Page 1

SWRU234b

2.1 Introduction

The CC1110 on the SmartRFCC1110 target

board is preprogrammed with a link test which

operates at 868.3 MHz, and uses GFSK

modulation and a bit rate of 2.4 kbps.

The link test runs a point-to-point communication

between a Slave and a Master node based on

the SimpliciTI 1.1.0 protocol.

First the Master and Slave nodes must be

configured as described in the following

sections. The two nodes will then establish a

link. When this link is established, the Master

starts to periodically send packets to the Slave.

Between each transmission, the Master goes to

receive mode and waits 250 ms for an

acknowledgement packet from the Slave. The

Slave node is in receive mode waiting for

packets from the Master. For each received

packet, the Slave automatically responds with

an acknowledgement packet.

2.2 Powering the boards

Place 2 AAA batteries in the battery holders

placed on the bottom side of each of the

SmartRFCC1110-868 boards. Place the jumper

on the power selection connector P1 between

pin 1 and pin 2 on each board.

Applying power to the SmartRFCC1110-868

starts the preprogrammed link test on the

CC1110 and the two LEDs on the board are on

for 1 s.

Warning! To minimize risk of personal

injury or property damage, never use

rechargeable batteries to power the board.

Do not leave the board powered when

unattended.

2.3 Configure the Master Node

Press the S1/MASTER button that is placed on

the left hand side of the board. When this

button is pushed, the two LEDs on this board

will blink rapidly. The Master now waits for a

Slave node to establish a link.

Note that the boards only respond to the first

button push. To reconfigure the board, the

board must be reset, see point 2.9 in this

manual.

2.4 Configure the Slave Node

On the other board, press the S2/SLAVE button

that is placed on the right side of the board.

When the button has been pushed, the two

LEDs on this board will blink very slowly until a

link with a Master node is established. Note that

establishing the link may finish in less than 1 s

depending on the environment.

It is important to keep distance (more than 1

meter) between the two nodes when they are

trying to establish the link to avoid saturation.

This is because full output power (12 dBm) is

used for this communication between the nodes.

2.5 The LEDs on the Master Node

LEDs

State

Both LEDs

blink rapidly

The Master is trying to

establish a link with a

Slave

Green LED

on for 0.5 s

The Master has

received an ACK to a

packet sent, link ok

Red LED on

for 0.5 s

The Master has not

received an ACK to the

last 3 packets sent

Red LED on

for 3 s

If the Master does not

receive ACKs from the

SLAVE in ~70 s, the

Master will stop to send

packets to save power.

Press S1/MASTER to

resume the link test

Red LED on

for 5 s

For test only:

When the link is

established, pressing

the S2/SLAVE button

turns the red LED on for

5 s

2.6 The LEDs on the Slave node

LEDs

State

Both LEDs

blink slowly

The Slave is trying to

establish a link with a

Master

Red LED on

continuously

The link between the

Slave and Master is

established and the

Slave is in RX waiting

for packets from the

Master

Green LED

on for 0.5 s

while red LED

on

continuously

The Slave has received

a packet from the

Master and sent an

ACK, link ok

Caution! The kit contains ESD

sensitive components. Handle

with care to prevent permanent

damage. To minimize risk of

injury, avoid touching

components during operation if

symbolized as hot.

October 2012

CC1110 Mini Development Kit 868-915 MHz

Quick Start Guide

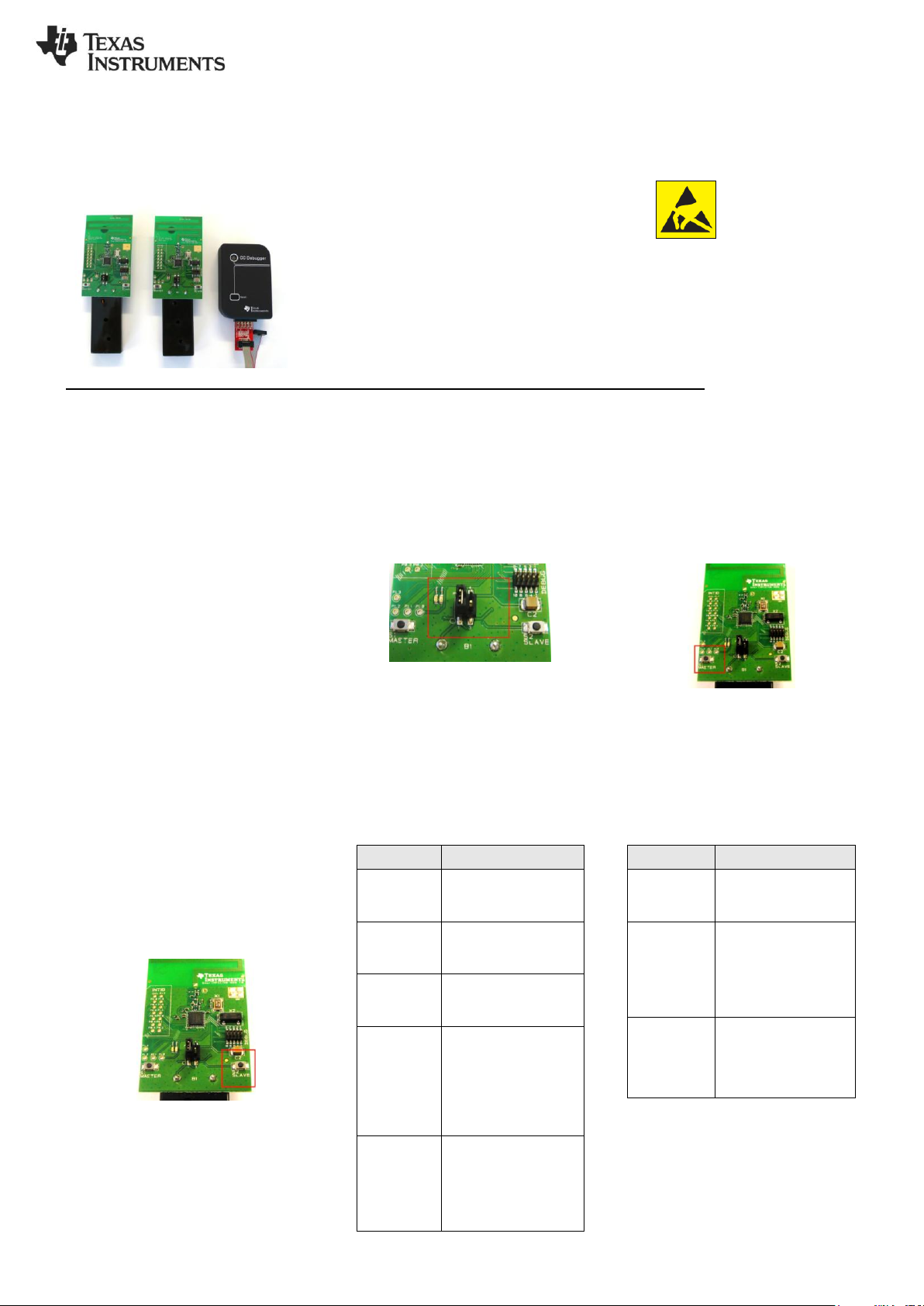

1 Kit Contents

2 x SmartRFCC1110-868 target boards

1 x CC Debugger

1 x 10- pin flat cable with 2x5 2.54 mm connector

1 x 10-pin flat cable with 2x5 1.27 mm connector

1 x Converter board 2.54 mm – 1.27 mm connector

1 x Mini USB cable

Batteries

CD with Evaluation Version of the IAR EW8051

Documentation

The hardware in this kit is FCC/IC certified and complies with ETSI/R&TTE over temperature from 0 to +35°C.

2 Running the Preprogrammed Link Test

Page 2

SWRU234b

2.7 Antenna Performance

The PCB antenna length on the

SmartRFCC1110-868 is tuned for optimal

performance with two AAA batteries present in

the battery holder. As this antenna is directive,

see DN024 www.ti.com/lit/swra227, it is

important to place the two nodes so that the

arrow in the silk print next to the antenna on

both boards points upwards towards the sky for

optimal performance.

2.8 Range testing

The preprogrammed link test is well suited for

range testing. Place the Slave in an open field

and bring the Master a known distance away.

Use the LED signaling to decide the link quality.

Note that the environment, antenna, etc greatly

affect the range, see DN018

www.ti.com/lit/swra169.

2.9 Resetting the board

The recommended reset sequence is:

Remove jumper on P1 completely

Push one of the buttons to discharge the

large capacitor on the power line. If this

capacitor is not discharged, the

SmartRFCC1110-868 boards may continue

to run the current application until the

capacitor is discharged. This may take

several seconds.

Replace the jumper on P1 to power the

board again

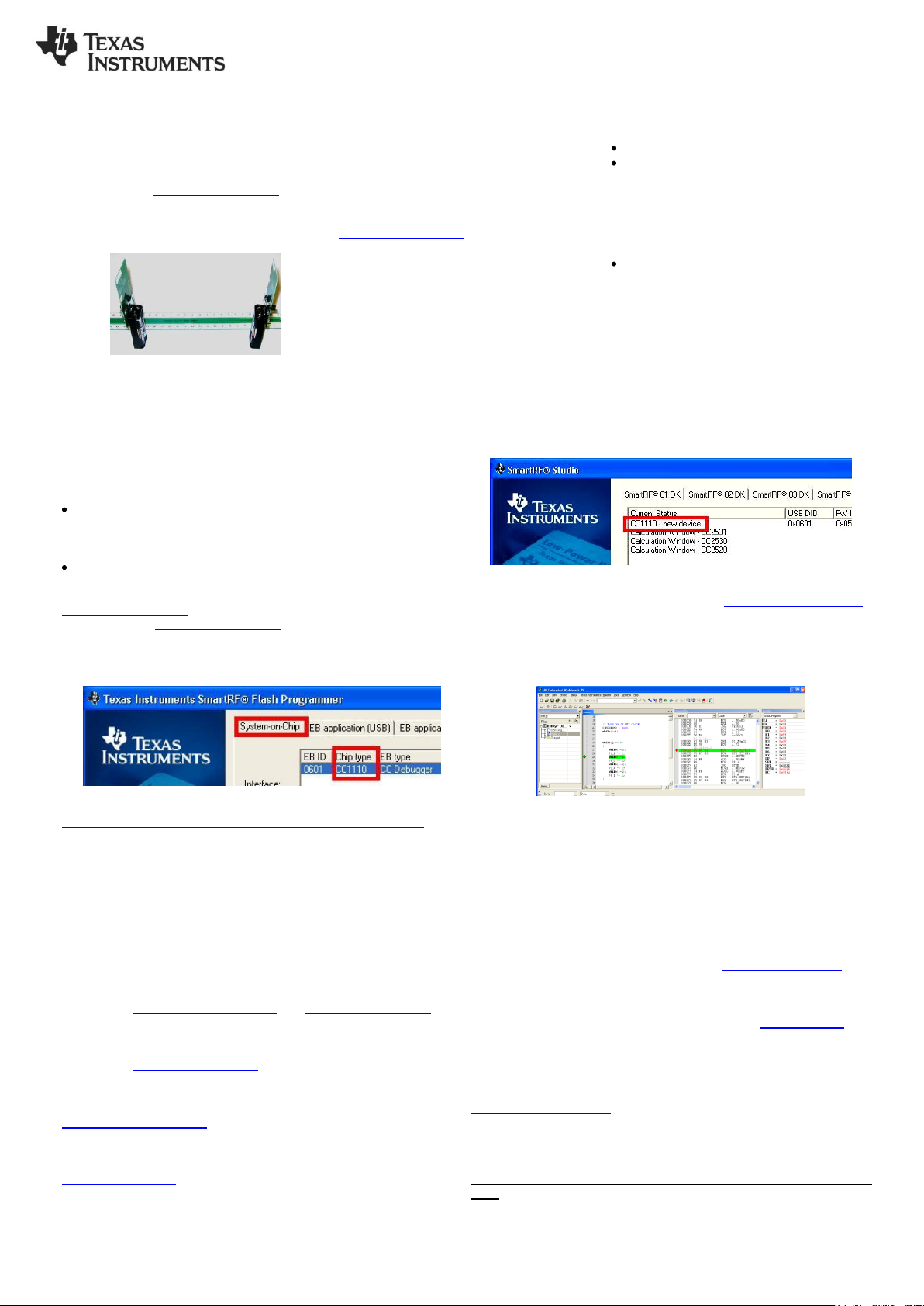

3.1 The CC Debugger

The CC Debugger connects to the PC via a mini USB and uses the

DEBUG interface to communicate with the radio. The tool can be used

for:

Programming the flash and debugging an application running on the

CC1110. The PC tools available for these purposes are the

SmartRF Flash Programmer from Texas Instruments and IAR

Embedded Workbench for 8051 from IAR Systems.

Testing the radio performance of CC1110 using SmartRF Studio.

For more details, please refer to the CC Debugger User’s Guide

www.ti.com/lit/swru197 and the CC1110 & CC2510 Mini Development

Kit User’s Guide www.ti.com/lit/swru236.

3.2 SmartRF Studio

SmartRF Studio can be used for RF testing, evaluation of CC1110 and to

find optimal register settings. It is available on www.ti.com/smartrfstudio.

3.3 Flash Programmer

The Flash Programmer application, available on the kit web page

http://focus.ti.com/docs/toolsw/folders/print/flash-programmer.html can

be used to program Intel HEX files, read the contents of CC1110 flash,

and several other operations.

3.4 IAR Embedded Workbench

To develop software, program and debug the CC1110, the IAR

Embedded Workbench for 8051 is recommended. An evaluation version

of IAR EW8051 is included in the kit. This free evaluation version and a

free code size limited version, can be downloaded from the web, see

www.iar.com/ew8051.

A. Available Software and User’s Guides

CC1110 & CC2510 Mini DK Software Example User’s Guide and

Source Code

Source and documentation for the link test for the SmartRFCC1110

target board www.ti.com/lit/zip/swrc133 and www.ti.com/lit/swru237

CC1110 & CC2510 Mini Development Kit User’s Guide

More documentation and details on the use of the SmartRFCC1110

target board www.ti.com/lit/swru236

CC1110, CC2510 Basic Software Examples

Source code for other, simple examples for the CC1110

www.ti.com/lit/zip/swrc117

SimpliciTI™ Network Protocol

An RF protocol targeting simple, small RF networks

www.ti.com/simpliciti

B. More information

The Low Power RF Online Community www.ti.com/lprf-forum has

forums, blogs and videos. Use the forums to find information, application

and design notes, FAQs, or to discuss and get help with your design.

On the Texas Instruments’ Low-Power RF web site www.ti.com/lprf, you

will find all our latest products, news and events updates, and much

more.

The TI LPRF eNewsletter keeps you up to date on e.g. new products,

application notes, software and events. Sign up at

www.ti.com/lprfnewsletter.

We hope you will enjoy working with the CC1110 Mini Development Kit

and associated Low-Power RF products from Texas Instruments.

Note that there should only be one active power source at any one

time.

October 2012

3 Using the CC Debugger with the Development Kit

Page 3

EVALUATION BOARD/KIT/MODULE (EVM) ADDITIONAL TERMS

Texas Instruments (TI) provides the enclosed Evaluation Board/Kit/Module (EVM) under the following conditions:

The user assumes all responsibility and liability for proper and safe handling of the goods. Further, the user indemnifies TI from all claims

arising from the handling or use of the goods.

Should this evaluation board/kit not meet the specifications indicated in the User’s Guide, the board/kit may be returned within 30 days from

the date of delivery for a full refund. THE FOREGOING LIMITED WARRANTY IS THE EXCLUSIVE WARRANTY MADE BY SELLER TO

BUYER AND IS IN LIEU OF ALL OTHER WARRANTIES, EXPRESSED, IMPLIED, OR STATUTORY, INCLUDING ANY WARRANTY OF

MERCHANTABILITY OR FITNESS FOR ANY PARTICULAR PURPOSE. EXCEPT TO THE EXTENT OF THE INDEMNITY SET FORTH

ABOVE, NEITHER PARTY SHALL BE LIABLE TO THE OTHER FOR ANY INDIRECT, SPECIAL, INCIDENTAL, OR CONSEQUENTIAL

DAMAGES.

Please read the User's Guide and, specifically, the Warnings and Restrictions notice in the User's Guide prior to handling the product. This

notice contains important safety information about temperatures and voltages. For additional information on TI's environmental and/or safety

programs, please visit www.ti.com/esh or contact TI.

No license is granted under any patent right or other intellectual property right of TI covering or relating to any machine, process, or

combination in which such TI products or services might be or are used. TI currently deals with a variety of customers for products, and

therefore our arrangement with the user is not exclusive. TI assumes no liability for applications assistance, customer product design,

software performance, or infringement of patents or services described herein.

REGULATORY COMPLIANCE INFORMATION

As noted in the EVM User’s Guide and/or EVM itself, this EVM and/or accompanying hardware may or may not be subject to the Federal

Communications Commission (FCC) and Industry Canada (IC) rules.

For EVMs not subject to the above rules, this evaluation board/kit/module is intended for use for ENGINEERING DEVELOPMENT,

DEMONSTRATION OR EVALUATION PURPOSES ONLY and is not considered by TI to be a finished end product fit for general consumer

use. It generates, uses, and can radiate radio frequency energy and has not been tested for compliance with the limits of computing

devices pursuant to part 15 of FCC or ICES-003 rules, which are designed to provide reasonable protection against radio frequency

interference. Operation of the equipment may cause interference with radio communications, in which case the user at his own expense will

be required to take whatever measures may be required to correct this interference.

General Statement for EVMs including a radio

User Power/Frequency Use Obligations: This radio is intended for development/professional use only in legally allocated frequency and

power limits. Any use of radio frequencies and/or power availability of this EVM and its development application(s) must comply with local

laws governing radio spectrum allocation and power limits for this evaluation module. It is the user’s sole responsibility to only operate this

radio in legally acceptable frequency space and within legally mandated power limitations. Any exceptions to this are strictly prohibited and

unauthorized by Texas Instruments unless user has obtained appropriate experimental/development licenses from local regulatory

authorities, which is responsibility of user including its acceptable authorization.

For EVMs annotated as FCC – FEDERAL COMMUNICATIONS COMMISSION Part 15 Compliant

Caution

This device complies with part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) This device may not cause

harmful interference, and (2) this device must accept any interference received, including interference that may cause undesired operation.

Changes or modifications not expressly approved by the party responsible for compliance could void the user's authority to operate the

equipment.

FCC Interference Statement for Class A EVM devices

This equipment has been tested and found to comply with the limits for a Class A digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference when the equipment is operated in a commercial

environment. This equipment generates, uses, and can radiate radio frequency energy and, if not installed and used in accordance with the

instruction manual, may cause harmful interference to radio communications. Operation of this equipment in a residential area is likely to

cause harmful interference in which case the user will be required to correct the interference at his own expense.

Page 4

FCC Interference Statement for Class B EVM devices

This equipment has been tested and found to comply with the limits for a Class B digital device, pursuant to part 15 of the FCC Rules.

These limits are designed to provide reasonable protection against harmful interference in a residential installation. This equipment

generates, uses and can radiate radio frequency energy and, if not installed and used in accordance with the instructions, may cause

harmful interference to radio communications. However, there is no guarantee that interference will not occur in a particular installation. If

this equipment does cause harmful interference to radio or television reception, which can be determined by turning the equipment off and

on, the user is encouraged to try to correct the interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

For EVMs annotated as IC – INDUSTRY CANADA Compliant

This Class A or B digital apparatus complies with Canadian ICES-003.

Changes or modifications not expressly approved by the party responsible for compliance could void the user’s authority to operate the

equipment.

Concerning EVMs including radio transmitters

This device complies with Industry Canada licence-exempt RSS standard(s). Operation is subject to the following two conditions: (1) this

device may not cause interference, and (2) this device must accept any interference, including interference that may cause undesired

operation of the device.

Concerning EVMs including detachable antennas

Under Industry Canada regulations, this radio transmitter may only operate using an antenna of a type and maximum (or lesser) gain

approved for the transmitter by Industry Canada. To reduce potential radio interference to other users, the antenna type and its gain should

be so chosen that the equivalent isotropically radiated power (e.i.r.p.) is not more than that necessary for successful communication.

This radio transmitter has been approved by Industry Canada to operate with the antenna types listed in the user guide with the maximum

permissible gain and required antenna impedance for each antenna type indicated. Antenna types not included in this list, having a gain

greater than the maximum gain indicated for that type, are strictly prohibited for use with this device.

Cet appareil numérique de la classe A ou B est conforme à la norme NMB-003 du Canada.

Les changements ou les modifications pas expressément approuvés par la partie responsable de la conformité ont pu vider l’autorité de

l'utilisateur pour actionner l'équipement.

Concernant les EVMs avec appareils radio

Le présent appareil est conforme aux CNR d'Industrie Canada applicables aux appareils radio exempts de licence. L'exploitation est

autorisée aux deux conditions suivantes : (1) l'appareil ne doit pas produire de brouillage, et (2) l'utilisateur de l'appareil doit accepter tout

brouillage radioélectrique subi, même si le brouillage est susceptible d'en compromettre le fonctionnement.

Concernant les EVMs avec antennes détachables

Conformément à la réglementation d'Industrie Canada, le présent émetteur radio peut fonctionner avec une antenne d'un type et d'un gain

maximal (ou inférieur) approuvé pour l'émetteur par Industrie Canada. Dans le but de réduire les risques de brouillage radioélectrique à

l'intention des autres utilisateurs, il faut choisir le type d'antenne et son gain de sorte que la puissance isotrope rayonnée équivalente

(p.i.r.e.) ne dépasse pas l'intensité nécessaire à l'établissement d'une communication satisfaisante.

Le présent émetteur radio a été approuvé par Industrie Canada pour fonctionner avec les types d'antenne énumérés dans le manuel

d’usage et ayant un gain admissible maximal et l'impédance requise pour chaque type d'antenne. Les types d'antenne non inclus dans

cette liste, ou dont le gain est supérieur au gain maximal indiqué, sont strictement interdits pour l'exploitation de l'émetteur.

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

Page 5

【【Important Notice for Users of this Product in Japan】】

This development kit is NOT certified as Confirming to Technical Regulations of Radio Law of Japan

If you use this product in Japan, you are required by Radio Law of Japan to follow the instructions below with respect to this product:

1. Use this product in a shielded room or any other test facility as defined in the notification #173 issued by Ministry of Internal Affairs and

Communications on March 28, 2006, based on Sub-section 1.1 of Article 6 of the Ministry’s Rule for Enforcement of Radio Law of

Japan,

2. Use this product only after you obtained the license of Test Radio Station as provided in Radio Law of Japan with respect to this

product, or

3. Use of this product only after you obtained the Technical Regulations Conformity Certification as provided in Radio Law of Japan with

respect to this product. Also, please do not transfer this product, unless you give the same notice above to the transferee. Please note

that if you could not follow the instructions above, you will be subject to penalties of Radio Law of Japan.

(address) 24-1, Nishi-Shinjuku 6 chome, Shinjuku-ku, Tokyo, Japan

http://www.tij.co.jp

【ご使用にあたっての注】

本開発キットは技術基準適合証明を受けておりません。

本製品のご使用に際しては、電波法遵守のため、以下のいずれかの措置を取っていただく必要がありますのでご注意ください。

1. 電波法施行規則第6条第1項第1号に基づく平成18年3月28日総務省告示第173号で定められた電波暗室等の試験設備でご使用いただく。

2. 実験局の免許を取得後ご使用いただく。

3. 技術基準適合証明を取得後ご使用いただく。

なお、本製品は、上記の「ご使用にあたっての注意」を譲渡先、移転先に通知しない限り、譲渡、移転できないものとします。

上記を遵守頂けない場合は、電波法の罰則が適用される可能性があることをご留意ください。

日本テキサス・インスツルメンツ株式会社

東京都新宿区西新宿6丁目24番1号

西新宿三井ビル

http://www.tij.co.jp

Texas Instruments Japan Limited

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

SPACER

Page 6

EVALUATION BOARD/KIT/MODULE (EVM)

WARNINGS, RESTRICTIONS AND DISCLAIMERS

For Feasibility Evaluation Only, in Laboratory/Development Environments. Unless otherwise indicated, this EVM is not a finished

electrical equipment and not intended for consumer use. It is intended solely for use for preliminary feasibility evaluation in

laboratory/development environments by technically qualified electronics experts who are familiar with the dangers and application risks

associated with handling electrical mechanical components, systems and subsystems. It should not be used as all or part of a finished end

product.

Your Sole Responsibility and Risk. You acknowledge, represent and agree that:

1. You have unique knowledge concerning Federal, State and local regulatory requirements (including but not limited to Food and Drug

Administration regulations, if applicable) which relate to your products and which relate to your use (and/or that of your employees,

affiliates, contractors or designees) of the EVM for evaluation, testing and other purposes.

2. You have full and exclusive responsibility to assure the safety and compliance of your products with all such laws and other applicable

regulatory requirements, and also to assure the safety of any activities to be conducted by you and/or your employees, affiliates,

contractors or designees, using the EVM. Further, you are responsible to assure that any interfaces (electronic and/or mechanical)

between the EVM and any human body are designed with suitable isolation and means to safely limit accessible leakage currents to

minimize the risk of electrical shock hazard.

3. You will employ reasonable safeguards to ensure that your use of the EVM will not result in any property damage, injury or death, even

if the EVM should fail to perform as described or expected.

4. You will take care of proper disposal and recycling of the EVM’s electronic components and packing materials.

Certain Instructions. It is important to operate this EVM within TI’s recommended specifications and environmental considerations per the

user guidelines. Exceeding the specified EVM ratings (including but not limited to input and output voltage, current, power, and

environmental ranges) may cause property damage, personal injury or death. If there are questions concerning these ratings please contact

a TI field representative prior to connecting interface electronics including input power and intended loads. Any loads applied outside of the

specified output range may result in unintended and/or inaccurate operation and/or possible permanent damage to the EVM and/or

interface electronics. Please consult the EVM User's Guide prior to connecting any load to the EVM output. If there is uncertainty as to the

load specification, please contact a TI field representative. During normal operation, some circuit components may have case temperatures

greater than 60°C as long as the input and output are maintained at a normal ambient operating temperature. These components include

but are not limited to linear regulators, switching transistors, pass transistors, and current sense resistors which can be identified using the

EVM schematic located in the EVM User's Guide. When placing measurement probes near these devices during normal operation, please

be aware that these devices may be very warm to the touch. As with all electronic evaluation tools, only qualified personnel knowledgeable

in electronic measurement and diagnostics normally found in development environments should use these EVMs.

Agreement to Defend, Indemnify and Hold Harmless. You agree to defend, indemnify and hold TI, its licensors and their representatives

harmless from and against any and all claims, damages, losses, expenses, costs and liabilities (collectively, "Claims") arising out of or in

connection with any use of the EVM that is not in accordance with the terms of the agreement. This obligation shall apply whether Claims

arise under law of tort or contract or any other legal theory, and even if the EVM fails to perform as described or expected.

Safety-Critical or Life-Critical Applications. If you intend to evaluate the components for possible use in safety critical applications (such

as life support) where a failure of the TI product would reasonably be expected to cause severe personal injury or death, such as devices

which are classified as FDA Class III or similar classification, then you must specifically notify TI of such intent and enter into a separate

Assurance and Indemnity Agreement.

Mailing Address: Texas Instruments, Post Office Box 655303, Dallas, Texas 75265

Copyright © 2012, Texas Instruments Incorporated

Loading...

Loading...