Page 1

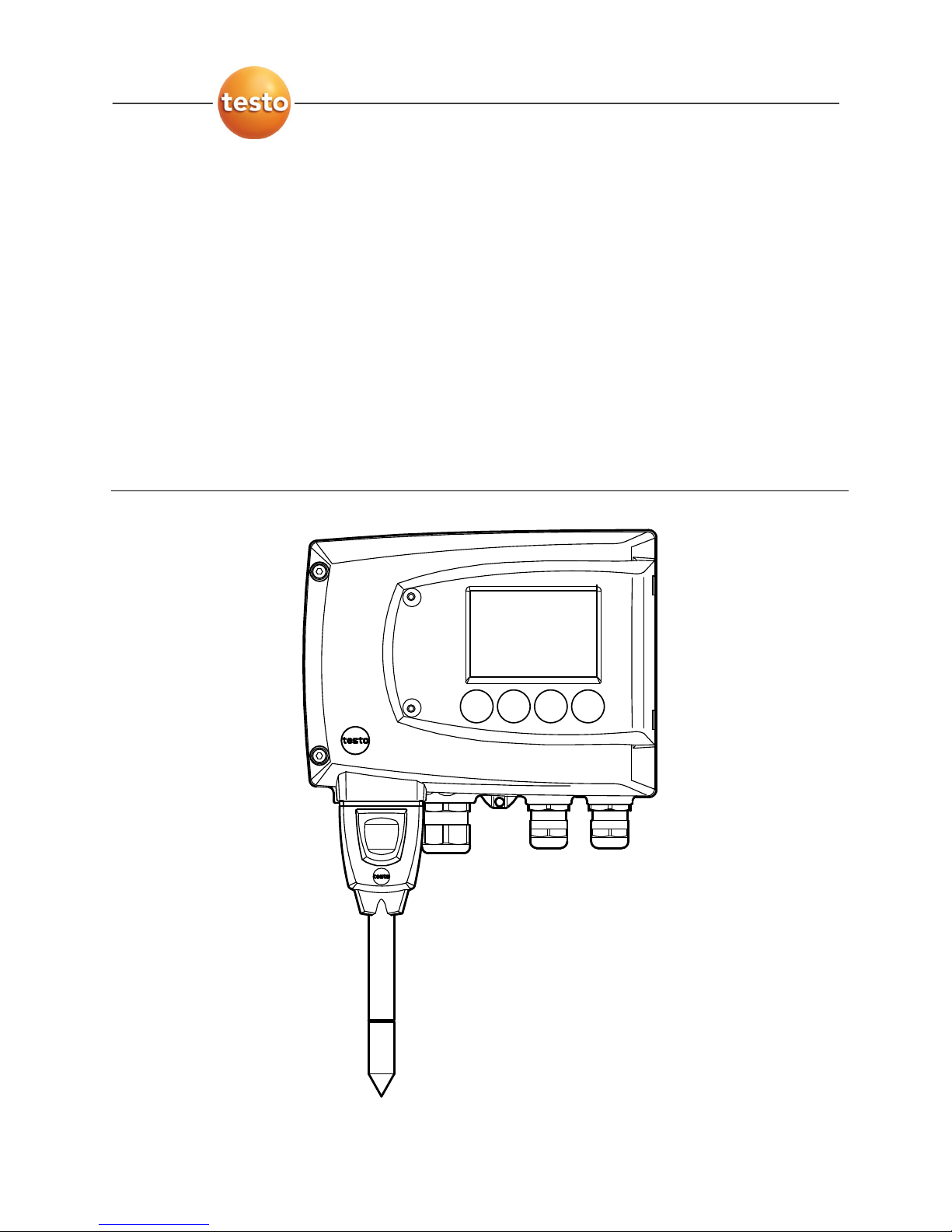

testo 6681 Profibus · Humidity transmitte

r

with Profibus module

testo 6610 · Probes

P2A software · Parameterizing, adjusting and analyzing

software

Instruction manual Volume 1 en

Page 2

Page 3

Safety and the environment

3

Safety and the environment

Avoiding electrical hazards

Never use the instrument and connected probes to measure on or near live

parts!

Damaged mains cables must only be replaced by authorized personnel.

Only have the transmitter wired and connected by authorized personnel with

the voltage disconnected.

You must always comply with the regulations applicable in your country to the

opening and repair of electrical equipment.

Avoiding personal injury/damage to equipment

Installation, setting and calibration work must only be carried out by qualified

and authorized personnel!

Only open the instrument when this is expressly described in the instruction

manual for installation, maintenance or repair purposes.

Observe the permissible storage, transport and operating temperatures.

Never store or operate the product with solvents and do not use any

desiccants.

Do not use the instrument for control purposes at the same time as operating

or servicing the transmitter.

Only operate the product properly, for its intended purpose and within the

parameters specified in the technical data. Do not use force.

Carry out only the maintenance and repair work that is described in the

documentation. Follow the prescribed steps when doing so. Use only

OEM spare parts from Testo.

Any additional work must only be carried out by authorized personnel.

Otherwise Testo will not accept any responsibility for the proper functioning of

the instrument after repair and for the validity of certifications.

Protecting the environment

Send the product back to Testo at the end of its useful life. We will ensure

that it is disposed of in an environmentally friendly manner.

Page 4

4

About this document

About this document

Please read this documentation through carefully and familiarize yourself with

the product before putting it to use. Keep this document to hand so that

you can refer to it when necessary. Hand this documentation on to any

subsequent users of the product.

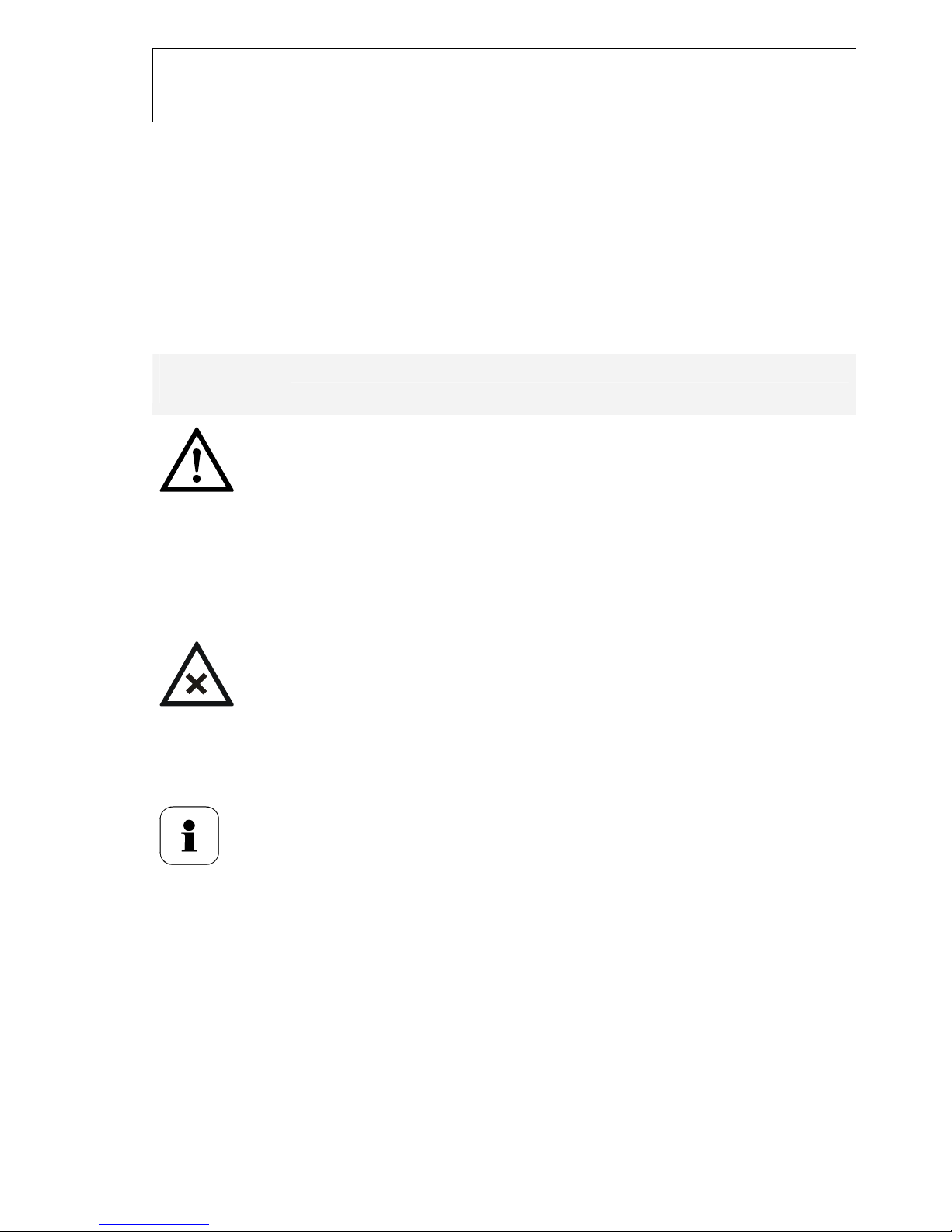

The following conventions are followed in this document:

Character/

display:

Explanation/example

With the signal word Warning!:

Warns against hazards which could result in serious physical

injury if the precautionary measures indicated are not taken,

e.g.:

De-energize the mains connection before connecting the

transmitter!

With the signal word Caution!:

Warns against hazards which could result in minor physical

injury or damage to equipment if the precautionary

measures indicated are not taken, e.g.:

Observe the permissible operating temperature!

Important information, e.g.:

Administrator rights are required to install the program under

Windows

®

2000, XP and Vista.

Aim of action, e.g.:

Assembling the instrument at the process

connection:

Requirement that must be met, e.g.:

USB drivers are installed.

Page 5

About this document

5

Character/

display:

Explanation/example

1

Steps are numbered if a certain sequence of actions must

be followed, e.g.:

1 Loosen and remove housing screws.

2 Remove the upper part of housing.

A step is not numbered if there are no further steps or if the

step is optional, e.g.:

Insert probe connector into socket of testo 6681 until it

engages.

" to "

Example entries are in inverted commas, e.g.:

The value "0" results in ....

Bold type

Elements of the program interface or instrument display,

e.g.:

The instrument designation appears in the

instrument/parameter file list.

Select Main Menu Channel 1 and confirm with SET.

…>…

Functions/paths within a menu, e.g.:

Start > All Programmes > Testo > P2A Software.

[ ]

Buttons which start an action, e.g.:

Confirm the software key with [OK].

CAPITAL

LETTERS

Keys on the instrument or keypad, e.g.:

Press ESC.

Page 6

6

Contents

Contents

1 TRANSMITTER ............................................................................................ 9

1.1 Specifications ........................................................................................... 9

1.1.1 Functions and use ...................................................................... 9

1.1.2 Scope of delivery ........................................................................ 9

1.1.3 Accessories............................................................................... 10

1.1.4 Technical Data .......................................................................... 10

1.1.5 Dimensions ............................................................................... 12

1.2 Product description ................................................................................ 13

1.2.1 At a glance ................................................................................ 13

1.2.2 Usable probes ........................................................................... 14

1.2.3 Display and keypad .................................................................. 15

1.2.4 Service interface ....................................................................... 15

1.2.5 Relay board (option) ................................................................. 15

1.2.6 Analog outputs .......................................................................... 16

1.2.7 Parameters ............................................................................... 16

1.2.8 Scaling ...................................................................................... 17

1.2.9 Alarm handling .......................................................................... 19

1.3 Commissioning ...................................................................................... 20

1.3.1 Insert Profibus module (Order no. 0554 6686) ......................... 20

1.3.2 Assembling the instrument ....................................................... 22

1.3.3 Connecting the instrument ........................................................ 25

1.3.4 Connect instrument to the bus system ..................................... 42

1.3.5 Configure Profibus module using EDD ..................................... 49

1.3.6 Adjusting the instrument ........................................................... 55

1.4 Operation ............................................................................................... 66

1.4.1 Relationship between user menu and mini-DIN socket is

active ......................................................................................... 66

1.4.2 Key cover .................................................................................. 67

1.4.3 Password protection ................................................................. 68

1.4.4 Structure of user menu ............................................................. 69

1.4.5 Overview of the testo 6681 user menu ........................................... 70

1.4.6 The individual main menus ....................................................... 72

Page 7

Contents

7

1.5 Status, warning and error messages ..................................................... 84

1.5.1 Status messages ...................................................................... 84

1.5.2 Warning messages ................................................................... 85

1.5.3 Transmitter error messages ...................................................... 87

1.5.4 Status codes in cyclical service ................................................ 88

1.5.5 Handling alarm messages ........................................................ 88

1.5.6 Namur fault conditions .............................................................. 90

1.6 Maintenance and cleaning ..................................................................... 91

1.6.1 Maintaining the instrument ........................................................ 91

1.6.2 Cleaning the instrument ............................................................ 91

Page 8

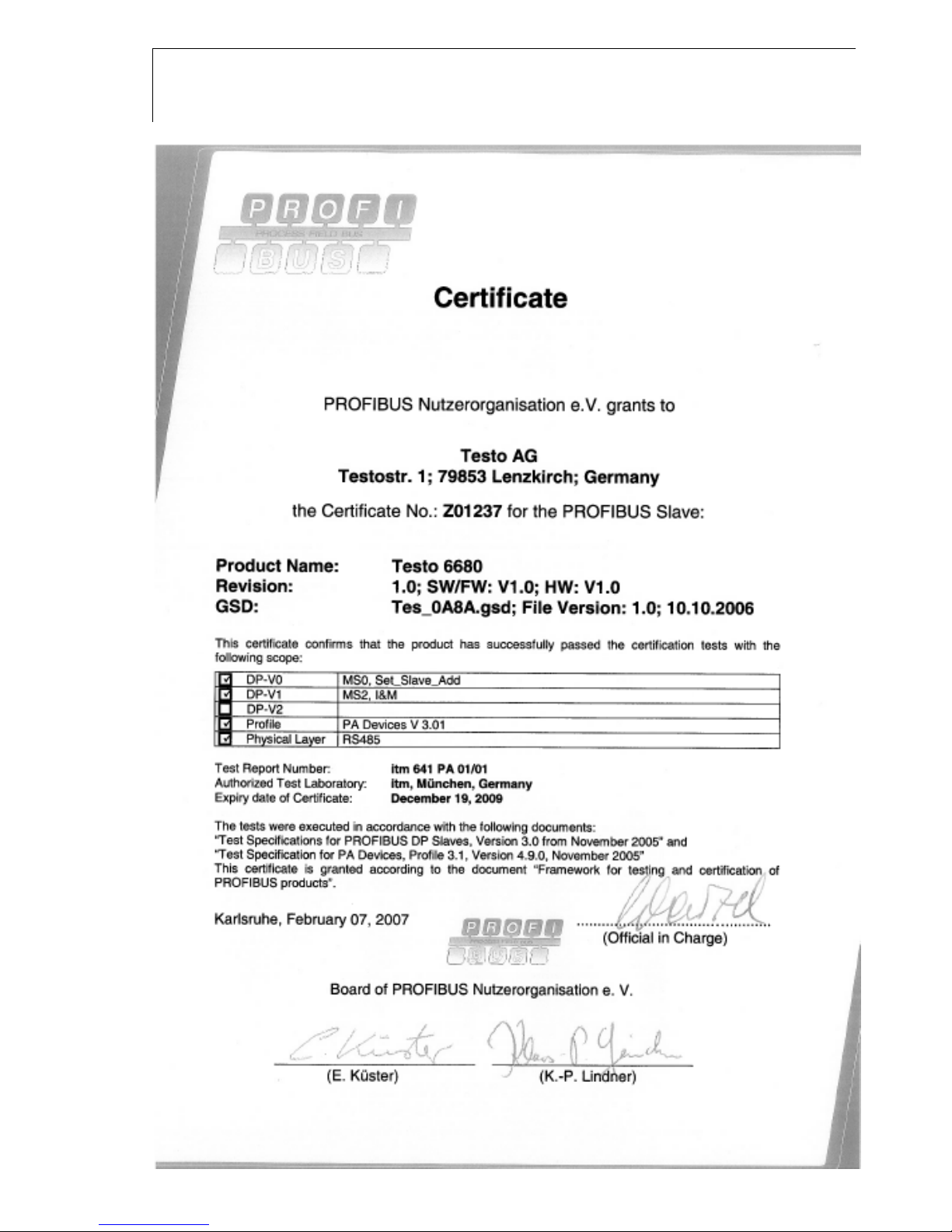

8

Certificate

Page 9

testo 6681 Profibus - 1.1 Specifications

9

1 Transmitter

1.1 Specifications

1.1.1 Functions and use

The testo 6681 humidity transmitter with Profibus module is used in

conjunction with plug-in, adjusted probes from the testo 6610 range.

Please refer to volume 2, chapter 2, page 97 for information

about commissioning, operating and maintaining the

testo 6610 probe.

The testo 6681 humidity transmitter is suitable for the following applications

with Profibus networking, for example:

Process instrumentation

Clean rooms

Test benches

Drying processes

Production and storage air quality

Complex room climate applications.

1.1.2 Scope of delivery

The scope of delivery of the testo 6681 humidity transmitter includes the

following:

Key cover

Rear panel bracket

Page 10

10

testo 6681 Profibus - 1.1 Specifications

1.1.3 Accessories

The following accessories are available for the testo 6681 humidity

transmitter:

Protection caps for probes

Mains unit

P2A software (parameterizing, adjusting and analyzing software)

Assembly accessories.

Information about accessories and their order numbers can

be found in volume 2, chapter 4.2, page 167 or on the

website at www.testo.com.

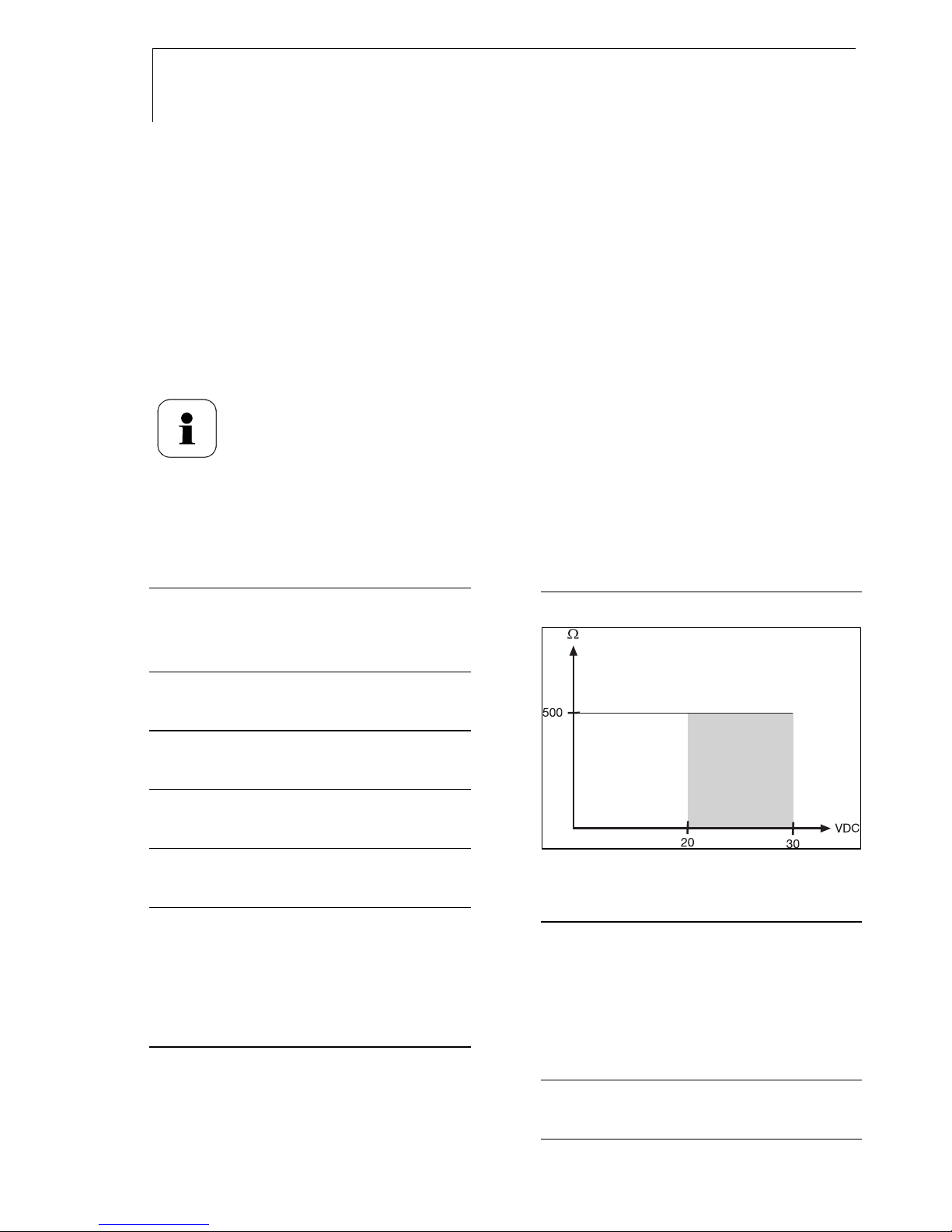

1.1.4 Technical Data

Parameters

Humidity (various variables and units)

Temperature (°C/°F)

Measuring range

Depends on probe

Accuracy

Depends on probe

Resolution

0.1 % RH or 0.1 °C/0.1 °F

Meas. cycle

1/s

Interface

Mini-DIN for P2A software

(parameterizing and adjusting

software) and handheld testo

400/650

Optional Profibus-DP module

Voltage supply

4-wire (separate signal and supply

lines):

20 - 30 V AC/DC,

300 mA power consumption

Maximum load

- 4-wire: 500 (power output)

Analogue output*

0 to 1 V ± 1.5 mV (4-wire) or

0 to 5 V ± 7.5 mV (4-wire) or

0 to 10 V ± 15 mV (4-wire) or

0 to 20 mA ± 0.03 mA (4-wire) or

4 to 20 mA ± 0.03 mA (4-wire)

Resolution of analog output

12 bit

Relay

4 relays, 250 V AC/DC, 3 A (optional)

Page 11

testo 6681 Profibus - 1.1 Specifications

11

Display

2-line LCD with plain text line

(optional)

Housing operating temperature

-40 to +70 °C/-40 to +158 °F, with display

from 0 to 50 °C/+32 to +122 °F

With integrated relay: -40 - +60 °C

Storage temperature

- 40 to 80 °C/-40 to +176 °F

Housing, weight

Metal: 1.960 kg

Profibus: 0.610 kg

Protection class

IP 65 only if the transmitter is wired

and/or seal plugs are inserted

Directives, standards and tests

EC Directive: 2004/108/EC

Warranty

Duration: 2 years

Warranty conditions: See web page

www.testo.com/warranty

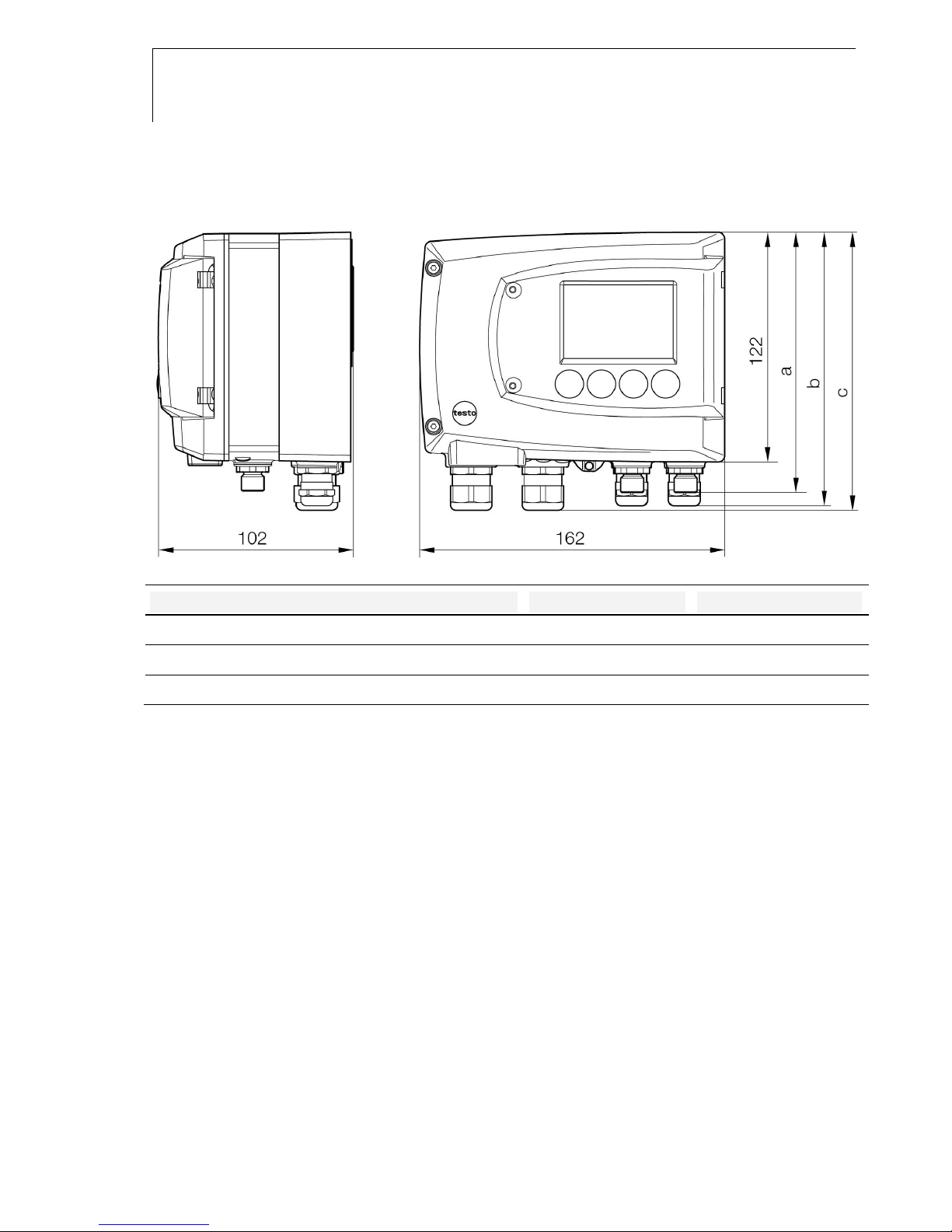

Page 12

12

testo 6681 Profibus - 1.1 Specifications

1.1.5 Dimensions

Dimensions in mm a b

With M 20 cable couplings 144 147

With NPT cable couplings 144 144

With M plug-in connections 143

Page 13

testo 6681 Profibus - 1.2 Product description

13

1.2 Product description

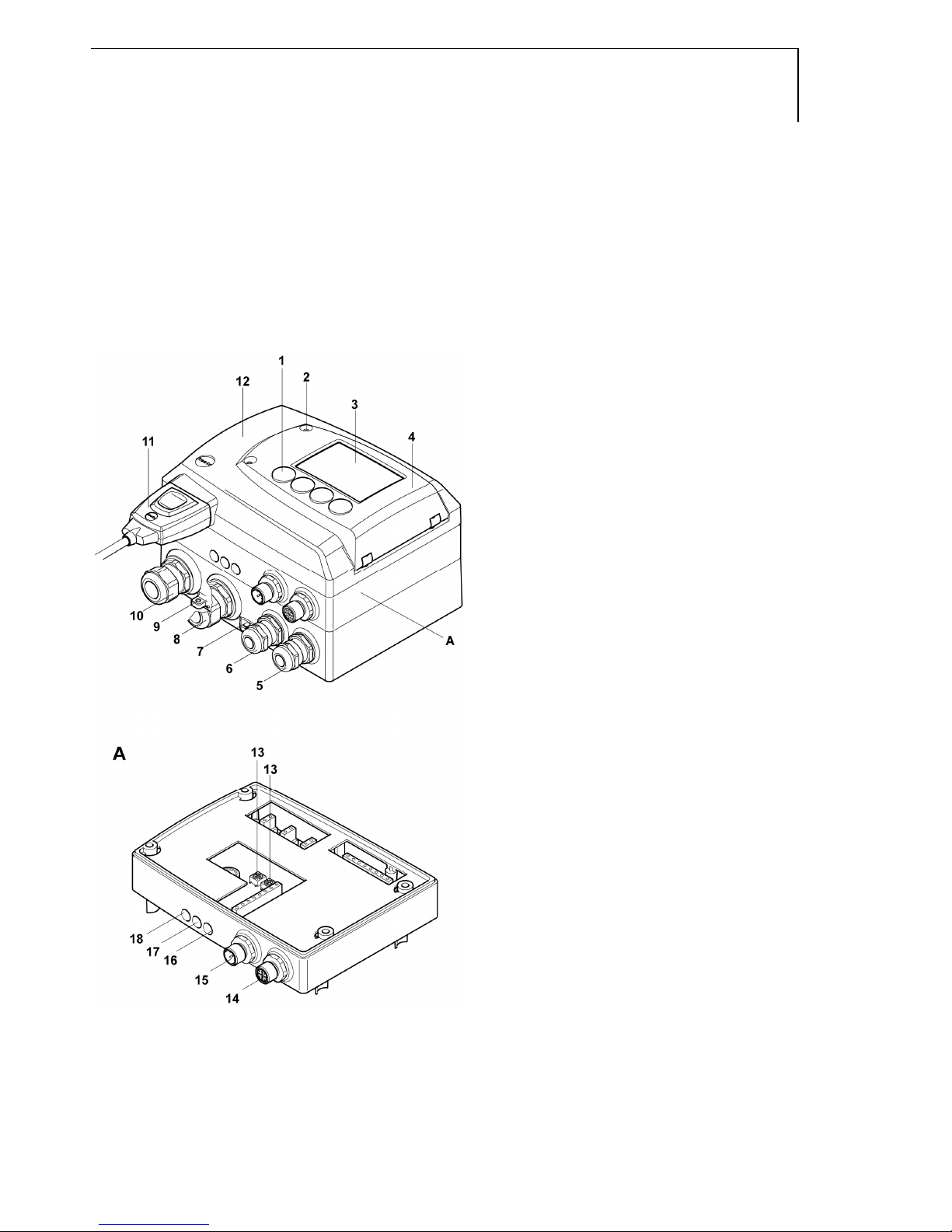

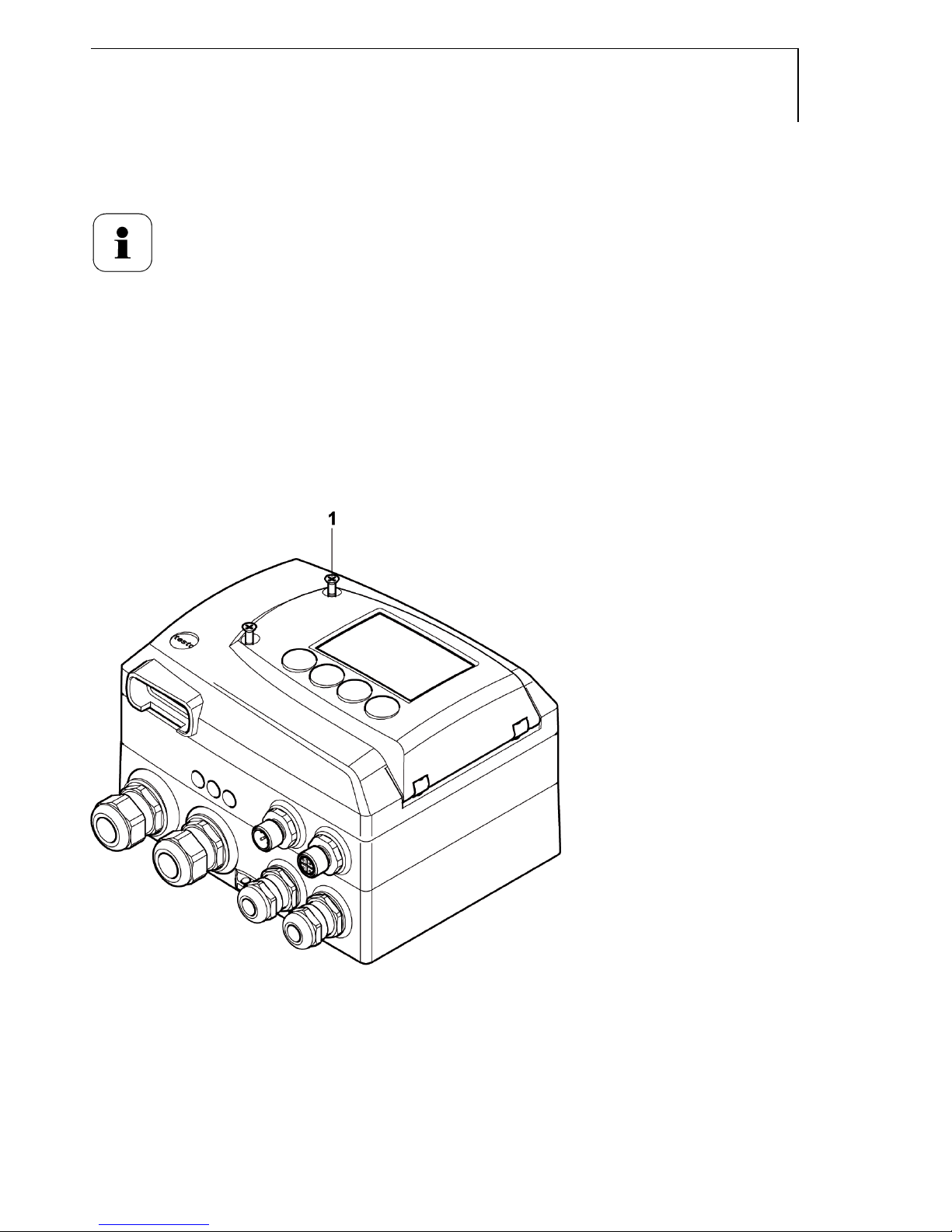

1.2.1 At a glance

1 Keys (with optional display)

2 Service flap screw

connection (self-locking,

2x)

3 Display (optional)

4 Service flap

5 M 16 x 1.5 screw

connection*, e.g. analog

outputs

6 M 16 x 1.5 screw

connection*, e.g. voltage

supply

7 Eyelet for measuring point

panel

8 M 20 x 1.5 screw

connection*, e.g. relay R 3

and R 4

9 Earthing/PE connection

10 M 20 x 1.5 screw

connection*, e.g. relay R 1

and R 2

11 Probe connector

(testo 6610)

12 Upper part of housing

* Alternatively, NPT cable

couplings or M plug-in

connections are available

A

Profibus module

13 Rotary encoder switch for

addressing

14 Profibus M12 socket

15 Profibus M12 connector

16 LED: Bus error

17 LED: System error

18 LED: Supply

Page 14

14

testo 6681 Profibus - 1.2 Product description

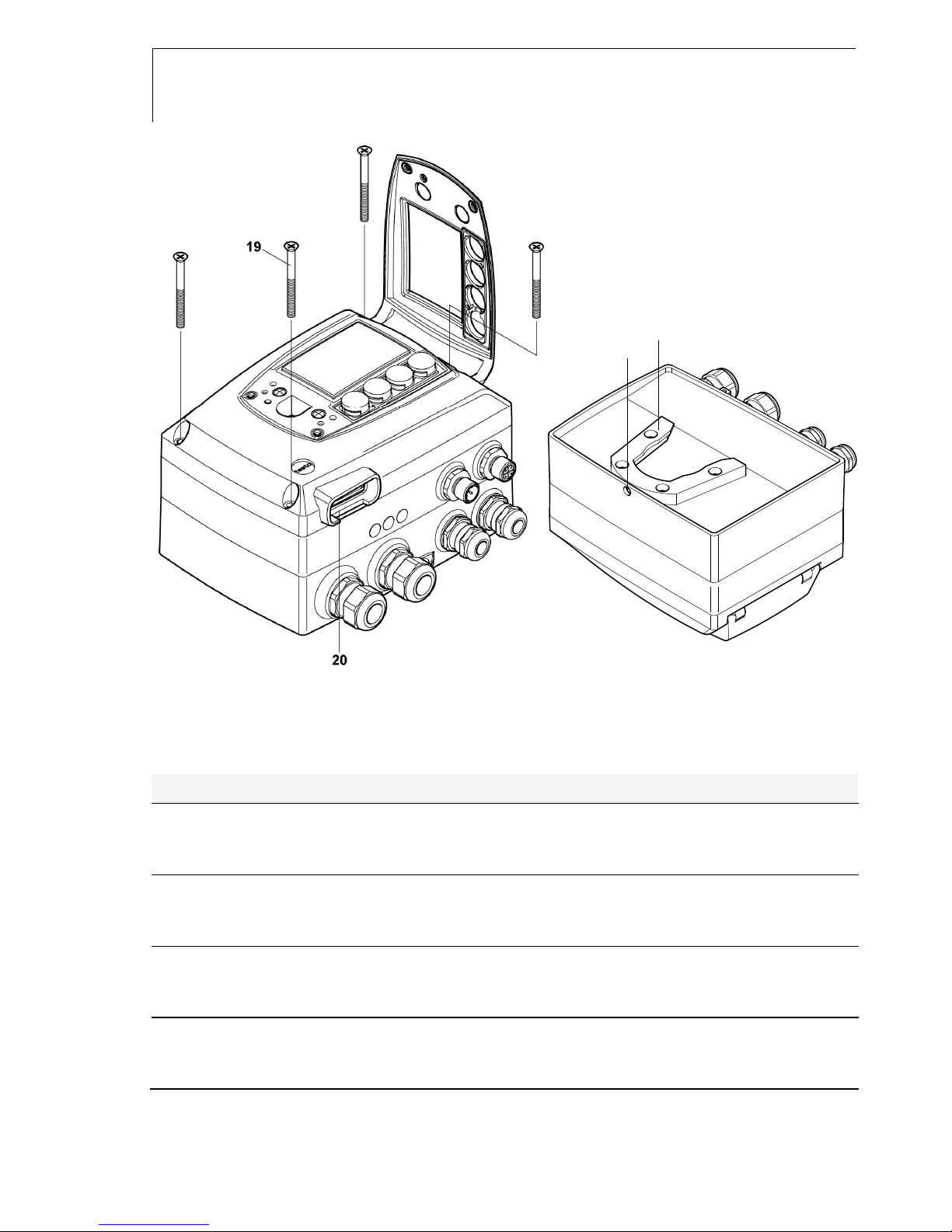

19 Housing screws (4x)

20 Socket for probe connector

21 Hole for fastening to rear

panel bracket (M3 x 6

screw)

22 Plastic bracket for assembly

on rear panel

22

21

1.2.2 Usable probes

The testo 6681 humidity transmitter can be used with the following probes:

Probe Article no. Characteristic

testo 6611 0555 6610-L11 Wall probe version; accuracy to ± 1 % RH;

temperature range -20 °C to +70 °C/-4 to +158 °F,

sensor plugged

testo 6612 0555 6610-L12 Duct probe version; accuracy to ± 1 % RH;

temperature range -30 °C to 150 °C/-22 to +302 °F,

sensor soldered/optionally plugged

testo 6613 0555 6610-L13 Cable probe version; accuracy to ± 1 % RH;

temperature range -70 °C to +180 °C/-94 to

+356 °F, sensor soldered/optionally plugged

testo 6614 0555 6610-L14 Heated cable probe version; accuracy to ± 1.0 %

RH; temperature range -40 °C to +180 °C/

-40 to +356 °F, sensor soldered

Page 15

testo 6681 Profibus - 1.2 Product description

15

Probe Article no. Characteristic

testo 6615 0555 6610-L15 Trace humidity cable probe version;

accuracy ± 6 K at -60 °Ctd;

temperature range -40 °C to +120 °C/-40 to

+248 °F, sensor soldered

testo 6617 0555 6610-L17 Cable with cover electrode monitoring probe

version; accuracy to ± 1.2 % RH; temperature range

-40 °C to +180 °C/-40 to +356 °F, sensor soldered

1.2.3 Display and keypad

The display option allows the testo 6681 humidity transmitter to be operated

via the display and four keys.

The LCD display consists of two 7-segment lines for displaying readings and

units and of an information line (for status messages, for example).

The brightness and contrast of the display and the background lighting

(permanent or off) can be changed via the user menu or the P2A software.

1.2.4 Service interface

Behind the service flap is the parameterizing socket (mini-DIN) as an

interface to the P2A software or Testo handheld instrument

(testo 400/testo 650).

1.2.5 Relay board (option)

This has a floating switch capacity of 250 V AC/3 A. The switching limits and

hysteresis can be set via the display or the P2A software or via the Profibus.

Further features include:

Function of changeover contacts (NC/NO contacts) freely selectable

12 terminals for a total of 4 relays.

If no relays are available, settings for monitoring limit values

or alarms can still be controlled via the display. The alarm

status will be shown on the display.

Only have the transmitter wired and connected by authorized

personnel with the voltage disconnected.

Page 16

16

testo 6681 Profibus - 1.2 Product description

1.2.6 Analog outputs

For analog outputs, the testo 6681 has either

2 or optionally 3 current outputs of 4 to 20 mA/0 to 20 mA (4-wire) or

2 or optionally 3 voltage outputs of 0 to 1 V/0 to 5 V/0 to 10 V (4-wire).

The transmitter can be ordered with a third analog output as an option.

If the Profibus module is integrated directly into the

testo 6681 humidity transmitter (order code B77), it has two

current outputs 4 ...20 mA.

1.2.7 Parameters

The following parameters are displayed:

Relative humidity in %RH (technical)

Relative humidity in % WMO* (calculation according to the WMO

standard)

Temperature °C and °F

Dewpoint in °Ctd and °Ftd

Absolute humidity in g/m³ and gr/ft³

Degree of humidity in g/kg and gr/lb

Enthalpy in kJ/kg and BTU/lb

Psychrometer temperature in °Ctw and °Ftw

Water vapour partial pressure in hPa and "H

2

O (inch H2O)

Water content in ppm

vol

and % vol

Dewpoint of H

2O2

mixture in °Ctm and °Ftm

Mixture humidity H

2O2

in %RHm

*It is possible that condensation appears as of a displayed humidity

starting from 70 % and is shown on the display. This unit is used in

meteorology, for example. According to the WMO, the Magnus

coefficient is used for sub-cooled water in the calculation of relative

humidity.

Calculated humidity variables correspond to the medium of

air. With other gases/gas compositions, deviations may

occur, e.g. with the enthalpy

Page 17

testo 6681 Profibus - 1.2 Product description

17

1.2.8 Scaling

There are three types of min./max. values:

1 The measuring range

The maximum sensor performance is in this range. Values outside of

the measuring range are displayed via messages, for example. Refer

to table (see below) for the measuring range.

2 Standard scaling

The output signals are assigned to this measuring range as standard:

- during delivery if no entries are made in the order code

- after exchanging the unit, the measuring range recorded in the

instrument is applied as standard.

The transmitter even retains its scaling with the voltage

disconnected.

Refer to table (see below) for the measuring range.

3 The maximum settings for the manual scaling

- the values are not expressly given in the table. The maximum limits

can be calculated as follows:

X = difference between MIN. and MAX. value of the standard scaling

(Max. value of standard) + (50 % of X)

(Min. value of standard) - (50 % of X)

- It is thus possible to scale beyond the measuring range, e.g. for the

adjustment of the scaling limits to standard values of a PLC.

However, the physical measurement range limits are the deciding

factor when defining alarms.

Page 18

18

testo 6681 Profibus - 1.2 Product description

Parameter Unit Probe

Measuring

range

Physical

at 1013 hPa

Standard

scaling

MUF

measuring

range

MIN MAX MIN MAX

Temperature °C 6611 -20

+70

-20 +70

°F 6611 -4 +158

-4

+158

°C 6612 -30 +150

-30 +150

°F 6612 -22 +302

-22 +302

°C 6613 -70 +180

-70 +180

°F 6613 -94 +356

-94 +356

°C 6614, 6617 -40 +180

-40 +180

°F 6614, 6617 -40 +356

-40 +356

°C 6615 -40 +120

-40 +120

°F 6615 -40 +248

-40 +248

relative humidity % RH 0 +100

0

+100

WMO relative humidity % RH 0 +100

0

+100

Mixture humidity H2O2 % RHm 0 100

0

100

Dewpoint °Ctd 6611 -20

+70

-80 +100

°Ftd 6611 -4 +158 -112 +212

°Ctd

6612, 6613, 6614,

6617

-20

+100

-80 +100

°Ftd

6612, 6613, 6614,

6617

-112 +212 -112 +212

°Ctd 6615 -60

+30

-80 +100

°Ftd 6615 -148 +212 -112 +212

Mixture dewpoint (H2O2) °Ctm -20 +100

-20 +100

°Ftm -4 +212

-4

+212

Absolute humidity g/m3 all probes 0

600

0

2000

gr/ft3 0

250

0

800

Degree of humidity g/kg all probes 0 13300

0

9500

gr/lb 0 93000

0

66500

Enthalpy kJ/kg -40 99999

-40 8000

BTU/lb -18 43000

-18 3500

Psychrometer temperature °Ctw -40

100

-40 180

°Ftw -58

210

-40 356

Page 19

testo 6681 Profibus - 1.2 Product description

19

Parameter Unit Probe

Measuring

range

Physical

at 1013 hPa

Standard

scaling

MUF

measuring

range

MIN MAX MIN MAX

Water content

ppm vol

H2O 0 99999

0

99999

% vol 0

100

0

100

Water vapour partial pressure hPa 0 1000

0

7000

inchH2O 0

400

0

2800

1.2.9 Alarm handling

For upper and lower alarm limits, individual alarms as well as collective

alarms can be specified. If the collective alarm function is activated, an alarm

is triggered as soon as the alarm limit of an alarm is exceeded, if this alarm is

assigned to the collective alarm.

The testo 6681 monitors limit values using relays. If a reading is outside the

limit values, a relay to be specified by the user is switched.

If the reading reverts to more than a specified hysteresis below or above the

limit value, the alarm is cancelled.

In addition, information about the occurrence of error/status messages can

be provided by means of a collective alarm relay, see chapter 1.5, Status,

warning and error messages, page 84.

If multiple alarm messages are activated at the same time,

the last alarm is shown. If the alarm is cancelled again, the

previous messages are no longer shown.

Example:

If the condensation of the probe begins, the "Condensation"

message appears on the display and the "Start" status

display. If the condensation is over, the status display

changes from "Start" to "End".

Page 20

20

testo 6681 Profibus - 1.3 Commissioning

1.3 Commissioning

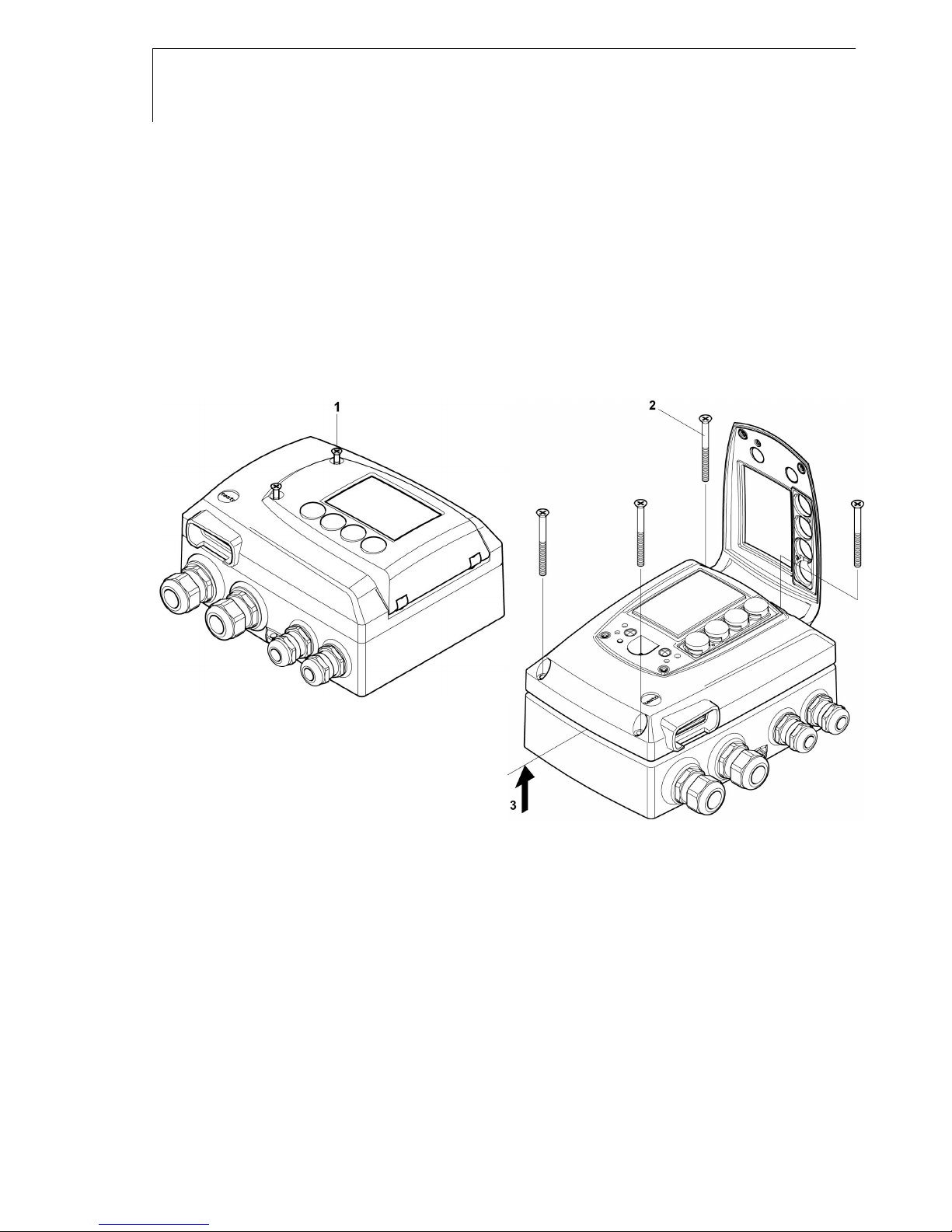

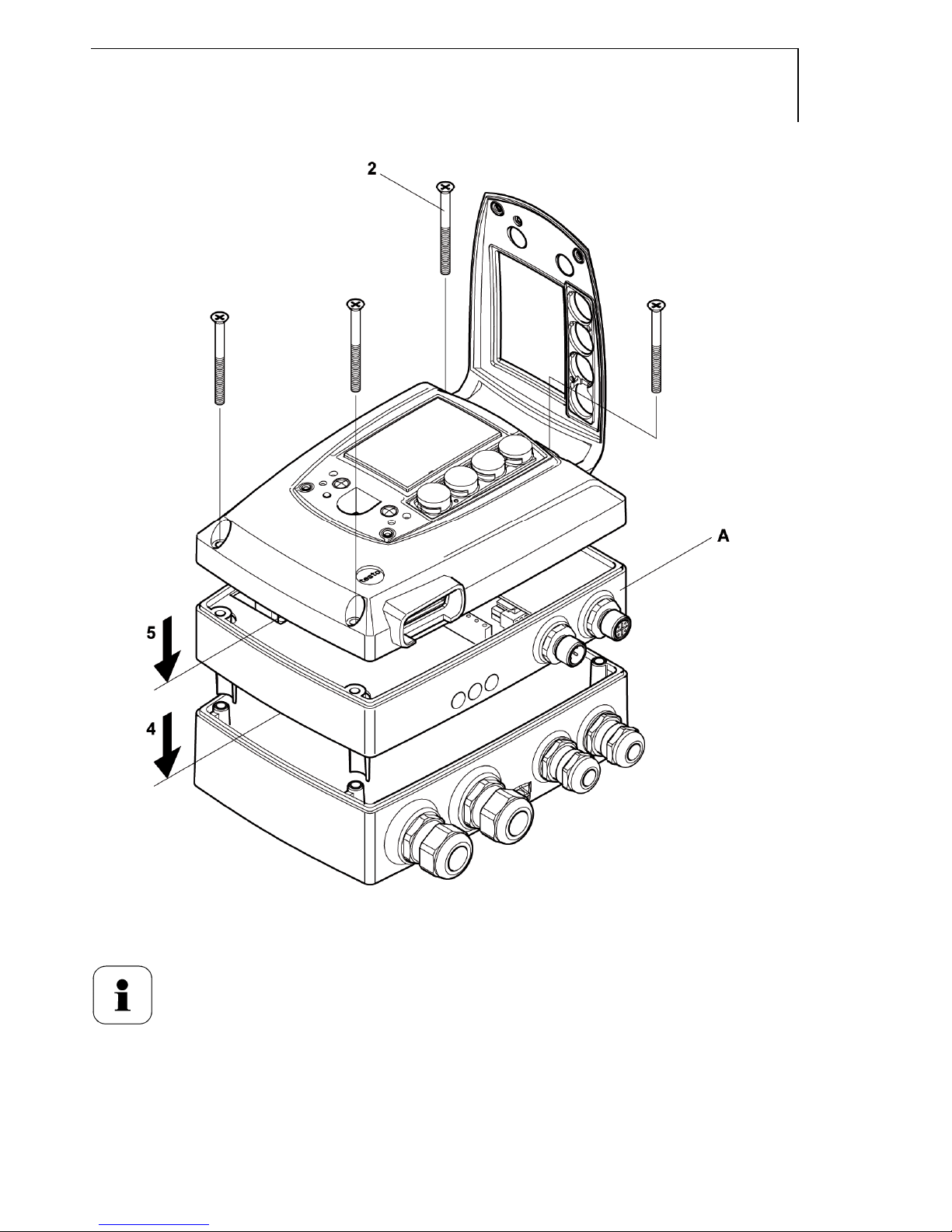

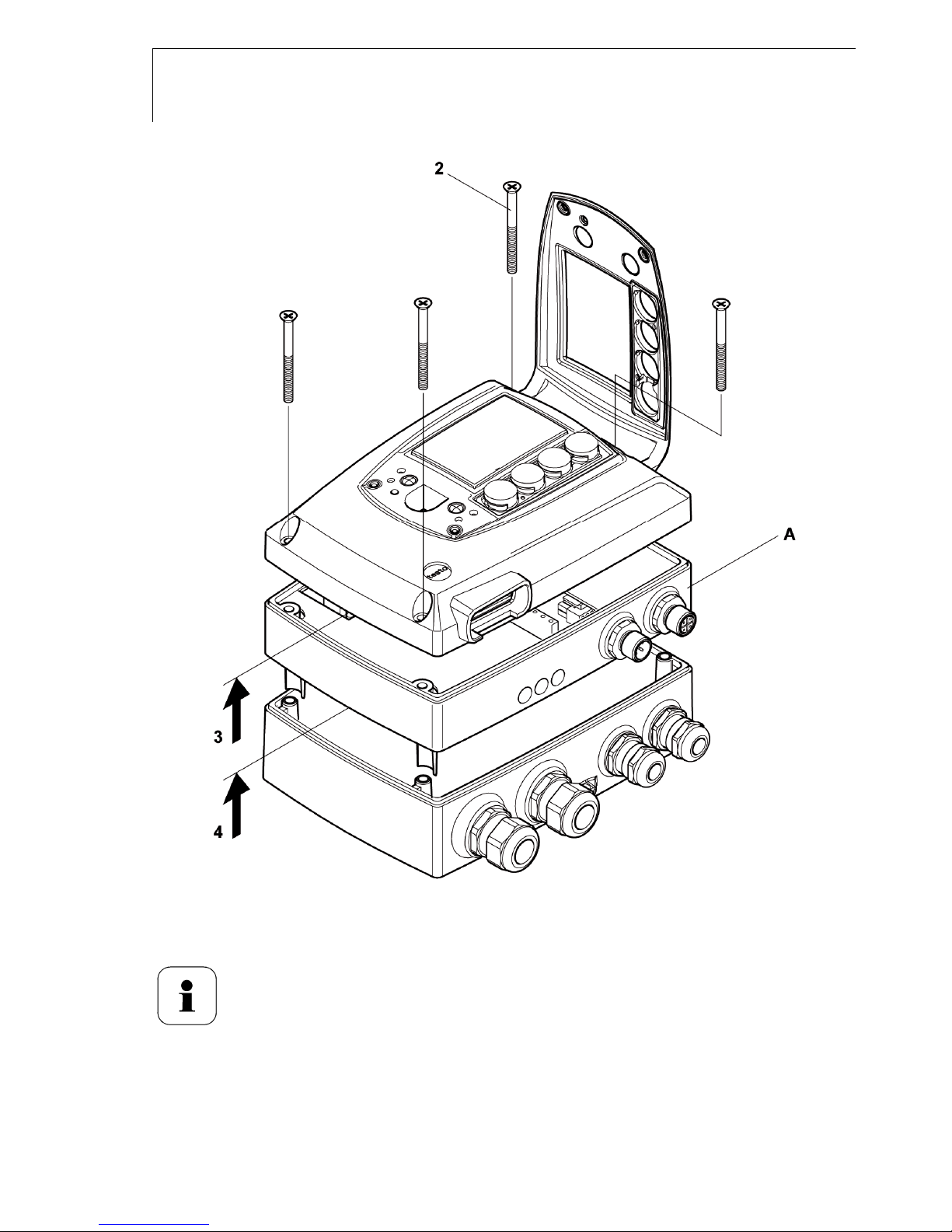

1.3.1 Insert Profibus module (Order no.

0554 6686)

The Profibus module can be ordered retroactively as an accessory. It can

easily be installed in the testo 6681 humidity transmitter.

The probe connector must be disconnected.

4 Loosen screw connection (1) of service flap and open the flap.

5 Loosen and remove housing screws (2).

6 Remove upper part of housing (3) and place on a clean surface.

Page 21

testo 6681 Profibus - 1.3 Commissioning

21

7 Place Profibus module (A) on lower part of instrument (4).

If necessary, manually set the address using the rotary

encoder switches (see chapter 1.3.3.6, page 37 before fixing

the instrument in place.

8 Set on upper part of instrument (5) and fix in place using housing screws

(2).

Page 22

22

testo 6681 Profibus - 1.3 Commissioning

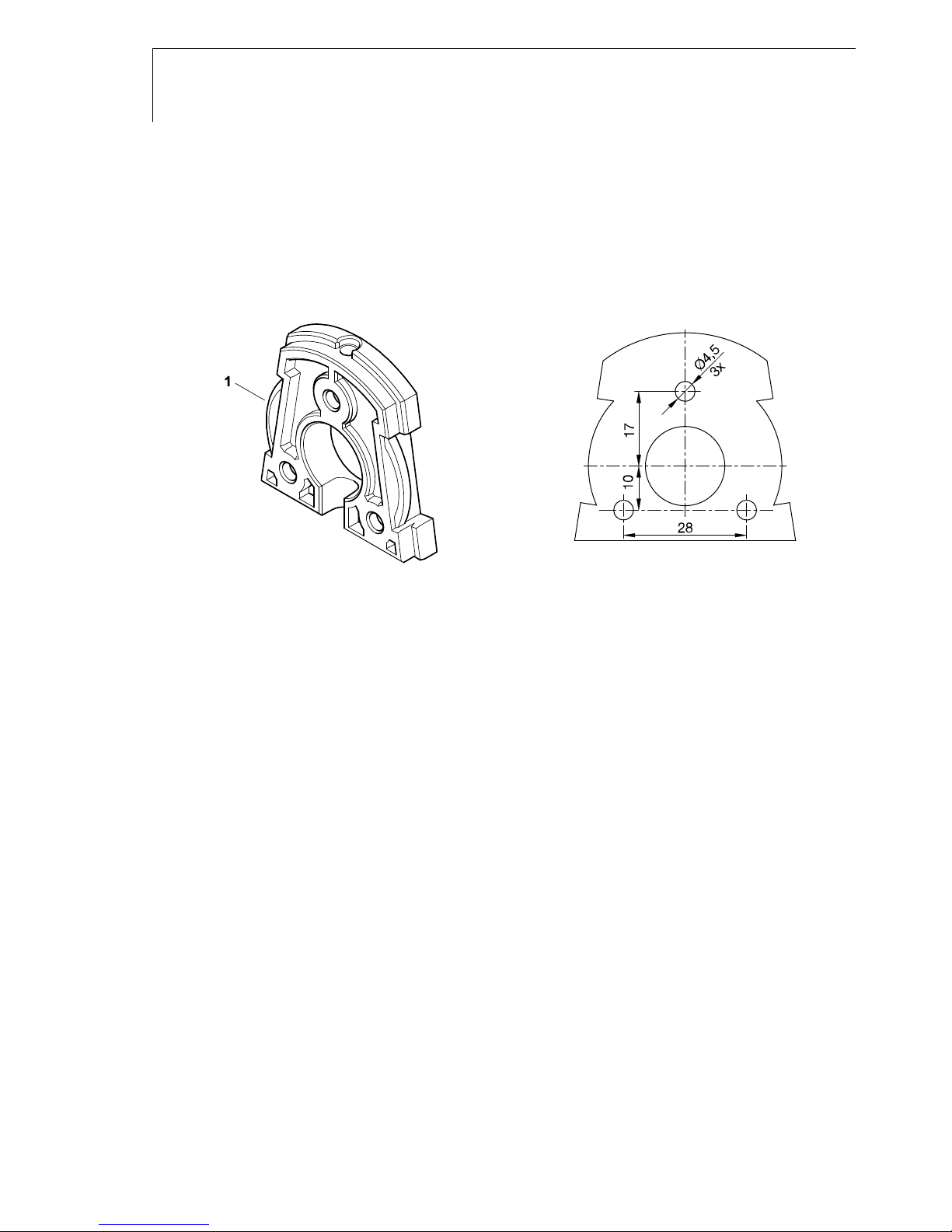

1.3.2 Assembling the instrument

1.3.2.1 Wall mounting

(for testo 6611/6613/6614/6615/6617 probes)

Attaching rear panel bracket

1 Remove locking screw (item (4) of drawing on page 21) and detach rear

panel bracket from plastic bracket (item (2) of drawing on page 21).

2 Hold rear panel bracket in assembly position and mark the three drill

holes.

3 Drill three holes ( 5 mm) and insert dowels where necessary.

4 Screw on rear panel bracket.

Remember that the clamping brackets (1) must face the wall.

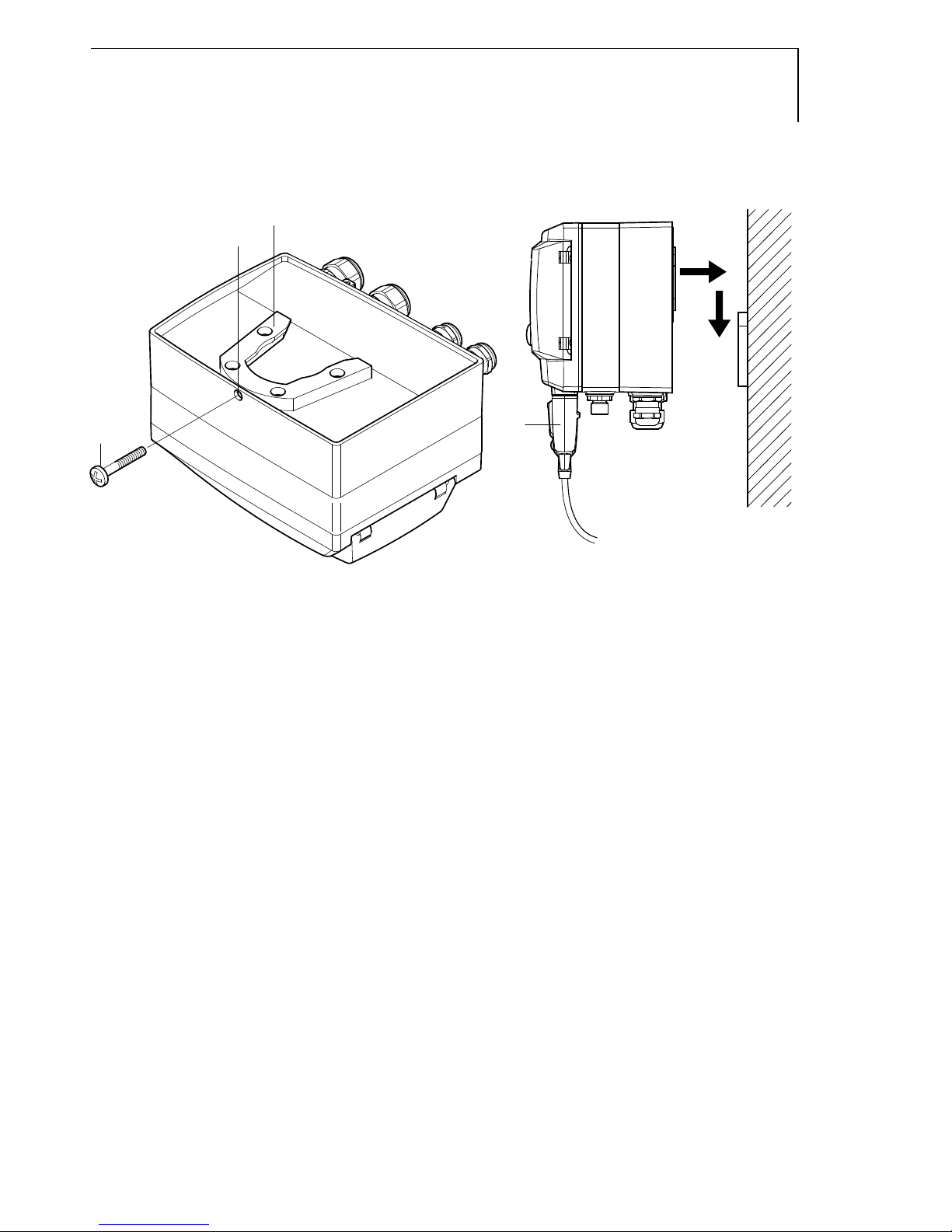

Page 23

testo 6681 Profibus - 1.3 Commissioning

23

Fastening instrument to rear panel bracket

2

3

4

5

1 Slide plastic bracket (2) on the back of instrument onto rear panel bracket

until it engages (see arrows).

2 Insert screw (4) through hole (3) and screw into rear panel bracket.

3 Insert probe connector (5) into socket until it engages.

Page 24

24

testo 6681 Profibus - 1.3 Commissioning

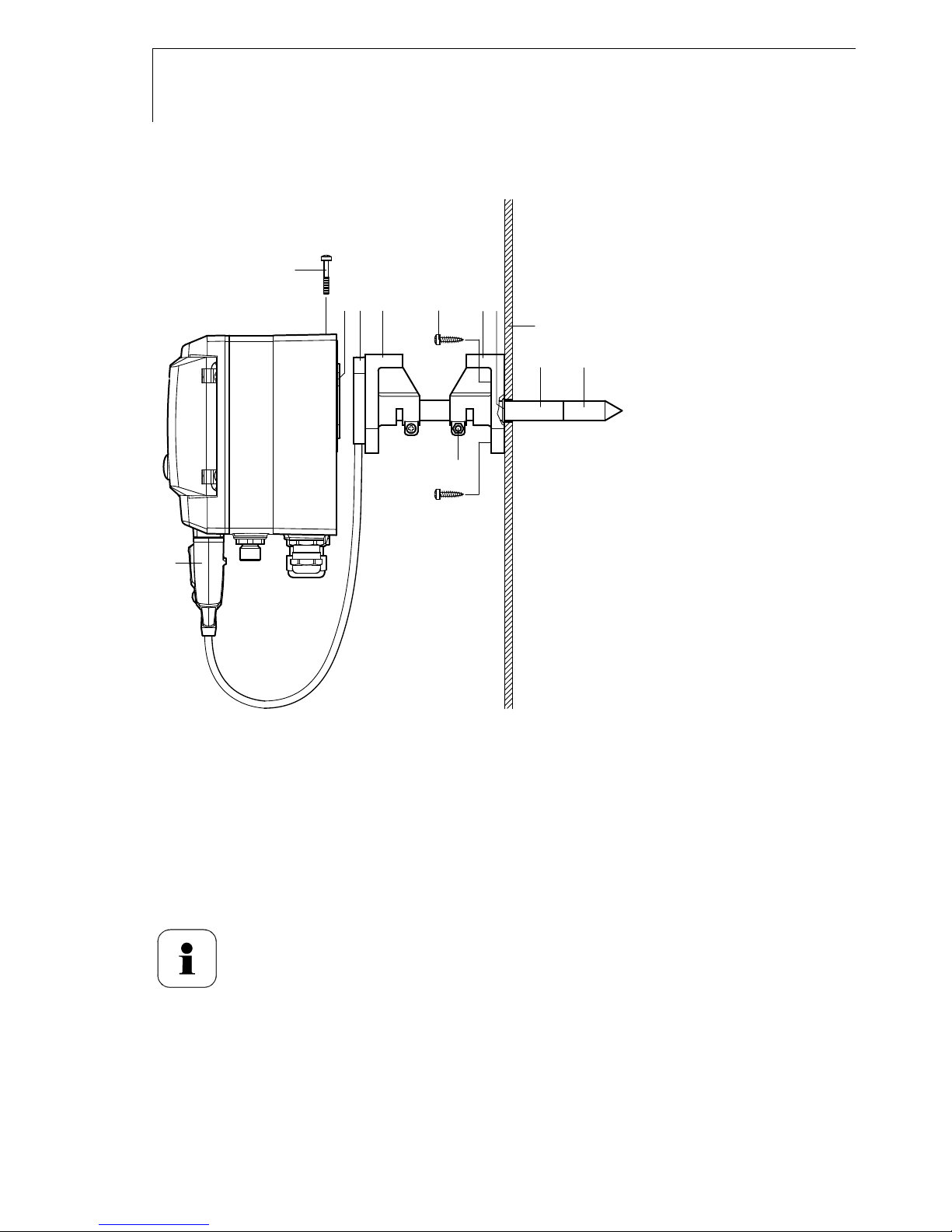

1.3.2.2 Duct mounting (for testo 6612 probes)

3

10

5

1

4

11

2

6

9

12

7

8

1 Hold wall/duct bracket (order no. 0554 6651) (6) against duct wall (8) and

mark drill holes for wall/duct bracket and probe shaft.

2 Drill a hole ( 12,5 mm) in the duct wall to feed through the probe shaft.

3 Fasten wall/duct bracket (6) to duct wall with screws (5).

4 Push probe shaft (9) with filter (10) through the middle hole of the

mounting bracket.

The wall/duct bracket (6) has an O-ring (7) to seal it against

the duct. Feed the probe shaft (9) carefully through the

wall/duct bracket so that the O-ring is not damaged.

5 Fix the correct position of the probe shaft (9) with screw (11) and mark

(insert probe shaft as far as possible).

Page 25

testo 6681 Profibus - 1.3 Commissioning

25

6 Slide plastic bracket (2) on the back of the transmitter onto bracket (3, 4)

until it engages.

Take the weight of the transmitter into account. Ensure that

the brackets (4, 6) are fastened securely.

7 Insert screw (1) through hole on the top of the instrument and screw into

bracket (3).

8 Insert probe connector (12) into socket until it engages.

1.3.3 Connecting the instrument

Opening the instrument

1 Loosen screw connection (1) of service flap and open the flap.

Page 26

26

testo 6681 Profibus - 1.3 Commissioning

2 Loosen and remove housing screws (2).

Important.

The Profibus module (A) is already separated from the upper

and lower parts of the instrument when the housing screws

(2) are removed.

3 Remove upper part of housing (3) and place on a clean surface.

4 Remove Profibus module (A) from lower part of housing (4) and also

place on a clean surface.

Page 27

testo 6681 Profibus - 1.3 Commissioning

27

Warning!

Electrical voltage.

Danger of short-circuit!

De-energize the mains connection before connecting the

transmitter!

Only have the transmitter wired and connected by authorized

personnel with the voltage disconnected.

Page 28

28

testo 6681 Profibus - 1.3 Commissioning

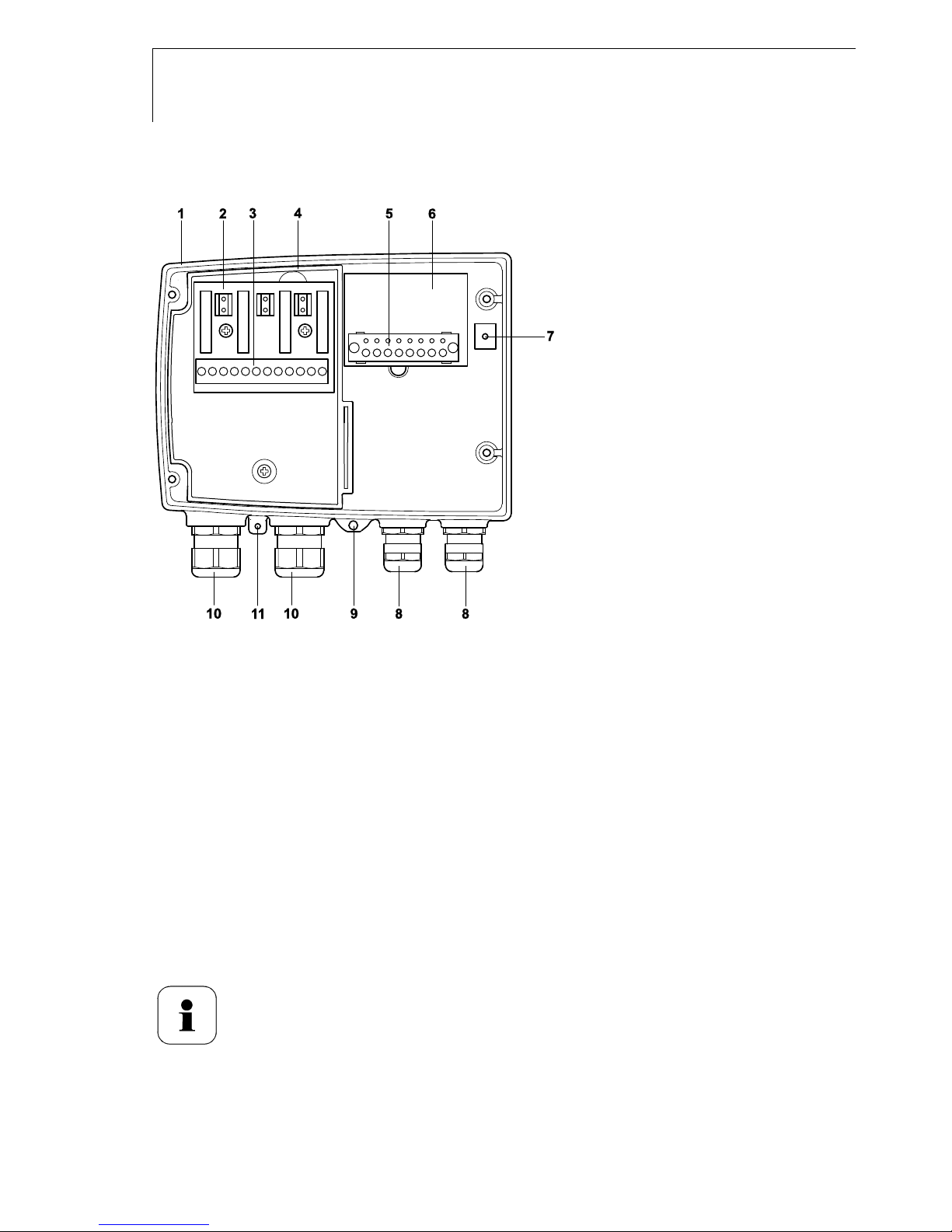

1.3.3.1 Overview of terminals

1 Lower part of housing

2 Relay board (option)

3 Relay terminals

4 Insulating trough for relay

board

5 Terminal strip for voltage

supply and analog outputs*

* The transmitter testo 6681 with

integrated Profibus module (order

code B 77) has two current

outputs 4 to 20 mA.

6 Terminal board

7 Earthing terminal (internal)

8 M 16 x 1.5 screw

connection**

9 Earthing terminal (external)

10 M 20 x 1.5 screw

connection*

11 Eyelet for measuring point

panel

** Alternatively, NPT cable coupling

or M plug-in connection.

The following description of the terminals refers to this

overview and its numbering.

Page 29

testo 6681 Profibus - 1.3 Commissioning

29

1.3.3.2 Connecting voltage supply and analog outputs

Terminal strip for voltage supply and

analog outputs (item (5) of Overview

of terminals, chapter 1.3.3.1, page

28).

1 Feed cable with voltage supply and analog signal lines through opened

M 16 x 1.5 screw connection (item (8) in Overview of terminals, chapter

1.3.3.1, page 28.

2 Strip the cable ends, clamp wire end ferrules on and screw down onto

voltage terminals.

3 Close M 16 x 1.5 screw connection (item (8) in Overview of terminals,

chapter 1.3.3.1, page 28.

Wiring diagram for 2-wire system (4 - 20 mA)

12 to 24 VDC

0 V

2 or 3 channels

4 to 20 mA, max. load 100 to 750

(at 24 V)

Page 30

30

testo 6681 Profibus - 1.3 Commissioning

If the channels have to be galvanically isolated, a separate

mains unit must be used for each channel.

Wiring diagram for 4-wire system

(0 to 20 mA/4 to 20 mA/0 to 1 V/0 to 5 V/0 to 10 V)

+

-

+

-

+

-

+

-

+

-

CH1

CH2 CH3

24V

Requirement for the connecting cable of the supply:

Insulated with cross-section of at least 0.25 sq. mm.

The supply line must be secured against exceeding 8 A.

An OFF switch must be installed in an easily accessible

position close by and be marked as such.

1 Feed connection cables of the two, or optionally three, channels through

opened M 16 x 1.5 screw connection (item (8) in Overview of terminals,

chapter 1.3.3.1, page 28.

2 Strip the cable ends, clamp wire end ferrules on and screw to channel

terminals as shown in diagram.

3 Close M 16 x 1.5 screw connection (item (8) in Overview of terminals,

chapter 1.3.3.1, page 28.

0 V

20 to 30 V

AC/DC

2 or 3 channels

0 to 20 mA/

4 to 20 mA/

max. load per 500

0 to 1 V/0 to 5 V/0 to 10 V

Page 31

testo 6681 Profibus - 1.3 Commissioning

31

Connecting the analog outputs is only required if you also

wish for analog monitoring in addition to use of the readings

via Profibus (e.g. for local signal use).

1.3.3.3 Connecting the relay outputs

Only have the transmitter wired and connected by authorized

personnel with the voltage disconnected.

Relay terminal strip (item (3)

of Overview of terminals,

chapter 1.3.3.1, page 28.

There is the option of twelve terminals for a total of four relays. The

designations NC/C/NO (normally closed contact/root or pin/normally open

contact) are etched on the surface of the board.

Using PG screw connection

4 Feed connection cables for the relays through opened M 20 x 1.5 screw

connection (item (10) of Overview of terminals, chapter 1.3.3.1, page 28.

5 Strip cable ends and clamp on wire end ferrules.

6 Connect relays according to chosen function (NC/NO) (see diagrams

below; relay 1 is shown as an example of a connection).

Using plug-in connections (optional)

Only insert or disconnect the plug-in connection when the

voltage is disconnected.

1 Clean the connector of the probe line and the coupling of any foreign

matter.

Do not disconnect the connector of the probe line from the

instrument for extended periods to protect against

contamination.

Page 32

32

testo 6681 Profibus - 1.3 Commissioning

Connection note

For the connection, a double-insulated mains cable

(sheathed cable) with a cross-section of at least 1.5 sq.

mm must be used.

Cable connection (2) may not be routed in a loop within

the tray (1).

It is recommended that you always tie 3 cores to one

another using a cable tie (3).

The insulation of the cable must be fed at least 5 mm (4)

into the tray.

Page 33

testo 6681 Profibus - 1.3 Commissioning

33

Use of relay as NC contact (NC = normally closed)

The busy light (alarm/status light) is permanently on until the

relay opens or the circuit is interrupted. This circuit can

therefore be used to monitor the functionality of the alarm

circuit, as a cable break, for instance, is indicated by the busy

light going off.

Use of relay as NO contact (NO = normally open)

250 V AC/DC, 3 A

Alarm/status light

(example of installation)

250 V AC/DC, 3 A

Alarm/status light

(

example of installation

)

Page 34

34

testo 6681 Profibus - 1.3 Commissioning

The busy light (alarm/status light) only comes on when the

relay is switched (closed). Monitoring the functionality of the

alarm circuit is therefore not possible with this switching

operation.

2 Close M 20 x 1.5 screw connection (item (10) in Overview of terminals,

chapter 1.3.3.1, page 28.

1.3.3.4 Plug-in connection option

As an option, the PG screw connections of the signal and supply lines can be

replaced with plug-in connections that are installed at the housing (see Fig. 1

and 2). The relay cabling occurs via standard cable entries and PG screw

connections, see Fig. 3 and 4

Plug-in connections for power supply and channels

M12 plug-in connection (5-pin) socket (1)

View of the plug-in connections in the installed state from outside.

Pin Assignment.

1 V 24 -

2 V 24 +

3 + Ch 1

4 - Ch 1

5 PE

Transmitter housing

Page 35

testo 6681 Profibus - 1.3 Commissioning

35

M12 plug-in connection (5-pin) connector (2)

Pin Assignment.

1 - Ch 2

2 + Ch 2

3 + Ch 3

4 - Ch 3

5 PE

1.3.3.5 Creating the PE/earthing terminal

As the testo 6681 has a metal housing, we recommend that the instrument

be earthed. This can be done using the earthing terminal within the

instrument (1) or the earthing terminal outside of the instrument (2).

Only use the external earthing terminal in dry interiors.

Page 36

36

testo 6681 Profibus - 1.3 Commissioning

Using the earthing terminal within the instrument

1 Guide PE line (yellow-green) (5) through the cable coupling (x) and fit

cable lug (8). Fix this to the side of the instrument (6) using M 5 screw

(3), washer (4) and snap ring (7) on the internal earthing terminal (1).

2 Place the other cable end on an appropriate (PE) earth conductor, e.g.

an earthing bar.

Using an earthing terminal outside of the instrument

1 Use shielded cable (5) with cable lug (8). Fix this in place using M 5

screw (3), washer (4) and snap ring(7) on the external earthing terminal

(2).

2 Place the other cable end on an appropriate (PE) earth conductor, e.g.

an earthing bar.

3 Set Profibus module on lower part of housing (see arrow).

4 For the configuration of the Profibus module, see following chapter.

If you do not wish to perform a configuration, close the transmitter (see

chapter 1.3.3.7, page 40)

Page 37

testo 6681 Profibus - 1.3 Commissioning

37

1.3.3.6 Manually set address

To ensure that the individual bus subscribers can be addressed directly by

the master, it is necessary that every bus subscriber is assigned a unique

address.

Important:

The address of a subscriber may only be assigned once!

Repeated assignment of an address leads to bus faults!

In the condition on delivery for the testo 6681 with Profibus

module, the switch setting FF is set.

If you wish to set the address using the Profibus

parameterization software, e.g. Siemens Simatic PDM (see

chapter 1.3.5.4, page 51), the default setting is required.

The manual setting of the address (hard address) overrides

the setting via the parameterization software (soft address).

The testo 6681 must be disconnected from the bus system.

1 Open transmitter (see Section Opening the instrument, chapter 1.3.3,

page 25).

Page 38

38

testo 6681 Profibus - 1.3 Commissioning

2 With a Phillips screwdriver, set the address via the rotary encoder

switches (1) and (2) at Profibus module (see following Section ).

3 Insert Profibus module and close instrument (see chapter 1.3.3.7, page

40).

Table of addresses

The addressing of the bus subscribers is performed via the rotary encoder

switches (items (1) and (2), see drawing on page 30) in a hexadecimal

system (see table).

dec (1) (2) dec (1) (2) dec (1) (2) dec (1) (2)

0 0 0

16 1 0 32 2 0 48

3 0

1 0 1 17 1 1

33 2 1 49

3 1

2 0 2 18 1 2 34 2 2 50 3 2

3 0 3 19 1 3 35 2 3 51 3 3

4 0 4 20 1 4 36 2 4 52 3 4

5 0 5 21 1 5 37 2 5 53 3 5

6 0 6 22 1 6 38 2 6 54 3 6

7 0 7 23 1 7 39 2 7 55 3 7

8 0 8 24 1 8 40 2 8 56 3 8

9 0 9 25 1 9 41 2 9 57 3 9

10 0 A 26 1 A 42 2 A 58 3 A

11 0 B 27 1 B 43 2 B 59 3 B

12 0 C 28 1 C 44 2 C 60 3 C

13 0 D 29 1 D 45 2 D 61 3 D

14 0 E 30 1 E 46 2 E 62 3 E

15 0 F 31 1 F 47 2 F 63 3 F

Page 39

testo 6681 Profibus - 1.3 Commissioning

39

dec (1) (2) dec (1) (2) dec (1) (2) dec (1) (2)

64 4 0

80 5 0 96 6 0 112

7 0

65 4 1 81 5 1

97 6 1 113

7 1

66 4 2 82 5 2 98 6 2 114 7 2

67 4 3 83 5 3 99 6 3 115 7 3

68 4 4 84 5 4 100 6 4 116 7 4

69 4 5 85 5 5 101 6 5 117 7 5

70 4 6 86 5 6 102 6 6 118 7 6

71 4 7 87 5 7 103 6 7 119 7 7

72 4 8 88 5 8 104 6 8 120 7 8

73 4 9 89 5 9 105 6 9 121 7 9

74 4 A 90 5 A 106 6 A 122 7 A

75 4 B 91 5 B 107 6 B 123 7 B

76 4 C 95 5 C 108 6 C 124 7 C

77 4 D 93 5 D 109 6 D 125 7 D

78 4 E 94 5 E 110 6 E 126 7 E

79 4 F 95 5 F 111 6 F

Page 40

40

testo 6681 Profibus - 1.3 Commissioning

1.3.3.7 Closing the instrument

1 Place Profibus module (A) on lower part of instrument (1).

2 Set on upper part of instrument (2) and fix in place using housing screws

(3).

Page 41

testo 6681 Profibus - 1.3 Commissioning

41

3 Close the service flap and tighten screws (4).

Page 42

42

testo 6681 Profibus - 1.3 Commissioning

1.3.4 Connect instrument to the bus system

Overview

1 Terminati

ng

resistor

2 Profibus

3 Profibus

Characteristics

RS485 transmission technology

Baud rates between 9 kBit/s and 12 Mbit/s

Connected in linear structure (see Fig. above).

Stubs

These should be avoided, as they cause reflections on the bus and thereby

disruptions in communication (especially as of transfer rates 1.5 Mbits/s).

Connecting a bus monitor or similar is also an example of a stub, so these

instruments should only be connected via active stubs (see Section

Terminating resistor, chapter 1.3.4.2, page 45).

Page 43

testo 6681 Profibus - 1.3 Commissioning

43

Number of subscribers

A maximum of 32 subscribers may be attached per segment (2).

If more than 32 subscribers are to be integrated into the Profibus or the

network dimensions are to be expanded, so-called repeaters (3) are to be

installed which connect the individual bus segments with one another.

However, a maximum of 9 repeaters (3) should be inserted in the

transmission path between the Profibus master and the bus subscriber.

In total, a maximum of 126 subscribers (including repeaters) can be

connected to the bus. The repeaters do not require their own bus address,

but are included in the number of bus subscribers.

Note the bus terminating resistors (1) (see Section Terminating resistor,

chapter 1.3.4.2, page 45)

Page 44

44

testo 6681 Profibus - 1.3 Commissioning

1.3.4.1 Data transfer and baud rate

With the RS485 transmission technology, the use of shielded and twisted

two-wire line of cable type A is recommended in accordance with EN 50170:

Loop resistance < 110 /km

Surge impedance 135 to 165 (at f= 3 to 20 MHz)

Wire diameter > 0.64 mm

Wire cross-section > 0.34 sq. mm

Effective capacitance < 30 pF/m.

Depending on the transfer rate and number of repeaters,

distances up to 10 km can be achieved using this

transmission technology.

Line lengths

The line length depends on the baud rate (see table).

Baud rate in kBit/s 9.6 19.2 93.75 187.5 500 1500 12000

Line length in m

(cable type A)

1200 1200 1200 1000 400 200 100

Bus cycle time

The bus cycle time is dependent on the

number of bus subscribers and the

selected transfer rate (see Fig.).

Subscribers

Bus cycle time (ms)

Page 45

testo 6681 Profibus - 1.3 Commissioning

45

1.3.4.2 Electrical connection

To simplify the connection of the transmitter to the Profibus, the Profibus

module of the testo 6681 has pre-fabricated plug-and-socket connections.

Using the connector (2) and the socket (1) (accessory 0554 6683), the

testo 6681 can be connected to the existing cable infrastructure in the linear

structure of the Profibus.

The pin-assignment of the connector and the socket as per IEC 60947-5-2 is

as follows:

Pin 1 Supply voltage VP (5 V)

Pin 2 RxD/TxD-N A line

Pin 3 Reference potential to VP

(DGND)

Pin 4 RxD/TxD-N B line

Pin 5 Shield or protective earth

When using both plug-in connections, the communication of

the bus is necessarily interrupted during the integration of the

removal of a field instrument.

Page 46

46

testo 6681 Profibus - 1.3 Commissioning

Alternatively, the transmitter can be connected to the bus system via a T

plug-in connection (3) (accessory 0554 6687).

Using the T plug-in connection (3) the field instruments (4) can be

disconnected during Measuring Mode and the bus communication is not

interrupted. However, the T plug-in connections (3) are only advantageous up

to a transfer speed of 1.5 MBits/s.

Terminating resistor

To prevent disruptions in communication due to reflections, a bus terminator

(1) must be attached to the beginning and end of every bus (2) (accessory

0554 6688).

Page 47

testo 6681 Profibus - 1.3 Commissioning

47

Shielding

To safeguard the Profibus from electromagnetic influences, you should

use shielded cable type A data cables (see chapter 1.3.4.1, page 44).

route the bus cables as far away from all live cables as possible.

connect the double-sided cable shield to each connective bus subscriber.

ensure optimum equipotential bonding between the individual bus

subscribers (e.g. by means of equipotential bonding line/common

earthing bar).

Without equipotential bonding the differences in potential may

lead to low-frequency equalizing currents and, in extreme

cases, to destruction of the cables.

If no equipotential bonding can be ensured within the system,

we recommend only applying the shield on one side and

establishing capacitive connections for all further earthing

points.

Use of the external earthing terminal only in interiors

1 Equipotential

bonding strip

2 Equipotential

bonding line

3 Data cable

4 Transmitter

(slave)

5 Master

Page 48

48

testo 6681 Profibus - 1.3 Commissioning

1.3.4.3 Configuration

The communication in the Profibus occurs cyclically (permanent data

exchange such as e.g. the humidity and temperature readings) as well as

acyclically (data exchange dependent on event such as e.g. status, warning

and error messages).

The testo 6681 has two measurement channels that are provided for the

Profibus interface.

Parameters can be found in chapter 1.2.7, page 16.

In the condition on delivery, measurement channel 1 is set

with temperature (°C) and measurement channel 2 with

relative humidity (% RH) for Profibus.

To Change the factory settings for the testo 6681 via

Profibus, the Profibus parameterization tool Siemens Simatic

PDM is required, for example (see chapter 1.3.5, page 49).

For the cyclical service, you must ensure that the GSD file

(General Station Description) was read into the master

class 1 in the configuration tool.

The GSD can be obtained under:

www.profibus.com/pb/applications/gsd,

www.testo.com or can

be downloaded from the product CD that is included with

the testo 6681.

Page 49

testo 6681 Profibus - 1.3 Commissioning

49

1.3.5 Configure Profibus module using EDD

1.3.5.1 Start parameterizing software

The following description of the configuration using the

Process Device Manager (PDM) refers to the stand-alone

version of the Siemens Simatic PDM software.

The project planning and parameterization tool Siemens Simatic PDM

can be master class 2 (at least version 6.0 SP2).

1 Start the software Simatic PDM

The program window is opened.

2 In the right selection window, select the testo 6680 by double clicking.

The Simatic PDM - User dialogue is opened.

3 Select:

Maintenance engineer to read out the settings of the testo 6681 or

Specialist to parameterize the measurement channels (see Section Menu

item Output, chapter 1.3.5.3, page 50).

4 Confirm with [OK].

Page 50

50

testo 6681 Profibus - 1.3 Commissioning

1.3.5.2 Overview of user interface

The individual menu items are

shown in a tree structure in

the left selection window (1).

In the right selection window

(2) input fields can be opened

by clicking on the white fields

(3) with the right mouse

button.

When settings are changed,

status (4) changes from Initial

val to Changed.

1.3.5.3 Menu items

Menu items Explanation

Operation

unit

Entry of the exact designation of the measuring point.

Device

Selection of the identification number with which the

instrument registers on the Profibus.

You may select:

Manufacturer-specific

Instrument registers itself with the identification

number 0A8A

hex

.

For commissioning the instrument in cyclical data

communication, the manufacturer GSD is required.

Profile-specific

Instrument registers itself with the identification

number 9701

hex

.

For commissioning the instrument in cyclical data

communication, the corresponding profile GSD of the

Profibus user organization (PNO) is required.

2

4

1

3

Page 51

testo 6681 Profibus - 1.3 Commissioning

51

As the testo 6681 is the first humidity transmitter with a

Profibus interface, no standardized humidity profile exists at

this point, meaning that Manufacturer-specific should be

selected.

Input Description of the Profibus input measurement channels, i.e.

the parameters that the Profibus interface should be provided

with. With testo 6681, these are the channels Temperature

Transducer and Humidity Transducer.

Output

Select the parameter settings for unit, filter time constants,

reading scaling, limit values, etc.

1.3.5.4 Set address

FF must be set at the Profibus module (see chapter 1.3.3.7, page 40).

1 Click on [Set address].

2 Enter addresses and confirm with [Assign Address].

The address is assigned and saved directly.

Page 52

52

testo 6681 Profibus - 1.3 Commissioning

Important:

The address of a subscriber may only be assigned once.

Repeated assignment leads to bus faults.

1.3.5.5 Parameter settings

In the Output menu item you can perform the parameter settings. To simplify

the multitude of entry steps, an entry assistant is available for this.

Start assistant

Select Device > Menu Transmitter setup in the menu bar.

The dialogue is opened.

Instrument settings tab

Changing parameterizations is only possible when the write

protection of the variables is removed.

If the write protection is activated, the settings can only be

shown.

Page 53

testo 6681 Profibus - 1.3 Commissioning

53

1 Click on [Read Device Settings].

The display of the instrument settings is updated and the parameters,

units and status of the write lock are thereby adopted in the

testo 6681.

2 Select Write locking Off and click on [Apply read-only settings].

Write protection is now deactivated.

3 In the Channel Settings list field, set the required parameters via the

Channel 1 and Channel 2 pull-down menus.

Using Profibus, the temperature can only be set on channel 1.

The humidity values on the other hand can be set on both

channels, but a humidity value selected on one measurement

channel cannot be set on the other measurement channel.

The units are updated when the parameter is changed. Alternative

units that correspond to the parameter can be set using the pull-down

menu.

4 Confirm with [Apply Channel Settings].

The values are updated, the status was changed.

Relay parameters tab

In the user menu of the testo 6681 or in the P2A software, the relay

status Not used or Profibus is set. Otherwise the message

no access appears from Profibus.

Profibus

Not used

MAX

General alarm

With Profibus

parameterization

tool

With P2A software

or user menu

Page 54

54

testo 6681 Profibus - 1.3 Commissioning

1 Click on [Read relay parameters from transmitter].

The display of the relay settings is updated and the relay parameters

set in the testo 6681 are applied.

For usage and parameterization of the relay, testo 6686 must

be equipped with the relay options (order code H01 or H02).

Precondition for changing relay parameterizations is that you

have deactivated the write protection beforehand in the

Device Settings tab

2 Select the required relay usage in the Apply relay parameters list field

using the Limit Relay X pull-down menu (see table) below.

Pull-down menu

selection

Description

Relay is not being used means that neither the transmitter nor the

Profibus are using the relay.

Relay parameters

managed by device

means that the relays are assigned using the

testo 6681.

Limit Lo-Lo channel x means that the relay should be used as the

main alarm for monitoring the lower limit value.

Limit Lo channel x means that the relay should be used as the pre-

alarm for monitoring the lower limit value.

Limit Hi-Hi channel x means that the relay should be used as the

main alarm for monitoring the lower limit value.

Limit Hi channel x means that the relay should be used as the pre-

alarm for monitoring the upper limit value.

3 Confirm with [Apply Relay Parameters].

Using [Relay Factory Settings] all relays are reset to Relay is not being

used.

A precondition for this is that the write protection was deactivated

beforehand and that the relays were used by the Profibus.

Page 55

testo 6681 Profibus - 1.3 Commissioning

55

1.3.6 Adjusting the instrument

The testo adjusting concept allows the entire signal chain from the sensor

signal (probe) and the digital signal (within the transmitter) through to the

analog signal (transmitter output signal) to be adjusted (see diagram).

1-point adjustment 2-point adjustment Analog adjustment

Adjustment via

testo 400/650 handheld

instrument with

adjustment adapter

P2A software

User menu

A

djustment 11.3 % RH and

75.3 % RH via

A

djustment keys (1, 2)

P2A software

A

djustment 20 % rH and

80 % rH via

User menu

Adjustment using a precise

multimeter and transmission

of analog reference value in

P2A software or

User menu

Either the 1-point adjustment or 2-point adjustment is suitable for adjusting

the sensor signal - digital signal chain.

The testo 6681 transmitter has digital probes whose adjustment information

is stored in the probes' internal memory. Both 1-point and 2-point

adjustments can thus be carried out on another testo 6681 (e.g. in the

calibration laboratory).

Page 56

56

testo 6681 Profibus - 1.3 Commissioning

1.3.6.1 Overview: Adjustment keys and test contacts

1 Status LED

2 Contact ch. 1 +

3 Contact ch. 1 -

4 Adjust key 11.3 %

5 Service interface

6 Adjust key 75,3 %

7 Contact ch. 2 +

8 Contact ch. 2 -

1.3.6.2 1-point adjustment (Offset)

In the 1-point adjustment, the reading at the working point is raised to the reference

value so that there is no longer any deviation in the working point. The reference

condition can be measured using a precise handheld instrument (e.g. testo 400/650

with precision humidity probe) or be created in an air conditioning cabinet.

The advantage of the 1-point adjustment is the good measuring result in the

working range. But the further away the measurement is from the working

point, the greater the deviation can become. The 1-point adjustment should

therefore only be used for a relatively narrow measuring range (working

range), e.g. clean room applications, air conditioning applications for storage

and similar.

Deviation

after

before

Working range

WP

e.g. scale = 0 - 100 % RH

Page 57

testo 6681 Profibus - 1.3 Commissioning

57

The 1-point adjustment can be performed

via the user menu (see chapter 1.4.6.9, page 81) or

via the P2A software (see volume 2, chapter 3, page 135) or

directly by means of a Testo handheld instrument (testo 400/650) (see

description of how to proceed below).

Please note that the 1-point adjustment is generally

performed on the basis of the % RH and °C/°F parameters.

Adjusting testo 6681 using Testo handheld instrument

The service flap is open, a testo 400/650 handheld instrument with a

precision humidity probe is ready.

1 Connect Testo handheld instrument 400/650 (1) with connected humidity

reference probe (3) (order no. reference set 0699 3656/20) to the service

interface (5) of the testo 6681 via the adjustment adapter (2) (connected

to the probe socket 1 of the handheld instrument).

1

2

3

4

5

Page 58

58

testo 6681 Profibus - 1.3 Commissioning

2 Expose the humidity probe (4) of the testo 6681 and the reference probe

(3) to the same reference conditions (e.g. in the humidity generator) and

allow climatic conditions to equalize.

3 Switch on the testo 400/650. The two-part display of the handheld

instrument will show the values of the transmitter on the left, and the

values of the reference probe on the right. The humidity and temperature

values are adjusted to the reference probe using the Probe > Probe

Adjustment menu item on the testo 400/650.

The 1-point adjustment is performed for both the humidity and the

temperature.

4 Disconnect the adapter (2) from the service interface (5).

5 Close the service flap.

1.3.6.3 2-point adjustment

With the 2-point adjustment, the parameter is adjusted to the reference value

at the two standard adjustment points 11.3 % RH and 75.3 % RH or 20 % RH

and 80 % RH. The reference conditions are created either by using Testo

humidity adjustment set (order no. 0554 0660, only for adjustment points 20

%RH and 80 %RH) or in the humidity generator.

In the 2-point adjustment, the deviations between the reading and the

nominal value are minimized across the entire measuring range. The 2-point

adjustment is therefore recommended for large working ranges, e.g. in drying

processes.

The 2-point adjustment can be performed

via P2A software (see volume 2, chapter 3, page 135) or

using the adjustment keys under the service flap, see description of how to

proceed below.

Deviation

after

before

Page 59

testo 6681 Profibus - 1.3 Commissioning

59

The 2-point adjustment for the adjustment points 20 %RH and 80 %RH is

carried out via the user menu.

A 2-point adjustment cancels any previous 1-point

adjustment.

Adjustment with the standard Testo adjustment salt pots is

not suitable for the testo 6614 (heated for high-humidity

applications) and testo 6615 (trace humidity) probes. The

reference conditions should be generated in a humidity

generator to adjust these probes.

In addition, these probes can also be adjusted at a third

adjustment point by Testo Service.

testo 6614: third adjustment point at 90 % RH

testo 6615: third adjustment point at -40 °Ctd/-40 °Ftd.

Page 60

60

testo 6681 Profibus - 1.3 Commissioning

Adjusting testo 6681 using adjustment keys

The 2-point adjustment for the adjustment points 20 %RH and

80 %RH is carried out via the user menu.

The service flap of the testo 6681 is open.

1 Expose the humidity probe of the testo 6681 to the reference condition of

11.3 % RH for at least 1.5 hours at 25 °C.

11.3 % RH

1.5 h

11.3 % RH

1.5 h

75.3 % RH

1.5 h

75.3 % RH

1.5 h

or

(salt pots) (humidity generator)

Page 61

testo 6681 Profibus - 1.3 Commissioning

61

2 After this equalization period, press the 11.3 % adjustment key (4) for at

least 10 seconds with something like a ball-point pen that is not too

sharp. The LED (1) flashes when the adjustment process begins. At the

same time, the 2-point adjustment 11.3 % status message appears on

the display

Completion of the adjustment is signalled by the LED (1) coming on

permanently and the Probe reset status message is shown.

Carry out the adjustment analogously for the reference condition

75.3 % RH. Press on the 75.3 % RH adjustment key (6) to do this.

3 Close the service flap.

1.3.6.4 Analog output adjustment

The analog output adjustment is only required if the analog

outputs are used in addition to the Profibus output.

The purpose of adjusting the analog outputs is to adjust the signal chain from

the digital signal (within the transmitter) to the analog outputs. The signal type

that was appointed for the transmitter is adjusted respectively for each

channel (e.g. 4 to 20 mA or 0 to 1 V, etc.)

Page 62

62

testo 6681 Profibus - 1.3 Commissioning

1 Status LED

2 Contact ch. 1 +

3 Contact ch. 1 -

4 Adjust key 11.3 %

5 Service interface

6 Adjust key 75.3 %

7 Contact ch. 2 +

8 Contact ch. 2 -

Analog outputs 1 and 2 adjusted

A precise multimeter (minimum resolution of 6.5 digits, accuracy of

100

A, e.g. Agilent 34401A) is available.

If only a simple multimeter is available, the analog outputs

may not be adjusted.

The service flap is open.

1 Connect the inputs of the multimeter with the contacts (2) and (3) for

channel 1 or with contacts (7) and (8) for channel 2.

2 Transfer the reference analog value measured with the multimeter to the

P2A software (see volume 2, chapter 3, page 135) or enter it via the user

menu (see chapter 1.4.6.9, page 81).

3 Disconnect connections between multimeter and contacts of the

testo 6681 and close service flap.

Adjusting analog output 3 (optional)

If the optional third analog output is to be adjusted, a cable

connection to measure the analog value must be installed.

Do this by proceeding as follows:

Page 63

testo 6681 Profibus - 1.3 Commissioning

63

1 Open transmitter (see chapter 1.3.3, page 25).

2 Connect measuring cable to the terminals of the third analog output and

guide through the cable coupling and out of the transmitter.

3 Reassemble upper part of transmitter.

4 Connect cable ends to the inputs of the multimeter.

5 Transfer the reference analog value measured with the multimeter to the

P2A software (see volume 2, chapter 3, page 135) or enter it via the user

menu (see chapter 1.4.6.9, page 81).

6 Remove the upper part of the transmitter, detach the cable connections

for the adjustment of the 3rd analog output and reassemble the

transmitter.

1.3.6.5 High-humidity adjustment for testo 6614

With the testo 6614, the rear of the Testo humidity sensor is heated, creating

a microclimate around the sensor (within the filter) that is constantly 5 K

warmer than the actual process conditions. As can be seen in the Mollier

diagram, this reduces the relative humidity at the sensor from around

100 % RH to a lower value, e.g. 73 % RH. In this range, the reaction time of

the sensor is noticeably shorter than in the condensation range and the risk

of the sensor corroding is also reduced. Using the separate temperature

probe, the testo 6681 transmitter compensates the microclimate conditions

and displays the process readings.

Mollier diagram

After heating

"Microclimate"

sensor conditions

e.g. 73 % RH

100 % RH

High-humidity process

conditions

Mist

Page 64

64

testo 6681 Profibus - 1.3 Commissioning

The reference conditions (11.3 % RH and 75.3 % RH) for the

2-point adjustment of the testo 6614 should be generated in a

humidity generator, as humidity adjustment sets cannot be

used due to the heat generated. The adjustment can also be

carried out at a third adjustment point (90 % RH) by Testo

Service so that optimum accuracy is also achieved in the high

humidity ranges.

1.3.6.6 Self adjustment of testo 6615 trace humidity

probe

Conventional trace humidity probes show a steep rise in measuring

uncertainty at low humidities. In the trace humidity probe of the testo 6615,

these measuring uncertainties are corrected by means of an automatic selfadjustment process. This means that extremely accurate measuring results

are also attained to -60 °Ctd.

To this end, a temperature sensor is fitted on the back of the testo 6615

which is used as a heater. A humidity and temperature value pair is taken in

both the unheated and heated state. The deviation of the probe obtained

from these pairs of values is automatically corrected.

The graph shows the effect of the self-adjustment, e.g. during the Init. phase.

1 Self-adjustment

2 Correction of measurement value

Page 65

testo 6681 Profibus - 1.3 Commissioning

65

3 Process dew point temperature

For the effectiveness of the self-adjustment the following prerequisites are

decisive over the duration of the self-adjustment.

The process temperature should not vary by more than 0.5K

The dew point temperature should remain stable, as far as possible

The process pressure should not vary excessively

If these prerequisites cannot be fulfilled, the values obtained

during the last successful self-adjustment will be maintained.

All adjustment processes are saved in the history of the transmitter, see

Transmitter history page 160.

testo 6615:

Fühler-

verhalten

Analog-

Ausgang

°Ctpd/

°Ftpd

„Zykluszeit Selbstabgleich“

Heizphase

Heizphase

Parameter

„Dauer Heizphase“

The heating time and storing of cycles can be edited in the P2A software; for

example, they can be deactivated by setting the two parameters to "0".

testo 6615:

probe

behaviour

Analog

output °Ctpd/

°Ftpd

Paramete

r

"Duration self-adjustment time"

"Self-adjustment cycle time"

Sel

f

-adjustment time

Page 66

66

testo 6681 Profibus - 1.4 Operation

Important:

Deactivating the adjustment function of the testo 6615

will reduce measuring accuracy and should therefore

be restricted to the shortest possible length of time.

During the heating phase, the relay and analog

outputs, the display value and output value are

"frozen", see diagram above. Self-adjustment active

is shown in the display until it has finished. The factory

setting for the Self-adjustment time (incl. heating time,

calculation time, cooling time) is 30 minutes per day.

The cycle time can be edited via the operating menu or

the P2A software.

In the factory setting, a third adjustment point (-

40 °Ctd) is approached for the testo 6615 in addition to

the 2-point adjustment.

This special adjustment can be performed again by

your Testo Service team if necessary.

1.4 Operation

1.4.1 Relationship between user menu and

mini-DIN socket is active

The testo 6681 can be parameterized using either the user menu or the P2A

software (see volume 2, chapter 2, page 97).

The testo 6681 humidity transmitter can only be operated via

the display and keypad if the display option is available.

If the testo 6681 is connected to the P2A software, the user

menu is blocked for the duration of the communication. The

message Service plug is shown in the display of the

testo 6681. As soon as the P2A software is disconnected, the

user menu is accessible again.

Page 67

testo 6681 Profibus - 1.4 Operation

67

1.4.2 Key cover

To prevent unauthorized operation of the keys, the standard key frame can

be replaced with a key cover.

If the key cover has been assembled, the service flap must be opened for

operation (see Section Opening the instrument, chapter 1.3.3, page 25).

Attaching the key cover

The service flap is open, see Opening the instrument, chapter 1.3.3,

page 25.

1 Undo screws (3) and remove key frame (2).

2 Insert key cover (1) into service flap and tighten screws (3).

3 Close and screw down the service flap.

Page 68

68

testo 6681 Profibus - 1.4 Operation

1.4.3 Password protection

The user menu can be protected with a four-digit numerical code (see Editing

Main Menu Settings, chapter 1.4.6.5, page 75) so that access to the user

menu is denied to unauthorized persons not familiar with this numerical code.

If the password protection is not to be used, the numerical code "0000" must

be entered. This is also the status upon delivery.

Page 69

testo 6681 Profibus - 1.4 Operation

69

1.4.4 Structure of user menu

At the main menu level, the user menu comprises the following:

Main menu of channel 1

Main menu of channel 2

Main menu of channel 3 (if this option is available)

Main Menu Alarm

Editing Settings main menu

Analysis main menu

Main Menu Messages

Ident main menu

Adjustment main menu

Reset main menu

Four keys enable the user to navigate/scroll through the menus and

enter/amend values and settings:

Key Function/description

SET

In Measuring Mode: changes to parameterization

In Parameterizing Mode: confirms a selection or setting

ESC

Leaves a menu (without modifying any settings)

Selecting: scrolls through menus (downwards) or selectable alternatives

Editing: changes to next digit (to the right)

Selecting: scrolls through menus (upwards) or selectable alternatives

Editing: increases the value of the current digit by 1

19.3 °C

57.8 % RH

-4.1 °Ctd

Channel 1 display

Channel 2 display

Channel 3 display or for messages

Page 70

70

testo 6681 Profibus - 1.4 Operation

1.4.5 Overview of the testo 6681 user menu

Page 71

testo 6681 Profibus - 1.4 Operation

71

Page 72

72

testo 6681 Profibus - 1.4 Operation

1.4.6 The individual main menus

1.4.6.1 Editing main menu of channel 1

An overview is given in Overview of the testo 6681 user menu, chapter 1.4.5,

page 70).

You can perform basic settings for channel 1.

1 In Measuring Mode, press SET, select Main Menu Channel 1 using or

and confirm selection with SET.

One of the following parameters can now be selected using or , after

which the selection must be confirmed with SET:

Channel 1 unit

The parameter for this channel is selected.

Selection: % RH, °C, °F, °Ctd, °Ftd, g/m³, gr/ft³, g/kg, gr/lb, kJ/kg,

BTU/lb, °Ctw, °Ftw, "H2O, hPa, ppm

vol

, % Vol, °Ctm, °Ftm.

Edit/select parameter with or , confirm with SET or abort input

with ESC.

Scale minimum for channel 1

The lower scale limit is edited;

Unit as selected above (example: 4 mA = 0 % RH).

Editing the value: Scroll one digit to the right using , increase value

of digit by 1 using . Confirm with SET or abort entry with ESC.

Scale maximum for channel 1

The upper scale limit is edited;

Unit as selected above (example: 20 mA = 100 % RH).

Editing the value: Scroll one digit to the right using , increase value

of digit by 1 using . Confirm with SET or abort entry with ESC.

Signal delay ("Damping") for channel 1

The analog signal can be delayed ("Damping"); a time constant is

selected for this (1 = no delay; 15 = longest delay).

Edit/select parameter using or , confirm with SET or cancel entry

via ESC.

2 Continue to Main Menu Channel 2 using or or return to Measuring

Mode by pressing ESC.

1.4.6.2 Editing main menu of channel 2

See channel 1.

Page 73

testo 6681 Profibus - 1.4 Operation

73

1.4.6.3 Editing main menu of channel 3 (if this option is

available)

See channel 1.

1.4.6.4 Editing Main Menu Alarm

With the alarm, the relays, available as options, are programmed. In addition,

the alarm statuses are shown on the display (top right) (even without relays).

You can choose whether the alarm is to be used to monitor limit values or as

a collective alarm. If an alarm is to be used to monitor limit values, you can

choose between monitoring the minimum or maximum value and set a limit

value and hysteresis for each alarm.

Note:

If the relays are already assigned using the Profibus, these

can no longer be parameterized via the transmitter.

3 In Measuring Mode, press SET, select Main Menu Alarm using or

and confirm selection with SET.

Four alarms can be parameterized.

4 Select Alarm x using or and confirm selection with SET.

Page 74

74

testo 6681 Profibus - 1.4 Operation

Using alarm to monitor limit values

5 Select Channel x (e.g. "Channel 1") using or and confirm selection

with SET.

6 Select Max control or Min control with or (see graphic).

7 Press SET and edit limit value and hysteresis: Scroll one digit to the

right using , increase value of digit by 1 using . Confirm with SET or

abort entry with ESC.

8 Return to Channel x by pressing ESC.

9 Return to Alarm x by pressing ESC.

10 Change to the other relays using or and perform settings in the

same way.

Using alarm as collective alarm or not using it at all

If the collective alarm is assigned to an alarm, the relay is switched as soon

as (at least) one of the warning or error messages of the testo 6681

transmitter (or the connected testo 6610 probe) is activated.

Note:

The messages affecting the collective alarm can only be

selected in the P2A software, see volume 2, chapter 2, page

97.

Alarm is selected (see previous steps 1 and 2).

11 Specify with or whether Alarm x is to be used as the Alarm relay

or is to be not used. Confirm selection with SET and return to Alarm x.

Monitoring minimum Monitoring maximum

Hysteresis Hysteresis

Limit value Limit value

Off

Off

On On

Cannel 2

e.g. °C

NO contact

NC contact

On On

Off

Off

Page 75

testo 6681 Profibus - 1.4 Operation

75

12 Change to another alarm using or and perform settings in the same

way.

13 Continue to Main Menu Settings using or or return to Measuring

Mode by pressing ESC.

1.4.6.5 Editing Main Menu Settings

You can edit instrument settings and other settings.

In Measuring Mode, press SET, select Main Menu Settings using or

and confirm selection with SET.

You can edit settings for:

Display

Language

H

2O2

proportion by weight entry (optional with 3rd analog output)

Unit: %

Absolute pressure unit

Selection: bar, psi, mPa, hPa

Absolute pressure

Unit as selected above.

Code

Editing display settings

You can set the brightness and contrast of the display.

1 Select Display Settings using or and confirm selection with SET.

2 Select Backlight or Contrast using or and confirm selection with

SET.

One of the following parameters can now be selected using or , after

which the selection must be confirmed with SET:

Backlight

The display illumination is changed.

Edit/select parameter with or , confirm with SET or cancel entry

with ESC (the effect of the change in parameter can be seen during

input).

Contrast

The brightness difference between the display background and the

displayed values is changed.

Page 76

76

testo 6681 Profibus - 1.4 Operation

Edit/select parameter with or , confirm with SET or cancel entry

with ESC (the effect of the change in parameter can be seen during

input).

Backlight on 24 h

Using or select On or Off and confirm with SET.

Off: The display light switches off automatically if no button was

pressed for 30 seconds.

On: The display light is activated

3 Go back to Display Settings by pressing ESC and continue to

Language using or .

Selecting language

You can select the language for the plain text line in the display.

Press SET, select required language with or , confirm selection with

SET and return to Language.

Only choose a language that you can understand well.

Editing H

2O2

proportion by weight (optional with 3rd analog output)

This menu is only used to parameterize humidity measurements in H

2O2

atmospheres (e.g. in sterilization processes) and determines whether °Ctm or

°Ftm is the output parameter.

This menu is only used to parameterize humidity measurements in H

2O2

atmospheres (e.g. in sterilization processes) and determines whether

°Ctm,°Ftm or %rFm is the output parameter.

4 Select H

2O2

Weight Proportion using or and confirm selection with

SET.

The selection H

2O2

passively vaporized or H2O2 actively vaporized

in the submenu describes whether H

2O2

is created through

evaporation or is actively evaporated in the process.

5 Select H

2O2

passively vaporized or H2O2 actively vaporized using

or and confirm with SET.

6 Editing proportion by weight of H

2O2

in % (% H2O2 proportion by weight

in the liquid end solution): Scroll one digit to the right using , increase

value of digit by 1 using . Confirm with SET or abort entry with ESC.

Page 77

testo 6681 Profibus - 1.4 Operation

77

7 Using ESC return to H2O2 proportion by weight and continue to

Absolute pressure unit using or .

Selecting absolute pressure unit (Abs. pressure unit)

This parameter determines the humidity variables, standardised atmospheric

dewpoint (°CtA, °FtA), relative humidity (g/kg or gr/lb) and water content

(ppm

vol

or % vol).

1 Press SET, select desired unit (selection: bar, psi, mPa, hPa) using or

confirm selection with SET or cancel with ESC.

2 Continue to Absolute Pressure with or .

Editing absolute pressure (Abs. pressure value)

You can set a value for the process absolute pressure.

1 Using or , select Abs. pressure value and confirm selection with

SET.

The absolute pressure is displayed.

2 Scroll one digit to the right using , increase value of digit by 1 using .

Confirm with SET or abort entry with ESC.

3 Press SET and return to Abs. pressure value.

4 Return to Main Menu Settings by pressing ESC.

5 Continue to Main Menu Analysis using or or return to Measuring

Mode by pressing ESC.

Editing code settings

You can set the access code (password).

If a code other than "0000" (factory setting) is set, the

transmitter can only be operated once this code has been

entered via the menu.

1 Select Code using or and confirm selection with SET.

2 Scroll one digit to the right using , increase value of digit by 1 using .

Confirm with SET or abort entry with ESC.

3 Return to Code by pressing ESC.

Page 78

78

testo 6681 Profibus - 1.4 Operation

1.4.6.6 Editing Analysis main menu

You can test the functionality of analog and relay outputs. In addition, you

can read off the minimum and maximum values (since the last voltage supply

or reset of the min./max. values).

Testing functionality of analog outputs

This function affects the analog outputs directly, not only the

test contacts.