Page 1

testo ASET15 1

User Manual

Page 2

2

Page 3

Content

3

Content

1 Declaration of Warranty ............................................................................................... 5

1.1. Type of Designation ....................................................................................................................... 5

1.2. Manufacturer ................................................................................................................................ 5

1.3. Warranty ....................................................................................................................................... 5

2 Precautions ................................................................................................................... 5

2.1. Foreword ....................................................................................................................................... 5

2.2. Liabilities ....................................................................................................................................... 5

2.2.1. Liability to Content ............................................................................................................... 6

2.3. Copyright © ................................................................................................................................... 6

3 Safety ............................................................................................................................ 6

3.1. Risk Types ...................................................................................................................................... 6

3.1.1. Aerosol Contamination......................................................................................................... 6

3.1.2. Hot Surfaces – Burn Hazards................................................................................................. 6

3.1.3. Electrical Safety .................................................................................................................... 6

3.1.4. Mechanical Shock................................................................................................................. 6

3.2. Labels and Explanations ................................................................................................................. 7

4 System Overview........................................................................................................... 8

4.1. Dilution and Conditioning .............................................................................................................. 8

4.1.1. Principle ............................................................................................................................... 8

4.1.2. ThermoDilution .................................................................................................................... 8

4.2. Definitions ..................................................................................................................................... 9

4.3. Abbreviation, Units and Symbols .................................................................................................... 9

4.4. The System .................................................................................................................................. 10

4.5. Control Elements and Connections............................................................................................... 11

4.5.1. Important Remarks ............................................................................................................ 11

4.5.2. Front View ......................................................................................................................... 11

4.5.3. Gas Connectors .................................................................................................................. 12

4.5.4. Rear View........................................................................................................................... 13

5 Installation and Setup ................................................................................................. 14

5.1. Integrating testo MD19-3E into the testo ASET15-1 ...................................................................... 14

5.2. Gas/Aerosol Connections ............................................................................................................. 15

5.2.1. Quick Couplings at the front of testo ASET15-1 ................................................................... 15

5.2.2. Connect a Sensor to the Measuring Gas Inlet of the Evaporation Tube ................................ 15

6 Operating Instructions ................................................................................................ 16

6.1. Start Up ....................................................................................................................................... 16

6.2. Evaporation Tube Heating Up Procedure ...................................................................................... 16

6.3. Flows and Control LED's in Air Supply Part .................................................................................... 17

6.3.1. Signal LED Information ....................................................................................................... 18

6.3.2. Flow Settings and Dilution Factors ...................................................................................... 18

Page 4

Content

4

6.3.3. Influence of Instrumentation Connected to the Additional ET Inlet Port .............................. 18

6.4. Remote Operation ....................................................................................................................... 19

7 Electrical Connections ................................................................................................. 20

7.1. Mains Supply ............................................................................................................................... 20

7.2. Analog/Digital Interface ............................................................................................................... 20

7.3. Remote Control ........................................................................................................................... 22

8 Maintenance and Calibration ...................................................................................... 22

8.1. Evaporation Tube......................................................................................................................... 22

8.2. Parts with Limited Lifetime .......................................................................................................... 22

8.3. Storage, Acclimatization............................................................................................................... 22

8.4. Operation Environment Requirements ......................................................................................... 23

9 Appendix ..................................................................................................................... 24

9.1. Extent of Delivery ........................................................................................................................ 24

9.2. Specification, Technical Data ........................................................................................................ 24

9.3. Thermophoretic Losses ................................................................................................................ 25

9.4. Definitions, Units and Conversion Table ....................................................................................... 26

10 Designation of All testo ASET15-1 Air Supply / Evaporation Tube Elements ............... 27

Page 5

1 Declaration of Warranty

5

1 Declaration of Warranty

Manual Version History:

Version: V1.1

Date: September 2016

1.1. Type of Designation

This user manual refers to the instrument type and version as listed below. It replaces all

previously dated user manuals for this instrument.

Type: testo ASET15-1

1.2. Manufacturer

Testo SE & Co. KGaA

Testo-Strasse 1

79853 Lenzkirch

Germany

Tel: +49 7653 681 5062

Fax: +49 7653 681 95062

web: www.testo-particle.com

email: sales-nanoparticle@testo.de

For technical support contact your local service contractor or Testo techsupport.

email: support-nanoparticle@testo.de

1.3. Warranty

Testo SE & Co. KGaA warrants that this product adheres to the specified properties for a period

of twelve (12) months from the date of delivery.

Excluded from the warranty are all parts subjected to normal wear as any fuses, batteries or

other consumable parts. Also excluded are: Defects resulting from abnormal use, in particular

outside the intended purpose; lack of maintenance; improper use or malicious damage. Warranty

is void if actions are carried out which are not described in the documentation nor authorized by

Testo SE & Co. KGaA.

Testo SE & Co. KGaA does not provide any warranty on finished goods manufactured by others.

Only the original manufacturer's warranty applies.

There are no user-serviceable parts inside testo ASET15-1 and some very sensitive parts. Do not

open your testo ASET15-1, as you may damage it. Warranty is voided if the case is opened and

warranty-seal is broken.

Parts repaired or replaced as a result of repair services are warranted to be free from defects in

workmanship and material, under normal use, for 90 days from the date of shipment.

2 Precautions

2.1. Foreword

This manual guides you through the installation, starting up, operation and maintenance

procedures of the testo ASET15-1. In detail you will find information about the system as

safety

functionality of the testo ASET15-1, technical information and specifications

installation of the testo ASET15-1 and accessories

handling, operation, maintenance and troubleshooting

Follow the instructions provided by this manual for safe and proper operation of the testo

ASET15-1 Air Supply / Evaporation Tube.

Before installing and operating the testo ASET15-1, the operator or service has

to read carefully this manual. For improper function, damages or injuries caused

by ignoring the instructions by this manual no liabilities are accepted.

2.2. Liabilities

Testo SE & Co. KGaA accepts no liability to improper function or injury caused by

neglecting the instructions provided by this manual or instructed person.

improper installation, operation, application, or maintenance.

operation by untrained staff.

Page 6

3 Safety

6

any technical modification not carried out by Testo SE & Co. KGaA or an authorized

service partner.

use of not genuine spare parts.

2.2.1. Liability to Content

The content of this manual is generated with most accurateness. Testo SE & Co. KGaA does not

guarantee completeness, correctness and being up to date. Testo SE & Co. KGaAreserves the

right to revise the content of the manual at any time and without notice.

Follow the guidelines below to ensure proper operation of the instrument:

Read this instruction manual before installation and operation.

Always use genuine replacement parts supplied by Testo SE & Co. KGaA.

For operating the testo MD19-3E Rotating Disk Diluter integrated in the testo ASET15-1,

refer to the testo MD19-3E user manual.

2.3. Copyright ©

All work and contents done or generated by Testo SE & Co. KGaAare subject of the German

copyright © and law for intellectual property. This copyright includes all specification data of the

instrument or part of it, electrical and fluidic and mechanical schematics, pictures, diagrams and

text. Copying, editing, publishing or any other utilisation requires a written agreement of

Testo SE & Co. KGaA.

3 Safety

3.1. Risk Types

The following diagram shows typical risks that could cause damage or injury while handling the

testo ASET15-1 Air Supply / Evaporation Tube.

Fig.3.1 : risk types

3.1.1. Aerosol Contamination

Toxic aerosols may escape from the device, if the excess and measuring gas ports are not

properly connected to the sensors downstream or an offtake.

3.1.2. Hot Surfaces – Burn Hazards

The evaporation tube is heated up to 400°C/752°F. Therefore, the pipes and other parts on the

rear side of the device may be hot and must not be touched. Always ensure good air circulation

around the heated parts. Do not use the device if the fan for gas cooling on the rear side of the

device does not work properly.

3.1.3. Electrical Safety

When in operation any electrical equipment can produce dangerous voltages. Failure to observe

the warnings may result in serious injury or damage. It is, therefore, mandatory that only suitably

qualified personnel use this instrument. Satisfactory and safe operation of this instrument calls for

proper handling in transportation, storage, installation as well as careful control and maintenance.

3.1.4. Mechanical Shock

Parts of the Instrument are thermally insulated by a quartz glass tube that may be damaged

when exposed to intense mechanical shock. The device should be handled with care.

Page 7

3 Safety

7

3.2. Labels and Explanations

When operating the testo ASET15-1, the user always is operating under certain risk factors as

electricity, hot surfaces, and the aerosols which are processed by the dilution and conditioning

system. Therefore the testo ASET15-1 includes several safety features. Nevertheless, some

precautions still need to be taken to ensure safe and reliable operation. Listed labels, Caution

and Warning are explained in general, and the further specific labels refer to type of hazard and

danger.

Caution

Caution means be careful. If you do not follow the manual instruction you might

cause an instrument or accessories damage, but no human injury. Also Caution

refers to important information about installation, operation and maintenance.

Warning

Warning means that improper operation could cause a serious human or

instrument damage or injury with consequence of irrevocable instrument

damage.

Electric Shock

Hazardous voltage. Contact may cause electric shock or burn. Turn off and lock

out system power before servicing.

Electric Ground

This sign indicates that the mains connector and cabinet ground are connected

to protective earth PE.

Skin Burn

Hot surface. Do not touch. To avoid possible skin burns, wear heat protection

gloves or turn heating off and allow surfaces to cool down before servicing.

Ensure good air circulation around labeled parts.

Aerosol

Aerosols containing invisible nanoparticles and toxic exhaust gases are handled.

Some aerosols may escape from the testo ASET15-1 if the excess gas and

measuring gas ports are not thoroughly connected to an offtake and the aerosol

sucking sensors.

Page 8

4 System Overview

8

4 System Overview

4.1. Dilution and Conditioning

4.1.1. Principle

testo ASET15-1 Air Supply / Evaporation Tube is an accessory for the testo MD19 which is the

Rotating Disk Diluter with external diluter head for performing the primary dilution as close as

possible to the aerosol source.

This combination complies with the method of ThermoDilution according to the regulation for

nanoparticle measurement UN-ECE R83 and R49. ThermoDilution with testo MD19 and testo

ASET15-1 separates sampling, dilution and conditioning of the aerosol into the following steps:

Primary dilution of combustion engine emissions from tail pipe or CVS with the testo

MD19-diluter. testo ASET15-1 generates the primary dilution air for the testo MD19diluter with a calibrated and controlled flow of 1.5 l/min.

Removal of volatile particles in the Evaporation Tube where the temperature can be

adjusted up to 400°C (recommended heating temperature according to GRPEdraft = 300 °C). No recondensation takes place in the cooling down zone assuming the

measuring gas is below the dew point after primary dilution.

Secondary dilution in an adjustable dilution factor range from 1 to 11 in a mixing

assembly whose construction minimizes thermophoretic losses. The primary diluted

measuring gas from the primary testo MD19-3E diluter with a flow of 1.5 l/min and the

evaporation tube is diluted with secondary dilution air generated in testo ASET15-1. Its

flow is adjustable in a calibrated range of 0...15 l/min corresponding to a dilution factor

range of 1...11. The total measuring gas flow, up to 16.5 l/min enables the user

furthermore to connect nanoparticle instrumentation, which consumes higher measuring

gas flows than can be drawn from the testo MD19-diluter, whose diluted measuring gas

flow is limited to 5 l/min.

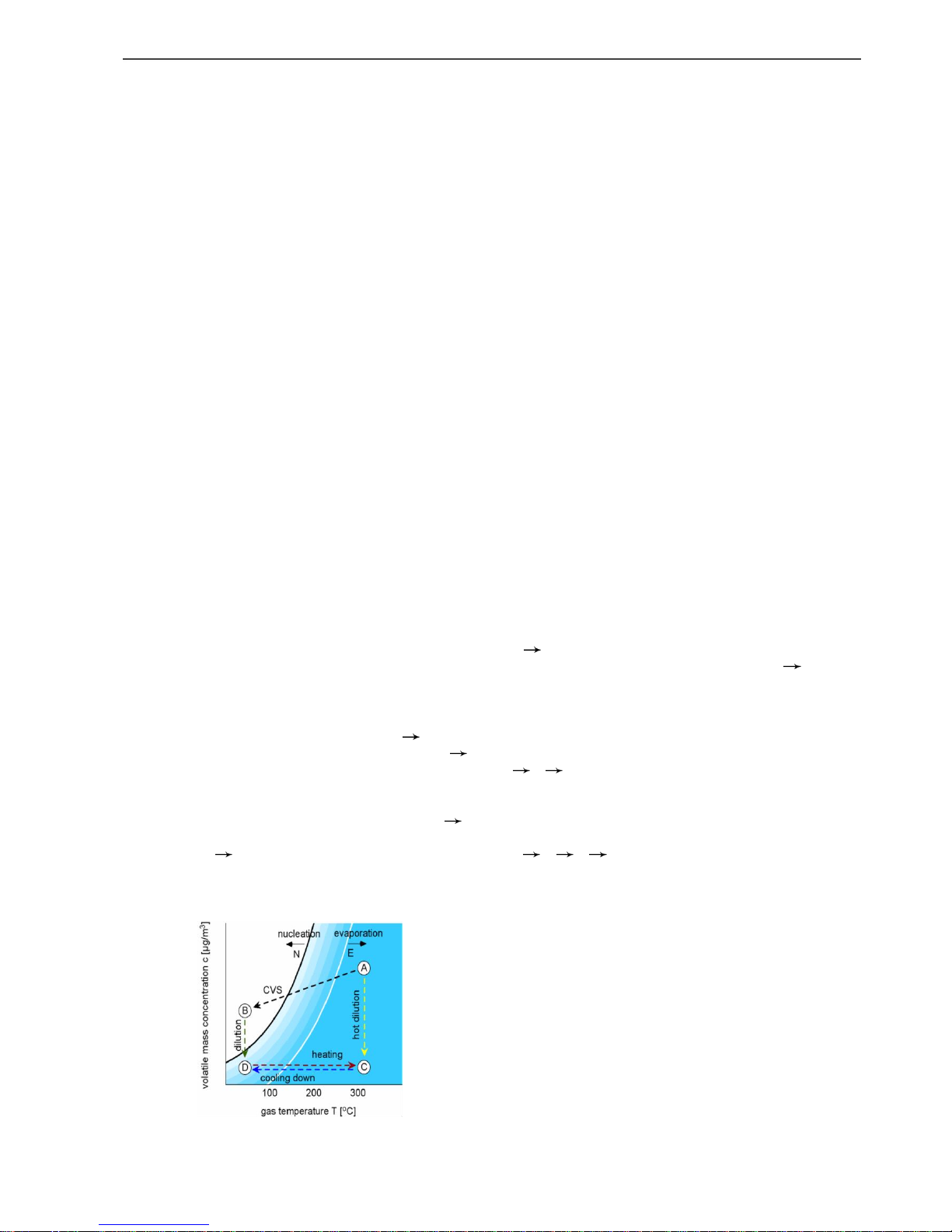

4.1.2. ThermoDilution

Fig. 4.1 shows a schematic plot of the mass concentration of a volatile compound against the

temperature of the surrounding gas. In a dilution tunnel both the concentration and the

temperature of the substance are reduced (path A

B). During dilution, the compound passes

its dew point and nucleates into nanodroplets (curve N). Subsequent secondary dilution (B

D)

will reduce the number concentration of the droplets, but is unable to evaporate them, because of

a hysteresis effect between nucleation and evaporation.

A strategy to avoid the mere formation of nanodroplets is direct sampling from the hot exhaust in

combination with hot dilution (A

C). Given a sufficient dilution factor, the volatiles will not

nucleate during subsequent cooling (C

D) even though the same final state is assumed as

through dilution tunnel and secondary dilution (A

B

D). However, in some applications e.g.

measurement on CVS tunnel, direct sampling is not possible, and nanodroplets already exist in

the gas sample (B). In those cases the diluted gas sample (D) has to be heated above the

evaporation point of the compound (C

D, crossing curve E). Like with hot dilution, the

compound remains in vapor phase upon subsequent cooling

(C

D). The combination of diluter and heater (B

D C

D) is known as ThermoDiluter.

Hot dilution is realized in Testo rotating disk diluters. Together with Testo rotating disk diluter

testo MD19-3E the testo ASET15-1 forms a complete ThermoDiluter system.

Fig.4.1: volatile mass diagram

Page 9

4 System Overview

9

4.2. Definitions

Air Supply

primary and secondary dilution air supply part of testo ASET15-1

Evaporation

Tube

thermally insulated stainless steel tube with electronically controlled

heater on the testo ASET15-1 rear side for heating up the primarily

diluted measuring gas.

Raw gas

undiluted aerosol from the emission source

Measuring gas

primary or secondary diluted aerosol from the emission source

(combustion engine or CVS).

Primary dilution

Takes place in testo MD19-3E rotating disk diluter before the

measuring gas enters into the evaporation tube.

Secondary

dilution

Dilution of the primarily diluted and thermally conditioned measuring

gas at the outlet of the evaporation tube.

4.3. Abbreviation, Units and Symbols

testo ASET15-1

Air Supply Evaporation Tube; 15 = 15 l/min air supply; 1 = version 1

CVS

Constant Volume Sample – fullstream dilution tunnel in vehicle test

benches

DF

Dilution Factor in secondary dilution: DF = (QAS + QMD)/ QMD

PCRF

Particle Concentration Reduction Factor

LED

Light Emitting Diode – used as signal lamps at the front of the testo

ASET15-1

l/min (STP)

Standard liter per minute: unit for gas volume flow at Standard

Temperature and Preasure (STP: 1013,25 hPa, 0°C)

testo MD19-3E

Type designation for Testo rotating disk diluters

QMD

primary diluted measuring gas flow from the testo MD19-3E primary

diluter

QAS

secondary dilution air flow from the air supply part of testo ASET15-1

QMG

secondary diluted measuring gas flow to the connected instrumentation

QEX

excess secondary diluted measuring gas gas flow

Page 10

4 System Overview

10

4.4. The System

Fig.4.4 : function principle – pneumatic diagram of testo ASET15-1 with integrated testo

MD19-3E

12 Excess measuring gas output

13 Measuring gas output

25 Safety cage to inhibit skin contact to the hot parts situated at the rear or the unit

32 Additional evaporation tube inlet port

34 Thermally insulated evaporation tube

37 Secondary dilution mixing chamber

39 Heat sink

The testo ASET15-1 is power supplied by one phase electricity. An internal pump feeds filtered

air to the integrated testo MD19-3E, where raw gas is added and therewith primary dilution is

carried out.

The testo ASET15-1 Air Supply / Evaporation Tube with integrated testo MD19-3E

Rotating Disk Diluter can be combined with the testo CU-2 digital control unit and therewith

Page 11

4 System Overview

11

remote controlled via Ethernet. The components are mounted in standard 19" cases and can

easily be integrated in a test bench equipped with 19" racks and Ethernet connections.

Fig. 4.2 shows all pneumatic components of the ThermoDilution system consisting of the testo

ASET15-1 and the testo MD19-3E. The pathways of dilution air, raw gas and diluted measuring

gas are visible.

No external dilution air is needed. Ambient air is drawn and filtered inside the case of the testo

ASET15-1 and fed to the testo MD19-3E where it is needed to dilute some raw gas. The primarily

diluted gas then returns to the testo ASET15-1. In the evaporation tube volatile particle

components are transformed into the gas phase. Finally a certain adjustable amount of

secondary dilution air is added in order to reduce the gas temperature, to enhance the measuring

gas flow, and to achieve particle concentrations within the range of the particle sensors set

downstream the dilution system.

4.5. Control Elements and Connections

4.5.1. Important Remarks

The testo ASET15-1 and testo MD19-3E are constructed for dilution and conditioning of exhaust

or flue gas from combustion processes in diesel engines, light oil burners or wood or coal

combustion. It may also be used for gases or aerosols emerging from other processes.

Electric Shock

When in operation, any electrical equipment can produce dangerous voltages.

Ignoring these warnings may result in serious injury or damage of the equipment.

It is mandatory that only suitably qualified personnel are allowed to work on this

instrument. Satisfactory and safe operation of this instrument necessitates

proper handling in transportation, storage and installation as well as careful

control and maintenance.

Skin Burn

Parts of the testo MD19-3E diluter head are heated up to 160°C / 320°F. Also

the outer surface of the testo ASET15-1 evaporation tube becomes a hot surface

when the temperature inside is increased up to 400°C / 752°F. Always use heat

protection gloves when handling hot parts.

Aerosol

Diluted or undiluted aerosol may escape from the system if the gas return port of

the testo MD19-3E is are not thoroughly connected to an offtake or if the

additional evaporation tube inlet port 33) of testo ASET15-1 is open. If some gas

escapes at the excess gas port 12) it is filtered and contains no particles but may

contain diluted gaseous toxic exhaust components.

4.5.2. Front View

In Fig. 4.3 all ports and operating elements situated at the front side of testo ASET15-1 with

integrated testo MD19-3E are shown. The testo ASET15-1 elements are described below the

figure while the testo MD19-3E controls are explained in the testo MD19-3E operations manual.

Fig.4.3 : front view of testo ASET15-1 with integrated testo MD19-3E

Page 12

4 System Overview

12

1 Air supply control elements: primary dilution air feed and secondary dilution

2 Evaporation Tube control elements (conditioner parameters)

3 Remote control LED green: remote dark: local

4 Secondary dilution air supply ON/OFF switch

5 Sec. dil. air supply LED green: OK red: flow error dark: OFF

6 testo MD19-3E air supply ON/OFF switch

7 testo MD19-3E air supply LED green: OK red: flow error dark: OFF

8 10 turn potentiometer for secondary dilution air supply setting

9 High excess gas flow LED yellow: excess gas flow > 1.5 l/min

10 Sufficient excess gas flow LED green: excess gas flow = 0.3...1.5 l/min

11 Low excess gas flow LED red: excess gas is critically low: < 0.3 l/min

12 Excess measuring gas output

13 Quick coupling for measuring gas output to sensor(s)

14 Heating current too high LED red: current too high (short circuit)

15 Heating current OK LED green: current within range

16 Heating current too low LED red: current too low (interrupt)

17 Evaporation tube heating ON/OFF swich

18 Actual evaporation tube temperature (red)

19 Evaporation tube temperature setpoint (green)

20 Temperature controller status field

21 Temperature controller control field

4.5.3. Gas Connectors

The excess gas port 12) and measuring gas port 13) of testo ASET15-1 can be connected to an

offtake and to the subsequent sensor(s) using the connectors shown in Fig. 4.4.

Fig.4.4 : excess and measuring gas connectors

22 Female gas coupling for connecting a 6 mm ID tube to excess gas port

23 Male gas plug for connecting a 6 mm ID tube to measuring gas port

(delivered with testo MD19-3E Rotating Disk Diluter)

Connecting any device to the front aerosol output of the testo MD19-3E would affect the flows

inside and therewith the dilution properties of the system. The testo MD19-3E is internally

connected to the testo ASET15-1 and no additional connection is needed. The gas plug 23) out

of the testo MD19-3E delivery is used to connect any measuring instrumentation to the testo

ASET15-1.

Page 13

4 System Overview

13

4.5.4. Rear View

Fig. 4.5 and 4.6 show all testo ASET15-1 elements and connections which are situated at the

rear side of the unit. The hot parts are covered by a safety protection cage which has been

removed in Fig. 4.6.

Fig.4.5 : rear view of testo ASET15-1 with safety cage mounted

24 Safety cage fixation nuts

25 Safety cage to inhibit skin contact to the hot parts situated at the rear side of the unit

26 Digital/analog interface of the integrated testo MD19-3E rotating disk diluter

27 Digital/analog interface to connect the testo ASET15-1 to the CU-2 digital control unit

28 Fuse of the integrated testo MD19-3E: 5A slow

29 Fuse of testo ASET15-1: 5A slow

30 Mains switch

31 Mains connector

32 Additional evaporation tube inlet port (closed)

Skin Burn

Hot surfaces are inside the heat protection cage. Always ensure good air

circulation around the rear of testo ASET15-1 when it is in operation. Always

wear heat protection gloves or turn heating off and allow surfaces to cool down

before removing the heat protection cage.

Fig.4.6 : rear view of testo ASET15-1 with safety cage removed

33 Evaporation Tube inlet

34 Thermally insulated evaporation tube

35 Electrical cable of the heater

36 Secondary dilution air inlet

37 Secondary dilution mixing chamber

38 Temperature sensor of the evaporation tube

39 Heat sink

Page 14

5 Installation and Setup

14

40 Connection between mixing chamber and heat sink 39)

41 Fan for cooling the components integrated in the testo ASET15-1

42 Heat sink cooling fan

43 Measuring gas outlet connection to front panel

Aerosol

Never operate the testo ASET15-1 with open additional evaporation tube inlet

port 32). This port is only used for calibration issues. Any air or aerosol flow on

this port will influence the dilution conditions in the device. If the port is open

during operation, the environment of the unit may be contaminated by escaping

aerosols.

5 Installation and Setup

Note: Numbers – e.g. 8) = secondary dilution setting potentiometer – refer to the operating

elements illustrated in chapter 4.5.

The testo ASET15-1 Air Supply / Evaporation Tube is a secondary dilution unit and cannot be

operated without an inserted primary testo MD19-3E Rotating Disk Diluter.

5.1. Integrating testo MD19-3E into the testo ASET15-1

The testo ASET15-1 without any primary diluter integrated is shown in Fig. 5.1. The testo MD193E Rotating Disk Diluter can be plugged into the testo ASET15-1 housing if the pneumatic ports

at the rear side of the plug-in are equipped with the quick couplings shown in Fig. 5.2 .

Fig.5.1: testo ASET15-1 without integrated testo MD19-3E Rotating Disk Diluter

The control unit of the primary diluter is plugged into the testo ASET15-1 housing and fixed with

six screws located at the top and the bottom of the testo MD19-3E front panel. To remove the

testo MD19-3E from the testo ASET15-1 these screws have to be solved and the unit can be

pulled out.

Fig.5.2: Plug-in unit rear view with suitable quick couplings testo MD19-3E

Page 15

5 Installation and Setup

15

5.2. Gas/Aerosol Connections

5.2.1. Quick Couplings at the front of testo ASET15-1

testo ASET15-1 is equipped with two quick coupling elements to connect the device to an excess

gas offtake (male coupling 12)) and to the subsequent sensor(s) (female coupling 13)). One

female excess gas coupling 22) is included in testo ASET15-1 delivery and one male measuring

gas plug 23) is delivered with testo MD19-3E rotating disk diluter. Both coupling elements are

also available from Testo SE & Co. KGaA.

Fig. 5.3 shows how the male plug of a tube is disconnected from the female quick coupling.

Pushing down the button at the top of the quick coupling will release the plug which can be pulled

out then.

Fig.5.3: handling of quick coupling at the front side

The plug catching ring will remain down when the plug is disconnected from the coupling. When

a plug is pulled in, the ring and button will jump up and automatically lock the plug. If the plug

cannot be inserted, the fixation ring might be in the wrong position. Push down the release button

and insert the plug again.

The excess gas connection 12) meets the same standard but male and female connectors are

exchanged.

5.2.2. Connect a Sensor to the Measuring Gas Inlet of the Evaporation Tube

The connection of a sensor e.g. a particle counter (CPC) to the additional evaporation tube inlet

port 32) might be of interest to measure the loss of volatile particles in the evaporation tube by

evaporation. To prepare the connection of the sensor proceed as follows:

Dismount the safety cage 25) by loosening the 5 nuts 24).

Remove the closing cover from the additional evaporation tube inlet port 32).

Mount the short stainless steel tube to the additional inlet using the Swagelock stainless

steel nut and the two PTFE ferrules. All these parts are included in the accessories.

Remount the safety cage before you connect your sensor to the steel tube.

Drawing measuring gas on the inlet to the evaporation tube reduces the flow in the evaporation

tube and influences therefore the setting of the dilution factor as explained in chapter 6.3.3.

Page 16

6 Operating Instructions

16

6 Operating Instructions

6.1. Start Up

Instructions in the following chapters are given for operation with an integrated

testo MD19-3E rotating disk diluter mounted in the left half of the testo ASET15-1

rack case.

For starting up some measurements using the dilution system consisting of the testo MD19-3E

and testo ASET15-1 follow these steps:

Connect the connector 31) at the rear side of the testo ASET15-1 case to mains supply.

The mains switch 30) should remain switched off. Details of the power supply are

described in chapter 7.

Prepare the testo MD19-3E Rotating Disk Diluter to be ready for operation according to

the testo MD19-3E manual. Connect its diluter head via pneumatical and electrical

connection to the control unit which has to be integrated into testo ASET15-1.

Connect the nanoparticle instrumentation to the measuring gas output 13) using the gas

connector plug 23) for tubes with inner diameter 6 mm.

Connect the waste gas output of the testo MD19-3E to the exhaust or a separate offtake.

Connect the excess measuring gas output of the testo ASET15-1 12) to an exhaust

suction system

The two gases must be independently connected to the exhaust suction. The

pulsation of the testo MD19-3E pump might have an influence on the flow regulation

in the Air Supply of the testo ASET15-1.

The tube connected to testo MD19-3E pump outlet can fill with liquid from

condensation if the diluter head is connected to undiluted engine exhaust which is

cooled down on its way to the control unit.

Ensure the raw gas pump switch on the testo MD19-3E front panel and the testo MD19-

3E air supply switch 6), the dilution air supply switch 4), and the evaporation tube heating

switch 17) on the testo ASET15-1 front panel are all in OFF position.

Switch on the mains switch 30) at the rear side of the unit.

Switch on testo MD19-3E dilution air supply 6) at the testo ASET15-1 front panel. The

testo MD19-3E air supply LED 7) indicates if the electronically controlled dilution air flow

is within its specified tolerance of +/- 3 % (green) or not (red).

6.2. Evaporation Tube Heating Up Procedure

The temperature inside the evaporation tube 34) is measured in the gas stream and indicated on

the actual temperature display 18) at the top of the temperature controller which is shown in Fig.

6.1. The evaporation tube heating is activated and deactivated using switch 17). Heating only

makes sense if dilution air is supplied to the primary diluter and measuring gas passes the

evaporation tube. Nevertheless there is no risk of damage by overheating even if no gas passes

the evaporation tube.

Fig.6.1: TemperatureController

Page 17

6 Operating Instructions

17

If the actual temperature display 18) shows , press in the control

field 21) during 2 sec to switch on the temperature controller.

Press and then and/or to change the temperature setpoint. If the desired

value is indicated by the setpoint display 19), safe by pushing again.

Switch on the evaporation tube heating with toggle switch 17) to connect the controller

power output to the heater.

The green heating current OK LED 15) indicates that supply voltage (24 VDC) is applied

to the heating and the current is within its tolerance.

If one of the red heating current LED's 14) or 16) lights, the current is too low or too high,

probably caused by a defective heating element or an interrupt in the electric circuit. The

evaporation tube should be switched off immediately and the device has to be checked

and repaired by the manufacturer or a local service provider.

Wait until the measured gas temperature 18) agrees with the set value 19) within +/- 2 °C.

During the heating up phase the heating current OK LED 15) lights continuously green.

The LED starts blinking in intervals of a few seconds when the measured gas

temperature approaches the set value. When the set value is reached the heating

on/off-duty cycle stabilizes on a ratio depending on the adjusted temperature.

Heating up times are approximately 2.5 min from ambient to 200 °C and 4 min to 300 °C.

Due to attachment of low volatile substances on its inner surface, the evaporation

tube may produce particles itself if operated at temperatures above the previous

operation point. In this case, the attached volatile material evaporates, and may

re-nucleate being measured by the connected instrumentation. When the

evaporation tube temperature is increased, it is recommended to run the testo

ASET15-1 with stopped rotating diluter disk but active testo MD19-3E dilution air

supply to rinse the tube with filtered air until no undesired particles are detected

anymore. This process may last up to 20 minutes.

6.3. Flows and Control LED's in Air Supply Part

Note: All flows mentioned in this manual are standard volume flows in [l/min] which means liters

per minute at standard conditions: 1013,25 hPa / 0°C.

testo ASET15-1 in its pneumatic function is an adjustable diluter where two calibrated flows QMD

and QAS are mixed in the secondary dilution mixing chamber 37). Fig. 6.2 shall help to

understand the setting of the secondary dilution air in the air supply part of testo ASET15-1.

Fig.6.2: secondary dilution flows

Measuring gas flow QMD (standard 1.5 l/min) from the testo MD19-3E Rotating Disk Diluter enters

the secondary dilution mixing chamber. Secondary diluted measuring gas flow QMG is drawn from

the instrumentation connected on the measuring gas output 13).

It is evident that QAS must be adjusted to a value where Q

MD

+

Q

AS

>

QMG and therewith Q

EX

>

0 to

ensure no gas is sucked backwards through the excess gas tube and added to the measuring

gas.

Page 18

6 Operating Instructions

18

6.3.1. Signal LED Information

The excess flow Q

EX

=

Q

MD

+

Q

AS

−

QMG is internally measured and examined in relation to three

criterions signalized with tree control LED's:

The sufficient excess flow LED 10) lights green if QEX is within the minimal excess

range 0.3 ... 1.5 l/min.

The high excess flow LED 9) lights yellow if Q

EX

>

1.5 l/min. This means the excess gas

flow exceeds the minimal excess flow range. Depending on QEX a certain backpressure

can arise. At 16.5 l/min excess gas (i.e. maximum secondary dilution and no measuring

gas drawn by a sensor) this backpressure can reach up to 16 mbar.

The low excess gas flow LED 11) lights red if Q

EX

<

0.3 l/min. The excess gas flow is

nearly zero and could even get negative due to slight flow changes. There is a certain

risk of ambient air sucked backwards through the excess gas tube and mixed to the

measuring gas.

6.3.2. Flow Settings and Dilution Factors

The primarily diluted flow QMD is adjusted and calibrated to a standard flow of 1.5 l/min. This

amount of filtered dilution air is fed to the inserted primary diluter testo MD19-3E. It is added

there by some raw gas and returns then to the testo ASET15-1 for further conditioning.

QAS can be set on the scaled 10-turn secondary dilution air potentiometer 8) or via analog input

signal. The reading on the potentiometer from 1.00 ... 11.00 and the input signal range

0 ... 10 V DC correspond to a flow QAS of 0 ... 1 5 l/min.

With Q

MD

=

1.5 l/min the potentiometer reading corresponds directly to the secondary dilution

factor.

Examles:

E

x

a

m

p

l

e

s

:

pot. setting = 2

Q

AS

= (2 – 1) ∙

1.5 l/min = 1.5 l/min

dilution factor DF =

DF

=

= 2

pot. setting = 5

Q

AS

= (5 – 1) ∙

1.5 l/min = 6.0 l/min

DF

=

= 5

6.3.3. Influence of Instrumentation Connected to the Additional ET Inlet Port

If a sensor is connected to the additional evaporation tube inlet port 32) and draws a certain

amount of measuring gas, the flow in the evaporation tube is reduced and therewith the dilution is

affected. To calculate the secondary dilution factor, the flow drawn from the evaporation tube inlet

port has to be known. If this flow cannot be determined otherwise, it can be calculated as the

difference between the excess gas flow measured with and without the drawing sensor.

The excess gas flow can be measured on pin 5 of the testo ASET15-1 interface connector 27),

according to the pin assignment which is described in chapter 7.2.

1...5 VDC relates to 0...5 l/min excess gas flow. This means that a flow change of 1 l/min causes

a voltage difference of 1.25 VDC, or 1 VDC corresponds to 0.8 l/min:

respectively

Example:

A sensor S1 is connected to the additional evaporation tube inlet port 32).

A constant measuring gas flow QMG is drawn from the measuring gas outlet 13)

at the front panel. The testo ASET15-1 potentiometer 8) is set to 2.

If S1 is sampling, the voltage at pin 5 is U

ON

= 2.13 V

If S1 is not sampling, the voltage is U

OFF

= 2.50 V

Q

S1

=

= 0.3 l/min

pot. setting = 2 Q

AS

= (2 – 1) ∙

1.5 l/min = 1.5 l/min

dilution factor DF =

= 2.25 instead of 2.

Page 19

6 Operating Instructions

19

Air Supply Local Operation

Start up the system following chapter 6.1 and heat up the evaporation tube.

Start the instrumentation connected to the testo ASET15-1 therewith the measuring gas

flow desired for the pending measurements is drawn from the measuring gas output 13).

Set the secondary dilution air supply potentiometer 8) on its mechanical zero position to

set the secondary dilution factor to 1.0 which actually means no secondary dilution.

Switch on the secondary dilution air supply 4). The secondary dilution air supply LED 5)

lights red first and turns to green after a few seconds to indicate the secondary air supply

pump working properly.

If the connected sensors draw less than 1.2 l/min, the sufficient excess measuring gas

flow LED 10) lights green as soon as the flows are stable. The testo MD19-3E raw gas

pump can be switched on and the measurements can start if the primary diluter is ready

and no secondary dilution is required e.g. due to too high concentrations in the

measuring gas or for reducing thermophoretic losses according to appendix A.3.

If a higher amout of measuring gas is drawn, the low measuring gas flow LED 11) lights

red indicating that the excess gas flow is below 0.3 l/min or could even be negative which

would mean air was sucked backwards through the excess gas port 12) and mixed in an

undefined way with the measuring gas.

In this case enhance the secondary dilution flow QAS by adjusting the secondary dilution

air supply potentiometer 8) until the light signal changes to the green flow OK LED 10).

Increase the flow 0.1...0.3 potentiometer units over the limit where the green LED starts

to light to find the ideal measuring gas flow setting.

The secondary dilution can be used to increase the total dilution factor as well as to

reduce thermophoretic losses. If it is set as high as more measuring gas is conditioned

and provided than needed by the connected sensor(s), a certain back pressure can arise

in the measuring gas stream due to the filter in the excess gas tube. Therefore the high

excess gas LED 9) lights yellow if more than 1.5 l/min pass the excess gas port. This

back pressure can reach up to 16 mbar at maximum secondary dilution and zero

measuring gas flow.

The total particle concentration reduction factor PCRF is the product of the primary dilution factor

set at the testo MD19-3E, the secondary dilution factor set at the testo ASET15-1 and the inverse

of one minus the fraction which is not lost due to thermophoretic losses.

Example:

testo MD19-3E primary dilution factor: 30

testo ASET15-1 secondary dilution factor: 3

thermophoretic loss (see appendix A.3): 10% = 0.1

PCRF =

= 100

Note: When switching OFF the secondary dilution air supply switch 4), wait at least 10 seconds

before restarting in order to avoid short peak flows in the order of 20 l/min on the measuring gas

output 13)

6.4. Remote Operation

Remote communication with testo ASET15-1 is possible with analog and digital inputs and

outputs at the digital/analog interface 27) at the rear side of the device. The signals on this

connector are described in chapter 7.2.

Besides the remote interface of the integrated testo MD19-3E Rotating Disk Diluter is connected

to the corresponding plug 26) at the rear side of the testo ASET15-1 case. The function and pin

assignment of this connector are the same as the ones of the connector at the rear side of the

testo MD19-3E stand alone case which are described in the testo MD19-3E user manual.

Page 20

7 Electrical Connections

20

7 Electrical Connections

7.1. Mains Supply

Connect the power cord plug to a grounded power socket. The IEC mains connector 31) on the

rear side of the testo ASET15-1 case includes the mains switch 30). The fuse holders 28) and

29) for integrated testo MD19-3E Rotating Disk Diluter and testo ASET15-1 itself are located on

the rear side of the laboratory case, besides the mains switch / mains connector. The one phase

power cord delivered with the instrument is equipped with a country-specific plug and protective

earth.

Mains supply voltage: 90 ... 240 VAC, 50/60 Hz, max. 600 VA

Fuse type testo MD19-3E: slow switching fuse 250 V, 5 A, t, 5 x 20 mm

Fuse type testo ASET15-1: slow switching fuse 250 V, 5 A, t, 5 x 20 mm

Warning

In case of a blown fuse, replace it only with the specified type of fuse. If the fuse is

repeatedly blown, the dilution unit must be sent to the manufacturer or to an

instructed service station for checking and repair.

Electric Shock

Make sure that the protecting ground pin of the country specific plug is correctly

connected to the protecting ground contact of your socket. If the plug is replaced,

ensure the yellow/green ground wire of the cable is properly connected to the new

ground pin or the case is otherwise connected to protective earth which is usually

indicated by the sign.

7.2. Analog/Digital Interface

The 25 pole D-Sub connectors at the rear side of the testo ASET15-1 case and the pin

assignment of the testo ASET15-1 remote interface 27) are shown in Fig. 7.1.

Fig.7.1: testo MD19-3E and testo ASET15-1 remote interfaces

The digital inputs and outputs are standard 5 V logic levels.

Digital inputs: High level: > 3.0 VDC low level: < 0.7 VDC

The load resistance of the device is R

in

> 10

kΩ

Digital outputs: High level: 5.0 +/- 0.2 VDC low level: < 0.7 VDC,

The source resistance of the device is R

out

<

3.5 kΩ

The analog signals are 0...10 VDC signals.

Analog inputs: The load resistance of the device is R

in

>

1.0 MΩ

Analog outputs: The source current of output signals can be I

S

≤ 5

mA.

Dsub

pin

signal description

local

equivalent

or signal

analog

/ digital

in-

/

output

signal range

1

evaporation tube actual

temperature

disp. 18)

A

O

0...10 VDC =

0...400°C

2

evaporation tube temperature

setpoint

disp. 19)

A

I

0...10 VDC =

0...400°C

3

analog ground

A

0 VDC for analog

inputs / outputs

4

evaporation tube current I

heat

too high

LED 14)

D

O

0 VDC: OK 5 VDC: I

heat

too high

Page 21

7 Electrical Connections

21

Dsub

pin

signal description

local

equivalent

or signal

analog

/ digital

in-

/

output

signal range

5

excess gas mass flow

A O 1...5 VDC= 0...5 l/min

6

secondary dilution air setpoint

pot. 8)

A

I

2.5...10 VDC =

0...15 l/min

7

not connected

8

not connected

9

secondary air supply pump

ON/OFF

switch 4)

D I 0 VDC: OFF 5 VDC: ON

10

not connected

11

actual testo MD19 -3E dilution

air flow (1.5 l/min)

A

O

fixed value within

3.2...3.8 VDC

12

remote operation

LED 3)

D

I

0 VDC: local 5 VDC:

remote

13

digital ground

D

0 VDC for digital

inputs / outputs

14

secondary dilution air supply

flow error

LED 5)

D O 0 VDC: OK 5 VDC: error

15

evaporation tube current I

heat

too low

LED 16)

D

O

0 VDC: OK 5 VDC: I

heat

too low

16

evaporation tube heating

ON/OFF

switch 17)

D I 0 VDC: OFF 5 VDC: ON

17

primary dilution testo MD193E air flow error

LED 7)

D

O

0 VDC: OK 5 VDC: dil

air error

18

actual secondary dilution air

flow

A

O

2.5...10 VDC =

0...15 l/min

19

low excess gas flow

LED 11)

D

O

0 VDC: OK 5 VDC: QEX

too low

20

not connected

21

not connected

22

not connected

23

not connected

24

primary dilution testo MD193E air ON/OFF

D I 0 VDC: OFF 5 VDC: ON

25

analog ground

A

0 VDC for analog

inputs / outputs

Page 22

8 Maintenance and Calibration

22

7.3. Remote Control

Switching the device to remote operation is done by connecting a digital HIGH-signal to pin 12 of

the interface connector 27). Remote operation is indicated by the green lighting remote control

LED 3). Switches and potentiometer on the front panel are inactive and all additional functions

are controlled by digital and analog signals listed in chapter 7.2.

The 25 pole D-Sub connector 26) is used for the remote control of the primary dilution unit. For

details plesase refer to the user manual of the testo MD19-3E Rotating Disk Diluter.

8 Maintenance and Calibration

8.1. Evaporation Tube

Chemical compounds in the primary diluted measuring gas can be deposited on the inside

surface of the evaporation tube. Depending on their evaporation temperature they can be origin

of nucleation particles in the heating up process. As already recommended in chapter 6.2 such

artifact particles should be removed by feeding filtered particle free air through the primary diluter

when the temperature in the Evaporation Tube is increased to a higher set value and start the

measurement not before no particles are measured in the instrumentation.

The best procedure to clean the Evaporation Tube is to heat it up to the max. temperature of

400°C and feed filtered particle free air. Leave the temperature at 400°C until no particles are

detected by the instrumentation anymore. Depending on the degree of pollution this procedure

can last up to 60 minutes. Do this procedure before or after longer measuring programs.

8.2. Parts with Limited Lifetime

Filter media and moving parts like air supply pumps inside the testo ASET15-1 have limited

lifetimes due to ambient air pollution and mechanical abrasion. Insufficient flows due to these

components are indicated by the testo MD19-3E air supply LED 7) and the secondary dilution air

supply LED 5).

If the testo MD19-3E air supply LED 7) remains red for longer than a few seconds after

the pump is switched on it indicates insufficient dilution air flow either caused by a testo

MD19-3E air supply pump defect or an overloaded testo MD19-3E air supply filter.

The testo MD19-3E air supply pump typically reaches 10'000...15'000 hours operating

time.

The secondary dilution air supply LED 5) remains red if the secondary dilution air flow is

not reached. This might be caused by a pump defect or overloaded secondary dilution air

filters.

The secondary dilution air pump reaches 5'000...10'000 hours operating time.

Pump maintenance and filter replacement should be done by Testo SE & Co. KGaA and/or an

instructed local service provider.

8.3. Storage, Acclimatization

Fast ambient temperature changes may result in condensed water on and inside the instrument.

This may cause serious damage of electronic parts, e.g. the controller or safety devices.

Do not store the instrument outdoor, the storage environment must be clean and dry.

After long time storage or transport with cold ambient conditions or thermal fluctuation,

the instrument requires to adapt slowly to the local ambient conditions before starting up.

If condensed water has been formed, wait at least 12 hours before installation and

starting up.

Avoid mechanical damage and agitation.

Storage temperature range: -10°C to +60°C.

Page 23

8 Maintenance and Calibration

23

8.4. Operation Environment Requirements

Caution

Read this section carefully before setting up testo ASET15-1 Air Supply /

Evaporation Tube. Testo SE & Co. KGaA is not liable if the instrument is

damaged, caused by the operation environment not meeting the requirements.

Caution

The testo ASET15-1 Air Supply / Evaporation Tube is designed to be installed in

a laboratory, test stand or a temporary test set-up. The instrument is not

intended to be used outdoor or in a dusty or wet environment.

IP protection

degree

IP 20. testo ASET15-1 is protected against accidental contact to

dangerous parts of the instrument. It is not protected against intrusion

of sand, dust or water. Avoid operation in dusty or wet environment for

safe and reliable operation.

operating temperature range

The operating ambient temperature range is +10°C to +40°C if free air

circulation around the device is ensured.

humidity range

The ambient relative humidity range (RH) is 0% to 80%,

max. 80%@30°C, linearly degrading to 50%@40°C, non condensing.

shocks and

vibrations

Avoid operation under any kind of shock or vibration.

Page 24

9 Appendix

24

9 Appendix

9.1. Extent of Delivery

testo ASET15-1 delivery consists of the following items:

item #

description

1

testo ASET15-1 Air Supply / Evaporation Tube

2

testo ASET15-1 accessories box, containing:

3 user manual to testo ASET15-1 Air Supply / Evaporation Tube

4

IEC power cord

for Switzerland

or

for Germany, France, Italy, Korea, etc.

or

for USA, Canada, Japan, etc.

or

for United Kingdom, etc.

5 1 female gas coupling for connecting a 6 mm ID tube to the excess gas port

6 1 Swagelok nut 8 mm OD SS-8M2-1

7 1 Stainless steel tube 8/6 mm x 70 mm length

8 1 Swagelok PTFE front ferrule 8 mm T-8M3-1

9 1 Swagelok PTFE back ferrule 8 mm T-8M4-1

9.2. Specification, Technical Data

aerosol

primarily diluted exhaust gases or air which contains nanoparticles

inlet gas flow

1.5 l/min, actively fed to the primary diluter and returning from there;

accuracy: 3%

air supply flow

0...15.0 l/min; accuracy: 3% of set value + 0.1 l/min ex

dilution factor

1...11

measuring gas

1.2...16.2 l/min measuring gas, directly depending on dilution factor

excess gas

min. 0.3 l/min

power supply

90...240 VAC, 50/60 Hz, max. 600 VA with integrated testo MD19-3E

local operation

primary dilution air supply pump switch, secondary air supply pump

switch, scaled 10-turn secondary dilution setting potentiometer,

evaporation tube switch, evaporation tube temperature control panel,

LED indicators

remote

operation

• in combination with CU-2 digital control unit

• controlled by digital (5 VDC) and analog (0...10 VDC) signals

via 25-pole D-Sub female interface connector on rear side

Evaporation

Tube

temperatures

ambient...400°C / 752°F; accuracy +/- 2°C/4°F

approx. heating up times: ambient to 200°C: 2 min

ambient to 300°C: 4 min

ambient to 400°C: 7 min

Page 25

9 Appendix

25

assembly

3U-19" case for rack mounting with handles

left ½-19” half wired for testo MD19-3E primary diluter plug-in

evaporation tube mounted on rear side of 19” case

dimensions (w

∙ h ∙

d): 485

∙

146

∙

530 mm

weight

without testo MD19-3E primary diluter ca. 13.5 kg

with integrated testo MD19-3E : ca. 19.1 kg

complete withtesto MD19-3E and CU-2: ca. 26.7 kg

operating

conditions

T

amb

: 10 ... 40 °C

0...80% relative humidity, max. 80%@30°C, linearly degrading to

50%@40°C, non-condensing

calibration

• standard calibration with CAST soot particles, 80 nm,

testo ASET15-1 operated with cold (ambient temperature) and heated

evaporation tube

• UN-ECE R83 calibration possible with integrated testo MD19-3E

Rotating Disk

diluter

conformity

testo ASET15-1 Air Supply Evaporation Tube is in conformity with the

following standards or other related documents:

EN 61326-1 : 2006 / B1 Electrical equipment for measurement, control

and laboratory use. EMC requirements.

EN 61010-1 : 2001 Safety requirements for electrical equipment

for measurement, control and laboratory use.

and therefore is in conformity with the following European Directives in

their current versions:

2014/30/EU Electromagnetic compatibility

2006/95/EG Low voltage directive

9.3. Thermophoretic Losses

Thermophoretic particle losses occur due to the temperature gradient when a hot aerosol passes

cool surfaces. This effect can be reduced by cooling down the aerosol quickly when it leaves the

hot area. In the testo ASET15-1 the effect appears in the aerosol tubing downstream the

evaporation tube and can be reduced significantly by setting a higher secondary dilution factor

which means a large amount of cool air is added to the hot measuring gas cooling it down

immediately when it comes from the evaporation tube 34) and enters the mixing chamber 37).

The diagram in Fig. A.1 shows the typical thermophoretic losses in the evaporation tube heated

up to 300°C measured on testo ASET15-1 with 82 nm soot particles. Each testo ASET15-1 is

calibrated individually for most accurate loss determination.

Fig.A.1: secondary dilution flows

Page 26

9 Appendix

26

9.4. Definitions, Units and Conversion Table

Pressure

Pascal

Bar

Pound per square inch

(Pa)

(bar)

(psi)

1 Pa

1

1.0 · 10-5

1.450 · 10-4

1 bar

1.0 · 105

1

14.504

1 psi

6 894.8

0.0689

1

Length

Meter

Centimeter

Millimeter

Micromete

r

Nanometer

Inch

(m)

(cm)

(mm)

(μm)

(nm)

(") = (in)

1 m 1 100

1 000

1.0 · 106

1.0 · 109

39.37

1 cm

0.01

1

10

1.0 · 104

1.0 · 107

0.3937

1 mm

0.001

0.1 1 1 000

1.0 · 106

0.0394

1 μm

1.0 · 10-6

1.0 · 10-4

1.001

1

1 000

3.937 · 10-5

1 nm

1.0 · 10-9

1.0 · 10-7

1.0 · 10-6

0.001

1

3.937 · 10-8

1 " = 1 in

0.0254

2.54

25.4

2.54 · 104

2.54 · 107

1

Temperature

Celsius

Fahrenheit

(°C)

(°F)

0 °C

0

32

T[°C] = (T[°F]-32)/1.8

100 °C

100

212

T [°F] = T[°C] · 1.8 + 32

0 °F

-17.78

0

100 °F

37.78

100

Mass

Kilogram

Gram

Pound

Ounce

(kg)

(g)

(lb)

(oz)

1 kg

1

1 000

2.205

35.27

1 g

0.001

1

0.0022

0.0353

1 lb

0.4536

453.6

1

16

1 oz

0.0283

28.35

0.0625

1

Volumetric

Cubic

Meter

Liter

Milliliter

Cubic Inch

Cubic Foot

(m3)

(l)

(ml) =

(ccm)

(cin)

(cft)

1 m3

1

1 000

1.0 · 106

61 024

35.315

1 l

0.001

1

1000

61.024

0.0353

1 ml = 1 c

cm

1.0 · 10-6

0.001

1

0.0610

3.531 · 10-5

1 cin

1.639 · 10-5

0.0164

16.387

1

5.787 · 10-4

1 cft

0.0283

28.317

2.832 · 104

1728

1

Volumetric flow

(l / min)

(m3 / h)

1 l / min

1

0.060

1 m3 / h

16.667

1

Page 27

10 Designation of All testo ASET15-1 Air Supply / Evaporation Tube Elements

27

1 l =

1 standard liter at 0 °C, 1 013.25 hPa

Units

Length

m

meter

cm

Centimeter

mm

Millimeter

nm

Nanometer

Mass

kg

kilogram

g

gram

Time

h

hour

min

minute

s

second

Electricit

y

A

ampère

V

volt

VA

voltamp

ère

Ω

ohm

10 Designation of All testo ASET15-1 Air Supply / Evaporation Tube

Elements

1 Air supply control elements: primary dilution air feed and secondary dilution)

2 Evaporation Tube control elements (conditioner parameters)

3 Remote control LED green: remote dark: local control

4 Secondary dilution air supply ON/OFF switch

5 Sec. dil. air supply LED green: OK red: flow error dark:: OFF

6 testo MD19-3E air supply ON/OFF switch

7 testo MD19-3E air supply LED green: OK red: flow error dark:: OFF

8 10 turn potentiometer for secondary dilution air supply setting

9 High excess gas flow LED yellow: excess gas flow > 1.5 l/min

10 Sufficient excess gas flow LED green: excess gas flow = 0.3...1.5 l/min

11 Low excess gas flow LED red: excess gas flow is critically low: < 0.3 l/min

12 Excess measuring gas output

13 Quick coupling for measuring gas output to sensor(s)

14 Heating current too high LED red: current too high (short circuit)

15 Heating current OK LED green: current within range

16 Heating current too low LED red: current too low (interrupt)

17 Evaporation tube heating ON/OFF swich

18 Actual evaporation tube temperature (red)

19 Evaporation tube temperature setpoint (green)

20 Temperature controller status field

21 Temperature controller control field

22 Male gas coupling for connecting a 6 mm ID tube to measuring gas port (delivered with testo

MD19-3E Rotating Disk Diluter)

23 Female gas coupling for connecting a 6 mm ID tube to excess gas port

24 Safety cage fixation nuts

25 Safety cage to inhibit skin contact to the hot parts situated at the rear of the unit

26 Digital/analog interface of the integrated testo MD19-3E rotating disk diluter

27 Digital/analog interface to connect the testo ASET15-1 to the CU-2 digital control unit

28 Fuse of integrated testo MD19-3E: 5A slow

29 Fuse of testo ASET15-1: 5A slow

30 Mains switch

31 Mains connector

32 Additional ET inlet port (closed)

33 Evaporation tube inlet

34 Thermally insulated evaporation tube

35 Electrical heater cable

Page 28

10 Designation of All testo ASET15-1 Air Supply / Evaporation Tube Elements

28

36 Secondary dilution air inlet

37 Secondary dilution mixing chamber

38 ET temperature sensor

39 Heat sink

40 Connection between mixing chamber and heat sink 39)

41 Fan for cooling the components integrated in the testo ASET15-1

42 Heat sink cooling fan

43 Outlet connection to front panel

Fig. : front view of testo ASET15-1 with integrated testo MD19-3E

Fig. : excess and measuring gas connectors

Fig. : rear view of testo ASET15-1 with safety cage mounted

Fig. : rear view of testo ASET15-1 with safety cage removed

Page 29

Page 30

Testo SE & Co. KGaA

Testo-Strasse 1

79853 Lenzkirch Germany

phone: +49 7653 681 5062

fax: +49 7653 681 95062

e-mail: sales-nanoparticle@testo.de

Loading...

Loading...