Page 1

Instruction manual en

testo 6721 Dew point monitor

P2A software for testo 6721

Page 2

2

Page 3

3

Contents

Contents 3

Safety and the environment 4

Part 1: testo 6721

Specifications 5

Commissioning 8

Assembling the instrument 8

Wiring the instrument 9

Connecting the instrument 11

Parameterizing/adjusting/analyzing the instrument 11

Maintaining the product 11

Tips and assistance 12

Part 2: testo P2A Software

Specifications 13

First steps 14

Installing the software/driver 14

Starting the software 14

Product description 15

Using the product 16

Tips and assistance 19

????

Contents 3

deenfresitptsvnl

Page 4

4 Safety and the environment

Safety and the environment

About this document

i Please read this documentation through carefully and familiarize yourself with

the product before putting it to use. Keep this documentation to hand so

that you can refer to it when necessary. Hand this documentation on to any

subsequent users of the product.

i Pay particular attention to information emphasized by the following symbols:

· Important.

Avoiding personal injury/damage to equipment

i Never store the product together with solvents and do not use any

desiccants.

i Only operate the product properly, for its intended purpose and within the

parameters specified in the technical data. Do not use force.

i Only carry out the maintenance and repair work that is described in the

documentation. Follow the prescribed steps when doing so. Use only OEM

spare parts from Testo.

Protecting the environment

i Send the product back to Testo at the end of its useful life. We will ensure

that it is disposed of in an environmentally friendly manner.

Page 5

5

deenfresitptsvnl????

testo 6721 - Specifications

PART 1: TESTO 6721

Specifications

Functions and use

The 6721 is a dew point monitor for monitoring trace humidity in the following

applications:

· Trace humidity monitoring in compressed air systems, e.g. upstream of pneumatic

machines.

· Monitoring (compressed air) low-temperature driers.

· Monitoring (compressed air) membrane driers.

The product must only be assembled, wired and connected by qualified

personnel.

The product must

not

be used in areas at risk of explosion!

Ordering overview

0555 6721 Axx / Fxx / Kxx

A01 G½" process connection

A02 NPT ½" process connection

F01 Dew point °Ctd / GW 1 / GW 2 / hysteresis

F02 Dew point °Ftd / GW 1 / GW 2 / hysteresis

K01 German/English instruction manual

K02 French/English instruction manual

K03 Spanish/English instruction manual

K04 Italian/English instruction manual

K05 Dutch/English instruction manual

K06 Japanese/English instruction manual

K07 Chinese/English instruction manual

Page 6

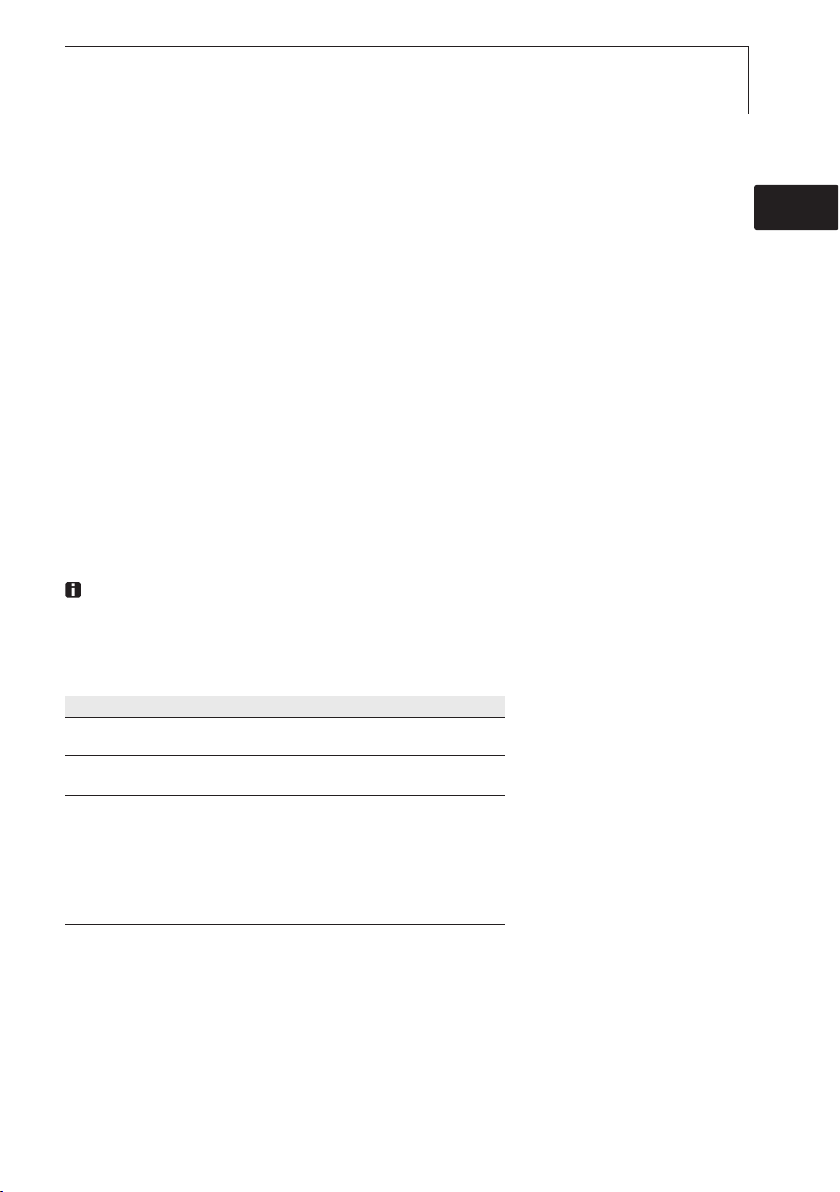

6 testo 6721 - Specifications

33

176

72

56

➋

92

42

➊

➌

Technical details

Parameters, measuring range

· Dew point temperature (trace humidity):

-30 - 30 °Ctd/-22 - 86 °Ftd

Accuracy

· Dew point temperature at 25 °C/77 °F process

temperature:

±4 K (-30…-20°Ctd/-22…-4°Ftd),

±3 K (-20…-10°Ctd/-4…14°Ftd),

±2 K (-10…0°Ctd/14…32°Ftd),

±1 K (>0°Ctd/>32°Ftd)

Resolution

· 0.1 °Ctd/0.1 °Ftd

Meas. cycle

· 1/s

Other instrument data

· Humidity sensor: Testo humidity sensor (with special

trace humidity adjustment)

· Temperature sensor: NTC

· Output variable: Dew point (°Ctd or °Ftd) via two

switching outputs

· Measuring medium: Compressed air (filtered and

dried, ISO 8573 classes 2-4-2)

· Operating temperature: 0 - 50 °C/32 -122 °F, ideally

between 10 °C and 35 °C/50 °F

· Pressure range: max. 20 bar (abs)

· Connection: G½" (0555 6721-A01) or NPT½"

(0555 6721-A02)

· Supply: 24 V AC/V DC (20 - 30 V AC/V DC permissible)

· Power consumption: 50 mA

· Interfaces: mini-DIN interface for

parameterizing/adjusting/analyzing using testo

P2A Software

· Switching outputs: 2 x floating, switching voltage

24 V DC/V AC, switching current 0.5 A, optional wiring

as NC or NO contact

· Limit values (2x) and switching hysteresis (1x):

Free choice within the measuring range by means of

order code, or setting via testo P2A Software

· Sensor protection: Sintered stainless steel filter,

12 mm diameter

· Housing material: plastic PAA GF30

· Housing dimensions: 167 x 33 x 33 mm

· Protection class: IP65 (with adapter connected or with

protective tab on closed interface.)

· Ambient temperature: 0 - 50 °C/32 - 122 °F

· Storage temperature: -40 - 70 °C/-40 - 158 °F

· Weight: 240 g

Directives, standards and tests

· EC Directive: 2004/108/EEC

Warranty

· Duration: 2 years

· Warranty conditions: see website

www.testo.com/warranty

Dimensions:

21ø

33

167

0555 6721-A01: G½

0555 6721-A02: NPT½"

Installation depth in process

Wrench size

Page 7

7

deenfresitptsvnl????

testo 6721 - Product description

Product description

At a glance

Sensor protection: Sintered stainless steel cap.

Fixing the sensor assembly: Threaded pin.

Screwed socket: G ½ (0555 6721-A01) or NPT ½" (0555 6721-A02).

Fixing the housing cover: 2 countersunk screws.

Connector socket for switching contact connector.

Connector socket for external interface (mini-DIN Testo), plug.

Factory settings

Characteristic 0555 6721-F01 0555 6721-F02

Unit °Ctd °Ftd

Limit value for switching output 1 5 45

Limit value for switching output 2 10 55

Hysteresis 1 2

Page 8

8 testo 6721 - Commissioning

Commissioning

Assembling the instrument

²

Assembling tthe iinstrument aat tthe pprocess cconnection:

If assembling without a measurement chamber: The sections of pipe

where the instrument is assembled are depressurized.

1 To ensure leaktightness: Wrap the thread of the screwed socket using

sealing tape (e. g. PTFE) or insert a copper sealing ring (internal diameter

of 21 mm).

2 Assemble the instrument according to the application in hand:

Applications/assembly options

A Process temperatures < 15 °C or > 35 °C (max. 200 °C):

Assembly with measurement chamber and cooling coil.

B Process temperatures of 15 - 35 °C, quick assembly/dismantling of instrument is required, sufficient

incident flow through sensor (1l/min) not present:

Assembly with measurement chamber.

If media are contaminated: connect preliminary filter (0554 3311) upstream

C Process temperatures of 15 - 35 °C, installation of sensor directly in the process is possible, quick

assembly/dismantling of instrument is not required, sufficient incident flow through sensor (1l/min)

present, compressed air is not contaminated:

Assembly without measurement chamber and without cooling coil

A

A

➊➋

➌

G 1/2

➎➍

0555 6721-A01

➏

B

G 1/2

C

NPT 1/2"

C

NPT 1/2"

0555 6721-A02

Page 9

9

deenfresitptsvnl????

testo 6721 - Commissioning

Process connection, quick-release compressed-air fastener NW 7.2 or G 1/2" or

NPT 1/2" thread

PTFE tube (0669 2824/4) or cooling coil (0554 3304).

Preliminary filter 0554 3331

When using the preliminary filter, it must be ensured that there is

sufficient flow (1 l/min) in the measurement chamber by cleaning the

filter regularly.

Measurement chamber (0554 3303).

testo 6721 dew point monitor.

Assembling the measurement chamber on the dew point monitor.

Only apply force at the hexagon (AF 27)!

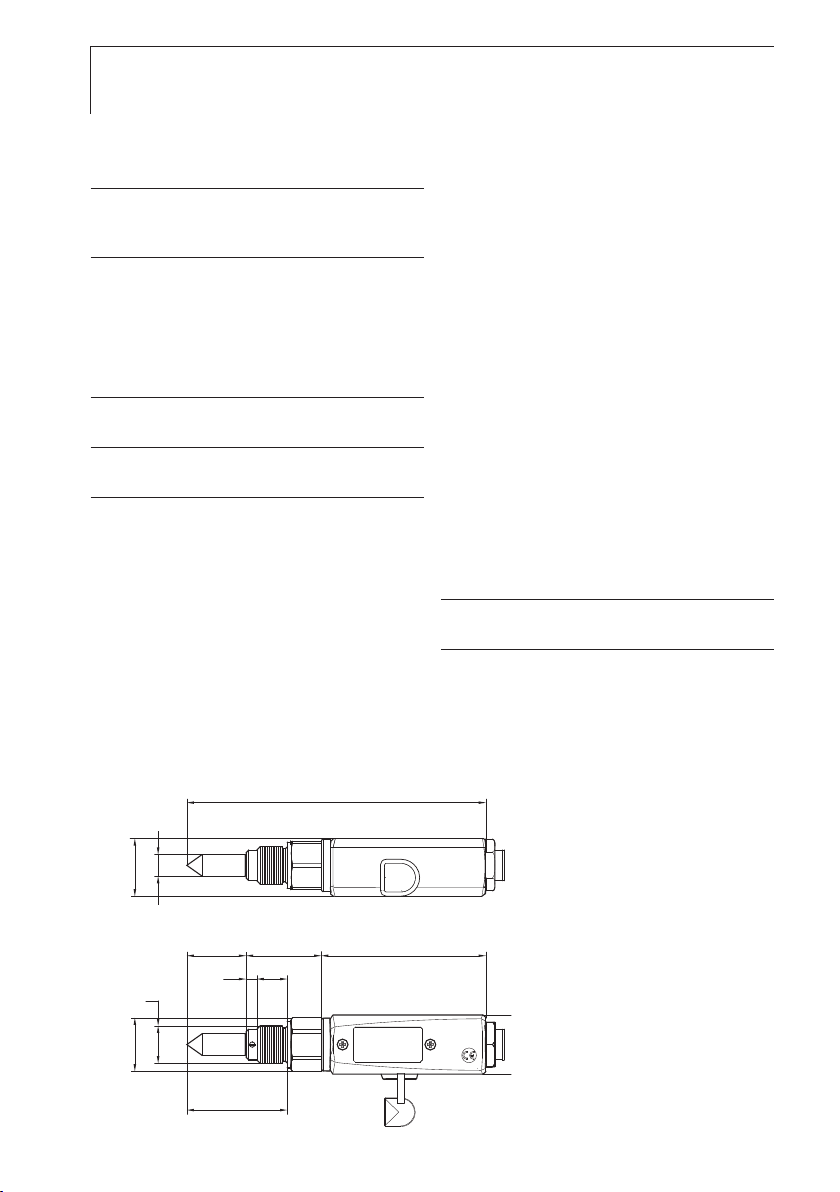

Wiring the instrument

The testo 6721 is supplied with the right connector to which a cable can be

soldered by the customer. Alternatively, the 5 m accessories cable with the

pre-fabricated connector (0554 6720) can be used.

²

Fabrication oof cconnection ccable bby tthe ccustomer:

Testo recommends an 8-wire line with a tightly plaited shield, wire crosssection of 0.25 - 0.5 mm².

1 Remove top part of connector from bottom

part of connector (screw cap).

2 Open line fixture on top part of connector

(screw cap/union nut ) and feed through

lines of connecting cable.

Page 10

10 testo 6721 - Commissioning

3

Solder ends of lines to the pins in the bottom

part of the connector :

Two separate switching points can be created

using the two switching contacts which can

each be configured as either a NC contact

(1-3, 9-5) or NO contact (1-2, 9-6)

.

Assignment of the pins

1 Root/pin for switching contact 1

2 NO contact for switching contact 1

3 NC contact for switching contact 1

4 Supply -

5 NC contact for switching contact 2

6 NO contact for switching contact 2

7 Functional earth

8 Supply +

9 Root/pin for switching contact 2

4 Fasten top part of connector to bottom part

of connector (screw cap) and close line fixture

(screw cap/union nut).

²

Feeding wwiring tthrough wwith aaccessories ccable 00554 6720:

i Shorten length of line (5 m) if necessary.

i Connect the ends of the line according to the colour assignment:

Two separate switching points can be created using the two switching

contacts which can each be configured as either a NC contact (grey-pink,

brown-green) or NO contact (grey-yellow, brown-white).

Colour Assignment

grey root/pin for switching contact 1

yellow NO contact for switching contact 1

pink NC contact for switching contact 1

red supply +

green NC contact for switching contact 2

white NO contact for switching contact 2

black Functional earth

blue supply brown root/pin for switching contact 2

Page 11

11

deenfresitptsvnl????

testo 6721 - Commissioning

Connecting the instrument

²

Connecting tthe sswitching ccontact cconnector tto tthe iinstrument:

i Fasten switching contact connector to the port of the instrument

(connector with rotary protection).

Parameterizing/adjusting/analyzing the

instrument

The instrument is parameterized, adjusted and analyzed using the P2A

Software, see “Part 2: testo P2A Software”.

Maintaining the product

±

Cleaning tthe hhousing:

i Clean the housing with a damp cloth (soap suds) if it is dirty. Do not use

aggressive cleaning agents or solvents!

±

Cleaning tthe ssensor pprotection ccap, mmeasurement cchamber, ccooling ccoil aand

preliminary ffilter:

If used in process conditions involving oil or dust, the sintered stainless steel

filter and, if used, the measurement chamber, preliminary filter and cooling

coil must be cleaned regularly.

i Remove the measurement chamber and cooling coil/unscrew sensor

protection cap/unscrew preliminary filter and blow out with compressed

air or place in an ultrasonic bath.

±

Cleaning tthe ssensor:

During cleaning, avoid touching the sensor at all costs.

Do not clean the sensor mechanically, as this can damage the cover

electrode.

i Screw off filter cover.

i Carefully rinse the mirrored surface with isopropyl alcohol and/or distilled

water.

i Allow the sensor to dry completely.

Page 12

12 testo 6721 - Tips and assistance

Tips and assistance

Questions and answers

Question Possible causes/solutions

Faulty switch signal - Test limit values and hysteresis using P2A Software

- View adjustment history using P2A Software: Faulty adjustment?

If we could not answer your question, please contact your dealer or Testo

Customer Service. Contact details can be found on the guarantee card or on

the Internet at: www.testo.com

Accessories and spare parts

Designation Article no.

Parameterizing, adjusting and analyzing software (P2A Software incl. adapter cable for USB to mini-DIN) 0554 6020

Measurement chamber for optimum incident flow through humidity sensor, max. 15 bar, for G½" thread 0554 3303

Cooling coil for process temperatures above 35 °C (up to 200 °C) 0554 3304

Preliminary filter to protect measurement chamber and sensors against contamination 0554 3311

Sintered stainless steel filter 0554 0647

Connector with 5 m cable 0554 6720

Alarm box for testo 6721 dew point monitor, without cable 0555 6720 0554 6722

PTFE tube with compressed air connections, 2 m, max. 9 bar 0699 2824/4

Mains unit (bench unit), 90 - 264 V AC/24 V DC (350mA) 0554 1748

Mains unit (top-hat rail mounting), 90 - 264 V AC/24 V DC (2.5A) 0554 1749

For a complete list of all accessories and spare parts, please refer to the

product catalogues and brochures or look up our website at: www.testo.com

Page 13

13

deenfresitptsvnl????

testo P2A Software - Specifications

PART 2: TESTO P2A SOFTWARE

Specifications

Functions and use

The testo P2A Software (0554 6020) is parameterizing, adjusting and analyzing

software for Testo transmitters. It is not supplied with the testo 6721.

System requirements

Operating system

· Windows 2000 SP4

· Windows XP

Computer

· Pentium processor of at least 400 MHz or equivalent

· 128 MB RAM

· Graphics resolution of at least 1,024 x 768

· Unused hard drive capacity of at least 15 MB

· CD-ROM drive

· USB interface or corresponding adapter

Page 14

14 testo P2A Software - First steps

First steps

Installing the software/driver

The CD supplied with the testo 6721 contains an update of the P2A Software

including all the latest instrument drivers. Install this update once you have

installed the P2A Software (0554 6020).

Administrator rights under Windows® 2000 and XP are required for the

installation of the testo P2A Software program.

±

Installing tthe PP2A SSoftware:

1 Insert the “P2A Software” CD (0554 6020).

If the installation program does not start automatically:

i Start Setup.exe file from the CD-directory (access via My Computer or

Windows Explorer).

2 Follow the instructions of the installation program.

±

Installing tthe UUSB ddrivers:

The USB driver CD is supplied with the P2A Software

Before installing the USB drivers, please read the separate documentation

enclosed with the USB driver CD.

The installation of the USB driver is the prerequisite for the faultless use of

the P2A software.

±

P2A SSoftware uupdate:

1 Insert the product CD (supplied with the testo 6721).

If the installation program does not start automatically:

i Start Setup.exe file from the CD-directory (access via My Computer or

Windows Explorer).

2 Follow the instructions of the installation program.

Starting the software

±

Starting tthe pprogram:

i Select: > Programs > Testo > P2A Software.

Page 15

15

deenfresitptsvnl????

testo P2A Software - Product description

Product description

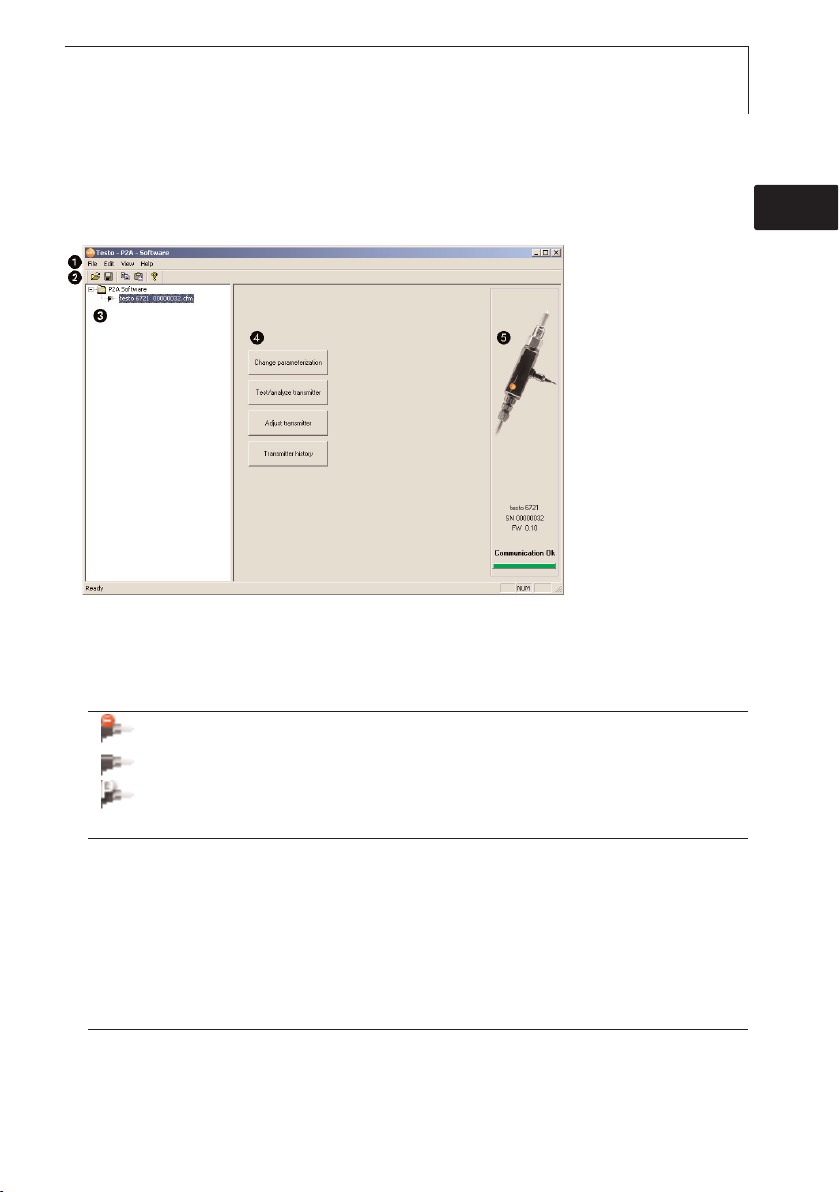

User interface

Menu bar.

Toolbar.

File list: List of all instrument/parameter files.

File symbols

· : Instrument file, connection to the unit has not been established.

· : Instrument file, connection to the unit has been established.

· : Parameter file.

File identifications

· Instrument files: “[Type] [serial number].cfm”; file identifications cannot be changed.

Instrument files contain all the data relating to a particular instrument. These are the parameter data and

represent the parameterization and adjustment history of the instrument.

· Parameter files: “[Type] [serial number] [date] [time].cfp”; file identifications can be changed.

Parameter files only contain parameter data. These can be copied to another instrument or parameter file for

the same type of instrument so that several instruments have the same parameter settings.

List of functions.

File information:

Information displayed

· Instrument files: Type, serial number, firmware version and connection status of the instrument.

· Parameter file: Type, serial number and firmware version of instrument with which the parameter file was

created.

· Connection status (instrument files only): “red” connection is active, “green” connection is inactive.

Page 16

16 testo P2A Software - Using the product

Using the product

±

Establishing aa cconnection wwith tthe ddevice:

Several instruments can be connected to the PC and administered via the

P2A software, but only one connection can ever be active at any one time.

Non-wired instruments can also be connected to the P2A Software for

parameterization/adjustment. The supply to the instruments is then effected

via the USB interface.

1 Connect the USB/mini-DIN adapter to the external interface (mini-DIN) of

the instrument.

2 Connect the USB connector of the adapter to the PC.

- The instrument file for the instrument connected appears in the

instrument file/parameter file list.

±

Selecting tthe iinstrument/parameter ffile, aactivating aa cconnection wwith tthe

device:

i Click on the requisite instrument/parameter file.

- The selected file is highlighted in colour.

- For instrument files only: if a connection with the instrument has been

established, this is automatically activated.

±

Changing aan iinstrument/parameter ffile:

The required instrument/parameter file is selected.

1 Click on Change parameterization button.

2 Enter parameters in the corresponding fields.

3 Click on Apply to confirm entries.

4 To leave the parameterization screen, click on OK.

±

Saving tthe pparameters iin aa pparameter ffile:

The parameter data for the selected instrument/parameter file can be saved.

Only parameter data stored in the standard file can be loaded into an

instrument!

The required instrument/parameter file is selected.

1 In the menu bar, click on File > Save as.

2 Select the storage location and enter the file name.

3 Click on Save to confirm entries.

Page 17

17

deenfresitptsvnl????

testo P2A Software - Using the product

±

Opening aa pparameter ffile:

All parameter files stored in the standard directory path are automatically

displayed in the file list when the software is started. Parameter files stored in

other directories can also be opened.

Only parameter data stored in the standard file can be loaded into an

instrument!

1 In the menu bar, click on File > Open.

2 Select the storage location and click on the requisite parameter file.

3 Click on Open to confirm entries.

±

Copying tthe pparameter ddata:

The parameter data for an instrument/parameter file can be transferred to

another instrument/parameter file for the same type of instrument. History

data for instrument files are not transferred.

1 Select file from which the parameter data are to be copied.

2 In the menu bar, click on Edit > Copy.

3 Select the file which is to be modified.

4 In the menu bar, click on Edit > Paste.

±

Analyzing/testing tthe iinstrument:

The required instrument file is selected.

1 Click on Test/ analyze transmitter button.

2 Perform tasks:

Options

· Carry out factory reset: Reset the parameter unit, scaling limits and adjustment to the factory settings

(values device-specific, see type label).

· Transmitter tests: Manually switch switching outputs to test functionality.

· Min./max. values: Change to display of minimum/maximum values.

3 Click on Apply to confirm entries.

4 To leave the analyzing/test screen, click on OK.

Carrying oout aa 11-ppoint aadjustment:

±

A 1-point adjustment (offset) can be performed. A dew point mirror is

recommended as a reference measuring instrument for pressure dew point

temperatures < 0 °Ctd.

1 Click on Adjust transmitter button.

2 Expose the reference measuring instrument and the instrument to be

adjusted to the same constant conditions and wait for equalization period

to lapse.

Page 18

18 testo P2A Software - Using the product

3

Enter reference value and perform adjustment by clicking on Carry out 1point adjustment.

i To reset an offset value, click on Set Offset to zero.

4 Click on Apply to confirm entries.

±

Viewing aa ttransmitter hhistory:

The current history data as stored in the instrument file are always displayed.

A distinction is made between parameterization and adjustment histories.

Dates and times refer to the PC time when the P2A Software was being

used.

History data are only stored in the instrument file (PC), not in the testo

6721.

1 Click on Transmitter history button.

2 To move between the views, click on Parameterization history or Adjustment

history.

i To print the history data, click on Print.

±

Deleting pparameters ffrom aan iinstrument/parameter ffile:

The parameter data for the selected instrument/parameter file can be

deleted.

The required instrument/parameter file is selected.

1 Right-click on the instrument/parameter file.

2 Select Delete.

3 Click on Ye s to confirm.

±

Creating aa nnew ffolder:

The folder to which the new folder is to be added is selected.

1 In the menu bar, click on File > Add Folder.

2 Give the new folder a name.

Page 19

19

deenfresitptsvnl????

testo P2A Software - Tips and assistance

Tips and assistance

Questions and answers

Question Possible causes/solutions

Connection to instrument cannot

be established. · Check connecting cable and plug contacts.

· USB driver not/incorrectly installed: Re-install.

Adjustment is to be reversed. · Carry out factory reset: Click on

Test/analyze transmitter > click

on Carry out factory reset.

If we could not answer your question, please contact your dealer or Testo

Customer Service. Contact details can be found on the guarantee card or on

the Internet at: www.testo.com

Page 20

testo AG

Postfach 11 40, 79849 Lenzkirch

Testo-Straße 1, 79853 Lenzkirch

Telephone: +49 (0) 7653 681-0

Fax: +49 (0) 7653 681-100

E-mail: info@testo.de

Internet: http://www.testo.com

www.testo.com

0970 6720 de 03 V01.00

Loading...

Loading...