Page 1

Compressed air counter

DN 15-50

testo 6441-6444

Measurement of norm volume flow in the measuring range

0.25 to 700 m

quantity in m

3

/h (DN15 to DN50 or ½’’-2’’); consumption

3

; media temperature in °C

We measure it.

Highest flexibility thanks to different signal outputs:

- Analog output 4 to 20 mA (4-wire)

- Pulse output

- 2 switch outputs (parameterizable: consumption or volume

flow-dependent, opener, closer, hysteresis, window)

Built-in totalizer, even without additional analysis unit

Operating menu with LED display

The compressed air counters testo 6441 to testo 6444

are designed for the measurement, monitoring and

recording of compressed air consumption, and therefore

also for the determination of leakages in compressed

air systems, consumption-based allocation of costs and

the implementation of peak load management. Using

the compressed air counters testo 6441 to testo 6444,

transparency of consumption is created for compressed

air, similarly as for the media current, water or gas, thus

increasing the motivation of those responsible for the

m3/h; l/

3

min; m

°C

process regarding cost reduction measures and energy

savings. The compressed air counters testo 6441 to testo

6444 record norm volume flow according to the calorimetric

principle, which means the measurement procedure is

independent of the process pressure and does not cause a

permanent pressure drop. While the thermal, glass-coated

ceramic sensor offers a high level of robustness and fast

response times, the integrated inflow and outflow pipes

ensure optimum accuracy.

www.testo.com

Page 2

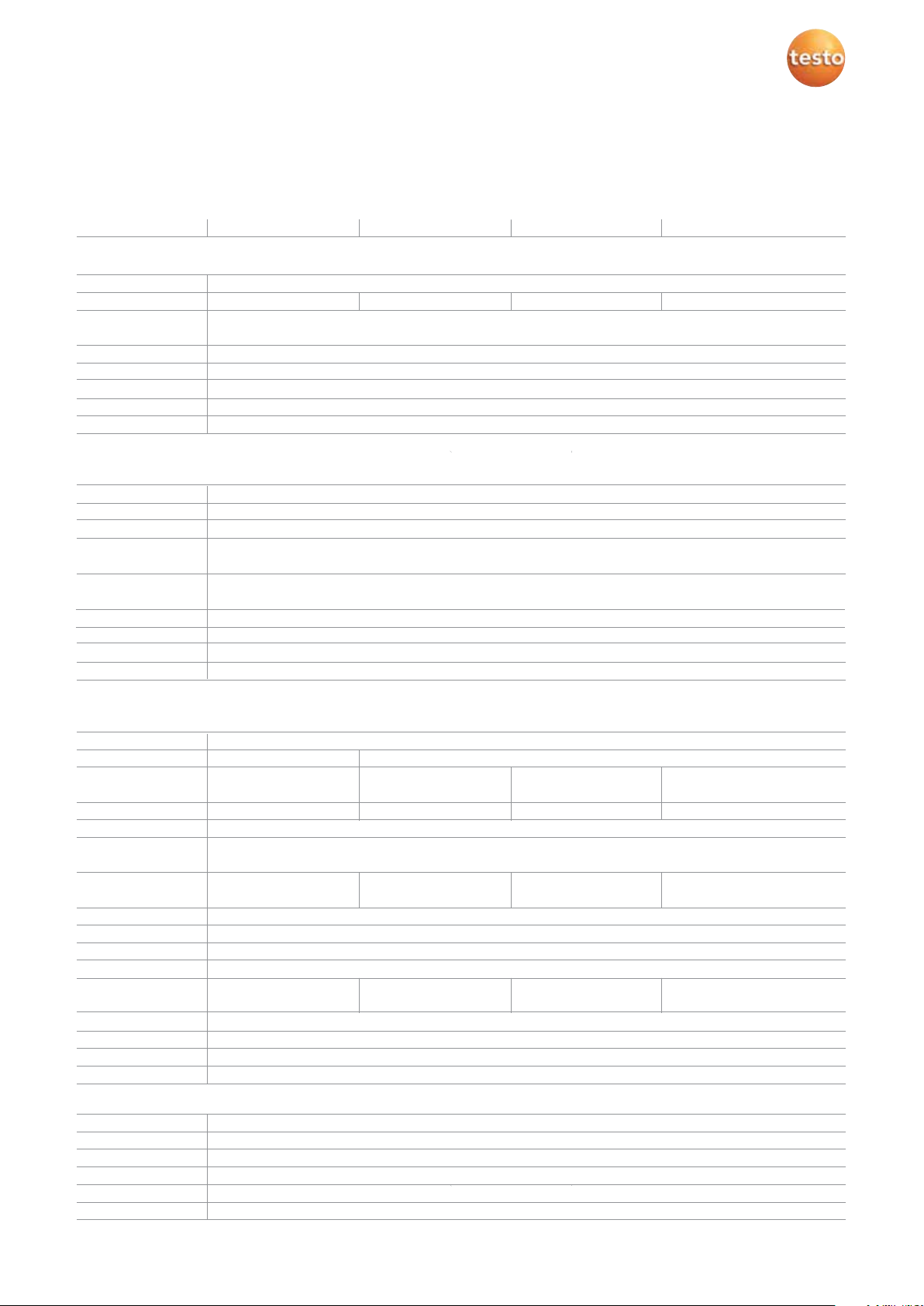

testo 6441-6444 – Compressed air counter DN 15-50 We measure it.

Technical data

testo 6441 testo 6442 testo 6443 testo 6444

Measurement parameters

(Norm) volume flow

Selectable units m3/h; l/min; m

Measuring range (1:300)

Accuracy

(norm volume flow)

Sensor

Response time

Temperature

Unit °C

Measuring range 0 to +60 °C / 32 °F to +140 °F

1

0.25 to 75 m

For compressed air quality classes (ISO 8573: particles-humidity-oil) 1-4-1: ±3 % of meas. value ±0.3 % of final value

For compressed air quality classes (ISO 8573: particles-humidity-oil) 3-4-4: ±6 % of meas. value ±0,6 % of final value

Thermal, glass-coated ceramic sensor (calorimetric measurement procedure)

<0.1 sec (for damping parameter = 0), delayable via operating menu (0 to 1 sec)

3

/h

0.75 to 225 m3/h 1.3 to 410 m3/h 2.3 to 700 m3/h

Inputs and outputs

Analog outputs

Output type 4 to 20 mA (4-wire) freely scalable between zero and measuring range end

Load max. 500 Ω

Further outputs

Pulse output Consumption quantity counter (value remains available after reset or power cut due to non-volatile memory), value 1 or 10

Switch output 2 switch outputs, parameterizable (consumption or volume flow-dependent, opener, closer, hysteresis, window), loadable

Supply

Voltage supply 19 to 30 V DC

Current consumption <100 mA

Connection M12 x 1 plug, loadable up to 250 mA, short-circuit-proof (synchronized), reverse-polarity-proof, overload-proof

3

m

, pulse length 0.02 s to 2 s, 24 VDC level

with max. 20 to 30 VDC or 250 mA each, switch status is displayed via 2 LEDs

3

General technical data

Design

Material housing PBT (GF 20%), diecast zinc, silica-free

Long measurement stretch

Pipe diameter DN 15 (for 1/2“ pipes) DN 25 (for 1“ pipes) DN 40 (for 1 1/2“ pipes) DN 50 (for 2“ pipes)

Weight 0.9 kg 1.1 kg 3.0 kg 3.8 kg

Display

Material 4-figure alphanumerical display, two operating buttons, operating menu, LED (4 x green for phys. units, 3 x yellow for

Max. display value

norm volume flow

Temperature display 0 to +60 °C, measurement error ±2 K, (+32 to +140 °F)

Operation

Parameterization 2 operating buttons

Installation

Measurement stretch:

thread (both sides) /

material

Miscellaneous

Protection class IP 65/III

EMC according to guideline 89/336 EEC

Media contact Materials stainless or galvanized steel, PEEK, polyester, Viton, anodized aluminium ceramic

display x 1,000 or switch status)

300 mm 475 mm

90 m3/h 270 m3/h 492 m3/h 840 m3/h

R 1/2, outer thread

Stainless steel 1.4301

R1, outer thread

Stainless steel 1.4301

R1 1/2, outer thread

Stainless steel 1.4401

R2, outer thread

Stainless steel 1.4401

Operating conditions

Humidity (sensor) re. humidity <90 %RH

Operating temperature (housing) 0 to +60 °C (+32 to +140 °F)

Storage temperature -25 to +85 °C (-13 to +185 °F)

Measurement medium Compressed air

Process pressure PN 16 (max 16bar/232psi)

Air quality ISO 8573: recommended classes 1-4-1

1

Specifications according to DIN 2533 (+15 °C, 1013.25 hPa, 0 %RH)

Page 3

testo 6441-6444 – Compressed air counter DN 15-50 We measure it.

Technical drawings

testo 6441

testo 6442

testo 6443

testo 6444

Page 4

testo 6441-6444 – Compressed air counter DN 15-50 We measure it.

Options / Ordering example

5 options

DN 15-50

Output 1

OUT 1

Output 2

OUT 2

M12 socket

on cable

testo 6441

to testo

6444

BN = brown

WH = white

BK = black

BU = blue

Define in

menu

M12 plug on

instrument

A

(Switch)

Hno / Hnc

Fno / Fnc

Hno / Hnc

Fno / Fnc

(Switch)

B

(Switch)

Hno / Hnc

Fno / Fnc

I

Current

signal

Hno / Hnc

Fno / Fnc

BN

WH

OUT

2

BK

OUT

1

BU

A/C* A/D* C/B* B/D*

C

ImP *

(Pulse)

(Switch)

D

ImP *

(Pulse)

I

Current

signal

E

(Switch)

Hno / Hnc

Fno / Fnc

or

ImP (Pulse)

ImP

(Pulse)

0981 8354/msp/I/01.2015Subject to change without notice.

L + (19 to 30 VDC)

0 VDC

* If menu selection ImPR = Yes -> Pulse output

If menu selection ImPR = No -> Switch output (pre-selection counter)

Terminal allocation

1 Supply connection 19 to 30 VDC (+)

2 OUT 2 (analog output (4 to 20 mA) or switch output

3 Supply connection 0 V (-)

4 OUT 1 (pulse output or switch output)

Order data testo 6441 to testo 6444

with analog, pulse and switch output *

with analog, pulse and switch output *

with analog, pulse and switch output *

pulse and switch output *

* a connection cable, e.g. part no. 0699 3393, is required for operation

Wire colours for cable 0699 3393

brown

white

blue

black

Part no.

0555 6441testo 6441 compressed air counter with integrated inflow/outflow, diameter DN15 (1/2),

0555 6442testo 6442 compressed air counter with integrated inflow/outflow, diameter DN25 (1),

0555 6443testo 6443 compressed air counter with integrated inflow/outflow, diameter DN40 (1 1/2),

0555 6444testo 6444 compressed air counter with integrated inflow/outflow, diameter DN50 (2), with analog,

www.testo.com

Loading...

Loading...