TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

1

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

D

Extremely Low Offset Voltage ...1 µV Max

D

Extremely Low Change on Offset Voltage

With Temperature . . . 0.003 µV/°C Typ

D

Low Input Offset Current

500 pA Max at T

A

= – 55°C to 125°C

D

AVD. . . 135 dB Min

D

CMRR and k

SVR

. . . 120 dB Min

D

Single-Supply Operation

D

Common-Mode Input Voltage Range

Includes the Negative Rail

D

No Noise Degradation With External

Capacitors Connected to V

DD–

description

The TLC2652 and TLC2652A are high-precision

chopper-stabilized operational amplifiers using

Texas Instruments Advanced LinCMOS

process. This process in conjunction with unique

chopper-stabilization circuitry produces opera

tional amplifiers whose performance matches or

exceeds that of similar devices available today.

Chopper-stabilization techniques make possible

extremely high dc precision by continuously

nulling input offset voltage even during variation in

temperature, time, common-mode voltage, and

power supply voltage. In addition, low-frequency

noise voltage is significantly reduced. This high

precision, coupled with the extremely high input

impedance of the CMOS input stage, makes the

TLC2652 and TLC2652A an ideal choice for

low-level signal processing applications such as

strain gauges, thermocouples, and other

transducer amplifiers. For applications that

require extremely low noise and higher usable

bandwidth, use the TLC2654 or TLC2654A

device, which has a chopping frequency of

10 kHz.

The TLC2652 and TLC2652A input common-mode range includes the negative rail, thereby providing superior

performance in either single-supply or split-supply applications, even at power supply voltage levels as low as

±1.9 V.

Two external capacitors are required for operation of the device; however , the on-chip chopper-control circuitry

is transparent to the user. On devices in the 14-pin and 20-pin packages, the control circuitry is made accessible

to allow the user the option of controlling the clock frequency with an external frequency source. In addition, the

clock threshold level of the TLC2652 and TLC2652A requires no level shifting when used in the single-supply

configuration with a normal CMOS or TTL clock input.

Copyright 1999, Texas Instruments Incorporated

PRODUCTION DATA information is current as of publication date.

Products conform to specifications per the terms of Texas Instruments

standard warranty. Production processing does not necessarily include

testing of all parameters.

Please be aware that an important notice concerning availability, standard warranty, and use in critical applications of

Texas Instruments semiconductor products and disclaimers thereto appears at the end of this data sheet.

Advanced LinCMOS is a trademark of Texas Instruments Incorporated.

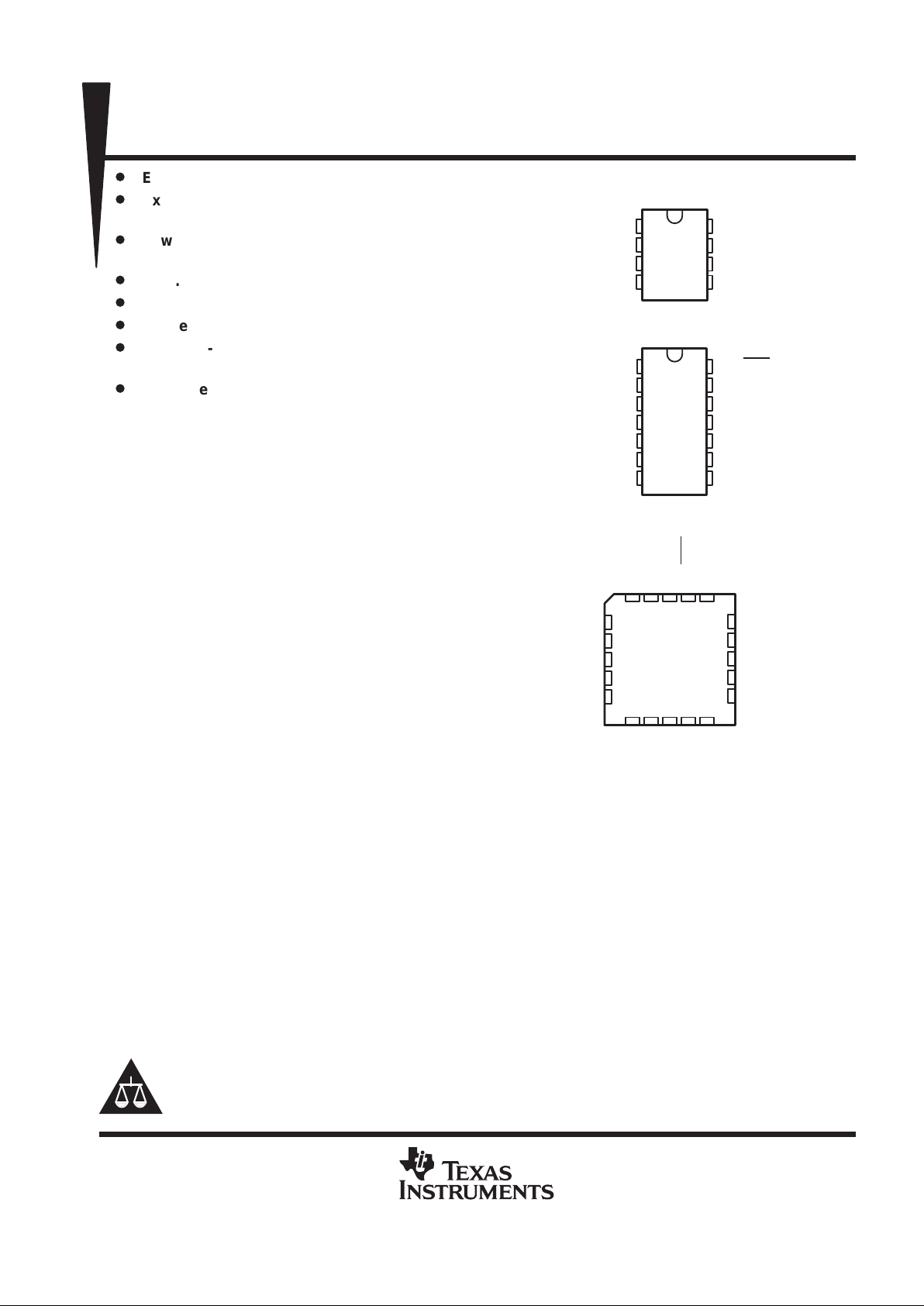

1

2

3

4

8

7

6

5

C

XA

IN–

IN+

V

DD–

C

XB

V

DD+

OUT

CLAMP

D008, JG, OR P PACKAGE

NC – No internal connection

1

2

3

4

5

6

7

14

13

12

11

10

9

8

C

XB

C

XA

NC

IN–

IN+

NC

V

DD–

INT/EXT

CLK IN

CLK OUT

V

DD+

OUT

CLAMP

C RETURN

D014, J, OR N PACKAGE

(TOP VIEW)

3212019

910111213

4

5

6

7

8

18

17

16

15

14

CLK OUT

NC

V

DD+

NC

OUT

NC

NC

IN–

NC

IN+

FK PACKAGE

(TOP VIEW)

INT/EXT

NC

CLAMP

CLK IN

NC

NC

XA

V

C RETURN

XB

V

DD–

V

(TOP VIEW)

On products compliant to MIL-PRF-38535, all parameters are tested

unless otherwise noted. On all other products, production

processing does not necessarily include testing of all parameters.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

2

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

description (continued)

Innovative circuit techniques are used on the TLC2652 and TLC2652A to allow exceptionally fast overload

recovery time. If desired, an output clamp pin is available to reduce the recovery time even further.

The device inputs and output are designed to withstand –100-mA surge currents without sustaining latch-up.

Additionally the TLC2652 and TLC2652A incorporate internal ESD-protection circuits that prevent functional

failures at voltages up to 2000 V as tested under MIL-STD-883C, Method 3015.2; however, care should be

exercised in handling these devices as exposure to ESD may result in degradation of the device parametric

performance.

The C-suffix devices are characterized for operation from 0°C to 70°C. The I-suffix devices are characterized

for operation from –40°C to 85°C. The Q-suffix devices are characterized for operation from –40°C to125°C.

The M-suffix devices are characterized for operation over the full military temperature range of –55°C to125°C.

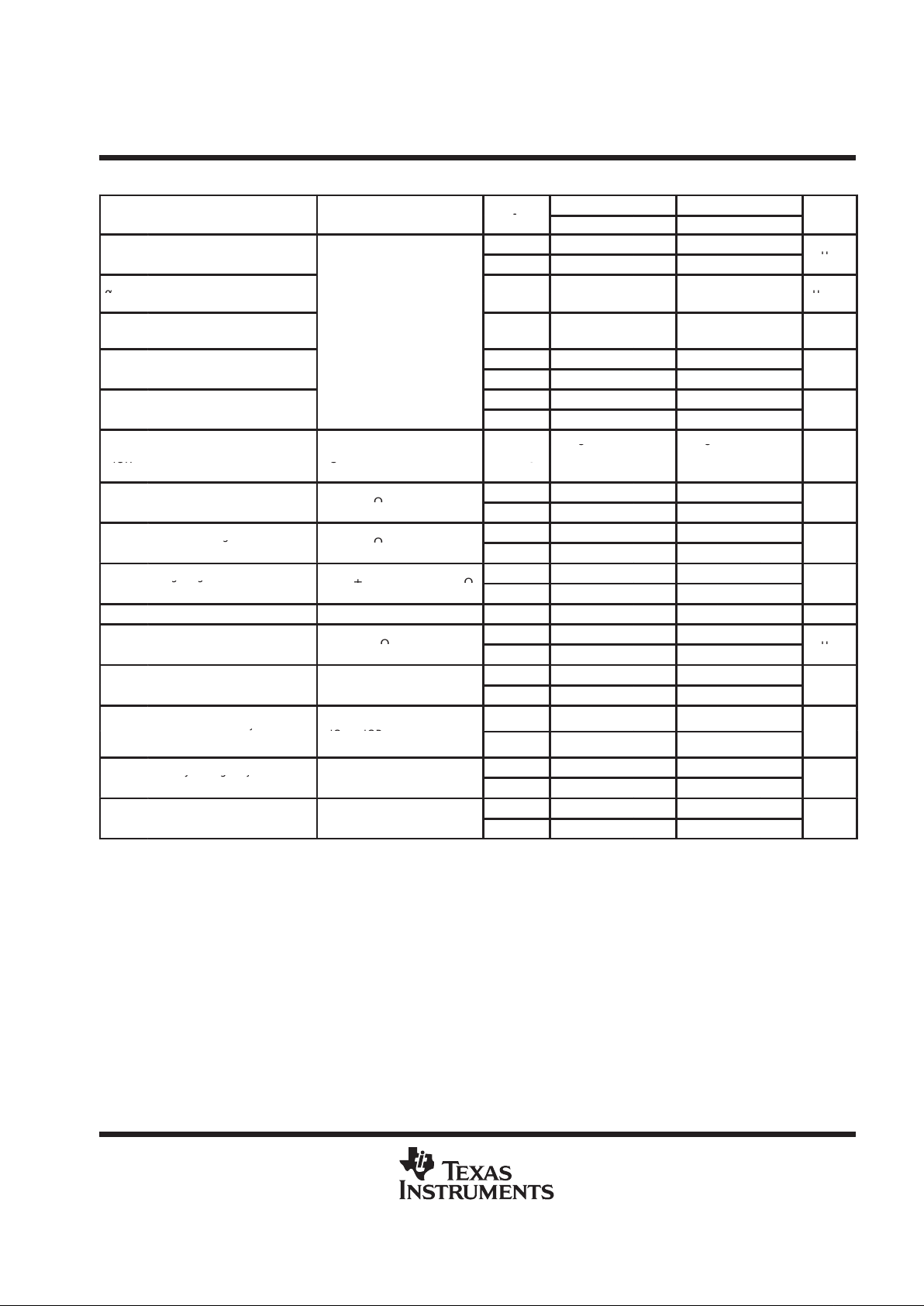

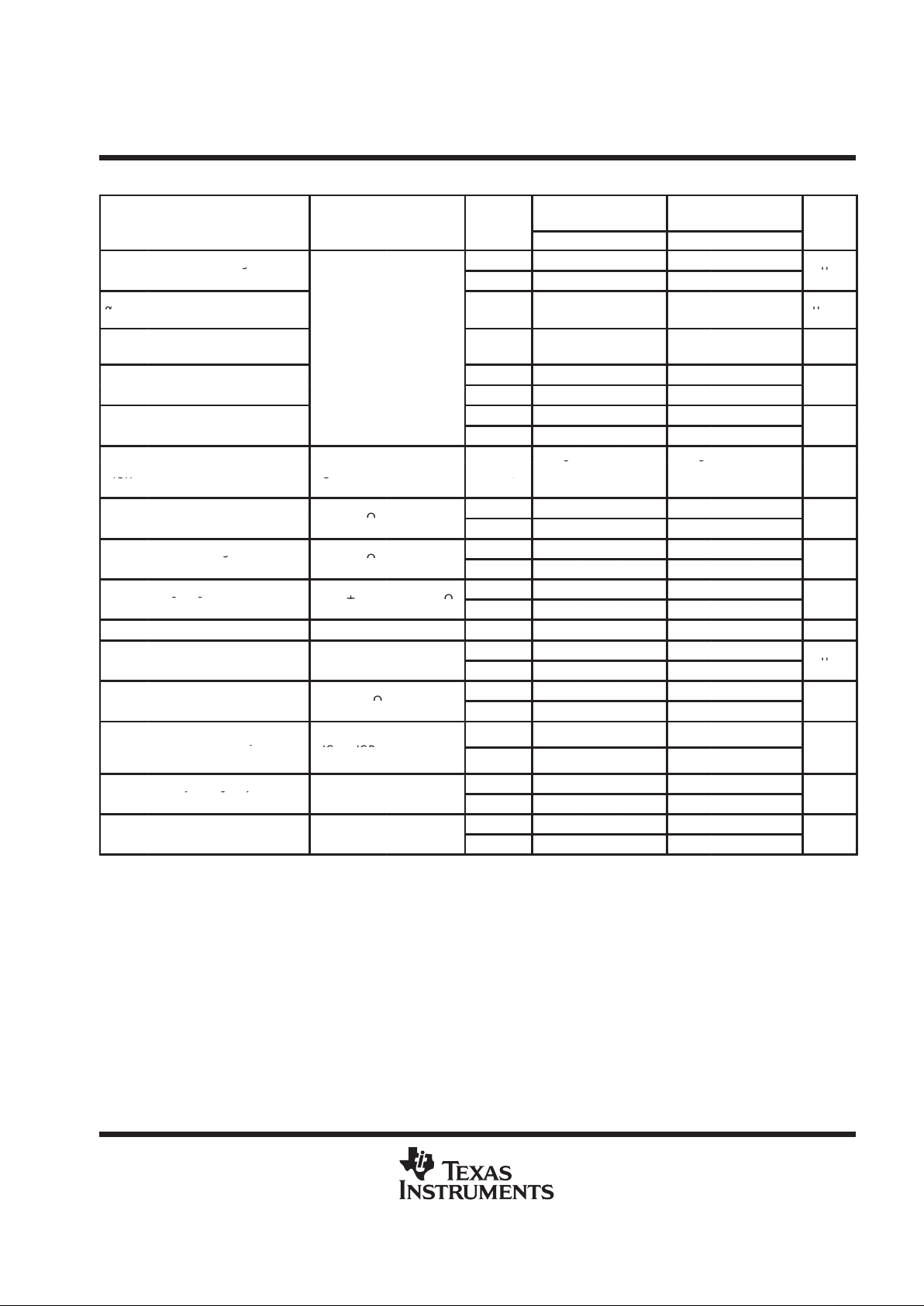

AVAILABLE OPTIONS

PACKAGED DEVICES

8 PIN 14 PIN 20 PIN

CHIP

T

A

VIOmax

AT 25°C

SMALL

OUTLINE

(D008)

CERAMIC

DIP

(JG)

PLASTIC

DIP

(P)

SMALL

OUTLINE

(D014)

CERAMIC

DIP

(J)

PLASTIC

DIP

(N)

CHIP

CARRIER

(FK)

FORM

(Y)

0°C

to

1 µV

TLC2652AC-8D

—

—

TLC2652ACP

TLC2652AC-14D

—

—

TLC2652ACN

—

—

TLC2652Y

70°C

3 µV

TLC2652C-8D

—

TLC2652CP

TLC2652C-14D

—

TLC2652CN

—

–40°C

to

1 µV

TLC2652AI-8D

—

—

TLC2652AIP

TLC2652AI-14D

—

—

TLC2652AIN

—

—

—

85°C

3 µV

TLC2652A-8D

—

TLC2652IP

TLC2652I-14D

—

TLC2652IN

—

–40°C

to

3.5 µV TLC2652Q-8D — — — — — — —

125°C

µ

–55°C

3 µV TLC2652AM-8D TLC2652AMJG TLC2652AMP TLC2652AM-14D TLC2652AMJ TLC2652AMN TLC2652AMFK

to

125°C

µ

3.5 µV TLC2652M-8D TLC2652MJG TLC2652MP TLC2652M-14D TLC2652MJ TLC2652MN TLC2652MFK

—

The D008 and D014 packages are available taped and reeled. Add R suffix to the device type (e.g., TLC2652AC-8DR). Chips are tested at 25°C.

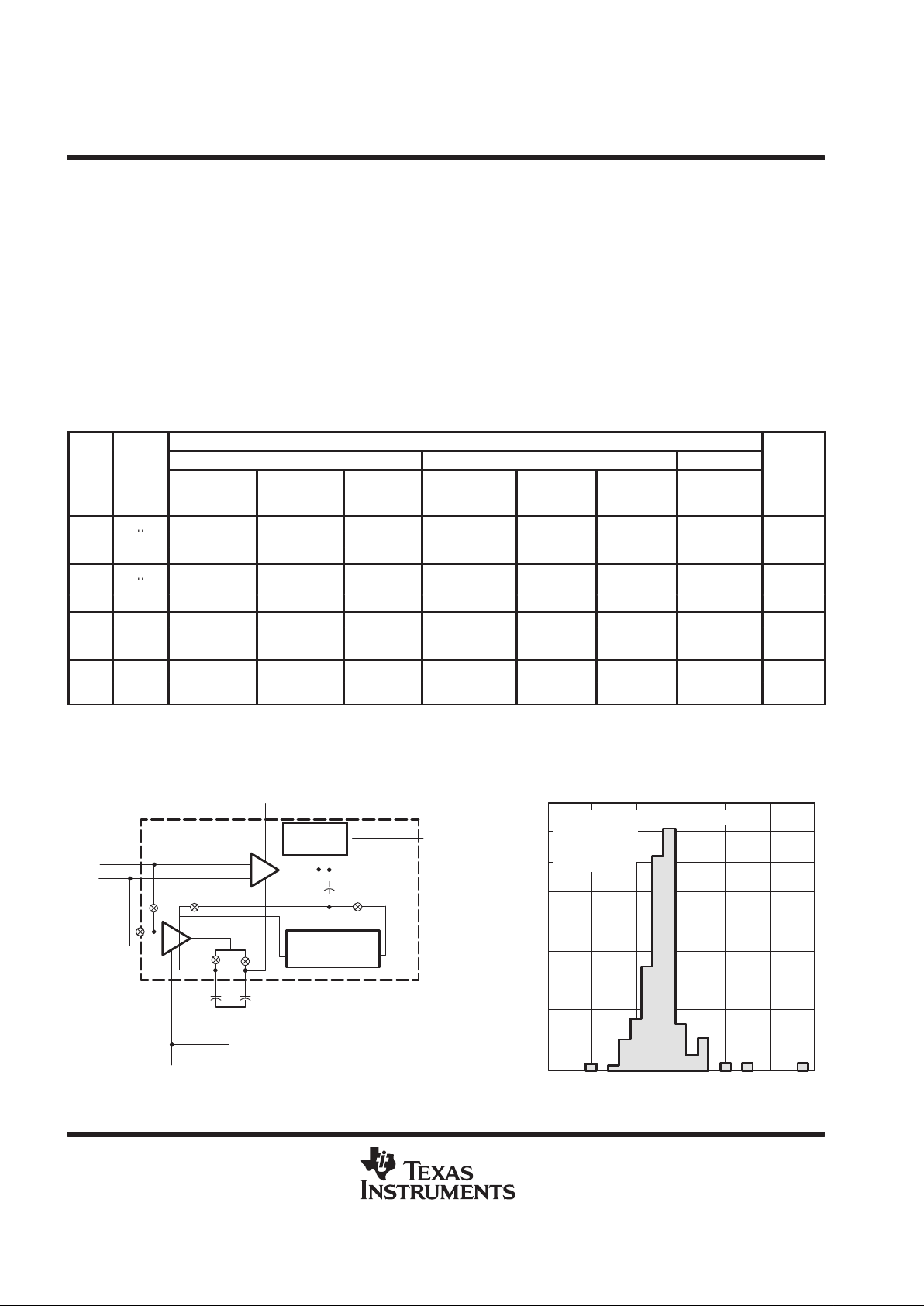

functional block diagram

Clamp

Circuit

CLAMP

OUT

C RETURN

V

DD–

Compensation-

Biasing

Circuit

V

DD+

A

B

B

A

IN+

IN–

C

XA

C

XB

External Components

Null

Main

+

–

+

–

AB

DISTRIBUTION OF TLC2652

INPUT OFFSET VOLTAGE

Percentage of Units – %

VIO – Input Offset Voltage – µV

–3 –2 –1 0 1 2 3

0

4

8

12

16

20

24

28

32

36

150 Units Tested From 1 Wafer Lot

V

DD±

= ±5 V

TA = 25°C

N Package

C

IC

5

4

2

3

6

7

8

Pin numbers shown are for the D (14 pin), JG, and N packages.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

3

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

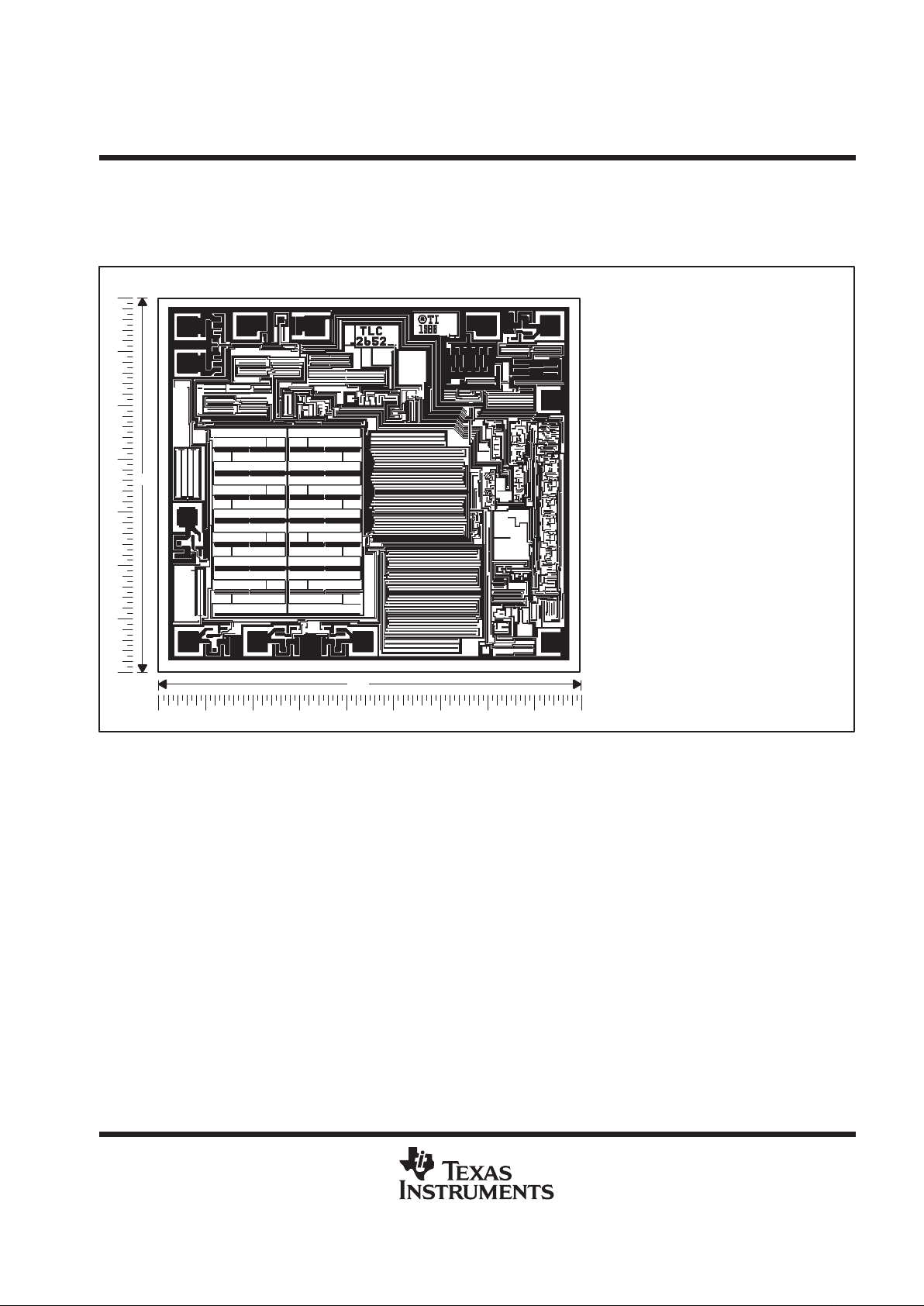

TLC2652Y chip information

This chip, when properly assembled, displays characteristics similar to the TLC2652C. Thermal compression

or ultrasonic bonding may be used on the doped-aluminum bonding pads. Chips may be mounted with

conductive epoxy or a gold-silicon preform.

BONDING PAD ASSIGNMENTS

CHIP THICKNESS: 15 TYPICAL

BONDING PADS: 4 × 4 MINIMUM

TJmax = 150°C

TOLERANCES ARE ±10%.

ALL DIMENSIONS ARE IN MILS.

PIN (7) IS INTERNALLY CONNECTED

TO BACKSIDE OF CHIP.

FOR THE PINOUT, SEE THE FUNCTIONAL

BLOCK DIAGRAM.

90

80

(13)

(12) (11) (10) (9)

(8)

(1)

(7)(5)(4)

(2)

(14)

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

4

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

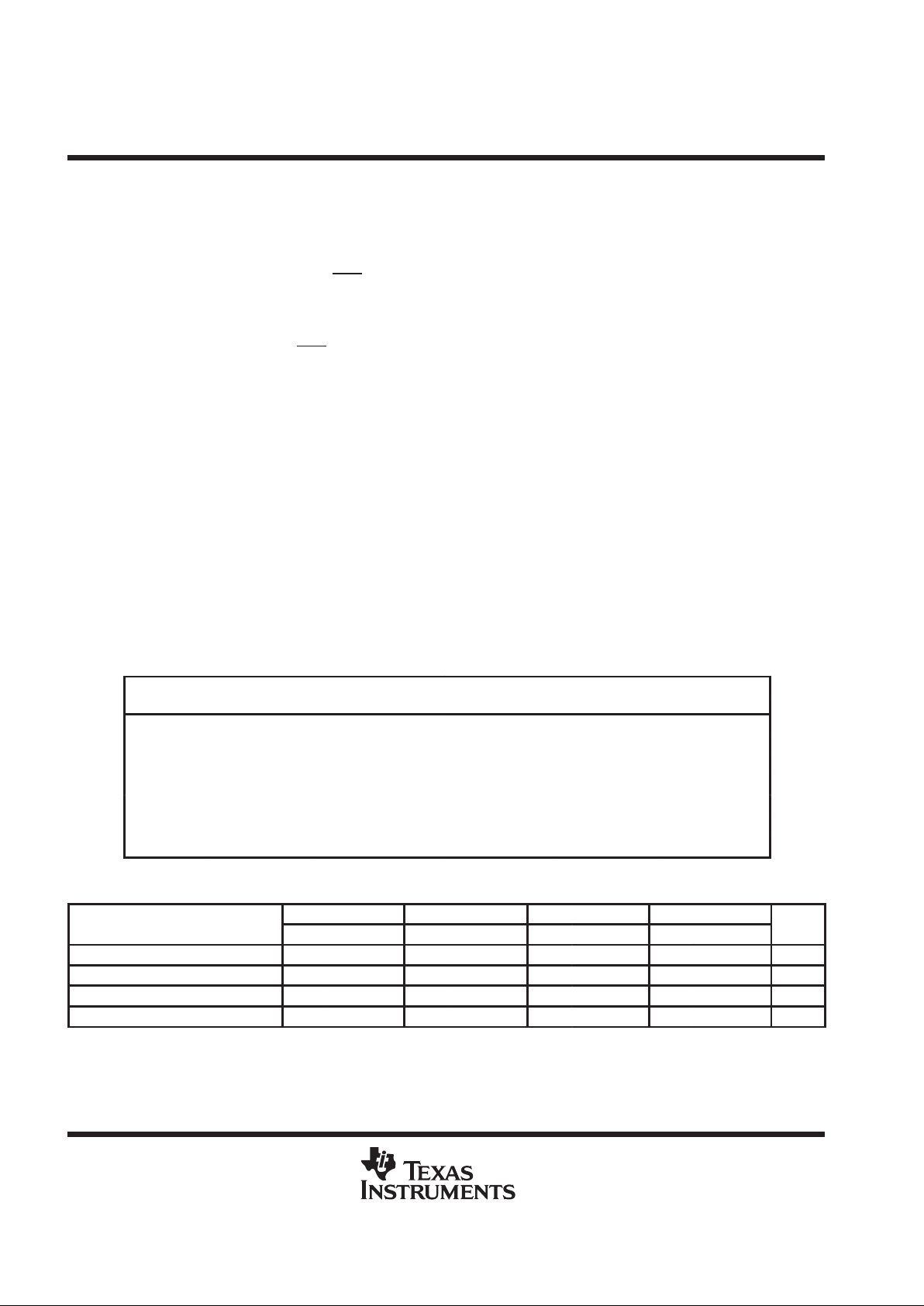

absolute maximum ratings over operating free-air temperature range (unless otherwise noted)

‡

Supply voltage V

DD+

(see Note 1) 8 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Supply voltage V

DD–

(see Note 1) –8 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Differential input voltage, V

ID

(see Note 2) ±16 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input voltage, V

I

(any input, see Note 1) ±8 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Voltage range on CLK IN and INT/EXT

V

DD

– to V

DD–

+ 5.2 V. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Input current, I

I

(each input) ±5 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Output current, I

O

±50 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Duration of short-circuit current at (or below) 25°C (see Note 3) unlimited. . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Current into CLK IN and INT/EXT

±5 mA. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Continuous total dissipation See Dissipation Rating Table. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Operating free-air temperature range, T

A

: C suffix 0°C to 70°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

I suffix –40°C to 85°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Q suffix –40°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

M suffix –55°C to 125°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Storage temperature range –65°C to 150°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Case temperature for 60 seconds: FK package 260°C. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 10 seconds: D, N, or P package 260°C. . . . . . . . . . . . .

Lead temperature 1,6 mm (1/16 inch) from case for 60 seconds: J or JG package 300°C. . . . . . . . . . . . . . . .

†

Stresses beyond those listed under “absolute maximum ratings” may cause permanent damage to the device. These are stress ratings only, and

functional operation of the device at these or any other conditions beyond those indicated under “recommended operating conditions” is not

implied. Exposure to absolute-maximum-rated conditions for extended periods may affect device reliability.

NOTES: 1. All voltage values, except differential voltages, are with respect to the midpoint between V

DD+

and V

DD–

.

2. Differential voltages are at IN+ with respect to IN–.

3. The output may be shorted to either supply. Temperature and/or supply voltages must be limited to ensure that the maximum

dissipation rating is not exceeded.

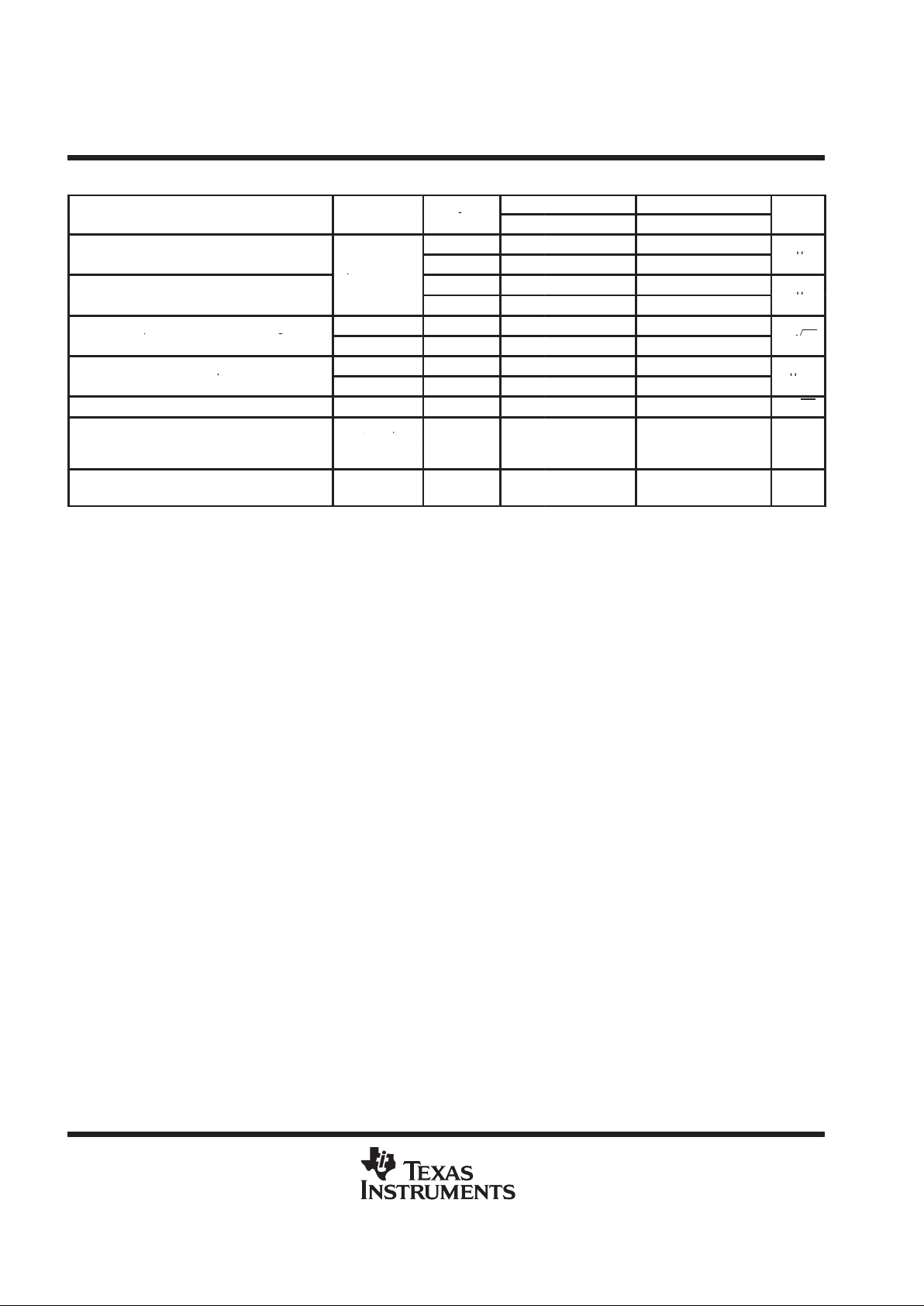

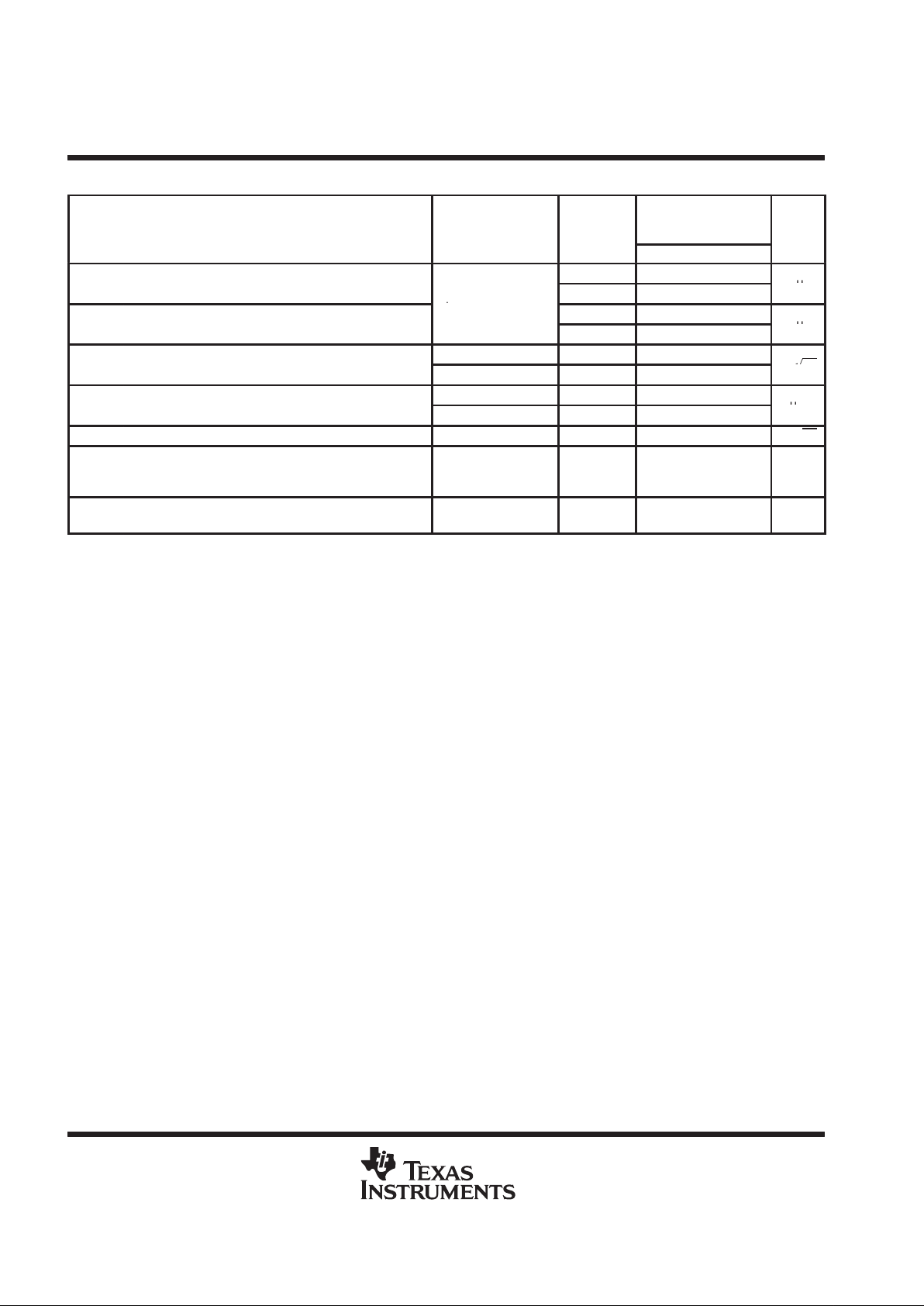

DISSIPATION RATING TABLE

T

≤ 25°C DERATING FACTOR T

= 70°C T

= 85°C T

= 125°C

PACKAGE

A

POWER RATING ABOVE TA = 25°CAPOWER RATINGAPOWER RATINGAPOWER RATING

D008 725 mV 5.8 mW/°C 464 mW 377 mW 145 mW

D014 950 mV 7.6 mW/°C 608 mW 494 mW 190 mW

FK 1375 mV 11.0 mW/° C 880 mW 715 mW 275 mW

J 1375 mV 11.0 mW/°C 880 mW 715 mW 275 mW

JG 1050 mV 8.4 mW/°C 672 mW 546 mW 210 mW

N 1575 mV 12.6 mW/°C 1008 mW 819 mW 315 mW

P 1000 mV 8.0 mW/°C 640 mW 520 mW 200 mW

recommended operating conditions

C SUFFIX I SUFFIX Q SUFFIX M SUFFIX

MIN MAX MIN MAX MIN MAX MIN MAX

UNIT

Supply voltage, V

DD±

±1.9 ±8 ±1.9 ±8 ±1.9 ±8 ±1.9 ±8 V

Common-mode input voltage, V

IC

V

DD–VDD+

–1.9 V

DD–VDD+

–1.9 V

DD–VDD+

–1.9 V

DD–VDD+

–1.9 V

Clock input voltage V

DD–VDD–

+5 V

DD–

V

DD–

+5 V

DD–VDD–

+5 V

DD–VDD–

+5 V

Operating free-air temperature, T

A

0 70 –40 85 –40 125 –55 125 °C

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

5

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

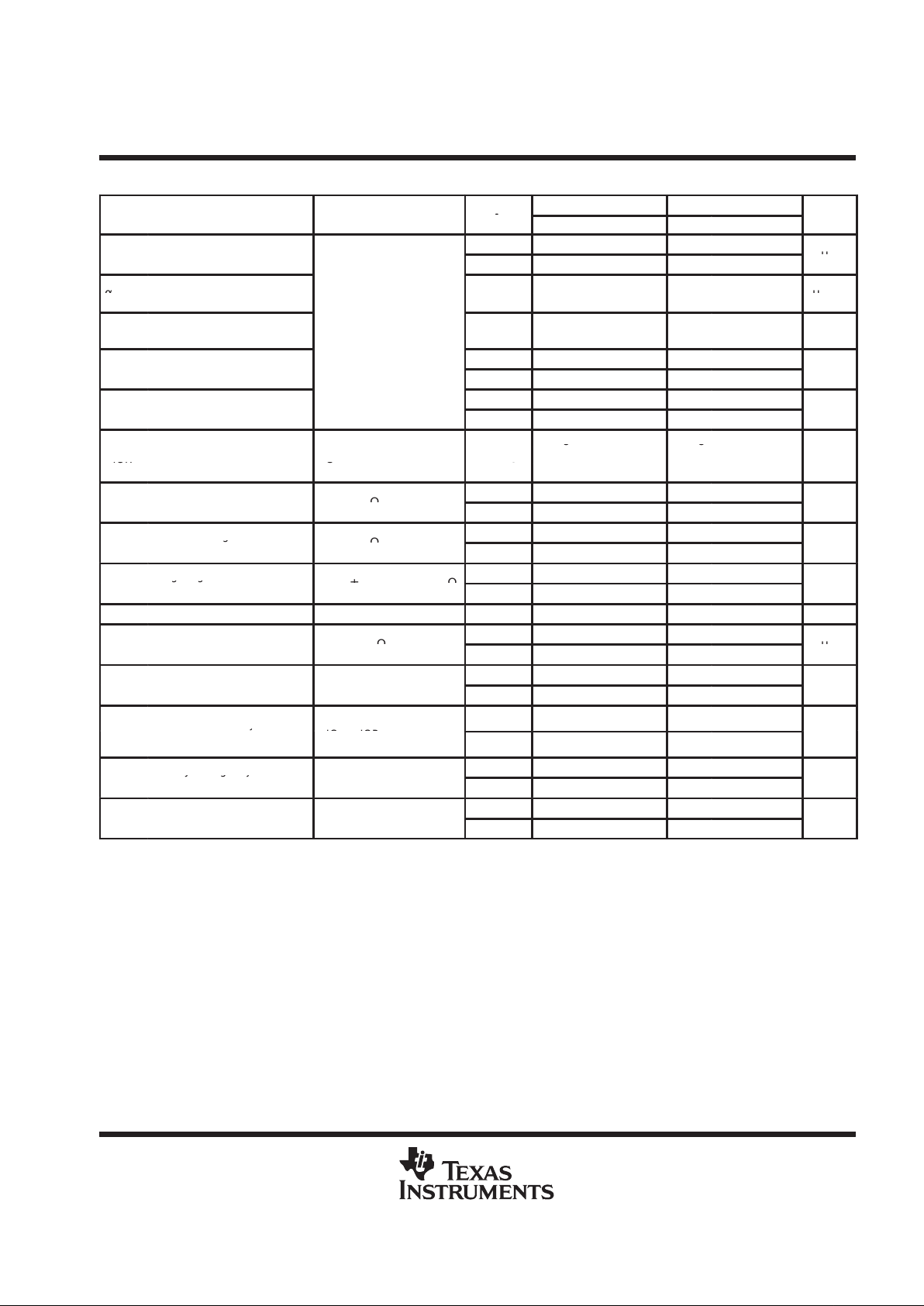

electrical characteristics at specified free-air temperature, VDD± = ±5 V (unless otherwise noted)

TLC2652C TLC2652AC

PARAMETER

TEST CONDITIONS

T

A

†

MIN TYP MAX MIN TYP MAX

UNIT

p

25°C 0.6 3 0.5 1

VIOInput offset voltage

Full range 4.35 2.35

µ

V

T emperature coef ficient of

°

α

VIO

input offset voltage

Full range

0.003

0.03

0.003

0.03µV/°C

Input offset voltage long-term

drift (see Note 4)

VIC = 0, RS = 50 Ω

25°C

0.003 0.06 0.003 0.02 µV/mo

p

25°C 2 2

p

IIOInput offset current

Full range 100 100

pA

p

25°C 4 4

p

IIBInput bias current

Full range 100 100

pA

–5 –5

V

ICR

C

ommon-mode input voltage

RS = 50 Ω Full range

5to5

to

V

ICR

range

S

g

3.1 3.1

Maximum positive peak

25°C 4.7 4.8 4.7 4.8

V

OM+

output voltage swing

R

L

=

10 kΩ

,

See Note 5

Full range 4.7 4.7

V

Maximum negative peak

25°C –4.7 –4.9 –4.7 –4.9

V

OM–

g

output voltage swing

R

L

= 10 kΩ,

See Note 5

Full range –4.7 –4.7

V

Large-signal differential

25°C 120 150 135 150

A

VD

gg

voltage amplification

V

O

= ±4 V,

R

L

= 10

kΩ

Full range 120 130

dB

f

ch

Internal chopping frequency 25°C 450 450 Hz

p

25°C 25 25

Clamp on-state current

R

L

=

100 kΩ

Full range 25 25

µ

A

p

25°C 100 100

p

Clamp off-state current

V

O

= –4 V to 4

V

Full range 100 100

pA

Common-mode rejection

VO = 0,

25°C 120 140 120 140

CMRR

j

ratio

V

IC

=

V

ICR

min,

RS = 50 Ω

Full range 120 120

dB

Supply-voltage rejection ratio

V

DD±

= ±1.9 V to ±8 V, 25°C 120 135 120 135

k

SVR

ygj

(∆V

DD±

/∆VIO)

VO = 0,

RS = 50 Ω

Full range 120 120

dB

pp

25°C 1.5 2.4 1.5 2.4

IDDSupply current

Full range 2.5 2.5

mA

†

Full range is 0° to 70°C.

NOTES: 4. Typical values are based on the input offset voltage shift observed through 168 hours of operating life test at TA = 150°C extrapolated

at TA = 25° using the Arrhenius equation and assuming an activation energy of 0.96 eV .

5. Output clamp is not connected.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

6

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

operating characteristics specified free-air temperature, V

DD±

= ±5 V

TEST

TLC2652C TLC2652AC

PARAMETER

CONDITIONS

T

A

†

MIN TYP MAX MIN TYP MAX

UNIT

25°C 2 2.8 2 2.8

SR+Positive slew rate at unity gain

VO = ±2.3 V ,

Full range 1.5 1.5

V/µs

R

L

=

10 kΩ

,

C

= 100 pF

25°C 2.3 3.1 2.3 3.1

SR–Negative slew rate at unity gain

C

L

=

100 F

Full range 1.8 1.8

V/µs

Equivalent input noise voltage

f = 10 Hz 25°C 94 94 140

V

n

qg

(see Note 6)

f = 1 kHz

25°C 23 23 35

n

V/√H

z

Peak-to-peak equivalent input

f = 0 to 1 Hz 25°C 0.8 0.8

V

N(PP)

q

noise voltage

f = 0 to 10 Hz

25°C 2.8 2.8

µ

V

I

n

Equivalent input noise current f = 10 kHz 25°C 0.004 0.004 fA/√Hz

f = 10 kHz

,

Gain-bandwidth product

f 10 kHz,

RL = 10 kΩ,

25°C 1.9 1.9 MHz

L

CL = 100 pF

φm

Phase margin at unity gain

RL = 10 kΩ,

CL = 100 pF

25°C 48° 48°

†

Full range is 0° to 70°C.

NOTE 6: This parameter is tested on a sample basis for the TLC2652A. For other test requirements, please contact the factory . This statement

has no bearing on testing or nontesting of other parameters.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

7

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

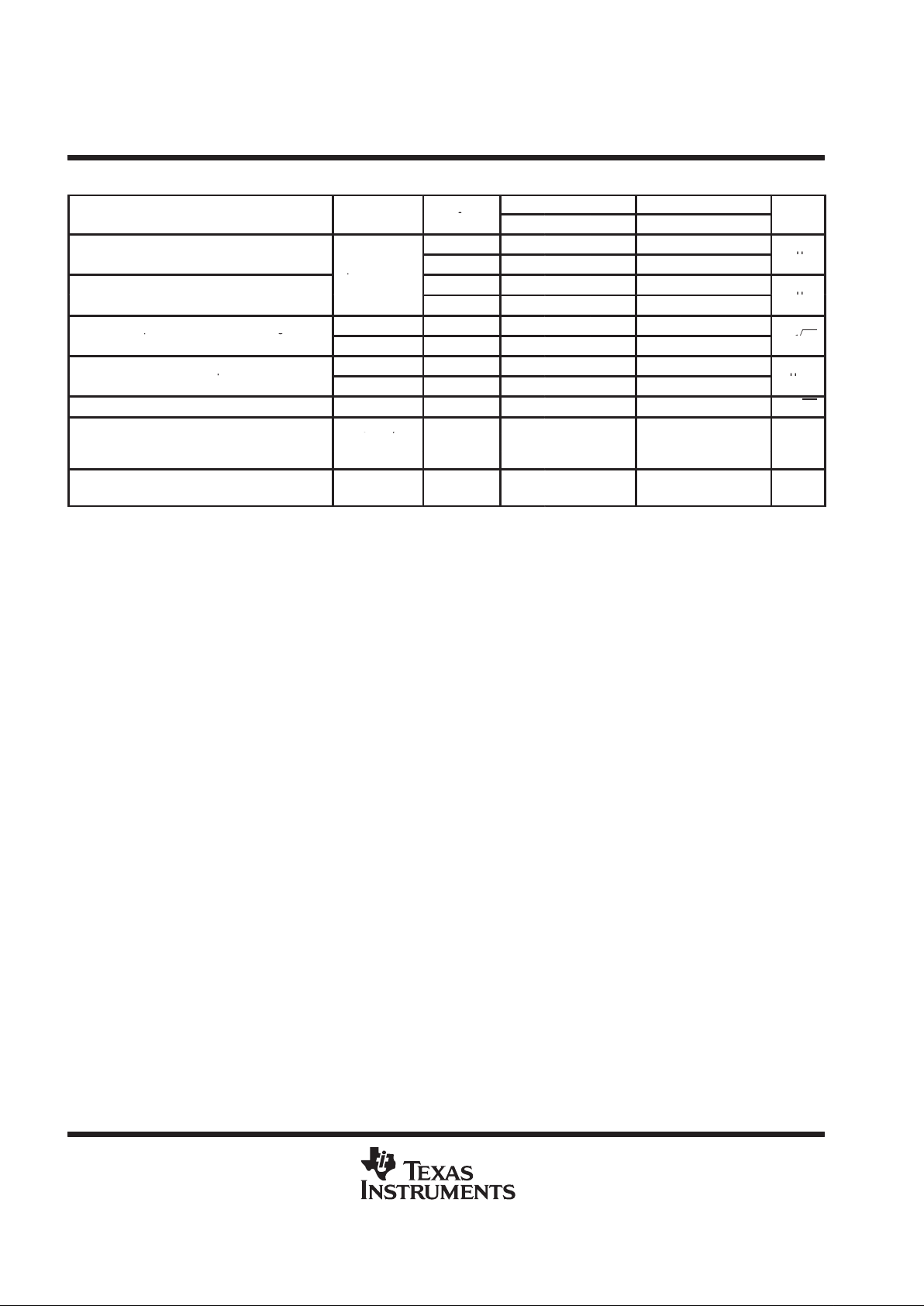

electrical characteristics at specified free-air temperature, VDD± = ±5 V (unless otherwise noted)

TLC2652I TLC2652AI

PARAMETER

TEST CONDITIONS

T

A

†

MIN TYP MAX MIN TYP MAX

UNIT

p

25°C 0.6 3 0.5 1

VIOInput offset voltage

Full range 4.95 2.95

µ

V

T emperature coef ficient of

°

α

VIO

input offset voltage

Full range

0.003

0.03

0.003

0.03µV/°C

Input offset voltage

long-term drift (see Note 4)

VIC = 0, RS = 50 Ω

25°C

0.003 0.06 0.003 0.02 µV/mo

p

25°C 2 2

p

IIOInput offset current

Full range 150 150

pA

p

25°C 4 4

p

IIBInput bias current

Full range 150 150

pA

–5 –5

V

ICR

C

ommon-mode inpu

t

RS = 50 Ω Full range

5to5

to

V

ICR

voltage range

S

g

3.1 3.1

Maximum positive peak

25°C 4.7 4.8 4.7 4.8

V

OM+

output voltage swing

R

L

=

10 kΩ

,

See Note 5

Full range 4.7 4.7

V

Maximum negative peak

25°C –4.7 –4.9 –4.7 –4.9

V

OM–

g

output voltage swing

R

L

= 10 kΩ,

See Note 5

Full range –4.7 –4.7

V

Large-signal differential

25°C 120 150 135 150

A

VD

gg

voltage amplification

V

O

= ±4 V,

R

L

= 10

kΩ

Full range 120 125

dB

Internal chopping frequency 25°C 450 450 Hz

p

25°C 25 25

Clamp on-state current

R

L

=

100 kΩ

Full range 25 25

µ

A

p

25°C 100 100

p

Clamp off-state current

V

O

= –4 V to 4

V

Full range 100 100

pA

Common-mode rejection

VO = 0,

25°C 120 140 120 140

CMRR

j

ratio

V

IC

=

V

ICR

min,

RS = 50 Ω

Full range 120 120

dB

Supply-voltage rejection

V

DD±

= ±1.9 V to ±8 V, 25°C 120 135 120 135

k

SVR

ygj

ratio (∆V

DD±

/∆VIO)

VO = 0,

RS = 50 Ω Full range 120 120

dB

pp

25°C 1.5 2.4 1.5 2.4

IDDSupply current

V

O

=

0

,

No load

Full range 2.5 2.5

mA

†

Full range is –40° to 85°C.

NOTES: 4. Typical values are based on the input offset voltage shift observed through 168 hours of operating life test at TA = 150°C extrapolated

at TA = 25° using the Arrhenius equation and assuming an activation energy of 0.96 eV .

5. Output clamp is not connected.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

8

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

operating characteristics at specified free-air temperature, V

DD±

= ±5 V

TEST

TLC2652I TLC2652AI

PARAMETER

CONDITIONS

T

A

†

MIN TYP MAX MIN TYP MAX

UNIT

25°C 2 2.8 2 2.8

SR+Positive slew rate at unity gain

VO = ±2.3 V ,

Full range 1.4 1.4

V/µs

R

L

=

10 kΩ

,

C

= 100 pF

25°C 2.3 3.1 2.3 3.1

SR–Negative slew rate at unity gain

C

L

=

100 F

Full range 1.7 1.7

V/µs

Equivalent input noise voltage

f = 10 Hz 25°C 94 94 140

V

n

qg

(see Note 6)

f = 1 kHz

25°C 23 23 35

n

V/√H

z

Peak-to-peak equivalent input

f = 0 to 1 Hz 25°C 0.8 0.8

V

N(PP)

q

noise voltage

f = 0 to 10 Hz

25°C 2.8 2.8

µ

V

I

n

Equivalent input noise current f = 1 kHz 25°C 0.004 0.004 pA/√Hz

f = 10 kHz

,

Gain-bandwidth product

f 10 kHz,

RL = 10 kΩ,

25°C 1.9 1.9 MHz

L

CL = 100 pF

φm

Phase margin at unity gain

RL = 10 kΩ,

CL = 100 pF

25°C 48° 48°

†

Full range is –40° to 85°C.

NOTE 6: This parameter is tested on a sample basis for the TLC2652A. For other test requirements, please contact the factory . This statement

has no bearing on testing or nontesting of other parameters.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

9

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics at specified free-air temperature, VDD± = ±5 V (unless otherwise noted)

PARAMETER TEST CONDITIONS

T

A

†

TLC2652Q

TLC2652M

TLC2652AM

UNIT

A

MIN TYP MAX MIN TYP MAX

Input offset voltage

25°C 0.6 3.5 0.5 3

V

IO

g

(see Note 7)

Full range 10 8

µ

V

T emperature coef ficient of

∗

∗

°

α

VIO

input offset voltage

Full range

0.003

0.03∗0.003

0.03

∗

µ

V/°C

Input offset voltage

long-term drift (see Note 4)

VIC = 0, RS = 50 Ω

25°C

0.003 0.06

∗

0.003 0.02∗µV/mo

p

25°C 2 2

p

IIOInput offset current

Full range 500 500

pA

p

25°C 4 4

p

IIBInput bias current

Full range 500 500

pA

–5 –5

V

ICR

C

ommon-mode inpu

t

RS = 50 Ω Full range

5to5

to

V

ICR

voltage range

S

g

3.1 3.1

Maximum positive peak

25°C 4.7 4.8 4.7 4.8

V

OM+

output voltage swing

R

L

= 10 kΩ,

See Note 5

Full range 4.7 4.7

V

Maximum negative peak

25°C –4.7 –4.9 –4.7 –4.9

V

OM–

g

output voltage swing

R

L

=

10 kΩ

,

See Note 5

Full range –4.7 –4.7

V

Large-signal differential

25°C 120 150 135 150

A

VD

gg

voltage amplification

V

O

= ±4 V,

R

L

= 10

kΩ

Full range 120 120

dB

f

ch

Internal chopping frequency 25°C 450 450 Hz

p

25°C 25 25

Clamp on-state current

V

O

= –5 V to 5

V

Full range 25 25

µ

A

p

25°C 100 100

p

Clamp off-state current

R

L

=

100 kΩ

Full range 500 500

pA

Common-mode rejection

VO = 0,

25°C 120 140 120 140

CMRR

j

ratio

V

IC

=

V

ICR

min,

RS = 50 Ω

Full range 120 120

dB

Supply-voltage rejection

V

DD±

= ±1.9 V to ±8 V, 25°C 120 135 120 135

k

SVR

ygj

ratio (∆V

DD±

/∆VIO)

VO = 0,

RS = 50 Ω Full range 120 120

dB

pp

25°C 1.5 2.4 1.5 2.4

IDDSupply current

V

O

=

0

,

No load

Full range 2.5 2.5

mA

∗

On products compliant to MIL-PRF-38535, this parameter is not production tested.

†

Full range is –40° to 125°C for Q suffix, –55° to 125°C for M suffix.

NOTES: 4. Typical values are based on the input offset voltage shift observed through 168 hours of operating life test at TA = 150°C extrapolated

at TA = 25° using the Arrhenius equation and assuming an activation energy of 0.96 eV .

5. Output clamp is not connected.

7. This parameter is not production tested. Thermocouple effects preclude measurement of the actual VIO of these devices in high

speed automated testing. VIO is measured to a limit determined by the test equipment capability at the temperature extremes. The

test ensures that the stabilization circuitry is performing properly.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

10

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

operating characteristics specified free-air temperature, V

DD±

= ±5 V

PARAMETER TEST CONDITIONS

T

A

†

TLC2652Q

TLC2652M

TLC2652AM

UNIT

MIN TYP MAX

25°C 2 2.8

SR+Positive slew rate at unity gain

VO = ±2.3 V ,

Full range 1.3

V/µs

R

L

=

10 kΩ

,

C

= 100 pF

25°C 2.3 3.1

SR–Negative slew rate at unity gain

C

L

=

100 F

Full range 1.6

V/µs

p

f = 10 Hz 25°C 94

VnEquivalent input noise voltage

f = 1 kHz 25°C 23

n

V/√H

z

p

p

f = 0 to 1 Hz 25°C 0.8

V

N(PP)

Peak-to-peak equivalent input noise voltage

f = 0 to 10 Hz 25°C 2.8

µ

V

I

n

Equivalent input noise current f = 1 kHz 25°C 0.004 pA/√Hz

Gain-bandwidth product

f = 10 kHz,

RL = 10 kΩ,

CL = 100 pF

25°C 1.9 MHz

φ

m

Phase margin at unity gain

RL = 10 kΩ,

CL = 100 pF

25°C 48°

†

Full range is –40° to 125°C for the Q suffix, –55° to 125°C for the M suffix.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

11

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

electrical characteristics at V

DD±

= ±5 V, TA = 25°C (unless otherwise noted)

TLC2652Y

PARAMETER

TEST CONDITIONS

MIN TYP MAX

UNIT

V

IO

Input offset voltage 0.6 3 µV

Input offset voltage long-term drift (see Note 4)

0.003 0.006 µV/mo

I

IO

Input offset current

V

IC

=

0

,

R

S

=

50 Ω

2 pA

I

IB

Input bias current 4 pA

–5

V

ICR

Common-mode input voltage range RS = 50 Ω

5

to

V

ICR

gg

S

3.1

V

OM+

Maximum positive peak output voltage swing RL = 10 kΩ, See Note 5 4.7 4.8 V

V

OM–

Maximum negative peak output voltage swing RL = 10 kΩ, See Note 5 –4.7 –4.9 V

A

VD

Large-signal differential voltage amplification VO = ±4 V, RL = 10 kΩ 120 150 dB

f

ch

Internal chopping frequency 450 Hz

Clamp on-state current RL = 100 kΩ 25 µA

Clamp off-state current VO = –4 V to 4 V 100 pA

CMRR Common-mode rejection ratio

VO = 0,

RS = 50 Ω

VIC = V

ICR

min,

120 140 dB

pp

V

DD±

= ±1.9 V to ±8 V,

k

SVR

Suppl

y-v

oltage rejection ratio (∆V

DD±

/∆VIO)

RS = 50 Ω VO = 0,

120

135

dB

I

DD

Supply current VO = 0, No load 1.5 2.4 mA

NOTES: 4. Typical values are based on the input offset voltage shift observed through 168 hours of operating life test at TA = 150°C extrapolated

at TA = 25° using the Arrhenius equation and assuming an activation energy of 0.96 eV .

5. Output clamp is not connected.

operating characteristics at V

DD±

= ±5 V, TA = 25°C

TLC2652Y

PARAMETER

TEST CONDITIONS

MIN TYP MAX

UNIT

SR+ Positive slew rate at unity gain

V

= ±2.3 V , R

= 10 kΩ,

2 2.8 V/µs

SR– Negative slew rate at unity gain

O

,

CL = 100 pF

L

,

2.3 3.1 V/µs

p

f = 10 Hz 94

VnEquivalent input noise voltage

f = 1 kHz 23

n

V/√H

z

p

p

f = 0 to 1 Hz 0.8

V

N(PP)

Peak-to-peak equivalent input noise voltage

f = 0 to 10 Hz 2.8

µ

V

I

n

Equivalent input noise current f = 1 kHz pA/√Hz

Gain-bandwidth product

f = 10 kHz,

CL = 100 pF

RL = 10 kΩ,

1.9 MHz

φ

m

Phase margin at unity gain RL = 10 kΩ, CL = 100 pF 48°

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

12

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Table of Graphs

FIGURE

V

IO

Normalized input offset voltage vs Chopping frequency 1

vs Common-mode input voltage 2

I

IB

Input bias current

vs Common mode in ut voltage

vs Chopping frequency

2

3

IB

gq y

vs Free-air temperature 4

p

vs Chopping frequency 5

IIOInput offset current

gq y

vs Free-air temperature 6

Clamp current vs Output voltage 7

V

(OPP)

Maximum peak-to-peak output voltage vs Frequency 8

p

p

vs Output current 9, 10

VOMMaximum peak output voltage

vs Free-air temperature

,

11, 12

p

vs Frequency 13

AVDLarge-signal differential voltage amplification

qy

vs Free-air temperature 14

pp

vs Supply voltage 15

Chopping frequenc

y

yg

vs Free-air temperature 16

pp

vs Supply voltage 17

IDDSupply current

yg

vs Free-air temperature 18

p

vs Supply voltage 19

IOSShort-circuit output current

yg

vs Free-air temperature 20

vs Supply voltage 21

SR

Slew rate

yg

vs Free-air temperature 22

p

Small-signal 23

Pulse response

g

Large-signal 24

V

N(PP)

Peak-to-peak equivalent input noise voltage vs Chopping frequency 25, 26

V

n

Equivalent input noise voltage vs Frequency 27

p

vs Supply voltage 28

Gain-bandwidth product

yg

vs Free-air temperature 29

vs Supply voltage 30

φ

m

Phase margin

vs Su ly voltage

vs Free-air temperature

30

31

φ

m

g

vs Load capacitance 32

Phase shift vs Frequency 13

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

13

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

†

NORMALIZED INPUT OFFSET VOLTAGE

vs

CHOPPING FREQUENCY

–10

0

10

20

30

40

50

60

70

100 1 k 10 k 100 k

Chopping Frequency – Hz

V

DD±

= ±5 V

VIC = 0

TA = 25°C

VIO – Normalized Input Offset – uV

V

IO

Vµ

Figure 1

–5

VIC – Common-Mode Input Voltage – V

IIB – Input Bias Current – pA

10

5

0

01

15

20

INPUT BIAS CURRENT

vs

COMMON-MODE INPUT VOLTAGE

25

2345

I

IB

V

DD±

= ±5 V

TA = 25°C

–4 –3 –2 –1

Figure 2

Figure 3

Chopping Frequency – Hz

30

10

0

60

20

IIB – Input Bias Current – pA

50

40

70

INPUT BIAS CURRENT

vs

CHOPPING FREQUENCY

100 1 k 10 k 100 k

IB

I

V

DD±

= ±5 V

VIC = 0

TA = 25°C

TA – Free-Air Temperature – °C

1

100

25 45 65 105 125

INPUT BIAS CURRENT

vs

FREE-AIR TEMPERATURE

85

10

V

DD±

= ±5 V

VO = 0

VIC = 0

IIB – Input Bias Current – pA

IB

I

Figure 4

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

14

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

†

INPUT OFFSET CURRENT

vs

CHOPPING FREQUENCY

Chopping Frequency – Hz

20

10

5

0

25

15

100 1 k 10 k 100 k

IIO – Input Offset Current – pA

I

IO

V

DD±

= ±5 V

VIC = 0

TA = 25°C

Figure 5 Figure 6

IIO – Input Offset Current – pA

I

IO

TA – Free-Air Temperature – °C

6

4

2

0

25 45 65 85

8

INPUT OFFSET CURRENT

vs

FREE-AIR TEMPERATURE

10

105 125

V

DD±

= ±5 V

VIC = 0

|VO| – Output Voltage – V

1 nA

100 pA

10 pA

1 pA

4 4.2 4.4 4.6

CLAMP CURRENT

vs

OUTPUT VOLTAGE

4.8 5

100 nA

10 nA

V

DD±

= ±5 V

TA = 25°C

Negative Clamp Current

100 µA

10 µA

1 µA

Positive Clamp Current

|Clamp Current|

Figure 7

8

4

2

0

10

6

100 1 k 10 k 1 M

VO(PP) – Maximum Peak-to-Peak Output Voltage – V

f – Frequency – Hz

MAXIMUM PEAK-TO-PEAK OUTPUT

VOLTAGE

vs

FREQUENCY

V

O(PP)

V

DD±

= ±5 V

RL = 10 kΩ

TA = 125°C

TA = –55°C

Figure 8

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

15

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

†

Figure 9

|IO| – Output Current – mA

4.6

4.4

4.2

4

0 0.4 0.8 1.2

4.8

MAXIMUM PEAK OUTPUT VOLTAGE

vs

OUTPUT CURRENT

5

1.6 2

V

DD±

= ±5 V

TA = 25°C

V

OM+

V

OM–

|VOM| – Maximum Peak Output Voltage – V

|V

OM

Figure 10

|IO| – Output Current – mA

7.1

6.9

6.7

0 0.4 0.8 1.2

7.3

MAXIMUM PEAK OUTPUT VOLTAGE

vs

OUTPUT CURRENT

7.5

1.6 2

V

DD±

= ±7.5 V

TA = 25°C

V

OM+

V

OM–

|VOM| – Maximum Peak Output Voltage – V

|V

OM

Figure 11

TA – Free-Air Temperature – °C

0

–75 0 25 50

2.5

MAXIMUM PEAK OUTPUT VOLTAGE

vs

FREE-AIR TEMPERATURE

5

75 100 125

V

DD±

= ±5 V

RL = 10 kΩ

–2.5

VOM – Maximum Peak Output Voltage – V

V

OM

–5

–50 –25

Figure 12

VOM – Maximum Peak Output Voltage – V

0

4

MAXIMUM PEAK OUTPUT VOLTAGE

vs

FREE-AIR TEMPERATURE

8

TA – Free-Air Temperature – °C

–75 0 25 50 75 100 125

V

DD±

= ±7.5 V

RL = 10 kΩ

V

OM

–50 –25

–8

–4

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

16

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

†

20

0

40

60

80

10 100 1 k 10 k 100 k

f – Frequency – Hz

LARGE-SIGNAL DIFFERENTIAL VOLTAGE

AMPLIFICATION AND PHASE SHIFT

vs

FREQUENCY

1 M 10 M

100

120

220°

200°

180°

160°

140°

120°

100°

80°

60°

V

DD±

= ±5 V

RL = 10 kΩ

CL = 100 pF

TA = 25°C

A

VD

–20

–40

Phase Shift

AVD – Large-Signal Differential

A

VD

Voltage Amplification – dB

Figure 13

Phase Shift

Figure 14

–50 –25

145

140

135

–75 0 25 50

150

LARGE-SIGNAL DIFFERENTIAL VOLTAGE

AMPLIFICATION

vs

FREE-AIR TEMPERATURE

155

75 100 125

TA – Free-Air Temperature – °C

V

DD±

= ±7.5 V

RL = 10 kΩ

VO = ±4 V

AVD – Large-Signal Differential

A

VD

Voltage Amplification – dB

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

17

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

†

Figure 15

|V

DD±

| – Supply Voltage – V

480

460

440

420

012345

500

520

CHOPPING FREQUENCY

vs

SUPPLY VOLTAGE

540

678

T

A

= 25°C

Chopping Frequency – kHz

Figure 16

–50 –25

TA – Free-Air Temperature – °C

430

420

410

400

–75 0 25 50

440

450

CHOPPING FREQUENCY

vs

FREE-AIR TEMPERATURE

460

75 100 125

V

DD±

= ±5 V

Chopping Frequency – kHz

Figure 17

|VDD ±| – Supply Voltage – V

IDD – Supply Current – mA

I

DD

1.2

0.8

0.4

0

0235

1.6

SUPPLY CURRENT

vs

SUPPLY VOLTAGE

2

78

146

T

A

= 25°C

TA = –55°C

TA = 125°C

VO = 0

No Load

–50 –25

TA – Free-Air Temperature – °C

1.2

0.8

0.4

0

–75 0 50

1.6

SUPPLY CURRENT

vs

FREE-AIR TEMPERATURE

2

100 125

25 75

V

DD±

= ±5 V

V

DD±

= ±7.5 V

V

DD±

= ±2.5 V

VO = 0

No Load

IDD – Supply Current – mA

I

DD

Figure 18

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

18

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

†

Figure 19

–4

0

–12

012345

IOS – Short-Circuit Output Current – mA

4

8

SHORT-CIRCUIT OUTPUT CURRENT

vs

SUPPLY VOLTAGE

12

678

|VDD ±| – Supply Voltage – V

I

OS

VO = 0

TA = 25°C

–8

VID = –100 mV

VID = 100 mV

Figure 20

–50 –25

0

–10

–15

–75 0 25 50

5

10

SHORT-CIRCUIT OUTPUT CURRENT

vs

FREE-AIR TEMPERATURE

15

75 100 125

TA – Free-Air Temperature – °C

VID = 100 mV

VID = –100 mV

V

DD±

= ±5 V

VO = 0

IOS – Short-Circuit Output Current – mA

I

OS

–5

Figure 21

2

1

0

0123 45

3

4

678

|V

DD±

| – Supply Voltage – V

SLEW RATE

vs

SUPPLY VOLTAGE

RL = 10 kΩ

CL = 100 pF

TA = 25°C

SR–

SR+

SR – Slew Rate – V?us

sµ

V/

Figure 22

–50 –25

2

1

0

–75 0 25 50

SR – Slew Rate – V?us

3

SLEW RATE

vs

FREE-AIR TEMPERATURE

4

75 100 125

TA – Free-Air Temperature – °C

sµ

V/

V

DD±

= ±5 V

RL = 10 kΩ

CL = 100 pF

SR+

SR–

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

19

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

Figure 23

–25

t – Time – µs

VO – Output Voltage – mV

0

–75

–100

0123

25

75

VOLTAGE-FOLLOWER

SMALL-SIGNAL

PULSE RESPONSE

100

4567

50

V

O

V

DD±

= ±5 V

RL = 10 kΩ

CL = 100 pF

TA = 25°C

–50

Figure 24

t – Time – µs

VO – Output Voltage – V

V

O

0

–1

–3

–4

0 5 10 15 20

1

3

VOLTAGE-FOLLOWER

LARGE-SIGNAL

PULSE RESPONSE

4

25 30 35 40

–2

2

V

DD±

= ±5 V

RL = 10 kΩ

CL = 100 pF

TA = 25°C

Figure 25

fch – Chopping Frequency – kHz

PEAK-TO-PEAK INPUT NOISE VOLTAGE

vs

CHOPPING FREQUENCY

0

0.2

0.4

0.6

0.8

1

1.2

1.4

1.6

1.8

0246810

VN(PP) – Peak-to-Peak Input Noise Voltage –uV

N(PP)

V

V

DD±

= ±5 V

RS = 20 Ω

f = 0 to 1 Hz

TA = 25°C

µV

Figure 26

fch – Chopping Frequency – kHz

3

2

1

0

0246

VN(PP) – Peak-to-Peak Input Noise Voltage – uV

4

PEAK-TO-PEAK INPUT NOISE VOLTAGE

vs

CHOPPING FREQUENCY

5

810

N(PP)

V

V

DD±

= ±5 V

RS = 20 Ω

f = 0 to 1 Hz

TA = 25°C

µV

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

20

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

†

Vn – Equivalent Input Noise Voltage – nV/Hz

80

40

20

0

100

60

1 10 100 1 k

f – Frequency – Hz

EQUIVALENT INPUT NOISE VOLTAGE

vs

FREQUENCY

V

n

V

DD±

= ±5 V

RS = 20 Ω

TA = 25°C

nV/ Hz

Figure 27 Figure 28

|V

CC±

| – Supply Voltage – V

1.9

1.8

012345

Gain-Bandwidth Product – MHz

2

GAIN-BANDWIDTH PRODUCT

vs

SUPPLY VOLTAGE

2.1

678

R

L

= 10 kΩ

CL = 100 pF

TA = 25°C

Figure 29

–50

TA – Free-Air Temperature – °C

2

1.8

1.4

1.2

–75 0 25 50

Gain-Bandwidth Product – MHz

2.2

2.4

GAIN-BANDWIDTH PRODUCT

vs

FREE-AIR TEMPERATURE

2.6

75 100 125

V

DD±

= ±5 V

RL = 10 kΩ

CL = 100 pF

–25

Figure 30

|V

CC±

| – Supply Voltage – V

om – Phase Margin

0235

PHASE MARGIN

vs

SUPPLY VOLTAGE

78146

R

L

= 10 kΩ

CL = 100 pF

TA = 25°C

φ

m

50°

48°

46°

44°

42°

40°

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

21

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

TYPICAL CHARACTERISTICS

†

Figure 31

–50 –25

50°

48°

46°

44°

42°

40°

TA – Free-Air Temperature – °C

–75 0 50

PHASE MARGIN

vs

FREE-AIR TEMPERATURE

100 12525 75

V

DD±

= ±5 V

RL = 10 kΩ

CL = 100 pF

om – Phase Margin

φ

m

Figure 32

0 200 400 600

PHASE MARGIN

vs

LOAD CAPACITANCE

800 1000

V

DD±

= ±5 V

RL = 10 kΩ

TA = 25°C

CL – Load Capacitance – pF

om – Phase Margin

φ

m

60°

50°

40°

30°

20°

10°

0°

†

Data at high and low temperatures are applicable only within the rated operating free-air temperature ranges of the various devices.

APPLICATION INFORMATION

capacitor selection and placement

The two important factors to consider when selecting external capacitors CXA and CXB are leakage and

dielectric absorption. Both factors can cause system degradation, negating the performance advantages

realized by using the TLC2652.

Degradation from capacitor leakage becomes more apparent with the increasing temperatures. Low-leakage

capacitors and standoffs are recommended for operation at T

A

= 125°C. In addition, guard bands are

recommended around the capacitor connections on both sides of the printed circuit board to alleviate problems

caused by surface leakage on circuit boards.

Capacitors with high dielectric absorption tend to take several seconds to settle upon application of power, which

directly affects input offset voltage. In applications where fast settling of input offset voltage is needed, it is

recommended that high-quality film capacitors, such as mylar, polystyrene, or polypropylene, be used. In other

applications, however, a ceramic or other low-grade capacitor can suffice.

Unlike many choppers available today , the TLC2652 is designed to function with values of C

XA

and CXB in the

range of 0.1 µF to 1 µF without degradation to input offset voltage or input noise voltage. These capacitors

should be located as close as possible to the C

XA

and C

XB

pins and returned to either V

DD–

or C RETURN. On

many choppers, connecting these capacitors to V

DD–

causes degradation in noise performance. This problem

is eliminated on the TLC2652.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

22

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

internal/external clock

The TLC2652 has an internal clock that sets the chopping frequency to a nominal value of 450 Hz. On 8-pin

packages, the chopping frequency can only be controlled by the internal clock; however, on all 14-pin packages

and the 20-pin FK package, the device chopping frequency can be set by the internal clock or controlled

externally by use of the INT/EXT

and CLK IN pins. T o use the internal 450-Hz clock, no connection is necessary .

If external clocking is desired, connect INT/EXT

to V

DD–

and the external clock to CLK IN. The external clock

trip point is 2.5 V above the negative rail; however, CLK IN can be driven from the negative rail to 5 V above

the negative rail. If this level is exceeded, damage could occur to the device unless the current into CLK IN is

limited to ±5 mA. When operating in the single-supply configuration, this feature allows the TLC2652 to be driven

directly by 5-V TTL and CMOS logic. A

divide-by-two frequency divider interfaces with

CLK IN and sets the clock chopping frequency.

The duty cycle of the external is not critical but

should be kept between 30% and 60%.

overload recovery/output clamp

When large differential input voltage conditions

are applied to the TLC2652, the nulling loop

attempts to prevent the output from saturating by

driving C

XA

and CXB to internally-clamped voltage

levels. Once the overdrive condition is removed,

a period of time is required to allow the built-up

charge to dissipate. This time period is defined as

overload recovery time (see Figure 33). Typical

overload recovery time for the TLC2652 is

significantly faster than competitive products;

however, if required, this time can be reduced

further by use of internal clamp circuitry

accessible through CLAMP if required.

The clamp is a switch that is automatically activated when the output is approximately 1 V from either supply

rail. When connected to the inverting input (in parallel with the closed-loop feedback resistor), the closed-loop

gain is reduced, and the TLC2652 output is prevented from going into saturation. Since the output must source

sink current through the switch (see Figure 7), the maximum output voltage swing is slightly reduced.

thermoelectric effects

T o take advantage of the extremely low of fset voltage drift of the TLC2652, care must be taken to compensate

for the thermoelectric effects present when two dissimilar metals are brought into contact with each other (such

as device leads being soldered to a printed circuit board). Dissimilar metal junctions can produce thermoelectric

voltages in the range of several microvolts per degree Celsius (orders of magnitude greater than the 0.01-µV/°C

typical of the TLC2652).

To help minimize thermoelectric effects, careful attention should be paid to component selection and

circuit-board layout. Avoid the use of nonsoldered connections (such as sockets, relays, switches, etc.) in the

input signal path. Cancel thermoelectric effects by duplicating the number of components and junctions in each

device input. The use of low-thermoelectric-coefficient components, such as wire-wound resistors, is also

beneficial.

0

0 10203040

VI – Input Voltage – mV VO – Output Voltage – V

t – Time – ms

0

50 60 70 80

V

I

V

O

V

DD±

= ±5 V

TA = 25°C

Figure 33. Overload Recovery

–5

–50

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

23

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

latch-up avoidance

Because CMOS devices are susceptible to latch-up due to their inherent parasitic thyristors, the TLC2652 inputs

and output are designed to withstand –100-mA surge currents without sustaining latch-up; however, techniques

to reduce the chance of latch-up should be used whenever possible. Internal protection diodes should not, by

design, be forward biased. Applied input and output voltages should not exceed the supply voltage by more than

300 mV. Care should be exercised when using capacitive coupling on pulse generators. Supply transients

should be shunted by the use of decoupling capacitors (0.1 µF typical) located across the supply rails as close

to the device as possible.

The current path established if latch-up occurs is usually between the supply rails and is limited only by the

impedance of the power supply and the forward resistance of the parasitic thyristor. The chance of latch-up

occurring increases with increasing temperature and supply voltage.

electrostatic discharge protection

The TLC2652 incorporates internal ESD-protection circuits that prevent functional failures at voltages at or

below 2000 V. Care should be exercised in handling these devices, as exposure to ESD may result in

degradation of the device parametric performance.

theory of operation

Chopper-stabilized operational amplifiers offer the best dc performance of any monolithic operational amplifier .

This superior performance is the result of using two operational amplifiers, a main amplifier and a nulling

amplifier, plus oscillator-controlled logic and two external capacitors to create a system that behaves as a single

amplifier. With this approach, the TLC2652 achieves submicrovolt input offset voltage, submicrovolt noise

voltage, and offset voltage variations with temperature in the nV/°C range.

The TLC2652 on-chip control logic produces two dominant clock phases: a nulling phase and an amplifying

phase. The term chopper-stabilized derives from the process of switching between these two clock phases.

Figure 34 shows a simplified block diagram of the TLC2652. Switches A and B are make-before-break types.

During the nulling phase, switch A is closed shorting the nulling amplifier inputs together and allowing the nulling

amplifier to reduce its own input offset voltage by feeding its output signal back to an inverting input node.

Simultaneously , external capacitor C

XA

stores the nulling potential to allow the offset voltage of the amplifier to

remain nulled during the amplifying phase.

Null

Amplifier

IN+

IN–

Main Amplifier

V

O

V

DD–

C

XA

C

XB

B

A

B

A

+

+

–

–

Figure 34. TLC2652 Simplified Block Diagram

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

24

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

APPLICATION INFORMATION

theory of operation (continued)

During the amplifying phase, switch B is closed connecting the output of the nulling amplifier to a noninverting

input of the main amplifier. In this configuration, the input offset voltage of the main amplifier is nulled. Also,

external capacitor C

XB

stores the nulling potential to allow the offset voltage of the main amplifier to remain

nulled during the next nulling phase.

This continuous chopping process allows offset voltage nulling during variations in time and temperature over

the common-mode input voltage range and power supply range. In addition, because the low-frequency signal

path is through both the null and main amplifiers, extremely high gain is achieved.

The low-frequency noise of a chopper amplifier depends on the magnitude of the component noise prior to

chopping and the capability of the circuit to reduce this noise while chopping. The use of the Advanced LinCMOS

process, with its low-noise analog MOS transistors and patent-pending input stage design, significantly reduces

the input noise voltage.

The primary source of nonideal operation in chopper-stabilized amplifiers is error charge from the switches. As

charge imbalance accumulates on critical nodes, input offset voltage can increase, especially with increasing

chopping frequency . This problem has been significantly reduced in the TLC2652 by use of a patent-pending

compensation circuit and the Advanced LinCMOS process.

The TLC2652 incorporates a feed-forward design that ensures continuous frequency response. Essentially , the

gain magnitude of the nulling amplifier and compensation network crosses unity at the break frequency of the

main amplifier. As a result, the high-frequency response of the system is the same as the frequency response

of the main amplifier. This approach also ensures that the slewing characteristics remain the same during both

the nulling and amplifying phases.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

25

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

D (R-PDSO-G**) PLASTIC SMALL-OUTLINE PACKAGE

14 PIN SHOWN

4040047/D 10/96

0.228 (5,80)

0.244 (6,20)

0.069 (1,75) MAX

0.010 (0,25)

0.004 (0,10)

1

14

0.014 (0,35)

0.020 (0,51)

A

0.157 (4,00)

0.150 (3,81)

7

8

0.044 (1,12)

0.016 (0,40)

Seating Plane

0.010 (0,25)

PINS **

0.008 (0,20) NOM

A MIN

A MAX

DIM

Gage Plane

0.189

(4,80)

(5,00)

0.197

8

(8,55)

(8,75)

0.337

14

0.344

(9,80)

16

0.394

(10,00)

0.386

0.004 (0,10)

M

0.010 (0,25)

0.050 (1,27)

0°–8°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Body dimensions do not include mold flash or protrusion, not to exceed 0.006 (0,15).

D. Falls within JEDEC MS-012

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

26

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

FK (S-CQCC-N**) LEADLESS CERAMIC CHIP CARRIER

4040140/D 10/96

28 TERMINAL SHOWN

B

0.358

(9,09)

MAX

(11,63)

0.560

(14,22)

0.560

0.458

0.858

(21,8)

1.063

(27,0)

(14,22)

A

NO. OF

MINMAX

0.358

0.660

0.761

0.458

0.342

(8,69)

MIN

(11,23)

(16,26)

0.640

0.739

0.442

(9,09)

(11,63)

(16,76)

0.962

1.165

(23,83)

0.938

(28,99)

1.141

(24,43)

(29,59)

(19,32)(18,78)

**

20

28

52

44

68

84

0.020 (0,51)

TERMINALS

0.080 (2,03)

0.064 (1,63)

(7,80)

0.307

(10,31)

0.406

(12,58)

0.495

(12,58)

0.495

(21,6)

0.850

(26,6)

1.047

0.045 (1,14)

0.045 (1,14)

0.035 (0,89)

0.035 (0,89)

0.010 (0,25)

121314151618 17

11

10

8

9

7

5

432

0.020 (0,51)

0.010 (0,25)

6

12826 27

19

21

B SQ

A SQ

22

23

24

25

20

0.055 (1,40)

0.045 (1,14)

0.028 (0,71)

0.022 (0,54)

0.050 (1,27)

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. This package can be hermetically sealed with a metal lid.

D. The terminals are gold plated.

E. Falls within JEDEC MS-004

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

27

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

J (R-GDIP-T**) CERAMIC DUAL-IN-LINE PACKAGE

1

20

0.290

(7,87)

0.310

0.975

(24,77)

(23,62)

0.930

(7,37)

0.245

(6,22)

(7,62)

0.300

181614

PINS **

0.290

(7,87)

0.310

0.785

(19,94)

(19,18)

0.755

(7,37)

0.310

(7,87)

(7,37)

0.290

0.755

(19,18)

(19,94)

0.785

0.245

(6,22)

(7,62)

0.300A0.300

(7,62)

(6,22)

0.245

A MIN

A MAX

B MAX

B MIN

C MIN

C MAX

DIM

0.310

(7,87)

(7,37)

0.290

(23,10)

0.910

0.300

(7,62)

(6,22)

0.245

0°–15°

Seating Plane

0.014 (0,36)

0.008 (0,20)

4040083/D 08/98

C

8

7

0.020 (0,51) MIN

B

0.070 (1,78)

0.100 (2,54)

0.065 (1,65)

0.045 (1,14)

14 PIN SHOWN

14

0.015 (0,38)

0.023 (0,58)

0.100 (2,54)

0.200 (5,08) MAX

0.130 (3,30) MIN

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. This package can be hermetically sealed with a ceramic lid using glass frit.

D. Index point is provided on cap for terminal identification only on press ceramic glass frit seal only.

E. Falls within MIL STD 1835 GDIP1-T14, GDIP1-T16, GDIP1-T18, GDIP1-T20, and GDIP1-T22.

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

28

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

JG (R-GDIP-T8) CERAMIC DUAL-IN-LINE PACKAGE

0.310 (7,87)

0.290 (7,37)

0.014 (0,36)

0.008 (0,20)

Seating Plane

4040107/C 08/96

5

4

0.065 (1,65)

0.045 (1,14)

8

1

0.020 (0,51) MIN

0.400 (10,20)

0.355 (9,00)

0.015 (0,38)

0.023 (0,58)

0.063 (1,60)

0.015 (0,38)

0.200 (5,08) MAX

0.130 (3,30) MIN

0.245 (6,22)

0.280 (7,11)

0.100 (2,54)

0°–15°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. This package can be hermetically sealed with a ceramic lid using glass frit.

D. Index point is provided on cap for terminal identification only on press ceramic glass frit seal only.

E. Falls within MIL-STD-1835 GDIP1-T8

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

29

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

N (R-PDIP-T**) PLASTIC DUAL-IN-LINE PACKAGE

20

0.975

(24,77)

0.940

(23,88)

18

0.920

0.850

14

0.775

0.745

(19,69)

(18,92)

16

0.775

(19,69)

(18,92)

0.745

A MIN

DIM

A MAX

PINS **

0.310 (7,87)

0.290 (7,37)

(23.37)

(21.59)

Seating Plane

0.010 (0,25) NOM

14/18 PIN ONL Y

4040049/C 08/95

9

8

0.070 (1,78) MAX

A

0.035 (0,89) MAX

0.020 (0,51) MIN

16

1

0.015 (0,38)

0.021 (0,53)

0.200 (5,08) MAX

0.125 (3,18) MIN

0.240 (6,10)

0.260 (6,60)

M

0.010 (0,25)

0.100 (2,54)

0°–15°

16 PIN SHOWN

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Falls within JEDEC MS-001 (20 pin package is shorter then MS-001.)

TLC2652, TLC2652A, TLC2652Y

Advanced LinCMOS PRECISION CHOPPER-STABILIZED

OPERATIONAL AMPLIFIERS

SLOS019C – SEPTEMBER 1988 – REVISED FEBRUARY 1999

30

POST OFFICE BOX 655303 • DALLAS, TEXAS 75265

MECHANICAL DATA

P (R-PDIP-T8) PLASTIC DUAL-IN-LINE PACKAGE

4040082/B 03/95

0.310 (7,87)

0.290 (7,37)

0.010 (0,25) NOM

0.400 (10,60)

0.355 (9,02)

58

41

0.020 (0,51) MIN

0.070 (1,78) MAX

0.240 (6,10)

0.260 (6,60)

0.200 (5,08) MAX

0.125 (3,18) MIN

0.015 (0,38)

0.021 (0,53)

Seating Plane

M

0.010 (0,25)

0.100 (2,54)

0°–15°

NOTES: A. All linear dimensions are in inches (millimeters).

B. This drawing is subject to change without notice.

C. Falls within JEDEC MS-001

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgement, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. Testing and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty. Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

CERT AIN APPLICATIONS USING SEMICONDUCTOR PRODUCTS MAY INVOLVE POTENTIAL RISKS OF

DEATH, PERSONAL INJURY, OR SEVERE PROPERTY OR ENVIRONMENTAL DAMAGE (“CRITICAL

APPLICATIONS”). TI SEMICONDUCTOR PRODUCTS ARE NOT DESIGNED, AUTHORIZED, OR

WARRANTED TO BE SUITABLE FOR USE IN LIFE-SUPPORT DEVICES OR SYSTEMS OR OTHER

CRITICAL APPLICATIONS. INCLUSION OF TI PRODUCTS IN SUCH APPLICA TIONS IS UNDERST OOD TO

BE FULLY AT THE CUSTOMER’S RISK.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 1999, Texas Instruments Incorporated

Loading...

Loading...