Texas Furnaces 2ac12030-2, 2ac12036-2 Installation Guide

LG

Installation Instructions & Use and care

MANUAL

LG

website http://www.LG.ca

LG Central Air Conditioning

Remote Condensing Unit

InstallationInstructions

These Instructions Should be carefully read and kept with the production for future reference

Attention Installer:

System installer’s guide

Check list (Page 11.) shall be

completed as per instructions

—2—

CONTENTS

INSTALLATION

SAFETY................................................................................................................................................................2

SHIPPING INSPECTION...............................................................................................................................

.......3

UNIT DIMENSIONS...............................................................................................................................

...............3

MINIMUM CLEARANCES...............................................................................................................................

.....3

INSTALLATION LOCATION...............................................................................................................................

.3

REMOVING EXISTING CONDENSING UNIT......................................................................................................3

REFRIGERANT HANDLING...............................................................................................................................

.4

LINE SET INSTALLATION...................................................................................................................................4

INSTALLATION....................................................................................................................................................5

METERING DEVICES...........................................................................................................................................5

BRAZING CONNECTIONS..................................................................................................................................5

LEAK JESTING....................................................................................................................................................5

EVACUATION.......................................................................................................................................................6

LINE SET REFRIGERANT(CHARGE) ADJUSTMENT AND RELEASE OF CHARGE ......................................7

ELECTRICAL........................................................................................................................................................7

CONDENSING UNIT WIRING DIAGRAM............................................................................................................8

SYSTEM START-UP / FINAL CHARGE ADJUSTMENT.....................................................................................8

FINAL CHARGE ADJUSTMENT..........................................................................................................................9

FOR TXV...............................................................................................................................................................9

FINAL CHECKS..................................................................................................................................................10

USE AND CARE

CARE AND MAINTENANCE..............................................................................................................................10

SYSTEM INSTALLER'S GUIDE - CHECK LIST................................................................................................11

USE AND CARE MANUAL ................................................................................................................................14

LIMITED WARRANTY........................................................................................................................................17

SAFETY

• Understand the following safety terms:

oDanger!- Identifies hazards that will result in personal injury or death.

o Warning! - Identifies hazards that could result in personal injury or death.

o Caution! - Identifies unsafe practices that will result in minor personal Injury, property damage, or

product damage.

• Read all installation instructions thoroughly prior to installing product.

• Warning! Always use disconnect switch to disconnect power to condensing unit prior to

opening control box. Never locate disconnect switch on unit.

• Caution! Follow all local plumbing, electrical, and any other codes that may apply.

• Wear safety glasses and gloves.

• EPA requires all refrigerant to be recovered. Do not blow charge into atmosphere.

• Danger! Do not sniff or inhale refrigerant. Personal injury and death is possible.

—3—

SHIPPING INSPECTION

This product was carefully inspected at the factory and released to the transportation company with no known

damage. Inspect carton for damage to help locate potential areas of damage. Remove carton and inspect entire

unit for damage. If damage is found, report it immediately to the carrier.

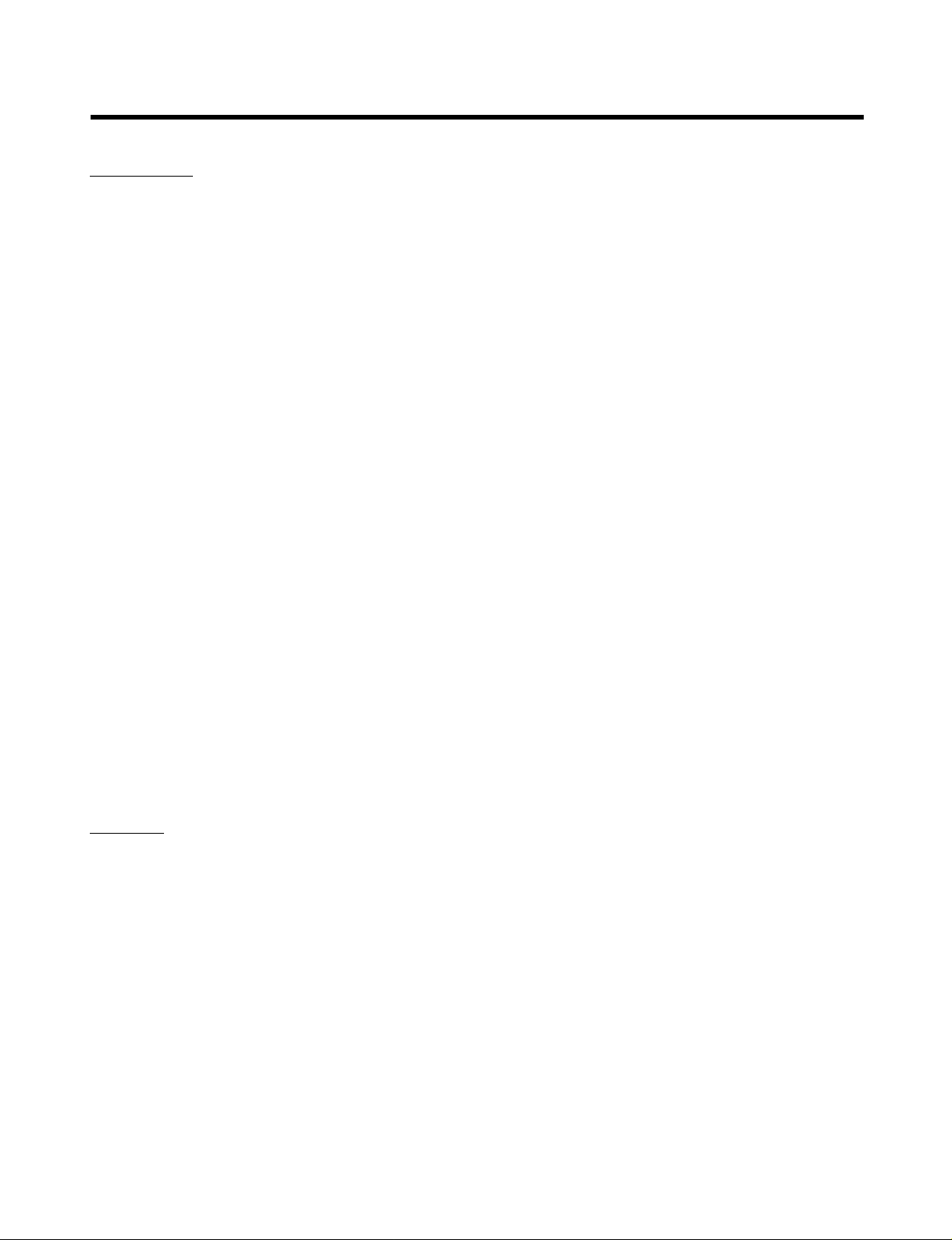

UNIT

DIM

ENSIONS

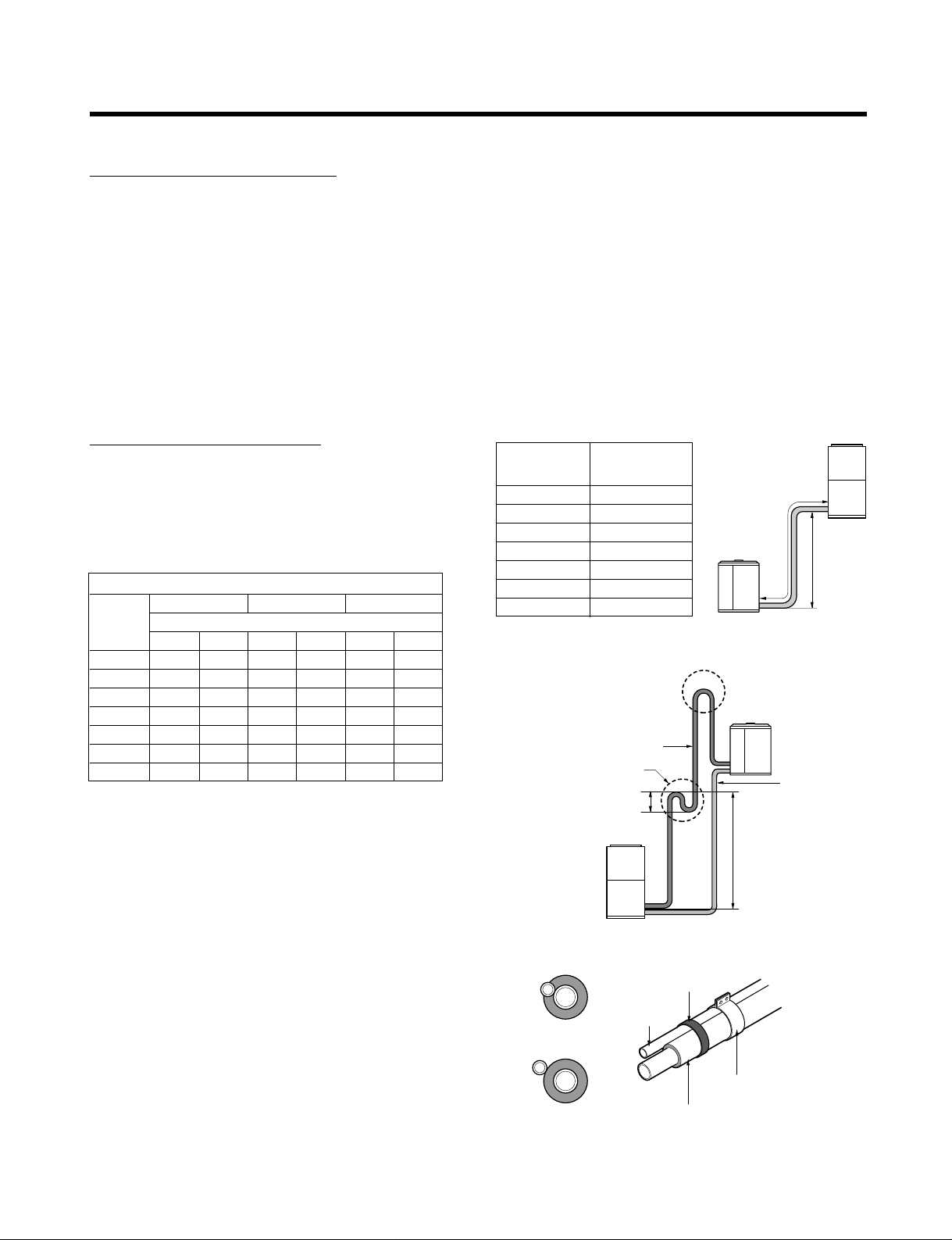

Physical Data, 12 SEER Models

12"

12" 6"

60"

SIDE VIEW

TOP VIEW

Fig. 1

C

BA

A

B

C

1.5 Ton

2421/32

2211/16

2711/16

2.0 Ton

2421/32

2211/16

2711/16

2.5 Ton

2421/32

2211/16

2711/16

3.0 Ton

2421/32

2211/16

2711/16

3.5 Ton

28

27

325/8

4.0 Ton

28

27

325/8

5.0 Ton

-

-

-

Table 1

MINIMUM CLEARANCES (SEE FIGURE 1)

• 30" clearance to service panel

• 6" clearance to one side of the unit.

• 12" clearance to two other sides of unit.

• 24" Clearance between two condensing units.

• 60" clearance above unit.

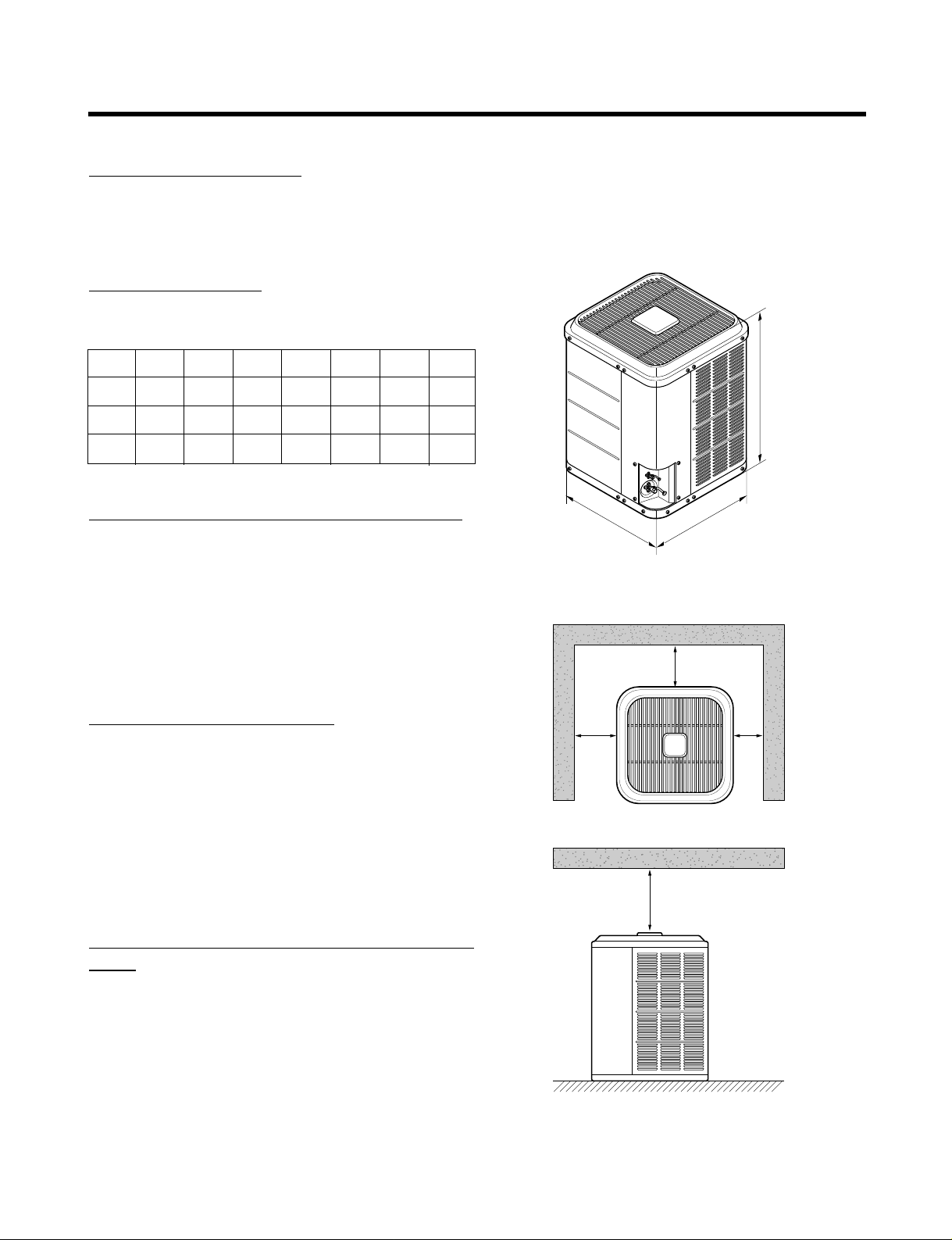

INSTALLATION LOCATION

•Away from windows

• Do not install under gas appliance vent

• At least 36" away from clothes dryer vent

• On a solid, level pad

• Isolated from the building structure (Avoid vibration

transmission)

REMOVING EXISTING CONDENSING

UNIT

• Warning! Electrical shock can cause severe

injury or death. Use disconnect switch to disconnect power to unit.

• Warning! Recover all refrigerant from prior

unit to avoid personal injury or death.

REFRIGERANT LINE LENGTH (ft)

COND 0 - 24 25 - 49 50 - 85

UNIT Line Diameter (in. OD)

(TONS) Suct Liq Suct Liq Suct Liq

1.5 3/4" 3/8" 3/4" 3/8" 3/4" 3/8"

2 3/4" 3/8" 3/4" 3/8" 3/4" 3/8"

2.5 3/4" 3/8" 7/8" 3/8" 7/8" 1/2"

3 3/4" 3/8" 7/8" 3/8" 1-

1/8"1/2

"

3.5 7/8"3/8"1-1/8"3/8"1-1/8"1/2

"

4 7/8"3/8"1-1/8"3/8"1-1/8"1/2

"

5 7/8"3/8"1-1/8"3/8"1-1/8"1/2

"

Table 2

—4—

REFRIGERANT HANDLING

• Warning! Do not sniff or inhale refrigerant. Personal injury or death may occur.

• Warning! Avoid contact with liquid refrigerant. Wear gloves and safety glasses to avoid frost-

bite and blindness.

• Warning! Never apply flame to refrigerant cylinder. Possible explosion resulting in personal

injury or death is possible.

• Warning! Never fill a cylinder more than 80% full of liquid refrigerant.

• Always recover refrigerant. EPA requires all refrigerant to be recovered.

• Warning! Always use EPA certified testing equipment and certified refrigerant tanks. Make

sure tanks have passed a hydrostatic test performed in last 5 years.

Outdoor unit

Max. 50ft

Max. "X"ft

Indoor unit

Outdoor unit

Must be above top of

condenser coil

Gas line

at each 35ft

Oil trap

6"

Indoor unit

Liquid line

Must be above top of

condenser coil

L

INE SET INSTALLATION

• Verify proper diameter sizes for liquid line and vapor

lines.

• Long line sets may require larger diameter vapor line

(See Table 2).

• The maximum line set length is listed in Table 3. Refer

to Figure 2 for dimension measurement.

• The factory oil charge is sufficient for Max. length in

table 3.

• Caution! Same line sets may require longer

than maximum. length listed in table 3, please

contact your wholesaler or/and distributor

before installation.

• Indoor unit may be a maximum of 50 feet above outdoor unit (See Figure 2).

• For every 35 feet that the outdoor unit is above the

indoor unit, an oil trap must be installed (See Figure 3).

• Vapor line must be insulated (See Figure 4).

• Insulate liquid line if ambient temperatures exceed

120˚F

• Liquid and vapor lines must not make metal-to-metal

contact.

• Avoid unnecessary turns.

Fig. 3

Fig. 2

Insulated vapor Line

Liquid Line

Tape

Sheet Metal Hanger

Incorrect

Correct

Fig. 4

COND UNIT LENGTH "X"

(TONS) IN FT MAX.

1.5 75

285

2.5 85

385

3.5 85

485

585

Table 3

—5—

INST

ALL

ATION

• Set unit on pad with electrical control box close to house.

• Bolt to pad if local codes require.

• If installed on rooftop, unit must be securely mounted with vibration isolators to prevent vibration transmission.

METERING DEVICES

For piston (0rifice):

• Indoor piston must be changed to required piston size provided with condensing unit. Piston size is listed on

rating plate.

• Piston is located between liquid line set and indoor coil distributor.

BRAZING CONNECTIONS

I. Ends of the refrigerant lines must be cut square, deburred, and cleaned.

2. Sweep refrigerant lines with Nitrogen or other inert gas.

3. Caution! Wrap service valve with wet rag to avoid overheating (It is recommended, to

removed the valve core prior to brazing).

4. Use a brazing alloy rod with minimum 2% silver.

5. After brazing, quench joint with water or wet rag and re-install vale core.

6. Re-install valve core, if removed.

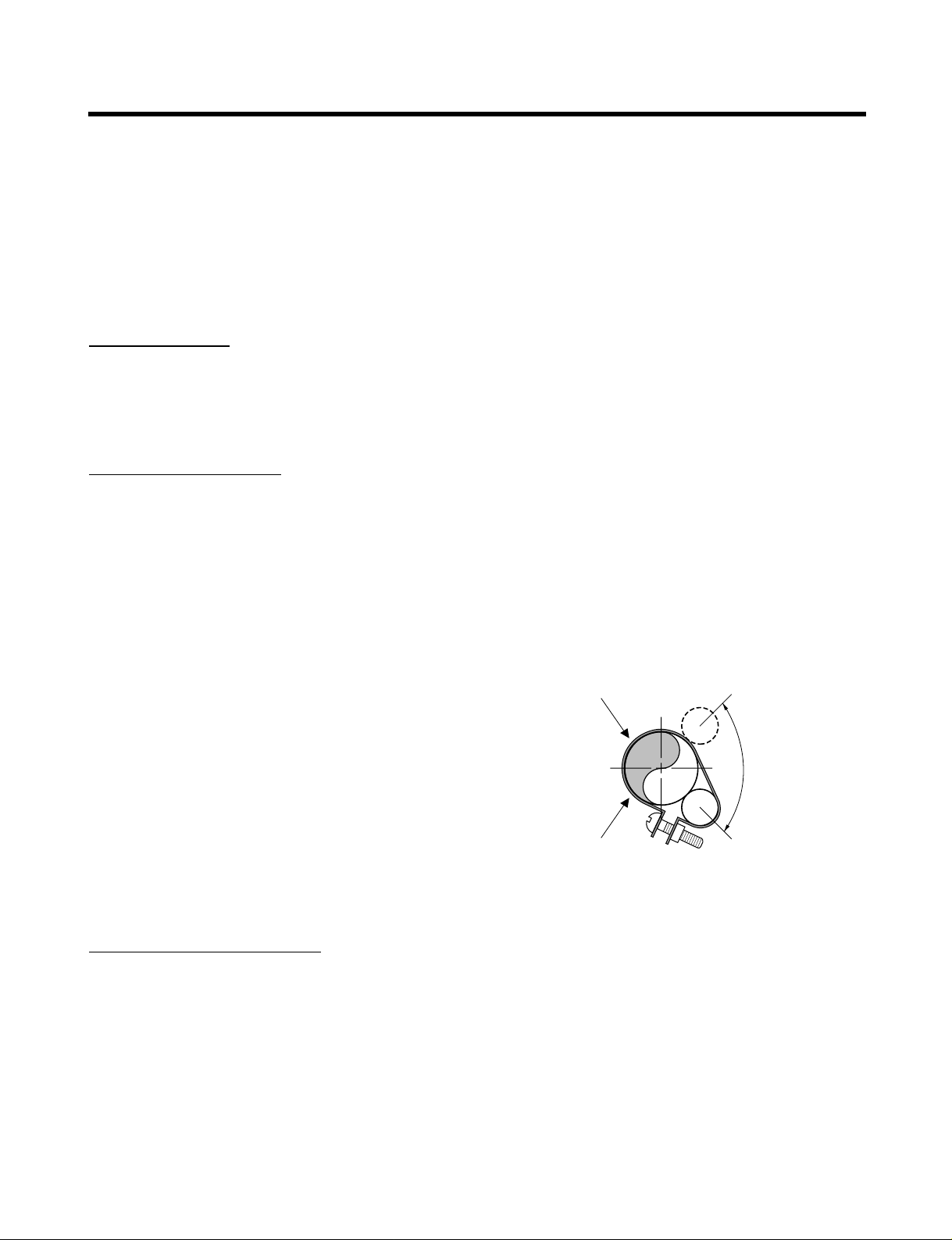

3/4" & smaller

vator line

on smaller lines,

bulb may be mounted

on top

do not mount

bulb on bottom

of line

7/8" & larger

vator line

Bulb

vator

Line

12

39

Fig. 5

For TXV:

• Caution! Remove piston located between liquid line set and indoor coil distributor.

• Screw TXV into distributor assembly.

• Connect pressure equalizer tube w/ flare nut to indoor

coil pressure port.

• Caution! Always make sure the suction line is

cleaned before clamping the bulb in place.

• On lines that are 3/4" O.D. or smaller, the bulb may

be installed on top of the line or side mounted (preferably at the 10 or 2 o'clock position) (See Figure 5).

• On lines that are 7/8" O.D. or larger, the remote bulb

should be installed at 45˚ or at approximately the 4 or

8 o'clock position (See Figure 5).

• Insulate temperature bulb with foam insulation.

• Do not make direct contact with ductwork, floor joists, wall studs, walls, and plumbing.

• Leave slack between building and unit to avoid vibration transmission.

• Seal wall penetration with RTV or other suitable caulk.

• Do not strap line set to joists with wire or strapping in direct contact.

• Liquid line filter drier is factory-installed in unit.