Page 1

Differential Pressure Transmitter testo 6340

Ideal for cleanroom applications

∆P

testo 6340

Page 2

2

testo 6340

testo 6340

Highest stability even at lowest pressures

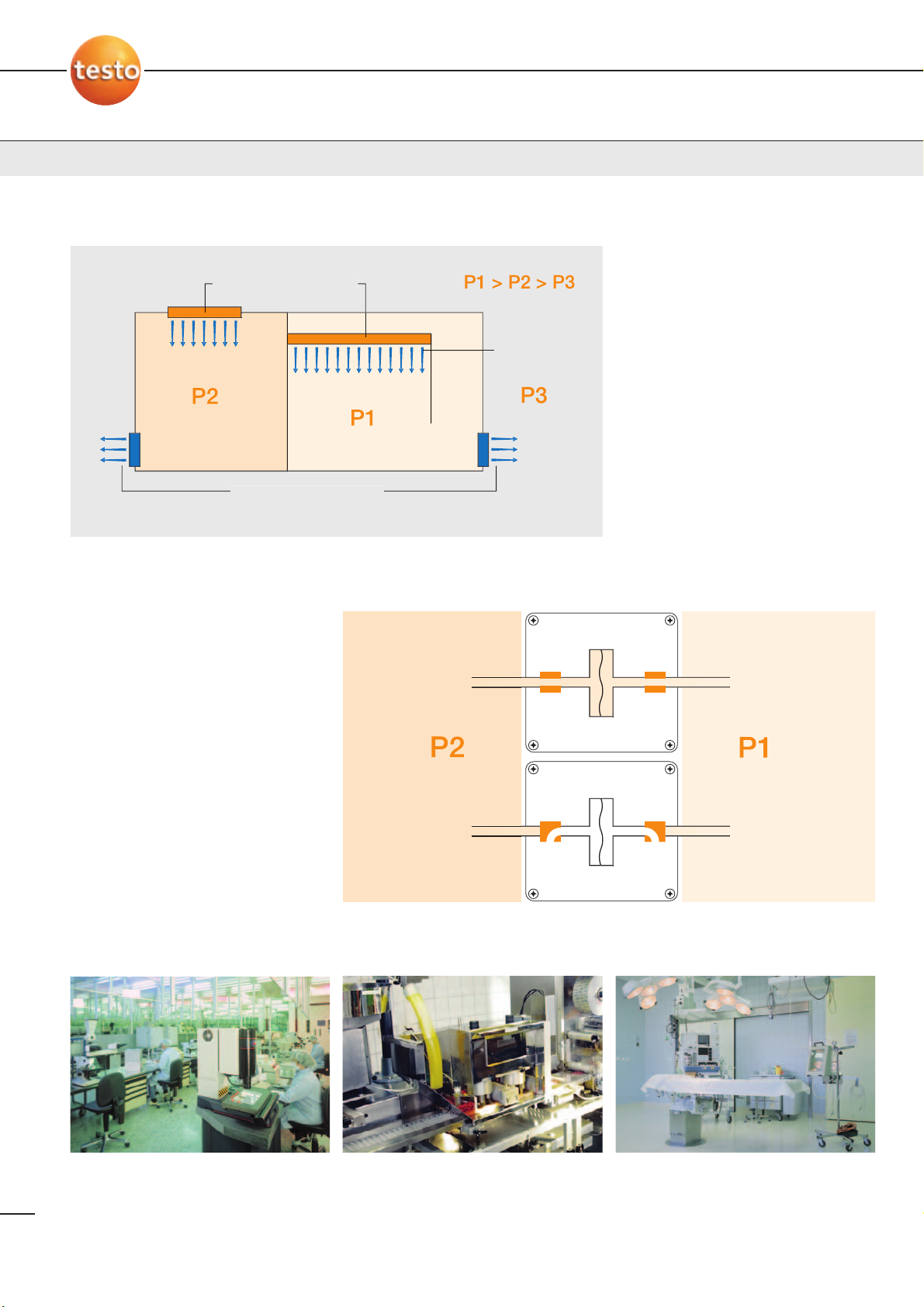

Positive pressure at filling points helps to sustain

hygiene conditions when filling food and

pharmaceuticals

Negative pressure helps prevent the spread of germs

and dust particles in hospitals and research

laboratories, positive pressure secures operating

theatres.

Defined pressure differences between cleanroom and

adjoining rooms assure quality

Zero ppoint sstability pplays aa pparticularly

important rrole aat llowest ppressures ((10 PPa oor

50 PPa mmeasurement rrange).

While conventional ∆P transmitters require

frequent recalibration, the testo 6341/6343 is

equipped with

automatic zzero ppoint

adjustment

. The solenoid valves vent both

sides of the pressure measurement cell in an

hourly cycle. Consequently, the

microprocessor automatically corrects the

zero signal - highest stability is the result.

Supply air via HEPA-/ULPA

filter

Outlet air (50 to 500 air

exchanges / h)

Laminar flow

e.g. 0.5 m/s

Outer zone

Measurement

Adjustment

Critical zone

Normal zone

Critical zone

Normal zone

Whether ccleanroom, ggrayroom, ooperating

theatre oor ffilling ssystem:

Lowest differential pressures between the

different rooms or zones must be sustained in

order to avoid the in-flow of contaminated air.

Continuous measurement and control of

these low differential pressures are required

(according to ISO 14644: 5 to 20 Pa).

This must be proven annually in accordance

with

ISO 114644

-1/B (against zero potential

and against neighbouring rooms).

Page 3

3

testo 6340 – Product features

The testo 6340 product line

testo 6341:

0 to 10 Pa, with automatic zero point

adjustment, without display

testo 6342:

0 to 50 Pa, without display

testo 6343:

0 to 10 Pa, with automatic zero point

adjustment, with display

testo 6344:

0 to 50 Pa, with display

testo 66341 aand 66343 –– TThe hhigh eend ssolution

among tthe llow ∆P ttransmitters

•

Zero ppoint ddrift == 00

on account of automatic zeroing

• High long-term stability and reproducibility

•

No ttemperature ddependency:

The automatic zeroing is

performed at process temperature.

•

Overload-pproof

(if \>140 % of the measurement range is

applied, the solenoid valves close; the cell is vented on both

sides)

• Optional display (testo 6343)

testo 66342 aand 66344 –– tthe rreliable ttransmitters

among tthe llow ∆P ttransmitters

•

Very llow zzero ppoint ddrift

as well as very good long-term

stability and reproducibility thanks to the optimised

measurement cell

•

Very llow ttemperature ddependency

(temperature

compensated measurement cell)

• Optional display (testo 6344)

testo 66349 –– tthe vvariants oof tthe aabove ddescribed ttypes

Measurement ranges up to +/- 1000 mbar, other pressure and cable connections as well as (in testo 6341/43) a RS 232 digital output

and a metallic housing are available based on the testo 6341 to 6344 instruments

Patented iinductive mmeasurement ccell

The patented differential pressure

measurement cell in the testo 6340

transmitter operates with highest stability. A

core, with a magnetic coating on both sides,

is located in the middle of the concentrically

undulating copper beryllium membrane. Any

deflection causes sensitive changes in the

inductances of both coils L1 and L2.

Coil L 1

Coil L 2

Pressure connection P1

Pressure connection P2

Core with magnetic coating on both

sides

Copper beryllium membrane

Page 4

testo 6342

testo 6344

testo 6341/6343

testo 6340

Technical data

Model testo 6341/6343 testo 6342/6344

Item Part no.

Display Only with testo 6343 Only with testo 6344

Meas. range 0 to 10 Pa (= 0,1 mbar/0,04 inch H

2

O) 0 to 50 Pa (= 0,5 mbar/0,02 inch H2O)

Meas. range on request 10 Pa to +/-100 kPa (i.e. up to 1000 mbar) 50 Pa to +/-100 kPa (i.e. 1000 mbar)

Housing (ABS plastic) 6341: 120 x 122 x 85 mm 6342: 80 x 120 x 73 mm

6343: 120 x 122 x 105 mm 6344:120 x 122 x 75 mm

Measurement inaccuracy 0,35 Pa + 0,5% of mv 0,35 Pa + 0,6% of mv

(0.3 Pa = meas. inaccuracy of reference) (0.3 Pa = meas. inaccuracy of reference)

Protection class IP54 standard (plastic housing)

IP65 on request (metal housing)

IP54 Standard (plastic housing)

Output signal 4 to 20 mA (load max. 500 Ohm)

0 to 20 mA/0 to 10 V can be adjusted locally;

RS232 on request

4 to 20 mA (load max. 500 Ohm)

Usable measurement range -5% to +110 % of fsv

Overload 200 times (above 25 mbar: 6 bar) 10 times (above 200 mbar: 2 times)

Zero point drift None (automatic zero point adjustment) 0.5 % of full scale value/year

Hysteresis 0,1% of fsv 0,1% of fsv

Power supply 24 VDC (20,5 to 28,5 VDC) 24 VDC (20,5 to 28,5 VDC)

Time constants 0/1/2.5/5/10/20/30/40 s can be adjusted

Oper. temp. 0 to +60 °C 0 to +60 °C

Storage temp. -10 to +70 °C -10 to +70 °C

Cable screw connections 2 x PG9 2 x PG7

Pressure connections 2 x d 6.5 for houses ø 4 or 5 mm 2 x d 6.5 for houses ø 4 or 5 mm

Weight

0555 6341

1500 g 6342: 300 g , 6344: 800 g

Output signal Linear to differential pressure Linear to differential pressure

Measuring medium Air, non-aggressive gases Air, non-aggressive gases

Ordering data

To :

Power supply unit (DIN rail

mounting) 90 to

264VAC/24VDC (3A)

(0554 1749)

4...20 mA

24 VDC

To the

process

5 metre silicone hose, 4 mm inner

diameter, 1.5 mm wall thickness

can withstand load up to 700 mbar

(0554 0440)

or

230 VAC

AALLAARRMM

with alarm unit

DDIISSPPLLAAYY AANNDD SSWWIITTCCHH

testo 54 - 2 AC (5400.7553)

Option LCD

(nur testo 6343)

0555 6342

0555 6343

0555 6344

ISO calibration with 5 points (0/25/50/75/100/0 % of full scale value) 0520 0005

5 metre silicone hose, 4 mm inner diameter, 1.5 mm wall thickness

can withstand load up to 700 mbar

0554 0440

External testo 54 – 2 AC display,2 relay outputs (up to 300 VAC, 3 A), 230 VAC 5400 7553

Power supply unit (desk-top) 90 to 264VAC/24VDC (350mA) 0554 1748

Power supply unit (DIN rail mounting) 90 to 264VAC/24VDC (3A) 0554 1749

ISO calibration with 5 points (0/25/50/75/100/0 % of full scale value) 0520 0105

Subject to change without notice.

Can be set by factory if required

-5% to +105 % of fsv

Technical Data – Ordering Data

testo 6341 ∆P transmitter 0 to 10 Pa, automatic zeroing, without display

testo 6342 ∆P transmitter 0 to 50 Pa, without display

testo 6343 ∆P transmitter 0 to 10 Pa, automatic zeroing, with display

testo 6344 ∆P transmitter 0 to 50 Pa, with display

Loading...

Loading...