Page 1

testo 570 · Digital manifold

Instruction manual

Page 2

2

Page 3

1 Contents

1 Contents

1 Contents ................................................................................................... 3

2 Safety and the environment .................................................................... 4

2.1. About this document ........................................................................ 4

2.2. Ensure safety ................................................................................... 5

2.3. Protecting the environment .............................................................. 5

3 Specifications .......................................................................................... 6

3.1. Use .................................................................................................. 6

3.2. Technical data ................................................................................. 6

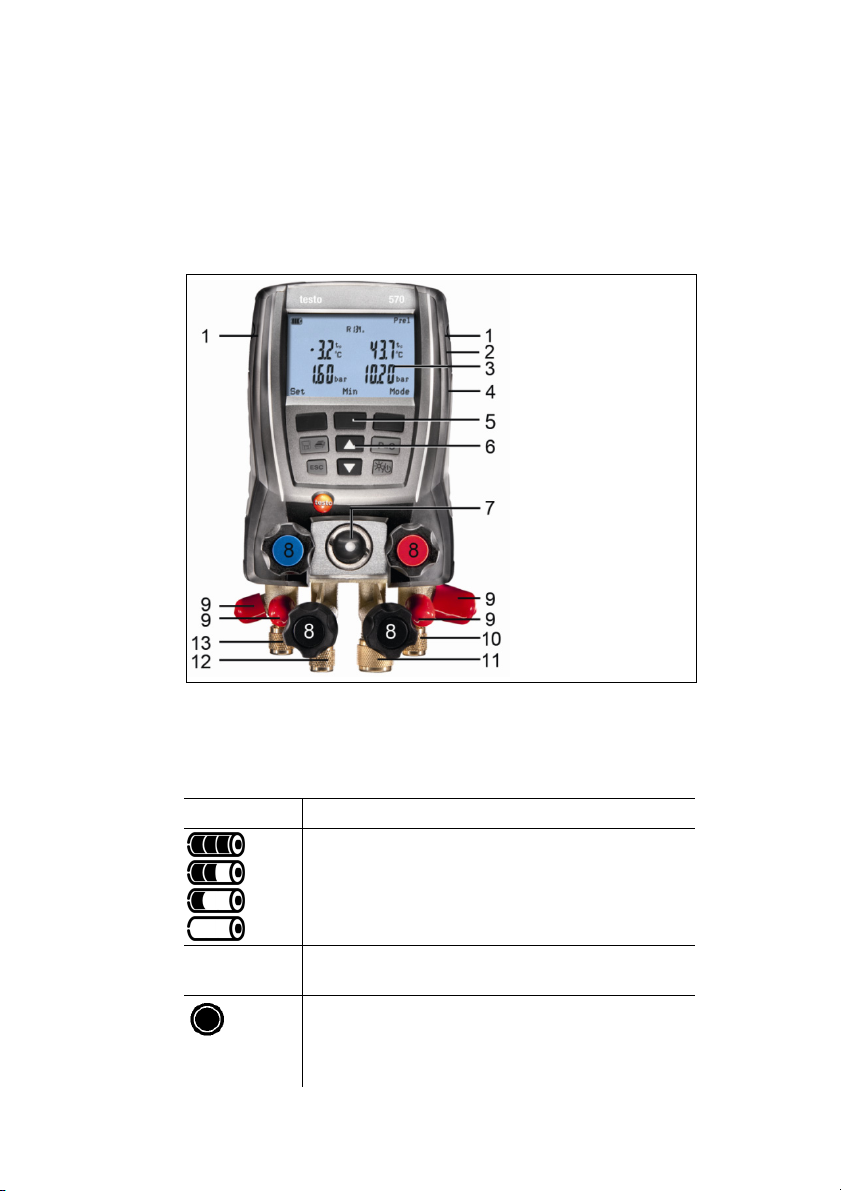

4 Product description ................................................................................. 9

4.1. Overview.......................................................................................... 9

5 First steps .............................................................................................. 11

6 Using the product .................................................................................. 15

6.1. Preparing for measurement ........................................................... 15

6.1.1. Connecting temperature probe, Testo 552 and accessories .......................... 15

6.1.2. Switching the instrument on ........................................................................... 17

6.1.3. Choosing the measuring mode ...................................................................... 18

6.2. Performing the measurement ........................................................ 19

6.2.1. Measuring ...................................................................................................... 19

6.2.2. Tightness test / pressure drop test ................................................................. 20

6.2.3. Evacuation / vacuum display .......................................................................... 21

6.2.4. Vacuum measurement ................................................................................... 21

6.2.5. Charging ........................................................................................................ 22

6.2.6. Emptying ........................................................................................................ 22

6.2.7. Pressure/Compressor .................................................................................... 23

6.2.8. Current ........................................................................................................... 23

6.2.9. Efficiency calculation ...................................................................................... 23

6.3. Saving measurement values ......................................................... 23

6.4. Printing measurement values ........................................................ 25

7 Maintaining the product ........................................................................ 26

8 Tips and assistance ............................................................................... 28

8.1. Questions and answers ................................................................. 28

8.2. Measurement parameters ............................................................. 28

8.3. Error reports .................................................................................. 29

8.4. Accessories and spare parts ......................................................... 29

9 Appendix ................................................................................................ 30

9.1. Basis of calculation COP ............................................................... 30

3

Page 4

2 Safety and the environment

2 Safety and the environment

2.1. About this document

Use

> Please read this documentation through carefully and

familiarize yourself with the product before putting it to use. Pay

particular attention to the safety instructions and warning advice

in order to prevent injuries and damage to the products.

> Keep this document to hand so that you can refer to it when

necessary.

> Hand this documentation on to any subsequent users of the

product.

Symbols and writing standards

Representation Explanation

Warning advice, risk level according to the

signal word:

Warning! Serious physical injury may occur.

Caution! Slight physical injury or damage to

the equipment may occur.

> Implement the specified precautionary

measures.

Note: Basic or further information.

1. ...

2. ...

Action: more steps, the sequence must be

followed.

> ... Action: a step or an optional step.

- ... Result of an action.

Menu Elements of the instrument, the instrument

display or the program interface.

[OK] Control keys of the instrument or buttons of

the program interface.

... | ... Functions/paths within a menu.

“...” Example entries

4

Page 5

2.2. Ensure safety

> Do not operate the instrument if there are signs of damage at

the housing, mains unit or feed lines.

> Do not perform contact measurements on non-insulated, live

parts.

> Do not store the product together with solvents. Do not use any

desiccants.

> Carry out only the maintenance and repair work on this

instrument that is described in the documentation. Follow the

prescribed steps exactly. Use only original spare parts from

Testo.

> The objects to be measured or the measurement environment

may also pose risks: Note the safety regulations valid in your

area when performing the measurements.

> If the measuring instrument falls or another comparable

mechanical load occurs, the pipe sections of the refrigerant

hoses may break. The valve positioners may also be damaged,

whereby further damage to the interior of the measuring

instrument may occur that cannot be identified from the outside.

The refrigerant hoses must therefore be replaced with new,

undamaged refrigerant hoses every time the measuring

instrument falls or following any other comparable mechanical

load. Send the measuring instrument to Testo Customer

Service for a technical check for your own safety.

> Electrostatic charging can destroy the instrument. For online

measurement (instrument connected to PC/laptop) or when

using the mains unit in particular, you should therefore integrate

all components (system, valve manifold of the manifold gauge,

refrigerant bottle, etc.) into the equipotential bonding (earthing

system) prior to measurement. Please see the safety

instructions for the system and the refrigerant used.

2 Safety and the environment

2.3. Protecting the environment

> Dispose of faulty rechargeable batteries/spent batteries in

accordance with the valid legal specifications.

> At the end of its useful life, send the product to the separate

collection for electric and electronic devices (observe local

regulations) or return the product to Testo for disposal.

> Refrigerant gases can harm the environment. Please note the

applicable environmental regulations.

5

Page 6

3 Specifications

3 Specifications

3.1. Use

The testo 570 is a digital manifold for commissioning, maintenance

and service work on refrigeration systems and heat pumps. It can

be used for fault diagnose and online measurements on

refrigeration systems and heat pumps. The testo 570 is only to be

used by qualified expert personnel.

With its functions the testo 570 replaces mechanical manifolds,

thermometers and pressure/temperature charts. Pressures and

temperatures can be applied, adapted, tested and monitored.

Its scope of functions can be considerably extended by means of

extensive, separately available accessories, e.g. various

temperature sensors, clamp probe, oil pressure probe,

PC software.

The testo 570 is compatible with most of the non-corrosive

refrigerants, water and glycol. The testo 570 is not compatible with

ammoniac refrigerants.

3.2. Technical data

Then product must not be used in explosive environments!

Feature Values

Measurement

parameters

Pressure: kPa/MPa/bar/psi

Temperature: °C / °F / K

Vacuum: hPa / mbar/ Torr / inH

inHg / Pa

Current: A

Measuring sensor

Pressure: 2 x pressure sensor

Temperature: 3 x NTC

Measuring cycle 0.75 s

Connections

Pressure connections: 3 x 7/16" UNF+ 1x

5/8“

NTC measurement

Interfaces 3x Mini-DIN, 1x Mini-USB, 1 x IR

O / Micron /

2

1

1

via clamp probe (optional accessory)

6

Page 7

3 Specifications

Feature Values

Measurement

ranges

Pressure measurement range

HP/LP: -100…5000 kPa / -0.1…5 Mpa

/ -1…50 bar (rel) / -14.7…725 psi

Temperature measurement

range: -50…+150 °C / -58…302 °F

Measurement range vacuum (rel): -1…0 bar

/ -14.7…0 psi

Overload 52 bar, 5200 kPa, 5.2 Mpa, 754 psi

Resolution

Resolution pressure: 0.01 bar / 0.1 psi /

1 kPa / 0.001 Mpa

Resolution temperature: 0.1 °C / 0.1 °F /

0.1 K

Vacuum resolution: 1 hPa / 1 mbar / 0.5 Torr

Accuracy (nominal

temperature

22 °C/71.6°F)

/ 0.5 inH

Pressure: ±0.5% of final value (±1 digit)

Temperature (-40…302 °F/-40…+150 °C):

±0.5 °C (±1 Digit), ±0.9 °F (±1 digit), ±0.5 K

O / 0.02 inHg / 500 Micron / 100 Pa

2

(±1 digit)

Vacuum: 1% of final value (±1 digit)

No. of refrigerants 40

Selectable

refrigerants

No refrigerant, R12, R22, R123, R134a,

R227, R290, R401A, R401B, R402A, R402B,

R404A, R406A, R407A, R407C, R408A,

R409A, R410A, R411A, R413A, R414B,

R416A, R417A, R420A, R421A, R421B,

R422A, R422B, R422D, R424A, R427A,

R434A, R437A, R438A, R502, R503, R507,

R600, R600a, R744 (only in the permissible

measurement range up to 50 bar), R1234yf

Further refrigerants can be

downloaded under www.testo.com.

Memory capacity

10000 single measurements or 50 series

measurements (each with a measuring cycle

of 2 s, measurement period 100 h)

Measuring cycle 2 s...24 h (freely selectable)

Measurable media

Measurable media: all media that are stored

in the testo 570. Not measurable: ammonia

(R717) and other refrigerants which contain

ammonia

7

Page 8

3 Specifications

Feature Values

Ambient conditions

Housing Material: ABS / PA / TPE

IP-class 42 (position in use hanging down)

Power supply

Display Type: Illuminated LCD

Directives,

standards and tests

Warranty Duration: 2 years

Operating temperature: -20 to 50 °C / -4 to

122°F

Storage temperature: -20...60 °C / -4...140 °F

Humidity in area of use: 10 ... 90 %RH

Dimensions approx. 280 x 135 x 75 mm

Weight: approx. 1200 g (without batteries)

Current source: 4 x 1.5 V rechargeable/nonrechargeable batteries

Type AA / Mignon / LR6

Battery life: > 40h (display light off)

Response time: 0.5 s

EC Directive: 2004/108/EC

Terms of warranty: see website

www.testo.com/warranty

8

Page 9

4 Product description

4.1. Overview

Display and control elements

4 Product description

1 Sensor socket Mini-DIN for NTC-temperature sensor, with

socket cover.

2 Suspension attachment, foldable (backside).

3 Display Instrument status icons:

Icon Meaning

no battery

Battery capacity: >75% / >50% / >25% / <10%

Instrument is operated with power supply unit.

indication

The measurement value is saved; in case of a

single measurement the inner circle flashes

once, with serial measurements the circle

flashes with each save procedure.

9

Page 10

4 Product description

4 Battery compartment. Charging rechargeable batteries inside

5 Multi-function keys: The relevant function appears in the

6 Control keys:

Key Function

[ ]

[ESC]

[▲]

[▼]

[p=0] Zero the pressure sensor in the range +1 to

[]

7 Inspection glass for refrigerant flow.

8 4 x valve actuators.

9 4 x hose brackets for refrigerant hoses.

10 Connection 7/16“ UNF, brass.

11 Connection 5/8“ UNF, brass, for vacuum pump.

12 Connection 7/16“ UNF, brass, for e.g. refrigerant cylinders, with

13 Connection 7/16“ UNF, brass.

the instrument is not possible!

display.

Save or print measurement data.

Exit the menu option.

Up-key: Change display view.

Down-key: Change display view.

-1.3 bar.

Switch instrument on / off; short actuation

during operation: switches illumination on /

off.

High pressure, for refrigerant hoses with quick release screw

fitting, passage for valve actuator lockable.

screw cap.

Low pressure for refrigerant hoses with quick release screw

fitting, passage for valve actuator lockable.

10

Page 11

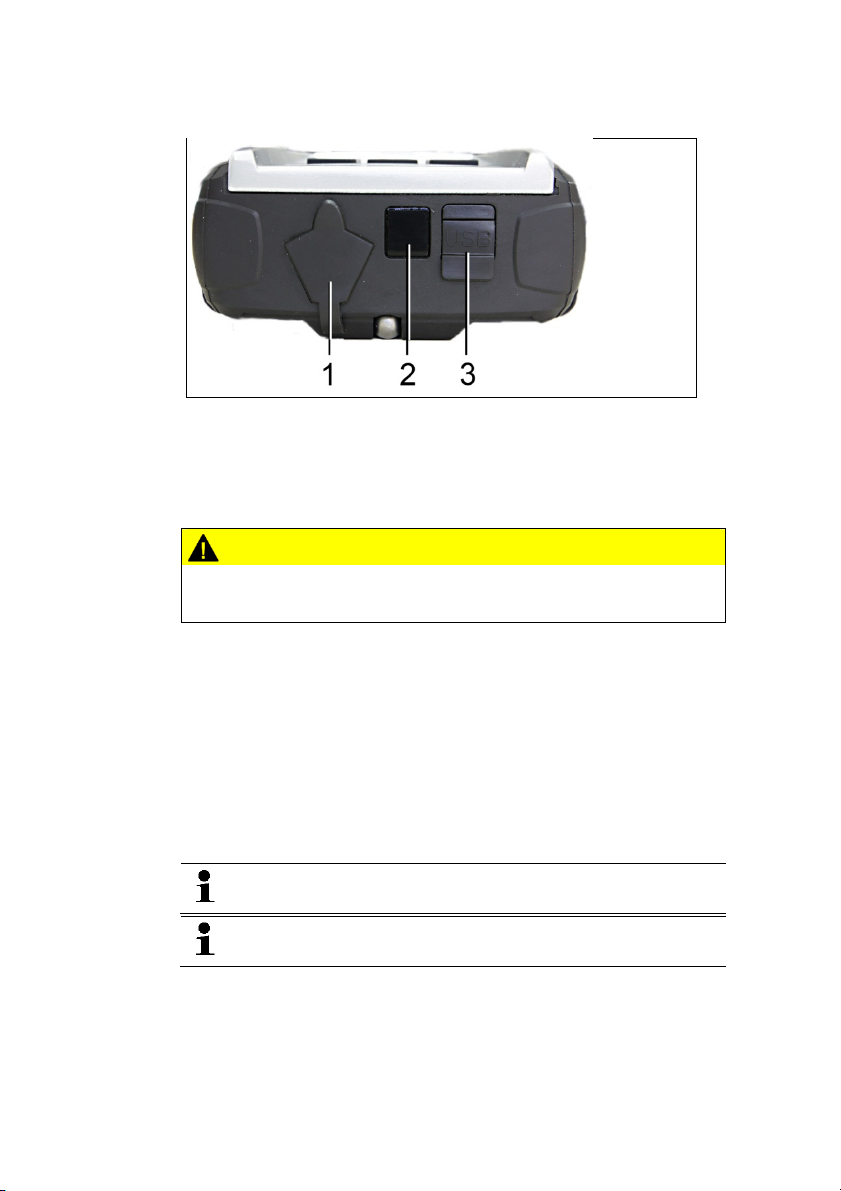

5 First steps

Interfaces

1 Mini-DIN connection for optional temperature sensors, testo 552

and accessories

2 IR-interface for testo protocol printer

3 Mini-USB connection for power supply unit and connection to

PC

CAUTION

Risk of injury from infrared beam!

> Do not direct infrared beam at human eyes!

5 First steps

Inserting batteries/rechargeable batteries

1. Unfold the suspension attachment and open the battery

compartment (clip lock).

2. Insert the batteries (scope of delivery) or rechargeable batteries

(4 x 1.5 V, type AA / NiMH / AA) into the battery compartment.

Observe the polarity!

3. Close the battery compartment.

When not in use for long period: Take out the batteries /

rechargeable batteries.

Recharge the rechargeable batteries completely before

using the instrument.

11

Page 12

5 First steps

Switching the instrument on

> Press [].

- Initializing phase:

• All display segments light up (duration: 2s).

- Measurement view is opened.

The first time the instrument is switched on after a battery has been

inserted or replaced, the following factory settings are stored:

• Language: English UK

• Date: 01/01/2011

• Time: 12:00

• Temperature unit: °C

• Pressure unit: bar

• Vacuum unit: mbar

• Pressure mode: prel

• Weight unit: kg

• Refrigerant: R12

To change the default settings:

See Making settings, page 13.

12

Display

1 Selected pressure mode

2 Condensation temperature/ acc. to temperature sensor right /

subcooling / differential temperature sensor left&right. The

display reading of measurement values varies in dependence

on the set mode

See also Performing the measurement, page 19.

3 [Min/Max/Mean/Normal] (exemplary for pressure/temperature

mode): The middle multi-function key can be used to display the

minimum, maximum and mean values.

4 [Mode] selectable via the right multi-function key

See also Performing the measurement, page 19.

Page 13

5 First steps

5 [Set] selectable via the left multi-function key

6 Evaporation temperature / acc. to temperature sensor A /

superheating

7 Chosen refrigerant

8 Battery status indication/rech. batt. charge indication

Making settings

1. Press [Set].

- The configuration menu is opened.

2. Select function and set parameters:

Key functions

Representation Explanation

[▲] or [▼]

[Ok]

[ESC]

Choose function/setting

Activate function or confirm parameter/setting

Exit the configuration menu

Adjustable parameters

Refrigerant: Select the refrigerant from the list:

Representation Explanation

R... Refrigerant number of refrigerant acc. to

ISO 817

T... Special Testo designation for certain

refrigerants

---

no refrigerant selected.

With the software testo Easy Kool you can feed additional

refrigerants into the instrument, see separate operating

instructions.

Efficiency calc.: Select the procedure (COP heat pump) and enter

the required parameters (may vary in dependence on selected

procedure). The inputs have an effect on the measuring mode

efficiency calc.

See also Performing the measurement, page 19.

See also Basis of calculation COP, page 30.

Temperature unit: Select the desired unit.

Pressure unit: Select the desired unit.

Vacuum unit: Set pressure unit for vacuum.

Pressure mode: Depending on the chosen unit for pressure:

Change between absolute and relative pressure displays.

13

Page 14

5 First steps

Vacuum pressure mode: Select the pressure mode for the

evacuation mode.

See also Performing the measurement, page 19.

Weight unit: Select the desired unit from the list.

Measuring mode: Select normal mode, combi mode

Display Mode Function

none Normal mode

Normal function of the digital

manifold

Auto

Combi mode

When combi mode is

activated the digital manifold

testo 570 automatically

reverses the display of high

and low pressure. This

automatic reversal occurs

when the pressure in the low

pressure side is 1 bar higher

than the pressure in the high

pressure side. This switching

over is indicated by ---flashing in the display. This

mode is particularly suitable

for air conditioning systems

that provide cooling and

heating.

Date/Time: Adjust the flashing number with [▲] and [▼] and press

[◄]

and [►] to go to the next numerical block. Confirm the input

with [OK].

Language (This setting influences the date format): Select the

language from the list and press [OK] to confirm.

Probe type: Select the desired probe type from the list.

Device info: Show serial number and firmware version.

14

Operating the valve actuators

With respect to the refrigerant flow path the digital manifold

behaves just like a conventional four-way manifold. The passages

are opened by opening the valves. The applied pressure is

measured with the valves closed and the valves opened.

> Open valve: Turn valve actuator anticlockwise.

> Close valve: Turn valve actuator clockwise.

Page 15

6 Using the product

WARNING

Tighten the valve actuator only hand-tight. Do not use any tools for

tightening, this could damage the thread.

WARNING

Valve positioner tightened too tightly.

• Damage to the PTFE seal (1).

• Mechanical deformation of the valve piston (2) leading to the

PTFE seal (1) falling out.

• Damage to the thread of the threaded spindle (3) and the valve

screw (4).

• Broken valve knob (5).

Tighten the valve positioner only hand-tight. Do not use any tools

to tighten the valve positioner.

6 Using the product

6.1. Preparing for measurement

6.1.1. Connecting temperature probe, Testo 552 and

15

accessories

Sensors must be connected before the measuring

instrument is switched on, so that they are recognised by

the instrument.

Page 16

6 Using the product

Surface temperature sensor

An NTC temperature sensor (accessory) must be connected for

measuring the pipe temperature and for automatic calculation of

superheating and subcooling.

Deactivating the surface compensation factor for immersion

and air temperature probe

A surface compensation factor has been set in the measuring

instrument to reduce the measuring errors in the main field of

applications. This reduces measuring errors when using surface

temperature probes.

If the measuring instrument testo 570 is used in combination with

insertion or air temperature probes (accessories), this factor must

be deactivated:

1. Press [Set].

2. Select the Probe type.

3. Select Immersion probe.

4. Press [Esc].

- The surface compensation factor has been deactivated in the

• In combination with the testo 570, the testo 552 can be

used as an external high-precision vacuum probe, if

connected to the front of the testo 570 using the

connection cable 0554 5520. The firmware version 1.09

or later must be installed for this.

• Before connecting both devices, the testo 552 must be

switched on.

• The testo 570 will only connect to the testo 552 once

Evacuation mode has been activated.

• The required pressure unit display must be set in the

testo 570.

• In order to be able to use the readings from the testo

552 via the testo 570 in the EasyKool software, you

need EasyKool software version 4.0 or later.

• (See testo 552 instruction manual.)

device.

For measurements with a surface temperature probe the

probe type must be reset to surface probe.

Each time the device is switched on the surface

compensation factor is activated again as standard.

16

Page 17

6 Using the product

Accessories

Clamp probe and oil pressure probe can only plugged to

connection (1).

Position the accessory as appropriate for the measurement task:

Measurement task

Position

(measurement channel)

Superheating

At the end of the evaporator / inlet of

compressor

Subcooling

At the end of the condenser / inlet of

expansion valve

Differential temperature On the measurement object

Current measurement On the electrical consumers

Charging/emptying On the system

Oil lubrication of the

compressor

On compressor oil measurement

fitting

6.1.2. Switching the instrument on

> Press [].

Zeroing the pressure sensors

Zero the pressure sensors before every measurement.

✓ All connections must be pressureless (ambient pressure).

> Press [P=0] to execute zeroing.

Connecting the refrigerant hoses

Before each measurement check whether the refrigerant

hoses are in flawless condition.

17

Page 18

6 Using the product

✓ The valve actuators are closed.

1. Connect the refrigerant hoses for low-pressure side (blue) and

high-pressure side (red) to the measuring instrument.

2. Connect the refrigerant hoses to the system.

WARNING

The measuring instrument dropping down or any other comparable

mechanical load can cause breakage of the pipe pieces in the

refrigerant hoses. The valve actuators may also suffer damage,

which in turn could result in further damage inside the measuring

instrument, which may not be detectable from outside.

> For your own safety you should return the measuring

instrument to the Testo Service for technical inspection.

> You should therefore always replace the refrigerant hoses with

new ones after the measuring instrument has dropped down or

after any comparable mechanical loading.

6.1.3. Choosing the measuring mode

1. Press [Mode].

- The configuration menu is opened.

2. Choose the measuring mode.

Key functions

Representation Explanation

[▲] or [▼]

[Ok]

[ESC]

Select measuring mode

Enable measuring mode

Exit the menu

Selectable functions

• Pressure/Temperature

• Tightness test

• Evacuation

• Charging

• Emptying

• Pressure/Compressor

• Current

• Efficiency calc.

See also Performing the measurement, page 19.

18

Page 19

6 Using the product

6.2. Performing the measurement

WARNING

Risk of injury caused by pressurized, hot, cold or toxic

refrigerants!

> Wear protective goggles and safety gloves.

> Before applying pressure to the measuring instrument: Always

fasten the measuring instrument on the suspension attachment

to prevent it from falling down (danger of breakage)

> Before each measurement check the refrigerant hoses for

flawless condition and correct connection. Do not use any tools

to connect the hoses, tighten hoses only hand-tight (max.

torque 5.0 Nm / 3.7ft*lb).

> Comply with the permissible measuring range (-1…50 bar).

Pay particular attention in systems with refrigerant R744, since

these are frequently operated with higher pressures.

6.2.1. Measuring

✓ The actions described in the chapter “Preparing for

measurement” have been performed.

The mode Pressure/Temperature is set as standard when

starting the device.

1. Apply pressure to the measuring instrument.

2. Read the measurement values.

With zeotropic refrigerants, the evaporation temperature

to/Ev is displayed after the complete evaporation / the

condensation temperature tc/Co is displayed after complete

condensation.

The measured temperature must be assigned to the

superheating or subcooling side (toh <--> tcu). Dependent on

this assignment, the display will show t

or t

/T2 resp. ∆tcu/SC, depending on the selected display.

cu

- Reading and display illumination are flashing.

• 1 bar before the critical pressure of the refrigerant is

reached,

• when the max. permissible pressure of 49 bar is acceded.

/T1 resp. ∆toh/SH

oh

19

Page 20

6 Using the product

Key functions

> [▲]

Possible display combinations:

Evaporation pressure

Refrigerant evaporation

temperature to/Ev

or (only with inserted temperature sensor)

Evaporation pressure

Measured temperature t

or (only with inserted temperature sensor)

Evaporation pressure

Superheating ∆t

or (only with third inserted temperature sensor T3)

or (only with plugged on clamp probe)

Evaporation pressure

or [▼]: Change the readings display.

Condensation pressure

Refrigerant condensation

temperature tc/Co

Condensation pressure

/T1

Measured temperature tcu/T2

oh

Condensation pressure

/SH

oh

Subcooling ∆tcu/SC

Condensation pressure

Measured temperature T3/T3

Condensation pressure

Measured current value

or (only with inserted oil pressure probe)

Evaporation pressure

Condensation pressure

Measured oil pressure P

With two inserted NTC sensors (T1/T2) ∆t is additionally displayed.

> [Min/Max/Mean/Normal]: Show Min. / Max. measurement

values, mean values (since switching on).

6.2.2. Tightness test / pressure drop test

The temperature compensated tightness test can be used

to check the leak tightness of systems. For this purpose

both the system pressure and the ambient temperature are

measured over a defined period of time. For this purpose a

temperature sensor to measure the ambient temperature

may be connected (recommendation: Deactivate the

surface compensation factor and use NTC air sensors Art.No. 0613 1712).

See also Deactivating the surface compensation factor for

immersion and air temperature probe, page 16.

This provides information about the temperature

20

ext

Page 21

compensated differential pressure and about the

temperature at the beginning/end of the test as a result. If

no temperature sensor is connected, you may also perform

the tightness test without temperature compensation.

✓ The actions described in the chapter “Preparing for

measurement” have been performed.

1. Press [Mode].

2. Select [Tightness test].

- The tightness test view is opened. ∆P is displayed.

3. Start the tightness test: Press [Start].

4. End the tightness test: Press [Stop].

- The result is displayed.

6.2.3. Evacuation / vacuum display

The measurement takes place in the low pressure side.

✓ The actions described in the chapter “Preparing for

measurement” have been performed.

✓ The vacuum pump is connected to the 5/8’’ connection on the

valve block.

1. Press [Mode].

2. Select [Evacuation].

- The evacuation view is opened. The current pressure and the

evaporation temperature of water (H2O) is displayed.

6 Using the product

6.2.4. Vacuum measurement

In order to achieve optimal measuring accuracy in vacuum

measurement, the measuring instrument must be zeroed at

21

ambient pressure.

Zeroing at ambient pressure must be performed for each

vacuum measurement.

• In combination with the testo 570, the testo 552 can be

used as an external high-precision vacuum probe, if

connected to the front of the testo 570 using the

connection cable 0554 5520. The firmware version

1.09 or later must be installed for this.

• Before connecting both devices, the testo 552 must be

switched on.

• The testo 570 will only connect to the testo 552 once

Page 22

6 Using the product

• The required pressure unit display must be set in the

• In order to be able to use the readings from the testo

• (See testo 552 instruction manual.)

✓ The actions described in the chapter “Preparing for

measurement” have been performed.

✓ The desired units have been set.

See Making settings, page 13.

1. Press [].

2. Zero the measuring instrument at ambient pressure [p=0].

3. Press [Mode].

4. Select [Evacuation].

- The evacuation view is displayed.

5. Start evacuation of the system.

6.2.5. Charging

✓ The actions described in the chapter “Preparing for

measurement” have been performed.

1. Press [Mode].

2. Select [Charging].

- The charging view is opened.

3. Enter the value read on the refrigerant scales: Press [Change].

4. Adjust the flashing number with [▲]

and [►] to go to the next number.

5. Confirm the input with [OK].

6. Choose the memory location.

7. Press [Save].

Evacuation mode has been activated.

testo 570.

552 via the testo 570 in the EasyKool software, you

need EasyKool software version 4.0 or later.

and [▼] and press [◄]

6.2.6. Emptying

✓ The actions described in the chapter “Preparing for

measurement” have been performed.

1. Press [Mode].

2. Select [Emptying].

- The emptying view is opened.

3. Enter the value read on the refrigerant scales: Press [Change].

22

Page 23

6 Using the product

4. Adjust the flashing number with [▲]

and [►] to go to the next number.

5. Confirm the input with [OK].

6. Choose the memory location.

7. Press [Save].

6.2.7. Pressure/Compressor

✓ Oil pressure probe connected to the upper Mini-DIN connection.

1. Press [Mode].

2. Select [Pressure/Compressor].

- The measurement values for low pressure side and oil pressure

(p

) are displayed.

ext

6.2.8. Current

✓ Clamp probe connected to the upper Mini-DIN connection.

1. Press [Mode].

2. Select [Current].

- The measurement value of the current measurement is

displayed.

6.2.9. Efficiency calculation

1. Press [Mode].

2. Select [Efficiency calc.].

- The efficiency calculation is displayed.

See also Basis of calculation COP, page 30.

and [▼] and press [◄]

6.3. Saving measurement values

The testo 570 is able to record a series measurement of up to

999 h.

The testo 570 is able to save up to:

• 10000 single measurements or

• 50 series measurements in a measuring cycle of 2 seconds

over a maximum period of 100 hours.

Depending on the selected measuring cycle, only a certain

measurement period can be set. Here is an overview of the

possible settings.

23

Page 24

6 Using the product

Measurement period

(hhh:mm)

000:00…099:59 2 seconds

100:00…240:59 10 seconds

241:00…999:59 30 seconds

Measurements can be assigned to the individual categories

Customer, Measurement place, Installation and Component and

saved, already in the device.

Minimum possible measuring cycle

If the selected measurement duration is not a multiple of

the set measuring cycle, it is reduced to the next

possible measurement duration. In this case, the

instrument displays the automatically adjusted

measurement duration at the start of the measurement.

In the device the following standard categories have been

pre-set: Customer / Measplace / Installation /

Component.

These categories can be changed (e.g. testo / Cellar 1 /

Office building 1 / Compressor) and supplemented via the

testo software Easy Kool, see separate operating

instructions.

24

Saving a single measurement

✓ The desired measuring mode has been selected.

1. Press [ ].

2. Select Single measurement.

3. Select Save.

4. Select the desired memory location: Press [▲]

the desired value and press [◄]

and [►] to toggle between

and [▼] to set

Customer / Measplace / Installation / Component.

- The set measurement view is displayed. The memory symbol

is displayed.

5. Press [Save].

- The memory symbol flashes and disappears after the

measurement data have been saved.

Saving a serial measurement

Depending on the duration of the serial measurement

electric power supply via power supply unit may be

required.

Page 25

6 Using the product

✓ The desired measuring mode has been selected.

1. Press [ ].

2. Select Serial measurement.

3. Setting the measuring cycle: Adjust the flashing number with

[▲] and [▼] and press [◄] and [►] to go to the next number.

Confirm the input with [OK].

4. Set measurement period: Adjust the flashing number with [▲]

and [▼] and press [◄] and [►] to go to the next number.

Confirm the input with [OK].

5. Select the desired memory location: Press [▲]

the desired value and press [◄]

and [►] to toggle between

and [▼] to set

Customer / Measplace / Installation / Component.

- The set measurement view is displayed. The memory symbol

is displayed.

6. Press [Start].

- The memory symbol flashes in the set measuring cycle

when saving the measurement values. Clock (00:00:00) shows

the remaining measuring duration.

7. Press [Stop].

- The serial measurement was stopped. Clock (00:00:00) shows

the residual measuring duration.

- The measurement view is displayed.

6.4. Printing measurement values

From the measuring mode

✓ The desired measuring mode has been selected.

✓ The testo printer (0554 0549) has been switched on.

1. Press [ ].

2. Select Single measurement.

3. Align IR interfaces testo 570 and testo printer.

4. Select Print.

- The set measurement view and printing... is displayed.

- The printout is generated.

From the device memory

1. Press [ ].

2. Select Memory.

25

Page 26

7 Maintaining the product

3. Navigate to the saved measuring protocol.

4. Align IR interfaces testo 570 and testo printer.

5. Select Print.

- The printout is generated.

The saved measuring protocols can be viewed through the

7 Maintaining the product

software Easy Kool.

Cleaning the instrument

> If the housing of the instrument is dirty, clean it with a damp

cloth.

Do not use any aggressive cleaning agents or solvents! Weak

household cleaning agents and soap suds may be used.

Keeping connections clean

> Keep screw connections clean and free of grease and other

deposits, clean with a moist cloth as required.

Removing oil residues

> Carefully blow out oil residues in valve block using compressed

air.

26

Ensuring the measuring accuracy

Testo Customer Service would be glad to further assist you if you

so wish.

> Check instrument regularly for leaks (recommended: annually).

Keep to the permissible pressure range!

> Calibrate instrument regularly (recommended: annually).

Changing batteries/rechargeable batteries

When the battery/rechargeable battery is changed,

customer-specific settings such as date/time are reset to

the factory settings.

Page 27

7 Maintaining the product

✓ Instrument is switched off.

1. Fold out the suspension device, loosen the clip and remove the

cover of the battery compartment.

2. Remove empty batteries/rechargeable batteries and insert new

batteries/rechargeable batteries (4x 1.5 V, type AA, Mignon,

LR6) in the battery compartment. Observe the polarity!

3. Set on and close cover of the battery compartment (clip must

engage).

4. Switch the instrument on.

5. Check factory settings, and change if necessary:

See Making settings, page 13.

Changing the valve or valve positioner handle

WARNING

Change of the valve positioners and valves by the customer is not

permissible.

> Send the measuring instrument to the Testo Customer Service.

27

Page 28

8 Tips and assistance

8 Tips and assistance

8.1. Questions and answers

Question Possible causes / solution

flashes

Batteries are almost empty.

> Change batteries.

The device switches itself

off.

uuuu lights instead of the

measurement parameter

display

oooo lights instead of the

measurement parameter

display

Residual capacity of batteries too low.

> Change batteries.

The permissible measuring range has

been fallen short of.

> Keep to the permitted measuring

range.

The permissible measuring range has

been exceeded.

> Keep to the permitted measuring

range.

8.2. Measurement parameters

Designation Description

∆toh SH Superheating, evaporation pressure

∆tcu SC Subcooling, condensation pressure

to Ev Refrigerant evaporation temperature

tc Co Refrigerant condensation temperature

toh T1 Measured temperature, evaporation

tcu T2 Measured temperature, condensation

T3 T3 Measured temperature

28

Page 29

8.3. Error reports

Question Possible causes/solution

---- is lit up instead of

measurement parameter

display

Display EEP FAIL

Sensor or cable defective

> Please contact your dealer or

Testo Customer Service

Eeprom defective

> Please contact your dealer or

Testo Customer Service

If you have any questions, please contact your dealer or Testo

Customer Service. The contact details can be found on the back of

this document or on the Internet at www.testo.com/service-

8.4. Accessories and spare parts

contact

Description Article no.

Clamp probe for temperature measurement

on pipes

The pipe wrap probe with Velcro tape for

pipes with a diameter of up to 75 mm, Tmax.

+75 °C, NTC

Water tight NTC surface probe 0613 1912

Sturdy precision NTC air probe 0613 1712

Pipe wrap probe for pipe diameters from 5 to

65 mm

Clamp probe for measuring current

consumption on compressors with switchable

measuring range

Oil pressure probe to check the oil filling level

in the compressor

Power supply unit, 5 VDC 500 mA with Euro

plug, 100-250 VAC, 50-60 Hz

Software EasyKool 0554 5604

High speed Testo printer with wireless

infrared interface, 1 roll of thermal paper and

4 AA-batteries

8 Tips and assistance

0613 5505

0613 4611

0613 5605

0554 5607

0638 1742

0554 0447

0554 0549

29

Page 30

9 Appendix

USB connecting cable Device-PC 0449 0047

Transport case for measuring instrument,

0516 5505

probes and hoses

Connecting cable 0554 5520

Testo 552 0560 5520

For a complete list of all accessories and spare parts, please refer

to the product catalogues and brochures or look up our website

9 Appendix

www.testo.com

9.1. Basis of calculation COP

Heat pump

The heating power and the efficiency calculation. COP heat pump

are calculated by the testo 570 as follows:

• Heating power = Volumetric flow rate x density of medium x

specific heat capacity x ∆T (K) / 3600

• COP = Heating power / power consumption

Designation Unit Input range Factory

Power

consumption

Volume flow m3/h 00.0-99.9 20.0 Volumetric flow rate of

Density of

medium

Specific heat

capacity

The following values can be entered via [Set] | [Efficiency calc.]:

Description

setting

kW 0,000–9,999 2,000 Electric power

consumption of system

(e.g. compressor)

fluid in the secondary

circuit of the heat pump

(e.g. brine circuit)

kg/m³ 0000.0-9999.9 1000.0 Density of medium in

secondary circuit (e.g.

water, brine, etc.)

kJ/(kg

x K)

0,000-9,999 4,182 Specific heat capacity

of medium in

secondary circuit (e.g.

water, brine, etc.)

30

Page 31

9 Appendix

The display of the testo 570 shows the following values:

• COP

• Heating power (kW)

• Feed temperature secondary circuit (e.g. brine circuit) T1 (°C)

• Return temperature secondary circuit (e.g. brine circuit) T2 (°C)

31

Page 32

9 Appendix

32

Page 33

Page 34

0970 5700 en 05 V01.09

Loading...

Loading...