Page 1

testo 6383 · differential pressure transmitter

testo 6610 · Probes

P2A software · Parameterizing, adjusting and analyzing

software

Instruction manual Volume 1

Page 2

2

Page 3

1 Safety and the environment

3

Pos: 1 /TD/Überschriften/MUF/Sicher heit und Umwelt @ 3\mod_1234793958627_79. doc @ 26223 @ 1

1 Safety and the environment

Pos: 2 /TD/Sicherheit und Umwelt/Sicher heit gewährleisten/MUF 63xx/Elektr i sche Gefahren vermeiden @ 3\mod_12347946092 99_79.doc @ 26280 @ 5

Avoiding electrical hazards

> Never use the instrument and connected probes to measure on

or near live parts!

> Damaged mains cables must only be replaced by authorize d

personnel.

> Only have the transmitter wired and connected by authorized

personnel with the voltage disconnected.

> You must always comply with the regulations applicable in your

country for opening and repairing electrical equipm ent.

Pos: 3 /TD/Sicherheit und Umwelt/Sicher heit gewährleisten/MUF 63xx/Personen- und Sachschäden vermeiden @ 3\mod_1234794744 768_79.doc @ 26299 @ 5

Avoiding personal injury and damage to equipment

> Installation, setting and calibration work must only be carried

out by qualified and authorized personnel!

> Only open the instrument when this is expressly described in

the instruction manual for installation, maintenance or repair

purposes.

> Observe the permissible storage, transport and operating

temperature.

Pos: 4 /TD/Sicherheit und Umwelt/Sicher heit gewährleisten/Nicht mit Lösungsmi tteln lagern @ 0\mod_1175692375179_79.d oc @ 583 @

> Do not store the product together with solvents. Do not use any

desiccants.

Pos: 5 /TD/Sicherheit und Umwelt/Sicher heit gewährleisten/MUF 63xx/Bei W ar tung MUF nicht zur Regelung verwenden @ 3\mod_123479 48523 77_79.doc @ 26318 @

> Do not use the instrument for control purposes at the same time

as operating or servicing the transmitter.

Pos: 6 /TD/Sicherheit und Umwelt/Sicher heit gewährleisten/Produkt bestim mun gsg emäß verwenden @ 0\mod_1173781261848_79. doc @ 386 @

> Only operate the product properly, for its intended purpose and

within the parameters specified in the technical data. Do not

use any force.

Pos: 7 /TD/Sicherheit und Umwelt/Sicher heit gewährleisten/Nur beschriebene W artungsarbeiten durchführen @ 0\mod_11756 92705195_79.doc @ 601 @

> Carry out only the maintenance and repair work on this

instrument that is described in the documentation. Follow the

prescribed steps exactly. Use only original spare parts from

Testo.

Pos: 8 /TD/Sicherheit und Umwelt/Sicher heit gewährleisten/MUF 63xx/Fachperson al @ 3\mod_1234794940409_79.doc @ 26337 @

Any additional work must only be carried out by authorized

personnel. Otherwise testo will not accept any responsibility for the

proper functioning of the instrument after repair and for the validity

of certifications.

Page 4

2 About this document

4

Pos: 9 /TD/Überschriften/MUF/Umwelt sc hü tzen @ 3\mod_1234858757571_79.doc @ 26363 @ 5

Protecting the environment

Pos: 10 /TD/Sicherheit und Umwelt/Umwel t schützen/Produkt entsorgen @ 0\mod_1173780 307072_79.doc @ 357 @

> At the end of its useful life, send the product to the separate

collection for electric and electronic devices (observe local

regulations) or return the product to Testo for disposal.

Pos: 11 /TD/Überschriften/MUF/Zu diese m Dokument @ 3\mod_1234793991331_79.doc @ 26242 @ 1

2 About this document

Pos: 12 /TD/Sicherheit und Umwelt/Zu diese m Dokument/Verwendung (Standard) @ 0\ mod_1173775068554_79.doc @ 337 @ 5

Use

> Please read this documentation through carefully and

familiarize yourself with the product before putting it to use. Pay

particular attention to the safety instructions and warning advice

in order to prevent injuries and damage to the products.

> Keep this document to hand so that you can refer to it when

necessary.

> Hand this documentation on to any subsequent users of the

product.

Pos: 13 /TD/Sicherheit und Umwelt/Zu diese m Dokument/Symbole und Schreibkonventi one n/Warnhinweis WARNUNG @ 2\mod_1207646966234_7 9.doc @ 14398 @

WARNING

Indicates potential serious injuries

Pos: 14 /TD/Sicherheit und Umwelt/Zu diese m Dokument/Symbole und Schreibkonventi one n/Warnhinweis VORSICHT @ 2\mod_1207651 416515_79.doc @ 14416 @

CAUTION

indicates potential minor injuries

Pos: 15 /TD/Sicherheit und Umwelt/Zu diese m Dokument/Symbole und Schreibkonv. Sof t ware [Standard] @ 0\mod_1190203332543_79.d oc @ 4883 @ 5

Symbols and writing standards

Representa-

tion

Explanation

Note: Basic or further information.

1. ...

2. ...

Action: more steps, the sequence must be

followed.

> ... Action: a step or an optional step.

- ... Result of an action.

Menu

Elements of the program interface.

[OK]

Buttons of the program interface.

... | ... Functions/paths within a menu.

“...” Example entries

Pos: 16 /TD/--- Seitenwechsel --- @ 0\mod_1173774430601_0.doc @ 283 @

Page 5

3 Contents

5

Pos: 17 /TD/Überschriften/MUF/Inhal t @ 3\mod_1234794019831_79.doc @ 26261 @ 1

3 Contents

1 Safety and the environment....................................................................3

2 About this document...............................................................................4

3 Contents...................................................................................................5

4 Transmitter...............................................................................................7

4.1. Specifications ..................................................................................7

4.1.1. Functions and use ...........................................................................................7

4.1.2. Scope of delivery .............................................................................................7

4.1.3. Accessories .....................................................................................................7

4.1.4. Technical data .................................................................................................8

4.1.5. Dimensions....................................................................................................12

4.2. Product description........................................................................13

4.2.1. At a glance.....................................................................................................13

4.2.2. Usable probes................................................................................................14

4.2.3. Display and keypad........................................................................................15

4.2.4. Service interface............................................................................................15

4.2.5. Relay board (option) ......................................................................................15

4.2.6. Analog outputs...............................................................................................16

4.2.7. Parameters....................................................................................................16

4.2.8. Scaling .........................................................................................................17

4.2.9. Alarm handling...............................................................................................19

4.3. Commissioning..............................................................................20

4.3.1. Mounting preparations ...................................................................................20

4.3.2. Connecting the instrument.............................................................................21

4.3.2.1. Overview of terminals........................................................................22

4.3.2.2. Connecting voltage supply and analog outputs.................................23

4.3.2.3. Connecting the relay outputs ............................................................24

4.3.2.4. Closing the instrument......................................................................27

4.3.2.5. Adjusting the instrument....................................................................29

4.3.2.6. Overview: Adjustment keys and test contacts...................................30

4.3.2.7. 1-point adjustment (offset - humidity/temperature)............................30

4.3.2.8. Analog output adjustment .................................................................32

4.3.2.9. n-point adjustment (pressure)...........................................................33

4.3.2.10. High-humidity adjustment for testo 6614....................................34

4.3.2.11. Self adjustment of testo 6615 trace humidity probe....................35

4.4. Operation.......................................................................................36

4.4.1. Relationship between user menu and mini-DIN socket is active....................36

4.4.2. Password protection ......................................................................................36

4.4.3. Structure of user menu ..................................................................................37

4.4.4. Overview of the testo 6383 user menu...........................................................38

4.4.5. The individual main menus ............................................................................41

4.4.5.1. Editing main menu of channel 1........................................................41

Page 6

3 Contents

6

4.4.5.2. Editing Main Menu Channel 2 (if this option is available)..................41

4.4.5.3. Editing Main Menu Channel 3 (if this option is available)..................42

4.4.5.4. Editing Main Menu Alarm..................................................................42

4.4.5.5. Editing Main Menu Settings..............................................................44

4.4.5.6. Editing Main Menu Analysis..............................................................47

4.4.5.7. Editing Message main menu.............................................................49

4.4.5.8. Calling up Main Menu Ident..............................................................50

4.4.5.9. Editing Main Menu Adjust.................................................................50

4.4.5.10. Editing Reset main menu...........................................................52

4.5. Status, warning and error messages ............................................53

4.5.1. Status messages...........................................................................................54

4.5.2. Warning messages........................................................................................55

4.5.3. Transmitter error messages ...........................................................................56

4.5.4. Handling alarm messages .............................................................................58

4.5.5. Namur fault conditions...................................................................................59

4.6. Maintenance and cleaning............................................................ 61

4.6.1. Maintaining the instrument.............................................................................61

4.6.2. Cleaning the instrument.................................................................................61

Pos: 18 /TD/--- Seitenwechsel --- @ 0\mod_1173774430601_0.doc @ 283 @

Page 7

4 Transmitter

7

Pos: 19 /TD/Überschriften/MUF/1 Messu mfor mer @ 3\mod_1234258401060_79.doc @ 23894 @ 1

4 Transmitter

Pos: 20 /TD/Überschriften/MUF/1.1/2. 1/ 3.1 Leistungsbeschreibung @ 3\mod_123 4258595211_79.doc @ 23951 @ 2

4.1. Specifications

Pos: 21 /TD/Leistungsbeschreibung/Ver wendung/MUF63xx/MUF 6383,84 @ 4\mod_125 1793 491331_79.doc @ 47763 @ 3

4.1.1. Functions and use

The testo 6383 transmitter is suitable for the following applications,

amongst others:

• Clean rooms

• Complex room climate applications

Pos: 22 /TD/Leistungsbeschreibung/Li eferumfang/MUF 63xx/MUF 6383, 6385 @ 4\mod_1 254749193798_79.doc @ 51251 @ 3

4.1.2. Scope of delivery

The scope of delivery of the testo 6383 transmitter includes the

following:

• With KMAT version D04: Integrated humidity probe

• Sealing frame

• Instruction manual

• Calibration report

• CD-ROM with operating instructions (PDF), configuration files

for Ethernet module and P2A update (this can only be used in

conjunction with the P2A software, which has to be ordered

separately).

Pos: 23 /TD/Leistungsbeschreibung/Li eferumfang/MUF 63xx/Zubehör Übersic ht 638x @ 3\mod_1234448071530_79.doc @ 25136 @ 3

4.1.3. Accessories

The following accessories are available for the testo 6383

transmitter, amongst others:

• Protection caps for probes

• Mains unit

• P2A software (parameterizing, adjusting and analyzing

software)

• Assembly accessories

Information about accessories and their order numbers can

be found in volume 2, Accessories and spare parts or on

the website at www.testo.com.

Page 8

4 Transmitter

8

Pos: 24 /TD/Leistungsbeschreibung/ Technische Daten/MUF 63xx/MUF 6383 @ 4\mod_12 5249 9023732_79.doc @ 48869 @ 355555555555555 5555 55555

4.1.4. Technical data

Parameters

• Differential pressure

• Temperature

• Humidity

Differential pressure accuracy

The specifications are only valid if the positive pressure is

applied at the positive pressure connection.

• 0.3 % of measuring range, additional 0.3 Pa intrinsic error 1

• T

K slope drift

= 0.02 % of measuring range per degree Kelvin of

deviation from nominal temperature 22 °C

• T

K zero point drift

= 0 %, as zeroing with solenoid valve2

Humidity and temperature accuracy

• Depends on probe

Humidity and temperature measuring range

• Depends on probe

1

Measuring uncertainty in accordance with GUM: ±0.5 % of measuring range

final value ±0.3 Pa.

GUM (Guide to the Expression of Uncertainty in Measurement): ISO guideline for determining the

measuring uncertainty in order to render global measurement results comparable.

The following uncertainties are used during the inquiry:

• Hysteresis

• Linearity

• Reproducibility

• Adjustment area/factory calibration

• Test location

2

Minor mixtures of the media may occur at the positive and negative pressure

side due to the automatic zeroing cycle.

Page 9

4 Transmitter

9

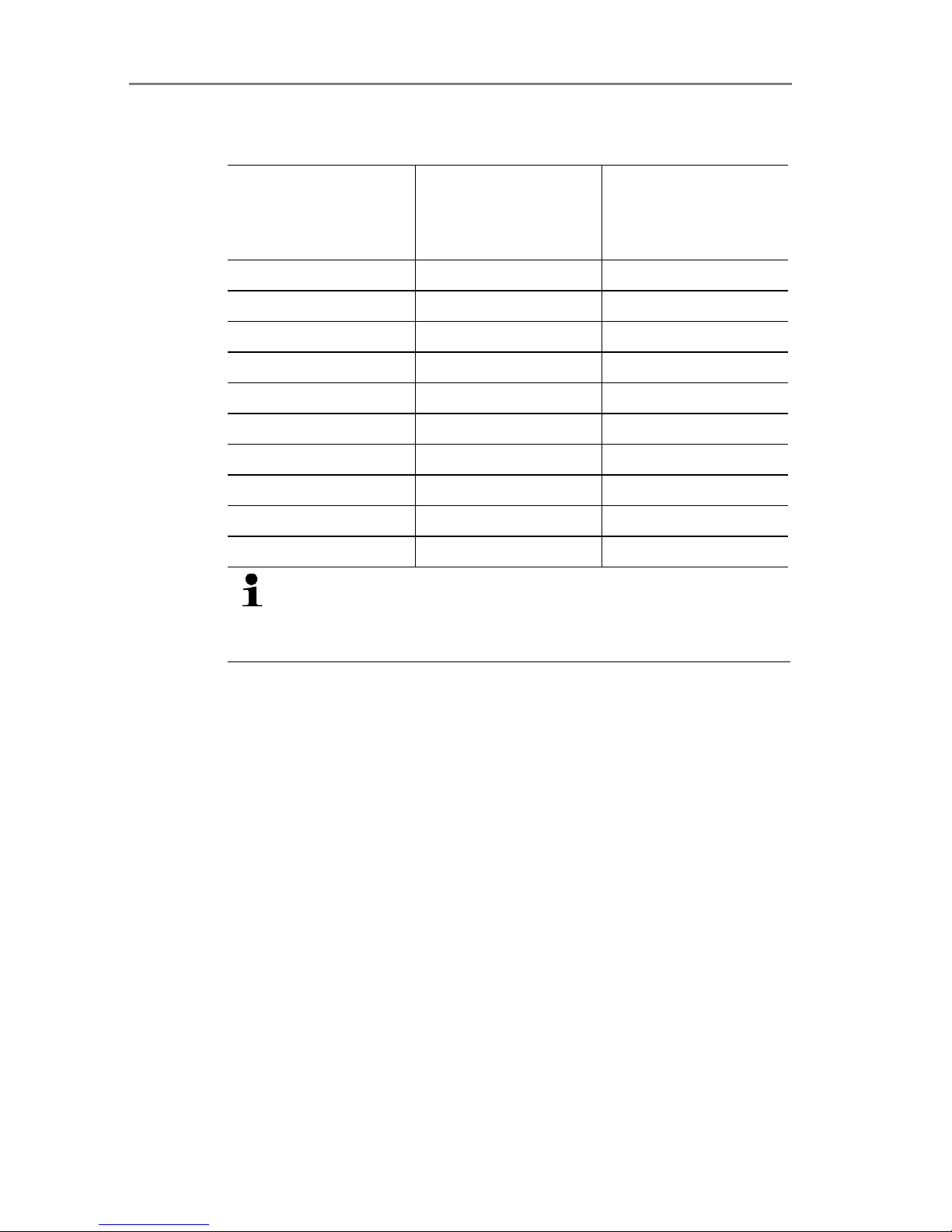

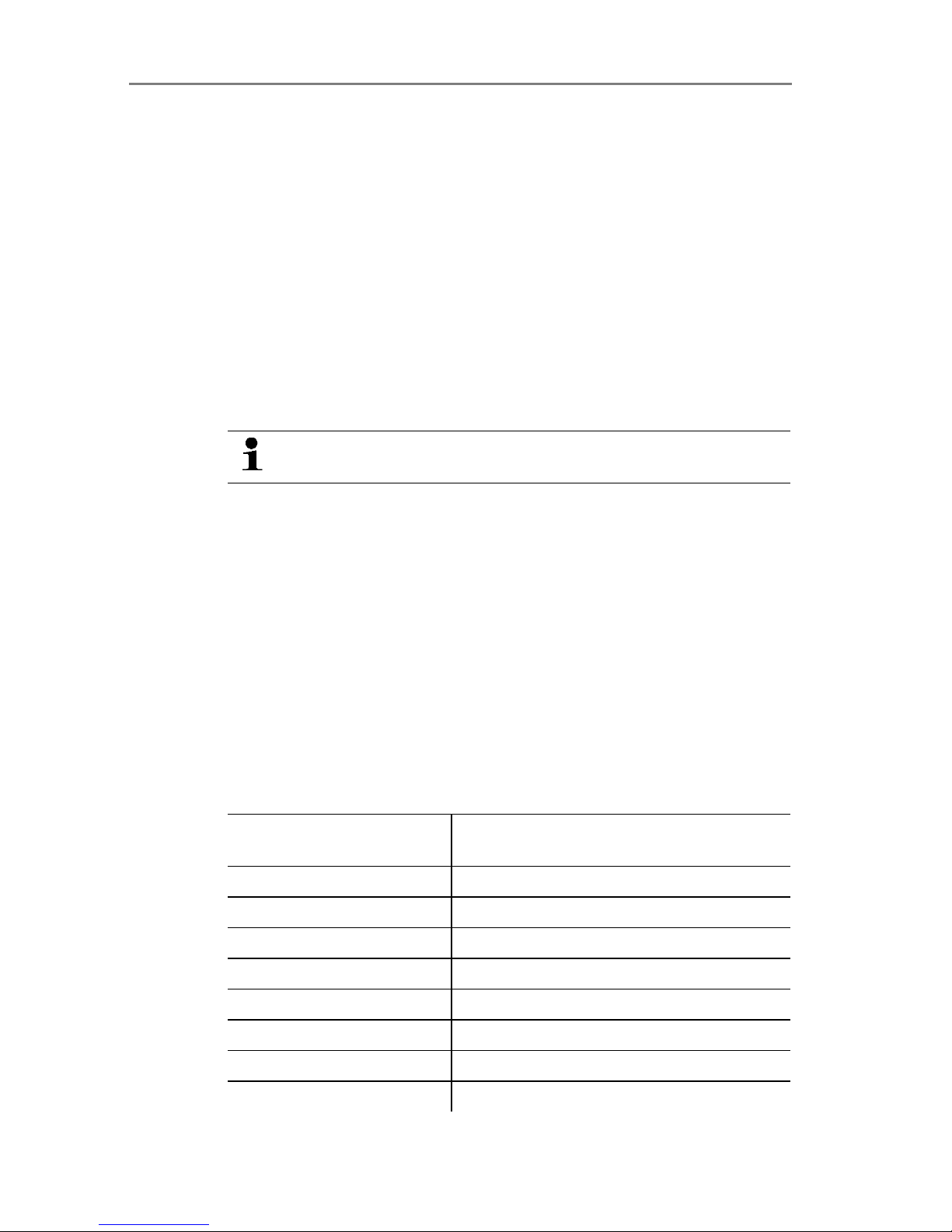

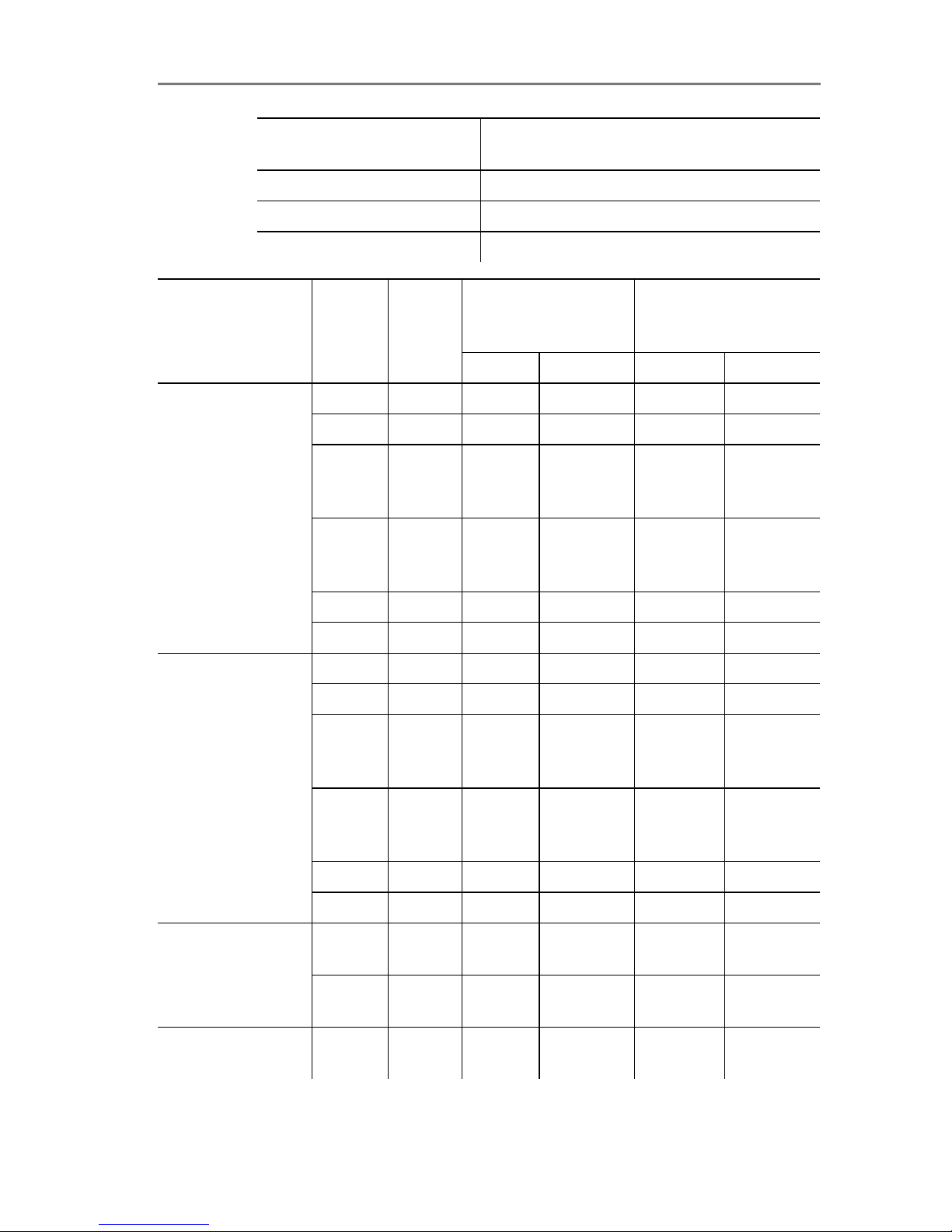

Pressure measuring range, resolution and overload of

differential pressure

Pressure

measuring range

depending on

version ordered

Resolution Overload

0 to 50 Pa 0.1 Pa 20,000 Pa

0 to 50 Pa 0.1 Pa 20,000 Pa

0 to 100 Pa 0.1 Pa 20,000 Pa

0 to 500 Pa 0.1 Pa 20,000 Pa

0 to 10 hPa 0.01 hPa 200 hPa

-10 to 10 Pa 0.1 Pa 20,000 Pa

-50 to 50 Pa 0.1 Pa 20,000 Pa

-100 to 100 Pa 0.1 Pa 20,000 Pa

-500 to 500 Pa 0.1 Pa 20,000 Pa

-10 to 10 hPa 0.01 hPa 200 hPa

Upon delivery and following a factory reset the readings are

shown in the display in the unit that was ordered via the

KMAT option Fxx, see Ordering options for testo 6383

transmitter (0555 6383), page 133.

Humidity and temperature resolution

• 0.1 % RH or 0.01 °C/0.01 °F

Meas. cycle

• 1/sec

Interface

• Mini-DIN for P2A software (parameterizing and adjusting

software) and handheld testo 400/650

• optional: Ethernet interface

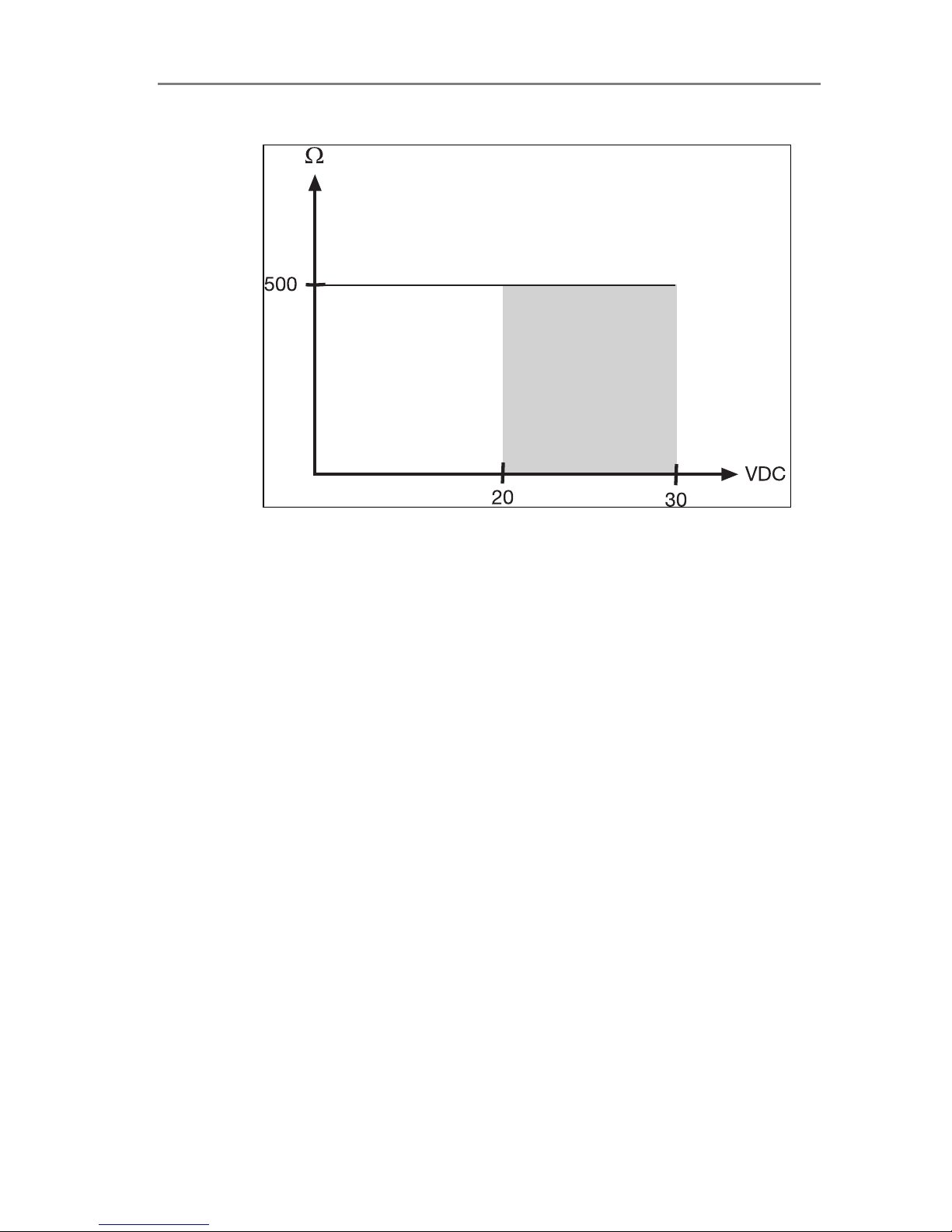

Voltage supply

• 4-wire (separate signal and supply lines): 20 to 30 V AC/DC,

300 mA power consumption

Maximum load

• 4-wire: 500 Ω (power output)

Page 10

4 Transmitter

10

Maximal load

• 4-wire: 10 kΩ (voltage output)

Analog output

• 0 to 1 V ± 1.5 mV (4-wire) or

• 0 to 5 V ± 7.5 mV (4-wire) or

• 0 to 10 V ± 15 mV (4-wire) or

• 0 to 20 mA ± 0.03 mA (4-wire) or

• 4 to 20 mA ± 0.03 mA (4-wire)

Resolution of analog output

• 12 bit

Relay

• 4 relays, 250 V AC/DC, 3 A (optional)

Display

• 2-line LCD with plain text line (optional)

Operating temperature

• -5 to 50 °C/23 to 122 °F

Page 11

4 Transmitter

11

Storage temperature

• -20 to 60 °C/-4 to 140 °F

Process temperature

• -20 to 65 °C/-4 to 149 °F

Oper. humidity

• 0 to 90 % RH

Housing, weight

• Metal/plastic

• Version with integrated humidity probe: approx. 1.35 kg

• Version with preparation for external humidity probe: approx.

1.26 kg

Protection class, frontal

• IP 65 only if the transmitter is wired and/or sealing plugs are

inserted

Directives, standards and tests

• EC Directive: 2004/108/EC

Warranty

• Duration: 2 years

• Warranty conditions: see website www.testo.com/warranty

Page 12

4 Transmitter

12

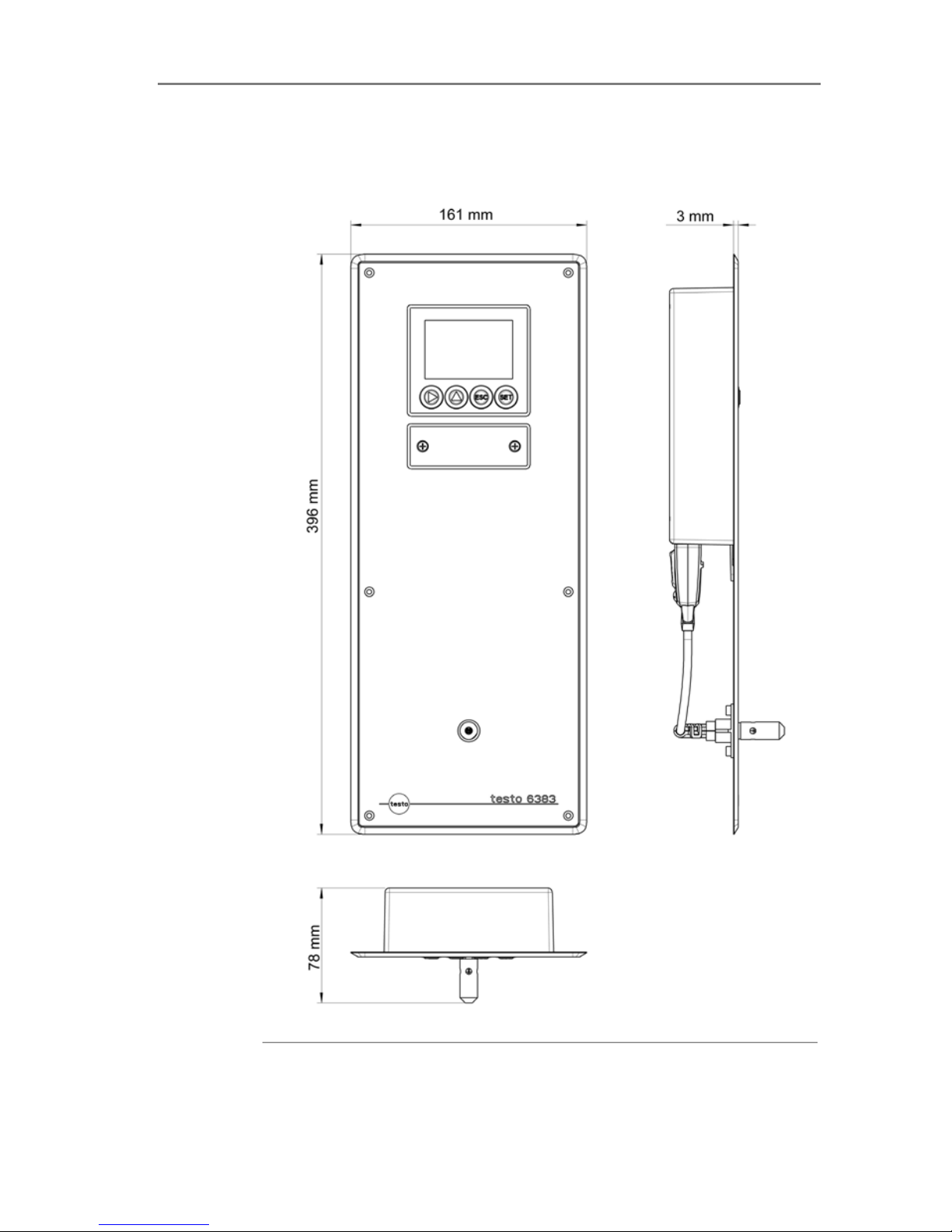

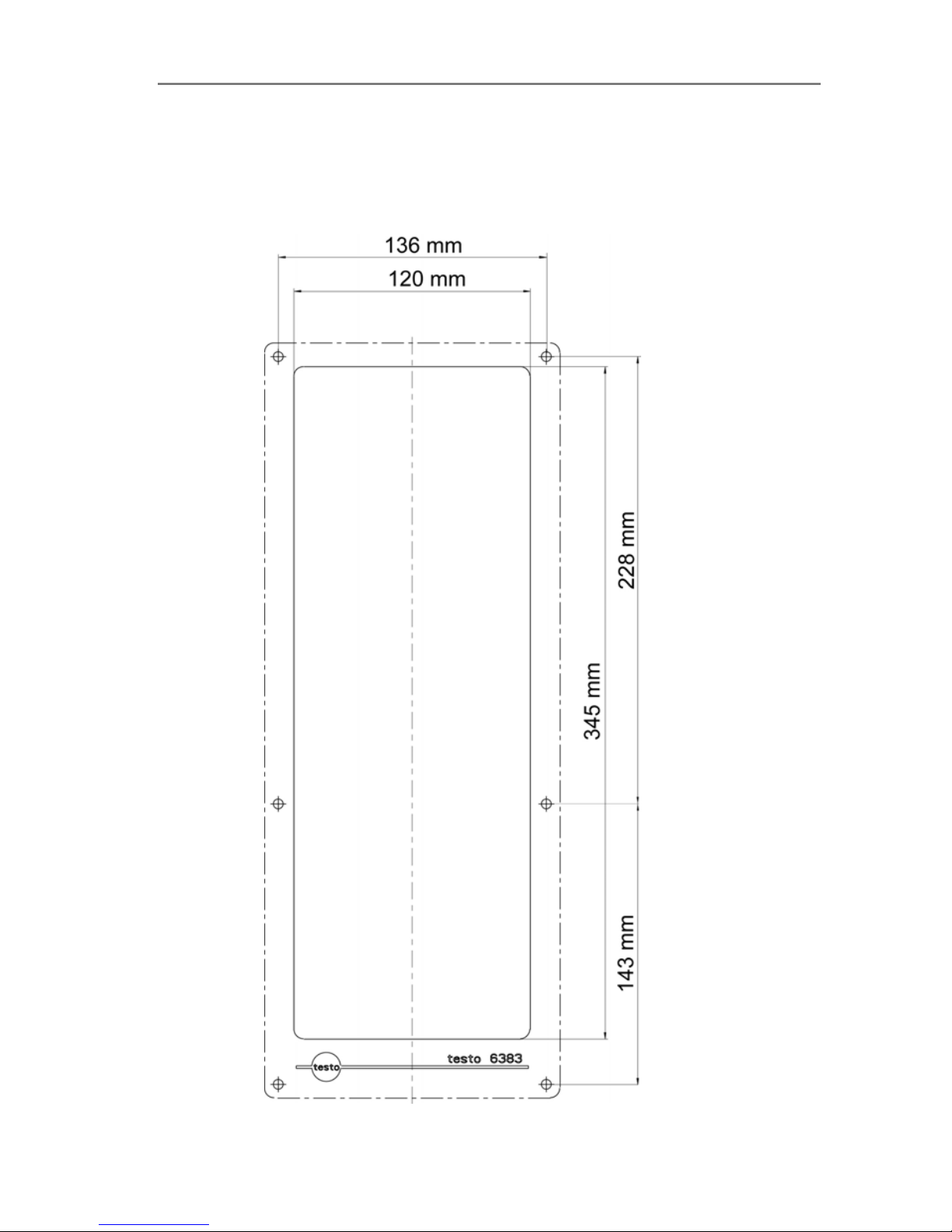

Pos: 25 /TD/Leistungsbeschreibung/ Technische Daten/MUF 63xx/MUF Panel lang Ab messungen @ 4\mod_1255092618418_79.doc @ 51743 @ 3

4.1.5. Dimensions

Page 13

4 Transmitter

13

Pos: 26 /TD/Überschriften/MUF/1.2/2. 2 P r oduktbeschreibung @ 3\mod_123425872 3551 _79.doc @ 24008 @ 2

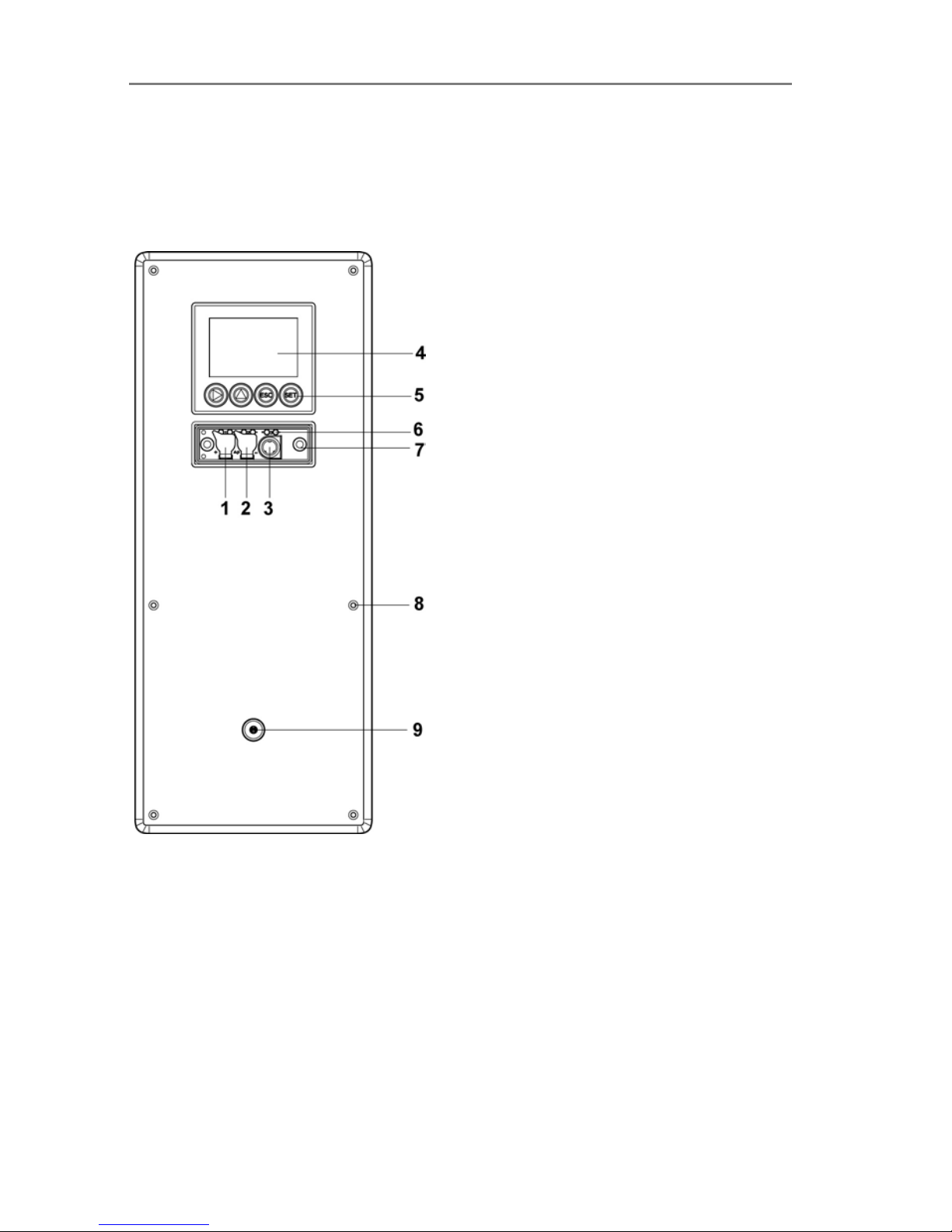

4.2. Product description

Pos: 27 /TD/Produktbeschreibung/Übersi cht/MUF 63xx/Auf einen Blick 6383 @ 4\mod_1 252499456455_79.doc @ 48901 @ 3

4.2.1. At a glance

1 Sealing plugs on the positive

pressure test connection

2 Sealing plugs on the

negative pressure test

connection

3 Socket for service plug

4 Display (optional)

5 Keys (only with optional

display)

6 Test rods for the analog

outputs

7 Service cover screw

connection (self-locking,

2 pcs.)

8 Openings for screws for

fastening to the wall

9 Only with integrated humidity

probe (KMAT option D04):

Opening for the integrated

humidity probe

Page 14

4 Transmitter

14

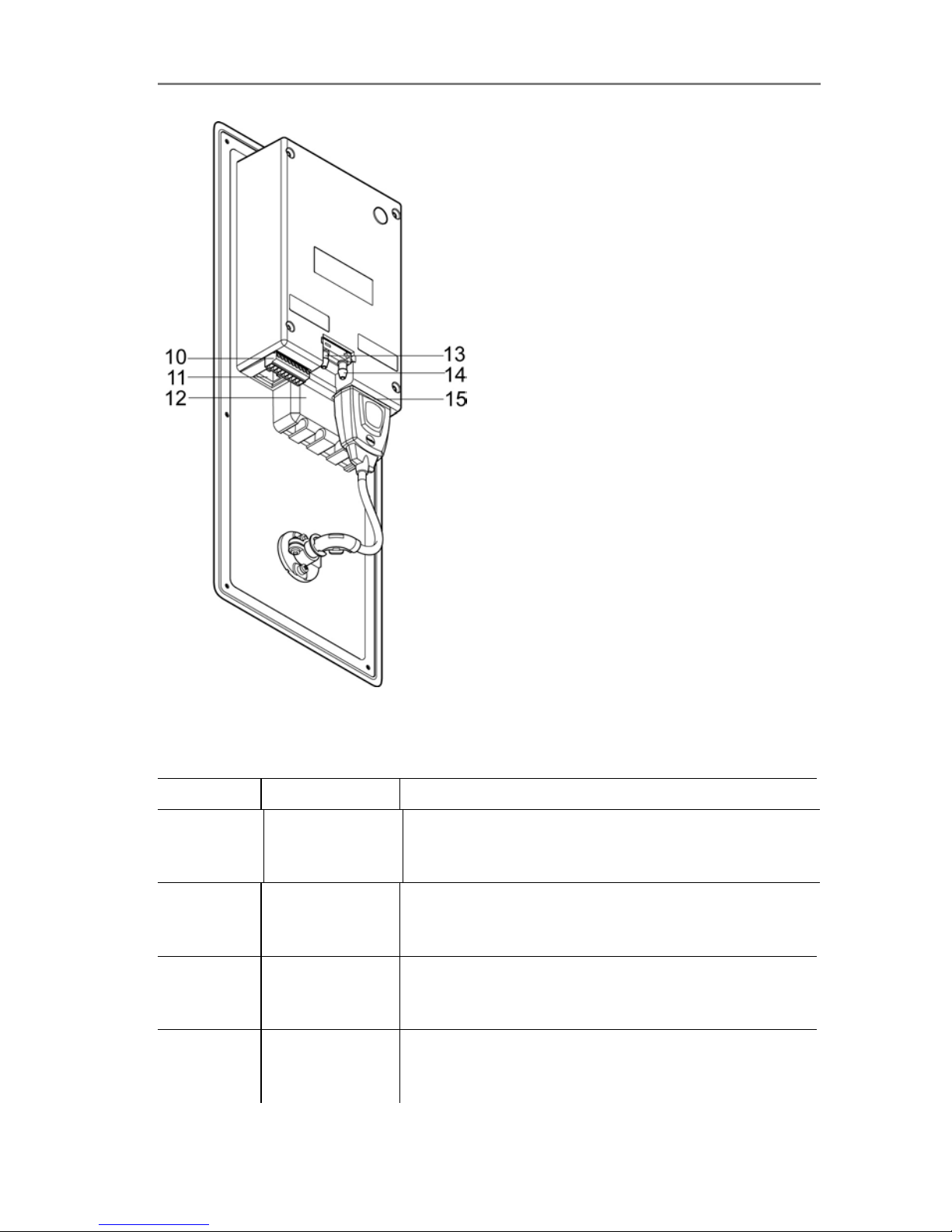

10 9-pin connector for the

current/voltage supply

11 Covered Ethernet interface

(non-functional)

12 Relay cover with 12-pin

connector underneath for

relay connection (option)

13 Negative pressure

connection

14 Positive pressure connection

15 Probe socket

Pos: 28 /TD/Produktbeschreibung/Übersi cht/MUF 63xx/Verwendbare Fühler Pane l @ 4\mod_1252670326817_79.doc @ 50119 @ 3

4.2.2. Usable probes

The testo 6383 transmitter can be used with the following probes:

Probes Article no. Characteristic

Integrated

humidity

probe

KMAT option

D04

Wall probe version; accuracy to ±1 % RH;

temperature range -20 to +70 °C/-4 to +158 °F,

plug-on sensor

testo 6612 0555 6610-L12

Duct probe version; accuracy to ±1 % RH;

temperature range -30 to +150 °C/

-22 to +302 °F, sensor soldered

testo 6613 0555 6610-L13

Cable probe version; accuracy to ±1 % RH;

temperature range -40 to +180 °C/

-40 to +356 °F, sensor soldered

testo 6614 0555 6610-L14

Heated cable probe version; accuracy to ±1.0 %

RH; temperature range -40 to +180 °C/

-40 to +356 °F, sensor soldered

Page 15

4 Transmitter

15

Probes Article no. Characteristic

testo 6615 0555 6610-L15

Trace humidity cable probe version; accuracy

±1 K at 0 °Ctd/+32 °Ftd; temperature range

-40 to 120 °C/-40 to +248 °F, sensor soldered

testo 6617 0555 6610-L17

Cable with cover electrode monitoring probe

version; accuracy to ± 1.2 % RH; temperature

range -40 to 180 °C/

-40 to +356 °F, sensor soldered

Pos: 29 /TD/Produktbeschreibung/Übersi cht/MUF 63xx/Display und Tastatur @ 3\ mod_1234773965059_79.doc @ 25650 @ 3

4.2.3. Display and keypad

The display option allows operation of the testo 6383 transmitter via

the display and four keys.

The LCD display consists of two 7-segment lines for displaying

readings and units and of an information line (for status messages,

for example).

The brightness and contrast of the display and the backgrou nd

lighting (permanent or off) can be changed via the user menu or the

P2A software.

Pos: 30 /TD/Überschriften/MUF/1.2. x Serviceschnittstelle @ 3\mod_12373068 91654_79.doc @ 29795 @ 3

4.2.4. Service interface

Pos: 31 /TD/Produktbeschreibung/Übersi cht/MUF 63xx/Serviceschnittste lle 638x @ 3\mod_1234774092911_79.doc @ 25669 @

The parameterizing socket (mini-DIN) is located behind the service

flap as an interface to the P2A software or Testo handheld

instrument (testo 400/testo 650).

Pos: 32 /TD/Produktbeschreibung/Übersi cht/MUF 63xx/Relaisplatine (Op ti on) @ 3\mod_1234774184843_79.doc @ 25688 @ 3

4.2.5. Relay board (option)

This has a floating switch capacity of 250 V AC/3 A. The switching

limits and hysteresis as well as the function as relay for the

collective alarm can be set via the display or the P2A software.

Further features include:

• Function of changeover contacts (NC/NO contacts) freely

selectable

• 12 terminals for a total of 4 relays.

If no relays are available, settings for monitoring limit values

or alarms can still be controlled via the display. The alarm

status will be shown on the display.

Only have the transmitter wired and connected by

authorized personnel with the voltage disconnected.

Page 16

4 Transmitter

16

Pos: 33 /TD/Produktbeschreibung/Übersi cht/MUF 63xx/Analogausgänge 638 x @ 3\mo d_1 234774341528_79.doc @ 25707 @ 3

4.2.6. Analog outputs

As analog outputs, the testo 6383 has either

• 1 or optionally 3 current outputs of 0 to 20 mA (4-wire)/4 to

20 mA (4-wire) or

• 1 or optionally 3 voltage outputs of 0 to 1 V/0 to 5 V/0 to 10 V

(4-wire).

The transmitter can be ordered with three analog outputs as an

option.

The optional three channels are galvanically isolated.

Pos: 34 /TD/Produktbeschreibung/Übersi cht/MUF 63xx/Messgrößen 6383/6385 @ 3\ m od_1 234774693900_79.doc @ 25745 @ 3

4.2.7. Parameters

The following parameters are displayed

• Differential pressure in Pa, hPa, kPa, mbar, bar, mmH

2

O, inch

H

2

O, inch HG, kg/cm2, PSI

• Relative humidity in % RH (technical)

• Relative humidity in % WMO* (calculation according to the

WMO standard)

• Degree of humidity in g/kg and gr/lb

• Absolute humidity in g/m³ and gr/ft³

• Water content in ppm (vol) and % vol

• Psychrometer temperature in °C

tw

and °Ftw

• Enthalpy in kJ/kg and BTU/lb

• Water vapour partial pressure in hPa and inch H

2

O

• Dewpoint temperature in °C

td

and °Ftd

• Standardized dewpoint in °C

tdA ,

standardized at atmospheric

pressure (1013 hPa); precondition: Absolute process pressure.

• Dewpoint of H

2O2

mixture in °Ctm and °Ftm.

* It is possible that condensation appears as of a displayed

humidity starting from 70 % and is shown on the display. This

unit is used in meteorology, amongst others. When calculating

the relative humidity the Magnus coefficient with undercooled

water is used in accordance with WMO.

Calculated humidity variables correspond to the medium of

air. With other gases/gas compositions, deviations may

occur, e.g. with the enthalpy.

• Temperature °C and °F

Page 17

4 Transmitter

17

Pos: 35 /TD/Produktbeschreibung/Übersi cht/MUF 63xx/Skalierung @ 3\mod_123477 5406989_79.doc @ 25783 @ 3

4.2.8. Scaling

There are three types of min./max. values:

1 The measuring range: The maximum sensor performance is in

this range. Values outside of the measuring range are displayed

via messages, for example. Measuring range, see table

(below).

2 Standard scaling: The output signals are assigned to this

measuring range as standard:

◦ during delivery if no entries are made in the order code

◦ after exchanging the un it, the measuring range recorded in

the instrument is applied as standard.

The transmitter even retains its scaling with the voltage

disconnected.

Measuring range, see table (below).

3 The maximum settings for the manual scaling

◦ The maximum limits can be calculated as follows:

X = difference between MIN. and MAX. value of the

standard scaling

(Max. value of standard) + (50 % of X)

(Min. value of standard) - (50 % of X)

◦ It is thus possible to scale beyond the measuring rang e, e.g.

for the adjustment of the scaling limits to standard values of

a PLC.

With the alarm definition, however, the physical measuring

range limits are decisive.

Pos: 36 /TD/Produktbeschreibung/Übersi cht/MUF 63xx/Tabelle Skalierung M UF Pan el Druck @ 4\mod_1251818135359_79.doc @ 48019 @

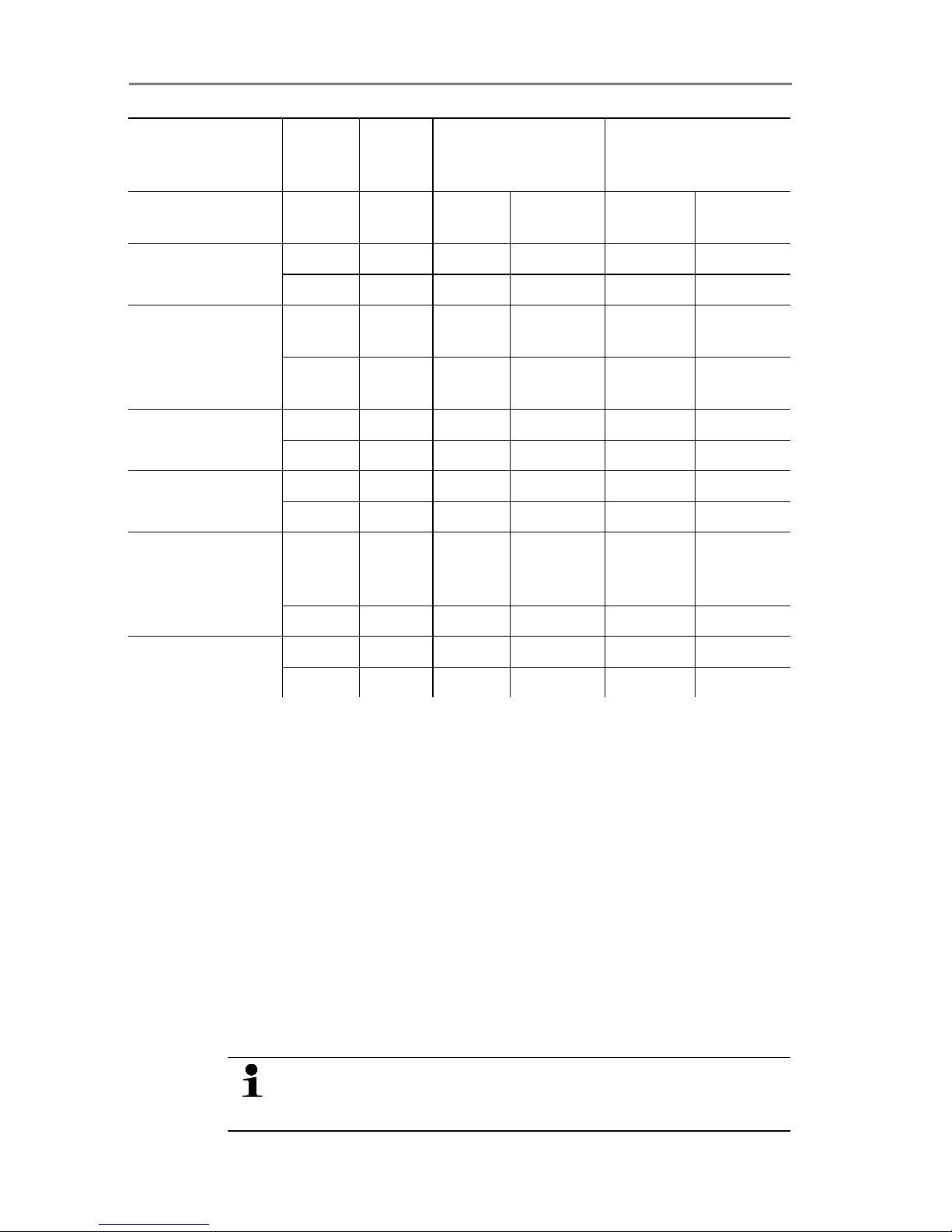

Measuring

range/standard scaling

Maximum scaling

0 to 50 Pa -5 to 15 Pa

0 to 50 Pa -25 to 75 Pa

0 to 100 Pa -50 to 150 Pa

0 to 500 Pa -250 to 750 Pa

0 to 10 hPa -5 to 15 hPa

-10 to 10 Pa -20 to 20 Pa

-50 to 50 Pa -100 to 100 Pa

-100 to 100 Pa -200 to 200 Pa

Page 18

4 Transmitter

18

Measuring

range/standard scaling

Maximum scaling

0 to 50 Pa -5 to 15 Pa

-500 to 500 Pa -1000 to 1000

-10 to 10 hPa -20 to 20 hPa

Pos: 37 /TD/Produktbeschreibung/Übersi cht/MUF 63xx/Tabelle Skalierung Fühl er Panel @ 5\mod_1257519388289_79.doc @ 52767 @

Physical

measuring range

at 1013 hPa

Standard scaling of

transmitter

measuring range

Parameter Unit Probes

MIN MAX MIN MAX

°C 6611 -20 +70 -20 +70

°F 6611 -4 +158 -4 +158

°C

6613,

6614,

6617

-40 +180 -40 +180

°F

6613,

6614,

6617

-40 +356 -40 +356

°C 6615 -40 +120 -40 +120

Temperature

°F 6615 -40 +248 -40 +248

°Ctd 6611 -20 +70 -80 +100

°Ftd 6611 -4 +158 -112 +212

°Ctd

6613,

6614,

6617

-20 +100 -80 +100

°Ftd

6613,

6614,

6617

-4 +212 -112 +212

°Ctd 6615 -60 +30 -80 +100

Dewpoint

°F

td

6615 -76 +86 -112 +212

g/m3

all

probes

0 600 0 2000

Absolute

humidity

gr/ft

3

all

probes

0 250 0 800

relative humidity % RH

all

probes

0 100 0 100

Page 19

4 Transmitter

19

Physical

measuring range

at 1013 hPa

Standard scaling of

transmitter

measuring range

WMO relative

humidity

% RH 0 100 0 100

°Ctm -20 +100 -20 +100

Mixture dewpoint

(H

2O2

)

°F

tm

-4 +212 -4 +212

g/kg

all

probes

0 13300 0 9500

Degree of

humidity

gr/lb

all

probes

0 93000 0 66500

kJ/kg -40 99999 -40 8000 Enthalpy

BTU/lb -18 43000 -18 3500

°Ctw -40 100 -40 180

Psychrometer

temperature

°Ftw -58 210 -40 356

ppm

(vol)

H

2

O

0 99999 0 99999 Water content

% vol 0 100 0 100

hPa 0 1000 0 7000

Water vapour

partial pressure

inchH2O 0 400 0 2800

Pos: 38 /TD/Produktbeschreibung/Übersi cht/MUF 63xx/Alarmbehandlung @ 3\mod _12 34776787635_79.doc @ 25821 @ 3

4.2.9. Alarm handling

For upper and lower alarm limits, individual alarms as well as

collective alarms can be specified. If the collective alarm function is

activated, an alarm is triggered as soon as the alarm limit of an

alarm is exceeded, if this alarm is assigned to the collective alarm.

The testo 6383 monitors limit values with the help of relays. If a

reading is outside the limit values, a relay to be specified by the

user is switched.

If the reading reverts to more than a specified hysteresis below or

above the limit value, the alarm is cancelled.

In addition, information about the occurrence of error/status

messages can be provided by means of a collective alarm relay,

see Status, warning and error messages, page 53

If multiple alarm messages are activated at the same time,

the last alarm is shown. If the alarm is cancelled again, the

previous messages are no longer shown.

Page 20

4 Transmitter

20

Pos: 39 /TD/Überschriften/MUF/1.3/2. 3 I nbetriebnahme @ 3\mod_1234258805768_7 9.doc @ 24027 @ 2

4.3. Commissioning

Pos: 40 /TD/Erste Schritte/MUF 63xx/W andm ont age Panel @ 4\mod_1251818568448_79.doc @ 48051 @ 3

4.3.1. Mounting preparations

Page 21

4 Transmitter

21

1. Create a wall opening (approx. 120 mm x 220 mm) at the

mounting location.

2. Hold 6383 in assembly position and mark the drill holes.

3. Drill holes suitable for the screws to be used.

4. Connect 6383.

Pos: 41 /TD/Erste Schritte/MUF 63xx/Gerä t anschließen Panel @ 4\mod_125206550656 6_79. doc @ 48245 @ 3

4.3.2. Connecting the instrument

WARNING

Electrical voltage

Danger of injury!

> De-energize the mains connection before connecting the

transmitter.

Only have the transmitter wired and connected by

authorized personnel with the voltage disconnected.

Page 22

4 Transmitter

22

Pos: 42 /TD/Erste Schritte/MUF 63xx/Ansc hlussübersicht 6383 @ 4\mod_125170832 7447 _79.doc @ 47697 @ 4

4.3.2.1. Overview of terminals

1 Terminal strip for voltage

supply and analog outputs

3 Relay cover (option)

2 Relay terminal strip (option),

below the relay cover

4 Insulating trough for relay

board (option), below the

relay cover

The following description of the terminals refer to this

overview and its numbering.

Pos: 43 /TD/Erste Schritte/MUF 63xx/Spannu ngsversorgung/Analogausgänge an sc hließen 6383/6385 @ 4\mod_1254489681844 _79.doc @ 51173 @ 45

Page 23

4 Transmitter

23

4.3.2.2. Connecting voltage supply and analog outputs

Terminal strip for voltage

supply and analog outputs,

item (1) of overview of

terminals

Wiring diagram for 4-wire system (0 to 20 mA/4 to 20 mA/0 to 1

V/0 to 5 V/0 to 10 V)

1 1 or 3 channels,

0 to 20 mA/4 to

20 mA max.

load per 500 Ω

0 to 1 V/0 to

5

V /

0 to 10 V

2 Functional earth

Requirement for the connecting cable of the supply:

• Shielded and insulated with cross-section of at least

0.25 sq. mm, maximum 1.5 sq. mm without wire end sleeves.

• T he supply line must be secured against exceeding

0.5 A.

• An OFF switch must be installed in an easily accessible

position close by and be marked as such.

1. Disconnect terminal strip for voltage supply and analog outputs.

2. Strip the cable ends, clamp wire end ferrules on and screw

down with voltage terminals/channel terminals.

3. Tie together each of the two adjacent cores using a cable tie.

4. Attach terminal strip for voltage supply and analog outputs.

Page 24

4 Transmitter

24

Pos: 44 /TD/Erste Schritte/MUF 63xx/Re lai sa usgänge anschließen Panel @ 4\mod_12518 14425917_79.doc @ 47891 @ 4555

4.3.2.3. Connecting the relay outputs

Only have the transmitter wired and connected by

authorized personnel with the voltage disconnected.

Relay terminal strip,

item (2) of overview of

terminals

There is the option of twelve terminals for a total of four relays.

1. Remove relay cover.

2. Disconnect relay terminal strip.

3. Strip cable ends and clamp on wire end ferrules.

4. Connect relays according to chosen function (NC/NO) (see

diagrams below; relay 1 is shown as an example of a

connection).

Connection note

• For the connection, a double-insulated mains cable

(sheathed cable) with a cross-section of at least 1.5

mm² must be used.

• Cable connection (2) may not be routed in a loop within

the relay trough (1).

Page 25

4 Transmitter

25

• It is recommended that you always tie 2 adjacent cores

to one another using a cable tie (3).

• T he insulation of the cable must be fed at least 5 mm

(4) into the relay tray up to the elevated part.

Use of relay as NC contact (NC = normally closed)

1 Alarm/status light

(example of installation)

2 250 V AC/DC, 3 A

The busy light (alarm/status light) is permanently on until

the relay opens or the circuit is interrupted. This circuit can

therefore be used to monitor the functionality of the alarm

circuit, as a cable break, for instance, is indicated by the

busy light going off.

Page 26

4 Transmitter

26

Use of relay as NO contact (NO = normally open)

1 Alarm/status light

(example of installation)

2 250 V AC/DC, 3 A

The busy light (alarm/status light) only comes on when the

relay is switched (closed). Monitoring the functionality of the

alarm circuit is therefore not possible with this switching

operation.

5. Insert relay terminal strip into socket.

6. Set on relay cover.

Page 27

4 Transmitter

27

Pos: 45 /TD/Erste Schritte/MUF 63xx/Gerä t schließen 6383 @ 4\mod_1252501761161_79.doc @ 48997 @ 4

4.3.2.4. Closing the instrument

1. Connect probe.

• Version with int egrated humidity probe:

1. Insert probe into probe socket.

2. Guide probe through opening of front plate.

3. Tighten screw at opening.

• Version with external h umid ity probe:

> Insert probe into probe socket.

Page 28

4 Transmitter

28

4. Pull sealing frame (1) over the edge of the 6383.

5. Screw on 6383. Initially, only tighten the screws slightly. When

all screws are in position, also align 6383 and tighten the

screws.

6. Seal 6383 using a measure appropriate for the installation point

(e.g. with a silicone strip).

Pos: 46 /TD/Erste Schritte/MUF 63xx/Gerä t abgleichen 6383/6385 @ 4\mod_1252502215678 _79.doc @ 49029 @ 4

Page 29

4 Transmitter

29

4.3.2.5. Adjusting the instrument

The testo adjusting concept allows the entire signal chain from the

sensor signal (probe) and the digital signal (within the transmitter)

through to the analog signal (transmitter output signal) to be

adjusted (see diagram).

1-point adjustment

Adjustment via

• testo 400/650

handheld instrument

with adjustment

adapter

• P2A software

• User menu

Analog adjustment n-point adjustment

Adjustment using a

precise multimeter and

transmission of analog

reference value in

• User menu or

• P2A software

Adjustment using a

precise pressure sensor

and transmission of

analog reference value in

• User menu or

• P2A software

The 1-point adjustment is suitable for adjusting the sensor signal digital signal chain.

The testo 6383 transmitter has digital probes whose adjustment

information is stored in the probes' internal memory. The 1-point

adjustment can thus be carried out on another testo 6383 (e.g. in

the calibration laboratory).

Page 30

4 Transmitter

30

Pos: 47 /TD/Erste Schritte/MUF 63xx/Übersi cht Abgleichtasten und Prüfkontak te 6383/6385 @ 4\mod_1252502914330_79.doc @ 49061 @ 4

4.3.2.6. Overview: Adjustment keys and test contacts

1 Contact ch. 1

2. Contact ch. 2

3. Contact ch. 3

4. Service interface

Pos: 48 /TD/Erste Schritte/MUF 63xx/1-Pun kt-Abgleich (Offset) @ 3\mod_1234790066 779_79.doc @ 26106 @ 45

4.3.2.7. 1-point adjustment (offset - humidity/temperature)

In the 1-point adjustment, the reading at the working point is raised

to the reference value so that there is no longer any deviation in the

working point. The reference condition can be measured using a

precise handheld instrument (e.g. testo 400/650 with precision

humidity probe) or be created in an air conditioning cabinet.

1 Deviation

2 Working point

3 Working range

The advantage of the 1-point adjustment is the good measuring

result in the working range. But the further away the measurement

is from the working point, the greater the deviation can become.

The 1-point adjustment should therefore only be used for a

Page 31

4 Transmitter

31

relatively narrow measuring range (working range), e.g. clean room

applications, air conditioning applications for storage and similar.

The 1-point adjustment can be performed

• via the user menu (see Editin g Main Menu Adjust, page 50) or

• via the P2A software (see volume 2, 1-point adjustment, page

122) or

• directly by means of a T esto handhel d instrument

(testo 400/650) (see description of how to proceed below).

Please note that the 1-point adjustment is generally performed on

the basis of the % RH and °C/°F parameters.

Adjusting testo 6383 using testo handheld instrument

✓ The service flap is open, a testo 400/650 handheld instrument

with a precision humidity probe is ready.

1. Connect testo handheld instrument 400/650 (1) with connected

humidity reference probe (3) (order no. reference set

0699 3656/20) to the service interface (5) of the testo 6383 via

the adjustment adapter (2) (connected to probe socket 1 of the

handheld instrument).

2. Expose the humidity probe (4) of the testo 6383 and the

reference probe (3) to the same reference conditions (e.g. in

the humidity generator) and allow climatic conditions to

equalize.

3. Switch on the testo 400/650. The two-part display of the

handheld instrument will show the values of the transmitter on

the left, and the values of the reference probe on the right. The

humidity and temperature values are adjusted to the reference

probe using the Probe > Probe Adjustment menu item on the

Page 32

4 Transmitter

32

testo 400/650. The 1-point adjustment is performed for both the

humidity and the temperature.

4. Disconnect the adjustment adapter (2) from the service

interface (5).

5. Close the service flap.

Pos: 49 /TD/Erste Schritte/MUF 63xx/Hin weis 6614, 6615 @ 3\mod_1234791706885_79.doc @ 26163 @

Adjustment with the standard testo adjustment salt pots is

not suitable for the testo 6614 (heated for high-humidity

applications) and testo 6615 (trace humidity) probes.

The reference conditions should be generated in a humidity

generator to adjust these probes. In addition, these probes

can also be adjusted at a third adjustment point by Testo

Service.

• testo 6614: third adjustment point at 90 % RH

• testo 6615: third adjustment point at -40 °Ctd/-40 °Ftd

Pos: 50 /TD/Erste Schritte/MUF 63xx/Analo gausgangs-Abgleich 6383/6385 @ 4\mod_125 2498044594_79.doc @ 48837 @ 45

4.3.2.8. Analog output adjustment

The purpose of adjusting the analog outputs is to adjust the signa l

chain from the digital signal (within the transmitter) to the analog

outputs. The signal type that was appointed for the transmitter is

adjusted respectively for each channel (e.g. 4 to 20 mA or 0 to 1 V,

etc.).

1 Contact ch. 1

2. Contact ch. 2

3. Contact ch. 3

4. Service interface

Page 33

4 Transmitter

33

Adjusting analog outputs 1, 2 and 3 (optional)

✓ With testo 6383 with current output: Load of max. 500 Ω is

connected to channel that is to be adjusted (see Connecting

voltage supply and analog outputs, page 23)

✓ A precise multi meter (minimum requirement: resolution 6.5

digits, at least 5-times more accurate than the 6383) is

available.

If only a simple multimeter is available, the analog outputs

must not be adjusted.

✓ The service cover is open.

1. Connect the inputs of the multimeter with the contacts (1) and

(2) for channel 1 or with contacts (3) and (4) for channel 2, (5)

and (6) for channel 3.

2. Transfer the reference analog value measured with the

multimeter into the P2A software (see volume 2, Adjusting the

analog output, page 125) or enter it via the user menu (see

Editing Main Menu Adjust, page 50).

3. Disconnect connections between the multimeter and the

contacts of the testo 6383 and close the service cover.

Pos: 51 /TD/Erste Schritte/MUF 63xx/n-Pun kt-Abgleich _638x @ 3\mod_1237384429887_ 79.doc @ 29990 @ 4

4.3.2.9. n-point adjustment (pressure)

With an n-point adjustment, the parameters at the 3-6

measurement points are adjusted to the reference value. T he

reference conditions are obtained by using a precise pressure

sensor that should be 5-times more accurate than the transmitter.

1 Positive pressure connection

2. Negative pressure connection

3. Pressure sensor

The number of measuring points is set to 3 by the factory

and can only be changed using the P2A software (see n-

point adjustment page 124)

Page 34

4 Transmitter

34

The n-point adjustment must always be carried out to its full

extent and in good time at all selected measurement points.

✓ A precise pr essure sensor (5-times more accurate than the

transmitter, e.g. DPC precision pressure sensor from testo

industrial services) is available.

1. Connect the positive output of the pressure sensor (3) to the

positive pressure connection of the transmitter (1) and the

negative output of the pressure sensor (3) to the negative

pressure connection of the transmitter (2).

2. Transfer the reference pressure value created with the pressure

sensor into the P2A software (see volume 2, n-point

adjustment, page 124) or enter it via the user menu (see Editing

Main Menu Adjust, page 50).

3. Repeat step 2 for all of the measuring points.

4. Disconnect connections between the pressure sensor and the

pressure connections of the testo 6383.

Pos: 52 /TD/Erste Schritte/MUF 63xx/Hochf euchteabgleich beim testo 6614 @ 3\mod_123 5661029461_79.doc @ 26922 @ 4

4.3.2.10. High-humidity adjustment for testo 6614

With the testo 6614, the rear of the Testo humidity sensor is

heated, creating a microclimate around the sensor (within the filter)

that is constantly 5 K warmer than the actual process conditions.

Page 35

4 Transmitter

35

As can be seen in the Mollier diagram, this reduces the relative

humidity at the sensor from around 100 % RH to a lower value, e.g.

73 % RH. In this range, the reaction time of the sensor is noticeably

shorter than in the condensation range and the risk of the sensor

corroding is also reduced. Using the separate temperature probe,

the testo 6383 transmitter compensates the microclimate conditions

and displays the process readings.

The reference conditions (11.3 % RH and 75.3 % RH) for

the 2-point adjustment of the testo 6614 should be

generated in a humidity generator, as humid ity adjustment

sets cannot be used due to the heat generated.

The adjustment can also be carried out at a third

adjustment point (90 % RH) by Testo Service so that

optimum accuracy is also achieved in the high humidity

ranges.

Pos: 53 /TD/Erste Schritte/MUF 63xx/Selb stabgleich des Restfeuchtefühlers tes to 6615 @ 3\mod_1235661074070_79.doc @ 26942 @ 4

4.3.2.11. Self adjustment of testo 6615 trace humidity probe

Conventional trace humidity probes show a steep rise in measuring

uncertainty at low humidities. In the testo 6615 trace humidity

probe, these measuring uncertainties are corrected by means of an

automatic self-adjustment process. This means that extremely

accurate measuring results are also attained to -60 °Ctd.

To this end, a temperature sensor is fitted on the back of the

testo 6615 which is used as a heater. A humidity and temperature

value pair is taken in both the unheated and heated state. The

deviation of the probe obtained from these pairs of values is

automatically corrected.

Page 36

4 Transmitter

36

The heating time and storing of cycles can be edited in the P2A

software; for example, they can be deactivated by setting the two

parameters to "0".

• Deactivating th e adjustment function of the testo 6615

will reduce measuring accuracy and should therefore be

restricted to the shortest possible length of time.

• During the heating phase, the relay and analog outputs,

the display value and output value are "frozen", see

diagram above. Self-adjustment active is shown in the

display until it has finished. The factory setting for selfadjustment time (incl. heating time, calculation time,

cooling time) requires 30 minutes daily.

• In the factory setting, a third adjustment point

(-40 °Ctd) is approached for the testo 6615 in addition

to the 2-point adjustment. This special adjustment can

be performed again by your Testo Service team if

necessary.

Pos: 54 /TD/Überschriften/MUF/1.4 Bedi enung @ 3\mod_1234443160034_79.doc @ 25001 @ 2

4.4. Operation

Pos: 55 /TD/Produkt verwenden/MUF 63xx/Zusa mmenhang Bedienmenü – Mini DIN Buchse akti v @ 3\mod_1234454016014_79.doc @ 25213 @ 3

4.4.1. Relationship between user menu and mini-DIN

socket is active

The testo 6383 can be parameterized using either the user menu or

the P2A software (see volume 2, Parameterizing, adjusting and

analyzing software (P2A software) page 101).

The testo 6383 transmitter can only be operated via the

display and keypad if the display option is available.

If the testo 6383 is connected to the P2A software, the user

menu is blocked for the duration of the communication. The

message Service plug is shown in the display of the testo

6383. As soon as the P2A software is disconnected, the

user menu is accessible again.

Pos: 56 /TD/Produkt verwenden/MUF 63xx/Pass wortschutz _638x @ 3\mod_1234455136144 _79.doc @ 25251 @ 3

4.4.2. Password protection

The user menu can be protected with a four-digit numerical code

(see Editing Main Menu Settings, page 44) so that access to the

user menu is denied to unauthorized persons not familiar with this

numerical code.

If the password protection is not to be used, the numerical code

"0000" must be entered. This is also the status upon delivery.

Page 37

4 Transmitter

37

Pos: 57 /TD/Produkt verwenden/MUF 63xx/Auf bau des Bedienmenüs 638x @ 3\mod_1234455236596 _79.doc @ 25270 @ 3

4.4.3. Structure of user menu

At the main menu level, the user menu comprises the following:

• Main Menu Channel 1

• Main menu of channel 2 (if this option is available)

• Main menu of channel 3 (if this option is available)

• Main Menu Alarm

• Main Menu Settings

• Main Menu Analysis

• Main Menu Messages

• Main Menu Ident

• Main Menu Adjust

• Main Menu Reset

1 Channel 1 display

2 Channel 2 display

3 Channel 3 display or for

messages

Four keys enable the user to navigate/scroll through the menus and

enter/amend values and settings:

Key Function/description

SET

• In Measuring Mode: changes to

parameterization

• In Parameterizing Mode: confirms a

selection or setting

ESC

• Leaves a menu (without modifying any

settings)

X • Selecting: scrolls through menus

(downwards) or selectable alternatives

• Editing: chang es to ne xt digit (to the right)

Page 38

4 Transmitter

38

Key Function/description

S • Selecting: scrolls through menus (upwards)

or selectable alternatives

• Editing: increa ses t he value of the current

digit by 1

Pos: 58 /TD/Produkt verwenden/MUF 63xx/Über sicht Bedienmenü @ 3\mod_1234510821302 _79.doc @ 25303 @ 3

4.4.4. Overview of the testo 6383 user menu

Page 39

4 Transmitter

39

Page 40

4 Transmitter

40

Page 41

4 Transmitter

41

Pos: 59 /TD/Produkt verwenden/MUF 63xx/Haup tmenü Kanäle bearbeiten @ 3\mod_12345111 1915 8_79.doc @ 25322 @ 34

4.4.5. The individual main menus

4.4.5.1. Editing main menu of channel 1

An overview is given in Overview of the testo 6383 user menu,

page 38).

You can perform basic settings for channel 1.

1. In the Measuring Mode press SET, select Main Menu

Channel 1 with X or S and confirm selection with SET.

One of the following parameters can now be selected using X

or S, after which the selection must be confirmed with SET:

• Channel 1 Unit

The parameter for this channel is selected.

Edit/select parameter with X or S, confirm with SET or abort

entry with ESC.

• Scale minimum for channel 1:

The lower scale limit is edited; Unit as selected above.

Editing the value: Scroll one digit to the right using X and

increase value of digit by 1 using S. Confirm with SET or abort

entry with ESC.

• Scale maximum for channel 1

The upper scale limit is edited;

Unit as selected above.

Editing the value: Scroll one digit to the right using X and

increase value of digit by 1 using S. Confirm with SET or abort

entry with ESC.

• Signal delay ("Attenuation") for channel 1

The analog signal can be delayed ("Attenuation"); a time

constant is selected for this (1 = no delay; 15 = longest delay)

Edit/select parameter with X or S, confirm with SET or abort

entry with ESC.

2. Continue to the main menu with X or S or return to Measuring

Mode with ESC.

Pos: 60 /TD/Produkt verwenden/MUF 63xx/Haup tmenü Kanal 2/3 638x @ 3\mod_1236085000820_79. doc @ 27312 @ 44

4.4.5.2. Editing Main Menu Channel 2 (if this option is available)

See channel 1.

Page 42

4 Transmitter

42

4.4.5.3. Editing Main Menu Channel 3 (if this option is available)

See channel 1.

Pos: 61 /TD/Produkt verwenden/MUF 63xx/Haup tmenü Alarm bearbeiten 638x @ 3\mod_123451 8541 385_79.doc @ 25341 @ 455

4.4.5.4. Editing Main Menu Alarm

With the alarm, the relays, available as options, are programmed.

In addition, the alarm statuses are shown on the display (top right)

(even without relays).

You can choose whether the alarm is to be used to monitor limit

values or as a collective alarm. If an alarm is to be used to monitor

limit values, you can choose between monitoring the minimum or

maximum value and set a limit value and hysteresis for each alarm.

In addition, every alarm can be linked to a clearly visible visual

alarm (display background lighting flashes).

An alarm delay between 0 and 240 seconds can still be assigned to

every alarm used for limit value monitoring so that both the

corresponding relay effect and the visual alarm are delayed. If the

alarm status goes out within the set alarm delay time, neither the

visual alarm nor a relay connection is triggered. .

With an alarm status present, the visual alarm and all relay outputs

can be reset by means of acknowledgement. The triggering of a

new alarm cannot be enabled until after the alarm status goes out.

1. In the Measuring Mode press SET, select Main Menu Alarm

with X or S and confirm select ion with SET.

- F our alarms can be parameterized.

2. Select Alarm x with X or S and confirm sele ction with SET.

Using alarm to monitor limit values

NO contact

Monitoring minimum Monitoring maximum

Hysteresis

Hysteresis

Limit value Limit value

Page 43

4 Transmitter

43

NC contact

Monitoring minimum Monitoring maximum

Hysteresis

Hysteresis

Limit value Limit value

3. Select Channel x (e.g. "Channel 1") with X or S and confirm

selection with SET.

4. Select Max control or Min control with X or S (see graphic).

5. Press SET and edit Limit value as well as Hysteresis: Scroll

one digit to the right using X and increase value of digit by 1

using S. Confirm with SET or abort entry with ESC.

6. Select Visual alarm with X or S. Select YES or NO wit h X or

S. Confirm with SET or abort entry with ESC.

7. Press SET and edit Alarm delay: Scroll one digit to the right

using X and increase value of digit by 1 using S (0 to 240

seconds possible). Confirm with SET or abort entry with ESC.

8. Return to Channel x with ESC.

9. Return to Alarm x with ESC.

10. Change to the other relays using X or S and perform settings

in the same

wa

y.

Using alarm as collective alarm or not using it at all

If an alarm is assigned to the collective alarm, the relay is switched

and a visual alarm can be issued via the display as soon as (at

least) one of the warning or error messages of the testo 6383

transmitter (or the connected testo 6610 probe) becomes active.

The messages affecting the collective alarm can only be

selected in the P2A software, see volume 2, Using the

software, page 104

✓ Alarm is selected (see previous steps 1 and 2).

1. Use X or S to determine whether Alarm x should be used as a

Collective alarm or not used. Confirm selection with SET.

2. If collective alarm is selected: Select Visual alarm with X or S.

Select YES or NO with X or S. Confirm with SET and return to

Alarm x.

Page 44

4 Transmitter

44

3. Change to another alarm using X or S and perform settings in

the same way.

4. Return to Main Menu Alarm with ESC.

5. Continue to Main Menu Settings with X or S or return to

Measuring Mode with ESC.

Pos: 62 /TD/Produkt verwenden/MUF 63xx/Haup tmenü Einstellungen bearbeiten 6383/6 385 @ 4\mod_1252503503580_79.doc @ 49125 @ 4555 55

4.4.5.5. Editing Main Menu Settings

You can edit instrument settings and other settings.

> In Measuring Mode, press SET, select Main Menu Settings

using X or S and confirm selection with SET.

You can edit settings for:

• Display

• Language

• Code

• Units

◦ Absolute pressure

◦ Area

◦ Temperature

• Humidity process data

◦ H2O2 percentage by weight

◦ Humidity process pressure

Editing display settings

You can set the brightness and contrast of the display.

1. Select Display Settings with X or S and confirm selection wit h

SET.

2. Select Backlight or Contrast with X or S and confirm

selection with SET.

One of the following parameters can now be selected using X or

S, after which the selection must be confirmed with SET:

• Backlight

The display illumination is changed.

Edit/select parameter with X or S, confirm with SET or cancel

entry with ESC (the effect of the change in parameter can be

seen during input).

• Contrast

Page 45

4 Transmitter

45

The brightness difference between the display background and

the displayed values is changed.

Edit/select parameter with X or S, confirm with SET or cancel

entry with ESC (the effect of the change in parameter can be

seen during input).

• Backlight 24h o n

Select On or Off using X or S and confirm with SET.

Off: The display light switches off automatically if no button was

pressed for 10 seconds.

On: The display light is activated

3. Return to Display Settings with ESC and useX or S to

continue to Language.

Selecting language

You can select the language for the plain text line in the display.

> Press SET, select required language with X or S, confirm

selection with SET and return to Language.

Only choose a language that you can understand well.

Editing code settings

You can set the access code (password).

If a code other than "0000" (factory setting) is set, the

transmitter can only be operated once this code has been

entered via the menu.

1. Select Code with X or S and confirm selection with SET.

2. Scroll one digit to the right using X and increase value of digit

by 1 using S. Confirm with SET or abort entry with ESC.

3. Return to Code with ESC and useX or S to continue to

Change parameters.

Select unit (Change unit)

This setting affects the displayed unit of all readings.

1. Press SET, select Change parameters with X or S, confirm

selection with SET or cancel with ESC.

2. Select Change unit with X or S, confirm selection with SET or

cancel with ESC.

Page 46

4 Transmitter

46

3. Select the required variable (absolute

pressure/area/temperature) with X or S, confirm selection with

SET or cancel with ESC.

4. Select the required unit with X or S, confirm selection with SET

or cancel with ESC.

5 Return to Change unit with ESC.

6. Return to Change parameters with ESC.

7. Return to Main Menu Settings with ESC.

Editing Humidity process data

This menu is only used to parameterize humidity measurem ents in

H

2O2

atmospheres (e.g. in sterilization processes) and determines

whether °Ctm or °Ftm is the output parameter.

1. Select Humidity process data with X or S and confirm

selection with SET.

2. Select H202 weight prop. with X or S, confirm selection with

SET or cancel with ESC.

The selection H

2O2

water or H2O2 vapour in the submenu

describes whether H2O2 is generated by means of evaporation

or is actively vaporized in the process.

3. Select H

2O2

water or H2O2 vapour with X or S and confirm

with SET.

4. Edit proportion by weight of the H

2O2

in % (% H2O2 proportion

by weight in the liquid initial solution): Scroll one digit to the right

using X and increase value of digit by 1 using S. Confirm with

SET or abort entry with ESC.

5. Return to H202 weight prop. with ESC and useX or S to

continue to Humidity process pressure.

6. Select Humidity process pressure with X or S and confirm

selection with SET.

7. Edit humidity process pressure: Scroll one digit to the right

using X and increase value of digit by 1 using S. Confirm with

SET or abort entry with ESC.

8. Return to Change parameters with ESC.

9. Return to Main Menu Settings with ESC.

Pos: 63 /TD/Produkt verwenden/MUF 63xx/Haup tmenü Analyse bearbeiten 6383/6385 @ 4\mod_1 252507887718_79.doc @ 49449 @ 45555

Page 47

4 Transmitter

47

4.4.5.6. Editing Main Menu Analysis

You can test the functionality of analog and rela y outputs. In

addition, you can read off the minimum and maximum values (since

the last voltage supply or reset of the min./max. values).

Testing functionality of analog outputs

This function affects the analog outputs directly, not only

the test contacts.

1. In the Measuring Mode press SET, select main menu Analysis

with X or S and confirm select ion with SET.

- Test Analog Output is shown.

2. Press SET and choose between Analog output 1, 2, 3 with X

or S.

3. Press SET, scroll one digit to the right using X and increase

value of digit by 1 using S. Any analog output value can be

predefined, e.g. for an analog output of 4 to 20 mA, the value

"6.0 mA". Confirm with SET or abort entry with ESC.

4. Accept setting by pressing SET and test with multimeter

(minimum requirement: resolution 6.5 digits, at least 2-times

more accurate than the 6383) as follows:

Analog output 1, 2 or 3: Via test contacts under service cover,

see diagram.

1 Positive test

contact

channel 1

2 Negative test

contact

channel 1

3 Multimeter

4. Return to Test Analog Output with ESC and useX or S to

continue to Test Relay Output.

Page 48

4 Transmitter

48

Testing functionality of the pressure sensor (Test pressure

sensor)

This function is only required to calibrate the pressure

sensor.

Testing functionality of relay outputs

1. Press SET and choose between Alarm 1, 2, 3, 4 with X or S.

2. Press SET.

The relay can now be tested. You can choose between OFF

and ON using X or S. If ON is chosen, the NO contact is

closed, the NC contact opened. If OFF is chosen, the NC

contact is closed, the NO contact opened.

3. To test, route a measuring cable from the relay terminals (see

Connecting the relay outputs, page 24) out of the transmitter to

a multimeter (resistance measurement) or continuity tester.

4. Return to Test Relay Output with SET (starts relay test) or

ESC (exits the menu without relay test).

Reading off min./max. values of channels

To reset the max./min. values, see Editing Reset main menu, page

52

1. Read off the min./max. values of the three channels in

succession with X or S and return to the Main Menu Analysis

with ESC.

2. Continue to Main Menu Message with X or S or return to

Measuring Mode with ESC.

Pos: 64 /TD/Produkt verwenden/MUF 63xx/Haup tmenü Meldungen bearbeiten @ 3\mod_123452 6541417_79.doc @ 25398 @ 4

Page 49

4 Transmitter

49

4.4.5.7. Editing Message main menu

Messages can be confirmed/acknowledged, the last messages can

be called up and the display of the messages can be switched on

or off.

1 Operating hours at the

time of message

2 Message code (see

Status, warning and error

messages, page 53).

3 Message text

4 Message number

(example: "4/7" refers to

the fourth of seven

messages)

5 Number of messages

present (example: "4/7"

refers to the fourth of

seven messages)

Using the P2A software (see volume 2, Parameterizing,

adjusting and analyzing software (P2A software), page 101 )

you can predefine whether messages are to be shown in

the display.

1. In the Measuring Mode press SET, select Main Menu Message

with X or S and confirm select ion with SET.

2. Confirm Confirm message using SET.

3. Select Last messages with X or S and confirm with SET.

4. Scroll between the warning and error messages recorded so far

using X or S and return to Last messages using ESC.

5. Select Information with X or S and confirm with SET.

6. Scroll between the status messages recorded so far using X or

S and return to Information using ESC.

7. Continue to Display of message with X or S.

ON: Measurements are shown on the display in Measuring

Mode.

OFF: No messages shown on display.

8. Select ON or OFF with X or S and confirm selection with SET.

9. Return to Main Menu Message with ESC.

Page 50

4 Transmitter

50

10. Continue to Main Menu Ident with X or S or return to

Measuring Mode with ESC.

An overview of the messages can be found in Status,

warning and error messages, page 53

Pos: 65 /TD/Produkt verwenden/MUF 63xx/Haup tmenü Ident abfragen 638x @ 3\mod_12345269 9773 1_79.doc @ 25417 @ 4

4.4.5.8. Calling up Main Menu Ident

1 Instrument or

probe type

2 Build number

3 Firmware

version

4 Serial number

The serial numbers of the transmitter and probe can be read off.

1. In the Measuring Mode press SET, select Main Menu Ident

with X or S and confirm select ion with SET.

- The type, firmware version, build number and serial number of

the transmitter are displayed.

This information is required when servicing.

2. Return to Main Menu Ident with ESC or read off the type,

firmware release, build number and serial number of the probe

with X or S and then return to Main Menu Ident with X or S.

3. Continue to Main Menu Adjust with X or S or return to

Measuring Mode with ESC.

Pos: 66 /TD/Produkt verwenden/MUF 63xx/Haup tmenü Abgleich bearbeiten 6383/6385 @ 4\ mod _12 52503280594_79.doc @ 49093 @ 4555

4.4.5.9. Editing Main Menu Adjust

A reference value can be entered for both relative humidity (RH)

and temperature (°C/°F) for the 1-point adjustment. Please refer to

the description in 1-point adjustment (offset humidity/temperature), page 30

Reference values for pressure can be entered for the n-point

adjustment. Please refer to the description in n-point adjustment

(pressure), page 33

Page 51

4 Transmitter

51

In addition, the analog outputs can be adjusted. Also see Analog

output adjustment, page 32 for instructions on how to do this.

Enter reference value for 1-point adjustment

Please also refer to 1-point adjustment (offset humidity/temperature), page 30

1. In the Measuring Mode press SET, select main menu Adjust

with X or S and confirm select ion with SET.

- Reference value % RH is displayed.

2. Press SET, edit value: Scroll one digit to the right using X and

increase value of digit by 1 using S. Confirm with SET or abort

entry with ESC.

3. Continue to Reference value temp with X or S.

4. Press SET, Reference value °C or Reference value °F is

displayed.

5. Press SET, edit value: Scroll one digit to the right using X and

increase value of digit by 1 using S. Confirm with SET or abort

entry with ESC.

6. Continue to Analog Adj. Ch. 1 with X or S.

7. Continue with the adjustment of the analog outputs (see belo w,

step 2) or press ESC to return to main menu Adjust.

8. Continue to main menu Reset with X or S or return to

Measuring Mode with ESC.

Performing analog adjustment

Please refer to Analog output adjustment, page 32.

1. In the Measuring Mode press SET, select main menu Adjust

with X or S and confirm select ion with SET.

Each channel is adjusted at three points in the analog

range (at 10 %; 50 %; 90°% of the analog scale).

2. Select Analog Adj. Ch. 1 with X or S and confirm with SET.

3. Use X or S to select Adj. Point 1.

4. Press SET. Read off multimeter display (e.g. 5601 mA) and

enter this value in the user menu. Do this by scrolling one digit

to the right using X and increasing the value of digit by 1 using

S. Confirm with SET or abort entry with ESC.

5. Use X or S to select Adj. Point 2.

6. Press SET. Read off multimeter display (e.g. 12,001 mA) and

enter this value in the user menu. Do this by scrolling one digit

Page 52

4 Transmitter

52

to the right using X and increasing the value of digit by 1 using

S. Confirm with SET or abort entry with ESC.

7. Use X or S to select Adj. Point 3.

8. Press SET. Read off multimeter display (e.g. 18,401 mA) and

enter this value in the user menu. Do this by scrolling one digit

to the right using S and increasing the value of digit by 1 using

X. Confirm with SET or abort entry with ESC.

9. With X or S continue to Analog Adj. Ch. 2or 3 (repeat steps 3

to 8).

10. Return to main menu Adjust with ESC.

11. Continue to main menu Reset with X or S or return to

Measuring Mode with ESC.

Performing the pressure adjustment

Please refer to n-point adjustment (pressure), page 33.

1. In the Measuring Mode press SET, select main menu Adjust

with X or S and confirm select ion with SET.

The pressure adjustment can be performed at 3 to 6

adjustment points.

2. Select Adjust Pressure with X or S and confirm with SET.

3. Use X or S to select Adj. Point 1.

4. Press SET. Read off pressure sensor display (e.g. 30.1 Pa) and

enter this value in the user menu. Do this by scrolling one digit

to the right using X and increasing the value of digit by 1 using

S. Confirm with SET or abort entry with ESC.

5. Repeat steps 1 to 4 for adjustment points 2 to 6.

6. Return to main menu Adjust with ESC.

7. Continue to main menu Reset with X or S or return to

Measuring Mode with ESC.

Pos: 67 /TD/Produkt verwenden/MUF 63xx/Haup tmenü Reset bearbeiten 638x @ 3\mod_123452 9155 827_79.doc @ 25455 @ 4

4.4.5.10. Editing Reset main menu

You can reset the factory settings for the following:

• Instrument

• Sensor/probe

• Min./max. values

Resetting to the factory settings means resetting to the

order specification, i.e. the specific condition at the time of

supply to the customer.

Page 53

4 Transmitter

53

1. In the Measuring Mode press SET, select Main Menu Reset

with X or S and confirm select ion with SET.

- Reset Device to factory settings is displayed.

2. Select the setting to be reset using X or S and confirm

selection with SET.

- Reset Completed is displayed.

3. Return to the reset setting with ESC or SET and return to Main

Menu Reset with ESC.

4. Continue to Main Menu Channel 1 with X or S or return to

Measuring Mode with ESC.

Pos: 68 /TD/Überschriften/MUF/1.5 Sta tus-, Warn- und Fehlermeldungen @ 3\mod_123444 2925442_79.doc @ 24963 @ 2

4.5. Status, warning and error messages

Pos: 69 /TD/Produkt verwenden/MUF 63xx/Sta tus-Warnmeldungen/Status-, W arn- und Fehlermeldungen 638x @ 3\mod_1234441087981 _79.doc @ 24844 @

To achieve optimum operational reliability (machine ava ilability),

the transmitter shows the following via the user menu or the P2A

software

• Status messages

• Warning messages

• Error messages

The status and warning messages for the respective testo 6610

probes connected to the transmitter can be evaluated via the P2A

software.

All messages are stored in the transmitter with an operating hours

stamp. Use the user menu (see Editing Message main menu, page

49) or the P2A software (see volume 2, Transmitter history, page

126) to view the message history.

In the transmitter, the last 60 status messages and the last 120

error and warning messages are stored in a ring memory. There is

no limit in the P2A software.

Pos: 70 /TD/Produkt verwenden/MUF 63xx/Sta tus-Warnmeldungen/Statusmeldung en 6383/6385 @ 4\mod_1252506138420_79.doc @ 49257 @ 3

Page 54

4 Transmitter

54

4.5.1. Status messages

Status messages show the current operating status of the testo

6383.

Message Display Description

02506

Sensor

initialization

Message appears while the

transmitter is starting up. If the

message disappears, the

transmitter is ready for operation.

01D19 Service plug

The Mini-DIN socket is connected

to: the USB adapter for P2A

software, the adjustment adapter

or the service plug (is not

recorded/no number)

00300 New limit value

The limit value has been changed

or shifted

00301 Scaling changed The scaling has been changed

00500 Transmitter reset

The transmitter was reset to the

factory settings and is restarted.

0052F Reset Min/Max

Resets all saved Min/Max values

for all channels

02518 Probe reset

Probe reset: The probe performs a

reset

00503

Reset device to

fact

A factory reset of the transmitter

was performed

02503

Reset probe to

fact

A factory reset of the probe was

performed

00530

Change solenoid

valve

The solenoid valve should be

changed

00307

User Setting

Change

User Setting Change: General

settings were changed for the

transmitter.

00117 Adjustment DeltaP

An n-point adjustment was

performed.

02104 Analog adjustment

An analog adjustment has been

made

02101 1-point adjustment A 1-point adjustment is performed.

Page 55

4 Transmitter

55

Message Display Description

02105

Self-adjustment

active

For testo 6615 probe only: The

probe performs an automatic selfadjustment

Pos: 71 /TD/Produkt verwenden/MUF 63xx/Sta tus-Warnmeldungen/Warnmeldungen 6 383/ 6385 @ 4\mod_1252506208031_79.doc @ 49289 @ 3

4.5.2. Warning messages

Warning messages show an early warning or a current malfunction

which may negatively impact measuring.

Message Display Cause Remedying of fault

00809

Pressure too

high**

The process pressure

exceeds the pressure

intended for the

transmitter

Remove the transmitter

from the process and

take any necessary

measures to lower the

pressure

00E00 T ambient high**

The ambient

temperature exceeds

the permissible

temperature for the

transmitter

Take necessary

measures to lower

ambient temperature,

e.g. through venting or

cooling

00E01 T ambient low**

The ambient

temperature is below

the permissible

temperature for the

transmitter

Take necessary

measures to raise

ambient temperature,

e.g. through heating

00E04/00E

05

Supply voltage

low**

The supply voltage is

below the minimum

voltage required for the

transmitter

Take measures to

ensure sufficient

voltage supply

02822 T process high**

The process

temperature exceeds

the temperature

designated for the

probe

Remove the probe from

the process and take

any necessary

measures to lower the

process temperature

02821 T process low**

The process

temperature is below

the temperature

designated for the

probe

Take necessary

measures to raise

process temperature

0081C Alarm 1**

Depending on the

parameterization of the

relays

Depending on the

parameterization of the

relays

Page 56

4 Transmitter

56

Message Display Cause Remedying of fault

0081D Alarm 2**

Depending on the

parameterization of the

relays

Depending on the

parameterization of the

relays

0081E Alarm 3**

Depending on the

parameterization of the

relays

Depending on the

parameterization of the

relays

0081F Alarm 4**

Depending on the

parameterization of the

relays

Depending on the

parameterization of the

relays

02806 Condensation*

100 % RH has been

reached, condensation

developing

Take measures to

reduce process

humidity

02807

Values less than

0 % RH**

The adjustment or

sensor is faulty

Check adjustment (via

P2A adjustment history,

perform 2-point

adjustment where

necessary). If the

problem persists,

contact Testo Service

02809

Sensor early

warning*

For testo 6617 probe

only: The cover

electrode of the sensor

is damaged; this may

soon cause the sensor

to break

Carry out visual

inspection. If the mirrorlike surface of the

sensor is dirty or

damaged, contact

Testo Service

* Early warning

** Current malfunction

Pos: 72 /TD/Produkt verwenden/MUF 63xx/Sta tus-Warnmeldungen/Fehlermeldung en Messumformer 638x @ 3\mod_123453585107 6_79. doc @ 25512 @ 3

4.5.3. Transmitter error messages

Error messages show a current malfunction.

Message Display Cause Remedying of fault

03401 No probe signal

The probe

communication is

interrupted

Ensure that the probe

connector is fully

engaged in the

transmitter.

If communication still

cannot be established,

contact Testo Service

Page 57

4 Transmitter

57

Message Display Cause Remedying of fault

03508 Wrong probe