S6410/S6420 Access Control Reader

* Information submitted for FCC, Industry

Canada, RTTE, CE & ETL certification:

A92ACS6410 &A92ACS6420 *

Installation Guide

11-06-21-713 09/02

Packing List

This package includes:

Qty. Description

1 S6410 or S6420 Reader with back plate

2 #6 Phillips-head machine mounting screws

2 #6 Phillips-head self-tapping mounting screws

1 Phillips-head cover screw

1 Security-head cover screw

1 Installation guide (this sheet)

If any items are missing from the package, please contact the

appropriate technical support agent:

USA

1-888-937-6536 or

1 (972)-575-4364

Belgium (English) +32 (0)2 7455455

France (English) +33 4 93 22 22 00

Germany +49 (0)8161 80 2200

Italy +39 (0)39 6568 210

Netherlands (English) +31 (0)546 879 222

Spain +34 902 19 73 96

Sweden (English) +46 (0)8 58755527

UK +44 (0)1604 88 4088

or visit us at: www.ti-rfid.com

Specifications

Reader Model S6410 Wall Plate S6420 Mullion

Part number RI-H4R-S6H3-00 RI-H4R-S5H3-00

Operating Frequency 13.56 MHz

Supported Protocols ISO/IEC 15693 (Vicinity)

Supply Voltage

Power Consumption 90 mA Quiescent, 200 mA Read, 300 mA Max

RS-485 Baud Rates 9600, 19200, 38400 (Default)

Communication

Interface

Data Signal Integrity 500 feet Wiegand, 4000 feet RS-485

Data Output Format

Operating Temperature

Storage Temperature -40°C to +85°C

Humidity 90% RH at 70°C

Protection Class IP64, Potted

Regulatory Approvals FCC, R&TTE (CE), UL-94 and UL-294 (ETL)

Overall Dimensions

Weight ~8.5 oz (~241 g) ~4.8 oz (~136 g)

9 - 14 VDC, built-in overvoltage

and reverse polarity protection

Wiegand 26-64 bit and RS-485 protocol

DES Encryption Mode (Cyper Text),

Wiegand UID Mode, Wiegand ASCII mode

-20°C to +70°C

5.0” x 5.0” x 1.0”

(12.7 x 12.7 x 2.5 cm)

5.0” x 1.7” x 1.0”

(12.7 x 4.3 x 2.5 cm)

Complete warranty information can be found on the website at:

www.ti-rfid.com

© Copyright Texas Instruments. 2002

All rights reserved.

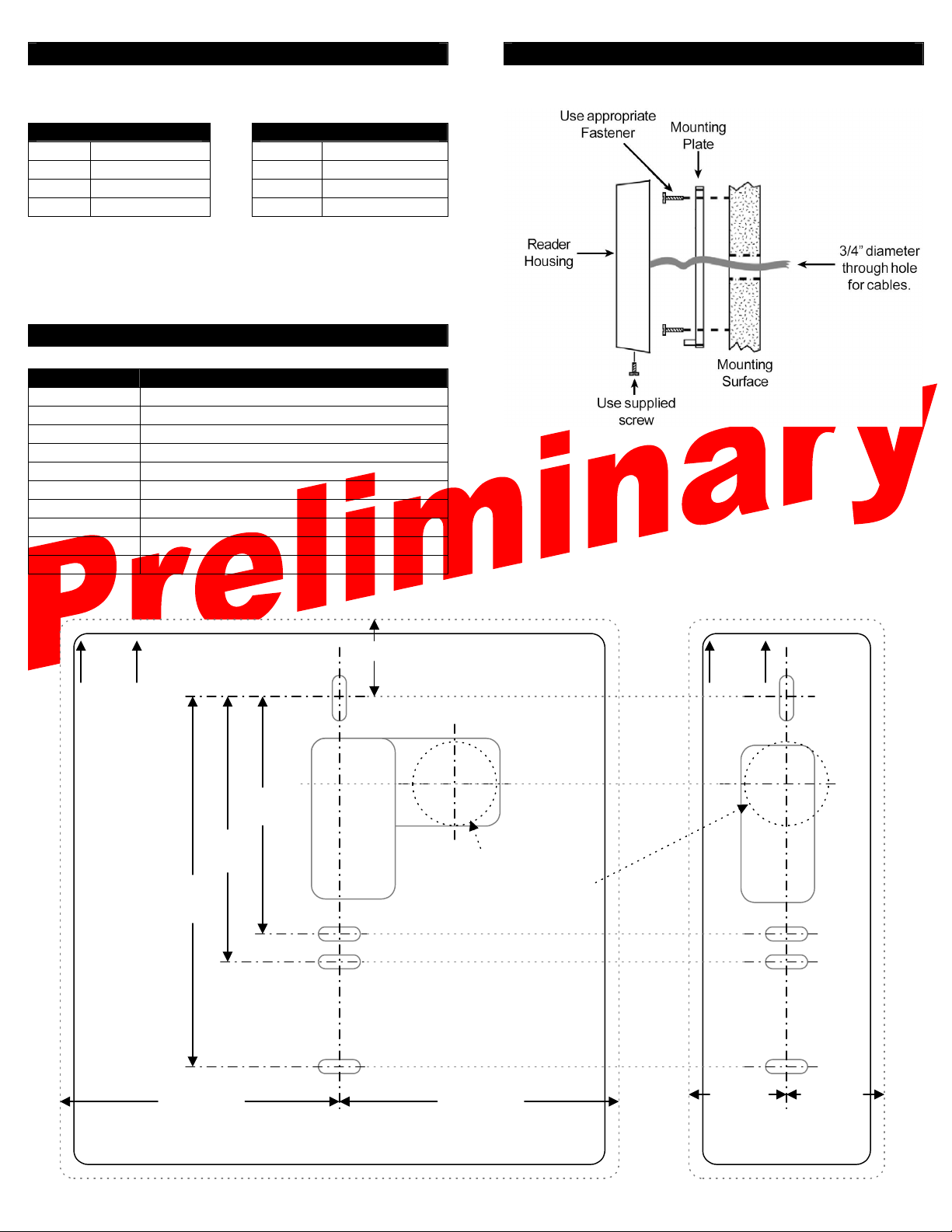

Before You Begin

Determine the installation method, which parts are needed, and

which wires will be used. These instructions assume that the unit

is being installed on an unprepared flat surface. If this unit is to be

installed in an electrical box or door mullion opening, skip to step

3 of the installation instructions.

Typical Installation

1. Use appropriate template (from back) to mark hole locations

for wire and screws. A set of self-tapping screws is included,

however the holes may be pre-drilled if desired.

2. Drill a 3/4” (20 mm) maximum diameter hole for wire to pass

through. Placement of this hole is arbitrary, but it must align

with the opening of the back plate.

3. Slide wiring cable through mounting plate prior to connecting

wires. Be sure the flat side of the plate is toward the wall.

4. Connect wires per the wire guide. Cap any unused wires to

prevent shorting.

5. Screw mounting plate onto surface using the appropriate

screws provided.

6. Attach the housing to the mounting plate by inserting the

upper tab(s) of the housing into the slots in the plate.

7. Secure the front housing using either the included security-

head cover screw or the Phillips-head cover screw.

8. Test unit for proper functionality. This can be accomplished

by bringing a card into the read field with power applied to the

reader. The LED’s and audio should function as desired.

Note that this test can only be performed when the unit is in

it’s default (Wiegand) mode as shipped.

* Information submitted for FCC, Industry Canada, RTTE, CE

& ETL certification: A92ACS6410, A92ACS6420 *

Determining Which Wires Will Be Used

The following wire connections are essential for proper

functionality in RS-485 or Wiegand mode.

Wiegand Mode RS-485 Mode

Black Ground Black Ground

Red Power Red Power

Green Data (0) Gray Data (A or -)

White Data (1) Violet Data (B or +)

The remaining wires may be connected as desired to customize

functionality of the audio and LED indicators. See the S6400

User’s Guide (11-06-21-711) for more information regarding the

use of these wires.

Complete Wire Guide

Color Function

Black Ground (GND)

Red Power (9-14 VDC)

Gray RS-485(A or -)

Violet RS-485(B or +)

Green Wiegand Data(0)

White Wiegand Data(1)

Brown Red LED

Orange Green LED

Yellow Audio

Blue Hold

Mounting

Note: Optimum read range can be achieved by pushing excess

wire through opening in wall. Wire accumulated inside reader

housing may cause read range to diminish.

UP UP

2 1/8"

(54 mm)

2 3/8"

(60 mm)

3 5/16"

(84 mm)

2 1/2" min.

(63 mm)

Allow 1" (25 mm) min.

for reader cover

Optimum location for

cable entry hole.

3/4" (20 mm) MAX

2 1/2" min.

(63 mm)

7/8" min.

(22 mm)

7/8" min.

(22 mm)

Wall Plate Template Mullion Template

Loading...

Loading...