Page 1

Committing to the future

testo 6351

Differential pressure transmitters with high accuracy and long-term stabilty

SPECIFICATIONS

testo 6351

The differential pressure transmitter testo 6351 was

developed specially for monitoring differential pressure

in the measuring range from 50 Pa to 2000 hPa. In

cleanroom technology, the maintenance of positive

pressure prevents the entry of contaminated air. In

order to keep the cleanroom conditions constant, the

transmitter additionally calculates the parameters

volume flow and flow velocity from the measured

differential pressure.

Subject to change without notice.

SPECIFICATIONS

testo 6351

• Measurement of differential pressure, flow velocity

and volume flow

• Automatic zero-point adjustment guarantees high,

temperature-independent accuracy and long-term

stability

• Plastic housing

• Display with multi-language operating menu and

optical alarm display

• Ethernet, relay and analog outputs allow optimum

integration into individual automation systems

• Self-monitoring of the transmitter and early warning

function guarantee high system availablity

• The P2A software for parameterization, adjustment

and analysis saves time and costs in commissioning

and maintenance

The testo 6351 is particularly outstanding thanks to

the automatioc zero-point adjustment which ensures

high accuracy and long-term stability.

The integrated self-monitoring and early warning

function also guarantees the operator high system

availability.

Areas of application:

• Differential pressure monitoring between cleanrooms

• Differential pressure monitoring in filling processes

• Monitoring differential pressure, volume flow and

flow velocity in critical air conditioning technology

(VAC systems)

Status 07.10.2009

Page 1/4

• Scalability of ±50 percent of the measuring range

final value and free scalability within the measuring

range

• Configurable alarm management with adjustable

response delay and alarm acknowledgement

tteessttoo

AG · Testo-Strasse 1 · D-79853 Lenzkirch · www.testo.com

DS 6351 EN/msp/A/07.10.2009

Page 2

Differential pressure transmitters with high accuracy and long-term stabilty

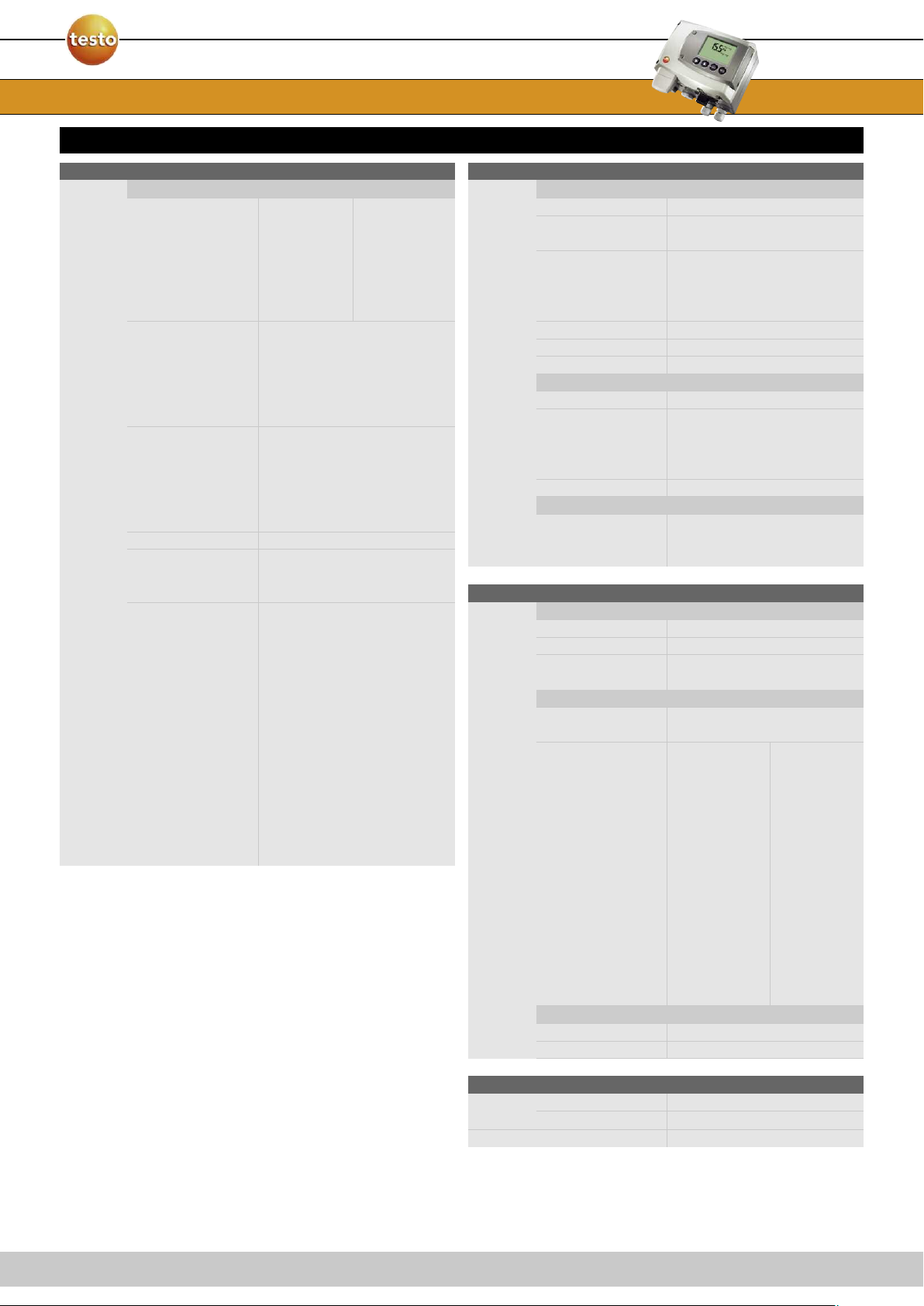

Technical data

testo 6351

Parameters

ifferential pressure

D

easuring range 0 to 50 Pa

M

Measurement uncertainty* ±0,8% of measurement range final value

Selectable units Differential pressure in Pa, hPa, kPa,

Sensor Piezoresistive sensor

Autom. Zero-point

adjustment

Overload capacity

* Measurement inaccuracy according to GUM: ±0.8% of measurement range final

value ±0.3 Pa

GG

uide to the Expression of UUncertainty in MMeasurement):

GUM (

ISO guideline for the determination of measurement inaccuracy, in order to make

measurements comparable worldwide.

The following inaccuracies are used for the determination:

– Hysteresis

– Linearity

– Reproducibility

– Long-term stability

– Adjustment site/factory calibration

– Test site

to 100 Pa

0

0 to 500 Pa

0 to 10 hPa

0 to 50 hPa

to 100 hPa

0

to 500 hPa

0

to 1000 hPa

0

to 2000 hPa

0

±0.3 Pa

Temperature gain drift: 0.02% of

measuring range per Kelvin deviaton

rom nominal temperature 22 °C

f

ero point drift: 0% (thanks to cyclic

Z

zero-point adjustment)

mbar, bar, mmH

G, inch H

H

alculated variables: Volume flow in

C

3

m

low velocity in m/s, ft/min

F

via magnetic valve

Frequency adjustable: 15 sec, 30

sec, 1 min, 5 min, 10 min

MMeeaassuurriinngg rraannggee OOvveerrllooaadd

0 to 50 Pa 20000 Pa

0 to 100 Pa 20000 Pa

0 to. 500 Pa 20000 Pa

0 to 10 hPa 200 hPa

0 to 50 hPa 750 hPa

0 to 100 hPa 750 hPa

0 to 500 hPa 2500 hPa

0 to 1000 hPa 2500 hPa

0 to 2000 hPa 2500 hPa

-50 to 50 Pa 20000 Pa

-100 to 100 Pa 20000 Pa

-500 to 500 Pa 20000 Pa

-10 to. 10 hPa 200 hPa

-50 to 50 hPa 750 hPa

-100 to 100 hPa 750 hPa

-500 to 500 hPa 2500 hPa

-1000 to 1000 hPa 2500 hPa

-2000 to 2000 hPa 2500 hPa

2

h, l/min, Nm

/

O

50 to 50 Pa

100 to 100 Pa

-

-500 to 500 Pa

-10 to 10 hPa

-50 to 50 hPa

100 to 100 hPa

500 to 500 hPa

1000 to 1000 hPa

2000 to 2000 hPa

-

O, kg/cm2, PSI, inch

2

3

h, Nl/min

/

Inputs/outputs

nalog outputs

A

uantity 1

Q

Output type 0/4 to 20 mA (4-wire) (24 VAC/DC)

caling Differential pressure: scalable ±50% of

S

Meas. cycle 1/sec

Resolution 12 bit

Max. load max. 500 Ω

Other outputs

Ethernet Optional with Ethernet module

elay Optional: 4 relays (free allocation to

R

igital Mini-DIN for P2A software

D

Supply

oltage supply 20 to 30 VAC/DC, 300 mA current

V

eneral technical data

G

Model

Material Plastic housing

Dimensions 162 x 122 x 77 mm

Weight 0.7 kg; optional: Ethernet intermediary

Display

Display Optional: 3-line LCD with

Resolution

Miscellaneous

Protection class IP 65

EMC EU guideline 2004/108/EC

to 1/5 to 10 V (4-wire) (24 VAC/DC)

0

measuring range final value;

freely scalable within measuring range

measurement channels or as collective

alarm in operating menu/P2A), up to

250 VAC/3A (NO or NC)

consumption, galvanically separate

ignal and supply line

s

layer 0.6 kg

multi-language operating menu

MMeeaassuurriinngg rraannggee RReessoolluuttiioonn

0 to 50 Pa 0,1 Pa

0 to 100 Pa 0,1 Pa

0 to 500 Pa 0,1 Pa

0 to 10 hPa 0,01 hPa

0 to 50 hPa 0,01 hPa

0 to 100 hPa 0,1 hPa

0 to 500 hPa 0,1 hPa

0 to 1000 hPa 1 hPa

0 to 2000 hPa 1 hPa

-50 to 50 Pa 0,1 Pa

-100 to 100 Pa 0,1 Pa

-500 to 500 Pa 0,1 Pa

-10 to 10 hPa 0,01 hPa

-50 to 50 hPa 0,01 hPa

-100 to 100 hPa 0,1 hPa

-500 to 500 hPa 0,1 hPa

-1000 to 1000 hPa 1 hPa

-2000 to 2000 hPa 1 hPa

Status 07.10.2009

Page 2/4

Subject to change without notice.

tteessttoo

AG · Testo-Strasse 1 · D-79853 Lenzkirch · www.testo.com

Operating conditions

display

Operating temperatureWith / without

Storage temperature -20 to +60 °C / -4 to +140 °F

Process temperature -20 to +65 °C / -4 to +149 °F

-5 to +50 °C / +23 to +122 °F

DS 6351 EN/msp/A/07.10.2009

Page 3

+

-

+

-

+

-

+

-

+

-

CH1

CH2 CH3

24V

1

77

122

162

a

b

Differential pressure transmitters with high accuracy and long-term stabilty

Technical drawings

122 mm

7 mm

7

162 mm

testo 6351

Connection plan

Status 07.10.2009

Subject to change without notice.

tteessttoo

AG · Testo-Strasse 1 · D-79853 Lenzkirch · www.testo.com

Page 3/4

DS 6351 EN/msp/A/07.10.2009

Page 4

Differential pressure transmitters with high accuracy and long-term stabilty

The following options can be specified for the testo 6351:

testo 6351

AXX Messbereich

AXX Measuring range

BXX Analogausgang / Versorgung

BXX Analog display/supply

XX Display

XX Display / menu language

C

C

XX Gehäusefarbe

XX Cable input

E

D

XX Einheit

XX Ethernet

F

E

KXX Sprache der Bedienungsanleitung

FXX Differential pressure/flow velocity unit (pre-

set)

(für zweisprachige Papier-Bedienungs -

nleitung)

a

HXX Relay

KXX Instruction manual language

Example:

Order code for transmitter testo 6351 with

the following options:

- Measuring range 0 to 100 Pa

- Analog output / supply 0 to 5 V

(4-wire, 24 VAC/DC)

- with display/English

- Cable entry NPT 1/2“

- with Ethernet module

- Differential pressure mbar / min / max

- 4 relay outputs, limit value monitoring

- Instruction manual language

German/English

AXX Measuring range

A02 0 to 50 Pa

A03 0 to 100 Pa

A04 0 to 500 Pa

05 0 to 10 hPa

A

07 0 to 50 hPa

A

08 0 to 100 hPa

A

A09 0 to 500 hPa

A10 0 to 1000 hPa

A11 0 to 2000 hPa

A22 -50 to 50 Pa

23 -100 to 100 Pa

A

24 -500 to 500 Pa

A

A25 -10 to 10 hPa

A27 -50 to 50 hPa

A28 -100 to 100 hPa

A29 -500 to 500 hPa

A30 -1000 to 1000 hPa

31 -2000 to 2000 hPa

A

BXX Analog display/supply

B02 0 to 1 V (4-wire, 24 VAC/DC)

B03 0 to 5 V (4-wire, 24 VAC/DC)

B04 0 to 10 V (4-wire, 24 VAC/DC)

B05 0 to 20 mA (4-wire, 24 VAC/DC)

B06 4 to 20 mA (4-wire, 24 VAC/DC)

CXX Display / menu language

00 without display

C

C02 with display/English

C03 with display/German

C04 with display/French

C05 with display/Spanish

C06 with display/Italian

C07 with display/Japanese

C08 with display/Swedish

DXX Cable input

D01 Cable input M16 (relay: M20)

D02 Cable entry NPT 1/2“

D03 Cable contact via M-plug connection for signal

and supply

EXX Ethernet

E00 without Ethernet module

E01 with Ethernet module

XX Differential pressure/flow velocity unit (pre-

F

set)

F01 Pa / min / max

F02 hPa / min / max

F03 kPa / min / max

04 mbar / min / max

F

05 bar / min / max

F

06 mmH2O / min / max

F

F07 mmH2O / min / max

F08 inch HG / min / max

F09 kg/cm² / min / max

F10 PSI / min / max

11 m/s / min / max

F

12 ft/min / min / max

F

F13 m³/h / min / max

F14 l/min / min / max

F15 Nm³/h / min / max

F16 Nl/min / min / max

XX Relay

H

00 without relay

H

01 4 relay outputs, limit value monitoring

H

H02 4 relay outputs, channel 1 limit values and

collective alarm

KXX Instruction manual language

K01 German/English instruction manual

K02 French/English instruction manual

K03 Spanish/English instruction manual

K04 Italian/English instruction manual

K05 Dutch/English instruction manual

K06 Japanese/English instruction manual

K07 Chinese/English instruction manual

K08 Swedish/English instruction manual

0555 6351 A03 B03 C02 D02 E01 F04 H01 K01

Scaling: 50% of

measuring range

final value; freely

electable within

s

easuring range

m

Status 07.10.2009

Subject to change without notice.

tteessttoo

AG · Testo-Strasse 1 · D-79853 Lenzkirch · www.testo.com

Page 4/4DS 6351 EN/msp/A/07.10.2009

Loading...

Loading...