Page 1

Committing to the future

testo 6383

Differential pressure transmitter in cleanroom-conform panel design

SPECIFICATIONS

testo 6383

The differential pressure transmitter testo 6383 was

developed specially for monitoring low differential

pressures in the measuring range from 10 Pa to 10

hPa. In cleanroom technology, the maintenance of

positive pressure prevents the entry of contaminated

air in critical zones. Thanks to an optional internal or

external probe from the probe series 6610, the

additional recording of humidity and temperature with

one instrument is also possible.

Subject to change without notice.

SPECIFICATIONS

testo 6383

• Measurement of differential pressure; optional:

humidity and temperature

• Automatic zero-point adjustment guarantees high,

temperature-independent accuracy and long-term

stability

• Low measurement range up to 10 Pa ensures

highest precision at lowest pressures

• Flat housing allows flush surface integration in the

cleanroom wall

• Display with multi-language operating menu and

optical alarm display

• Ethernet, relay and analog outputs allow optimum

integration into individual automation systems

The testo 6383 is particularly outstanding thanks to

the automatioc zero-point adjustment which ensures

high accuracy and long-term stability.

The integrated self-monitoring and early warning

function also guarantees the operator high system

availability.

Areas of application:

• Monitoring positive and negative pressure in

cleanrooms, operating theatres and isolation rooms

• Optional monitoring of humidity and temperature in

cleanrooms

Status 12.02.2010

• Self-monitoring of the transmitter and early warning

function guarantee high system availablity

• The P2A software for parameterization, adjustment

and analysis saves time and costs in commissioning

and maintenance

• Scalability of ±50 percent of the measuring range

final value and free scalability within the measuring

range

• Configurable alarm management with adjustable

response delay and alarm acknowledgement

tteessttoo

AG · Testo-Strasse 1 · D-79853 Lenzkirch · www.testo.com

Page 1/4

DS 6383 EN/msp/A/12.02.2010

Page 2

Differential pressure transmitter in cleanroom-conform panel design

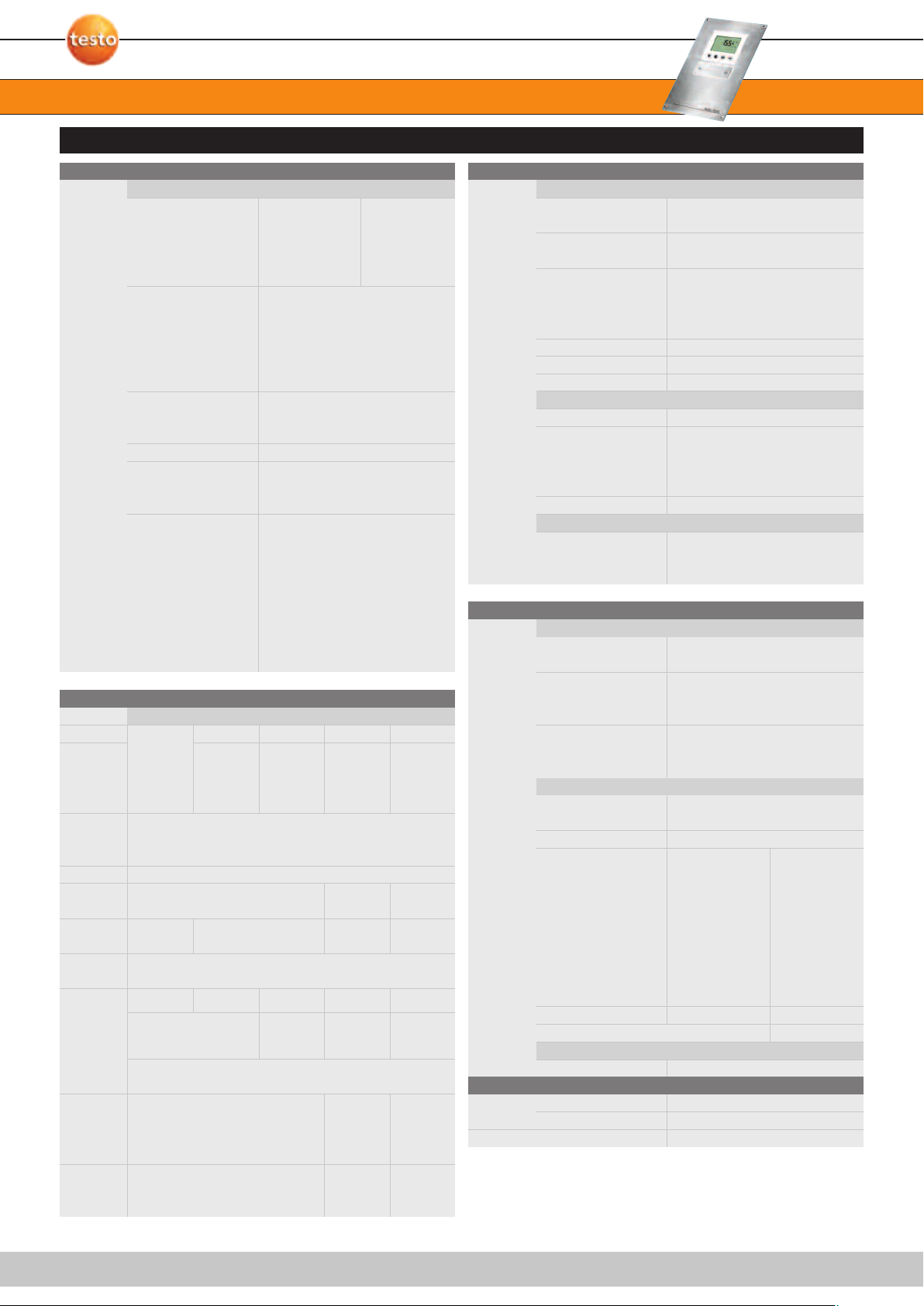

Technical data

testo 6383

Parameters

ifferential pressure

D

easuring range 0 to 10 Pa

M

Measurement uncertainty* ±0.3% of measurement range final value

electable units Differential pressure in Pa, hPa, kPa,

S

Sensor Piezoresistive sensor

Autom. Zero-point

adjustment

verload

O

Parameters

Humidity/temperature optional

Probe

Type

Parameters

Integrated

probe

%RH / °C/°F / °Ctd/ °Ftd/ g/kg / gr/lb / g/m3 / gr/ft³ / ppmV / °Cwb

testo 6613 testo 6614 testo 6615 testo 6617

Channel Duct heated Cable trace

/ °Fwb / kJ/kg / mbar / inch H

MMeeaass.. rraannggee

Humidity /

trace humidity

Temperature

-20 to +70 °C

-4 to +158 °F

MMeeaassuurreemmeenntt

uunncceerrttaaiinnttyy**

Humidity

Integrated

probe

±1.0 %RH for 0 to 90 %RH /

±1.4 %RH for 90 to 100 % RH

testo 6613 testo 6614 testo 6615 testo 6617

for deviations from media temp. ±25 °C:±0.02 %RH/K

Dewpoint

Temp. at

+25°C /

±0.15 °C / 32.2 °F

Pt1000 1/3 Class B

+77°F

Subject to change without notice.

10 to +10 Pa

to 50 Pa

0

0 to 100 Pa

0 to 500 Pa

0 to 10 hPa

50 to +50 Pa

-

-100 to +100 Pa

-500 to +500 Pa

-10 to +10 hPa

±0.3 Pa

Temperature gain drift: 0.02% of

easuring range per Kelvin deviaton

m

rom nominal temperature 22 °C

f

ero point drift: 0% (thanks to cyclic

Z

ero-point adjustment)

z

2

, kg/cm

bar, bar, mmH

m

G, inch H

H

O

2

O

2

PSI, inch

,

via magnetic valve

Frequency adjustable: 15 sec, 30 sec, 1

min, 5 min, 10 min

MMeeaassuurriinngg rraannggeeOOvveerrllooaad

d

0 to 10 Pa 20000 Pa

to 50 Pa 20000 Pa

0

0 to 100 Pa 20000 Pa

0 to 500 Pa 20000 Pa

to 10 hPa 200 hPa

0

-10 to 10 Pa 20000 Pa

-50 to 50 Pa 20000 Pa

-100 to 100 Pa 20000 Pa

-500 to 500 Pa 20000 Pa

-10 to 10 hPa 200 hPa

Cable with

humidity

cover electrode monitoring

O / °Ctm (H2O2)/°Ftm (H2O2) / % Vol

2

0 to 100 %RH -60 to +30 °C td 0 to 100 %RH

-40 to +180 °C

-40 to +356 °F

±1.0 %RH for 0

to100 %RH

-40 to +120 °C

-40 to +248 °F

±1 K at

0 °C

td

±2 K at

-40°C

td

±4 K at

-50 °C

td

±0.15 °C/

32.2 °F

Pt100 1/3 Class B

-40 to +180 °C

-40 to +356 °F

±1.2 %RH for

0 to 90 %RH /

±1.6 %RH for 90

to 100 %RH

±0.15 °C/

32.2 °F

Pt1000 1/3 Class

B

Inputs/outputs

nalog outputs

A

uantity Standard: 1;

Q

ith optional humidity probe: 3

w

Output type 0/4 to 20 mA (4-wire) (24 VAC/DC)

0 to 1/5 to 10 V (4-wire) (24 VAC/DC)

Scaling Differential pressure: scalable ±50% of

measuring range final value;

reely scalable within measuring range

f

Meas. cycle 1/sec

esolution 12 bit

R

Max. load max. 500 Ω

ther outputs

O

Ethernet Optional

Relay Optional: 4 relays (free allocation to

measurement channels or as collective

alarm in operating menu/P2A), up to

50 VAC/3A (NO or NC)

2

Digital Mini-DIN for P2A software

Supply

oltage supply 20 to 30 VAC/DC, 300 mA current

V

consumption, galvanically separate

signal and supply line

General technical data

Model

Material Front plate stainless steel, housing

plastic

Dimensions without humidity/temperature:

246 x 161 x 47 mm

with humidity/temperature:

396 x 161 x 78 mm

Weight Version without humidity: 0.9 kg;

Version with integrated humidity

probe:1.35 kg; version with preparation

for external humidity probe: 1.26 kg

Display

Display optional: 3-line LCD with

multi-language operating menu

Resolution

Differential pressure

MMeeaassuurriinngg rraannggee RReessoolluuttiioonn

0 to 10 Pa 0.1 Pa

0 to 50 Pa 0.1 Pa

0 to 100 Pa 0.1 Pa

0 to 500 Pa 0.1 Pa

0 to 10 hPa 0.01 hPa

-10 to 10 Pa 0.1 Pa

-50 to 50 Pa 0.1 Pa

-100 to 100 Pa 0.1 Pa

-500 to 500 Pa 0.1 Pa

-10 to 10 hPa 0.01 hPa

Humidity

Temperature

0.1 %RH

0.01 °C / 0.01 °F

Miscellaneous

Protection class IP 65

Operating conditions

With / without

display

Operation temperature -5 to +50 °C / +23 to +122 °F

Storage temperature -20 to +60 °C / -4 to +140 °F

Process temperature -20 to +65 °C / -4 to +149 °F

* Measurement inaccuracy according to GUM.

measurement range final value ±0.3 Pa;

inaccuracy contribution +0.007 * MW (in %RH).

UU

ncertainty in MMeasurement): ISO guideline for the determination of measurement

inaccuracy, in order to make measurements comparable worldwide. The following

inaccuracies are used for the determination: hysteresis, linearity, reproducibility, long-term

stability (only for differential pressure), adjustment site/factory calibration, test site.

FFoorr ddiiffffeerree nnttiiaall pprreessssuurree::

FFoorr hhuummiiddiittyy::

Additional humidity-dependent

GGUUMM(GG

0.5% of

uide to the Expression of

Status 12.02.2010

Page 2/4

DS 6383 EN/msp/A/12.02.2010

tteessttoo

AG · Testo-Strasse 1 · D-79853 Lenzkirch · www.testo.com

Page 3

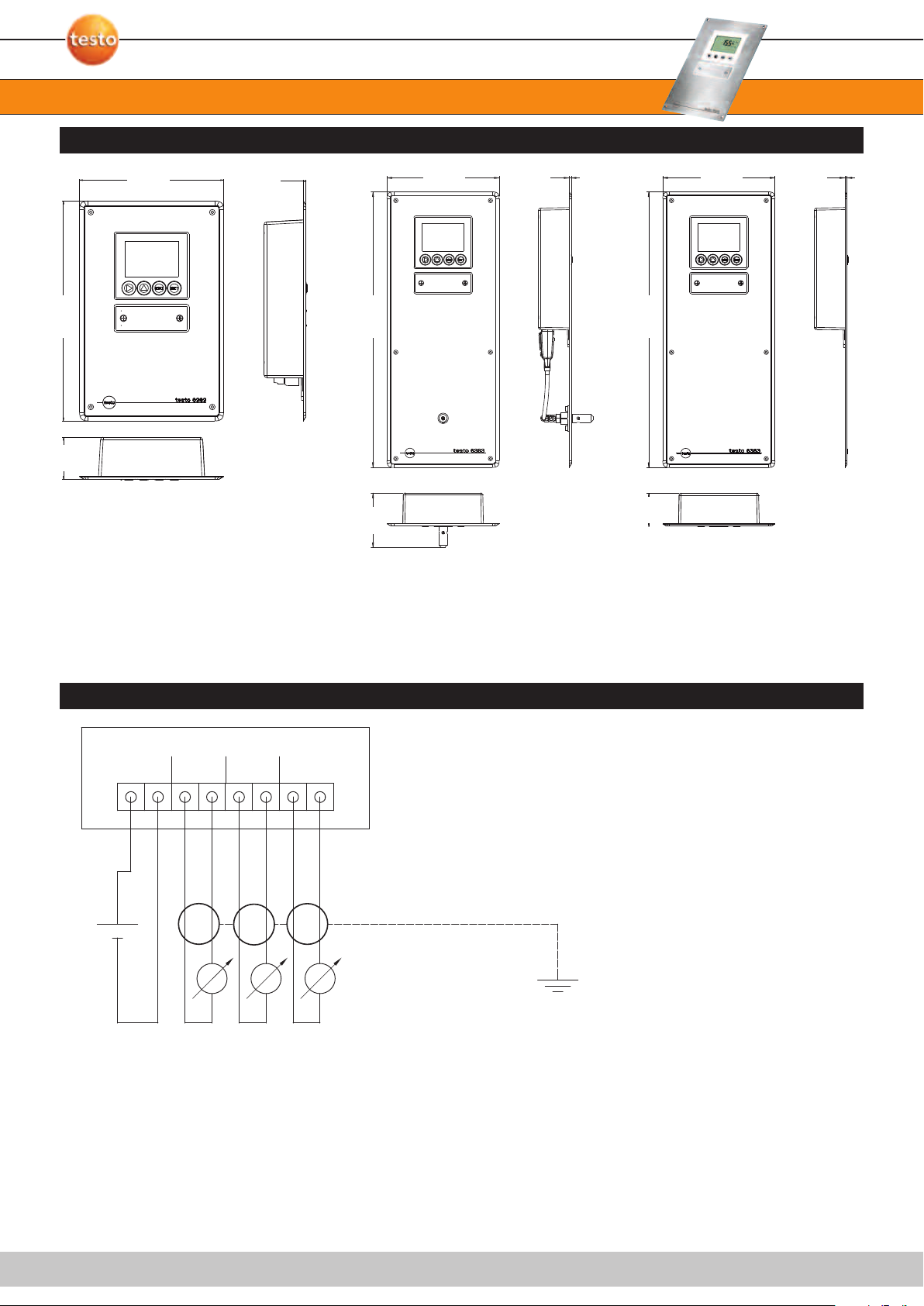

+

-

+

-

+

-

+

-

+

-

CH1

CH2 CH3

24V

1

20-30 V

AC/DC

0V

Differential pressure transmitter in cleanroom-conform panel design

Technical drawings

161 mm

3 mm

161 mm

3 mm 3 mm

61 mm

1

testo 6383

246 mm

47 mm

Connection plan

396 mm

78 mm

396 mm

47 mm

Subject to change without notice.

tteessttoo

AG · Testo-Strasse 1 · D-79853 Lenzkirch · www.testo.com

Page 3/4

DS 6383 EN/msp/A/12.02.2010 Status 12.02.2010

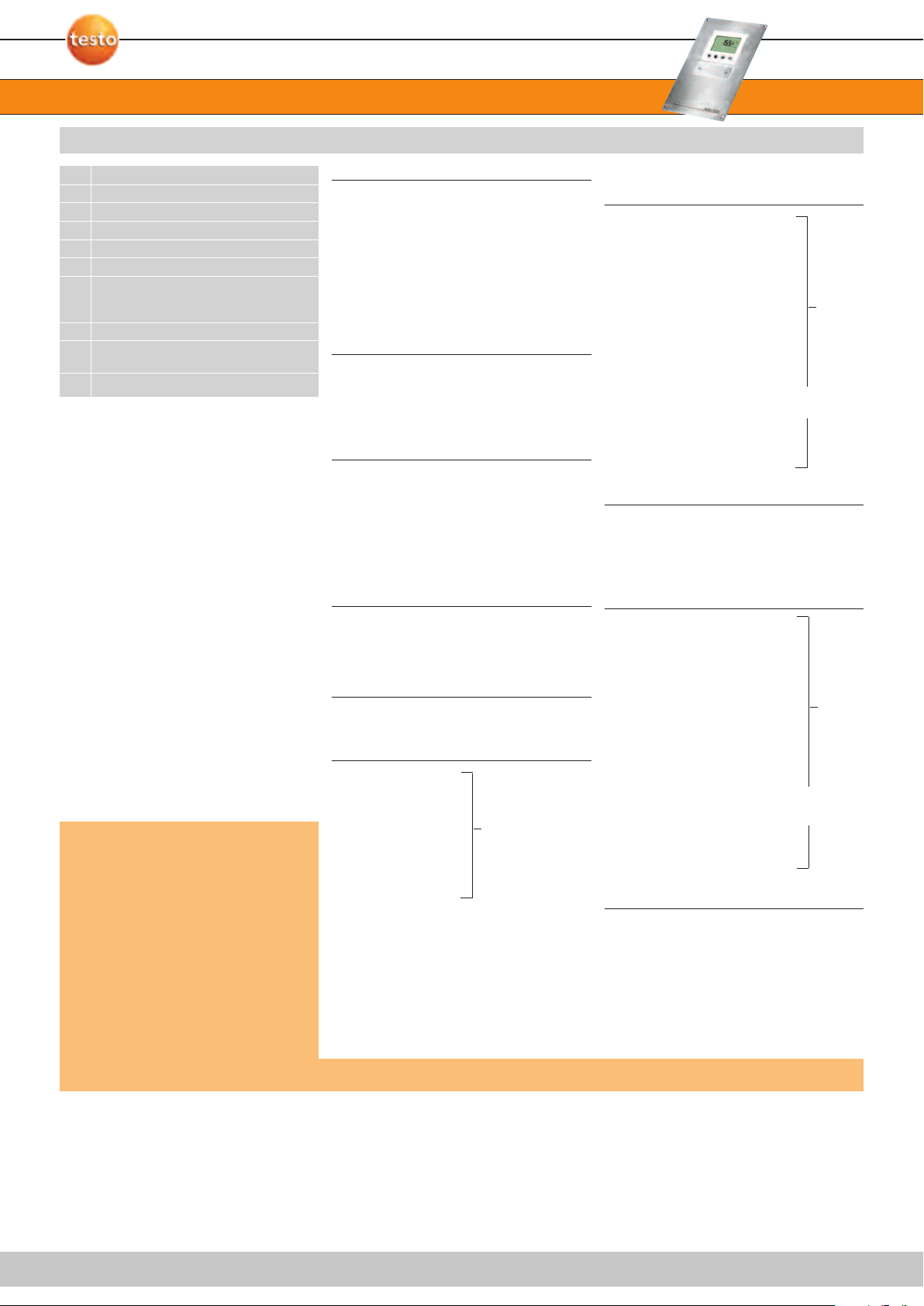

Page 4

Differential pressure transmitter in cleanroom-conform panel design

The following options can be specified for the testo 6383:

testo 6383

AXX Messbereich

AXX Measuring range

BXX Analogausgang / Versorgung

BXX Analog display/supply

XX Display

XX Display / menu language

C

C

XX Gehäusefarbe

XX Integrated humidity probe

E

D

XX Einheit

XX Ethernet

F

E

FXX Differential pressure unit (pre-set)

KXX Sprache der Bedienungsanleitung

(für zweisprachige Papier-Bedienungs -

GXX opt. Analog output for humidity probe

nleitung)

a

connection (probe series testo 6610) units

pre-set)

(

HXX Relay

IXX Units channel 3 (pre-set, only if opt.

humidity probe connection available)

KXX Instruction manual language

Example:

Order code for transmitter testo 6383 with

the following options:

- Measuring range -10 to 10 Pa

- Analog output 4 to 20 mA

(4-wire,, 24 VAC/DC)

- with German display

- preparation for external humidity/

temperature probe testo 6610

- with Ethernet module

- Differential pressure unit kg/cm² / min / max

- opt. Analog output for °Ctd / min / max

- without relay

- Unit channel 3 g/m³ / min / max

- Instruction manual language

German/English

AXX Measuring range

A01 0 to 10 Pa

A02 0 to 50 Pa

A03 0 to 100 Pa

04 0 to 500 Pa

A

05 0 to 10 hPa

A

21 -10 to 10 Pa

A

A22 -50 to 50 Pa

A23 -100 to 100 Pa

A24 -500 to 500 Pa

A25 -10 to 10 hPa

BXX Analog display / supply

02 0 to 1 V (4-wire, 24 VAC/DC)

B

B03 0 to 5 V (4-wire, 24 VAC/DC)

B04 0 to 10 V (4-wire, 24 VAC/DC)

B05 0 to 20 mA (4-wire, 24 VAC/DC)

B06 4 to 20 mA (4-wire, 24 VAC/DC)

XX Display / menu language

C

00 without display

C

02 with display/English

C

C03 with display/German

C04 with display/French

C05 with display/Spanish

C06 with display/Italian

C07 with display/Japanese

08 with display/Swedish

C

XX Integrated humidity probe

D

D00 no humidity/temperature probe

D04 humidity probe integrated in panel

D05 preparation for external humidity/

temperature probe testo 6610

EXX Ethernet

E00 without Ethernet module

E01 with Ethernet module

FXX Differential pressure unit (pre-set)

F01 Pa / min / max

F02 hPa / min / max

F03 kPa / min / max

F04 mbar / min / max

F05 bar / min / max

F06 mmH

F07 mmH

F08 inch HG / min / max

F09 kg/cm² / min / max

F10 PSI / min / max

O / min / max

2

O / min / max

2

Scaling: 50% of

measuring range

final value; freely

selectable within

measuring range

GXX opt. Analog output for humidity probe

connection (probe series testo 6610) units

pre-set)

(

G01 %RH / min / max

G02 °C/Min/Max

03 °F/Min/Max

G

04 °Ctd / min / max

G

05 °Ftd / min / max

G

G06 g/kg / min / max

G07 gr/lb /Min/Max

G08 g/m³ / min / max

G09 gr/ft³ / min / max

10 ppmV / min / max

G

11 °Cwb / min / max

G

G12 °Fwb / min / max

G13 kJ/kg / min / max (enthalpy)

G14 mbar / min / max (water vapour partial pressure)

G15 inch H

16 °Ctm (mixture dewpoint for H

G

17 °Ftm (mixture dewpoint for H

G

G18 % Vol

HXX Relay

H00 without relay

H01 4 relay outputs, limit value monitoring

H02 4 relay outputs, channel 1 limit values and

XX Units channel 3 (pre-set, only if opt. humidity

I

I01 % RH/Min/Max

I02 °C/Min/Max

I03 °F/Min/Max

I04 °Ctd / min / max

I05 °Ftd / min / max

I06 g/kg / min / max

I07 gr/lb /Min/Max

I08 g/m³ / min / max

I09 gr/ft³ / min / max

I10 ppmV / min / max

I11 °Cwb / min / max

I12 °Fwb / min / max

I13 kJ/kg / min / max (enthalpy)

I14 mbar / min / max (water vapour partial pressure)

I15 inch H

I16 °Ctm (mixture dewpoint for H

I17 °Ftm (mixture dewpoint for H

I18 % Vol

KXX Instruction manual language

K01 German/English instruction manual

K02 French/English instruction manual

K03 Spanish/English instruction manual

K04 Italian/English instruction manual

K05 Dutch/English instruction manual

K06 Japanese/English instruction manual

K07 Chinese/English instruction manual

K08 Swedish/English instruction manual

O / min/ max (water vapour partial

2

pressure)

ollective alarm

c

probe connection available)

O / min/ max (water vapour partial

2

pressure)

2O2

2O2

2O2

2O2

)

)

)

)

0555 6383 A21 B06 C03 D05 E01 F09 G04 H00 I08 K01

only possible

when D04 or

05 selected

D

only possible

when D04 or

D05 selected

Status 12.02.2010

Page 4/4

Subject to change without notice.

tteessttoo

AG · Testo-Strasse 1 · D-79853 Lenzkirch · www.testo.com

DS 6383 EN/msp/A/12.02.2010

Page 5

testo 6383 / testo 6381 / testo 6351

Committing to the future

Differential Pressure Monitoring in Cleanroom Technology

Highest accuracy and long-term stability with the new transmitters from Testo

Page 6

Differential pressure measurement in cleanroom applications

2

Input air via HEPA/ULPA filter

Typical exhaust air: (50 - 500

air exchanges / h)

Laminar flow e. g.

0.5 m/s

Outside zone

Critical zone

Normal zone

Whether in cleanrooms, greyrooms, OP theatres or

filling systems:

Lowest differential pressures must be maintained

between different rooms or zones in order to prevent

contaminated air from entering.

For this reason, continuous measurement and regulation

of these low differential pressures (according to

cleanroom norm ISO 14644: 5 - 20 Pa) is required.

Annual proof (against zero potential and against adjacent

rooms) of this must be provided according to ISO 14644

.

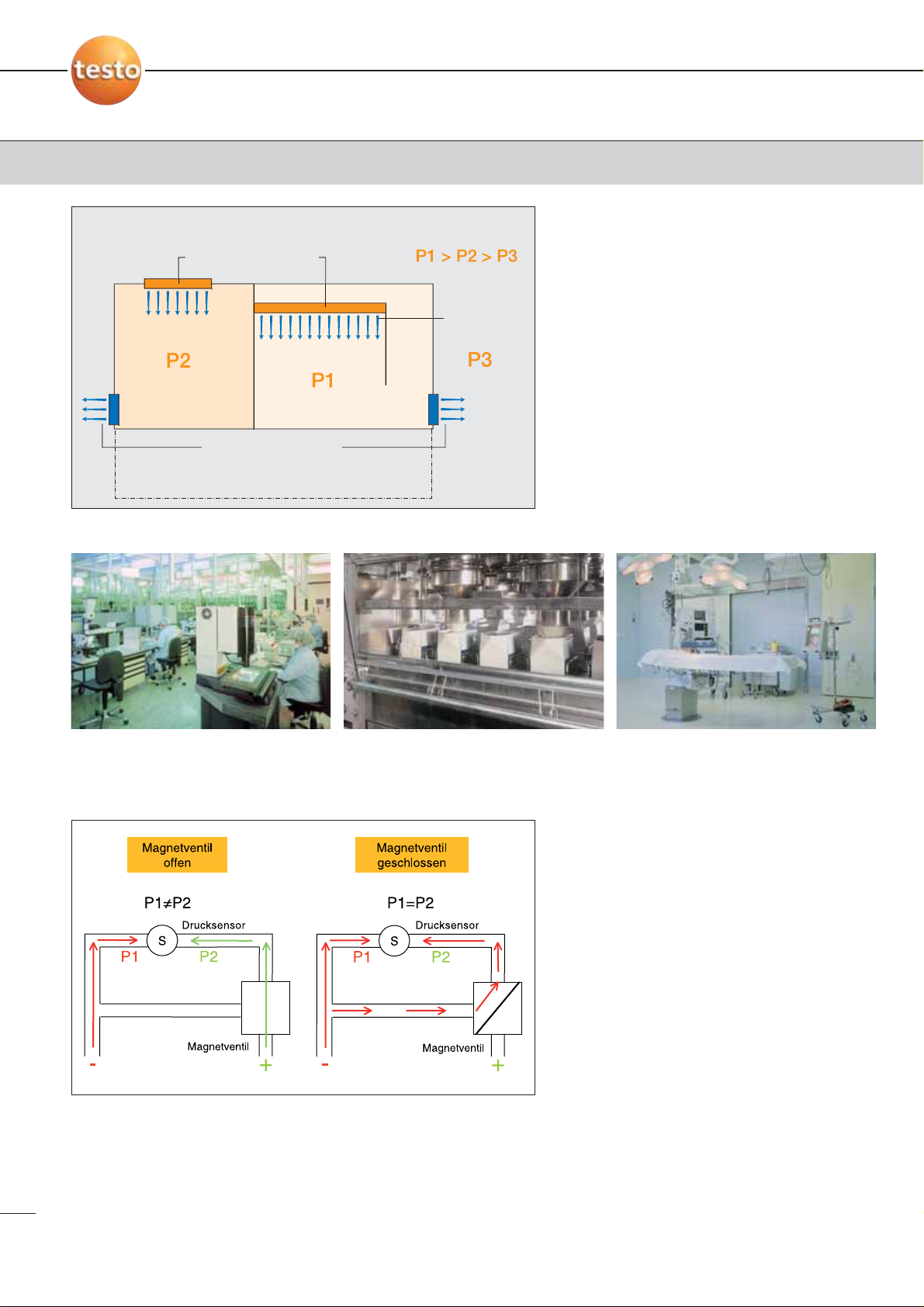

Functional principle of the automatic zero-point adjustment of the Testo differential pressure transmitter

In hospitals and research laboratories, the pressure

difference (negative pressure) prevents the spread of

germs and dust

Pressure maintenance in cleanrooms

Cleanroom

Automatic zero-point adjustment guarantees highest,

temperature-independent accuracy and long-term

stability

The zero-point stability of differential pressure transmitters

plays a particularly crucial role at lowest pressures (10 Pa

or 50 Pa measurement range). Whereas conventional

differential pressure transmitters require manual readjustment of the zero point, the new transmitter series

from Testo is equipped with an automatic

microprocessor-controlled zero-point adjustment. It

ensures a low level of temperature-dependency of the

pressure sensor, guaranteeing the user high accuracy

and long-term stability.

In the automatic zero-point adjustment, a magnetic valve

causes both sides of the pressure sensor to be exposed

to the same pressure a cyclic intervals. This guarantees

highest accuracy in cleanroom processes!

Positive pressure in the filling room maintains the

hygiene conditions during filling operations in the food

and pharamceuticals industry

Defined pressure differences between cleanrooms and

adjacent rooms ensure quality

Normal measurement Zero-point adjustment

Page 7

Overview of differential pressure transmitters from Testo

3

testo 6383

Parameters

Selectable measuring ranges

Housing

Area of application:

Usual installation site in

cleanroom

Differential pressure

Optional: humidity/temperature

testo 6381

Differential pressure

Flow velocity

Volume flow

Optional: Humidity/temperature

testo 6351

Differential pressure

Flow velocity

Volume flow

10 Pa to 10 hPa 10 Pa to 1000 hPa 50 Pa to 2000 hPa

Flat stainless steel housing for

flush wall installation (panel

design)

Metal housing Plastic housing

Critical zone: Surface flush

installation in cleanroom wall

Normal zone or

outside zone

Normal zone or

outside zone

Differential pressure monitoring

between cleanrooms (optional:

simultaneous measurement of

temperature and humidity)

Monitoring positive and negative

pressure in cleanrooms,

operating theatres and isolation

rooms

Additional monitoring of humidity

and temperature in cleanrooms

(optional)

Differential pressure monitoring

between cleanrooms (optional:

simultaneous measurement of

temperature and humidity)

Differential pressure monitoring in

filling processes and spraypainting systems

Monitoring drying processes

Differential pressure monitoring

between cleanrooms

Differential pressure monitoring in

filling processes in the process

industry

Critical air conditioning

technology (VAC systems)

Optimizing processes and saving time in commissioning and maintenance

The Testo transmitters are delivered ready to use. For

professional application, the following functions are available

via the easy-to-use software:

–Parameterization of unit and scale

–Sensor adjustment and adjustment of the analog outputs

(humidity: 1-point, 2-point; pressure: n-point)

–Parameterization and adjustment history of all activities of the

P2A software are registered in the PC

An adjustment of the entire signal chain is possible directly at

the measurement site thanks to the external interface.

This saves time in commissioning and maintenance.

In addition to this, complete parameter files can be stored in

the PC. The parameterization of spare transmitters or similar

measuring points is thus possible with minimal time

expenditure.

Ethernet networking

– Integration of the transmitters into customers’ Ethernet network

– Integration of the transmitters into measurement data monitoring systems, e.g. testo Saveris

TM

Using the P2A software, unit and scale can be easily parameterized, for example

Page 8

Differential pressure transmitters for installation in critical zones

testo 6383 – Overview of features and benefits:

· Measurement of differential pressure, optional:humidity and

temperature

· Automatic zero-point adjustment guarantees high, temperatureindependent accuracy and long-term stability

· Low measurement range up to 10 Pa ensures highest precision at

lowest pressures

· Flat housing allows flush surface integration in the cleanroom wall

4

testo 6383 for differential pressure

measurement

testo 6383 with integrated humidity probe

· Combination of differential pressure, humidity, and temperature

measurement in one instrument saves investment costs

(exchangeable digital humidity probes see page 10)

· Display with multi-language operating menu and optical alarm

display

· Ethernet, relay and analog outputs allow optimum integration into

individual automation systems

· Self-monitoring of the transmitters guarantees high system

availability

· The P2A software for parameterization, adjustment and analysis

saves time and costs in commissioning and maintenance

· Scalable measuring range by ±50 percent of the measuring range

final value, and free scalability within the measuring range, allow

optimum adaptation to the control requirements

Areas of application:

· Monitoring positive and negative pressure in cleanrooms, operating

theatres and isolation rooms

· Additional monitoring of humidity and temperature in cleanrooms

(optional)

Configuration options testo 6383:

This results in a typical ordering code:

0555 6383 AXX BXX CXX DXX EXX FXX GXX HXX IXX KXX

B02

B03

B04

B05

B06

C00

C02

C03

C04

C05

C06

C07

C08

K01

K02

K03

K04

K05

K06

K07

K08

D00

D04

D05

H00

H01

H02

F01

F02

F03

F04

F05

F06

F07

F08

F09

F10

G01

G02

G03

G04

G05

G06

G07

G08

G09

G10

G11

G12

G13

G14

G15

G16

G17

B02 0 to 1 V (4-wire, 24 VAC/DC)

B03 0 to 5 V (4-wire, 24 VAC/DC)

B04 0 to 10 V (4-wire, 24 VAC/DC)

B05 0 to 20 mA (4-wire, 24 VAC/DC)

B06 4 to 20 mA (4-wire, 24 VAC/DC)

without display without operating buttons

with display, with operating buttons / English

with display, with operating buttons / German

with display, with operating buttons / French

with display, with operating buttons / Spanish

with display, with operating buttons / Italian

with display, with operating buttons / Japanese

with display, with operating buttons / Swedish

no humidity/temperature probe

humidity/temperature probe integrated in panel

preparation for external humidity/

temperature probe testo 6610

Pa / min / max

hPa / min / max

kPa / min / max

mbar / min / max

bar / min / max

mmH

2

O / min / max

mmH

2

O / min / max

inch HG / min / max

kg/cm² / min / max

PSI / min / max

% RH/Min/Max

°C/Min/Max

°F/Min/Max

°C

td

/ min / max

°F

td

/ min / max

g/kg / min / max

gr/lb /Min/Max

g/m³ / min / max

gr/ft³ / min / max

ppmV / min / max

°C

wb

/ min / max

°F

wb

/ min / max

kJ/kg /Min/Max (enthalpy)

hPa /min/max

(water vapour partial pressure)

mmH

2

O / min / max

(Water vapour partial pressure)

°C

tm

(mixture dewpoint for H2O2)

°F

tm

(mixture dewpoint for H2O2)

without relay

4 relay outputs, limit value monitoring

4 relay outputs, channel 1 limit values and

collective alarm

German/English instruction manual

French/English instruction manual

Spanish/English instruction manual

Italian/English instruction manual

Dutch/English instruction manual

Japanese/English instruction manual

Chinese/English instruction manual

Swedish/English instruction manual

Order no. 0555 6383

A01 Bxx Cxx Dxx Exx Fxx Gxx Hxx Ixx Kxx

E00

E01

without Ethernet module

with Ethernet module

Axx Measuring range

Bxx Analog display/supply

Cxx Display

Dxx Integrated humidity probe

Exx Ethernet

Fxx Differential pressure unit (pre-set)

Gxx opt. Analog output for humidity

probe connection testo 6610 / units (pre-set)

Hxx Relay

Ixx Units channel 3 (pre-set, only if opt. humidity probe connection

available)

Kxx IM languages (for bilingual printed IMs)

A01

A02

A03

A04

A05

A21

A22

A23

A24

A25

0 to 10 Pa

0 to 50 Pa

0 to 100 Pa

0 to 500 Pa

0 to 10 hPa

-10 to 10 Pa

-50 to 50 Pa

-100 to 100 Pa

-500 to 500 Pa

-10 to 10 hPa

I01

I02

I03

I04

I05

I06

I07

I08

I09

I10

I11

I12

I13

I14

I15

I16

I17

% RH/Min/Max

°C/Min/Max

°F/Min/Max

°C

td

/ min / max

°F

td

/ min / max

g/kg / min / max

gr/lb /Min/Max

g/m³ / min / max

gr/ft³ / min / max

ppmV / min / max

°C

wb

/ min / max

°F

wb

/ min / max

kJ/kg /Min/Max (enthalpy)

hPa /min/max

(water vapour partial pressure)

mmH

2

O / min / max

(Water vapour partial pressure)

°C

tm

(mixture dewpoint for H2O2)

°F

tm

(mixture dewpoint for H2O2)

Scaling: ±50% of

measuring range;

freely selectable

within measuring

range

Only with

selection

D04 orD05

Only with

selection

D04 or

D05

Page 9

5

testo 6383 – differential pressure, humidity and temperature

testo 6383

Supply

Display

Differential pressure

Analog outputs

Other outputs

Housing

Miscellaneous

Display

optional: 3-line LCD with multi-language

operating menu

Technical data testo 6383

Parameters

Measuring range 0 to 10 Pa

0 to 50 Pa

0 to 100 Pa

0 to 500 Pa

0 to 10 hPa

-10 to +10 Pa

-50 to +50 Pa

-100 to +100 Pa

-500 to +500 Pa

-10 to +10 hPa

Measurement uncertainty*

0.3% of measurement range final value ±0.3 Pa

Meas. cycle 1/sec

Resolution 12 bit

Scaling Differential pressure: scalable ±50% of

measuring range final value;

freely scalable within measuring range

Overload capacity Measuring range Overload

0 to 10 Pa 20000 Pa

0 to to 50 Pa 20000 Pa

0 to

to 100 Pa 20000 Pa

0

to to 500 Pa 20000 Pa

0 to to 10 hPa 200 hPa

-10 to to 10 Pa 20000 Pa

-50 to to 50 Pa 20000 Pa

-100 to

to 100 Pa 20000 Pa

-500

to to 500 Pa 20000 Pa

-10 to to 10 hPa 200 hPa

Inputs/outputs

Output type 0/4 to 20 mA (4-wire) (24 VAC/DC)

0 to 1/5 to 10 V (4-wire) (24 VAC/DC)

Relay Optional: 4 relays (free allocation to

measurement channels or as collective

alarm in operating menu/P2A software),

up to 250 VAC/3A (NO or NC)

Voltage supply 20 to 30 VAC/DC, 300mA current

consumption, galvanically separate

signal and supply line

General technical data

Material Stainless steel housing

Dimensions

without humidity/temperature: 246 x 161 x 47 mm

with humidity/temperature: 396 x 161 x 78 mm

Resolution pressure Measuring range Resolution

0 to 10 Pa 0.1 Pa

0 to 50 Pa 0.1 Pa

0 to 100 Pa 0.1 Pa

0 to 500 Pa 0.1 Pa

0 to 10 hPa 0.01 hPa

-10 to 10 Pa 0.1 Pa

-50 to 50 Pa 0.1 Pa

-100 to 100 Pa 0.1 Pa

-500 to 500 Pa 0.1 Pa

-10 to 10 hPa 0.01 hPa

Operating temperature (housing) -5 to 50 °C/23 to 122 °F

Storage temperature -20 to 60 °C/-4 to 140 °F

Protection class IP 65

Operating conditions

Selectable units Pa, further pressure units see

configuration options p. 4

Sensor Piezoresistive sensor

Autom. Zero-point

adjustment

via magnetic valve, frequency settable:

15 sec, 30 sec,

1 min, 5 min, 10 min

Humidity

Measuring range

Version with integrated probe:

0 to 100 %RH;

Version with external probe:dependent on

connected probe (see p. 10)

Measurement uncertainty dependent on connected probe (see p. 10)

Selectable units %RH, further calculated humidity

parameters see configuration options p. 4

Sensor Capacitive sensor

Temperature dependency/

coefficient

±0.02 %RH (at temperatures deviating

from 25 °C)

Measuring range

dependent on connected probe (see p.

10)

Measurement uncertainty 0.15 °C / 32.2 °F

Selectable units °C / °F

Sensor Pt 1000 1/3 Class B;

Pt 100 1/3 Class B (with probe testo

6615)

Digital output Mini-DIN for P2A software

Ethernet Optional

Temperature

* Measurement inaccuracy according to GUM: ±0,5% of measur ement range final

value ±0.3 Pa

GUM (Guide to the Expression of Uncertainty in Measurement):

ISO guideline for the determination of measurement inaccuracy, in order to make

measurement results internationally comparable.

The following inaccuracies are used for the determination:

– Hysteresis

– Linearity

– Reproducibility

– Long-term stability

– Adjustment site/factory calibration

– Test site

Resolution humidity

0.1 %RH

Temperature resolution

0.01 °C / °F

Standard reference

EU guideline 2004/108/EC

Weight Version without humidity:0.9 kg;

Version with integrated humidity probe:

1.350 kg; version with preparation for

external humidity probe: 1.260 kg

Load max. 500 Ω

Quantity Standard: 1; for humidity/temperature

(optional): 3

Page 10

6

Differential pressure transmitters for installation in normal zones

testo 6381– Overview of features and

benefits:

· Measurement of differential pressure, flow

velocity, volume flow; optional: humidity and

temperature

· Automatic zero-point adjustment guarantees

high, temperature-independent accuracy and

long-term stability

· Low measurement range up to 10 Pa ensures

very high precision at lowest pressures

· The robust metal housing protects from tough

ambient conditions

· Combination of differential pressure, humidity,

and temperature measurement in one

instrument saves investment costs

(exchangeable digital humidity probe see

page 10)

·

Display with multi-language operating

menu and optical alarm display

· Ethernet, relay and analog outputs allow

optimum integration into individual automation

systems

· Self-monitoring of the transmitters guarantees

high system availability

· The P2A software for parameterization,

adjustment and analysis saves time and costs

in commissioning and maintenance

· Scalable measuring range by ±50 percent of

the measuring range final value, and free

scalability within the measuring range, allow

optimum adaptation to the control

requirements

Areas of application:

· Differential pressure monitoring between

cleanrooms (optional: simultaneous

measurement of ambient temperature and

humidity)

· Monitoring drying processes

· Differential pressure monitoring in filling

processes and spray-painting systems

Configuration options testo 6381:

This results in a typical ordering code:

0555 6381 AXX BXX CXX DXX EXX FXX GXX HXX IXX KXX

B02

B03

B04

B05

B06

C00

C02

C03

C04

C05

C06

C07

C08

K01

K02

K03

K04

K05

K06

K07

K08

D01

D02

D03

H00

H01

H02

F01

F02

F03

F04

F05

F06

F07

F08

F09

F10

F11

F12

F13

F14

F15

F16

G00

G01

G02

G03

G04

G05

G06

G07

G08

G09

G10

G11

G12

G13

G14

G15

G16

G17

0 to 1 V (4-wire, 24 VAC/DC)

0 to 5 V (4-wire, 24 VAC/DC)

0 to 10 V (4-wire, 24 VAC/DC)

0 to 20 mA (4-wire, 24 VAC/DC)

4 to 20 mA (4-wire, 24 VAC/DC)

without display without operating buttons

with display, with operating buttons / English

with display, with operating buttons / German

with display, with operating buttons / French

with display, with operating buttons / Spanish

with display, with operating buttons / Italian

with display, with operating buttons / Japanese

with display, with operating buttons / Swedish

Cable input M16 (relay: M20)

Cable entry NPT 1/2“

Cable contact via M-plug connection for signal

and supply

Pa / min / max

hPa / min / max

kPa / min / max

mbar / min / max

bar / min / max

mmH

2

O / min / max

mmH

2

O / min / max

inch HG / min / max

kg/cm² / min / max

PSI / min / max

m/s / min / max

ft/min / min / max

m³/h / min / max

l/min / min / max

Nm³/h / min / max

Nl/min / min / max

without connection possibility for

humidity probe testo 6610

% RH/Min/Max

°C/Min/Max

°F/Min/Max

°C

td

/ min / max

°F

td

/ min / max

g/kg / min / max

gr/lb /Min/Max

g/m³ / min / max

gr/ft³ / min / max

ppmV / min / max

°C

wb

/ min / max

°F

wb

/ min / max

kJ/kg /Min/Max (enthalpy)

hPa /min/max

(water vapour partial pressure)

mmH

2

O / min / max

(Water vapour partial pressure)

°C

tm

(mixture dewpoint for H2O2)

°F

tm

(mixture dewpoint for H2O2)

without relay

4 relay outputs, limit value monitoring

4 relay outputs, channel 1 limit values and

collective alarm

German/English instruction manual

French/English instruction manual

Spanish/English instruction manual

Italian/English instruction manual

Dutch/English instruction manual

Japanese/English instruction manual

Chinese/English instruction manual

Swedish/English instruction manual

Order no. 0555 6381 A01 Bxx Cxx Dxx Exx Fxx Gxx Hxx Ixx Kxx

E00

E01

without Ethernet module

with Ethernet module

Axx Measuring range

Bxx Analog display/supply

Cxx Display

Dxx Cable input

Exx Ethernet

Fxx Differential pressure/flow velocity unit (pre-set)

Gxx opt. Analog output for humidity probe

A01

A02

A03

A04

A05

A07

A08

A09

A10

A21

A22

A23

A24

A25

A27

A28

A29

A30

0 to 10 Pa

0 to 50 Pa

0 to 100 Pa

0 to 500 Pa

0 to 10 hPa

0 to 50 hPa

0 to 100 hPa

0 to 500 hPa

0 o 1000 hPa

-10 to 10 Pa

-50 to 50 Pa

-100 to 100 Pa

-500 to 500 Pa

-10 to 10 hPa

-50 to 50 hPa

-100 to 100 hPa

-500 to 500 hPa

-1000 to 1000 hPa

I01

I02

I03

I04

I05

I06

I07

I08

I09

I10

I11

I12

I13

I14

I15

I16

I17

% RH/Min/Max

°C/Min/Max

°F/Min/Max

°C

td

/ min / max

°F

td

/ min / max

g/kg / min / max

gr/lb /Min/Max

g/m³ / min / max

gr/ft³ / min / max

ppmV / min / max

°C

wb

/ min / max

°F

wb

/ min / max

kJ/kg /Min/Max (enthalpy)

hPa /min/max

(water vapour partial pressure)

mmH

2

O / min / max

(Water vapour partial pressure)

°C

tm

(mixture dewpoint for H2O2)

°F

tm

(mixture dewpoint for H2O2)

Scaling

±50% of

measuring

range; freely

selectable within

measuring range

only

possible

when GCode (from

G01)

selected)

connection testo 6610 / units (pre-set)

Hxx Relay

Ixx Units channel 3 (pre-set, only if opt. humidity

probe connection available)

Kxx IM languages (for bilingual printed IMs)

with

connection

possibility

testo 6610

Page 11

7

testo 6381

testo 6381 – differential pressure, humidity and flow velocity

Supply

Display

Differential pressure

Analog outputs

Other outputs

Housing

Miscellaneous

Display optional: 3-line LCD with multi-language

operating menu

Parameters

Measuring range 0 to 10 Pa

0 to 50 Pa

0 to 100 Pa

0 to 500 Pa

0 to 10 hPa

0 to 50 hPa

0 to 100 hPa

0 to 500 hPa

0 to 1000 hPa

-10 to 10 Pa

-50 to 50 Pa

-100 to 100 Pa

-500 to 500 Pa

-10 to 10 hPa

-50 to 50 hPa

-100 to 100 hPa

-500 to 500 hPa

-1000 to 1000 hPa

Measurement uncertainty* 0.5% of measurement range final value ±0.3 Pa

Meas. cycle 1/sec

Resolution 12 bit

Scaling Differential pressure: scalable ±50% of

measuring range final value; freely

scalable within measuring range

Overload capacity Measuring range Overload

0 to 10 Pa 20000 Pa

0 to 50 Pa 20000 Pa

0 to 100 Pa 20000 Pa

0 to 500 Pa 20000 Pa

0 to 10 hPa 200 hPa

0 to 50 hPa 750 hPa

0 to 100 hPa 750 hPa

0 to 500 hPa 2500 hPa

0 to 1000 hPa 2500 hPa

-10 to 10 Pa 20000 Pa

-50 to 50 Pa 20000 Pa

-100 to 100 Pa 20000 Pa

-500 to 500 Pa 20000 Pa

-10 to 10 hPa 200 hPa

-50 to 50 hPa 750 hPa

-100 to 100 hPa 750 hPa

-500 to 500 hPa 2500 hPa

-1000 to 1000 hPa 2500 hPa

Inputs/outputs

Output type 0/4 to 20 mA (4-wire) (24 VAC/DC)

0 to 1/5 to 10 V (4-wire) (24 VAC/DC)

Relay Optional: 4 relays (free allocation to

measurement channels or as collective

alarm in operating menu/P2A software), up

to 250 VAC/3A (NO or NC)

Voltage supply 20 to 30 VAC/DC, 300 mA current

consumption, galvanically separate

signal and supply line

General technical data

Material Metal housing

Dimensions 162 x 122 x 77 mm

Resolution pressure Measuring range Resolution

0 to 10 Pa 0.1 Pa

0 to 50 Pa 0.1 Pa

0 to 100 Pa 0.1 Pa

0 to 500 Pa 0.1 Pa

0 to 10 hPa 0.01 hPa

0 to 50 hPa 0.01 hPa

0 to 100 hPa 0.1 hPa

0 to 500 hPa 0.1 hPa

0 to 1000 hPa 1 hPa

-10 to 10 Pa 0.1 Pa

-50 to 50 Pa 0.1 Pa

-100 to 100 Pa 0.1 Pa

-500 to 500 Pa 0.1 Pa

-10 to 10 hPa 0.01 hPa

-50 to 50 hPa 0.01 hPa

-100 to 100 hPa 0.1 hPa

-500 to 500 hPa 0.1 hPa

-1000 to 1000 hPa 1 hPa

Protection class

IP 65

Selectable units Pa, further pressure and flow velocity

units see configuration options p. 6

Sensor Piezoresistive sensor

Autom. Zero-point

adjustment

via magnetic valve,

frequency settable: 15 sec, 30 sec,

1 min, 5 min, 10 min

Humidity

Measuring range

dependent on connected probe (see p. 10)

Measurement uncertainty dependent on connected probe (see p. 10)

Selectable units %RH, further calculated humidity

parameters see configuration options p. 6

Sensor Capacitive sensor

Temperature

dependency/coefficient

±0.02 %RH (at temperatures deviating

from 25 °C)

Measuring range

dependent on connected probe (see p.

10)

Measurement uncertainty 0.15 °C / 32.2 °F

Selectable units °C / °F

Sensor Pt 1000 1/3 Class B;

Pt 100 1/3 Class B (testo 6615)

Digital output Mini-DIN for P2A software

Ethernet Optional with Ethernet module

Temperature

Weight 1,960 kg; optional: Ethernet intermediary

layer 0.610 kg

Operating temperature (housing) -5 to 50 °C/23 to 122 °F

Storage temperature -20 to 60 °C/-4 to 140 °F

Operating conditions

Standard reference

EU guideline 2004/108/EC

Technical data testo 6381

Resolution humidity

0.1 %RH

Temperature resolution

0.01 °C / °F

Load max. 500 Ω

Quantity Standard: 1; for humidity/temperature

(optional): 3

* Measurement inaccuracy according to GUM: ±0.8% of measurement range final

value ±0.3 Pa

GUM (Guide to the Expression of Uncertainty in Measurement): ISO guideline for

the determination of measurement inaccuracy, in order to make measurement

results internationally comparable.

The following inaccuracies are used for the determination:

Hysteresis / Linearity / Reproduceability / Long-term stability / Adjustment

site/factory calibration / Test site

Page 12

8

Differential pressure transmitters for installation in normal zones

Configuration options testo 6351:

testo 6351

–

Overview of features and

benefits:

· Measurement of differential pressure, flow

velocity and volume flow

· Automatic zero-point adjustment

guarantees high, temperature-independent

accuracy and long-term stability

· Plastic housing

· Display with multi-language operating

menu and optical alarm display

· Ethernet, relay and analog outputs allow

optimum integration into individual

automation systems

· Self-monitoring of the transmitters

guarantees high system availability

· The P2A software for parameterization,

adjustment and analysis saves time and

costs in commissioning and maintenance

· Scalable measuring range by ±50 percent

of the measuring range final value, and free

scalability within the measuring range,

allow optimum adaptation to the control

requirements

Areas of application:

· Differential pressure monitoring between

cleanrooms

· Differential pressure monitoring in filling

processes

· Monitoring differential pressure, volume

flow and flow velocities in critical air

conditioning technology (VAC systems)

B02

B03

B04

B05

B06

C00

C02

C03

C04

C05

C06

C07

C08

K01

K02

K03

K04

K05

K06

K07

K08

D01

D02

D03

H00

H01

H02

F01

F02

F03

F04

F05

F06

F07

F08

F09

F10

F11

F12

F13

F14

F15

F16

0 to 1 V (4-wire, 24 VAC/DC)

0 to 5 V (4-wire, 24 VAC/DC)

0 to 10V (4-wire, 24 VAC/DC)

0 to 20 mA (4-wire, 24 VAC/DC)

4 to 20 mA (4-wire, 24 VAC/DC)

without display without operating buttons

with display, with operating buttons / English

with display, with operating buttons / German

with display, with operating buttons / French

with display, with operating buttons / Spanish

with display, with operating buttons / Italian

with display, with operating buttons / Japanese

with display, with operating buttons / Swedish

Cable input M16 (relay: M20)

Cable entry NPT 1/2“

Cable contact via M-plug connection for

signal and supply

Pa / min / max

hPa / min / max

kPa / min / max

mbar / min / max

bar / min / max

mmH

2

O / min / max

mmH

2

O / min / max

inch HG / min / max

kg/cm² / min / max

PSI / min / max

m/s / min / max

ft/min / min / max

m³/h / min / max

l/min / min / max

Nm³/h / min / max

Nl/min / min / max

without relay

4 relay outputs, limit value monitoring

4 relay outputs, channel 1 limit values and collective alarm

German/English instruction manual

French/English instruction manual

Spanish/English instruction manual

Italian/English instruction manual

Dutch/English instruction manual

Japanese/English instruction manual

Chinese/English instruction manual

Swedish/English instruction manual

Order no. 0555 6351

A01 Bxx Cxx Dxx Exx Fxx Hxx Ixx

Jxx Kxx

E00

E01

without Ethernet module

with Ethernet module

Axx Measuring range

Bxx Analog display/supply

Cxx Display

Dxx Cable input

Exx Ethernet

A02

A03

A04

A05

A07

A08

A09

A10

A11

A22

A23

A24

A25

A27

A28

A29

A30

A31

0 to 50 Pa

0 to 100 Pa

0 to 500 Pa

0 to 10 hPa

0 to 50 hPa

0 to 100 hPa

0 to 500 hPa

0 to 1000 hPa

0 to 2000 hPa

-50 to 50Pa

-100 to 100 Pa

-500 to 500 Pa

-10 to 10 hPa

-50 to 50 hPa

-100 to 100 hPa

-500 to 500 hPa

-1000 to 1000 hPa

-2000 to 2000 hPa

Scaling: ±50%

of measuring

range; freely

selectable

within

measuring

range

Fxx Differential pressure/flow velocity unit (pre-set)

Hxx Relay

Kxx IM languages (for bilingual printed IMs)

This results in a typical ordering code:

0555 6351 AXX BXX CXX DXX EXX FXX HXX IXX KXX

Page 13

9

testo 6351

testo 6351 – Differential pressure and flow velocity

Supply

Display

Differential pressure

Analog outputs

Other outputs

Housing

Miscellaneous

Display Optional: 3-line LCD with multi-language

operating menu

Parameters

Measuring range 0 to 50 Pa

0 to 100 Pa

0 to 500 Pa

0 to 10 hPa

0 to 50 hPa

0 to 100 hPa

0 to 500 hPa

0 to 1000 hPa

0 to 2000 hPa

-50 to 50 Pa

-100 to 100 Pa

-500 to 500 Pa

-10 to 10 hPa

-50 to 50 hPa

-100 to 100 hPa

-500 to 500 hPa

-1000 to 1000 hPa

-2000 to 2000 hPa

Measurement uncertainty* ±0.8% of measurement range final value

±0.3 Pa

Meas. cycle 1/sec

Resolution 12 bit

Scaling Differential pressure: scalable ±

50% of

measuring range final value;

freely scalable within measuring range

Overload capacity Measuring range Overload

0 to 50 Pa 20000 Pa

0 to 100 Pa 20000 Pa

0 to 500 Pa 20000 Pa

0 to 10 hPa 200 hPa

0 to 50 hPa 750 hPa

0 to 100 hPa 750 hPa

0 to 500 hPa 2500 hPa

0 to 1000 hPa 2500 hPa

0 to 2000 hPa 2500 hPa

-50 to 50 Pa 20000 Pa

-100 to 100 Pa 20000 Pa

-500 to 500 Pa 20000 Pa

-10 to 10 hPa 200 hPa

-50 to 50 hPa 750 hPa

-100 to 100 hPa 750 hPa

-500 to 500 hPa 2500 hPa

-1000 to 1000 hPa 2500 hPa

-2000 to 2000 hPa 2500 hPa

Inputs/outputs

Output type 0/4 to 20 mA (4-wire) (24 VAC/DC)

0 to 1/5 to 10 V (4-wire) (24 VAC/DC)

Relay Optional: 4 relays (free allocation to

measurement channels or as collective

alarm in operating menu/P2A software), up

to 250 VAC/3A (NO or NC)

Voltage supply 20 to 30 VAC/DC, 300mA current

consumption, galvanically separate

signal and supply line

General technical data

Material Plastic housing

Dimensions 162 x 122 x 77 mm

Resolution pressure Measuring range Resolution

0 to 50 Pa 0.1 Pa

0 to 100 Pa 0.1 Pa

0 to 500 Pa 0.1 Pa

0 to 10 hPa 0.01 hPa

0 to 50 hPa 0.01 hPa

0 to 100 hPa 0.1 hPa

0 to 500 hPa 0.1 hPa

0 to 1000 hPa 1 hPa

0 to 2000 hPa 1 hPa

-50 to 50 Pa 0.1 Pa

-100 to 100 Pa 0.1 Pa

-500 to 500 Pa 0.1 Pa

-10 to 10 hPa 0.01 hPa

-50 to 50 hPa 0.01 hPa

-100 to 100 hPa 0.1 hPa

-500 to 500 hPa 0.1 hPa

-1000 to 1000 hPa 1 hPa

-2000 to 2000 hPa 1 hPa

Protection class

IP 65

Selectable units Pa, further pressure and flow velocity

units see configuration options p. 8

Sensor Piezoresistive sensor

Autom. Zero-point

adjustment

via magnetic valve, frequency settable:

15 sec, 30 sec,

1 min, 5 min, 10 min

Digital output Mini-DIN for P2A software

Ethernet Optional with Ethernet module

Weight 0.7 kg; optional: Ethernet intermediary

layer: 0.6 kg

Operating temperature (housing) -5 to 50 °C/23 to 122 °F

Storage temperature -20 to 60 °C/-4 to 140 °F

Operating conditions

Standard reference

EU guideline 2004/108/EC

Load max. 500 Ω

Technical data testo 6351

Quantity 1

* Measurement inaccuracy according to GUM: ±0.8% of measurement range final

value ±0.3 Pa

GUM (Guide to the Expression of Uncertainty in Measurement):

ISO guideline for the determination of measurement inaccuracy, in order to make

measurement results internationally comparable.

The following inaccuracies are used for the determination:

– Hysteresis

– Linearity

– Reproducibility

– Long-term stability

– Adjustment site/factory calibration

– Test site

Page 14

External probes for testo 6383 and testo 6381 – probe series testo 6610

10

testo 6611* testo 6612 testo 6613 testo 6614 testo 6615 testo 6617

Type Wall

%rF; %RH; °C

tpd

/°F

tpd

; g/m³ / gr/ft³; g/kg / gr/lb; kj/kg; BTU/lb; °Ctw/°Ftw;

hPa; inch H

2O2

; ppm vol %; %vol; °Ctm(H2O2)/ °Ftm(H2O2)

Stainless steel

Sheathed, FEP

ABS plastic

Channel Cable

-30 to +150 °C,

-22 to +302 °F

see trace humidity

0 to 100 %RH

Heated cable

Trace humidity

cable (selfadjustment)

Cable with

covering electrode

monitoring

200 mm 200/500 mm200/300/500/

800 mm

Customized for

duct version

1 to 10 bar (probe tip)

1 bar (probe end)

1 to 16 bar (probe tip)

1 bar (probe end)

1 bar positive

pressure (probe tip)

1 bar (probe end)

Selectable units

0 to 100 %RH

-20 to +70 °C,

-4 to +158 °F

Measuring range

Temperature

Probe shaft

Cable

Connector

±0.15 °C / 32.2 °F (Pt 1000 1/3 Class B)

Measurement inaccuracy ** (at 25 °C / 77°F)

Indoor climate

probe wall

installation

Process humidity

probe, duct

installation

Process humidity

probe, flexible

installation with

cable

Humidity probe for

high humiidity

applications/for

danger of

condensation

Humidity probe for

trace

humidity/pressure

dewpoint (with selfadjustment)

Humidity probe with

self-monitoring for

sensor-damaging

media

Probe shaft diameter 12 mm

Probe shaft length

Cable length 1/2/5/10 m

Process pressure

1 bar positive pressure (probe tip)

120/200/300/500/

800 mm

±1 K at 0° C

td

±2K at -40° C

td

±4K at -50° C

td

-40 to +180 °C/-40 to +356 °F

-40 to +120 °C,

-40 to +248 °F

-40 to +180 °C /

-40 to +356 °F

±0.15 °C / 32.2 °F

Pt1000 1/3 Class B

±0.15 °C / 32.2 °F

Pt100 1/3 class B

Humidity

±1,0 %RH (0 to 90%); ±1.4 %RH (90 to 100%)

Measurement uncertainty** (25 °C)

0.02 %RH/K

Measurement inaccuracy (for deviations

from media temperature of ±25 °C)

Temperature

°C / °FSelectable units

better than 0.2 %RHReproduceability

Trace humidity

-60 to +30 °C

td

/

-76 to +86 °F

td

Measuring range

Measurement uncertainty

Probe

Area of use

Parameters

General technical data

Operating conditions

* Technical data also apply to the integrated humidity probe of the testo 6383.

Probe testo 6611 cannot be connected to thetesto 6383.

see trace humidity

±1.0 %RH

(0 to 100%)

±1.2 %RH (0 to 90%);

±1.6 %RH (90 to 100%)

**

DDeetteerrmmiinnaattiioonn ooff hhuummiiddiittyy mmeeaassuurreemmeenntt iinnaaccccuurraaccyy aaccccoorrddiinngg ttoo GGUUMM

GUM (Guide to the Expression of Uncertainty in Measurement):

ISO guideline for the determination of measurement inaccuracy, in order to make

measurement results internationally comparable.

The following inaccuracies are used for the determination:

– Hysteresis

– Linearity

– Reproducibility

– Long-term stability

– Adjustment site/factory calibration

– Test site

Page 15

Configuration options testo 6610

11

L11 L12 L13 L14 L15 L17

––X–––

XXXXXX

–XX–––

–XXXXX

–XX–––

Ordering procedure:

Thanks to the digital probe interface, the transmitter and the probe can be ordered separately from each other, see ordering example above.

0555 6610 Lxx Mxx

L11

L12

L13

L14

L15

L17

Probe 6611 (wall version)

Probe 6612 (duct version up to 150 °C)

Probe 6613 (cable version up to 180 °C)

Probe 6614 (heated cable version)

Probe 6614 (heated cable version)

Probe 6617 (self-monitored cable version)

M01

M02

M03

M04

M06

M07

M08

Sintered stainless steel filter

Metal wire protection cap

Sintered Teflon filter

Open metal protection cap

Teflon filter with drip hole

Teflon filter with drip hole and condensation protector

Filter for H

2O2

atmospheres*

N00

N01

N02

N05

N10

N23

without cable

Probe length 1 m

Probe length 1 m

Probe length 5 m

Probe length 10 m

Probe length, specially for duct versions

P12

P20

P30

P50

P80

Probe length 300 mm

Probe length 200 mm

Probe length 300 mm

Probe length 500 mm

Probe length 800 mm

Nxx Pxx

Ordering example testo 6613 probes

Cable probe, -40 to +180 °C

Sintered stainless steel filter

Cable length 2 m

Probe length 300 mm

씮

0555 6610 L13 / M01 / N02 / P30

specially for high humidity (testo 6614 only)

L11 L12 L13 L14 L15 L17

X–––––

––XXXX

––XXXX

––XXXX

––XXXX

–X––––

*

On H2O2processes:

Testo offers a transmitter which can also be used in hydrogen peroxide (H

2O2

) processes - e. g. in sterilization. The sensor is protected with

the help of a special probe (Code M08). In addition, the so-called „mixture dewpoint“ °C

tm

/°Ftmis issued.

Probe

connector

Probe length

Probe length

Probe

Filter

Page 16

12

Accessories for all transmitters

Mains unit (desktop instrument) 110 to 240 VAC / 24 VDC (350 mA) 0554 1748

Mains unit (top-hat rail mounting) 90 to 264 VAC / 24 VDC (2.5 A) 0554 1749

Process display testo 54-2 AC, two relay outputs (to 250 VAC / 300 VDC, 3A), mains supply 90 to 260 VAC 5400 7553

Process display testo 54-7 AC, two relay outputs (to 250 VAC / 300 VDC, 3A), mains supply 90 to 260 VAC,

with RS485 output for online monitoring and with totalizer display 5400 7555

Ethernet module for installation by the customer (for testo 6351 and testo 6381 only) 0554 6656

Ethernet plug (for testo 6351 and testo 6381 only) 0554 6653

P2A software (parameterization, adjustment, analysis) incl. USB adapter 5546020

Silicon hose ID 4 transparent 0086 0001, by the metre

Tygon hose ID 4.8 transparent 0086 0031, by the metre

Humidity adjustment set 11.3 / 75.3 %RH (for testo 6381 and testo 6383 only) 0554 0660

Adjustment and extension cable, 10 m (for testo 6381and testo 6383 only) 0554 6610

Pitot tube, length 350 mm, stainless steel (for testo 6351 and testo 6381 only) 0635 2145

Pitot tube, length 1000 mm, stainless steel (for testo 6351 and testo 6381 only) 0635 2345

Ordering data for accessories Order no.

햳

햲

Ethernet module

(Intermediary layer)

Ethernet

The Ethernet module is an

intermediary layer („sandwich“

design), which can be optionally

integrated into the transmitters

testo 6681/6351 ex-works. It can

also be subsequently easily and

quickly retrofitted on site. Two

LEDs provide the responsible

system operator with information

on the status of the voltage

supply and the LAN connection.

The cable can be used to carry

out an adjustment of a humidity

probe from the probe series testo

6610 - either on site or in a

laboratory. The cable also serves

as an extension between the

transmitter and the respective

probe.

Advantages of the adjustment

By using an industrial Ethernet

plug, IP65 housing protection can

be guaranteed, enabling the

transmitter to withstand the

sometimes rough and demanding

conditions in industrial processes.

and extension cable:

– Flexible installation and

maintenance of the humidity

probe

– Extension of the normal

humdity probe cable by 10 m

– Cable has protection class

IP65

1

Ethernet intermediary layer testo 6381/6351 for installation by customer

2

Adjustment and extension cable for external humidity probes

Page 17

13

Testo – Your partner for calibration, validation and qualification

testo SaverisTM– Simple, secure and efficient measurement data monitoring

Validation / qualification

The Testo subsidiary testo industrial services

(TIS) offers you customized validation and

qualification for pharmaceutical projects:

– DQ, IQ, OQ, PQ (qualification)

– Mapping/distribution measurements (for

optimum probe site determination)

– Customized risk analysis incorporating

GAMP5

– Documentation optionally in Testo or

customer format

More information: www.testo-industrial-services.de

Calibration:

Calibration service in laboratories and on site in

numerous countries. Contact your local Testo

subsidiary, testo industrial services or Testo’s

sales partner in your country.

Calibration and validation/qualification services

The measurement data monitoring system measures pressure, temperature and

humidity values in the environment and in processes.

find out more at: www.testo.com/saveris

In industrial processes, exact

temperatures, humidity values and

pressure relationships play a crucial

role.

In a multitude of applications, testo

Saveris helps to collect, safely store

and present these data wirelessly

(analog coupler) or via Ethernet. A

selection of alarms that can be used

flexibly supports the responsible

parties to keep the values in the

required range.

Typical applications:

•Monitoring ambient storage and

production

conditions

•Monitoring humidity values,

e. g. in air-conditioned cabinets

•Monitoring temperatures,

e. g. during heat treatment or in airconditioned cabinets

Integrate the new transmitters into testo Saveris

TM

Page 18

Testo: At your service!

Subject to change without notice.

Please ask for our more information:

Monitoring Instruments for Food Production, Transport and Storage

Measurement Engineering for Restaurants, Catering and

Supermarkets

Measurement Engineering for Air Conditioning and Ventilation

Measurement Engineering for Heating and Installation

Measurement Solutions for Emissions, Service and Thermal

Processes

Measurement Solutions for Refrigeration Technology

Stationary Measurement Solutions for Air Conditioning, Drying,

Cleanrooms and Compressed Air

Measurement Solutions for Production, Quality Control and

Maintenance

Measurement Solutions for Climate Applications in Industry

Reference Measurement Technology for Industry

Measuring Instruments for Temperature

Measuring Instruments for Humidity

Measuring Instruments for Velocity

Measuring Instruments for Pressure and Refrigeration

Multi-Function Measuring Instruments

Measuring Instruments for Flue Gas and Emissions

Measuring Instruments for RPM, Analysis, Current/Voltage

Measuring Instruments For Indoor Air Quality, Light And Sound

Stationary Measurement Technology Humidity / Differential

Pressure / Temperature / Process Displays

Stationary Measurement Technology Compressed Air Humidity /

Compressed Air Consumption

0981 6274/msp/R/Q/08.2009

Loading...

Loading...