Page 1

testo 6321 · differential pressure transmitter

P2A software · Parameterizing, adjusting and analyzing

software

Instruction manual

Page 2

2

Page 3

1 Safety and the environment

Pos: 1 /TD/Überschriften/MUF/Sicherheit und Umwel t @ 3\mod_1234793958627_7 9.doc @ 26223 @ 1

1 Safety and the environment

Pos: 2 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/MUF 63xx/Elek trische Gefahren ver meiden @ 3\mod_12347946092 99_79.doc @ 26280 @ 5

Avoiding electrical hazards

> Never use the instrument and connected probes to measure on

or near live parts!

> Damaged mains cables must only be replaced by authorized

personnel.

> Only have the transmitter wired and connected by authorized

personnel with the voltage disconnected.

> You must always comply with the regulations applicable in your

Pos: 3 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/MUF 63xx/Per sonen- und Sachschäden ver meiden @ 3\mod_1234794744 768_79.doc @ 26299 @ 5

country for opening and repairing electrical equipment.

Avoiding personal injury and damage to equipment

> Installation, setting and calibration work must only be carried

out by qualified and authorized personnel!

> Only open the instrument when this is expressly described in

the instruction manual for installation, maintenance or repair

purposes.

> Observe the permissible storage, transport and operating

Pos: 4 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/Nicht mit Lös ungsmitteln lagern @ 0\ mod_1175692375179_79.d oc @ 583 @

temperature.

> Do not store the product together with solvents. Do not use any

Pos: 5 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/MUF 63xx/Bei W artung MUF nicht zur Regelun g verwenden @ 3\mod_123479 4852377_79.doc @ 26318 @

desiccants.

> Do not use the instrument for control purposes at the same time

Pos: 6 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/Produkt besti mmungsgemäß verwenden @ 0\mod_1173781261848 _79.doc @ 386 @

as operating or servicing the transmitter.

> Only operate the product properly, for its intended purpose and

within the parameters specified in the technical data. Do not

Pos: 7 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/Nur beschri ebene Wartungsarbeite n durchführen @ 0\mod_11756 92705195_79.doc @ 601 @

use any force.

> Carry out only the maintenance and repair work on this

instrument that is described in the documentation. Follow the

prescribed steps exactly. Use only original spare parts from

Pos: 8 /TD/Sicherheit und Umwelt/Sicherheit gewähr leisten/MUF 63xx/Fac hpersonal @ 3\mod_12347949 40409_79.doc @ 26337 @

Testo.

Any additional work must only be carried out by authorized

personnel. Otherwise testo will not accept any responsibility for the

proper functioning of the instrument after repair and for the validity

of certifications.

3

Page 4

2 About this document

Pos: 9 /TD/Überschriften/MUF/Umwelt schützen @ 3\mod_ 1234858757571_79. doc @ 26363 @ 5

Pos: 10 /TD/Sicherheit und Umwelt/Umwelt schützen/Pr odukt entsorgen @ 0\mod_ 1173780307072_79.doc @ 357 @

Protecting the environment

> At the end of its useful life, send the product to the separate

collection for electric and electronic devices (observe local

Pos: 11 /TD/Überschriften/MUF/Zu diesem Dokument @ 3\mod_ 1234793991331_79. doc @ 26242 @ 1

2 About this document

Pos: 12 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Ver wendung (Standard) @ 0\mod_1173775068554_79. doc @ 337 @ 5

regulations) or return the product to Testo for disposal.

Use

> Please read this documentation through carefully and

familiarize yourself with the product before putting it to use. Pay

particular attention to the safety instructions and warning advice

in order to prevent injuries and damage to the products.

> Keep this document to hand so that you can refer to it when

necessary.

> Hand this documentation on to any subsequent users of the

Pos: 13 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy mbole und Schreibkonven tionen/War nhinweis WARNUNG @ 2\mod_12076469662 34_79.doc @ 14398 @

Pos: 14 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy mbole und Schreibkonven tionen/War nhinweis VORSICHT @ 2\mod_1207651 416515_79.doc @ 14416 @

Pos: 15 /TD/Sicherheit und Umwelt/Zu diesem Dokument/Sy mbole und Schreibkonv. Sof tware [Standard] @ 0\mod_1190203332543_79. doc @ 4883 @ 5

product.

WARNING

CAUTION

Indicates potential serious injuries

indicates potential minor injuries

Symbols and writing standards

Representa-

Explanation

tion

Note: Basic or further information.

1. ...

2. ...

Action: more steps, the sequence must be

followed.

> ... Action: a step or an optional step.

- ... Result of an action.

Menu

[OK]

Elements of the program interface.

Buttons of the program interface.

... | ... Functions/paths within a menu.

“...” Example entries

Pos: 16 /TD/--- Seitenwechsel --- @ 0\mod_1173774430601_0.doc @ 283 @

4

Page 5

3 Contents

Pos: 17 /TD/Überschriften/MUF/Inhalt @ 3\mod_123479 4019831_79.doc @ 26261 @ 1

3 Contents

1 Safety and the environment....................................................................3

2 About this document...............................................................................4

3 Contents ...................................................................................................5

4 Transmitter...............................................................................................7

4.1. Specifications ..................................................................................7

4.1.1. Functions and use ...........................................................................................7

4.1.2. Scope of delivery .............................................................................................7

4.1.3. Dimensions ......................................................................................................7

4.1.4. Technical data .................................................................................................8

4.2. Product description........................................................................11

4.2.1. At a glance..................................................................................................... 11

4.2.2. Scaling ......................................................................................................... 12

4.3. Commissioning ..............................................................................13

4.3.1. Assembling the instrument............................................................................. 13

4.3.1.1. Wall mounting...................................................................................13

4.3.2. Wiring the instrument .....................................................................................14

4.3.2.1. 4-wire system....................................................................................16

4.3.2.2. 3-wire system....................................................................................16

4.4. Maintenance and cleaning.............................................................17

4.4.1. Cleaning housing ...........................................................................................17

4.4.2. Namur fault conditions ...................................................................................17

5 Parameterizing, adjusting and analyzing software (P2A software) ...18

5.1. Specifications ................................................................................18

5.1.1. Functions and use .........................................................................................18

5.1.2. System requirements.....................................................................................19

5.1.3. Scope of delivery ...........................................................................................19

5.2. First steps......................................................................................20

5.2.1. Installing the software/driver ..........................................................................20

5.2.1.1. Installing P2A software......................................................................20

5.2.1.2. Installing USB driver .........................................................................20

5.2.1.3. P2A software upgrade ......................................................................20

5.2.2. Starting the software......................................................................................20

5.2.2.1. Starting the program.........................................................................20

5.2.2.2. Establishing a connection with the instrument...................................20

5.2.2.3. Activating the connection with the instrument....................................21

5

Page 6

3 Contents

5.3.

Using the software ........................................................................ 21

5.3.1. User interface ................................................................................................21

5.3.2. Editing instrument/parameter file ...................................................................24

5.3.2.1. Changing instrument/parameter file.................................................. 24

5.3.2.2. Creating a new instrument file...........................................................26

5.3.2.3. Saving parameters............................................................................26

5.3.2.4. Opening the parameter file ...............................................................26

5.3.2.5. Copying and pasting parameters......................................................27

5.3.2.6. Deleting instrument/parameter file....................................................27

5.3.3. Analyzing/testing the transmitter....................................................................27

5.3.3.1. Analyzing/testing the instrument.......................................................28

5.3.3.2. Carrying out factory reset.................................................................. 28

5.3.3.3. Testing analog output .......................................................................28

5.3.3.4. Displaying min./max. values..............................................................30

5.3.4. Adjusting the transmitter ................................................................................31

5.3.4.1. n-point adjustment ............................................................................31

5.3.4.2. Adjusting the analog output ..............................................................32

5.3.5. Transmitter history.........................................................................................33

6 Tips and assistance .............................................................................. 36

6.1. Questions and answers ................................................................ 36

6.2. Accessories and spare parts......................................................... 36

6.2.1. Ordering options for testo 6321 transmitter (0555 6321)................................37

Pos: 18 /TD/--- Seitenwechsel --- @ 0\mod_1173774430601_0.doc @ 283 @

6

Page 7

Pos: 19 /TD/Überschriften/MUF/1 Messumformer @ 3\ mod_1234258401060_79.doc @ 23894 @ 1

4 Transmitter

Pos: 20 /TD/Überschriften/MUF/1.1/2.1/3.1 Leis tungsbeschreibung @ 3\ mod_1234258595211_79. doc @ 23951 @ 2

4.1. Specifications

Pos: 21 /TD/Leistungsbeschreibung/Verwendung/ MUF63xx/MUF 6321 @ 3\mod_1241 608910962_79.doc @ 32625 @ 3

4.1.1. Functions and use

The testo 6321 transmitter is suitable for the following applications,

amongst others:

• Air conditioning and ventilation technology

◦ Monitoring ventilation and filtration systems

◦ Monitoring fans

Pos: 22 /TD/Leistungsbeschreibung/Lieferu mfang/MUF 63xx/MUF 6781 @ 3\mod_12 38162497483_79.doc @ 30275 @ 3

◦ Monitoring exhaust air volumetric flow rates

4.1.2. Scope of delivery

The scope of delivery of the testo 6321 transmitter includes the

following:

• Assembly accessories

• Operating instructions

• Calibration report

• CD-ROM with operating instructions (PDF) and P2A update

(this can only be used in conjunction with the P2A software,

Pos: 23 /TD/Leistungsbeschreibung/Technische Dat en/MUF 63xx/MUF 6781 Ab messungen @ 3\mod_123980633 0094_79.doc @ 31183 @ 3

which has to be ordered separately).

4 Transmitter

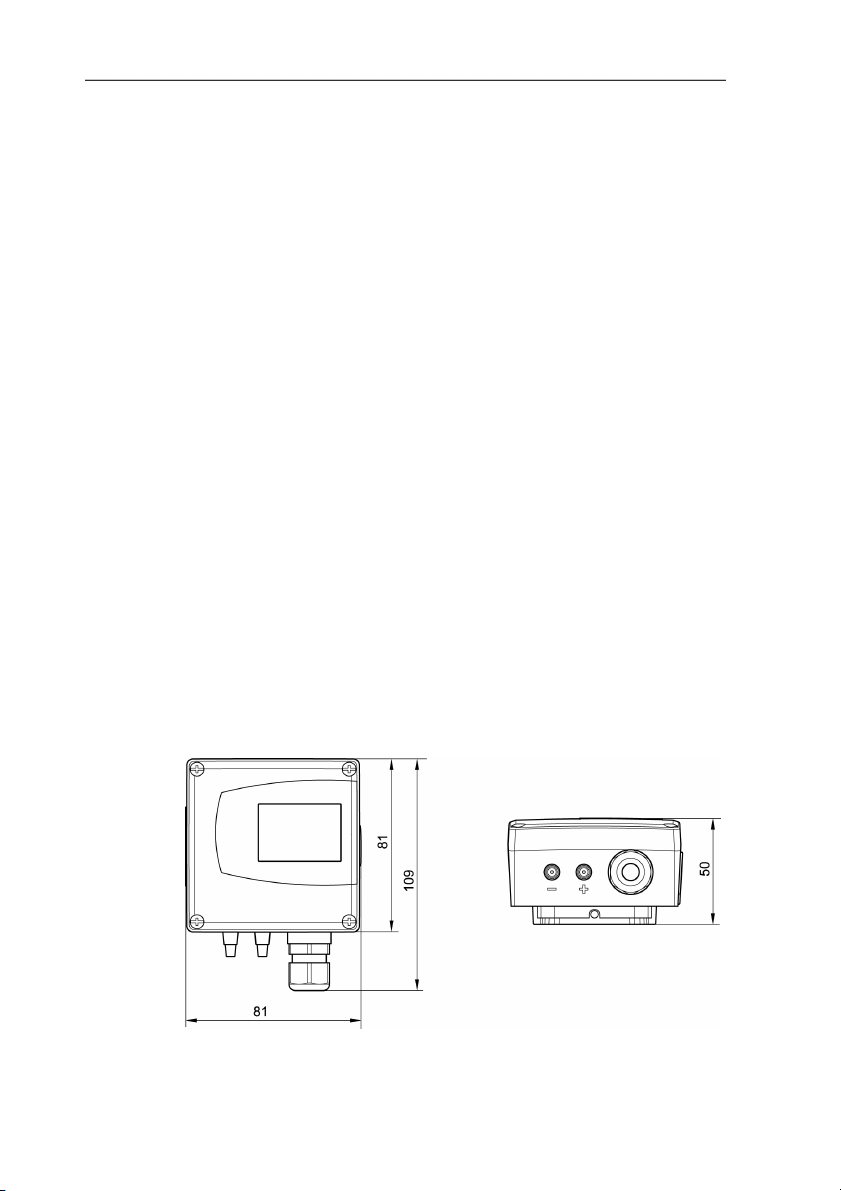

4.1.3. Dimensions

7

Page 8

4 Transmitter

Pos: 24 /TD/Leistungsbeschreibung/Technische Dat en/MUF 63xx/MUF 6321 @ 3\mod _1241601145321_79. doc @ 32604 @ 355555555555555 55555

4.1.4. Technical data

Parameter

• Differential pressure

Accuracy1

The specifications are only valid if the positive pressure is

applied at the positive pressure connection.

• 1.2 % of measuring range, additional ±0.3 Pa intrinsic error 2

• T

K slope drift

= 0.05 % of measuring range per degree Kelvin of

deviation from nominal temperature 22 °C

• T

K zeroing drift

= 0 % (by means of automatic zeroing)

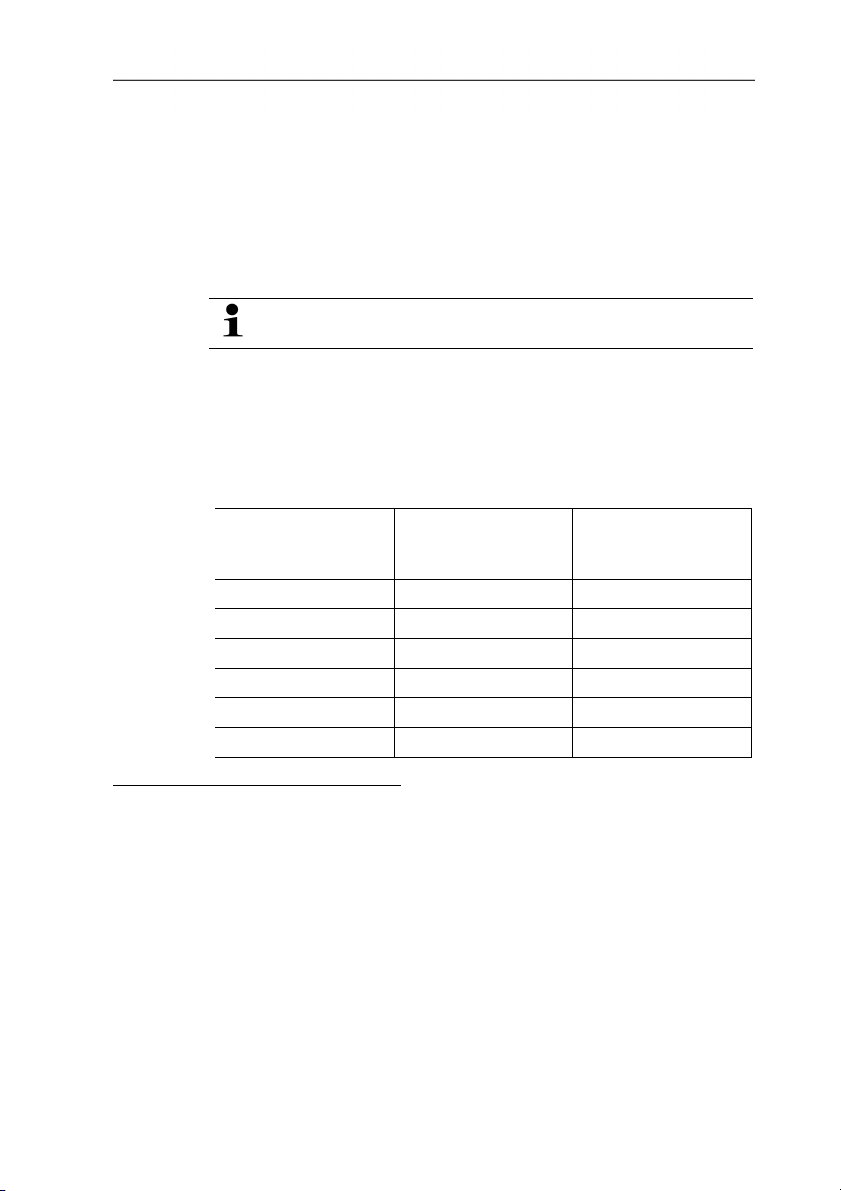

Measuring range, resolution and overload

Measuring range

depending on

version ordered

0 to 100 Pa 0.1 Pa 20,000 Pa

0 to 10 hPa 0.01 hPa 200 hPa

0 to 20 hPa 0.01 hPa 200 hPa

0 to 50 hPa 0.01 hPa 750 hPa

0 to 100 hPa 0.1 hPa 750 hPa

0 to 500 hPa 0.1 hPa 2500 hPa

Resolution Overload

1

At 25 °C. A stabilization period of approx. 30 min must be taken into account

upon commissioning the instrument.

2

Measuring uncertainty in accordance with GUM: ±1.2 % of measuring range

final value ±0.3 Pa.

GUM (Guide to the Expression of Uncertainty in Measurement): ISO guideline for determining the

measuring uncertainty in order to render global measurement results comparable.

The following uncertainties are used during the inquiry:

• Hysteresis

• Linearity

• Reproducibility

• Long-term stability

• Adjustment area/factory calibration

• Test location

8

Page 9

4 Transmitter

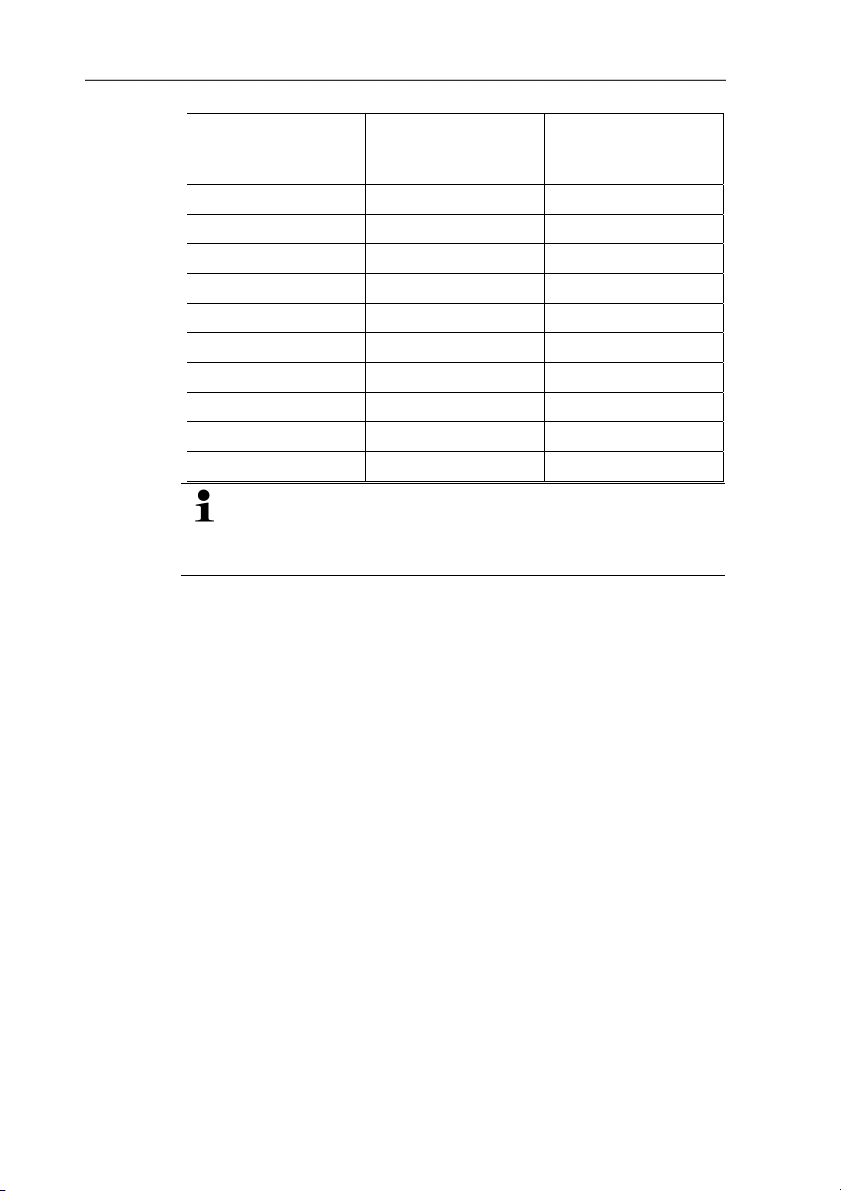

Measuring range

Resolution Overload

depending on

version ordered

0 to 1000 hPa 1 hPa 2500 hPa

0 to 2000 hPa 1 hPa 2500 hPa

-100 to 100 Pa 0.1 Pa 20,000 Pa

-10 to 10 hPa 0.01 hPa 200 hPa

-20 to 20 hPa 0.01 hPa 200 hPa

-50 to 50 hPa 0.01 hPa 750 hPa

-100 to 100 hPa 0.1 hPa 750 hPa

-500 to 500 hPa 0.1 hPa 2500 hPa

-1000 to 1000 hPa 1 hPa 2500 hPa

-2000 to 2000 hPa 1 hPa 2500 hPa

Upon delivery and following a factory reset the readings are

shown in the display in the unit that was ordered via the

KMAT option Fxx, see Ordering options for testo 6321

transmitter (0555 6321) page 37.

Meas. cycle

• 1/sec

Zeroing cycle

• Set to 1 min at the factory

Interface

• Mini-DIN for P2A software (adjustment and parameterization

software)

Voltage supply

• 3 or 4-wire (separate signal and supply lines): 20 to 30 V

AC/DC, 300 mA power consumption

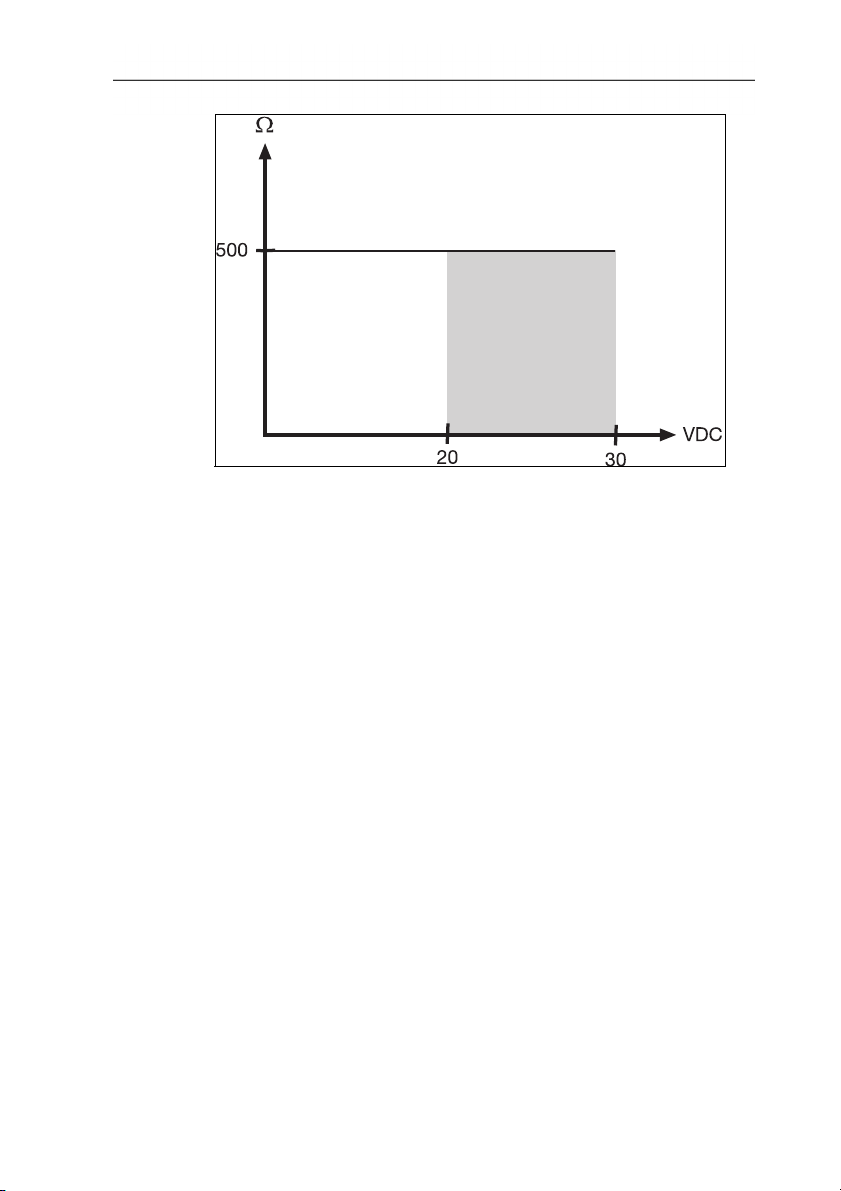

Maximum load

• 4-wire: 500 Ω (power output)

9

Page 10

4 Transmitter

Maximal load

• 10 kΩ (voltage output)

Analog output

• 0 to 1 V ± 2.5 mV (4-wire) or

• 0 to 5 V ± 12.5 mV (4-wire) or

• 0 to 10 V ± 25 mV (4-wire) or

• 4 to 20 mA ± 0.05 mA (4-wire)

• T

= 0.05 %K of measuring range per degree Kelvin of

K

deviation from nominal temperature 22 °C

10

Resolution of analog output

• 12 bit

Display

• 2-line LCD (optional)

Operating temperature

• -5 to 50 °C

Storage temperature

• -20 to 60 °C

Page 11

Application humidity

• 0 to 90 % RH

Housing, weight

• Plastic, approx. 160 g

Protection class

• IP 65 only if the transmitter is wired and/or sealing plugs are

inserted

Directives, standards and tests

• EC Directive: 2004/108/EC

Warranty

• Duration: 2 years

Pos: 25 /TD/Überschriften/MUF/1.2/2.2 Produktb eschreibung @ 3\mod_12342 58723551_79.doc @ 24008 @ 2

4.2. Product description

Pos: 26 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Auf einen Blick MUF 6321 @ 3\mod_1241599865646 _79.doc @ 32583 @ 3

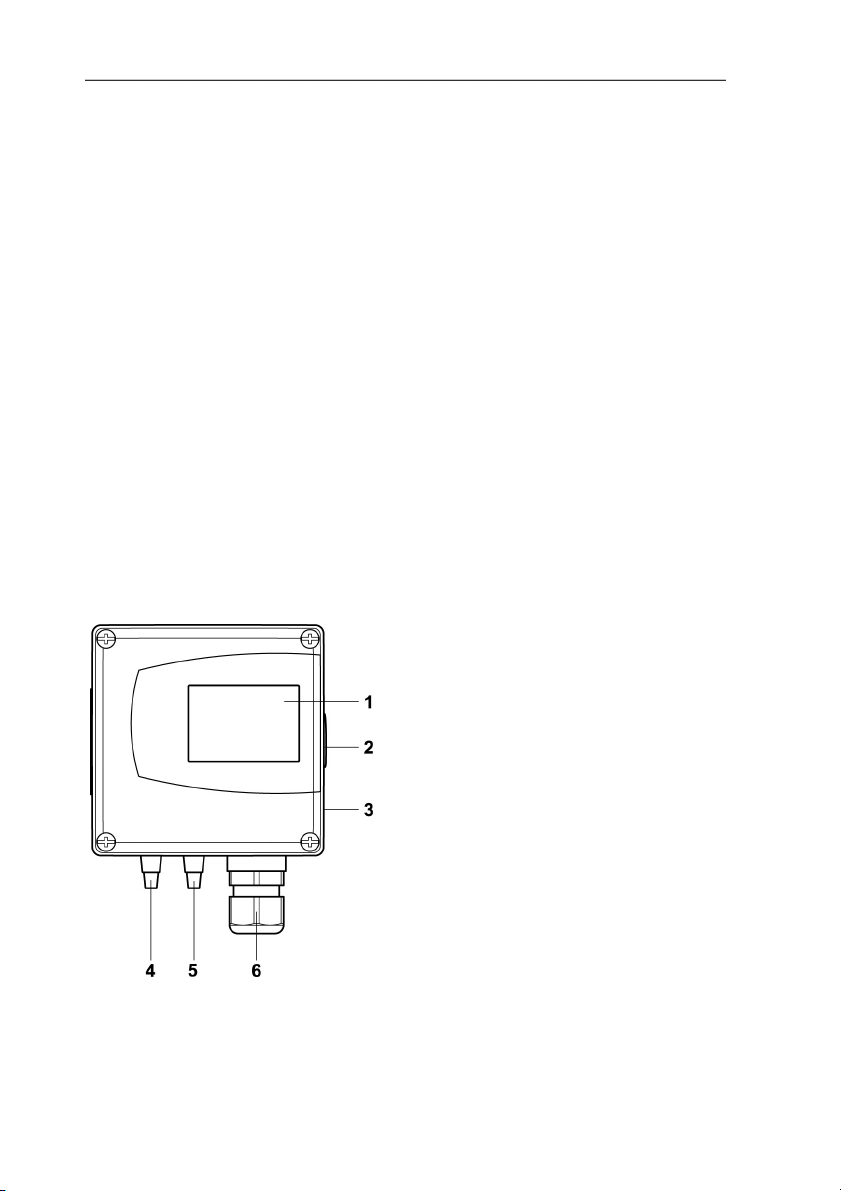

4.2.1. At a glance

• Warranty conditions: see website www.testo.com/warranty

1 Display for showing reading

(optional, cannot be retrofitted)

2 Service interface (mini-DIN port)

3 Wall bracket (on rear)

4 Negative pressure connection

5 Positive pressure connection

6 M 16 x 1.5 screw connection, e.g.

analog output

4 Transmitter

Pos: 27 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Skalierung 6321 @ 4\ mod_1252938938948_ 79.doc @ 50283 @ 3

11

Page 12

4 Transmitter

4.2.2. Scaling

There are three types of min./max. values:

1 The measuring range: The maximum sensor performance is in

this range. Measuring range, see table (below).

2 Standard scaling: The output signals are assigned to this

measuring range as standard:

◦ during delivery if no entries are made in the order code

◦ after exchanging the unit, the measuring range recorded in

Pos: 28 /TD/Produktbeschreibung/Übersicht/ MUF 63xx/Tabelle Skalier ung MUF 6321 @ 3\mod_1241617696 391_79.doc @ 32646 @

the instrument is applied as standard.

The transmitter even retains its scaling with the voltage

disconnected.

Measuring range, see table (below).

3 The maximum settings for the manual scaling

◦ The maximum limits can be calculated as follows:

X = difference between MIN. and MAX. value of the

standard scaling

(Max. value of standard) + (50 % of X)

(Min. value of standard) - (50 % of X)

◦ It is thus possible to scale beyond the measuring range, e.g.

for the adjustment of the scaling limits to standard values of

a PLC.

With the alarm definition, however, the physical measuring

range limits are decisive.

Measuring range/

standard scaling

0 to 100 Pa -50 to 150

0 to 10 hPa -5 to 15

0 to 20 hPa -10 to 30

0 to 50 hPa -25 to 75

0 to 100 hPa -50 to 150

0 to 500 hPa -250 to 750

0 to 1000 hPa -500 to 1500

0 to 2000 hPa -1000 to 3000

-100 to 100 Pa -200 to 200

-10 to 10 hPa -20 to 20

Maximum scaling

12

Page 13

4 Transmitter

Measuring range/

Maximum scaling

standard scaling

-20 to 20 hPa -30 to 30

-50 to 50 hPa -100 to 100

-100 to 100 hPa -200 to 200

-500 to 500 hPa -1000 to 1000

-1000 to 1000 hPa -2000 to 2000

-2000 to 2000 hPa -4000 to 4000

Pos: 29 /TD/Überschriften/MUF/1.3/2.3 Inbetri ebnahme @ 3\mod_123425880576 8_79.doc @ 24027 @ 2

4.3. Commissioning

Pos: 30 /TD/Erste Schritte/MUF 63xx/Wandmontage 635 x_6321 @ 3\mod_123606556800 6_79.doc @ 27063 @ 3455

4.3.1. Assembling the instrument

4.3.1.1. Wall mounting

Attaching rear panel bracket

1. Remove locking screw (see item (4) of drawing below) and

detach rear panel bracket from plastic bracket (see item (2) of

drawing below).

2. Hold rear panel bracket in assembly position and mark the three

drill holes.

3. Drill three holes (Ø 5 mm) and insert dowels where necessary.

4. Screw on rear panel bracket.

Remember that the clamping brackets (1) must face the wall.

13

Page 14

4 Transmitter

Pos: 31 /TD/Erste Schritte/MUF 63xx/Gerät verdraht en 6321 @ 3\mod_12416180871 15_79.doc @ 32667 @ 344

Fastening instrument to rear panel bracket

1. Slide plastic bracket (2) on the back of instrument onto rear

panel bracket until it engages (see arrows).

2. Insert screw (4) through hole (3) and screw into rear panel

bracket.

4.3.2. Wiring the instrument

WARNING

Electrical voltage!

> When routing cables, ensure that there is a space between the

signal line and the interfering external lines.

> If electromagnetic interference is likely, use a shielded and/or

twisted cable. Connect the shield to the earth on the side

facing away from the transmitter.

> If overvoltages are likely, install overvoltage protection devices.

WARNING

Electrical voltage

Danger of injury!

> De-energize the mains connection before connecting the

transmitter.

14

Page 15

4 Transmitter

CAUTION

Damage to electronic components!

> The terminal strip can be removed from the circuit board in

order to screw on the cable ends. After wiring, be sure to

completely attach the terminal strip on the contact pins as preassembled.

Only have the transmitter wired and connected by

authorized personnel with the voltage disconnected.

1. Loosen and remove housing screws (1).

2. Remove upper part of housing (2) from lower part of housing (3)

and place on a clean surface.

3. Wire instrument (see 3-wire system page 16, 4-wire system

page 16).

4 Place upper part of housing (2) on lower part of housing (3) and

tighten with housing screws (1).

5. On instruments with display: Remove protective film (4) from

the display cutout of the housing cover.

15

Page 16

4 Transmitter

4.3.2.1. 4-wire system

Voltage output (4-wire, 0 to 1 V/0 to 5 V/0 to 10 V)/voltage output

(4-wire, 4 to 20 mA):

U = 20 to 30 V DC/AC

4.3.2.2. 3-wire system

All ground connections are connected to one another (= one

collective ground connection).

CAUTION

Destruction of the instrument in the event of incorrect

polarity!

> When connecting the voltage supply, place collective ground

connection on PIN 2!

16

Page 17

Pos: 32 /TD/Überschriften/MUF/1.6 Wartung und Reinigu ng @ 3\mod_1234443039129 _79.doc @ 24982 @ 2

4.4. Maintenance and cleaning

Pos: 33 /TD/Produkt instand halten/MUF 63xx/Gehäuse rei nigen 6321 @ 3\mod_124109 2795617_79.doc @ 32303 @ 3

4.4.1. Cleaning housing

• Only clean the housing carefully with a moist cloth.

• Do not use aggressive cleaning agents.

Pos: 34 /TD/Produkt verwenden/MUF 63xx/Status-W arnmeldungen/Namur Fehlerb edingungen 6321 @ 4\mod_12 53024846257_79.doc @ 50363 @ 3

• Do not use any solvents.

4.4.2. Namur fault conditions

If the faults named in the following table occur, the analog outputs

output special values that enable a general fault warning in the

higher-level control system. The values correspond to the "Namur"

Status

message in

the display

Watchdog

error

Value below

min. scale

Value above

max. scale

Pressure too

high

Pos: 35 /TD/Überschriften/MUF/3 Parametrier- , Abgleich und Analysesoft ware (P2A-Software) @ 3\ mod_1234258523713_79. doc @ 23932 @ 1

industry standard.

Class

Display

Analog output

value in the

display

4 to 20 mA 1 V 5 V 10 V

Error

Previous

3.8 mA 1.1 V 5.5 V 11 V

value stops

Underrange Reading 3.8 mA 0 V 0 V 0 V

Overrange Reading 20.5 mA 1.1 V 5.5 V 11 V

Overrange ooooo · 20.5 mA 1.1 V 5.5 V 11 V

4 Transmitter

17

Page 18

5 Parameterizing, adjusting and analyzing software (P2A software)

5 Parameterizing, adjusting and analyzing

Pos: 36 /TD/Überschriften/MUF/1.1/2.1/3.1 Leis tungsbeschreibung @ 3\ mod_1234258595211_79. doc @ 23951 @ 2

5.1. Specifications

Pos: 37 /TD/Leistungsbeschreibung/Verwendung/ MUF63xx/MUF 63xx P2A @ 3\mod_123 4258967326_79.doc @ 24065 @ 355

software (P2A software)

The P2A software is used for the parameterizing, adjustment and

analysis of testo transmitters. The following applies:

• Generally, all newer testo transmitters (as of 2007) are

supported.

• Included with every testo transmitter that is bought new is a CD

that contains a free upgrade of the software, which includes the

device drivers for all transmitters that can be attached at this

time.

• This upgrade can be downloaded at any time via the testo

homepage "www.testo.com/Download/P2A".

The software must only be bought one time, even for owners of

several testo transmitters.

5.1.1. Functions and use

In the P2A software, two different file types are used: The

instrument and the parameter file.

Instrument file

The parameters of a particular transmitter are stored in its so-called

instrument file. Using this file, the parameters can be edited and the

instrument can be tested and adjusted.

Instrument files also contain the respective histories in addition to

the parameter data, i.e. "log books" are kept for the previous

parameterizations, adjustments and messages (see Transmitter

history page 33).

Instrument files are ".cfm" format files.

18

Parameter file

Parameter files are not tied to a specific individual transmitter and

contain only parameter data/no history data.

If you use various instruments of the same type, you can create

parameter files once (e.g. by saving the appropriate instrument file

as the parameter file) and transmit these onto the other

instruments.

Page 19

5 Parameterizing, adjusting and analyzing software (P2A software)

Parameter files are ".cfp" format files.

Pos: 38 /TD/Leistungsbeschreibung/Systemvoraus setzungen/MUF 63xx @ 3\ mod_1234260654399_ 79.doc @ 24084 @ 3555

5.1.2. System requirements

Operating system

• Windows® 2000 SP4

• Windows® XP Home/Professional

• Windows® Vista

Computer

• Pentium processor of at least 400 MHz or equivalent

• 128 MB RAM

• Graphics resolution of at least 1024 x 768

• Unused hard drive capacity of at least 15 MB

• CD-ROM drive

• USB interface

• At least Internet Explorer 5.0.

Software

The P2A software must be purchased and installed separately from

the transmitter. If it is a new software version, the transmitter is

already supported completely. Older P2A software versions can be

updated via the P2A software upgrade (cf. product CD included

Pos: 39 /TD/Leistungsbeschreibung/Lieferu mfang/MUF 63xx/MUF 63xx P2A @ 3\mo d_1234260991646_79.doc @ 24103 @ 3

with the transmitter).

5.1.3. Scope of delivery

Included in the scope of delivery are:

• P2A software

19

• USB driver

When working with the parameterizing, adjusting and

analyzing software (P2A software), previous knowledge of

Windows

in this instruction manual relates to Windows

®

operating systems is assumed. The description

®

XP.

Page 20

5 Parameterizing, adjusting and analyzing software (P2A software)

Pos: 40 /TD/Überschriften/MUF/3.2 Erste Schri tte @ 3\mod_1234258633304_79. doc @ 23970 @ 2

5.2. First steps

Pos: 41 /TD/Erste Schritte/MUF 63xx/P2A/Software/ Treiber installier en @ 3\mod_123426119206 5_79.doc @ 24123 @ 3444

5.2.1. Installing the software/driver

Administrator rights are required to install programs and

drivers under Windows

®

2000 SP4, XP and Vista.

5.2.1.1. Installing P2A software

1. Insert CD with P2A software.

✓ If the installation program does not start automatically:

> Open Windows Explorer and start the file Setup.exe on the

product CD.

2. Follow the directions of the installation wizard.

5.2.1.2. Installing USB driver

Before installing the USB driver, please read the separate

documentation that is enclosed with the USB driver CD.

5.2.1.3. P2A software upgrade

1. Insert product CD (supplied with the transmitter).

2. Open Windows® Explorer and start the file P2A upgrade.exe

on the product CD.

Pos: 42 /TD/Erste Schritte/MUF 63xx/P2A/Software st arten _6321 @ 3\mod_12422 85508828_79.doc @ 32883 @ 3444

3. Follow the directions of the installation wizard.

5.2.2. Starting the software

5.2.2.1. Starting the program

> Select: [Start] > All Programs > Testo > P2A Software.

- The program window is opened (see User interface page 21).

5.2.2.2. Establishing a connection with the instrument

Multiple instruments can be attached, however only one connection

is active at all times.

✓ USB driver is installed (see Installing USB driver page 20).

1. Start the P2A software.

2. Connect adapter (supplied with the P2A software) to the service

interface of the instrument (see item 2, At a glance page 11).

20

Page 21

5 Parameterizing, adjusting and analyzing software (P2A software)

3. Connect instrument/adapter to the PC via the USB interface.

- The instrument file of the attached instrument is shown in the

file list.

5.2.2.3. Activating the connection with the instrument

> Click on the desired instrument file.

- The selected file is marked in colour and the connection with

the instrument is activated.

If a connection with the instrument is established when the program

is started, the corresponding instrument file is marked

Pos: 43 /TD/Überschriften/MUF/3.3 Software verwend en @ 3\mod_1234258679599_ 79.doc @ 23989 @ 2

5.3. Using the software

Pos: 44 /TD/Produkt verwenden/MUF 63xx/P2A/Software verwenden @ 3\mod_12342626 54547_79.doc @ 24162 @ 3

5.3.1. User interface

automatically.

1 Menu bar:

Menu Command Explanation

File Open

Shows the Windows dialogue for

searching and opening files.

Save as

Saves the parameters of an

instrument or parameter file

under a new name.

21

Page 22

5 Parameterizing, adjusting and analyzing software (P2A software)

Menu Command Explanation

Edit Copy

Copies the parameters of the

marked instrument or parameter

file in the cache.

Paste

Pastes the parameters from the

cache in the marked instrument

or parameter file.

View Toolbar

Status bar

?

Check instrument

connections

Activates/deactivates the toolbar

or status bar.

Checks the connections to a

connected instrument without the

instrument having to be

activated.

Service

A text file with the most important

information on the computer and

the software is opened via

Display service data.

Information

Shows the version number of the

P2A software.

2 Toolbar: Shows the Windows-compliant icons for editing.

3 File:

Icon File Explanation

Symbol shows a

transmitter

Instrument

file

Instrument file

Connection to the instrument has

been established.

<Type> <Serial number>.cfm

File name should not be

changed.

Symbol shows a

transmitter with a red

minus sign in the upper

left corner

Instrument

file

Instrument file

Connection to the instrument has

not been established.

22

Page 23

5 Parameterizing, adjusting and analyzing software (P2A software)

Icon File Explanation

Symbol shows a

transmitter with a white

P for parameter file in

the upper left corner

Parameter

file

<Type> <Serial number>

<Date> <Time>.cfp

File name can be changed.

The name can be selected freely,

but it is recommended that you

retain the reference to the

instrument.

Parameter files are always

marked red; the parameter

values they contain are only

forwarded to the instrument after

being transmitted to the

instrument file.

4 Function buttons: Dialogues on editing and testing the

instrument are opened by means of the buttons.

[Change parameterization] see Changing instrument/parameter

file page 24

[Test/analyze transmitter] see Chapter Analyzing/testing the

transmitter page 27

[Adjusting the transmitter] see Chapter Adjusting the transmitter

page 31

[Transmitter history] see Transmitter history page 33

5 File information:

Status Shown in the window

An instrument file is

selected

A parameter file is

selected

Type, serial number, firmware version of the

instrument.

Type, serial number and firmware version of

instrument for which the parameter file was

created.

Connection status Green = connection is active

Red = connection is inactive

6 Status bar: Shows the current status when editing via the menu

bar.

23

Page 24

5 Parameterizing, adjusting and analyzing software (P2A software)

Pos: 45 /TD/Produkt verwenden/MUF 63xx/P2A/Geräte-/ Parameterdatei bear beiten @ 3\mod_1234358080 444_79.doc @ 24303 @ 34

5.3.2. Editing instrument/parameter file

5.3.2.1. Changing instrument/parameter file

✓ The desired instrument/parameter file is marked.

1. Click on [Change parameterization].

- The Properties of <Instrument type> <Serial number>

dialogue is opened with the Change parameterization register.

If the parameters were transmitted from other parameter files into

the instrument file, a message is shown with which you can

transmit the new parameters to the connected instrument using

[Yes].

> If the parameters should not be transmitted, click on [No].

Pos: 46 /TD/Produkt verwenden/MUF 63xx/P2A/Einhei t / Analogausgang ohne Relai s @ 4\mod_1244205188941_ 79.doc @ 44503 @

2. Change or enter parameters in the corresponding fields.

Field Explanation

Unit/

Analog output

All analog outputs are parameterized in this

mask.

24

Page 25

Pos: 47 /TD/Produkt verwenden/MUF 63xx/P2A/Geräteda tei erzeugen @ 3\mod_123 7206865717_79.doc @ 29703 @ 4

5 Parameterizing, adjusting and analyzing software (P2A software)

Field Explanation

Unit/analog output

(graphic)

Unit: 0 to 1 V/5 V/10 V or 4 to 20 mA.

Vertical: Current version of the analog output

(cannot be changed).

Horizontal: Min./max. scale end points of

selected unit.

The curve changes in accordance with the

entered value of scale minimum and

maximum.

Scale minimum/

maximum

The endpoints of the scaling can be selected

up to the stored scale minimum and

maximum. In the process, scaling can take

place beyond the measuring range in order

to adjust the analog output to the customer

system, see Scaling page 12.

Unit Selection of the physical unit.

When changing the unit, standard values are

set for scale minimum and maximum.

Signal delay

(graphic)

Curve changes according to the set signal

delay.

Signal delay Time interval in stages 1 – 15:

1 = no delay

15 = longest delay.

The signal delay is added to the reaction time

of the sensor. The signal delay shows

averaging over the time interval of the

selected stage in seconds:

Example

Stage 10 = average of the readings from the

last 10 seconds.

The delay of the signal in relation to the change in the

process is also significantly influenced by the selection of

the particle filter.

25

Page 26

5 Parameterizing, adjusting and analyzing software (P2A software)

5.3.2.2. Creating a new instrument file

It is possible to create an instrument file without restarting the P2A

software.

✓ Transmitter must be connected.

1. Click on File > New connection in the menu bar.

Pos: 48 /TD/Produkt verwenden/MUF 63xx/P2A/Parame ter speichern @ 3\mod_12343 58425697_79.doc @ 24322 @ 4

- Connection to the transmitter is established.

5.3.2.3. Saving parameters

Parameters can be saved in new parameter files.

1. Mark instrument/parameter file.

2. Click on File > Save as in the menu bar.

3. Select storage location and enter the file name.

4. Click on [Save].

- The new parameter file is shown in the file list.

Only the parameters are saved from an instrument file; the history

Pos: 49 /TD/Produkt verwenden/MUF 63xx/P2A/Parame terdatei öffnen @ 3\mod_1234 358634164_79.doc @ 24341 @ 4

data are not adopted.

The original name (Instrument type, Serial number) is

suggested with the current date/time as standard, e.g.

"testo 6321 01234578 061120 1403.cfp".

For a standard installation, the files are saved under

"C:\Documents and Settings\All Users\Shared

Documents\P2A Software". The path can differ depending

on the version of the operating system.

5.3.2.4. Opening the parameter file

All parameter files stored in the standard directory path are

automatically displayed in the file list when the software is started.

You can also open parameter files that are stored in other

directories.

1. Click on File > Open in the menu bar.

2. Select the storage location and click on the requisite file.

3. Click on [Open].

- The selected file is opened. This can be changed and saved

(see Editing instrument/parameter file page 24).

26

Page 27

5 Parameterizing, adjusting and analyzing software (P2A software)

Pos: 50 /TD/Produkt verwenden/MUF 63xx/P2A/Parame ter kopieren/einfügen @ 3\ mod_1234358826054_7 9.doc @ 24360 @ 4

5.3.2.5. Copying and pasting parameters

The parameters of a parameter file can be transmitted to an

instrument file or another parameter file from the same instrument

type.

1. Select file from which parameters are to be copied.

2. Click on Edit > Copy in the menu bar.

3. Select the file which is to be modified.

4. Click on Edit > Paste in the menu bar.

Pos: 51 /TD/Produkt verwenden/MUF 63xx/P2A/Geräte-/ Parameterdatei lösc hen @ 3\mod_12343590251 94_79.doc @ 24379 @ 4

- The parameters are transmitted to the file.

You can also use the common keyboard shortcuts for

copying (CTRL+C) and pasting (CTRL+V).

Parameters can also be transmitted using drag & drop,

where you drag the icon of the parameter file onto the icon

of the target instrument file.

5. Connect and select corresponding instrument.

6. Click on [Change parameterization].

7. Confirm confirmation request.

- Parameter data are transferred to the instrument.

5.3.2.6. Deleting instrument/parameter file

Instrument/parameter files can be deleted from the file list.

1. Click on the file that is to be deleted with the right mouse button.

2. Select the command Delete in the context menu.

Pos: 52 /TD/Überschriften/MUF/x.x.x Messumformer analysieren / testen @ 3\mo d_1237380874787_79.doc @ 29928 @ 3

5.3.3. Analyzing/testing the transmitter

Pos: 53 /TD/Produkt verwenden/MUF 63xx/P2A/Messu mformer analysieren/tes ten 632x @ 3\mod_12421392 84458_79.doc @ 32824 @ 4

27

- The instrument or parameter file is deleted from the list.

In this section, you can test the outputs of the connected

instrument, read off the limit values and reset the parameters to the

factory settings.

The function is only available for instrument files.

Page 28

5 Parameterizing, adjusting and analyzing software (P2A software)

5.3.3.1. Analyzing/testing the instrument

✓ The required instrument file is marked.

1. Click on [Test/analyze transmitter].

- The Properties of <Instrument type> <Serial number>

dialogue is opened with the Test/analyze transmitter register.

2. Perform action:

Action Explanation

Carry out factory

reset

Test analog output

Reset the unit, limit value and hysteresis

parameters to factory settings (see below).

Test channel 1 (see Testing analog output

page 28).

Display min./max.

values

Overview of the minimum and maximum

values measured since the last reset of the

transmitter (see Displaying min./max. values

page 30).

Pos: 54 /TD/Produkt verwenden/MUF 63xx/P2A/Wer ksreset durchführen @ 3\mod_1 237379864072_79.doc @ 29887 @ 4

3. Click on [OK] or [Cancel] to close the dialogue.

5.3.3.2. Carrying out factory reset

✓ The required instrument file is marked.

1. Click on [Test/analyze transmitter].

- The Properties of <Instrument type> <Serial number>

dialogue is opened with the Test/analyze transmitter register.

2. Mark transmitter test.

- Current operating hours are shown.

3. Confirm control query to perform the reset.

- The values are reset to the customer-specific factory settings.

Pos: 55 /TD/Produkt verwenden/MUF 63xx/P2A/Analogaus gang testen 6321 @ 4\mod_12 44461179628_79.doc @ 44787 @ 4

4. Click on [OK] or [Cancel] to close the dialogue.

5.3.3.3. Testing analog output

✓ The required instrument file is marked.

1. Click on [Test/analyze transmitter].

- The Properties of <Instrument type> <Serial number>

dialogue is opened with the Test/analyze transmitter register.

2. Mark channel and test values.

28

Page 29

5 Parameterizing, adjusting and analyzing software (P2A software)

Field/button Explanation

Transmitter test Monitoring of analog outputs

Current reading Readings are updated every second.

Unit

Unit according to the type of analog

output.

Default value

Freely definable output value for the

respective type of analog output (V or

mA), 1 decimal place.

[Activate] The entered defined value is

forwarded to the analog output by

clicking. The current reading is frozen.

A warning informs that the value is

being transmitted to the connected

instrument in the event of existing

cabling.

Now check the analog output using a

precise multimeter.

[Deactivate] Finish entering the electrical variables

at the analog output.

The analog output returns to the

current reading again.

3. Click on [OK] or [Cancel] to close the dialogue.

- The analog output returns to Measuring Mode again.

29

Page 30

5 Parameterizing, adjusting and analyzing software (P2A software)

Pos: 56 /TD/Produkt verwenden/MUF 63xx/P2A/Min-/Ma x-Werte anzeigen 635 x @ 3\mod_1242135985269_79.doc @ 32803 @ 4

5.3.3.4. Displaying min./max. values

The transmitter saves the minimum or maximum value for each

channel (measured since the last voltage supply or since the last

manual reset).

✓ The required instrument file is marked.

1. Click on [Test/analyze transmitter].

- The Properties of <Instrument type> <Serial number>

dialogue is opened with the Test/analyze transmitter register.

2. Mark Min./max. values.

Field/button Explanation

Min./max. values

View the min./max. values of each channel.

Only the values within the measuring range

are shown.

30

Channel Channel 1 min./max.

Value Min. or max. value, 1 decimal place.

Unit

Unit selected in Unit/analog output.

3. Reset Min./max. values.

4. Click on [Reset min./max. values].

5. Confirm control query to perform the reset.

- The values are reset to the factory settings.

Page 31

5 Parameterizing, adjusting and analyzing software (P2A software)

Pos: 57 /TD/Überschriften/MUF/x.x.x Messumformer abgleichen @ 4\mod_12445 30152797_79.doc @ 44885 @ 3

5.3.4. Adjusting the transmitter

Pos: 58 /TD/Produkt verwenden/MUF 63xx/P2A/Messu mformer abgleichen 6321 @ 4\ mod_1244460546736_79. doc @ 44755 @

6. Click on [OK] or [Cancel] to close the dialogue.

This function is used to adjust an attached instrument. The

following adjustments may be carried out using the software:

• Analog adjustment (entry via assistant/wizard)

Pos: 59 /TD/Produkt verwenden/MUF 63xx/P2A/n-Punkt- Abgleich _6321 @ 3\mod_1242 221387590_79.doc @ 32853 @ 4

• n-point adjustment (entry via assistant/wizard)

5.3.4.1. n-point adjustment

With an n-point adjustment, the parameters at the 3-6

measurement points are adjusted to the reference value. The

reference conditions are obtained by using a precise pressure

sensor that should be 5-times more accurate than the transmitter.

✓ A precise pressure sensor (5-times more accurate than the

transmitter, e.g. DPC precision pressure sensor from testo

industrial services) is available.

1. Connect positive output of the pressure sensor (3) to the

positive pressure connection of the transmitter (2) and the

negative output of the pressure sensor (3) to the negative

pressure connection of the transmitter (1).

1 Negative pressure connection

2. Positive pressure connection

3. Pressure sensor

4. Connect transmitter to PC via service plug.

5. Mark the instrument file of the connected instrument in the P2A

software.

6. Click on [Adjusting the transmitter].

- The Properties of <Instrument type> <Serial number>

dialogue is opened with the Adjusting the transmitter register.

7. Mark n-point adjustment.

8. Click on [Start wizard …] and follow the instructions of the

wizard.

- The adjustment is performed when the wizard is closed.

31

Page 32

5 Parameterizing, adjusting and analyzing software (P2A software)

Field Explanation

How much pressure

is actually applied

Required field: Entry of the value read off at

the pressure sensor.

The n-point adjustment must always be carried out to its full

extent and in good time at all selected adjustment points.

9. Disconnect connections between the pressure sensor and the

Pos: 60 /TD/Produkt verwenden/MUF 63xx/P2A/Analogaus gang abgleichen _6321 @ 4\mod_1244461217550_7 9.doc @ 44819 @ 4

pressure connections of the testo 6321.

5.3.4.2. Adjusting the analog output

1. Connect precision multimeter (see Wiring the instrument page

14).

2. Mark the instrument file of the connected instrument.

3. Click on [Adjusting the transmitter].

- The Properties of <Instrument type> <Serial number>

dialogue is opened with the Adjusting the transmitter register.

4. Click on [Start wizard …] and follow the instructions of the

wizard.

- The adjustment is performed when the wizard is closed.

32

Page 33

5 Parameterizing, adjusting and analyzing software (P2A software)

Field Explanation

Default value

The analog output value from the last

performed adjustment is given at the output.

Value of the factory adjustment:

• Lower adjustment point: approx. 10 % of

the max. value

• Centre adjustment point: approx. 50 % of

the max. value

• Upper adjustment point: approx. 90 % of

the max. value

Measured analog

value

Pos: 61 /TD/Überschriften/MUF/2.3.5 Messumformer- Historie @ 3\mod_123737 3806926_79.doc @ 29846 @ 3

5.3.5. Transmitter history

Pos: 62 /TD/Produkt verwenden/MUF 63xx/P2A/Messu mformer-Historie 6321 @ 4\m od_1244458681753_79.d oc @ 44723 @

Required field: Entry of the value read off at

the multimeter.

Parameterizations and adjustment processes are registered in the

transmitter with an operating hours stamp.

In the history overviews (explained later in more detail), past

processes and events can be made visible.

For entries that are performed using the P2A software, the

name of the user logged into Windows appears in the User

field, while the date/time and operating hour are shown in

the Date/time field.

1. Mark the instrument file of the connected instrument.

33

Page 34

5 Parameterizing, adjusting and analyzing software (P2A software)

2. Click on the [Transmitter history] button.

- The Properties of <Instrument type> <Serial number>

dialogue is opened with the Transmitter history register.

3. Click on the required entry in the list to change the display.

Field Explanation

Operating hours /

date/time

User

Operating hour/time stamp at which the

change at the instrument was performed.

Name with which the user is logged into the

operating system.

Comments

Type of parameter change, e.g. "Unit of

channel 1 from Pa to hPa".

34

Page 35

5 Parameterizing, adjusting and analyzing software (P2A software)

Field Explanation

Selection of adjustment histories: n-point adjustments / Analog

adjustments.

Operating hours /

date/time

User

Operating hour/time stamp at which the

change at the instrument was performed.

Name with which the user is logged into the

operating system.

Channel Analog adjustment: Channel 1.

Specification Analog adjustment: Current reading.

Multimeter

Analog adjustment: Value read off at

reference instrument.

Offset

Analog adjustment: Deviation at time of

adjustment.

Pressure

specification

n-point adjustment: Value read off at

pressure sensor.

Unit Unit during the adjustment.

> To print out the history data, click on [Print].

The printing job is automatically sent to the default printer

for the operating system.

With [Set up printer …] a different printer can be selected

or the printout can be edited.

35

Page 36

6 Tips and assistance

Pos: 63 /TD/Überschriften/8. Tipps und Hilfe @ 0\mod_11 73789887985_79.doc @ 406 @ 1

6 Tips and assistance

Pos: 64 /TD/Überschriften/8.1 Fragen und Antworten @ 0\ mod_1177402017078_79. doc @ 1093 @ 2

6.1. Questions and answers

Pos: 65 /TD/Tipps und Hilfe/Fragen und Antworten/MUF 6321 @ 3\ mod_1241681063453_79. doc @ 32693 @

4. Click on [OK] or [Cancel] to close the dialogue.

Question Possible causes/solution

Connection to instrument

Check connection cable/plug contacts

cannot be established

Malfunction (with and

without display)

Analysis using the P2A software, see

Analyzing/testing the transmitter

page 27

Adjustment is to be

reversed

When does a stable

Carry out factory reset (Test/analyze

transmitter).

After approx. 20 seconds

current reading appear?

If we could not answer your question, please contact your dealer or

Testo Customer Service. For contact details see the rear side of

Pos: 66 /TD/Überschriften/8.2 Zubehör und Ersatztei le @ 0\mod_1177402058734 _79.doc @ 1102 @ 2

6.2. Accessories and spare parts

Pos: 67 /TD/Tipps und Hilfe/Zubehör und Ersatzteile/ MUF63xx/Zubehör Ersa tzteile MUF 6321 @ 3\mod_123997 5742627_79.doc @ 3171 5 @

this document or the web page www.testo.com/service-contact

Description Article no.

Interface and software

P2A software (parameterizing, adjusting,

analyzing) incl. USB adapter

Supply

Mains unit (desktop, wall-mounted) 0554 1748

Mains unit (top-hat rail mounting) 0554 1749

Hose

Silicone hose ID 4 transparent

TYGON hose ID 4.8 transparent

Calibration

Standard ISO calibration certificate,

transmitter only

0554 6020

0086 0001, sold by

the metre

0086 0031, sold by

the metre

0520 1000

36

Page 37

6 Tips and assistance

Description Article no.

Standard DKD calibration certificate,

0520 1200

transmitter only

For a complete list of all accessories and spare parts, please refer

to the product catalogues and brochures or look up our website at:

Pos: 68 /TD/Tipps und Hilfe/Zubehör und Ersatzteile/ MUF63xx/Bestellopti onen MUF 6321 @ 3\mod_12399757 48830_79.doc @ 31736 @ 3

www.testo.com

6.2.1. Ordering options for testo 6321 transmitter

(0555 6321)

Order code Characteristic

Axx Measuring range

A03 0 to 100 Pa

A05 0 to 10 hPa

A06 0 to 20 hPa

A07 0 to 50 hPa

A08 0 to 100 hPa

A09 0 to 500 hPa

A10 0 to 1000 hPa

A11 0 to 2000 hPa

A23 -100 to 100 Pa

A25 -10 to 10 hPa

A26 -20 to 20 hPa

A27 -50 to 50 hPa

A28 -100 to 100 hPa

A29 -500 to 500 hPa

A30 -1000 to 1000 hPa

A31 -2000 to 2000 hPa

Bxx Analog

output/supply

B02 0 to 1 V (4-wire, 24 V AC/DC)

B03 0 to 5 V (4-wire, 24 V AC/DC)

B04 0 to 10 V (4-wire, 24 V AC/DC)

B06 4 to 20 mA (4-wire, 24 V AC/DC)

37

Page 38

6 Tips and assistance

Order code Characteristic

Cxx Display

C00 Without display

C01 With display

Exx Housing colour

and logo

E01 Grey housing, testo logo in colour

E02 White housing, without testo logo

E03 White housing, black-and-white testo logo

Fxx Differential

pressure unit

F01 Pa/Min/Max

F02 hPa/Min/Max

F03 kPa/Min/Max

F04 mbar/Min/Max

F05 bar/Min/Max

F06 mm H2O /Min/Max

F07 inch H2O /Min/Max

F08 inch HG /Min/Max

F09 kg/cm2 /Min/Max

F10 PSI/Min/Max

Kxx Languages of

instruction manual

K01 German/English instruction manual

K02 French/English instruction manual

K03 Spanish/English instruction manual

K04 Italian/English instruction manual

K05 Dutch/English instruction manual

K06 Japanese/English instruction manual

K07 Chinese/English instruction manual

C

=== Ende der Liste für Textmarke Inhalt ===

38

Page 39

Page 40

0970 6321 en 01 V01.00 V01.40-1

Loading...

Loading...