Testo 6381 Operating Manual

testo 6381 Ethernet · differential pressure transmitter

testo 6610 · Probes

P2A software · Parameterizing, adjusting and analyzing

software

Instruction manual

2

1 Safety and the environment

Pos: 1 /TD/Überschriften/MUF/Sicherheit und Umwel t @ 3\mod_1234793958627_7 9.doc @ 26223 @ 1

1 Safety and the environment

Pos: 2 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/MUF 63xx/Elek trische Gefahren ver meiden @ 3\mod_12347946092 99_79.doc @ 26280 @ 5

Avoiding electrical hazards

> Never use the instrument and connected probes to measure on

or near live parts!

> Damaged mains cables must only be replaced by authorized

personnel.

> Only have the transmitter wired and connected by authorized

personnel with the voltage disconnected.

> You must always comply with the regulations applicable in your

Pos: 3 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/MUF 63xx/Per sonen- und Sachschäden ver meiden @ 3\mod_1234794744 768_79.doc @ 26299 @ 5

country for opening and repairing electrical equipment.

Avoiding personal injury and damage to equipment

> Installation, setting and calibration work must only be carried

out by qualified and authorized personnel!

> Only open the instrument when this is expressly described in

the instruction manual for installation, maintenance or repair

purposes.

> Observe the permissible storage, transport and operating

Pos: 4 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/Nicht mit Lös ungsmitteln lagern @ 0\ mod_1175692375179_79.d oc @ 583 @

temperature.

> Do not store the product together with solvents. Do not use any

Pos: 5 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/MUF 63xx/Bei W artung MUF nicht zur Regelun g verwenden @ 3\mod_123479 4852377_79.doc @ 26318 @

desiccants.

> Do not use the instrument for control purposes at the same time

Pos: 6 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/Produkt besti mmungsgemäß verwenden @ 0\mod_1173781261848 _79.doc @ 386 @

as operating or servicing the transmitter.

> Only operate the product properly, for its intended purpose and

within the parameters specified in the technical data. Do not

Pos: 7 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/Nur beschri ebene Wartungsarbeite n durchführen @ 0\mod_11756 92705195_79.doc @ 601 @

use any force.

> Carry out only the maintenance and repair work on this

instrument that is described in the documentation. Follow the

prescribed steps exactly. Use only original spare parts from

Pos: 8 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/MUF 63xx/Fac hpersonal @ 3\mod_12347949 40409_79.doc @ 26337 @

Testo.

Any additional work must only be carried out by authorized

personnel. Otherwise testo will not accept any responsibility for the

proper functioning of the instrument after repair and for the validity

of certifications.

3

2 About this document

Pos: 9 /TD/Überschriften/MUF/Umwelt schützen @ 3\mod_ 1234858757571_79. doc @ 26363 @ 5

Pos: 10 /TD/Sicherheit und Umwelt/Umwelt schützen/Pr odukt entsorgen @ 0\mod_ 1173780307072_79.doc @ 357 @

Protecting the environment

> At the end of its useful life, send the product to the separate

collection for electric and electronic devices (observe local

Pos: 11 /TD/Überschriften/MUF/Zu diesem Dokument @ 3\mod_ 1234793991331_79. doc @ 26242 @ 1

2 About this document

Pos: 12 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Ver wendung (Standard) @ 0\mod_1173775068554_79. doc @ 337 @ 5

regulations) or return the product to Testo for disposal.

Use

> Please read this documentation through carefully and

familiarize yourself with the product before putting it to use. Pay

particular attention to the safety instructions and warning advice

in order to prevent injuries and damage to the products.

> Keep this document to hand so that you can refer to it when

necessary.

> Hand this documentation on to any subsequent users of the

Pos: 13 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy mbole und Schreibkonven tionen/War nhinweis WARNUNG @ 2\mod_12076469662 34_79.doc @ 14398 @

Pos: 14 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy mbole und Schreibkonven tionen/War nhinweis VORSICHT @ 2\mod_1207651 416515_79.doc @ 14416 @

Pos: 15 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy mbole und Schreibkonv. Sof tware [Standard] @ 0\mod_1190203332543_79. doc @ 4883 @ 5

product.

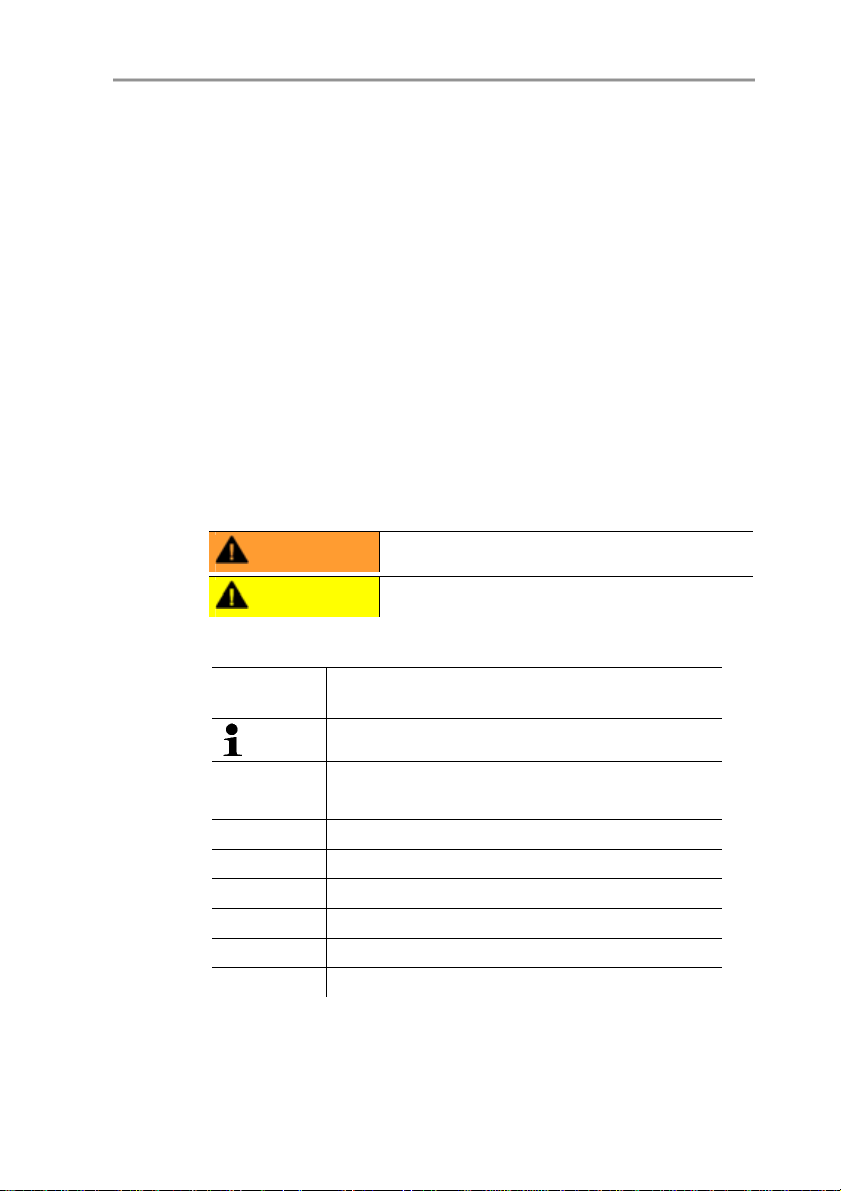

WARNING

CAUTION

Indicates potential serious injuries

indicates potential minor injuries

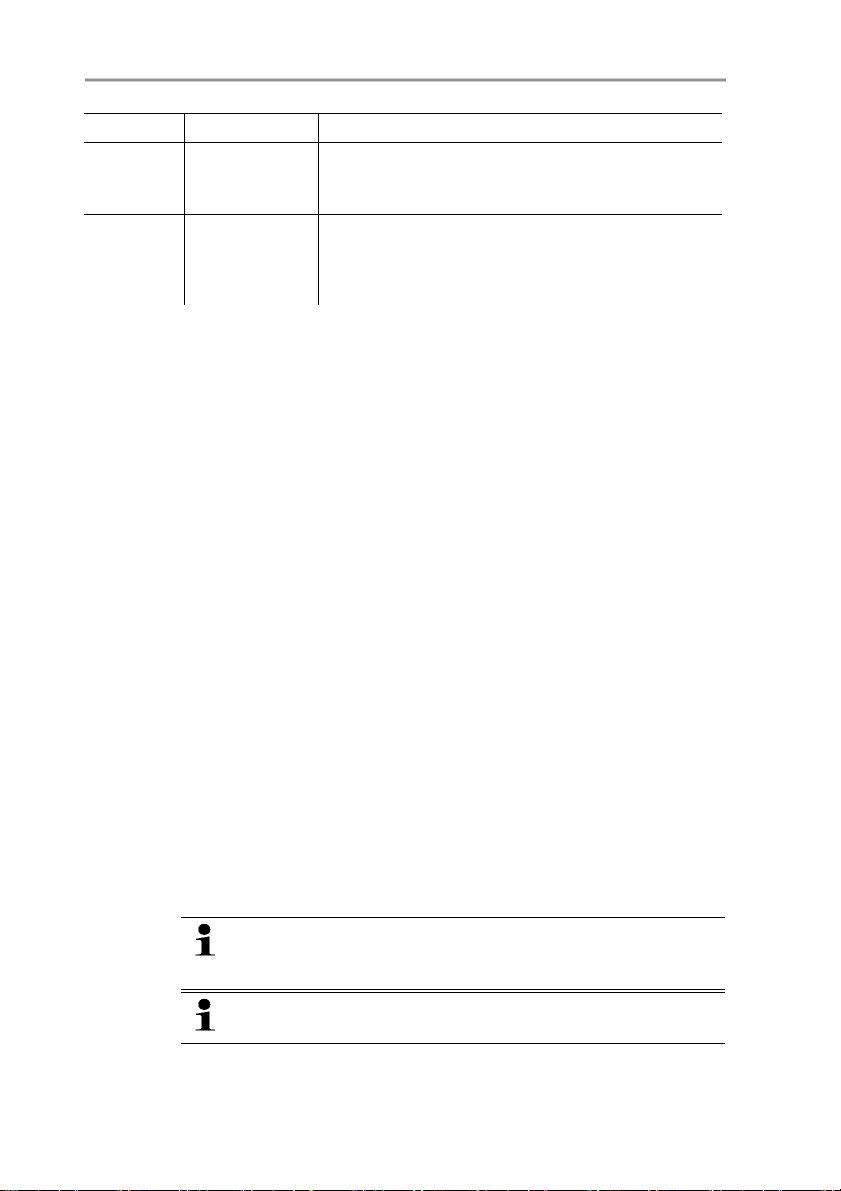

Symbols and writing standards

Representa-

Explanation

tion

Note: Basic or further information.

1. ...

2. ...

Action: more steps, the sequence must be

followed.

> ... Action: a step or an optional step.

- ... Result of an action.

Menu

[OK]

Elements of the program interface.

Buttons of the program interface.

... | ... Functions/paths within a menu.

“...” Example entries

Pos: 16 /TD/--- Seitenwechsel --- @ 0\mod_1173774430601_0.doc @ 283 @

4

3 Contents

Pos: 17 /TD/Überschriften/MUF/Inhalt @ 3\mod_123479 4019831_79.doc @ 26261 @ 1

3 Contents

1 Safety and the environment....................................................................3

2 About this document...............................................................................4

3 Contents...................................................................................................5

4 Transmitter...............................................................................................9

4.1. Specifications ..................................................................................9

4.1.1. Functions and use ...........................................................................................9

4.1.2. Scope of delivery .............................................................................................9

4.1.3. Accessories ...................................................................................................10

4.1.4. Technical data ...............................................................................................10

4.1.5. Dimensions ....................................................................................................14

4.2. Product description........................................................................15

4.2.1. At a glance..................................................................................................... 15

4.2.2. Usable probes................................................................................................ 16

4.2.3. Display and keypad........................................................................................17

4.2.4. Service interface ............................................................................................17

4.2.5. Relay board (option) ......................................................................................17

4.2.6. Analog outputs...............................................................................................18

4.2.7. Parameters ....................................................................................................18

4.2.8. Scaling 19

4.2.9. Alarm handling...............................................................................................22

4.3. Commissioning ..............................................................................23

4.3.1. Inserting Ethernet module (order no. 0554 6656)...........................................23

4.3.2. Assembling the instrument............................................................................. 25

4.3.2.1. Wall mounting (for testo 6611, 6613, 6614, 6615, 6617 probes)....... 25

4.3.2.2. Duct mounting (for testo 6612 probes).............................................. 26

4.3.3. Connecting the instrument .............................................................................27

4.3.3.1. Overview of terminals........................................................................29

4.3.3.2. Connecting voltage supply and analog outputs.................................30

4.3.3.3. Connecting the relay outputs ............................................................31

4.3.3.4. Plug-in connection option..................................................................34

4.3.3.5. Creating the PE/earthing terminal .....................................................35

4.3.3.6. Setting the Ethernet module..............................................................36

4.3.3.7. Closing the instrument ......................................................................38

4.3.4. Ethernet communication ................................................................................39

4.3.4.1. Types of operation............................................................................39

4.3.4.2. Mains connection.............................................................................. 39

4.3.4.3. LED status displays ..........................................................................40

4.3.4.4. testo 6381 as Saveris subscriber ......................................................40

4.3.4.5. Integration into customer's Ethernet system......................................41

4.3.4.6. Adjusting the instrument....................................................................51

4.3.4.7. Overview: Adjustment keys and test contacts................................... 52

5

3 Contents

4.3.4.8. 1-point adjustment (offset - humidity/temperature)............................ 53

4.3.4.9. 2-point adjustment (humidity/temperature)........................................ 55

4.3.4.10. Analog output adjustment ..........................................................57

4.3.4.11. n-point adjustment (pressure) .................................................... 58

4.3.4.12. High-humidity adjustment for testo 6614.................................... 59

4.3.4.13. Self adjustment of testo 6615 trace humidity probe....................60

4.4. Operation ...................................................................................... 62

4.4.1. Relationship between user menu and mini-DIN socket is active....................62

4.4.2. Key cover ...................................................................................................... 62

4.4.3. Password protection ......................................................................................63

4.4.4. Structure of user menu ..................................................................................63

4.4.5. Overview of the testo 6381 user menu ..........................................................65

4.4.6. The individual main menus ............................................................................68

4.4.6.1. Editing main menu of channel 1........................................................68

4.4.6.2. Editing Main Menu Channel 2 (if this option is available) ..................68

4.4.6.3. Editing Main Menu Channel 3 (if this option is available) ..................69

4.4.6.4. Editing Main Menu Alarm.................................................................. 69

4.4.6.5. Editing Main Menu Settings ..............................................................71

4.4.6.6. Editing Main Menu Analysis.............................................................. 75

4.4.6.7. Editing Message main menu.............................................................76

4.4.6.8. Calling up Main Menu Ident..............................................................78

4.4.6.9. Editing Main Menu Adjust.................................................................78

4.4.6.10. Editing Reset main menu........................................................... 81

4.5. Status, warning and error messages ............................................ 81

4.5.1. Status messages ...........................................................................................82

4.5.2. Warning messages ........................................................................................83

4.5.3. Transmitter error messages........................................................................... 85

4.5.4. Handling alarm messages .............................................................................86

4.5.5. Namur fault conditions ...................................................................................88

4.6. Maintenance and cleaning ............................................................ 89

4.6.1. Maintaining the instrument............................................................................. 89

4.6.2. Cleaning the instrument.................................................................................89

5 testo 6610 probes..................................................................................90

5.1. Specifications................................................................................90

5.1.1. Functions and use .........................................................................................90

5.1.1.1. Digital probes:................................................................................... 90

5.1.1.2. The Testo humidity sensor................................................................90

5.1.1.3. Self-diagnosis...................................................................................91

5.1.2. Design of the probe .......................................................................................92

5.1.3. Accessories ...................................................................................................92

5.2. Product description .......................................................................93

5.2.1. Overview of probe and filter types.................................................................. 93

5.2.1.1. Probe version....................................................................................93

5.2.1.2. Determining the accuracy/measuring uncertainty .............................93

5.2.1.3. Ordering options for testo 6610 probe (0555 6610)...........................94

5.2.1.4. Protection caps................................................................................. 96

6

3 Contents

5.2.2. testo 6611 wall probe..................................................................................... 96

5.2.3. testo 6612 duct probe ....................................................................................99

5.2.4. testo 6613 cable probe ................................................................................103

5.2.5. testo 6614 heated cable probe.....................................................................106

5.2.6. testo 6617 cable probe (self-monitoring)...................................................... 113

5.2.6.1. Self-monitoring of cover electrode...................................................114

5.3. Commissioning ............................................................................117

5.3.1. Installing the probe ......................................................................................117

5.3.1.1. Installing the testo 6611 wall probe................................................. 117

5.3.1.2. 2.3.1.2 Installing the testo 6612 duct probe..................................... 117

5.3.1.3. 2.3.1.3 Installing testo 6613/6614/6615/6617 probes...................... 117

5.3.2. Connecting/removing the probe to/from the transmitter................................122

5.4. Maintenance and cleaning...........................................................122

5.4.1. Replacing filters/protection caps ..................................................................122

5.4.1.1. Replacing the filter/protection caps for testo 6611 wall version.......122

5.4.1.2. Replacing the filter/protection cap for testo 6612 duct version ........123

5.4.1.3. Replacing the filter/protection cap for duct versions........................ 124

5.4.2. Cleaning the instrument and filter/protection cap .........................................124

5.4.3. Replacing the sensor ...................................................................................124

6 Parameterizing, adjusting and analyzing software (P2A software).125

6.1. Specifications ..............................................................................125

6.1.1. Functions and use .......................................................................................125

6.1.2. System requirements...................................................................................126

6.1.3. Scope of delivery .........................................................................................126

6.2. First steps....................................................................................127

6.2.1. Installing the software/driver ........................................................................127

6.2.1.1. Installing P2A software....................................................................127

6.2.1.2. Installing USB driver .......................................................................127

6.2.1.3. P2A software upgrade ....................................................................127

6.2.2. Starting the software....................................................................................127

6.2.2.1. Starting the program.......................................................................127

6.2.2.2. Establishing a connection with the instrument.................................127

6.2.2.3. Activating the connection with the instrument..................................128

6.3. Using the software.......................................................................128

6.3.1. User interface ..............................................................................................128

6.3.2. Editing instrument/parameter file .................................................................131

6.3.2.1. Changing instrument/parameter file................................................131

6.3.2.2. Creating a new instrument file.........................................................140

6.3.2.3. Saving parameters..........................................................................140

6.3.2.4. Opening the parameter file..............................................................141

6.3.2.5. Copying and pasting parameters ....................................................141

6.3.2.6. Deleting instrument/parameter file ..................................................142

6.3.3. Analyzing/testing the transmitter ..................................................................142

6.3.3.1. Analyzing/testing the instrument .....................................................142

6.3.3.2. Carrying out factory reset................................................................ 143

6.3.3.3. Testing analog output .....................................................................143

7

3 Contents

6.3.3.4. Testing switch output relays 1 to 4.................................................. 145

6.3.3.5. Displaying min./max. values............................................................146

6.3.4. Adjusting the transmitter ..............................................................................149

6.3.4.1. 1-point adjustment ..........................................................................149

6.3.4.2. 2-point adjustment ..........................................................................151

6.3.4.3. n-point adjustment ..........................................................................152

6.3.4.4. Adjusting the analog output ............................................................153

6.3.5. Transmitter history.......................................................................................154

7 Tips and assistance............................................................................159

7.1. Questions and answers .............................................................. 159

7.2. Accessories and spare parts....................................................... 159

7.2.1. Ordering options for 6381 transmitter (0555 6381) ......................................162

7.2.2. Ordering options for testo 6610 probes (0555 6610)....................................166

Pos: 18 /TD/--- Seitenwechsel --- @ 0\mod_1173774430601_0.doc @ 283 @

8

Pos: 19 /TD/Überschriften/MUF/1 Messumformer @ 3\ mod_1234258401060_79.doc @ 23894 @ 1

4 Transmitter

Pos: 20 /TD/Überschriften/MUF/1.1/2.1/3.1 Leis tungsbeschreibung @ 3\ mod_1234258595211_79. doc @ 23951 @ 2

4.1. Specifications

Pos: 21 /TD/Leistungsbeschreibung/Verwendung/ MUF63xx/MUF 638x Ethernet @ 3\ mod_1234443770405_79. doc @ 25020 @ 3

4.1.1. Functions and use

The testo 6381 transmitter with Ethernet module is used together

with the plug-in, adjusted probes from the testo 6610 family.

Please refer to volume 2, testo 6610 probes, page 90 for

information about commissioning, operating and maintaining the

testo 6610 probe.

The testo 6381 transmitter is suitable for the following applications

with Ethernet networking, amongst others:

• Clean rooms

• Test benches

• Drying processes

• Filling processes

• Painting systems

• Monitoring flow velocities or volumetric flow rates in air

conditioning systems

In addition to the signal transmission of the readings to a control

unit via analog outputs, the measurement data can simultaneously

be recorded, documented and visualized via Ethernet.

Furthermore, it is possible to issue an alarm for those responsible

Pos: 22 /TD/Leistungsbeschreibung/Lieferu mfang/MUF 63xx/MUF 63xx Ether net @ 3\mod_12344473084 72_79.doc @ 25117 @ 3

for the process, if necessary.

4 Transmitter

4.1.2. Scope of delivery

The scope of delivery of the testo 6381 transmitter includes the

following:

• Key cover

• Rear panel bracket

• Ethernet module

• Instruction manual

• Calibration report

• CD-ROM with operating instructions (PDF), configuration files

for Ethernet module and P2A update (this can only be used in

conjunction with the P2A software, which has to be ordered

separately).

9

4 Transmitter

Pos: 23 /TD/Leistungsbeschreibung/Lieferu mfang/MUF 63xx/Zubehör Übersicht 638x @ 3\mod_123444 8071530_79.doc @ 25136 @ 3

4.1.3. Accessories

The following accessories are available for the testo 6381

transmitter, amongst others:

• Protection caps for probes

• Mains unit

• P2A software (parameterizing, adjusting and analyzing

software)

• Assembly accessories

Information about accessories and their order numbers can

be found in volume 2, Accessories and spare parts or on

Pos: 24 /TD/Leistungsbeschreibung/Technische Dat en/MUF 63xx/MUF 638 x Ethernet @ 3\mod_12344482961 23_79.doc @ 25156 @ 35555555 55555555555555555

the website at www.testo.com.

4.1.4. Technical data

Parameters

• Differential pressure

• Humidity (various variables and units)

• Temperature (°C/°F)

Differential pressure accuracy

The specifications are only valid if the positive pressure is

applied at the positive pressure connection.

• 0.5 % of measuring range, additional 0.3 Pa intrinsic error 1

• T

K slope drift

= 0.03 % of measuring range per degree Kelvin of

deviation from nominal temperature 22 °C

• T

K zeroing drift

= 0 %, as zeroing with solenoid valve2

1

Measuring uncertainty in accordance with GUM: ±0.8 % of measuring range

final value ±0.3 Pa.

GUM (Guide to the Expression of Uncertainty in Measurement): ISO guideline for determining the

measuring uncertainty in order to render global measurement results comparable.

The following uncertainties are used during the inquiry:

• Hysteresis

• Linearity

• Reproducibility

• Adjustment area/factory calibration

• Test location

10

4 Transmitter

Humidity and temperature accuracy

• Depends on probe

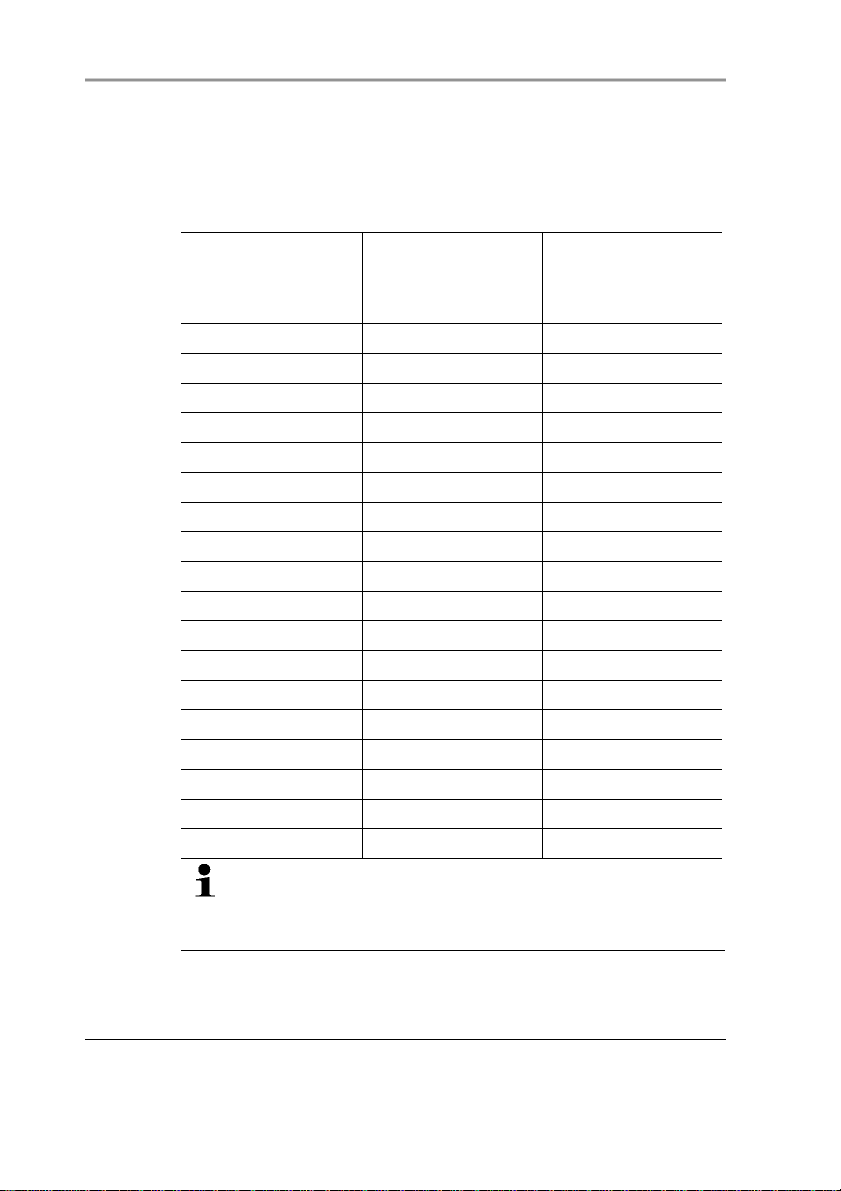

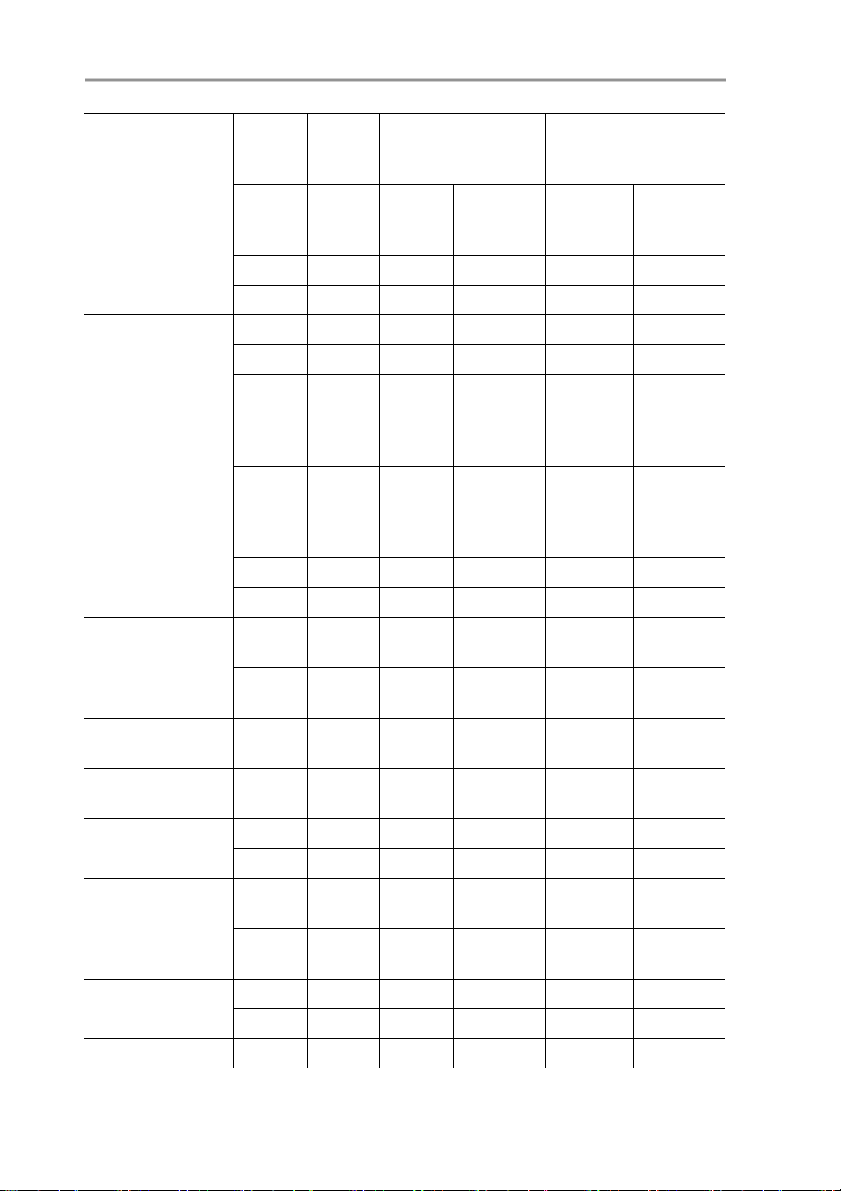

Pressure measuring range, resolution and overload of

differential pressure

Pressure

Resolution Overload

measuring range

depending on

version ordered

0 to 50 Pa 0.1 Pa 20,000 Pa

0 to 50 Pa 0.1 Pa 20,000 Pa

0 to 100 Pa 0.1 Pa 20,000 Pa

0 to 500 Pa 0.1 Pa 20,000 Pa

0 to 10 hPa 0.01 hPa 200 hPa

0 to 50 hPa 0.01 hPa 750 hPa

0 to 100 hPa 0.1 hPa 750 hPa

0 to 500 hPa 0.1 hPa 2500 hPa

0 to 1000 hPa 1 hPa 2500 hPa

-10 to 10 Pa 0.1 Pa 20,000 Pa

-50 to 50 Pa 0.1 Pa 20,000 Pa

-100 to 100 Pa 0.1 Pa 20,000 Pa

-500 to 500 Pa 0.1 Pa 20,000 Pa

-10 to 10 hPa 0.01 hPa 200 hPa

-50 to 50 hPa 0.01 hPa 750 hPa

-100 to 100 hPa 0.1 hPa 750 hPa

-500 to 500 hPa 0.1 hPa 2500 hPa

-1000 to 1000 hPa 1 hPa 2500 hPa

Upon delivery and following a factory reset the readings are

shown in the display in the unit that was ordered via the

KMAT option Fxx, see Ordering options for 6381 transmitter

(0555 6381), page 162.

Humidity and temperature measuring range

• Depends on probe

2

Minor mixtures of the media may occur at the positive and negative pressure

side due to the automatic zeroing cycle.

11

4 Transmitter

Humidity and temperature resolution

• 0.1 % RH or 0.01 °C/0.01 °F

Meas. cycle

• 1/sec

Interface

• Mini-DIN for P2A software (parameterizing and adjusting

software) and handheld testo 400/650

Voltage supply

• 4-wire (separate signal and supply lines): 20 to 30 V AC/DC,

300 mA power consumption

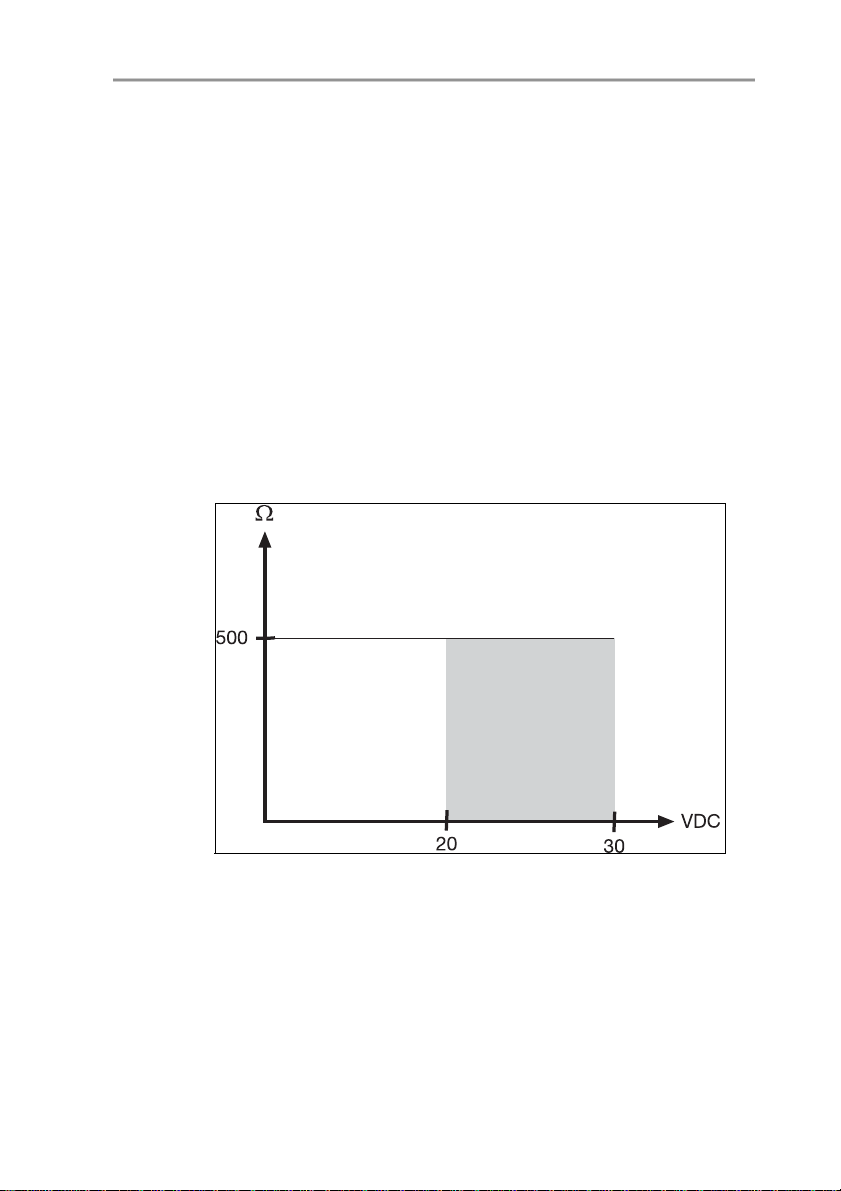

Maximum load

• 4-wire: 500 Ω (power output)

12

Maximal load

• 4-wire: 10 kΩ (voltage output)

Analog output

• 0 to 1 V ± 1.5 mV (4-wire) or

• 0 to 5 V ± 7.5 mV (4-wire) or

• 0 to 10 V ± 15 mV (4-wire) or

• 0 to 20 mA ± 0.03 mA (4-wire) or

• 4 to 20 mA ± 0.03 mA (4-wire)

Resolution of analog output

• 12 bit

Relay

• 4 relays, 250 V AC/DC, 3 A (optional)

Display

• 2-line LCD with plain text line (optional)

Operating temperature

• -5 to 50 °C/23 to 122 °F

Storage temperature

• -20 to 60 °C/-4 to +140 °F

Process temperature

• -20 to 65 °C/-4 to 149 °F

Oper. humidity

• 0 to 90 % RH

4 Transmitter

Housing, weight

• Metal: 1.960 kg

• Ethernet module: 0.610 kg

Protection class

• IP 65 only if the transmitter is wired properly (closed cable

entries), Ethernet connector, Harting PushPull connector and

humidity probe are inserted and/or sealing plugs are inserted.

Directives, standards and tests

• EC Directive: 2004/108/EC

• DIN 14644-4

• EN 61000-6-2 interference immunity

• EN 61000-6-3 interference emission

• EN 61326-1+A1+A2

13

4 Transmitter

Ethernet module

• Interface:

◦ 1 x mini-DIN

◦ 1 x RJ45 (Ethernet 10 BaseT/100 BaseTX)

• LED:

2 x green

Warranty

• Duration: 2 years

Pos: 25 /TD/Leistungsbeschreibung/Technische Dat en/MUF 63xx/MUF 63xx Ab messungen @ 3\mod_123445067 1494_79.doc @ 25194 @ 3

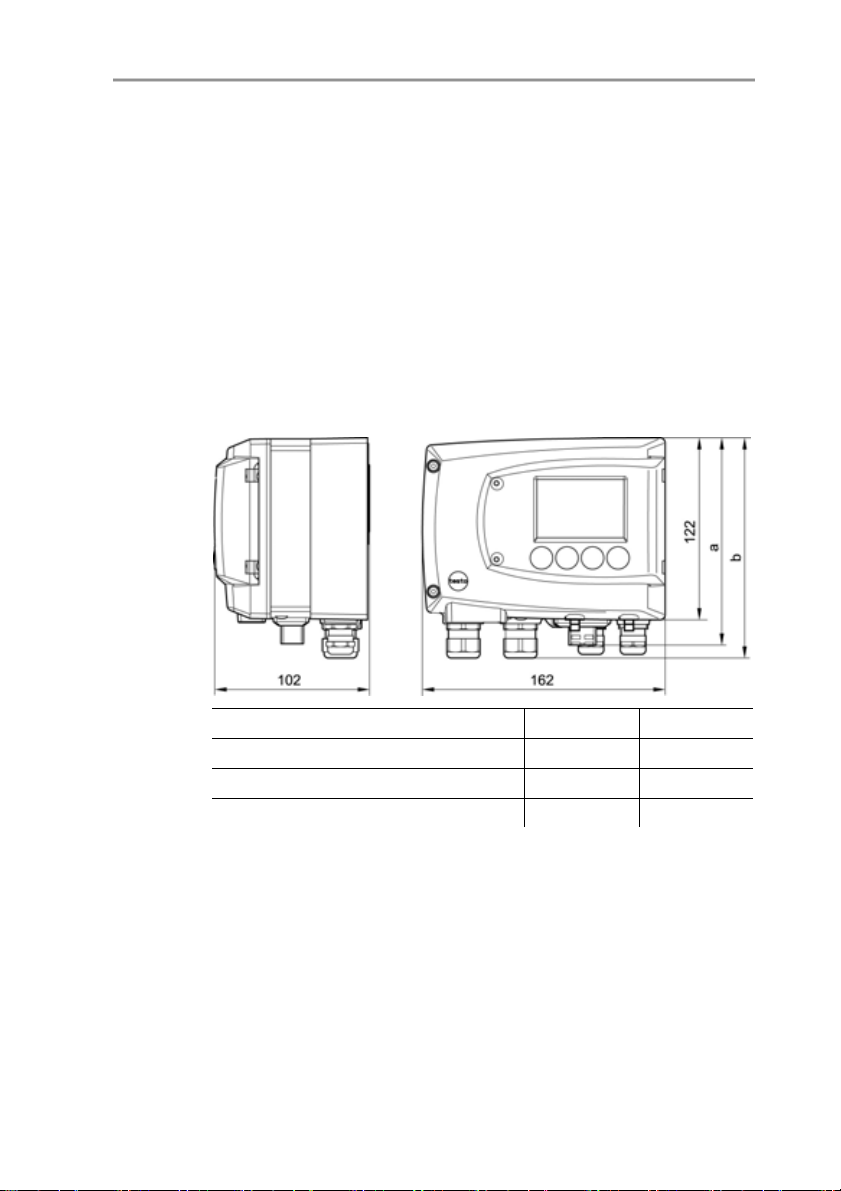

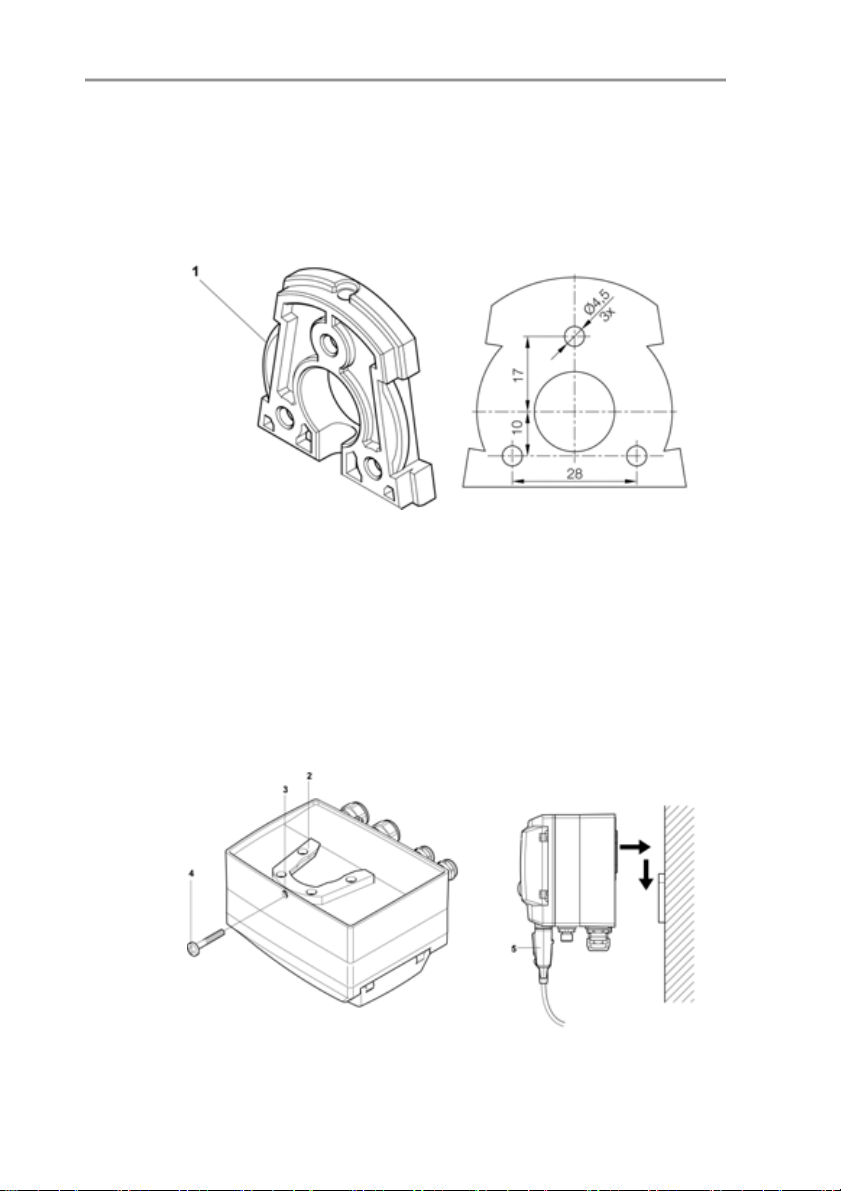

4.1.5. Dimensions

• Warranty conditions: see website www.testo.com/warranty

Pos: 26 /TD/Überschriften/MUF/1.2/2.2 Produktb eschreibung @ 3\mod_12342 58723551_79.doc @ 24008 @ 2

14

Dimensions in mm a b

with M20 cable couplings 144 147

With NPT cable coupling 144 144

With M plug-in connection 143

4.2. Product description

Pos: 27 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Auf einen Blick MUF 638 x Ethernet @ 3\mod_1234772 621147_79.doc @ 25612 @ 3

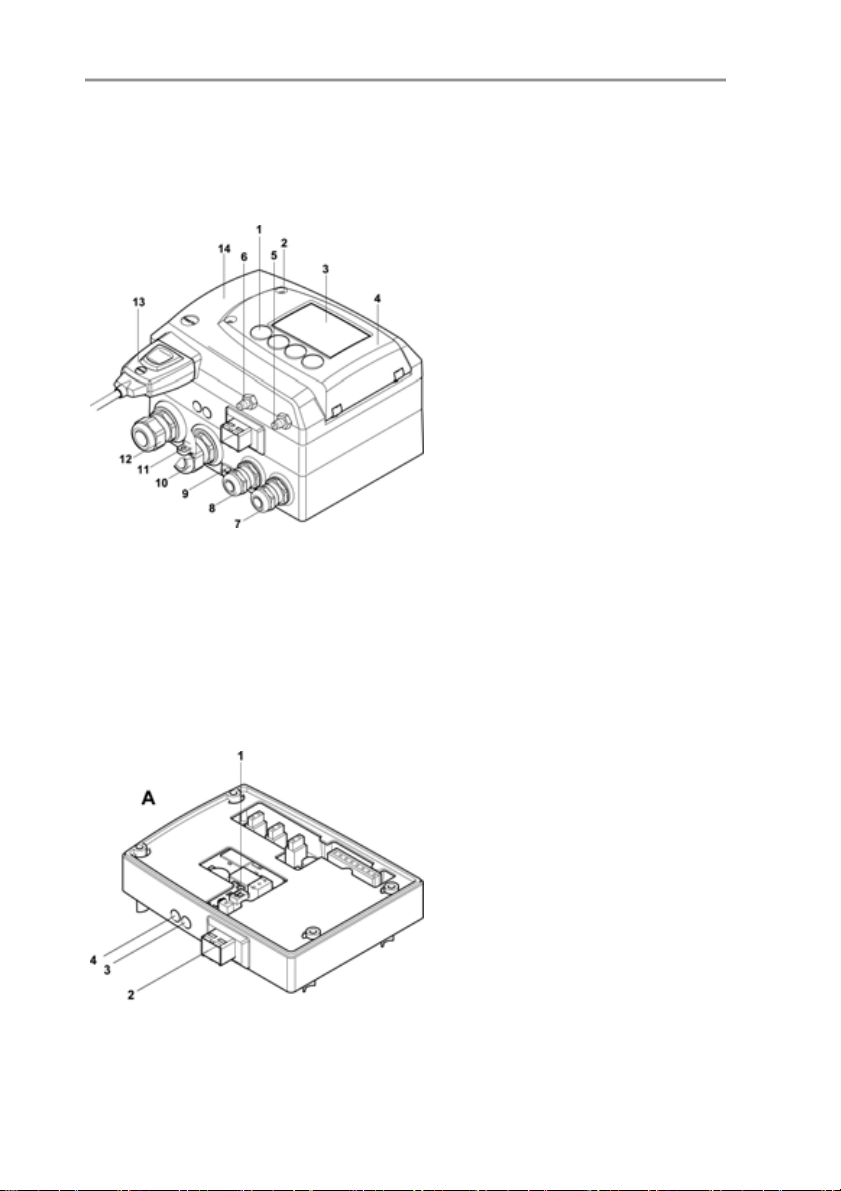

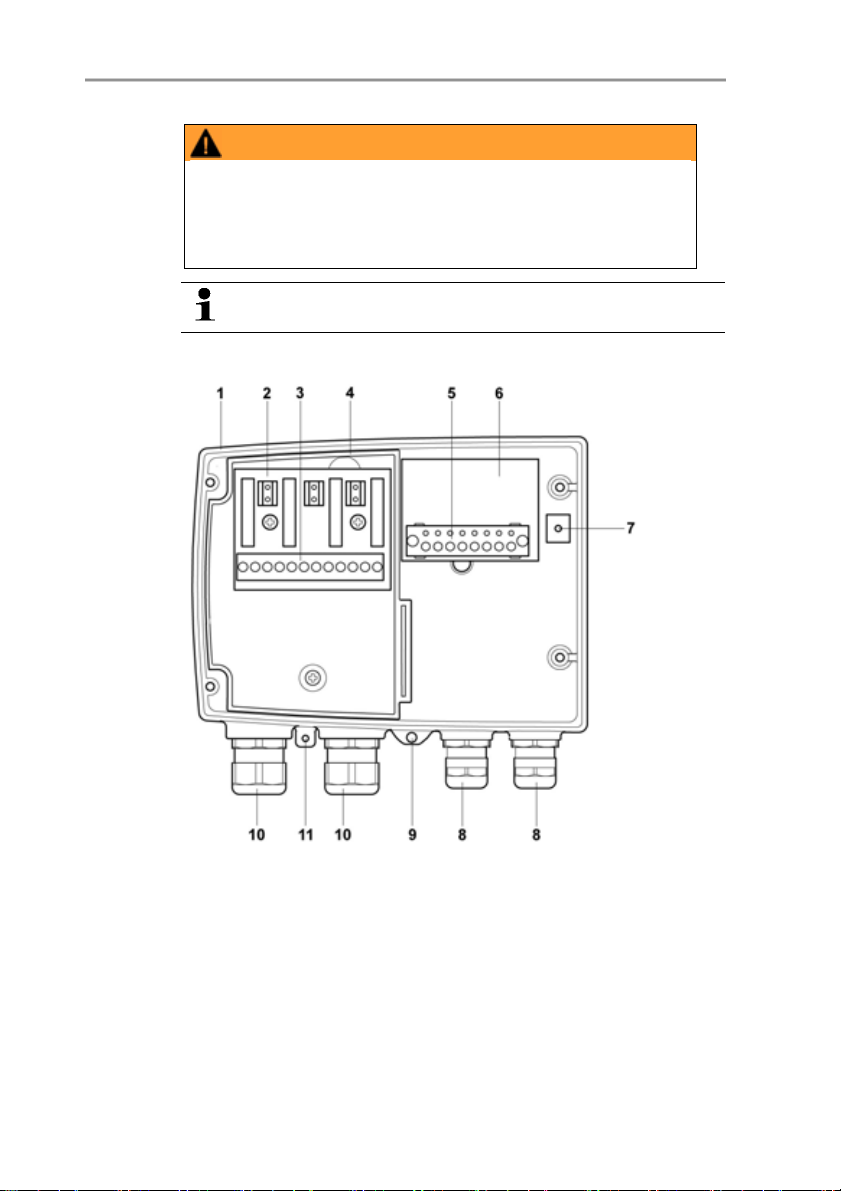

4.2.1. At a glance

1 Keys (only with optional display)

2 Service flap screw connection

(self-locking, 2 pcs.)

3 Display (optional)

4 Service flap

5 Negative pressure connection

6 Positive pressure connection,

marked with a red washer

7 M 16 x 1.5 screw connection*,

e.g. analog outputs

8 M 16 x 1.5 screw connection*,

e.g. voltage supply

9 Earthing/PE connection

10 M 20 x 1.5 screw connection*,

e.g. R3 and R4 relays

11 Eyelet for measuring point panel

12 M 20 x 1.5 screw connection*,

e.g. R1 and R2 relays

13 Probe connector (testo 6610)

14 Upper part of housing

* Alternatively, NPT cable

couplings or M plug-in

connections are available

A Ethernet module

1 DIP switch

2 Ethernet port

3 LED: LAN connection status

4 LED: Supply

4 Transmitter

15

4 Transmitter

Pos: 28 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Verwendbare Füh ler 638x @ 3\mod_1234773201901 _79.doc @ 25631 @ 3

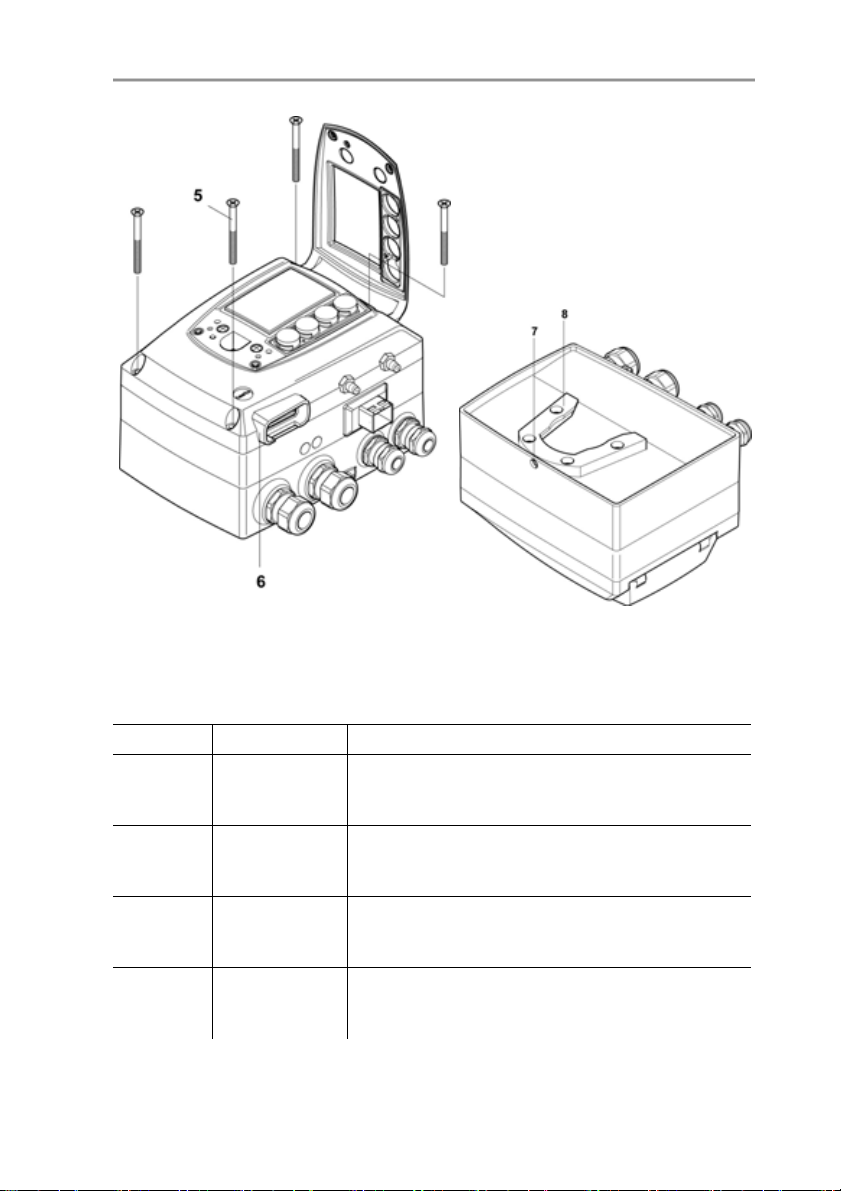

5 Housing screws

6 Socket for probe connector

7 Hole for fastening to rear panel

bracket (M3 x 6 screw)

8 Plastic bracket for assembly on

rear panel

4.2.2. Usable probes

Probes Article no. Characteristic

testo 6611 0555 6610-L11

testo 6612 0555 6610-L12

testo 6613 0555 6610-L13

testo 6614 0555 6610-L14

16

The testo 6381 transmitter can be used with the following probes:

Wall probe version; accuracy to ±1 % RH;

temperature range -20 to +70 °C/-4 to +158 °F,

sensor plugged in

Duct probe version; accuracy to ±1 % RH;

temperature range -30 to +150 °C/

-22 to +302 °F, sensor soldered

Cable probe version; accuracy to ±1 % RH;

temperature range -40 to +180 °C/

-40 to +356 °F, sensor soldered

Heated cable probe version; accuracy to ±1.0 %

RH; temperature range -40 to +180 °C/

-40 to +356 °F, sensor soldered

Probes Article no. Characteristic

testo 6615 0555 6610-L15

Trace humidity cable probe version; accuracy

±1 K at 0 °Ctd/+32 °Ftd; temperature range

-40 to 120 °C/-40 to +248 °F, sensor soldered

testo 6617 0555 6610-L17

Cable with cover electrode monitoring probe

version; accuracy to ± 1.2 % RH; temperature

range -40 to 180 °C/

-40 to +356 °F, sensor soldered

Pos: 29 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Display und Tastat ur @ 3\mod_1234773965059 _79.doc @ 25650 @ 3

4.2.3. Display and keypad

The display option allows operation of the testo 6381 transmitter via

the display and four keys.

The LCD display consists of two 7-segment lines for displaying

readings and units and of an information line (for status messages,

for example).

The brightness and contrast of the display and the background

lighting (permanent or off) can be changed via the user menu or the

Pos: 30 /TD/Überschriften/MUF/1.2.x Servicesc hnittstelle @ 3\mod_1237 306891654_79.doc @ 29795 @ 3

4.2.4. Service interface

Pos: 31 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Serviceschni ttstelle 638x @ 3\mod_123 4774092911_79.doc @ 25669 @

Pos: 32 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Relaisplati ne (Option) @ 3\mod_1234774 184843_79.doc @ 25688 @ 3

P2A software.

The parameterizing socket (mini-DIN) is located behind the service

flap as an interface to the P2A software or Testo handheld

instrument (testo 400/testo 650).

4 Transmitter

4.2.5. Relay board (option)

This has a floating switch capacity of 250 V AC/3 A. The switching

limits and hysteresis as well as the function as relay for the

collective alarm can be set via the display or the P2A software.

Further features include:

• Function of changeover contacts (NC/NO contacts) freely

selectable

17

• 12 terminals for a total of 4 relays.

If no relays are available, settings for monitoring limit values

or alarms can still be controlled via the display. The alarm

status will be shown on the display.

Only have the transmitter wired and connected by

authorized personnel with the voltage disconnected.

4 Transmitter

Pos: 33 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Analogausgänge 6 38x @ 3\mod_1234774341528 _79.doc @ 25707 @ 3

4.2.6. Analog outputs

As analog outputs, the testo 6381 has either

• 1 or optionally 3 current outputs of 0 to 20 mA (4-wire)/4 to

20 mA (4-wire) or

• 1 or optionally 3 voltage outputs of 0 to 1 V/0 to 5 V/0 to 10 V

(4-wire).

The transmitter can be ordered with three analog outputs as an

option.

Pos: 34 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Messgrößen 638x @ 4\ mod_1248354361572_79. doc @ 46349 @ 3

The optional three channels are galvanically isolated.

4.2.7. Parameters

The following parameters are displayed

• Differential pressure in Pa, hPa, kPa, mbar, bar, mmH

2

, PSI, inch HG, inch H2O

kg/cm

• Volumetric flow rate3 in m3/h, l/min, Nm3/h, Nl/min

• Flow

4

in m/s, ft/min

• Relative humidity in % RH (technical)

• Relative humidity in % WMO* (calculation according to the

WMO standard)

• Degree of humidity in g/kg and gr/lb

• Absolute humidity in g/m³ and gr/ft³

• Water content in ppm (vol) and % vol

• Psychrometer temperature in °C

and °Ftw

tw

• Enthalpy in kJ/kg and BTU/lb

• Water vapour partial pressure in hPa and H

• Dewpoint temperature in °C

• Standardized dewpoint in °C

and °Ftd

td

standardized at atmospheric

tdA ,

O

2

pressure (1013 hPa); precondition: Absolute process pressure.

* It is possible that condensation appears as of a displayed

humidity starting from 70 % and is shown on the display. This

unit is used in meteorology, amongst others. When calculating

3

Calculated

4

To prevent fluctuating flow rate values at the zero point (depressurized), the

flow rate values are only calculated as of differential pressures > 0.2 Pa or

> 0.1 % of the respective measuring range (whichever is the greater). With

smaller differential pressures, the flow rate value remains at 0.00 m/s.

2

O,

18

the relative humidity the Magnus coefficient with undercooled

water is used in accordance with WMO.

Calculated humidity variables correspond to the medium of

air. With other gases/gas compositions, deviations may

occur, e.g. with the enthalpy.

• Dewpoint of H2O2 mixture in °Ctm and °Ftm

Pos: 35 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Skalierung @ 3\mo d_1234775406989_79.doc @ 25783 @ 3

• Temperature °C and °F

4.2.8. Scaling

There are three types of min./max. values:

1 The measuring range: The maximum sensor performance is in

this range. Values outside of the measuring range are displayed

via messages, for example. Measuring range, see table

(below).

2 Standard scaling: The output signals are assigned to this

measuring range as standard:

◦ during delivery if no entries are made in the order code

◦ after exchanging the unit, the measuring range recorded in

Pos: 36 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Tabelle Skalier ung MUF 638x @ 3\mod_1236343950 039_79.doc @ 27502 @

the instrument is applied as standard.

The transmitter even retains its scaling with the voltage

disconnected.

Measuring range, see table (below).

3 The maximum settings for the manual scaling

◦ The maximum limits can be calculated as follows:

X = difference between MIN. and MAX. value of the

standard scaling

(Max. value of standard) + (50 % of X)

(Min. value of standard) - (50 % of X)

◦ It is thus possible to scale beyond the measuring range, e.g.

for the adjustment of the scaling limits to standard values of

a PLC.

With the alarm definition, however, the physical measuring

range limits are decisive.

4 Transmitter

19

4 Transmitter

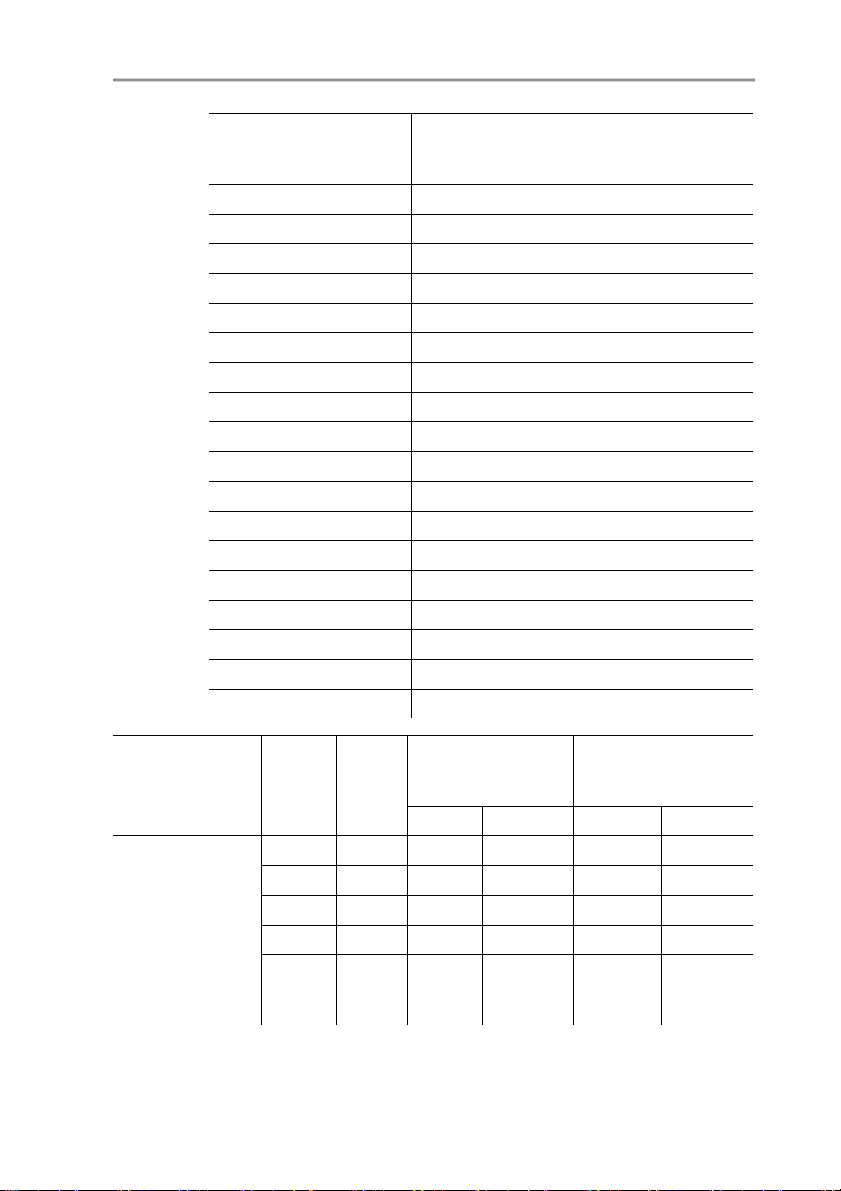

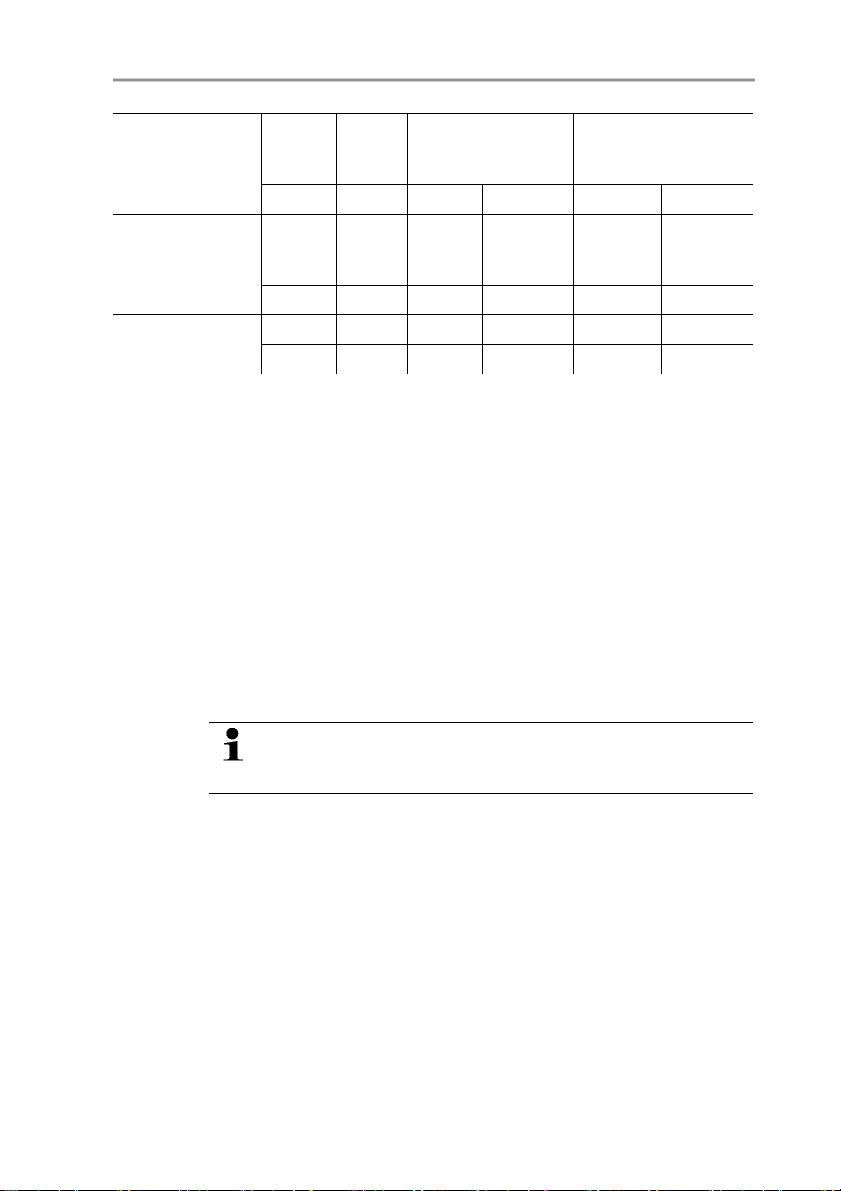

Measuring

range/standard

scaling

0 to 50 Pa -5 to 15 Pa

0 to 50 Pa -25 to 75 Pa

0 to 100 Pa -50 to 150 Pa

0 to 500 Pa -250 to 750 Pa

0 to 10 hPa -5 to 15 hPa

0 to 50 hPa -25 to 75 hPa

0 to 100 hPa -50 to 150 hPa

0 to 500 hPa -250 to 750 hPa

0 to 1000 hPa 500 to 1500 hPa

-10 to 10 Pa -20 to 20 Pa

-50 to 50 Pa -100 to 100 Pa

-100 to 100 Pa -200 to 200 Pa

-500 to 500 Pa -1000 to 1000 Pa

-10 to 10 hPa -20 to 20 hPa

-50 to 50 hPa -100 to 100 hPa

-100 to 100 hPa -200 to 200 hPa

-500 to 500 hPa -1000 to 1000 hPa

-1000 to 1000 hPa -2000 to 2000 hPa

Pos: 37 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Tabelle Skalier ung Fühler 638x @ 3\mod_123477 5771238_79.doc @ 25802 @

Parameter Unit Probes

Temperature

°C 6611 -20 +70 -20 +70

°F 6611 -4 +158 -4 +158

°C 6612 -30 +150 -30 +150

°F 6612 -22 +302 -22 +302

°C

6613,

6614,

6617

Maximum scaling

Physical

measuring range

at 1013 hPa

Standard scaling of

transmitter

measuring range

MIN MAX MIN MAX

-40 +180 -40 +180

20

4 Transmitter

°F

°C 6615 -40 +120 -40 +120

°F 6615 -40 +248 -40 +248

Dewpoint

°Ctd 6611 -20 +70 -80 +100

°Ftd 6611 -4 +158 -112 +212

°Ctd

°Ftd

°Ctd 6615 -60 +30 -80 +100

6615 -76 +86 -112 +212

°F

td

Absolute

g/m3

humidity

3

gr/ft

relative humidity % RH

WMO relative

% RH 0 100 0 100

humidity

Mixture dewpoint

(H

)

2O2

Degree of

°Ctm -20 +100 -20 +100

°Ftm -4 +212 -4 +212

g/kg

humidity

gr/lb

kJ/kg -40 99999 -40 8000 Enthalpy

BTU/lb -18 43000 -18 3500

Psychrometer

-40 100 -40 180

°C

tw

6613,

6614,

6617

6612,

6613,

6614,

6617

6612,

6613,

6614,

6617

all

probes

all

probes

all

probes

all

probes

all

probes

Physical

measuring range

at 1013 hPa

Standard scaling of

transmitter

measuring range

-40 +356 -40 +356

-20 +100 -80 +100

-4 +212 -112 +212

0 600 0 2000

0 250 0 800

0 100 0 100

0 13300 0 9500

0 93000 0 66500

21

4 Transmitter

temperature

Water content

-58 210 -40 356

°F

tw

ppm

0 99999 0 99999

(vol)

H2O

% vol 0 100 0 100

Water vapour

partial pressure

Pos: 38 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Alarmbehandlu ng @ 3\mod_1234776787635 _79.doc @ 25821 @ 3

hPa 0 1000 0 7000

inchH

O 0 400 0 2800

2

4.2.9. Alarm handling

For upper and lower alarm limits, individual alarms as well as

collective alarms can be specified. If the collective alarm function is

activated, an alarm is triggered as soon as the alarm limit of an

alarm is exceeded, if this alarm is assigned to the collective alarm.

The testo 6381 monitors limit values with the help of relays. If a

reading is outside the limit values, a relay to be specified by the

user is switched.

If the reading reverts to more than a specified hysteresis below or

above the limit value, the alarm is cancelled.

In addition, information about the occurrence of error/status

messages can be provided by means of a collective alarm relay,

Pos: 39 /TD/Überschriften/MUF/1.3/2.3 Inbetri ebnahme @ 3\mod_123425880576 8_79.doc @ 24027 @ 2

see Status, warning and error messages, page 81

If multiple alarm messages are activated at the same time,

the last alarm is shown. If the alarm is cancelled again, the

previous messages are no longer shown.

Physical

measuring range

at 1013 hPa

Standard scaling of

transmitter

measuring range

22

4 Transmitter

4.3. Commissioning

Pos: 40 /TD/Erste Schritte/MUF 63xx/Ethernet-spe zifisch/Ethernet modul einsetzen 638x @ 3\m od_1234874603926_79.d oc @ 26424 @ 3

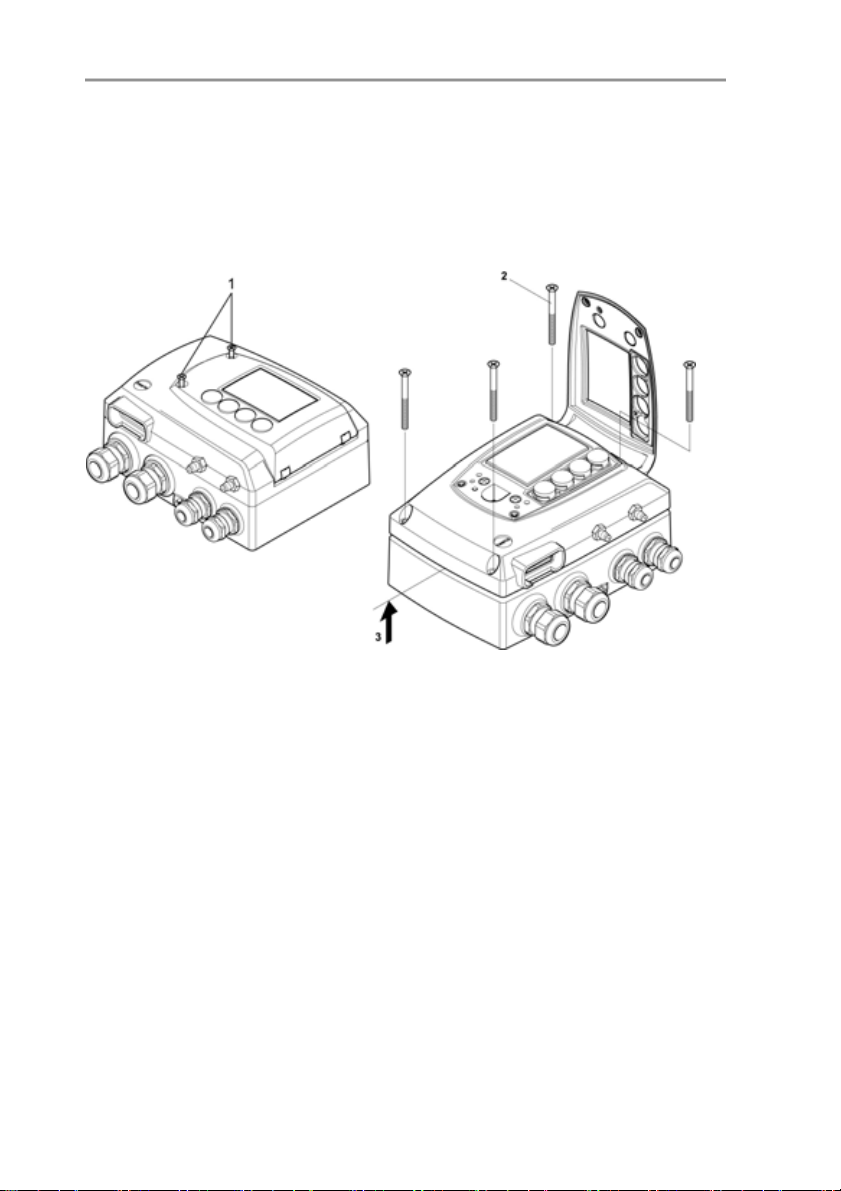

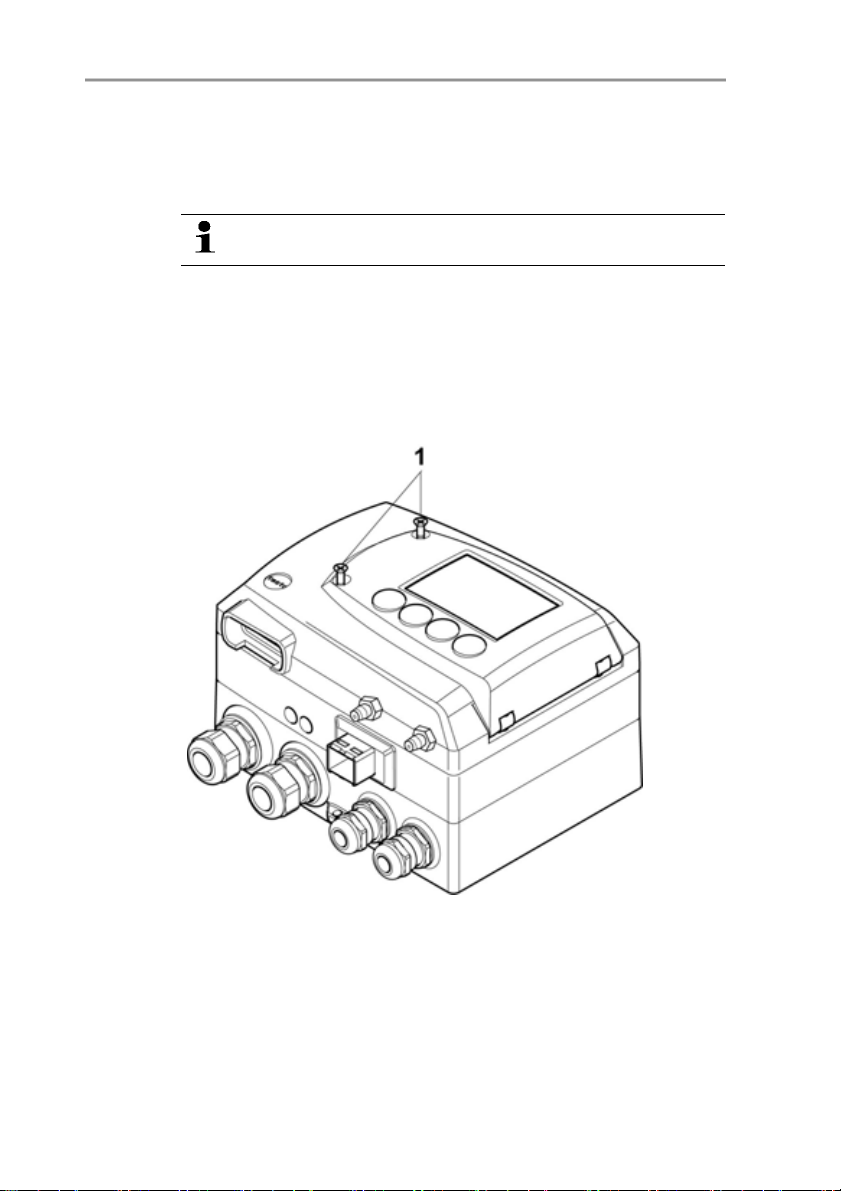

4.3.1. Inserting Ethernet module (order no. 0554 6656)

The Ethernet module can be ordered retroactively as an accessory.

It can easily be installed in the testo 6381 transmitter.

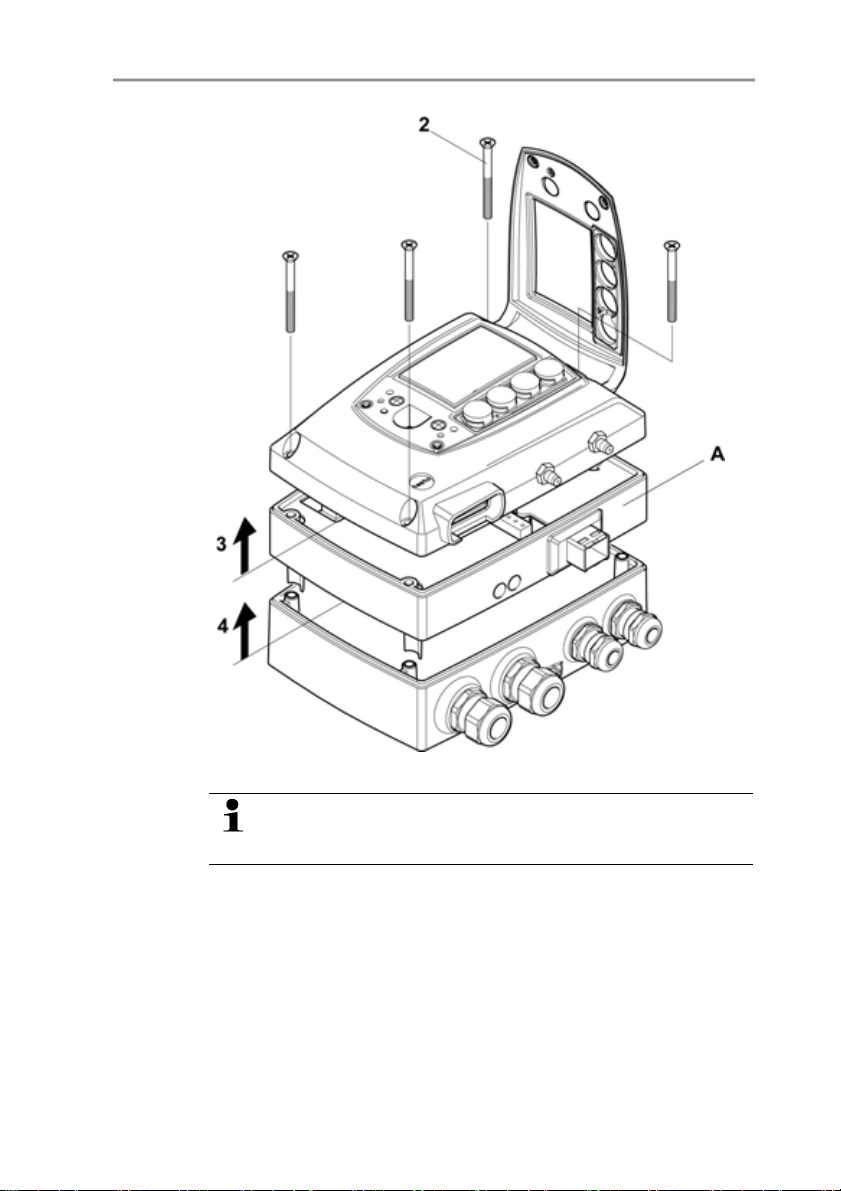

✓ The probe connector must be disconnected.

1. Loosen screw connection (1) of service flap and open the flap.

2. Loosen and remove housing screws (2).

3. Remove upper part of housing (3) and place on a clean surface.

23

4 Transmitter

24

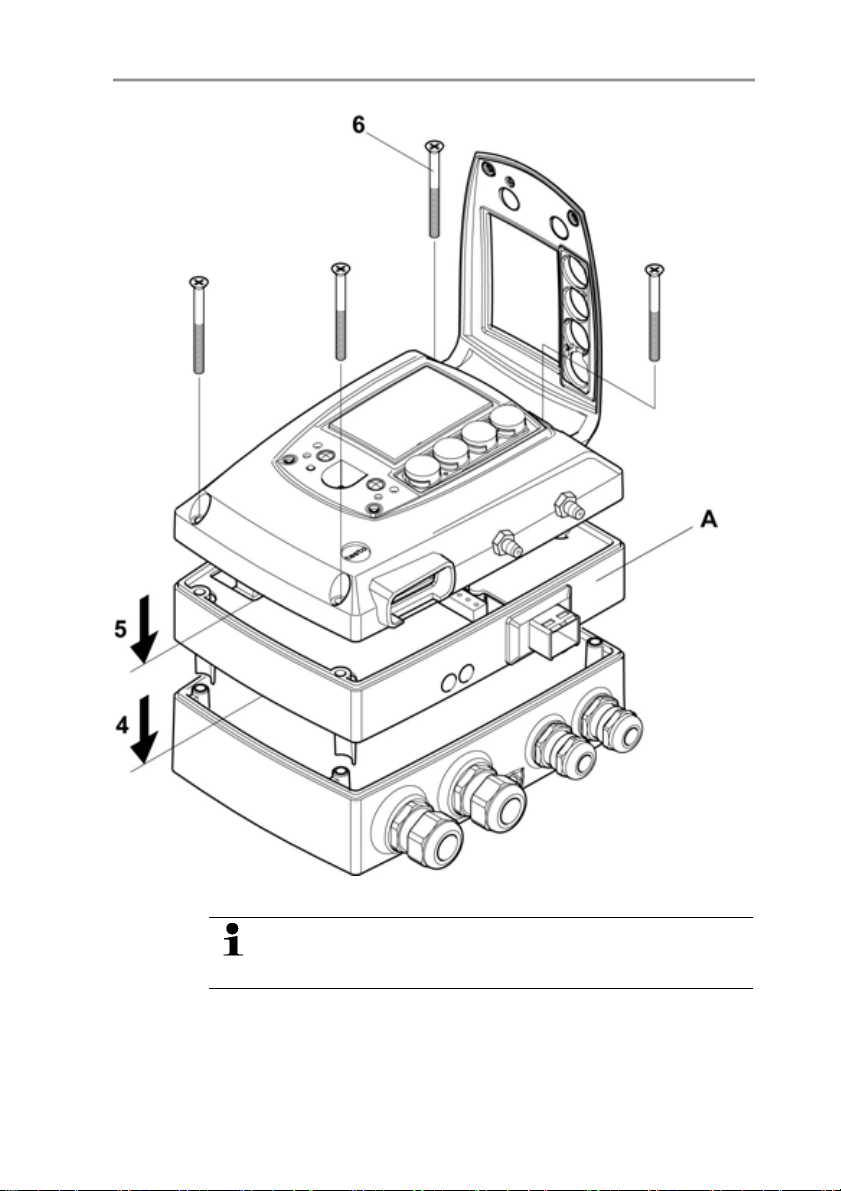

4. Place Ethernet module (A) on lower part of instrument (4).

First set the desired operating mode via the DIP switch (see

Setting the Ethernet module, page 36) before fixing the

instrument in place.

5. Set on upper part of instrument (5) and fix in place using the

housing screws (6) provided in the accessories.

4 Transmitter

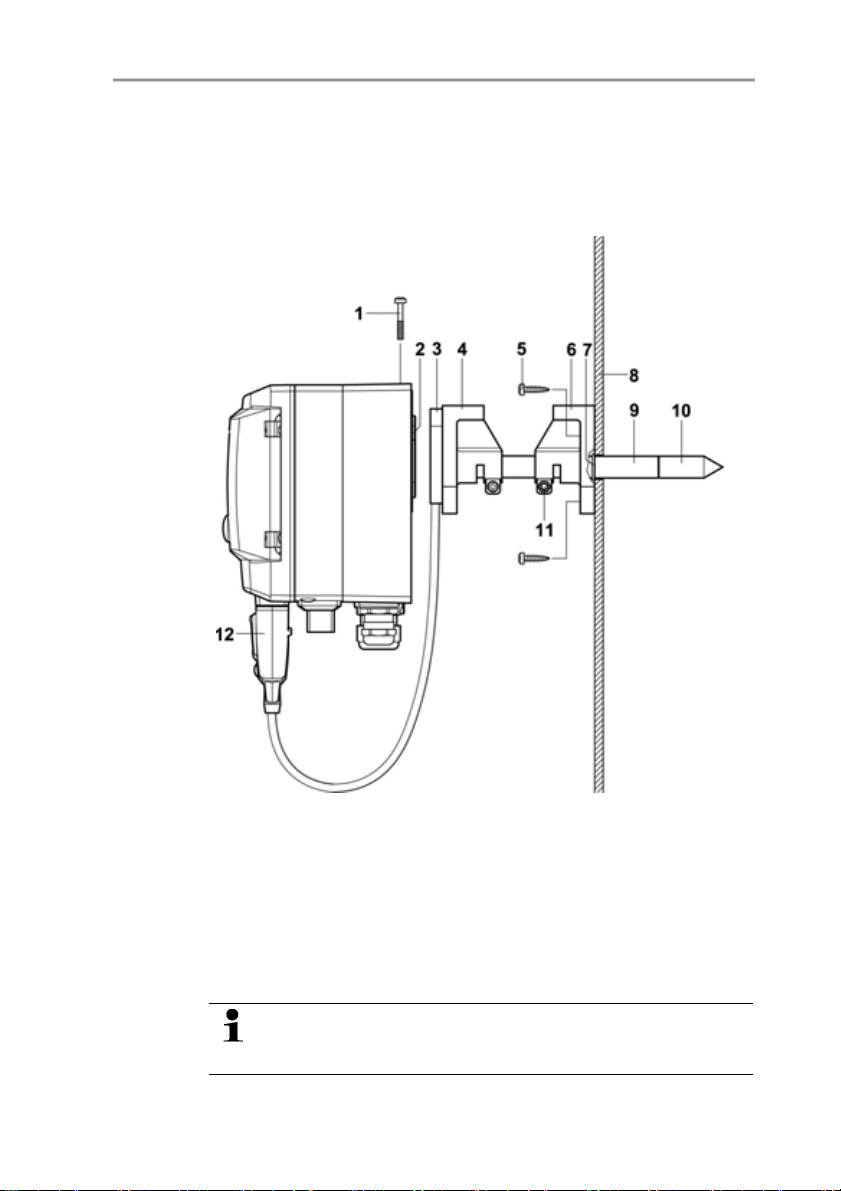

Pos: 41 /TD/Erste Schritte/MUF 63xx/Wandmontage 638 x @ 3\mod_1234777599007_79. doc @ 25840 @ 3455

4.3.2. Assembling the instrument

4.3.2.1. Wall mounting (for testo 6611, 6613, 6614, 6615, 6617 probes)

Attaching rear panel bracket

1. Remove locking screw (see item (4) of drawing below) and

detach rear panel bracket from plastic bracket (see item (2) of

drawing below).

2. Hold rear panel bracket in assembly position and mark the three

drill holes.

3. Drill three holes (Ø 5 mm) and insert dowels where necessary.

4. Screw on rear panel bracket.

Remember that the clamping brackets (1) must face the wall.

Fastening instrument to rear panel bracket

1. Slide plastic bracket (2) on the back of instrument onto rear

panel bracket until it engages (see arrows).

25

4 Transmitter

2. Insert screw (4) through hole (3) and screw into rear panel

bracket.

Pos: 42 /TD/Erste Schritte/MUF 63xx/Kanalmontage @ 3\m od_1234778800983_79.d oc @ 25859 @ 4

4.3.2.2. Duct mounting (for testo 6612 probes)

3. Insert probe connector (5) into socket until it engages.

26

1. Hold wall/duct bracket (order no. 0554 6651) (6) against duct

wall (8) and mark drill holes for wall/duct bracket and probe

shaft.

2. Drill a hole (Ø 12.5 mm) in the duct wall to feed through the

probe shaft.

3. Fasten wall/duct bracket (6) to duct wall with screws (5).

4. Push probe shaft (9) with filter (10) through the middle hole of

the mounting bracket.

The wall/duct bracket (6) has an O-ring (7) to seal it against

the duct. Feed the probe shaft (9) carefully through the

wall/duct bracket so that the O-ring is not damaged.

5. Fix the correct position of the probe shaft (9) with screw (11)

and mark (insert probe shaft as far as possible).

6. Slide plastic bracket (2) on the back of the transmitter onto

bracket (3, 4) until it engages.

Take the weight of the transmitter into account. Ensure that

the brackets (4, 6) are fastened securely.

7. Insert screw (1) through the hole on the top of the instrument

and screw into bracket (3).

Pos: 43 /TD/Erste Schritte/MUF 63xx/Gerät anschließ en Ethernet @ 3\mod_1234779 843987_79.doc @ 25897 @ 35

8. Insert probe connector (12) into socket until it engages.

4.3.3. Connecting the instrument

4 Transmitter

Opening the instrument

1. Loosen screw connection (1) of service flap and open the flap.

27

4 Transmitter

28

2. Loosen and remove housing screws (2).

The Ethernet module (A) is already detached from the

upper and lower parts of the housing by removing the

housing screws (2).

3. Remove upper part of housing (3) and place on a clean surface.

4. Remove Ethernet module (A) from lower part of housing (4) and

also place on a clean surface.

WARNING

Electrical voltage

Danger of injury!

> De-energize the mains connection before connecting the

transmitter.

Only have the transmitter wired and connected by

Pos: 44 /TD/Erste Schritte/MUF 63xx/Anschlussüber sicht 638x @ 3\mod_12347 80656658_79.doc @ 25935 @ 4

4.3.3.1. Overview of terminals

authorized personnel with the voltage disconnected.

4 Transmitter

1 Lower part of housing 7 Earthing terminal (internal)

2 Relay board (option) 8 M 16 x 1.5 screw connection*

3 Relay terminals 9 Earthing terminal (external)

4 Insulating trough for relay

10 M 20 x 1.5 screw connection*

board

5 Terminal strip for voltage

supply and analog outputs

6 Terminal board

11 Eyelet for measuring point

panel

* Alternatively, NPT cable

coupling or M plug-in connection

29

4 Transmitter

The following description of the terminals refer to this

Pos: 45 /TD/Erste Schritte/MUF 63xx/Spannungsver sorgung/Analogausgä nge anschließen 638x @ 3\ mod_1234784598344_79. doc @ 25954 @ 45

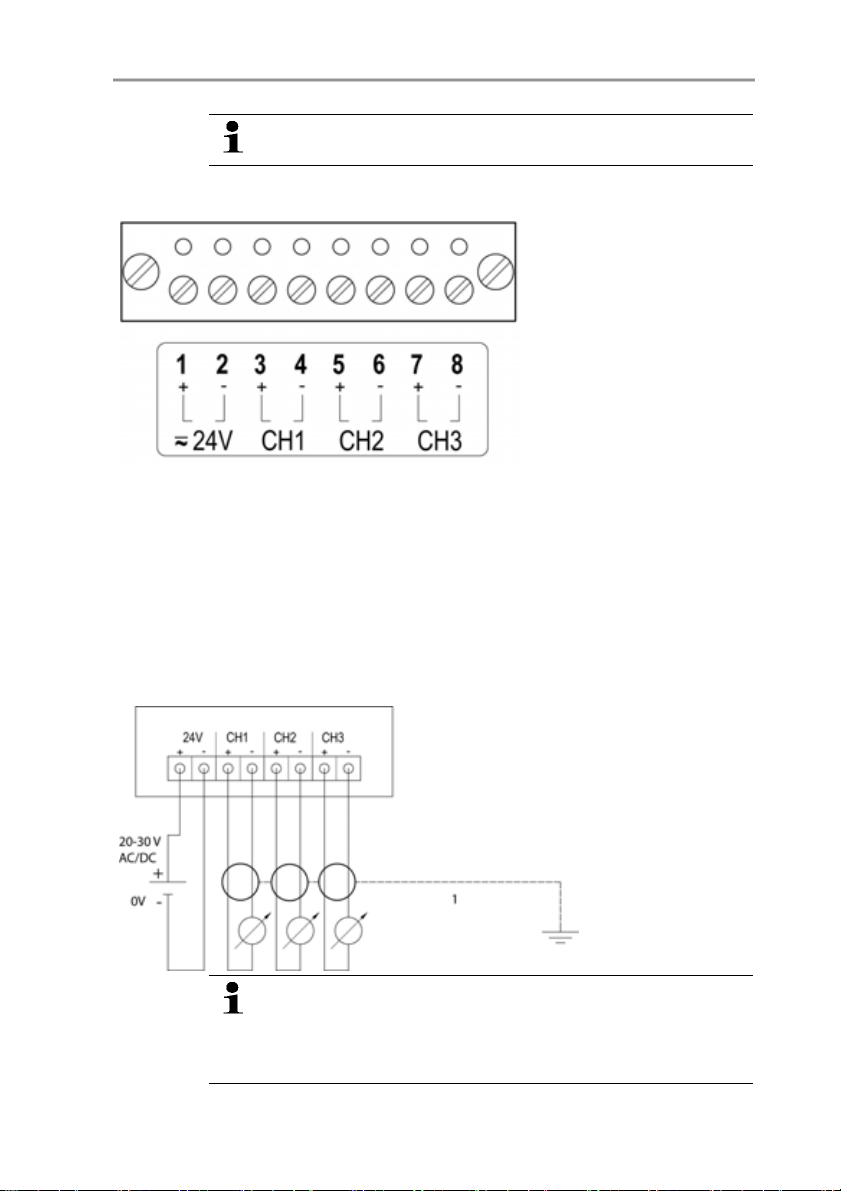

4.3.3.2. Connecting voltage supply and analog outputs

overview and its numbering.

Terminal strip for voltage

supply and analog outputs,

item (5) of overview of

terminals, page 29

1. Feed cable with voltage supply and analog signal lines through

opened M 16 x 1.5 screw connection (item (8) in the overview of

terminals, page 29).

2. Strip the cable ends, clamp wire end ferrules on and screw

down onto voltage terminals.

3. Close M 16 x 1.5 screw connection (item (8) in the overview of

terminals, page 29).

30

Wiring diagram for 4-wire system (0 to 20 mA/4 to 20 mA/0 to

1 V/0 to 5 V/0 to 10 V)

1 1 or 3 channels,

0 to 20 mA/4 to

20 mA max.

load per 500 Ω

0 to 1 V/0 to

5

V /

0 to 10 V

Requirement for the connecting cable of the supply:

• Insulated with cross-section of at least 0.25 mm².

• The supply line must be secured against exceeding

0.5 A.

Loading...

Loading...