 5mA 0.4 V

V

= 4.5V, IO = 15mA 1.1 V

DD

5pF

POWER SUPPLY

Supply Voltage V

Operating Supply Current I

DD

CC

Power Dissipation V

Mode 0 6 7.5 mA

Mode 3 8 9.5 mA

= 5V, Mode 0 30 37.5 mW

DD

V

= 5V, Mode 3 40 47.5 mW

DD

4.5 5 5.5 V

OPERATING TEMPERATURE –40 +85 °C

NOTES: (1) All typical values are at T

line through the transfer curve for V

typical information parameter not tested.

= +25°C. (2) Ensured by design. (3) Integral nonlinearity is defined as one-half the peak-to-peak deviation of the best fit

A

+ = –250mV to +250mV, expressed either as the number of LSBs or as a percent of measured input range (500mV). (4) Only

IN

MAX UNITS

30 pF

ADS1202

SBAS275

www.ti.com

3

Page 4

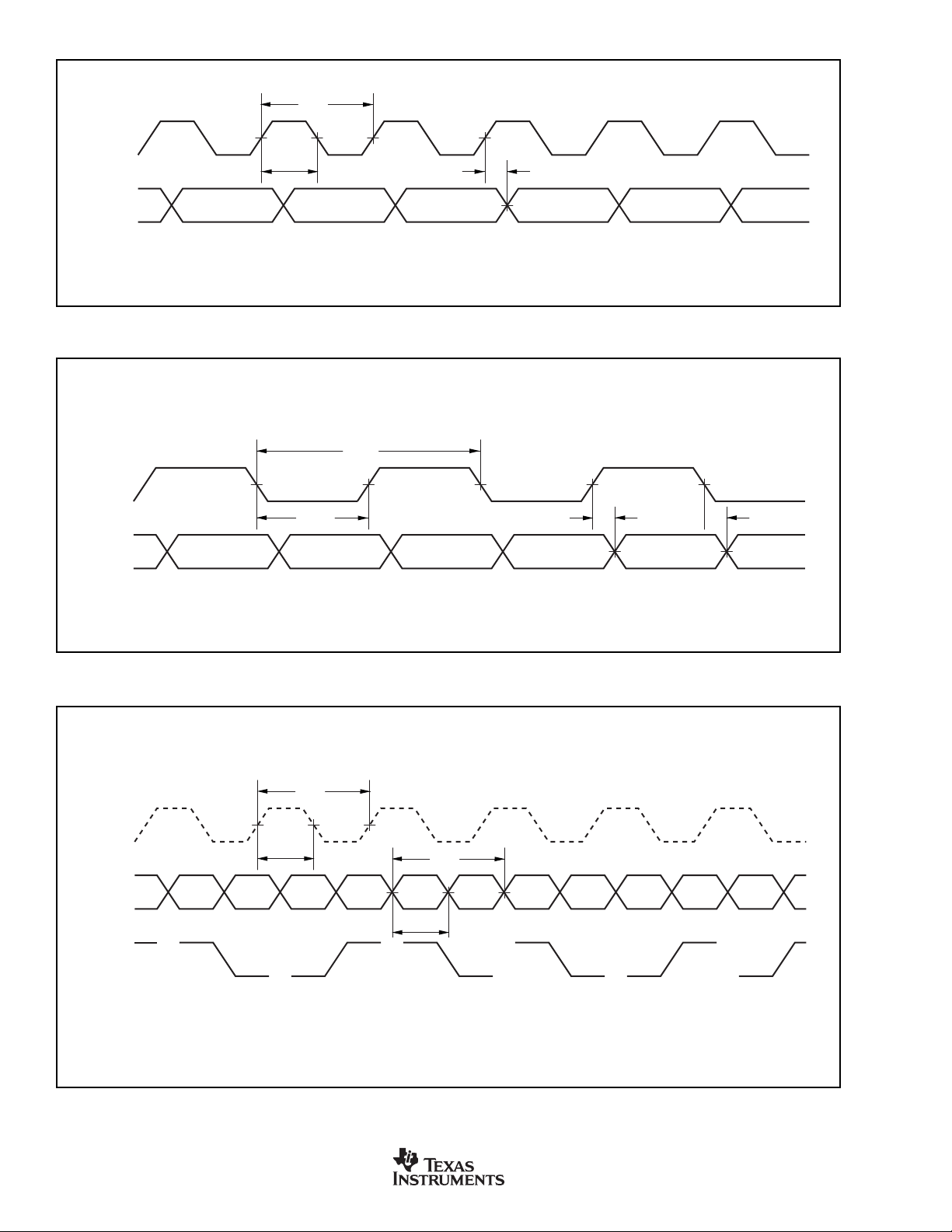

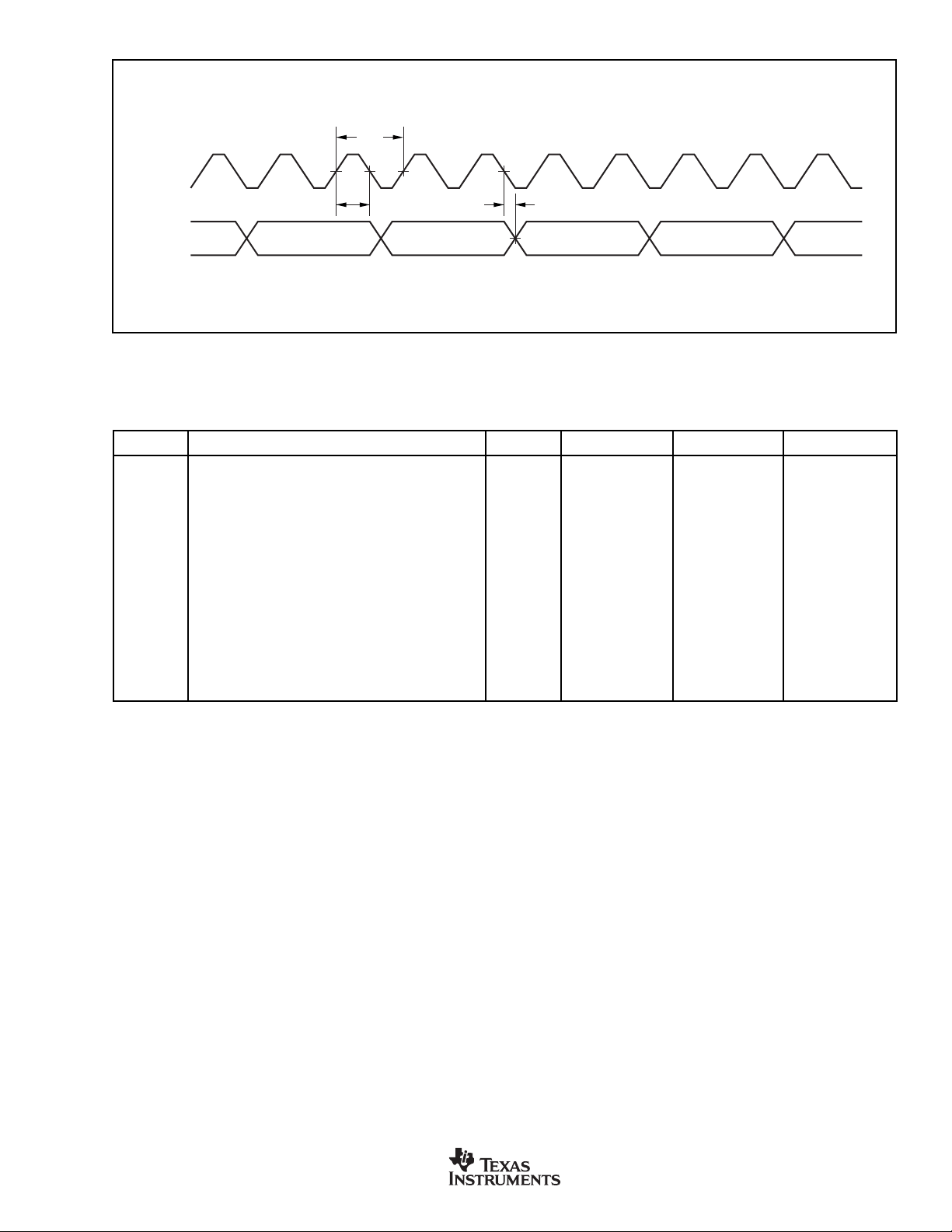

TIMING DIAGRAMS

MCLK

MDAT

DIAGRAM 1: Mode 0 Operation.

MCLK

t

C1

t

W1

t

C2

t

D1

MDAT

DIAGRAM 2: Mode 1 Operation.

MCLK

MDAT

t

W2

t

C1

t

w1

t

C3

t

w3

t

D2

t

D3

10 1100

DIAGRAM 3: Mode 2 Operation.

4

www.ti.com

ADS1202

SBAS275

Page 5

TIMING DIAGRAMS (Cont.)

t

C4

MCLK

t

w4

t

D4

MDAT

DIAGRAM 4: Mode 3 Operation.

TIMING CHARACTERISTICS

over recommended operating free-air temperature range –40°C to +85°C, VDD = 5V, and MCLK = 10MHz, unless otherwise noted.

SPEC DESCRIPTION MODE MIN MAX UNITS

t

C1

t

W1

t

D1

t

C2

t

W2

t

D2

t

D3

t

C3

t

W3

t

C4

t

W4

t

D4

t

R1

t

F1

NOTE: All input signals are specified with t

Clock Period 0 90 110 ns

Clock HIGH Time 0 tC1/2 – 5t

/2 + 5 ns

C1

Data delay after rising edge of clock 0 tC1/4 – 10 tC1/4 + 10 ns

Clock Period 1 180 220 ns

Clock HIGH Time 1 tC2/2 – 5t

/2 + 5 ns

C2

Data delay after rising edge of clock 1 tC2/4 – 10 tC2/4 + 10 ns

Data delay after falling edge of clock 1 tC2/4 – 10 tC2/4 + 10 ns

Clock Period 2 90 110 ns

Clock HIGH Time 2 tC3/2 – 5t

/2 + 5 ns

C3

Clock Period 3 45 55 ns

Clock HIGH Time 3 10 tC4 – 10 ns

Data delay after falling edge of clock 3 0 10 ns

Rise Time of Clock 3 0 10 ns

Fall Time of Clock 3 0 10 ns

= tF = 5ns (10% to 90% of VDD) and timed from a voltage level of (VIL + VIH)/2. See timing diagrams 1 thru 4.

R

ADS1202

SBAS275

www.ti.com

5

Page 6

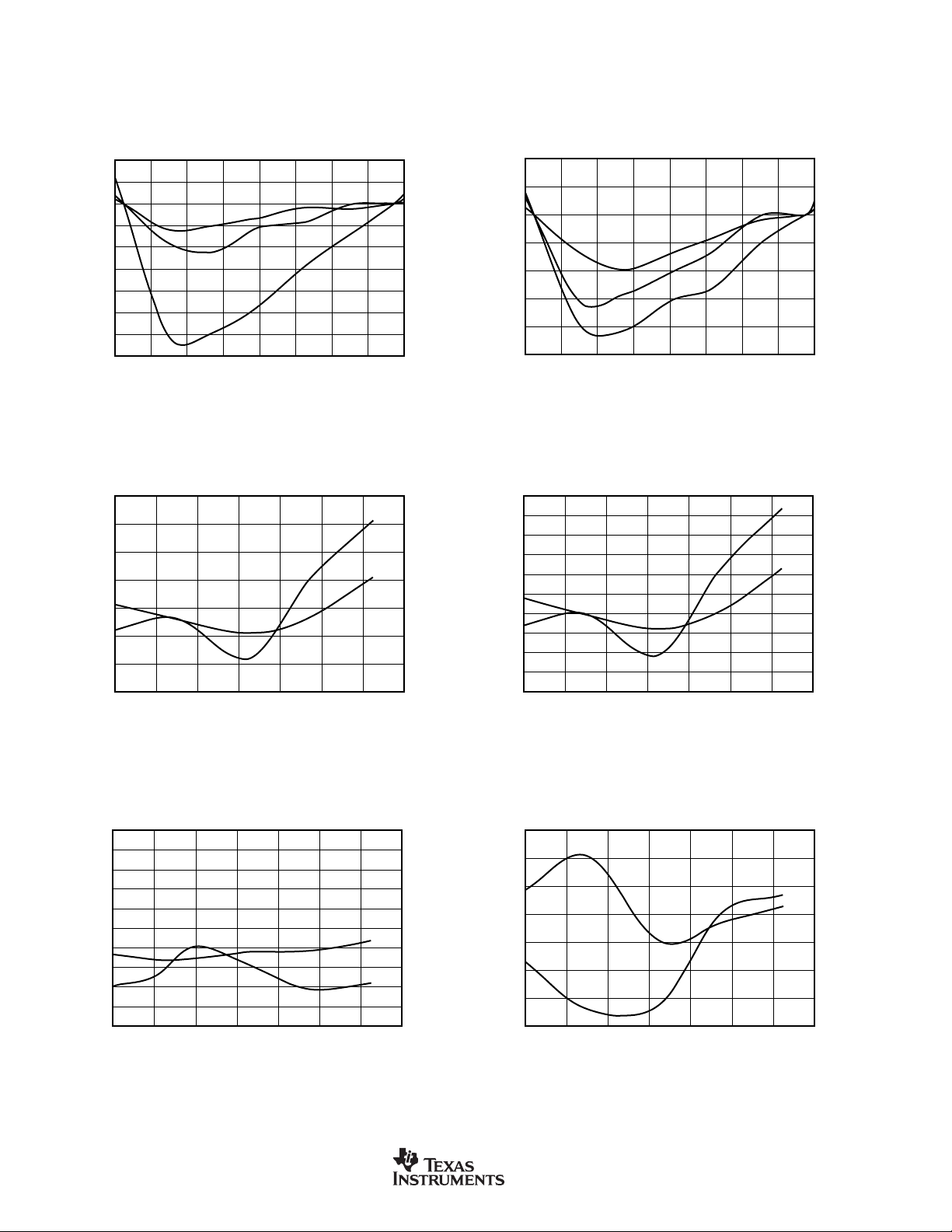

TYPICAL CHARACTERISTICS

VDD = 5V, +In = –250mV to 250mV, –In = 0V, and MCLK = 10MHz, unless otherwise noted.

INTEGRAL NONLINEARITY vs INPUT SIGNAL (Mode 0)

2

1

0

–1

–2

–3

INL (LSB)

–4

–5

–6

–7

INTEGRAL NONLINEARITY vs TEMPERATURE

7

6

5

4

3

INL (LSB)

2

1

0

–40 –20 200408060 100

25°C

–40°C

+85°C

0–320 –240 –80–160 80 240160 320

Differential Input Voltage (mV)

Mode 0

Mode 3

Temperature (°C)

INTEGRAL NONLINEARITY vs INPUT SIGNAL (Mode 3)

2

1

0

–1

–2

INL (LSB)

–3

–4

–5

0.010

0.009

0.008

0.007

0.006

0.005

INL (%)

0.004

0.003

0.002

0.001

INTEGRAL NONLINEARITY vs TEMPERATURE

0

–40 –20 200408060 100

25°C

–40°C

0–320 –240 –80–160 80 240160 320

Differential Input Voltage (mV)

Mode 0

Mode 3

Temperature (°C)

+85°C

300

200

100

0

–100

–200

–300

Offset (µV)

–400

–500

–600

–700

–40 –20 200408060 100

6

OFFSET vs TEMPERATURE

Mode 3

Mode 0

Temperature (°C)

www.ti.com

0.14

0.12

0.10

0.08

0.06

Gain (%)

0.04

0.02

0

–40 –20 200408060 100

GAIN vs TEMPERATURE

Mode 3

Mode 0

Temperature (°C)

ADS1202

SBAS275

Page 7

TYPICAL CHARACTERISTICS (Cont.)

SIGNAL-TO-NOISE RATIO vs TEMPERATURE

–40 –20 200408060 100

Temperature (°C)

SNR (dB)

71.0

70.8

70.6

70.4

70.2

70.0

69.8

69.6

69.4

69.2

69.0

Mode 0

Mode 3

EFFECTIVE NUMBER OF BITS

vs DECIMATION RATIO

0 400 800 1200 1600 2000

Decimation Ratio (OSR)

ENOB

16

14

12

10

8

6

4

Sinc

3

Filter

Sinc

2

Filter

VDD = 5V, +In = –250mV to 250mV, –In = 0V, and MCLK = 10MHz, unless otherwise noted.

80

70

60

50

40

30

RMS Noise (µV)

20

10

0

–320 –240 –80–160 0 24016080 320

71.0

70.6

70.2

RMS NOISE vs INPUT VOLTAGE LEVEL

Differential Input Voltage (mV)

SIGNAL-TO-NOISE + DISTORTION

vs TEMPERATURE

Mode 3

69.8

SINAD (dB)

69.4

69.0

–40 –20 200408060 100

Temperature (°C)

SPURIOUS-FREE DYNAMIC RANGE

AND TOTAL HARMOINIC DISTORTION

95

93

91

89

87

85

83

SFDR (dB)

81

79

77

75

–40 –20 200408060 100

ADS1202

SBAS275

vs TEMPERATURE (Mode 0)

SFDR

THD

Temperature (°C)

Mode 0

0.5Vp-p

5kHz

–95

–93

–91

–89

–87

–85

THD (dB)

–83

–81

–79

–77

–75

www.ti.com

SPURIOUS-FREE DYNAMIC RANGE

AND TOTAL HARMOINIC DISTORTION

95

93

91

89

87

85

83

SFDR (dB)

81

79

77

75

–40 –20 200408060 100

vs TEMPERATURE (Mode 3)

SFDR

THD

Temperature (°C)

–95

–93

–91

–89

–87

–85

–83

–81

–79

–77

–75

THD (dB)

7

Page 8

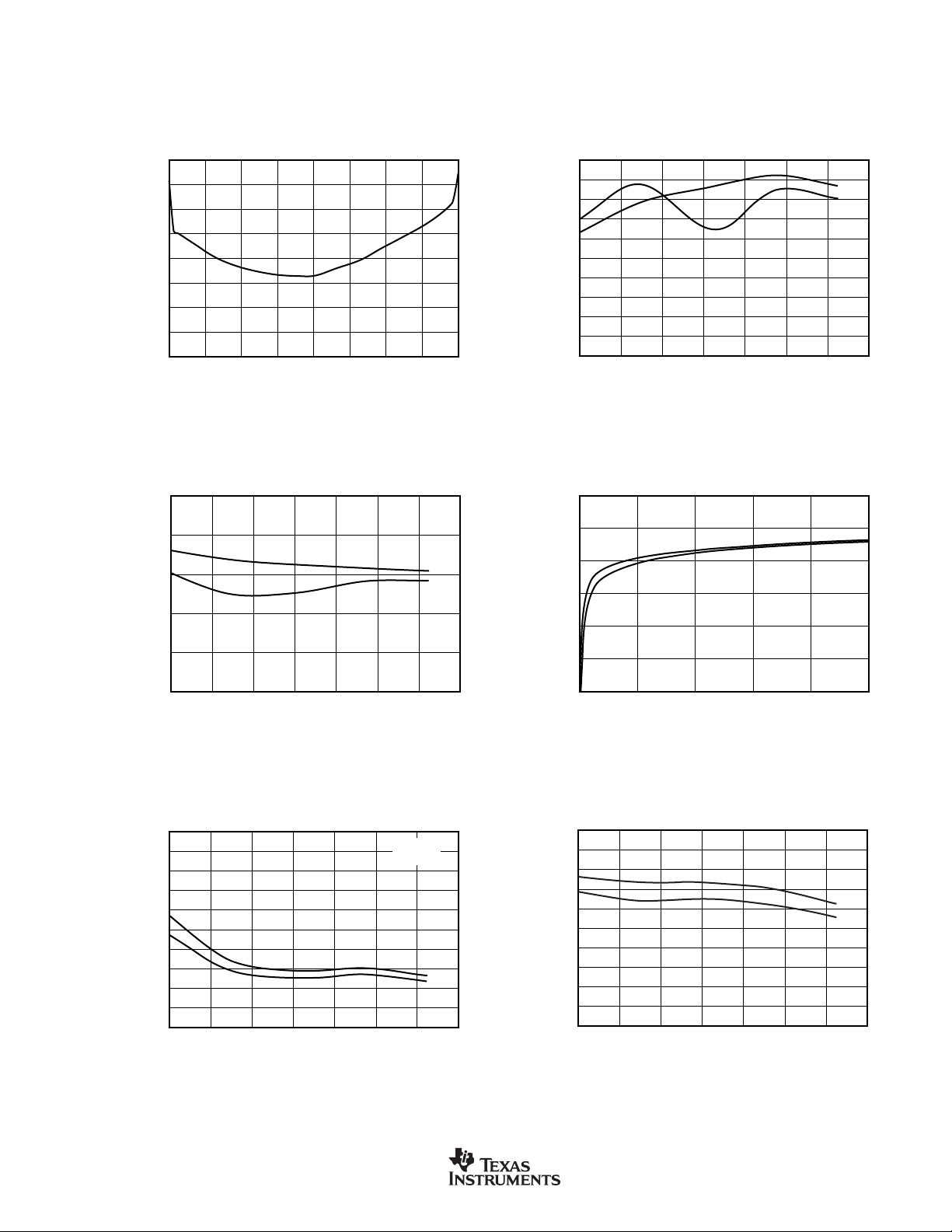

TYPICAL CHARACTERISTICS (Cont.)

SPURIOUS-FREE DYNAMIC RANGE

AND TOTAL HARMOINIC DISTORTION

vs INPUT FREQUENCY (Mode 3)

110

Input Frequency (kHz)

SFDR

THD

SFDR (dB)

THD (dB)

110

100

90

80

70

60

50

–110

–100

–90

–80

–70

–60

–50

OSR = 256

Sinc

3

Filter

VDD = 5V, +In = –250mV to 250mV, –In = 0V, and MCLK = 10MHz, unless otherwise noted.

SPURIOUS-FREE DYNAMIC RANGE

AND TOTAL HARMOINIC DISTORTION

110

vs INPUT FREQUENCY (Mode 0)

–110

100

90

80

SFDR (dB)

70

60

50

110

0

–20

–40

–60

–80

Magnitude (dB)

–100

SFDR

OSR = 256

3

Sinc

Filter

THD

Input Frequency (kHz)

FREQUENCY SPECTRUM

(4096 Point FFT, f

= 1kHz, 0.5Vp-p)

IN

Mode 0

–100

–90

–80

–70

–60

–50

THD (dB)

0

–20

–40

–60

–80

Magnitude (dB)

–100

FREQUENCY SPECTRUM

(4096 Point FFT, f

= 5kHz, 0.5Vp-p)

IN

Mode 0

–120

–140

10.5

10.2

9.9

9.6

MCLK (MHz)

9.3

9.0

8

–40 –20 0 20 40 60 80 100 120

CLOCK FREQUENCY vs TEMPERATURE

802 641014161812 20

Frequency (kHz)

Temperature (°C)

www.ti.com

–120

–140

100

95

90

85

80

75

70

CMRR (dB)

65

60

55

50

1 10 100

802 641014161812 20

Frequency (kHz)

COMMON-MODE REJECTION RATIO

vs FREQUENCY

Frequency of Power Supply (Hz)

ADS1202

SBAS275

Page 9

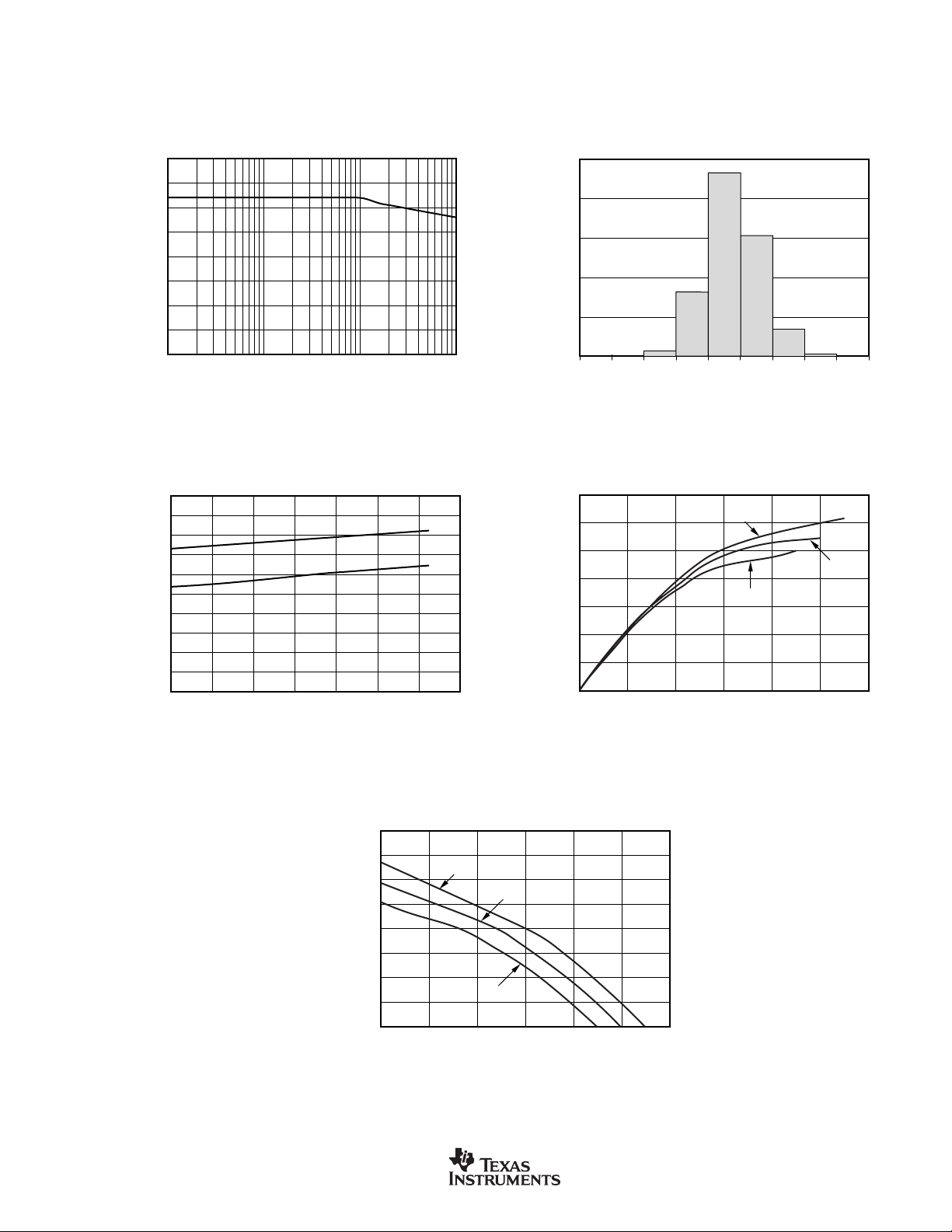

TYPICAL CHARACTERISTICS (Cont.)

2000

1800

1600

1400

1200

1000

800

600

400

200

0

HISTOGRAM OF OUTPUT DATA

ppm of FS

–1114

–1053

–992

–931

–870

–809

–748

–687

–626

Number of Occurrences

MCLK AND MDAT

TYPICAL SINK CURRENT

3012 456

Output Voltage V

OL

(V)

Output Current I

OL

(mA)

70

60

50

40

30

20

10

0

5.5V

5V

4.5V

k

VDD = 5V, +In = –250mV to 250mV, –In = 0V, and MCLK = 10MHz, unless otherwise noted.

POWER-SUPPLY REJECTION RATIO

90

85

80

75

70

PSRR (dB)

65

60

55

50

100 1k 10k 100

POWER-SUPPLY CURRENT vs TEMPERATURE

10

9

8

7

6

5

4

Current (mA)

3

2

1

0

–40 –20 200408060 100

vs FREQUENCY

Frequency of Power Supply (Hz)

Mode 0

Mode 3

Temperature (°C)

ADS1202

SBAS275

80

70

60

(mA)

50

OH

40

30

20

Output Current I

10

0

MCLK AND MDAT

TYPICAL SOURCE CURRENT

5.5V

5V

4.5V

3012 456

Output Voltage V

(V)

OH

www.ti.com

9

Page 10

GENERAL DESCRIPTION

The ADS1202 is a single-channel, 2nd-order, CMOS analog

modulator designed for medium to high resolution conversions from DC to 39kHz with an oversampling ratio (OSR) of

256. The output of the converter (MDAT) provides a stream

of digital ones and zeros. The time average of this serial

output is proportional to the analog input voltage. The combination of an ADS1202 and a Digital Signal Processor

(DSP) that is programmed to implement a digital filter results

in a medium resolution A/D converter system. This system

allows flexibility with the digital filter design and is capable of

A/D conversion results that have a dynamic range that

exceeds 85dB with OSR = 256.

THEORY OF OPERATION

The differential analog input of the ADS1202 is implemented

with a switched capacitor circuit. This switched capacitor

circuit implements a 2nd-order modulator stage, which digitizes the input signal into a 1-bit output stream. The sample

clock (MCLK) provides the switched capacitor network and

modulator clock signal for the A/D conversion process, as

well as the output data-framing clock. The clock source can

be internal as well as external. Different frequencies for this

clock allow for a variety of solutions and signal bandwidths

(however, this can only be utilized in mode 3). The analog

input signal is continuously sampled by the modulator and

compared to an internal voltage reference. A digital stream,

which accurately represents the analog input voltage over

time, appears at the output of the converter.

+5V+5V

M

27Ω

27Ω

0.1µF0.1µF

10nF

M0

V

V

M1

IN

IN

ADS1202

+

–

V

MCLK

MDAT

GND

DD

0.1µF

FIGURE 1. Connection Diagram for the ADS1202 Delta-Sigma Modulator Including DSP.

V

DDO

SPICLK

SPISIMO

V

SSO

DSP

10

www.ti.com

ADS1202

SBAS275

Page 11

ANALOG INPUT STAGE

Analog Input

The input design topology of the ADS1202 is based on a fully

differential switched-capacitor architecture. This input stage

provides the mechanism to achieve low system noise, high

common-mode rejection (90dB), and excellent power-supply

rejection. The input impedance of the analog input is dependant on the input capacitor and modulator clock frequency

(MCLK), which is also the sampling frequency of the modulator. Figure 2 shows the basic input structure of the ADS1202.

The relationship between the input impedance of the ADS1202

and the modulator clock frequency is:

A

Ω

=

(

)

IN

The input impedance becomes a consideration in designs

where the source impedance of the input signal is HIGH. In

this case, it is possible for a portion of the signal to be lost

across this external source impedance. The importance of this

effect depends on the desired system performance. There are

two restrictions on the analog input signal to the ADS1202.

Under no conditions should the current into or out of the

analog inputs exceed 10mA. The absolute input voltage range

must stay in the range GND – 0.4V to V

the inputs exceed these limits, the input protection diodes on

the front end of the converter will begin to turn on. In addition,

12

f MHz

•107

MCLK

()

+ 0.3V. If either of

DD

(1)

the linearity of the device is ensured only when the analog

voltage applied to either input resides within the range defined

by –320mV and +320mV.

Modulator

The modulator sampling frequency (CLK) can be operated

over a range of a few MHz to 12MHz in mode 3. The

frequency of MCLK can be decreased to adjust for the clock

requirements of the application. The external MCLK must

have double the modulator frequency.

The modulator topology is fundamentally a 2nd-order, chargebalancing A/D converter, as the one conceptualized in Figure 3.

The analog input voltage and the output of the 1-bit Digital-toAnalog Converter (DAC) are differentiated, providing an analog

voltage at X

to their individual integrators. The output of these integrators

progress in a negative or positive direction. When the value of

the signal at X

output of the comparator switches from negative to positive, or

positive to negative, depending on its original state. When the

output value of the comparator switches from HIGH to LOW or

vice versa, the 1-bit DAC responds on the next clock pulse by

changing its analog output voltage at X

to progress in the opposite direction. The feedback of the

modulator to the front end of the integrators forces the value of

the integrator output to track the average of the input.

and X3. The voltage at X2 and X3 are presented

2

equals the comparator reference voltage, the

4

, causing the integrators

6

AIN+

Switching Frequency

= CLK

AIN–

FIGURE 2. Input Impedance of the ADS1202.

X

X(t)

f

S

2

Integrator 1

1.5pF

1.5pF

R

SW

350kΩ (typ)

R

SW

350kΩ (typ)

X

3

V

Integrator 2

CM

C

INT

7pF (typ)

C

INT

7pF (typ)

X

V

REF

4

High

Impedance

> 1GΩ

High

Impedance

> 1GΩ

f

CLK

Comparator

DATA

FIGURE 3. Block Diagram of the 2nd-Order Modulator.

ADS1202

SBAS275

www.ti.com

X

6

D/A Converter

11

Page 12

DIGITAL OUTPUT

The timing diagram for the ADS1202 data retrieval is shown

in the Timing Diagrams. When an external clock is applied to

MCLK, it is used as a system clock by the ADS1202, as well

as a framing clock for data out (this procedure, however, can

only be utilized in mode 3). The modulator output data, which

is a serial stream, is available on the MDAT pin. Typically,

MDAT is read on the falling edge of MCLK.

An input differential signal of 0V will ideally produce a stream

of ones and zeros that are HIGH 50% of the time and LOW

50% of the time. A differential input of 256mV will produce a

stream of ones and zeros that are HIGH 80% of the time. A

differential input of –256mV will produce a stream of ones

and zeros that are HIGH 20% of the time. The input voltage

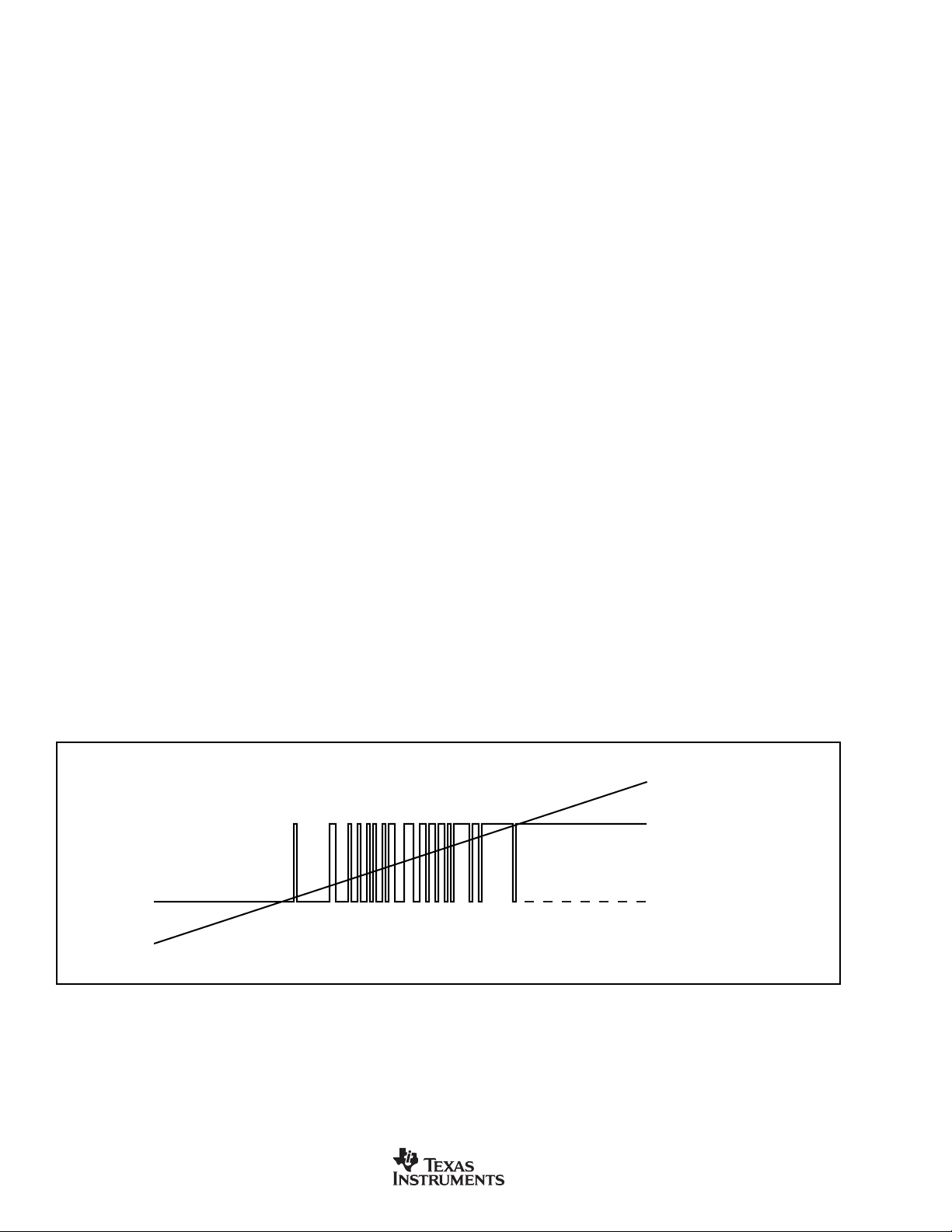

versus the output modulator signal is shown in Figure 4.

DIGITAL INTERFACE

INTRODUCTION

The analog signal that is connected to the input of the delta-sigma

modulator is converted using the clock signal (CLK) applied to the

modulator. The result of the conversion, or modulation, is the

output signal DATA from the delta-sigma modulator.

In most applications where direct connection is realized

between delta-sigma modulator and DSP or uC, two standard signals are provided. The MDAT and MCLK signals

provide the easiest means of connection. If it is required to

reduce the number of connection lines, having two signals is

sometimes not an optimal solution.

The receiver, DSP, or other control circuit must sample the

output data signal from the modulator at the precise sampling

instant. To do this, sampling a clock signal at the receiver is

needed in order to synchronize with the clock signal at the

transmitter. The delta-sigma modulator clock signal, receiver,

filter, and clock must be synchronized. Three general meth-

ods can be used to obtain this synchronization. The first

method has the delta-sigma modulator and the filter receive

the clock signal from the master clock. The second method

has the delta-sigma modulator transmit the clock signal

together with the data signal. The third method has the filter

derivate the clock signal from the received waveform itself.

An ideal solution is a delta-sigma modulator with a flexible

interface, such as the ADS1202, which can provide flexible

output format on the output lines MCLK and MDAT, thus

covering different modes of operation. The signal type that

can be provided is selected with control signals M0 and M1.

FLEXIBLE DELTA-SIGMA INTERFACE

Figure 5 illustrates the flexible interface of the ADS1202

delta-sigma converter. The control signals M0 and M1 are

entered in the decoder that decodes the input code and

selects the desired mode of operation. Five output signals

from the decoder control the RC oscillator, multiplexer MUX1,

multiplexer MUX2, multiplexer MUX3, and multiplexer MUX4.

MUX1 is controlled by the decoder signal. When the internal

RC oscillator is used, the control signal from the decoder

enables the RC oscillator. At the same time, MUX1 uses the

INTCLK signal as a source for the output signal from MUX1,

which is entering the code generator. If the external clock is

used, the control signal from the decoder disables the internal RC oscillator and the control signal from the decoder, and

positions MUX1 so that EXTCLK provides the output signal

from MUX1 as the input in the code generator.

MUX2 selects the output clock, OCLK. The control signal

coming from the decoder controls the output clock. Two

signals come from the code generator as a half clock frequency, CLK/2, and as a quarter clock frequency, CLK/4,

and provide MUX2 with the input signal. The control signal

will select two different output modes on the OCLK signal as

half clock or quarter clock.

Modulator Output

Analog Input

FIGURE 4. Analog Input Versus Modulator Output of the ADS1201.

12

www.ti.com

+FS (Analog Input)

–FS (Analog Input)

ADS1202

SBAS275

Page 13

M0

M1

Interface Circuit

Decoder

MUX1

MUX2

AIN

MCLK

RC

Oscillator

MUX4

INTCLK

EXTCLK

OCLK

FIGURE 5. Flexible Interface Block Diagram.

The code generator receives the clock signal from MUX1 and

generates the delta-sigma modulator clock (CLK) divided as

half clock (CLK/2) and quarter clock (CLK/4). At the same

time, the continuous data stream (DATA) coming from the

delta-sigma modulator is elaborated by the Code Generator.

Twinned binary coding (also known as split phase or Manchester coding) is implemented and then output from the code

generator to MUX3.

MUX3 selects the source of the output bit stream data,

MDAT. The control signal coming from the decoder controls

the input source of MDAT. Two signals are coming in to the

MUX3, one directly from the delta-sigma modulator and the

other from the code generator. The control signal from the

decoder can select two different output modes on the signal

MDAT: bit stream from a delta-sigma modulator or twinned

binary coding of the same signal.

The last control signal from the decoder controls MUX4.

MUX2 selects the input or output clock, the MCLK signal.

The control signal coming from the decoder controls the

direction of the clock. One signal entering MUX4 from MUX2

comes as a clock signal OCLK. Another signal leaves MUX4

and provides an input to MUX1 as an external clock, EXTCLK.

Code

Generator

CLK/2

CLK/4

CLK DATA

∆∑

Modulator

MUX3

MDAT

The control signal from the decoder can select two different

modes on MCLK, one as an output of the internal clock signal

and another as the input for the external clock signal.

As a function of two control signals (M0 and M1), the decoder

circuit, using five control signals, will set multiplexers in order

to obtain the desired mode of operation.

DIFFERENT MODES OF OPERATION

Figure 5 presents mode selectors (input signals M0 and M1)

that enter the flexible interface circuit and decoder that

decodes the input code, and select the desired mode of

operation. With two control lines it is possible to select four

different modes of operation mode 0, mode 1, mode 2, and

mode 3, which are shown in Table I.

MODE DEFINITION M1 MO

0 Internal Clock, Synchronous Data Output LOW LOW

1 Internal Clock, Synchronous Data Output, LOW HIGH

Half Output Clock Frequency

2 Internal Clock, Manchester Coded Data Output HIGH LOW

3 External Clock, Synchronous Data Output HIGH HIGH

TABLE I. Mode Definition and Description.

ADS1202

SBAS275

www.ti.com

13

Page 14

Mode 0

In mode 0 both input signals, M0 and M1, are LOW. The

control signal coming from the decoder enables the internal

RC oscillator that provides the clock signal INTCLK as an

input to MUX1. The control signal coming from the decoder

also positions MUX1 so that the output signal, which is an

input signal for the code generator, is INTCLK. Another

control signal from the decoder circuit positions MUX3 so

that the source for the output signal MDAT is the signal

arriving directly from the delta-sigma modulator, DATA. MUX2

is positioned for the mode controlled by the signal coming

from the decoder so output signal OCLK is CLK/2. The signal

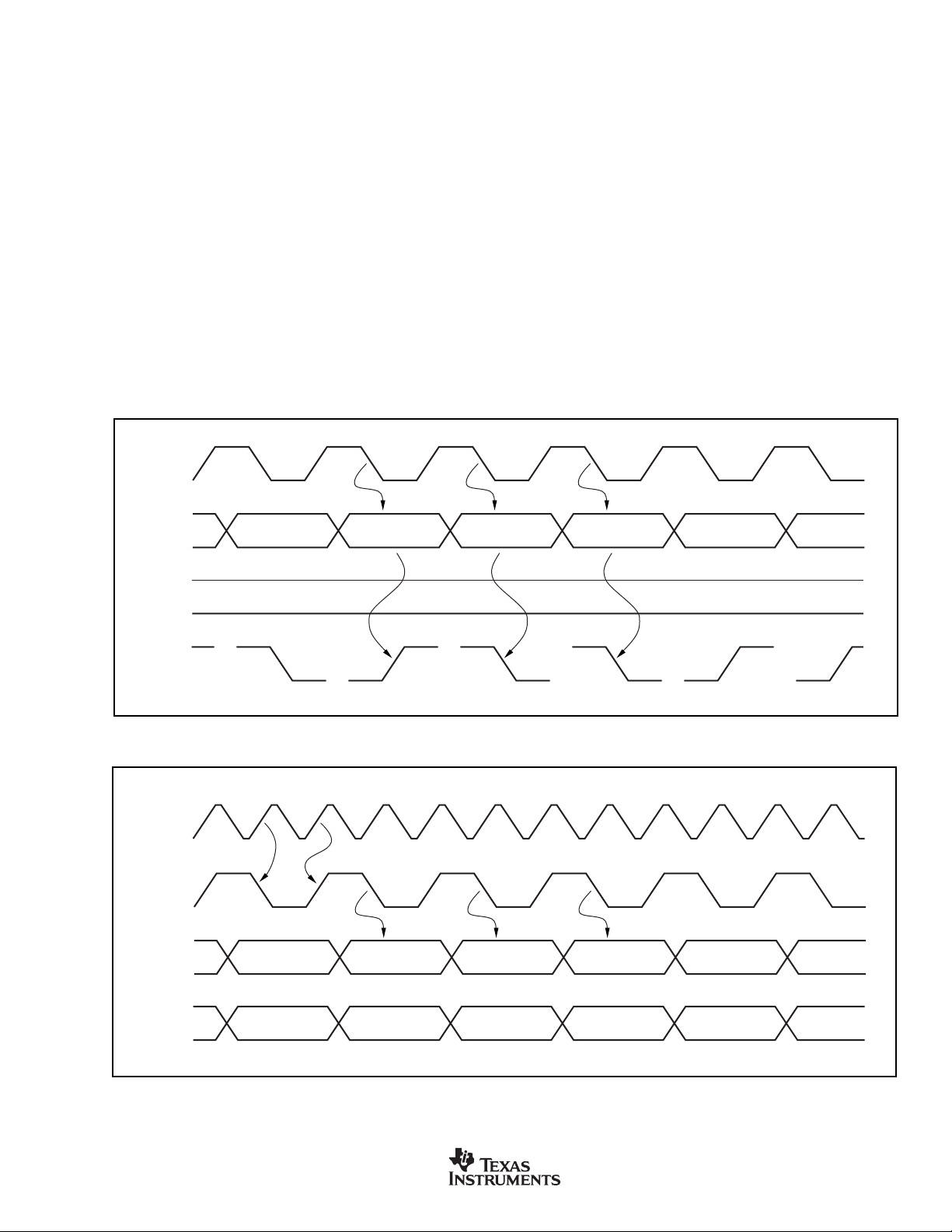

timings for mode 0 operation are presented in Figure 6. In

this mode, DSP or µC read MDAT data on every rising edge

of the MCLK output clock.

CLK

Mode 1

In mode 1, the input signal M0 is HIGH and M1 is LOW (see

Table I). The first control signal coming from the decoder

enables the internal RC oscillator that provides clock signal

INTCLK as an input to MUX1. The second control signal

coming from the decoder positions MUX1 so that the output

signal that is the input signal to the code generator is

INTCLK. The output signal from the delta-sigma modulator,

DATA, is also the MDAT signal coming from the modulator

because the control signal from the decoder positions MUX3

for that operation. MUX2 is positioned for the mode controlled by the control signal coming from the decoder with an

OCLK of CLK/2. Output clock signal MCLK comes through

MUX4 from MUX2 as OCLK or CLK/2. The signal timings for

mode 1 operation are presented in Figure 7. In this mode,

DSP or µC read data on every edge, rising and falling, of the

output clock.

DATA

MCLK

MDAT

FIGURE 6. Signal Timing in Mode 0.

CLK

DATA

MCLK

MDAT

FIGURE 7. Signal Timing in Mode 1.

14

www.ti.com

ADS1202

SBAS275

Page 15

Mode 2

In mode 2, M0 is low and M1 is HIGH (see Table I). The control

signal coming from the decoder enables the internal RC oscillator that provides the clock signal INTCLK as an input to MUX1.

Another control signal coming from the decoder positions MUX1

so that the output signal that is the input signal to the code

generator is INTCLK. The output signal MDAT comes from the

code generator because the control signal from the decoder

positions MUX3 for that operation. The DATA signal coming

from the delta-sigma modulator enters the code generator,

where it combines with the clock signal, and twinned binary

coding is implemented as split phase or Manchester coding,

providing the output signal for MUX3. The MCLK output clock

is not active, as multiplexers MUX2 and MUX4 are positioned

for this mode controlled by the control signals coming from the

decoder. The signals timings for mode 2 operation are presented in Figure 8. In this mode, DSP or µC need to derive the

clock signal from the received waveform itself. Different clock

recovery networks can be implemented.

CLK

Mode 3

mode 3 is similar to mode 0; the only difference is that an

external clock (EXTCLK) is provided. In mode 3, both input

signals M0 and M1 are HIGH (see Table I). The control

signal coming from the decoder disables the internal RC

oscillator. The input signal EXTCLK provides the clock

signal as an input to MUX1. The control signal coming from

the decoder positions MUX1 so that the output signal that

is the input signal to the code generator is EXTCLK. The

output signal MDAT is the DATA signal coming directly from

the delta-sigma modulator because the control signal from

the decoder positions MUX3 for that operation. The signal

timings for mode 3 operation are presented in Figure 9. In

this mode, DSP or µC read data on every falling edge of the

input clock.

DATA

MCLK

MDAT

FIGURE 8. Signal Timing in Mode 2.

MCLK

CLK

DATA

MDAT

FIGURE 9. Signal Timing in Mode 3.

ADS1202

SBAS275

www.ti.com

15

Page 16

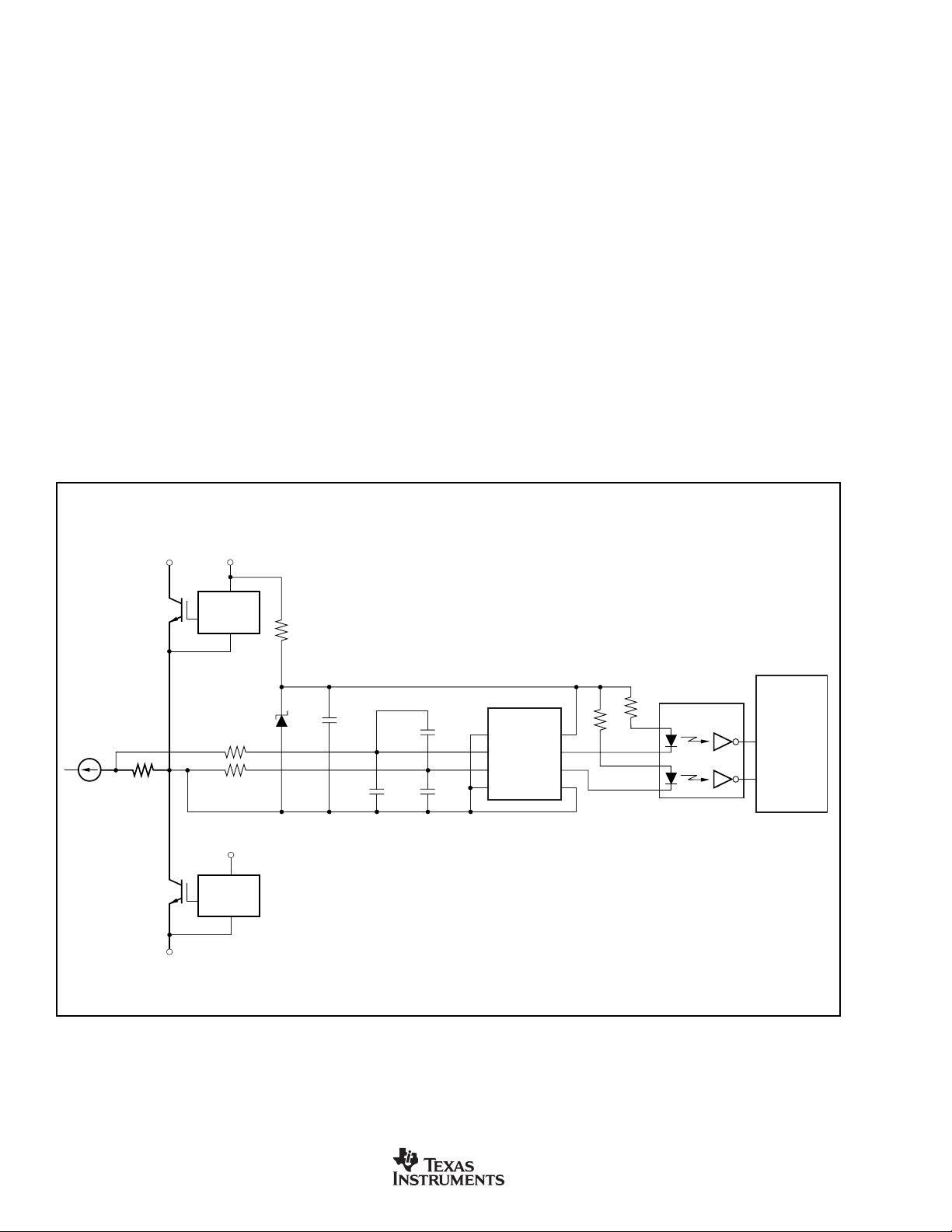

APPLICATIONS

Mode 0 operation in a typical application is shown in Figure

10. Measurement of the motor phase current is done via the

shunt resistor. For better performance, both signals are

filtered. R

signal, R

C

in combination with R2 and R3 filter the common-mode

4

input noise. In this configuration, the shunt resistor is connected via three wires with the ADS1202.

The power supply is taken from the upper gate driver power

supply. A decoupling capacitor of 0.1µF is recommended for

filtering the power supply. If better filtering is required, an

additional 1µF to 10µF capacitor can be added.

The control lines M0 and M1 are both LOW while the part is

operating in mode 0. Two output signals, MCLK and MDAT,

are connected directly to the optocoupler. The optocoupler

can be connected to transfer a direct or inverse signal

because the output stage has the capacity to source and sink

the same current. The discharge resistor is not needed in

parallel with optocoupler diodes because the output driver

has the capacity to keep the LED diode out of the charge.

and C2 filter noise on the noninverting input

2

and C3 filter noise on the inverting input signal, and

3

The DSP can be directly connected at the output of two

channels of the optocoupler, C28x or C24x. In this configuration, the signals arriving at C28x or C24x are standard

delta-sigma modulator signals and are connected directly to

the SPICLK and SPISIMO pins. Being a delta-sigma converter, there is no need to have word synch on the serial

data, so SPI is ideal for connection. McBSP would work as

well in SPI mode.

When component reduction is necessary, the ADS1202 can

operate in mode 2, as shown in Figure 11. M1 is HIGH and

M0 is LOW. Only the noninverting input signal is filtered.

R

and C2 filter noise on the input signal. The inverting input

2

is directly connected to the GND pin, which is simultaneously

connected to the shunt resistor.

The output signal from the ADS1202 is Manchester coded. In

this case, only one signal is transmitted. For that reason, one

optocoupler channel is used instead of two channels, as in

the previous example of Figure 10. Another advantage of this

configuration is that the DSP will use only one line per

channel instead of two. That permits the use of smaller DSP

packages in the application.

R

SENSE

HV+

HV–

Floating

Power Supply

Gated

Drive Circuit

R

2

27Ω

R

3

27Ω

Power

Supply

Gated

Drive Circuit

R

D

5.1V

1

C28x

R

5

C

1

1

0.1µF

C

2

0.1µF

C

4

10nF

C

3

0.1µF

ADS1202

M0

+

V

IN

–

V

IN

M1

V

MCLK

MDAT

GND

R

4

DD

Optocoupler

C24x

SPICLK

SPISIMO

or

FIGURE 10. Application Diagram in Mode 0.

16

www.ti.com

ADS1202

SBAS275

Page 17

FIGURE 11. Application Diagram in Mode 2.

R

SENSE

R

2

27Ω

D

1

5.1V

R

1

C

1

0.1µF

ADS1202

C

2

0.1µF

R

4

M0

V

IN

+

V

IN

–

M1

V

DD

MCLK

MDAT

GND

HV+

HV–

Floating

Power Supply

Gated

Drive Circuit

C28x

or

C24x

Optocoupler

Gated

Drive Circuit

Power

Supply

Floating

HV+

Power Supply

Gate Drive

Circuit

R

2

27Ω

+

R

FIGURE 12. Application Diagram without Galvanical Isolation in Mode 0.

SENSE

–

C

2

0.1µF

ADS1202

M0

+

V

IN

–

V

IN

M1

V

MCLK

MDAT

GND

C28x

or

C24x

CV

DD

C

1

DD

0.1µF

SPICLK

SPISIMO

DV

DD

ADS1202

SBAS275

www.ti.com

17

Page 18

+

–

R

R

27Ω

SENSE

1

C

1

0.1µF

ADS1202

M0

V

+

IN

–

V

IN

M1

V

MCLK

MDAT

GND

DD

C

4

0.1µF

ADS1202

M0

V

+

IN

–

V

IN

M1

ADS1202

M0

V

+

IN

V

–

IN

M1

V

MCLK

MDAT

GND

V

MCLK

MDAT

GND

DD

DD

+

–

+

–

R

R

R

27Ω

SENSE

R

27Ω

SENSE

2

C

2

0.1µF

3

C

3

0.1µF

FIGURE 13. Parallel Operation of ADS1202 in Mode 3.

LAYOUT CONSIDERATIONS

POWER SUPPLIES

The ADS1202 requires only one power supply (VDD). If there

are separate analog and digital power supplies on the board,

a good design approach is to have the ADS1202 connected

to the analog power supply. Another approach to control the

noise is the use of a resistor on the power supply. The

connection can be made between the ADS1202 powersupply pins via a 10Ω resistor. The combination of this

resistor and the decoupling capacitors between the powersupply pins on the ADS1202 provide some filtering. The

analog supply that is used must be well regulated and low

noise. For designs requiring higher resolution from the

ADS1202, power-supply rejection will be a concern. The

digital power supply has high-frequency noise that can be

capacitively coupled into the analog portion of the ADS1202.

This noise can originate from switching power supplies,

microprocessors, or digital signal processors. High-frequency

noise will generally be rejected by the external digital filter at

integer multiples of MCLK. Just below and above these

frequencies, noise will alias back into the passband of the

digital filter, affecting the conversion result. Inputs to the

ADS1202, such as V

present before the power supply is on. Violating this condition could cause latch-up. If these signals are present before

the supply is on, series resistors should be used to limit the

+, VIN–, and MCLK should not be

IN

C

5

0.1µF

C28x

or

C24x

CV

DD

C

6

0.1µF

SPICLK

SPISIMO

SPISIMO

SPISIMO

DV

DD

CLK

input current. Experimentation may be the best way to

determine the appropriate connection between the ADS1202

and different power supplies.

GROUNDING

Analog and digital sections of the design must be carefully

and cleanly partitioned. Each section should have its own

ground plane with no overlap between them. Do not join the

ground planes, but connect the two with a moderate signal

trace underneath the converter. For multiple converters,

connect the two ground planes as close as possible to one

central location for all of the converters. In some cases,

experimentation may be required to find the best point to

connect the two planes together.

DECOUPLING

Good decoupling practices must be used for the ADS1202

and for all components in the design. All decoupling capacitors, specifically the 0.1µF ceramic capacitors, must be

placed as close as possible to the pin being decoupled. A

1µF and 10µF capacitor, in parallel with the 0.1µF ceramic

capacitor, must be used to decouple V

one 0.1µF ceramic capacitor must be used to decouple V

to GND, as well as for the digital supply on each digital

component.

to GND. At least

DD

DD

18

www.ti.com

ADS1202

SBAS275

Page 19

PW (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PINS SHOWN

0,65

M

0,10

0,10

0,25

0,50

0,75

0,15 NOM

Gage Plane

28

9,80

9,60

24

7,90

7,70

2016

6,60

6,40

4040064/F 01/97

0,30

6,60

6,20

8

0,19

4,30

4,50

7

0,15

14

A

1

1,20 MAX

14

5,10

4,90

8

3,10

2,90

A MAX

A MIN

DIM

PINS **

0,05

4,90

5,10

Seating Plane

0°–8°

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0,15.

D. Falls within JEDEC MO-153

PACKAGE DRAWING

ADS1202

SBAS275

www.ti.com

19

Page 20

MECHANICAL DATA

MTSS001C – JANUARY 1995 – REVISED FEBRUARY 1999

PW (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PINS SHOWN

0,65

1,20 MAX

14

0,30

0,19

8

4,50

4,30

PINS **

7

Seating Plane

0,15

0,05

8

1

A

DIM

6,60

6,20

14

0,10

M

0,10

0,15 NOM

0°–8°

2016

Gage Plane

24

0,25

0,75

0,50

28

A MAX

A MIN

NOTES: A. All linear dimensions are in millimeters.

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion not to exceed 0,15.

D. Falls within JEDEC MO-153

3,10

2,90

5,10

4,90

5,10

4,90

6,60

6,40

7,90

7,70

9,80

9,60

4040064/F 01/97

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

1

Page 21

IMPORTANT NOTICE

Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications,

enhancements, improvements, and other changes to its products and services at any time and to discontinue

any product or service without notice. Customers should obtain the latest relevant information before placing

orders and should verify that such information is current and complete. All products are sold subject to TI’s terms

and conditions of sale supplied at the time of order acknowledgment.

TI warrants performance of its hardware products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty . Testing and other quality control techniques are used to the extent TI

deems necessary to support this warranty . Except where mandated by government requirements, testing of all

parameters of each product is not necessarily performed.

TI assumes no liability for applications assistance or customer product design. Customers are responsible for

their products and applications using TI components. T o minimize the risks associated with customer products

and applications, customers should provide adequate design and operating safeguards.

TI does not warrant or represent that any license, either express or implied, is granted under any TI patent right,

copyright, mask work right, or other TI intellectual property right relating to any combination, machine, or process

in which TI products or services are used. Information published by TI regarding third–party products or services

does not constitute a license from TI to use such products or services or a warranty or endorsement thereof.

Use of such information may require a license from a third party under the patents or other intellectual property

of the third party , or a license from TI under the patents or other intellectual property of TI.

Reproduction of information in TI data books or data sheets is permissible only if reproduction is without

alteration and is accompanied by all associated warranties, conditions, limitations, and notices. Reproduction

of this information with alteration is an unfair and deceptive business practice. TI is not responsible or liable for

such altered documentation.

Resale of TI products or services with statements different from or beyond the parameters stated by TI for that

product or service voids all express and any implied warranties for the associated TI product or service and

is an unfair and deceptive business practice. TI is not responsible or liable for any such statements.

Mailing Address:

Texas Instruments

Post Office Box 655303

Dallas, Texas 75265

Copyright 2002, Texas Instruments Incorporated

Loading...

Loading...