Page 1

Trace Humidity Monitoring up to -90 °C

td

testo 6781

Committing to the future

New, condensation-proof sensor with sol-gel technology

Page 2

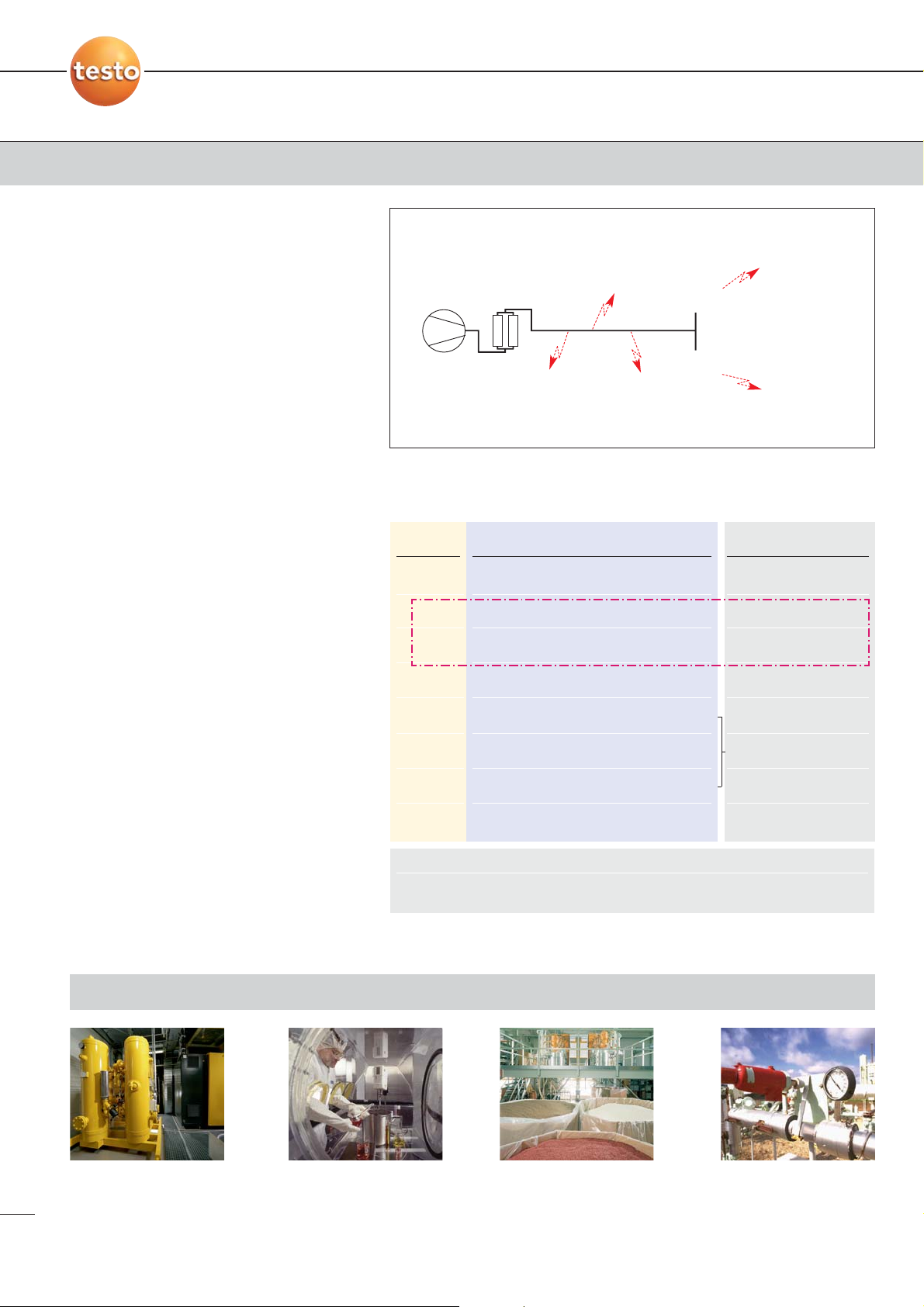

Highest compressed air quality requirements

2

Monitor trace humidity, avoid damage

Air, compressed air and gases are used in all

areas of industry. Humidity is normally

undesirable because it can cause damage or

impair the quality of the end product, as the

adjacent graphic shows.

Optimizing the regulation of adsorption

dryers

The regeneration cycle can be reduced by

controlling the parameter trace humidity

(°C

td

). That saves energy costs!

Gas engineering: humidity

causes damage and reduces

the value of the gas in the

system

Granulate drying: dry air is a

requirement for product quality

Medical compressed air:

minimum humidity as a hygiene

requirement

Compressed air systems: dryer

monitoring to avoid damage

caused by humidity

Trace humidity monitoring with testo 6781 avoids follow-on

damage caused by humidity

>>

Manufacture Distribution Consumer

Corrosion in pipes

and components

Pneumatic drives:

– Interrupted lubrication

– Mechanical damage

Formation of ice in

outside and low-

Compressor

Dryer

e.g. medical

compressed

air

Damp powder

sticks together

Bacterial growth

(European drug

legislation)

e.g. transport air for

pharma. powder

ISO 8573

Action Compressed air drying

testo 6781

Monitoring/controlling

Class

1

2

3

4

5

6

7

-70

-40

-20

3

7

10

–

-94

-40

-4

37

44

50

–

0,003

0,12

0,88

5,51

7,28

8,93

–

0,37

18

147

1083

1432

1756

–

Semi-conductor prod.

Granule dryer

Transport air

Working/energy air

Blow air

°C

td

°F

td

g/m

3

ppm

v

(at 7 bar)

Trace humidity Typical application

Applications in the monitoring of compressed air quality

What is compressed air quality?

The international standard ISO 8573 defines

seven classes of compressed air quality and

defines the humidity, the oil content, the

particle content etc. which the compressed

air is allowed to have. Class 1 represents the

highest requirements. Class 2, for example, is

fulfilled when the pressure dewpoint does not

exceed -40 °C

td

or -40 °Ftd, or an absolute

humidity of 0.12 g of water vapour per m

3

or

18 ppm

V

(parts per million by volume) (see

table on right).

The main way of ensuring compliance with a

quality class involves installing a suitable dryer

e. adsorption dryer). Its monitoring and,

where appropriate, its control, is handled by

the testo 6781.

Page 3

Pressure dewpoint transmitter testo 6781 up to -90 °C

td

3

Configuration options for the testo 6781

This results in a typical ordering code:

0555 6781 AXX BXX CXX FXX KXX MXX

B02

B03

B04

B05

B06

C00

C02

C03

C04

C05

C06

C07

C08

K01

K02

K03

K04

K05

K06

K07

K08

F01

F02

F03

F04

F05

F06

F07

F08

F09

F10

F11

0 to 1 V (4-wire, 24 VAC/DC)

0 to 5 V (4-wire, 24 VAC/DC)

0 to 10 V (4-wire, 24 VAC/DC)

0 to 20 mA (4-wire, 24 VAC/DC)

4 to 20 mA (4-wire, 24 VAC/DC)

without display

with display/English

with display/German

with display/French

with display/Spanish

with display/Italian

with display/Japanese

with display / Swedish

°C

td

/ min / max

°F

td

/ min / max

% RH/Min/Max

%RH / min / max

°C

tdA

/ min / max

°F

tdA

/ min / max

ppmV / min / max

g/m³ / min / max

g/ft³ / min / max

g/kg / min / max

g/lb / min / max

German/English instruction manual

French/English instruction manual

Spanish/English instruction manual

Italian/English instruction manual

Dutch/English instruction manual

Japanese/English instruction manual

Chinese/English instruction manual

Swedish/English instruction manual

Order no. 0555 6781

A01 Bxx Cxx Fxx Kxx

Axx Process connection

Bxx Analog display/supply

Cxx Display

Fxx Humidity parameter / min limit value / max-limit value / hysteresis (pre-set)

Kxx IM languages (for bilingual printed IMs)

Mxx Protective filter

A01

A02

Process connection G1/2

Process connection NPT 1/2’’

Mxx

M01

M03

Sintered stainless steel cap

Sintered PTFE filter

· Measurement of dewpoints in the

measuring range -90 to +30 °C

td

· New, very condensation-proof sensor with

sol-gel technology guarantees highest

process security and fast response

· Display with multi-language user menu.

· Atomatic self-adjustment ensures high

accuracy and long reliability

· Self-monitoring guarantees high systam

availability

· The P2A software for parameterization,

adjustment and analysis saves time and

costs in commissioning and maintenance

Areas of application:

· Pressure dewpoint measurement in the

ISO Classes 1 (<-70 °C

td

) and 2 (<-40 °Ctd)

· Monitoring of adsorbtion dryers, granulate

dryers and medical compressed air

· Quality assurance for noble gas

preparation

Page 4

4

Pressure dewpoint transmitter testo 6781 up to -90 °C

td

Supply

Analog outputs

Other outputs

Resolution 12 bit

Load max. 500 Ω

Meas. cycle 1/sec

Inputs/outputs

Current/accuracy 0 to 20 mA ±0.03 mA (4-wire)

4 to 20 mA ± 0.03 mA (4-wire)

Output type 0 to 1 V ±1.5 mV (4-wire)

0 to 5 V ± 7.5 mV (4-wire)

0 to 10 V ±15 mV (4-wire)

Digital Mini-DIN for P2A software

Voltage supply 20 to 30 VAC/DC, 300 mA current

consumption, galvanically separate

signal and supply line

- Hysteresis

- Linearity

- Reproducibility

* Determination measurement inaccuracy according to GUM

GUM (GGuide to the Expression of UUncertainty in MMeasurement): ISO guideline for the

determination of measurement inaccuracy, in order to make measurements

comparable worldwide. The following inaccuracies are used for the determination:

This total view results in an additional dewpoint-dependent and process-dependent

inaccuracy contribution of ±0.03 K x measurement value (in °Ctd) + 0.2 K x (25 °C process temperature in °C).

Outside the stated measuring range, a measurement inaccuracy of ±5 K applies

(typically).

Display

Model

Miscellaneous

Display optional: 2-line LCD with multi-language

operating menu

General technical data

Material Metal housing

Dimensions 208 x 60 x 35 mm

Weight 0.5 kg

Resolution

Protection class IP 65

EMC EU guideline 2004/108/EC

- Adjustment site/factory

calibration

- Test site

Measuring range Resolution

0 to +100 %RH 0,001

0,001 to 28 g/kg 0,001

0,01 to 194 g/lb 0,01

0 to 31 g/m3 0,001

0,001 to 14 g/ft3 0,001

1 to 42500 ppm(V) 1

-90 to +30 °Ctd 0,1

-130 to +86 °Ftd 0,1

-110 to +30 °CtdA 0,1

-165 to +86 °FtdA 0,1

-40 to +70 °C 0,01

-40 to +158 °F 0,01

Technical data

Operation temperatureWithout

display

With display

-40 to +70 °C / -40 to +158 °F

Storage temperature -40 to +80 °C / -40 to +176 °F

Operation temperature -20 to +80 °C / -4 to +176 °F

Storage temperature 0 to +50 °C / +32 to +122 °F

Process temperature -40 to +70 °C / -40 to +158 °F

Process pressure max. 50 bar

Operating conditionsOperating conditions

Humidity/trace humidity

Parameters

Measuring range -90 to 30 °Ctd / -130 to 86 °Ftd

Measurement uncertainty* -20 °C

td

to -40 °Ctd: ±1,5K

-40 °C

td

to -60 °Ctd: ±2K

-60 °Ctdto -75 °Ctd: ±2,5K

Response time t63 ≤ 3s for switch

from -75 °C

td

to -30 °C

td

t90 ≤ 9s for switch

from -75 °C

td

to -30 °C

td

t63 ≤ 300s for switch

from -30 °C

td

to -75 °C

td

t90 ≤ 1080s for switch

from -30 °C

td

to -75 °C

td

Autom. self-adjustment Cycle adjustable:

1 h / 6 h / 12 h / 24 h

Units °Ctd, °Ftd, %rF, %RH

Calculated variables °C

tdA

, °F

tdA

(normed atmosph.

dewpoint), ppmV, g/m³, g/ft³, g/kg, g/lb

Page 5

5

Accessories – tailored to every application

Precision measurement chamber up to 35 bar (ideal for lowest humidity) for optimum flow impact onto sensor

with freely adjustable flow valve Pre-setting of valve: 1 l/min at 7 bar 0554 3312

Flow-through gauge for precision measurement chamber for adjusting specific flow impact onto sensor when process pressure

deviates from pre-setting of flow valve 0554 3313

2 m PTFE hose with compressed air connections up to +140 °C / +284 °F (max. 9 bar / 130psi),

only with measurement chamber (only up to -60 °Ctd) 0699 2824/4

Preliminary filter to protect measurement chamber and sensors against contamination 0554 3311

Cooling coil for process temperatures higher than 50 °C (up to 200 °C), only with measurement chamber 0554 3304

Mains unit (desktop instrument) 110 to 240 VAC/24 VDC (350 mA) 0554 1748

Mains unit (top-hat rail mounting) 90 to 264 VAC/24 VDC (2.5 A) 0554 1749

Process display testo 54-2 AC, two relay outputs (to 250 VAC / 300 VDC, 3A), mains supply 90 to 230 VAC 5400 7553

Process display testo 54-7 AC, two relay outputs (to 250 VAC / 300 VDC, 3 A), mains supply 90 to 260 VAC,

with RS485 output for online monitoring and with totalizer display 54007555

Certificates

ISO calibration certificate, two adjustment points -10/-40 °C

tpd

at 6 bar 0520 0136

Humidity ISO calibration certificate, pressure dewpoint measuring instruments, freely selectable calibration points 0520 0116

from -40 to 0 °C

tpd

at 6 bar (-40 to 32 °F

tpd

) at 87 psi

Accessories for testo 6781 Order no.

햳

햶

햴

햲

Selection assistance for applications

Pre-filter is additionally used for

contaminated air and when process

pressure corresponds to pre-setting of

precision measurement chamber

For dry air (e.g. granulate dryers, max.

140 °C), a PTFE tube is additionally used

and the valve of the measuring chamber

is opened fully

(suitable up to -60 °C

td

).

Use of precision measurement chamber

for clean air and when process pressure

corresponds to pre-setting

A

B

C

D

E

NPT ½”-thread

G ½-

thread

testo 6781

testo 6781

햲

햲

햲

햵

햵

햳

Flow-through gauge is additionally used

when air is clean and process pressure

deviates from pre-setting of precision

measurement chamber (1 to 35 bar)

The cooling coil is additionally used for

process temperatures >50°C (to 200°C)

and process pressure corresponding to

the pre-setting

햴

햲

햲

햶

Page 6

0981 6284/msp/R/Q/02.2010 Subject to change without notice.

Optimizing processes and saving time in commissioning and maintenance

On-site adjustment

The Testo transmitters are delivered ready to use. For

professional application, the following functions are available

via the easy-to-use software

– Parameterization of unit and scale

– Sensor adjustment (1-point) and adjustment of the analog

outputs

– Parameterization and adjustment history of all activities of

the P2A software are registered in the PC

P2A software

A selected working point can be easily adjusted by manually

entering a reference value.

Just a few operatring steps are sufficient in the P2A

software to carry out the adjustment.

Conclusion: Saved time and lower operating costs!

P2A software = P aramerization

A djustment

A nalysis

find out more at: www.testo.com/saveris

– Integration of transmitters for all

measurement parameters with

standardized current and voltage

interfaces,

e. g. 4 to 20 mA, 0 to 10 V

– testo Saveris analog coupler available as

a wireless or Ethernet version

Now new:

Integrate the testo 6781 into

testo Saveris

TM

using the testo

Saveris analog coupler

Using the P2A software, unit and scale can be easily parameterized, for example.

The measurement data monitoring system measures temperature and

humidity values in the environment and in processes.

Integrate the testo 6781 into testo Saveris

TM

In industrial processes, exact temperatures,

humidity values and pressure relationships

play a crucial role.

In a multitude of applications, testo Saveris

helps to collect, safely store and present

these data wirelessly or via Ethernet. A

selection of alarms that can be used flexibly

supports the responsible parties to keep

the values in the required range.

Loading...

Loading...