Page 1

查询UC2823A供应商

High Speed PWM Controller

FEATURES

Improved versions of the

•

UC3823/UC3825 PWMs

Compatible with Voltage or

•

Current-Mode Topologies

Practical Operation at Switching

•

Frequencies to 1MHz

50ns Propagation Delay to Output

•

High Current Dual Totem Pole

•

Outputs (2A Peak)

Trimmed Oscillator Discharge Current

•

Low 100µA Startup Current

•

• Pulse-by-Pulse Current Limiting

Comparator

• Latched Overcurrent Comparator With

Full Cycle Restart

DESCRIPTION

The UC3823A & B and the UC3825A & B family of PWM control ICs are

improved versions of the standard UC3823 & UC3825 family. Performance

enhancements have been made to several of the circuit blocks. Error ampli

fier gain bandwidth product is 12MHz while input offset voltage is 2mV. Cur

rent limit threshold is guaranteed to a tolerance of 5%. Oscillator discharge

current is specified at 10mA for accurate dead time control. Frequency ac

curacy is improved to 6%. Startup supply current, typically 100µA, is ideal

for off-line applications. The output drivers are redesigned to actively sink

current during UVLO at no expense to the startup current specification. In

addition each output is capable of 2A peak currents during transitions.

Functional improvements have also been implemented in this family. The

UC3825 shutdown comparator is now a high-speed overcurrent comparator

with a threshold of 1.2V. The overcurrent comparator sets a latch that en

sures full discharge of the soft start capacitor before allowing a restart.

While the fault latch is set, the outputs are in the low state. In the event of

continuous faults, the soft start capacitor is fully charged before discharge

to insure that the fault frequency does not exceed the designed soft start

period. The UC3825 Clock pin has become CLK/LEB. This pin combines

the functions of clock output and leading edge blanking adjustment and has

been buffered for easier interfacing.

application

INFO

available

UC1823A,B/1825A,B

UC2823A,B/2825A,B

UC3823A,B/3825A,B

-

-

-

-

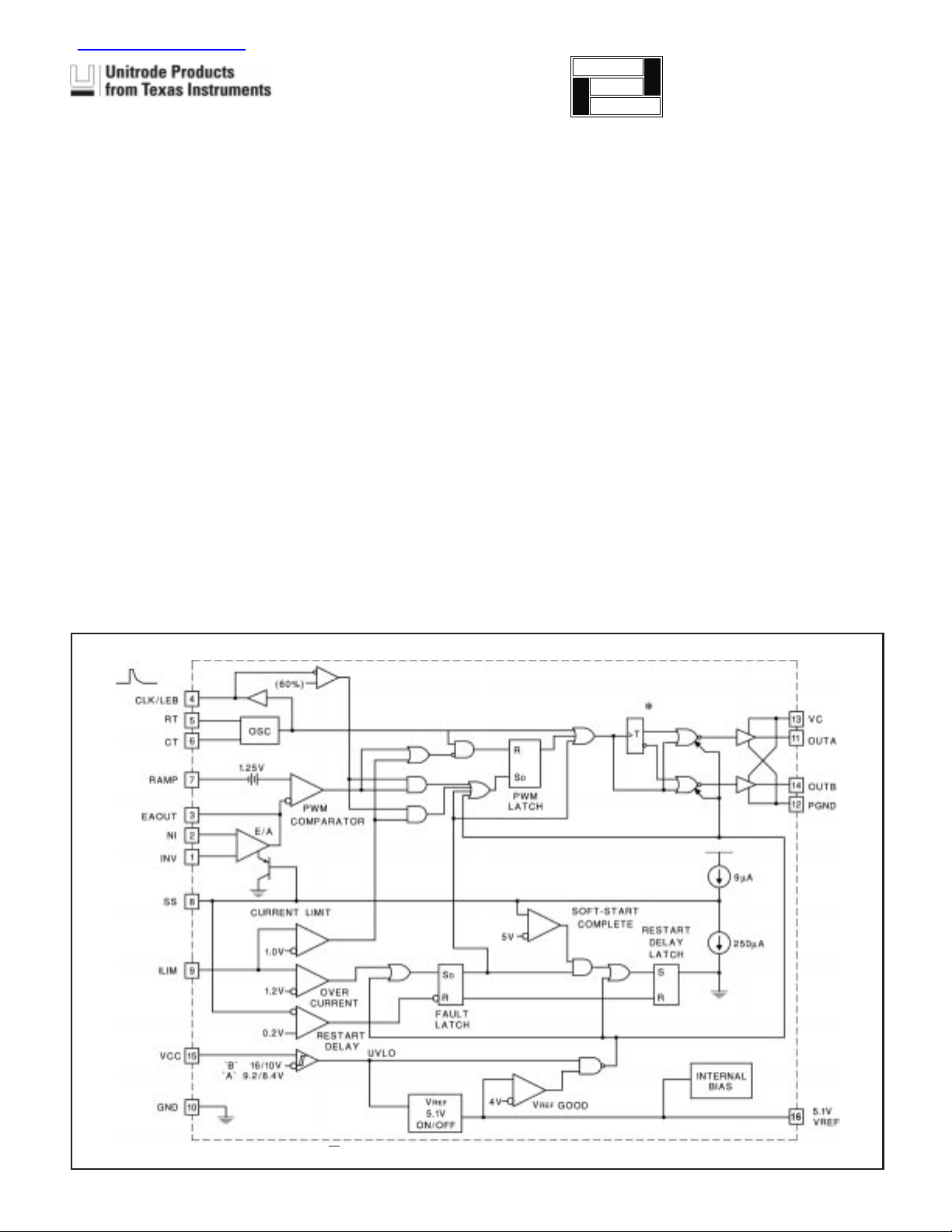

BLOCK DIAGRAM

(continued)

* Note: 1823A,B Version Toggles Q and Q are always low

SLUS334A - AUGUST 1995 - REVISED NOVEMBER 2000

UDG-95101

Page 2

DESCRIPTION (cont.)

The UC3825A,B has dual alternating outputs and the

same pin configuration of the UC3825. The UC3823A,B

outputs operate in phase with duty cycles from zero to

less than 100%. The pin configuration of the UC3823A,B

is the same as the UC3823 except pin 11 is now an out

put pin instead of the reference pin to the current limit

comparator. “A” version parts have UVLO thresholds

identical to the original UC3823/25. The “B” versions

have UVLO thresholds of 16 and 10V, intended for ease

of use in off-line applications.

Consult Application Note U-128 for detailed technical

and applications information. Contact the factory for fur

ther packaging and availability information.

Device UVLO Dmax

UC3823A 9.2V/8.4V < 100%

UC3823B 16V/10V < 100%

UC3825A 9.2V/8.4V < 50%

UC3825B 16V/10V < 50%

UC1823A,B/1825A,B

UC2823A,B/2825A,B

UC3823A,B/3825A,B

ABSOLUTE MAXIMUM RATINGS

Supply Voltage (VC, VCC) . . . . . . . . . . . . . . . . . . . . . . . . . 22V

Output Current, Source or Sink (Pins OUTA, OUTB)

DC . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 0.5A

Pulse (0.5µs) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2.2A

Power Ground (PGND). . . . . . . . . . . . . . . . . . . . . . . . . . . ±0.2V

-

Analog Inputs

(INV, NI, RAMP). . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 7V

(ILIM, SS). . . . . . . . . . . . . . . . . . . . . . . . . . . . . . –0.3V to 6V

Clock Output Current (CLK/LEB) . . . . . . . . . . . . . . . . . . . –5mA

Error Amplifier Output Current (EAOUT) . . . . . . . . . . . . . . 5mA

Soft Start Sink Current (SS) . . . . . . . . . . . . . . . . . . . . . . . 20mA

Oscillator Charging Current (RT) . . . . . . . . . . . . . . . . . . . –5mA

Power Dissipation at TA= 60°C . . . . . . . . . . . . . . . . . . . . . . 1W

Storage Temperature Range . . . . . . . . . . . . . –65°C to +150°C

-

Junction Temperature. . . . . . . . . . . . . . . . . . . –55°C to +150°C

Lead Temperature (Soldering, 10 sec.). . . . . . . . . . . . . . 300°C

All currents are positive into, negative out of the specified ter

minal. Consult Packaging Section of Databook for thermal limi

tations and considerations of packages.

-

-

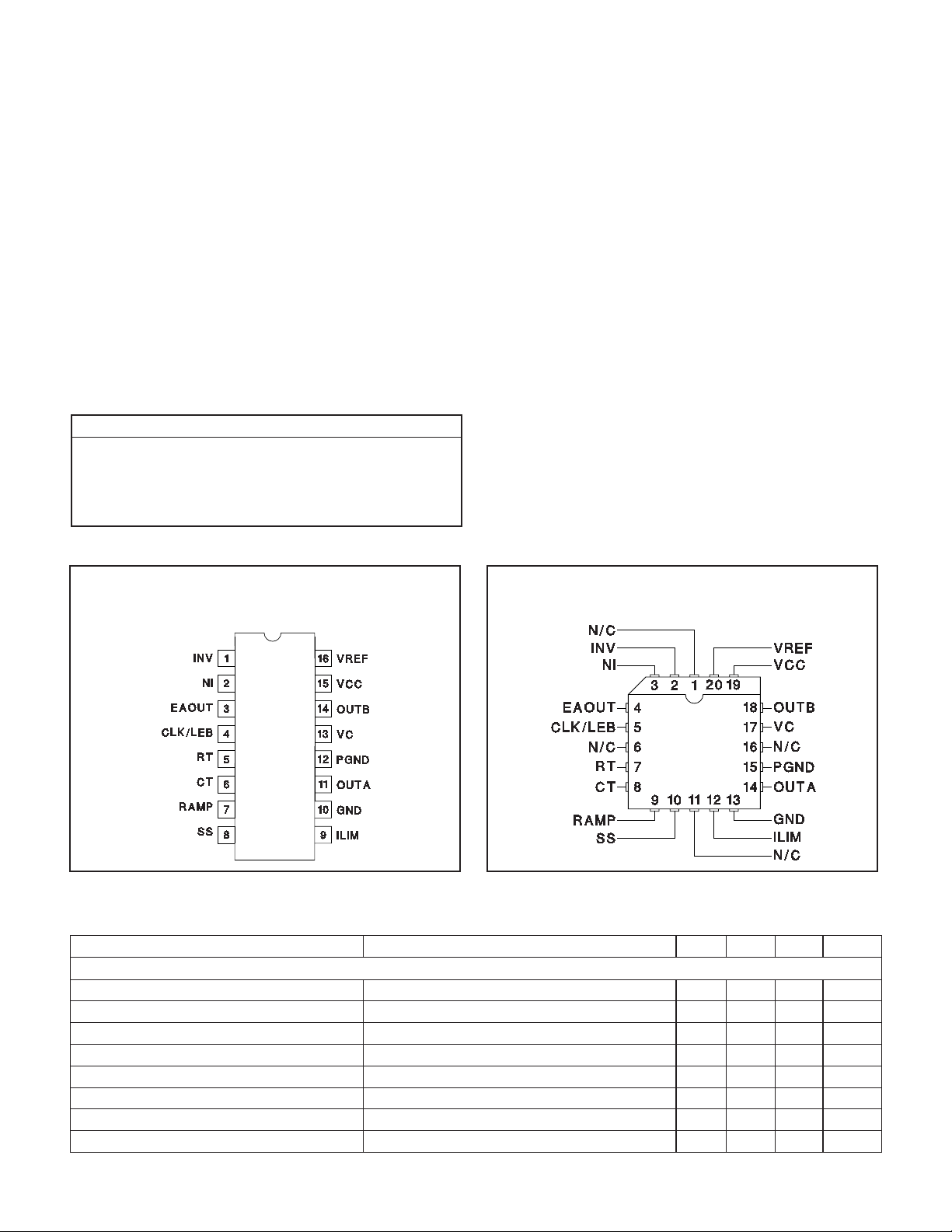

CONNECTION DIAGRAMS

DIL-16, SOIC-16, (Top View)

J or N Package;DW Package

ELECTRICAL CHARACTERISTICS:

the UC1823A,B and UC1825A,B; –40°C to +85°C for the UC2823A,B and UC2825A,B; 0°C to +70°C for the UC3823A,B and

UC3825A,B; RT = 3.65k, CT= 1nF, VCC = 12V, TA=T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Reference Section

Output Voltage T

Line Regulation 12 < VCC < 20V 2 15 mV

Load Regulation 1mA < I

Total Output Variation Line, Load, Temp 5.03 5.17 V

Temperature Stability T

Output Noise Voltage 10Hz < f < 10kHz (Note 1) 50 µVRMS

Long Term Stability T

Short Circuit Current VREF = 0V 30 60 90 mA

Unless otherwise stated, these specifications apply for TA= –55°C to +125°C for

J.

= 25°C, Io = 1mA 5.05 5.1 5.15 V

J

< 10mA 5 20 mV

O

< TA<T

MIN

= 125°C, 1000 hours (Note 1) 5 25 mV

J

MAX

PLCC-20, LCC-20, (Top View)

Q, L Packages

(Note 1) 0.2 0.4 mV/°C

2

Page 3

UC1823A,B/1825A,B

UC2823A,B/2825A,B

UC3823A,B/3825A,B

ELECTRICAL CHARACTERISTICS:

Unless otherwise stated, these specifications apply for TA= –55°C to +125°C for

the UC1823A,B and UC1825A,B; –40°C to +85°C for the UC2823A,B and UC2825A,B; 0°C to +70°C for the UC3823A,B and

UC3825A,B; RT = 3.65k, CT= 1nF, VCC = 12V, TA=T

J.

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Oscillator Section

Initial Accuracy T

= 25°C (Note 1) 375 400 425 kHz

J

Total Variation Line, Temperature (Note 1) 350 450 kHz

Voltage Stability 12V < VCC < 20V 1 %

Temperature Stability T

MIN

< TA<T

Initial Accuracy RT= 6.6k, CT = 220pF, T

(Note 1) 5 %

MAX

= 25°C (Note 1) 0.9 1 1.1 MHz

A

Total Variation RT = 6.6k, CT = 220pF (Note 1) 0.85 1.15 MHz

Clock Out High 3.7 4 V

Clock Out Low 0 0.2 V

Ramp Peak 2.6 2.8 3 V

Ramp Valley 0.7 1 1.25 V

Ramp Valley to Peak 1.6 1.8 2 V

Oscillator Discharge Current RT = Open, V

= 2V 9 10 11 mA

CT

Error Amplifier Section

Input Offset Voltage 210mV

Input Bias Current 0.6 3 µA

Input Offset Current 0.1 1 µA

Open Loop Gain 1V < V

CMRR 1.5V < V

< 4V 60 95 dB

O

< 5.5V 75 95 dB

CM

PSRR 12V < VCC < 20V 85 110 dB

Output Sink Current V

Output Source Current V

Output High Voltage I

Output Low Voltage I

= 1V 1 2.5 mA

EAOUT

= 4V –0.5 –1.3 mA

EAOUT

= –0.5mA 4.5 4.7 5 V

EAOUT

= 1mA 0 0.5 1 V

EAOUT

Gain Bandwidth Product F = 200kHz 6 12 MHz

Slew Rate (Note 1) 6 9 V/µs

PWM Comparator

RAMP Bias Current V

= 0V –1 –8 µA

RAMP

Minimum Duty Cycle 0%

Maximum Duty Cycle 85 %

Leading Edge Blanking R = 2k, C = 470pF 300 375 450 ns

LEB Resistor V

EAOUT Zero D.C. Threshold V

Delay to Output V

CLK/LEB

RAMP

EAOUT

= 3V 8.5 10 11.5 kohm

= 0V 1.1 1.25 1.4 V

= 2.1V, V

= 0 to 2V Step (Note 1) 50 80 ns

RAMP

Current Limit/Start Sequence/Fault Section

Soft Start Charge Current VSS= 2.5V 8 14 20 µA

Full Soft Start Threshold 4.3 5 V

Restart Discharge Current V

= 2.5V 100 250 350 µA

SS

Restart Threshold 0.3 0.5 V

ILIM Bias Current 0 < V

< 2V 15 µA

ILIM

Current Limit Threshold 0.95 1 1.05 V

3

Page 4

UC1823A,B/1825A,B

UC2823A,B/2825A,B

UC3823A,B/3825A,B

ELECTRICAL CHARACTERISTICS:

the UC1823A,B and UC1825A,B; –40°C to +85°C for the UC2823A,B and UC2825A,B; 0°C to +70°C for the UC3823A,B and

UC3825A,B; RT = 3.65k, CT= 1nF, VCC = 12V, TA=T

PARAMETER TEST CONDITIONS MIN TYP MAX UNITS

Current Limit/Start Sequence/Fault Section (cont.)

Over Current Threshold 1.14 1.2 1.26 V

ILIM Delay to Output V

Output Section

Output Low Saturation I

Output High Saturation I

UVLO Output Low Saturation I

Rise/Fall Time C

UnderVoltage Lockout

Start Threshold UCX823B and X825B only 16 17 V

Stop Threshold UCX823B and X825B only 9 10 V

UVLO Hysteresis UCX823B and X825B only 5 6 7 V

Start Threshold UCX823A and X825A only 8.4 9.2 9.6 V

UVLO Hysteresis UCX823A and X825A only 0.4 0.8 1.2 V

Supply Current

Startup Current VC = VCC = V

Icc 28 36 mA

Unless otherwise stated, these specifications apply for TA= –55°C to +125°C for

J.

= 0 to 2V Step (Note 1) 50 80 ns

ILIM

= 20mA 0.25 0.4 V

OUT

= 200mA 1.2 2.2 V

I

OUT

= 20mA 1.9 2.9 V

OUT

= 200mA 2 3 V

I

OUT

= 20mA 0.8 1.2 V

O

= 1nF (Note 1) 20 45 ns

L

(start) –0.5V 100 300 µA

TH

Note 1:Guaranteed by design.Not 100% tested in production.

APPLICATIONS INFORMATION

OSCILLATOR

The UC3823A,B/3825A,B oscillator is a saw tooth. The

rising edge is governed by a current controlled by the RT

pin and value of capacitance at the CT pin. The falling

edge of the sawtooth sets dead time for the outputs. Se

lection of RT should be done first, based on desired

maximum duty cycle. CT can then be chosen based on

desired frequency, RT, and D

are:

V

RT

=

()

10 1–

()

CT

=

3

mA D

()

MAX

D

••16.

MAX

()

RT F

Recommended values for RT range from 1k to 100k.

Control of D

less than 70% is not recommended.

MAX

. The design equations

MAX

Oscillator

-

UDG-95102

4

Page 5

APPLICATIONS INFORMATION (cont.)

OSCILLATOR (cont.)

UC1823A,B/1825A,B

UC2823A,B/2825A,B

UC3823A,B/3825A,B

Oscillator Frequency vs. RTand CTCurve

UDG-95103

LEADING EDGE BLANKING

The UC3823A,B/3825A,B performs fixed frequency

pulse width modulation control. The UC3823A,B outputs operate together at the switching frequency and

can vary from 0 to some value less than 100%. The

UC3825A,B outputs are alternately controlled. During

every other cycle, one output will be off. Each output

then, switches at one-half the oscillator frequency, varying in duty cycle from 0 to less than 50%.

Maximum Duty Cycle vs RTCurve

UDG-95104

LEB Operational Waveforms

To limit maximum duty cycle, the internal clock pulse

blanks both outputs low during the discharge time of

the oscillator. On the falling edge of the clock, the ap

propriate output(s) is driven high. The end of the pulse

is controlled by the PWM comparator, current limit com

parator, or the overcurrent comparator.

Normally the PWM comparator will sense a ramp

crossing a control voltage (error amp output) and termi

nate the pulse. Leading edge blanking (LEB) causes

the PWM comparator to be ignored for a fixed amount

of time after the start of the pulse. This allows noise in

herent with switched mode power conversion to be re

jected. The PWM ramp input may not require any

filtering as result of leading edge blanking.

To program a Leading Edge Blanking period, connect a

capacitor, C, to CLK/LEB. The discharge time set by C

and the internal 10k resistor will determine the blanked

interval. The 10k resistor has a 10% tolerance. For

more accuracy, an external 2k 1% resistor, R, can be

added, resulting in an equivalent resistance of 1.66k

with a tolerance of 2.4%.The design equation is:

-

-

-

= 0.5 • (R | | 10k) • C.

-

-

t

LEB

Values of R less than 2k should not be used

Leading edge blanking is also applied to the current

limit comparator. After LEB, if the ILIM pin exceeds the

one volt threshold, the pulse is terminated. The over

current comparator, however, is not blanked. It will

catch catastrophic over current faults without a blanking

delay. Any time the ILIM pin exceeds 1.2V, the fault

latch will be set and the outputs driven low. For this rea

son, some noise filtering may be required on the ILIM

pin.

UDG-95105

-

5

Page 6

APPLICATIONS INFORMATION (cont.)

UC1823A,B/1825A,B

UC2823A,B/2825A,B

UC3823A,B/3825A,B

UVLO,SOFT START AND FAULT MANAGEMENT

Soft start is programmed by a capacitor on the SS pin. At

power up, SS is discharged. When SS is low, the error

amp output is also forced low. As the internal 9µA source

charges the SS pin, the error amp output follows until

closed loop regulation takes over.

Anytime ILIM exceeds 1.2V, the fault latch will be set and

the output pins will be driven low. The soft start cap is

then discharged by a 250µA current sink. No more output

pulses are allowed until soft start is fully discharged, and

ILIM is below 1.2V. At this point the fault latch will be re

set and the chip will execute a soft start.

Should the fault latch be set during soft start, the outputs

will be immediately terminated, but the soft start cap will

not be discharged until it has been fully charged. This re-

ACTIVE LOW OUTPUTS DURING UVLO

The UVLO function forces the outputs to be low and considers both VCC and VREF before allowing the chip to

operate.

Soft Start and Fault Waveforms

-

UDG-95106

sults in a controlled hiccup interval for continuous

fault conditions.

Output V and I During UVLO

Simplified Schematic

PWM APPLICATIONS

Current Mode

UDG-95108

UDG-95107

Voltage Mode

UDG-95110UDG-95109

6

Page 7

APPLICATIONS INFORMATION (cont.)

UC1823A,B/1825A,B

UC2823A,B/2825A,B

UC3823A,B/3825A,B

SYNCHRONIZATION

The oscillator can be synchronized by an external pulse

inserted in series with the timing capacitor. Program the

free running frequency of the oscillator to be 10 to 15%

slower than the desired synchronous frequency.The

pulse width should be greater than 10ns and less than

half the discharge time of the oscillator.The rising edge of

the CLK/LEB pin can be used to generate a synchroniz

ing pulse for other chips.Note that, the CLK/LEB pin will

no longer accept an incoming synchronizing signal.

General Oscillator Synchronization

UDG-95111

Operational Waveforms

-

UDG-95112

Two Units

UDG-95113

HIGH CURRENT OUTPUTS

Each totem pole output of the UC3823A,B and

UC3825A,B can deliver a 2 amp peak current into a capacitive load. The output can slew a 1000pF capacitor 15

volts in approximately 20 nanoseconds. Separate collec

tor supply (VC) and power ground (PGND) pins help de

couple the IC's analog circuitry from the high power gate

drive noise. The use of 3 Amp Schottky diodes (1N5120,

USD245 or equivalent) as shown in the figure from each

output to both VC and PGND are recommended. The di

odes clamp the output swing to the supply rails, neces

sary with any type of inductive/capacitive load, typical of a

MOSFET gate. Schottky diodes must be used because a

low forward voltage drop is required. DO NOT USE stan

dard silicon diodes.

Although a "single ended" device, two output drivers are

available on the UC3823A,B devices. These can be “par

alleled” by the use of a one-half ohm (noninductive) resis

tor connected in series with each output for a combined

peak current of 4 amps.

Power MOSFET Drive Circuit

-

-

-

-

-

-

-

UDG-95114

7

Page 8

APPLICATIONS INFORMATION (cont.)

GROUND PLANES

UC1823A,B/1825A,B

UC2823A,B/2825A,B

UC3823A,B/3825A,B

Each output driver of these devices is capable of 2A

peak currents. Careful layout is essential for correct op

eration of the chip. A ground plane must be employed.

A unique section of the ground plane must be desig

nated for high di/dt currents associated with the output

stages. This point is the power ground to which the

PGND pin is connected. Power ground can be sepa

rated from the rest of the ground plane and connected

at a single point, although this is not strictly necessary

if the high di/dt paths are well understood and ac

counted for. VCC should be bypassed directly to power

ground with a good high frequency capacitor. The

sources of the power MOSFET should connect to

power ground as should the return connection for input

power to the system and the bulk input capacitor. The

output should be clamped with a high current Schottky

diode to both VCC and PGND. Nothing else should be

connected to power ground.

-

VREF should be bypassed directly to the signal portion

of the ground plane with a good high frequency capaci

tor. Low ESR/ESL ceramic 1µF capacitors are recom

-

mended for both VCC and VREF. All analog circuitry

should likewise be bypassed to the signal ground

plane.

-

-

Open Loop Test Circuit

This test fixture is useful for exercising many of the

UC3823A,B, UC3825A,B functions and measuring their

specifications. As with any wideband circuit, careful

UDG-95115

grounding and bypass procedures should be followed.

The use of a ground plane is highly recommended.

UNITRODE CORPORATION

7 CONTINENTAL BLVD.• MERRIMACK, NH 03054

TEL. (603) 424-2410 • FAX (603) 424-3460

UDG-95116

8

Page 9

IMPORTANT NOTICE

T exas Instruments and its subsidiaries (TI) reserve the right to make changes to their products or to discontinue

any product or service without notice, and advise customers to obtain the latest version of relevant information

to verify, before placing orders, that information being relied on is current and complete. All products are sold

subject to the terms and conditions of sale supplied at the time of order acknowledgment, including those

pertaining to warranty, patent infringement, and limitation of liability.

TI warrants performance of its semiconductor products to the specifications applicable at the time of sale in

accordance with TI’s standard warranty. T esting and other quality control techniques are utilized to the extent

TI deems necessary to support this warranty . Specific testing of all parameters of each device is not necessarily

performed, except those mandated by government requirements.

Customers are responsible for their applications using TI components.

In order to minimize risks associated with the customer’s applications, adequate design and operating

safeguards must be provided by the customer to minimize inherent or procedural hazards.

TI assumes no liability for applications assistance or customer product design. TI does not warrant or represent

that any license, either express or implied, is granted under any patent right, copyright, mask work right, or other

intellectual property right of TI covering or relating to any combination, machine, or process in which such

semiconductor products or services might be or are used. TI’s publication of information regarding any third

party’s products or services does not constitute TI’s approval, warranty or endorsement thereof.

Copyright 2000, Texas Instruments Incorporated

Loading...

Loading...