Page 1

testo 550 · Digital manifold

Instruction manual

Page 2

2

Page 3

2 Safety and the environment

1 Content

1 Content .....................................................................................................3

2 Safety and the environment....................................................................4

2.1. About this document........................................................................4

2.2. Ensure safety...................................................................................5

2.3. Protecting the environment..............................................................5

3 Specifications ..........................................................................................6

3.1. Use ..................................................................................................6

3.2. Technical data .................................................................................6

4 Product description.................................................................................8

4.1. Overview..........................................................................................8

5 First steps ................................................................................................9

6 Using the product..................................................................................11

6.1. Preparing for measurement ...........................................................11

6.1.1. Connecting the temperature probe.................................................................11

6.1.2. Switching the instrument on........................................................................... 11

6.1.3. Selecting the measuring mode.......................................................................13

6.2. Performing the measurement ........................................................14

7 Maintaining the product........................................................................16

8 Tips and assistance...............................................................................18

8.1. Questions and answers .................................................................18

8.2. Measurement parameters .............................................................18

8.3. Error reports ..................................................................................19

8.4. Accessories and spare parts .........................................................19

3

Page 4

2 Safety and the environment

2 Safety and the environment

2.1. About this document

Use

> Please read this documentation through carefully and

familiarize yourself with the product before putting it to use. Pay

particular attention to the safety instructions and warning advice

in order to prevent injuries and damage to the products.

> Keep this document to hand so that you can refer to it when

necessary.

> Hand this documentation on to any subsequent users of the

product.

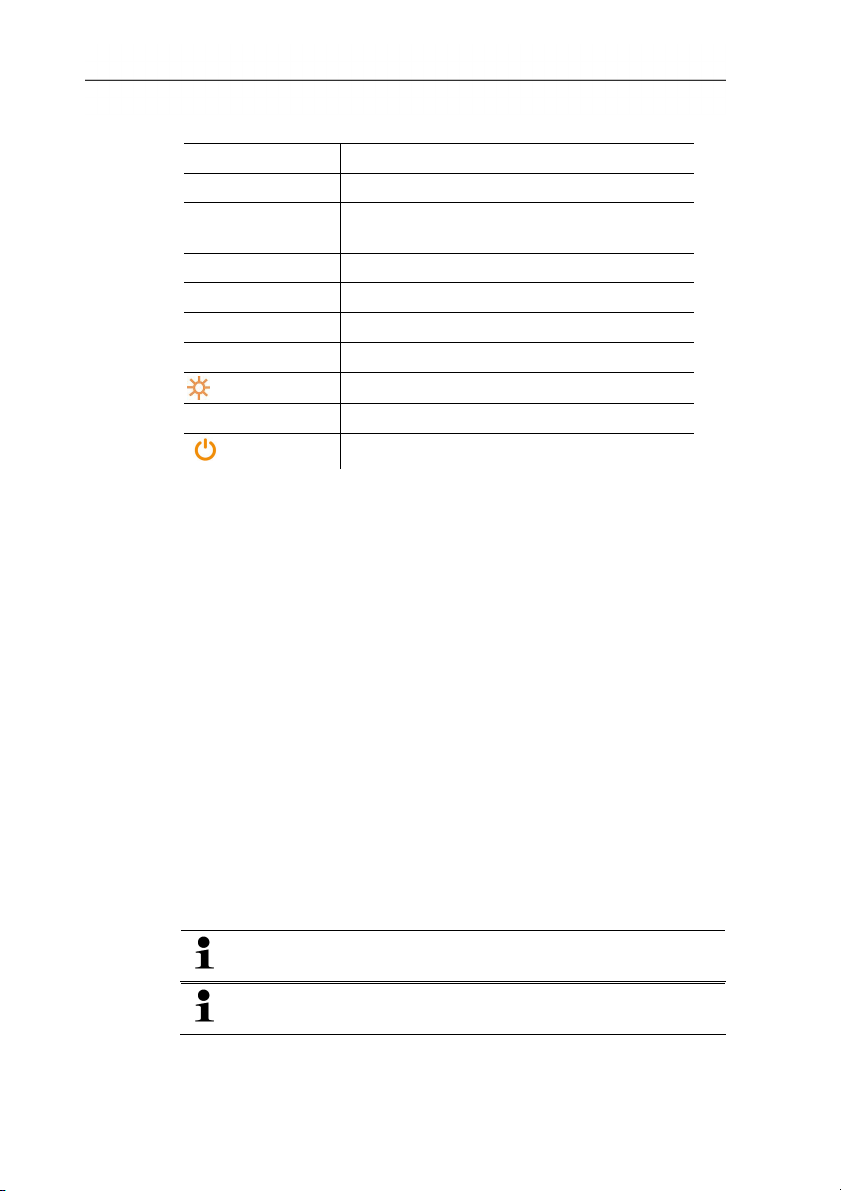

Symbols and writing standards

Represen-

Explanation

tation

Warning advice, risk level according to the signal

word:

Warning! Serious physical injury may occur.

Caution! Slight physical injury or damage to the

equipment may occur.

> Implement the specified precautionary

measures.

Note: Basic or further information.

1. ...

2. ...

Action: more steps, the sequence must be

followed.

> ... Action: a step or an optional step.

- ... Result of an action.

Menu Elements of the instrument, the instrument

displays or the program interface.

[OK] Elements of the instrument, the instrument

displays or the program interface.

... | ... Functions/paths within a menu.

“...” Example entries

4

Page 5

2.2. Ensure safety

> Do not operate the instrument if there are signs of damage at

the housing, mains unit or feed lines.

> Do not perform contact measurements on non-insulated, live

parts.

> Do not store the product together with solvents. Do not use any

desiccants.

> Carry out only the maintenance and repair work on this

instrument that is described in the documentation. Follow the

prescribed steps exactly. Use only original spare parts from

testo.

> The objects to be measured or the measurement environment

may also pose risks: Note the safety regulations valid in your

area when performing the measurements.

> If the measuring instrument falls or another comparable

mechanical load occurs, the pipe sections of the refrigerant

hoses may break. The valve positioners may also be damaged,

whereby further damage to the interior of the measuring

instrument may occur that cannot be identified from the outside.

The refrigerant hoses must therefore be replaced with new,

undamaged refrigerant hoses every time the measuring

instrument falls or following any other comparable mechanical

load. Send the measuring instrument to Testo Customer

Service for a technical check for your own safety.

2 Safety and the environment

2.3. Protecting the environment

> Dispose of faulty rechargeable batteries/spent batteries in

accordance with the valid legal specifications.

> At the end of its useful life, send the product to the separate

collection for electric and electronic devices (observe local

regulations) or return the product to testo for disposal.

> Refrigerant gases can harm the environment. Please note the

applicable environmental regulations.

5

Page 6

3 Specifications

3 Specifications

3.1. Use

The testo 550 is a digital manifold for maintenance and servicing

work at refrigeration systems and heat pumps. It must only be used

by qualified authorized personnel.

The testo 550 replaces mechanical manifolds, thermometers and

pressure/temperature tables by means of its functions. Pressures

and temperatures can be loaded, adjusted, tested and monitored.

The testo 550 is compatible with most non-corrosive refrigerants,

water and glycol. The testo 550 is not compatible with refrigerants

that contain ammonia.

3.2. Technical data

The product must not be used in areas at risk of explosion!

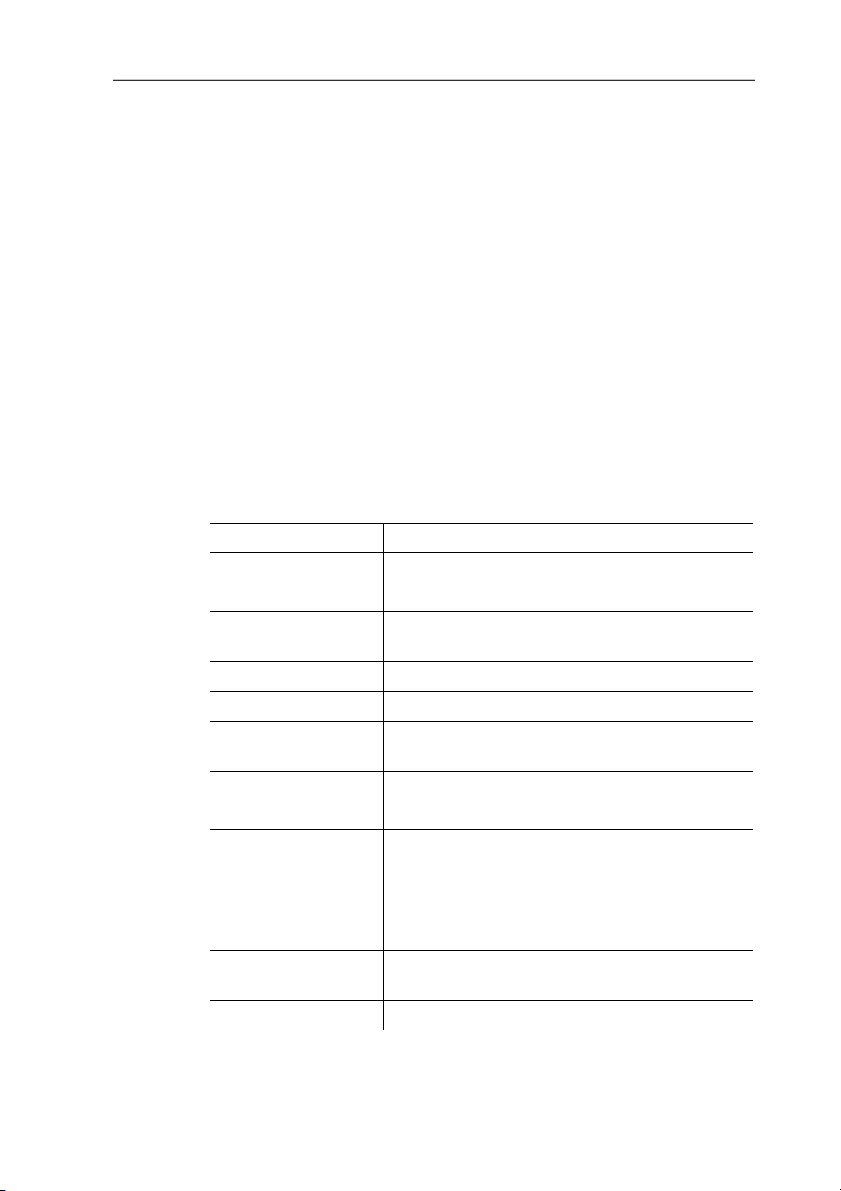

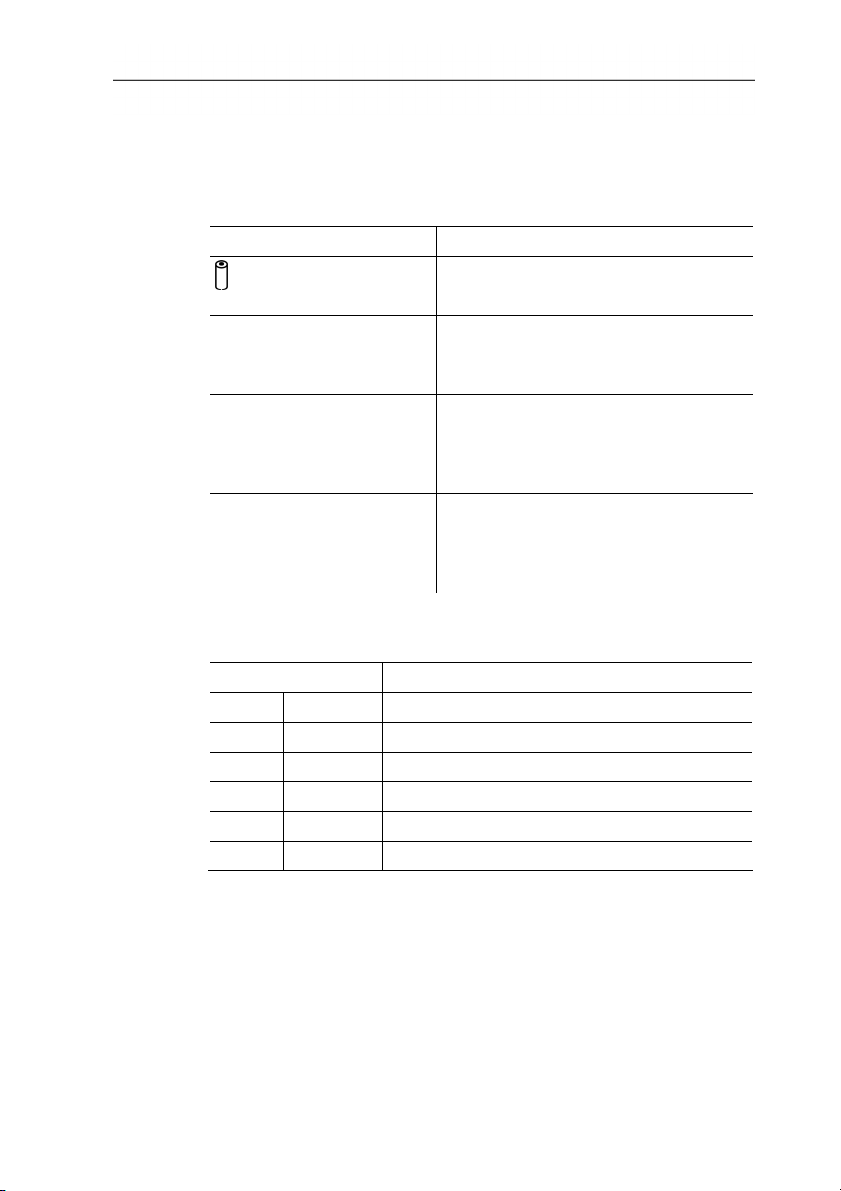

Characteristic Values

Parameters Pressure: kPa / MPa / bar / psi

Temperature: °C/°F/K

Sensor

Pressure: 2 x pressure sensor, temperature:

2 x NTC

Pressure media FCKW, FKW, N, H2O

Meas. cycle 0.75 s

Measurement

Quantity: 4

channels

Interfaces Pressure connections: 3 x 7/16" UNF

NTC measurement

Measuring ranges

Pressure measuring range HP/LP:

-1 to 40 bar (rel)/-14.7 to 580 psi (rel)/

100 to 4000 kPa (rel)/0.1 to 4 MPa (rel)

Temperature measuring range:

-50 to +150 °C/-58 to 302 °F

Humidity application

10 to 90 % RH

range

Overload 60 bar, 6000 kPa, 6 MPa, 870 psi

6

Page 7

3 Specifications

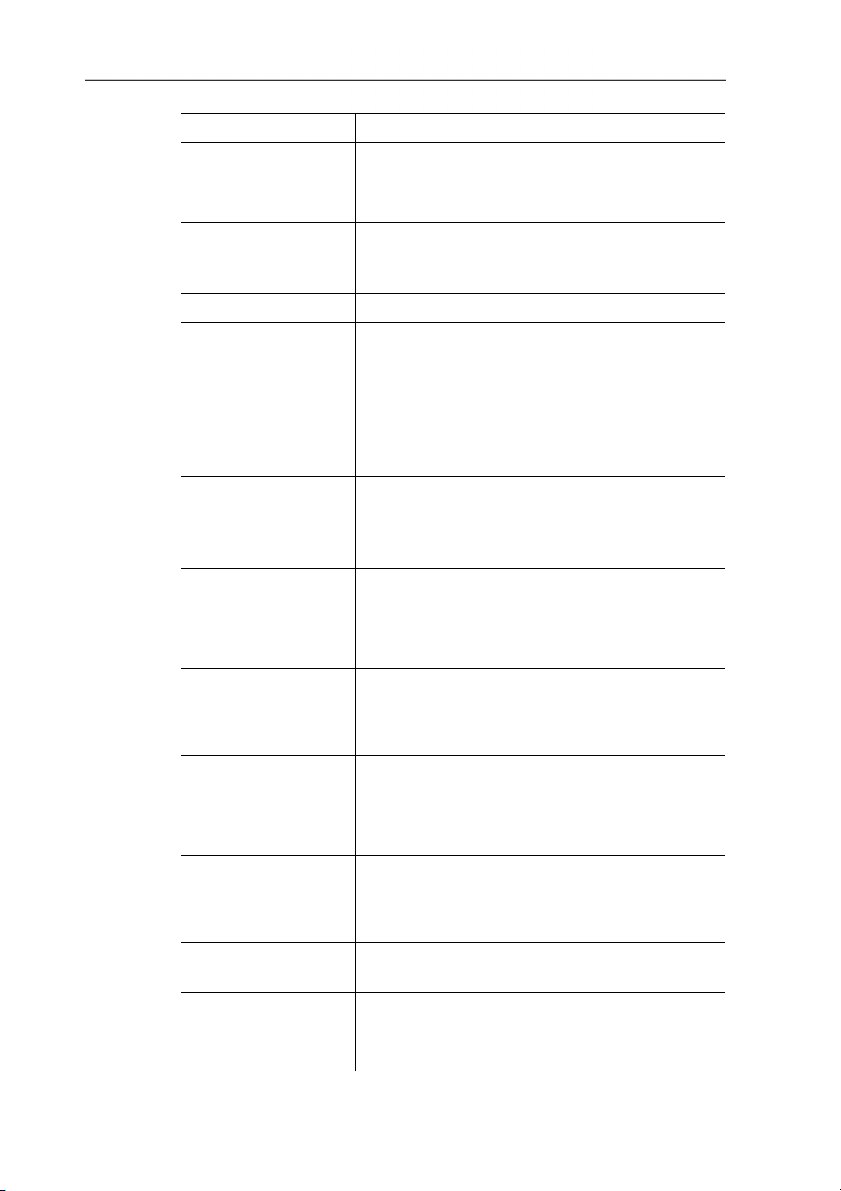

Characteristic Values

Resolution

Pressure resolution: 0.01 bar/0.1 psi/

1 kPa/0.001 MPa

Temperature resolution: 0.1 °C/0.1 °F

Accuracy (nominal

temperature

22 °C/71.6 °F)

Pressure: ±0.75 % of final value (±1 digit)

Temperature: ±0.5 K (±1 digit)

No. of refrigerants 32

Selectable

refrigerants

No refrigerant, R12, R22, R123, R134a,

R290, R401A, R401B, R402A, R402B,

R404A, R406A, R407A, R407C, R408A,

R409A, R410A, R414B, R416A, R417A,

R420A, R421A, R421B, R422A, R422B,

R422D, R424A, R434A, R437A, R502,

R503, R507, R718 (H2O)

Measurable media

Measurable media: All media that are stored

in the testo 550. Not measurable: Ammonia

(R717) and other refrigerants which contain

ammonia

Ambient conditions

Operating temperature: -10 to 50 °C/

14 to 122 °F

Storage temperature: -20 to 60 °C/

-4 to 140 °F

Housing Material: ABS/PA/TPU

Dimensions: 265 x 135 x 75 mm

Weight: approx. 1000 g (without batteries)

Power supply

Current source: Rechargeable

batteries/batteries 4x 1.5 V, type

AA/mignon/LR6

Battery life: approx. 40 h (display light off)

Display Type: Illuminated LCD

Updating of readings: 1 s

Response time: 0.5 s

Directives,

EC Directive: 2004/108/EC

standards and tests

Warranty Duration: 2 years

Warranty conditions: see website

www.testo.com/warranty

7

Page 8

4 Product description

4 Product description

4.1. Overview

Display and control elements

1 Mini-DIN probe socket for NTC temperature probe, with socket

cover

2 Foldable suspension device, with eyelet for padlock (on rear)

3 Display. Instrument status icons:

Icon Significance

/ /

Battery capacity: >75 %/>50 %/>25 %/<10 %

Select measuring mode (see Selecting the

measuring mode, page 13)

4 Battery compartment. It is not possible to charge rechargeable

batteries in the instrument!

8

Page 9

5 First steps

5 Control keys:

Key Function

[Set]

Set units

[R, Start/ Stop] Select refrigerant/ Start/stop / Tightness

test

[Mode]

[Min/Max/Mean]

[▲]

[p=0]

[▼]

[ ]

Switching measuring mode

Display min./max./mean values

Up key: Change display view

Pressure zeroing

Light key: Switch display light on/off

Down key: Change display view

Switching the instrument on/off

6 Sight glass for refrigerant flow

7 2 x valve positioner

8 3 x hose parkers for refrigerant hoses

9 3 x connections 7/16" UNF, brass

Left/right: Low pressure/high pressure, for refrigerant hoses with

quick connect fitting, passage can be locked via valve

positioner. Centre: for refrigerant bottles, for example, with

sealing cap.

5 First steps

Inserting batteries/rechargeable batteries

1. Fold out the suspension device and open the battery

compartment (clip lock).

2. Insert batteries (included in delivery) or rechargeable batteries

(4x 1.5 V, type AA/Mignon/LR6) in the battery compartment.

Observe the polarity!

3. Close the battery compartment.

When not in use for long period: Remove

batteries/rechargeable batteries.

Completely charge rechargeable batteries before using the

instrument.

9

Page 10

5 First steps

Switching the instrument on

> Press [

].

- Initialization phase:

• All display segments are lit (length of time: 2 s).

- Measurement view is opened.

Performing settings

1. Press [Set].

- The configuration menu is opened and the adjustable

parameter flashes.

2. Set parameters:

Key functions

Representation Explanation

[▲] or [▼]

[Set]

Adjustable parameters

Change parameter, select unit

Select units/parameters

Representation Explanation

°C, °F

bar, kPa, MPa, psi

Pabs, Prel or psia,

psig

Set temperature unit.

Set unit of pressure.

Depending on the selected unit of pressure:

Switch between absolute and relative

pressure display.

29.92 inHg/

Set current absolute pressure (see table)

1.013 bar

/ /

Select measuring mode (see Selecting the

measuring mode, page 13)

10

− Settings will be applied following the final selection.

Operating valve positioner

The digital manifold acts like a conventional two-way manifold with

regard to the refrigerant path: The passages are opened by

opening the valves. The adjacent pressure is measured with valves

closed as well as with them open.

> Open valve: Turn valve positioner anticlockwise.

> Close valve: Turn valve positioner clockwise.

Page 11

WARNING

Only tighten valve positioner with your hand! Do not use any tools

when tightening as otherwise the thread may be damaged.

6 Using the product

6.1. Preparing for measurement

6.1.1. Connecting the temperature probe

For measurement of the pipe temperature and for the automatic

calculation of overheating and undercooling, an NTC temperature

probe (accessory) must be connected.

Probes must be connected before the measuring instrument is

switched on so that they are recognized by the measuring

instrument.

6.1.2. Switching the instrument on

> Press [ ].

6 Using the product

Zeroing pressure sensors

Carry out a zeroing of the pressure sensors before every

measurement.

✓ The connections of the low-pressure and high-pressure side

must be depressurized (ambient pressure).

> Press [P=0] button to perform zeroing.

Connecting the refrigerant hoses

✓ The valve positioners are closed.

1. Connect refrigerant hoses for low-pressure side (blue) and highpressure side (red) to the measuring instrument.

2. Connect refrigerant hoses to the system.

11

Page 12

6 Using the product

If the measuring instrument falls or another comparable

mechanical load occurs, the pipe sections of the refrigerant hoses

may break. The valve positioners may also be damaged, whereby

further damage to the interior of the measuring instrument may

occur that cannot be identified from the outside.

> Send the measuring instrument to Testo Customer Service for

> The refrigerant hoses must therefore be replaced with new,

Setting the refrigerant

1. Press [R, Start/Stop].

- The refrigerant menu is opened and the currently selected

2. Set the refrigerant:

Key functions

Representation Explanation

[▲] or [▼]

[R, Start/Stop] Confirm setting and leave the refrigerant

WARNING

a technical check for your own safety.

undamaged refrigerant hoses every time the measuring

instrument falls or following any other comparable mechanical

load.

refrigerant flashes.

Change refrigerant

menu.

12

Refrigerant that can be set

Representation Explanation

R... Refrigerant number of the refrigerant in

accordance with ISO 817

...T testo special designation for certain

refrigerants

---

No refrigerant selected.

Example "Set refrigerant R401B"

1. Press [▲] or [▼] repeatedly until R401B flashes.

2. Press [R, Start/Stop] to confirm the setting.

Page 13

Ending the refrigerant selection

> Press [R, Start/Stop] or automatically after 30 s if no button

was pressed.

6.1.3. Selecting the measuring mode

1. Press [Set] several times

2. Select function with [▲] or [▼] .

3. Save setting: press [Set] .

- Measuring mode is dsplayed.

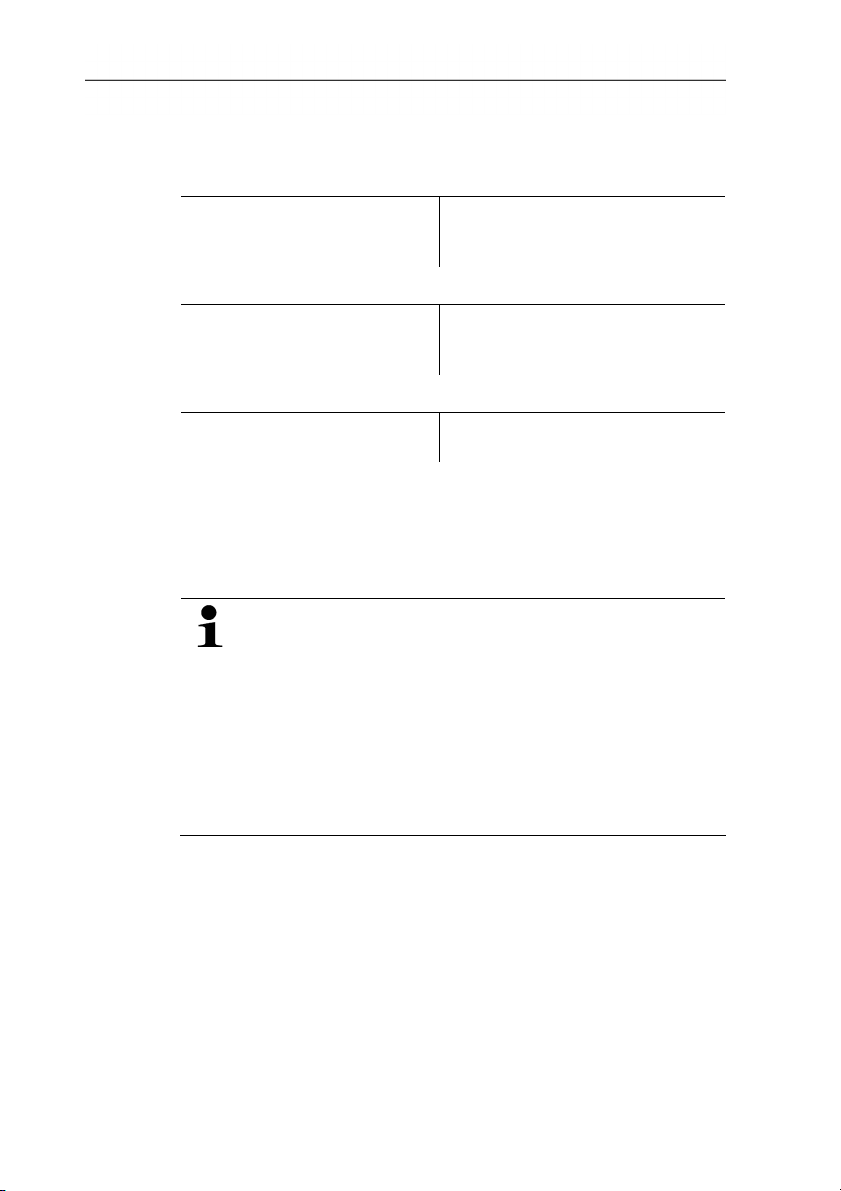

Display Mode Function

Refrigeration

system

Heat pump

Automatic mode

6 Using the product

Normal functionality of

the digital manifold

Normal functionality of

the digital manifold

If the automatic mode

is activated, the

testo 550 digital

manifold automatically

changes the display of

the high and low

pressure. This

automatic change

occurs when the

pressure on the lowpressure side is 1 bar

higher than the

pressure on the highpressure side. During

the change, Load

(2 s) is shown in the

display.

This mode is

especially suited to air

conditioning systems

which cool and heat.

13

Page 14

6 Using the product

6.2. Performing the measurement

WARNING

Risk of injury caused by refrigerant that is at high pressure,

hot, cold, or poisonous!

> Wear safety goggles and protective gloves.

> Before pressurizing the measuring instrument: Always fasten

the measuring instrument at the suspension device in order to

prevent it from falling (risk of breakage)

> Check if the refrigerant hoses are intact and connected

correctly before each measurement. Do not use a tool to

connect the hoses. Only tighten the hoses by hand (max.

torque 5.0 Nm/3.7 ft*lb).

> Measures with the occurrence of danger.

Measuring

✓ The steps described in the chapter "Preparing for

measurement" have been completed.

1. Pressurize the measuring instrument.

2. Read off readings.

With zeotropic refrigerants, the evaporation temperature

to/Ev is displayed after the complete evaporation/the

condensation temperature tc/Co is displayed after the

complete condensation.

14

The measured temperature must be assigned to the

superheating or the subcooling side (toh <--> tcu).

Depending on this assignment, t

/SC is shown depending on the selected display.

Δt

cu

/T1 or Δtoh/SH or tcu/T2 or

oh

- Reading and display illumination flash:

• 1 bar before reaching the critical pressure of the refrigerant,

• upon exceeding the max. permissible pressure of 40 bar.

Page 15

6 Using the product

Key functions

> [▲]

or [▼]: Change the reading display.

Possible display combinations:

Evaporation pressure

Refrigerant evaporation

temperature to/Ev

Condensation pressure

Refrigerant condensation

temperature tc/Co

or (only with connected temperature probe)

Evaporation pressure

Measured temperature t

Condensation pressure

/T1

Measured temperature tcu/T2

oh

or (only with connected temperature probe)

Evaporation pressure

Superheating Δt

/SH.

oh

Condensation pressure

Subcooling Δtcu/SC

With two connected NTC probes, Δt is also shown.

> [Mean/Min/Max]: Record readings, display min./max. readings,

mean values (since switching on).

Tightness test/pressure drop test

Systems can be tested for tightness with the temperaturecompensated tightness test. The system pressure and the

ambient temperature are measured over a defined period

for this. A temperature probe can be connected that

measures the ambient temperature for this

(recommendation: NTC air probe, art. no. 0613 1712).

Information about the temperature-compensated differential

pressure and about the temperature at the beginning/end of

the test exists as a result. If no temperature probe is

connected, the tightness test can be performed without

temperature compensation.

✓ The steps described in the chapter "Preparing for

measurement" have been completed.

1. Press [Mode] (leakage test view).

2. Start the leakage test: Press [R, Start/Stop].

3. End the leakage test: Press [R, Start/Stop].

- Result is displayed.

4. Confirm message: Press [Mode].

- You automatically jump to the evacuation/vacuum display

menu.

15

Page 16

7 Maintaining the product

Evacuation/vacuum display

The measurement is performed on the low-pressure side.

5. Press [Mode].

- Result is displayed on the low-pressure side.

6. Press [Mode].

7 Maintaining the product

- The measuring mode is displayed.

Cleaning the instrument

> If the housing of the instrument is dirty, clean it with a damp

cloth.

Do not use any aggressive cleaning agents or solvents! Weak

household cleaning agents or soap suds can be used.

Keeping connections clean

> Keep screw connections clean and free of grease and other

deposits, clean with a moist cloth as required.

Exchanging refrigerant hoses regularly

WARNING

If the measuring instrument falls or another comparable

mechanical load occurs, the pipe sections of the refrigerant hoses

may break. The valve positioners may also be damaged, whereby

further damage to the interior of the measuring instrument may

occur that cannot be identified from the outside.

> Send the measuring instrument to Testo Customer Service for

a technical check for your own safety.

> The refrigerant hoses must therefore be replaced with new,

undamaged refrigerant hoses every time the measuring

instrument falls or following any other comparable mechanical

load.

16

Removing oil residues

> Carefully blow out oil residues in valve block using compressed

air.

Page 17

7 Maintaining the product

Ensuring the measuring accuracy

Testo Customer Service would be glad to further assist you if you

so wish.

> Check instrument regularly for leaks (recommended: annually).

Keep to the permissible pressure range!

> Calibrate instrument regularly (recommended: annually).

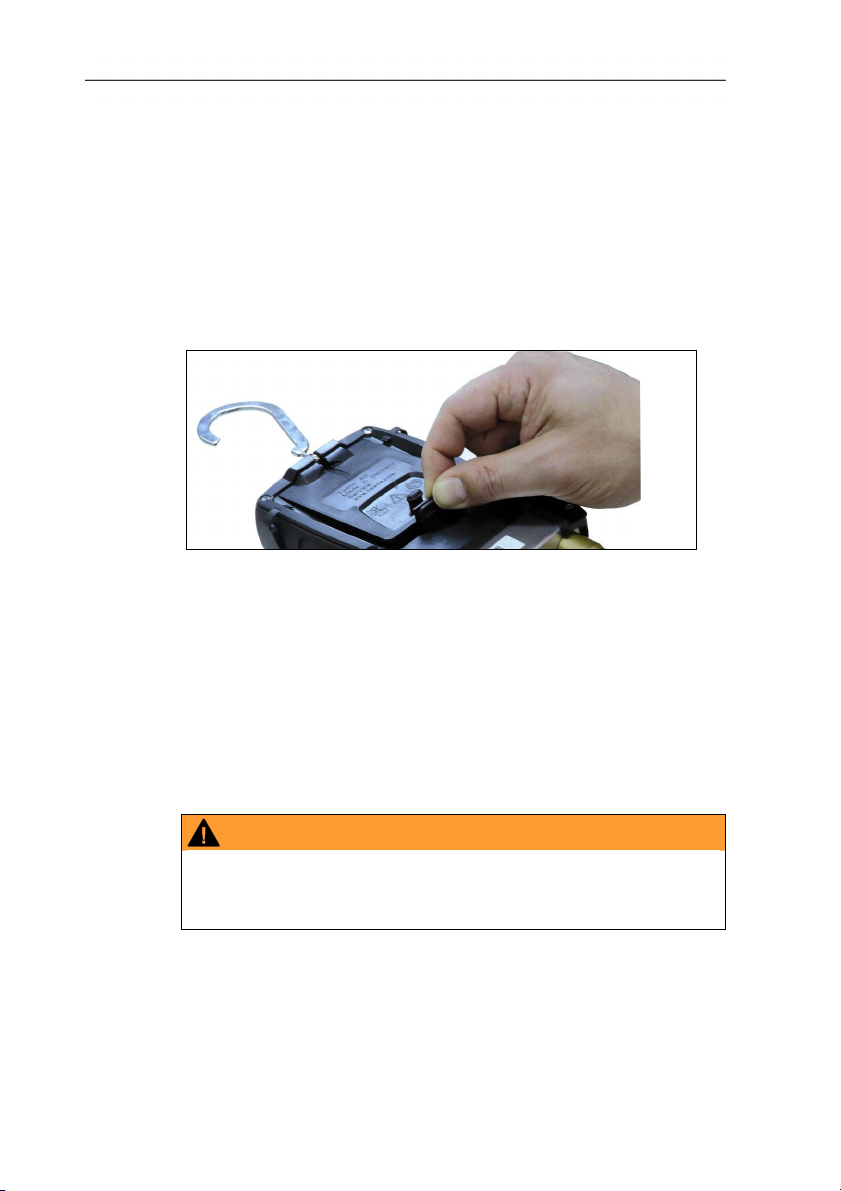

Changing batteries/rechargeable batteries

✓ Instrument is switched off.

1. Fold out the suspension device, loosen the clip and remove the

cover of the battery compartment.

2. Remove empty batteries/rechargeable batteries and insert new

batteries/rechargeable batteries (4x 1.5 V, type AA, Mignon,

LR6) in the battery compartment. Observe the polarity!

3. Set on and close cover of the battery compartment (clip must

engage).

4. Switch the instrument on.

Changing the valve or valve positioner handle

WARNING

Change of the valve positioners and valves by the customer is not

permissible.

> Send the measuring instrument to the Testo Customer Service.

17

Page 18

8 Tips and assistance

8 Tips and assistance

8.1. Questions and answers

Question Possible causes/solution

flashes

Batteries are almost empty.

> Change batteries.

The instrument switches

off automatically.

Residual capacity of the batteries is

too low.

> Change batteries.

uuuu lights up instead of

the parameter display

The permissible measuring range has

been undershot.

> Keep to the permitted measuring

range.

oooo lights up instead of

the parameter display

The permissible measuring range has

been exceeded.

> Keep to the permitted measuring

range.

8.2. Measurement parameters

Name Description

Δtoh SH Superheating, evaporation pressure

Δtcu SC Subcooling, condensation pressure

to Ev Refrigerant evaporation temperature

tc Co Refrigerant condensation temperature

toh T1 Measured temperature, evaporation

tcu T2 Measured temperature, condensation

18

Page 19

8.3. Error reports

Question Possible causes/solution

---- is lit up instead of

measurement parameter

display

Display EEP FAIL

8 Tips and assistance

Sensor or cable defective

> Please contact your dealer or

Testo Customer Service

Eeprom defective

> Please contact your dealer or

Testo Customer Service

8.4. Accessories and spare parts

Description Article no.

Clamp probe for temperature measurement

at pipes

Pipe wrap probe with Velcro tape for pipe

diameters of up to max. 75 mm, Tmax.

+75 °C, NTC

Watertight NTC surface probe 0613 1912

Precise, robust NTC air probe 0613 1712

Transport case for measuring instrument,

probe and hoses

For a complete list of all accessories and spare parts, please refer

to the product catalogues and brochures or look up our website at:

www.testo.de

If you have any questions, please contact your dealer or Testo

Customer Service. The contact details can be found on the back of

this document or on the Internet at www.testo.com/service-

contact.

0613 5505

0613 4611

0516 5505

19

Page 20

0970 5501 en 01 V01.00

Loading...

Loading...