Page 1

testo 6446 compressed air meter

Instruction manual

Page 2

Page 3

Contents

1 GENERAL INFORMATION ........................................................................... 5

1.1 Incoming goods inspection, transportation and storage ....................................... 5

2 SAFETY PRECAUTIONS .............................................................................. 6

2.1 Intended use ......................................................................................................... 6

2.2 Installation, commissioning and operation ............................................................ 7

2.3 Exclusion of liability ............................................................................................... 8

3 DESIGN AND FUNCTION ............................................................................. 9

3.1 Electric sensor unit .............................................................................................. 10

3.2 Compac stainless steel sealing cone .................................................................. 12

3.3 Compac welding neck flange (V flange) steel ..................................................... 12

3.4 Dummy plugs included as standard .................................................................... 13

3.5 Measuring station ................................................................................................ 14

3.6 ISO calibration points .......................................................................................... 14

4 TECHNICAL DATA ..................................................................................... 15

4.1 Thermal mass flow sensor .................................................................................. 15

4.2 Accessories ......................................................................................................... 16

4.2.1 Connecting cable with electric isolation .................................................... 16

4.2.2 Replacement sensor ................................................................................. 16

4.2.3 Calibration options .................................................................................... 16

5 INSTALLATION ........................................................................................... 17

5.1 Determining the installation point ........................................................................ 17

5.2 Length measurements of the compressed air meter .......................................... 18

5.3 Installation position ............................................................................................. 19

5.4 Required measuring section ............................................................................... 20

5.5 Direction of flow .................................................................................................. 20

5.6 Installation of the compressed air meter ............................................................. 21

5.6.1 Installation of the measuring station ......................................................... 21

5.6.2 Installing the sensor in the measuring station .......................................... 22

22

5.7 Sensor replacement ............................................................................................ 23

5.8 Electrical connection ........................................................................................... 24

5.8.1 4-wire pin assignment ............................................................................... 24

5.8.2 5-wire pin assignment (accessory) ........................................................... 25

Page 4

Contents

6 OPERATION ............................................................................................... 26

6.1 Operation and display elements ......................................................................... 26

6.2 Types of operation .............................................................................................. 28

6.2.1 Run mode 28

6.2.2 Display mode 28

6.2.3 Programming mode – parameter configuration ........................................ 28

7 MENU .......................................................................................................... 29

7.1 Menu overview ................................................................................................... 29

7.2 Menu explanation ............................................................................................... 30

8 PROGRAMMING AND PARAMETRISATION ............................................ 31

8.1 Programming ...................................................................................................... 31

8.2 Parametrising scenarios ..................................................................................... 33

8.2.1 Settings for flow monitoring ...................................................................... 33

8.2.2 Settings for consumption quantity monitoring .......................................... 34

8.2.3 Settings for temperature monitoring ......................................................... 36

8.2.3.1 Configuring the analogue value for temperature ...................................... 36

8.2.4 User settings (optional) ............................................................................ 37

8.2.5 Service functions ...................................................................................... 39

8.2.6 Pulse setting 40

8.2.7 Hysteresis function ................................................................................... 41

8.2.8 Window function ....................................................................................... 41

8.2.9 Scaling the measuring range .................................................................... 42

9 REPAIR ....................................................................................................... 43

9.1 Error messages .................................................................................................. 43

9.2 Cleaning the sensor ............................................................................................ 43

9.2.1 Cleaning agents ....................................................................................... 43

9.3 Recalibration ....................................................................................................... 44

10 TROUBLESHOOTING ................................................................................ 45

10.1 Replacing damaged parts ................................................................................... 45

10.2 Replacing O-rings and sealing rings ................................................................... 45

10.3 Return shipment ................................................................................................. 45

10.4 Disposal .............................................................................................................. 45

Page 5

1

GENERAL INFORMATION

1.1 Incoming goods inspection, transportation and storage

• Take note of undamaged packaging!

Communicate damages to the packaging to your supplier. Retain the

damaged packaging until the matter is settled.

• Make sure there is no damaged contents!

Communicate damages to the contents to your supplier. Retain the

damaged goods until the matter is settled.

• Check the scope of delivery for completeness by referring to the

shipping documents and your order.

• The instrument is to be packaged for storage and transport in a way

that protects it from impacts and moisture. The original packaging

offers optimum protection. The permissible ambient conditions are also to

be observed ( see 4 Technical data).

• If you have any questions, please contact your supplier or their

sales office.

5

Page 6

2

SAFETY PRECAUTIONS

Read this instruction manual before commissioning the

compressed air meter. Store this instruction manual in a location

that is accessible for all users at all times.

2.1 Intended use

The compressed air meter is intended exclusively for use in pipe

systems for working compressed air, provided that the calibration

certificate does not explicitly allow use with other gases.

WARNING

ATTENTION

The structural design allows for operation in pressurised

systems up to PN 16 (DN 65 bis DN 200) and PN 14 (DN 250)

Any use other than that described will compromise the

safety of persons and the entire measuring system and is

therefore not permitted.

The manufacturer shall accept no liability for damages that

occur as a result of improper or inappropriate use or

installation.

To prevent damage to the instruments or health risks occurring

the measuring units must never be manipulated with tools

unless expressly defined in this instruction manual.

The compressed air meter may only be operated under the ambient

conditions specified in the technical data. Otherwise, inaccurate

measurements will occur and instrument malfunctions cannot be ruled out.

To ensure the safety of the user and the functionality of the instruments,

the commissioning steps, checks and maintenance work recommended by

the manufacturer are to be complied with and carried out.

These instructions do not contain complete detailed information for the

sake of transparency. Should you require further information or should a

specific problem occur that is not comprehensively handled in the

instructions, you can request the required information directly from the

manufacturer.

6

Page 7

2.2 Installation, commissioning and operation

The compressed air meter was built and tested reliably according to

state-of-the-art technology and left the factory in an appropriately safe

condition.

As the user, you are responsible for compliance with all valid

safety regulations, including:

• Installation specifications

• Local standards and regulations.

The manufacturer has undertaken all necessary measures to ensure

safe operation. The user must ensure that the instruments are set up

and installed in such a way that their safe use is not affected.

This instruction manual contains information and warnings that must

be followed by the user in order to ensure safe operation.

• Installation, commissioning, operation and maintenance of the

measuring unit may only be performed by trained, authorised

personnel.

The personnel must be authorised for the specified tasks by the

system operator.

• The authorised personnel must have read and understood this

instruction manual and comply with the instructions set out in it.

• Check all connections for correctness before commissioning the

complete measuring station.

• Do not commission damaged products and keep these from being

inadvertently commissioned. Mark the damaged products as

defective.

• Faults at the measuring point are only to be corrected by authorised

and specially trained personnel.

• If faults cannot be corrected, the products must be taken out of

operation and be safeguarded from inadvertent commissioning.

• Repairs that are not described in this instruction manual may only be

carried out directly by the manufacturer or by the service organisation.

7

Page 8

2.3 Exclusion of liability

Liability of the manufacturer and its vicarious agents shall exist only in the

event of deliberate acts or gross negligence. The extent of liability shall be

limited to the value of the respective order placed with the manufacturer.

The manufacturer shall accept no liability for damages that occur due to

non-observance of the safety instructions or non-compliance with the

instruction manual or the operating conditions. Consequential damages

are excluded from the liability.

Use the components only in the supplied combination.

Due to the design, they are not necessarily compatible

Note

with older compressed air meters.

8

Page 9

3 DESIGN AND FUNCTION

Overview of components

1 Sensor unit 2 Straight pin as alignment aid

3 Hexagon socket head screw M 10 4 Dummy plug

5 Dummy plug holder both sides 6 Direction of flow arrow

7 Measuring station 8 Brass sealing plug

9 Hexagon screw depending on DN 10 Viton O-rings

11 Compac steel welding

neck flange

12 Compac stainless steel sealing

cone

9

Page 10

The equipment is supplied loosely pre-assembled in 2 parts:

sensor and station. Also included in the scope of delivery:

•

Calibration certificate in compliance with ISO/IEC 17025

3.1 Electric sensor unit

The sensor records the standard volumetric flow of the working

compressed air according to the calorimetric measurement principle.

The standard volumetric flow is calculated on the basis of DIN ISO 2533

(1013.25 mbar, 15 °C and 0% relative humidity), unless otherwise stated

on the calibration certificate. The relevant unit is Nm³/h or Nl/min.

Observe the general operating conditions for compressed air

systems. The air quality of the working compressed air influences the

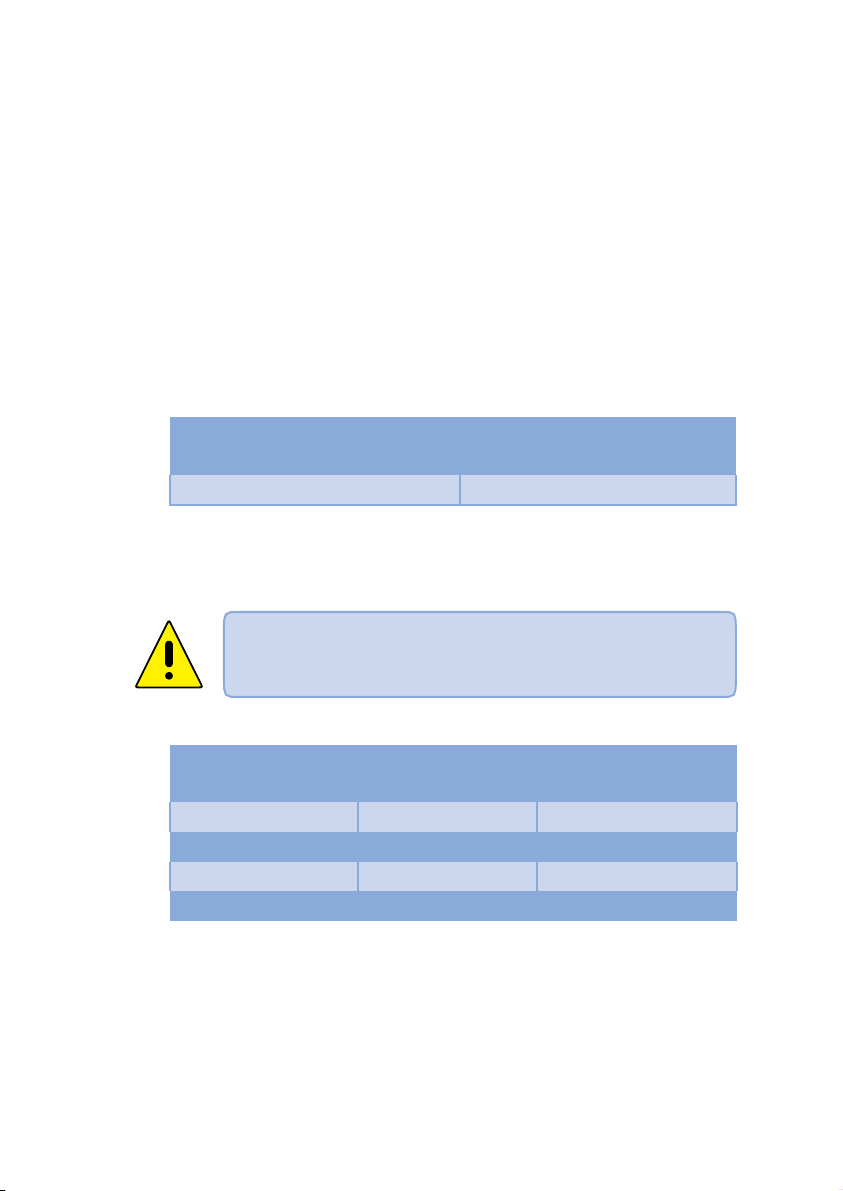

measuring accuracy as follows:

Quality classes according to

ISO 8573-1 particle/humidity/oil

1-4-1

3-4-4

Measuring signals

Measurement errors

± (3% of reading + 0.3% of final

value of measuring range)

± (6% of reading, + 0.6% of final

value of measuring range)

The instrument shows the current process values on a display. It

generates 2 output signals according to the parametrization.

•

Current flow rate

•

Current consumption quantity (pulse output module and totaliser)

Display

•

Current volume flow in Nm³/h or Nl/min

•

Current consumption quantity in Nm³

•

Current average speed in Nm/s

•

Current media temperature in °C

•

Switching states of the respective outputs

10

Page 11

Sensor output 1

•

Switch signal as the limit value for volume flow or flow velocity, hysteresis or

window function as N/O or N/C contact.

•

Quantity monitoring using the preset counter.

Sensor output 2

•

Switch signal as the limit value for volume flow, flow velocity or

temperature, hysteresis or window function as N/O or N/C contact.

•

Analogue signal (4-20 mA) for volume flow, flow velocity or temperature.

Relative measuring range (%)

Measuring range

Recording/

display range

0.33% (0.4%) - 100% 0% to 120%

The absolute measuring range depends on the nominal width (see

following table).

Absolute measuring range

The compressed air meter may be used to measure the

volume flow of working compressed air with up to 16 bar

(DN 65 to DN 200) or 14 bar (DN 250) overpressure.

WARNING

Nominal width Measuring range Recording/

display range

DN 65 6.7-2,000 m³/h 0.11-2,400 m³/h

DN 80 9.2-2,750 m³/h 0.15-3,300 m³/h

DN 100 15-4,400 m³/h 0.24-5,280 m³/h

DN 125 23-7,000 m³/h 0.39-8,400 m³/h

11

Page 12

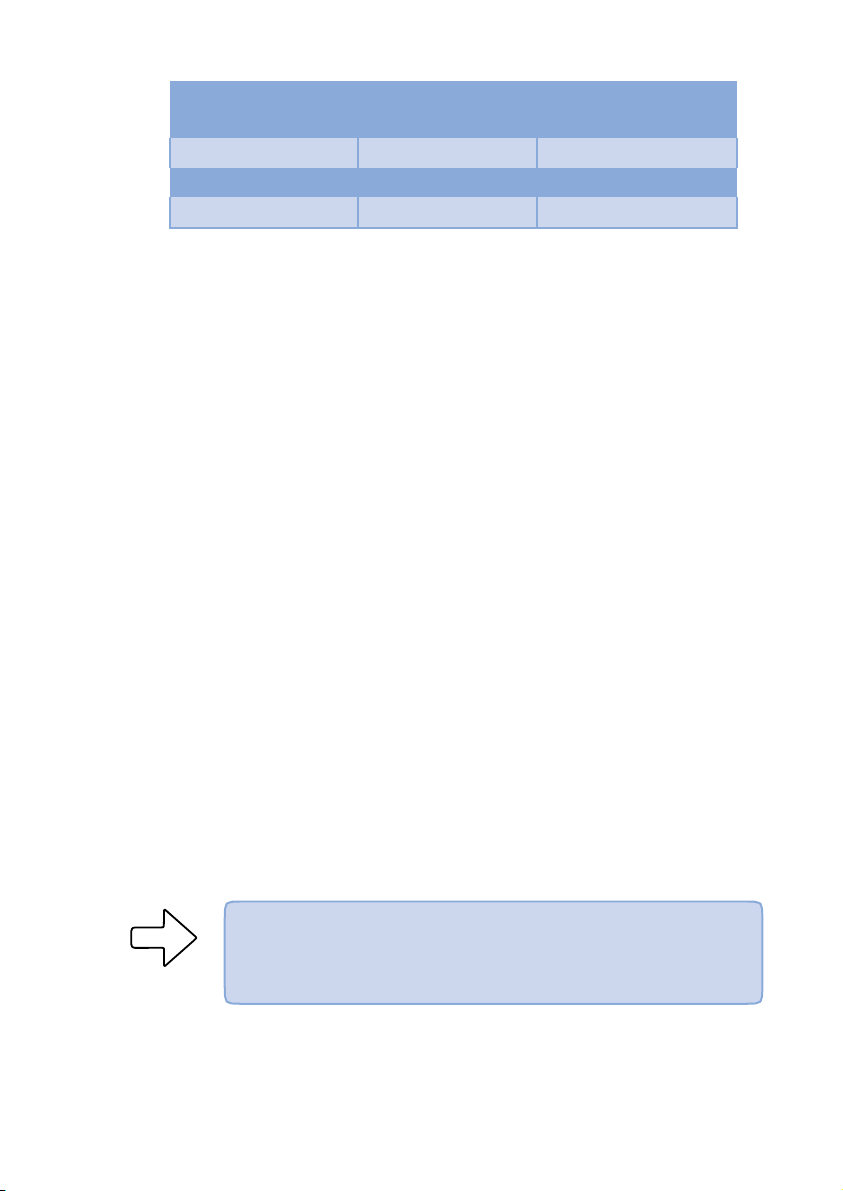

Nominal width Measuring range Recording/

display range

DN 150 33-10,000 m³/h 0.55-12,000 m³/h

DN 200 58-17,500 m³/h 0.97-21,000 m³/h

DN 250 92-27,500 m³/h 1.53-33,000 m³/h

Specifications according to DIN ISO 2533 (15 °C, 1013 mbar and 0%

rel. humidity).

3.2 Compac stainless steel sealing cone

The Compac sealing cone makes up the intersection between the

measuring station and sensor. Please note the following design details for

correct positioning of the components after welding in the pipeline

according to the direction of flow: The straight pin of the measuring station

engages in the one-sided bore of the Compac sealing cone.

This is designed with a slot that receives the sensor pin in the downstream

direction of flow.

3.3 Compac welding neck flange (V flange) steel

The connection between the measuring point interface and the pipe

system is made by the Compac welding neck flanges. These seal twice –

both metal-wise and against an O-ring made of Viton in a circumferential

groove in the measuring station. The advantages of these flanges in

comparison to standard DIN flanges with flat seals are the significantly

smaller construction volume and thus material volume and weight, lower

bolt tightening forces and the prevention of overstraining of the seal (with

regard to deformation and compression) – with higher density efficiency

and leakage reliability. Slight scratches in the contact surfaces are

tolerated without loss of function due to the high compressive force.

Example: DN 250 at PN 100

•

Compac flange weight 15 kg

• Previous DIN flange weight 81 kg

12

To avoid a mixed seam in the welded joint to the pipeline,

make sure that the Compac flanges are made of steel or

Note

An alternative to the welding neck flange (V flange) is to fit a Compac threaded

flange (G flange).

stainless steel according to the pipeline.

Page 13

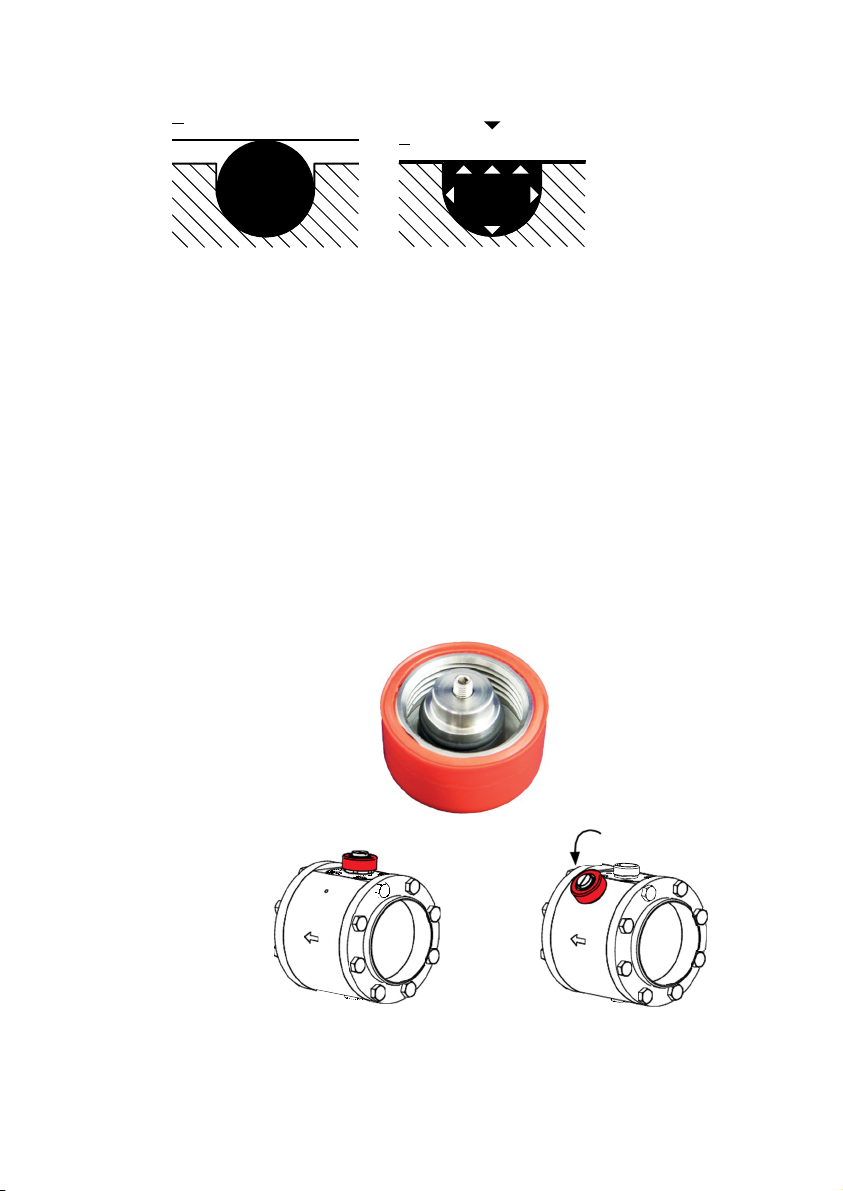

Sealing principle of the Compac flange

P

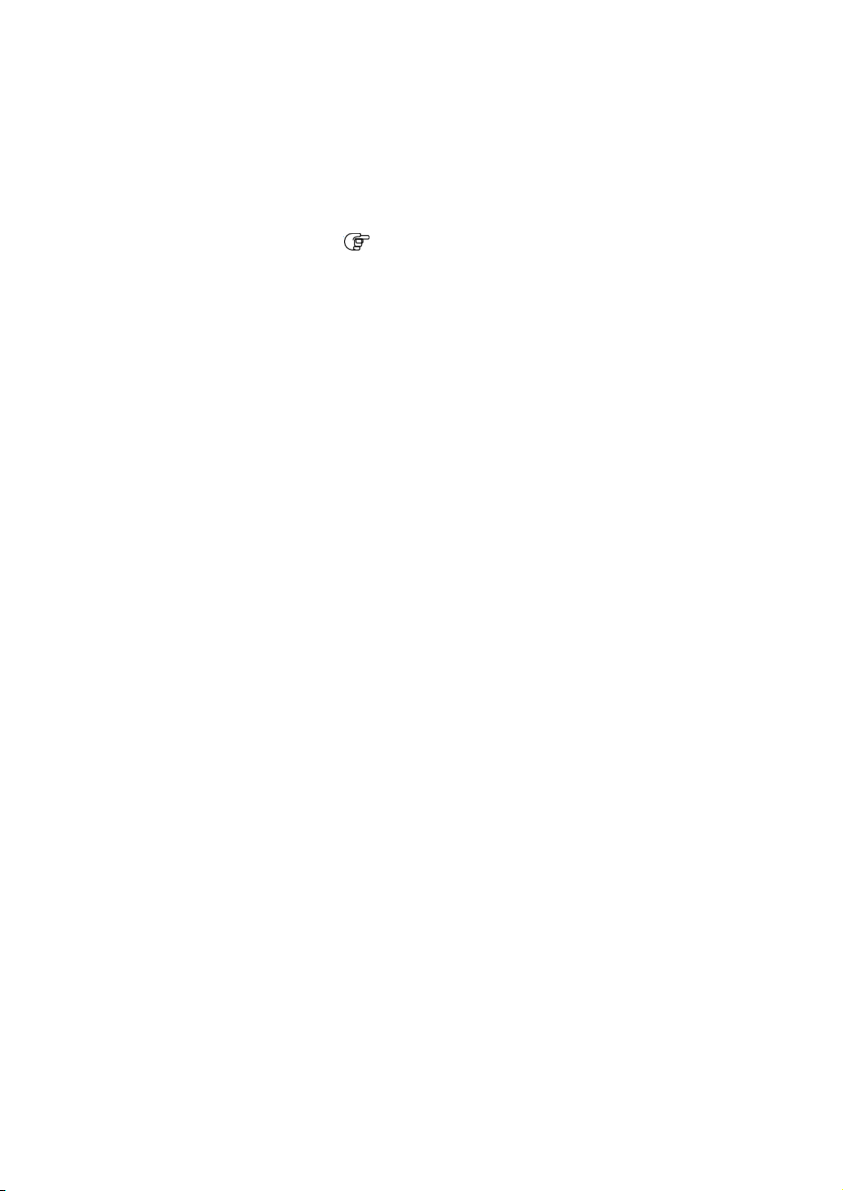

3.4 Dummy plugs

The dummy plug is made of stainless steel and has a bright red plastic

protective cap to stop it unintentionally loosening.

It secures the measuring point interface while the sensor is uninstalled,

e.g. when changing the sensor for recalibration. For this purpose, it is

screwed onto the sealing cone (Fig. 1) when the line is

depressurized.

The dummy plug seals both metal-wise and redundantly via an O-ring.

A significant advantage over simple dummy plugs is that the trapped

compressed air can escape safely under pressure during

(unintentional) disassembly. When turning the union nut, enough

thread turns remain to prevent it "shooting off". If the sensor is

installed, the dummy plug is stored near the device in one of the

holders (tapped bore) – as shown in Figure 2.

1

included as standard

2

13

Page 14

3.5 Measuring station

The measuring station with Compac welding neck flanges is used to

precision-mount the electronic volume flow sensor. The measuring station

is welded into the pipelines with the Compac welding neck flanges in line

with the flow direction (see engraved direction arrow). The nominal width

of the measuring station and welding neck flange must match the

nominal pipe width ( see 3). To prevent a mixed seam during welding,

the material of the parts must also be the same.

The compressed air meter is designed for nominal pipe widths from

DN 65 to DN 250.

3.6 ISO calibration points

The compressed air meter is supplied calibrated to its nominal width.

A minimum of six measuring points are parametrised with specified

nominal widths, standard temperatures and pressures, then moved to the

test stand where the standard volume is tested. The calibration certificate

in compliance with ISO/IEC 17025 is included in the scope of delivery.

14

Page 15

4 TECHNICAL DATA

4.1 Thermal mass flow sensor

The thermal mass flow sensor for the compressed air volume flow

measurement is independent of the process pressure and the media

temperature.

Sensor Thermal glass-coated ceramic sensor

Media Compressed air

Accuracy For compressed air quality classes (ISO 8573:

particles to humidity to oil) 1:4:1: ±3% of

reading, ±0.3% of final value for compressed air

quality classes (ISO 8573) 3:4:4: ±6% of

reading, ±0,6% of final value

Temperature monitoring ±2 °C

Reproducibility ±1.5% of reading

Display, operation 4-digit, alphanumerical display, two operating

buttons, user menu, operating menu, 5 x green

LED (measurement units), 1 x green LED

(function display 103), 2 x yellow LED (switching

status)

Display units* Nl/min, Nm³/h, Nm/s, Nm³, °C

Measuring dynamics 1:300

Response time < 0.1 s

Pressure-tight up to 16 bar (DN 250 to 14 bar)

Media temperature 0 to + 60 °C (rel. humidity max. 90%)

Perm. ambient temp. 0 to + 60 °C

Perm. storage temp. -20 to + 85 °C

Media contact V2A (1.4301) or galvanised steel, glass-coated

ceramic, PEEK, polyester, Viton, anodised

aluminium

Housing materials PBT-GF 20, PC (APEC), Makrolon, V2A

(1.4301) or galvanised steel, Viton

Protection class IP65 / III

Electrical connection M12 x 1 connector, can be loaded to 250 mA,

short-circuit-proof

Power supply 19 to 30 VDC, voltage supply < 100 mA

Readiness delay 1 s

Based on the small size, the sensor only has a small contact

surface. The pressure loss is thus negligible (typically

1 mbar).

Note

* The measurement, display and adjustment ranges are related to the

standard volume flow according to DIN ISO 2533 (15 °C, 1013 mbar and 0%

rel. humidity) if not otherwise stated in the calibration protocol of the sensor.

15

Page 16

Output signals

Analog output 4-20 mA, measuring range scaleable

max. load 500 Ω pulse output

DN 65 - DN 80: 1 pulse/1 Nm³

DN 100 – DN 250: 1 pulse/10 Nm³

Current carrying capacity 2 x 250 mA, short-circuit-proof, protected against

polarity reversal, overload-proof

EMC

IEC 1000/4/2 ESD 4/8 kV

IEC 1000/4/3 HF radiated 10 V/m

IEC 1000/4/4 burst 2 kV

IEC 1000/4/6 HF grid-bound 10 V

4.2 Accessories

4.2.1 Connecting cable with electric isolation

A connecting cable with an electrical isolator integrated into the connector

is available as an accessory. The cable is 5 metres long and is used for

the galvanic isolation of the sensor output to the electronics to which it is

attached. The cable is delivered with an appropriate connector for the

mass flow sensor on one side and with open cable ends on the other side.

4.2.2 Replacement sensor

The replacement sensor serves as a replacement in case of damage to or

loss of the original mass flow sensor.

When ordering a new sensor, please indicate the certificate

number of the old sensor in order to take account of

Note

customer-specific measuring conditions directly during

calibration.

4.2.3 Calibration options

• ISO certificate

An ISO certificate from the manufacturer documents six measuring points

including the measuring conditions.

16

Page 17

5

INSTALLATION

Installation may only be carried out by authorised, qualified

staff, e.g. pipeline engineers. Please observe the relevant

national regulations.

WARNING

WARNING

The electrical connections are to be performed by a

qualified electrician.

To install and remove the sensor the line must be

depressurized. Ensure that the line section cannot be

inadvertently used (lockout-tagout).

5.1 Determining the installation point

Please always observe the technical data see 4.1). The place of

installation is to meet the following criteria:

• Medium does not condense at the place of installation, i.e. measuring

location only behind a suitable compressed air dryer, which ensures

an appropriate pressure dew point. Otherwise the specified measuring

accuracy cannot be guaranteed.

• Ambient temperature of maximum + 60 °C (note any potential thermal

radiation).

• Take account of the inflow and outflow section ( see 5.4).

• Take account of the direction of flow ( see 5.5).

• Well accessible with low vibration.

• A min. 200 mm space is needed to remove the sensor.

17

Page 18

5.2 Length measurements of the compressed air meter

L

18

Inch DN L

2½" 65 148 125 70.3 2.9 184 8 13 106

3" 80 160 141 82.5 3.2 198 8 13 118

4" 100 160 165 107.1 3.6 223 8 13 144

5" 125 172 205 131.7 4 255 12 13 168

6" 150 180 235 159.3 4.5 284 8 17 200

8" 200 180 290 207.3 5.9 336 12 17 252

10" 250 196 355 260.4 6.3 396 12 21 315

mm

Ø D1

mm

Ø D2

mm S mm

H1

mm

N SL

mm

LK

mm

Page 19

5.3 Installation position

Do not install the sensor in the crossed-out installation positions

shown in the following graphic in point 6. Otherwise, in the event of a

limited flow rate, the specified accuracy cannot be maintained.

Diagrams:

1.

2.

3.

4.

5.

6.

The arrow shows the direction of flow for the medium.

1: Vertical installation position, direction of flow horizontally to the left,

probe downwards

2: Horizontal installation position, direction of flow vertically downwards,

probe to the rear

3: Horizontal installation position, direction of flow horizontally to the rear,

probe to the left (heated sensor element upwards)

4: Vertical installation position, direction of flow horizontally to the right,

probe upwards

5: Horizontal installation position, direction of flow vertically upwards, probe

to the rear

Horizontal installation position, direction of flow horizontally to the rear,

6:

probe to the right (heated sensor element downwards, problems

possible at low flow rates)

19

Page 20

5.4 Required measuring section

Take account of the required inflow and outflow section in

order to achieve the specified measuring accuracy. The

inflow section refers to the pipeline length upstream of the

Note

Total measurement section = inflow section + outflow section

Outflow section = 5 x D

Inflow route = 15 x D + B

D = pipe diameter [mm]

B = additional calming section

compressed air meter and the outflow section to the

pipeline length downstream of the compressed air meter,

as seen in the direction of flow for the medium.

Changes to the

pipe diameter

90° elbow B = 5 x pipe diameter

Two 90° elbows, one level

Two 90° elbows, two levels

Valve, slider B = 35 x pipe diameter

B = 5 x pipe diameter

B = 10 x pipe diameter

B = 15 x pipe diameter

5.5 Direction of flow

Always take the direction of flow into account when

installing the measuring station. This is indicated by the

Note

20

arrow engraved on the side of the measuring station. The

arrow points in the direction that the medium flows in the

pipeline.

Page 21

5.6 Installation of the compressed air meter

To avoid a mixed seam in the welded joint to the pipeline,

make sure that the Compac flanges are made of steel or

Note

WARNING

WARNING

5.6.1 Installation of the measuring station

stainless steel according to the pipeline.

To install and remove the compressed air meter the line

must be depressurized. Ensure that the line section cannot

be inadvertently used (lockout-tagout).

A stable stepladder is required for all assembly work

carried out up to 2.5 metres off the floor (height of the

pipe). A working platform must be provided for work at

greater heights. If the measuring point cannot be accessed by

a platform, then scaffolding or other equipment must be

used to provide a safe working platform.

1. Depressurize the pipe section at the installation point and secure it

against accidental reconnection (lockout-tagout).

2. Weld the Compac welding neck flange to the existing pipeline with no

torsion, taking national regulations into account, to achieve

optimal tightness.

Make sure that the measuring station is installed in the

direction of flow – see arrow. Otherwise, there may be

Note

sensor measuring inaccuracies.

21

Page 22

3. Screw the measuring station between the flanges according to the

direction of flow. Fix the screws in diagonal order for even force

distribution.

5.6.2 Installing the sensor in the measuring station

Make sure that the pipeline is depressurized before

installing the sensor. Make sure that the Compac sealing

cone is always closed either with a sensor or a dummy

plug.

WARNING

1. To install the sensor unscrew the dummy plug from the sealing cone

and temporarily store it in the holder on the side of the measuring

station.

2.

Remove the red protective transportation cap from the tip of the sensor

and keep it for the next time you remove the sensor.

22

3. Install the sensor in the sealing cone of the measuring station. Take

notice of the correct installation position of the sensor. Due to the

design, the sensor can only be screwed onto the sealing cone in one

direction (bolt/groove principle). The head of the sensor, i.e. the

display, points in the direction of the inflow. If this is not the case, the

measuring station has to be turned between the flanges.

Page 23

4. Fix the sensor to the measuring station with the union nut and without

tools.

5. The mechanical installation of the compressed air meter is now

complete.

5.7 Sensor replacement

The removal of the mounted sensor may be necessary for maintenance,

cleaning and calibration purposes.

Never remove the sensor or the dummy plug from the

sealing cone when the line is under pressure – this may be

WARNING

1. Switch off the pressure in the line and check to make sure no

2. Remove the electrical connecting cable by unscrewing the connector

3. Remove the sensor without tools from the measuring station pulling it

4. Mount the dummy plug ( 3.4) on the sealing cone.

life-threatening!

pressure is applied! Secure the system to ensure it cannot be

inadvertently switched on!

from the sensor by hand. Protect the connector from contamination

and moisture.

up and out vertically.

5. Protect the sensor tip with the red protective transportation cap.

23

Page 24

5.8 Electrical connection

Disconnect the system from the power supply when connecting.

The instrument may only be installed by a qualified

electrician. Follow the national and international regulations

regarding the installation of electrical engineering systems. The

voltage supply is to be laid out in accordance with EN50178,

WARNING

Note

5.8.1 4-wire pin assignment

If you use the standard connection, the following pin assignment applies to

the connecting cable or the pin assignment directly on the sensor.

SELV, and PELV. To meet the "limited voltage" requirements

according to UL 508, the instrument must be supplied from a

galvanically isolated source and protected against shortcircuits by means of an overcurrent device.

If you are connecting the sensor directly or using a 4-wire

connecting cable, proceed as set out in 5.8.1.

If you are using the optionally available 5-wire connecting cable

with potential-free pulse output ( see 4.2.2), proceed as set

out in 5.8.2 when connecting the sensor.

24

BN L+

2

1

3

4

WH OUT2/InD

BK OUT1

BU L

Pin no. Wire colour Assignment

1 Brown +L (19-30 V DC)

2 White

OUT2

/InD

3 Blue 0 V DC (GND)

4 Black OUT1

Page 25

5.8.1.1 1 x pulse output, 1 x analog output (condition on delivery)

The OUT1 output is used as a PNP signal output (pulse) and the OUT2

output is used as an analog output. This is the configuration in which the

sensors are delivered.

Pin = designation (wire colour)

1= BN (brown)

2= WH (white)

3 = BU (blue)

4 = BK (black)

5.8.1.1 2 x pulse output

Both of the available OUT1and OUT2 outputs are each used as a PNP

signal output (pulse).

5.8.2 5-wire pin assignment (accessory)

If the optional connecting cable for electrical isolation is used ( see

4.2.2), then the following assignments apply.

Pin no. Wire colour Assignment

1 Brown +L (19 to 30 V DC) sensor supply

2 Pink + potential-free pulse output (collector) OUT1

3 White - potential-free pulse output (emitter) OUT1

4 Green OUT2

5 Black 0 V DC (GND)

25

Page 26

The potential-free pulse output OUT1 is specified for this connecting

cable as follows:

Line type LiYCY

Length 5 m

Switching capacity 500 mA

Max. switching voltage 36 V

Min. switching voltage 5 V

Switch contact resistance 0.21 Ω

Insulation voltage 5.3 kV

Protected against polarity

reversal

6 OPERATION

Thermal mass flow sensor

Familiarise yourself with the operation and programming of the sensor.

The sensor is calibrated ex factory and provided with default settings for

each nominal width.

Yes

6.1 Operation and display elements

The following illustration shows the control and display unit of the sensor

from above.

1 2 3 4 5 6

/h

3

Nm

Nm/s

Nm

°C

26

9

10

3

Nl/min

Mode/Enter Set

3

10

7 8

SP2

SP1

11

Page 27

Type Description

Indicator LEDs

①

to

LED

⑧

LED

LED

LED

LED

LED and

LED and

flashing

LED

LED

LED

LED

Four-digit

⑨

alphanumeric

display

flashing

SP2

SP1

Illuminated LED = display unit set

Current flow rate (Nl/min)

When the LED lights up, displayed value x 1000

Current flow rate (Nm3/h)

When the LED lights up, displayed value x 1000

Current flow velocity (Nm/s)

Current consumption quantity since last reset (Nm3)

Consumption quantity before the last reset in (Nm3)

Current consumption quantity since last reset in 103 (Nm3)

(Values > 9999 are displayed in 103 exponential mode)

Consumption quantity before last reset in 103 (Nm3)

(Values > 9999 are displayed in 103 exponential mode)

= 103 exponential mode

Current media temperature in °C

Switching status of the respective output (LED also

indicates the status of the input during an active external

reset)

Switching status of the respective ouput

Display of the current volume flow (for setting

Uni = Lmin or nm3h and SELd = FLOW)

Display of the current flow velocity (for setting Uni =

nmS and SELd = FLOW)

Display of the meter reading (for setting SELd = TOTL)

Display of the current media temperature (for setting

SELd = TEMP)

Display of the parameters and parameter values

⑩

⑪

Button

Mode/Enter

Programming

button

Set

Selection of the parameters and confirmation of the

parameter values

Setting the parameter values

Changing the display unit in run mode

27

Page 28

6.2 Types of operation

6.2.1 Run mode

After switching on the supply voltage, the instrument is in run mode.

It carries out its measurement and evaluation functions and provides

output signals according to the set parameters.

The display shows the current measurement values and the yellow LEDs

show the switch status of the outputs.

The display unit may be changed temporarily. For this purpose, press the

Set button briefly. After 15 seconds, the instrument returns to the display

unit that was set in the Uni menu item.

The totaliser (consumption quantity counter) stores interim values every

10 minutes as well as the amount of time elapsed of the automatic reset.

After a drop in voltage, this value is available as the current status of the

totaliser (the possible loss of data can amount to a maximum of

10 minutes).

6.2.2 Display mode

Display of the parameters and set parameter values.

The instrument is switched to display mode by briefly pressing

Mode/Enter.

Internally, it remains operational.

The set parameter values can be read independently of this:

To scroll through the parameters briefly press the Mode/Enter button.

The corresponding parameter value is displayed for approximately

15 seconds by briefly pressing the Set button. After a further

15 seconds, the instrument returns to run mode.

6.2.3 Programming mode – parameter configuration

28

The instrument is switched to programming mode if a parameter is

selected and the Set button is pressed for longer than 5 seconds (the

parameter value flashes, then is continuously increased). Internally, the

instrument also remains operational.

It continues to carry out its monitoring functions with the existing

parameters until the change is completed.

You can change the parameter value using the Set button and confirm

by pressing the Mode/Enter button.

The instrument returns to measurement mode if no buttons are pressed for

15 seconds afterwards.

Page 29

7

MENU

7.1 Menu overview

In the menu overview, indicates the

Mode

button on the sensor.

Nl/min

Nm3/h

S

M

M

M

M

M

M

M

M

M

M

M

15s

S

S

M

S

S

S

S

S

S

M

M

S

M

S

M

M

M

M

M

S

M

S

M

M

Nm/s

15s

S

M

Set

button and the

3

Nm

S

15s

Nm3*

S

S

15s

M

M

M

M

M

M

M

M

M

M

M

M

M

M

S

°C

15s

S

M

S

M

S

M

S

M

S

M

S

M

S

M

S

M

S

M

S

M

S

M

S

M

S

M

S

M

(Nm³)* = volume flow amount before the last reset

The parameter values given in digits represent factory settings or

random examples.

29

Page 30

A

7.2 Menu explanation

SP1/rP1

Switching point or Return switching point Upper/lower limit

value for flow rate

ImPS

Pulse value

ImPR Repeat pulse yes = active = pulse output or no = not active =

preset counter function

OU1 Initial function for OUT1 (flow rate or consumption quantity):

- Switching signal for limit values: Hysteresis function Hno and

Hnc or window function Fno and Fnc

o = normally open = N/O contact; c = normally closed = N/C

contact

- Pulse or switching signal for quantity counter

OU2 Initial function for OUT2 (flow rate or temperature):

o Switching signal for limit values: Hysteresis function or

window function, N/O contact or N/C contact respectively

o Analogue signal: 4-20 mA [I]

Alternatively: Configure OUT2 (pin 2) as an input for an

external reset signal: Setting: OU2 = InD

SP2/rP2 Switch point or return switch point

Upper/lower limit value for flow rate or temperature

SP2 and rP2 are only active when OU2 = Hno, Hnc, Fno or Fnc

ASP/

EP

DIn2

Analogue starting value/Analogue end value for flow rate or

temperature

Configuration of the input (pin 2) for counter reset

EF Extended Functions/opens menu level 2

HI/LO

Maximum value memory/minimum value memory for flow rate

FOU1 Behaviour of output 1 in the event of an internal error

FOU2 Behaviour of output 2 in the event of an internal error

dAP

rTo

diS

Uni

Measuring value damping/damping constant in seconds

Counter reset: manual reset/time-controlled reset

Updating rate and orientation of display

Standard unit of measurement for flow rate: Nl/min, Nm³/h

or Nm/s

SELd

Standard display measurement parameter:

Flow value, meter reading or media temperature

30

Page 31

SEL2 Standard measurement parameter for evaluation using

OUT2:

1. Limit value signal or analogue signal for flow rate

2. Limit value signal or analogue signal for temperature

rEF.P

rEF.T

LFC Low flow cut-off

rES

Standard pressure measurement and display values refer to for

the flow rate

Standard temperature measurement and display values refer to

for flow rate

Reset – reset to factory settings

8 PROGRAMMING AND

PARAMETRISATION

8.1 Programming

Each parameter setting requires 3 steps: select

parameter – set value – confirm

Press the Mode/Enter button until the

required parameter appears on the

display.

Press and hold the Set button.

The current parameter value flashes

for 5 seconds. It is then increased*

(in increments by pressing once or

continuously by pressing and holding

the button).

Press the Mode/Enter button briefly (=

confirmation). The parameter is

displayed again and the new parameter

value applies.

Changing further parameters: Start again with step 1.

Ending programming: Wait for 15 seconds or press the

Mode/Enter button until the current

measuring value appears again.

31

Page 32

* To reduce the value:

Allow the display to run through to the maximum setting value. After this,

the run-through starts again from the minimum setting value. Set the

display unit Uni before you set the values for the SPx, rPx, ASP and AEP

parameters. In this way, rounding up/down errors are avoided during the

internal conversion into other units and the exact values required are

provided.

Condition at delivery: Uni = nm3h.

If no button is pressed for 15 seconds during the configuration process,

the instrument returns to run mode with unchanged values.

Switching from menu level 1 to level 2

Press the Mode/Enter button until

EF is displayed.

Briefly press Set.

The first parameter of the submenu is

displayed: HI.

Locking – unlocking

To prevent unintentional wrong entries the instrument can be electronically

locked. Condition at delivery: Not locked.

32

Make sure that the instrument is in

normal work mode.

Press Mode/Enter +

Set for

10 seconds.

is displayed.

Loc

During operation, Loc is briefly

displayed, if you try to change the

parameter values.

To unlock: Press for 10 seconds

Mode/Enter +

Set. uLoc is displayed.

Page 33

8.2 Parametrising scenarios

8.2.1 Settings for flow monitoring

8.2.1.1 Configuring limit monitoring with OUT1

Uni

OU1

SP1

rP1

8.2.1.2 Configuring limit monitoring with OUT2

Uni

SEL2

FLOW

OU2

SP2

rP2

select and specify unit of measurement ( see 8.2.4).

select and set the switching function.

Hno = hysteresis function/NO contact

Hnc = hysteresis function/NC contact

Fno = window function/NO contact

Fnc = window function/NC contact

select and set value with which the output switches.

select and set value with which the output switches back.

select and specify unit of measurement ( see 8.2.4).

select and set.

select and set the switching function.

Hno

= hysteresis function/NO contact

Hnc

= hysteresis function/NC contact

Fno

= window function/NO contact

Fnc

= window function/NC contact

select and set value with which the output switches.

select and set value with which the output switches back.

33

Page 34

8.2.1.3 Configuring the analogue value for flow rate

Uni

SEL2

FLOW

OU2

ASP

select and specify unit of measurement ( see 8.2.4).

select and

set.

select and set the function.

I

= flow-proportionate current signal (4 to 20 mA)

select and set value with which the

minimum value

is output.

AEP

select and set value with which the

maximum value

is output.

8.2.2 Settings for consumption quantity monitoring

8.2.2.1 Configuring quantity monitoring through pulse output

OU1

ImP

ImPS

select and

set.

select and set the flow volume with which 1 pulse is

emitted each time ( see 8.2.6).

ImPR

YES

select and

set.

> Pulse repetition is active.

each time the value set in

Output 1

ImPS

is reached.

emits a counting pulse

8.2.2.2 Configuring the quantity monitoring using the preset counter

OU1

ImP

ImPS

select and

set.

select and set the flow volume with which

output 1

is

activated ( see 8.2.6).

34

ImPR

NO

select and

set.

> Pulse repetition is not active. The output switches ON when

the value set in

ImPS

is reached. It remains switched until the

counter is reset.

Page 35

8.2.2.3 Configuring program-controlled reset

rTo

Set

select; continue with a) or

a)

reset counter manually

Press until

rES.T

is displayed, then briefly press

b)

Set

Set

b)

enter value for time-controlled reset

Press until the required value is displayed (intervals of 1

hour to 8 weeks), then briefly press

Press until

rES.T

is displayed, then briefly press

Mode/Enter

8.2.2.4 Deactivating counter reset

rTo

OFF

select and

set.

The counter is reset only after overrun (= factory setting).

Overrun: the counter is reset to 0 after the maximum value

(9 999 999 Nm³).

8.2.2.5 Configuring counter reset using an external signal

OU2

InD

Din2

select and

set.

select and set the reset signal.

HIGH

= reset for high signal

LOW

= reset for low signal

+EDG

= reset for rising flank

-EDG

= reset for falling flank

Mode/Enter

.

Mode/Enter

.

.

LED 7 ( see 6.1 Controls and indicators) also indicates the input status during

an active external reset.

35

Page 36

8.2.3 Settings for temperature monitoring

8.2.3.1 Configuring limit monitoring with OUT2

SEL2

TEMP

select and

set.

OU2 select and set the switching function.

Hno = hysteresis function/NO contact

Hnc = hysteresis function/NC contact

Fno = window function/NO contact

Fnc = window function/NC contact

SP2 select and set value with which the output switches.

rP2 select and set value with which the output switches back.

8.2.3.1 Configuring the analogue value for temperature

SEL2

TEMP

OU2 select and set the function.

ASP

AEP

select and

set.

I = temperature-proportionate current signal (4 to 20 mA)

select and set value with which the minimum value is output.

select and set value with which the maximum value is output.

36

Page 37

8.2.4 User settings (optional)

8.2.4.1 Specifying the standard unit of measurement for flow rate

Uni select and specify unit of measurement.

Lmin = flow volume per standard litre/minute

nm3h = flow volume per standard cubic metre/hour

nmS = flow velocity per standard metre/second

The setting only affects the flow rate value.

Set the display unit before you set the values for the SPx, rPx,

ASP and AEP parameters. In this way, rounding up/down errors

are avoided during the internal conversion into other units and

the exact values required are provided.

8.2.4.2 Configuring the standard display

SELd select and specify standard measurement parameter.

FLOW = display shows current flow rate value in standard unit

of measurement

TOTL = display shows current meter reading in Nm3 or

1000 Nm

TEMP = display shows current media temperature in °C

3

diS select and specify updating rate and orientation of display.

d1 = reading update every 50 ms

d2 = reading update every 200 ms

d3 = reading update every 600 ms

rd1, rd2, rd3 = display as with d1, d2, d3; rotated by 180°

OFF = display is off in working mode; by pressing the button,

the process value appears for 15 seconds.

8.2.4.3 Setting measuring value damping

dAP select and set damping constant in seconds (t value

63%).

37

Page 38

8.2.4.4 Configuring the error characteristics of the outputs

FOU1 select and specify value

On = output 1 switches ON in the event of an

error.

OFF = output 1 switches OFF in the event of

an error.

> With both values – ON and OFF – the meter no longer runs in

the event of an error.

OU = output 1 switches as defined with the parameters

irrespective of any error.

FOU2 select and specify value

On = output 2 switches ON in the event of an error; the

analogue signal goes to the upper end value (22 mA).

OFF = output 2 switches OFF in the event of an error; the

analogue signal goes to the lower end value (3.5 mA).

OU = output 2 switches as defined with the parameters

irrespective of any error. The course of the analogue

signal complies with IEC60947-5-7.

3

13

12

38

)

-30% -20% 0%

100% 120% 130%

Page 39

8.2.4.5 Setting the standard pressure which measurement and display

values refer to for flow rate

rEF.P select and set the required standard pressure. Setting

range: 950 to 1050 hPa in 1 hPa increments.

8.2.4.6 Setting the standard temperature which measurement and display

values refer to for flow rate

rEF.T select and set the required standard temperature. Setting

range: 0 to 25 °C in 1 °C increments.

8.2.4.7 Setting the low flow cut-off

LFC

select and set the limit value.

Setting range: 0.1 to 0.8 Nm³/h in 0.1 Nm³/h increments.

8.2.5 Service functions

8.2.5.1 Reading min./max. values for flow rate

HI

LO

Set

or

select; press

briefly.

HI = maximum value; LO = minimum value

Deleting memory

HI

LO

or

select.

Set press and hold it down until [----] is displayed.

Press Mode/Enter briefly.

It is a good idea to clear the memory as soon as the

instrument is used for the first time under normal working

conditions.

39

Page 40

8.2.5.2 Resetting all parameters to factory setting

After resetting to factory setting, the memory value is zero.

Note

rES

select.

Set press and hold it down until [----] is displayed.

Press Mode/Enter briefly.

It is recommended noting down the individual settings before

carrying out this function.

8.2.6 Pulse setting

ImPS Pulse settings in 7 ranges

ImPS is only active when OU1 = ImP

Display

1 4 0.001 to 9.999 0.001 Nm3 0.001 to 9.999 Nm3

2 4 10.00 to 99.99 LED 10.00 to 99.99 Nm3

3 4 100.0 to 999.9 0.1 Nm3 100.0 to 999.9 Nm3

4 4 1000 to 9999 1 Nm3 1000 to 9999 Nm3

5 4+6 10.00 to 99.99 10 Nm3 10 000 to 99 990 Nm3

6 4+6 100.0 to 999.9 100 Nm3 100 000 to 999 900 Nm3

7 4+6 1000 to 1000 1 000 000 Nm3

Incremental

range

Setting range

40

Page 41

8.2.7 Hysteresis function

- Set OU1 to ImP

- Press Mode/Enter until ImPS is displayed.

Press and hold Set.

> The current numerical value flashes for 5 seconds, then one

of the four digits is active (digit flashes; can be changed).

- Setting the required pulse value:

- First select the required setting range (1, 2, 3, etc.): Press

and hold the Set button until the setting range has the

required value.

- Enter the value from left (first digit) to right (fourth digit).

- Press Mode/ Enter briefly when all 4 digits are set.

If Set is kept pressed down, the display will go through all ranges.

When it reaches the final value, it returns to the first one. Release

Set briefly and begin with the setting again.

The hysteresis keeps the switching status of the

output stable if the flow rate fluctuates around the

nominal value. When the flow rate increases, the

output switches upon reaching the switch point

SPx. If the flow rate decreases again, the output

only switches back when the return switch point

rPx is reached.

The hysteresis is adjustable:

First the switch point is determined, then the

return switch point at the required distance.

8.2.8 Window function

The window function allows a defined OK range

to be monitored. If the flow rate fluctuates

between switch point SPx and return switch point

rPx, the output is switched through (window

function/NO contact) or opened (window

function/NC contact).

The size of the window is adjustable by the

distance between SPx and rPx.

SPx = upper value; rPx = lower value.

41

Page 42

8.2.9 Scaling the measuring range

- With the analog starting point parameter ASP, you determine at which

measuring value the output signal is 4 mA.

- With the analog end point parameter AEP, you determine at which

measuring value the output signal is 20 mA.

- Minimum distance between ASP and AEP = 25% of final value of

measuring range

MEW = final value of measuring range

The output signal is between 4 and 20 mA in the set measuring range.

Further signals are:

• Flow rate above the measuring range: output signal > 20 mA

• Flow rate below the measuring range: output signal between 3.6 and

4 mA.

42

Page 43

9 REPAIR

9.1 Error messages

Display Description

UL

OL Recording range exceeded

SC1 Flashing: short-circuit in switching output 1*

SC2 Flashing: short-circuit in switching output 2*

SC Flashing: short-circuit in both switching outputs*

Err Flashing: Malfunction in probe

* The affected output is switched off as long as the short-circuit lasts.

Measuring value < -20% of final value of measuring

range (temperature)

(Flow rate > 120% of final value of measuring range)

These messages are shown even when the display is off.

Note

9.2 Cleaning the sensor

You must clean the sensor:

• Before each calibration/inspection (at least 1 x per year)

• Regularly during operation.

You can remove the sensor and clean it manually.

9.2.1 Cleaning agents

For cleaning the sensor, use agents containing surfactants (alkaline) or

water-soluble organic solvents (e.g. ethanol).

Isopropanol is recommended for cleaning various contamination, especially

greases and oils.

43

Page 44

Clean the sensor with approved cleaning agents only.

Do not use any chafing (abrasive) cleaning agents. These

can lead to irreparable damages to the sensor.

Carry out a new inspection after the cleaning, as required.

ATTENTION

Note

During cleaning, take care not to mechanically stress the

sensor plates, as they may break, causing irreparable

damage to the sensor. (Rinse the sensor, do not clean

mechanically.)

The sensor is to be cleaned in an ultrasound bath within

2 minutes. For example, a solution of 99% distilled water with

1% EM-404 from EMAG (aluminium and die-cast cleaner)

serves as a cleaning agent. Place the sensor in the mixed

solution – the sensor tip must be completely immersed. Switch

on the ultrasound unit for 2 minutes.

Rinse the sensor tip with pure distilled water and allow it to air

dry.

9.3 Recalibration

Due to contamination (e.g. oil, water and particles) and component drift, an

annual recalibration of the sensor is recommended. Regular calibrations

are essential for cost transparency and correct billing.

44

Page 45

10 TROUBLESHOOTING

10.1 Replacing damaged parts

If faults cannot be corrected, the products must be taken

out of operation and be safeguarded from inadvertent

commissioning. Replace all damaged parts immediately.

Damages to the compressed air meter that affect the pressure

WARNING

To order spare parts please contact our Service team, either by phone on

+49 7653 6810 or email to info@testo.de.

10.2 Replacing O-rings and sealing rings

• Keep the sealing surfaces clean.

• Remove any adhered residues from time to time.

• In the event of leakage, contact your supplier.

ATTENTION

integrity may only be remedied by authorised personnel.

After each repair, the technical data of the specifications must

be checked by qualified personnel, e.g. by means of a pressure

test.

Danger of the medium escaping! Replacement of the seals

may only be performed by authorised personnel.

10.3 Return shipment

In case of repair, please send the sensor to the supplier in its original

packaging.

10.4 Disposal

The sensor design takes environmental compatibility into account in

the best way possible. According to the EU directive 2002/96/EC,

compressed air meters must be conveyed to a separate collection

point for electrical and electronic devices or may be sent to the

supplier for disposal. They may not be added to the unsorted

municipal waste.

Please observe the local regulations.

45

Page 46

Page 47

Page 48

0970 6446 en 03

Loading...

Loading...