ADS1146

ADS1147

ADS1148

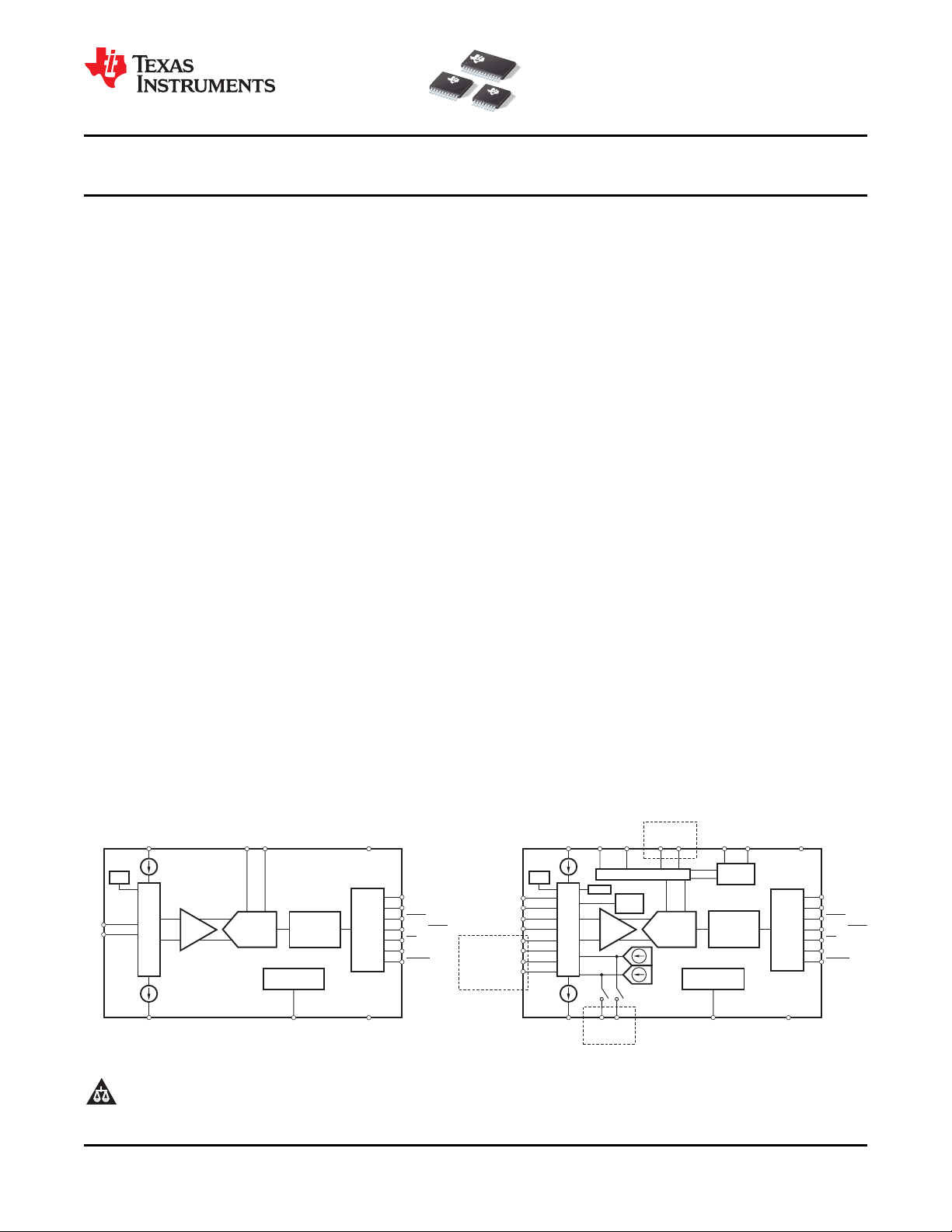

Input

Mux

3rdOrder

DS

Modulator

REFP REFN

PGA

Burnout

Detect

Burnout

Detect

DVDD

DGND

ADS1146

AVSS

AIN0

AIN1

SCLK

DIN

DRDY

DOUT/DRDY

CS

START

RESET

AVDD

InternalOscillator

Adjustable

Digital

Filter

Serial

Interface

and

Control

CLK

Input

Mux

3rdOrder

DS

Modulator

REFP1 REFN1 VREFOUT VREFCOM

REFP0/

GPIO0

REFN0/

GPIO1

Burnout

Detect

Burnout

Detect

DVDD

DGND

IEXC1AVSS

AIN0/IEXC

AIN1/IEXC

AIN2/IEXC/GPIO2

AIN3/IEXC/GPIO3

AIN4/IEXC/GPIO4

AIN5/IEXC/GPIO5

AIN6/IEXC/GPIO6

AIN7/IEXC/GPIO7

ADS1148 Only

SCLK

DIN

DRDY

DOUT/DRDY

CS

START

RESET

AVDD

IEXC2

InternalOscillator

Voltage

Reference

Serial

Interface

and

Control

V

BIAS

GPIO

CLK

ADS1148 Only

ADS1147

ADS1148

PGA

System

Monitor

Adjustable

Digital

Filter

Dual

Current

DACs

VREFMux

ADS1148 Only

V

BIAS

www.ti.com

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

16-Bit Analog-to-Digital Converters for Temperature Sensors

Check for Samples: ADS1146, ADS1147, ADS1148

1

FEATURES

23

• 16 Bits, No Missing Codes

• Data Output Rates Up to 2kSPS

• Single-Cycle Settling for All Data Rates

• Simultaneous 50/60Hz Rejection at 20SPS

DESCRIPTION

The ADS1146, ADS1147, and ADS1148 are

highly-integrated, precision, 16-bit analog-to-digital

converters (ADCs). The ADS1146/7/8 feature an

onboard, low-noise, programmable gain amplifier

(PGA), a precision delta-sigma ADC with a

• 4 Differential/7 Single-Ended Inputs (ADS1148) single-cycle settling digital filter, and an internal

• 2 Differential/3 Single-Ended Inputs (ADS1147)

• Matched Current Source DACs

• Internal Voltage Reference

• Sensor Burnout Detection

• 4/8 General-Purpose I/Os (ADS1147/8)

• Internal Temperature Sensor

• Power Supply and V

Monitoring

REF

(ADS1147/8)

• Self and System Calibration

• SPI™-Compatible Serial Interface

• Analog Supply Operation:

+2.7V to +5.25V Unipolar, ±2.5V Bipolar

• Digital Supply: +2.7V to +5.25V

• Operating Temperature –40°C to +125°C

APPLICATIONS

• Temperature Measurement

– RTDs, Thermocouples, and Thermistors

• Pressure Measurement

• Industrial Process Control

oscillator. The ADS1147 and ADS1148 also provide a

built-in voltage reference with 10mA output capacity,

and two matched programmable current

digital-to-analog converters (DACs). The

ADS1146/7/8 provide a complete front-end solution

for temperature sensor applications including thermal

couples, thermistors, and resistance temperature

detectors (RTDs).

An input multiplexer supports four differential inputs

for the ADS1148, two for the ADS1147, and one for

the ADS1146. In addition, the multiplexer has a

sensor burnout detect, voltage bias for

thermocouples, system monitoring, and

general-purpose digital I/Os (ADS1147 and

ADS1148). The onboard, low-noise PGA provides

selectable gains of 1 to 128. The delta-sigma

modulator and adjustable digital filter settle in only

one cycle, for fast channel cycling when using the

input multiplexer, and support data rates up to

2kSPS. For data rates of 20SPS or less, both 50Hz

and 60Hz interference are rejected by the filter.

The ADS1146 is offered in a small TSSOP-16

package, the ADS1147 is available in a TSSOP-20

package, and the ADS1148 in a TSSOP-28 package.

All three devices operate over the extended specified

temperature range of –40°C to +105°C.

1

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of Texas

Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

2SPI is a trademark of Motorola, Inc.

3All other trademarks are the property of their respective owners.

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of the Texas

Instruments standard warranty. Production processing does not

necessarily include testing of all parameters.

Copyright © 2009–2010, Texas Instruments Incorporated

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

This integrated circuit can be damaged by ESD. Texas Instruments recommends that all integrated circuits be handled with

appropriate precautions. Failure to observe proper handling and installation procedures can cause damage.

ESD damage can range from subtle performance degradation to complete device failure. Precision integrated circuits may be more

susceptible to damage because very small parametric changes could cause the device not to meet its published specifications.

www.ti.com

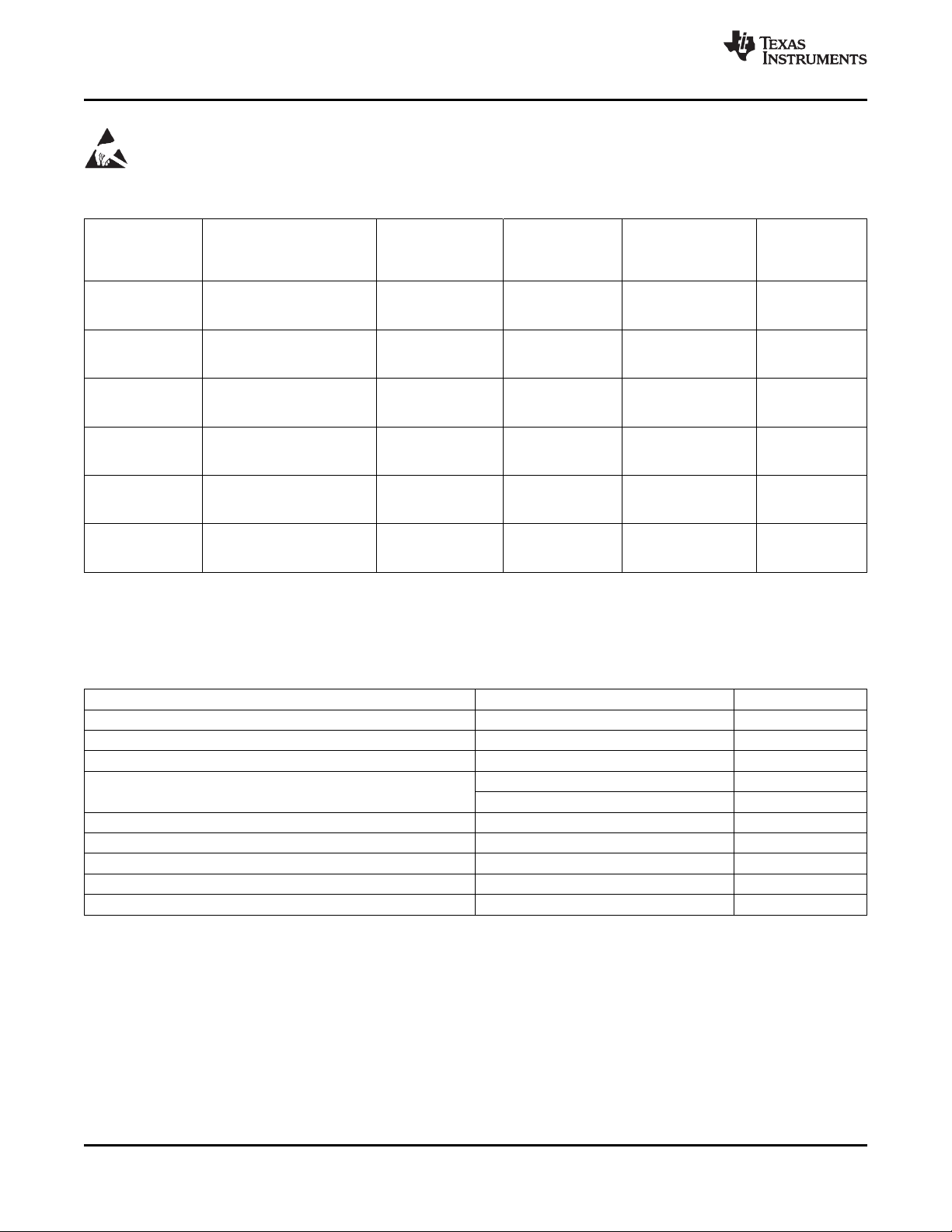

PACKAGE/ORDERING INFORMATION

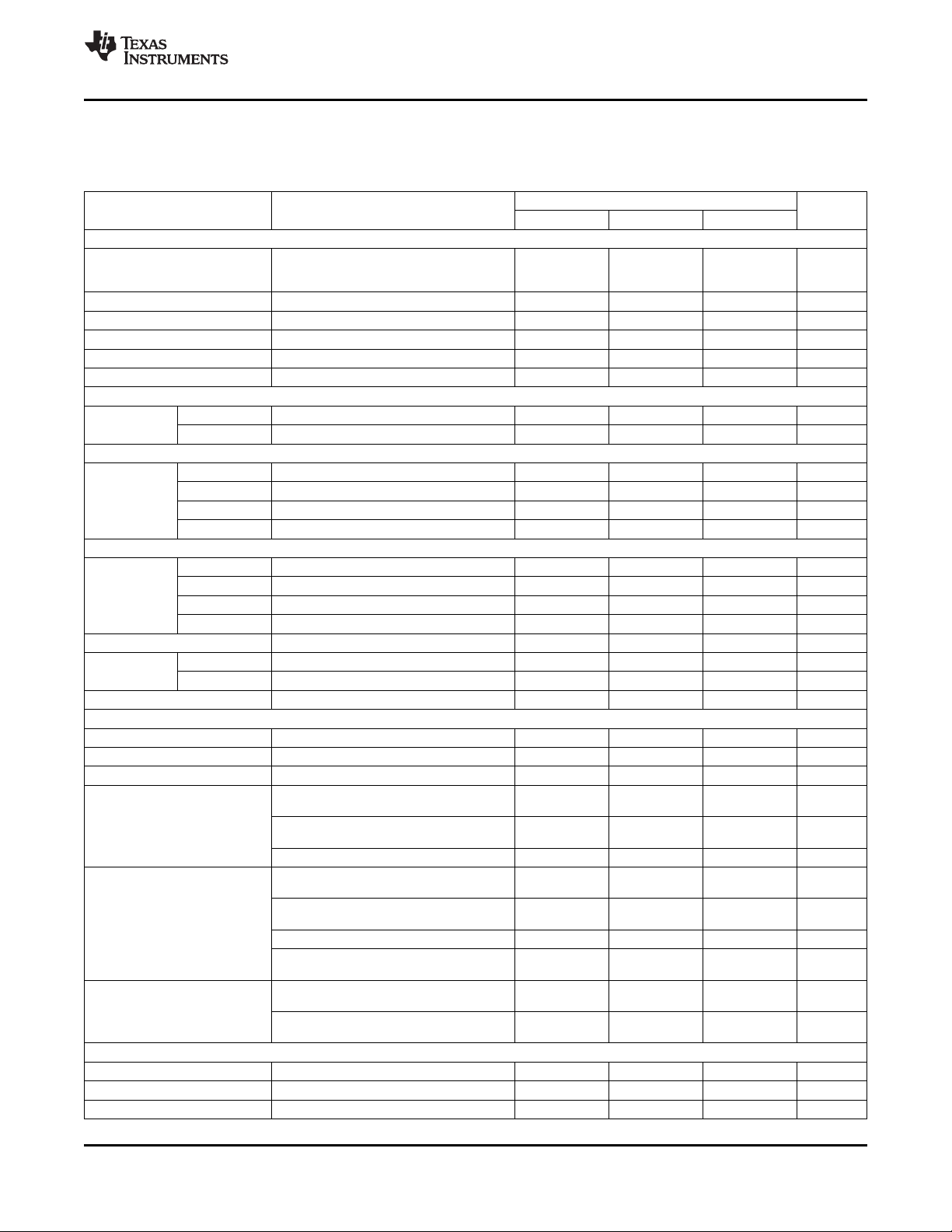

PRODUCT RESOLUTION INPUTS REFERENCE SOURCES LEAD

ADS1246 24 bits or External NO TSSOP-16

ADS1247 24 bits or Internal or External YES TSSOP-20

ADS1248 24 bits or Internal or External YES TSSOP-28

ADS1146 16 bits or External NO TSSOP-16

ADS1147 16 bits or Internal or External YES TSSOP-20

ADS1148 16 bits or Internal or External YES TSSOP-28

(1) For the most current package and ordering information, see the Package Option Addendum at the end of this document, or visit the

device product folder on ti.com.

ABSOLUTE MAXIMUM RATINGS

(1)

NUMBER OF VOLTAGE CURRENT PACKAGE-

1 Differential

1 Single-Ended

2 Differential

3 Single-Ended

4 Differential

7 Single-Ended

1 Differential

1 Single-Ended

2 Differential

3 Single-Ended

4 Differential

7 Single-Ended

(1)

DUAL SENSOR

EXCITATION

Over operating free-air temperature range, unless otherwise noted.

ADS1146, ADS1147, ADS1148 UNIT

AVDD to AVSS –0.3 to +5.5 V

AVSS to DGND –2.8 to +0.3 V

DVDD to DGND –0.3 to +5.5 V

Input current

Analog input voltage to AVSS AVSS – 0.3 to AVDD + 0.3 V

Digital input voltage to DGND –0.3 to DVDD + 0.3 V

Maximum junction temperature +150 °C

Operating temperature range –40 to +125 °C

Storage temperature range –60 to +150 °C

(1) Stresses beyond those listed under Absolute Maximum Ratings may cause permanent damage to the device. These are stress ratings

only, and functional operation of the device at these or any other conditions beyond those indicated is not implied. Exposure to

absolute-maximum-rated conditions for extended periods may affect device reliability.

100, momentary mA

10, continuous mA

2 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): ADS1146 ADS1147 ADS1148

ADS1146

ADS1147

ADS1148

www.ti.com

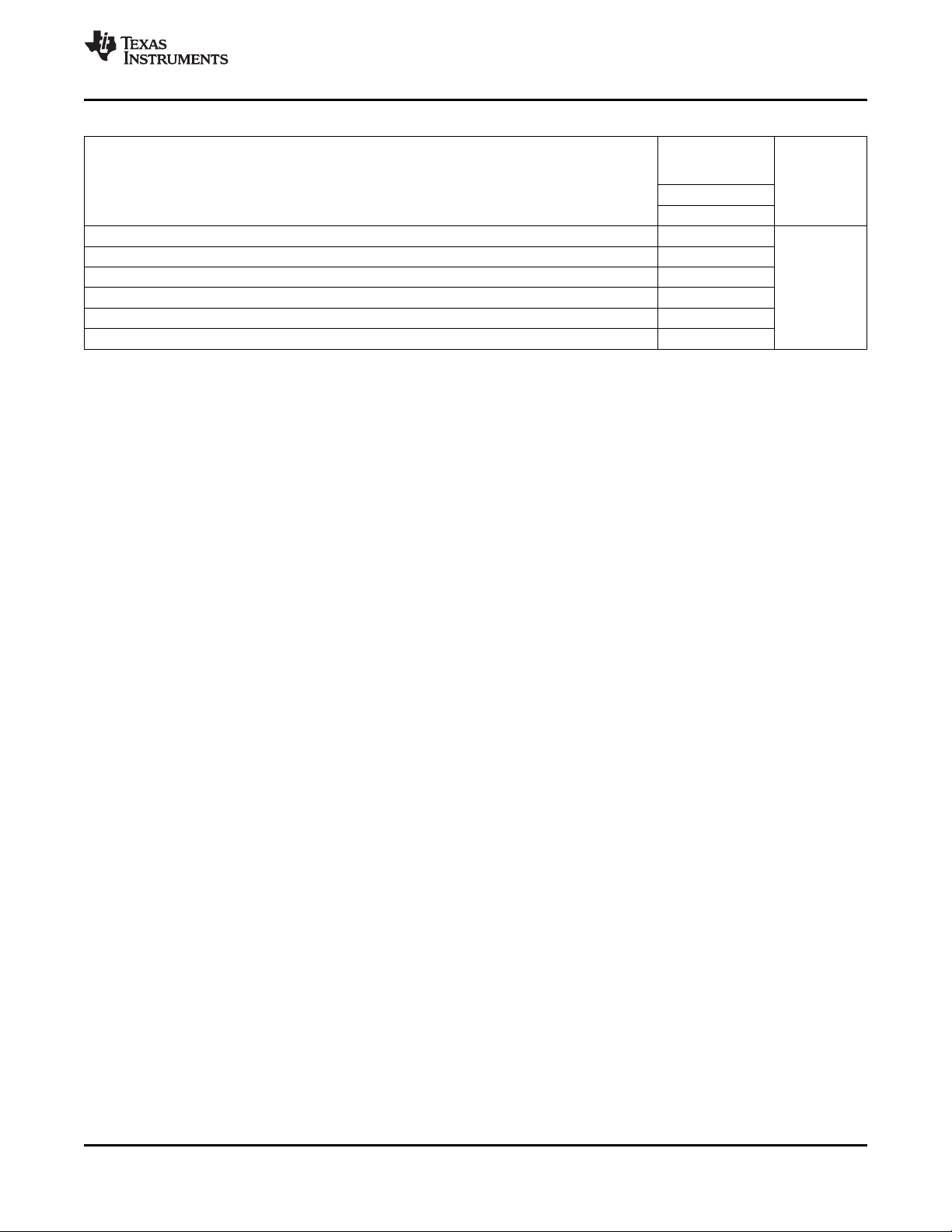

THERMAL INFORMATION

THERMAL METRIC

q

JA

q

JC(top)

q

JB

y

JT

y

JB

q

JC(bottom)

Junction-to-ambient thermal resistance

Junction-to-case(top) thermal resistance

Junction-to-board thermal resistance

Junction-to-top characterization parameter

Junction-to-board characterization parameter

Junction-to-case(bottom) thermal resistance

(1) For more information about traditional and new thermal metrics, see the IC Package Thermal Metrics application report, SPRA953.

(2) The junction-to-ambient thermal resistance under natural convection is obtained in a simulation on a JEDEC-standard, high-K board, as

specified in JESD51-7, in an environment described in JESD51-2a.

(3) The junction-to-case (top) thermal resistance is obtained by simulating a cold plate test on the package top. No specific

JEDEC-standard test exists, but a close description can be found in the ANSI SEMI standard G30-88.

(4) The junction-to-board thermal resistance is obtained by simulating in an environment with a ring cold plate fixture to control the PCB

temperature, as described in JESD51-8.

(5) The junction-to-top characterization parameter, yJT, estimates the junction temperature of a device in a real system and is extracted

from the simulation data for obtaining qJA, using a procedure described in JESD51-2a (sections 6 and 7).

(6) The junction-to-board characterization parameter, yJB, estimates the junction temperature of a device in a real system and is extracted

from the simulation data for obtaining qJA, using a procedure described in JESD51-2a (sections 6 and 7).

(7) The junction-to-case (bottom) thermal resistance is obtained by simulating a cold plate test on the exposed (power) pad. No specific

JEDEC standard test exists, but a close description can be found in the ANSI SEMI standard G30-88.

(1)

(2)

(3)

(4)

(5)

(6)

(7)

SBAS453C –JULY 2009–REVISED APRIL 2010

ADS1146,

ADS1147,

ADS1148

UNITS

PW

28

79.5

31.8

40.9

3.0

°C/W

41.1

n/a

Copyright © 2009–2010, Texas Instruments Incorporated Submit Documentation Feedback 3

Product Folder Link(s): ADS1146 ADS1147 ADS1148

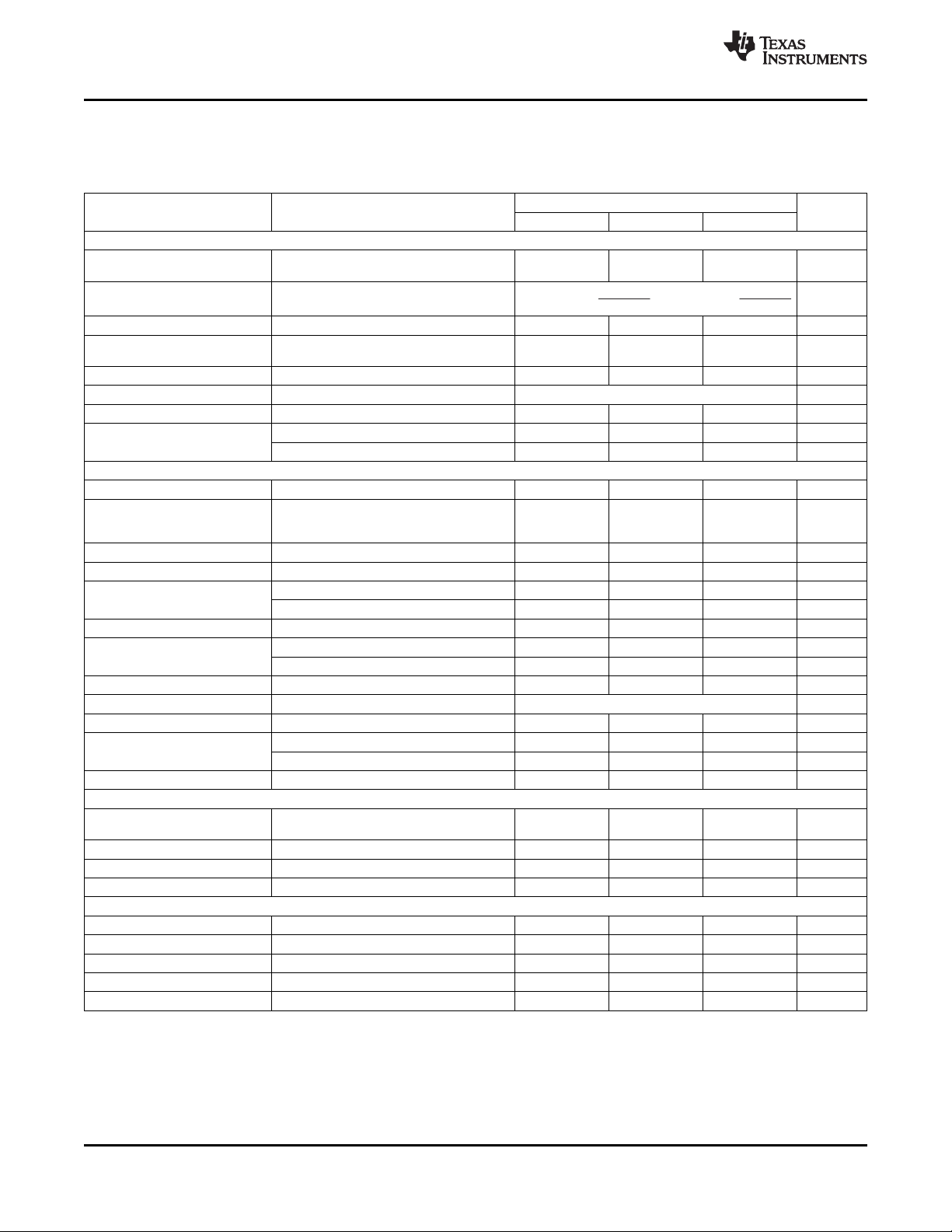

(V )(Gain)

IN

2

AVSS 0.1V+ +

AVDD 0.1V- -

(V )(Gain)

IN

2

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

ELECTRICAL CHARACTERISTICS

Minimum/maximum specifications apply from –40°C to +105°C. Typical specifications are at +25°C. All specifications at

AVDD = +5V, DVDD = +3.3V, AVSS = DGND = 0V, V

noted.

PARAMETER CONDITIONS MIN TYP MAX UNIT

ANALOG INPUTS

Full-scale input voltage

(VIN= ADCINP – ADCINN)

Common-mode input range V

Differential input current 100 pA

PGA gain settings

Burnout current source 0.5, 2, or 10 mA

Bias voltage (AVDD + AVSS)/2 V

Bias voltage output impedance 400 Ω

Mux leakage current

SYSTEM PERFORMANCE

Resolution No missing codes 16 Bits

Data rate 160, 320, 640, SPS

Integral nonlinearity (INL) Differential input, end point fit, PGA = 1 ±0.5 ±1 LSB

Offset error After calibration 1 LSB

Offset drift

Gain error Excluding V

Gain drift

ADC conversion time Single-cycle settling See Table 15

Noise See Table 5 and Table 6

Normal-mode rejection See Table 8

Common-mode rejection

Power-supply rejection AVDD, DVDD at dc 100 dB

VOLTAGE REFERENCE INPUT

Voltage reference input (AVDD – AVSS)

(V

= V

– V

REF

REFP

Negative reference input (REFN) AVSS – 0.1 REFP – 0.5 V

Positive reference input (REFP) REFN + 0.5 AVDD + 0.1 V

Reference input current 30 nA

ON-CHIP VOLTAGE REFERENCE

Output voltage 2.038 2.048 2.058 V

Output current

Load regulation 50 mV/mA

(2)

Drift

Startup time See Table 9 ms

) – 1

REFN

(1)

(1) Do not exceed this loading on the internal voltage reference.

(2) Specified by the combination of design and final production test.

PGA = 1 100 nV/°C

PGA = 128 15 nV/°C

errors ±0.5 %

REF

PGA = 1, excludes V

PGA = 128, excludes V

At dc, PGA = 1 90 dB

At dc, PGA = 32 100 dB

TA= –40°C to +105°C 20 50 ppm/°C

REF

REF

= +2.048V, and oscillator frequency = 4.096MHz, unless otherwise

REF

ADS1146, ADS1147, ADS1148

±V

/PGA 2.7/PGA V

REF

1, 2, 4, 8, 16, 32,

64, 128

5, 10, 20, 40, 80,

1000, 2000

drift 1 ppm/°C

drift –3.5 ppm/°C

0.5 V

±10 mA

www.ti.com

pA

pA

4 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): ADS1146 ADS1147 ADS1148

ADS1146

ADS1147

ADS1148

www.ti.com

ELECTRICAL CHARACTERISTICS (continued)

Minimum/maximum specifications apply from –40°C to +105°C. Typical specifications are at +25°C. All

specifications at AVDD = +5V, DVDD = +3.3V, AVSS = DGND = 0V, V

4.096MHz, unless otherwise noted.

PARAMETER CONDITIONS MIN TYP MAX UNIT

CURRENT SOURCES (IDACS)

Output current 500, 750, 1000, mA

Voltage compliance All currents AVDD – 0.7 V

Initial error All currents, each IDAC –6 ±1.0 6 % of FS

Initial mismatch All currents, between IDACs ±0.03 %of FS

Temperature drift Each IDAC 200 ppm/°C

Temperature drift matching Between IDACs 10 ppm/°C

SYSTEM MONITORS

Temperature

sensor reading

GENERAL-PURPOSE INPUT/OUTPUT (GPIO)

Logic levels

DIGITAL INPUT/OUTPUT (other than GPIO)

Logic levels

Input leakage DGND < V

Clock input

(CLK)

Internal oscillator frequency 3.89 4.096 4.3 MHz

POWER SUPPLY

DVDD 2.7 5.25 V

AVSS –2.5 0 V

AVDD AVSS + 2.7 AVSS + 5.25 V

DVDD current Normal mode, DVDD = 3.3V,

AVDD current

Power dissipation

TEMPERATURE RANGE

Specified –40 +105 °C

Operating –40 +125 °C

Storage –60 +150 °C

Voltage TA= +25°C 118 mV

Drift 405 mV/°C

V

IH

V

IL

V

OH

V

OL

V

IH

V

IL

V

OH

V

OL

Frequency 1 4.5 MHz

Duty cycle 25 75 %

IOH= 1mA 0.8AVDD V

IOL= 1mA AVSS 0.2 AVDD V

IOH= 1mA 0.8DVDD V

IOL= 1mA DGND 0.2 DVDD V

< DVDD ±10 mA

DIGITAL IN

Normal mode, DVDD = 5V,

data rate = 20SPS, internal oscillator

data rate = 20SPS, internal oscillator

Sleep mode 0.2 µA

Converting, AVDD = 5V,

data rate = 20SPS, external reference

Converting, AVDD = 3.3V,

data rate = 20SPS, external reference

Sleep mode 0.1 µA

Additional current with internal reference

enabled

AVDD = DVDD = 5V, data rate = 20SPS,

external reference, internal oscillator

AVDD = DVDD = 3.3V, data rate = 20SPS,

external reference, internal oscillator

REF

ADS1146, ADS1147, ADS1148

0.7AVDD AVDD V

AVSS 0.3AVDD V

0.7DVDD DVDD V

DGND 0.3DVDD V

SBAS453C –JULY 2009–REVISED APRIL 2010

= +2.048V, and oscillator frequency =

50, 100, 250,

1500

230 mA

210 mA

225 µA

212 µA

180 mA

2.3 mW

1.4 mW

Copyright © 2009–2010, Texas Instruments Incorporated Submit Documentation Feedback 5

Product Folder Link(s): ADS1146 ADS1147 ADS1148

DVDD

DGND

CLK

RESET

REFP0/GPIO0

REFN0/GPIO1

REFP1

REFN1

VREFOUT

VREFCOM

AIN0/IEXC

AIN1/IEXC

AIN4/IEXC/GPIO4

AIN5/IEXC/GPIO5

SCLK

DIN

DOUT/DRDY

DRDY

CS

START

AVDD

AVSS

IEXC1

IEXC2

AIN3/IEXC/GPIO3

AIN2/IEXC/GPIO2

AIN7/IEXC/GPIO7

AIN6/IEXC/GPIO6

1

2

3

4

5

6

7

8

9

10

11

12

13

14

28

27

26

25

24

23

22

21

20

19

18

17

16

15

ADS1148

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

www.ti.com

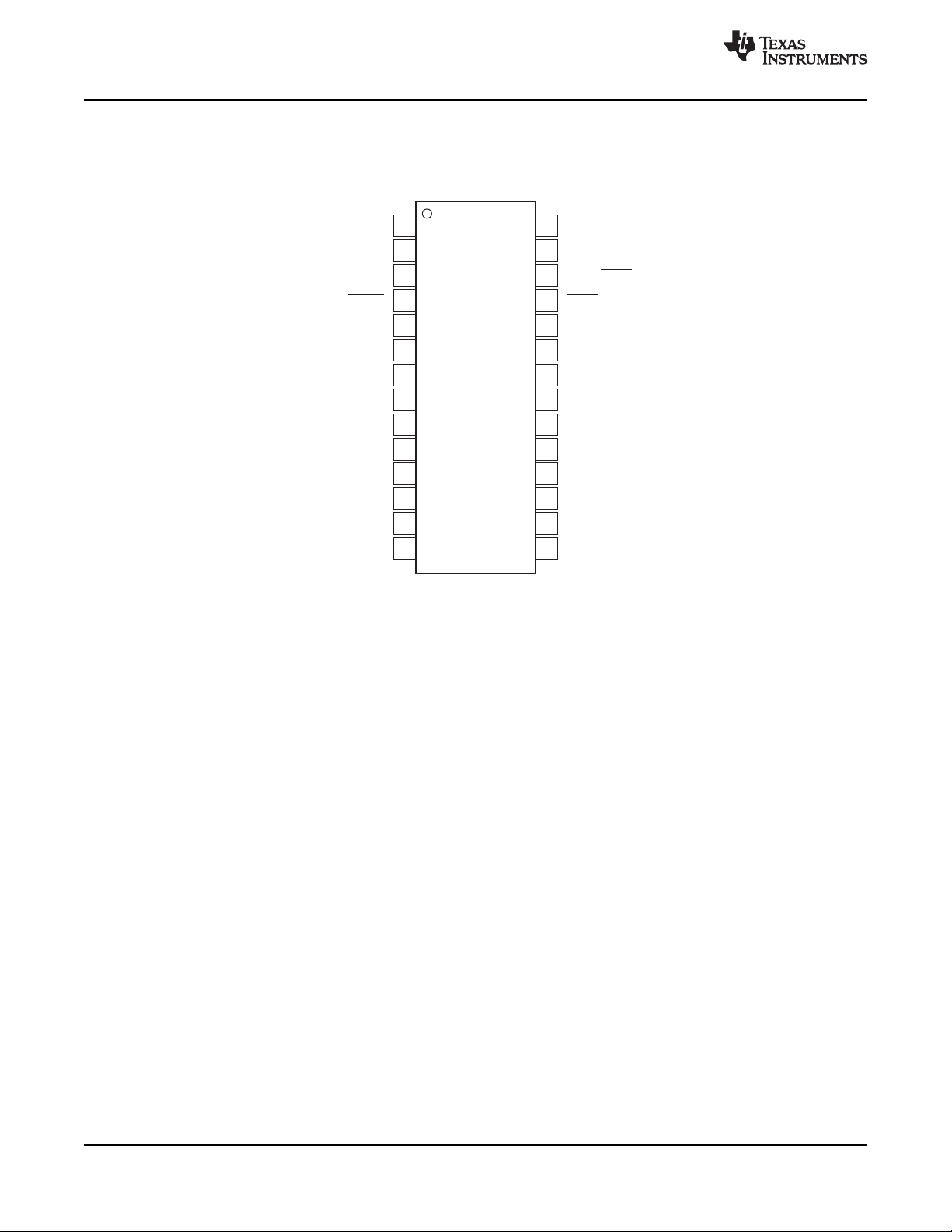

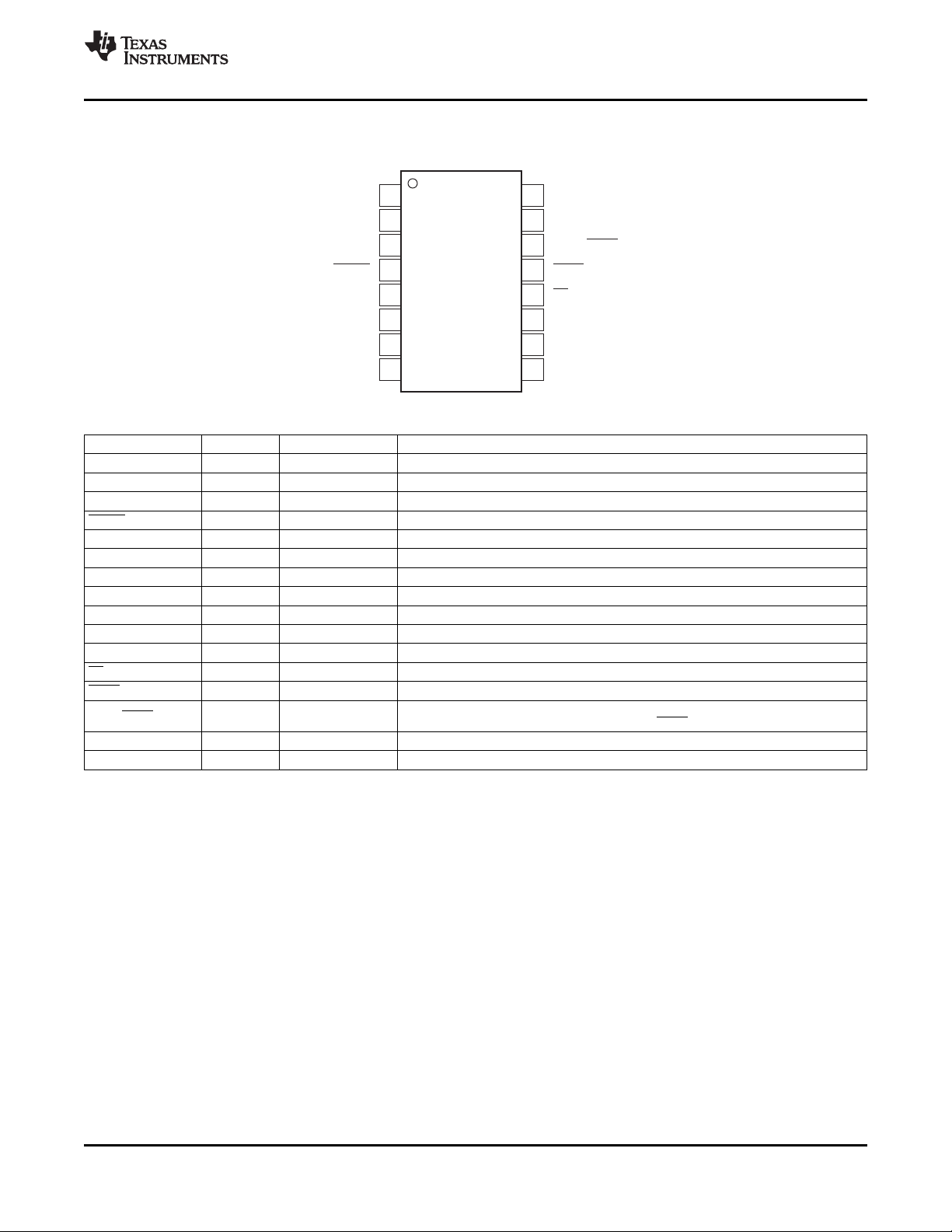

PIN CONFIGURATIONS

PW PACKAGE

TSSOP-28

(TOP VIEW)

6 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): ADS1146 ADS1147 ADS1148

www.ti.com

SBAS453C –JULY 2009–REVISED APRIL 2010

ADS1148 (TSSOP-28) PIN DESCRIPTIONS

NAME PIN NO. FUNCTION DESCRIPTION

DVDD 1 Digital Digital power supply

DGND 2 Digital Digital ground

CLK 3 Digital input External clock input. Tie this pin to DGND to activate the internal oscillator.

RESET 4 Digital input Chip reset (active low). Returns all register values to reset values.

REFP0/GPIO0 5

REFN0/GPIO1 6

REFP1 7 Analog input Positive external reference 1 input

REFN1 8 Analog input Negative external reference 1 input

VREFOUT 9 Analog output Positive internal reference voltage output

VREFCOM 10 Analog output

AIN0/IEXC 11 Analog input Analog input 0, optional excitation current output

AIN1/IEXC 12 Analog input Analog input 1, optional excitation current output

AIN4/IEXC/GPIO4 13

AIN5/IEXC/GPIO5 14

AIN6/IEXC/GPIO6 15

AIN7/IEXC/GPIO7 16

AIN2/IEXC/GPIO2 17

AIN3/IEXC/GPIO3 18

IEXC2 19 Analog output Excitation current output 2

IEXC1 20 Analog output Excitation current output 1

AVSS 21 Analog Negative analog power supply

AVDD 22 Analog Positive analog power supply

START 23 Digital input Conversion start. See text for complete description.

CS 24 Digital input Chip select (active low)

DRDY 25 Digital output Data ready (active low)

DOUT/DRDY 26 Digital output

DIN 27 Digital input Serial data input

SCLK 28 Digital input Serial clock input

Analog input Positive external reference input 0, or

Digital in/out general-purpose digital input/output pin 0

Analog input Negative external reference 0 input, or

Digital in/out general-purpose digital input/output pin 1

Negative internal reference voltage output. Connect this pin to AVSS when using a unipolar

supply, or to the midvoltage of the power supply when using a bipolar supply.

Analog input Analog input 4, optional excitation current output, or

Digital in/out general-purpose digital input/output pin 4

Analog input Analog input 5, optional excitation current output, or

Digital in/out general-purpose digital input/output pin 5

Analog input Analog input 6, optional excitation current output, or

Digital in/out general-purpose digital input/output pin 6

Analog input Analog input 7, optional excitation current output, or

Digital in/out general-purpose digital input/output pin 7

Analog input Analog input 2, optional excitation current output, or

Digital in/out general-purpose digital input/output pin 2

Analog input Analog input 3, optional excitation current output, or

Digital in/out general-purpose digital input/output pin 3

Serial data out output, or

data out combined with data ready (active low when DRDY function enabled)

ADS1146

ADS1147

ADS1148

Copyright © 2009–2010, Texas Instruments Incorporated Submit Documentation Feedback 7

Product Folder Link(s): ADS1146 ADS1147 ADS1148

DVDD

DGND

CLK

RESET

REFP0/GPIO0

REFN0/GPIO1

VREFOUT

VREFCOM

AIN0/IEXC

AIN1/IEXC

SCLK

DIN

DOUT/DRDY

DRDY

CS

START

AVDD

AVSS

AIN3/IEXC/GPIO3

AIN2/IEXC/GPIO2

1

2

3

4

5

6

7

8

9

10

20

19

18

17

16

15

14

13

12

11

ADS1147

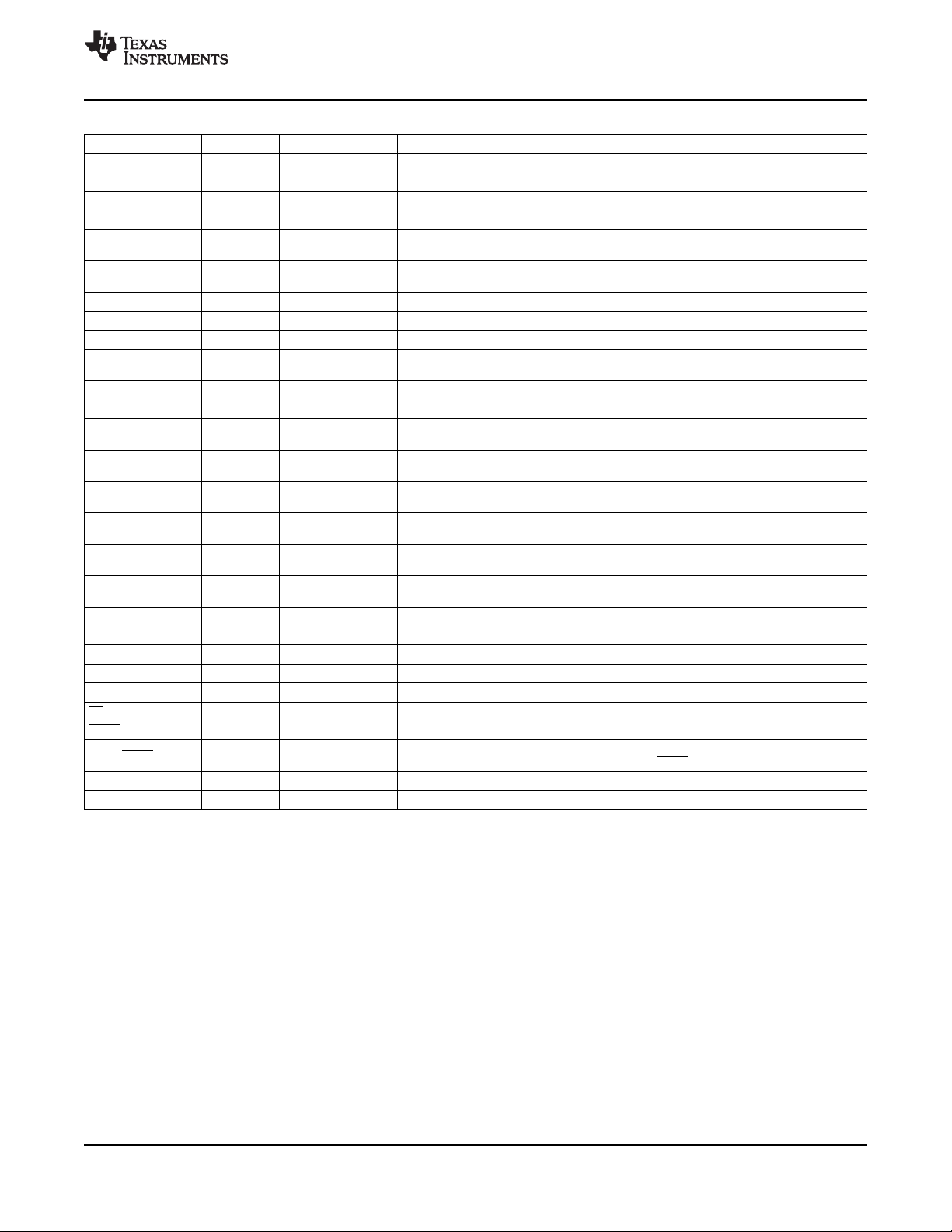

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

PW PACKAGE

TSSOP-20

(TOP VIEW)

ADS1147 (TSSOP-20) PIN DESCRIPTIONS

NAME PIN NO. FUNCTION DESCRIPTION

DVDD 1 Digital Digital power supply

DGND 2 Digital Digital ground

CLK 3 Digital input External clock input. Tie this pin to DGND to activate the internal oscillator.

RESET 4 Digital input Chip reset (active low). Returns all register values to reset values.

REFP0/GPIO0 5

REFN0/GPIO1 6

VREFOUT 7 Analog output Positive internal reference voltage output

VREFCOM 8 Analog output

AIN0/IEXC 9 Analog input Analog input 0, optional excitation current output

AIN1/IEXC 10 Analog input Analog input 1, optional excitation current output

AIN2/IEXC/GPIO2 11

AIN3/IEXC/GPIO3 12

AVSS 13 Analog Negative analog power supply

AVDD 14 Analog Positive analog power supply

START 15 Digital input Conversion start. See text for description of use.

CS 16 Digital input Chip select (active low)

DRDY 17 Digital output Data ready (active low)

DOUT/DRDY 18 Digital output

DIN 19 Digital input Serial data input

SCLK 20 Digital input Serial clock input

Analog input Positive external reference input, or

Digital in/out general-purpose digital input/output pin 0

Analog input Negative external reference input, or

Digital in/out general-purpose digital input/output pin 1

Negative internal reference voltage output. Connect this pin to AVSS when using a unipolar

supply, or to the midvoltage of the power supply when using a bipolar supply.

Analog input Analog input 2, optional excitation current output, or

Digital in/out general-purpose digital input/output pin 2

Analog input Analog input 3, with or without excitation current output, or

Digital in/out general-purpose digital input/output pin 3

Serial data out output, or

data out combined with data ready (active low when DRDY function enabled)

www.ti.com

8 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): ADS1146 ADS1147 ADS1148

DVDD

DGND

CLK

RESET

REFP

REFN

AINP

AINN

SCLK

DIN

DOUT/DRDY

DRDY

CS

START

AVDD

AVSS

1

2

3

4

5

6

7

8

16

15

14

13

12

11

10

9

ADS1146

www.ti.com

SBAS453C –JULY 2009–REVISED APRIL 2010

PW PACKAGE

TSSOP-16

(TOP VIEW)

ADS1146 (TSSOP-16) PIN DESCRIPTIONS

NAME PIN NO. FUNCTION DESCRIPTION

DVDD 1 Digital Digital power supply

DGND 2 Digital Digital ground

CLK 3 Digital input External clock input. Tie this pin to DGND to activate the internal oscillator.

RESET 4 Digital input Chip reset (active low). Returns all register values to reset values.

REFP 5 Analog input Positive external reference input

REFN 6 Analog input Negative external reference input

AINP 7 Analog input Positive analog input

AINN 8 Analog input Negative analog input

AVSS 9 Analog Negative analog power supply

AVDD 10 Analog Positive analog power supply

START 11 Digital input Conversion start. See text for description of use.

CS 12 Digital input Chip select (active low)

DRDY 13 Digital output Data ready (active low)

DOUT/DRDY 14 Digital output

DIN 15 Digital input Serial data input

SCLK 16 Digital input Serial clock input

Serial data out output, or

data out combined with data ready (active low when DRDY function enabled)

ADS1146

ADS1147

ADS1148

Copyright © 2009–2010, Texas Instruments Incorporated Submit Documentation Feedback 9

Product Folder Link(s): ADS1146 ADS1147 ADS1148

SCLK

DOUT[7] DOUT[6] DOUT[5] DOUT[4] DOUT[1] DOUT[0]

DIN[0] DIN[7] DIN[6] DIN[5] DIN[4] DIN[1] DIN[0]

CS

DOUT/

(1)

DRDY

DIN

t

CSSC

t

DIST

t

DIHD

t

SCLK

t

SCCS

t

CSDO

t

DOPD

t

SPWL

t

SPWH

t

DOHD

SCLK

(3)

1 2 3 87654

DRDY

t

STD

t

DTS

t

PWH

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

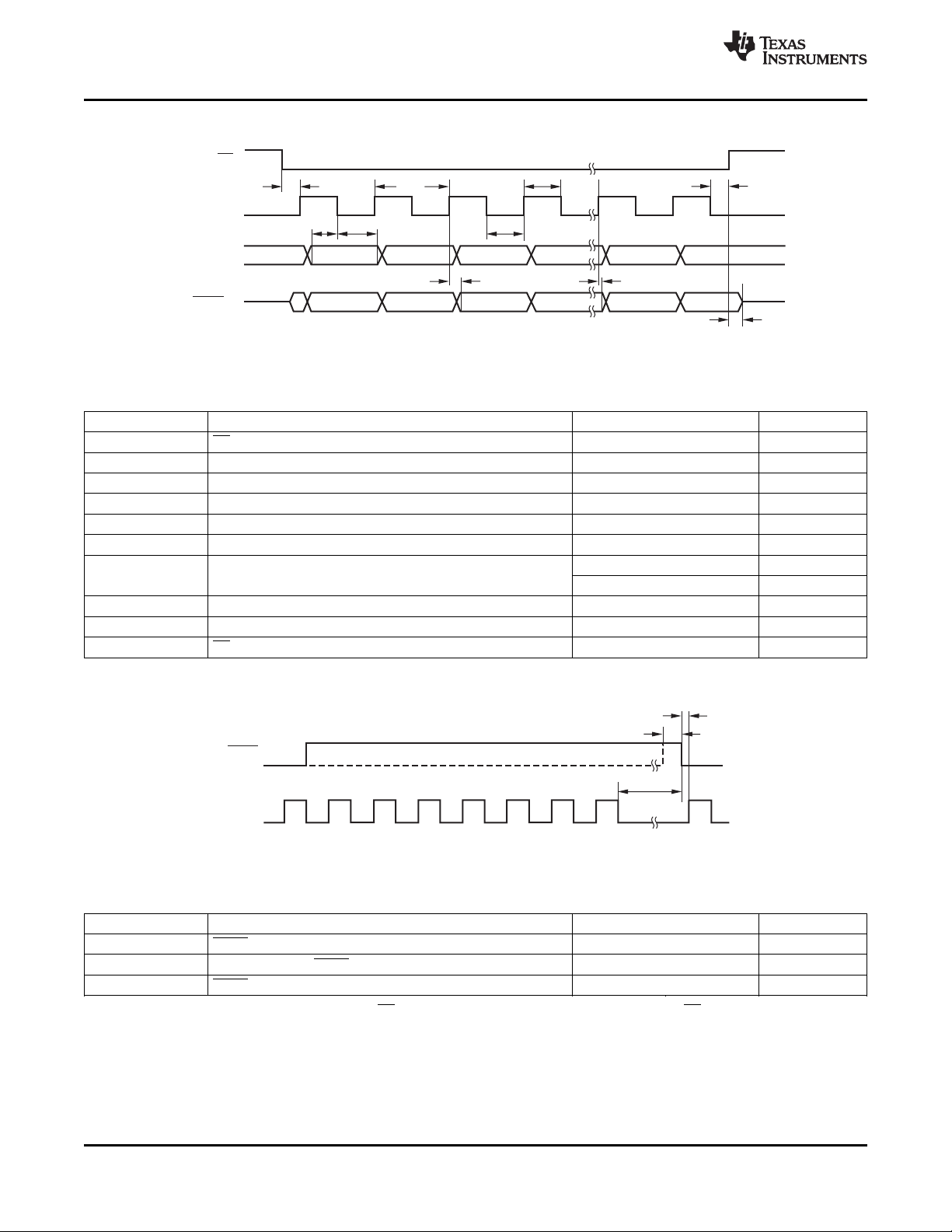

TIMING DIAGRAMS

www.ti.com

Figure 1. Serial Interface Timing

Table 1. Timing Characteristics for Figure 1

(1)

SYMBOL DESCRIPTION MIN MAX UNIT

t

CSSC

t

SCCS

t

DIST

t

DIHD

t

DOPD

t

DOHD

t

SCLK

t

SPWH

t

SPWL

t

CSDO

CS low to first SCLK high (set up time) 10 ns

SCLK low to CS high (hold time) 7 t

DIN set up time 5 ns

DIN hold time 5 ns

SCLK rising edge to new data valid 30 ns

DOUT hold time 0 ns

SCLK period

500 ns

64 conversions

SCLK pulse width high 0.25 0.75 t

SCLK pulse width low 0.25 0.75 t

CS high to DOUT high impedance 10 ns

(1) DRDY MODE bit = 0.

(2) t

OSC

= 1/f

. The default clock frequency f

CLK

= 4.096MHz.

CLK

OSC

SCLK

SCLK

(2)

t

PWH

t

S TD

t

DTS

(3) This timing diagram is applicable only when the CS pin is low. SCLK need not be low during t

(4) SCLK should only be sent in multiples of eight during partial retrieval of output data.

10 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated

Figure 2. SPI Interface Timing to Allow Conversion Result Loading

(3) (4)

Table 2. Timing Characteristics for Figure 2

SYMBOL DESCRIPTION MIN MAX UNIT

DRDY pulse width high 3 t

SCLK low prior to DRDY low 5 t

DRDY falling edge to SCLK rising edge 30 ns

Product Folder Link(s): ADS1146 ADS1147 ADS1148

STD

when CS is high.

OSC

OSC

t

START

START

SCLK

CS

RESET

t

RESET

t

RHSC

www.ti.com

SBAS453C –JULY 2009–REVISED APRIL 2010

Figure 3. Minimum START Pulse Width

Table 3. Timing Characteristics for Figure 3

SYMBOL DESCRIPTION MIN MAX UNIT

t

START

START pulse width high 3 t

Figure 4. Reset Pulse Width and SPI Communication After Reset

ADS1146

ADS1147

ADS1148

OSC

Table 4. Timing Characteristics for Figure 4

SYMBOL DESCRIPTION MIN MAX UNIT

t

RESET

t

RHSC

(1) For f

= 4.096MHz, scales proportionately with f

OSC

RESET pulse width low 4 t

RESET high to SPI communication start 0.6

frequency.

OSC

(1)

OSC

ms

Copyright © 2009–2010, Texas Instruments Incorporated Submit Documentation Feedback 11

Product Folder Link(s): ADS1146 ADS1147 ADS1148

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

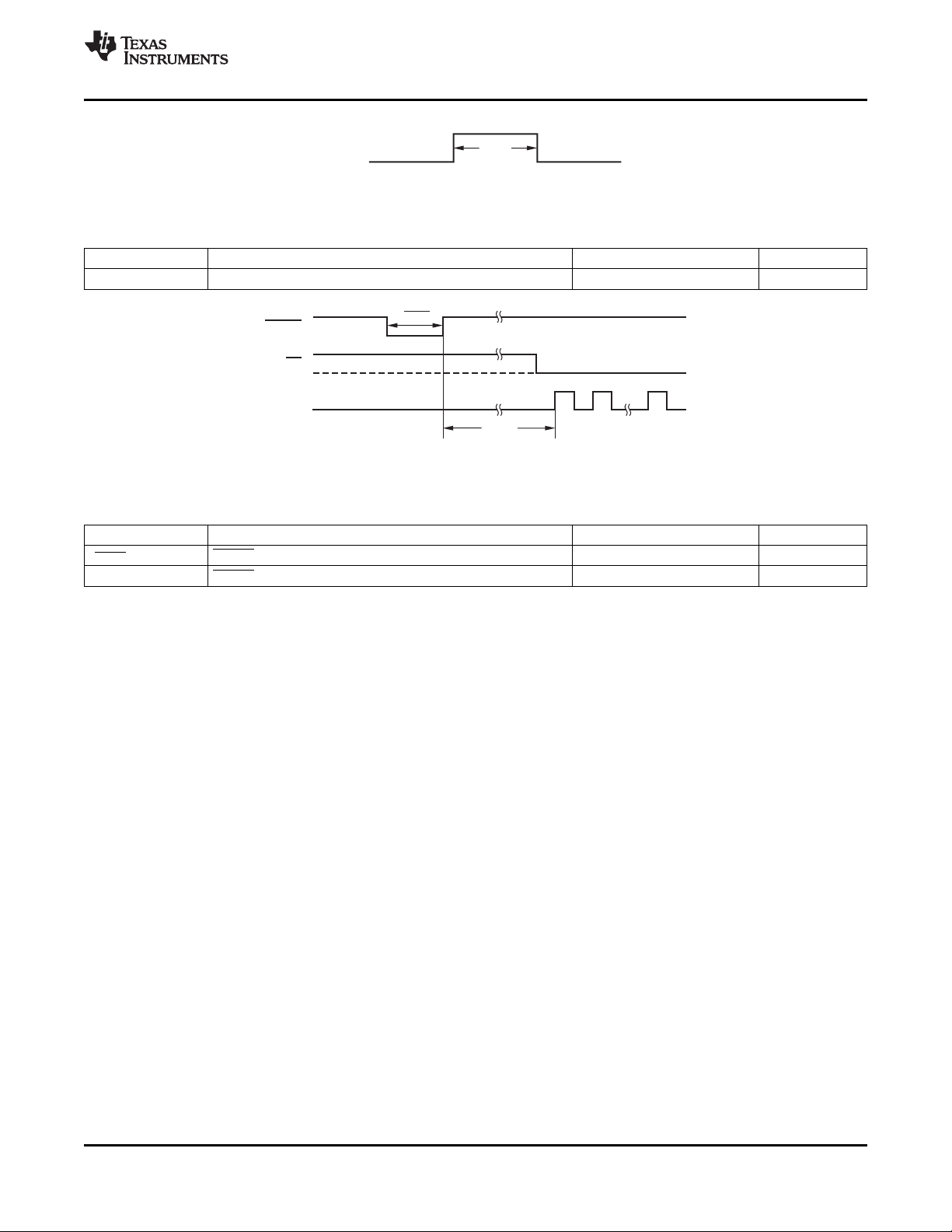

NOISE PERFORMANCE

The ADS1146/7/8 noise performance can be optimized by adjusting the data rate and PGA setting. As the

averaging is increased by reducing the data rate, the noise drops correspondingly. Increasing the PGA value

reduces the input-referred noise, particularly useful when measuring low-level signals. Table 5 and Table 6

summarize noise performance of the ADS1146/7/8. The data are representative of typical noise performance at

T = +25°C. The data shown are the result of averaging the readings from multiple devices and were measured

with the inputs shorted together.

Table 5 lists the input-referred noise in units mVPP. In many of the settings, especially at lower data rates, the

inherent device noise is less than 1LSB. For these cases, the noise is rounded up to 1LSB. Table 6 lists the

corresponding data in units of ENOB (effective number of bits) where:

ENOB = ln(Full-Scale Range/Noise)/ln(2) (1)

www.ti.com

DATA RATE

At V

Table 5. Noise in mV

= 2.048V, AVDD = 5V, and AVSS = 0V

REF

PGA SETTING

PP

(SPS) 1 2 4 8 16 32 64 128

5 62.50

10 62.50

20 62.50

40 62.50

80 62.50

160 62.50

320 62.50

(1)

(1)

(1)

(1)

(1)

(1)

(1)

31.25

31.25

31.25

31.25

31.25

31.25

(1)

(1)

(1)

(1)

(1)

(1)

15.63

15.63

15.63

15.63

15.63

15.63

(1)

(1)

(1)

(1)

(1)

(1)

7.81

7.81

7.81

7.81

7.81

7.81

(1)

(1)

(1)

(1)

(1)

(1)

3.91

3.91

3.91

3.91

3.91

3.91

(1)

(1)

(1)

(1)

(1)

(1)

1.95

1.95

1.95

1.95

1.95

1.95

(1)

(1)

(1)

(1)

(1)

(1)

(1)

0.98

(1)

0.98

(1)

0.98

(1)

0.98

1.09 0.98

1.88 1.57

35.30 17.52 8.86 4.35 3.03 2.44 2.34

640 93.06 45.20 18.73 12.97 6.51 4.20 3.69 3.50

1000 284.59 129.77 61.30 33.04 16.82 9.08 5.42 4.65

2000 273.39 130.68 67.13 36.16 19.22 9.87 6.93 6.48

(1) Peak-to-peak noise rounded up to 1LSB.

Table 6. Effective Number of Bits From Peak-to-Peak Noise

At V

DATA RATE

(SPS) 1 2 4 8 16 32 64 128

5 16 16 16 16 16 16 16 16

10 16 16 16 16 16 16 16 16

20 16 16 16 16 16 16 16 15.8

40 16 16 16 16 16 16 16 15.4

80 16 16 16 16 16 16 15.8 15.0

160 16 16 16 16 16 16 15.1 14.3

320 16 15.8 15.8 15.8 15.8 15.4 14.7 13.7

640 15.4 15.5 15.7 15.3 15.3 14.9 14.1 13.2

1000 13.8 13.9 14.0 13.9 13.9 13.8 13.5 12.7

2000 13.9 13.9 13.9 13.8 13.7 13.7 13.2 12.3

= 2.048V, AVDD = 5V, and AVSS = 0V

REF

PGA SETTING

0.49

0.49

0.55

0.75

(1)

(1)

12 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): ADS1146 ADS1147 ADS1148

800

700

600

500

400

300

200

100

0

Temperature( C)°

AnalogCurrent( A)m

-40 -20 0 20 40 60 80 100 120

5/10/20SPS

40/80/160SPS

320/640/1kSPS

2kSPS

330

310

290

270

250

230

210

190

Temperature( C)°

DigitalCurrent( A)m

-40 -20 0 20 40 60 80 100 120

5/10/20SPS

40/80/160SPS

320/640/1kSPS

2kSPS

DVDD=5V

1.002

1.001

1.000

0.999

0.998

0.997

0.996

0.995

0.994

0.993

0.992

0.991

AVDD(V)

NormalizedOutputCurrent

2.0 2.5 3.0 3.5 4.0 4.5 5.0 5.5 6.0

750 Am

250 Am

1.5mA

500 Am

100 Am

1mA

50 Am

IDACCurrentSettings

0.004

0.003

0.002

0.001

0

-0.001

-0.002

-0.003

-0.004

Temperature( C)°

IEXC1 IEXC2(- mA)

-40 -20 0 20 40 60 80 100 120

1.5mASetting,10Units

www.ti.com

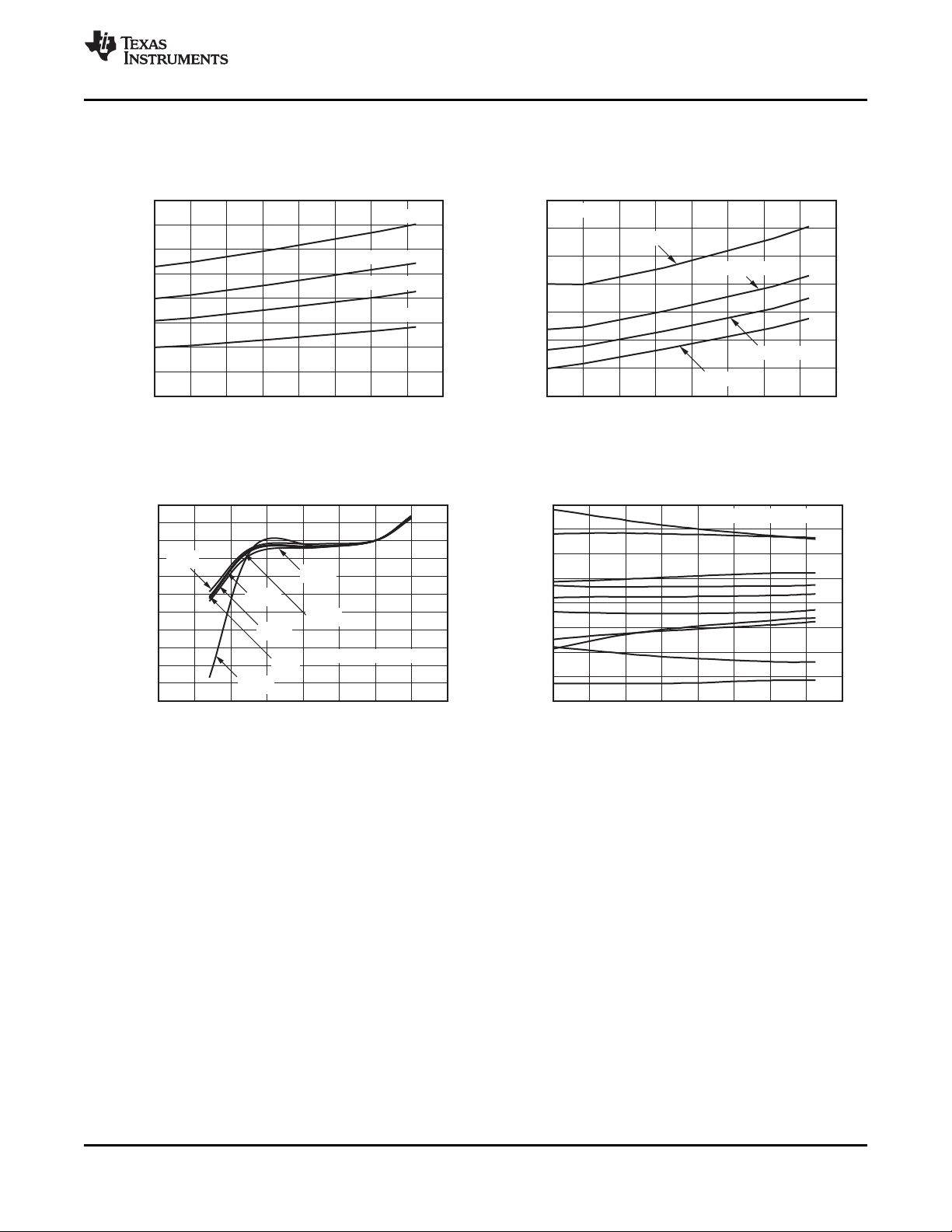

At TA= +25°C, AVDD = 5V, V

ANALOG CURRENT DIGITAL CURRENT

SBAS453C –JULY 2009–REVISED APRIL 2010

TYPICAL CHARACTERISTICS

= 2.5V, and AVSS = 0V, unless otherwise noted.

REF

vs TEMPERATURE vs TEMPERATURE

Figure 5. Figure 6.

ADS1146

ADS1147

ADS1148

IDAC LINE REGULATION IDAC DRIFT

Figure 7. Figure 8.

Copyright © 2009–2010, Texas Instruments Incorporated Submit Documentation Feedback 13

Product Folder Link(s): ADS1146 ADS1147 ADS1148

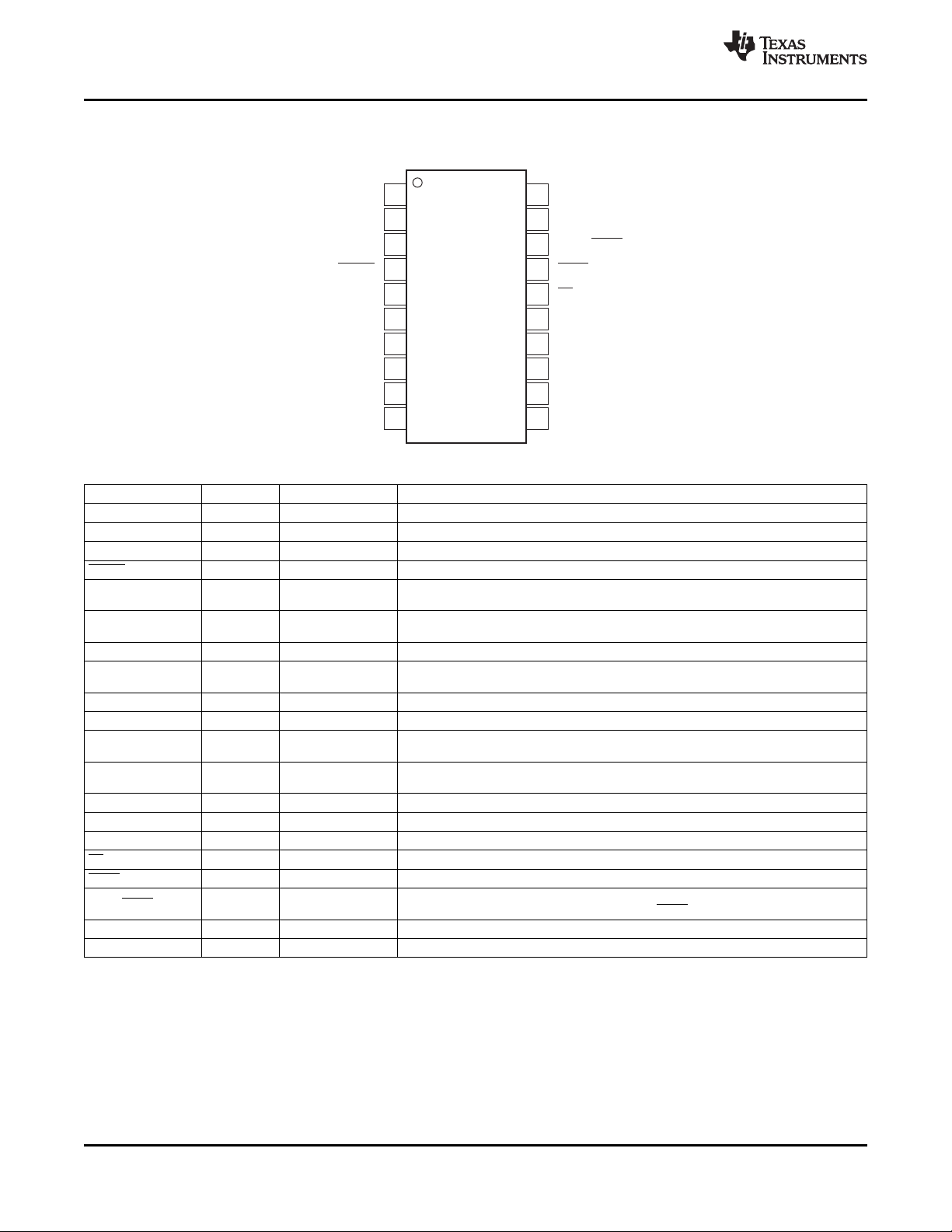

Input

Mux

3rdOrder

DS

Modulator

REFP REFN

PGA

Burnout

Detect

Burnout

Detect

DVDD

DGND

ADS1146

AVSS

AIN0

AIN1

SCLK

DIN

DRDY

DOUT/DRDY

CS

START

RESET

AVDD

InternalOscillator

Adjustable

Digital

Filter

Serial

Interface

and

Control

CLK

V

BIAS

Input

Mux

3rdOrder

DS

Modulator

REFP1 REFN1 VREFOUT VREFCOM

REFP0/

GPIO0

REFN0/

GPIO1

Burnout

Detect

Burnout

Detect

DVDD

DGND

IEXC1AVSS

AIN0/IEXC

AIN1/IEXC

AIN2/IEXC/GPIO2

AIN3/IEXC/GPIO3

AIN4/IEXC/GPIO4

AIN5/IEXC/GPIO5

AIN6/IEXC/GPIO6

AIN7/IEXC/GPIO7

ADS1148 Only

SCLK

DIN

DRDY

DOUT/DRDY

CS

START

RESET

AVDD

IEXC2

InternalOscillator

Voltage

Reference

Serial

Interface

and

Control

V

BIAS

GPIO

CLK

ADS1148 Only

ADS1147

ADS1148

PGA

System

Monitor

Adjustable

Digital

Filter

Dual

Current

DACs

VREFMux

ADS1148 Only

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

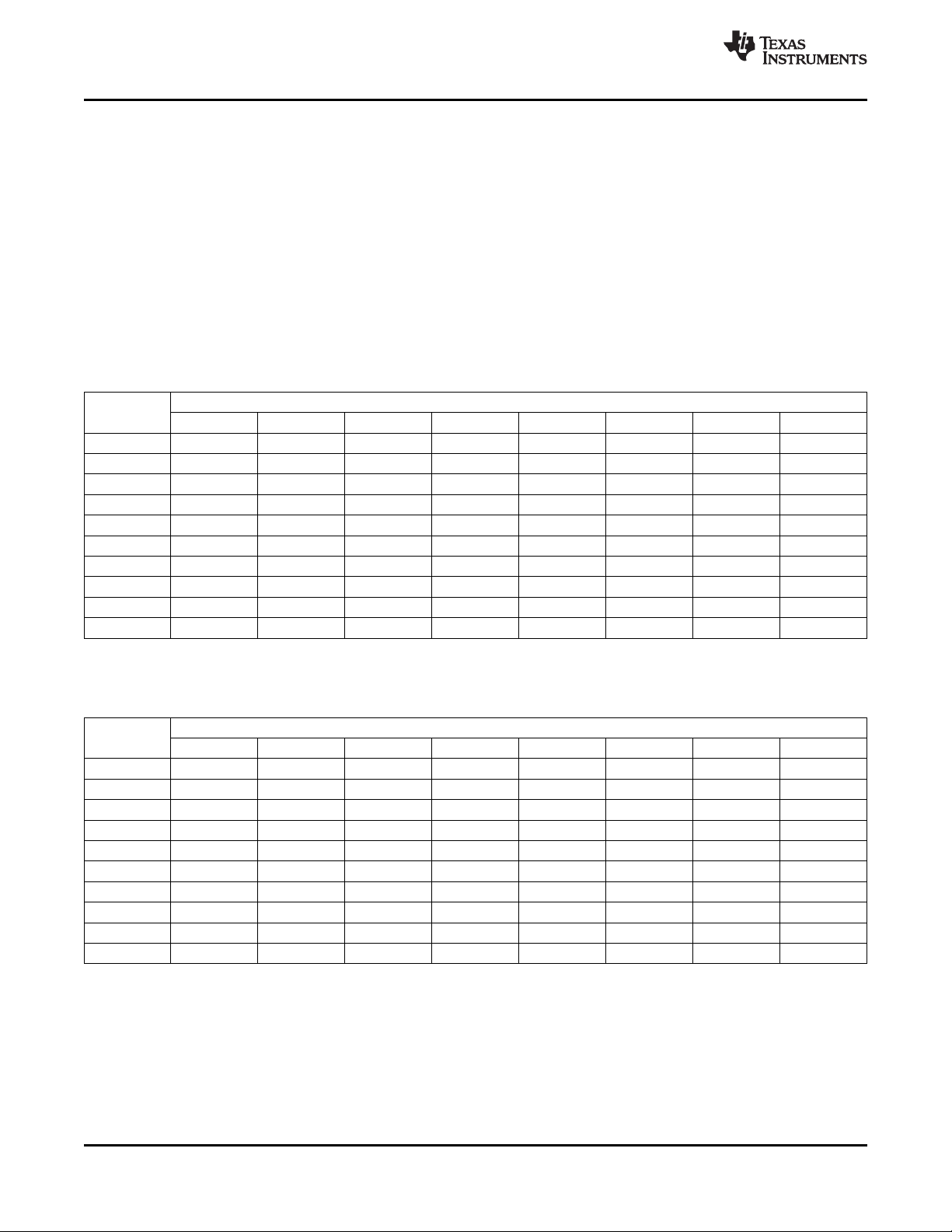

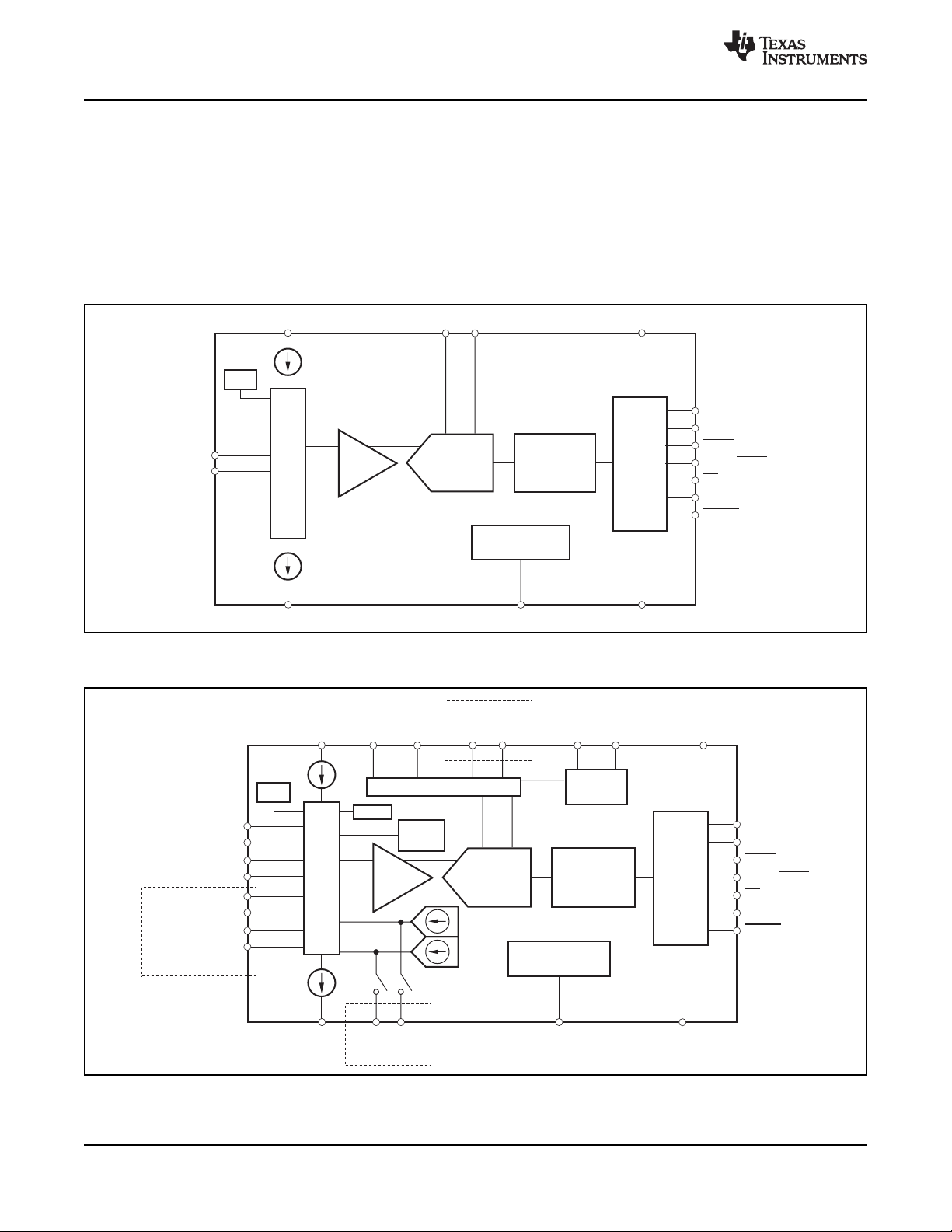

GENERAL DESCRIPTION

OVERVIEW

The ADS1146, ADS1147 and ADS1148 are highly input multiplexer with system monitoring capability

integrated 24-bit data converters. Each device and general-purpose I/O settings, a very low-drift

includes a low-noise, high-impedance programmable voltage reference, and two matched current sources

gain amplifier (PGA), a delta-sigma (ΔΣ) ADC with an for sensor excitation. Figure 9 and Figure 10 show

adjustable single-cycle settling digital filter, internal the various functions incorporated into each device.

oscillator, and a simple but flexible SPI-compatible

serial interface.

The ADS1147 and ADS1148 also include a flexible

www.ti.com

Figure 9. ADS1146 Diagram

14 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated

Figure 10. ADS1147, ADS1148 Diagram

Product Folder Link(s): ADS1146 ADS1147 ADS1148

SystemMonitors

Temperature

Diode

VREFP

VREFN

VREFP1/4

VREFN1/4

VREFP0/4

VREFN0/4

AVDD/4

AVSS/4

DVDD/4

DGND/4

ADS1148Only

ADS1147/8Only

VBIAS

AIN0

AIN1

VBIAS

AIN2

VBIAS

AIN3

VBIAS

AIN4

VBIAS

AIN5

VBIAS

AIN6

VBIAS

AIN7

AVDD

IDAC1

IDAC2

AVDD

VBIAS

PGA

AIN

P

AVSS

AVDD

BurnoutCurrentSource

(0.5 A,2 A,10m m mA)

BurnoutCurrentSource

(0.5 A,2 A,10m m mA)

AIN

N

To

ADC

AVSS

AVSS

AVSS

AVSS

AVSS

AVSS

AVSS

AVSS

AVDD

AVDD

AVDD

AVDD

AVDD

AVDD

AVDD

AVDD

AVDD AVDD

ADS1146

ADS1147

ADS1148

www.ti.com

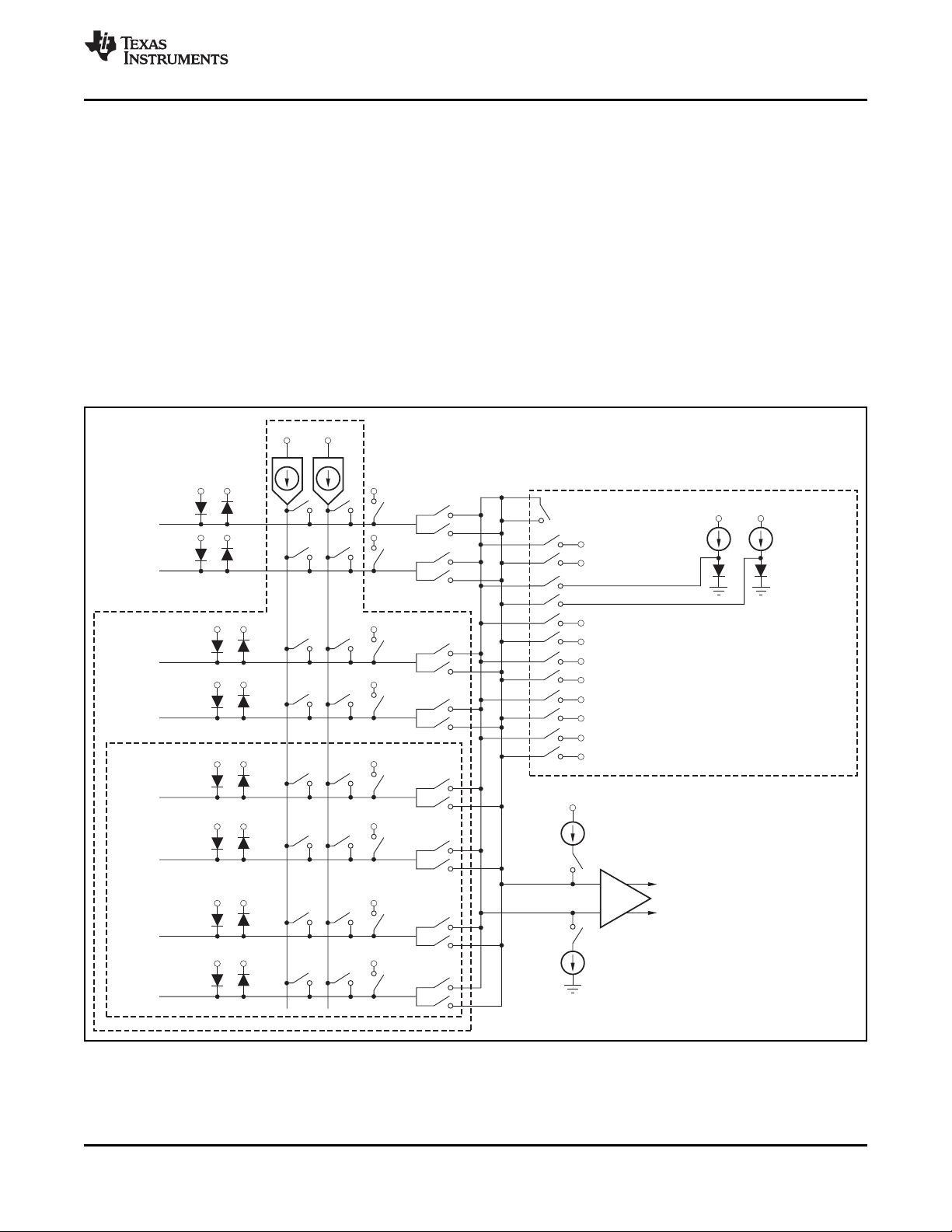

ADC INPUT AND MULTIPLEXER Any analog input pin can be selected as the positive

The ADS1146/7/8 ADC measures the input signal

through the onboard PGA. All analog inputs are

connected to the internal AINPor AINNanalog inputs

through the analog multiplexer. A block diagram of

the analog input multiplexer is shown in Figure 11.

The input multiplexer connects to eight (ADS1148),

four (ADS1147), or two (ADS1146) analog inputs that

can be configured as single-ended inputs, differential

inputs, or in a combination of single-ended and

differential inputs. The multiplexer also allows the

on-chip excitation current and/or bias voltage to be On the ADS1147 and ADS1148, the analog inputs

selected to a specific channel. can also be configured as general-purpose

input or negative input through the MUX0 register.

The ADS1146/7/8 have a true fully differential mode,

meaning that the input signal range can be from

–2.5V to +2.5V (when AVDD = 2.5V and AVSS =

–2.5V).

Through the input multiplexer, the ambient

temperature (internal temperature sensor), AVDD,

DVDD, and external reference can all be selected for

measurement. Refer to the System Monitor section

for details.

inputs/outputs (GPIOs). See the General-Purpose

Digital I/O section for more details.

SBAS453C –JULY 2009–REVISED APRIL 2010

Figure 11. Analog Input Multiplexer Circuit

Copyright © 2009–2010, Texas Instruments Incorporated Submit Documentation Feedback 15

Product Folder Link(s): ADS1146 ADS1147 ADS1148

REFN1REFP1

ADC

ADS1148 Only

REFN0REFP0

V

REFN

V

REFP

VREFCOMVREFOUT

ReferenceMultiplexer

Internal

Voltage

Reference

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

ESD diodes protect the ADC inputs. To prevent these As with the analog inputs, REFP0 and REFN0 can be

diodes from turning on, make sure the voltages on configured as digital I/Os on the ADS1147 and

the input pins do not go below AVSS by more than ADS1148.

100mV, and do not exceed AVDD by more than

100mV, as shown in Equation 2. Note that the same

caution is true if the inputs are configured to be

GPIOs.

AVSS – 100mV < (AINX) < AVDD + 100mV (2)

Settling Time for Channel Multiplexing

The ADS1146/7/8 is a true single-cycle settling ΔΣ

converter. The first data available after the start of a

conversion are fully settled and valid for use. The

time required to settle is roughly equal to the inverse

of the data rate. The exact time depends on the

specific data rate and the operation that resulted in

the start of a conversion; see Table 15 for specific

values.

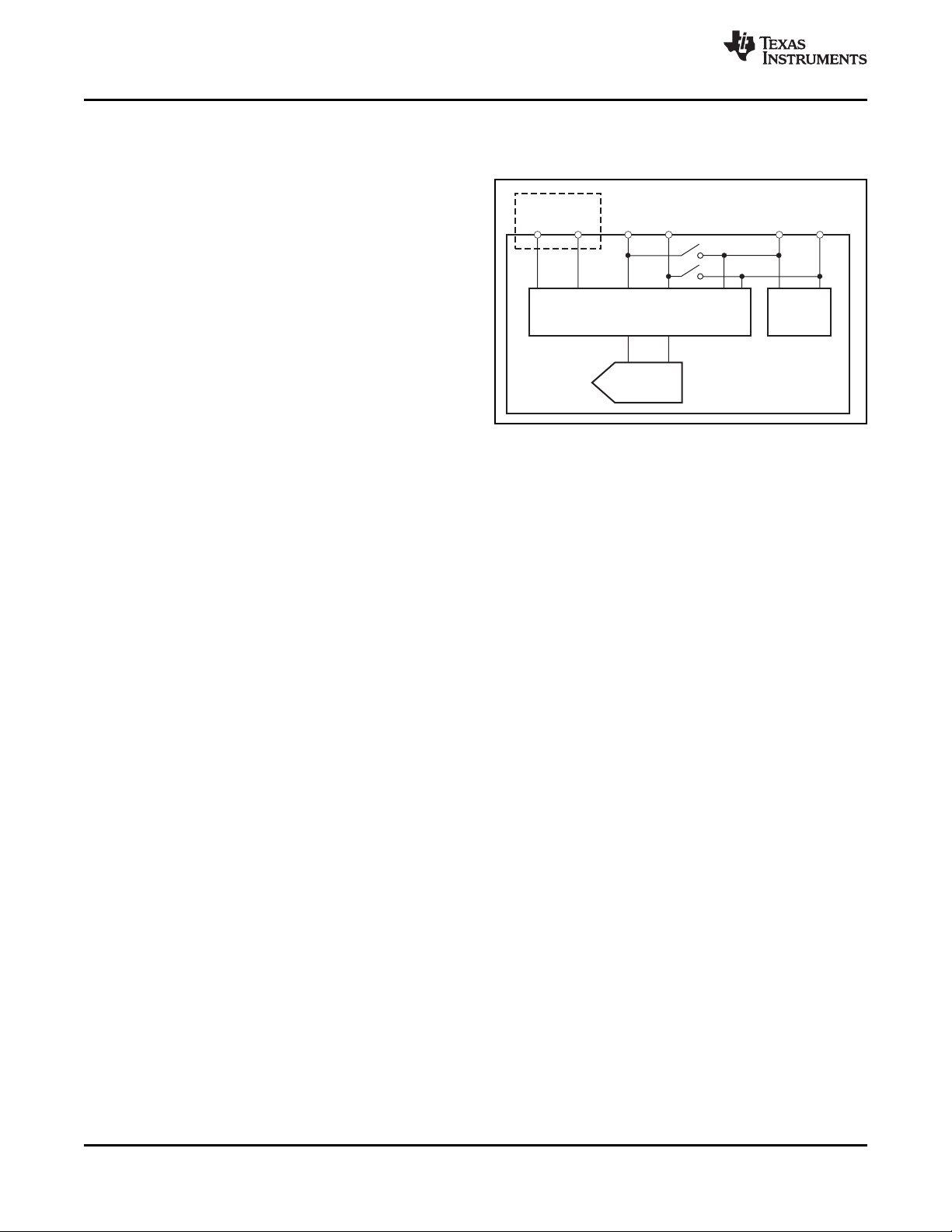

Figure 12. Reference Input Multiplexer

VOLTAGE REFERENCE INPUT

The voltage reference for the ADS1146/7/8 is the

differential voltage between REFP and REFN:

V

REF

= V

REFP

– V

REFN

In the case of the ADS1146, these pins are dedicated

inputs. For the ADS1147 and ADS1148, there is a

multiplexer that selects the reference inputs, as

shown in Figure 12. The reference input uses a buffer

to increase the input impedance.

The reference input circuit has ESD diodes to protect

the inputs. To prevent the diodes from turning on,

make sure the voltage on the reference input pin is

not less than AVSS – 100mV, and does not exceed

AVDD + 100mV, as shown in Equation 3:

AVSS – 100mV < (V

REFP

or V

) < AVDD + 100mV (3)

REFN

www.ti.com

16 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): ADS1146 ADS1147 ADS1148

(V )(Gain)

IN

2

AVSS+0.1V +

£ V

CMI

£

()

(V )(Gain)

IN

2

AVDD 0.1V- -

ADC

A1

454W

454W

7.5pF

A2

7.5pF

7.5pF

7.5pF

R

R

C

AIN

P

AIN

N

www.ti.com

LOW-NOISE PGA

The ADS1146/7/8 feature a low-drift, low-noise, high

input impedance programmable gain amplifier (PGA).

The PGA can be set to gain of 1, 2, 4, 8, 16, 32, 64,

or 128 by register SYS0. A simplified diagram of the

PGA is shown in Figure 13.

Figure 13. Simplified Diagram of the PGA

The PGA consists of two chopper-stabilized

amplifiers (A1 and A2) and a resistor feedback

network that sets the gain of the PGA. The PGA input

is equipped with an electromagnetic interference

(EMI) filter, as shown in Figure 13. Note that as with

any PGA, it is necessary to ensure that the input

voltage stays within the specified common-mode

input range specified in the Electrical Characteristics.

The common-mode input (V

range shown in Equation 4:

) must be within the

CMI

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

(4)

MODULATOR

A third-order modulator is used in the ADS1146/7/8.

The modulator converts the analog input voltage into

a pulse code modulated (PCM) data stream. To save

power, the modulator clock runs from 32kHz up to

512kHz for different data rates, as shown in Table 7.

DIGITAL FILTER

The ADS1146/7/8 use linear-phase finite impulse

response (FIR) digital filters that can be adjusted for

different output data rates. The digital filter always

settles in a single cycle.

Table 8 shows the exact data rates when an external

oscillator equal to 4.096MHz is used. Also shown is

the signal –3dB bandwidth, and the 50Hz and 60Hz

attenuation. For good 50Hz or 60Hz rejection, use a

data rate of 20SPS or slower.

The frequency responses of the digital filter are

shown in Figure 14 to Figure 24. Figure 17 shows a

detailed view of the filter frequency response from

48Hz to 62Hz for a 20SPS data rate. All filter plots

are generated with 4.096MHz external clock.

Table 7. Modulator Clock Frequency for Different

Data Rates

DATA RATE f

(SPS) (kHz)

5, 10, 20 32

40, 80, 160 128

320, 640, 1000 256

2000 512

MOD

Table 8. Digital Filter Specifications

DATA RATE –3dB BANDWIDTH fIN= 50Hz ±0.3Hz fIN= 60Hz ±0.3Hz fIN= 50Hz ±1Hz fIN= 60Hz ±1Hz

5SPS 2.26Hz –106dB –74dB –81dB –69dB

10SPS 4.76Hz –106dB –74dB –80dB –69dB

20SPS 14.8Hz –71dB –74dB –66dB –68dB

40SPS 9.03Hz

80SPS 19.8Hz

160SPS 118Hz

320SPS 154Hz

(1) Values shown for f

Copyright © 2009–2010, Texas Instruments Incorporated Submit Documentation Feedback 17

640SPS 495Hz

1000SPS 732Hz

2000SPS 1465Hz

= 4.096MHz.

OSC

Product Folder Link(s): ADS1146 ADS1147 ADS1148

(1)

ATTENUATION

20

0

-20

-40

-60

-80

-100

-120

0 40 60

Frequency(Hz)

Magnitude(dB)

80 100 120 140 160 180 200

50 52 54 56 58 60

-60

-70

-80

-90

-100

-110

-120

48

Frequency(Hz)

Magnitude(dB)

62

20

0

-20

-40

-60

-80

-100

-120

0 40 60

Frequency(Hz)

Magnitude(dB)

80 100 120 140 160 180 200

200

0

-20

-40

-60

-80

-100

-120

0 400 600

Frequency(Hz)

Magnitude(dB)

800 1000 1200 1400 1600 1800 2000

20

0

-20

-40

-60

-80

-100

-120

0 40 60

Frequency(Hz)

Magnitude(dB)

80 100 120 140 160 180 200

200

0

-20

-40

-60

-80

-100

-120

0 400 600

Frequency(Hz)

Magnitude(dB)

800 1000 1200 1400 1600 1800 2000

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

Figure 14. Filter Profile with Data Rate = 5SPS Figure 17. Detailed View of Filter Profile with Data

Rate = 20SPS between 48Hz and 62Hz

www.ti.com

Figure 15. Filter Profile with Data Rate = 10SPS

Figure 18. Filter Profile with Data Rate = 40SPS

Figure 16. Filter Profile with Data Rate = 20SPS

Figure 19. Filter Profile with Data Rate = 80SPS

18 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): ADS1146 ADS1147 ADS1148

200

0

-20

-40

-60

-80

-100

-120

0 400 600

Frequency(Hz)

Magnitude(dB)

800 1000 1200 1400 1600 1800 2000

1

0

-20

-40

-60

-80

-100

-120

0 2 3

Frequency(kHz)

Magnitude(dB)

4 5 6 7 8 9 10

500

0

-20

-40

-60

-80

-100

-120

0 1000 1500

Frequency(Hz)

Magnitude(dB)

2000 2500 3000 3500 4000 4500 5000

2

0

-20

-40

-60

-80

-100

-120

0 4 6

Frequency(kHz)

Magnitude(dB)

8 10 12 14 16 18 20

500

0

-20

-40

-60

-80

-100

-120

0 1000 1500

Frequency(Hz)

Magnitude(dB)

2000 2500 3000 3500 4000 4500 5000

ADS1146

ADS1147

ADS1148

www.ti.com

Figure 20. Filter Profile with Data Rate = 160SPS Figure 23. Filter Profile with Data Rate = 1kSPS

SBAS453C –JULY 2009–REVISED APRIL 2010

Figure 21. Filter Profile with Data Rate = 320SPS Figure 24. Filter Profile with Data Rate = 2kSPS

CLOCK SOURCE

The ADS1146/7/8 can use either the internal

oscillator or an external clock. Connect the CLK pin to

DGND before power-on or reset to activate the

internal oscillator. Connecting an external clock to the

CLK pin at any time deactivates the internal oscillator,

with the device then operating on the external clock.

After the device switches to the external clock, it

cannot be switched back to the internal oscillator

without cycling the power supplies or resetting the

device.

Figure 22. Filter Profile with Data Rate = 640SPS

Copyright © 2009–2010, Texas Instruments Incorporated Submit Documentation Feedback 19

Product Folder Link(s): ADS1146 ADS1147 ADS1148

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

INTERNAL VOLTAGE REFERENCE EXCITATION CURRENT SOURCE DACS

The ADS1147 and ADS1148 include an onboard The ADS1147 and ADS1148 provide two matched

voltage reference with a low temperature coefficient. excitation current sources for RTD applications. For

The output of the voltage reference is 2.048V with the three- or four-wire RTD applications, the matched

capability of both sourcing and sinking up to 10mA of current sources can be used to cancel the errors

current. caused by sensor lead resistance. The output current

The voltage reference must have a capacitor

connected between VREFOUT and VREFCOM. The

value of the capacitance should be in the range of

1mF to 47mF. Large values provide more filtering of The two matched current sources can be connected

the reference; however, the turn-on time increases to dedicated current output pins IOUT1 and IOUT2

with capacitance, as shown in Table 9. For stability (ADS1148 only), or to any AIN pin (ADS1147 and

reasons, VREFCOM must have a path with an ADS1148); refer to the ADS1147/48 Detailed

impedance less than 10Ω to ac ground nodes, such Register Definitions section for more information. It is

as AVSS (for a 0V to 5V analog power supply), or possible to connect both current sources to the same

GND (for a ±2.5V analog power supply). In case this pin. Note that the internal reference must be turned

impedance is higher than 10Ω, a capacitor of at least on and properly compensated when using the

0.1mF should be connected between VREFCOM and excitation current source DACs.

an ac ground node (for example, GND). Note that

because it takes time for the voltage reference to

settle to the final voltage, care must be taken when

the device is turned off between conversions. Allow

adequate time for the internal reference to fully settle.

Table 9. Internal Reference Settling Time

VREFOUT SETTLING TIME TO REACH THE

CAPACITOR ERROR SETTLING ERROR

1mF

4.7mF

47mF

±0.5% 70ms

±0.1% 110ms

±0.5% 290ms

±0.1% 375ms

±0.5% 2.2ms

±0.1% 2.4ms

The onboard reference is controlled by the registers;

by default, it is off after startup (see the ADS1147/48

Detailed Register Definitions section for more details).

Therefore, the internal reference must first be turned

on and then connected via the internal reference

multiplexer. Because the onboard reference is used

to generate the current reference for the excitation

current sources, it must be turned on before the

excitation currents become available.

of the current source DACs can be programmed to

50mA, 100mA, 250mA, 500mA, 750mA, 1000mA, or

1500mA.

SENSOR DETECTION

The ADS1146/7/8 provide a selectable current

(0.5mA, 2mA, or 10mA) to help detect a possible

sensor malfunction.

When enabled, two burnout current sources flow

through the selected pair of analog inputs to the

sensor. One sources the current to the positive input

channel, and the other sinks the same current from

the negative input channel.

When the burnout current sources are enabled, a

full-scale reading may indicate an open circuit in the

front-end sensor, or that the sensor is overloaded. It

may also indicate that the reference voltage is

absent. A near zero reading may indicate a

short-circuit in the sensor.

BIAS VOLTAGE GENERATION

A selectable bias voltage is provided for use with

ungrounded thermocouples. The bias voltage is

(AVDD + AVSS)/2 and can applied to any analog

input channel through internal input multiplexer. The

bias voltage turn-on times for different sensor

capacitances are listed in Table 10.

www.ti.com

Table 10. Bias Voltage Settling Time

SENSOR CAPACITANCE SETTLING TIME

0.1mF 220ms

1mF 2.2ms

10mF 22ms

200mF 450ms

20 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): ADS1146 ADS1147 ADS1148

IOCFG

AINx/GPIOx

ToAnalogMux

DIOWRITE

IODIR

DIOREAD

REFx0/GPIOx

www.ti.com

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

GENERAL-PURPOSE DIGITAL I/O

The ADS1148 has eight pins and the ADS1147 has

four pins that serve a dual purpose as either analog

inputs or general-purpose digital inputs/outputs

(GPIOs).

Figure 25 shows a diagram of how these functions

are combined onto a single pin. Note that when the

pin is configured as a GPIO, the corresponding logic

is powered from AVDD and AVSS. When the

ADS1147 and ADS1148 are operated with bipolar

analog supplies, the GPIO outputs bipolar voltages.

Care must be taken loading the GPIO pins when

used as outputs because large currents can cause

droop or noise on the analog supplies.

Figure 25. Analog/Data Interface Pin

SYSTEM MONITOR

The ADS1147 and ADS1148 provide a system

monitor function. This function can measure the

analog power supply, digital power supply, external

voltage reference, or ambient temperature. Note that

the system monitor function provides a coarse result.

When the system monitor is enabled, the analog

inputs are disconnected.

Power-Supply Monitor

The system monitor can measure the analog or

digital power supply. When measuring the power

supply, the resulting conversion is approximately 1/4

of the actual power supply voltage.

Conversion result = (VSP/4)/V

REF

(5)

Where VSPis the selected supply to be measured.

External Voltage Reference Monitor

The ADS1146/7/8 can be selected to measure the

external voltage reference. In this configuration, the

monitored external voltage reference is connected to

the analog input. The result (conversion code) is

approximately 1/4 of the actual reference voltage.

Conversion result = (V

Where V

is the external reference to be

REX

REX

/4)/V

REF

(6)

monitored.

NOTE: The internal reference voltage must be

enabled when measuring an external voltage

reference using the system monitor.

Ambient Temperature Monitor

On-chip diodes provide temperature-sensing

capability. When selecting the temperature monitor

function, the anodes of two diodes are connected to

the ADC. Typically, the difference in diode voltage is

118mV at +25°C with a temperature coefficient of

405mV/°C.

Note that when the onboard temperature monitor is

selected, the PGA is automatically set to '1'.

However, the PGA register bits in are not affected

and the PGA returns to its set value when the

temperature monitor is turned off.

Copyright © 2009–2010, Texas Instruments Incorporated Submit Documentation Feedback 21

Product Folder Link(s): ADS1146 ADS1147 ADS1148

ADC

S

OFC

Register

Final

Output

OutputData

Clippedto16Bits

´

+

-

FSCRegister

400000h

FinalOutputData= (Input OFC[2:1])- ´

FSC[2:0]

400000h

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

CALIBRATION Note that while the offset calibration register value

The conversion data are scaled by offset and gain

registers before yielding the final output code. As

shown in Figure 26, the output of the digital filter is

first subtracted by the offset register (OFC) and then

multiplied by the full-scale register (FSC). A digital

clipping circuit ensures the output code does not The full-scale or gain calibration is a 24-bit word

exceed 16 bits. Equation 7 shows the scaling. composed of three 8-bit registers. The full-scale

Figure 26. Calibration Block Diagram

(7)

The values of the offset and full-scale registers are

set by writing to them directly, or they are set

automatically by calibration commands.

Offset Calibration Register: OFC[2:0]

The offset calibration is a 24-bit word, composed of

three 8-bit registers. The upper 16 bits, OFC[2:1], are

the most important for calibration and can correct

offsets ranging from –FS to +FS, as shown in

Table 11. The lower eight bits, OFC[0], provide

sub-LSB correction and are used by the ADS1146/7/8

calibration commands. If an ADS1146/7/8 calibration

command is issued and the offset register is then

read for storage and re-use later, it is recommended

that all 24 bits of the OFC be used. When the

calibration commands are not used and the offset is

corrected by writing a user-calculated value to the

OFC register, it is recommended that only that only

OFC[2:1] be used and that OFC[0] be left as all

zeros.

Table 11. Final Output Code versus Offset

Calibration Register Setting

FINAL OUTPUT CODE WITH

OFFSET REGISTER VIN= 0

7FFFFFh 8000000h

000001h FFFFFFh

000000h 000000h

FFFFFFh 000000h

8000000h 7FFFFFh

1. Excludes effects of noise and inherent offset

errors.

can correct offsets ranging from –FS to +FS (as

shown in Table 11), make sure to avoid overloading

the analog inputs.

Full-Scale Calibration Register: FSC[2:0]

calibration value is 24-bit, straight binary, normalized

to 1.0 at code 400000h. Table 12 summarizes the

scaling of the full-scale register. Note that while the

full-scale calibration register can correct gain errors

> 1 (with gain scaling < 1), make sure to avoid

overloading the analog inputs. The default or reset

value of FSC depends on the PGA setting. A different

factory-trimmed FSC Reset value is stored for each

PGA setting which provides outstanding gain

accuracy over all the ADS1146/7/8 input ranges.

Note: The factory-trimmed FSC reset value loads

automatically loaded whenever the PGA setting

changes.

Table 12. Gain Correction Factor versus

Full-Scale Calibration Register Setting

FULL-SCALE REGISTER GAIN SCALING

800000h 2.0

400000h 1.0

200000h 0.5

000000h 0

Calibration Commands

The ADS1146/7/8 provide commands for three types

of calibration: system gain calibration, system offset

calibration and self offset calibration. Where absolute

accuracy is needed, it is recommended that

calibration be performed after power on, a change in

temperature, a change of PGA and in some cases a

change in channel. At the completion of calibration,

the DRDY signal goes low indicating the calibration is

finished. The first data after calibration are always

valid. If the START pin is taken low or a SLEEP

command is issued after any calibration command,

the devices goes to sleep after completing calibration.

System Gain Calibration

System gain calibration corrects for gain error in the

signal path. The system gain calibration is initiated by

sending the SYSGCAL command while applying a

full-scale input to the selected analog inputs.

Afterwards the full-scale calibration register (FSC) is

updated. When a system gain calibration command is

issued, the ADS1146/7/8 stop the current conversion

and start the calibration procedure immediately.

www.ti.com

22 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): ADS1146 ADS1147 ADS1148

CalibrationTime=

50

f

OSC

32

f

MOD

16

f

DATA

+

+

www.ti.com

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

System Offset and Self Offset Calibration

System offset calibration corrects both internal and

external offset errors. The system offset calibration is

initiated by sending the SYSOCAL command while

applying a zero differential input (VIN= 0) to the

selected analog inputs. The self offset calibration is

initiated by sending the SELFOCAL command.

During self offset calibration, the selected inputs are

disconnected from the internal circuitry and a zero

differential signal is applied internally. With both offset

calibrations the offset calibration register (OFC) is

updated afterwards. When either offset calibration

command is issued, the ADS1146/7/8 stop the

current conversion and start the calibration procedure

immediately.

Calibration Timing

When calibration is initiated, the device performs 16

consecutive data conversions and averages the

results to calculate the calibration value. This

provides a more accurate calibration value. The time

required for calibration is shown in Table 13 and can

be calculated using Equation 8:

(8)

Table 13. Calibration Time versus Data Rate

DATA RATE (SPS) CALIBRATION TIME (ms)

5 3201.01

10 1601.01

20 801.012

40 400.26

80 200.26

160 100.14

320 50.14

640 25.14

1000 16.14

2000 8.07

ADC SLEEP MODE

Power consumption can be dramatically reduced by

placing the ADS1146/7/8 into sleep mode. There are

two ways to put the device into sleep mode: the sleep

command (SLEEP) and through the START pin.

During sleep mode, the internal reference status

depends on the setting of the VREFCON bits in the

MUX1 register; see the Register Descriptions section

for details.

ADC CONTROL

ADC Conversion Control

The START pin provides easy and precise control of

conversions. Pulse the START pin high to begin a

conversion, as shown in Figure 27 and Table 14. The

conversion completion is indicated by the

DOUT/DRDY pin going low. When the conversion

completes, the ADS1146/7/8 automatically shuts

down to save power. During shutdown, the

conversion result can be retrieved; however, START

must be taken high before communicating with the

configuration registers. The device stays shut down

until the START pin is once again taken high to begin

a new conversion. When the START pin is taken

back high again, the decimation filter is held in a

reset state for 32 modulator clock cycles internally to

allow the analog circuits to settle.

The ADS1146/7/8 can be configured to convert

continuously by holding the START pin high, as

shown in Figure 28. With the START pin held high,

the ADC converts the selected input channels

continuously. This configuration continues until the

START pin is taken low.

The START pin can also be used to perform the

synchronized measurement for the multi-channel

applications by pulsing the START pin.

1. For f

Copyright © 2009–2010, Texas Instruments Incorporated Submit Documentation Feedback 23

= 4.096MHz.

OSC

Product Folder Link(s): ADS1146 ADS1147 ADS1148

Converting

START

DOUT/DRDY

SCLK

DRDY

ADS1146/7/8

Status

Shutdown

1 2 3 16

t

CONV

t

START

Converting Converting Converting Converting

START

DOUT/DRDY

ADS1146/7/8

Status

DataReady DataReady DataReady

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

Figure 27. Timing for Single Conversion Using START Pin

Table 14. START Pin Conversion Times for Figure 27

SYMBOL DESCRIPTION DATA RATE (SPS) VALUE UNIT

5 200.295 ms

10 100.644 ms

20 50.825 ms

40 25.169 ms

t

CONV

Time from START pulse to DRDY and

DOUT/DRDY going low

80 12.716 ms

160 6.489 ms

320 3.247 ms

640 1.692 ms

1000 1.138 ms

2000 0.575 ms

www.ti.com

NOTE: SCLK held low in this example.

Figure 28. Timing for Conversion with START Pin High

24 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): ADS1146 ADS1147 ADS1148

ADS1146

ADS1147

ADS1148

www.ti.com

RESET The filter is reset two system clocks after the last bit

When the RESET pin goes low, the device is

immediately reset. All the registers are restored to

default values. The device stays in reset mode as

long as the RESET pin stays low. When it goes high,

the ADC comes out of reset mode and is able to

convert data. After the RESET pin goes high, and

when the system clock frequency is 4.096MHz, the

digital filter and the registers are held in a reset state

for 0.6ms when f

= 4.096MHz. Therefore, valid

OSC

SPI communication can only be resumed 0.6ms after

the RESET pin goes high, as shown in Figure 4.

When the RESET pin goes low, the clock selection is

reset to the internal oscillator.

of the SYNC command is sent. The reset pulse

created internally lasts for two multiplier clock cycles.

If any write operation takes place in the MUX0

register, the filter is reset regardless of whether the

value changed or not. Internally, the filter pulse lasts

for two system clock periods. If any write activity

takes place in the VBIAS, MUX1, or SYS0 registers,

the filter is reset as well, regardless of whether the

value changed or not. The reset pulse lasts for 32

modulator clocks after the write operation. If there are

multiple write operations, the resulting reset pulse

may be viewed as the ANDed result of the different

active low pulses created individually by each action.

Table 15 shows the conversion time after a filter

Digital Filter Reset Operation reset. Note that this time depends on the operation Apart from the RESET command and the RESET pin,

the digital filter is reset automatically when either a

write operation to the MUX0, VBIAS, MUX1, or SYS0

initiating the reset. Also, the first conversion after a

filter reset has a slightly different time than the

second and subsequent conversions.

registers is performed, when a SYNC command is

issued, or the START pin is taken high.

SBAS453C –JULY 2009–REVISED APRIL 2010

Table 15. Data Conversion Time

FIRST DATA CONVERSION TIME AFTER FILTER RESET

HARDWARE RESET, RESET

COMMAND, START PIN HIGH,

SYNC COMMAND, MUX0 MUX1, or SYS0 REGISTER CONVERSION TIME AFTER

REGISTER WRITE WRITE FILTER RESET

NOMINAL EXACT DATA SYSTEM SYSTEM SYSTEM

DATA RATE RATE CLOCK CLOCK CLOCK

(SPS) (SPS) (ms)

5 5.019 199.264 816188 200.266 820290 199.250 816128

10 10.038 99.639 408124 100.641 412226 99.625 408064

20 20.075 49.827 204092 50.828 208194 49.812 204032

40 40.151 24.920 102076 25.172 103106 24.906 102016

80 80.301 12.467 51068 12.719 52098 12.453 51008

160 160.602 6.241 25564 6.492 26594 6.226 25504

320 321.608 3.124 12796 3.250 13314 3.109 12736

640 643.216 1.569 6428 1.695 6946 1.554 6368

1000 1000.000 1.014 4156 1.141 4674 1.000 4096

2000 2000.000 0.514 2108 0.578 2370 0.500 2048

(1) For f

= 4.096MHz.

OSC

(1)

NO. OF NO. OF NO. OF

CYCLES (ms)

WAKEUP COMMAND, VBIAS, SECOND AND SUBSEQUENT

(1)

CYCLES (ms) CYCLES

Copyright © 2009–2010, Texas Instruments Incorporated Submit Documentation Feedback 25

Product Folder Link(s): ADS1146 ADS1147 ADS1148

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

www.ti.com

Data Format

The ADS1146/7/8 output 16 bits of data in binary

twos complement format. The least significant bit

(LSB) has a weight of (V

/PGA)/(215– 1). The

REF

positive full-scale input produces an output code of

7FFFh and the negative full-scale input produces an

output code of 8000h. The output clips at these codes

for signals exceeding full-scale. Table 16 summarizes

the ideal output codes for different input signals.

Table 16. Ideal Output Code vs Input Signal

INPUT SIGNAL, V

(AINP– AINN) IDEAL OUTPUT CODE

≥ +V

REF

(+V

/PGA)/(215– 1) 0001h DIN

REF

0 0000h

(–V

/PGA)/(215– 1) FFFFh

REF

≤ –(V

/PGA) × (215/215– 1) 8000h

REF

IN

/PGA 7FFFh

1. Excludes effects of noise, linearity, offset, and

gain errors.

Digital Interface

The ADS1146/7/8 provide a standard SPI serial

communication interface plus a data ready signal

(DRDY). Communication is full-duplex with the

exception of a few limitations in regards to the RREG

command and the RDATA command. These

limitations are explained in detail in the SPI

Commands section of this data sheet. For the basic

serial interface timing characteristics, see Figure 1

and Figure 2 of this document.

CS

This pin is the chip select pin (active low). The CS pin

activates SPI communication. CS must be low before

data transactions and must stay low for the entire SPI

communication period. When CS is high, the

DOUT/DRDY pin enters a high-impedance state.

Therefore, reading and writing to the serial interface

are ignored and the serial interface is reset. DRDY

pin operation is independent of CS.

Taking CS high deactivates only the SPI

communication with the device. Data conversion

continues and the DRDY signal can be monitored to

check if a new conversion result is ready. A master

device monitoring the DRDY signal can select the

appropriate slave device by pulling the CS pin low.

SCLK

This signal is the serial clock signal. SCLK provides

the clock for serial communication. It is a

Schmitt-trigger input, but it is highly recommended

that SCLK be kept as clean as possible to prevent

glitches from inadvertently shifting the data. Data are

shifted into DIN on the falling edge of SCLK and

shifted out of DOUT on the rising edge of SCLK.

This pin is the data input pin. DIN is used along with

SCLK to send data to the device. Data on DIN are

shifted into the device on the falling edge of SCLK.

The communication of this device is full-duplex in

nature. The device monitors commands shifted in

even when data are being shifted out. Data that are

present in the output shift register are shifted out

when sending in a command. Therefore, it is

important to make sure that whatever is being sent on

the DIN pin is valid when shifting out data. When no

command is to be sent to the device when reading

out data, the NOP command should be sent on DIN.

DRDY

This pin is the data ready pin. The DRDY pin goes

low to indicate a new conversion is complete, and the

conversion result is stored in the conversion result

buffer. The SPI clock must be low in a short time

frame around the DRDY low transition (see Figure 2)

so that the conversion result is loaded into both the

result buffer and the output shift register. Therefore,

no commands should be issued during this time

frame if the conversion result is to be read out later.

This constraint applies only when CS is asserted.

When CS is not asserted, SPI communication with

other devices on the SPI bus does not affect loading

of the conversion result. After the DRDY pin goes

low, it is forced high on the first falling edge of SCLK

(so that the DRDY pin can be polled for '0' instead of

waiting for a falling edge). If the DRDY pin is not

taken high after it falls low, a short high pulse is

created on it to indicate the next data are ready.

26 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): ADS1146 ADS1147 ADS1148

SCLK

D[15]

1 2 14 1 2 815 163

D[14] D[13] D[2] D[1] D[0]

DOUT/

(1)

DRDY

DRDY

SCLK

DIN

1

1

D[15] D[14]D[15]D[14] D[13]

NOP NOP

D[2] D[1] D[0] D[0]

2

2

3 14 15

16

16

DOUT/

(1)

DRDY

DRDY

ADS1146

ADS1147

ADS1148

www.ti.com

DOUT/DRDY DOUT/DRDY goes low, the data can be clocked out

This pin has two modes: data out (DOUT) only, or by providing 16 SCLKs. In order to force

data out (DOUT) combined with data ready (DRDY). DOUT/DRDY high (so that DOUT/DRDY can be

The DRDY MODE bit determines the function of this polled for a '0' instead of waiting for a falling edge), a

pin. In either mode, the DOUT/DRDY pin goes to a no operation command (NOP) or any other command

high-impedance state when CS is taken high. that does not load the data output register can be

When the DRDY MODE bit is set to '0', this pin

functions as DOUT only. Data are clocked out at

rising edge of SCLK, MSB first (see Figure 29).

When the DRDY MODE bit is set to '1', this pin

functions as both DOUT and DRDY. Data are shifted

out from this pin, MSB first, at the rising edge of

SCLK. This combined pin allows for the same control

but with fewer pins.

When the DRDY MODE bit is enabled and a new

conversion is complete, DOUT/DRDY goes low if it is

high. If it is already low, then DOUT/DRDY goes high

sent after reading out the data. Because SCLKs can

only be sent in multiples of eight, a NOP can be sent

to force DOUT/DRDY high if no other command is

pending. The DOUT/DRDY pin goes high after the

first rising edge of SCLK after reading the conversion

result completely (see Figure 31). The same condition

also applies after an RREG command. After all the

register bits have been read out, the rising edge of

SCLK forces DOUT/DRDY high. Figure 32 illustrates

an example where sending four NOP commands after

an RREG command forces the DOUT/DRDY pin

high.

and then goes low (see Figure 30). Similar to the

DRDY pin, a falling edge on the DOUT/DRDY pin

signals that a new conversion result is ready. After

SBAS453C –JULY 2009–REVISED APRIL 2010

(1) CS tied low.

Figure 29. Data Retrieval with the DRDY MODE Bit = 0 (Disabled)

(1) CS tied low.

Figure 30. Data Retrieval with the DRDY MODE Bit = 1 (Enabled)

Copyright © 2009–2010, Texas Instruments Incorporated Submit Documentation Feedback 27

Product Folder Link(s): ADS1146 ADS1147 ADS1148

SCLK

DIN

1

1

D[15] D[14]D[15]D[14] D[13]

NOP NOP NOP

D[2] D[1] D[0] D[0]

2

2

3 14 15 16 1 2 8

16

DOUT/

(1)

DRDY

DRDY

SCLK

DOUT/

(1)

DRDY

DIN NOP

1

reg[7] reg[1] reg[0]

2 1 2 7 87 8

NOP

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

(1) DRDY MODE bit enabled, CS tied low.

Figure 31. DOUT/DRDY Forced High After Retrieving the Conversion Result

www.ti.com

(1) DRDY MODE bit enabled, CS tied low.

Figure 32. DOUT/DRDY Forced High After Reading Register Data

The DRDY MODE bit modifies only the DOUT/DRDY

pin functionality. The DRDY pin functionality remains

unaffected.

SPI Reset

SPI communication can be reset in several ways. In

order to reset the SPI interface (without resetting the

registers or the digital filter), the CS pin can be pulled

high. Taking the RESET pin low causes the SPI

interface to be reset along with all the other digital

functions. In this case, the registers and the

conversion are reset.

SPI Communication During Sleep Mode

When the START pin is low or the device is in sleep

mode, only the RDATA, RDATAC, SDATAC,

WAKEUP, and NOP commands can be issued. The

RDATA command can be used to repeatedly read the

last conversion result during sleep mode. Other

commands do not function because the internal clock

is shut down to save power during sleep mode.

28 Submit Documentation Feedback Copyright © 2009–2010, Texas Instruments Incorporated

Product Folder Link(s): ADS1146 ADS1147 ADS1148

ADS1146

ADS1147

ADS1148

www.ti.com

REGISTER DESCRIPTIONS

ADS1146 REGISTER MAP

Table 17. ADS1146 Register Map

ADDRESS REGISTER BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

00h BCS BCS1 BCS0 0 0 0 0 0 1

01h VBIAS 0 0 0 0 0 0 VBIAS1 VBIAS0

02h MUX1 CLKSTAT 0 0 0 0 MUXCAL2 MUXCAL1 MUXCAL0

03h SYS0 0 PGA2 PGA1 PGA0 DR3 DR2 DR1 DR0

04h OFC0 OFC7 OFC6 OFC5 OFC4 OFC3 OFC2 OFC1 OFC0

05h OFC1 OFC15 OFC14 OFC13 OFC12 OFC11 OFC10 OFC9 OFC8

06h OFC2 OFC23 OFC22 OFC21 OFC20 OFC19 OFC18 OFC17 OFC16

07h FSC0 FSC7 FSC6 FSC5 FSC4 FSC3 FSC2 FSC1 FSC0

08h FSC1 FSC15 FSC14 FSC13 FSC12 FSC11 FSC10 FSC9 FSC8

09h FSC2 FSC23 FSC22 FSC21 FSC20 FSC19 FSC18 FSC17 FSC16

0Ah ID ID3 ID2 ID1 ID0 0 0 0

DRDY

MODE

SBAS453C –JULY 2009–REVISED APRIL 2010

ADS1146 DETAILED REGISTER DEFINITIONS

BCS—Burnout Current Source Register. These bits control the settling of the sensor burnout detect current

source.

BCS - ADDRESS 00h RESET VALUE = 01h

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

BCS1 BCS0 0 0 0 0 0 1

Bits[7:6] BCS[1:0]

These bits select the magnitude of the sensor burnout detect current source.

00 = Burnout current source off (default)

01 = Burnout current source on, 0.5mA

10 = Burnout current source on, 2mA

11 = Burnout current source on, 10mA

Bits[5:0] These bits must always be set to '000001'.

Copyright © 2009–2010, Texas Instruments Incorporated Submit Documentation Feedback 29

Product Folder Link(s): ADS1146 ADS1147 ADS1148

ADS1146

ADS1147

ADS1148

SBAS453C –JULY 2009–REVISED APRIL 2010

ADS1146 DETAILED REGISTER DEFINITIONS (continued)

VBIAS—Bias Voltage Register. This register enables a bias voltage on the analog inputs.

VBIAS - ADDRESS 01h RESET VALUE = 00h

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

0 0 0 0 0 0 VBIAS1 VBIAS0

Bits[7:2] These bits must always be set to '000000'.

Bits[1:0] VBIAS[1:0]

These bits apply a bias voltage of midsupply (AVDD + AVSS)/2 to the selected analog input. Bit 0

is for AIN0, and bit 1 is for AIN1.

0 = Bias voltage not enabled (default)

1 = Bias voltage is applied to the analog input

MUX—Multiplexer Control Register.

MUX - ADDRESS 02h RESET VALUE = x0h

BIT 7 BIT 6 BIT 5 BIT 4 BIT 3 BIT 2 BIT 1 BIT 0

CLKSTAT 0 0 0 0 MUXCAL2 MUXCAL1 MUXCAL0

Bit 7 CLKSTAT

This bit is read-only and indicates whether the internal or external oscillator is being used.

0 = Internal oscillator in use

1 = External oscillator in use

Bits[6:3] These bits must always be set to '0000'.

Bits[2:0] MUXCAL[2:0]

These bits are used to select a system monitor. The MUXCAL selection supercedes selections

from the VBIAS register.

000 = Normal operation (default)

001 = Offset calibration. The analog inputs are disconnected and AINP and AINN are internally

connected to midsupply (AVDD + AVSS)/2.

010 = Gain calibration. The analog inputs are connected to the voltage reference.

011 = Temperature measurement. The inputs are connected to a diode circuit that produces a

voltage proportional to the ambient temperature of the device.

www.ti.com