Page 1

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

Instruction manual

Infrared measuring instrument

testo 845

Contents

General information ....................................................26

1. Safety instructions ............................................27

2. Intended purpose ..............................................28

3. Product description ..........................................29

3.1 Display and operating elements ....................................29

3.2 Interfaces ....................................................................30

3.3 Voltage supply ..............................................................30

4. Commissioning ................................................31

5. Operation ..........................................................31

5.1 Connecting probes ......................................................31

5.2 Switching on / off ........................................................32

6. Setting instrument ............................................32

6.1 Instrument configuration ..............................................32

6.2 Measurement configuration ..........................................34

6.3 Degree of emission ......................................................37

6.4 Storing measurement protocols ..................................37

6.5 Printing measurement protocols ..................................38

6.6 Printing current readings ..............................................38

6.7 Reading memory full ....................................................38

7. Programming ....................................................39

7.1 Installing software ............................................................39

7.2 Connecting testo 845 to a PC ............................................39

7.3 Setting up connection ........................................................39

7.4 Opening connection ..........................................................40

7.5 Programming testo 845 ....................................................40

7.6 Disconnecting ....................................................................41

8. Measuring ........................................................42

9. Care and maintenance ......................................45

10. Questions and answers ....................................46

11. Technical data ..................................................47

12. Accessories / spare parts ..................................48

Page 2

26

General information

General information

This chapter provides important information on the use of this documentation.

This documentation contains information which must be observed in order to

ensure safe and efficient application of the product.

Read this document carefully and familiarize yourself with the operation of the

product before putting it to use. Keep this document close to hand in order to

be able to refer to it when necessary.

Symbols

Symbol Meaning Comments

Warning! Read the warning carefully and take the safety measures described!

Serious injury can occur if the safety measures are not taken.

Attention! Read the warning carefully and take the safety measures described!

Information Provides useful tips and information.

±, 1, 2 Handling objective Describes the objective reached by the following handling steps.

Prerequisite Prerequisite must be fulfilled in order for a step to be carried out as

i, 1, 2, ... (Handling) step Carry out handling steps. Observe the order for numbered handling

Text Display text Text appears in instrument display.

Taste

- Result Describes the result of a (handling) step previously carried out.

º Cross reference Reference to further or more detailed information.

Operating key Press key.

Function key Press key.

Light injury or object damage can occur if the safety measures are

not taken.

Observe the order for numbered handling objectives

described

steps!

Page 3

1. Safety instructions

27

1. Safety instructions

This chapter describes general rules which must be observed in order to

ensure safe use of the product.

Avoiding damage and injury

i Do not use the measuring instrument on or close to live components.

i Never store the instrument together with solvents, do not use dessicants.

i Infrared measurement: When measuring live components, observe the

necessary safety distance.

Product safety / Preserving warranty claim

i Use the measuring instrument only within the parameters given in the

Technical Data.

i Use the instrument only for the purpose for which it is intended. Do not use

force.

i Do not subject to electromagnetic radiation (microwaves, induction heating),

static electricity, heat or extreme temperature fluctuations.

i Do not subject handles and wires to temperatures over 70 °C if these are not

expressly approved for higher temperatures. Temperature information on

probes/sensors refers only to the measuring range of the sensors.

i Open the measuring instrument for maintenance or repair purposes only if

this is expressly described in the documentation.

Carry out only maintenance and repair work which is described in the documentation. When doing so, observe the steps prescribed. For safety

reasons, use only original Testo replacement parts.

i Laser radiation! Do not look into the laser beam. Laser class 2.

deenfresitptsvnl????

Correct disposal

i Hand in defective rechargeable batteries / empty batteries to the correct

collecting points.

i Send the product back to Testo if it is no longer to be used. We will dispose

of it ecologically.

Page 4

2. Intended purpose28

2. Intended purpose

This chapter describes the areas of application for which the instrument is

intended.

Use the product only for the areas for which it was designed. In case of doubt

please consult Testo.

The testo 845 is a compact infrared thermometer for the non-contact

measurement of surface temperatures. Using connected probes, additional

measurements can be made with the testo 845.

The product may

· In areas where there is a danger of explosion.

· For diagnostic measurements in medicine.

For reasons of Patent Law, the testo 845 may not be used in Great Britain in

combination with the humidity module.

not

be used in the following areas:

Page 5

3. Product description

29

3. Product description

This chapter provides an overview of the components of the product and their

functions.

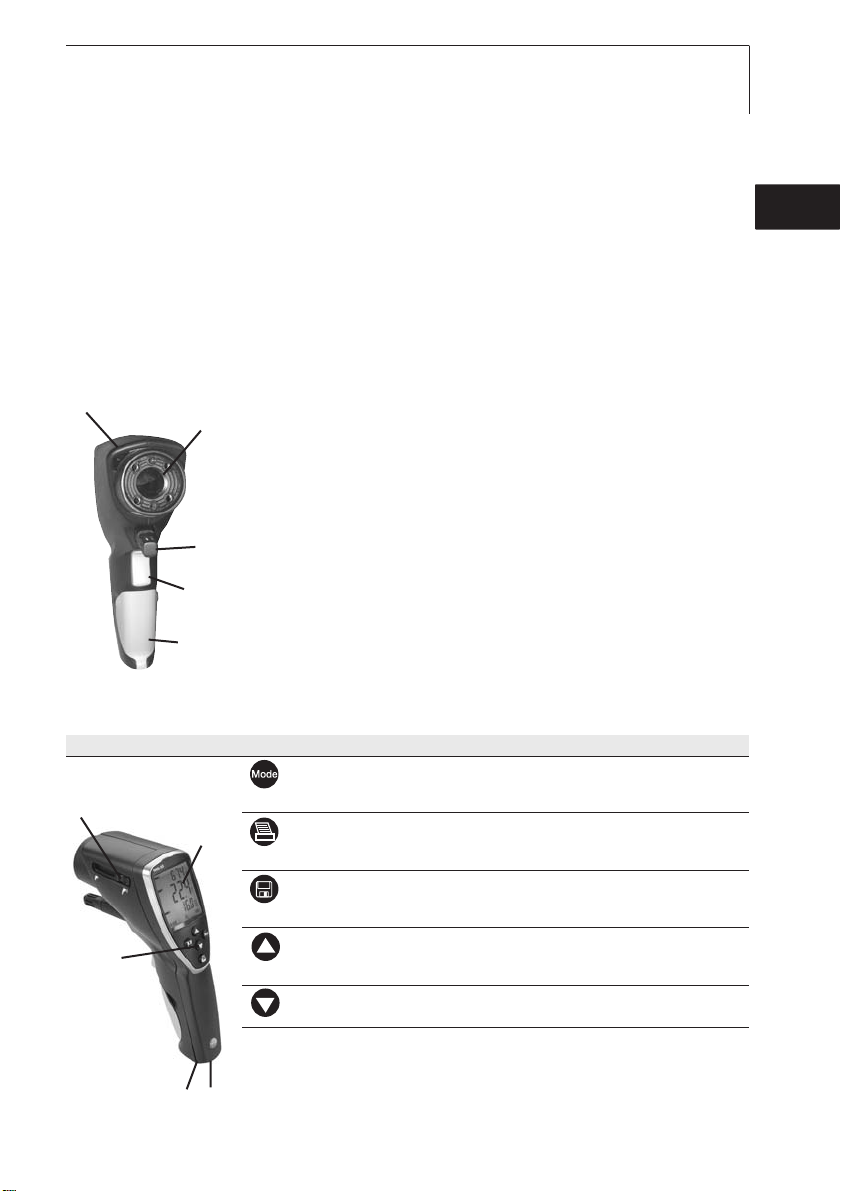

3.1 Display and operating elements

Overview

Button functions

Button Functions

Infrared sensor

Humidity module

(standard with 0563 8451; retrofittable for 0563 8450)

Measurement trigger

Battery compartment

IR diode for printer

Display

Slide switch

Operating buttons

Probe socket

USB interface

Change configuration settings

deenfresitptsvnl????

Printout of values on Testo IR printer

Instrument configuration: activate adjustment

Store a measurement protocol

Measurement and instrument configuration menu: apply values and

jump to next setting menu

Switch between possible display images

Measurement and instrument configuration menu: change setting values

Page 6

3. Product description30

Display

Display Functions

+ °C/°F Temperature reading IR

+ °C/°F Temperature reading contact probe

+ % Ambient humidity value in % relative humidity

+ °C/°F Ambient temperature reading

+ °Ctd Ambient dewpoint

+ °C ∆td Dewpoint distance

3.2 Interfaces

USB interface

The mains unit (accessory) for the voltage supply of the instrument can be

connected via the USB interface on the underside of the instrument.

Measurement / instrument data can be exchanged with a PC via the

USB interface. The measuring instrument is a HighPower instrument, an additional USB-hub may be necessary!

Probe socket(s)

Plug-in thermocouple probes type K can be connected via the probe socket on

the underside of the instrument.

3.3 Voltage supply

The voltage supply is provided by two mignon batteries (included in delivery) or

rechargeable batteries or via a USB mains unit (accessories). Rechargeable

batteries cannot be charged in the instrument.

Page 7

4. Commissioning

31

4. Commissioning

This chapter describes the handling steps necessary for commissioning the

instrument.

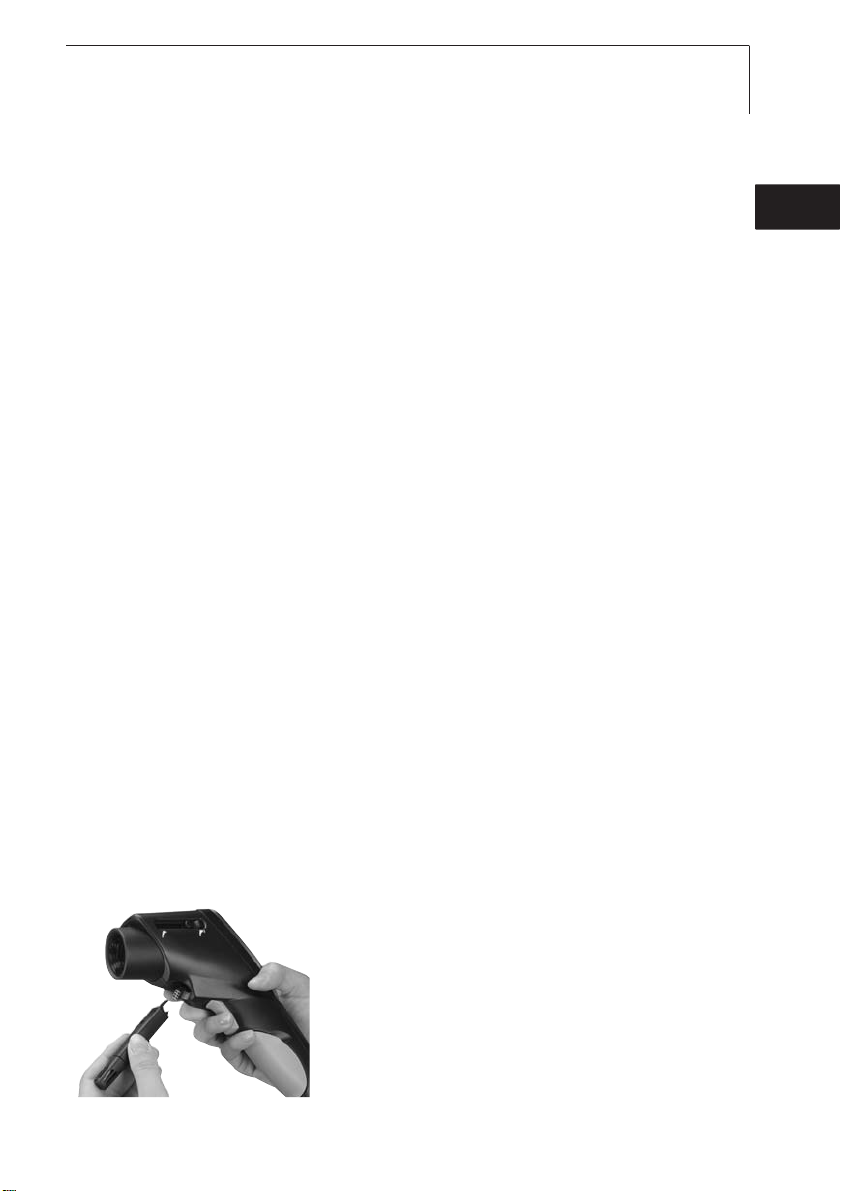

Batteries/rechargeable bbatteries

²

1 Open the battery compartment cover in the handle.

2 Fit batteries / rechargeable batteries (2 x Mignon) into the battery

compartment. Observe polarity!

3 Close the battery compartment cover.

5. Operation

This chapter describes the handling steps which are carried out often when

using the instrument

5.1 Connecting probes

Plug-in probes

Plug-in probes must be connected before switching on the measuring

instrument in order for them to be recognized by the instrument.

i Insert the connection plug of the probe into the probe socket of the

instrument.

Connecting humidity module 0636 9784

Placeholder sensoranbau

i Open the cover carefully using a suitable tool.

i Remove the cover from the connection plug.

i Connect the humidity module to the plug and

push into the housing.

deenfresitptsvnl????

Page 8

5. Operation32

5.2 Switching on / off

Switching iinstrument oon:

²

i Press measurement trigger and hold down

- The measurement display is opened: The current measurement value

and the min. / max. values are displayed

Switching iinstrument ooff:

²

i The instrument switches off automatically after 10 s if no button is

pressed.

6. Setting instrument

This chapter describes the handling steps required to adapt the measuring

instrument for special measurement tasks.

6.1 Instrument configuration

The basic settings for the measuring instrument are carried out in the configuration menu.

The configuration mode can be exited at any time. To do this, press .

Instrument switches to measurement display. Changes already applied

with in the configuration mode are saved.

Opening cconfiguration mmode:

1

The instrument is switched on and is in measurement display.

i Hold down measurement trigger and briefly press : °C is displayed.

- The instrument is now in configuration mode.

Setting ttemperature:

2

The configuration mode is open, °C is displayed.

i Set °C/°F with / °C/°F and confirm with .

The setting is applied with and the instrument jumps to the next function.

º Continue with handling objective SETTING DISPLAY ILLUMINATION.

Page 9

Setting ddisplay iillumination:

3

The configuration menu is open, °C is displayed.

i Go to menu Display illumination On/Off with .

Select the desired option with / and confirm with .

ºContinue with SET CONTINUOUS MEASUREMENT.

.

6. Setting instrument

33

deenfresitptsvnl????

Setting ccontinuous mmeasurement

4

The configuration mode is open, °C is displayed.

i Go to menu Auto on/off with (2x).

(see also Chapter 8. Measuring)

Select the desired option with / and confirm with .

The laser function is not available during continuous measurement.

º Continue with handling objective SETTING LASER.

Setting llaser:

5

The configuration mode is open, °C is displayed.

i Go to menu Laser on/off with (3x).

Select the desired option with / and confirm with .

º Continue with handling objective SETTING DATE.

Setting ddate:

6

The configuration mode is open, °C is displayed.

i Go to menu Setting date with (4x).

Setting day: Select the desired day with / and confirm with .

Setting month: Select the desired month with / and

confirm with

Setting year: Select the desired year with

º Continue with handling objective SETTING TIME.

.

/

and confirm with .

:

Setting ttime:

7

The configuration mode is open, °C is displayed.

i Go to menu Setting time with (7x).

Setting hour: Select the desired hour with / and confirm with .

Setting minute: Select the desired minute with / and confirm

with .

º Continue with handling objective

%RH (only with integrated humidity module)

ADJUSTING HUMIDITY MODULE AT 11.3 AND 75.3

.

Page 10

6. Setting instrument34

Adjusting hhumidity mmodule aat 111.3 aand 775.3 %%rF

8

dity module)

Before checking or calibrating, the probe and the checking and calibrating

set should be stored at a constant temperature range (+20 to +30 °C) for

approx. 12 hours.

To calibrate the humidity module in the test container, carefully pull the

humidity probe out of the testo 845. The test container can be stored

horizontally during calibration.

- The minimum assimilation time for checks with the probe inserted into the

test container is 15 minutes.

- A minimum assimilation time of one hour is recommended for calibration.

- Keep away from all external interference (direct heat radiation, draughts

etc.).

- Observe directions for use “Control and humidity adjustment set) (Order

No. 0973 1820).

The configuration mode is open, °C is displayed.

i Go to menu Adjusting humidity module at 11.3 and 75.3 %RH with .

i Activate adjustment with . The corrected value is displayed for 3 s.

º Continue with handling objective FACTORY SETTINGS.

:

(only with integrated humi-

Factory ssettings:

9

The configuration mode is open, °C is displayed.

i Go to menu Factory settings (reset) with .

The values return to the delivery status. .

Select the desired option with / and confirm with .

Return to main menu.

6.2 Measurement configuration

In the configuration menu, settings for measurement are carried out.

The configuration mode can be exited at any time. To do this, press .

Instrument switches to measurement display. Changes already applied

with in the configuration mode are saved.

Opening cconfiguration mmode:

1

The instrument is switched on and is in measurement display.

i Press drücken.

- The instrument is now in configuration mode.

Page 11

Setting ddegree oof eemission ((ε):

2

The configuration mode is open.

i Set value with / and confirm with .

º Continue with SELECTION OF ALARM VALUE TO BE MONITORED.

6. Setting instrument

35

deenfresitptsvnl????

Selection oof aalarm vvalue tto bbe mmonitored ((

3

The configuration mode is open.

dtd, Ir, rH Surface

):

Select the desired option with / and confirm with .

º Continue with handling objective SETTING UPPER LIMIT VALUE (IR).

or

º Continue with handling objective SETTING LIMIT VALUE ∆TD

or

º Continue with handling objective SETTING LIMIT VALUE RHSI.

Setting uupper llimit vvalue ((Ir):

4

The configuration mode is open.

i Select upper limit value with / and confirm with .

If the upper limit value is exceeded, the max. value is displayed in the top

line (symbol for exceeded upper limit value appears). The IR temperature

is displayed as the main value. The corresponding limit/alarm value is

displayed in the lower line. The alarm symbol appears. If an acoustic alarm

has been selected, it sounds. If the value drops back under the limit value,

the instrument returns to the display previously shown.

º Continue with SETTING LOWER LIMIT VALUE (IR).

Setting llower llimit vvalue ((Ir):

5

The configuration mode is open.

i Select lower limit value with / and confirm with .

If the lower limit value is exceeded, the max. value is displayed in the top

line (symbol for exceeded lower limit value appears). The IR temperature

is displayed as the main value. The corresponding limit/alarm value is

displayed in the lower line. The alarm symbol appears. If an acoustic alarm

has been selected, it sounds. If the value climbs back over the limit value,

the instrument returns to the display previously shown.

º Continue with handling objective AUDIBLE ALARM ON/OFF.

Page 12

6. Setting instrument36

Setting llimit vvalue ((dtd)

6

The configuration mode is open

i Set the limit value with / and confirm with .

(only in combination with the humidity module)

When monitoring dewpoint distance, only one limit value can be selected

If the set limit value is exceeded, the limit value is displayed in the top line.

The current dewpoint distance is displayed as the main value. The min.

value is displayed in the lower line. The alarm symbol flashes. If an

acoustic alarm has been selected, it sounds. If the value climbs back over

the limit value, the instrument returns to the display previously shown.

º Continue with AUDIBLE ALARM ON/OFF.

SSeettttiinngg lliimmiitt vvaalluuee ((

7

The configuration mode is open.

i Select limit value with / and confirm with .

rH Surface

))

(only in combination with humidity module):

For surface moisture, only one limit value can be selected. If the set limit

value is exceeded, the limit value is displayed in the top line. The current

surface moisture is displayed as the main value. The min. value is display

ed in the lower line. The alarm symbol flashes. If an acoustic alarm has

been selected, it sounds. If the value climbs back over the limit value, the

instrument returns to the display previously shown.

º Continue with handling objective AUDIBLE ALARM ON/OFF.

Audible aalarm ((

8

The configuration mode is open.

i Select the desired option with / and confirm with .

º Continue with DELETE MEMORY YES/NO.

BEEP On/OFF

):

:

Delete mmemory yyes/no ((

9

The configuration mode is open.

i Select the desired option with / and confirm with .

dEL On/OFF

):

Return to measurement menu.

ELETE MEMORY deletes the entire contents of the memory.

D

Page 13

6. Setting instrument

37

6.3 Degree of emission

Materials have different degrees of emission, i.e. they produce different quantities of electromagnetic radiation. The degree of emission of the testo 845 is set

at 0.95 ex-works. This is optimal for measurements of non-metals, plastics and

food (paper, ceramics, plaster, wood, paints and lacquers).

Because of their low or inconsistent degrees of emission, bright metals and

metal oxides have only limited suitability for IR measurements.

Apply emission-enhancing coatings such as paint or emission adhesive tape

(Order No. 0554 0051) to the object to be measured. If this is not possible,

measure with a contact thermometer.

Degree of emission table for important materials (typical values)

Material (Temperature) ε

Aluminium, bright rolled (170°C) 0,04

Cotton (20°C) 0,77

Concrete (25°C) 0,93

Ice, smooth (0°C) 0,97

Iron, sanded (20)°C 0,24

Iron with casting skin (100°C) 0,80

Iron with rolling skin (20°C) 0,77

Plaster (20°C) 0,90

Glass (90°C) 0,94

Rubber, hard (23°C) 0,94

Rubber, soft grey (23°C) 0,89

Wood (70°C) 0,94

Cork (20°C) 0,70

Material (Temperature) ε

Cooling element, black anodized (50°C) 0,98

Copper, slightly oxidized (20°C) 0,04

Copper, oxidized (130°C) 0,76

Plastics: PE, PP, PVC (20°C) 0,94

Brass, oxidized (200°C) 0,61

Paper (20°C) 0,97

Porcelain (20°C) 0,92

Black paint, matt (80°C) 0,97

Steel, heat-treated surface (200°C) 0,52

Steel, oxidized (200°C) 0,79

Clay, fired (70°C) 0,91

Transformer lacquer (70°C) 0,94

Bricks, mortar, plaster (20°C) 0,93

deenfresitptsvnl????

6.4 Storing measurement protocols

To store a measurement protocol, the button must be pressed. The instrument can be in measurement or HOLD mode. The main value continues to be

displayed during storage. The current protocol number is displayed in the lower

line. The storage symbol +M is additionally displayed. 90 measurement protocols can be displayed.

Page 14

6. Setting instrument38

6.5 Printing measurement protocols

In this chapter, the printing of measurement protocols is explained

Printing mmeasurement pprotocols:

1

The instrument is in measurement display (Hold mode).

i Hold down and press . Call up memory menu.

Select stored measurement protocol with / and confirm with .

Measurement protocol values are displayed.

View further stored measurement protocols with / .

Start printout with .

Return to memory menu with .

The IR diode is situated on the front of the testo 845. Point the

testo 845 at the printer.

Return to measurement menu with .

The configuration menu can be exited at any time. To do this, press

. Instrument switches to measurement display. Changes already

carried out in the configuration menu are stored.

6.6 Printing current readings

In this chapter, the printing of current readings is explained

Printing ccurrent vvalues:

1

The instrument is in measurement display (Hold mode).

Start printout with .

6.7 Reading memory full

When 90 measurement protocols have been stored, FULL is displayed. Delete

reading memory as required.

Page 15

7. Programmieren

39

7. Programming

This chapter describes the handling steps necessary to create measurement

programmes.

7.1 Installing software

In order to adapt the programming of the testo 845 to your individual needs,

you require a PC in which the software testo ComSoft (included in delivery) and

the USB driver have been installed. You will find the instructions for the installation and operation of the software and the USB driver in the instruction manuals

for testo ComSoft and the USB driver.

i After successfully installing the software, connect

7.2 Connecting testo 845 to a PC

i Connect the USB connection cable to your PC.

i Connect the USB connection cable to the testo 845.

i Start the software testo ComSoft.

7.3 Setting up connection

testo 8845 tto tthe PPC

.

deenfresitptsvnl????

i Start software

i Select the function

The window

The connection to the testo 845 found is set up automatically and the

name of the connection appears in

or

i Select the function

The window

i Select

i Enter the name of the connection and click on

testo 845

testo CComSoft

Autodetect

Autodetect

New device

New device setup wizard

in the instrument choice and click on

.

in the menu bar

opens.

in the menu bar

Archive

opens.

.

Instrument

Instrument

Next

Next

.

.

.

.

Page 16

7. Programming40

7.4 Opening connection

i Double-click on the connection to be opened in the window

Archive.

If a measurement protocol has been stored in the testo 845, the protocol

symbol and the short title of the protocol appear under the opened connection.

Using oone cconnection ffor sseveral ttesto 8845

You can connect different testo 845 via one connection. When the testo

845 is changed, the connection must be broken and then re-made for the

new testo 845, otherwise the software will not be able to identify it.

7.5 Programming testo 845

Programming deletes all values stored in testo 845.

i Read any existing data out of the testo 845 before programming (see

instruction manual for the software testo ComSoft).

i Select the function

This function is only active when the name of the connection is marked in

colour. If this is not the case:

i First click on the name of the connection and then

control

- The window for programming the testo 845 opens.

.

device control

in the menu bar

Instrument

Instrument> device

.

7.5.1 Programming testo 845

Instrument

Date and time:

The set date and time of the testo 845 are displayed.

i To synchronize the date and time with the clock in your PC, select

synchronize

Options

i Set degree of emission. Mark displayed value and alter.

i Set unit °C/°F.

.

Page 17

7. Programming

Activate/deactivate laser, continuous measurement and illumination.

i

i Enter headers for printer.

Measurement configuration

Limit values (Factory setting)

Infrared Dew point distance Surface moisture

upper limit value 950.0 - -20.0

lower limit value 10.0 -40.0 -

41

deenfresitptsvnl????

i Activate/deactivate

Reset

i Activate/deactivate

- Delete memory.

Memory contents are deleted.

- Factory settings

Instrument settings are returned to factory settings

Humidity module adjustment

i Press

i To adjust press the buttons 11.3% and 75.3%.

Adjustment humidity module

The window

Close window

Audible alarm

Allow store deletion

Dialog

opens.

button.

7.5.2 Ending programming

i Click on

Apply

to apply the programming carried out to testo 845.

7.6 Disconnecting

i In the window

with the right-hand mouse key.

i Select

The connection to testo 845 is disconnected.

Close

Archive

.

, click on the connection you want to disconnect

Page 18

8. Measuring42

8. Measuring

This chapter describes the handling steps required to carry out measurements

with the product.

Measurement ppoint, ddistance

Depending on the distance between the measuring instrument and the object

to be measured, a certain measurement point is recorded.

Measurement optics (Ratio distance : measuring point)

Close ffocus mmeasurement

Set close focus measurement in the instrument.

The symbol is shown in the display

Ø 543 mm

Ø 263 mm

Ø 151 mm

Laser

Ø 20mm

Ø1 mm

Far ffield mmeasurement

Set far field measurement in the instrument.

The symbol is shown in the display.

Ø 279 mm

Ø 130mm

2000 mm

10000 mm

1000 mm

Ø 40 mm

5000 mm

600 mm

Ø 16mm

1200 mm

2000 mm

70 mm

Ø 20 mm

Page 19

8. Measuring

Carrying oout mmeasurements:

²

Scrolling through the measurement menus is possible with the measure-

ment trigger pressed down as well as in the Hold mode.

Hold mmode

In the hold mode the last recorded measurement readings are frozen

.

Continuous mmeasurement sswitched ooff

The instrument measures as long as the measurement trigger is pressed. The

instrument goes into Hold mode when the measurement trigger is released.

The Hold mode is exited as soon as the measurement trigger is pressed again.

The max. and min. values are reset.

Continuous mmeasurement sswitched oon

The measuring instrument measures without the use of the measurement trigger. The Hold mode is activated by pressing the measurement trigger. The

instrument continues to measure as soon as the measurement trigger is pressed again. The max. and min. values are reset.

43

deenfresitptsvnl????

IR mmeasurement (( )

1

The instrument is switched on and is in measurement display. Max and

Min are activated.

IR measurement is an optical measurement.

Keep the lens clean.

Do not measure if the lens is fogged.

IR mmeasurement aand TTC pprobes (( / ))

2

Measurement menu only active when TC probe is plugged in.

Select the desired option with / .

² Setting degree of emission

Instrument is in Hold mode.

.

Set degree of emission with and / .

During setting, must be held down.

The IR temperature value is updated with every alteration of the

emission value. The degree of emission of surfaces can thus

be determined.

Page 20

8. Measuring44

Observe minimum penetration depth for immersion / penetration probes:

10 x probe diameter

Avoid applications in aggressive acids or alkalis.

Do not make measurements on sharp edges with cross-band surface probes.

Display:

1. Max. value, 2. IR temperature, 3. Min. value

IR mmeasurement aand hhumidity mmodule (( / ))

3

Measurement menu only active when humidity probe is plugged in.

Select the desired display mode with / .

Display:1. Humidity, 2. IR-Temperature, 3. Dewpoint

Temperature aand hhumidity mmodule (( ))

4

Measurement menu only active when humidity probe is plugged in.

Select the desired display mode with / .

Display:1. Humidity, 2. IR-Temperature, 3. Dewpoint

Dewpoint ddistance (( )

5

Measurement menu only active when humidity probe is plugged in.

Display of dewpoint distance incl. max. and min. values.

Select the desired display mode with / .

Display:1. Max. value, 2. Dewpoint distance, 3. Min. value

Surface mmoisture

6

Walls and ceilings in danger of mould can be localized based on the surface

moisture. The surface moisture is measured from 0 to 1.0 (0 = dry, 1 = very

damp). According to DIN EN ISO 13788, the danger of mould on surfaces

exists if the moisture level rises above 0.8 over several days. The testo 845

calculates the surface moisture from the surface temperature (IR) and the

dewpoint of the air.

Measurement menu only active when humidity probe is plugged in.

Display of surface moisture incl. max. and min. values.

Select the desired display mode with / .

Display:1. Max value, 2. Calculated surface moisture, 3. Min. value

Page 21

9. Care and maintenance

45

9. Care and maintenance

This chapter describes the handling steps which contribute to maintaining the

functionality of the product and to extending its useful life.

Cleaning tthe hhousing:

±

i If dirty, clean the housing with a damp cloth (soap solution). Do not use

any aggressive cleaning products or solvents!

Changing bbattery // rrechargeable bbattery:

±

The instrument is switched off.

1 Open the battery compartment in the handle.

2 Remove empty batteries / rechargeable

batteries

Pull the battery removal strip

or

push on the upper part of the battery with

your finger. The battery is released.

3 Remove batteries and replace with new

batteries. Observe polarity!

4 ReClose battery compartment.

deenfresitptsvnl????

Page 22

10. Questions and answers46

10. Questions and answers

Question Possible causes Possible solution

is lit. - Battery empty. Change battery.

Intrument cannot be - Battery empty. Change battery.

switched on.

Lasers light up briefly - Battery empty. Change battery.

after switching on,

then go out.

Measurement value - Measurement value outside -

- - - - lights up. measuring range.

Display FULL appears - Measurement protocol Delete memory

Err EE or Err HSEE Send instrument to Testo Customer Services

appears

If we were not able to answer your question, please contact your dealer or Testo

Customer Service.

memory full

Page 23

11. Technical data

47

11. Technical data

Description testo 845

Measurement parameter Temperature (°C / °F)

Measurement value recorder Infrared sensor

Measuring range • IR °C -35°C to +950°C

• Humidity module 0 to 100%RH

0 to +50°C

-20 to +50°C td

• Contact °C -35 to +950 °C

Resolution 0.1°C (°C measurement parameters)

0.1%RH (humidity)

0.1°C td (dewpoint)

Accuracy IR (at 23°C) +/- 1 digit +/- 2.5°C (-35 to -20.1°C)

+/-1.5°C (-20 to +19.9°C)

+/-0.75°C (+20.0 to +99.9°C)

+/-0.75% of m.v.(+100 to +950°C)

Accuracy °C contact (Type K) +/- 1 digit +/- 0.75°C (-35 to +75°C)

+/-1 % of m.v. (+75.1 to +950°C)

Accuracy humidity module +/- 1 digit +/- 2% RH (2 to 98% RH)

+/-0.5 °C (+10 to +40°C)

+/-1.0 °C (remaining range)

Emission factor adjustable 0.1 to 1.0

Wavelength 8 to14 µm

Switchable distance ratio Far field: 75:1 (16mm, distance 1200mm)

Close focus: 1mm, distance 70mm

Probe integrated infrared

Measurement rate t95: 150 ms

Scanning max./min./Alarm: 100 ms

Application temperature -20°C to +50°C

Storage temperature -40°C to +70°C

Battery type 2 x AA AlMn

Battery life 25 h (without laser)

10 h (with laser without backlight)

5 h (with laser and 50% backlight)

Battery exchange by user

Housing ABS (black, grey), metal cover

Display three-line with backlight

Dimensions testo 845 in mm (LBH) 155 x 58 x 195

Dimensions case in mm (LBH) 405 x 340 x 93

Weight testo 845 without humidity module 455 g

Weight testo 845 with humidity module 465 g

Weight instrument and case 2700 g

EU guideline 89/336/EWG

Sensitivity IR measurement: ± 2°C (± 3.6°F) for 640 MHz to 680 MHz in 2.5 V/m field.

(+20.0...+99,9°C)

Interference: trade-typical limit according to EN 61326-1

deenfresitptsvnl????

Page 24

12. Accessories / spare parts48

12. Accessories / spare parts

This chapter describes important accessories and spare parts for the

instrument

Description Order no.

Retrofittable humidity module 0636 9784

Surface probe with sprung TC band, short-term up to +500 °C,TC Type K 0602 0393

Surface probe with sprung TC band, short-term up to +500 °C,TC Type K, angled 0602 0993

Waterproof surface probe, TC Type K 0602 0693

Robust air probe, TC Type K 0602 1793

Testo report printer with wireless IRDA and infrared interface 0554 0547

Spare thermal paper for printer (6 rolls) 0554 0569

Spare thermal paper for printer (6 rolls), long-term legible (10 years) 0554 0568

External charger incl. 4 Ni.MH rechargeable batteries 300 mA, 50/60 Hz, 12 VA/instrument 0554 0610

Mains unit, 5 VDC/500 mA 0554 0447

Control and humidity adjustment set 11.3 %RH / 75.3 %RH 0554 0660

Adhesive tape for polished surfaces, ε=0.93, heat-proof up to +300 °C 0554 0051

Silicone heat-conducting paste (14g) Tmax = +260 °C 0554 0004

ISO calibration certificate, calibration points +60 °C, +120 °C, +180 °C 0520 0002

ISO calibration certificate, calibration points -18 °C, 0 °C, +60 °C 0520 0401

Page 25

Test Equipment Depot - 800.517.8431

99 Washington Street, Melrose, MA 02176

TestEquipmentDepot.com

0977.8450/03/T/wh/30.05.2006

Loading...

Loading...