Page 1

99 Washington Street

Melrose, MA 02176

Phone 781-665-1400

Toll Free 1-800-517-8431

Visit us at www.TestEquipmentDepot.com

testo 330i · Flue gas measuring instrument

testo 330i LX · Flue gas measuring instrument

Instruction manual

Page 2

2

Page 3

1 Contents

1 Contents

1 Contents ................................................................................................... 3

2 Safety and the environment .................................................................... 6

3 Use ............................................................................................................ 6

4 Product description ................................................................................. 8

4.1. Measuring instrument ...................................................................... 8

4.1.1. Overview .......................................................................................................... 8

Terminal panel left/right ................................................................................... 9

4.1.2.

4.2. Modular flue gas probe .................................................................. 10

5 First steps .............................................................................................. 11

5.1. Commissioning .............................................................................. 11

5.2. Getting to know the product ........................................................... 11

5.2.1. Connecting probes ......................................................................................... 11

Mains unit/rechargeable battery ..................................................................... 11

5.2.2.

5.2.3.

Switching on and connecting with a mobile terminal device ........................... 12

Switching off .................................................................................................. 13

5.2.4.

Using the App ................................................................................................ 13

5.2.5.

6 Using the product .................................................................................. 15

6.1. Performing settings ........................................................................ 15

6.1.1. Configuring measurements..................................................................... 15

6.1.2.

Graphics ........................................................................................................ 16

6.1.3. | Instrument setting

6.1.4. | Instrument settings | C

6.1.5. | Instrument settings | Sen

6.1.6. | Instrument settings | Sens

6.1.7. | Instrument settings | O

6.1.8. | Instrument settings | O

6.1.9. | Instrument settings | He

6.1.10. | Instrument settings | Switching t

Charging the rechargeable battery .................................................. 11

5.2.2.1.

Mains operation ............................................................................... 12

5.2.2.2.

s | Language ............................................................ 16

ountry version ................................................... 17

sor diagnosis ................................................ 17

or protection ................................................ 17

reference ........................................................ 17

2

addition .......................................................... 17

2

ight compensation .......................................... 17

he testo 330i off ................................. 18

3

Page 4

1 Contents

6.2.

Measuring ..................................................................................... 18

6.2.1. Preparing for measurement ........................................................................... 18

6.2.2. | Flue gas ................................................................................................ 22

6.2.3. |

6.2.4. |

6.2.5. | Smoke number

6.2.6. | Differential pres

6.2.7. | Differential t

6.2.8. | O

6.2.9. | Gas flow rate

6.2.10. | Oil flow rate

Checking the condensate container fill level .................................... 18

6.2.1.1.

Checking the particle filter ............................................................... 18

6.2.1.2.

Zeroing phases ................................................................................ 18

6.2.1.3.

Performing a gas path check ........................................................... 19

6.2.1.4.

Installing the probe mount testofix® ................................................ 19

6.2.1.5.

6.2.1.6.

Using the modular flue gas probe .................................................... 21

Draught ................................................................................................. 23

COundiluted ..........................................................................................

...................................................................................... 23

sure .............................................................................. 23

emp. ................................................................................... 24

supply air .......................................................................................... 24

2

......................................................................................... 24

........................................................................................... 25

23

6.3. Printing readings ........................................................................... 25

6.4. Report ........................................................................................... 26

6.4.1. Add to protocol (save measurement) ............................................................. 26

Finish protocol ............................................................................................... 26

6.4.2.

7 Maintaining the product ....................................................................... 28

7.1. Checking instrument status ........................................................... 28

7.1.1. | Instrument settings | Sensor diagnosis ................................................ 28

7.1.2. | Error list ............................................................................................... 28

7.2. Cleaning the measuring instrument .............................................. 28

7.3. Draining the condensate container ............................................... 28

7.4. Opening the measuring instrument ............................................... 29

7.5. Replacing the rechargeable battery .............................................. 33

7.6. Replacing sensors ........................................................................ 33

7.7. Cleaning the modular flue gas probe ............................................ 34

7.8. Replacing the probe module ......................................................... 35

7.9. Checking/replacing the particle filter ............................................. 35

7.10. Changing the thermocouple .......................................................... 36

7.11. Updating the instrument software ................................................. 37

4

Page 5

1 Contents

8 Technical data ........................................................................................ 38

8.1.1. Examinations and licenses ............................................................................ 38

8.1.2. Bluetooth® module ......................................................................................... 38

8.1.3. Measuring ranges and resolution ................................................................... 41

8.1.4. Accuracy and response time .......................................................................... 42

8.1.5. Other instrument data .................................................................................... 43

8.1.6. Declaration of conformity ............................................................................... 44

9 Tips and assistance ............................................................................... 45

9.1. Questions and answers ................................................................. 45

9.2. Contackt and Support .................................................................... 47

9.3. Accessories and spare parts ......................................................... 47

5

Page 6

3 Use

2 Safety and the environment

Please note the information in the document Commissioning and

Safety (printed version supplied with the product). Make sure that

all product users read and observe the safety information!

3 Use

testo 330i und testo 330i LX

The testo 330i / testo 330i LX is a flue gas measuring instrument

which in combination with a separate Android or iOS mobile device

and the testo 330i App enables professional flue gas analysis of

combustion systems:

• Small combustion systems (oil, gas, wood, coal)

• Low-temperature and condensing boilers

• Gas water heaters

These systems can be adjusted using the instrument and checked

for compliance with the applicable limit values.

The instrument has been verified as a short-term measuring

instrument and should not be used as a safety (alarm) instrument.

The following tasks can also be carried out using the instrument:

• Regulating the O

, CO and CO2, NO, NOx values in furnaces for

2

the purpose of ensuring optimal operation.

• Draught measurement.

• Measuring and regulating the gas flow pressure in gas water

heaters.

• Measuring and optimising the flow and return temperatures of

heating systems.

• Ambient measurement - CO and CO

• Detection of CH

(methane) and C3H8 (propane).

4

.

2

• The instrument can be used for measurements on combined

heat and power stations (CHP) in accordance with the

first German Federal Immission Control Ordinance (BImSchV).

• In principal, the CO sensor can also be used for

measurements on CHP stations. If you should carry out

more than 50 measurements on CHP stations per year,

please contact your nearest Testo service centre or send

the testo 330i to testo Service for inspection.

A worn NO

filter of the CO sensor can be ordered as a

x

spare part (item no. 0554 4150) and replaced.

6

Page 7

3 Use

Testo guarantees the functionality of its products when

used in accordance with their intended purpose. This

guarantee does not apply to features of Testo products in

combination with unauthorised third-party products.

Competitor products are not authorised by Testo.

As is common practice, Testo generally excludes support,

warranty or guarantee claims relating to functionality that

has not been guaranteed by Testo as part of the product

offered. Claims shall also be excluded in the event of

improper use or handling of the products, e.g. in

combination with unauthorised third-party products.

The use of the wireless module is subject to the regulations and

stipulations of the respective country of use, and the module may only

be used in countries for which a country certification has been granted.

The user and every owner has the obligation to adhere to these

regulations and prerequisites for use, and acknowledges that the resale, export, import etc. in particular in countries without wi r eless

permits, is his responsibility.

7

Page 8

4 Product description

4 Product description

4.1. Measuring instrument

4.1.1. Overview

1 Retaining bracket: for attaching to the probe mount testofix®

2 Terminal panel left

3 Status LEDs:

LED Display Meaning

Blue Off Instrument off or not ready

Red

Flashes (0.05 s

on/0.5 s off)

Flashes (0.5 s

on/0.5 s off)

Light is constant

Flashes (0.05 s

on/0.5 s off)

Flashes (0.5 s

on/0.5 s off)

Light is constant

Instrument on, start up phase

Instrument on, Bluetooth® Find

Device activated

Instrument on, Bluetooth

connection activated

Device error

Mains unit plugged in, battery

charging

Mains unit plugged in, battery

fully charged

®

4 ON/OFF button

5 Condensate container, condensate outlet plug

6 Terminal panel right

8

Page 9

7. Magnetic holder (on rear)

WARNING

Magnetic field

May be harmful to those with pacemakers.

> Keep a minimum distance of 15 cm between pacemaker and

instrument.

ATTENTION

Magnetic field

Damage to other devices!

> Keep a safe distance away from products that could be

damaged by the effects of magnetism (e.g. monitors,

4.1.2. Terminal panel left/right

computers or credit cards).

4 Product description

1 USB interface

2 Minus connection for differential pressure measurement

3 Mains unit socket

4 Flue gas socket

5 Probe socket

9

Page 10

4 Product description

4.2. Modular flue gas probe

1 Removable filter chamber with window and particle filter

2 Probe module lock release

3 Probe module

4 Connector plug for measuring instrument

5 Probe handle

6 Connecting cable

10

Page 11

5 First steps

5.1. Commissioning

Please note the information in the document Commissioning and

5.2. Getting to know the product

5.2.1. Connecting probes

Safety (printed version supplied with the product).

Always connect the probes to the flue gas socket or probe

socket before switching on the measuring instrument;

switch the measuring instrument off and restart after

replacing a probe.

Connecting flue gas probes/gas pressure

adapters/temperature adapters

> Insert the connector plug into the flue gas socket and lock by

slightly turning it clockwise (bayonet lock).

There must be no more than one extension lead (0554

1201) between measuring instrument and flue gas probe.

5 First steps

Connecting other probes

> Insert the connector plug of the probe into the probe socket.

5.2.2. Mains unit/rechargeable battery

If the mains unit is connected, the measuring instrument is

5.2.2.1. Charging the rechargeable battery

11

automatically powered from the unit.

The rechargeable battery can only be charged at an ambient

temperature of 0 to 35 °C. If the rechargeable battery pack has

discharged completely, the charging time at room temperature is

approx. 5-6 hrs.

1. Connect the instrument plug of the mains unit to the mains unit

socket on the measuring instrument.

Page 12

5 First steps

2. Plug the mains plug of the mains unit into a mains socket.

- The charging process starts (red LED flashes: 0.5 s on/0.5 s

off).

- The charging process stops automatically when the batter y is

charged (red LED is constant).

Rechargeable battery care

• Do not fully exhaust rechargeable batteries.

• Store rechargeable batteries only if charged and at low

temperatures, but not below 0 °C. The best storage conditions

are with a charge level of 30-70% and an ambient temperature

of 0-15 °C. Fully charge before using again.

• Optimal charging temperature at 20 °C ambient temperature.

• Trickle charging should not exceed 2 days.

5.2.2.2. Mains operation

1. Connect the instrument plug of the mains unit to the mains unit

socket on the measuring instrument.

2. Plug the mains plug of the mains unit into a mains socket.

- The measuring instrument is powered via the mains unit.

- If the measuring instrument is switched off and a rechargeable

battery is inserted, the charging process will start automatically.

Switching the measuring instrument on has the effect of

stopping the battery charging and the measuring instrument is

then powered via the mains unit.

5.2.3. Switching on and connecting with a mobile terminal

device

✓ The testo 330i App must be installed on your mobile terminal

device. Please note the information in the document

Commissioning and Safety (printed version supplied with the

product).

1. Switch on the measuring instrument: Press the key.

- Measuring instrument starts up: The blue LED flashes

(0.05 s on/0.5 s off).

- Connecting mode is activated: The blue LED flashes

(0.5 s on/0.5 s off).

2. Switch on the mobile terminal device.

12

Page 13

3. Start up the testo 330i App on your mobile terminal device.

- The Find device function is activated: Any compatible devices

within radio range are displayed (product name + last 4 digits of

the device serial number).

> Tap instrument designation to select an instrument.

- It may take around 30 s to establish the connection.

- A Bluetooth

constant.

If it is not poss

measures are displayed. If you are unable to implement these

successfully, please refer to the section Tips and assistance and/or

contact your dealer or Testo Customer Service.

- Measurement type Flue Gas screen is displayed.

®

ible to establish a connection, various corrective

5.2.4. Switching off

Measuring va

the measuring instrument is switched off.

> Switch off the measuring instrument: Press the key.

- This may happen: the pump starts and the sensors are rinsed

until the switch-off thresholds (O2 > 20%, other measurement

parameters < 50 ppm) are reached. The maximum rinsing

period is 3 minutes.

- The measuring instrument switches off.

5 First steps

connection is established: The blue LED is

lues that have not been saved are lost when

5.2.5. Using the App

Make sure you are familiar with how your mobile terminal device

works before using the App; observe the documentation for your

mobile terminal device.

Actions are mainly carried out by touching an icon, a symbol, or a

name.

13

Page 14

5 First steps

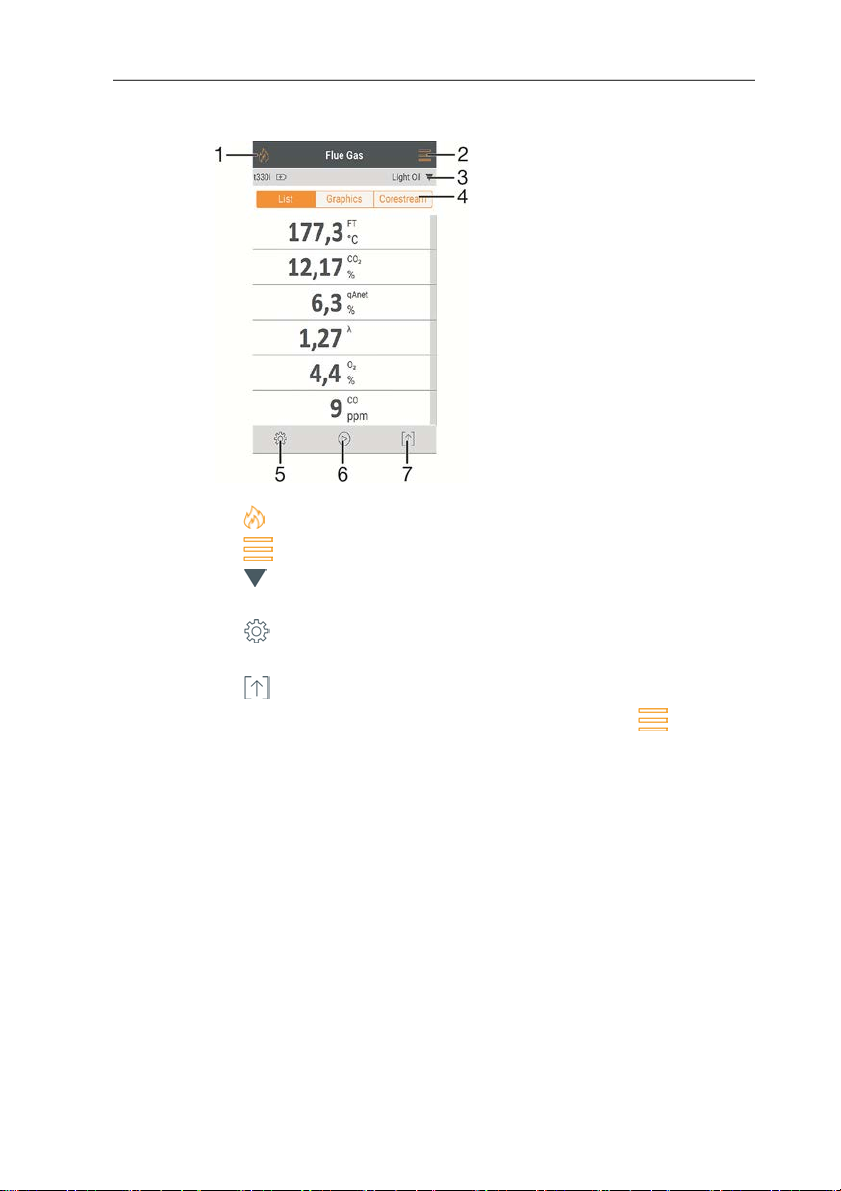

User interface

1 : Open the Measurement Types selection list

2 : Open/close the Menu selection list

3 : Open the Fuels selection list

4 Select reading display type

5 : Open the Options selection list

6 Start/stop measurement

7 : Open the Protocols selection list

Please also take note of the tutorial in the App under | Help |

Tutorial.

14

Page 15

6 Using the product

6.1. Performing settings

6.1.1. Configuring measurements

The measurement parameters/units and the number and order of

displayed measurement parameters in the reading display type can

be set in the List.

Only those parameters and units that are enabled in the reading

display appear in the measured value display, in the saved

measurement records and on the record printouts.

The settings only apply to the measurement type currently

activated.

Overview of measurement parameters (available selection depends

on the chosen measurement type, set fuel, and the sensors

available in the measuring instrument):

Display Measurement parameter

FT

AT

Itemp

Pump

O2

CO2

qAnet Flue gas loss without due consideration of the

Effn Efficiency without consideration of the heat value

qAgr. Flue gas loss with due consideration of the

Effg Efficiency with due consideration of the calorific

Draught

∆P

CO

uCO

NO

Flue gas temperature

Combustion air temperature

Instrument temperature

Pumping capacity

Oxygen

Carbon dioxide

calorific value range

range

calorific value range

value range

Flue draught

Differential pressure

Carbon monoxide

Carbon monoxide undiluted

Nitrogen monoxide

6 Using the product

15

Page 16

6 Using the product

Display Measurement parameter

NOx

λ

AmbCO

O2ref

Dew Pt

Performing actions

> To add a measurement parameter to the display list: Touch

Add to open the selection list of measurement parameters.

> To delete a measurement parameter from the display list:

Touch .

> Change the unit of a measurement parameter: Touch the

measurement parameter name to open the selection list of

measurement units.

> To change the position of a measurement parameter in the

display list: press down and drag.

> To accept changes: Touch Confirm.

6.1.2. Graphics

In the graphics reading display type, the reading progress can be

displayed as a line diagram.

A maximum of 4 measurement parameters can be set at any one

time. Only those measurement parameters/units can be displayed

that are available in the reading display type List.

> Touch to open the selection list of measurement

parameters/units.

The first four measurement parameters from the List reading display

type are used as the default setting for the graphics too.

Nitrogen oxide

Fuel-air ratio

Ambient carbon monoxide

Oxygen reference

Flue gas dewpoint temperature

6.1.3. | Instrument settings | Language

The user interface language can be set.

The number of available languages depends on the activated

country version.

16

Page 17

6 Using the product

6.1.4. | Instrument settings | Country version

The Country version configuration affects the measurement

parameters, fuels, fuel parameters, and the basis of and formulas

for calculations activated in the measurement box.

The country version setting affects the user screen languages that

can be enabled.

6.1.5. | Instrument settings | Sensor diagnosis

The instrument displays the current status of the sensors.

If a sensor is worn out, the display reads: Faulty

> Replace the sensor

6.1.6. | Instrument settings | Sensor protection

Threshold values can be set to protect the CO/NO sensors against

overload. The sensor protection is activated if the threshold is

exceeded:

• Fresh air dilution if exceeded

• Shutdown if exceeded again

When dilution is activated, the CO and CO undiluted values are

displayed in a blue font. On the printout, a “

*” is shown after the name

of both values to indicate dilution.

To disable sensor protection the threshold values must be set to

0 ppm.

6.1.7. | Instrument settings | O

The O2 reference value of the current fuel can be set.

6.1.8. | Instrument settings | O

The NO2 addition value can be set.

reference

2

addition

2

6.1.9. | Instrument settings | Height compensation

Extremely low absolute pressure causes wrong calculation of the

O

sensor service life. Therefore, when the measuring instrument is

2

used at great heights, the factory set value should be adjusted so

that an O2 sensor is not displayed prematurely as “expended”.

If using the measuring instrument at heights up to approx. 1800 m

above mean sea level (MSL), the factory setting (922 hPa, equals

approx. 800 m above MSL) can be retained.

17

Page 18

6 Using the product

The value can be input directly (Abs. pressure), or is automatically

calculated when entering the barometric pressure (Barom.

pressure) and Altitude.

6.1.10. | Instrument settings | Switching the testo 330i off

It is possible to switch the testo 330i off via the mobile terminal

device.

Measuring values that have not been saved are lost when

the measuring instrument is switched off.

> Switch off the measuring instrument: tap OK.

- T he following may happen: the pump starts and the sensors are

rinsed until the switch-off thresholds (O

> 20%, other

2

measurement parameters < 50 ppm) are reached. The

maximum rinsing period is 3 minutes.

- The measuring instrument switches off.

6.2. Measuring

6.2.1. Preparing for measurement

6.2.1.1. Checking the condensate container fill level

Regularly check the fill level of the condensate container and empty

it in good time; see Draining the condensate container, page 28.

6.2.1.2. Checking the particle filter

Regularly check the particle filter of the flue gas probe for

contamination and replace in good time; see Checking/replacing

the particle filter, page 35.

6.2.1.3. Zeroing phases

Measuring the combustion air temperature (AT)

If no combustion air temperature probe is connected, the

temperature measured by the thermocouple of the flue gas probe

during the zeroing phase is used as the combustion air

temperature. All dependent parameters are calculated using this

value. This method of measuring combustion air temperature is

sufficient for systems dependent on ambient air. However, ensure

that the flue gas probe is near the intake duct of the burner during

the zeroing phase!

If a combustion air temperature probe is connected, the combustion

air temperature is measured continuously via this probe.

18

Page 19

Gas zeroing

The gas sensors are automatically zeroed when the instrument is

switched on.

> To manually start zeroing of the gas sensors: | Zeroing Gas

Sensors.

Draught/pressure zeroing

The pressure sensors are continuously zeroed.

The flue gas probe can be in the flue gas duct during the zeroing

phase, if there is no overpressure in the duct and a separate AT

probe is plugged in. The minus connection for differential pressure

measurements must be clear (ambient pressure, not closed).

6.2.1.4. Performing a gas path check

Regularly check the measurement system (measuring instrument

+ flue gas probe) for leaks.

A high O2 value, in particular, may be an indicator of a leaking

measurement system.

> | Gas path check.

6.2.1.5. Installing the probe mount testofix®

6 Using the product

1. Insert the probe mount in the measurement aperture of the flue

gas duct, making sure the attachment pin is pointing

downwards.

19

Page 20

6 Using the product

2. Attach the probe mount to the flue gas duct by turning the fixing

ring clockwise.

20

3. Slide the measuring instrument onto the probe mount up to the

stop.

4. Check if the locking mechanism has latched into the probe

mount.

Page 21

5. Insert the flue gas probe through the probe mount into the flue

gas duct.

When using the testofix® probe mount, the measuring

instrument is exposed to heat radiating from the flue gas duct

during the measurement. In order to prevent consequently

affecting the combustion air temperature a AT probe with

cable must be used for the measurement!

6.2.1.6. Using the modular flue gas probe

6 Using the product

Checking the thermocouple

The thermocouple of the flue gas probe must not lie against the

probe cage.

> Check before use. Bend the thermocouple back if necessary.

Aligning the flue gas probe

The flue gas must be able to flow freely past the thermocouple.

> Align the probe by turning it as required.

21

Page 22

6 Using the product

Searching for the centre of flow

The tip of the probe must be in the core current of the flue gas flow.

1. Corestream | .

2. Align the flue gas probe in the flue gas duct so that the tip is in

the core current (area of the highest flue gas temperature

Max FT).

- Grey value/grey pointer: Display of current flue gas temperature

- Orange valu e/orange pointer: Display of maximum flue gas

temperature

> Reset values/pointer: .

6.2.2. | Flue gas

In order to obtain the correct readings, the fuel used must

be set before taking the readings

Fuels

> Select fuel

To achieve usable measurement results, the measurement

period of a flue gas measurement should be a minimum of

3 minutes and the measuring instrument should display

stable measured values.

If a separate measurement of CO undiluted has not yet

been carried out, this value is calculated using the readings

from the flue gas probe and is updated continuously.

1. .

- Readin gs are displayed.

If the Draught measurement parameter is activated in the reading

display, a draught measurement is automatically initiated in parallel

to the flue gas measurement. In the List measurement data

screen, the parallel draught measurement can be

22

Page 23

stopped/restarted. This draught measurement is performed

separately to a measurement of the Draught measurement type.

For the draught measurement, the minus connection for

differential pressure measurements must be clear (ambient

pressure, not closed).

> Tap the draught reading display or next to it.

3.

6.2.3. | Draught

2. .

The minus connection for differential pressure

measurements must be clear (ambient pressure, not

closed).

1. .

- T he reading is displayed.

The pressure sensor is continuously zeroed (every 10 s) to prevent

a drift during long measurements. The switching sound of the valve

can be heard during zeroing.

2. .

6.2.4. | COundiluted

✓ A multi-hole probe (0554 5762) must be connected.

6 Using the product

1. .

- T he reading is displayed.

2. .

6.2.5. | Smoke number

The values calculated by a smoke pump tester can be entered.

The parameters Smoke and Oil depos. are only available for oil

fuels.

6.2.6. | Differential pressure

WARNING

Dangerous mixture of gases

Danger of explosion!

> Make sure there are no leaks between the sampling point and

the measuring instrument.

> Do not smoke or use naked flames during measurement.

23

Page 24

6 Using the product

✓ The gas pressure set (0554 1203) must be connected.

✓ The minus connection for differential pressure measurement

must be depressurised at the beginning of measurement

(ambient pressure; the instrument not connected to the system

being checked), as the pressure sensor is zeroed.

1. .

- Zeroing the pre ssure sensor.

- T he reading is displayed.

2. Connect the instrument to the system being checked.

Do not measure for longer than 5 minutes, as the drift of the

pressure sensor could mean that the measured values are

outside the tolerance limits. Re-zero the pressure sensor for

3. .

longer measurements.

6.2.7. | Differential temp.

✓ The differential temperature set (0554 1208) must be

connected.

1. .

- T he measured values and the calculated differential

temperature ∆t (T1 - T2) are displayed.

2. .

6.2.8. | O

supply air

2

1. .

- T he reading is displayed.

2. .

6.2.9. | Gas flow rate

The function is only available if the chosen fuel is a gas.

The gas burner capacity is calculated by means of the volume of

gas consumed. To this end, a volume of gas is input into the app

and its consumption read out at the gas meter.

1. Set the volume of gas to watch for at the gas meter.

2. Set the calorific value of the burnt gas.

3. .

- T he measurement period is displayed.

24

Page 25

4. When the set gas volume is reached: .

- T he calculated gas flow rate and the gas burner capacity

(in kW) are displayed.

6.2.10. | Oil flow rate

The function is only available if the chosen fuel is an oil.

This function is used to calculate the capacity of the burner from

the set oil pressure and the oil flow rate of the oil nozzle.

> Set the oil flow rate of the oil nozzle and the oil pressure

- T he calculated oil burner capacity (in kW) is displayed.

6.3. Printing readings

The current readings can be printed using a report printer

(accessories: Testo printer 0554 0621).

Making print text settings

The reading printout can be supplemented with individual

information (header: company address; footer: name of technician).

1. | Protocols | Own Company Data.

2. Make the settings.

A logo cannot be included in the reading printout. This is only used

for a report issued in PDF format.

6 Using the product

Printing current readings

✓ The printer is switched on and within wireless range.

25

> | Print values.

Page 26

6 Using the product

6.4. Report

A report can be created of saved measurement data (readings) and

other information about the measurement.

Reports can be printed using a report printer (accessories: Testo

printer 0554 0621) or sent as a file attachment in an email. The

email application installed on the mobile terminal device is used for

6.4.1. Add to protocol (save measurement)

this.

The measurement data from the last measurement type carried out

are stored temporarily on the measuring instrument.

The clipboard is deleted when the measuring instrument

is switched off.

Measurements carried out can be saved to back up measurement

data and be used for a subsequent report:

> | Add to protocol.

The measurements are stored in the measuring instrument.

This memory is not suitable for use as a long-term

memory/archive! Generate a report of significant

measurements and save this in a suitable place.

6.4.2. Finish protocol

1. | Finish protocol.

or

| Protocols.

2. Open the input category:

3. Enter/select log data:

Category Description

Own Company

Data

26

Reports can be supplemented with individual

information (company address; name of the

technician).

A logo can only be included when issued in PDF

format.

Page 27

Category Description

Format and

print

Select version format(s):

• CSV (comma separated text file, e.g. for

Microsoft

• PDF

• Print values (Testo printer 0554 0621 required

(accessories))

• ZIV (XML file, complying with the regulatio ns of

the ‘Federal Association of Chimney Sweeps

Germany’).

Customer data

Enter contact details or Import Contact Data

(opens the application installed for contacts on the

mobile terminal device).

Comments

and pictures

Enter comments (file name of log, comment,

measuring location name) and Add pictures

(opens the application installed for photos and

videos on the mobile terminal device).

Pictures are only included when issued in PDF

format.

Select

measurements

All saved measurements are displayed in one of the

following time categories, depending on the

creation date: Today, Yesterday or Older.

The measurements selected to create the report

are identified with . New, saved measurements

are automatically identified.

To display saved readings to check them:

> .

To delete individual measurement:

> .

To delete all measurements of a time category:

> Touch next to the time category name.

To select/deselect a measurement for the report:

> .

®

Excel),

6 Using the product

All selected pictures and measurements are included in the

report. This means the report may reach a file size of several

megabytes. Before sending the report, check what your

mobile provider may charge for this!

4. Send.

27

Page 28

7 Maintaining the product

7 Maintaining the product

7.1. Checking instrument status

7.1.1. | Instrument settings | Sensor diagnosis

The current status of the sensors can be displayed.

To change expended sensors, see Replacing sensors , page 33.

7.1.2. | Error list

Instrument errors that have not yet been rectified can be displayed.

7.2. Cleaning the measuring instrument

> If the housing of the measuring instrument is dirty, clean it with

a damp cloth. Do not use any aggressive cleaning agents or

solvents! Mild household cleaning agents and soap suds may

be used.

7.3. Draining the condensate container

The fill level of the condensate container can be read from the

markings. Hold the instrument horizontally or vertically to check the

fill level.

The condensate consists of a weak mix of acids. Avoid skin

contact. Make sure that the condensate does not run over

the housing.

28

CAUTION

Condensate entering the gas path.

Damage to sensors and flue gas pump!

> Do not empty the condensate container while the flue gas

pump is in operation.

Page 29

7 Maintaining the product

1. Open the condensate outlet on the condensate container.

2. Let the condensate run out into a sink.

3. Wipe off any drops still on the condensate outlet with a cloth

and close the condensate outlet.

The condensate outlet must be completely closed,

otherwise measuring errors could occur if external air gets

in.

7.4. Opening the measuring instrument

Open the measuring instrument only when this is required for

measuring purposes (gas sensors/replacing battery).

✓ The measuring instrument must not be connected to a mains

socket via the mains unit. The measuring instrument must be

switched off.

When opening/assembling the instrument, take care not to

lose any removed screws. Placing a cloth on the work top is

recommended.

1. Lay the instrument face down so that the rear of the instrument

faces upwards and the side with the retaining bracket faces

you.

29

Page 30

7 Maintaining the product

2. Use a cross-head screwdriver to remove the two (short) screws

(1 and 2) from the retaining bracket.

30

3. Move the catch hook outwards (3) and push the back of the

instrument up and lift off.

> If the back of the instrument cannot be removed by hand, this

can easily be levered out by applying a screwdriver to both of

the recesses 4 and 5.

Page 31

7 Maintaining the product

4. Remove the orange locking clips upwards out of the instrument

casing (6).

5. Use a cross-head screwdriver to loosen and remove the 4

screws 7 to 10 (short screws) and the 4 screws 11 to 14 (long

screws).

6. Turn the instrument over and place on its back so that the front

is facing upwards.

7. Remove the condensate trap sealing plug from the condensate

outlet (15).

31

Page 32

7 Maintaining the product

8. Fold up/back the upper instrument casing and place next to the

lower casing (16). Do this carefully to prevent damaging hoses

and lines.

Assembly

Perform in reverse order to assemble. Please note:

> Lay hoses and lines in the designated ducts.

> Make sure that hoses and lines do not get stuck.

32

> Insert the teeth on the lower edge of the back of the housing

into the lower instrument casing and push at the height of the

symbols (17) and (18) to lock into place in the housing.

Page 33

7 Maintaining the product

7.5. Replacing the rechargeable battery

✓ Measuring instrument is open; see Opening the measuring

7.6. Replacing sensors

instrument, page 29.

1. Open the battery lock: Press the grey button (1) and push to the

left keeping the button pressed (2).

2. Remove the battery and insert a new rechargeable battery. Use

only Testo rechargeable battery 0515 0107!

3. Close the battery lock: Press the grey button and push to the

right keeping the button pressed until the battery engages.

A slot bridge (0192 1552) must be inserted in slots which

are not equipped with a sensor. Used sensors must be

disposed of as hazardous waste!

✓ Measuring instrument is open; see Opening the measuring

instrument, page 29.

1. Disconnect the hose connections from the faulty sensor

(1)/bridge (2).

33

Page 34

7 Maintaining the product

2. Remove the faulty sensor/bridge from the slot.

> For NO sensor: Remove the auxiliary circuit board.

Do not remove the auxiliary circuit board for the NO

sensor until immediately before installation. Do not

leave the sensor without auxiliary circuit board for

longer than 15 minutes.

3. Install new sensor/new bridge in the slot:

• Slot 1: O

• Slot 2: CO sensor or CO

• Slot 3: NO sensor or NO

sensor

2

sensor

low

sensor

low

4. Push the hose connections onto the sensor/bridge.

5. Close the measuring instrument.

When retrofitting a sensor, the associated measurement

parameter/unit must be enabled in the reading display.

7.7. Cleaning the modular flue gas probe

✓ Disconnect the flue gas probe from the measuring instrument

prior to cleaning.

1. Release the probe catch by pressing the key on the probe

handle and remove the probe module.

34

2. Blow compressed air through the flue gas ducts in probe

module and probe handle (see illustration). Do not use a brush!

3. Fit a new probe module on the probe handle and engage it in

place.

Page 35

7.8. Replacing the probe module

✓ Disconnect the flue gas probe from the measuring instrument.

1. Press the button on the top of the probe handle (1) and remove

the probe module (2).

2. Plug in the new probe module and lock it in place (3).

7 Maintaining the product

7.9. Checking/replacing the particle filter

Checking the particle filter:

Check the particle filter of the modular flue gas probe periodically

for contamination: check visually by looking through the window

of the filter chamber.

> If there is visible contamination or inadequate pump flow,

replace the filter.

35

Replacing the particle filter:

The filter chamber may contain condensate. This is not a

malfunction and will not cause wrong readings.

Page 36

7 Maintaining the product

1. Open the filter chamber: turn slightly anti-clockwise (1). Remove

the filter chamber (2).

2. Remove the filter plate (3) and replace it with a new one (4

[0554 3385]).

3. Attach the filter chamber and lock it: turn slightly clockwise.

7.10. Changing the thermocouple

1. Release the probe catch by pressing the key on the probe

handle and remove the probe module.

36

2. Remove the thermocouple pl ug-in head from the socket using a

screwdriver and pull the thermocouple out of the probe shaft.

3. Keep inserting the new thermocouple into the probe shaft until

the connection head clicks into place.

4. Fit a new probe module on the han dle and engage in place.

Page 37

7 Maintaining the product

7.11. Updating the instrument software

✓ The measuring instrument must be switched off.

1. Plug the measuring instrument mains unit into a mains socket.

2. Press and hold down for 10 s.

- Both status LEDs (blue/red) slowly flash alternately.

3. Insert the connecting cable (0449 0047) into the USB port on

the measuring instrument, then connect it to the PC.

- Your PC identifies the measuring instrument as a removable

medium.

4. Copy the new instrument software file (ap330ir.bin) to the

identified removable medium.

- Both status LEDs (blue/red) quickly flash alternately. This

process may take a few minutes.

5. Disconnect the connecting cable from the measuring

instrument.

- Once the instrument software has been updated, the measuring

instrument will automatically reboot and is ready for use again.

37

Page 38

8 Technical data

8 Technical data

8.1.1. Examinations and licenses

As declared in the Certificate of Conformity, this product complies

with Directive 2014/30/EU.

testo 330i / testo 330i LX with gas sensors O

compensated/NO, combustion air temperature sensor, flue gas

temperature sensor and differential pressure sensor (draught) is

TüV-tested in accordance with VDI 4206.

The CO sensor 0393 0101 (CO, H2-compensated) is TÜV-tested in

accordance with EN 50379 part 2.

The CO sensor 0393 0051 (CO, not H2-compensated) is TÜVtested in accordance with EN 50379 part 3.

For official measurements in accordance with the 1st BImSchV

(chimney sweeps), the measuring instrument must be checked

every six months by a technical testing body of the Guild of Master

Chimney Sweeps or another testing body recognised by the

authorities.

/CO, H2-

2

8.1.2. Bluetooth

Country Comments

Europa +

EFTA

Australia

38

®

module

EU countries:

Belgium (BE), Bulgaria (BG), Denmark (DK),

Germany (DE), Estonia (EE), Finland (FI),

France (FR), Greece (GR), Ireland (IE), Italy

(IT), Latvia (LV), Lithuania (LT), Luxembourg

(LU), Malta (MT), Netherlands (NL), Austria

(AT), Poland (PL), Portugal (PT), Romania

(RO), Sweden (SE), Slovakia (SK), Slovenia

(SI), Spain (ES), Czech Republic (CZ), Hungary

(HU), United Kingdom (GB), Republic of Cyprus

(CY).

EFTA countries:

Iceland, Liechtenstein, Norway, Switzerland

E1561

Page 39

Turkey Authorized

India Authorized

Canada Contai ns FCC ID: 4957A-MSR

Product IC ID: 6127B-2016t330i

IC Warnings

USA Contains FCC ID: RFRMS

FCC ID: WAF-2016t330i

FCC Warnings

Korea

8 Technical data

MSIP-RMM-TE1-330i

KCC Warning

Japan

Japan Information

Bluetooth SIG

List

TÜV TÜV by RgG 310

TÜV approved:

EN50379-1, -2, -3 / VDI4206-1

IC Warnings

39

Page 40

8 Technical data

This instrument complies with Part 15C of the FCC Rules and Industry

Canada RSS-210 (revision 8). Commissioning is subject to the following

two conditions:

(1) This instrument must not cause any harmful interference and

(2) this instrument must be able to cope with interference, even if

this has undesirable effects on operation.

Cet appareil satisfait à la partie 15C des directives FCC et au standard

Industrie Canada RSS-210 (révision 8). Sa mise en service est soumise

aux deux conditions suivantes :

(1) cet appareil ne doit causer aucune interférence dangereuse et

(2) cet appareil doit supporter toute interférence, y compris des

interférences qui provoquerait des opérations indésirables.

FCC Warnings

Information from the FCC (Federal Communications Commission)

For your own safety

Shielded cables should be used for a composite interface. This is to ensure

continued protection against radio frequency interference.

FCC warning statement

This equipment has been tested and found to comply with the limits for a

Class B digital device, pursuant to Part 15 of the FCC Rules. These limits

are designed to provide reasonable protection against harmful interference

in a residential installation. This equipment generates, uses and can radiate

radio frequency energy and, if not installed and used in accordance with the

instructions, may cause harmful interference to radio communications.

However, there is no guarantee that interference will not occur in a

particular installation. If this equipment does cause harmful interference to

radio or television reception, which can be determined by turning the

equipment off and on, the user is encouraged to try to correct the

interference by one or more of the following measures:

• Reorient or relocate the receiving antenna.

• Increase the separation between the equipment and receiver.

• Connect the equipment into an outlet on a circuit different from that to

which the receiver is connected.

• Consult the dealer or an experienced radio/TV technician for help.

Caution

Changes or modifications not expressly approved by the party responsible

for compliance could void the user's authority to operate the equipment.

Shielded interface cable must be used in order to comply with the emission

limits.

40

Page 41

Warning

This device complies with Part 15 of the FCC Rules.

Operation is subject to the following two conditions:

(1) this device may not cause harmful interference, and

(2) this device must accept any interference received,

including interference that may cause undesired operation.

KCC Warning

해당 무선 설비는 운용 중 전파혼신 가능성이 있음

Japan Information

当該機器には電波法に基づく、技術基準適合証明等を受けた特定

無線設備を装着している。

8.1.3. Measuring ranges and resolution

Measurement

parameter

O2 0 to 21 vol.% 0.1 vol.%

CO 0 to 4,000 ppm 1 ppm

CO

(H

-compensated)

2

CO

(H

-compensated)

2

with fresh air

dilution

CO

0 to 500 ppm 0.1 ppm

low

NO 0 to 3,000 ppm 1 ppm

CO environment

(via flue gas

probe)

Draught -9.99 to 40 hPa 0.01 hPa

∆P 0 to 300 hPa 0.1 hPa

Temperature -40 to 1,200 °C 0.1 °C (-40.0 to 999.9 °C)

Efficiency 0 to 120% 0.1%

Flue gas loss 0 to 99.9% 0.1%

Measuring range Resolution

0 to 8,000 ppm 1 ppm

0 to 30,000 ppm 1 ppm

0 to 2,000 ppm 1 ppm

1 °C (rest of range)

8 Technical data

41

Page 42

8 Technical data

Measurement

Measuring range Resolution

parameter

CO2 determination

(calculation from

O

)

2

Display range 0 to

CO

max

2

8.1.4. Accuracy and response time

Measurement

parameter

O2 ± 0.2 vol.% < 20 s (t90)

CO ± 20 ppm (0 to 400 ppm)

CO H2compensated

CO (H2compensated)

with fresh air

dilution

CO

± 2 ppm (0 to 39.9 ppm)

low

NO ± 5 ppm (0 to 100 ppm)

Draught

Accuracy

± 5% of m.v. (401 to 2,000 ppm)

± 10% of m.v. (2,001 to

4,000 ppm)

± 10 ppm or ± 10% of m.v.1 (0 to

200 ppm)

± 20 ppm or ± 5% of m.v.

to 2,000 ppm)

± 10% of m.v. (2,001 to

8,000 ppm)

± 200 ppm or ± 20% of m.v.1 (0

to 30,000 ppm)

± 5% of m.v. (rest of range)

± 5% of m.v. (101 to 2,000 ppm)

± 10% of m.v. (2,001 to

3,000 ppm)

± 0.02 ppm or ± 5% of m.v.

0.50 to 0.60 hPa)

± 0.03 hPa (0.61 to 3.00 hPa)

± 1.5% of m.v. (3.01 to

40.00 hPa)

1 ppm

1

(201

1

(-

Response

time

< 60 s (t90)

< 60 s (t90)

< 60 s (t90)

< 40 s (t90)

< 30 s (t90)

-

1

higher value is valid

42

Page 43

8 Technical data

Measurement

Accuracy

parameter

∆P ± 0.5 hPa (0.0 to 50.0 hPa)

± 1% of m.v. (50.1 to 100.0 hPa)

± 1.5% of m.v. (rest of range)

Temperature ± 0.5 °C (0.0 to 100.0 °C)

± 0.5% of m.v. (rest of range)

Efficiency - Flue gas loss - CO2

± 0.2 vol.% determination

(calculation from

)

O

2

8.1.5. Other instrument data

Flue gas analyzer

Feature Values

Storage and

-20 to 50 °C

transport

temperature

Operating

-5 to 45 °C

temperature

Max. surface

140 °C

temperature at the

measurement

aperture (with probe

mount)

Ambient humidity 0 to 90% RH, n on-condensing

Operating positions No restriction

Fill level of

condensate trap

9 ml

Corresponds with a service life of approx.

5 h (EL heating oil)/approx. 2.5 h (natural

gas) at 20 °C ambient temperature)

Power supply Li Ion battery: 3.7 V/2.6 Ah

Mains unit: 6 V/2.0 A

Protection class IP 40

Weight 720 g (excluding battery)

Response

time

-

depending on

the probe

43

Page 44

8 Technical data

Feature Values

Dimensions 270 x 160 x 57 mm

Memory 500,000 individual readings

Flue gas

overpressure

Negative pressure

Rechargeable

battery charging

temperature

Rechargeable

battery charge time

Rechargeable

battery life

Warranty

max. 50 mbar

max. 80 mbar

± 0 to 35 °C

approx. 5-6 h

6 h (pump on, 20 °C ambient temperature)

testo 330i

Measuring instrument: 48 months

Sensors O2, CO: 48 months

Other sensors:

Flue gas probe: 48 months

Thermocouple: 12 months

Rechargeable battery: 12 months

24 months

testo 330i LX

Measuring instrument: 48 months

Sensors O2, CO: 60 months

Other sensors:

Flue gas probe: 48 months

Thermocouple: 12 months

Rechargeable battery: 12 months

8.1.6. Declaration of conformity

You can find the EU declaration of conformity on the Testo

homepage under the product-specific downloads.

44

24 months

Page 45

9 Tips and assistance

9.1. Questions and answers

Question Possible causes/solution

Rechargeable battery low > Switch to mains operation.

Measuring instrument

switches off automatically

or cannot be switched on

Displayed battery capacity

seems to be faulty

Rechargeable battery has run out:

> Charge rechargeable batteries or

switch to mains operation.

Rechargeable battery was repeatedly

not fully discharged/charged:

> Discharge rechargeable battery

(until measuring instrument

switches off automatically) and

then charge fully.

Error message: Main

pump flow is too high

Gas outlet blocked:

> Make sure that the gas outlet is

clear.

Overpressure in flue gas duct too high

(> 50 mbar):

> Perform draught measurement.

Error message: Sensor

protection is active

The switch-off threshold of the CO

sensor was exceeded:

> Remove probe from flue gas duct.

Error message: Printing

not possible

Three acoustic signals

after switching on the

measuring instrument

App no longer responds to

command inputs

> Switch on printer.

> Move printer into wireless range.

Device error:

> Consult Testo Service or your

dealer.

> Open the overview of active

applications (refer to your

smartphone operating system

instructions) and close the App.

Instrument no longer

> Keep the button pressed down for

responds to command

inputs

measuring instrument.

9 Tips and assistance

10 s to reset and reboot the

45

Page 46

9 Tips and assistance

Question Possible causes/solution

It cannot establish a

Bluetooth connection!

or

Required instrument is not

in the Find Device display.

No instruments are shown

in the Find Device display.

Connection fails repeatedly

with a Bluetooth

message.

When using two printers:

The required printer not

found!

In Excel® the CSV format

is not displayed properly.

®

error

> Keep the button pressed down for

10 s to reset and reboot the

measuring instrument.

> Check the Bluetooth settings on

the mobile terminal device.

> Switch Bluetooth off and on again

on the mobile terminal device.

1. Keep the button pressed down for

10 s to reset and reboot the

measuring instrument.

2. Switch Bluetooth off and on again

on the mobile terminal device. If

necessary: switch the mobile

terminal device off and on again.

The mobile terminal device may be

connected to the other printer and this

connection is saved in the App.

> Close the App and restart it to

establish a new connection.

®

Open Excel

and create a new

template. Click on the Data tab and

activate the From Text menu. Select

the CSV file and adopt in the Excel

template.

46

Page 47

9 Tips and assistance

9.2.

9.3.

Contackt and Support

If we have not been able to answer your

your dealer or Testo Customer Service.

You can also send Testo an error report via

menu, select Send error report. Your e-mail app will be launched

automatically and an error report created. The report contains

information about your smart device and the operating system

used. Send the report to the automatically generated e-mail

address developmentsupport@testo.de. We will get back to you

as soon as possible with information for troubleshooting.

question, please contact

e-mail. In the Help

Accessories and spare parts

Printer

Description Article no.

Bluetooth®/IRDA printer, incl. mains unit 5 V/1.0 A

with micro USB cable

Mains unit 5 V/1.0 A with micro USB cable 0554 1105

Spare thermal paper for printer (6 rolls) 0554 0568

Modular flue gas probes

Description Article no.

Modular flue gas probe 180 mm, 500 °C, probe shaft

diameter: 8 mm, hose 0.6 m

Modular flue gas probe 300 mm, 500 °C, probe shaft

diameter: 8 mm, hose 0.6 m

Modular flue gas probe 180 mm, 500 °C, probe shaft

diameter: 6 mm, hose 0.6 m

Modular flue gas probe 300 mm, 500 °C, probe shaft

diameter: 6 mm, hose 0.6 m

Modular flue gas probe 180 mm, 500 °C, probe shaft

diameter: 8 mm, hose 2.2 m

Modular flue gas probe 300 mm, 500 °C, probe shaft

diameter: 8 mm, hose 2.2 m

Flexible flue gas probe 330 mm, T

term 200 °C, bending radius max. 90° for

measurements in difficult to access locations

180 °C, short-

max.

0554 0621

0600 9780

0600 9781

0600 9782

0600 9783

0600 9760

0600 9761

0600 9770

47

Page 48

9 Tips and assistance

Probe modules/accessories for modular flue gas probes

Description Article no.

Probe shaft module 180 mm, 500 °C, thermocouple

0554 9760

0.5 mm, probe shaft diameter: 8 mm

Probe shaft module 300 mm, 500 °C, thermocouple

0554 9761

0.5 mm, probe shaft diameter: 8 mm

Spare thermocouple for module 0554 9760,

0430 9760

0554 9762

Spare thermocouple for module 0554 9761,

0430 9761

0554 9763

Probe mount testofix®, 8 mm 0554 3006

Cone, 8 mm, steel 0554 3330

Multi-hole probe shaft, length 300 mm, Ø 8 mm, for

0554 5762

CO mean value calculation

Multi-hole probe shaft, length 180 mm, Ø 8 mm, for

0554 5763

CO mean value calculation

Flexible probe shaft module 0554 9770

Hose extension; 2.8 m; extension line probe-

0554 1202

instrument

Particle filter, 10 pcs. 0554 3385

Temperature probe

Description Article no.

Combustion air temperature (AT) probe, 300 mm 0600 9791

Combustion air temperature (AT) probe, 190 mm 0600 9787

Combustion air temperature (AT) probe, 60 mm 0600 9797

Fast reaction surface probe 0604 0194

Mini ambient air probe 0600 3692

48

Other probes

Description Article no.

O2 dual wall clearance probe 0632 1260

Gas leak probe 0632 3330

Differential temperature set, 2 pipe wrap probes,

0554 1208

adapter

Page 49

9 Tips and assistance

Desc

ription Article no.

Smoke pump tester, incl. oil, soot plates, for

0554 0307

measuring soot in flue gas

Retrofit/spare sensors

Description Article no.

O2 sensor 0393 0002

CO sensor 0393 0051

CO sensor H2-compensated 0393 0101

CO

sensor 0393 0103

low

NO sensor 0393 0151

NO

sensor on request

low

Cases

System case with double floor (height:180 mm) for

0516 3302

instrument, probes and accessories

System case (height: 130 mm) for instrument,

0516 3303

probes and accessories

Other accessories

Description Article no.

Mains unit 0554 1096

Spare rechargeable battery 0515 0107

Instrument/PC connecting cable 0449 0047

Additional filter 0133 0010

Flue draught set 0554 3150

Fine pressure probe 0638 0330

Set of capillary hoses 0554 1215

Solid fuel measurement module with adapter and

0600 9765

probe shaft with sintered filter

Sintered filter for solid fuel measurement probe shaft 0133 0035

Filter material for condensate trap on solid fuel

0133 0012

measurement adapter

NOx filter 0554 4150

49

Page 50

9 Tips and assistance

Description Article no.

Pressure test set for gas pipe testing 0554 1213

ISO calibration certificate for flue gas 0520 0003

50

Page 51

Test Equipment Depot - 800.517.8431

99 Washington Street, Melrose, MA 0

TestEquipmentDepot.com

2176

Page 52

Test Equipment Depot - 800.517.8431

99 Washington Street, Melrose, MA 02176

TestEquipmentDepot.com

0971 3340 e

n 03 en_GB

Loading...

Loading...