Page 1

Humidity Monitoring in Compressed Air

Increase safety - Cut costs

°C tpd

°F tpd

°C td

atm

°F td

atm

% RH

ppm

V

mg/m

3

°C / °F

testo 6740

Page 2

2

The humidity sensor

2

Optimal for trace humidity measurement

The testo humidity sensor is generally calibrated at several points to ensure minimum deviations. For trace

humidity measurement, a high-precision reference measurement (dewpoint mirror) is used to help carry out a

calibration at -40 °CtP (pressure dewpoint).

To demonstrate the accuracy of testo’s humidity sensors, five sensors were extensively tested in a large number

of international calibration institutes over a 5-year period. All the measurement results confirmed the high

accuracy of 1% RH.

Monitor trace humidity, avoid damage

Dry air, compressed air and dry gases are used in all areas of industry. Humidity is normally

undesirable because it can cause damage or impair the quality of the end product, as the

graphic underneath shows.

04/96

10/96

12/96

07/97

09/98

10/98

03/99

10/00

03/01

08/96

10/96

09/98

10/98

04/00

08/01

PTB

P

T

B

12/00

NRC

CRM

09/00

KRISS

J

Q

A

INTA

N

P

L

IMGC

N

IST

C

E

T

IA

T

·

That’s why you need the testo 6740 for effective trace humidity measurement

>>

Compression Distribution Consumer

Corrosion in pipes and

function elements

Pneumatic drives:

- interrupted lubrication

- mechanical damage

Formation of ice in

cold and external zones

Compressor Drier

e.g. medical

compressed air

Moist powder

conglutinated

Bacterial growth

(European drug

legislation)

e.g. transport air for

pharmaceutical powder

·

Gas engineering: humidity causes damage and reduces the

value of the gas in the system

Granulate drying: dry air is a

requirement for product quality

Medical compressed air:

minimum humidity as a hygiene

requirement

Compressed air systems: drier

monitoring to avoid damage

caused by humidity

05/00

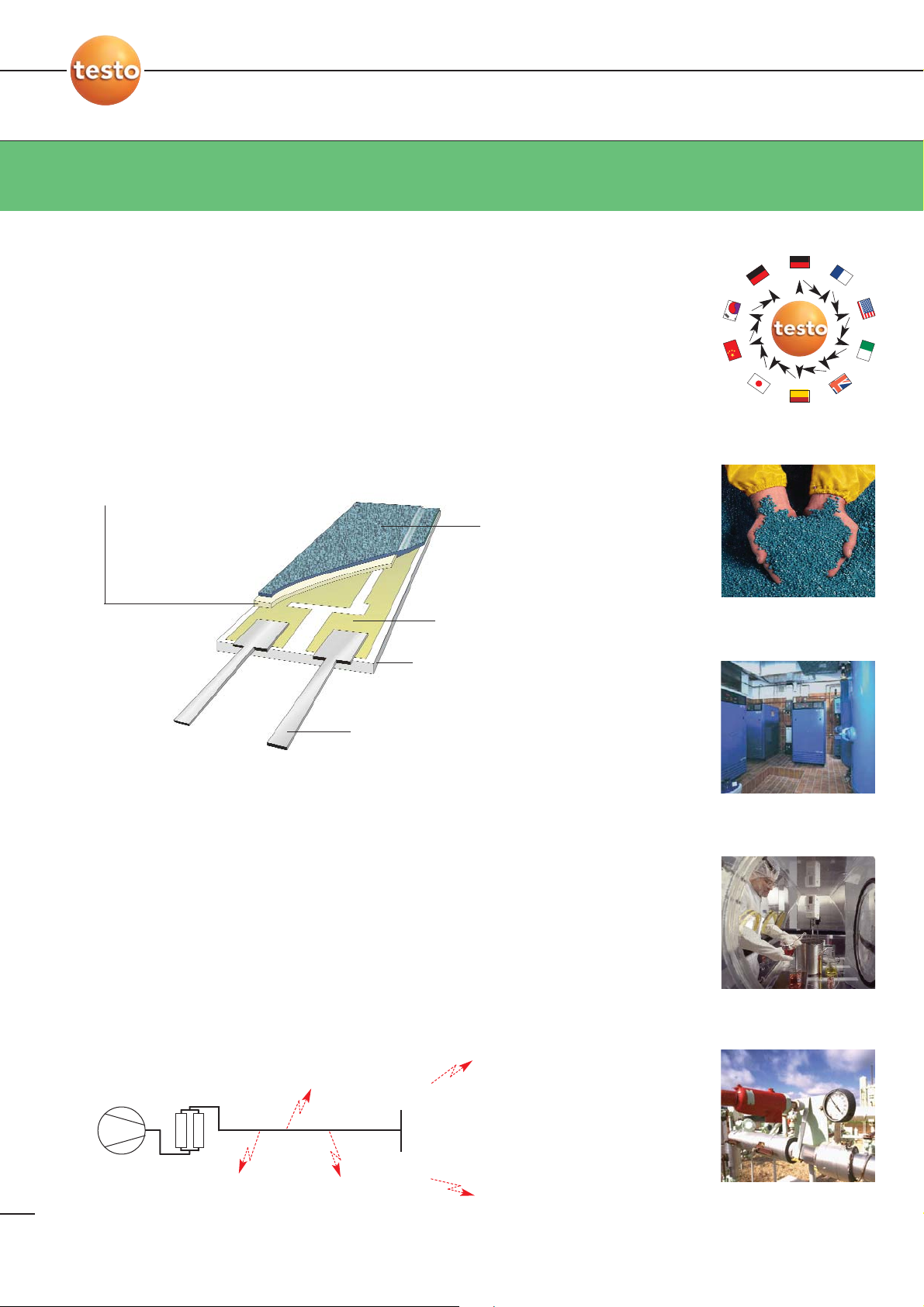

Dielectric layer

Polymer, changes dielectricity as

a function of relative humidity

Top electrode

Allows humidity to penetrate to

the dielectric layer and protects

against dirt

Carrier

Ceramic substrate for

mechanical protection

Connection pins

Special anti-

corrosion design

Bottom electrode

Page 3

33

Safeguard quality - Cut costs

What is compressed air quality?

The international standard ISO 8573 defines seven classes of

compressed air quality and lays down the humidity, the oil

content, the particle content etc. which the compressed air is

allowed to have. Class 1 represents the highest requirements.

Class 4 is satisfied if, for instance, the pressure dewpoint does

not exceed 3 °CtP or 37 °FtP or an absolute humidity of 6 g

water vapour per m3 or 8,150 ppmV(parts per million, relative to

the volume).

The main way of ensuring compliance with a quality class

involves installing a suitable drier. Its monitoring and, where

appropriate, its control (see below), is handled by the

testo 6740.

How can costs be reduced?

Of course, the main reason for using the testo 6740 is to

monitor and avoid excessive humidity in the system so as to

avoid damage (cf. p. 2 below). In addition, dryer operating costs

can be reduced sharply.

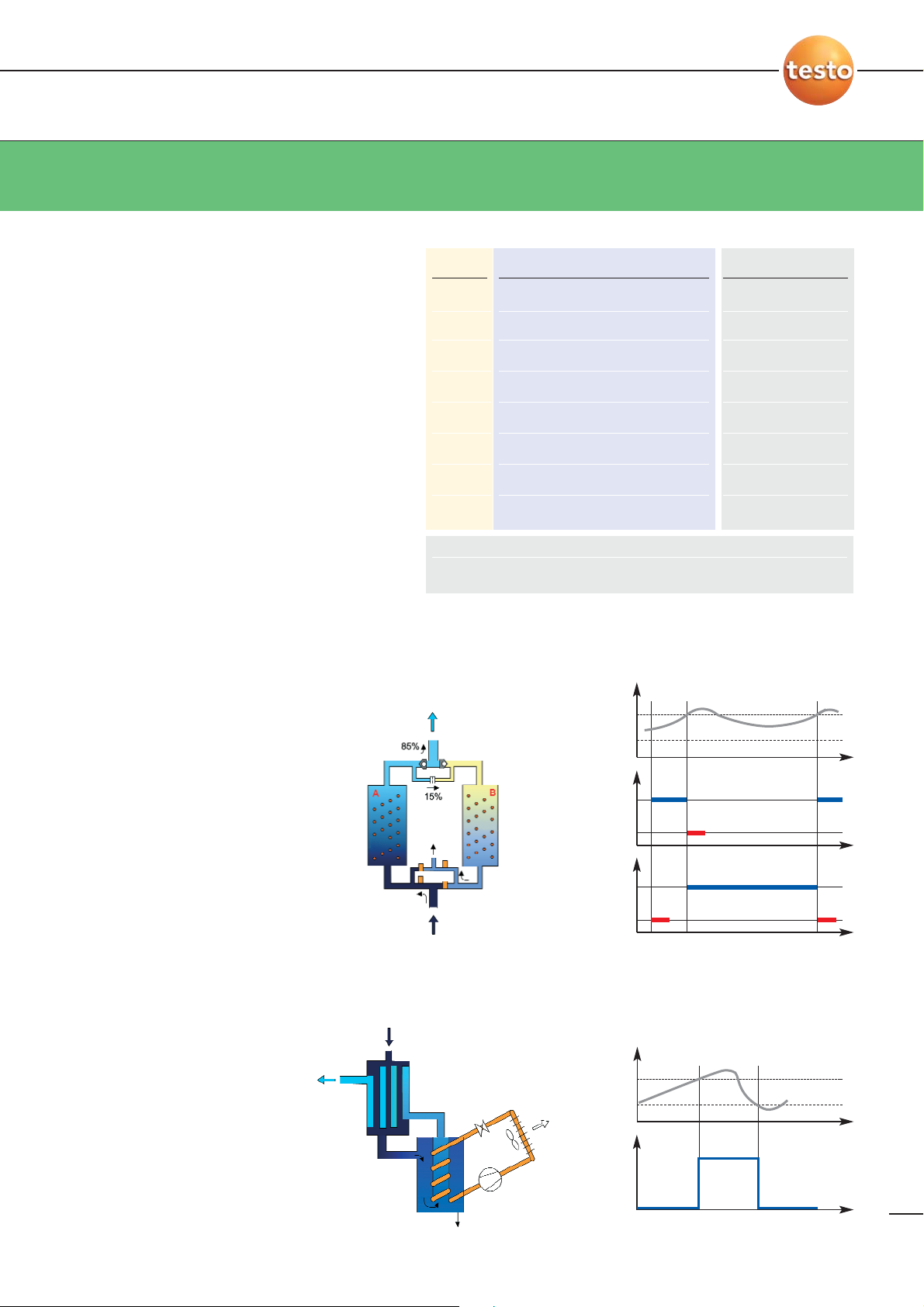

Adsorption driers:

If chamber switchover is humidity-controlled

using the testo 6740 rather than being time-

controlled (see diagram on the right), the dry

phases (blue) are normally much longer than the

regeneration phases (red). During this time no

regeneration air must be generated, so that the

compressors can be reduced from 100% to

about 85% volumetric flow rate. This results in

significant savings in operating costs.

Dry

compressed air

Humid

compressed air

Condensate

Humid

compressed air

Cooling driers:

In non-critical systems, low-temperature driers

can be switched off completely when air humid-

ity is low (e.g in the winter). The testo 6740

supplies the humidity measurement here as

well. If the humidity surges that occur when the

low-temperature driers are switched on are to

be avoided, a downstream low-temperature

drier can be kept in continuous operation to

trap this humidity. This results in tangible

savings in operating costs.

On -22°

Vessel A

Pressure dewpoint

(°Ctpd)

Drying

Regeneration

Drying

Regeneration

Vessel B

On -22°

Off -28°

Vessel A

Drying

Regeneration

Drying

Regeneration

Vessel B

Time

10°

2°

Low-

temperature

driers

Pressure

dewpoint

temperature

TimeOff

On

Off

Equipment Compressed air drier

Monitoring/

Control testo 6740

Typical application

Semi-cond. prod.

Granulate drier

Transport air

Pneu. tube conveyor

Vacuum eng.

Working/energy air

Blow air

ISO 8573

Class

1

2

3

4

5

6

7

Trace humidity

°Ctpd °Ftpd g/m

3

ppm

v

-70 -94 0.003 4

-40 -40 0.12 163

-20 -4 0.88 1200

3 37 6 8150

7 44 7.8 10600

10 50 9.4 12800

-- - -

Page 4

44

Features and benefits

Bright 7-segment display (optional)

- Housing can be rotated by 350°

The right process connection

- G

1

/2 or NPT1/2“

- Pressure-tight up to 50 bar

- With optional measurement chamber

Ultra-easy menu operation (cf. p.6) via buttons

- Select the humidity variable

- Change the scaling

- Set alarms, incl. hysteresis

- Carry out local 1-point calibration

- Test analog signal and alarm outputs

- Call up historic min./max. values

The long-term stable testo humidity sensor

with protocolled precision calibration at

residual humidity -40 °Ctpd

• Maximum reliability

- Long-term stability, testo humidity sensor applied 100,000 times over

- Demonstrably correct indication of measurement ranges and data

- Highest manufacturing quality

• Calculation of the most important trace humidity variables

- e.g. °Ctpd, °Ctd atmospheric, ppm

v

• Calibration protocol

• Convenient operation

- Via the display menu without additional aids

- Without display via the internal interface and

scaling adapter software (cf. p. 6)

- Local 1-point calibration

•

Analog output 4 .. 20 mA (2-wire)

• 2 limit signal outputs (optional)

- Pre- and main alarm

as floating contact

- 2 LEDs displaying the alarm status

Housing

Material Plastic, polyacrylamide

Dimensions 199.5x37 x37 (with analog output plug)

203.5x37 x37 (with limit signal output plug)

Ambient temperature -20 ... 70 °C

Storage temperature -40 ... 80 °C

Protection type IP 65

Rotation of housing By 350° (to align display)

Sensor and sensor protection

Humidity sensor testo humidity sensor with protocolled

trace humidity adjustment at -40° Ctpd

Temperature sensor NTC

Sensor guard Sintered stainless steel cap

Meas. uncertainty

Humidity +/- 1 K at 0 °Ctpd

+/- 3 K at -20 °Ctpd

+/- 4 K at -40 °Ctpd

Temperature +/- 0.5 K (0 ...50 °C)

Limit signal outputs (optional, 0554.3302)

Contacts

2 floating NO contacts, max. 30 V/0.5 A

Operating points

Standard: 4 °/12 °CtP,

with freely programmable display

Measuring range

Pressure dewpoint temperature (trace humidity) - 60 to +30 °Ctpd

at pressure dewpoints < 0 °Ctpd display of

frost point, at > 0 °Ctpd of dewpoint

Temperature 0 ... 50 °C

Atmospheric dewpoint - 80 ... - 15 °Ctd (at 30 bar rel.)

(cf. diagram on p.7) - 70 ... + 10 °Ctd (at 3 bar rel.)

- 60 ... + 30 °Ctd (at 0 bar rel.)

Pressure resistance testo 6740: Up to 50 bar absolute

Measurement chamber 0554.3303: Up to

15 bar absolute

Analog output

Signal 4 ... 20 mA, two-wire

Scaling Freely scalable via display/buttons

Standard: 4 ...20 mA = -60 ... +30 °Ctpd

Output variables °Ctpd, °Ftpd, °CtA (atm. dewpoint),

°FtA, %RH, ppm

V

, mg/m3, °C, °F

Resolution 12 Bit

Accuracy +/- 40 µA

Supply

Voltage 24 VDC (10 ... 30 VDC allowed); with alarm plug (0554 3302) 20 to 28 VDC

Max. load 10 VDC: 100 Ohm, 30 VDC: 950 Ohm, cf. p.7

EMC According to Directive 89 /336 EEC

Technical data testo 6740

Page 5

55

System components, ordering details

X

Basic instrument (incl. plug for analog signal output)

testo 6741, G 1/2 thread, without display 0555 6741

testo 6742, NPT 1/2“ thread, without display 0555 6742

testo 6743, G 1/2 thread, with display 0555 6743

testo 6744, NPT 1/2“ thread, with display 0555 6744

Accessories

Cable connection plug for analog output 4 ... 20 mA, with

2 floating switch contacts and 2 LEDs 0554 3302

Measurement chamber (for 6741, 6742), up to 15 bar 0554 3303

Cooling coil (up to 200 °C, use only with measurement chamber) 0554 3304

Scaling adapter for testo 6741 / 6742 incl. software 0554 3305

ISO calibration certificate, two calibration points (-10 °/-40 °Ctp at 6 bar) 0520 0136

ISO calibration certificate, pressure dewpoint (-40 °...0 °Ctpd at 6 bar)

Basic costs 0520 0116

Per calibration point (please indicate) 0520 0116

External display testo 54-2AC, 2 limit signal outputs (up to 300 VAC, 3 A),

supply 230 VAC

5400 7553

2 m teflon tube with compressed air connections 0669 2824/4

Power supply (bench unit) 90...264 VAC / 24 VDC (350 mA) 0554 1748

Power supply (DIN rail mounting) 90...264 VAC / 24 VDC (3 A) 0554 1749

Ordering data testo 6740 Order no.

Customised combinations

Every measuring point can be optimally configured. With or

without a display, with European G 1/2 thread or American

NPT 1/2” thread. With or without limit signal output.

Directly assembled, with measurement chamber or with

cooling coil. All combinations are possible, ensuring your

needs are met optimally.

Measurement chamber (0554 3303)

for optimal flows past the sensor

(valve can be infinitely adjusted) and

quick installation

Selection advice: choosing the right components for your application

For process temperatures > 50 °C (up

to 200 °C), use a cooling coil (0554.3304)

& measurement chamber (0554.3303).

For dirty, oily media, connect a

40 µm filter upstream

If neither A nor B is required:

just screw directly into the G1/2 or

NPT 1/2” thread. Depressurised

tube required during installation.

Use a measurement chamber

(0554.3303) for rapid assembly (no

depressurising before installation) and

better response time from the sensor (flow

past sensor can be infinitely adjusted)

Cooling coil (0554 3304)

for process temperatures

50 ...200 °C (only with

measurement chamber)

Teflon tube (0669 2824/4)

for dry air

The 4 types of the testo 6740 family

A

A

A B

B

C

For atmospheric dry air (e.g.

granulate driers), a teflon tube is

used and the valve of the

measuring chamber is opened fully.

At process temperatures

> 50 °C, connect a cooling coil

upstream.

EN

EN

testo 6741

G 1/2

G 1/2 thread

NPT 1/2”

NPT 1/2” thread

testo 6743

with display

testo 6744

with display

testo 6742

Standard: Analog output

4 ..20 mA (2-wire)

Optional (0554 3302):

2 limit signal outputs integrated

Analog output 4 ..20 mA (2-wire)

+ 2 limit signal outputs (floating)

+ 2 LEDs

without display with display

G 1/2 0555.6741 0555.6743

NPT 1/2” 0555.6742 0555.6744

C

C

B

In main line:

behind drier

Compressed air

quick connection

(plug NW 7.2)

Compressed air

quick connection

(plug NW 7.2)

G 1/4

internal

thread

G 1/2

internal

thread

Compressed air

quick connection

(jack NW 7.2)

Page 6

6

The ideal operating concept

6

Easy to operate with or without a display

Does the unit have to be changed from °Ctpd to ppmVor do the operating points need to be corrected? These and many other settings can be

easily configured via the display. Or - and this is particularly advantageous for OEM customers such as manufacturers of compressed

air driers - these adjustments can be handled by a PC running the scaling adapter software 0554.3305, even without a display.

With display, testo 6743, testo 6744

Without display, testo 6741, testo 6742

The display menu

Fully oriented to field requirements: Alternating display value and unit, option of switching off the display, password protection,

unit selection, etc. Try it out! You will certainly appreciate the intuitive operation.

The scaling adapter software permits mobile

access, perfect for OEM or service personnel

The display and buttons enable ultra-easy

menu operation with maximum convenience for the user

• Firmware version

• Digital values

• Keyboard test

• Further information

• Set absolute pressure

• Display min./max. value

• Test analog output

• Set/test limit signal output etc.

• Change units

• Change scaling

• Single-point calibration

• Reset

cf. below “The

display menu”

Select unit

Define scale

RSTADJALARMPROG

ResetReference

value input

(1-point

adjustment)

Lower

alarm

Upper

alarm

Hysteresis

Test

switching

outputs

Min. values

Max. values

User code

Time delay

On/Off

On/Off

Analog signal test

Absolute pressure**

UNIT

°Ctpd

°Ftpd

°CtA

°FtA

%RH

ppm

v

mg/m

3

°C

°F

4 mA *

20 mA *

* testo 6740 specifies typical scale defaults for the chosen UNIT.

These can be changed as desired.

** Only necessary for UNITs °CtA, °FtA (atm. dewpoint) or mg / m3(absolute

humidity)

CODE

Measuring mode

No display

Switch off

display

Alternating display

Measure value 6 s Unit 2 s

SET SET

1

1

2

2

3

3

Page 7

77

Pressure dewpoint or atmospheric dewpoint? - Wiring

Pressure dewpoint or atmospheric dewpoint?

Atmospheric air is able to store more water vapour than compressed

air. If the compressed air is cooled down, it reaches its dew

point (“pressure dewpoint” in °CtP or °FtP) at higher temperatures,

while atmospheric air can be cooled down further until condensate

is first produced (“atmospheric dewpoint” in °CtA or °FtA).

Only the pressure dewpoint is relevant to the monitoring of

compressed air systems for trace humidity because this indicates

how far away the “danger threshold” (= dewpoint) is. Since some

users are accustomed to working with an atmospheric dewpoint,

however, the testo 6740 allows the option of outputting both the

pressure dewpoint and the atmospheric dewpoint (the absolute

process pressure is input for the latter).

Pressure dewpoint (35 bar) is relieved to 4 bar. The pressure

dewpoint thus falls from 10 °CtP to -23 °CtP

Compressed air (7 bar) has a pressure dewpoint of 20 °CtP. This

corresponds to an atmospheric dewpoint of -8 °CtA.

The electrical wiring

What is RL?

The total resistance of the 2-wire connection, con-

sisting of the line, and possibly an external display and

control unit

Standard plug (4..20 mA, 2-wire)

Signal +

4...20 mA

Signal -

R

L

U=20..28

VDC

With switch contact plug

Order no. (0554 3302)

(4..20 mA, 2-wire plus 2

floating switch contacts):

8-core cable

Signal +

4...20 mA

Signal -

R

L

U=10..30

VDC

Supply +

Supply -

US ±

LS ±

ON, if value > US+HYS

OFF, if value < US-HYS

ON, if value > LS+HYS

OFF, if value < LS-HYS

RL= Load impedance, external load

U

10 V 300 Ohm -

24 V 650 Ohm 650 Ohm

30 V 950 Ohm -

LS = Lower Switch US = Upper Switch

B

B

A

B

A

11

2

ON

OFF

LS

HYS

ON

OFF

US °Ctpd

HYS

Absolute humidity [g/m3]

Atmospheric dewpoint [°CtA]

Pressure dewpoint [°CtP]

60

50

40

30

20

10

0

-10

-20

-30

-40

-50

-60

-70

-70 -60-50 -40 -30 -20 -10 0 10 20 30 40

0,003

0,011

0,038

0,117

0,330

0,690

2,156

4,868

9,356

17.148

30,078

50,672

70

35

14

7

4

2,5

0

Positive

pressure p

0

[bar]

11

2

Page 8

Subject to change without notice.

0981.2194/hd/AC/11.2003

Loading...

Loading...