Page 1

testo 6681 · Humidity transmitters

testo 6610 · Probes

P2A software · Parameterizing, adjusting and analyzing

software

Instruction manual en

Page 2

2

Safety and the environment

Safety and the environment

Avoiding electrical hazards

► Never use the instrument and connected probes to measure on or near

live parts!

► Damaged mains cables must only be replaced by authorized personnel.

► Only have the transmitter wired and connected by authorized personnel

with the voltage disconnected.

► You must always comply with the regulations applicable in your country

to the opening and repair of electrical equipment.

Avoiding personal injury/damage to equipment

► Installation, setting and calibration work must only be carried out by

qualified and authorized personnel!

► Only open the instrument when this is expressly described in the

instruction manual for installation, maintenance or repair purp oses.

► Observe the permissible storage, transport and operating temperatures.

► Never store or operate the product with solvents and do not use any

desiccants.

► Do not use the instrument for control purposes at the same time as

operating or servicing the transmitter.

► Only operate the product properly, for its intended purpose and within the

parameters specified in the technical data. Do not use force.

► Carry out only the maintenance and repair work that is described in the

documentation. Follow the prescribed steps when doing so. Use only

OEM spare parts from Testo.

Any additional work must only be carried out by authorized personnel.

Otherwise Testo will not accept any responsibility for the proper functioning of

the instrument after repair and for the validity of certifications.

Protecting the environment

► Send the product back to Testo at the end of its useful life. We will

ensure that it is disposed of in an environmentally friendly manner.

Page 3

About this document

About this document

► Please read this documentation through carefully and familiarize yourself

with the product before putting it to use. Keep this document to hand so

that you can refer to it when necessary. Hand this documentation on to

any subsequent users of the product.

► The following conventions are followed in this document:

Character/

display:

Explanation/example

With the signal word Warning!:

Warns against hazards which could result in serious physical

injury if the precautionary measures indicated are not taken,

e.g.:

De-energize the mains connection before connecting the

transmitter!

With the signal word Caution!:

3

Warns against hazards which could result in minor physical

injury or damage to equipment if the precautionary

measures indicated are not taken, e.g.:

Observe the permissible operating temperature!

Important information, e.g.:

Administrator rights are required to install the program under

Windows

®

2000, XP and Vista.

Aim of action, e.g.:

Assembling the instrument at the process

connection:

Requirement that must be met, e.g.:

USB drivers are installed.

Page 4

4

About this document

1

Steps are numbered if a certain sequence of actions must

be followed, e.g.:

1 Loosen and remove housing screws.

2 Remove the upper part of housing.

" to "

Bold type

…>…

[ ]

CAPITAL

LETTERS

A step is not numbered if there are no further steps or if the

step is optional, e.g.:

▪ Insert probe connector into socket of testo 6681 until

it engages.

Example entries are in inverted commas, e.g.:

The value "0" results in ....

Elements of the program interface or instrument display,

e.g.:

The instrument designation appears in the

instrument/parameter file list.

Select Main Menu Channel 1 and confirm with SET.

Functions/paths within a menu, e.g.:

Start > All Programmes > Testo > Transmitter Software.

Buttons which start an action, e.g.:

Confirm the software key with [OK].

Keys on the instrument or keypad, e.g.:

Press ESC.

Page 5

Contents

Contents

1 TRANSMITTER............................................................................................8

1.1 Specifications...........................................................................................8

1.1.1 Functions and use.......................................................................8

1.1.2 Scope of delivery.........................................................................8

1.1.3 Accessories.................................................................................9

1.1.4 Technical Data............................................................................9

1.1.5 Dimensions ...............................................................................10

1.2 Product description................................................................................11

1.2.1 At a glance................................................................................11

1.2.2 Usable probes...........................................................................12

1.2.3 Display and keypad...................................................................12

1.2.4 Service interface .......................................................................12

1.2.5 Relay board (option)..................................................................13

1.2.6 analog outputs...........................................................................13

1.2.7 Parameters................................................................................13

1.2.8 Scaling ......................................................................................14

1.2.9 Alarm handling..........................................................................17

1.3 Commissioning......................................................................................18

1.3.1 Assembling the instrument........................................................18

1.3.2 Connecting the instrument........................................................21

1.3.3 Adjusting the instrument............................................................33

1.4 Operation...............................................................................................42

1.4.1 Relationship between user menu and mini-DIN socket

is active.....................................................................................42

1.4.2 Key cover ..................................................................................42

1.4.3 Password protection..................................................................44

1.4.4 Structure of user menu..............................................................44

1.4.5 Ov e r v i e w o f t h e t e s t o 6 6 8 1 u s e r m e n u............................................46

1.4.6 The individual main menus .......................................................48

1.5 Status, warning and error messages.....................................................60

1.5.1 Status messages.......................................................................60

1.5.2 Warning messages ...................................................................61

1.5.3 Error messages.........................................................................63

1.5.4 Handling alarm messages ........................................................64

1.5.5 Namur fault conditions ..............................................................66

1.6 Maintenance and cleaning.....................................................................67

1.6.1 Maintaining the instrument........................................................67

1.6.2 Cleaning the instrument............................................................67

5

Page 6

6

Contents

2 TESTO 6610 PROBES...............................................................................68

2.1 Specifications.........................................................................................68

2.1.1 Functions and use.....................................................................68

2.1.2 Design of the probe...................................................................70

2.1.3 Accessories...............................................................................71

2.2 Product description................................................................................71

2.2.1 Overview of probe and filter types ............................................71

2.2.2 testo 6611 wall probe................................................................76

2.2.3 testo 6612 duct probe...............................................................79

2.2.4 testo 6613 cable probe .............................................................83

2.2.5 testo 6615 trace humidity cable probe (self-adjustment)..........90

testo 6617 cable probe (self-monitoring)...............................................94

2.2.6 testo 6622 duct probe...............................................................98

2.2.7 testo 6623 cable probe ...........................................................101

2.3 Commissioning....................................................................................104

2.3.1 Installing the probe..................................................................104

2.3.2 Connecting/removingthe probe to/from the transmitter ..........108

2.4 Maintenance and cleaning...................................................................109

2.4.1 Replacing filters/protection caps.............................................109

2.4.2 Cleaning the instrument and filter/protection cap ...................112

2.4.3 Replacing the sensor ..............................................................112

3 PARAMETERIZING, AD JUSTING AND ANALYZI NG SOFT WARE

SOFTWARE)..................................................................................113

(P2A

3.1 Specifications.......................................................................................113

3.1.1 Functions and use...................................................................113

3.1.2 System requirements..............................................................114

3.1.3 Scope of delivery ....................................................................114

3.2 First steps............................................................................................115

3.2.1 Installing the software/driver...................................................115

3.2.2 Starting the software...............................................................116

3.3 Using the software...............................................................................117

3.3.1 User interface..........................................................................117

3.3.2 Editing instrument/parameter file............................................119

3.3.3 Analyzing/testing the transmitter.............................................128

3.3.4 Adjusting the transmitter.........................................................134

3.3.5 Transmitter history ..................................................................139

Page 7

Contents

4 TIPS AND ASSISTANCE............................................................................145

4.1 Questions and answers.......................................................................145

4.2 Accessories and spare parts...............................................................146

4.2.1 Ordering options for testo 6681 transmitter (0555 6681)..................148

4.2.2 Ordering options for testo 6610 probes (0555 6610)......................152

7

Page 8

8

testo 6681 - 1.1 Specifications

1 Transmitter

1.1 Specifications

1.1.1 Functions and use

The testo 6681 humidity transmitter is used in conjunction with plug-in,

adjusted probes from the testo 6610 range.

Please refer to Chapter 2 testo 6610 probes for information

about commissioning, operating and maintaining the

The testo 6681 humidity transmitter is suitable for the following applications,

for example:

• Process instrumentation

• Clean rooms

• Test benches

• Drying processes

• Production and storage air quality

• Complex room climate applications.

testo 6610 probe.

1.1.2 Scope of delivery

The scope of delivery of the testo 6681 humidity transmitter includes the

following:

• Key cover

• Rear panel bracket

• CD-ROM with catalogue files (PDF) and P2A update (this can onl y be

used in conjunction with the P2A software, which has to be ordered

separately).

Page 9

testo 6681 - 1.1 Specifications

1.1.3 Accessories

The following accessories are available for the testo 6681 humidity

transmitter:

• Protection caps for probes

• Mains unit

• P2A software (parameterizing, adjusting and analyzing software)

• Assembly accessories.

Information about accessories and their order numbers can

be found in Chapter 4.2 Accessories and spare parts or on

the website at www.testo.com.

1.1.4 Technical Data

9

Parameters

- Humidity (various variables and

units)

- Temperature (°C/°F)

Measuring range

- Depends on probe

Accuracy

- Depends on probe

Resolution

- 0.1 % RH or 0.1 °C/0.1 °F

Meas. cycle

- 1/s

Interface

- Mini-DIN for P2A software

(parameterizing and adjusting

software) and handheld testo

400/650

- optional: Profibus-DP module

Voltage supply

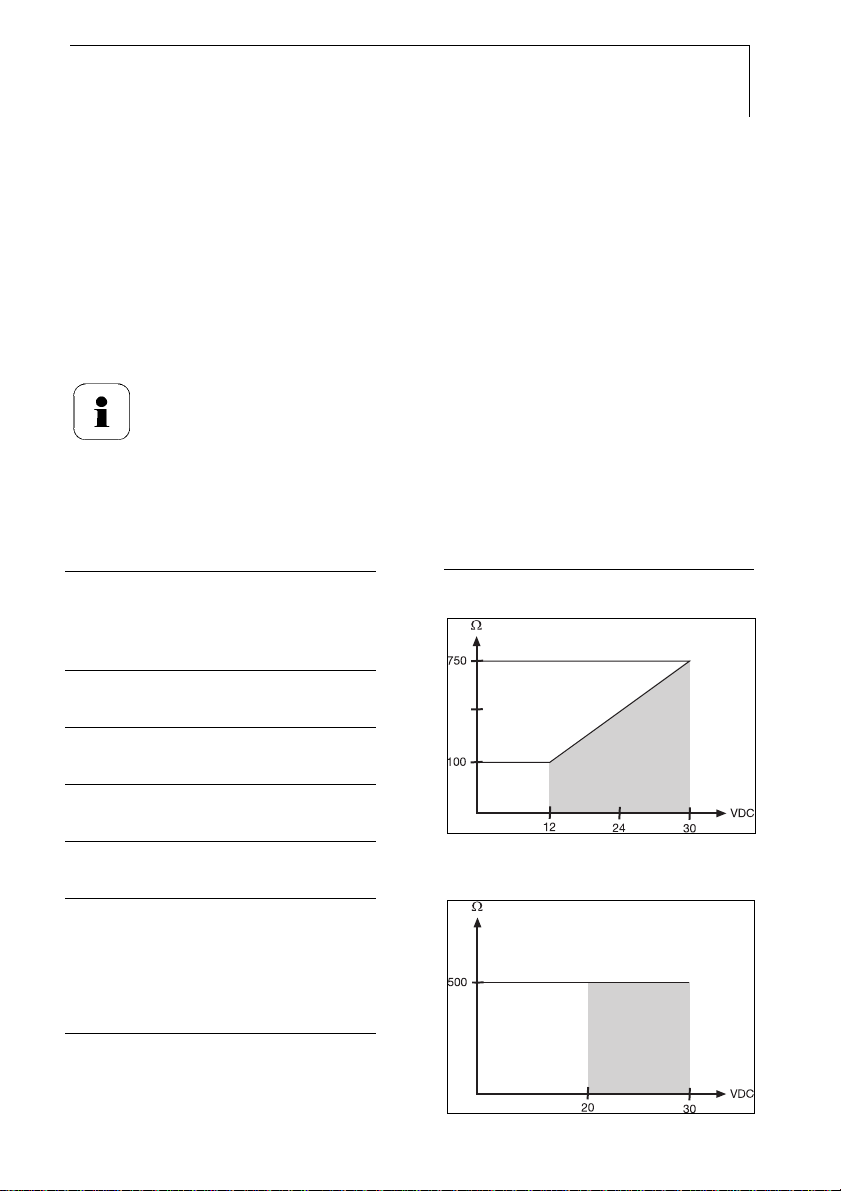

- 2-wire: 12 to 30 V DC

- 4-wire (separate signal and supply

lines):

20 - 30 V AC/DC,

300 mA power consumption

Maximum load

- 2-wire: 100 to 750 Ω

- 4-wire: 500 Ω (power output)

Page 10

10

testo 6681 - 1.1 Specifications

Analog output

- 4 to 20 mA ± 0.03 mA (2-wire) or

- 0 to 1 V ± 1.5 mV (4-wire) or

- 0 to 5 V ± 7.5 mV (4-wire) or

- 0 to 10 V ± 15 mV (4-wire) or

- 0 to 20 mA ± 0.03 mA (4-wire) or

- 4 to 20 mA ± 0.03 mA (4-wire)

Resolution of analog output

- 12 bit

Relay

- 4 relays, 250 V AC/DC, 3 A

(optional)

Display

- 2-line LCD with plain text line

(optional)

Housing operating temperature

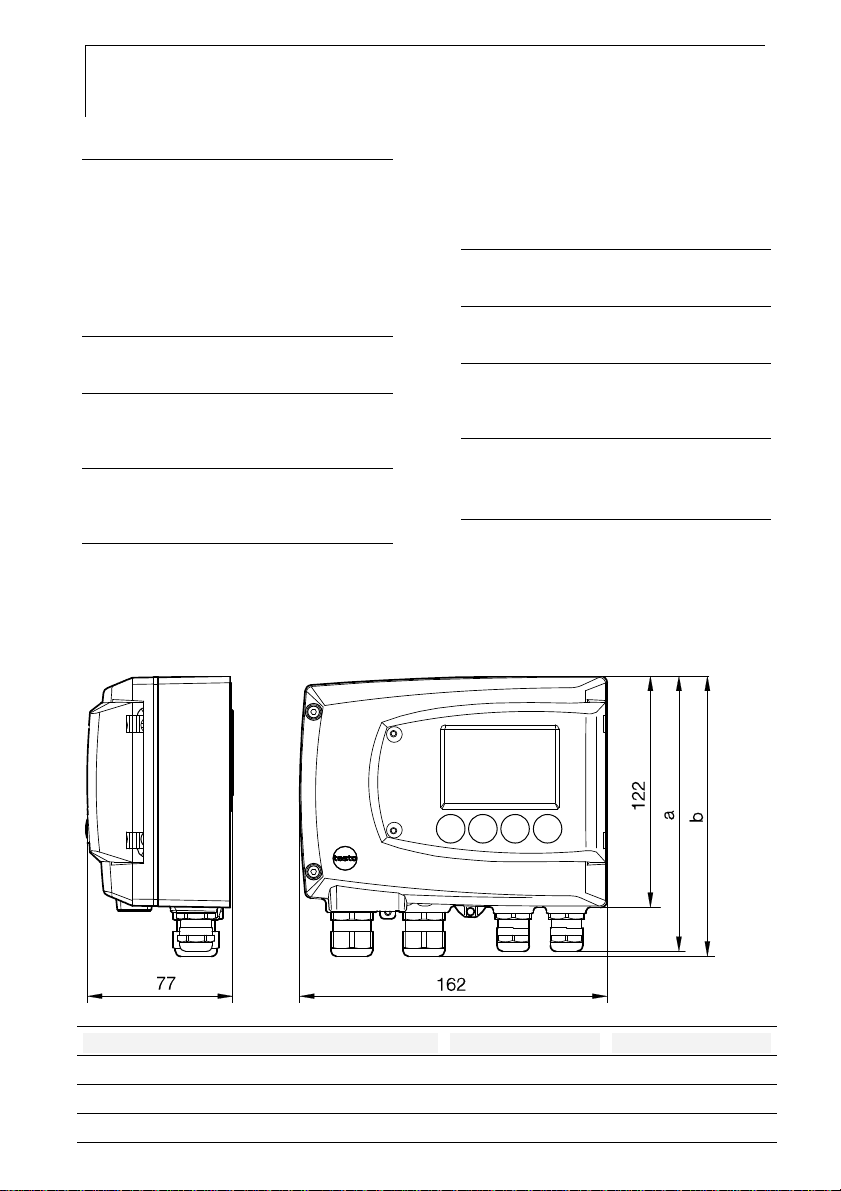

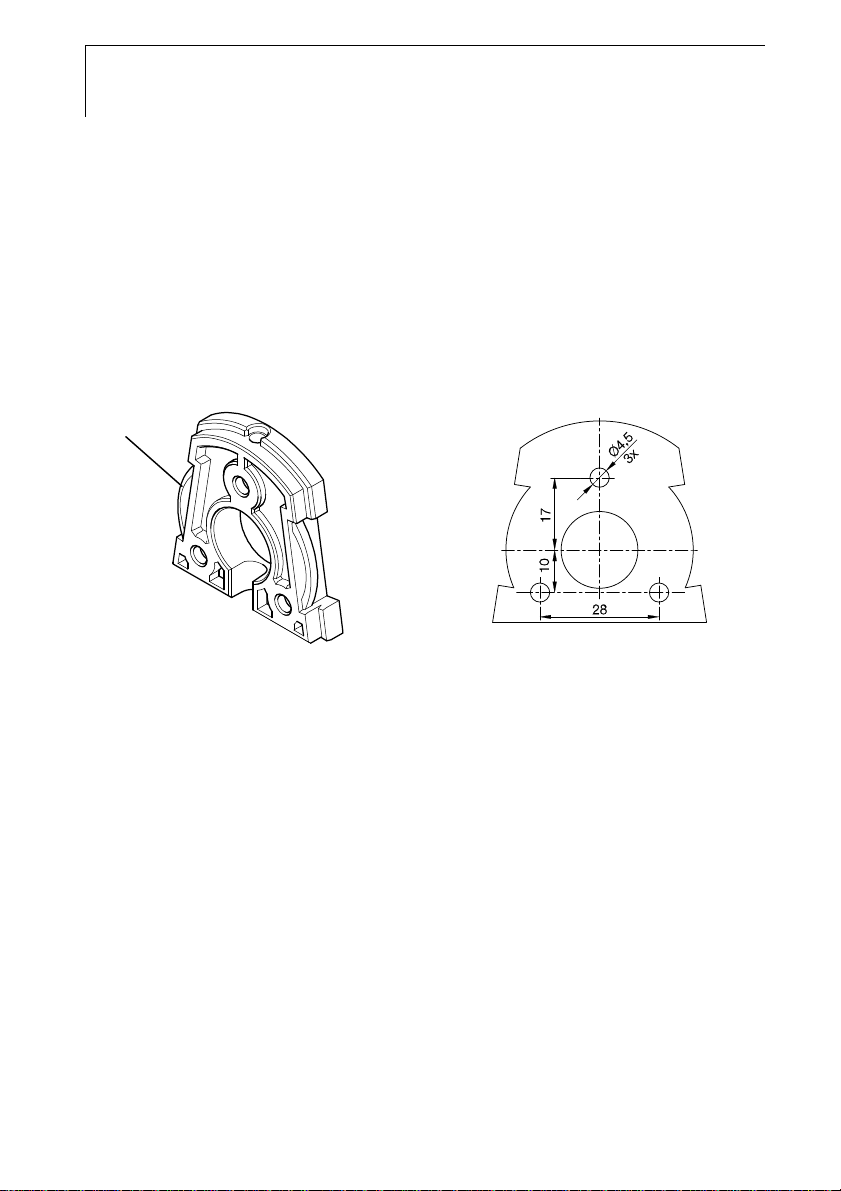

1.1.5 Dimensions

- -40 to 70 °C/-40 to +158 °F, with

display from 0 - 50 °C/+32 to

+122 °F

- With integrated relay: -40 to +60°C

Storage temperature

- - 40 to 80 °C/-40 to +176 °F

Housing, weight

- Metal, 1.960 kg/432 lb

Protection class

- IP 65 only if the transmitter is wired

and/or seal plugs are inserted

Directives, standards and tests

- EC Directive: 2004/108/EC

- EN 61326

Warranty

- Duration: 2 years

- Warranty conditions: See

guarantee card

Dimensions in mm a b

With M 20 cable couplings 144 147

With NPT cable couplings 144 144

With plug-in connections 143

Page 11

testo 6681 - 1.2 Product description

1.2 Product description

1.2.1 At a glance

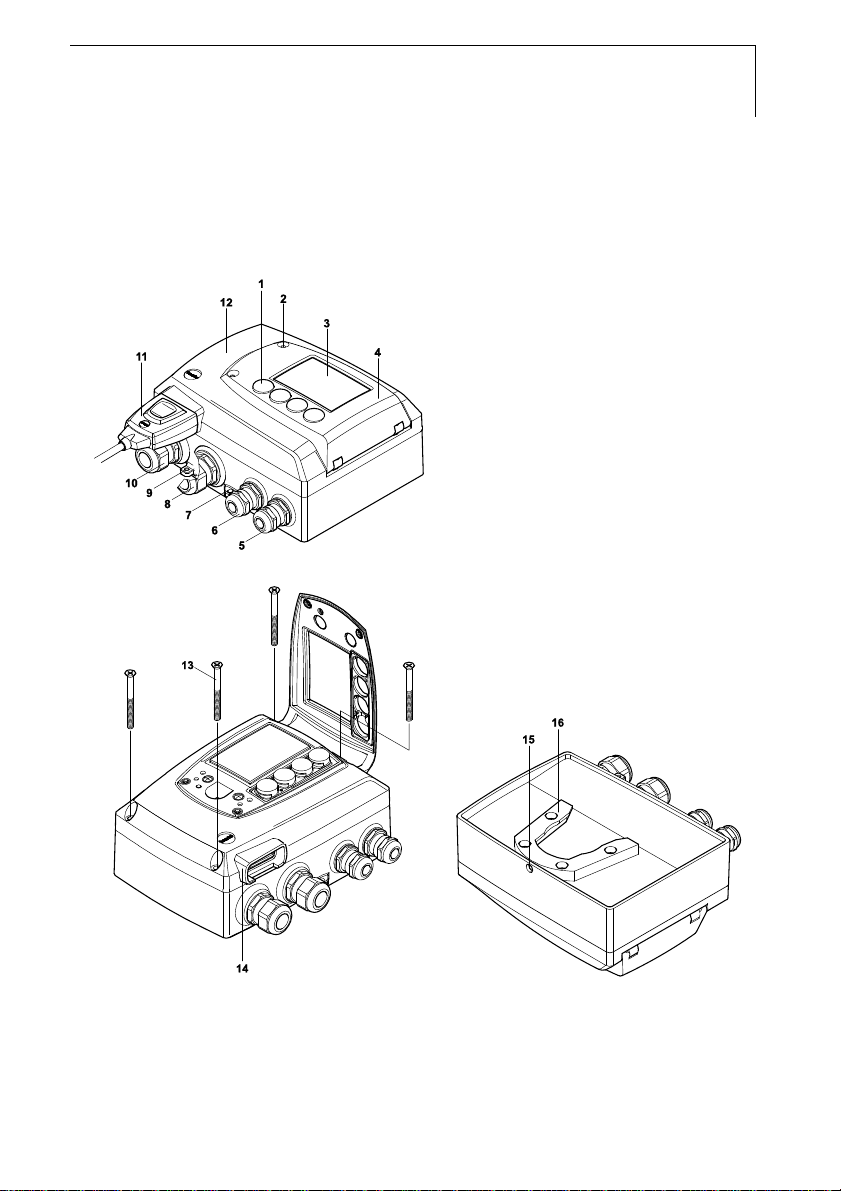

1 Keys (only with optional display)

2 Service flap screw connection

(self-locking, 2x)

3 Display (optional)

4 Service flap

5 M 16 x 1.5 screw connection*,

e.g. analog outputs

6 M 16 x 1.5 screw connection*,

e.g. voltage supply

7 Earthing/PE connection

8 M 20 x 1.5 screw connection*,

e.g. relay R 3 and R 4

9 Eyelet for measuring point panel

10 M 20 x 1.5 screw connection*,

e.g. relay R 1 and R 2

11 Probe connector (testo 6610)

12 Upper part of housing

* Alternatively, NPT cable

couplings or M plug-in

connections are available

11

13 Housing screws

14 Socket for probe connector

15 Hole for fastening to rear panel

bracket (M3 x 6 screw)

16 Plastic bracket for assembly on

rear panel

Page 12

12

testo 6681 - 1.2 Product description

1.2.2 Usable probes

The testo 6681 humidity transmitter can be used with the following probes:

probe Article no. Characteristic

testo 6611 0555 6610-L11 Wall probe version; accuracy to ± 1 % RH;

testo 6612 0555 6610-L12 Duct probe version; accuracy to ± 1 % RH;

testo 6613 0555 6610-L13 Cable probe version; accuracy to ± 1 % RH;

testo 6614 0555 6610-L14 Heated cable probe version; accuracy to

testo 6615 0555 6610-L15 Trace humidity cable probe version;

testo 6617 0555 6610-L17 Cable with cover electrode monitoring probe

testo 6622 0555 6610-L22 Duct probe version; accuracy to ± 1 % RH;

testo 6623 0555 6610-L23 Cable probe version; accuracy to ± 1 % RH;

temperature range -20 °C to +70 °C/-4 to +158 °F

temperature range -30 °C to +150 °C/-22 to +302 °F

temperature range -40 °C to +180 °C/-40 to +356 °F

± 1.0 % RH; temperature range -40 °C to +180 °C/

-40 to +356 °F

accuracy ± 6 K at -60 °Ctd;

temperature range -40 °C to +120 °C/-40 to +248 °F

version; temperature range -40 °C to +180 °C/-40

to +356 °F

temperature range -30 °C to 120 °C/-22 to +248 °F

temperature range -30 °C to +120 °C/-22 to +248 °F

1.2.3 Display and keypad

The display option allows the testo 6681 humidity transmitter to be operated

via the display and four keys.

The LCD display consists of two 7-segment lines for displaying readings and

units and of an information line (for status messages, for example).

The brightness and contrast of the display and the background lighting

(permanent or off) can be changed via the user menu or the P2A software.

1.2.4 Service interface

Behind the service flap is the parameterizing socket (mini-DIN) as an

interface to the P2A software or Testo handheld instrument

(testo 400/testo 650).

Page 13

testo 6681 - 1.2 Product description

1.2.5 Relay board (option)

This has a floating switch capacity of 250 V AC/3 A. The switching limits and

hysteresis as well as the function as relay for the collective alarm can be set

via the display or the P2A software. Further features include:

• Function of changeover contacts (NC/NO contacts) freely selectable

• 12 terminals for a total of 4 relays.

If no relays are available, settings for monitoring limit values

or alarms can still be controlled via the display. The alarm

status will be shown on the display

Only have the transmitter wired and connected by authorized

personnel with the voltage disconnected.

1.2.6 Analog outputs

For analog outputs, the testo 6681 has either

13

• 2 or optionally 3 current outputs of 4 to 20 mA (2-wire)/0 to 20 mA (4-

wire)/4 to 20 mA (4-wire) or

• 2 or optionally 3 voltage outputs of 0 to 1 V/0 to 5 V/0 to 10 V (4-wire).

The transmitter can be ordered with a third analog output as an option.

In 2-wire operation, channel 1 is used for the supply. The two or optionally

three channels are galvanically isolated in both 2- and 4-wire operation.

Operation with the testo 6614 heated probe, the testo 6615

trace humidity probe, the relay and profibus options or with

the background lighting of the optional display are only

possible in 4-wire operation.

1.2.7 Parameters

The following parameters are displayed:

• Relative humidity in %RH (technical)

• Relative humidity in % WMO* (calculation according to the WMO

standard)

Page 14

14

testo 6681 - 1.2 Product description

• Temperature °C and °F

• Dewpoint or pressure dewpoint in °Ctd and °Ftd

• Absolute humidity in g/m³ and gr/ft³

• Degree of humidity in g/kg and gr/lb

• Enthalpy in kJ/kg and BTU/lb

• Psychrometer temperature in °Ctw and °Ftw

• Water vapour partial pressure in hPa and "H

• Water content in ppm

• Dewpoint of H

2O2

and % vol

vol

mixture in °Ctm and °Ftm.

* It is possible that condensation appears as of a displayed humidity

starting from 70 % and is shown on the display.

Calculated humidity variables correspond to the medium of

air. With other gases/gas compositions, deviations may

occur, e.g. with the enthalpy

1.2.8 Scaling

There are three types of min./max. values:

O

2

1 The measuring range

The maximum sensor performance is in this range. Values outside of

the measuring range are displayed via messages, for example.

Measuring range, see table (below).

2 Standard scaling

The output signals are assigned to this measuring range as standard:

- during delivery if no entries are made in the order code

- after exchanging the unit, the measuring range recorded in the

instrument is applied as standard.

The transmitter even retains its scaling with the voltage

disconnected.

Measuring range, see table (below).

3 The maximum settings for the manual scaling

- the values are not expressly given in the table. The maximum limits

can be calculated as follows:

Page 15

testo 6681 - 1.2 Product description

X = difference between MIN. and MAX. value of the standard scaling

(Max. value of standard) + (50 % of X)

(Min. value of standard) - (50 % of X)

- It is thus possible to scale beyond the measuring range, e.g. for the

adjustment of the scaling limits to standard values of a PLC.

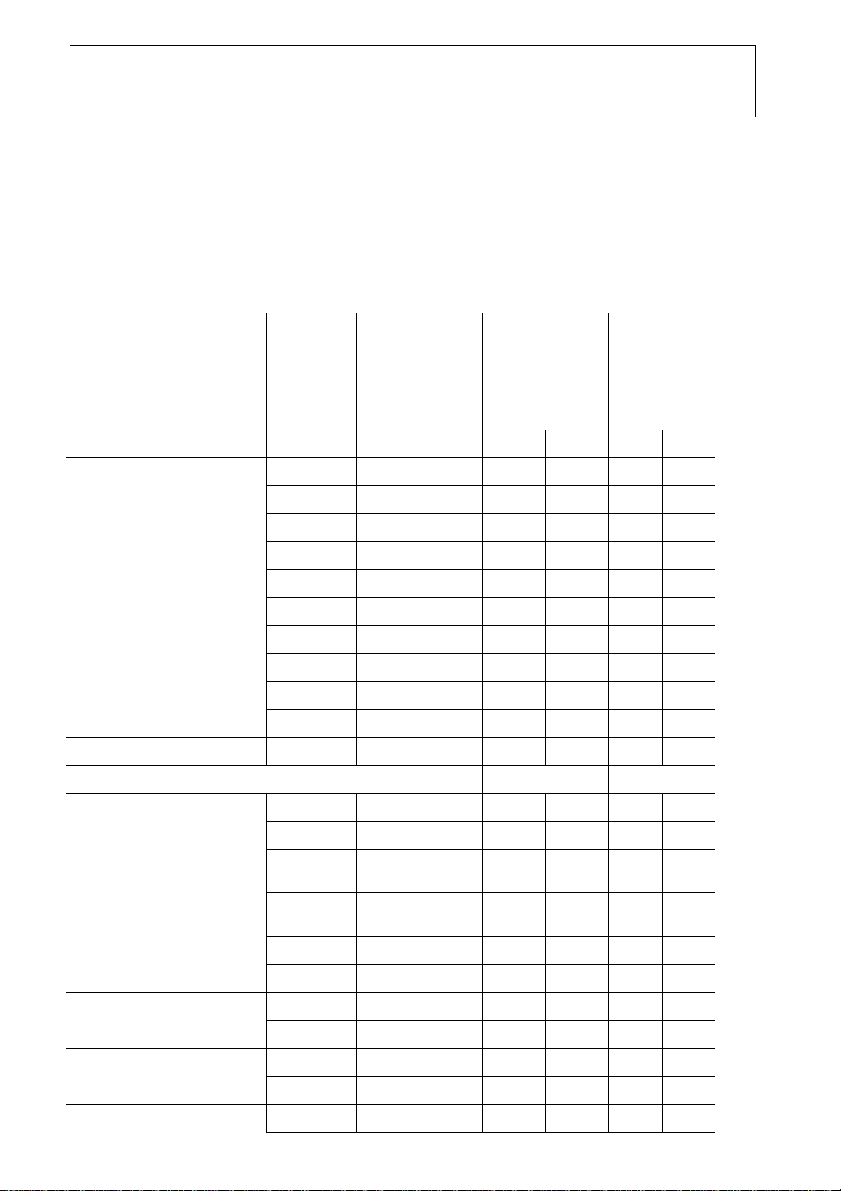

Standard

Measuring

range

Physical

Parameter Unit probe

Temperature °C 6611 -20 +70 -20 +70

°F 6611 -4 +158 -4 +158

°C 6612 -30 +150 -30 +150

°F 6612 -22 +302 -22 +302

°C 6613, 6614, 6617 -40 +180 -40 +180

°F 6613, 6614, 6617 -40 +356 -40 +390

°C 6615 -40 +120 -40 +120

°F 6615 -40 +248 -40 +248

°C 6622, 6623 -30 +120 -30 +120

°F 6622, 6623 -22 +248 -22 +248

relative humidity % RH 0 +100 0 +100

WMO relative humidity % RH, 0 +100 0 +100

Dewpoint/pressure dewpoint °Ctd 6611 -80 +70 -80 +100

°Ftd 6611 -112 +158 -112 +212

°Ctd 6615 -60 +30 -80 +100

°Ftd 6615 -148 +212 -112 +212

Mixture dewpoint (H2O2) °Ctm -20 +100 -20 +100

°Ftm -4 +212 -4 +212

Absolute humidity g/m3 all probes 0 600 0 2000

gr/ft3 0 250 0 800

Degree of humidity g/kg all probes 0 13300 0 950 0

°Ctd

°Ftd

6612, 6613, 6614,

6617, 6622, 6623

6612, 6613, 6614,

6617, 6622, 6623

at 1013 hPa

MIN MAX MIN MAX

-20 +100 -80 +100

-112 +212 -112 +212

scaling

MUF

measuring

range

15

Page 16

16

testo 6681 - 1.2 Product description

Standard

Measuring

range

Physical

Parameter Unit probe

gr/lb 0 93000 0 66500

Enthalpy kJ/kg -40 99999 -40 8000

BTU/lb -18 43000 -18 3500

Psychrometer temperature °Ctw -40 100 -40 180

°Ftw -58 210 -40 356

Water content ppm vol H2O 0 99999 0 99999

% vol 0 100 0 100

Water vapour partial pressure hPa 0 1000 0 7000

inchH2O 0 400 0 2800

at 1013 hPa

MIN MAX MIN MAX

scaling

MUF

measuring

range

Page 17

testo 6681 - 1.2 Product description

1.2.9 Alarm handling

For upper and lower alarm limits, individual alarms as well as collective

alarms can be specified. If the collective alarm function is activated, an alarm

is triggered as soon as the alarm limit of an alarm is exceeded, if this alarm is

assigned to the collective alarm.

The testo 6681 monitors limit values using relays. If a reading is outside the

limit values, a relay to be specified by the user is switched.

If the reading reverts to more than a specified hysteresis below or above the

limit value, the alarm is cancelled.

In addition, information about the occurrence of error/status messages can

be provided by means of a collective alarm relay, see Chapter 1.5 Status,

warning and error messages.

If multiple alarm messages are activated at the same time,

the last alarm is shown. If the alarm is cancelled again, the

previous messages are no longer shown.

Example:

17

If the condensation of the probe begins, the "Condensation"

message appears on the display and the "Start" status

display. If the condensation is over, the status display

changes from "Start" to "End".

Page 18

18

testo 6681 - 1.3 Commissioning

1.3 Commissioning

1.3.1 Assembling the instrument

1.3.1.1 Wall mounting

(for testo 6611/6613/6614/6615/6617/6622/6623

probes)

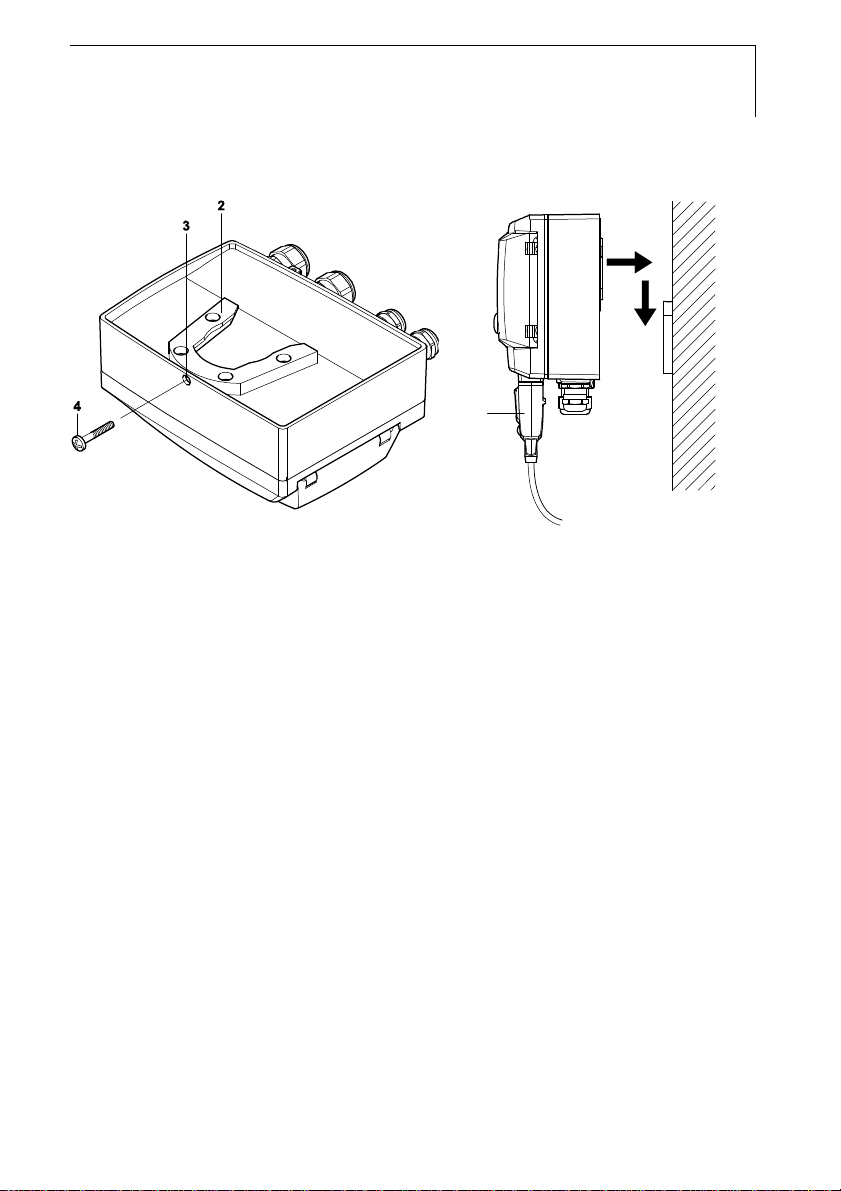

Attaching rear panel bracket

1

1 Remove locking screw (item (4) of drawing below) and detach rear

panel bracket from plastic bracket (item (2) of drawing below).

2 Hold rear panel bracket in assembly position and mark the three drill

holes.

3 Drill three holes (∅ 5 mm) and insert dowels where necessary.

4 Screw on rear panel bracket.

Remember that the clamping brackets (1)must face the wall.

Page 19

testo 6681 - 1.3 Commissioning

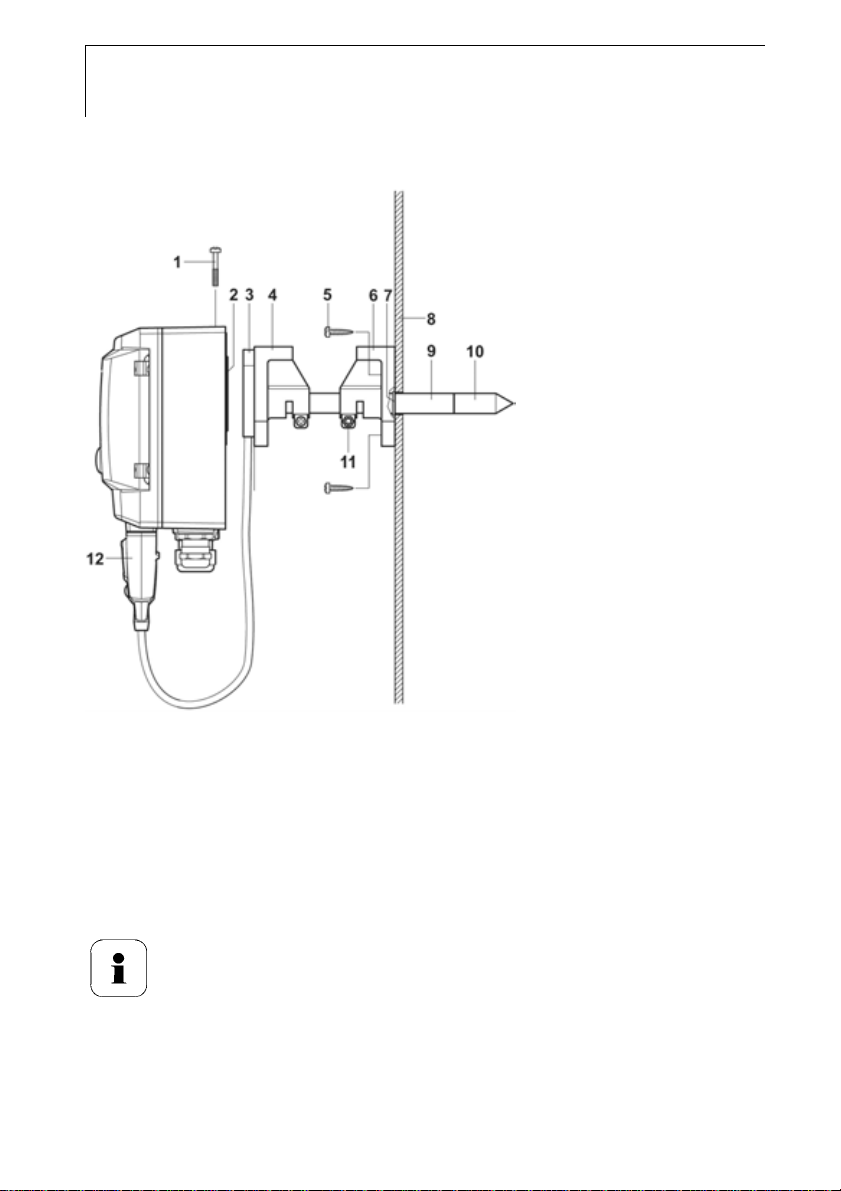

Fastening instrument to rear panel bracket

5

1 Slide plastic bracket (2) on the back of instrument onto rear panel

bracket until it engages (see arrows).

2 Insert screw (4) through hole (3) and screw into rear panel bracket.

3 Insert probe connector (5) into socket until it engages.

19

Page 20

20

testo 6681 - 1.3 Commissioning

1.3.1.2 Duct mounting (for testo 6612 probes)

1 Hold wall/duct bracket (order no. 0554 6651) (6) against duct wall (8)

and mark drill holes for wall/duct bracket and probe shaft.

2 Drill a hole (∅ 12.5 mm) in the duct wall to feed through the probe

shaft.

3 Fasten wall/duct bracket (6) to duct wall with screws (5).

4 Push probe shaft (9) with filter (10) through the middle hole of the

mounting bracket.

The wall/duct bracket (6) has an O-ring (7) to seal it against

the duct. Feed the probe shaft (9) carefully through the

wall/duct bracket so that the O-ring is not damaged.

5 Fix the correct position of the probe shaft (9) with screw (11) and mark

(insert probe shaft as far as possible).

6 Slide plastic bracket (2) on the back of the transmitter onto bracket (3,

4) until it engages.

Page 21

testo 6681 - 1.3 Commissioning

Take the weight of the transmitter into account. Ensure that

the brackets (4, 6) are fastened securely.

7 Insert screw (1) through the hole on the top of the instrument and

screw into bracket (3).

8 Insert probe connector (12) into socket until it engages.

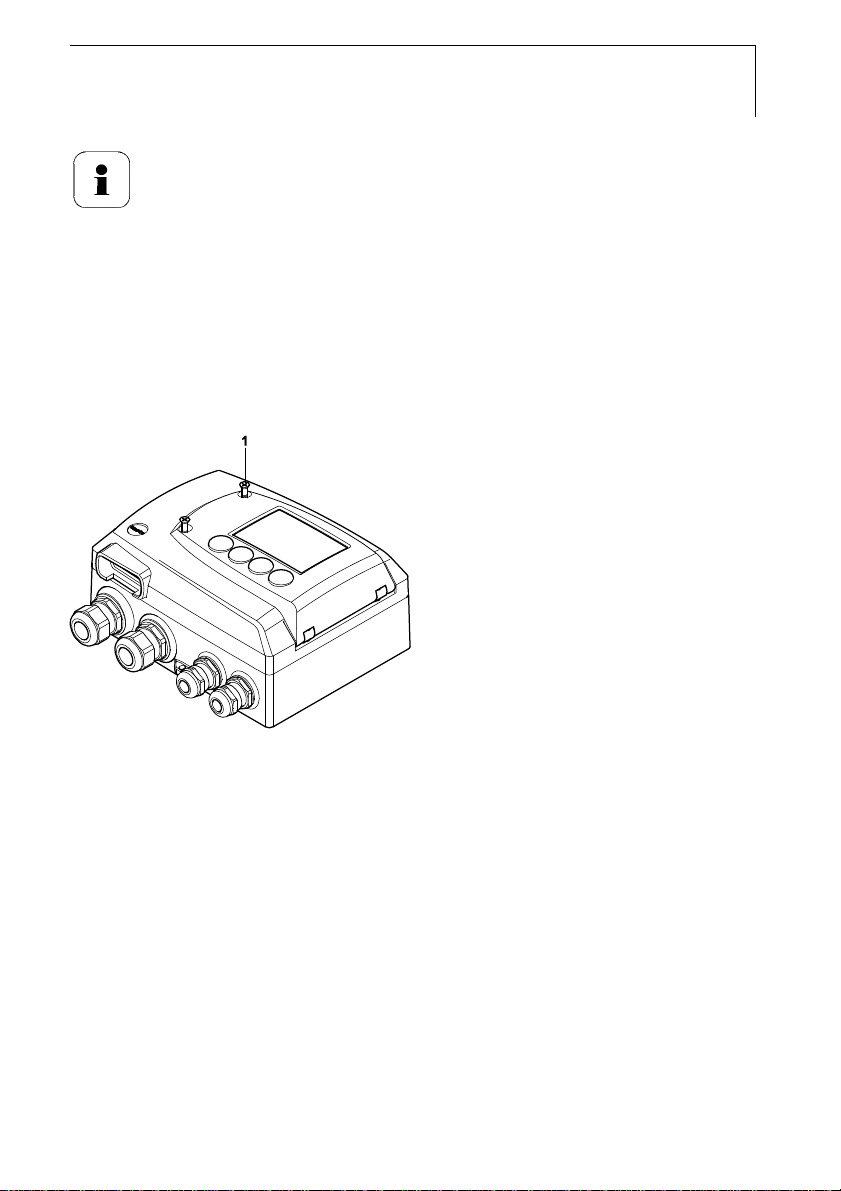

1.3.2 Connecting the instrument

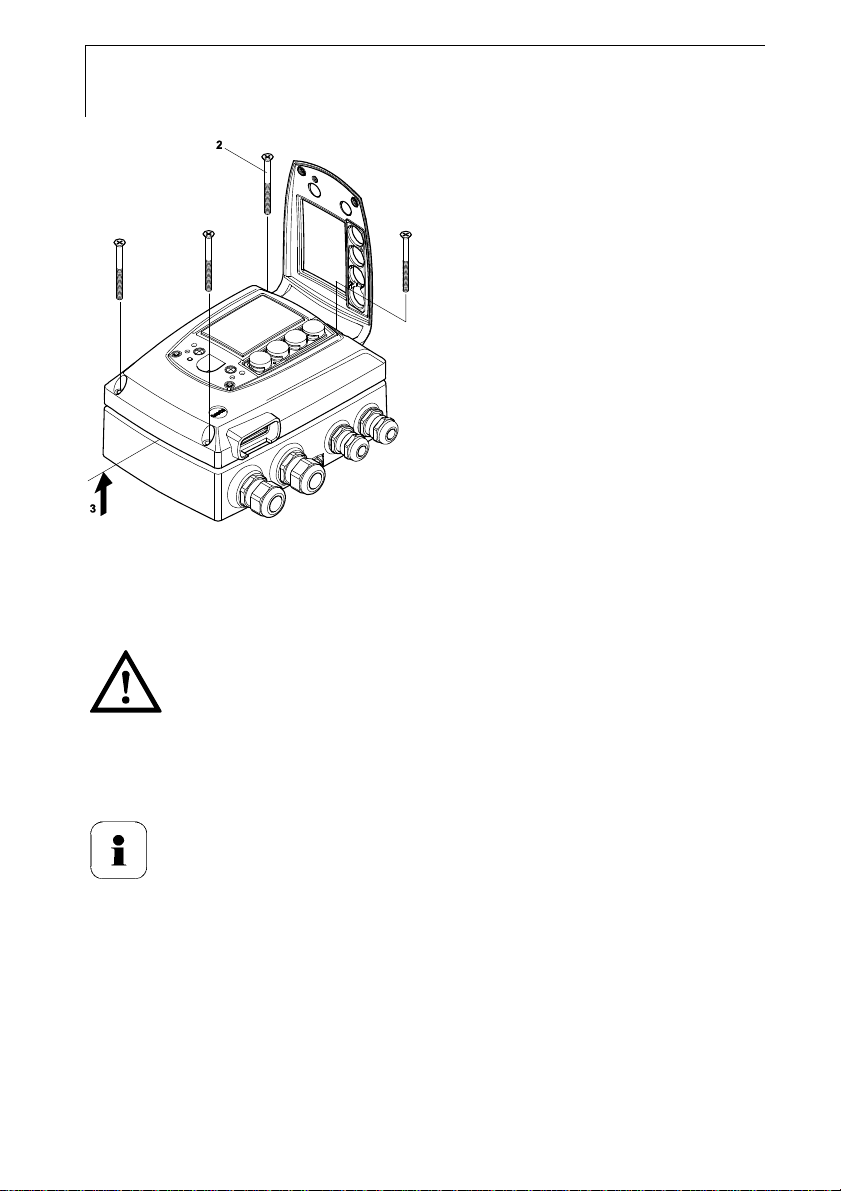

Opening the instrument

21

1 Loosen screw connection (1) of service flap and open the flap.

Page 22

22

testo 6681 - 1.3 Commissioning

2 Loosen and remove housing screws (2).

3 Remove upper part of housing from lower part (3) and place on a

clean surface.

Warning!

Electrical voltage.

Danger of injury!

De-energize the mains connection before connecting the

transmitter!

Only have the transmitter wired and connected by authorized

personnel with the voltage disconnected.

Page 23

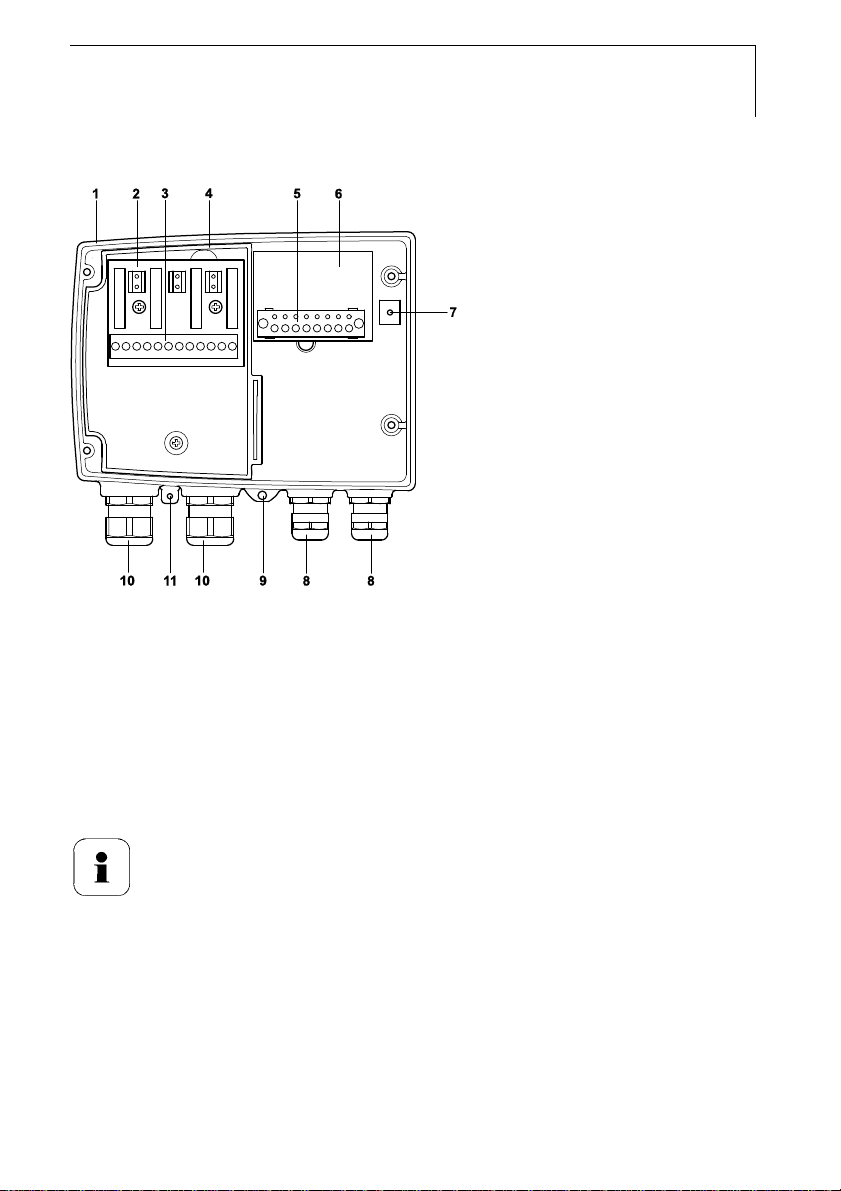

1.3.2.1 Overview of terminals

testo 6681 - 1.3 Commissioning

23

1 Lower part of housing

2 Relay board (option)

3 Relay terminals

4 Insulating trough for relay board

5 Terminal strip for voltage supply

and analog outputs

6 Terminal board

The following description of the terminals refer to this

overview and its numbering.

7 Earthing terminal (internal)

8 M 16 x 1.5 screw connection*

9 Earthing terminal (external)

10 M 20 x 1.5 scr ew connection*

11 Eyelet for measuring point panel

* Alternatively, NPT cable coupling

or M plug-in connection

Page 24

24

testo 6681 - 1.3 Commissioning

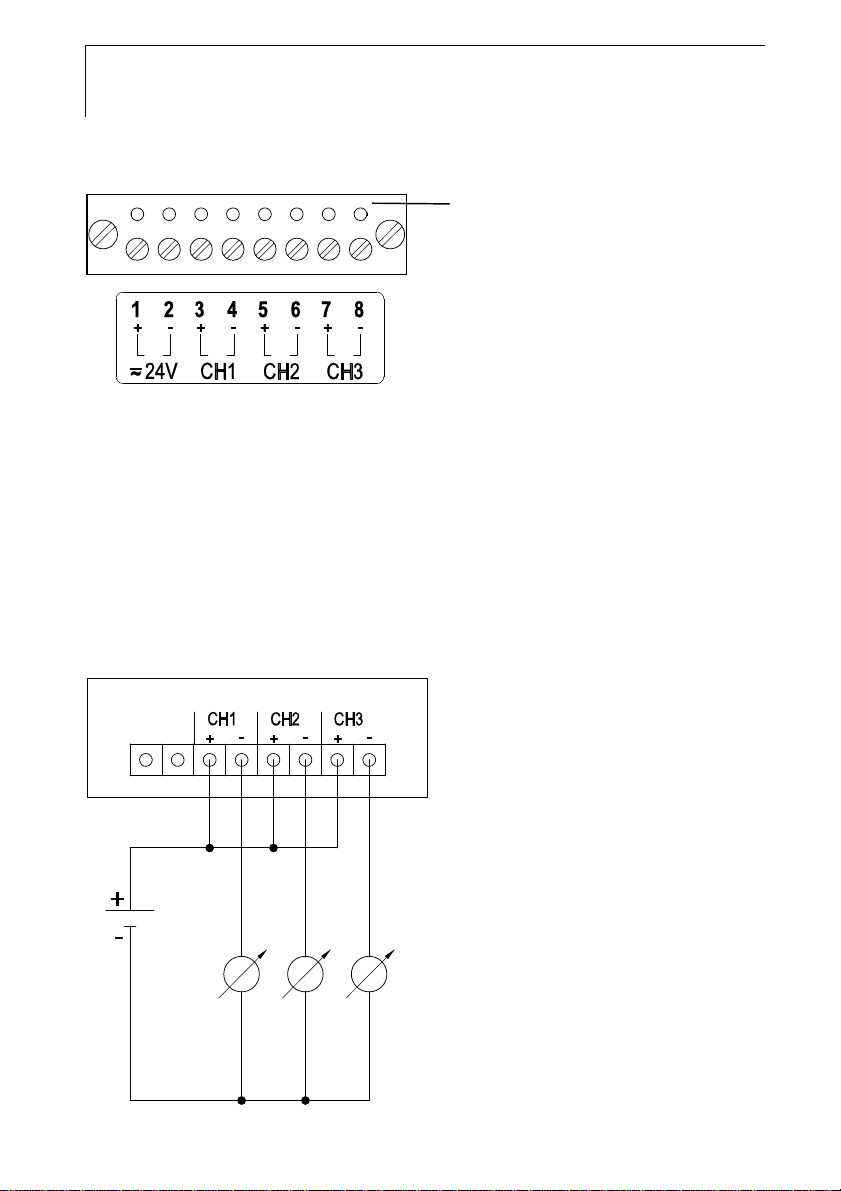

1.3.2.2 Connecting voltage supply and analog outputs

Terminal strip for voltage supply and

analog outputs, item (5) of Overview of

terminals, chapter 1.3.2.1.

1 Feed cable with voltage supply and analog signal lines through opened

M 16 x 1.5 screw connection (item (8) in Overview of terminals,

Chapter 1.3.2.1).

2 Strip the cable ends, clamp wire end ferrules on and screw down onto

voltage terminals.

3 Close M 16 x 1.5 screw connection (item (8) in Overview of terminals,

Chapter 1.3.2.1).

Wiring diagram for 2-wire system (4 - 20 mA)

12 to 30

0 V

2 or 3 channels

4 to 20 mA, max. load 100 to 750 Ω

Page 25

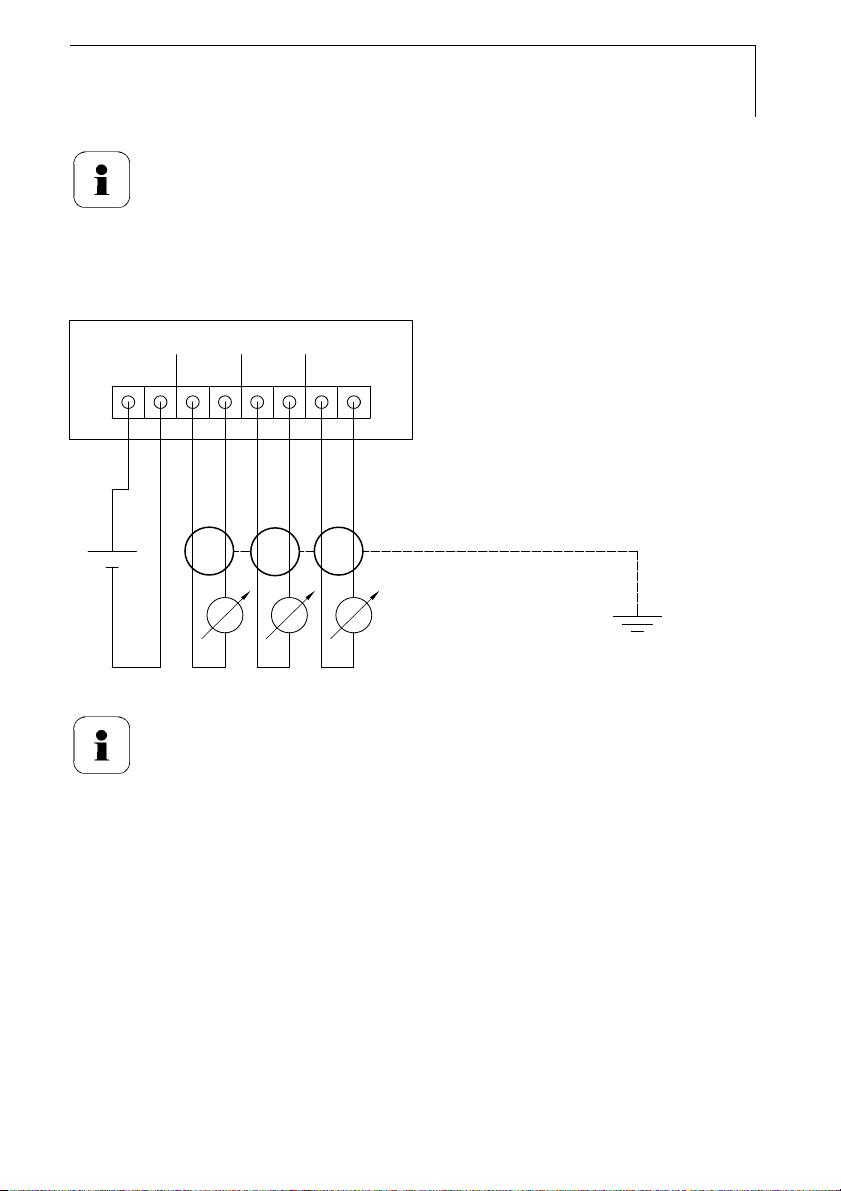

If the channels have to be galvanically isolated, a separate

mains unit must be used for each channel.

Wiring diagram for 4-wire system

(0 to 20 mA/4 to 20 mA/0 to 1 V/0 to 5 V/0 to 10 V)

CH1

20 to 30

V AC/DC

+

24V

-

+

CH2 CH3

-

+

-

-

+

+

-

0 V

2 or 3 channels

0 to 20 mA/

4 to 20 mA/

max. load per 500 Ω

0 to 1 V/0 to 5 V/0 to 10 V

testo 6681 - 1.3 Commissioning

25

Requirement for the connecting cable of the supply:

• Insulated with cross-section of at least 0.25 sq. mm.

• The supply line must be secured against exceeding 8 A.

• An OFF switch must be installed in an easily accessible

position close by and be marked as such.

1 Feed connection cables of the two, or optionally three, channels

through opened M 16 x 1.5 screw connection (item (8) in Overview of

terminals, chapter 1.3.2.1).

2 Strip the cable ends, clamp wire end ferrules on and screw to channel

terminals as shown in diagram.

3 Close M 16 x 1.5 screw connection (item (8) in Overview of terminals,

Chapter 1.3.2.1).

Page 26

26

testo 6681 - 1.3 Commissioning

1.3.2.3 Connecting the relay outputs

Only have the transmitter wired and connected by authorized

personnel with the voltage disconnected.

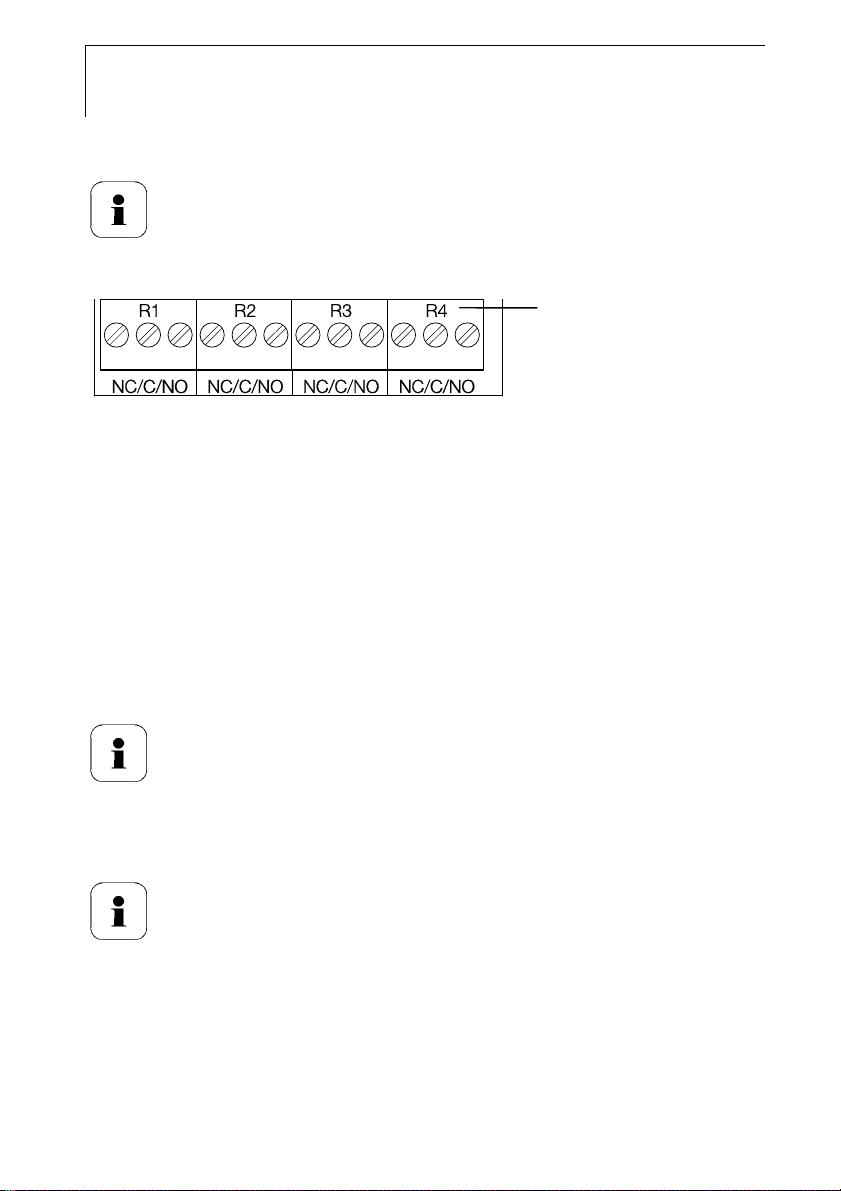

Relay terminal strip, item (3)

of Overview of terminals,

chapter 1.3.2.1

There is the option of twelve terminals for a total of four relays. The

designations NC/C/NO (normally closed contact/root or pin/normally open

contact) are etched on the surface of the board.

Using PG screw connection

1 Feed connection cables for the relays through opened M 20 x 1.5

screw connection (item (10) of Overview of terminals, chapter 1.3.2.1).

2 Strip cable ends and clamp on wire end ferrules.

3 Connect relays according to chosen function (NC/NO) (see diagrams

below; relay 1 is shown as an example of a connection).

Using plug-in connections (optional)

Only insert or disconnect the plug-in connection when the

voltage is disconnected.

4 Clean the connector of the probe line and the coupling of any foreign

matter.

Do not disconnect the connector of the probe line from the

instrument for extended periods to protect against

contamination.

Page 27

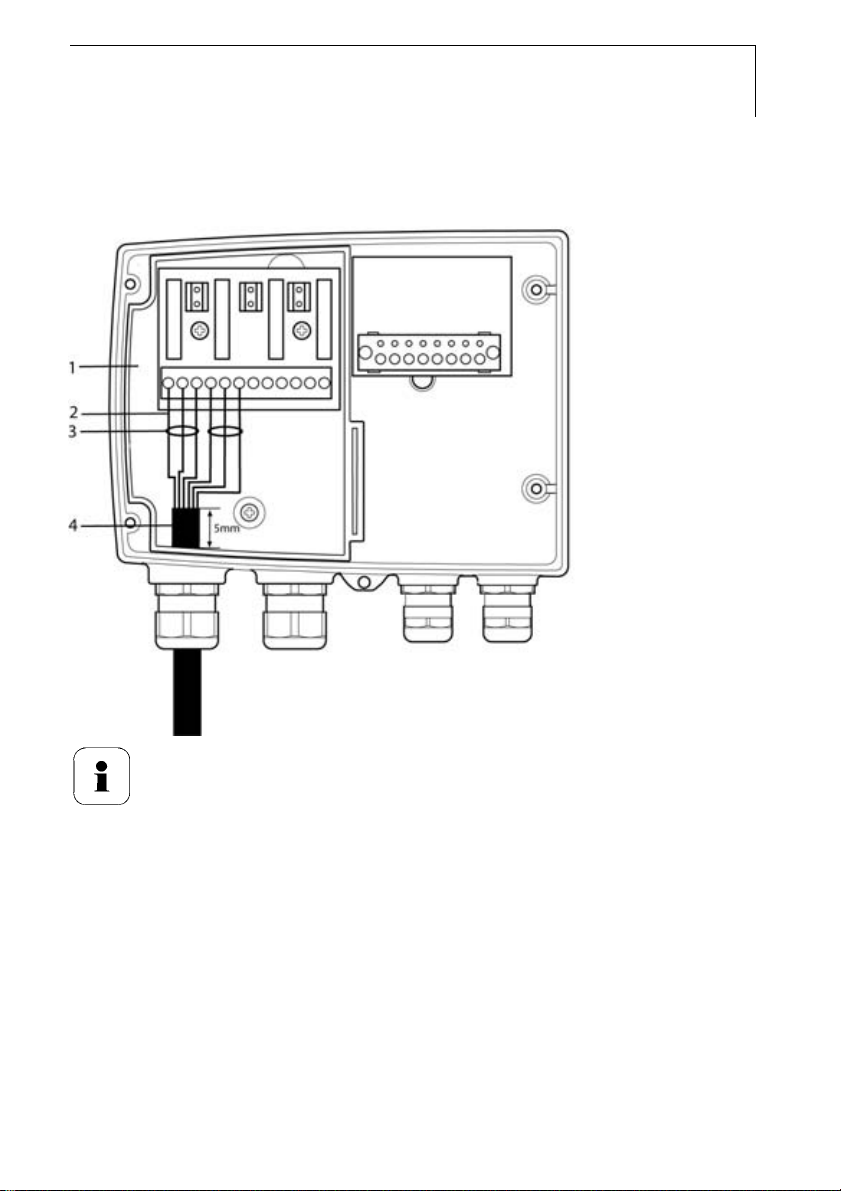

Connection note

testo 6681 - 1.3 Commissioning

27

• For the connection, a double-insulated mains cable

(sheathed cable) with a cross-section of at least 1.5 sq.

mm must be used.

• Cable connection (2) may not be routed in a loop within

the tray (1).

• It is recommended that you always tie 3 cores to one

another using a cable tie (3).

• The insulation of the cable must be fed at least 5 mm (4)

into the tray.

Page 28

28

(

)

testo 6681 - 1.3 Commissioning

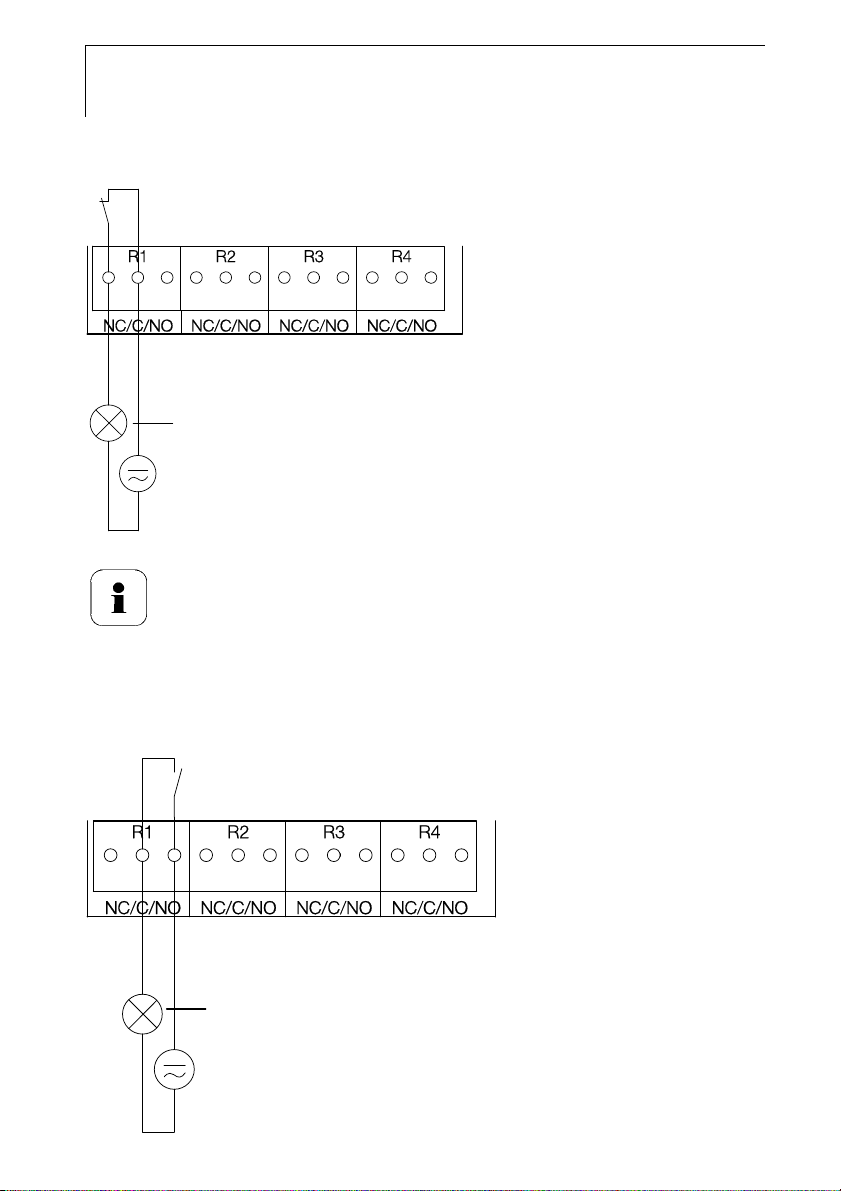

Use of relay as NC contact (NC = normally closed)

Alarm/status light

(example of installation)

250 V AC/DC, 3 A

The busy light (alarm/status light) is permanently on until the

relay opens or the circuit is interrupted. This circuit can

therefore be used to monitor the functionality of the alarm

circuit, as a cable break, for instance, is indicated by the busy

light going off.

Use of relay as NO contact (NO = normally open)

Alarm/status light

example of installation

250 V AC/DC, 3 A

Page 29

testo 6681 - 1.3 Commissioning

The busy light (alarm/status light) only comes on when the

relay is switched (closed). Monitoring the functionality of the

alarm circuit is therefore not possible with this switching

operation.

5 Close M 20 x 1.5 screw connection (item (10) in Overview of terminals,

Chapter 1.3.2.1).

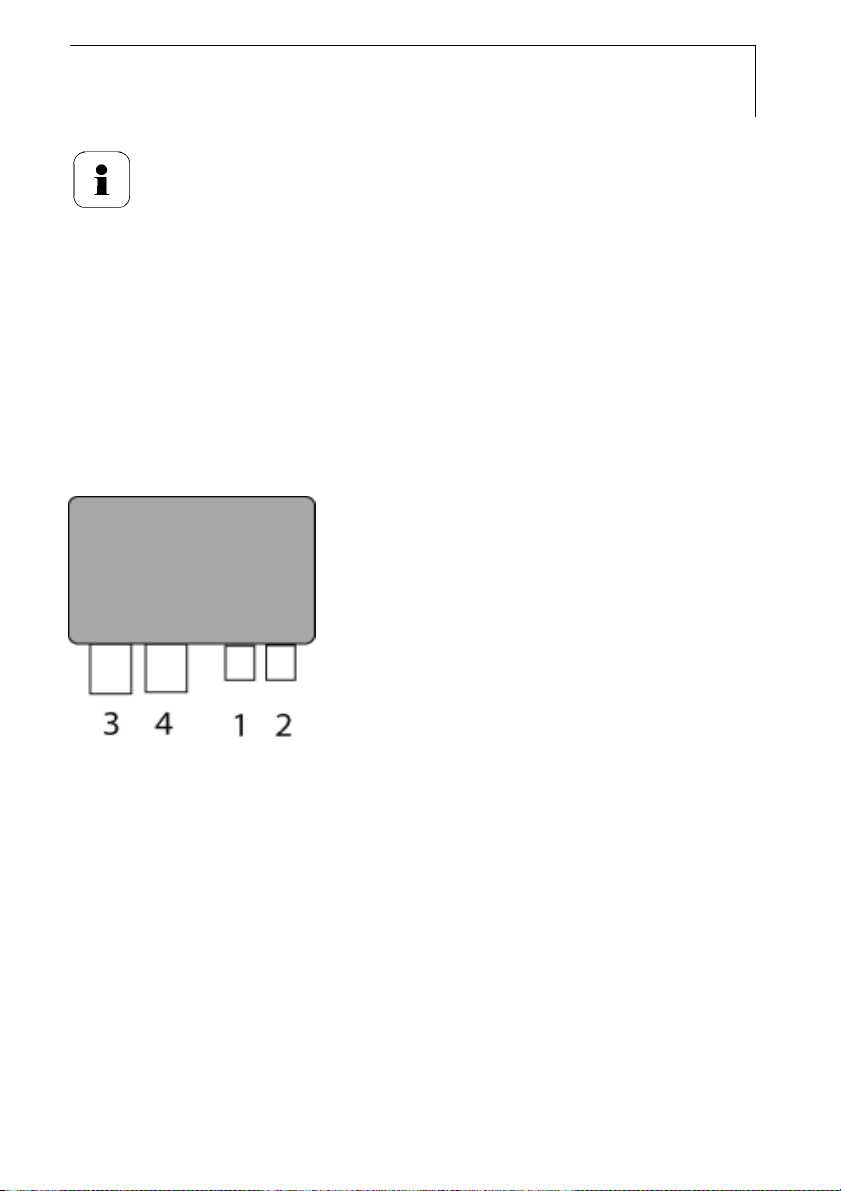

1.3.2.4 Plug-in connection option

As an option, the PG screw connections of the signal and supply lines can be

replaced with plug-in connections that are installed at the housing, see Fig. 1

and 2. The relay cabling occurs via standard cable entries and PG screw

connections, see Fig. 3 and 4.

Transmitter housing

29

Page 30

30

testo 6681 - 1.3 Commissioning

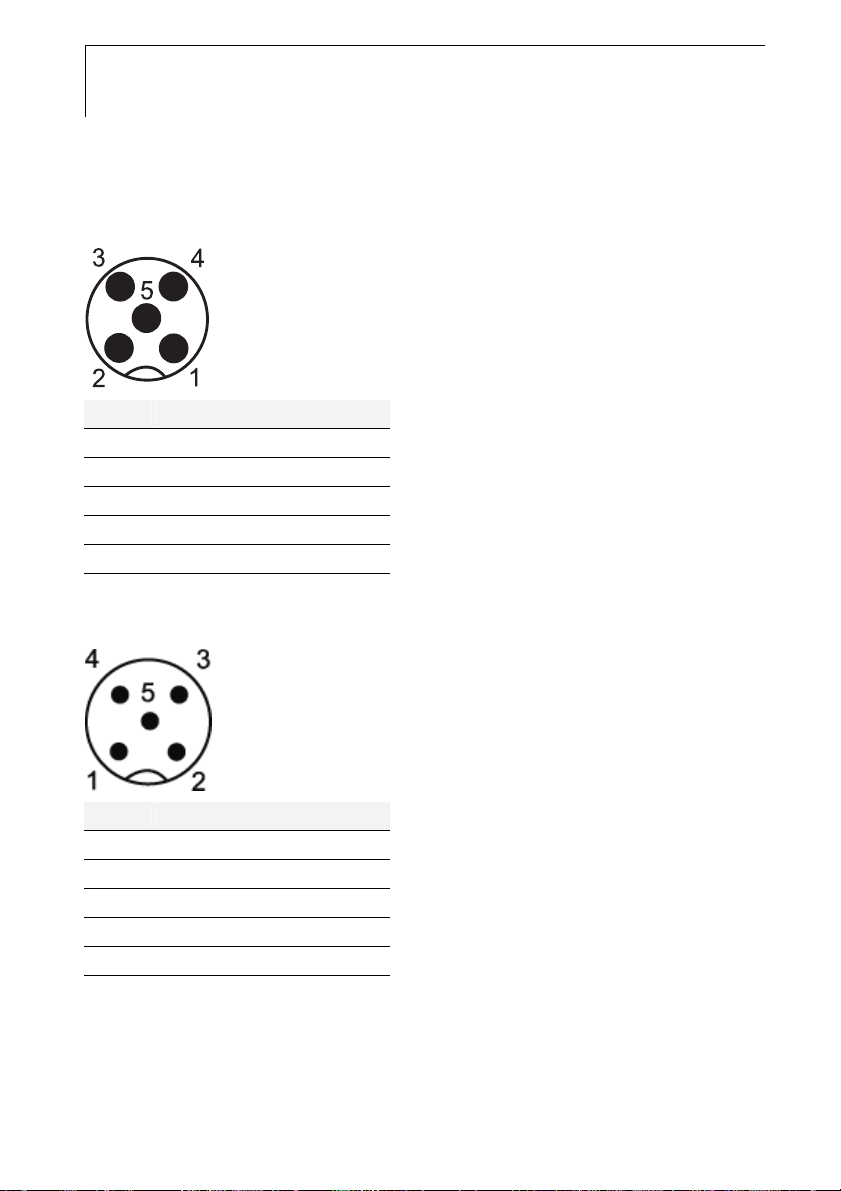

Plug-in connections for power supply and channels

M12 plug-in connection (5-pin) socket (1)

View of the plug-in connections in the installed state from outside

Pin Assignment.

1 V 24 2 V 24 +

3 + Ch 1

4 - Ch 1

5 PE

M12 plug-in connection (5-pin) connector (2)

Pin Assignment.

1 - Ch 2

2 + Ch 2

3 + Ch 3

4 - Ch 3

5 PE

Page 31

testo 6681 - 1.3 Commissioning

1.3.2.5 Creating the PE/earthing terminal

As the testo 6681 has a metal housing, we recommend that the instrument

be earthed. This can be done using the earthing terminal within the

instrument (1) or the earthing terminal outside of the instrument (2).

Only use the external earthing terminal in dry interiors.

31

Using the earthing terminal within the instrument

1 Guide PE line (yellow-green) (5) through the cable coupling (x) and fit

cable lug (8). Fix this to the side of the instrument (6) using M 5 screw

(3), washer (4) and snap ring (7) on the internal earthing terminal (1).

2 Place the other cable end on an appropriate (PE) earth conductor, e.g.

an earthing bar.

Using an earthing terminal outside of the instrument

1 Use shielded cable (5) with cable lug (8). Fix this using M 5 screw (3),

washer (4) and snap ring (7) on the external earthing terminal (2).

2 Place the other cable end on an appropriate (PE) earth conductor, e.g.

an earthing bar.

Page 32

32

testo 6681 - 1.3 Commissioning

1.3.2.6 Closing the instrument

1 Place upper part of instrument on top of lower part (see arrow) and fix

in place with housing screws (1).

2 Close the service flap and tighten screws (2).

Page 33

testo 6681 - 1.3 Commissioning

1.3.3 Adjusting the instrument

The testo adjusting concept allows the entire signal chain from the sensor

signal (probe) and the digital signal (within the transmitter) through to the

analog signal (transmitter output signal) to be adjusted (see diagram).

1-point adjustment 2-point adjustment Analog adjustment

33

Adjustment via

- testo 400/650 handheld

instrument with

adjustment adapter

- P2A software

- User menu

Adjustment via

- Adjustment keys (1, 2)

- P2A software

Adjustment using a precise

multimeter and

transmission of analog

reference value in

- P2A software or

- User menu

Either the 1-point adjustment or the 2-point adjustment is suitable for

adjusting the sensor signal - digital signal chain.

The testo 6681 transmitter has digital probes whose adjustment information

is stored in the probes' internal memory. Both 1-point and 2-point

adjustments can thus be carried out on another testo 6681 (e.g. in the

calibration laboratory).

Page 34

34

testo 6681 - 1.3 Commissioning

1.3.3.1 Overview: Adjustment keys and test contacts

1 Status LED

2 Contact ch. 1 +

3 Contact ch. 1 4 Adjust key 11.3 %

5 Service interface

6 Adjust key 75,3 %

7 Contact ch. 2 +

8 Contact ch. 2 -

1.3.3.2 1-point adjustment (offset)

In the 1-point adjustment, the reading at the working point is raised to the

reference value so that there is no longer any deviation in the working point.

The reference condition can be measured using a precise handhel d

instrument (e.g. testo 400/650 with precision humidity probe) or be created in

an air conditioning cabinet.

Deviation

WP

Working range

after

before

e.g. scale = 0 - 100 % RH

The advantage of the 1-point adjustment is the good measuring result in the

working range. But the further away the measurement is from the working

point, the greater the deviation can become. The 1-point adjustment should

therefore only be used for a relatively narrow measuring range (working

Page 35

testo 6681 - 1.3 Commissioning

range), e.g. clean room applications, air conditioning applications for storage

and similar.

The 1-point adjustment can be performed

• via the user menu (see Chapter 1.4.6.9) or

• via the P2A software (see Chapter 3) or

• directly by means of a Testo handheld instrument (testo 400/650) (se e

description of how to proceed below).

Please note that the 1-point adjustment is generally

performed on the basis of the % RH and °C/°F parameters.

Adjusting testo 6681 using Testo handheld instrument

The service flap is open, a testo 400/650 handheld instrument with a

precision humidity probe is ready.

5

1

2

3

4

35

1 Connect Testo handheld instrument 400/650 (1) with connected

humidity reference probe (3) (order no. reference set 0699 3656/20) to

Page 36

36

testo 6681 - 1.3 Commissioning

the service interface (5) of the testo 6681 via the adjustment adapter

(2) (connected to the probe socket 1 of the handheld instrument).

2 Expose the humidity probe (4) of the testo 6681 and the reference

probe (3) to the same reference conditions (e.g. in the humidity

generator) and allow climatic conditions to equalize.

3 Switch on the testo 400/650. The two-part display of the handheld

instrument will show the values of the transmitter on the left, and the

values of the reference probe on the right. The humidity and

temperature values are adjusted to the reference probe using the

Probe > Probe Adjustment menu item on the testo 400/650.

The 1-point adjustment is performed for both the humidity and the

temperature.

4 Disconnect the adapter (2) from the service interface (5).

5 Close the service flap.

1.3.3.3 2-point adjustment

With the 2-point adjustment, the parameter is adjusted to the reference value

at the two standard adjustment points 11.3 % RH and 75.3 % RH. The

reference conditions are created either by using Testo humidity adjustment

set (order no. 0554 0660) or in the humidity generator.

Deviation

after

before

In the 2-point adjustment, the deviations between the reading and the

nominal value are minimized across the entire measuring range. The 2-point

adjustment is therefore recommended for large working ranges, e.g. in drying

processes.

The 2-point adjustment can be performed

• via P2A software (see Chapter 3) or

• using the adjustment keys under the service flap, see description of

how to proceed below.

Page 37

testo 6681 - 1.3 Commissioning

Adjustment with the standard Testo adjustment salt pots is

not suitable for the testo 6614 (heated for high-humidity

applications) and testo 6615 (trace humidity) probes. The

reference conditions should be generated in a humidity

generator to adjust these probes.

In addition, these probes can also be adjusted at a third

adjustment point by Testo Service.

• testo 6614: third adjustment point at 90 % RH

• testo 6615: third adjustment point at -40 °Ctd/-40 °Ftd

Adjusting testo 6681 using adjustment keys

37

or

11.3 %

RH

75.3 %

RH

11.3 %

RH

75.3 %

RH

(salt pots) (humidity generator)

Page 38

38

testo 6681 - 1.3 Commissioning

The service flap of the testo 6681 is open.

1 Expose the humidity probe of the testo 6681 to the reference condition

of 11.3 % RH for at least 1.5 hours at 25 °C.

2 After this equalization period, press the 11.3 % adjustment key (4) for

at least 10 seconds with something like a ball-point pen that is not too

sharp. The LED (1) flashes when the adjustment process begins. At

the same time, the 2-point adjustment 11.3 % status message

appears on the display

Completion of the adjustment is signalled by the LED (1) coming on

permanently and the Probe reset status message is shown.

Carry out the adjustment analogously for the reference condition

75.3 % RH. Press on the 75.3 % RH adjustment key (6) to do this.

3 Close the service flap.

1.3.3.4 Analog output adjustment

The purpose of adjusting the analog outputs is to adjust the signal chain from

the digital signal (within the transmitter) to the analog outputs. The signal type

that was appointed for the transmitter is adjusted respectively for each

channel (e.g. 4 to 20 mA or 0 to 1 V, etc.).

1 Status LED

2 Contact ch. 1 +

3 Contact ch. 1 4 Adjust key 11.3 %

5 Service interface

6 Adjust key 75,3 %

7 Contact ch. 2 +

8 Contact ch. 2 -

Page 39

testo 6681 - 1.3 Commissioning

Analog outputs 1 and 2 adjusted

A precise multimeter (minimum resolution of 6.5 digits, accuracy of

100 mA, e.g. Agilent 34401A) is available.

If only a simple multimeter is available, the analog outputs

may not be adjusted.

The service flap is open.

1 Connect the inputs of the multimeter with the contacts (2) and (3) for

channel 1 or with contacts (7) and (8) for channel 2.

2 Transfer the reference analog value measured with the multimeter to

the P2A software (see Chapter 3) or enter it via the user menu (see

Chapter 1.4.6.9).

3 Disconnect connections between multimeter and contacts of the

testo 6681 and close service flap.

Adjusting analog output 3 (optional)

If the optional third analog output is to be adjusted, a cable

connection to measure the analog value must be installed.

Do this by proceeding as follows:

39

1 Open transmitter (see Chapter 1.3.2).

2 Connect measuring cable to the terminals of the third analog output

and guide through the cable coupling and out of the transmitter.

3 Reassemble upper part of transmitter (see Chapter 1.3.2.6).

4 Connect cable ends to the inputs of the multimeter.

5 Transfer the reference analog value measured with the multimeter to

the P2A software (see Chapter 3) or enter it via the user menu (see

Chapter 1.4.6.9).

6 Remove the upper part of the transmitter, detach the cable

connections for the adjustment of the 3rd analog output and

reassemble the transmitter.

Page 40

40

testo 6681 - 1.3 Commissioning

1.3.3.5 High-humidity adjustment for testo 6614

Mollier diagram

e.g. 73 % RH

"Microclimate"

sensor conditions

After heating

High-humidity process

conditions

Mist

With the testo 6614, the rear of the Testo humidity sensor is heated, creating

a microclimate around the sensor (within the filter) that is constantly 5 K

warmer than the actual process conditions. As can be seen in the Mollier

diagram, this reduces the relative humidity at the sensor from around

100 % RH to a lower value, e.g. 73 % RH. In this range, the reaction time of

the sensor is noticeably shorter than in the condensation range and the risk

of the sensor corroding is also reduced. Using the separate temperature

probe, the testo 6681 transmitter compensates the microclimate conditions

and displays the process readings.

100 % RH

The reference conditions (11.3 % RH and 75.3 % RH) for the

2-point adjustment of the testo 6614 should be generated in a

humidity generator, as humidity adjustment sets cannot be

used due to the heat generated. The adjustment can also be

carried out at a third adjustment point (90 % RH) by Testo

Service so that optimum accuracy is also achieved in the high

humidity ranges.

Page 41

testo 6681 - 1.3 Commissioning

1.3.3.6 Self adjustment of testo 6615 trace humidity

probe

Conventional trace humidity probes show a steep rise in measuring

uncertainty at low humidities. In the testo 6615 trace humidity probe, these

measuring uncertainties are corrected by means of an automatic selfadjustment process. This means that extremely accurate measuring results

are also attained to -60 °Ctd.

To this end, a temperature sensor is fitted on the back of the testo 6615

which is used as a heater. A humidity and temperature value pair is taken in

both the unheated and heated state. The deviation of the probe obtained

from these pairs of values is automatically corrected.

testo 6615:

testo 6615:

probe

Fühler-

behaviour

verhalten

"Duration of heating phase"

Parameter

parameter

„Dauer Heizphase“

"Self-adjustment cycle time"

„Zykluszeit Selbstabgleich“

41

Analog

Analog-

output °Ctd/

Ausgang

°Ftd

°Ctpd/

°Ftpd

Heizphase

Heating phase

Heating phase

Heizphase

The heating time and storing of cycles can be edited in the P2A software; for

example, they can be deactivated by setting the two parameters to "0".

Page 42

42

testo 6681 - 1.4 Operation

Important:

• Deactivating the adjustment function of the testo 6615

will reduce measuring accuracy and should therefore

be restricted to the shortest possible length of time.

• During the heating phase, the relay and analog

outputs, the display value and output value are

"frozen", see diagram above. Self-adjustment active

is shown in the display until it has finished. The factory

setting for the heating phase is 15 minutes per day.

• In the factory setting, a third adjustment point (-

40 °Ctd) is approached for the testo 6615 in addition to

the 2-point adjustment.

This special adjustment can be performed again by

your Testo Service team if necessary.

1.4 Operation

1.4.1 Relationship between user menu and

mini-DIN socket is active

The testo 6681 can be parameterized using either the user menu or the P2A

software (see Chapter 3).

The testo 6681 humidity transmitter can only be operated via

the display and keypad if the display option is available.

If the testo 6681 is connected to the P2A software, the user

menu is blocked for the duration of the communication. The

message Service plug is shown in the display of the

testo 6681. As soon as the P2A software is disconnected, the

user menu is accessible again.

1.4.2 Key cover

To prevent unauthorized operation of the keys, the standard key frame can

be replaced with a key cover (see below).

Page 43

testo 6681 - 1.4 Operation

If the key cover has been assembled, the service flap must be opened for

operation, see Section Opening the instrument, Chapter 1.3.2.

Attaching the key cover

43

The service flap is open, see Opening the instrument, Chapter 1.3.2.

1 Undo screws (3) and remove key frame (2).

2 Insert key cover (1) into service flap and tighten screws (3).

3 Close and screw down the service flap.

Page 44

44

testo 6681 - 1.4 Operation

1.4.3 Password protection

The user menu can be protected with a four-digit numerical code (see Editing

Main Menu Settings, Chapter 1.4.6.5) so that access to the user menu is

denied to unauthorized persons not familiar with this numerical code.

If the password protection is not to be used, the numerical code "0000" must

be entered. This is also the status upon delivery.

1.4.4 Structure of user menu

At the main menu level, the user menu comprises the following:

• Main menu of channel 1

• Main menu of channel 2

• Main menu of channel 3 (if this option is available)

• Main Menu Alarm

• Editing Settings main menu

• Analysis main menu

• Main Menu Messages

• Ident main menu

• Adjustment main menu

• Reset main menu

19.3 °C

57.8 % RH

-4.1 °Ctd

Channel 1 display

Channel 2 display

Channel 3 display or for messages

Page 45

testo 6681 - 1.4 Operation

Four keys enable the user to navigate/scroll through the menus and

enter/amend values and settings:

Key Function/description

SET

ESC

X

S

- In Measuring Mode: changes to parameterization

- In Parameterizing Mode: confirms a selection or setting

- Leaves a menu (without modifying any settings)

- Selecting: scrolls through menus (downwards) or selectable

alternatives

- Editing: changes to next digit (to the right)

- Selecting: scrolls through menus (upwards) or selectable alternatives

- Editing: increases the value of the current digit by 1

45

Page 46

46

testo 6681 - 1.4 Operation

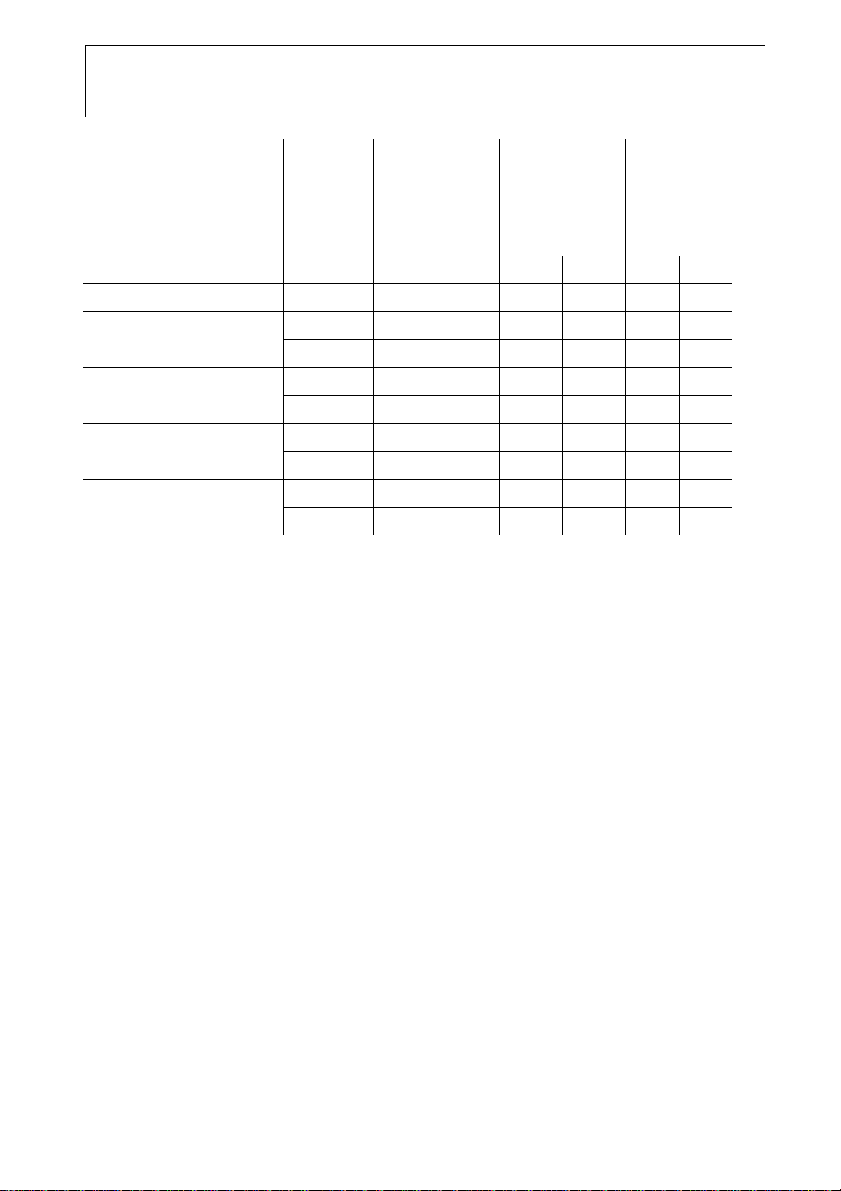

1.4.5 Overview of the testo 6681 user menu

Page 47

testo 6681 - 1.4 Operation

47

Page 48

48

testo 6681 - 1.4 Operation

1.4.6 The individual main menus

1.4.6.1 Editing Main Menu Channel 1

An overview is given in Overview of the testo 6681 user menu, Chapter 1.4.5.

You can perform basic settings for channel 1.

1 In Measuring Mode, press SET, select Main Menu Channel 1 using X

or S and confirm selection with SET.

One of the following parameters can now be selected using X or S, after

which the selection must be confirmed with SET:

• Channel 1 unit

The parameter for this channel is selected.

Selection: % RH, °C, °F, °Ctd, °Ftd, g/m³, gr/ft³, g/kg, gr/lb, kJ/kg,

BTU/lb, °Ctw, °Ftw, "H2O, hPa, ppm

Edit/select parameter with X or S, confirm with SET or abort input

with ESC.

• Scale minimum for channel 1

The lower scale limit is edited;

Unit as selected above (example: 4 mA = 0 % RH).

Editing the value: Scroll one digit to the right using X, increase value

of digit by 1 using S. Confirm with SET or abort entry with ESC.

• Scale maximum for channel 1

The upper scale limit is edited;

Unit as selected above (example: 20 mA = 100 % RH).

Editing the value: Scroll one digit to the right using X, increase value

of digit by 1 using S. Confirm with SET or abort entry with ESC.

• Signal delay ("Damping") for channel 1

The analog signal can be delayed("Damping"); a time constant is

selected for this (1 = no delay; 15 = longest delay).

Edit/select parameter using X or S, confirm with SET or cancel entry

via ESC.

2 Continue to Main Menu Channel 2 using X or S or return to

Measuring Mode by pressing ESC.

, % Vol, °Ctm, °Ftm.

vol

1.4.6.2 Editing main menu of channel 2

See channel 1.

1.4.6.3 Editing main menu of channel 3 (if this option is

available)

See channel 1.

Page 49

testo 6681 - 1.4 Operation

1.4.6.4 Editing Main Menu Alarm

With the alarm, the relays, available as options, are programmed. In addition,

the alarm statuses are shown on the display (top right) (even without

relays).You can choose whether the alarm is to be used to monitor limit

values or as a collective alarm. If an alarm is to be used to monitor limit

values, you can choose between monitoring the minimum or maximum value

and set a limit value and hysteresis for each alarm.

1 In Measuring Mode, press SET, select Main Menu Alarm using X or

S and confirm selection with SET.

Four alarms can be parameterized.

2 Select Alarm x using X or S and confirm selection with SET.

Using alarm to monitor limit values

Monitoring minimum Monitoring maximum

Hysteresis Hysteresis

On On

NO contact

Off Off

49

On On

Off

Limit value Limit value

NC contact

Off

Cannel 2

e.g. °C

3 Select Channel x (e.g. "Channel 1") using X or S and confirm

selection with SET.

4 Select Max control or Min control with X or S (see graphic).

5 Press SET and edit limit value and hysteresis: Scroll one digit to the

right using X, increase value of digit by 1 using S. Confirm with SET

or abort entry with ESC.

6 Return to Channel x by pressing ESC.

7 Return to Alarm x by pressing ESC.

8 Change to the other relays using X or S and perform settings in the

same way.

Page 50

50

testo 6681 - 1.4 Operation

Using alarm as collective alarm or not using it at all

If the collective alarm is assigned to an alarm, the relay is switched as soon

as (at least) one of the warning or error messages of the testo 6681

transmitter (or the connected testo 6610 probe) is activated.

Note:

The messages affecting the collective alarm can only be

selected in the P2A software, see Chapter 3.

Alarm is selected (see previous steps 1 and 2).

1 Specify with X or S whether Alarm x is to be used as the Alarm

relay or is not to be used. Confirm selection with SET and return to

Alarm x.

2 Change to another alarm using X or S and perform settings in the

same way.

3 Continue to Main Menu Settings using X or S or return to Measuring

Mode by pressing ESC.

1.4.6.5 Editing Main Menu Settings

You can edit instrument settings and other settings.

▪ In Measuring Mode, press SET, select Main Menu Settings usi ng X

or S and confirm selection with SET.

You can edit settings for:

• Display

• Language

• H

• Absolute pressure unit

• Absolute pressure

• Code

proportion by weight entry (optional with 3rd analog output)

2O2

Unit: %

Selection: bar, psi, mPa, hPa

Unit as selected above.

Editing display settings

You can set the brightness and contrast of the display.

1 Select Display Settings using X or S and confirm selection with

SET.

Page 51

testo 6681 - 1.4 Operation

2 Select Backlight or Contrast using X or S and confirm selection with

SET.

One of the following parameters can now be selected using X or S, after

which the selection must be confirmed with SET:

• Backlight

The display illumination is changed.

Edit/select parameter with X or S, confirm with SET or abort input

with ESC (the effect of the change in parameter can be seen during

input).

• Contrast

The brightness difference between the display background and the

displayed values is changed.

Edit/select parameter with X or S, confirm with SET or abort input

with ESC (the effect of the change in parameter can be seen during

input).

• Backlight on 24 h

Using X or S select On or Off and confirm with SET.

Off: The display light switches off automatically if no button was

pressed for 10 seconds.

On: The display light is activated

3 Go back to Display Settings by pressing ESC and continue to

Language using X or S.

51

Selecting language

You can select the language for the plain text line in the display.

▪ Press SET, select required langua ge with X or S, confirm selection

with SET and return to Language.

Only choose a language that you can understand well.

Editing H

This menu is only used to parameterize humidity measurements in H

atmospheres (e.g. in sterilization processes) and determines whether °Ctm

or °Ftm is the output parameter.

1 Select H

with SET.

proportion by weight (optional with 3rd analog output)

2O2

Weight Proportion using X or S and confirm selection

2O2

2O2

Page 52

52

testo 6681 - 1.4 Operation

The selection H2O2 Water or H2O2 Vapour in the submenu describes

whether H

2O2

in the process.

is created through evaporation or is actively evaporated

2 Select H

Water or H2O2Vapour using X or S and confirm with

2O2

SET.

3 Editing proportion by weight of H

in % (% H2O2 proportion by

2O2

weight in the liquid end solution): Scroll one digit to the right using X,

increase value of digit by 1 using S. Confirm with SET or abort entry

with ESC.

4 Go back to H

by pressing ESC and continue to Absolute pressure

2O2

unit using X or S.

Selecting absolute pressure unit (Abs. pressure unit)

This parameter determines the humidity variables, atmospheric dewpoint

(°CtA, °FtA), relative humidity (g/kg or gr/lb) and water content (ppm

or %

vol

vol).

1 Press SET, select desired unit (selection: bar, psi, mPa, hPa) using X

or S confirm selection with SET or cancel with ESC.

2 Continue to Absolute Pressure with X or S.

Editing absolute pressure(Abs. pressure value)

You can set a value for the process absolute pressure.

1 Using X or S, select Abs. pressure value and confirm selection with

SET.

The absolute pressure is displayed.

2 Scroll one digit to the right using X, increase value of digit by 1 using

S. Confirm with SET or abort entry with ESC.

3 Press SET and return to Abs. pressure value

4 Return to Main Menu Settings by pressing ESC.

5 Continue to Main Menu Analysis using X or S or return to Measuring

Mode by pressing ESC.

Editing code settings

You can set the access code (password).

Page 53

testo 6681 - 1.4 Operation

If a code other than "0000" (factory setting) is set, the

transmitter can only be operated once this code has been

entered via the menu.

1 Select Code using X or S and confirm selection with SET.

2 Scroll one digit to the right using X, increase value of digit by 1 using

S. Confirm with SET or abort entry with ESC.

3 Return to Code by pressing ESC.

1.4.6.6 Editing Analysis main menu

You can test the functionality of analog and relay outputs. In addition, you

can read off the minimum and maximum readings (since the last voltage

supply or reset of the min./max. values

Testing functionality of analog outputs

This function affects the analog outputs directly, not only the

test contacts.

1 In Measuring Mode, press SET, select Main Menu Analysis using X

or S and confirm selection with SET.

Test Analog Output is shown.

).

53

2 Press SET, choose between Analog Output 1, 2, 3 with X or S.

3 Press SET, scroll one digit to the right using X, increase value of digit

by 1 using S. Any analog output value can be predefined, e.g. for an

analog output of 4 to 20 mA, the value "6.0 mA". Confirm with SET or

abort entry with ESC.

4 Accept setting by pressing SET and test with multimeter (minimum

requirement: resolution of 6.5 digits, accuracy of 100 nA):

Analog output 1 or 2: via test contacts under service flap, see diagram.

Page 54

54

testo 6681 - 1.4 Operation

1 Channel 1 test

contacts

2 Service interface

3 Channel 2 test

contacts

4 Ends of channel 3

cables

5 Multimeter

Analog output 3: Connect measuring cables to terminals for channel 3,

guide measuring cables out of housing and perform measurement

outside of the transmitter, see diagram.

5 Return to Test Analog Output using ESC and continue to Test Relay

Output using X or S.

Testing functionality of relay outputs

1 Press SET, choose between Alarm 1, 2, 3, 4 with X or S.

2 Press SET.

The relay can now be tested. You can choose between OFF and ON

using X or S. If ON is chosen, the NO contact is closed, the NC

contact opened. If OFF is chosen, the NC contact is closed, the NO

contact opened.

3 To test, route a measuring cable from the relay terminals (see

Chapter 1.3.2.3) out of the transmitter to a multimeter (resistance

measurement) or continuity tester.

4 Go back to Test Relay Output by pressing either SET (starts relay

test) or ESC (exits the menu without relay test).

Reading off min./max. values of channels

To reset the max./min. values, see Chapter 1.4.6.10 Editing

Reset main menu

1 Read off the min./max. values of the three channels by pressing X or

S one after the other and return to Main Menu Analysis using ESC.

2 Continue to Main Menu Message using X or S or return to

Measuring Mode by pressing ESC.

Page 55

testo 6681 - 1.4 Operation

1.4.6.7 Editing Message main menu

Messages can be confirmed/acknowledged, the last messages can be called

up and the display of the messages can be switched on or off.

Operating hours at the time of

message

Message number/number of messages

present

Example: "4/7" refers to the fourth of

seven messages

Message text

348

4/7

Scaling changed

Using the P2A software (see Chapter 3) you can predefine

which of the messages are to be shown in the display.

h

55

1 In Measuring Mode, press SET, select Main Menu Message using X

or S and confirm selection with SET.

2 Confirm Confirm message using SET.

3 Select Last messages using X or S and confirm with SET.

4 Scroll between the messages recorded so far using X or S and press

ESC to return to Last messages.

5 Continue to Display of message with X or S.

ON: Measurements are shown on the display in Measuring Mode.

OFF: No messages shown on display.

6 Select ON or OFF using X or S and confirm selection with SET.

7 Return to Main Menu Message by pressing ESC.

8 Continue to Main Menu Ident using X or S or return to Measuring

Mode by pressing ESC.

An overview of the messages can be found in

Chapter 1.5 Status, warning and error messages.

Page 56

56

testo 6681 - 1.4 Operation

1.4.6.8 Calling up Main Menu Ident

6681

Instruments or probe type

2.01

Serial

The serial numbers of the transmitter and probe can be read off.

1 In Measuring Mode, press SET, select Main Menu Ident using X or S

and confirm selection with SET.

The type, firmware version and serial number of the transmitter are

displayed.

2 Press ESC to return to the Main Menu Ident or read off the type,

firmware version and serial number of the probe using X or S and

then press X or S to return to the Main Menu Ident.

3 Continue to Main Menu Adjust using X or S or return to Measuring

Mode by pressing ESC.

Firmware version

Serial number

1.4.6.9 Editing Adjust main menu

A reference value can be entered for both relative humidity (RH) and

temperature (°C/°F) for the 1-point adjustment. Please refer to the description

in Chapter 1.3.3.2.

In addition, the analog outputs can be adjusted. See Chapter 1.3.3.4 for

instructions on how to do this.

The 2-point adjustment cannot be performed via the user

menu. This is done using the adjustment buttons or P2A

software, see Chapter 1.3.3.3 or Chapter 3.

Page 57

testo 6681 - 1.4 Operation

Enter reference value for 1-point adjustment

Please also refer to Chapter 1.3.3.2.

1 In Measuring Mode, press SET, select Main Menu Adjust using X or

S and confirm selection with SET.

Reference value % RH is displayed.

2 Press SET, edit value: Scroll one digit to the right using X, increase

value of digit by 1 using S. Confirm with SET or cancel entry with

ESC.

3 Continue to Reference value temp with X or S.

4 Press SET and Reference value °C is displayed.

5 Press SET, edit value: Scroll one digit to the right using X, increase

value of digit by 1 using S. Confirm with SET or abort entry with ESC.

6 Continue to Reference value °F with X or S.

7 Press SET, edit value: Scroll one digit to the right using X, increase

value of digit by 1 using S. Confirm with SET or abort entry with ESC.

8 Continue to Analog Adj. Ch. 1 with X or S.

9 Continue with the adjustment of the analog outputs (see below, step 2)

or press ESC to return to Main Menu Adjustment.

10 Continue to Main Menu Reset using X or S or return to Measuring

Mode by pressing ESC.

57

Performing analog adjustment

Please refer to Chapter 1.3.3.4.

1 In Measuring Mode, press SET, select Main Menu Adjust using X or

S and confirm selection with SET.

Each channel is adjusted at three points in the analog range

(at 10 %; 50 %; 90°% of the analog scale).

2 Select Analog Adj. Ch. 1 using X or S and confirm with SET.

3 Select Adj. Point 1 using X or S.

Page 58

58

testo 6681 - 1.4 Operation

4 Press SET. Read off multimeter display (e.g. 5.601 mA) and enter this

value in the user menu. Do this by scrolling one digit to the right using

X and increasing the value of digit by 1 using S. Confirm with SET or

abort entry with ESC.

5 Select Adj. Point 2 using X or S.

6 Press SET. Read off multimeter display (e.g. 12,001 mA) and enter

this value in the user menu. Do this by scrolling one digit to the right

using X and increasing the value of digit by 1 using S. Confirm with

SET or abort entry with ESC.

7 Select Adj. Point 3 using X or S.

8 Press SET. Read off multimeter display (e.g. 18,401 mA) and enter

this value in the user menu. Do this by scrolling one digit to the right

using X and increasing the value of digit by 1 using S. Confirm with

SET or abort entry with ESC.

9 Continue to Analog Adj. Ch. 2 or 3 with X or S (repeat steps 3 to 8).

10 Return to Main Menu Adjust by pressing ESC.

11 Continue to Main Menu Reset using X or S or return to Measuring

Mode by pressing ESC.

Page 59

testo 6681 - 1.4 Operation

1.4.6.10 Editing Reset main menu

You can reset the factory settings for the following:

• Instrument

• Sensor/probe

• Min./max. values

Resetting to the factory settings means resetting to the order

specification, i.e. the specific condition at the time of supply to

1 In Measuring Mode, press SET, select Main Menu Reset using X or

S and confirm selection with SET.

Reset device to factory settings is displayed.

2 Select the setting to be reset using X or S and confirm selection with

SET.

Reset Completed is displayed.

3 Press ESC or SET to return to reset setting and press ESC to return to

Main Menu Reset.

4 Continue to Main Menu Channel 1 using X or S or return to

Measuring Mode by pressing ESC.

the customer.

59

Page 60

60

testo 6681 - 1.5 Status, warning and error messages

1.5 Status, warning and error

messages

To achieve optimum operational reliability (machine

availability), the transmitter provides the following via the user

menu (see Chapter 1.4) or the P2A software (see Chapter 3):

• Status messages,

• Warning messages and

• Error messages

for either the testo 6681 or the connected testo 661x probe

as applicable.

All messages are stored in the transmitter with an operating

hours stamp. Use the user menu (see Chapter 1.4.6.7) or

P2A software (see Chapter 3) to view the message history.

In the transmitter, the last 180 messages are stored in a ring

memory, but there is no restriction in the P2A software.

1.5.1 Status messages

Status messages show the current operating mode of the testo 6681.

Message Display Description

00300 New limit value The limit value has been changed or shifted

00301 Scaling changed The scaling has been changed

00500 Transmitter reset: The transmitter is reset to the factory settings

and is restarted.

0052F Reset Min/Max Resets all saved Min/Max values for all channels

02506 Probe co nnection A probe has been connected

01D19 Service plug The Mini-DIN socket is connected to: the USB

00307 User Setting Change User Setting Change: General settings were

02d07 Probe d isconnected No probe is connected

adapter for P2A software, the adjustment

adapter or the service plug (is not recorded/no

number)

changed for the transmitter.

Page 61

testo 6681 - 1.5 Status, warning and error messages

Message Display Description

02104 Analog out adjust An analog adjustment has been made

02101 1-point adjustment A 1-point adjustment is performed.

02102 2-point adjustment

11,3%

02103 2-point adjustment

75.3%

02105 Self-ad justment active For testo 6615 probe only: The probe performs

02518 Probe reset Probe reset: The probe performs a reset

As part of the 2-point adjustment, an adjustment

is performed at 11.3 % RH

As part of the 2-point adjustment, an adjustment

is performed at 75.3 % RH

an automatic self-adjustment

1.5.2 Warning messages

Warning messages show an early warning or a current malfunction which

may negatively impact measuring.

Message Display Cause Remedying of fault

02101 2-point adjustment

drift*

00E00 T ambient high** The ambient temperature

00E01 T ambient low** The ambient temperature is

00E02 Supply voltage

low**

In the 2-point adjustment,

corrections repeatedly

occur in the same direction;

this may indicate a sensor

drift

exceeds the permissible

temperature for the

transmitter

below the permissible

temperature for the

transmitter

The supply voltage is below

the minimum voltage

required for the transmitter

Send the probe into Testo

Service

Take necessary

measures to lower

ambient temperature, e.g.

through venting or cooling

Take necessary

measures to raise

ambient temperature, e.g.

through heating

Ensure sufficient voltage

supply

61

Page 62

62

testo 6681 - 1.5 Status, warning and error messages

Message Display Cause Remedying of fault

00E00 T process high** The process temperature

exceeds the temperature

designated for the probe

Remove the probe from

the process and take any

necessary measures to

lower the process

temperature

02806 Condensation* 100 % RH has been

reached, condensation

Take measures to reduce

process humidity

developing

02807 Valu es less than

0 % RH**

The adjustment or sensor

is faulty

Check adjustment (via

P2A adjustment history,

perform 2-point

adjustment where

necessary)

If the problem persists,

contact Testo Service

02809 Sensor early

warning*

For testo 6617 probe only:

The cover electrode of the

sensor is damaged; this

may soon cause the sensor

to break

Carry out visual

inspection

If the mirror-like surface of

the sensor is dirty or

damaged, contact Testo

Service

* Early warning

** Current malfunction

Page 63

testo 6681 - 1.5 Status, warning and error messages

1.5.3 Error messages

Error messages show a current malfunction.

Message Display Cause Remedying of fault

03401 No probe signal The probe communication

03508 Wrong probe The connected probe is not

01528 Watchdog error Due to a processor error,

0300A % RH sensor

short-circuit

0300B %RH sensor

broken

0300C T sensor short-

circuit

0300D T sensor broken The temperature sensor is

03105 Self-adjustment

error

is interrupted

compatible with the present

transmitter

the transmitter performs an

automatic restart

Short-circuit in humidity

sensor

The humidity sensor is

damaged (sensor broken)

Short-circuit in temperature

sensor

damaged (sensor broken)

For testo 6615 probe only:

The automatic selfadjustment was faulty

Ensure that the probe

connector is fully

engaged in the

transmitter.

If communication still

cannot be established,

contact Testo Service

Use a compatible probe

Note: The 660x probes

match the 665x

transmitter, and the 661x

probes the 668x

transmitter

If the problem occurs

frequently, contact Testo

Service

Contact Testo Service

Contact Testo Service

Contact Testo Service

Contact Testo Service

Contact Testo Service

63

Page 64

64

testo 6681 - 1.5 Status, warning and error messages

1.5.4 Handling alarm messages

Shown on the

display 1

Can be used for

collective alarm

Additional

2

Message

start/end

New limit value x x

Scaling changed x x

Transmitter reset x x

Reset Min/Max x

Transmitter refresh x

Probe connection

Service plug

User Setting Change x

Probe disconnected

Analog out adjust x x

1-point adjustment x x

2-point adjustment 11,3% x x

2-point adjustment 75.3% x x

Probe self-adjustment x x

Probe reset x x

2-point adjustment drift* x

T ambient high** x

T ambient low** x

Supply voltage low** x

T process high** x

Condensation* x

Values less than

x

0 % RH**

Sensor early warning* x

No probe signal x

Wrong probe

Watchdog error x

Page 65

testo 6681 - 1.5 Status, warning and error messages

Shown on the

display 1

% RH short-circuit x

%RH sensor broken x

T short-circuit x

T sensor broken x

Self-adjustment error

Can be used for

collective alarm

Additional

2

Message

start/end

*

If multiple messages/alarms are activate d at the same time, only the last

message/alarm is shown. If this is cancelled, the other messages that are

still active are no longer displayed.

**

The message can be assigned the collective alarm function, which means

that the collective alarm is activated as soon as at least one of the

messages assigned to it is activated. The collective alarm can be assigned

to each of the 4 optional relays. The collective alarm is then always the

same, as it can only be defined once.

Execute Confirm message function (via control keys at transmitter):

65

• The message/alarm is no longer shown on the display. If multiple

messages/alarms are active at the same time, all are reset

simultaneously.

• If at least one message is assigned to the collective alarm, the collective

alarm is reset. If the collective alarm is set on a relay, the relay is also

reset, meaning switched to its neutral position.

Page 66

66

testo 6681 - 1.5 Status, warning and error messages

1.5.5 Namur fault conditions

If the faults named in the following table occur, the analog outputs output

special values that enable a general fault warning in the higher-level control

system. The values correspond to the "Namur" industry standard.

Display message Class 0-20mA 4-20mA 1V 5V 10V

No communication Error 21mA 21mA 1.2V 5.5V 11V

No probe signal Error 21mA 21mA 1.2V 5.5V 11V

Wrong probe Error 21mA 21mA 1.2V 5.5V 11V

Watchdog error Error 21mA 21mA 1.2V 5.5V 11V

Values < 0 % RH Underrange 0mA 3.8mA 0V 0V 0V

Condensation Overrange 20.5mA 20.5mA 1.2V 5.5V 11V

%RH short-circuit Error 21mA 21mA 1.2V 5.5V 11V

%RH sensor broken Error 21mA 21mA 1.2V 5.5V 11V

T short-circuit Error 21mA 21mA 1.2V 5.5V 11V