Page 1

testo CU-2

User Manual

Page 2

2

Page 3

Content

3

Content

1 Declaration of Warranty ............................................................................................... 6

1.1. Type of Designation ....................................................................................................................... 6

1.2. Manufacturer ................................................................................................................................ 6

1.3. Warranty ....................................................................................................................................... 6

2 Precautions ................................................................................................................... 6

2.1. Foreword ...................................................................................................................................... 6

2.2. Liabilities ....................................................................................................................................... 6

2.2.1. Liability to Content............................................................................................................... 7

2.3. Copyright © .................................................................................................................................. 7

3 Safety ............................................................................................................................ 7

3.1. Risk Types...................................................................................................................................... 7

3.1.1. Electrical Safety ................................................................................................................... 7

3.2. Labels and Explanations ................................................................................................................. 7

4 System Overview .......................................................................................................... 8

4.1. Introduction .................................................................................................................................. 8

4.1.1. testo CU-2 Digital Control Unit ............................................................................................. 8

4.1.2. testo NanoMet Software ...................................................................................................... 8

4.2. Definitions ..................................................................................................................................... 8

4.3. Abbreviations, Units and Symbols .................................................................................................. 8

4.4. The System .................................................................................................................................. 10

4.4.1. Overview ........................................................................................................................... 10

4.4.2. Functionality ...................................................................................................................... 10

4.5. Control Elements and Connections .............................................................................................. 11

4.5.1. Front and Rear View .......................................................................................................... 11

4.5.2. Additional Analog and Digital In- and Output Connector 20) ............................................... 12

5 Installation and Setup ................................................................................................. 12

5.1. Hardware Setup........................................................................................................................... 12

5.2. Windows Embedded and Network Setup ..................................................................................... 12

5.2.1. Windows Embedded Login ................................................................................................. 12

5.2.2. Network Settings ............................................................................................................... 13

5.3. testo NanoMet Software Startup and Operation Mode Selection ................................................. 13

5.3.1. Manual Operation Mode .................................................................................................... 13

5.3.2. Software Control Mode ...................................................................................................... 14

5.3.3. Remote Computer Software Control Mode ........................................................................ 14

5.4. AK Host Remote Control Mode .................................................................................................... 15

6 testo NanoMet Operation ........................................................................................... 17

6.1. Main Measurement Tab .............................................................................................................. 17

6.1.1. Pause State ........................................................................................................................ 17

6.1.2. Standby State .................................................................................................................... 17

Page 4

Content

4

6.1.3. Measurement state ........................................................................................................... 18

6.1.4. Leak Test ........................................................................................................................... 18

6.1.5. Zero Test............................................................................................................................ 18

6.2. Measurement Configuration ........................................................................................................ 19

6.2.1. UN-ECE R83 Measurement and Test Cycle Definition .......................................................... 19

6.2.2. General Measurement Settings .......................................................................................... 20

6.3. System Configuration .................................................................................................................. 20

6.3.1. Measurement Instruments................................................................................................. 20

6.3.2. Dilution Instruments .......................................................................................................... 21

6.3.3. AK Interfaces ..................................................................................................................... 22

6.4. Analog Input and Output Signals Configuration ............................................................................ 22

6.4.1. Analog In ........................................................................................................................... 23

6.4.2. Analog Out......................................................................................................................... 23

6.4.3. Digital Out / Errors ............................................................ Fehler! Textmarke nicht definiert.

6.5. PNC Tab....................................................................................................................................... 24

6.6. testo NanoMet Control Panel and CPC Window ........................................................................... 24

6.6.1. testo NanoMet Control Panel ............................................................................................. 24

6.6.2. CPC Window ...................................................................................................................... 25

7 AK Host Operation ...................................................................................................... 25

7.1. AK Software Integration............................................................................................................... 25

7.2. AK Interfaces Specifications ......................................................................................................... 25

7.2.1. Serial Interface ................................................................................................................... 25

7.2.2. TCP/IP Interface ................................................................................................................. 26

7.3. AK Protocol Specification ............................................................................................................. 26

7.3.1. AK Command Telegram ...................................................................................................... 26

7.3.2. AK Response Telegram ....................................................................................................... 26

7.3.3. General AK Protocol Description ........................................................................................ 27

7.3.4. Handling of Certain Conditions ........................................................................................... 27

7.4. List of All AK Commands .............................................................................................................. 28

7.4.1. Control Commands – 'S' ..................................................................................................... 28

7.4.2. Write Commands – 'E' ........................................................................................................ 28

7.4.3. Read Commands – 'A' ........................................................................................................ 28

7.5. Descripton of All AK Commands ................................................................................................... 29

7.5.1. Control Commands – 'S' ..................................................................................................... 29

7.5.2. Write Commands – 'E' ........................................................................................................ 30

7.5.3. Read Commands – 'A' ........................................................................................................ 32

7.5.4. AK Errors List ..................................................................................................................... 34

8 Electrical Connections ................................................................................................. 35

8.1. Mains Supply ............................................................................................................................... 35

8.2. Dilution/Conditioning Devices...................................................................................................... 36

8.3. Analog/Digital Interface ............................................................................................................... 36

8.4. Standard Embedded Computer Ports ........................................................................................... 37

9 Maintenance and Calibration ...................................................................................... 38

Page 5

Content

5

9.1. Storage, Acclimatization .............................................................................................................. 38

9.2. Operation Environment Requirements......................................................................................... 38

10 Appendix ..................................................................................................................... 39

10.1. Extent of Delivery ........................................................................................................................ 39

10.2. Specification, Technical Data ....................................................................................................... 39

10.3. Designation of All testo CU-2 Digital Control Unit Operating Elements ......................................... 40

Page 6

1 Declaration of Warranty

6

1 Declaration of Warranty

Manual Version History:

Version: V1.03

Date: November 2018

1.1. Type of Designation

This user manual refers to the instrument and software type and version as listed below. It

replaces all previously dated user manuals for this instrument.

Type: testo CU-2

1.2. Manufacturer

Testo SE & Co. KGaA Tel: +49 7653 681 5062

Testo-Strasse 1 Fax: +49 7653 681 95062

79853 Lenzkirch web: www.testo.com

Germany email: info@testo.de

For technical support contact your local service contractor or Testo techsupport.

email: support-nanoparticle@testo.de

1.3. Warranty

Testo SE & Co. KGaA warrants that this product adheres to the specified properties for a period

of twelve (12) months from the date of delivery.

Excluded from the warranty are all parts subjected to normal wear as any fuses, batteries or

other consumable parts. Also excluded are: Defects resulting from abnormal use, in particular

outside the intended purpose; lack of maintenance; improper use or malicious damage. Warranty

is void if actions are carried out which are not described in the documentation nor authorized by

Testo SE & Co. KGaA.

Testo SE & Co. KGaA does not provide any warranty on finished goods manufactured by others.

Only the original manufacturer's warranty applies.

There are no user-serviceable parts inside testo CU-2 and some very sensitive parts. Do not

open your testo CU-2, as you may damage it. Warranty is voided if the case is opened and

warranty-seal is broken.

Parts repaired or replaced as a result of repair services are warranted to be free from defects in

workmanship and material, under normal use, for 90 days from the date of shipment.

2 Precautions

2.1. Foreword

This manual guides you through the installation, starting up, operation and maintenance

procedures of the testo CU-2. In detail you will find information about the system as

• safety

• functionality of the testo CU-2, technical information and specifications

• installation of the testo CU-2 and accessories

• handling, operation, maintenance and troubleshooting

Follow the instructions provided by this manual for safe and proper operation of the testo CU2 Digital Control Unit.

Before installing and operating the testo CU-2, the operator or service has to

read carefully this manual. For improper function, damages or injuries caused

by ignoring the instructions by this manual no liabilities are accepted.

2.2. Liabilities

Testo SE & Co. KGaA accepts no liability to improper function or injury caused by

• neglecting the instructions provided by this manual or instructed person.

• improper installation, operation, application, or maintenance.

• operation by untrained staff.

Page 7

3 Safety

7

• any technical modification not carried out by Testo SE & Co. KGaA or an authorized

service partner.

For operating the testo MD19-3E Rotating Disk Diluter and testo ASET15-1 Air

Supply / Evaporation Tube together with testo CU-2 Digital Control Unit, refer to the related user

manuals.

2.2.1. Liability to Content

The content of this manual is generated with most accurateness. Testo SE & Co. KGaA does not

guarantee completeness, correctness and being up to date. Testo SE & Co. KGaA reserves the

right to revise the content of the manual at any time and without notice.

2.3. Copyright ©

All work and contents done or generated by Testo SE & Co. KGaA are subject of the German

copyright © and law for intellectual property. This copyright includes all specification data of the

instrument or part of it, electrical and fluidic and mechanical schematics, pictures, diagrams and

text. Copying, editing, publishing or any other utilisation requires a written agreement of

Testo SE & Co. KGaA.

3 Safety

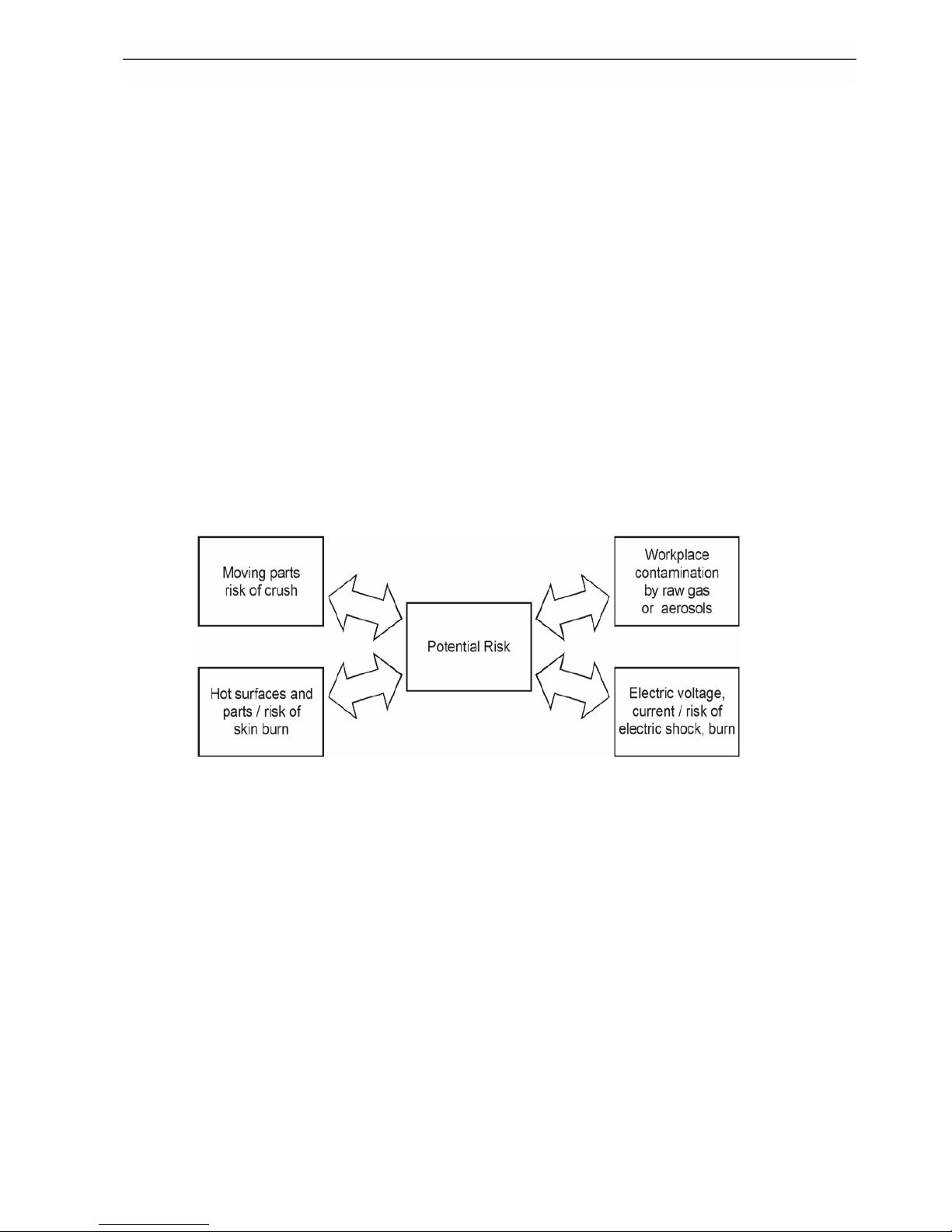

3.1. Risk Types

The diagram in Fig. 3.1 shows typical risks that could cause damage or injury while handling the

testo MD19-3E Rotating Disk Diluter or testo ASET15-1 Air Supply / Evaporation Tube. These

risks may also occur if these or other devices are used in combination with testo CU-2.

Fig. 3.1: risk types

Refer to the user manuals of the devices connected to the testo CU-2 digital control unit to learn

more about the risks which may occur operating them.

3.1.1. Electrical Safety

When in operation any electrical equipment can produce dangerous voltages. Failure to observe

the warnings may result in serious injury or damage. It is, therefore, mandatory that only suitably

qualified personnel use this instrument. Satisfactory and safe operation of this instrument calls for

proper handling in transportation, storage, installation as well as careful control and maintenance.

3.2. Labels and Explanations

Listed labels, Caution and Warning are explained in general, and the further specific labels refer

to type of hazard and danger.

Page 8

4 System Overview

8

Warning

Warning means that improper operation could cause a serious human or

instrument damage or injury with consequence of irrevocable instrument

damage.

Electric Shock

Hazardous voltage. Contact may cause electric shock or burn. Turn off and lock

out system power before servicing.

Electric Ground

This sign indicates that the mains connector and cabinet ground are connected

to protective earth PE.

4 System Overview

4.1. Introduction

4.1.1. testo CU-2 Digital Control Unit

testo CU-2 Digital Control Unit is an accessory for the testo MD19-3E which is the Rotating Disk

Diluter with external diluter head for performing the primary dilution as close as possible to the

aerosol source. testo CU-2 is equipped with interfaces to control testo MD19-3E Rotating Disk

Diluter and testo ASET15-1 Air Supply / Evaporation Tube and to read the digital signal of a

condensation particle counter CPC. Besides, several analog and digital input and output signals

can be handled.

4.1.2. testo NanoMet Software

The testo NanoMet software is intended to control the testo CU-2 Digital Control Unit and

therewith the connected particle measurement components like testo MD19-3E Rotating Disk

Diluter and testo ASET15-1 Air Supply / Evaporation Tube. The testo NanoMet software also

allows the user to read a digital signal from a CPC and to determine the functions of the analog

ports of testo CU-2.

The testo NanoMet software supports AK protocol. This permits the communication with an AK

host computer and therewith the easy integration of the testo CU-2 controlled particle

measurement system into a test rig.

4.2. Definitions

testo MD19-3E

third generation of Testo Rotating Disk Diluter with external diluter head

for primary dilution as close to the emission source as possible

testo ASET15-1

Testo Air Supply / Evaporation Tube unit supplies dilution air to the

testo MD19-3E primary diluter and undertakes the thermal conditioning

and secondary dilution of the aerosol

Raw gas undiluted aerosol from the emission source

Dilution air

filtered and therewith particle free compressed or ambient air which is

fed to the primary or secondary diluter

Measuring gas

primary or secondary diluted aerosol from the emission source

(combustion engine or CVS).

4.3. Abbreviations, Units and Symbols

LED

Light Emitting Diode

signal lamps at the front of testo MD19-3E, testo ASET15-1, and

testo CU-2

CVS

Constant Volume Sampler

test rig component; combustion engine exhaust dilution tunnel

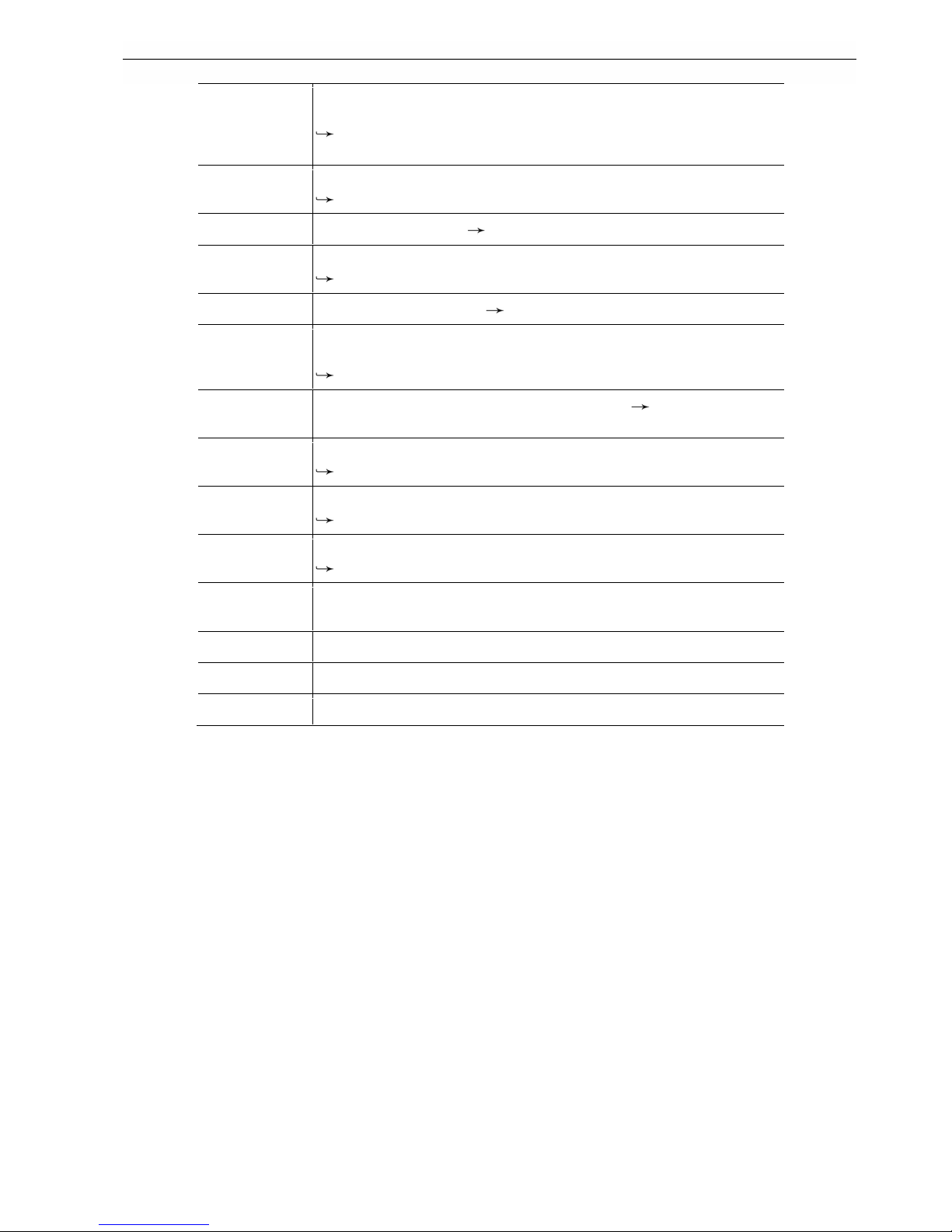

Page 9

4 System Overview

9

AK

ArbeitsKreis VDA (working committee of German automotive industry

alliance)

de facto standard communication protocol for test bench

components

PND1

primary Particle Number Diluter (ECE R83 compliant abbreviation)

Testo testo MD19-3E Rotating Disk Diluter

DF

PND1

primary Dilution Factor dilution factor of PND1 (testo MD19-3E)

PND2

secondary Particle Number Diluter (ECE R83 compliant abbreviation)

diluter part of testo ASET15-1

DF

PND2

secondary Dilution Factor dilution factor of PND2 (testo ASET15-1)

PCRF

Particle Concentration Reduction Factor (ECE R83 compliant

abbreviation)

total dilution factor comprising DF

PND1

, DF

PND2

and particle losses

fr

overall dilution (= concentration reduction) factor used as equivalent

of PCRF

PNC

Particle Number Counter (ECE R83 compliant abbreviation)

e.g. engine exhaust condensation particle counter EECPC from TSI

CPC

Condensation Particle Counter

product name of particle number counter manufactured by TSI

EECPC

Engine Exhaust Condensation Particle Counter

product name of ECE R83 compliant PNC manufactured by TSI

QMD

primary diluted measuring gas flow from the testo MD19-3E primary

diluter

QAS secondary dilution air flow from the air supply part of testo ASET15-1

QMG secondary diluted measuring gas flow to the connected instrumentation

QEX excess secondary diluted measuring gas gas flow

Page 10

4 System Overview

10

4.4. The System

4.4.1. Overview

Fig. 4.1 : testo ViPR system consisting of testo CU-2, testo MD19-3E, and testo

ASET15-1

Fig. 4.1 shows a testo ViPR system consisting of testo CU-2 Digital Control Unit, testo MD19-3E

Rotating Disk Diluter, testo ASET15-1 Air Supply / Evaporation Tube. Together with an engine

exhaust condensation particle counter (e.g. TSI 3790 EECPC or GRIMM 5.431) this system

meets PMP requirements and can be controlled via Ethernet.

4.4.2. Functionality

testo CU-2 Digital Control Unit is built in a standard 19" case and therewith can be integrated into

a 19" rack together with other devices like the controlled testo ASET15-1 with integrated testo

MD19-3E.

An embedded computer is built in with Windows Embedded Standard as operating system. This

permits to operate the unit in different modes: Manual control, local software control, remote

computer software control via Ethernet, or control by host computer via AK interface.

Besides the Testo aerosol conditioning system consisting of testo MD19-3E Rotating Disk Diluter

and testo ASET15-1 Air Supply / Evaporation Tube a TSI 3790 EECPC, GRIMM 5.431 or another

CPC particle counter can be controlled via serial port and up to 5 analog signals from other

external sources can be logged.

Data logged by testo CU-2 can be saved on the integrated flash memory, a USB memory stick or

to any network storage Windows Embedded can access via Ethernet.

Page 11

4 System Overview

11

4.5. Control Elements and Connections

4.5.1. Front and Rear View

Fig. 4.3: front view of testo CU-2

Fig. 4.3 shows the front of testo CU-2. There are no control elements except the power LED 1)

indicating if the device is switched ON or OFF. All connectors and the mains switch are located at

the rear side which is shown in Fig. 4.4. The testo CU-2 is either completely controlled via

Ethernet or locally by using keyboard, mouse and VGA monitor which can be connected to the

according ports.

Fig. 4.4: rear view of testo CU-2

1 Power LED

2 testo ASET15-1 Air Supply / Evaporation Tube (PND2 + VPR) interface

3 testo MD19-3E Rotating Disk Diluter (PND1) interface

4 male 25 pin D-Sub connector for analog and digital in- and output signals

5 USB connector of embedded computer

6 USB connector of embedded computer

7 USB connector of embedded computer used as default port for GRIMM 5.431 for

PMP R-83 measurements

8 USB connector of embedded computer

9 not used

10 LAN 2 connector of embedded computer; default setting: DHCP

11 LAN 1 connector of embedded computer; default IP adress: 192.168.1.129

12 VGA monitor connector of embedded computer

13 Male serial connector 1 of embedded computer used as default port for EECPC 3790 for

PMP R-83 measurements

14 Male serial 2 connector of embedded computer

15 not used

16 Female serial 3 connector to control testo CU-2 by AK host computer

17 Mains connector

18 Fuse holder; fuse: 250 V, 5.0 A, t

19 Mains switch

Page 12

5 Installation and Setup

12

The properties of the devices connected to testo CU-2 are specified in appendix A.2

4.5.2. Additional Analog and Digital In- and Output Connector 20)

testo CU-2 is delivered with a female connector 20) which is shown in Fig. 4.5. This connector

can be plugged into the external signals port 4). It is equipped with solder pins which can be used

as contacts for different analog and digital inputs and outputs:

• 5 analog input signals (–10...+10 VDC).

• 3 analog output signals which are configured by the testo NanoMet software

(0...+10 VDC).

• a digital input signal (0 or 5...25 VDC) which can be used to trigger data logging

• 2 digital alarm outputs delivering a 24 VDC signal in case of an error detected by the

testo NanoMet software. These alarm signals are also configured individually by the testo

NanoMet software.

Fig. 4.5: front and rear of external in- and output signals connector 20)

The pin assignment of the external signals port 4) and the specific connector 20) is described in

chapter 8.3.

5 Installation and Setup

Note: Numbers – e.g. 2) = testo ASET15-1 interface – refer to the operating elements illustrated

in chapter 4.5 and appendix A.3.

5.1. Hardware Setup

There are no big efforts to install testo CU-2 and combine it with testo MD19 Rotating Disk Diluter

and testo ASET15-1 Air Supply / Evaporation Tube.

Simply use standard 25 pin D-Sub cables to connect these devices to testo CU-2. The remote

control interface connector of the stand-alone testo MD19-3E is located at the rear side of the

testo MD19-3E laboratory case. If testo MD19-3E is integrated in an testo ASET15-1, the

interface connectors of both components are situated at the rear of the testo ASET15-1 case.

Both interfaces have to be connected to connectors 2) and 3) at the rear side of testo CU-2.

If analog input signals should be recorded or provided by testo CU-2, these external devices

might be connected to the external signals port 4), using a standard 25 pin D-Sub cable with

female connector, or using the external signals connector 20). Two alarm voltage signals can

also be tapped from the external signals port 4) and a trigger signal can be applied to start and

stop data logging. The pin assignment of the external signals port 4) and therewith the

connector 20) is described in chapter 8.3.

Connect the testo CU-2 to your computer network or directly to a host computer using a

crossover network cable, if the system should be remote controlled via Ethernet, use a 9 pin

RS-232 cable to connect it to an AK host computer, or add a VGA monitor, keyboard and mouse

to work directly on the testo CU-2.

The different operation modes are described in chapters 5.3 and 5.4.

5.2. Windows Embedded and Network Setup

5.2.1. Windows Embedded Login

testo CU-2 Digital Control Unit is delivered with Microsoft Windows Embedded installed. There

are two Windows users predefined:

user name

default

password

windows user

rights

remarks

Page 13

5 Installation and Setup

13

Admin Admin no restrictions

only recommended for remote

desktop operation and system setup

e.g. integration in local network

CU-2 CU-2 limited rights

recommended standard user,

automatically logged after system

boot up

For more detailed information or to integrate the testo CU-2 into your network please contact your

network administrator.

When the device is switched on, the embedded computer boots and the testo NanoMet software

is automatically started. The duration of operation system and testo NanoMet software startup is

about 100 seconds. After this time the system is ready for either manual operation of the dilution

system, or testo NanoMet software control, or AK host computer control.

5.2.2. Network Settings

testo CU-2 is equipped with two RJ45 sockets to connect the device to a Ethernet network. By

default the LAN 1 connection has no fix IP address but is set to DHCP while LAN 2 has assigned

the fixed IP address 192.168.1.129. LAN 1 connection using may be used to connect the device

to a network equipped with a DHCP server. LAN 2 is intended to be used for a direct connection

to a Windows PC using a crossover network cable.

As all other Windows settings the properties of both LAN connections can be changed in the

Windows system control panel when logged in as administrator.

The testo CU-2 can be found in the network either by using the IP address or the computer

name. The default computer name consists of the part 'testo-' and the serial number of the

individual device, e.g. 'testo-101999'.

5.3. testo NanoMet Software Startup and Operation Mode Selection

Plug in the power cable to the mains connector 17) and switch on the testo CU-2 unit using the

mains switch 19). Windows Embedded Standard boots and the testo NanoMet software is

automatically started. The system is ready for measuring appr. 100 seconds after switching on

the testo CU-2.

If a monitor is attached or the system is controlled by Windows desktop connection the testo

NanoMet user interface shown in Fig. 5.1 appears on the screen.

Fig. 5.1 : testo NanoMet user shell after system startup

5.3.1. Manual Operation Mode

After startup, the testo NanoMet software runs in the manual operation mode. The software

control menu contains the red 'Enable Software Control' button as shown in Fig. 5.2. Either the

Page 14

5 Installation and Setup

14

user can activate software control or the AK host computer can get control access via Ethernet or

serial port.

Fig. 5.2 : testo NanoMet control menu after software startup

Otherwise it might be helpful to remain in manual operation mode if dilution parameters have to

be determined like dilution factors or the total diluted measuring gas amount.

Neither the testo NanoMet software nor the AK host computer controls testo MD19-3E and testo

ASET15-1, even if they are physically connected to testo CU-2. The devices are locally operated

by the control elements at their front panels according to the instructions in the specific user

manuals. testo NanoMet software and AK host can read and log data provided by testo CU-2.

Data logging by testo NanoMet software is started by pushing the 'start data logging' button. The

AK interface is running in the background. Only AK read 'A' commands are possible. Control and

write commands from AK host are responded with 'state = busy' and the AK system runs in

'manual mode'

5.3.2. Software Control Mode

By clicking the software control button, the operator decides the testo NanoMet software to take

control over the aerosol conditioning system, i.e. testo MD19-3E Rotating Disk Diluter and testo

ASET15-1 Air Supply / Evaporation Tube. The software control button turns to grey and could

now be used to disable software control and return to manual control mode.

In software control mode, the system is operated via testo NanoMet user interface. The testo

NanoMet software has prior access to the data acquisition modules.

The AK interface is still running in the background. Only AK read 'A' commands are possible.

Control and write commands from AK host are responded with 'state = busy' and and the AK

system runs in 'manual mode'.

Manual software control mode is mostly used for system configuration, field measurement, or if

no other computer is available. It is possible to work directly on the embedded computer using

monitor, mouse, and keyboard directly connected to the control unit testo CU-2.

5.3.3. Remote Computer Software Control Mode

The system can be controlled by a remote-desktop connection. This is mostly used for

measurements on test-benches if the user operates in a control room and the devices are

mounted in a test cell. It is also used for system checks and configuration changes via Ethernet

without the need of being personally present.

The user directly works on the testo NanoMet software by using a remote-desktop connection. In

this case the operator has the screen from the embedded computer on his workstation monitor

and works on the embedded computer.

The remote desktop connection can be established using the remote desktop connection

software which is installed by default on Microsoft Windows XP professional or newer.

Appropriate remote desktop protocol (RDP) clients are also available for a number of other

operating systems like Windows 2000, 9x, and NT4, but also Mac OS X, Linux and others.

After startup of the RDP software, the testo CU-2 can be found in the network either using its

network computer name (e.g. 'matter-101999') or its IP address which are described in chapter

5.2.2.

The Windows Embedded Standard log-in window appears which is shown in Fig. 5.3.

Page 15

5 Installation and Setup

15

Fig. 5.3: log-in window

Even if the testo CU-2 system is started by default with the standard user 'Matter' without a

password needed, administrator rights are required for remote desktop operation.

An administrator account is created by default with both user name and password: Administrator

(mind the capital letter at the beginning of the password).

If you try to log-in as 'Administrator' for the first time after system startup, i.e. if the standard user

'Matter' is logged in, the message shown in Fig. 5.4 appears.

Fig. 5.4 : standard user log-out message

Confirm by clicking 'Yes' to log-out 'Matter' and change the user to 'Administrator'. After logging in

the testo NanoMet software is automatically started in the manual operation mode described in

chapter 5.3.1 with the control menu shown in Fig. 5.2.

5.4. AK Host Remote Control Mode

Using testo CU-2, the particle number measurement system can be integrated in a test rig. The

testo CU-2 Digital Control Unit can then be controlled by a host computer connected by serial

RS232 port or Ethernet connection. Communication protocol is AK over TCP/IP or RS232.

Detailed AK protocol specifications can be found in chapter 7.

A second host computer can be connected via Ethernet optionally. Only one of the host

computers can control the connected devices but the second one is able to read data using

AK 'A' commands.

The testo NanoMet software has to be in the Manual Operation Mode which is the default mode

after system start up. Then the AK master computer (Host A) can send remote command 'SREM'

to get priority. The testo NanoMet user interface will then be deactivated (software control mode

not available but data still can be read and recorded) and the second host (Host B) can only

execute 'A' commands. This is illustrated in the flow chart of Fig. 5.5.

Page 16

5 Installation and Setup

16

Fig. 5.5: testo NanoMet operation modes flow chart

The command 'SMAN' ends priority state of the master computer (Host A), operator may then

control the diluters manually, switch to software control and use the testo NanoMet software, or

the other host computer (Host B) can get priority by sending 'SREM'. In this case Host A can only

execute AK 'A' commands until Host B ends its priority by sending 'SMAN'.

Page 17

6 testo NanoMet Operation

17

6 testo NanoMet Operation

The testo NanoMet user shell consists of the testo NanoMet main window, the testo NanoMet

control panel, and the CPC control window.

The testo NanoMet main window contains five tabs to set measurement parameters, to select

operation mode and system state, to display the measured values and to do the data saving

settings.

6.1. Main Measurement Tab

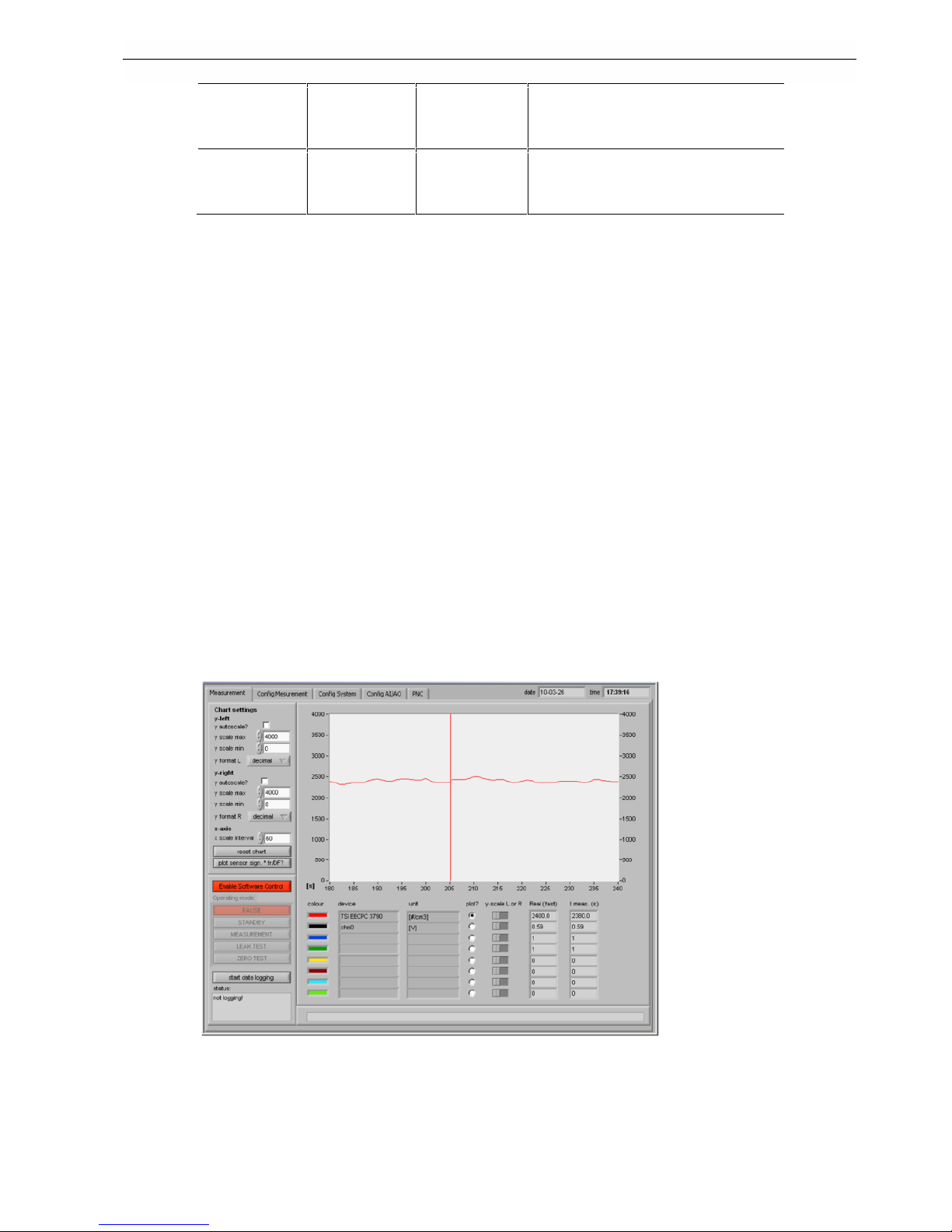

The 'Measurement' tab shown in Fig. 6.1 includes the software control menu which was already

described in chapter 5.3.1. It also displays the measured values, contains a chart where the

selected values are plotted, and an error bar at the bottom of the window, where auto-detected

errors are displayed.

Fig. 6.1: measurement tab

For every plotted signal it can be selected if the left or right y-axis should be used. In the chart

settings area, minimum and maximum values of these axes can be set. This is done

automatically if 'y auto scale' is selected. The set minimum and maximum values are useless

then. The 'x scale interval' determines how many seconds should be plotted in the chart. Default

value is 60 seconds, maximum is 1200 seconds = 2 hours.

The system state buttons in the software control menu are active when the system is operated in

the software control mode, as it is shown in Fig. 6.2. The system state is selected using these

buttons. The actual system state is marked by the red button.

6.1.1. Pause State

PAUSE state means that all pumps and heatings of testo MD19-3E and testo ASET15-1 are

switched off.

6.1.2. Standby State

STANDBY state means the system is ready for measurements. Pumps for sample gas and

dilution air are switched on as well as the heaters of primary dilution head and the evaporation

tube. Only the diluter disk is not rotating and therewith the dilution air passes the diluter without

being added by any amount or raw gas.

Page 18

6 testo NanoMet Operation

18

Fig. 6.2: testo NanoMet control menu in software control mode

6.1.3. Measurement state

In the MEASUREMENT state the disk starts to rotate. The system is ready to measure.

6.1.4. Leak Test

UN-ECE R83 reglementations require a system leakage test to be executed prior to each

measurement test cycle. This leakage test is effected by feeding filtered air into the inlet of the

entire particle sampling system. The particle counter shall then report a measured concentration

of less than 0.5 #/cm3.

This test can be performed automatically selecting the LEAK TEST state in the testo NanoMet

control menu. In this state all parameters are set as in the measurement state except that the

primary diluter disk is not rotating.

This means no raw gas is added and therewith the filtered dilution air passes the dilution system

instead of measuring gas. If the detected particle concentration does not recede to zero, either

the secondary dilution air flow is set too low which leads to ambient air sucked through the

excess air outlet port, or some leakage occurs, probably caused by a filter defect, by a failure at

the diluter disk, an untight connection, or by a sensor defect.

The leak test will start when 'start data logging' is clicked if the LEAK TEST state is selected.

After 2 minutes test duration the system returns to the STANDBY state. The data logged during

the leak test are saved in the selected data folder.

6.1.5. Zero Test

A PNC zero test is required once a day for UN-ECE R83 applications. In terms of this test filtered

air has to be feeded to the particle counter PNC. The PNC shall then report a measured

concentration of ≤ 0.2 #/cm3. The PNC shall show an increase in measured concentration to at

least 100 #/cm3 when challenged with ambient air and return to ≤ 0.2 #/cm3 when filtered air is

applied again.

The ZERO TEST state of the testo NanoMet software cannot supply ambient air to the PNC but

filtered air can be provided by the testo ASET15-1 when the primary dilution air supply is turned

off and neither measuring gas nor dilution air passes the evaporation tube and only dilution air

enters and leaves the secondary mixing chamber. If the amount of secondary dilution air exceeds

the inlet flow of the PNC, it can only draw filtered air. Ambient air can be provided by manually

pulling off the tube connector from the testo ASET15-1 measuring gas outlet.

If the PNC signal does not recede to zero during the zero test, either the secondary dilution air

filter or the sensor might be faulty.

The indicated particle concentration values during the zero test are recorded and saved in the

selected data folder during 2 minutes when 'start data logging' is clicked.

The ZERO TEST can also be used to isolate the reason for leakage found in a leak test. If the

signal turns to zero in the zero test but not in the leak test, the leakage will probably be found in

the primary dilution subsystem.

Page 19

6 testo NanoMet Operation

19

6.2. Measurement Configuration

The 'Config Measurement' tab shown in Fig. 6.3 serves to set the measurement parameters. It

will be selected what should be calculated by the software out of the measured particle

concentration values, how data logging will be started and stopped, and where the logged data

should be saved.

Fig. 6.3: measurement configuration tab

6.2.1. UN-ECE R83 Measurement and Test Cycle Definition

If the 'UN-ECE R83 measurement' button is activated, the measurements will follow a test cycle

consisting of up to 5 parts.

Each test of a cycle will be analyzed and particle number will be calculated in #/km according to

UN-ECE R83. The results are saved in the header of the saved file.

The desired test cycle is selected in the 'test cycle' menu. To change one of these predefined

cycles, it first must be selected, then the cycle name has to be entered in the text field right from

the 'test cycle' menu. The cycle part durations are entered in the fields below, and the newly

defined cycle is saved by clicking on the 'OK and save' button.

For the software to calculate the emissions in #/km, the 'cycle data information' window shown in

Fig. 6.4 appears after the data logging is completed. In this window, the amout of exhaust gas

volume and the virtually covered distance of the tested vehicle have to be entered for every cycle

part for the testo NanoMet software to calculate the emitted particle number per kilometer #/km.

The exhaust gas volume usually is the CVS total volume if the whole engine exhaust stream is

fed to and the particle sample was drawn from the CVS.

Page 20

6 testo NanoMet Operation

20

Fig. 6.4 : cycle data information window

6.2.2. General Measurement Settings

On the 'Config Measurement' tab it is also set if data logging will be started by a trigger signal or

manually and stopped manually or after a predetermined cycle time. Furthermore the sample rate

can be set between 2 and 5 Hz, and the signal averaging interval is set. This setting will have a

significant influence on the amount of data generated during the measurements.

By marking the 'include date in timestamp' control the date will also be saved in the first column

of each entry in the data storage file. This option is usually used for long time and overnight

measurements.

In the bottom line of the 'Config Measurement' tab the path can be set where the logged data

should be saved. This can either be locally on the internal memory of the embedded computer,

an added USB storage device, or an accessible folder in the network where the testo CU-2 digital

control unit is implemented.

The default folder for the logged data to be saved by the testo NanoMet software is

'D:\MEASUREMENT DATA' on the internal flash memory of the embedded computer. The

standard user 'CU-2' has no rights to access other folders.

6.3. System Configuration

The system components must be specified in the 'Config System' tab shown in Fig. 6.5. The

round check buttons can be activated independently of each other.

6.3.1. Measurement Instruments

With the round check button, it is set if any testo NanoMet controllable particle detection sensor is

attached and should be used for the measurements, or if just the dilution and conditioning

components testo MD19 -3E Rotating Disk Diluter and testo ASET15-1 Air Supply / Evaporation

Tube are controlled by the testo NanoMet software.

The port where the sensor is attached to the testo CU-2 digital control unit can be set.

Selectable sensors are TSI condensation particle counters CPC 3010, 37xx, engine exhaust

condensation particle counter EECPC 3790, GRIMM 5.431 or the EcoChem PAH monitor

PAS2000. The serial number and the measuring unit can be entered.

Furthermore, a CPC correction factor k can be entered, according UN-ECE R83 regulations. This

factor can be used to compensate a certain CPC signal deviation which possibly has been found

when the sensor has been compared to a reference device.

Page 21

6 testo NanoMet Operation

21

Fig. 6.5: system configuration tab

6.3.2. Dilution Instruments

As secondary dilution unit PND2 only the testo ASET15-1 Air Supply / Evaporation Tube can be

selected or not.

The testo MD19-3E is intended as primary dilution unit PND1. testo MD19-3E supports extended

remote control functions like to control the primary diluter temperature and the raw gas pump by

the testo NanoMet software as well as it is possible to read raw gas temperature and pressure

and several error informations by testo CU-2 Digital Control Unit. The testo NanoMet control

panel is added by these additional functions if testo MD19-3E is selected as primary diluter.

Along with the Rotating Disk Diluter version the rotating disk type has to be selected. The

10 cavities disk serves to realize lower dilution factors while higher dilution factors are achieved

using the 8 cavities disk, as it is described in the testo MD19-3E user manual.

The 'use fr or standard calibration' menu in the system configuration tab shown in Fig. 6.5 allows

to set if measurements should be performed using the attached devices applying their standard

calibrations, or if PMP compliant calibrations according UN-ECE R83 should be applied.

By clicking the 'change' button the calibration factors settings window shown in Fig. 6.6 can be

opened to insert the calibration data out of the documents delivered with the dilution components

to the testo NanoMet software.

As standard, the instruments are calibrated individually. The more extensive and more detailed

PMP calibration is done with the components combined to one system.

For setting up the system according UN-ECE R83, the nominal primary and secondary dilution

factors have to be approximately determined. The best fitting dilution settings out of the

calibration certificate have to be selected and entered into the corresponding fields of the

calibration factors window, together with the PCRF determined in line with these values during

the calibration procedure.

Page 22

6 testo NanoMet Operation

22

Fig. 6.6: calibration factors settings window

To use the standard calibration, simply the two calibration factors determined for both testo

MD19-3E diluter disks must be entered in the specific field. There is no need for testo ASET15-1

calibration figures because in terms of its calibration this device has been adjusted to meet

exactly its nominal dilution factors.

6.3.3. AK Interfaces

An AK host computer may either connect to the testo CU-2 Digital Control Unit via serial

connection or via TCP/IP using one of the two LAN connectors of the device.

If a serial connection should be used, COM4 is set by default. This port is equipped with a female

connector while COM1...COM3 have male connectors. This is done because in this case testo

CU-2 is connected to the AK server as a slave while the other COM ports are used to connect

other slave devices to testo CU-2 Digital Control Unit as master.

Another AK host may connect to testo CU-2, but this one can only execute AK 'A' (read)

commands because only one instance may control the system and therewith execute 'S' (control)

and 'E' (write) commands.

The detail parameters of the connection to the AK host can be set in the 'AK interfaces' section of

the 'Config System' tab.

6.4. Analog Input and Output Signals Configuration

On the 'Config AI/AO' tab shown in Fig. 6.7 the 5 analog inputs can be specified and the

functions of the 4 analog outputs can be selected out of the referring menus. Besides it is set if

one digital output signals should be used for all errors or if the two available signals should

indicate CPC and dilution system errors separately.

Page 23

6 testo NanoMet Operation

23

Fig. 6.7: analog input and output signals configuration tab

6.4.1. Analog In

Using the round check buttons, every analog input and output channel can be activated or

deactivated individually. Active input signals will be recorded in the measurement file during data

logging and will be available for being displayed on the 'Measurement' tab.

For every channel an analog DC voltage range within –10 V DC...+10 V DC can be specified to

equate a certain signal range. Furthermore, the signal can be named and serial number and

signal unit can be entered which will also be saved during data logging.

6.4.2. Analog Out

Fig. 6.8: analog and digital output signal menues

The 4 analog output signals can also be enabled individually. For every voltage output, one

signal can be selected from the menu which is opened by clicking on the signal selection bar.

The output voltage range is 0...+10 V DC. The signal range corresponding to this voltage limits is

set by the operator.

Page 24

6 testo NanoMet Operation

24

6.5. PNC Tab

The informations provided by the attached particle number counter PNC, i.e. TSI condensation

particle counter CPC are shown on the 'PNC tab' shown in Fig. 6.9.

Fig. 6.9: particle number counter PNC tab

If a TSI 37xx or GRIMM 5.431 particle counter is used, these informations are the detected

particle concentration which is also displayed at the CPC front display, the ambient conditions of

the CPC, the temperatures inside the sensor which are relevant for correct operation, the serial

number, any errors, and some operation parameters.

The TSI 3010 model only sends the vacuum information to the control device. This value is

important to ensure sufficient flow through its critical nozzle.

It is also possible to send certain commands to the particle number counter. These are to enable

or disable the automatic functions autofill and water removal for TSI 37xx models and the butanol

fill button for TSI 3010.

6.6. testo NanoMet Control Panel and CPC Window

6.6.1. testo NanoMet Control Panel

The testo NanoMet control panel is shown in Fig. 6.10. It serves to set dilution and conditioning

parameters like primary and secondary dilution factors and temperatures of primary diluter and

evaporation tube of testo ASET15-1. This window also allows to control the testo ASET15-1

pumps and the raw gas pump of testo MD19-3E and it provides information about the hardware

status, i.e. if the set dilution factor and temperatures are reached, if the pump flows are within

their specifications, and if the rotating disk motor works correctly.

Fig. 6.10: testo NanoMet control panel with testo MD19-3E control field

Page 25

7 AK Host Operation

25

The testo NanoMet control panel will be deactivated and its background color will change from

black to grey, if software control is disabled i.e. the system runs in manual or AK host control

mode. It gets active when software control is enabled.

6.6.2. CPC Window

If a 3010 or 37xx condensation particle counter CPC from TSI or GRIMM 5.431 is used as

particle number counter PNC, the actually measured value of this sensor is displayed in the CPC

window shown in Fig. 6.11 as well as the CPC status and a short description of automatically

detected CPC errors.

Fig. 6.11: CPC status window

7 AK Host Operation

7.1. AK Software Integration

The testo NanoMet operation modes are described in chapter 5.3 and 5.4 and illustrated in Fig.

5.5. An AK host computer can simply take control over the system by sending the 'SREM'

command after the software start up if testo NanoMet software control has not been activated

before.

The testo NanoMet software is started and therewith the system including AK module is ready

appr. 100 seconds after the testo CU-2 is switched on.

7.2. AK Interfaces Specifications

7.2.1. Serial Interface

The RS232 V24 9-pin male connector at the back of the unit is used to connect a master

computer with the following pin assignment:

Pin 3 = Txd (transmit)

Pin 2 = Rxd (receive)

Pin 5 = Gnd (ground)

All serial parameters fo the AK communication can be configured in the testo NanoMet software:

parameter

select

able values

default settings

baud rate

1200, 2400, 4800, 9600, 19'200, 38'400

9600

start bit

1 1

data bits

7 or 8

8

stop bits

1 or 2

1

parity

even, odd, none

none

handshake

Xon/Xoff

Xon/Xoff

Page 26

7 AK Host Operation

26

7.2.2. TCP/IP Interface

There are two RJ45 connector at the back of the unit for the TCP/IP communication. Both ports

may be used to connect one or two host computers to the testo CU-2.

There are two parameters necessary for the AK communication:

• IP addresses of the computer. These can be changed when logged in as administrator

on the embedded computer.

Default value for LAN2: 192.168.1.129, LAN1 is set to DHCP by default.

These addresses may have to be changed to connect the testo CU-2 to a network.

The embedded computer can be identified in a network by its network name.

Default name of testo CU-2 is 'MATTER-[Serial number]', e.g.: 'MATTER-101999'

• The AK port addresses can be configured in the testo NanoMet software. Each port must

be a number between 0 and 65535. Default values are 49152 (Host A) and 49153 (Host

B).

Both ports are used at the two IP addresses, respectively LAN ports.

Numbers from 0 up to 49151 should not be used, because they are officially registered

and reserved.

7.3. AK Protocol Specification

7.3.1. AK Command Telegram

protocol: hex: description

1. Byte STX

HEAD

02 start byte

2. Byte DON'T CARE (30)

any byte, configurable in testo

NanoMet software

default = 30 h = '0'

3. Byte FUNCT.CODE1

function code, 4 bytes

4. Byte FUNCT.CODE2

5. Byte FUNCT.CODE3

6. Byte FUNCT.CODE4

7. Byte BLANK

VARIABLE DATA

(length depending

on functional code)

20 blank (space, 20 h)

8. Byte 'K' 4B

K for channel / device with

following number

9. Byte NUMBER

device number,

always = 0, 1 byte

DATA

data depending on functional

code

n. Byte ETX END 03 end byte

7.3.2. AK Response Telegram

protocol:

hex: description

1. Byte

STX

HEAD

02

start byte

2. Byte

DON'T CARE (30)

any byte, configurable in testo

NanoMet software

default = 30 h = '0'

3. Byte

FUNCT.CODE1

function code, 4 bytes

Page 27

7 AK Host Operation

27

4. Byte

FUNCT.CODE2

5. Byte

FUNCT.CODE3

6. Byte

FUNCT.CODE4

7. Byte

BLANK

FIXED DATA

20

blank (space, 20 h)

8. Byte

ERROR STATUS

0 when no error, 1...9,

+1 every error status change

DATA

VARIABLE DATA

(length depending

on functional code)

data depending on functional

code, can also disappear

n. Byte

ETX END 03

end byte

7.3.3. General AK Protocol Description

• Every transfer always starts with 'STX', each 'STX' starts a new transfer

• The 'don't care' byte can take any content, excluding control signs or signs reserved by

AK commands. Default value is 0 (30 hex)

• Every function code always includes 4 bytes. A list of all codes can be found in the

following chapters.

• The function code may not contain blanks.

• If the command message contains no error, the response message contains the echo of

the function code and the error status number (0 to 9).

• The echo will be four question marks (????), if the function code has an error or is

unknown, or the command telegram has not a minimum length of 10 bytes.

• There are three groups of function codes:

S = Control commands

A = Read commands

E = Write commands

(S, A, E stands for the German words: 'Steuerbefehle', 'Abfragen', 'Einstellbefehle')

• The particle measurement system is a measurement device and not a functional engine.

Therefore, the identification respectively the channel number is always K0.

• Error status is '0' for an error free running of the system. The error status number will be

counted up from 1 to 9 with each change in the error status. The error status number will

be zero again after all errors are removed.

• The data set is variable. Each data set will begin with a blank (20 h) . A blank is also used

to separate characters of data. The separation with <CR><LF> will only be done, if the

following complete data will have more than 60 digits.

• The long and variable floating point or the E- format are allowed to display the digits of

numbers in the data set. You can find the used formats for all functional codes in the

following chapters. '+/-' may only be used for negative numbers. Digits without physical

meaning have to be removed.

• Every transfer always stops with 'ETX'

7.3.4. Handling of Certain Conditions

• If transfer of a data value is not possible, e.g. a device in the system is missing or it

cannot send a signal, the data will be replaced by a '#'

• The date is only valid with restrictions, e.g. temperature of CPC is not ready. Then data

will begin with '#'

• If a control or adjusting command is sent while the measuring device is in 'Manual' mode,

resp. not set to 'Remote', then response data set = 'OF' (offline)

• If the system is not able to send a response. The host computer has to realize the

missing response by 'time out'

Page 28

7 AK Host Operation

28

• If the system is occupied by executing a previous function, the new start of a control

command will lead to the response 'BS' (busy) in the data block of the response. The

running function will not be disturbed. Exception: The command was a software reset.

• If the system is operated in manual operation mode, also the command 'remote' will be

responded with 'BS'. In this mode only read commands can be used. All control and write

commands will be responded with 'BS'.

• If the data or parameters transfer is not complete (i.e. not expected format) in the

command telegram of the system, the host computer will get a 'SE' (Syntax Error) in the

data block of the response.

• If the system doesn't work with data or parameters of the command (data error,

parameter error) the host computer will get a 'DF' (Data Failure) in the data block of the

response.

• All setpoints set with write 'E' commands will be saved when testo CU-2 will be shut

down and they will be restored after rebooting and set to standby or measurement mode.

7.4. List of All AK Commands

7.4.1. Control Commands – 'S'

CODE: description:

SREM

REMOTE

– set system to AK host remote control mode

SMAN

MANUAL – disable remote control and set system to manual operation

SRES

RESET

– reset all functions and restart system

SPAU

PAUSE

– set system to pause state

STBY

STAND BY

– set system to stand by state

SMGA

MEASURE

– set system to STAND BY state

SNGA

ZERO TEST

– start automatic PNC zero concentration test

SLEC

LEAK TEST

– start automatic system (VPR+PNC) leak test

SINT

INTEGRATOR

START

– start integration, integral avarage

SINA

INTEGRATOR STOP

– stop integration started with SINT

7.4.2. Write Commands – 'E'

CODE: description:

ENOR

set standard conditions temperature and pressure

ETD1

set PND1 temperature

range: 20...150°C

EVD1

set

PND1 dilution factor

range: 15...300 (10 cav.) or 150...3000 (8 cav.)

EVD2

set PND2 dilution factor

range: 1...11

ETET

set ET temperature

range:

20...400°C

EDST

set PND1 diluter disk type and if secondary dilution PND2 shall be used or

7.4.3. Read Commands – 'A'

CODE: description:

ASTZ

STATUS

– read the current operation mode and system state

ASTF

ERROR STATUS

– read the numbers of all current failures

AKON

read the current diluted and undiluted particle number concentrations

APRF

read current

particle concentration reduction factor PCRF

Page 29

7 AK Host Operation

29

CODE: description:

AIKG

concentration integral average calculated since the command SINT

AIKO

concentration integral average calculated since command SINT or last AIKO

ANGA

read the result of the last ZERO TEST

ALEC

read the

result of the last LEAK TEST

ANOR

read the currently set standard conditions: standard temperature and

ATD1

read PND1 temperature

AVD1

read setpoint and actual value of primary dilution factor DF

PND1

AVD2

read setpoint and actual value of

secondary dilution factor DF

PND2

ATET

read evaporation tube ET temperature

AFD2

read the secondary dilution air supply flow Q

AS

in PND2

7.5. Descripton of All AK Commands

7.5.1. Control Commands – 'S'

SREM REMOTE – set system to AK host remote control mode

command: SREM K0 response: SREM E

E: error status 0...9

SMAN MANUAL – disable remote control and set system to manual operation mode

command: SMAN K0 response: SMAN E

E: error status 0...9

SRES RESET – reset all functions and restart system

system status after reset is MANUAL mode and PAUSE state

command: SRES K0 response: SRES E

E: error status 0...9

SPAU

PAUSE – set system to pause state: resting state after system start or

RESET

PND1 disk stopped, sample gas pump off, dilution air pumps off, PND1 and

ET heatings off

command: SPAU K0 response: SPAU E

E: error status 0...9

STBY STAND BY – set system to stand by state: ready for measurements

PND1 disk stopped, sample gas and dilution air pumps on, PND1 and ET

heating on

command: STBY K0 response: STBY E

E: error status 0...9

Page 30

7 AK Host Operation

30

SMGA MEASURE – change from STAND BY to measurement state

PND1 disk rotates, diluted gas flows to PNC

command: SMGA K0 response: SMGA E

E: error status 0...9

SNGA

ZERO TEST – start automatic PNC zero concentration test, duration: 2 min

during SNGA mode other S and E commands will be responded with 'BS'

(busy)

exceptions: 'SRES', 'STBY' or 'SPAU' will stop running zero test

according the UN-ECE R83 regulation the number concentration should be

< 0.2 #/ccm

the result of this test can be read with the command ANGA

command: SNGA K0 response: SNGA E

E: error status 0...9

SLEC

LEAK TEST – start automatic system (VPR+PNC) leak test, duration: 2 min

during SNGA mode other S and E commands will be responded with 'BS'

(busy)

exceptions: 'SRES', 'STBY' or 'SPAU' will stop the running leak test

according the UN-ECE R83 regulation the number concentration should be

< 0.5 #/ccm

the result of this test can be read with the command ALEC

command: SLEC K0 response: SLEC E

E: error status 0...9

SINT

INTEGRATOR START – start integration, integral avarage

integration of values runs until stopped with SINA or restarted with SINT

again

the avarage values can be read with AIKG or AIKO

command: SINT K0 response: SINT E

E: error status 0...9

SINA INTEGRATOR STOP – stop integration started with SINT

command: SINA K0 response: SINA E

E: error status 0...9

7.5.2. Write Commands – 'E'

ENOR

set standard conditions temperature and pressure

(system default: 273.15 K, 1013.25 mbar)

command:

ENOR K0 TTT

PPP

response: ENOR E

E: error status 0...9

TTT: absolute temperature [K] format: floating

point example: '273.15'

PPP: pressure [mbar] format: floating point

example: '1013.25'

Page 31

7 AK Host Operation

31

ETD1

set PND1 temperature the range: 20...150°C

setpoints out of range are rounded to the next lowest respectively highest

possible temperature

command: ETD1 K0 TTT response: ETD1 E

E: error status 0...9

TTT: temperature [°C] range: 20...150°C ECE

R83: 150°C

format: floating point example: '150.0'

EVD1

set PND1 dilution factor range: 15...300 (10 cav.) or 150...3000 (8 cav.)

range: 15...300 for 10 cavities disk or 150...3000 for 8 cavities disk (nominal

values)

setpoints out of range are rounded to the next lowest respectively highest

possible dilution factor

command: EVD1 K0 DDD response: EVD1 E

E: error status 0...9

DDD: dilution factor DF PND1 [ - ] range:

15...300 or 150...3000

format: floating point example: '20.0'

EVD2

set PND2 dilution factor range: 1...11

setpoints out of range are rounded to the next lowest respectively highest

possible temperature

command: EVD2 K0 DDD response: EVD2 E

E: error status 0...9

DDD: dilution factor DF PND2 [ - ] range:

1...11

format: floating point example: '10.0'

ETET set evap. tube ET temperature range: 20...400°C

command: ETET K0 TTT response: ETET E

E: error status 0...9

TTT: temperature [°C] range: 20...400°C ECE

R83: 300...400°C

format: floating point example: '300.0'

EDST

set PND1 diluter disk type and if secondary dilution PND2 shall be used or

not

choose 8 or 10 cavities disk. The disk selection but not the PND2 setting will

be stored and used after reset or system restart. If PND2 is disabled, air

supply pump is switched off and DF

PND2

=

1

command: EDST K0 CC D response: EDST E

E: error status 0...9

CC: used rotating disc format: integer,

2 digits '10' for 10 cavities or '08' for 8 cavities

disk

D: '0' for PND2/pump off '1' for PND2/pump

on

Page 32

7 AK Host Operation

32

7.5.3. Read Commands – 'A'

ASTZ

STATUS – read the current operation mode and system state

three modes inform if the system is manually or remote controlled by current

or another host

if system is remote operated by current host, system state is indicated

command:

ASTZ K0

response:

ASTZ E OOOO SSSS

E: error status 0...9

OOOO: operation mode:

'SREM': remote operation, current host

'SMAN': manual operation

only read commands possible

'SRBS': remote busy another host is in

remote mode (SREM)

SSSS: system state:

'SPAU' pause state

'STBY' standby state

'SMGA' measurement state

'SNGA' zeroing state

'SLEC' leak test mode

ASTF ERROR STATUS – read the numbers of all current failures

command:

ASTF K0

response:

ASTF E a b c d ...

E: error status 0...9

a, b, c, d ... sequence of the numbers of

current system errors which are listed in

chapter ??. example: '11 13 20' means:

– ET temperature wrong

– CPC not ready

– CPC liquid level too low

AKON

read the current diluted and undiluted particle number concentration:

concentration is corrected to the currently set standard conditions (ENOR)

command:

AKON K0

response:

AKON E CCC RRR FFF

E: error status 0...9

CCC: particle concentration corrected to std.

cond. [#/ccm]

E-format: example: '3.26E3' = 3'260 #/ccm

response is not affected by stopped disk

rotation

RRR: concentration CCC multiplied by PCRF

E-format: example: '3.26E5' = 326'000 #/ccm

if disk rotation is stopped, response will be

'NaN'

FFF: particle concentration reduction factor

PCRF format: floating point example: '100.0'

if disk rotation is stopped, response will be 'Inf'

APRF read current particle concentration reduction factor PCRF

command:

APRF K0

response:

APRF E FFF

E: error status 0...9

FFF: particle concentratio reduction factor

PCRF format: floating point example: '100.0'

if disk rotation is stopped, response will be 'Inf'

Page 33

7 AK Host Operatio

n

33

AIKG concentration integral average calculated since the command SINT

command:

AIKG K0

response:

AIKG E CCC RRR FFF

E: error status 0...9

CCC: particle concentration corrected to std.

cond. [#/ccm]

E-format: example: '3.26E3' = 3'260 #/ccm

response is not affected by stopped disk

rotation

RRR: concentration CCC multiplied by PCRF

E-format: example: '3.26E5' = 326'000 #/ccm

if disk rotation is stopped, response will be 'NaN'

FFF: particle concentration reduction factor

PCRF format: floating point example: '100.0'

if disk rotation is stopped, response will be 'Inf'

AIKO concentration integral average calculated since command SINT or last AIKO

command:

AIKO K0

response:

AIKO E CCC RRR FFF

E: error status 0...9

CCC: particle concentration corrected to std.

cond. [#/ccm]

E-format: example: '3.26E3' = 3'260 #/ccm

response is not affected by stopped disk

rotation

RRR: concentration CCC multiplied by PCRF

E-format: example: '3.26E5' = 326'000 #/ccm

if disk rotation is stopped, response will be 'NaN'

FFF: particle concentration reduction factor

PCRF format: floating point example: '100.0'

if disk rotation is stopped, response will be 'Inf'

ANGA

read the result of the last ZERO TEST (started by SNGA command before)

if no zero test has been done since start-up of the system, response is 'NaN'

according UN-ECE R83 the number concentration must be < 0.2 #/ccm

command: ANGA K0 response: ANGA E CCC MMM

E: error status 0...9

CCC: corrected particle concentration [#/ccm]

E-format: example: '0.05E0' = 0.05 #/ccm

MMM: duration in minutes since zero test has

been done

format: integer example '125' = 125 min

ALEC

read the result of the last LEAK TEST (started by SLEC command before)

if no leak test has been done since start-up of the system, response is 'NaN'

according UN-ECE R83 the number concentration must be < 0.5 #/ccm

command:

ALEC K0

response:

ALEC E CCC MMM

E: error status 0...9

CCC: corrected particle concentration [#/ccm]

E-format: example: '0.08E0' = 0.08 #/ccm

MMM: duration in minutes since leak test has

been done

format: integer example '125' = 125 min

Page 34

7 AK Host Operation

34

ANOR

read the currently set standard conditions: standard temperature and

pressure

command:

ANOR K0

response:

ANOR E

TTT PPP

E: error status 0...9

TTT: temperature [K]

format: floating point example: '273.15'

PPP: pressure [mbar]

format: floating point example: '1013.25'

ATD1 reads PND1 temperature

command:

ATD1 K0

response:

ATD1 E TTT

E: error status 0...9

TTT: temperature [°C] for ECE R83: 150°C

format: floating point example: '150.8'

AVD1

read setpoint and actual value of primary dilution factor DF

PND1

if PND1 rotating disk is stopped and therefore DF

PND1

is infinite, response is

'Inf'

command:

AVD1 K0

response:

AVD1 E DDD RRR

E: error status 0...9

DDD: DF

PND1

primary dilution factor setpoint

15...300 or 150...3000, depenting on used disk

format: floating point example: '20.0'

RRR: DF

PND1

primary dilution factor actual

value

format: floating point example: '20.2'

AVD2 read setpoint and actual value of secondary dilution factor DF

PND2

command:

AVD2 K0

response:

AVD2 E DDD RRR

E: error status 0...9

DDD: DF

PND2

setpoint range: 1...11

format: floating point example: '10.0'

RRR: actual DF

PND2

format: floating point example: '10.05'

ATET read evaporation tube ET temperature

command:

ATET K0

response:

ATET E TTT

E: error status 0...9

TTT: temperature [°C] range: 20...400°C ECE

R83: 300...400°C

format: floating point example: '300.5'

AFD2 read the secondary dilution air supply flow QAS in PND2

command:

AFD2 K0

response:

AFD2 E FFF

E: error status 0...9

FFF: flow in lN/min range: 0...15.0 lN/min

format: floating point example: '3.0'

7.5.4. AK Errors List

There are a number of errors which can be detected by the system and read out using the 'ASTF'

command. These error codes are listed below:

Page 35

8 Electrical Connections

35

# error notation description

1 Status PND1 not ready

2 PND1 temperature error

3 Dilution error failure in dilution factor

4 Motor error Rotating disk is blocked

5 Pump error raw gas pump not running

6 Dilution air flow PND1 failure

10 Dilution air flow PND2 failure flow failure or flow too low

11 Temperature ET wrong

Temperature of the evaporation tube differs 10°C

or more from setpoint

12

DF PND2 failure deviation

13 CPC status not ready

14 Saturator temp out of range

15 Condenser temp out of range

16 Optics temp out of range

17 Inlet flow rate out of range

Orifice pressure is < 10 or > 90 kPa. Apply

sufficient external vacuum.

18 Aerosol flow rate out of range

19 Laser power low

20 Liquid level low

21 Concentration out of range value detected by CPC > 1.0E4 #/ccm

22 Multiple Error at CPC

23 No CPC communication

CPC is not connected, switched off or cable

8 Electrical Connections

8.1. Mains Supply

Connect the power cord plug to a grounded power socket. The IEC mains connector 17) on the

rear side of the testo CU-2 case includes the mains switch 19) and the fuse holder 18). The one

phase power cord delivered with the instrument is equipped with a country-specific plug and

protective earth.

Mains supply voltage: 90 ... 240 VAC, 50/60 Hz, max. 140 VA

Fuse type: slow switching fuse 250 V, 5 A, t, 5 x 20 mm

Page 36

8 Electrical Connections

36

Warning

In case of a blown fuse, replace it only with the specified type of fuse. If the fuse

is repeatedly blown, the unit must be sent to the manufacturer or to an

instructed service station for checking and repair.

Electric Shock

Make sure that the protecting ground pin of the country specific plug is correctly

connected to the protecting ground contact of your socket. If the plug is

replaced, ensure the yellow/green ground wire of the cable is properly