Page 1

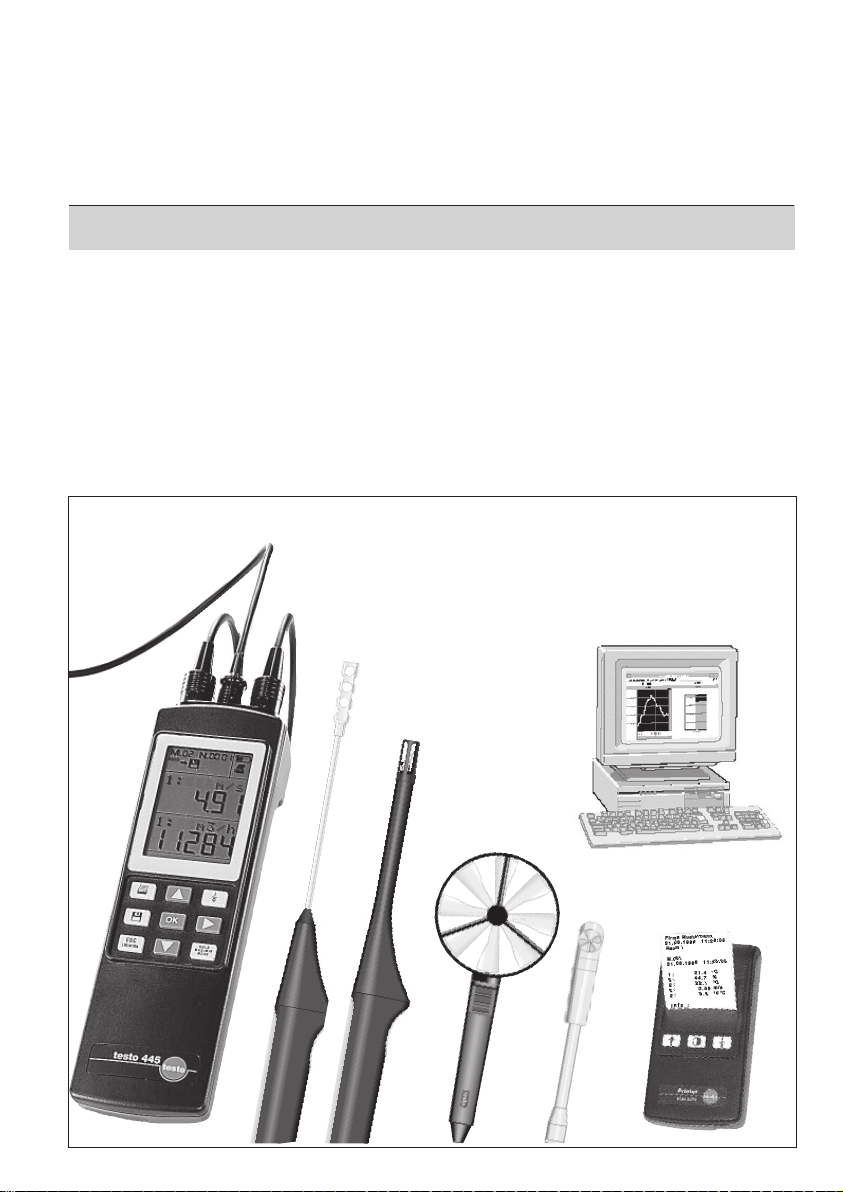

testo 445 · testo 645

Instruction manual en

Page 2

Contents

Contents ........................................................................................................................................... 2

Foreword ........................................................................................................................................... 3

Initial operation .................................................................................................................................. 4

First measurement ............................................................................................................................. 5

Instrument description

-Keypad/ connection assignment ................................................................................................... 6

-Display .......................................................................................................................................... 7

Overview of controls ....................................................................................................................... 8-9

1. Current measurement.................................................................................................................. 10

Switching on, selecting parameter in display ......................................................................... 10

Saving, printing .................................................................................................................... 10

2. Measurement functions 11-13

Freezing readings .................................................................................................................. 11

Maximum readings ................................................................................................................ 11

Minimum readings ................................................................................................................. 11

Multi-point mean calculation .................................................................................................. 12

Timed mean calculation ........................................................................................................13

3. Location selection ....................................................................................................................... 14

4. Parameter settings ................................................................................................................. 15-17

System adjustment (testo 645) ............................................................................................. 15

Adjusting humidity probes .....................................................................................................16

Displaying calculated humidity parameters (td°C; g/m3; g/kg; J/g)......................................... 16

Switches CO2 ppm Vol% (testo 445) ............................................................................... 16

Initialising differential pressure probe (testo 445) ................................................................... 17

Activating m/s in differential pressure probes (testo 445) ...................................................... 17

Activates volume flow and sets duct cross-sections

for velocity and differential pressure probes (testo 445) ........................................................ 17

5. Memory settings .....................................................................................................................18-21

Overview ............................................................................................................................... 18

Manual saving ....................................................................................................................... 19

Automatic saving ................................................................................................................... 19

Reading or printing memory contents ................................................................................... 20

Clearing memory contents .................................................................................................... 21

According to the conformity certificate, the instruments fulfill 2014/30/EC

guidelines.

©1999 Copyright Testo GmbH & Co.

The software and software structure included in the product testo 445/645 are protected by

copyright laws worldwide.

2

Page 3

Contents

6. Instrument configuration ......................................................................................................... 22-26

“AutoOFF” power save function ........................................................................................... 22

Setting power supply, with rechargeable battery or battery ................................................... 23

Setting date/time ................................................................................................................... 24

Setting parameters for absolute pressure and density compensation .................................... 25

Unit selection ........................................................................................................................ 26

Factory reset .............. 26

7. Velocity measurement ............................................................................................................27-28

Volume flow funnel (testo 445) .............................................................................................. 27

Pitot tube and pressure probe (testo 445) ............................................................................. 28

Thermal anemometer probes (testo 445) .............................................................................. 28

8. CO/CO2 measurement ...........................................................................................................29-30

Measuring absolute pressure ......................................................................................................31-32

Error messages ............................................................................................................................... 33

Technical data ............................................................................................................................ 34-35

Ordering data .............................................................................................................................36-41

Foreword

Dear Customer

You have made the right decision by choosing a measuring instrument from Testo. Every year,

thousands of customers purchase our high-quality products. There are many good reasons for this.

1) We offer value for money. Reliable quality at the right price.

2) Considerably longer guarantee periods of up to 3 years - depending on the instrument.

3) With over 40 years of specialist experience we are optimally equipped to solve your measuring

tasks.

4) Our high quality standards are confirmed by ISO 9001 certification.

5) It goes without saying that our instruments bear the CE mark required by the EU.

3

Page 4

Initial operation

Please read prior to measurement

Do not measure on live parts.

Do not switch instrument on or off with the button

Complete automatic saving before connecting instrument to the Comfort software.

If the instrument does not function remove battery and put it in again. The respective error

message is shown in the display. Refer to the information on “Error messages” on page 33 of

Observe storage and transport temperature and max. operating temperature (e.g. protect

When changing configurations (e.g. changing the probe), the instrument should be switched off

because the values specific to the probe can only be read when the instrument is switched on.

The V24 cable (PC connection) can be inserted anytime.

A simultaneous print command is not possible if the PC cable is connected.

Ensure that the contacts are correct in probes with a plug-in head.

The swivel nut in the probe handle should be securely tightened.

Opening the instrument, inexpert handling and use of force cancels your warranty.

- during instrument configuration

- during automatic saving

the Instruction manual.

measuring instrument from direct sunlight)

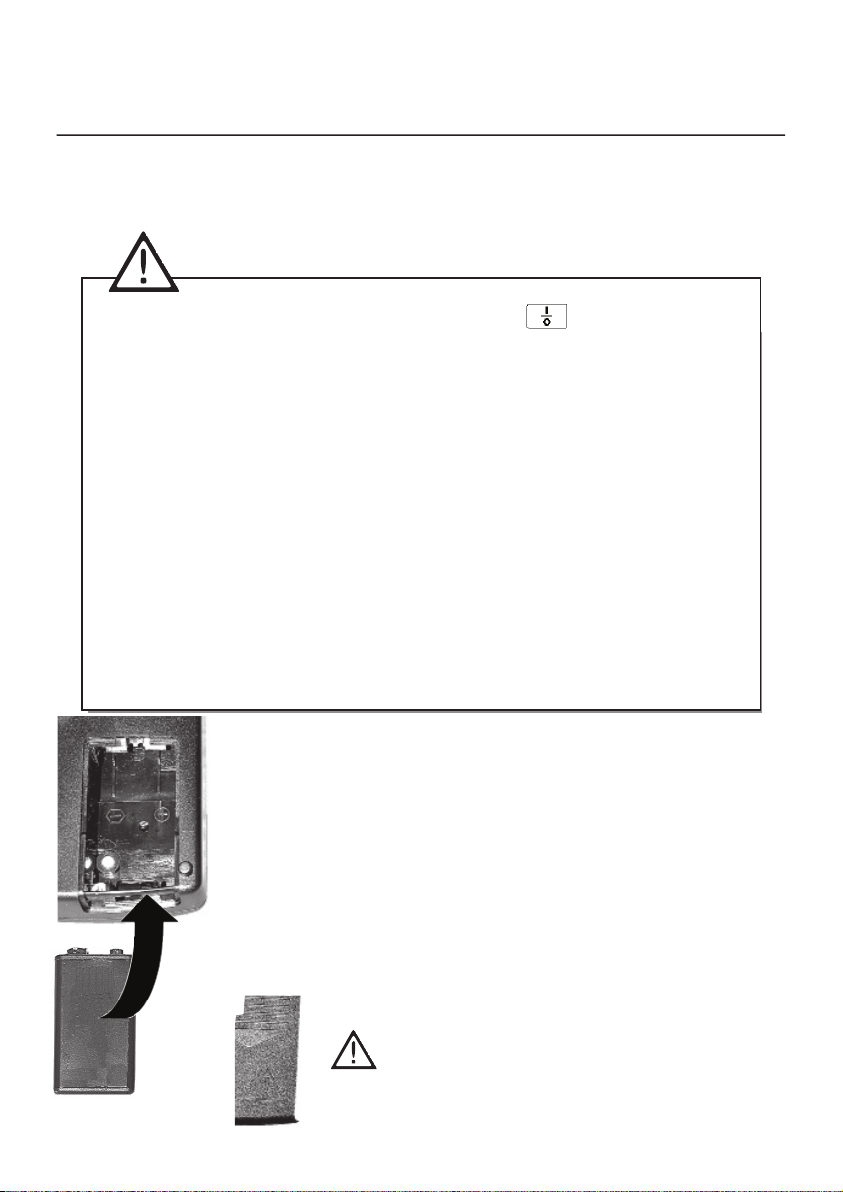

Putting in the batteries

9V block battery is included in delivery.

Open the battery compartment at the back of the instrument.

Put in block battery. Observe polarisation.

Close battery compartment.

Refer to “Power supply” Chapter for more information on

alternative power supply, charge, battery quality, charging

procedure.

Observe instrument configuration when using

rechargeable batteries.

4

Page 5

i

Instrument configuration

First measurement

A description of the instrument and an overview of the

controls guarantee a quick introduction.

Note: The measuring instrument must be switched off before a probe

is connected.

You will receive up-to-date readings once a probe is inserted and the

measuring instrument is switched on. However, you will still need to

update or define the data in the instrument:

Date/Time:

Auto Off:

Units:

Some things can only be set via PC software (See Ordering data):

Location name (8 characters)

Log head (24 characters), e.g. your company name -

is also printed when readings are printed.

5

Page 6

Keypad:

On/Off

Prints

Confirms menu

setting/

executes function

Saves

Return to current

measurement/

location

Arrow buttons

move the cursor

Instrument description

Keypad/Connection assignment

Connection assignment:

RS232

2

12V

testo 445

Socket 1:

– Thermal velocity probes

(heated wire or ball)

– Vanes (inductive)

– Temperature probes

(Type K/J/S T/C or NTC)

– Differential pressure probes

(piezoresistive)

– Absolute pressure probes

(piezoresistive)

– CO

probe

2

(2 beam infrared sensor)

– CO probe

Socket 2:

– Combined probe for humidity

(capacitive)

and temperature

(NTC or Ni 10000)

– 3-function probe for

humidity (capacitive),

temperature (NTC) and velocity

(ball)

RS232: PC connection

12V: Mains connection

1

Hold Max Min

Mean

testo 645

Socket 1:

– Temperature probes

(T/C type K/J/S or NTC)

Socket 2:

– Combined probe for humidity

(capactive)

and temperature

(NTC or Ni 10000)

– Temperature probes

(PT100)

RS232: Connection for PC

12V: Mains unit connection

6

Page 7

M. 00

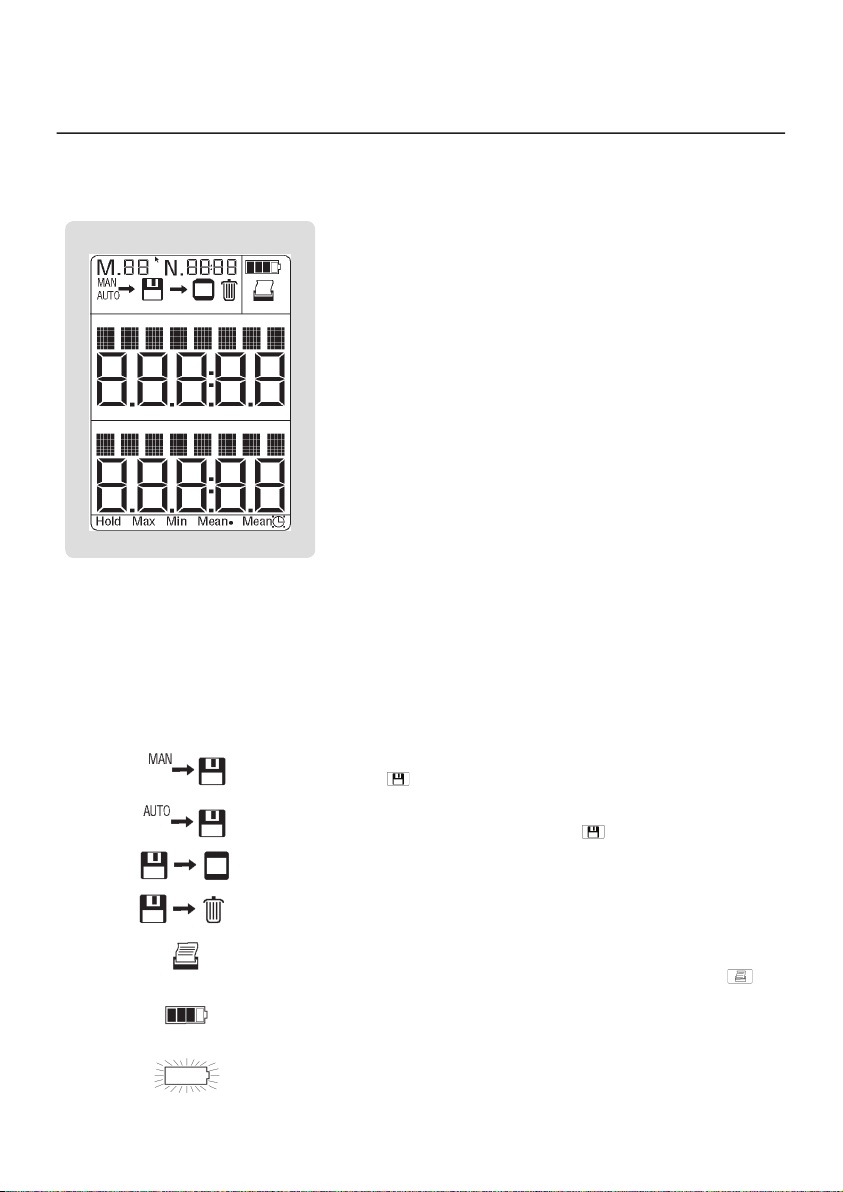

Instrument description

Display

The symbols on the top line are explained below

Name of input socket and parameter

Displays reading in line 1

Name of input socket and parameter

Displays reading in line 2

Displays measurement functions

Explanation of symbols:

Counter for the log number in the memory.

When saving manually: number of a measurement saved.

When saving automatically: number of a measurement series.

This counter is needed in order to be able to find single logs or a

measurement series when reading the memory.

N. 0000

Counter for saving a measurement cycle (is only required with

automatic saving).

The measurement cycle in a measurement series can be found.

Manual saving of a single measurement by pressing the save

button

Automatic saving program has been set up.

Saving is activated by pressing the

Symbol for reading contents of memory on display.

Symbol for deleting memory contents

If this symbol appears, the printing function is activated.

The symbol flashes while data is being transmitted. You can

print on the desktop printer by pressing the print button

Shows capacity of battery and rechargeable battery.

If the inner segment no longer appears (symbol flashes), the

battery has to be changed or the rechargeable battery has to be

recharged. The instrument switches itself off automatically after

1 minute.

.

button.

.

7

Page 8

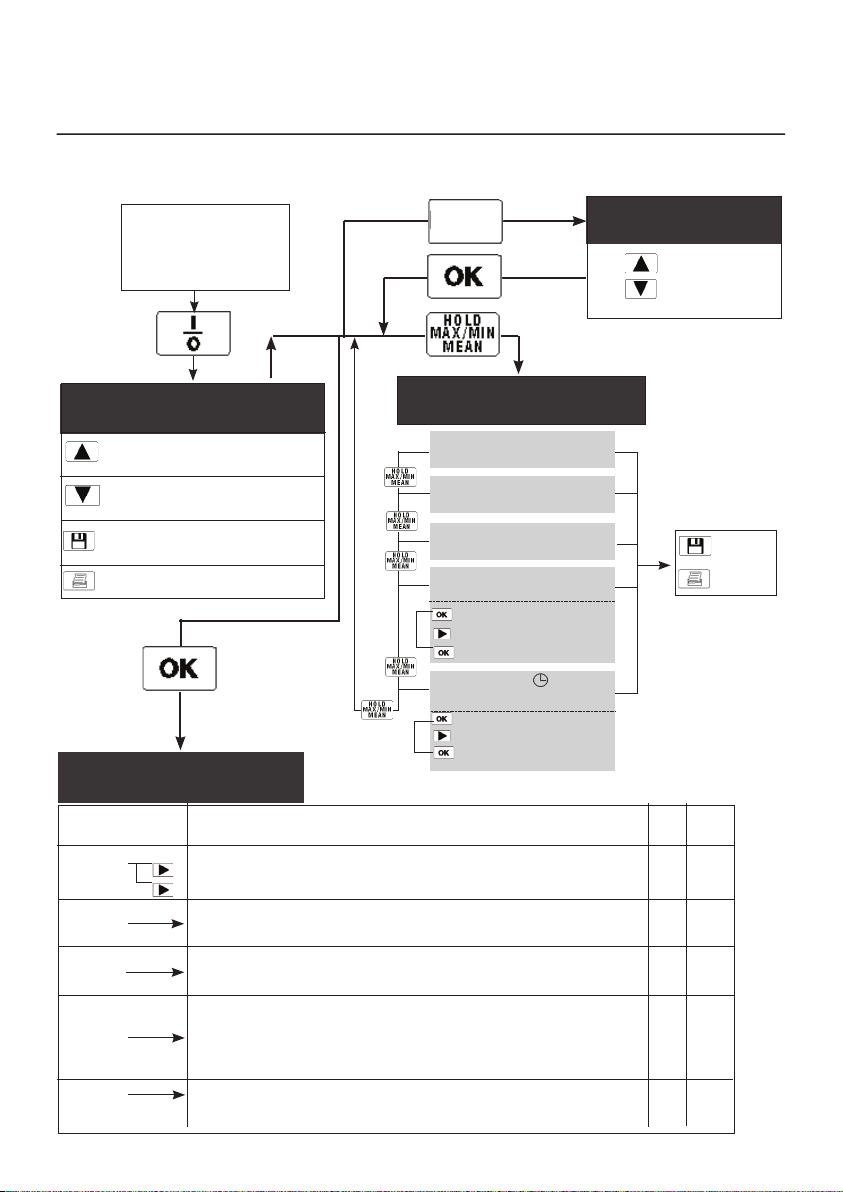

Overview of controls

Connect probe

corresponding to

connection assignment

(rear of instrument)

ESC

Location

3.

Location

1 Buttons to

...

select

99 location

1.

2. Measurement functions

Current measurement

Select reading in

the first line

Select reading in

the second line

Save manually or automatically,

depending on setting (5.)

Print readings

Multi-point mean calculation

HOLD

Freeze values

Display maximum values

MAX

Display minimum values

Timed mean calculation

MIN

MEAN•

Update values

Calculate mean

Reset mean

Start and end

Calculate mean

Reset mean

MEAN

4.

Parameter settings

Selected The setting functions are activated in accordance with the reading testo testo

parameter selected - flashing cursor in display (See 1.): 645 445

°C

(4.1)

% Humidity probe (0636.9740 and 0636.9715)/ X X

(4.2) Checks and adjusts 3-function probe (0635.1540)

td Select calculated humidity parameters: td°C dew point X X

(4.3) g/m3 - absolute humiidty, g/kg - degree of humidity, J/g - enthalpy

m/s, mbar Differential pressure probes: initialisation, activation/deactivation X

m3/h m/s, m

(4.4) Velocity probes: activation/deactivation m

Change cross-section input for an activated volume flow measurement X

ppm Switch between ppm and vol% with CO

(4.5) Initialisation of CO probe

System adjustment with EEPROM probe X

Reset - system adjustment X

3

/h in addition to mbar

3

/h in addition to m/s X

2 X

8

Manual

saving

Print

readings

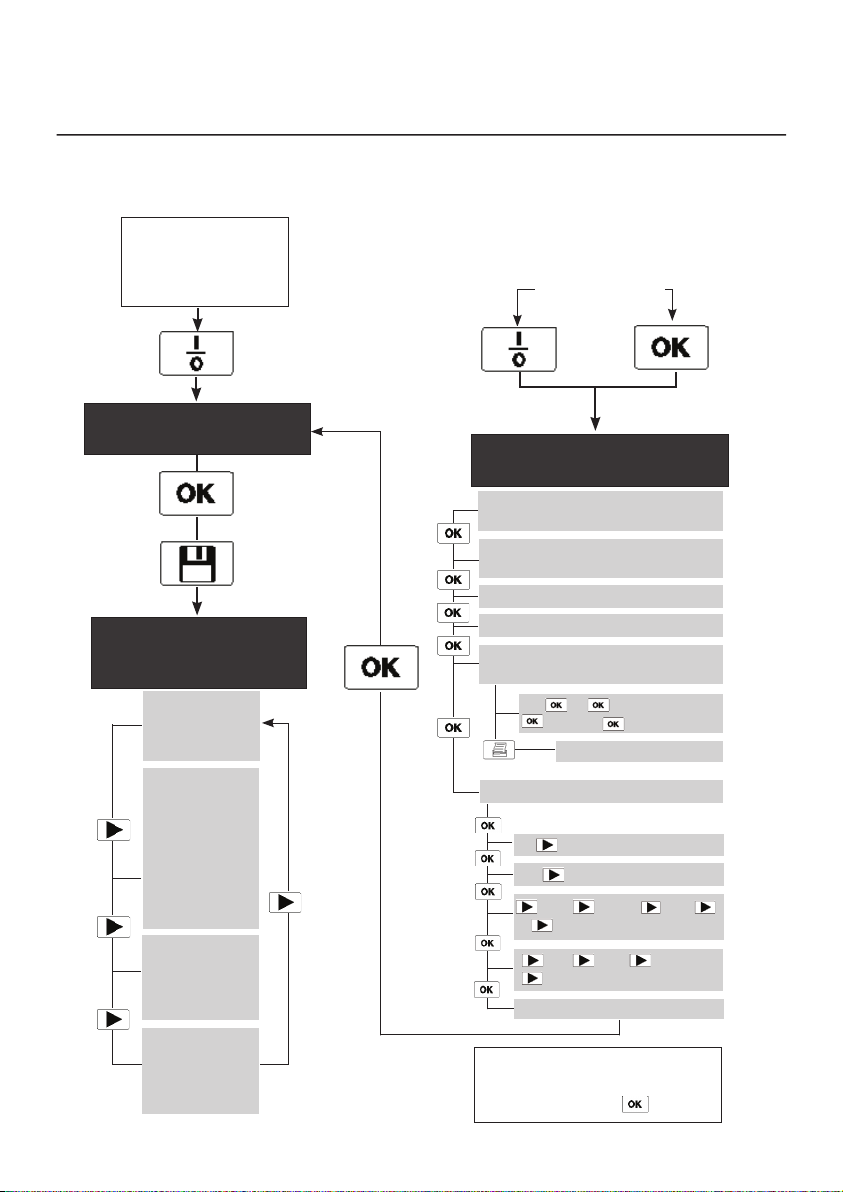

Page 9

Connect probe

corresponding to

connection assignment

(rear of instrument)

1.

Current measurement

5.

Memory

settings

MAN

Activate

manual

saving

AUTO

Program

automatic

saving

• Select meas.

cycles

• Set

measurement

rate

OUT

Read memory

contents on

display with

printing option

CLEAR

Clear memory

Note: Everything

in the memory is

deleted

Overview of controls

Simultaneously

6.

Instrument configuration

Activate - deactivate

automatic switch-off function

Select power supply

battery/rechargeable battery

Setting: Date

Setting: Time

Parameter setting for absolute

pressure and density compensation

°C, %, Abs.mbar,

°C°F

m/sfpm [ft/min] (testo 445)

m3/h m3/min m3/s

l/s cfm [ft3/min](testo 445)

hPa mbar psi

Factory reset

Note:

Flashing display is activated and is

confirmed by pressing

rho-g/m3,

Print parameters

Unit selection

O] (testo 445)

in W [”H

2

Pitot tube factor

.

9

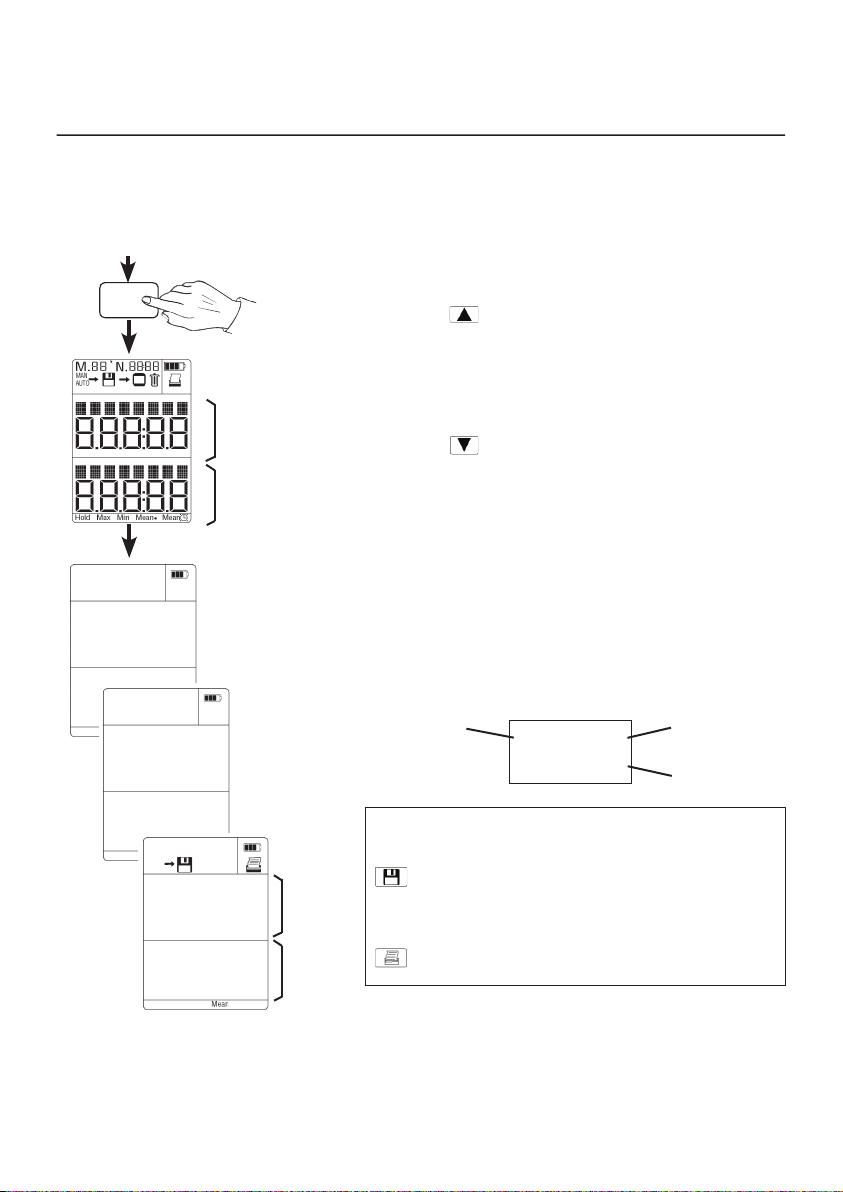

Page 10

1. Current measurement

Switching on / Selecting parameters / Saving / Printing

Connect measurement probes

I/0

Segment test

Line 1

Line 2

Battery / rech.

VBAT

battery power

8.5

Location

Location

1

Duct 1

M.05

N.0017

MAN

1:

m/s

58.06

1:

hPa

21.80

Current readings - different,

depending on probe(s)

connected.

Line 1

Line 2

All of the readings, made available by the probes connected

to socket 1 and 2, on both lines of the reading display can

be called up with the exception of the value selected in the

other line.

Scroll with

button in line 1:

Select socket.

Select parameter.

If this button in multi-function probes is pressed

repeatedly, it is possible to select the parameter (°C,

m/s...) to be displayed.

Scroll with

button in line 2:

Select socket.

Select parameter.

If this button in multi-function probes is pressed

repeatedly, it is possible to select the parameter (°C,

m/s...) to be displayed.

There are different processing options available in

the menus described below corresponding to the

parameters selected.

Example of a reading:

Selected

socket

1:

m/s

58.06

It is possible to activate the following functions during measuring at the touch of a button.

Save readings

Manual or automatic saving is determined by the

save setting (Chapter 5)

Print readings.

Note on printing:

A distance 0f 0.5 m should not be exceeded in order to

guarantee problem-free data transfer. Objects between

instrument and printer prevent the data from being

transferred. Please observe notes in the instruction manual

on the printer.

10

Parameter

Reading

Page 11

2. Meaurement functions

Hold/Max/Min

ESC

Location

Hold

Max/Min

Mean

Hold

Max/Min

Mean

Hold

Max/Min

Mean

M.05

N.0017

MAN

1:

58.06

1:

21.80

M.05

N.0017

MAN

1HLD

58.06

1HLD

21.60

M.05

N.0017

MAN

1MAX

73.37

1MAX

34.80

M.05

N.0017

MAN

1MIN

56.62

1MIN

Current measurement

m/s

hPa

Freezing values

m/s

hPa

Maximum readings since the

measurement began

m/s

hPa

Minimum readings since the

measurement began

m/s

hPa

Save reading

Print reading

Save maximum

measured value

Print maximum

measured value

Save measured

value

Print measured value

Hold

Max/Min

Mean

20.00

See multi-point/timed

mean calculation

11

Page 12

2. Measurement functions

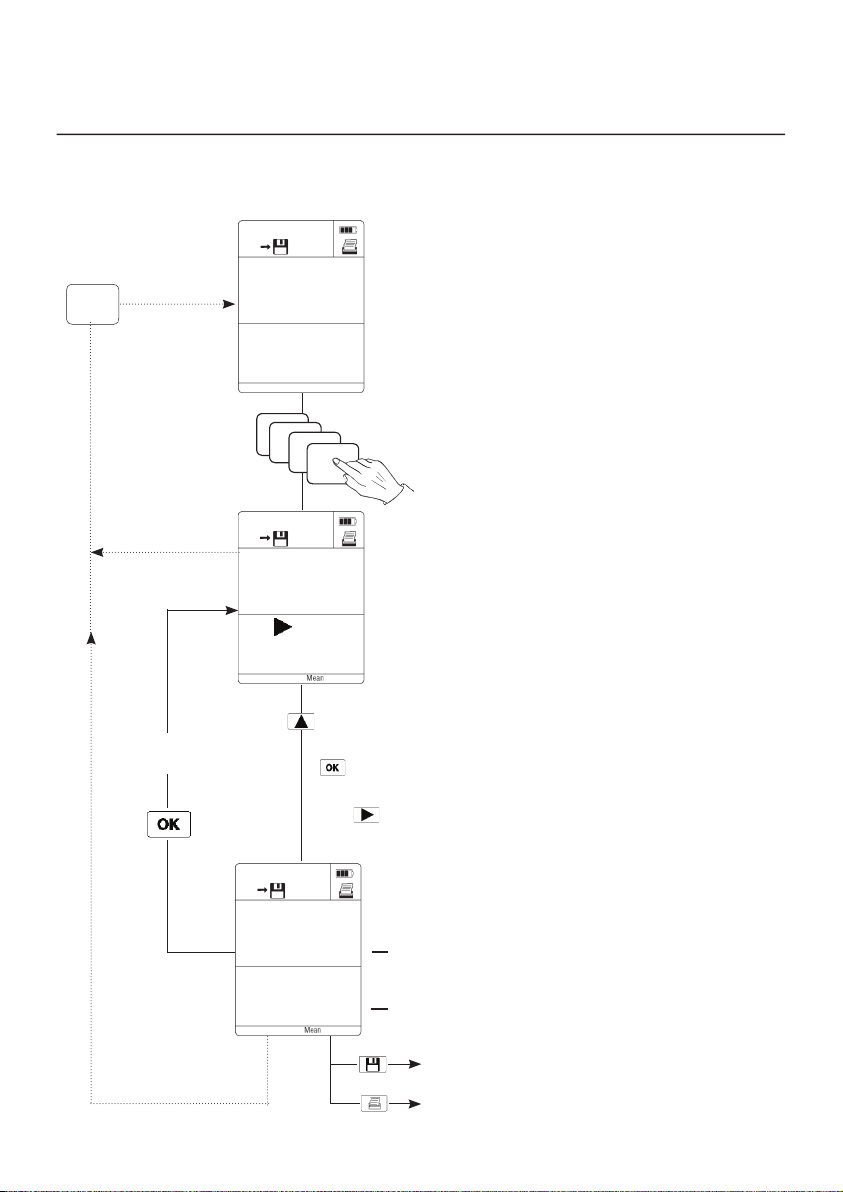

Multi-point mean calculation Mean•

Only for parameter in the 1st line

ESC

Location

New mean

calculation possible

M.05

N.0017

MAN

1:

58.06

1:

21.80

Hold

Hold

Max/Min

Hold

Max/Min

Mean

Max/Min

Mean

Max/Min

Mean

M.05

N.0017

MAN

1:

25.21

OK MEAN

Current measurement

m/s

hPa

Hold

Mean

Multi-point mean calculation

The mean is only calculated for the para-

m/s

meter selected in the first line.

Exception:

Selection of volume flow (see note on

page 13)

0

•

Select parameter required.

Update values.

M.05

N.0017

MAN

MEAN

m/s

25.21

MEAN NEW

Calculate mean

Mean

Number of updated

5

•

values

Save mean

Print mean

12

Page 13

2. Measurement functions

Current measurement

M.05

N.0017

MAN

Hold

1:

58.06

1:

m/s

hPa

Max/Min

Hold

Mean

Max/Min

Hold

Mean

Max/Min

Hold

Mean

Max/Min

Hold

Mean

Max/Min

Mean

21.80

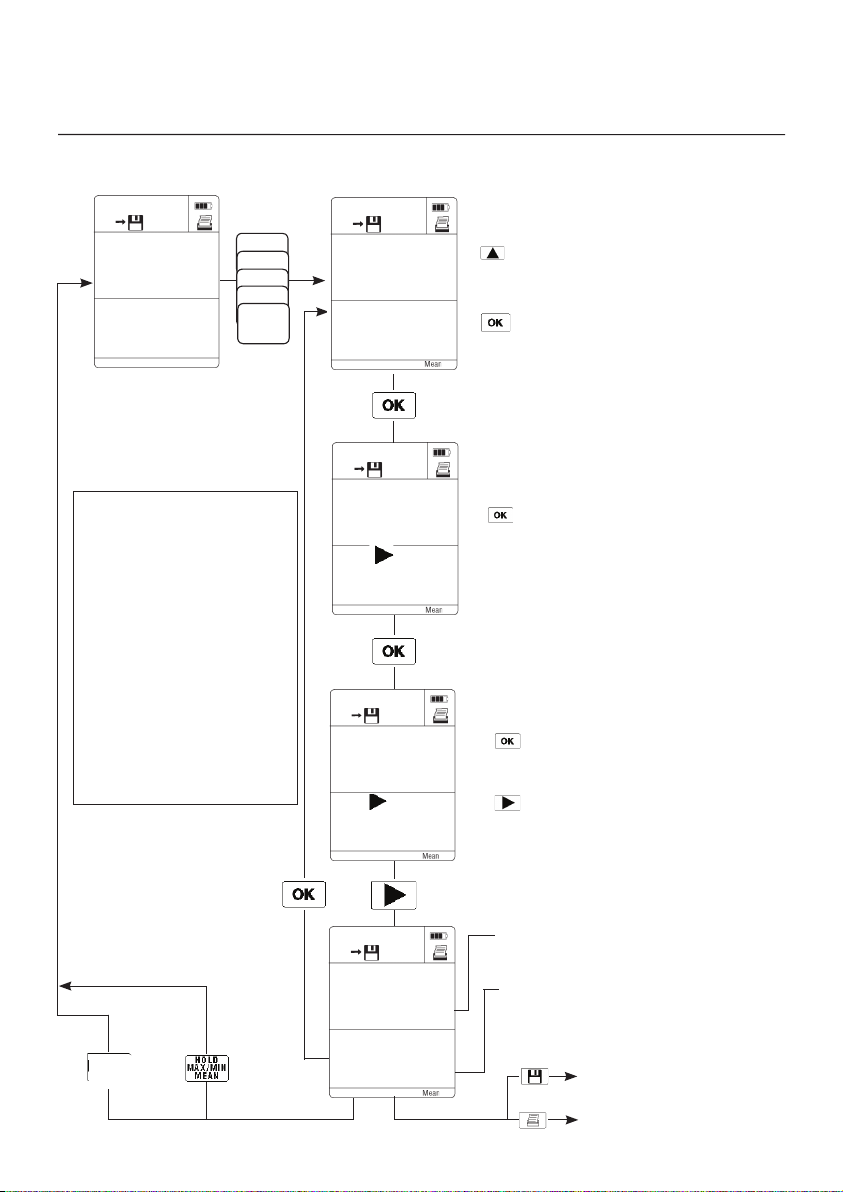

Note on saved or printed logs:

1. The log of a multi-point mean

calculation contains single value,

max. value, min. value and

mean value.

2. The log of a timed mean

calculation contains max.

value, min. value and mean

value.

Special solution for volume

flow selected:

3. Any additional velocity values

(m/s) are saved with the volume

flow values in the memory.

M.05

N.0017

MAN

1:

55.21

START

00:00

M.05

N.0017

MAN

1:

55.17

MEAN

END

00:10

M.05

N.0017

MAN

1:

55.20

MEAN

GO

m/s

m/s

m/s

Timed mean calculation Mean

Only for parameter in the 1st line

Select required reading.

Start timed mean calculation

Finish timed mean calculation.

Continue timed mean calculation

or

calculate mean.

New mean

calculation possible

ESC

or

Location

00:15

M.05

N.0017

MAN

MEAN

m/s

55.21

MEAN NEW

00:05

13

Mean

Timed duration of

mean calculation

Save mean.

Print mean.

Page 14

3. Location selection

M.05

N.0017

MAN

1:

58.06

1:

21.80

Location

m/s

hPa

ESC

Location

Duct 1

The location names Location 1 to 99 are specified by the factory.

Additional location names (8 characters) can only be loaded onto

1. Current

measurement

your instrument using PC software.

01

The cross-section

can only be called up if

volume flow is activated

(testo 445 instrument)

/ Select location

A

cm

50.0

Increase value

Decrease value

Select digit box

ESC

Location

Use ESC to go

to selection of

cross-section entry

Ø AxB, m2, Funnel)

Return to current

measurement

B

cm

50.0

or :

From now on all measured data which is saved or printed is

linked to the selected location or product names.

14

Increase value

Decrease value

Select digit box

Page 15

M.05

MAN

1:

2:

N.0017

°C

69.6

°C

70.0

CAL Re

M.05

MAN

1:CAL

OFFSET

N.0017

°C

70.0

00.4

4. Parameter settings

System adjustment

The setting functions are activated in accordance with the rea-

i

ding selected - flashing cursor in display.

System adjustment (only possible in testo 645):

testo 645 and probes with EEPROM (Part no. 0614.xxxx) can

be adjusted to the “zero error adjustment point”. The probe

characteristic saved in the measuring instrument is offset at a

measurement point. This is simply entered in the instrument at

the touch of a button. The following serves as a reference for

offset calculations:

- A Testo calibration certificate or

- A highly accurate Pt100 probe:

An accurate Pt100 probe measures the temperature at

socket 2; an inaccurate but quick probe measures in the

same substance; the offset correction must be such that both

probes show the same value.

Example: The reference probe in socket 2 measures 70.0 °C in

the vat.

The probe in socket 1 measures 69.6 °C.

Correct by 0.4 °C!

The respective flashing position can be changed using the

buttons or confirmed by pressing .

Current measurement

1:

RESET CAL

Current measurement

Note:

Offset is saved in probes with EEPROM and is automatically

recognised when the instrument is switched on.

In probes without EEPROM, the set offset is located in the

input socket.

The OFFSET value is displayed or printed when switching

on, saving or printing.

Deleting system adjustment: The set OFFSET is reset to 00.0.

15

Page 16

4. Parameter settings

Adjusting: humidity probes / humidity parameters /

ppm vol%

M.05

N.0017

MAN

2:

10.1

CAL %

M.05

N.0017

MAN

td°C

2:

12.9

1:

15246

M.05

N.0017

MAN

%

%

m/s

CAL11.3 %

11.1

NO YES

td°C g/m

The setting functions are activated in accordance with reading

i

selected - flashing cursor in display.

Adjusting humidity probes

Monitoring and adjusting humidity probes

(0636.9740/0636.9715) or 3-function probe (0635.1540).

To carry out the adjustment, immerse the probe in the

adjustment container belonging to the control and

adjustment set (Part no. 0554.0660). Observe the

instructions given in the Instruction manual (0973.1820)!

NO flashes No adjustment.

YES flashes The probe is adjusted.

Switch to YES/NO

Confirm selelction and return to measurement.

Displaying calculated humidity parameters.

If Testo`s combination humidity probe (e.g. 0636.9740) is

connected, testo 445 and testo 645 display a calculated humidity

parameter in addition to temperature and relative humidity. You

can select from the following parameters:

td°C

Dew point Absolute Degree Enthalpy

temperature humidity of humidity

Degree of humidity and enthalpy are pressure-dependent

parameters. Absolute pressure has to be set (See 6. Instrument

configuration -Parameter setting).

The respective selected parameter flashes.

g/m3 g/kg J/g td°C ...

Select

Confirm selection and return to measurement..

The selected humidity parameter is displayed.

2:

1:

ppm

ppm vol%

Switch between ppm and vol% if a CO2 probe is connected

(only possible in a testo 445 instrument).

ppm vol% ppm ...

The respective selected parameter flashes.

Select

Confirm selection and return to measurement.

16

Page 17

M.05

N.0017

MAN

1:

mbar

22.73

td°C

2:

hpa=0 m/s

m/s

4. Parameter settings

Initializing pressure probe / Activating velocity and volume flow

The setting functions are activated in accordance with

i

reading line selected - flashing cursor in display.

Differential pressure probe (testo 445 only):

Activating/deactivating m/s, m3/h, in addition to mbar;

initialisation

Velocity probes (testo 445 only):

Activating/deactivating m3/h, in addition to m/s

Zero adjustment of differential pressure probe (hPa) and

return to current measurement.

/ =

scroll

value

= Next

position

m/s

ON OFF

m3/h

ON OFF

...

100. cm

Ø AxB

100. cm

A

B

100, cm

Switch velocity speed (m/s) in the display on and off.

Switch ON/OFF

The respective flashing setting is confirmed with .

Switch volume flow (m3/h) in the display on and off.

Switch to ON/OFF

OFF flashes return to measurement.

ON blinkt Input of duct cross-section:

2

m

0.500 m

FUNNEL

Ø = round duct cross-section;

enter diameter.

AxB = rectangular duct;

enter side lengths A and B.

20

2

m

area in m

section area.

FUNNEL = Funnel factor in

volume flow funnel used

(See Instruction manual on

volume flow funnel).

Ø

2

= known cross-section

2

; enter cross-

...

Once the cross-section is entered, return to the current volume flow measurement.

17

Page 18

5. Memory settings

Overview

1. Current measurement

M.05

MAN

1:

58.06

1:

21.80

ESC

Location

MAN

MAN AUTO

MEMORY

N.0017

m/s

hPa

Press the button to get to the memory settings mode

i

Confirm flashing save symbol via button.

4 memory settings are possible. Select the required saving option

by pressing

MAN AUTO OUT CLEAR MAN ...

The symbol corresponding to the selection appears in the top line.

The function is activated with

Parameter settings

(See Chapter 4).

AUTO

AUTO OUT

MEMORY

:

.

OUT CLEAR

MEMORY

CLEAR MA

MEMORY

.

ESC

Location

18

Page 19

5. Memory settings

Manual / Automatic saving

MAN

MAN AUTO

MEMORY

ESC

Location

AUTO

CYCLE-N.

M.05

N.0017

MAN

1:

m3/h

19665

1:

21.85

AUTO

AUTO OUT

MORY

660

AUTO

CYCLE h

min sec

01:30

m/s

00

MAN

Manual saving:

Each time

the instrument and includes measured values, location, date and

time. The counter in the top left corner of the display shows the

number of logs saved for this location.

Saving a log with timed or multi-point mean calculation :

The log includes MIN value, MAX value and mean of the

measurement and also single values in multi-point mean

calculations.

AUTO

Automatic saving:

When this saving function is set, the instrument automatically

accepts the measured values at fixed intervals and saves them

(=logger operation).

The number of measuring cycles (CYCLE-N.) to be saved and

intervals (CYCLE) have to be programmed:

1. Cycle-N.

The instrument automatically offers the maximum possible number

of measuring cycles. Set required number using

/ / .

Confirm set value by pressing .

2. Cycle

Select interval in which the measured values are to be saved. The

blinking position can be changed using

Confirm set value by pressing .

Automatic saving is started by pressing

until the programmed measurement

series is accepted.

is pressed a log of the measurement is saved in

.

. The symbol flashes

M.05 N.0017

AUTO

1:

19665

1:

m3/h

m/s

M.06

AUTO

N.0001

19

ESC

Location

Cancel saving procedure.

Starts automatic saving again.

An additional measurement series is

added.

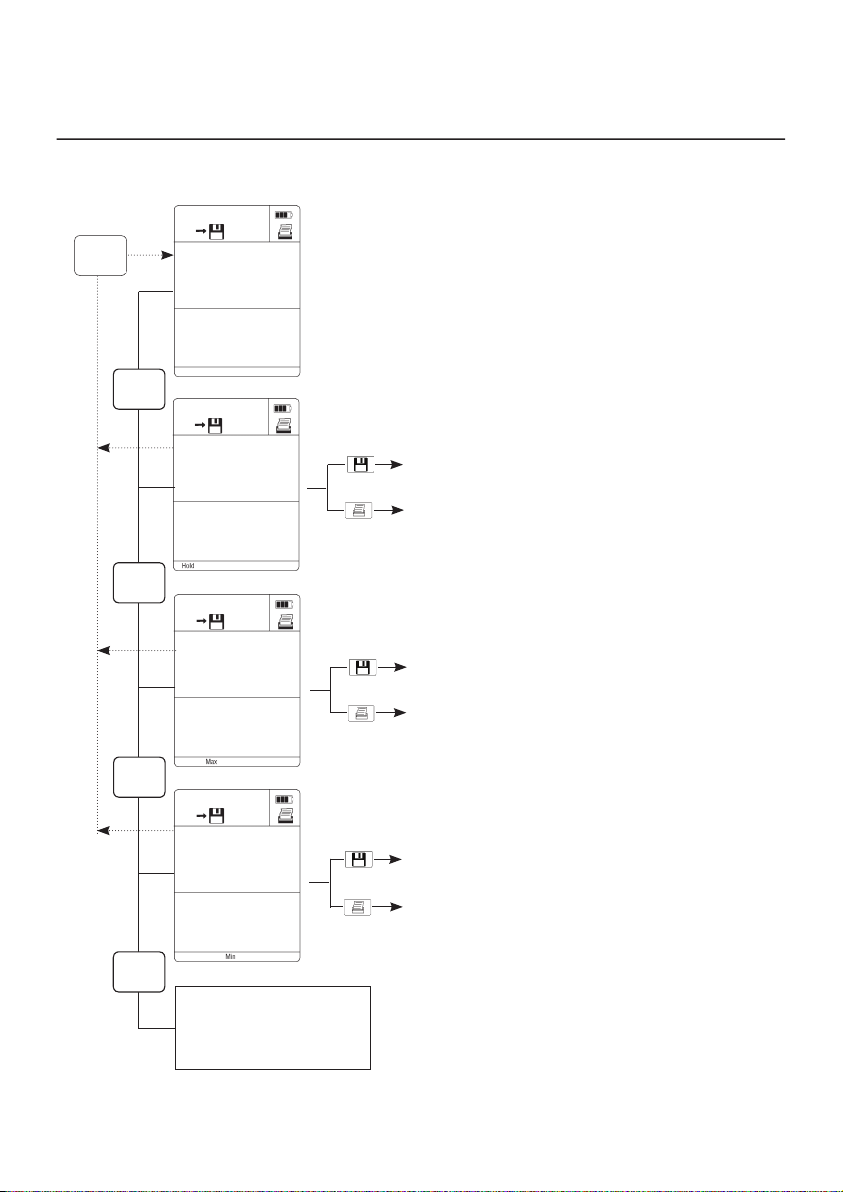

Page 20

OUT CLEAR

MEMORY

ESC

Location

Location

5. Memory settings

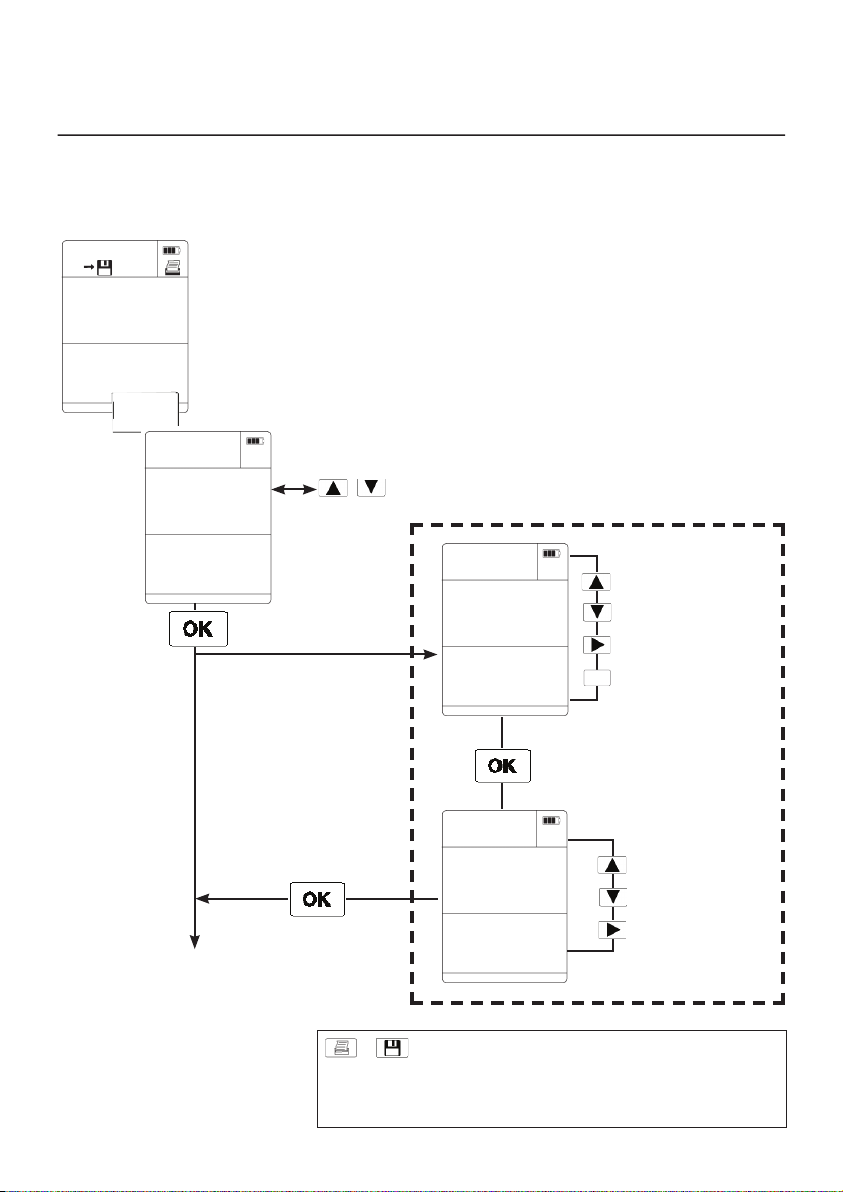

Reading or printing memory contents

Press the button to access the memory settings

i

mode. Confirm flashing save symbol via the button. Cancel printing by pressing the button.

OUT

1. Reading out or printing memory contents:

If the “OUT” display is flashing and the button is pressed,

printing of the complete memory

contents is started. Cancel printout by pressing the

button.

M.05 N.0017

Pizza

01:13

01.01

1998

M.05 N.0017

1:

79.7

°C

M.05 N.0017

1:

Duct 1

ESC

Location

ESC

Location

01

ESC

Location

ESC

Location

°C

2. Selecting the location:

is activated selection options appear in the display to select

If

the required location. Select location by pressing

If printing is activated by pressing at this

point, all of the logs

(measurement series and cycles) for this location are printed.

Cancel printout by pressing the button.

3. Selecting the log:

Confirm the location selected above by pressing

The M.0x counter flashes in the display.

Select the log no. by pressing

activates a printout of the

selected measurement log.

Press

Cancel printout by pressing the button

4. Selecting the measurement cycle: (only possible if a

measurement log consists of a measurement series):

Confirm the measurement log selected above by pressing

The N.0x counter flashes in the display.

Select the measurement cycle by pressing

to display the values measured.

activates a printout of the selected

measurement cycle.

.

.

.

.

.

79.7

The

ESC

button enables you to go back one step.

Location

20

Page 21

5. Memory settings

Clearing memory contents/Sample printouts

Press the button to access the memory settings mode. Confirm flashing save

i

CLEAR MA

MEMORY

Memory is

not cleared.

Printout of manual saving:

Messrs. Smith

31.08.1998

11:26:05

Raum 1

M.001

31.08.1998

11:20:05

1: 21.4 °C

2: 44.7 %

2: 22.1 °C

2: 0.55 m/s

2: 9.6 td°C

Info :

symbol via the button.

CLEAR Clearing memory:

NO YES

CLEAR

MAN

MAN AUTO

MEMORY

Header

Date of prinout

Location

Start of saving

Log

Save

Readings

YES NO

CLEAR

Memory is cleared

completely.

Current measurement

M.05

N.0017

MAN

1:

58.06

1:

21.80

Printout of automatic saving procedure:

Firma Mustermann

31.08.1998 11:27:32

Raum 1

M.002

31.08.1998 11:26:59

cycle: 00:0002

1:°C 2:% 2:°C

01 21.4 45.1 22.2

02 21.2 44.7 22.3

03 21.1 44.6 22.3

04 21.8 44.6 22.3

2:m/s 2:td°C

01 1.00 9.8

02 1.66 9.7

03 2.01 9.7

04 1.52 9.7

Info :

m/s

hPa

21

Page 22

Simultaneously

6. Instrument configuration

Power save function / Power supply

ESC

Location

The

i

button enables you to change to the current

measurement from every menu item.

AUTO-OFF

ON OFF

Auto Off function: On/Off

BAT ACCU

Battery: Battery or accu

ACCU BAT

See page 24

AUTO-OFF

OFF ON

The

(

The blinking position can be changed by pressing

Power save function

Auto OFF function is switched on (“ON”)

If a button has not been pressed in the last 5 minutes or

there is no communication with the PC, the instrument

switches off automatically.

Exceptions:

- the instrument does not switch off if the mains unit is

- the function is deactivated during timed and multi-point

button has to be kept pressed for approx. 2

seconds when switching on the instrument

button).

or confirmed by pressing .

plugged in

mean calculation

Important:

The instrument must be set at battery or rechargeable

battery operation.

Incorrect instrument setting

- Rechargeable battery operation is set and battery is put in:

If the mains unit is connected and the charging

procedure is confirmed:

- Battery operation is set and rechargeable battery is put in:

Rechargeable battery will not be charged.

22

Risk of explosion!!!!

Page 23

6. Instrument configuration

Power supply

Battery operation with 9 V block battery, alkali manganese IEC

6LR61.

Parallel power supply is possible with mains unit without damaging

batteries.

Zinc carbon batteries should not be used with thermal probes because

their inner resistance is too high and the probe is not supplied with

sufficient energy. The instrument switches off.

Rechargeable battery operation with Testo rechargeable battery

(Part no. 0515.0025), Type: Ni-MH IEC 6F22.

If the rechargeable battery is empty: Parallel power supply and

simultaneous recharging of the battery in the instrument with mains

unit.

Connect mains unit to recharge battery. Query as to whether

rechargable battery should be recharged.

Has a rechargeable battery or battery been put in? Check!

There is a risk of explosion if batteries have been put in! Select “NO” in

this case.

If a rechargeable battery is inside confirm Charge “Yes” with

The instrument can be switched off if a measurement is not

taking place. The rechargeable battery capacity and power is

displayed. Recharging takes approximately 6 hours if the rechargeable

battery is completely empty.

Correct battery recharging in the instrument via the mains unit can

only be guaranteed if the above mentioned Testo rechargeable

batteries are used. If other rechargeable battery types are used,

recharging will have to be carried out by an external recharger.

Note:

The instrument should be switched off before changing the battery/

rechargeable battery or when operating using mains unit without

rechargeable battery and battery. If the battery/rechargeable battery is

removed, the instrument loses the set values (date/time). The capacity

of the battery/rechargeable battery is shown in the display:

100 %

75 %

50 %

25 % (if the last segment is flashing the

battery/rechargeable battery is almost empty)

Operation

via mains

unit (Part

no. 0554.0088):

Insert mains unit in the mains unit socket of the instrument (see

connection assignment).

0 % (change battery/recharge rechargeable

battery). Instrument will switch off after 1 minute.

23

Page 24

DATE

01.01

1998

6. Instrument configuration

ESC

Location

The

i

Setting date

The flashing position in the display can be set

-

button enables you to change to the current

measurement from every menu item.

= scroll/ = next position -

/

Setting date/time

TIME

11:25

Setting the time

The blinking position in the display can be set

-

= scroll/ = next position -

/

24

Page 25

6. Instrument configuration

Parameters

1. Temperature

Parameter

°C

025.0

2. Humidity

3. Absolute pressure

4. Density

(calculated)

5. Pitot tube factor

Parameter

Factor

1.00

(testo 445)

(testo 445)

(testo 445

testo 645)

(testo 445)

(testo 445)

Parameter setting for pressure and density compensation:

Humidity (g/kg, J/g), velocity (measured with thermal probes) and

are pressure-dependent parameters.

CO

2

Density is included in the measurement when velocity is measured

using a Pitot tube.

testo 445/645 automatically carries out pressure and density

compensation. Temperature, humidity and absolute pressure

must be entered.

3 parameters can be measured on location using a Testo

humidity/temperature probe (e.g. Part no. 0636.9740) and the

Testo absolute pressure probe (Part no. 0638.1645). See the

Chapter “Measuring absolute pressure” for more information on

measuring absolute pressure without an absolute pressure probe.

Density is automatically calculated by the instrument based

on these 3 values:

Temperature

Humidity Density

Factory

settings:

Note:

If the density set in the factory is taken as the basis, the

measurement error can be up to 10% of the measurement when

velocity is measured using a Pitot tube. Parameters must be

determined and set in the instrument in order to achieve exact

measurements.

The flashing position in the display can be set.

-

/

= Confirm.

= Print parameter.

Pitot tube factor setting:

The factor for Pitot tubes from Testo is constantly at 1.00 and

does not need to be changed. If the Pitot tubes from other firms

are used, ask your supplier for the Pitot tube factor and save in

instrument.

Absolute pressure

Temperature 20 °C

Humidity 50 %RH Density 1199 g/m3

Absolute pressure 1013 mbar

= Scroll/ = Next position -

25

Page 26

°C

m

Unit

m3

hPa

Factory reset

M.05

MAN

2:

2:

Current measurement

mbar

N.0017

°C

20.0

%RH

51.8

6. Instrument configuration

Unit selection / Factory reset

ESC

Location

The

i

measurement from every menu item.

°C °F

The selected parameter flashes.

Select

confirms the selection.

m/s

The selected parameter flashes.

Select

confirms the selection.

m3/h

l/s cfm (ft3/min) (testo 445

only)

The selected parameter flashes.

Select

confirms the selection.

hPa

The selected parameter flashes

Select

confirms the selection.

Factory reset

Factory reset (confirm with ”Yes”) resets all of the settings in the

instrument configuration to the factory settings.

confirms the selection and switches to the display of the cur-

rent setting.

button enables you to change to the current

fpm (ft/min) (testo 445 only)

m3/m (m3/min) m3/s

mbar psi in W (”H2O) (testo 445 only)

26

Page 27

7. Velocity measurement

Volume flow funnel (testo 445)

A volume flow funnel is needed to measure the volume flow in a

ventilation opening (grid or outlet with dual wall clearance). The

opening of the funnel must be covered completely by the grid

(max. 190 x 190 mm with 0554.0400 or max. 350 x 350 mm with

0554.0410).

For the measurement, a velocity probe (0635.1041, 0628.0005

or 0635. 9540) is placed in the funnel’s hole, is positioned in the

middle and is aligned. The probe is snapped into the funnel’s

handle. Connect the probe to the instrument and switch on.

Position the cursor on the m/s parameter (

You will get to the “Parameter setting” menu by pressing .

Press to get the volume flow (m

Confirm the m

3

/h ON setting by pressing .

3

/h) in the display.

or ).

Press twice and confirm with .

(funnel/=funnel factor).

Enter the factor for the funnel used by you:

Funnel factor for funnel with part no. 0554.0400 = 20

Funnel factor for funnel with part no. 0554.0410 = 22

Press the funnel tightly on the opening. You can accept the

displayed reading as it is or you can carry out a timed mean

calculation if the readings fluctuate.

27

Page 28

7. Velocity measurement

Pitot tube and pressure probe (testo 445)

The measuring range is not symmetrical when the measurement

is carried out using differential pressure probes (see Technical

data on page 35)

Connect silicone hose to the correct connection plug (obser-

When measuring velocity with the Pitot tube, it is better to use the

0638.1445 pressure probe on account of its optimum accuracy.

The measuring range extends to approx. 40 m/s. Velocity is

calculated in the instrument using the pressure difference p in the

Pitot tube and based on the following formula:

m/s = S x 200000 x p [hPa]

rho [g/m3]

Press to activate the conversion. The “Parameter setting”

menu is displayed. m/s appears in the display when activated via

the button. Confirm the m/s ON setting with .

The next step is to decide, using the button, as to whether

the volume flow is to be calculated immediately (m3/h ON) or not

(m3/h OFF). Confirm input with .

Pitot tube factor S and the temperature, humidity and absolute

pressure parameters required to automatically calculate density

have to be set in the instrument configuration.

The Pitot tube factor for testo Pitot tubes is at a constant 1.00 and

does not need to be changed. If non-Testo Pitot tubes are used,

please ask your supplier for the factor and save it.

ve + and - on the probes.)

Thermal anemometer probes (testo 445)

The measuring principle of thermal anemometers with a heated

wire or heated ball sensor is based on the cooling down of the

sensor element via the air flow. The sensor element is heated to

100 °C for this purpose. The power needed to keep the sensor

constantly at this temperature is a measure of the strength of the

flow. According to this measuring principle, this probe requires a

heating up period after being switched on which appears as ”Count

Down” in the display. Measuring in accordance with this measuring

principle depends on the ambient pressure. The absolute pressure

can be set in the instrument configuration menu.

28

Page 29

CO/CO2 measurement (testo 445)

CO measurement (testo 445)

The connected probe 0632.1247 is initialised during the switchon phase (“Count Down” runs in the display). For this reason,

the measuring instrument should only be switched on in an

atmosphere free of CO. Values will be too low otherwise in

subsequent measurements.

If you want to initialize the instrument while switched on, place

the probe in an atmosphere free of CO. Press and confirm

initialisation of the CO probe (CO=0) by pressing again.

Connect probe before switching on the instrument

The protective cap must be on the probe during the initialisation

phase (otherwise risk of inaccurate measurements).

The initialisation cap should only be removed during the actual

measurement and should be replaced directly afterwards

(mechanical protection of sensor and adherence to

Cigarette smoke influences the measurement (min. 50 ppm).

accuracies).

A smoker’s breath influences the measurement by approx.

Switch on - Initialisation phase (60 s).

The ambient CO probe is initialised during the initialisation phase.

• Remove yellow protective cap.

• Probe can be put in shirt pocket, for example. The direction

of the flow on the probe influences the accuracy of the

measurement. Optimum measured results are achieved by

moving the probe gently back and forth. If the air blows headon on the sensor, the values measured will be too high.

29

5 ppm.

Page 30

CO2 measurement

CO2 measurement (testo 445)

The 0632.1240 probe measures concentrations from

0 to 1 vol % CO2. The unit can be switched between ppm and

vol% as described in “Parameter settings” on page 16.

The measuring principle is based on infrared absorption. The

probe has a relatively high power consumption on account of its

sensor. Use mains unit and rechargeable batteries for long-term

measurements.

Note: The correct reading is available 20 to 30 seconds after

being switched on.

The corresponding “Count Down” is displayed.

If there are major changes in the concentration, the probe needs

30 - 60 seconds to adapt itself to the outside world.

Gently swinging of the probe shortens the adaptation time.

Hold the probe as far away as possible from you to reduce

the influence of the CO2 level in your breath on the

measurement.

Pressure offset

Please note that the CO2 reading depends on absolute air pressure. This effect is compensated in the instrument.

Enter the correct absolute pressure for the location in the

“Instrument configuration” menu (see Chapter 6).

Permissible ambient temperature: 0 to +50 °C

Permissible storage temperature: -20 to +70 °C

30

Page 31

Measuring absolute pressure

Absolute pressure is calculated from:

• Elevation pressure (metres above NN)

The annual mean is 1013 mbar at sea level, the higher the

location above sea level, the lower the pressure.

• Barometric pressure

The annual mean is 1013 mbar regardless of height. This

pressure can deviate from the annual mean by ±20 mbar

depending on the weather (see display on nearest barometer).

• Differential pressure

is the positive or negative pressure in the duct.

You can determine the annual mean air pressure value for your

elevation using the following table and any additional fluctuation

using a barometer or ask your weather station for the exact air

pressure value.

Elevation

M.S.L

Table: Barometric elevation formula

Air pressure

(mbar)

Elevation

M.S.L

Air pressure

(mbar)

31

Elevation

M.S.L

Air pressure

(mbar)

Elevation

M.S.L

Air pressure

(mbar)

Page 32

Determining absolute pressure

Example:

If you are at 800 m above mean sea level, you have an annual

mean air pressure of 920 mbar.

The annual mean air pressure has to be reduced by 10 (910 mbar

air pressure) to correspond to the barometer display

(1003 mbar) and to the barometer’s height offset (to 1013 hPa).

Add the difference between your ambient air pressure and the

static process air pressure (e.g. positive pressure in an air duct

which is to be measured - can be measured using the differential

pressure probe at up to 100 mbar) to this (air) pressure value.

Example: We have measured an annual mean air pressure of

910 mbar. We will now add 90 mbar based on the static process

pressure. We therefore assume an absolute air pressure in the

measurement medium of 1000 mbar.

The table on page 31 is also saved in the Testo Comfort software.

Absolute pressure can be calculated automatically using this

software if the height above mean sea level, barometric pressure

and differential pressure are entered. The calculated absolute

pressure is then taken over by the instrument.

32

Page 33

Error messages

Error message Cause Remedy

Memory full The memory is full Clear memory

Measuring range has not The probe is not suitable

been reached for this measurement task.

The measured values are

outside the allowed

measuring range. Remove

probe from location.

Measuring range has been The probe is not suitable

exceeded for this measurement task.

The measured values are

outside the allowed

measuring range. Remove

probe from location.

1st possibilty Some probes cannot

Measuring range has been differentiate between

exceeded or has not been not reaching or not

reached exceeding a measuring

range. Remove probe from

measurement location.

The probe is not suitable

for this measuring task.

The measured values are

outside the measuring

range allowed.

2nd possibility Check if the probe is

Probe is not connected connected to the right

or is defect socket and that the

plug has been pushed in

far enough. Turn

instrument on and off

again

If the error message

returns, please contact

your nearest Testo

service point.

If we were unable to answer your question, please contact your distributor or Testo

Customer Service. For contact data, see back of this document or web page www.

testo.com/service-contact

33

Page 34

testo 645/445

Technical data - Instruments

testo 645/445

General technical data

Memory space: Up to 3000 readings

Power supply: Battery / rechargeable batt.

Alternative: 12 V mains unit

Battery recharging in instr.

Typical Temperature/humidity

battery probes, pressure probes,

lifetimes: vane probes:

30 to 45 h

Thermal probes,

CO2 probes, 3-function

probe:

>3 - 12 h

Reduce the hour times by

a factor of 5 if a 9V battery

is used.

Operating

temperature: 0 to +50 °C

Storage

temperature: -20 to +70 °C

Weight: Approx. 255 g incl. batteries

Other features - Automatic recognition of

all connected probes

- RS232 interface for

data management

(electrically isolated)

Temperature measurement

Type K (NiCr-Ni)

Measuring range: -200 to +1370 °C

Accuracy* ±0.3 °C or ±0.5 % of

at 22 °C: reading

(the larger value applies)

Additional error over

operating

temperature range: ±0.2 °C

Resolution: 0.1 °C

Type J (FeCu-Ni)

Measuring range: -200 to +1000 °C

Accuracy* ±0.3 °C or ±0.5 % of

at 22 °C: reading

(the larger value applies)

Additional error

over operating

temperature range: ±0.2 °C

Resolution: 0.1 °C

The following can also be connected:

thermocouple: Type S (Pt Rh-Pt)

NTC

Measuring range: -50 to +150 °C

Accuracy*: ±0.2 °C (-25 to +74.9 °C)

±0.4 °C (-50 to -25.1 °C/

+75 to +99.9 °C)

±0.5 % of reading

(+100 to +150 °C)

Resolution: 0.1 °C

Humidity measurement

Temperature: -20 to +180 °C

Measuring range: 0 to 100 %RH

Resolution: 0.1 %RH

System Up to 1.0 %RH

accuracy*: (see probe data)

Calc. humidity td, g/m

parameters: (pressure-compensated)

Warranty

Instruments 2 years

Probes 1 year

Terms of warranty: see website

www.testo.com/warranty

3

, g/kg, J/g

34

Page 35

testo 645

Technical data - Instruments

testo 645/445

Temperature measurement

Pt100

measuring range: -200 to +800 °C

Accuracy* ±0.2 °C or ±0.1 % of

at 22 °C: reading

(the larger value applies)

Additional error

over operating

temperature range: ±0.1 °C

Resolution: 0.1 °C

testo 445

Velocity measurement

Vane

Measuring range: 0 to 60 m/s

Resolution: 0.01 m/s

Accuracy: See probe data

Thermal anemometer

Measuring range: 0 to 20 m/s

Resolution: 0.01 m/s (0 to 10 m/s)

0.1 m/s (remaining range)

Accuracy: See probe data

Pitot tube

Measuring range: 0 to 10 mbar / 0 to 100 mbar

0 to 40 m/s / 0 to 100 m/s

Resolution: 0.01 m/s

Accuracy: See probe data

3

Volume flow in m

cfm (ft3/min)

Measuring range: 99,999 m3/h

/h, m3/min, l/s,

Pressure units can be switched:

mbar, psi; in W(”H2O)

Calculated velocity values

density compensated: 0 to 100 m/s

Calculated volume flow values:

m

3

/h, m3/min, l/s, cfm (ft3/min)

CO2 measurement

Measuring range: 0 to 10000 ppm

0 to 1 vol. %

Resolution: 1 ppm

0.0001 vol. %

Accuracy*: ±50 ppm ±2 % of reading

(0 to 5000 ppm)

±100 ppm ±3 % of reading

(remaining range)

CO measurement

Measuring range: 0 to 500 ppm

Resolution: 1 ppm

Accuracy*: ±5 ppm (0 to 100 ppm)

±5 % of measured value

(remaining range)

Pressure measurement

Measuring range: Resolution: Accuracy*:

-40 to 100 mbar 0.01 mbar ±0.1 mbar

(0 to 20 mbar)

1 % of reading

(rem. range)

-4 to 10 mbar 0.001 mbar ±0.01 mbar

2000 mbar 1 mbar ±2 mbar

* Accuracy: ±1 digit

35

Page 36

Ordering data

Measuring instruments/Accessories/Probes for testo 645 / 445

Measuring instruments

testo 645 humidity measuring instrument, with TopSafe

2 channel temperature (type K/J/S, NTC, Pt100 thermocouples) and humidity measuring instrument, with battery

and calibration protocol

testo 445 multi-function measuring instrument, with TopSafe

2 channel multi-function measuring instrument for temperature (type K/J/S thermocouples), humidity, velocity,

pressure, CO

, CO with battery and calibration protocol

2

Part no..

0563 6450

0560 4450

Accessories

Software

Comfort software “Professional” for data management, incl. data base, convenient analysis and graphics function 0554 0274

RS232 cable to connect measuring instrument - PC for the transfer of data 0409 0178

TopSafe / Cases

TopSafe protects instrument from dirt, water (IP 65) and impact - dishwasher-proof - with bench stand, belt clips and

probe clips to attach probe to TopSafe

System case, plastic for instrument, probes and additional accessories Clear layout of case contents by placing probes

in lid.

System case, aluminium for instrument, probes and additional accessories. Clear layout of case contents by placing

probes in lid.

Additional accessories

9 V rechargeable battery for testo 445, testo 645 measuring instruments 0515 0025

PT 100-probes

Standard immersion/penetration probe

Pipe: stainless steel

Highly accurate immersion/penetration probe -100...+350°C, 1/5,

Flexible precision immersion probe, cable between handle

and tip, heat-proof up to +300 °C

Meas. range / Accuracy t

-200...+400°C, Class A 20 Plug-in head 0604.0273

Class B

-100...+265°C, 1/5,

Class B

Connection cable Part no..

99

sec.

30 Plug-in head

80 Plug-in head 0628.0016*

) 0628.0015*

0516 0440

0516 0400

0516 0410

* With EEPROM: Precision adjustment for each probe at a measuring point

36

Page 37

Ordering data

Fühler für testo 645 / 445

NiCr-Ni probes

Meas. range / Accuracy t

Quick-action surface probe with sprung thermocouple strip -200...+300°C, Short-

term up to +500 °C,

Class 2

Spare measuring head for pipe clamp probe, for pipes with

-60...+130°C, Class 2 5 1,5 m, PVC 0602 0092

Connection Part no.

99

sec.

3 Plug-in head

Please order connection

(

cable 0430.0143)

a 2"diameter

Rapid response immersion/penetration probe -200...+400°C, Class 1 3 Plug-in head

Quick action immersion/penetration probe for measure-

-200...+600°C, Class 1 1 Plug-in head

ments in liquids

Quick action immersion/penetration probe for high tem-

-200...+1100°C, Class 1 1 Plug-in head

peratures

Quick action immersion/penetration probe for measure-

-200...+600°C, Class 1 <1 Plug-in head

ments in gases and liquids with a slim tip, low in mass

Please order connection

(

cable 0430.0143)

Please order connection

(

cable 0430.0143)

Please order connection

(

cable 0430.0143)

Please order connection

(

cable 0430.0143)

Plug-in measuring tips Ø 3 ffor high temperatures, bendable

a) Stainless steel outer coating 1.4541 L 750

b) Stainless steel outer coating 1.4541 L 1200

c) Inconel outer coating 2.4816 L 550

d) Inconel outer coating 2.4816 L 1030

-200..+900 °C

-200..+900 °C

-200..+1100 °C

-200..+1100 °C

3,5

3,5

3,5

3,5

Handle for plug-in measuring tips coiled cable

PUR

Accessories for NiCr-Ni probes

Adapter to connect NiCr-Ni thermocouples and probes with

open wire ends

Silicone heat paste (14g), Tmax = +260 °C to improve heat

transfer in surface probes

Connection cable for probes Length 1,5 m,

Connection cable for probes with plug-in head Length 5,0 m,

Extension cable between plug-in cable and instrument Length 5,0 m,

0.3 m, PVC 0600.1693

PUR

PUR

PUR

0604 0194

0604.0293

0604.0493

0604.0593

0604.9794

0600.5393

0600.5493

0600.5793

0600.5893

0600 5593

0554.0004

0430.0143

0430.0145

0409.0063

37

Page 38

Ordering data

Probes for testo 645 / 445

Humidity/temperature

Measuring range System

probes

Standard indoor air quality probe up to +70 °C 0 to 100 %RH, probe

Highly accurate reference humidity/temp.

probe incl. calibration certificate

Robust humidity probe e.g. for measuring

material moisture equilibrium or for measurements in exhaust ducts up to +120 °C

Robust high temperature probe up to +180 °C 0 to 100 %rH

Flexible humidity probe, does not retain shape

for measurements in inaccessible places

Pressure-tight probes for measuring remaining, e.g. in compressed air systems

Flexible, humidity probe (retains shape) for

measurements in inaccessible places

tip), -20 to +70°C

0 to 100 %RH, probe

tip), -20 to +70°C

0 to 100 %rH

-20 to +120°C

-20 to +180°C

0 to 100 %rH

-20 to +180°C

0 to 100 %rH

-30 to +50°C t

pd

0 to 100 %rH

-50 to +50°C t

pd

* Accuracy data at rated temperature of +25 °C, temperature coefficient ± 0.03% / °C

accuracy*

±2 %rH (2 to 98 %rH)

±0,4°C (0 to 50°C)

±0,5 °C (rem. range)

±1%rH (10 to 90 %rH

from +15 to+30°C)

±2%rH (rem. range

plus Tcomp.)

±0,4°C (0 to 50°C)

±0,5°C (rem. range)

±1%rH (10 to 90 %rH

from +15 to +30°C)

±2%rH (rem. range

.)

plus Tcomp

±0,4°C (0 to 50°C)

±0,5°C (rem. range))

±1%rH (10 to 90 %rH

from +15 to +30°C)

±2%rH (rem. range

plus Tcomp.)

±0,4°C (0 to 50°C)

±0,5°C (rem. range)

±2 %rH (2 to 98 %rH)

±0,4°C (0 to 50°C)

±0,5 °C (rem. range)

-30 to +50°C t

±0,9 to ±4°C t

-40 to +50°C t

±0,8 to ±4°C t

pd

pd

pd

pd

t99

sec.

<12

at 2m/s

<12

at

2m/s

<30

at

2m/s

<30

at

2m/s

<30

at

2m/s

1 to 5

min

typically

2 min

1 to 5

min

typically

2 min

Connection

cable

Plug-in head

Please order connecti-

(

on cable 0430.0143)

Plug-in head

Please order connecti-

(

on cable 0430.0143)

Plug-in head

Please order connecti-

(

on cable 0430.0143)

Plug-in head

Please order connecti-

(

on cable 0430.0143)

Plug-in head

Please order connecti-

(

on cable 0430.0143)

Plug-in head

Please order connecti-

(

on cable 0430.0143)

Plug-in head

Please order connecti-

(

on cable 0430.0143)

Part no.

0636 9740

0636 9741

0636 2140

0628 0021

0628 0022

0636 9840

0636 9841

38

Page 39

Ordering data

Probes for testo 645 / 445

Accessories for humidity/temperature probes, 3-function probe

Diameter Part no.

Caps for all humidity probes

Metal protection cage, material: stainless steel V4A. Quick adjustment time, robust and temperature-proof. Application: for velocities < 10 m/s

Cap with wire mesh filter. 12 mm 0554 0757

PTFE sintered filter, PTFE material. Not affected by condensation, water-repellent, resistant to corrosive substances. Applications: compressed air measurements, high humidity range (long-term

measurements), high velocities.

Stainless steel sintered cap, material: V2A stainless steel. Very robust, suitable for penetration, should

be cleaned with fresh air, mechanical protection of sensor. Application: large mechanical loads, high

velocities.

21 mm

12 mm

21 mm

12 mm

21 mm

12 mm

0554 0665

0554 0755

0554 0666

0554 0756

0554 0640

0554 0647

Additional accessories

Connection cable for probes with plug-in head, 1.5 m long, PUR coating material 0430 0143

Connection cable for probes with plug-in head, 5 m long, PUR coating material 0430 0145

Extension cable between plug-in head cable and instrument, 5 m long, PUR coating material 0409 0063

Telescope for probes with plug-in head, extension length: maximum 1 m, cable: 2.5 m, PUR coating

material

Control and adjustment set 11.3 % / 75.3 % for humidity probes and 3-function probe (please order

0554.0661 adapter for 3-function probe)

Control and storage humidity (33 %) for humidity probe and 3-function probe 0554 0636

Pressure probes

Pressure probe for measuring velocities gand differential pressure or absolute pressure

Accessories for pressure

Measuring range Accuracy Connection cable Part no..

-4 to 10 hPa

-40 to 100 hPa

2000 hPa (Abs.p)

Temp.max Material Length / Ø Part no..

±0,03 hPa

±0,1 hPa (0 to 20hPa)

±0,5% of m.v. (rem.)

±5 hPa

1,5 m, PUR 0638.1445

0430.0144

0554 0660

0638.1545

0638.1645

probes

Pitot tubes to measure velocity (in connection

with pressure probes); longer versions on request

Silicone hose to connect Pitot tube and pressure

probe, 5 m long

+350 °C

+350 °C

Chromium-plated brass

Chromium-plated brass

500 mm/7 mm

350 mm/7 mm

0635.2045

0635.2145

0554.0440

39

Page 40

Ordering data

Probes for testo 645 / 445

Velocity probes

Vane/temperature probe, can be attached to

handle or telescope

Vane/temperature probe, can be attached to

handle or telescope

Bendable vane probe for integrated velocity measurement Range of application: -20 to +60 °C

Bendable vane probe for integrated velocity measurement Range of application: -20 to +60 °

Low cost, robust hot bulb probe for measure-

ments in the lower velocity range

Robust hot bulb probe with handle and telescope

for measurements in the lower velocity range

Quick-reaction hot wire probe with telescope for

measurements in the lower velocity range with

direction recognition function

Flügelrad-Meßsonde mit Teleskop, T

High temperature probe with handle for long-term

measurements up to +350 °C

Accessories for velocity probes

Telescope for plug-in vane probes, max. 1 m long 2,3 m Silicon 0430 0941

Handle for plug-in vane probes 1,5 m Silicon 0430 3545

Volume flow funnel to measure the extraction

capacity in ventilation systems

Extension cable between connection cable and

instrument for plug-in vanes

+60°C Vane 0,4...40 m/s ±(0,2 m/s , +2 % of m.v.). 0628 0005

max

Sensor Meas. range Accuracy (System) Part no..

0,6 to 60 m/s

-30 to +140 °C

0,6 to 40 m/s

-30 to +140 °C

0,25 to 20 m/s ±(0,1 m/s +1,5 % of m.v.) 0635 9440

0,25 to 15 m/s ±(0,1 m/s +1,5 % of m.v.) 0635 9340

Hot bulb NTC 0 to 10 m/s

Hot bulb NTC 0 to 10 m/s

Hot bulb NTC 0 to 20 m/s

Vane, NiCr-Ni 0,6 to 20 m/s

Meas. range Dimension Connection cable Part no.

b) 20 to 400 m

-20 to +70 °C

-20 to +70 °C

-20 to +70 °C

-40 to +350 °C

3

/h 350x350 mm 0554 0410

±(0,2 m/s +1 % of m.v.) 0635 9540

±(0,2 m/s +1 % of m.v.) 0635 9640

±(0,03 m/s +5% of m.v.) 0635 1549

±(0,03 m/s +5% of m.v.) 0635 1049

±(0,03 m/s +4% of m.v.) 0635 1041

±2,5 % of final value 0635 6045

5 m, PUR 0409 0063

40

Page 41

Ordering data

Probes for testo 645 / 445

Additional probes

3-function probe for simultaneous measurement

of Ttemperature, humidity and velocity. With plugin head (please order 0430.0143 connection cable)

Comfort level probe for meas. degree of turbulence, with telescope and stand. Fulfills the requirements of DIN 1946 Part 2 or VDI 2080

2 probe for measuring indoor air qualityund and

CO

for monitoring workplace conditions

Sensor Meas. range Accuracy Part no.

Hot bulb

Capacitive

NTC

Hot bulb

NTC

0 to 10 m/s

0 to 100 %rF

(probe tip)

-20 to +70 °C

0 to 5 m/s

0 to 50 °C

0 to 10.000 ppm

0 to 1Vol.%

±(0,03 m/s +5 % v.Mw.)

±2 %rF (2 to 98 %rF)

±0,4 °C (0 to 50 °C)

±0,5 °C (rem. range)

±(0,03 m/s +4 % v. Mw.)

± 0,3 °C

±50 ppm ±2 % of m.v.

(0 to 5000 ppm)

±100 ppm ±3 % of m.v.

(rem. range)

0635 1540

0628 0009

0632 1240

41

Page 42

42

Page 43

43

Page 44

0970 4450 en 05 V02.00 en-GB

Loading...

Loading...