Page 1

Instruction manual en (international)

testo 556/testo 560

Refrigeration System Analyzer

Page 2

2

Page 3

Contents 3

Contents

Safety and the environment ..........................................................................4

Specifications ................................................................................................6

Product description ......................................................................................8

First steps ....................................................................................................10

Using the product ........................................................................................12

Setting the instrument ..........................................................................12

Preparing for measurement ..................................................................13

Measuring ............................................................................................15

Performing actions ................................................................................17

Maintaining the product ..............................................................................20

Tips and assistance ....................................................................................22

en

defresitptsvnl????

Page 4

Safety and the environment 4

Safety and the environment

About this document

i Please read this documentation through carefully and familiarize yourself with

the product before putting it to use. Keep this document to hand so that you

can refer to it when necessary. Hand this documentation on to any

subsequent users of the product.

i Pay particular attention to information emphasized by the following symbols:

· With the signal word

Warning!

:

Warns against hazards which could result in serious physical injury

if the precautionary measures indicated are not taken.

· With the signal word

Caution!

:

Warns against hazards which could result in minor physical injury

or damage to equipment if the precautionary measures indicated

are not taken.

· Important information!

Avoiding personal injury / damage to equipment

i Do not make measurements with the measuring instrument and its sensors

on or near live components unless the instrument is expressly approved for

current/voltage measurements!

i Never store the measuring instrument together with solvents and do not use

any desiccants.

i Only operate the measuring instrument properly, for its intended purpose

and within the parameters specified in the technical data. Do not use force.

i Only carry out the maintenance and repair work that is described in the

documentation. Follow the prescribed steps when doing so. Use only OEM

spare parts from Testo.

Page 5

Safety and the environment 5

Warning!

Danger of injury exists if highly pressurized hot, cold and/or toxic

refrigerants escape. For this reason, always wear protective glasses

and protective gloves when carrying out measurements and other

work on the refrigeration system.

If the measuring instrument falls down or is exposed to any other

comparable mechanical strain, the end connections of the refrigerant

hoses can break off. The valve knobs can also be damaged, which

can lead to further damage in the interior of the instrument, which is

not visible externally. For this reason, replace the refrigerant hoses

after any fall or comparable mechanical strain with new, undamaged

refrigerant hoses. For your own safety, send the instrument to Testo

customer service for technical testing.

Protecting the environment

i Refrigerant gases can harm the environment. Please note the applicable

environmental regulations.

i Take faulty rechargeable batteries / spent batteries to the collection points

provided for them.

i Send the product back to Testo at the end of its useful life. We will ensure

that it is disposed of in an environmentally friendly manner.

en

defresitptsvnl????

Page 6

Specifications6

Specifications

Functions and use

testo 556 and testo 560 are refrigeration system analyzers for maintenance and

service work on (large) refrigerating systems and heat pumps. The testo 560

furthermore offers a vacuum function for commissioning work. The instruments

may only be used by qualified authorized personnel.

With their functions, the testo 556 and the testo 560 replace mechanical

manifolds, thermometers and pressure/temperature tables. Pressures and

temperatures can be loaded, adjusted, tested and monitored.

The range of functions can be expanded through comprehensive, separately

available accessories, e. g.: Various temperature probes (also radio probes),

clamp-on probe*, refrigerant scale*, oil pressure probe*, PC software.

testo 556 and testo 560 are compatible with most non-corrosive refrigerants,

water and glycol. testo 556-1 and testo 560-1 are not compatible with

refrigerants which contain ammonia.

The product must

not

be used in areas at risk of explosion!

* Option not available as standard. Please ask your local Testo subsidiary.

Page 7

Specifications 7

Technical data

Parameters

· High-pressure pc , low-pressure po, oil pressure px:

kPa / MPa / bar / psi

· Vacuum pv: hPa / mbar / Pa / inH2O / psi / Micron /

Torr / inHG / bar

· Temperature: °C / °F / K

· Mass: kg, lb

· Current: A

Sensor

· Sensor: 2x pressure sensor,

only testo testo 560: 1x vacuum sensor

Interfaces

· Pressure connections 3x 7/16", 1x 5/8“

· 2x mini DIN socket: for Pt100 temperature probe,

clamp-on probe, pressure probe, scale

· Radio: Radio module for radio probe (accessories)

· IrDA: for compatible Testo protocol printer

· USB socket: for mains unit and data transmission

Measuring ranges

· High-pressure pc measuring range: 0...50bar (rel) /

0...725psi (rel) / 0...5000kPa (rel) / 0...5MPa (rel)

Overload limit 100bar / 1450psi / 10000kPa / 10MPa

· Low-pressure po measuring range: 0...25bar (rel) /

0...362.5psi (rel) / 0...2500kPa (rel) / 0...2.5MPa (rel)

Overload limit 50bar / 725psi / 5000kPa / 5MPa

· Vacuum pv measuring range (only testo:

0...200hPa (abs)/ 0...2.9psi (abs)

· Oil pressure

px measuring range: 0...15bar/

0...217psi

· Temperature measurement range: -50...+200°C / -

58...392°F

Resolution

· Resolution of hp, lp, oil pressure:0.1bar/1.45 psi/10 kPa/

0.01MPa

· Vacuum resolution: 0.1 hPa / 0.1 mbar / 10 Pa

0.04 inH

2

O / 0.0015 psi / 80 Micron / 0.08 Torr /

0.003 inHG / 0.0001 bar

· Temperature resolution: 0.1°C / 0.1°F

Accuracy (Nominal temperature 22°C/ 71.6°F, ±1 digit)

· Accuracy of hp, lp, oil pressure, vacuum: ±0.5%fs

Refrigerant

· Quantity: 30 (default), 40 (max.)

· Measurable media: All refrigerants, nitrogen, water,

glycol, only testo 556-2, testo 560-2:Ammonia (R717)

and other refrigerants which contain ammonia

Ambient conditions

· Operating temperature: -20...60°C/ -4...140°F, USB

socket 0...60°C/32...140°F.

· Storage temperature: -20...60°C/ -4...140°F

Housing

· Material: ABS/ PA/ TPU

· Dimensions: 265 x 135 x 75mm

· Weight: approx. 1250g

· Protection class: IP54

Voltage supply

· Current source: Rechargeable batteries / batteries

4x 1.5V, Type AA/mignon/ LR6 or mains unit

(accessory part), buffer battery 1x 3V LiIon CR2032

· Battery life: approx. 40h (display light off)

Display

· Type: Illuminated LCD

· Updating of readings: approx. 1s (depending on

number of probes)

Memory

· approx. 60000 readings

Directives, standards and tests

· EC Directive: 2004/108/EEC

Warranty

· Duration: 2 years

· Warranty conditions: See web page

www.testo.com/warranty

en

defresitptsvnl????

Page 8

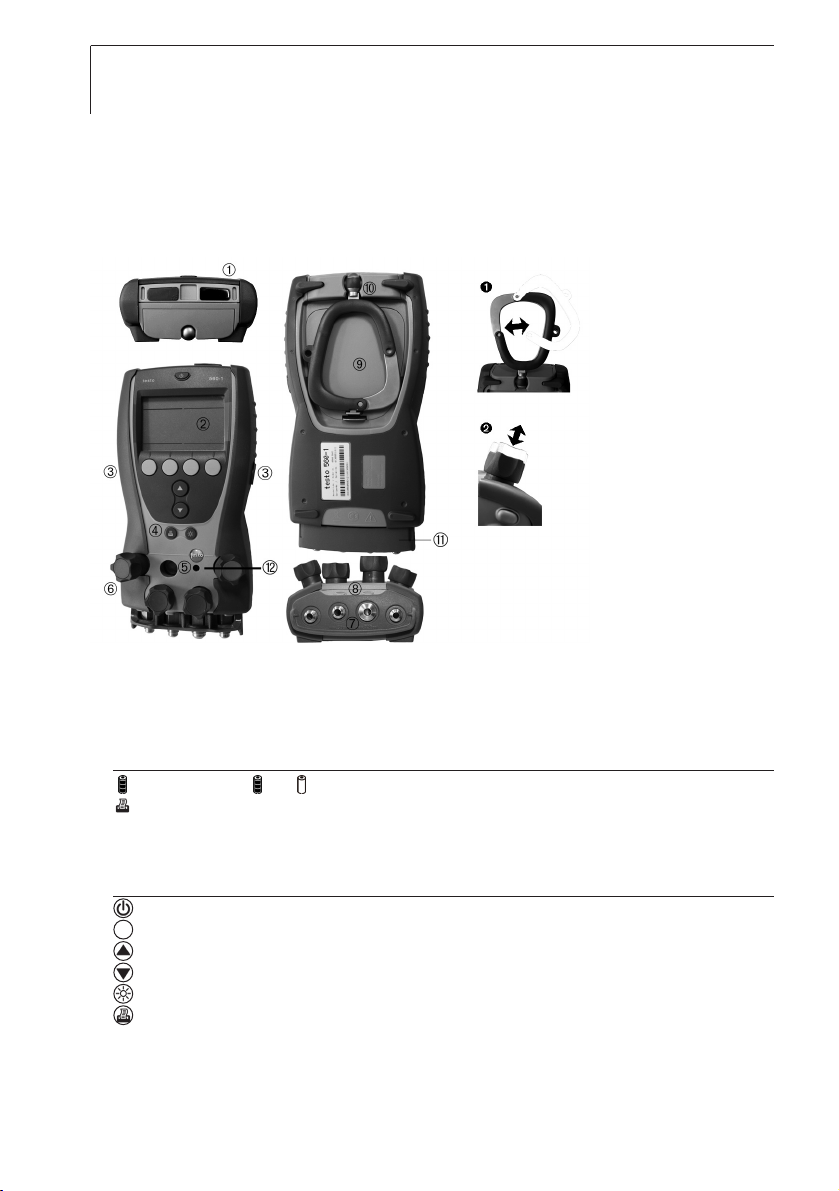

Product description8

Product description

At a glance

IrDA interface (printer),

USB socket (mains unit, PC data transmission).

Display: Low-pressure side (blue), high-pressure side (red)

Display symbols

: Battery capacity ( : full, : empty)

: Print function: sends data

2x mini-DIN probe sockets, with socket cover

Control keys

Key functions

: On/off button: Switching the instrument on/off.

: Function key (4x, orange): shows relevant function on the display.

: Up/down keys: changes display view.

: Light key: Switching the display /inspection glass illumination on/off.

: Print key: Sending data to the Testo protocol printer.

Inspection glass for measuring medium flow.

4x valve positioners, with two setting positions (see ).

Page 9

Product description 9

3x connections 7/16" UNF,

1x connection 5/8" UNF, testo 556-1 / 560-1: Brass, testo 556-2 / 560-2:

Stainless steel. Left /right: Low-pressure / high-pressure, centre: Evacuation

(5/8")/ filling (7/16"), for refrigerant hoses with quick connect fitting, passage

via valve positioner can be locked.

Unlock buttons for valve positioner.

Battery/ radio module compartment. It is not possible to charge

rechargeable batteries in the instrument!

Foldable suspension device, with eyelet for padlock (see ).

Plastic protector

Warning!

Do not remove plastic protector for measurement and transport. It protects the

screw connections of the measuring instrument from breaking off under

mechanical strain.

Automatically opening/closing vacuum protection valve: Protects the

integrated vacuum sensor from too high pressures.

After longer periods of non-use:

In depressurized state, use a blunt object to press the protective valve in, in

order to prevent jamming

Warning!

Danger oof iinjury ddue tto eescaping rrefrigerant

The danger of freezing

(fast evaporation of liquid), poisoning or asphyxiation (displacement

of air oxygen) exists for the user.

i Operate the instrument only with protective equipment (protective

goggles, protective gloves). For ammonia refrigerants, additionally

wear breathing equipment.

i Observe the descriptions of danger and information on protective

equipment in the safety data sheet of the respective refrigerant

use.

i In case of malfunction of the vacuum protection valve: Discontinue

using instrument and send in to Testo customer service.

Warning!

Externally connected instruments and accessories can be damaged by

electromagnetic discharge during the filling process.

en

defresitptsvnl????

Page 10

First steps10

First steps

²

Inserting bbatteries / rechargeable bbatteries/radio mmodule:

Radio probes may only be used in countries in which they are permitted

(see radio probe instructions).

A radio module (accessory part) is required for the use of radio probes.

The instrument can establish a connection with a maximum of two radio

probes.

Each radio probe has a probe ID (RF ID). This consists of the last 3

numbers of the serial no. and the position of the slide switch in the radio

probe (H or L).

1 Fold out the suspension device and open the battery compartment (clip

lock).

2 Insert buffer battery (included in delivery, 1x 3V lithium CR2032) in the

battery compartment. Observe the polarity (positive pole up)!

3 Push radio module (accessory) into the module slot underneath the buffer

battery until the module engages (contact strip facing up).

4 Insert batteries (included in delivery) or rechargeable batteries (4x 1.5V,

type AA / mignon / LR6) into the battery compartment. Observe the

polarity!

5 Close the battery compartment.

When not in use for long period: Read out memory and remove batteries

(not the buffer battery).

When operating the instrument with the mains unit, insert batteries in

order to avoid switching off the instrument in case of a power interruption.

²

Switching tthe iinstrument oon:

i Press .

- Initialization phase:

· All display segments are lit (length of time: 2s).

· Instrument designation, serial number and firmware version are

displayed (duration: 2s).

- Measurement view is opened.

-or-

Page 11

First steps 11

- Switching on the first time after changing the battery: Language is

displayed.

1 Set language using and and confirm entry with OK function key.

- Set the Batterytype (Rech/Bat) is displayed.

The type of battery used must be entered so that the calculation of the

battery capacity is carried out correctly.

2 Set battery type using and and confirm entry with OK function

key.

- Date/time are displayed.

3 Set blinking number with and and change to next number with

and .

4 Confirm the entry with the OK function key.

- The configuration menu is opened.

²

Switching tthe iinstrument ooff:

i Press .

²

Operate vvalve ppositioner:

The function of the valve positioners is independent of the selected setting

position. For easier operation, it is recommended that you unlock the

required valve positioners. For transport, the valve positioners should be

retracted.

i Unlock valve positioners: Press unlock button.

i Retract valve positioner: Press valve positioner into the housing. The

refrigeration system analyzer acts like a conventional four-way manifold

with regard to the refrigerant path. The passages are opened by opening

the valves. The adjacent pressure is measured with valves closed as well

as with them open.

i Open valve: Turn the valve positioner anticlockwise

i Close valve: Turn the valve positioner clockwise.

Warning!

Tighten valve positioner only hand-tight. Do not use tools to tighten

the valve positioner, as the thread may be damaged thereby!

en

defresitptsvnl????

Page 12

Using the product12

Using the product

Setting the instrument

²

Setting tthe iinstrument:

1 Press the Set function key.

- The configuration menu is opened.

2 Select function and set parameters:

Key functions

· : Select function / settings.

· : Select function or change parameters / settings.

·

OK : Activate function or confirm parameters / settings, exit configuration menu.

· Apply : Activate function or confirm parameters / settings, do not exit configuration menu.

· esc : Exit configuration menu (without saving).

Functions and settings / parameters

· P-relative/P-absolute :

· P=0 : Zero pressure sensors.

· pabs, prel : Change between absolute and relative pressure displays.

·

Refrigerant : Set refrigerant.

· R... : Refrigerant number of refrigerant according to ISO817.

· --- : No refrigerant selected.

· Memory :

·

Select installation : Activate customer / system. Select customer ( ), select system ( ).

Symbol * behind the designation: Protocols are stored in the memory.

· Free memory : Display of the free memory space.

· View protocol : Display measurement protocols. Select customer ( ), select system ( ).

Change display view ( ), select protocol ( ).

· Erase memory : Delete Customer, Installation, Protocol or entire memory (All).

·

Alt : Set height. Change blinking number ( ), change between numbers ( ).

· Device settings :

· Units : Set units for Pressure, Temperature, Vacuum, Altitude and Mass. Choose parameter

( ), choose unit ( ).

· Auto off : Switch automatic switch-off off (Off) or on (On) ( ), enter duration (minutes after button

was pressed for the last time) ( ).

·

Date/time (Format dependent upon selected language) : Set date (day, month, year) and time (hours,

minutes).

· Language : Set language (the setting affects the available units and the date format).

· PIN : Enter instrument PIN (protects a running measuring program from manual intervention),

deactivate PIN request (enter ----).

· Recharge/Standard Bat : Set battery type (important for correct calculation of battery capacity).

·

Factory settings : Reset instrument to condition upon delivery. Caution! Memory is deleted.

· Diagnostic : Display instrument data

Page 13

Using the product 13

· Probes :

·

Radio probe select : Carry out search for switched-on radio probes. Select probe ( ), assign

radio probe to low-pressure / high-pressure side (blue or red: Apply), delete probe assignment (select

---- and Apply).

· Probe search : Carry out search for connected probes or other accessories.

· Probe mapping : Assign radio probes / connected probes to the parameters. Select parameter (

), select probe ( or ), assign probe (Apply).

· Saturated steam table : Display saturated steam table. Select refrigerant ( ), change pressure

value ( ).

3 Press OK function key to save the settings and to exit the configuration

menu.

Preparing for measurement

²

Connecting tthe ttemperature pprobe / accessories:

Probes /accessories must be connected before the measuring instrument

is switched on so that they are recognized by the measuring instrument.

If probes / accessories are connected afterwards, a probe search must be

carried out: Set > Probes > Probe search. Alternative (only available in

standard measurement view): Set must be held down for 2s.

If radio probes are to be used, these must first be selected (Set > Probes >

Radio probe select) and assigned (Set > Probes > Probe mapping).

1 Open socket cover on the left / right side of the instrument.

2 Insert the connector of the accessory into the probe socket:

Accessories Measurement task (measurement channel) Socket

Temperature probe (blue) Overheating (toh) or temperature difference (t1) left

Temperature probe (red) Undercooling (tcu) or temperature difference (t2) right

Clamp-on probe* Compressor performance (l) right

Refrigerant scale* Fill / drain (m) right

Oil pressure probe* Oil lubrication of the compressor (px) right

* Option not available as standard. Please ask your local Testo subsidiary.

3 Position accessories according to measurement task:

Measurement task (measurement channel) Position

Overheating (toh) On the end of the evaporator

Undercooling (tcu) On the end of the liquefier

Temperature difference (1) Measured object 1

Temperature difference (t2) Measured object 2

Current measurement (l) On the electrical consumers

Fill / drain (m) On the system

Oil lubrication of the compressor (px) At compressor oil measurement fittings

en

defresitptsvnl????

Page 14

Using the product14

²

Zeroing tthe ppressure ssensors:

Carry out a zeroing of the pressure sensors before every measurement.

The measurement values can be falsified by a change in the position of

the measuring instrument. After zeroing, the position of the measuring

instrument must not be changed. Carry out zeroing before every

measurement in order to compensate faulty positioning or long-term zeropoint drift. Zeroing is only possible in a range of ±1bar(rel)/±14.5psi (rel)

or 0...2bar(abs) / ±29psi (abs).

1 Press Set function key.

- p=0 is displayed.

2 Press OK function key to carry out zeroing.

²

Connect rrefrigerant hhoses:

The valve positioners are closed.

1 Connect refrigerant hoses for low-pressure side (blue) and high-pressure

side (red) to the measuring instrument.

2 Connect refrigerant hoses to the system.

Warning!

If the measuring instrument falls down or is exposed to any other

comparable mechanical strain, the end connections of the refrigerant

hoses can break off. The valve knobs can also be damaged, which

can lead to further damage in the interior of the instrument, which is

not visible externally. For this reason, replace the refrigerant hoses

after any fall or comparable mechanical strain with new, undamaged

refrigerant hoses. For your own safety, send the instrument to Testo

customer service for technical testing.

Page 15

Using the product 15

Measuring

Warning!

Danger oof iinjury ddue tto hhighly ppressurized hhot, ccold oor ppoisonous

refrigerants!

i Always secure the measuring instrument with the carabiner

suspension hook before pressurizing the instrument, in order to

prevent falls (danger of breakage).

i Before each measurement, ensure that the refrigerant hoses are

intact and correctly connected. Do not use tools to connect the

hoses. Connect the hoses only hand-tight (max. torque 5.0Nm/

3.7ft*lb).

i Wear protective glasses and protective gloves.

i Observe permitted pressure range!

²

Measuring:

The steps described in the chapter "Preparing for measurement" have

been completed.

1 Check whether customer / system (assignment of the readings by saving),

pressure display (absolute / relative) and refrigerant are correctly selected,

see the chapter "Setting the instrument".

2 Pressurize the measuring instrument.

3 Read off readings or monitor trend display (next to the readings):

With zeotropic refrigerants, the evaporation temperature to is displayed

after the complete evaporation / is displayed after the complete

condensation tc.

en

defresitptsvnl????

Page 16

Using the product16

Key functions

· : Changing the reading display. The availability of the individual reading displays and the

parameters varies depending on the availability of the measuring signal (probe / accessories

connected, radio probe logged on, probe assigned).

· Function key

Hold/Min/Max : Record readings, display min.-/max. readings (since last switch on or

last reset).

· Function key RESET : Reset min. / max. readings. Only available if min. or max. readings are displayed.

- When critical pressure of refrigerant is reached: Reading and display

illumination blink.

²

Saving rreadings:

1 Press the Save function key.

2 Check if the customer / system are correctly selected,

If necessary: Change customer using change system using

function key.

3 Press OK function key to save.

²

Saving sseries oof rreadings:

1 Press the Save function key.

2 Check if the customer / system are correctly selected,

If necessary: Change customer using change system using

function key.

3 Press the Serial? function key.

________________________________________________________________ ________________________________________________________________

Refrigerant evaporation temperature t

o

Refrigerant condensation temperature t

c

Overheating Δtoh/ t

sh

UndercoolingΔtcu/ t

sc

________________________________________________________________ ________________________________________________________________

________________________________________________________________ ________________________________________________________________

Refrigerant evaporation temperature t

o

Refrigerant condensation temperature t

c

Measured temperature t

oh

Measured temperature t

cu

________________________________________________________________ ________________________________________________________________

________________________________________________________________ ________________________________________________________________

Temperature t

1

Temperature t

3

Temperature t

2

Temperature t

4

________________________________________________________________ ________________________________________________________________

________________________________________________________________ ________________________________________________________________

Evaporation pressure p

o

Condensation pressure p

c

Right probe socket measuring signal

________________________________________________________________ ________________________________________________________________

________________________________________________________________ ________________________________________________________________

Evaporation pressure p

o

Condensation pressure p

c

Refrigerant evaporation temperature t

o

Refrigerant condensation temperature t

c

________________________________________________________________ ________________________________________________________________

Page 17

Using the product 17

4

Enter parameters cycle/ cycle length (min. 2s, max. 60min) and duration

(in hours/ minutes) for series of readings: Set value using change

between parameters using function keys.

5 Confirm the entry with the OK function key.

With active PIN request, see the chapter "Setting the instrument":

i Enter PIN: Set number using , change between the numbers

using function keys.

6 Start the series of readings with the Start function key.

Performing actions

²

Fill oor ddrain:

In principle, the fill and drain actions are the same in terms of process, only

the values change conversely.

The maximum display range for the mass m is: -999.9 ..9999.9kg or.

-9999 ..99999g / lb / oz . Before starting the action, check the correct

setting of the unit, and in case of doubt switch to the “larger” unit (kg/ lb),

as no measurement value is displayed if the display range is exceeded or

fallen short of (display uuuuu/ ooooo).

1 Press the Action function key.

2 Using function keys, select Fill or Vacate and confirm entry using OK

function key.

3 Using set customer, set system using function keys and confirm

entry using OK function key.

4 Set refrigerant using and confirm entry using OK function key.

5 Connect refrigerant scale* to the right probe socket, switch on and

confirm using the OK function key.

* Option not available as standard. Please ask your local Testo subsidiary.

Only for the action Fill: An optional alarm can also be activated that will go

off when a defined fill level is reached (mass m or overheating T) (Alarm

blinks):

i Open input menu (Alarm?). Set alarm value ( : Set number, :

change between the numbers). Activate alarm (OK).

6 Close bottle and set on the scale. Confirm with OK function key.

7 Using the Start function key, start recording the filling or draining process

and open the valve of the the bottle.

en

defresitptsvnl????

Page 18

Using the product18

The option “Changing the reading display” is available, see chapter

“Measuring”.

8 If necessary: Change bottle (Bot. 02, continue with step 6).

9 After completion of the filling or draining process: Stop recording using the

Exit function key and confirm with the OK function key.

²

Macro ((only ttesto 5560):

The macro function serves to measure small pressures (max. 200hPa).

Measurement on the low-pressure side (pv) takes place via the vacuum

sensor (finer resolution). Note permissible pressure range!

1 Press the Action function key.

2 Using function keys, select Macro and confirm entry with the OK

function key.

3 Using set customer, set system using function keys and confirm

entry using OK function key.

The "Change reading display", "Display Hold/Max/Min", "Save reading /

series of readings" options are available, see the chapter "Performing the

measurement".

4 Create necessary connections and carry out macro pressure

measurement.

²

Evacuate ((only ttesto 5560):

Measurement on the low-pressure side (pv) takes place via the vacuum

sensor (finer resolution). Note permissible pressure range!

1 Press the Action function key.

2 Using function keys, select Evacuation and confirm entry with the OK

function key.

3 Using set customer, set system using function keys and confirm

entry using OK function key.

- The refrigerant is automatically set to H2O.

The "Change reading display", "Display Hold/Max/Min", "Save reading /

series of readings" options are available, see the chapter "Performing the

measurement".

4 Create necessary connections and carry out evacuation of the system.

²

Current mmeasurement ((current):

1 Press the Action function key.

2 Using function keys, select Current and confirm entry with the OK

function key.

Page 19

Using the product 19

3

Connect clamp-on probe* to the right probe socket and confirm using the

OK function key.

* Option not available as standard. Please ask your local Testo subsidiary.

The "Change reading display", "Display Hold/Max/Min", "Save reading /

series of readings" options are available, see the chapter "Performing the

measurement".

²

Calculate ppressure ddifference ((differential ppressure):

1 Press the Action function key.

2 Using function keys, select Pressure difference and confirm entry with

the OK function key.

3 Connect oil pressure probe* to the right probe socket and confirm using

the OK function key.

* Option not available as standard. Please ask your local Testo subsidiary.

4 Using the px=0 function key, zero the differential pressure probe

(unpressurized).

A zeroing is only possible in the following area:

±1bar(rel)/±14.5psi (rel) or 0...2bar(abs) / ±29psi (abs).

5 Confirm using OK function key bring probe into circuit.

The "Change reading display", "Display Hold/Max/Min", "Save reading /

series of readings" options are available, see the chapter "Performing the

measurement".

en

defresitptsvnl????

Page 20

Maintaining the product20

Maintaining the product

±

Cleaning tthe hhousing:

i If dirty, clean the housing with a damp cloth (soap solution). Do not use

aggressive cleaning products! Immediately remove oils, refrigerants and

solvents from the housing.!

±

Keep cconnections cclean:

i Keep screw connections clean and free of grease and other deposits,

clean with a moist cloth as required.

±

Regularly rreplace rrefrigerant hhoses

Warning!

If the measuring instrument falls down or is exposed to any other

comparable mechanical strain, the end connections of the refrigerant

hoses can break off. The valve knobs can also be damaged, which

can lead to further damage in the interior of the instrument, which is

not visible externally. For this reason, replace the refrigerant hoses

after any fall or comparable mechanical strain with new, undamaged

refrigerant hoses. For your own safety, send the instrument to Testo

customer service for technical testing.

±

Remove ooil rresidues:

i Carefully blow out oil residues in valve block using compressed air.

±

Ensure aaccuracy oof mmeasurement:

Testo customer service would be glad to further assist you if you so wish.

i Check instrument regularly for leaks (Recommended: annually). Keep to

the permissible pressure range!

i Calibrate instrument regularly (Recommended: annually).

±

Changing tthe bbatteries //rechargeable bbatteries //radio mmodule:

Instrument is switched off.

i Before removing the batteries: Read out memory to avoid data loss.

1 Fold out the suspension device and open the battery compartment (clip

lock).

2 Remove empty batteries / rechargeable batteries, empty buffer battery or

radio module.

Page 21

Maintaining the product 21

3

Insert batteries / rechargeable batteries, empty buffer battery battery, radio

module:

i Push radio module into the module slot underneath the buffer battery

(contact strip facing up).

i Insert new batteries / rechargeable batteries (4x 1.5V, type AA, mignon,

LR6). Observe the polarity!

i Insert new buffer battery (1x 3V lithium CR2032) in the battery

compartment. Observe the polarity (positive pole up)!

5 Close the battery compartment.

6 Set battery type and check / set date / time, see the chapter "First steps",

"Switch instrument on".

±

Replacing tthe vvalve oor tthe ppositioner kknob:

Warning!

Replacing of the positioner knob and the valve by the customer is not

allowed. Send the instrument to Testo customer service.

en

defresitptsvnl????

Page 22

Tips and assistance22

Tips and assistance

Questions and answers

Question Possible causes Possible solution

flashes. · Batteries are almost empty. · Change batteries.

Instrument switches ·

Auto Off function is switched on. · Switch function off.

itself off. · Residual capacity of the batteries is too low. · Change batteries.

uuuu illuminates instead · Permitted measuring range · Keep to the permitted measuring range.

of parameter display. was undershot.

oooo illuminates instead · Permitted measuring range · Keep to the permitted measuring range.

of parameter display. was exceeded.

---- illuminates instead · Probe not connected. · Connect probe.

of parameter display. · Probe break. · Replace probe.

Refrigerant escaping · Valve positioner not tight · Please contact your dealer

from valve positioner or Testo cutomer service.

testo 560 only

Evacuation function:

ooooo is displayed instead · connected pressure higher than · decrease pressure

of meas. parameter, despite atmospheric pressure · reset vacuum protection valve

vacuum is < 200 mbar · protective valve of vacuum (see arrow) with a blunt object

sensor has been triggered

If we could not answer your question, please contact your dealer or Testo

Customer Service. For contact data, see back of this document or web page

www.testo.com/service-contact

Page 23

Tips and assistance 23

Accessories and spare parts

Designation Article no.

Probe

Air probe, PT100 0609 1773

Surface probe, PT100 0609 1973

Immersion / penetration probe, PT100 0609 1273

Pipe wrap probe, PT100, with Velcro tape, 2.9m pipe 0609 5602

Pipe wrap probe, PT100, with spring clamping device 0609 5605

Miscellaneous

Refrigerant scale * 0554 5606

Clamp-on probe * 0554 5607

Oil pressure probe * 0638 1742

easyKool PC software 0554 5604

USB data transmission cable, instrument - PC 0449 0047

Padlock for instrument security 0554 1747

Stainless steel adapter for NH3(ammonia), 3x 7/16“ on 1/2“, 1x 5/8“ on 1/2“ 0554 5561

Protocol printer, IrDA 0554 0547

* Option not available as standard. Please ask your local Testo subsidiary.

For a complete list of all accessories, please refer to the product catalogs and

brochures or look up our website at: www.testo.com

en

defresitptsvnl????

Page 24

0970 5601 en 08 V02.01

Loading...

Loading...