Page 1

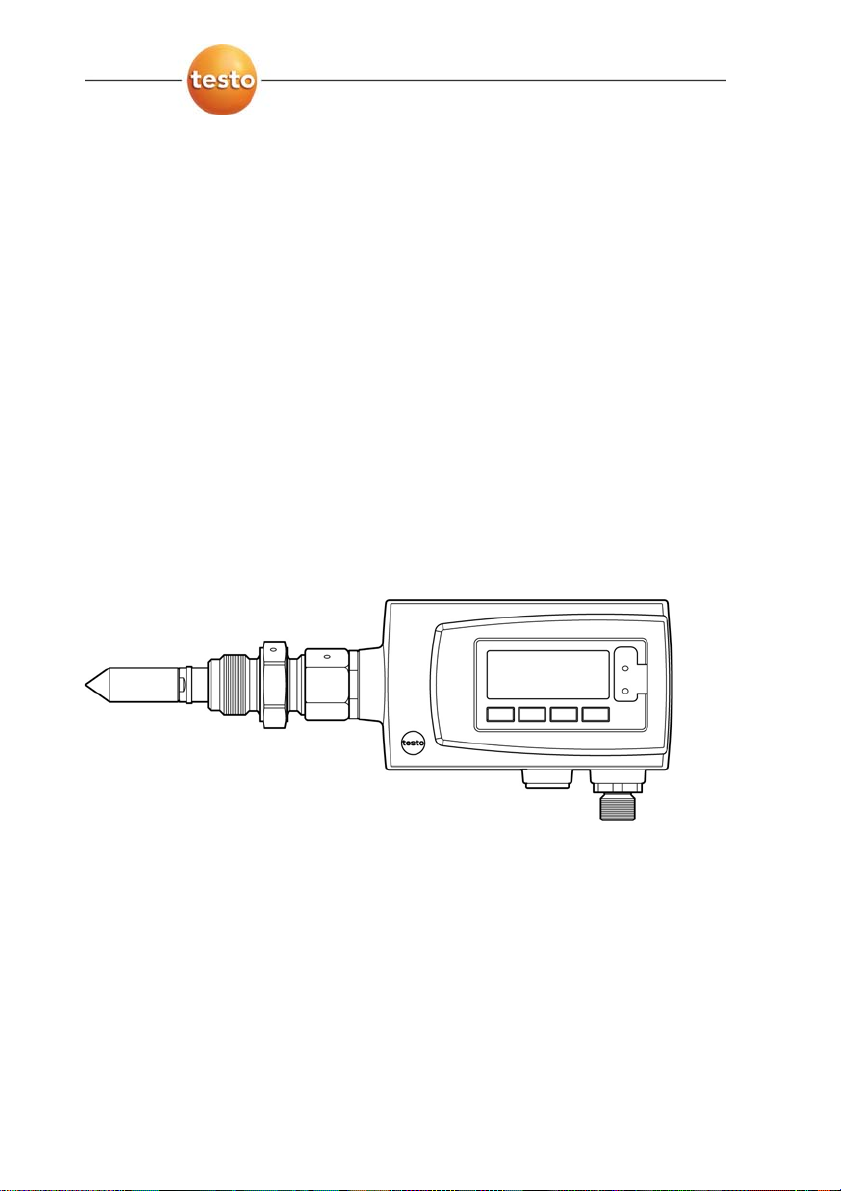

testo 6781 · Transmitter

P2A software · Parameterizing, adjusting and analyzing

Instruction manual

Page 2

2

Page 3

1 Safety and the environment

Pos: 1 /TD/Überschriften/MUF/Sicherheit und Umwel t @ 3\mod_1234793958627_79.doc @ 26223 @ 1

1 Safety and the environment

Pos: 2 /TD/Sicherheit und Umwelt/Sicherheit gewähr lei s ten/MUF 63xx/Elektrische Gefahren vermeiden @ 3\ mod_ 1234 794609299_79.doc @ 26280 @ 5

Avoiding electrical hazards

> Never use the instrument and connected probes to measure on

or near live parts!

> Damaged mains cables must only be replaced by authorized

personnel.

> Only have the transmitter wired and connected by authorized

personnel with the voltage disconnected.

> You must always comply with the regulations applicable in your

Pos: 3 /TD/Sicherheit und Umwelt/Sicherheit gewähr lei s ten/MUF 63xx/Personen- und Sachschäden vermeiden @ 3\ mod_1234794744768_79.doc @ 26299 @ 5

country for opening and repairing electrical equipment.

Avoiding personal injury and damage to equipment

> Installation, setting and calibration work must only be carried

out by qualified and authorized personnel!

> Only open the instrument when this is expressly described in

the instruction manual for installation, maintenance or repair

purposes.

> Observe the permissible storage, transport and operating

Pos: 4 /TD/Sicherheit und Umwelt/Sicherheit gewähr lei s ten/Nicht mit Lösungsmitteln lagern @ 0\mod_11756923 75179_79.doc @ 583 @

temperature.

> Do not store the product together with solvents. Do not use any

Pos: 5 /TD/Sicherheit und Umwelt/Sicherheit gewähr lei s ten/MUF 63xx/Bei Wartung MUF nicht zur Regelung verwende n @ 3\ mod_1234794852377_79.doc @ 26318 @

desiccants.

> Do not use the instrument for control purposes at the same time

Pos: 6 /TD/Sicherheit und Umwelt/Sicherheit gewähr lei s ten/Produkt bestimmungsgemäß verwenden @ 0\mod_11737 81261848_79.doc @ 386 @

as operating or servicing the transmitter.

> Only operate the product properly, for its intended purpose and

within the parameters specified in the technical data. Do not

Pos: 7 /TD/Sicherheit und Umwelt/Sicherheit gewähr lei s ten/Nur beschriebene Wartungsarbeiten durchf ühren @ 0\mod_1175692705195_79.doc @ 601 @

use any force.

> Carry out only the maintenance and repair work on this

instrument that is described in the documentation. Follow the

prescribed steps exactly. Use only original spare parts from

Pos: 8 /TD/Sicherheit und Umwelt/Sicherheit gewähr lei s ten/MUF 63xx/Fachpersonal @ 3\mod_1234794940409_7 9.doc @ 26337 @

Testo.

Any additional work must only be carried out by authorized

personnel. Otherwise testo will not accept any responsibility for the

proper functioning of the instrument after repair and for the validity

of certifications.

3

Page 4

2 About this document

Pos: 9 /TD/Überschriften/MUF/Umwelt schützen @ 3\mod_ 123 4858757571_79.doc @ 26363 @ 5

Pos: 10 /TD/Sicherheit und Umwelt/Umwelt schützen/Pr odukt entsorgen @ 0\mod_1173780307072_79.doc @ 357 @

Protecting the environment

> At the end of its useful life, send the product to the separate

collection for electric and electronic devices (observe local

Pos: 11 /TD/Überschriften/MUF/Zu diesem Dokument @ 3\mod_ 1234793991331_79.doc @ 26242 @ 1

2 About this document

Pos: 12 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Ver wendung (Standard) @ 0\mod_1173775068554_79.doc @ 337 @ 5

regulations) or return the product to Testo for disposal.

Use

> Please read this documentation through carefully and

familiarize yourself with the product before putting it to use. Pay

particular attention to the safety instructions and warning advice

in order to prevent injuries and damage to the products.

> Keep this document to hand so that you can refer to it when

necessary.

> Hand this documentation on to any subsequent users of the

Pos: 13 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy mbole und Schreibkonventionen/Warnhinweis W ARNUNG @ 2\mod_1207646966234_79.doc @ 14398 @

Pos: 14 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy mbole und Schreibkonventionen/Warnhinweis VORSIC HT @ 2\mod_1207651416515_79.doc @ 14416 @

Pos: 15 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy m bo le und Schreibkonv. Software [Standard] @ 0\mod_11902 0333 2543_79.doc @ 4883 @ 5

product.

WARNING

CAUTION

Indicates potential serious injuries

indicates potential minor injuries

Symbols and writing standards

Representa-

Explanation

tion

Note: Basic or further information.

1. ...

2. ...

Action: more steps, the sequence must be

followed.

> ... Action: a step or an optional step.

- ... Result of an action.

Menu

[OK]

Elements of the program interface.

Buttons of the program interface.

... | ... Functions/paths within a menu.

“...” Example entries

Pos: 16 /TD/--- Seitenwechsel --- @ 0\mod_1173774430601_0.doc @ 283 @

4

Page 5

3 Contents

Pos: 17 /TD/Überschriften/MUF/Inhalt @ 3\mod_123479 4019831_79.doc @ 26261 @ 1

3 Contents

1 Safety and the environment....................................................................3

2 About this document...............................................................................4

3 Contents...................................................................................................5

4 Transmitter...............................................................................................8

4.1. Specifications ..................................................................................8

4.1.1. Functions and use ...........................................................................................8

4.1.2. Scope of delivery .............................................................................................8

4.1.3. Accessories .....................................................................................................8

4.1.4. Technical data .................................................................................................9

4.1.5. Dimensions....................................................................................................13

4.2. Product description........................................................................14

4.2.1. System components ......................................................................................14

4.2.2. At a glance.....................................................................................................15

4.2.3. Display and keypad........................................................................................16

4.2.4. Service interface............................................................................................16

4.2.5. Analog outputs...............................................................................................16

4.2.6. Parameters....................................................................................................16

4.2.7. Scaling .........................................................................................................16

4.3. Commissioning..............................................................................17

4.3.1. Mechanical assembly.....................................................................................17

4.3.1.1. Without stainless steel mea surement chamber and cooling coil........18

4.3.1.2. With stainless steel measur em ent chamber (max. 35,000 hPa)........19

4.3.1.3. With stainless steel measurement chamber and cooling coil (max.

35,000 hPa)......................................................................................19

4.3.1.4. Connecting voltage supply and analog outputs.................................20

4.3.1.5. Plug-in connection for power supply and channel.............................21

4.3.2. Adjusting the instrument ................................................................................21

4.3.2.1. Self-adjustment.................................................................................21

4.3.2.2. 1-point adjustment by entering a refere nce value..............................22

4.3.2.3. Analog output adjustment.................................................................23

4.4. Operation.......................................................................................24

4.4.1. Relationship between user menu and mini-DIN socket is active....................24

4.4.2. Password protection ......................................................................................24

4.4.3. Structure of user menu ..................................................................................24

4.4.4. Overview of the testo 6781 user menu...........................................................26

4.4.5. The individual main menus ............................................................................28

4.4.5.1. Editing main menu of channel 1........................................................28

4.4.5.2. Editing Main Menu Alarm..................................................................29

4.4.5.3. Editing Main Menu Settings ..............................................................30

4.4.5.4. Editing Main Menu Analysis..............................................................32

4.4.5.5. Editing Message main menu.............................................................34

5

Page 6

3 Contents

4.4.5.6. Calling up Main Menu Ident..............................................................35

4.4.5.7. Editing Main Menu Adjust.................................................................35

4.4.5.8. Editing Reset main menu..................................................................37

4.5. Status, warning and error messages ............................................37

4.5.1. Status messages...........................................................................................38

4.5.2. Warning messages........................................................................................39

4.5.3. Transmitter error messages...........................................................................40

4.5.4. Handling alarm messages .............................................................................40

4.6. Maintenance and cleaning............................................................41

4.6.1. Maintaining the instrument............................................................................. 41

4.6.2. Cleaning the instrument.................................................................................41

5 Parameterizing, adjusting and analyzing software (P2A software) . . 42

5.1. Specifications................................................................................42

5.1.1. Functions and use .........................................................................................43

5.1.2. System requirements..................................................................................... 43

5.1.3. Scope of delivery...........................................................................................44

5.2. First steps ..................................................................................... 44

5.2.1. Installing the software/driver.......................................................................... 44

5.2.1.1. Installing P2A software.....................................................................44

5.2.1.2. Installing USB driver.........................................................................44

5.2.1.3. P2A software upgrade......................................................................45

5.2.2. Starting the software......................................................................................45

5.2.2.1. Starting the program......................................................................... 45

5.2.2.2. Establishing a connection wi th the instrument...................................45

5.2.2.3. Activating the connection w ith the instrument...................................45

5.3. Using the software........................................................................46

5.3.1. User interface................................................................................................46

5.3.2. Editing instrument/parameter file ...................................................................48

5.3.2.1. Changing instrument/parameter file..................................................48

5.3.2.2. Creating a new instrument file...........................................................55

5.3.2.3. Saving parameters............................................................................55

5.3.2.4. Opening the parameter file............................................................... 56

5.3.2.5. Copying and pasting parameters......................................................56

5.3.2.6. Deleting instrument/parameter file....................................................57

5.3.3. Analyzing/testing the transmitter....................................................................57

5.3.3.1. Analyzing/testing the instrument....................................................... 57

5.3.3.2. Carrying out factory reset..................................................................57

5.3.3.3. Testing analog output.......................................................................58

5.3.3.4. Displaying min./max. values..............................................................59

5.3.4. Adjusting the transmitter................................................................................60

5.3.4.1. 1-point adjustment............................................................................61

5.3.4.2. Adjusting the analog output.............................................................. 62

5.3.5. Transmitter history.........................................................................................63

6

Page 7

3 Contents

6

Tips and assistance...............................................................................67

6.1. Questions and answers.................................................................67

6.2. Accessories and spare parts .........................................................67

6.2.1. Ordering options for testo 6781 transmitter (0555 6781)................................69

Pos: 18 /TD/--- Seitenwechsel --- @ 0\mod_1173774430601_0.doc @ 283 @

7

Page 8

4 Transmitter

Pos: 19 /TD/Überschriften/MUF/1 Messumformer @ 3\ mod_1234258401060_79.doc @ 23894 @ 1

4 Transmitter

Pos: 20 /TD/Überschriften/MUF/1.1/2.1/3.1 Leis tungsbeschreibung @ 3\mod_1234258595211_79.doc @ 23951 @ 2

4.1. Specifications

Pos: 21 /TD/Leistungsbeschreibung/Verwendung/ MUF63xx/MUF 6781 @ 3\mod_1238162232871_79.doc @ 30254 @ 3

4.1.1. Functions and use

The testo 6781 transmitter was developed especially for low

dewpoint temperatures and is suitable for the following

applications, amongst others:

• Compressed air process engineering

• Clean-room technology

• Regulation and monitoring of compressed air driers

• Production and conveyance of gases

• Monitoring of humidity and temperature in medical compressed

Pos: 22 /TD/Leistungsbeschreibung/Lieferu mfang/ MUF 63xx/MUF 6781 @ 3\mod_1238162497483_79.doc @ 30275 @ 3

air or granulate driers

4.1.2. Scope of delivery

The scope of delivery of the testo 6781 transmitter includes the

following:

• Assembly accessories

• Operating instructions

• Calibration report

• CD-ROM with operating instructions (PDF) and P2A update

(this can only be used in conjunction with the P2A software,

Pos: 23 /TD/Leistungsbeschreibung/Lieferu mfang/ MUF 63xx/Zubehör Übersicht 635x @ 3\mod_1236084601953 _79.doc @ 27292 @ 3

which has to be ordered separately).

4.1.3. Accessories

The following accessories are available for the testo 6781

transmitter, amongst others:

• Mains unit

• P2A software (parameterizing, adjusting and analyzing

software)

8

• Assembly accessories

Information about accessories and their order numbers can

be found in Accessories and spare parts or on the

website at www.testo.com.

Page 9

Pos: 24 /TD/Leistungsbeschreibung/Technische Dat en/MUF 63xx/MUF 6781 @ 3\mod_1238162594608_79.doc @ 30296 @ 3555 5555555555555555555555

4.1.4. Technical data

4 Transmitter

Parameter

1

• Dewpoint temperature

Measuring range at 25 °C

• -90 to 30 °C

td

Meas. uncertainty2

-20 °Ctd to -40 °Ctd: +/-1,5 K

-40 °C

-60 °C

to -60 °Ctd: +/-2 K

td

to -75 °Ctd: +/-2,5 K3

td

The measuring uncertainty increases with high flow values.

1

Above 0 °Ctd the dewpoint temperature is shown and below 0 °Ctd the frost

point temperature is shown. In rare cases at frost point temperatures between

-35 °Ctd and 0 °Ctd differences between the 6781 and a dew mirror hygrometer

may occur.

2

Expanded basic uncertainty (K = 2) at a process temperature of 25 °C.

Measuring uncertainty according to GUM (Guide to the E xpression of Uncertainty in Measurement):

ISO guideline for determining the measuring uncertainty in order to render global measurement results

comparable.

The following uncertainties are used during the inquiry:

• Hysteresis

• Linearity

• Reproducibility

• Adjustment area/factory calibration

• Test location

An additional uncertainty factor independent of the dewpoint temperature and

process of ±0.03 K x reading (in °C

) + 0.2 K x (25 °C - process temperature in

td

°C) results from this overall view

Outside the stated range, a measurement inaccuracy of +/-5K (typically) applies.

3

At process temperatures > 25 °C the lower limit of the measuring range

increases by 0.5 K/K. The uncertainty values are valid for the respective

measuring range.

9

Page 10

4 Transmitter

Response time

≤ 3 s when changing from -75 °Ctd to -30 °Ctd

t

63

t

≤ 9 s when changing from -75 °Ctd to -30 °Ctd

90

t

≤ 300 s when changing from -30 °Ctd to -75 °C

63

td

t90 ≤ 1080 s when changing from -30 °Ctd to -75 °Ctd

Resolution

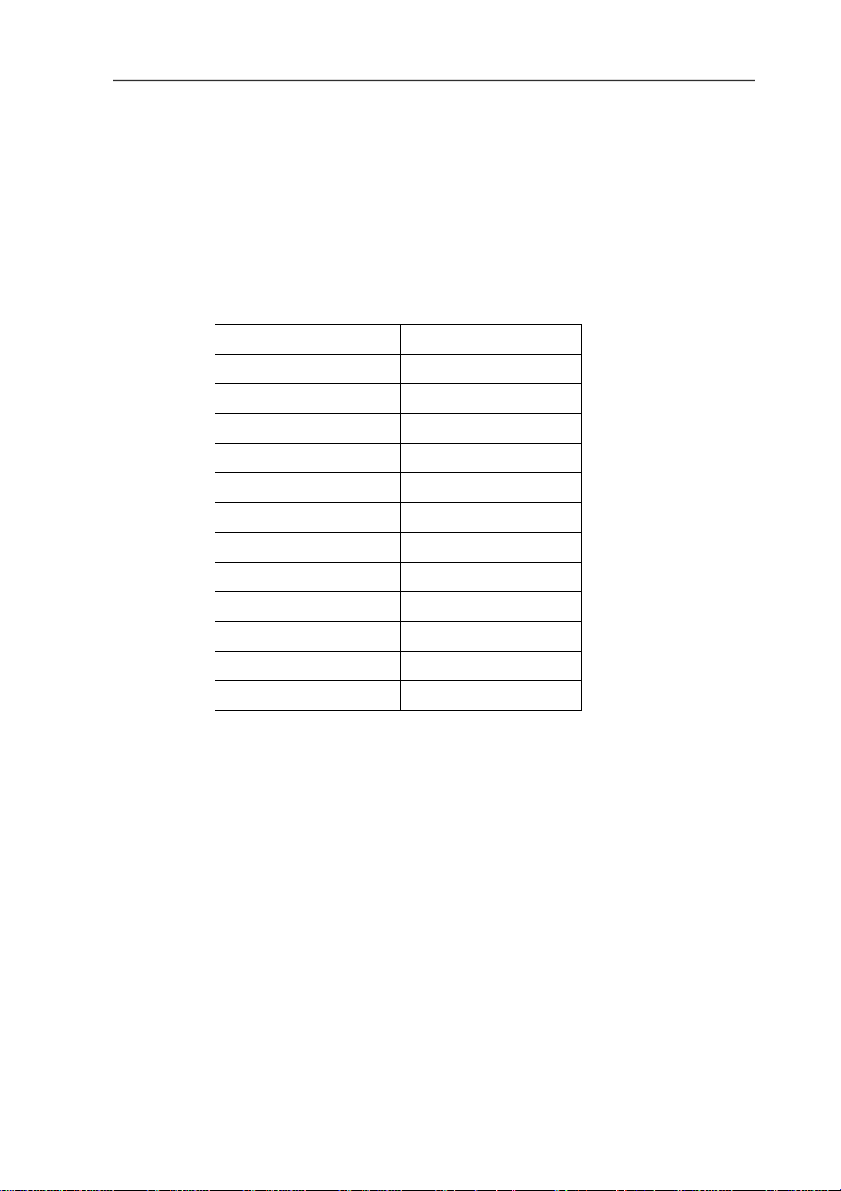

Measuring range Resolution

0 to 100 % RH 0.001

0.001 to 28 g/kg 0.001

0.01 to 194 gr/lb 0.01

0 to 31 g/m3 0.001

0.001 to 14 gr/ft3 0.001

1 to 42,500 ppm (vol) 1

-90 to 30 °Ctd 0.1

-130 to 86 °Ftd 0.1

-110 to 30 °C

-165 to 86 °F

0.1

tdA

0.1

tdA

-40 to 70 °C 0.01

-40 to 158 °F 0.01

10

Meas. cycle

• 1/sec

Interface

• Mini-DIN for P2A software (adjustment and parameterization

software)

Voltage supply

• 4-wire (separate signal and supply lines): 20 to 30 V AC/DC,

300 mA power consumption

Page 11

4 Transmitter

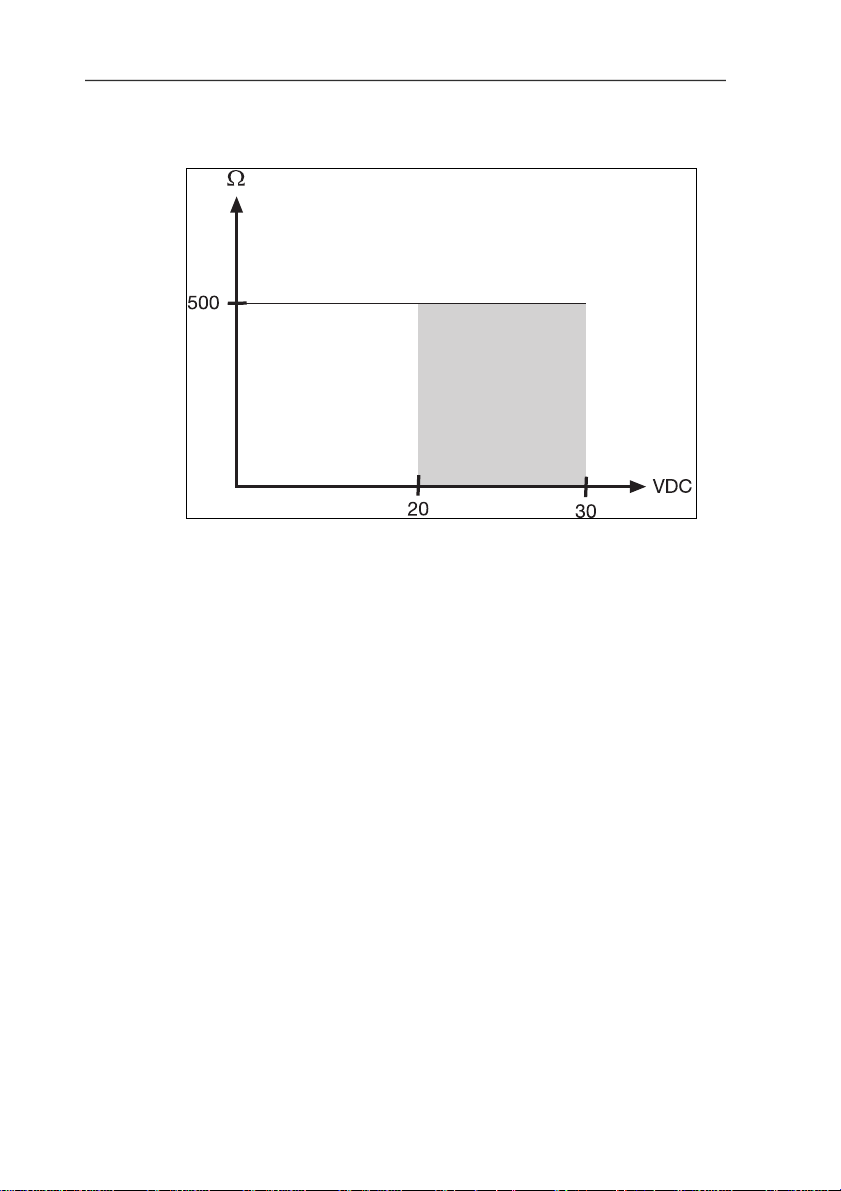

Maximum load

• 4-wire: 500 Ω (power output)

Maximal load

• 4-wire: 10 kΩ (voltage output)

Analog output

• 0 to 1 V ± 1.5 mV (4-wire) or

• 0 to 5 V ± 7.5 mV (4-wire) or

• 0 to 10 V ± 15 mV (4-wire) or

• 0 to 20 mA ± 0.03 mA (4-wire) or

• 4 to 20 mA ± 0.03 mA (4-wire)

Resolution of analog output

• 12 bit

Display

• 2-line LCD with plain text line (optional)

Operating temperature without display

• -40 to 70 °C

Operating temperature with display

• 0 to 50 °C

11

Page 12

4 Transmitter

Storage temperature without display

• -40 to 80 °C

Storage temperature with display

• -20 to 80 °C

Process temperature

• -40 to 70 °C

Application humidity

• 0 to 100 % RH

Pressure application range

• 50,000 hPa

Housing, weight

• Metal, 0.5 kg

Process connection

• G 1/2 or

• NPT 1/2"

12

Protection class

• IP 65 only if the transmitter is wired and/or sealing plugs are

inserted

Directives, standards and tests

• EC Directive: 2004/108/EC

• 6781 was manufactured in accordance with EC pressure

equipment Directive 97/23/EC, Article 3 Paragraph 3 as per

"sound engineering practice", taking the regulations to be

observed into account.

Warranty

• Duration: 2 years

• Warranty conditions: see website www.testo.com/warranty

Page 13

Pos: 25 /TD/Leistungsbeschreibung/Technische Dat en/MUF 63xx/MUF 6781 Abmessungen @ 3\mod_1239806330094_79. doc @ 31183 @ 3

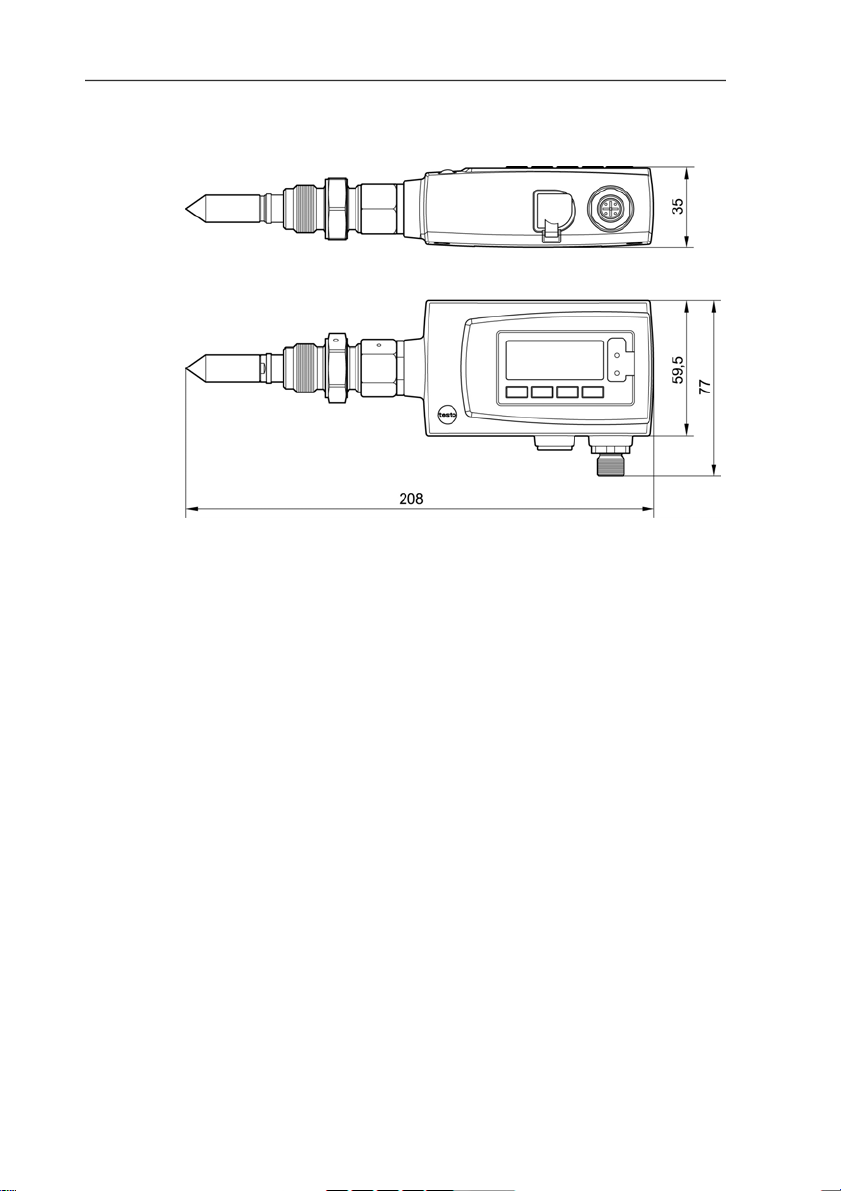

4.1.5. Dimensions

4 Transmitter

13

Page 14

4 Transmitter

Pos: 26 /TD/Überschriften/MUF/1.2/2.2 Produktb esc hreibung @ 3\mod_1234258723551_79.doc @ 24008 @ 2

4.2. Product description

Pos: 27 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Systemkomponenten 6781 @ 3\mod_1239868226476_7 9. doc @ 31305 @ 3

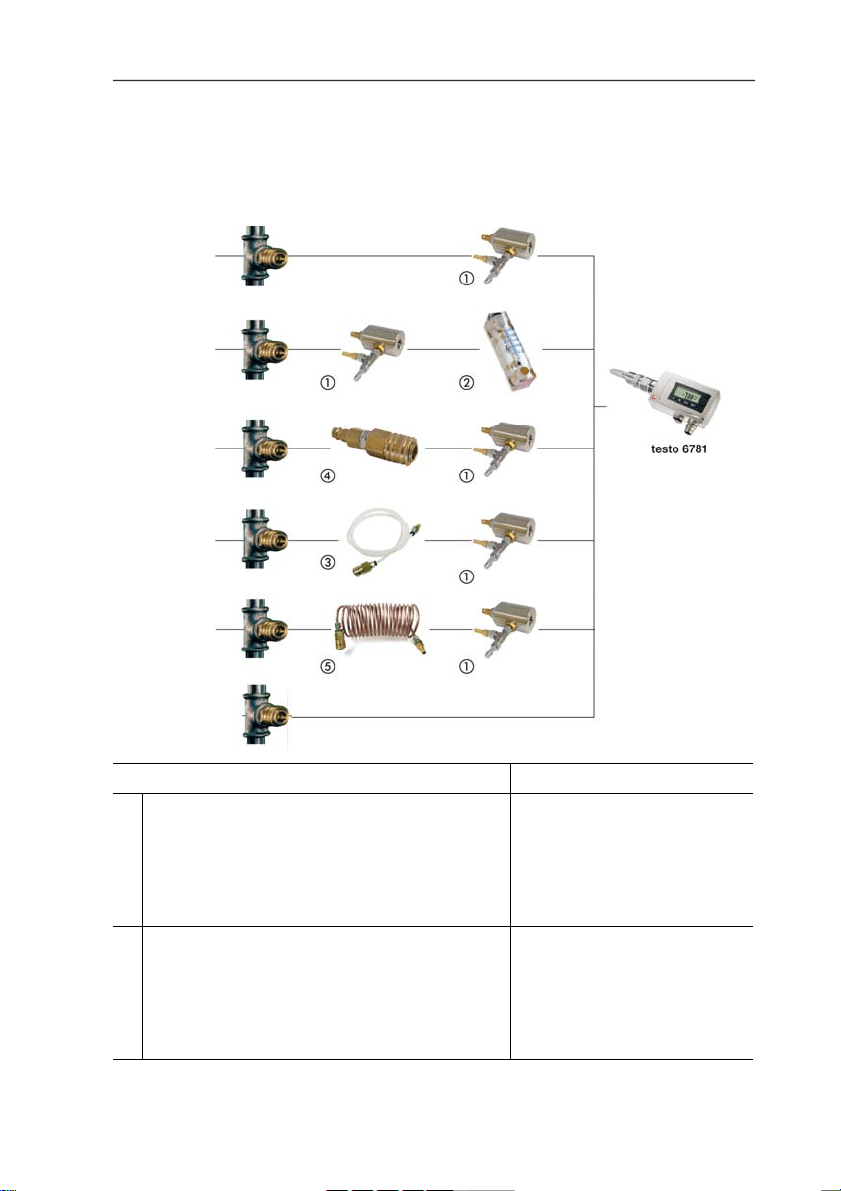

4.2.1. System components

Application System components

With clean air and a process pressure

A

corresponding to the presetting of the

measurement chamber (1), a measurement

chamber (1) is required for the rapid

• 1: Measurement chamber

• testo 6781 with

G1/2 thread

assembly (without de-pressurizing the

installation).

With clean air and a process pressure

B

greater than or less than 7000 hPa (1000 to

35,000 hPa) that therefore does not

correspond to the presetting of the inflow

valve, a measurement chamber (1) with a

• 1: Measurement chamber

• 2: Flow meter

• testo 6781 with

G1/2 thread

flow meter (2) is required.

14

Page 15

4 Transmitter

Application System components

For rapid assembly (without de-pressurizing

C

the installation), a measurement chamber (1)

is required. Connect a filter (4) upstream for

oily media.

• 4: Filter

• 1: Measurement chamber

• testo 6781 with

G1/2 thread

With dry air (max. 140 °C), a PTFE tube (3)

D

is used and the valve of the measurement

chamber (1) is opened to maximum (suitable

up to -60 °C

For process temperatures of 50 °C to 200 °C

E

).

td

and a process pressure corresponding to the

presetting, it is necessary to use a cooling

coil (5) and a measurement chamber (1).

Connect a filter upstream for oily media.

• 3: PTFE tube

• 1: Measurement chamber

• testo 6781 with

G1/2 thread

• Filter, if necessary

• 5: Cooling coil

• 1: Measurement chamber

• testo 6781 with

G1/2 thread

If A to E are not required. The thread is

F

screwed directly into the process.

De-pressurized tube required during

installation.

• testo 6781 with

G1/2 thread

or

• testo 6781 with N1/2"

thread

Pos: 28 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Auf einen Blick MUF 6781 @ 3\mod_1238165303035_79.doc @ 30317 @ 3

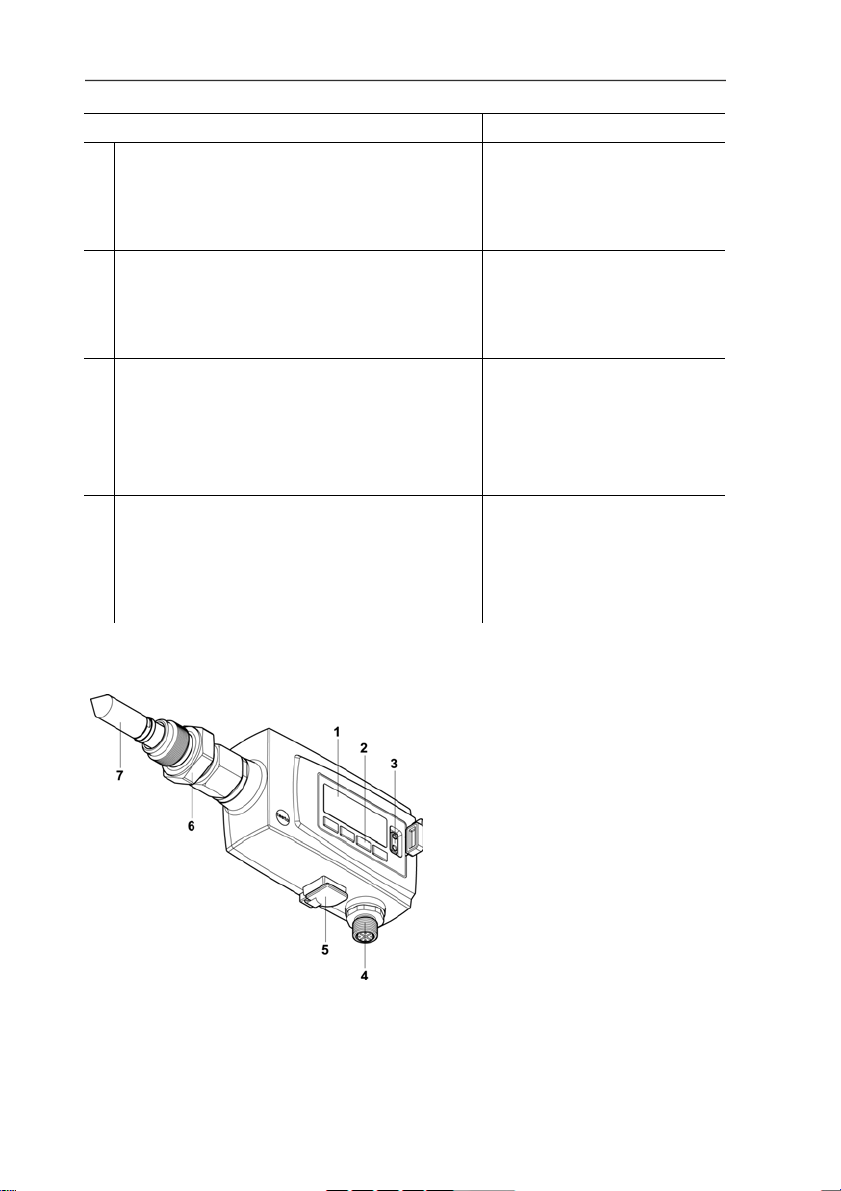

4.2.2. At a glance

1 Display (optio nal)

2 Keys (only with optional display)

3 Test contacts

4 M 16 x 1.5 screw connection,

e.g. analog output

5 Service flap with connection for

service plug

6 Screw connection with process

connection (G 1/2 or NPT 1/2")

7 Sintered cap over sensor unit

15

Page 16

4 Transmitter

Pos: 29 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Display und Tastatur 6781 @ 4\mod_1250064749770_79. doc @ 47423 @ 3

4.2.3. Display and keypad

The display option allows operation of the testo 6781 transmitter via

the display and four keys.

The LCD display consists of one 7-segment line for displaying

readings and units and of an information line (for status messages,

for example).

The brightness and contrast of the display and the background

lighting (permanent or off) can be changed via the user menu or the

Pos: 30 /TD/Überschriften/MUF/1.2.x Servicesc hni ttstelle @ 3\mod_1237306891654_79.doc @ 29795 @ 3

4.2.4. Service interface

Pos: 31 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Serviceschnittstelle 635x @ 3\mod_12372173884 92_79.doc @ 29723 @

P2A software.

The parameterizing socket (mini-DIN) is located behind the service

Pos: 32 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Analogausgänge 635x @ 3\mod_1234774510463_79.doc @ 25726 @ 3

flap as an interface to the P2A software.

4.2.5. Analog outputs

As analog outputs, the testo 6781 has either

• 1 current output of 0 to 20 mA (4-wire)/4 to 20 mA (4-wire) or

Pos: 33 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Messgrößen 6781 @ 3\mod_1239284685066_79.doc @ 31095 @ 3

• 1 voltage output of 0 to 1 V/0 to 5 V/0 to 10 V (4-wire)

4.2.6. Parameters

The following parameters are displayed:

• Relative humidity in % RH (technical)

• Degree of humidity in g/kg and gr/lb

• Absolute humidity in g/m³ and gr/ft³

• Water content in ppm (vol)

• Dewpoint temperature in °C

• Standardized dewpoint (at atmospheric pressure 1013 hPa) in

°C

and °F

Pos: 34 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Skalierung @ 3\mod_1234775406989_79.doc @ 25783 @ 3

tdA

• Temperature °C and °F

tdA

and °Ftd

td

4.2.7. Scaling

There are three types of min./max. values:

1 The measuring range: The maximum sensor performance is in

this range. Values outside of the measuring range are displayed

via messages, for example.

16

Page 17

2 Standard scaling: The output signals are assigned to this

measuring range as standard:

◦ during delivery if no entries are made in the order code

◦ after exchanging the unit, the measuring range recorded in

the instrument is applied as standard.

The transmitter even retains its scaling with the voltage

disconnected.

3 The maximum settings for the manual scaling

◦ The maximum limits can be calculated as follows:

X = difference between MIN. and MAX. value of the

standard scaling

(Max. value of standard) + (50 % of X)

(Min. value of standard) - (50 % of X)

◦ It is thus possible to scale beyond the measuring range, e.g.

for the adjustment of the scaling limits to standard values of

a PLC.

With the alarm definition, however, the physical measuring

Pos: 35 /TD/Überschriften/MUF/1.3/2.3 Inbetri ebnahme @ 3\mod_1234258805768_79.doc @ 24027 @ 2

4.3. Commissioning

Pos: 36 /TD/Erste Schritte/MUF 63xx/Mechanische Mon tag e 6781 @ 3\mod_1239807163104_79.doc @ 31204 @ 3444

range limits are decisive.

4 Transmitter

4.3.1. Mechanical assembly

• Carefully perform assembly work.

• Take special care with leaktightness. We recommend

inserting a metal sealing ring (internal diameter 21 mm).

• Do not use any hygroscopic materials for the sealing.

> Only use force on the union nut.

Depending on the application, there are three different assembly

options:

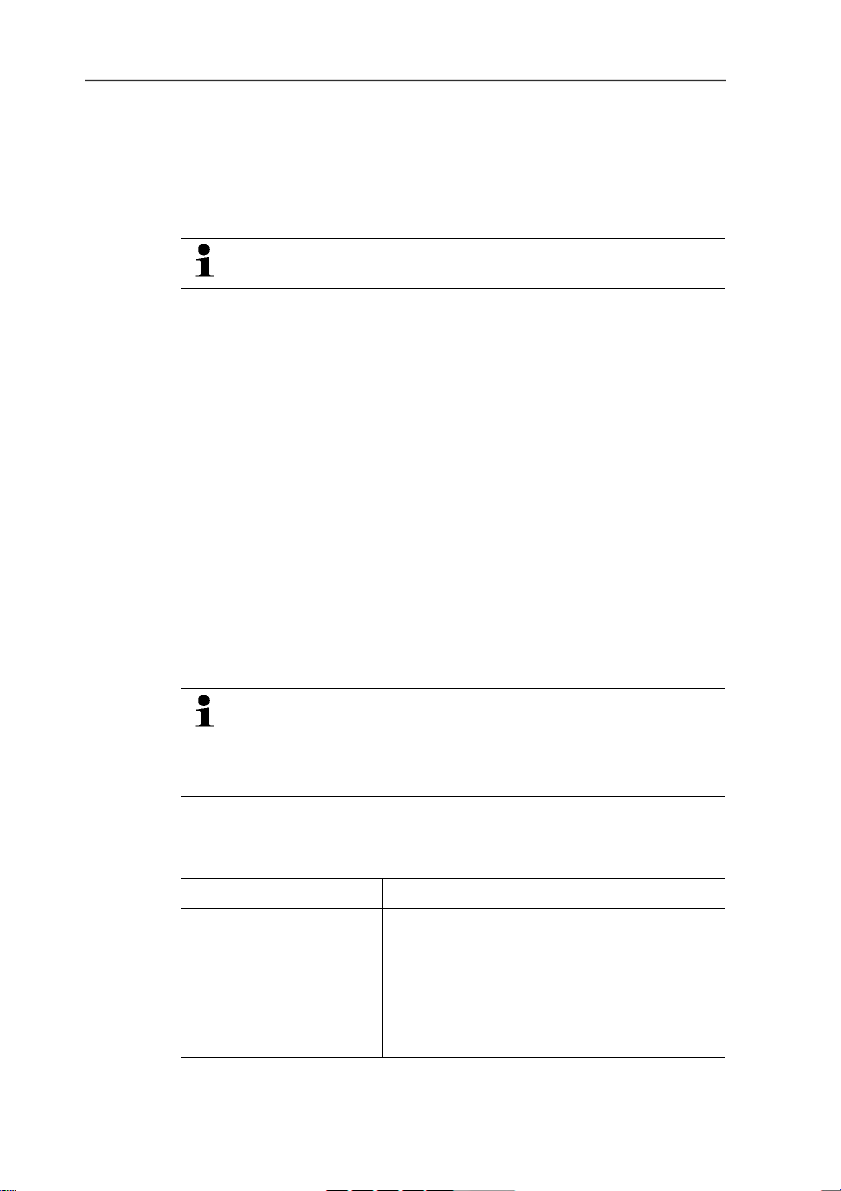

Assembly Application

Without stainless steel

measurement chamber

and cooling coil

• Process temperatures 0 to 50 °C

• Attachment of the sensor directly in

the process possible

• No fast assembly/dismantling of the

testo 6781 required and sufficient

inflow of the sensor (1 l/min.) exists

17

Page 18

4 Transmitter

Assembly Application

With stainless steel

measurement chamber

• Process temperatures 0 to 50 °C

• Fast assembly/dismantling of the

testo 6781 required and/or

• No sufficient inflow of the sensor

(1 l/min.) exists

With stainless steel

• Process temperatures 50 to 200 °C

measurement chamber

and cooling coil

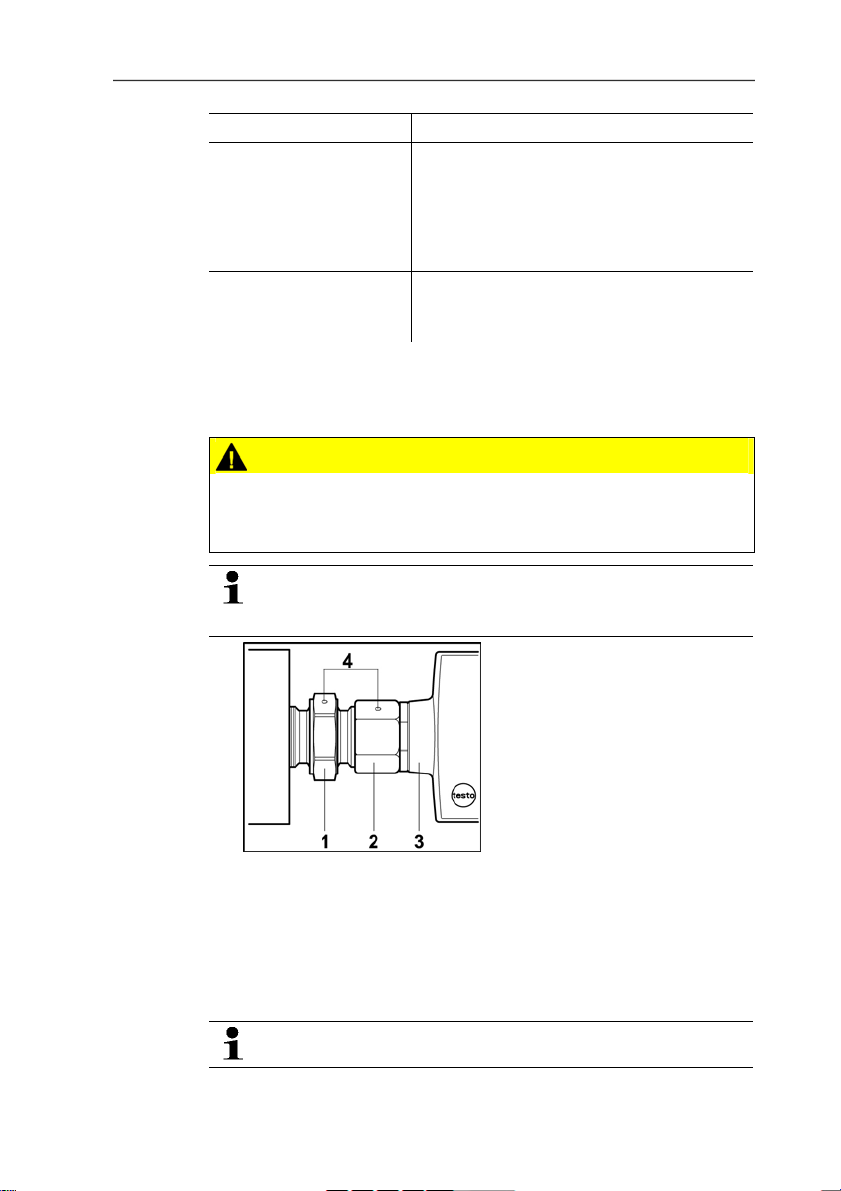

4.3.1.1. Without stainless steel measurement chamber and cooling

coil

CAUTION

Compressed air! Danger of injury!

> De-pressurize pipe sections (e.g. compressor off or use of

bypass) and vent them before opening.

Clamp ring screw connection is already pre-assembled.

Screw connection body (1) and union nut (2) have a pointshaped marking (4).

18

1. Screw thread in process.

2. Turn housing (3) to desired position without much exertion

of energy.

3. Tighten union nut (2) finger-tight.

4. Hold screw connection body (1) with a suitable spanner.

5. Tighten union nut (2) slightly past the marking (4).

An increased resistance can be felt when tightening.

Page 19

4 Transmitter

6. Close ventilation of the pipe section and pressurize the pipe

section again.

4.3.1.2. With stainless steel measurement chamber (max. 35,000 hPa)

1. Connect measurement chamber without testo 6781 transmitter

to quick-release compressed-air fastener for approx. 10 - 30

sec. to blow out any dirt deposits.

2. Remove measurement chamber from quick-release

compressed-air fastener.

3. Screw process connection (G1/2) of the testo 6781 transmitter

into the thread of the measurement chamber.

4. Mount 6781 as described under Without stainless steel

measurement chamber and cooling coil page 18.

5. Engage quick-release fastening of the measurement chamber

in the standardized socket of the compressed air line.

4.3.1.3. With stainless steel measurement chamber and cooling coil

(max. 35,000 hPa)

1. Connect measurement chamber without testo 6781 transmitter

to quick-release compressed-air fastener for approx. 10 - 30

sec. to blow out any dirt deposits.

2. Remove measurement chamber from quick-release

compressed-air fastener.

3. Screw process connection (G1/2) of the testo 6781 transmitter

into the thread of the measurement chamber.

4. Mount 6781 as described under Without stainless steel

measurement chamber and cooling coil page 18.

5. Engage quick-release fastening of the measurement chamber

in quick-release fastening of the cooling coil.

6. Engage second quick-release fastening of the cooling coil in the

standardized socket of the compressed air line.

19

Page 20

4 Transmitter

Pos: 37 /TD/Erste Schritte/MUF 63xx/Spannungsversor gung/Analogausgänge anschließen 6781 @ 3\mod_1239 9516 83334_79.doc @ 31673 @ 45

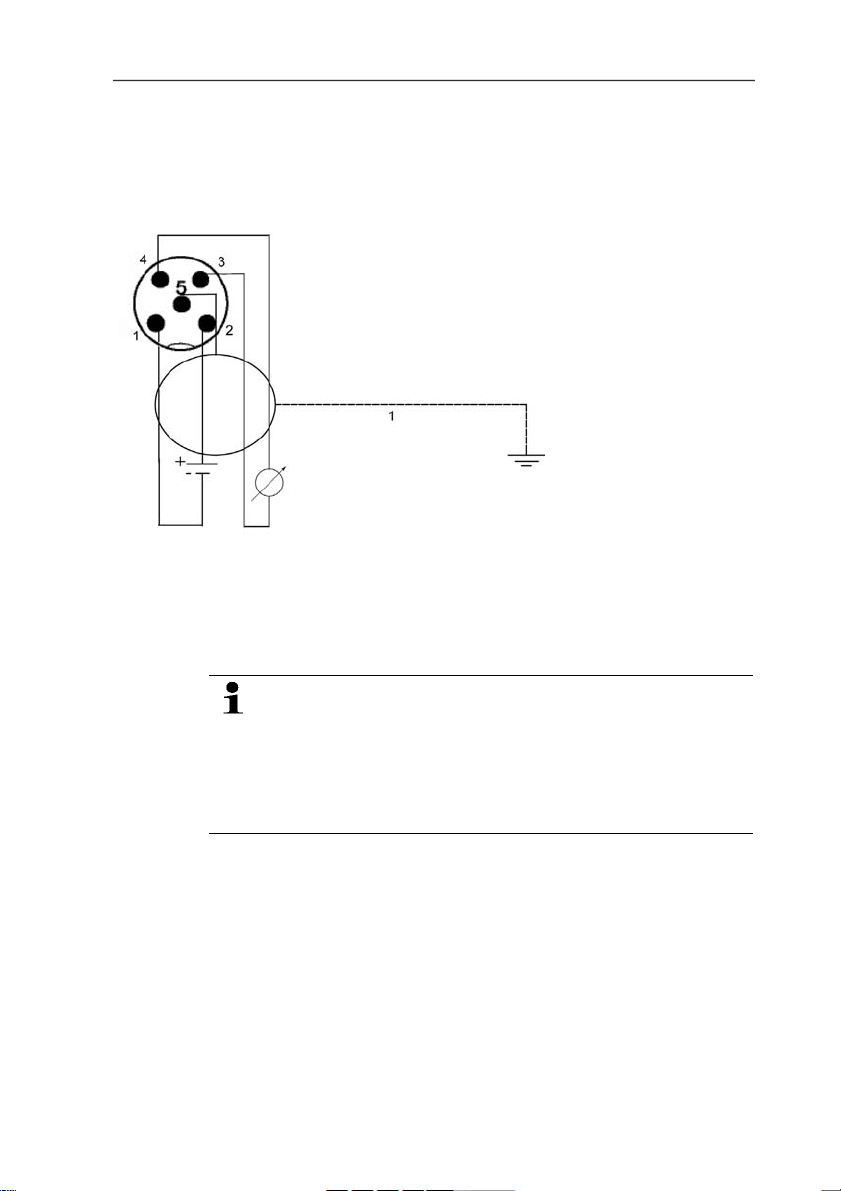

4.3.1.4. Connecting voltage supply and analog outputs

Wiring diagram for 4-wire system (0 to 20 mA/4 to 20 mA/0 to

1 V/0 to 5 V/0 to 10 V)

1-channel

0 to 20 mA/4 to 20 mA

max. load per 500 Ω

0 to 1 V/0 to 5 V/0 to

10 V

Pos: 38 /TD/Erste Schritte/MUF 63xx/Option Stecker verbindung 6781 @ 3\mod_1239951744567_79.doc @ 31694 @ 4

20

Requirement for the connecting cable of the supply:

• Shielded and insulated with cross-section of at least

0.25 mm

2

.

• The supply line must be secured against exceeding 8 A.

• An OFF switch must be installed in an easily accessible

position close by and be marked as such.

Page 21

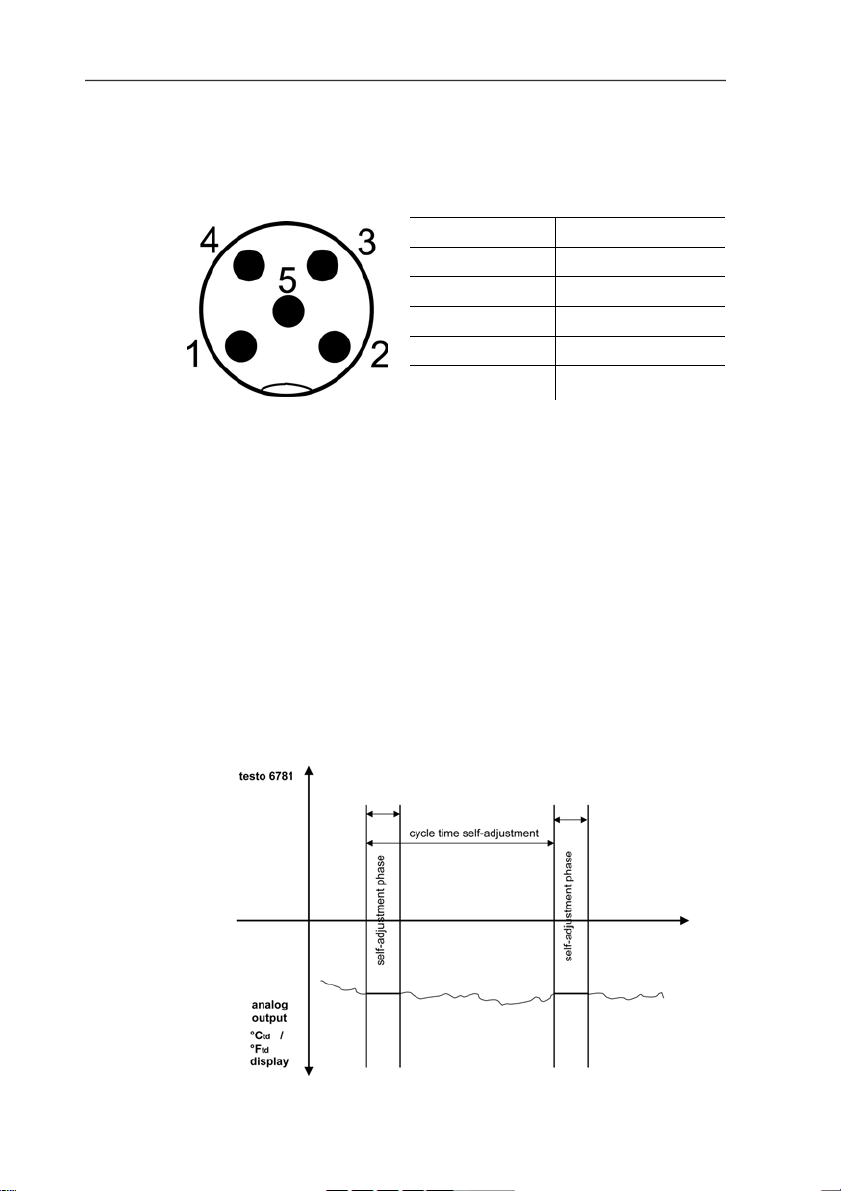

4.3.1.5. Plug-in connection for power supply and channel

M12 plug-in connection (5-pin) connector

View of the plug-in connection in the installed state from outside

PIN Assignment

1 -24 V

2 +24 V

3 + Ch1

4 - Ch1

5 PE

Pos: 39 /TD/Überschriften/MUF/1.3.3 Gerät abgleic hen @ 3\mod_1236081099337_79.doc @ 27173 @ 3

4.3.2. Adjusting the instrument

Pos: 40 /TD/Erste Schritte/MUF 63xx/1-Punkt-Abgleic h 6781 @ 3\mod_1239794807174_79.doc @ 31163 @ 44

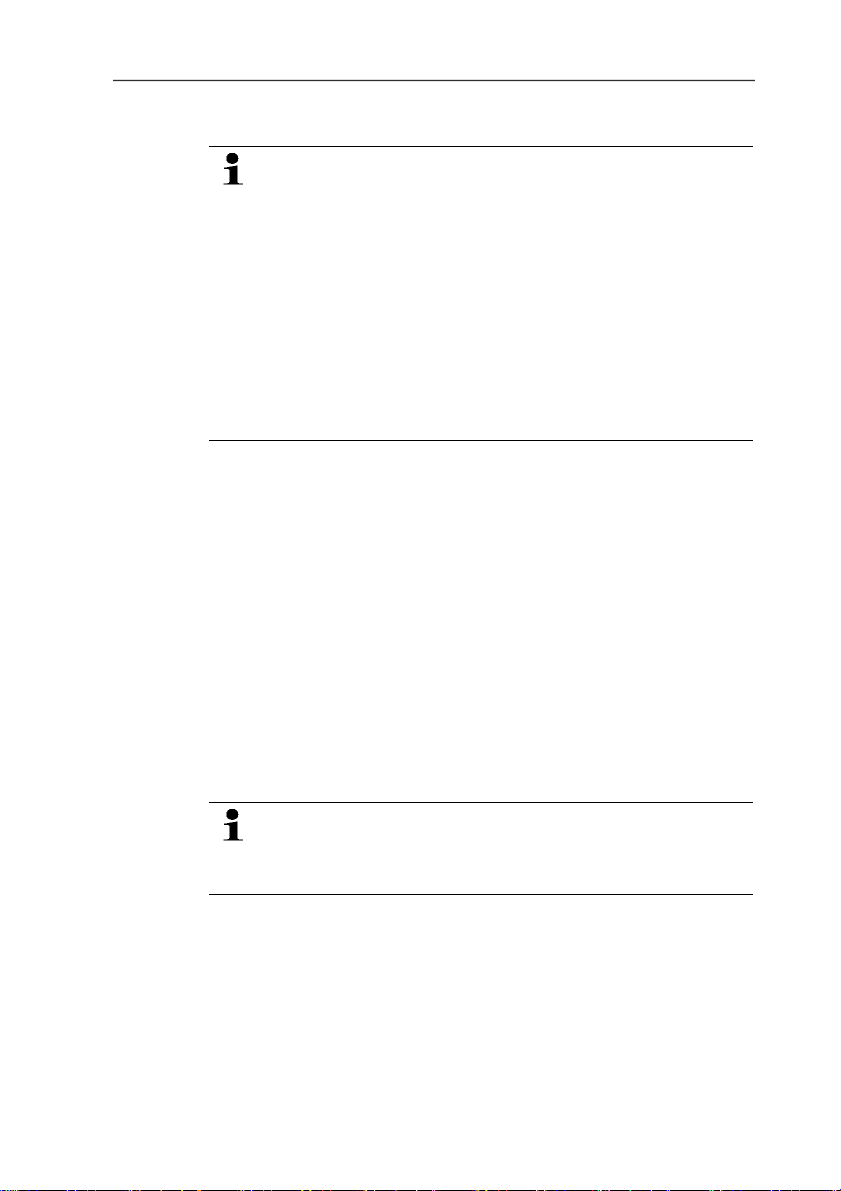

4.3.2.1. Self-adjustment

Conventional trace humidity sensors show a steep rise in

measuring uncertainty at low humidities. With the trace humidity

sensor of the testo 6781, these measuring uncertainties are

corrected by means of an automatic self-adjustment process. This

means that extremely accurate measuring results are also attained

in the range up to -90 °C

To this end, a temperature sensor which is used as a heater is

fitted on the back of the sensor element. A humidity and

temperature value pair is taken in both the unheated and heated

state. The deviation of the probe obtained from these pairs of

values is automatically corrected.

.

td

4 Transmitter

21

Page 22

4 Transmitter

• Deactivating the self-adjustment function of the testo

6781 will reduce measuring accuracy and should

therefore be restricted to the shortest possible length of

time.

• During the self-adjustment phase, the analog outputs,

the display value and the output value are "frozen".

Self-adjustment active is shown in the display until it

has finished. The self-adjustment time (incl. heating

time, calculation time, cooling time) is 30 minutes. The

cycle time can be edited in the P2A software, see Selfadjustment page 54.

• At temperature wn > 0 °C, the self-adjustment time

becomes longer.

4.3.2.2. 1-point adjustment by entering a reference value

Using the 1-point adjustment, you can enter a reference value for

one of the working points you have selected (e.g. -40 °C

this, you achieve a minimum target/actual deviation around this

working point.

But the further away the measurement is from the working point,

the greater the deviation can become. The 1-point adjustment

should therefore only be used for a relatively narrow measuring

range (working range)

✓ A reference measuring instrument (e.g. dewpoint mirror

hygrometer) is ready.

1. Expose the reference measuring instrument and testo 6781 to

the same constant conditions and wait for the equalization

period to expire.

The ideal accuracy is reached when at least two adjustment

cycles are run through at dewpoint temperatures above -60

°C

, whereby four adjustment cycles are recommended at

td

dewpoint temperatures below -60 °C

.

td

2. Measure the reference value and compare with the reading of

the testo 6781.

3. In the event of deviations of the values: Enter reference value

• via the user menu (see Enter reference value for 1-point

adjustment page 35) or

• via the P2A software (see 1-point adjustment page 61).

). With

td

22

Page 23

Pos: 41 /TD/Erste Schritte/MUF 63xx/Analogausgangs- Abgleich _6781 @ 3\mod_1241426437080_79.doc @ 32365 @ 45

4.3.2.3. Analog output adjustment

The purpose of adjusting the analog outputs is to adjust the signal

chain from the digital signal (within the transmitter) to the analog

outputs. The signal type that was appointed for the transmitter is

adjusted respectively for each channel (e.g. 4 to 20 mA or 0 to 1 V,

Pos: 42 /TD/Überschriften/MUF/1.4 Bedienung @ 3\mod_ 1234 443160034_79.doc @ 25001 @ 2

etc.).

Adjusting the analog output

✓ Load of max. 500 Ω is connected to channel 1 (see Plug-in

connection for power supply and channel page 21)

✓ A precise multimeter (minimum requirement: resolution 6.5

digits, at least 5-times more accurate than the 6781) is

available.

If only a simple multimeter is available, the analog outputs

may not be adjusted.

1. Connect the inputs of the multimeter with the contacts (1) and

(2) for channel 1.

2. Transfer the reference analog value measured with the

multimeter into the P2A software (see Adjusting the analog

output page 62) or enter it via the user menu (see Performing

analog adjustment page 36).

3. Disconnect connections between the multimeter and the

contacts of the testo 6781.

4 Transmitter

1 Contact ch. 1+

2. Contact ch. 1-

3. Service interface

23

Page 24

4 Transmitter

4.4. Operation

Pos: 43 /TD/Produkt verwenden/MUF 63xx/Zusammenhang Bedi enmenü – Mini DIN Buchse aktiv @ 3\mod_1234454016014_79. doc @ 25213 @ 3

4.4.1. Relationship between user menu and mini-DIN

socket is active

The testo 6781 can be parameterized using either the user menu or

the P2A software (see Parameterizing, adjusting and analyzing

software (P2A software) page 42).

The testo 6781 transmitter can only be operated via the

display and keypad if the display option is available.

If the testo 6781 is connected to the P2A software, the user

menu is blocked for the duration of the communication. The

message Service plug is shown in the display of the testo

6781. As soon as the P2A software is disconnected, the

Pos: 44 /TD/Produkt verwenden/MUF 63xx/Passwortschu tz _6781 @ 3\mod_1241422238033_79.doc @ 32323 @ 3

user menu is accessible again.

4.4.2. Password protection

The user menu can be protected with a four-digit numerical code

(see Calling up Main Menu page 35) so that access to the user

menu is denied to unauthorized persons not familiar with this

numerical code.

If the password protection is not to be used, the numerical code

Pos: 45 /TD/Produkt verwenden/MUF 63xx/Aufbau des Bedien menüs 6781 @ 3\mod_1239692809877_79.doc @ 31123 @ 3

"0000" must be entered. This is also the status upon delivery.

4.4.3. Structure of user menu

At the main menu level, the user menu comprises the following:

• Main Menu Channel 1

• Main Menu Alarm

• Main Menu Settings

• Main Menu Analysis

• Main Menu Messages

• Main Menu Ident

• Main Menu Adjust

24

• Main Menu Reset

Page 25

4 Transmitter

1 Display for messages

2 Channe l 1 display

Four keys enable the user to navigate/scroll through the menus and

enter/amend values and settings:

Key Function/description

SET

• In Measuring Mode: changes to

parameterization

• In Parameterizing Mode: confirms a

selection or setting

ESC

• Leaves a menu (without modifying any

settings)

X • Selecting: scrolls through menus

(downwards) or selectable alternatives

• Editing: changes to next digit (to the right)

S • Selecting: scrolls through menus (upwards)

or selectable alternatives

• Editing: increases the value of the current

digit by 1

25

Page 26

4 Transmitter

Pos: 46 /TD/Produkt verwenden/MUF 63xx/Übersicht Bedi en menü @ 3\mod_1234510821302_79.doc @ 25303 @ 3

4.4.4. Overview of the testo 6781 user menu

26

Page 27

4 Transmitter

27

Page 28

4 Transmitter

Pos: 47 /TD/Produkt verwenden/MUF 63xx/Hauptmenü Kanä le be arbeiten @ 3\mod_1234511119158_79.doc @ 25322 @ 34

4.4.5. The individual main menus

4.4.5.1. Editing main menu of channel 1

An overview is given in Overview of the testo 6781 user menu,

page 26).

You can perform basic settings for channel 1.

1. In the Measuring Mode press SET, select Main Menu

Channel 1 with X or S and confirm selection with SET.

One of the following parameters can now be selected using X

or S, after which the selection must be confirmed with SET:

• Channel 1 Unit

The parameter for this channel is selected.

Edit/select parameter with X or S, confirm with SET or abort

entry with ESC.

• Scale minimum for channel 1:

The lower scale limit is edited; Unit as selected above.

Editing the value: Scroll one digit to the right using X and

increase value of digit by 1 using S. Confirm with SET or abort

entry with ESC.

• Scale maximum for channel 1

The upper scale limit is edited;

Unit as selected above.

Editing the value: Scroll one digit to the right using X and

increase value of digit by 1 using S. Confirm with SET or abort

entry with ESC.

• Signal delay ("Attenuation") for channel 1

The analog signal can be delayed ("Attenuation"); a time

constant is selected for this (1 = no delay; 15 = longest delay)

Edit/select parameter with X or S, confirm with SET or abort

entry with ESC.

2. Continue to the main menu with X or S or return to Measuring

Pos: 48 /TD/Produkt verwenden/MUF 63xx/Hauptmenü Alar m bearbeiten 6781 @ 4\mod_1244645622570_79.doc @ 44953 @ 455

Mode with ESC.

28

Page 29

4.4.5.2. Editing Main Menu Alarm

The alarm statuses are shown on the display. You can choose

whether the alarm is to be used to monitor limit values or as a

collective alarm. If an alarm is to be used to monitor limit values,

you can choose between monitoring the minimum or maximum

value and set a limit value and hysteresis for each alarm.

In addition, every alarm can be linked to a clearly visible visual

alarm (display background lighting flashes).

An alarm delay between 0 and 240 seconds can still be assigned to

every alarm used for limit value monitoring so that the visual alarm

is delayed. If the alarm status goes out within the set alarm delay

time, the visual alarm is not triggered. .

With an alarm status present, the visual alarm can be reset by

means of acknowledgement. The triggering of a new alarm cannot

be enabled until after the alarm status goes out.

1. In the Measuring Mode press SET, select Main Menu Alarm

with X or S and confirm selection with SET.

- Four alarms can be parameterized.

2. Select Alarm x with X or S and confirm selection with SET.

4 Transmitter

Using alarm to monitor limit values

Monitoring minimum Monitoring maximum

Hysteresis

Limit value Limit value

Hysteresis

3. Select Channel x (e.g. "Channel 1") with X or S and confirm

selection with SET.

4. Select Max control or Min control with X or S (see graphic).

5. Press SET and edit Limit value as well as Hysteresis: Scroll

one digit to the right using X and increase value of digit by 1

using S. Confirm with SET or abort entry with ESC.

6. Select Visual alarm with X or S. Select YES or NO with X or

S. Confirm with SET or abort entry with ESC.

7. Press SET and edit Alarm delay: Scroll one digit to the right

using X and increase value of digit by 1 using S. Confirm with

SET or abort entry with ESC.

8. Return to Channel x with ESC.

29

Page 30

4 Transmitter

9. Return to Alarm x with ESC.

10. Change to the other alarms using X or S and perform settings

Using alarm as collective alarm or not using it at all

If an alarm is assigned to the collective alarm, the display flashes

as soon as (at least) one of the warning or error messages of the

testo 6781 transmitter becomes active.

✓ Alarm is selected (see previous steps 1 and 2).

1. Use X or S to determine whether Alarm x should be used as a

2. If collective alarm is selected: Select Visual alarm with X or S.

3. Change to another alarm using X or S and perform settings in

4. Return to Main Menu Alarm with ESC.

5. Continue to Main Menu Settings with X or S or return to

Pos: 49 /TD/Produkt verwenden/MUF 63xx/Hauptmenü Einst ellungen bearbeiten 6781 @ 4\mod_1244535897708_79.d oc @ 44917 @ 45555

in the same way.

The messages affecting the collective alarm can only be

selected in the P2A software, see Using the software page

46

Collective alarm or not used. Confirm selection with SET.

Select YES or NO with X or S. Confirm with SET and return to

Alarm x.

the same way.

Measuring Mode with ESC.

4.4.5.3. Editing Main Menu Settings

You can edit instrument settings and other settings.

> In Measuring Mode, press SET, select Main Menu Settings

using X or S and confirm selection with SET.

You can edit settings for:

• Display

• Language

• Code

• Unit

◦ Absolute pressure

◦ Temperature

• Humidity process data

30

Page 31

4 Transmitter

Editing display settings

You can set the brightness and contrast of the display.

1. Select Display Settings with X or S and confirm selection with

SET.

2. Select Backlight or Contrast with X or S and confirm

selection with SET.

One of the following parameters can now be selected using X or

S, after which the selection must be confirmed with SET:

• Backlight

The display illumination is changed.

Edit/select parameter with X or S, confirm with SET or cancel

entry with ESC (the effect of the change in parameter can be

seen during input).

• Contrast

The brightness difference between the display background and

the displayed values is changed.

Edit/select parameter with X or S, confirm with SET or cancel

entry with ESC (the effect of the change in parameter can be

seen during input).

• Backlight 24h on

Select On or Off using X or S and confirm with SET.

Off: The display light switches off automatically if no button was

pressed for 10 seconds.

On: The display light is activated

3. Return to Display Settings with ESC and useX or S to

continue to Language.

Selecting language

You can se

lect the language for the plain text line in the display.

> Press SET, select required language with X or S, confirm

selection with SET and return to Language.

Only choose a language that you can understand well.

31

Page 32

4 Transmitter

Editing code settings

You can set the access code (password).

1. Select Code with X or S and confirm selection with SET.

2. Scroll one digit to the right using X and increase value of digit

3. Return to Code with ESC and useX or S to continue to

Select unit

This setting affects the unit of the process data.

1. Press SET, select Change parameters with X or S, confirm

2. Select Change unit with X or S, confirm selection with SET or

3. Select the required variable (absolute pressure/temperature)

4. Select the required unit with X or S, confirm selection with SET

5 Return to Change unit with ESC.

6. Select Hu

7. Select Humidity process pressure with X or S, confirm

8. Scroll one digit to the right using X and increase value of digit

Pos: 50 /TD/Produkt verwenden/MUF 63xx/Hauptmenü Ana ly se bearbeiten 6781 @ 3\mod_1241425854399_79.doc @ 32344 @ 455

9. Return to Main Menu Settings by pressing ESC three times.

If a code other than "0000" (factory setting) is set, the

transmitter can only be operated once this code has been

entered via the menu.

by 1 using S. Confirm with SET or abort entry with ESC.

Change parameters.

selection with SET or cancel with ESC.

cancel with ESC.

with X or S, confirm selection with SET or cancel with ESC.

or cancel with ESC.

midity process data with X or S, confirm selection

with SET or cancel with ESC.

selection with SET or cancel with ESC.

by 1 using S. Confirm with SET or abort entry with ESC.

4.4.5.4. Editing Main Menu Analysis

You can check the function of analog outputs. In addition, you can

read off the minimum and maximum values (since the last voltage

supply or reset of the min./max. values).

32

Testing functionality of analog outputs

This function affects the analog outputs directly, not only

the test contacts.

Page 33

1. In the Measuring Mode press SET, select Main Menu Analysis

- Test Analog Output is shown.

2. Press SET, scroll one digit to the right using X and increase

3. Accept setting by pressing SET and test with multimeter

3. Return to Test Analog Output with ESC and continue to

Reading off min./max. values of channels

To reset the max./min. values, see Editing Reset main menu page

37

1. Read off the min./max. values of the channel in succession with

2. Continue to Main Menu Message with X or S or return to

Pos: 51 /TD/Produkt verwenden/MUF 63xx/Hauptmenü Meld unge n bearbeiten 6781 @ 3\mod_1240905240318_79.doc @ 32203 @ 4

4 Transmitter

with X or S and confirm selection with SET.

value of digit by 1 using S. Any analog output value can be

predefined, e.g. for an analog output of 4 to 20 mA, the value

"6.0 mA". Confirm with SET or abort entry with ESC.

(minimum requirement: resolution 6.5 digits, at least 2-times

more accurate than the 6781) as follows:

Analog output 1: Via test contacts under service flap, see

diagram.

1 Channe l 1

test contacts

2 Multimeter

Max./min. values with X or S.

X or S and return to the Main Menu Analysis with ESC.

Measuring Mode with ESC.

33

Page 34

4 Transmitter

4.4.5.5. Editing Message main menu

Messages can be confirmed/acknowledged, the last messages can

be called up and the display of the messages can be switched on

or off.

Using the P2A software (see Parameterizing, adjusting and

analyzing software (P2A software) page 42) you can

predefine whether messages are to be shown in the

display.

1. In the Measuring Mode press SET, select Main Menu Message

with X or S and confirm selection with SET.

2. Confirm Confirm message using SET.

3. Select Last messages with X or S and confirm with SET.

4. Scroll between the warning and error messages recorded so far

using X or S and return to Last messages using ESC.

5. Select Information with X or S and confirm with SET.

6. Scroll between the status messages recorded so far using X or

S and return to Information using ESC.

7. Continue to Display of message with X or S.

ON: Measurements are shown on the display in Measuring

Mode.

OFF: No messages shown on display.

8. Select ON or OFF with X or S and confirm selection with SET.

9. Return to Main Menu Message with ESC.

1 Message text

2 Additional information on

the message

3 Message num ber

(example: "4/7" refers to

the fourth of seven

messages)

4 Number of messages

present (example: "4/7"

refers to the fourth of

seven messages)

5 Message code (see

Status, warning and

error messages page

37).

34

Page 35

10. Continue to Main Menu Ident with X or S or return to

Measuring Mode with ESC.

An overview of the messages can be found in Status,

Pos: 52 /TD/Produkt verwenden/MUF 63xx/Hauptmenü Ident abf r agen 6781 @ 3\mod_1239269378840_79.doc @ 31053 @ 4

4.4.5.6. Calling up Main Menu Ident

warning and error messages page 37

4 Transmitter

1 Serial number

2 Instrument type

3 Build number

4. Firmware

version

1. In the Measuring Mode press SET, select Main Menu Ident

with X or S and confirm selection with SET.

- The type, firmware version, build number and serial number of

the transmitter are displayed.

This information is required when servicing.

2. Return to Main Menu Ident with ESC.

3. Continue to Main Menu Adjust with X or S or return to

Pos: 53 /TD/Produkt verwenden/MUF 63xx/Hauptmenü Abg lei c h bearbeiten 6781 @ 3\mod_1239867127747_79.doc @ 31254 @ 455

Measuring Mode with ESC.

4.4.5.7. Editing Main Menu Adjust

A reference value can be entered for the temperature (°C/°F) and a

reference value can be entered for the dewpoint (°C

1-point adjustment. Please refer to the description in Adjusting the

analog output page 62.

In addition, the analog outputs can be adjusted. Also see Analog

output adjustment page 23 for instructions on how to do this.

Enter reference value for 1-point adjustment

Please also refer to Analog output adjustment page 23.

1. In the Measuring Mode press SET, select Main Menu Adjust

with X or S and confirm selection with SET.

2. Select Reference value temp or Reference value Td with X

or S.

/°Ftd) for the

td

35

Page 36

4 Transmitter

Pos: 54 /TD/Produkt verwenden/MUF 63xx/Hauptmenü Rese t bear beiten 635x @ 3\mod_1238480830340_79.doc @ 30373 @ 4

3. Press SET, edit value: Scroll one digit to the right using X and

increase value of digit by 1 using S. Confirm with SET or abort

entry with ESC.

4. Continue to Analog Adj. Ch. 1 with X or S.

5. Continue with the adjustment of the analog outputs (see below,

step 2) or press ESC to return to Main Menu Adjust.

Performing analog adjustment

Please refer to Analog output adjustment page 23.

1. In the Measuring Mode press SET, select Main Menu Adjust

with X or S and confirm selection with SET.

Each channel is adjusted at three points in the analog

range (at 10 %; 50 %; 90°% of the analog scale).

2. Select Analog Adj. Ch. 1 with X or S and confirm with SET.

3. Use X or S to select Adj. Point 1.

4. Press SET. Read off multimeter display (e.g. 5601 mA) and

enter this value in the user menu. Do this by scrolling one digit

to the right using X and increasing the value of digit by 1 using

S. Confirm with SET or abort entry with ESC.

5. Use X or S to select Adj. Point 2.

6. Press SET. Read off multimeter display (e.g. 12,001 mA) and

enter this value in the user menu. Do this by scrolling one digit

to the right using X and increasing the value of digit by 1 using

S. Confirm with SET or abort entry with ESC.

7. Use X or S to select Adj. Point 3.

8. Press SET. Read off multimeter display (e.g. 18,401 mA) and

enter this value in the user menu. Do this by scrolling one digit

to the right using S and increasing the value of digit by 1 using

X. Confirm with SET or abort entry with ESC.

9. Return to Main Menu Adjust with ESC.

10. Continue to Main Menu Reset with X or S or return to

Measuring Mode with ESC.

36

Page 37

4.4.5.8. Editing Reset main menu

You can reset the factory settings for the following:

• Instrument

Pos: 55 /TD/Überschriften/MUF/1.5 Status-, W arn- und Fehlermeldungen @ 3\mod_1234442925442_79.doc @ 24963 @ 2

4.5. Status, warning and error messages

Pos: 56 /TD/Produkt verwenden/MUF 63xx/Status-W arnmeldungen/Status-, Warn- und Fehlermeldungen _6781 @ 3\ m od_1 241441355544_79.doc @ 32477 @

Pos: 57 /TD/Produkt verwenden/MUF 63xx/Status-W arnmeldungen/Statusmeldungen 678x @ 3\mod_12385082881 43_7 9.doc @ 30547 @ 3

• Min./max. values

Resetting to the factory settings means resetting to the

order specification, i.e. the specific condition at the time of

supply to the customer.

1. In the Measuring Mode press SET, select Main Menu Reset

with X or S and confirm selection with SET.

- Reset Device to factory settings is displayed.

2. Select the setting to be reset using X or S and confirm

selection with SET.

- Reset Completed is displayed.

3. Return to the reset setting with ESC or SET and return to Main

Menu Reset with ESC.

4. Continue to the Main Menu Channel 1 with X or S or return to

Measuring Mode with ESC.

To achieve optimum operational reliability (machine availability),

the transmitter shows the following via the user menu or the P2A

software

• Status messages

• Warning messages

• Error messages

in each case for the testo 6781 transmitter.

All messages are stored in the transmitter with an operating hours

stamp. Use the user menu (see Editing Message main menu page

34) or the P2A software (see Transmitter history page 63) to view

the message history.

In the transmitter, the last 60 status messages and the last 120

error and warning messages are stored in a ring memory. There is

no limit in the P2A software.

4 Transmitter

37

Page 38

4 Transmitter

4.5.1. Status messages

Status messages show the current operating status of the testo

6781.

Message Display Description

02506

Sensor

initialization

01D19 Service plug

00300 New limit value

00301 Scaling changed The scaling has been changed

02104 Analog out adjust

00500 Transmitter reset

0052F Reset Min/Max

00503

Reset device to

fact

00307

User Setting

Change

Message appears while the

transmitter is starting up. If the

message disappears, the

transmitter is ready for operation.

The Mini-DIN socket is connected

to: the USB adapter for P2A

software, the adjustment adapter

or the service plug (is not

recorded/no number)

The limit value has been changed

or shifted

An analog adjustment has been

made

The transmitter was reset to the

factory settings and is restarted.

Resets all saved Min/Max values

for all channels

A factory reset of the transmitter

was performed

User Setting Change: General

settings were changed for the

transmitter

Pos: 58 /TD/Produkt verwenden/MUF 63xx/Status-W arnmeldungen/Warnmeldungen 678x @ 3\mod_1238508265361_79. doc @ 30526 @ 3

38

Page 39

4 Transmitter

4.5.2. Warning messages

Warning messages show an early warning or a current malfunction

Message Display Cause Remedying of fault

00E00 T ambient high

00E01 T ambient low

00E02/00E

05

0081C Alarm 1

0081D Alarm 2

0081E Alarm 3

0081F Alarm 4

Pos: 59 /TD/Produkt verwenden/MUF 63xx/Status-W arnmeldungen/Fehlermeldungen Messumformer 635x/6781 @ 3\ mod_1236081613819_79.doc @ 27212 @ 3

which may negatively impact measuring.

The ambient

temperature exceeds

the permissible

temperature for the

transmitter.

The ambient

temperature is below

the permissible

temperature for the

transmitter.

Supply voltage

low

The supply voltage is

below the minimum

voltage required for the

transmitter.

Depending on the

parameterization of the

alarm.

Depending on the

parameterization of the

alarm.

Depending on the

parameterization of the

alarm.

Depending on the

parameterization of the

alarm.

Take necessary

measures to lower

ambient temperature,

e.g. through venting or

cooling.

Take necessary

measures to raise

ambient temperature,

e.g. through heating.

Take measures to

ensure sufficient

voltage supply.

Depending on the

parameterization of the

alarm.

Depending on the

parameterization of the

alarm.

Depending on the

parameterization of the

alarm.

Depending on the

parameterization of the

alarm.

39

Page 40

4 Transmitter

4.5.3. Transmitter error messages

Message Display Cause Remedying of fault

01505 Watchdog error

01115

01116

Pos: 60 /TD/Produkt verwenden/MUF 63xx/Status-W arnmeldungen/Behandlung von Alarmmeldungen 678x @ 3\mod_12 38508453754_79.doc @ 30589 @ 3

4.5.4. Handling alarm messages

Error messages show a current malfunction.

Due to a processor

error, the transmitter

performs an automatic

If the problem occurs

frequently, contact

Testo Service.

restart.

Low adjustment

temperature

High adjustment

temperature

Shown on the

display

4

The ambient

temperature is too low

during the pressure

adjustment.

The ambient

temperature is too high

during the pressure

adjustment.

Can be used for

collective alarm5

Take necessary

measures to raise

ambient temperature,

e.g. through heating.

Take necessary

measures to lower

ambient temperature,

e.g. through venting.

Additional

message end6

New limit value x

Scaling changed x

Alarm 1 x

Alarm 2 x

Alarm 3 x

Alarm 4 x

Transmitter reset x

Analog out adjust x

4

If multiple messages/alarms are activated at the same time, only the last

message/alarm is shown. If this is cancelled, the other messages that are still

active are no longer displayed.

5

The message can be assigned the collective alarm function, which means that

the collective alarm is activated as soon as at least one of the messages

assigned to it is activated.

6

The message is shown upon the occurrence of the event causing the message

as well as when closing. Two entries appear in the history in the P2A software:

Message text_start and Message text_end.

40

Page 41

4 Transmitter

Shown on the

display4

Can be used for

collective alarm5

T ambient high x x

T ambient low x x

Supply voltage low x x

Watchdog error x

Perform the Confirm message function (acknowledgement of the

alarm via the control keys on the transmitter):

• The message/alarm is no longer shown on the display and the

optical alarm goes out, where applicable. If multiple

messages/alarms are active at the same time, all are reset

simultaneously.

• If at least one message is assigned to the collective alarm, the

Pos: 61 /TD/Überschriften/MUF/1.6 Wartung und Reinigu ng @ 3\mod_1234443039129_79.doc @ 24982 @ 2

4.6. Maintenance and cleaning

Pos: 62 /TD/Produkt instand halten/MUF 63xx/Gerät wart en/ reinigen 6781 @ 4\mod_1244646493414_79.doc @ 44985 @ 33

collective alarm is reset.

4.6.1. Maintaining the instrument

We recommend that the adjustment and settings of the transmitter

be checked at regular intervals using the

• User menu (Operation page 24) or

• P2A software (Parameterizing, adjusting and analyzing software

(P2A software) page 42)

Additional

message end6

4.6.2. Cleaning the instrument

• Only clean the instrument carefully with a moist cloth.

• Do not use aggressive cleaning agents.

• Do not use any solvents.

Pos: 63 /TD/Produkt instand halten/MUF 63xx/Messka m mer, Abkühlstrecke, Sensor @ 3\mod_1238508590396_79.doc @ 30610 @ 55

41

• Do not touch or damage the sensor.

Protection cap, measurement chamber, cooling coil

If used in process conditions involving oil or dust, the protection cap

and, if used, the measurement chamber and cooling coil must be

cleaned regularly.

• Unscrew/remove protection cap, measurement chamber and

cooling coil and blow out with compressed air or place in an

ultrasonic bath.

Page 42

5 Parameterizing, adjusting and analyzing software (P2A software)

• Replace a heavily soiled protection cap with the same type of

protection cap.

The accuracy is only maintained when the ordered

protection cap is replaced by the same type of protection

cap.

Sensor cleaning

During sensor cleaning, avoid any contact with the sensor.

Do not mechanically clean the sensor, as otherwise the

cover electrode may be damaged.

1. Carefully unscrew protection cap.

2. Carefully rinse with isopropanol and/or distilled water.

3. Allow sensor to dry thoroughly.

Pos: 64 /TD/Überschriften/MUF/3 Parametrier- , Abgleich und Analysesoftware (P2A-Software) @ 3\mod_123 4258 523713_79.doc @ 23932 @ 1

4. Screw on protection cap.

5 Parameterizing, adjusting and analyzing

Pos: 65 /TD/Überschriften/MUF/1.1/2.1/3.1 Leis tungsbeschreibung @ 3\mod_1234258595211_79.doc @ 23951 @ 2

5.1. Specifications

Pos: 66 /TD/Leistungsbeschreibung/Verwendung/ MUF63xx/MUF 63xx P2A @ 3\mod_1234258967326_79.doc @ 24065 @ 355

software (P2A software)

The P2A software is used for the parameterizing, adjustment and

analysis of testo transmitters. The following applies:

• Generally, all newer testo transmitters (as of 2007) are

supported.

• Included with every testo transmitter that is bought new is a CD

that contains a free upgrade of the software, which includes the

device drivers for all transmitters that can be attached at this

time.

• This upgrade can be downloaded at any time via the testo

homepage "www.testo.com/Download/P2A".

The software must only be bought one time, even for owners of

several testo transmitters.

42

Page 43

5 Parameterizing, adjusting and analyzing software (P2A software)

5.1.1. Functions and use

In the P2A software, two different file types are used: The

instrument and the parameter file.

Instrument file

The parameters of a particular transmitter are stored in its so-called

instrument file. Using this file, the parameters can be edited and the

instrument can be tested and adjusted.

Instrument files also contain the respective histories in addition to

the parameter data, i.e. "log books" are kept for the previous

parameterizations, adjustments and messages (see Transmitter

Pos: 67 /TD/Leistungsbeschreibung/Systemvoraus setzungen/MUF 63xx @ 3\mod_1234260654399_79.doc @ 24084 @ 3555

history page 63).

Instrument files are ".cfm" format files.

Parameter file

Parameter files are not tied to a specific individual transmitter and

contain only parameter data/no history data.

If you use various instruments of the same type, you can create

parameter files once (e.g. by saving the appropriate instrument file

as the parameter file) and transmit these onto the other

instruments.

Parameter files are ".cfp" format files.

5.1.2. System requirements

Operating system

• Windows® 2000 SP4

• Windows® XP Home/Professional

• Windows® Vista

Computer

• Pentium processor of at least 400 MHz or equivalent

• 128 MB RAM

• Graphics resolution of at least 1024 x 768

• Unused hard drive capacity of at least 15 MB

• CD-ROM drive

• USB interface

43

Page 44

5 Parameterizing, adjusting and analyzing software (P2A software)

• At least Internet Explorer 5.0.

Software

The P2A software must be purchased and installed separately from

the transmitter. If it is a new software version, the transmitter is

already supported completely. Older P2A software versions can be

updated via the P2A software upgrade (cf. product CD included

Pos: 68 /TD/Leistungsbeschreibung/Lieferu mfang/ MUF 63xx/MUF 63xx P2A @ 3\mod_1234260991646_79.doc @ 24103 @ 3

with the transmitter).

5.1.3. Scope of delivery

Included in the scope of delivery are:

• P2A software

Pos: 69 /TD/Überschriften/MUF/3.2 Erste Schri tte @ 3\ mod _123 4258633304_79.doc @ 23970 @ 2

5.2. First steps

Pos: 70 /TD/Erste Schritte/MUF 63xx/P2A/Software/ Treiber installieren @ 3\mod_1234261192065_79. doc @ 24123 @ 3444

5.2.1. Installing the software/driver

• USB driver

When working with the parameterizing, adjusting and

analyzing software (P2A software), previous knowledge of

Windows

®

operating systems is assumed. The description

in this instruction manual relates to Windows

Administrator rights are required to install programs and

drivers under Windows® 2000 SP4, XP and Vista.

®

XP.

5.2.1.1. Installing P2A software

1. Insert CD with P2A software.

✓ If the installation program does not start automatically:

> Open Windows Explorer and start the file Setup.exe on the

product CD.

2. Follow the directions of the installation wizard.

5.2.1.2. Installing USB driver

Before installing the USB driver, please read the separate

44

documentation that is enclosed with the USB driver CD.

Page 45

5 Parameterizing, adjusting and analyzing software (P2A software)

5.2.1.3. P2A software upgrade

1. Insert product CD (supplied with the transmitter).

2. Open Windows® Explorer and start the file P2A upgrade.exe

on the product CD.

Pos: 71 /TD/Erste Schritte/MUF 63xx/P2A/Software st arten @ 3\mod_1234261605199_79.doc @ 24142 @ 3444

3. Follow the directions of the installation wizard.

5.2.2. Starting the software

5.2.2.1. Starting the program

> Select: [Start] > All Programs > Testo > P2A Software.

- The program window is opened (see User interface page 46).

5.2.2.2. Establishing a connection with the instrument

Multiple instruments can be attached, however only one connection

is active at all times.

✓ USB driver is installed (see Installing USB driver page 44).

1. Start the P2A software.

2. Connect adapter (supplied with the P2A software) to the service

interface of the instrument (see Service interface page 16).

3. Connect instrument/adapter to the PC via the USB interface.

- The instrument file of the attached instrument is shown in the

file list.

5.2.2.3. Activating the connection with the instrument

> Click on the desired instrument file.

- The selected file is marked in colour and the connection with

the instrument is activated.

If a connection with the instrument is established when the program

is started, the corresponding instrument file is marked

automatically.

45

Page 46

5 Parameterizing, adjusting and analyzing software (P2A software)

Pos: 72 /TD/Überschriften/MUF/3.3 Software verwend en @ 3\mod_1234258679599_79.doc @ 23989 @ 2

5.3. Using the software

Pos: 73 /TD/Produkt verwenden/MUF 63xx/P2A/Software verwenden @ 3\mod_1234262654547_79.doc @ 24162 @ 3

5.3.1. User interface

46

1 Menu bar:

Menu Command Explanation

File Open

Shows the Windows dialogue for

searching and opening files.

Save as

Saves the parameters of an

instrument or parameter file

under a new name.

Edit Copy

Copies the parameters of the

marked instrument or parameter

file in the cache.

Paste

Pastes the parameters from the

cache in the marked instrument

or parameter file.

View Toolbar

Status bar

Activates/deactivates the toolbar

or status bar.

Page 47

5 Parameterizing, adjusting and analyzing software (P2A software)

Menu Command Explanation

?

Check instrument

connections

Checks the connections to a

connected instrument without the

instrument having to be

activated.

Service

A text file with the most important

information on the computer and

the software is opened via

Display service data.

Information

Shows the version number of the

P2A software.

2 Toolbar: Shows the Windows-compliant icons for editing.

3 File:

Icon File Explanation

Symbol shows a

transmitter

Instrument

file

Instrument file

Connection to the instrument has

been established.

<Type> <Serial number>.cfm

File name should not be

changed.

Symbol shows a

transmitter with a red

minus sign in the upper

left corner

Symbol shows a

transmitter with a white

P for parameter file in

the upper left corner

Instrument

file

Parameter

file

Instrument file

Connection to the instrument has

not been established.

<Type> <Serial number>

<Date> <Time>.cfp

File name can be changed.

The name can be selected freely,

but it is recommended that you

retain the reference to the

instrument.

Parameter files are always

marked red; the parameter

values they contain are only

forwarded to the instrument after

being transmitted to the

instrument file.

47

Page 48

5 Parameterizing, adjusting and analyzing software (P2A software)

4 Function buttons: Dialogues on editing and testing the

instrument are opened by means of the buttons.

[Change parameterization] see Changing instrument/parameter

file page 48

[Test/analyze transmitter] see Chapter Analyzing/testing the

transmitter page 57

[Adjusting the transmitter] see Chapter Adjusting the transmitter

page 60

[Transmitter history] see Transmitter history page 63

5 File information:

Status Shown in the window

An instrument file is

selected

A parameter file is

selected

Type, serial number, firmware version of the

instrument.

Type, serial number and firmware version of

instrument for which the parameter file was

created.

Connection status Green = connection is active

Red = connection is inactive

6 Status bar: Shows the current status when editing via the menu

Pos: 74 /TD/Produkt verwenden/MUF 63xx/P2A/Geräte-/ Par ameterdatei bearbeiten @ 3\mod_1234358080444_79. doc @ 24303 @ 34

bar.

5.3.2. Editing instrument/parameter file

5.3.2.1. Changing instrument/parameter file

✓ The desired instrument/parameter file is marked.

1. Click on [Change parameterization].

- The Properties of <Instrument type> <Serial number>

dialogue is opened with the Change parameterization register.

If the parameters were transmitted from other parameter files into

the instrument file, a message is shown with which you can

transmit the new parameters to the connected instrument using

[Yes].

> If the parameters should not be transmitted, click on [No].

Pos: 75 /TD/Produkt verwenden/MUF 63xx/P2A/Einhei t / Analogausgang ohne Relais @ 4\mod_1244205188941_79.doc @ 44503 @

48

2. Change or enter parameters in the corresponding fields.

Page 49

5 Parameterizing, adjusting and analyzing software (P2A software)

Field Explanation

Unit/

Analog output

All analog outputs are parameterized in this

mask.

Unit/analog output

(graphic)

Unit: 0 to 1 V/5 V/10 V or 0...20 mA, 4 to 20

mA.

Vertical: Current version of the analog output

(cannot be changed).

Horizontal: Min./max. scale end points of

selected unit.

The curve changes in accordance with the

entered value of scale minimum and

maximum.

Scale minimum/

maximum

The endpoints of the scaling can be selected

up to the stored scale minimum and

maximum. In the process, scaling can take

place beyond the measuring range in order

to adjust the analog output to the customer

system.

Unit Selection of the physical unit.

When changing the unit, standard values are

set for scale minimum and maximum.

Signal delay

(graphic)

49

Curve changes according to the set signal

delay.

Page 50

5 Parameterizing, adjusting and analyzing software (P2A software)

Field Explanation

Signal delay Time interval in stages 1 – 15:

1 = no delay

15 = longest delay.

The signal delay is added to the reaction time

of the sensor. The signal delay shows

averaging over the time interval of the

selected stage in seconds:

Example

Stage 10 = average of the readings from the

last 10 seconds.

The delay of the signal in relation to the change in the

process is also significantly influenced by the selection of

Pos: 76 /TD/Produkt verwenden/MUF 63xx/P2A/Grenzwert e Relais 6781 @ 4\mod_1250579466639_79.doc @ 47463 @

the particle filter.

Field Explanation

Alarm values, alarm 1 to 4

In this mask, the display alarms

are parameterized.

50

Alarm x Four alarm values are available.

Not used Alarm is not used.

Hysteresis image and input

options are hidden.

Page 51

5 Parameterizing, adjusting and analyzing software (P2A software)

Field Explanation

Collective alarm

If selected messages appear, a

collective alarm can be triggered.

Selection of the messages (OR

linkage) by selecting the

checkbox.

Min control

If switched to ON (NO contact) or

OFF (NC contact) under the limit

value; in the event of a

subsequent exceeding of Limit

value plus Hysteresis, it is

switched to OFF (NO contact) or

ON (NC contact).

Max control

If switched to ON (NO contact) or

OFF (NC contact) above the limit

value; in the event of a

subsequent undershooting of

Limit value minus Hysteresis, it