Page 1

It’s Simple.

Protect the integrity of your products

and your brand during cold chain transportation.

NEW

documentation during the transport of foods and pharmaceutical goods.

testo 184 data logger: Temperature monitoring and quality data

Page 2

testo 184

Optimum temperatures

for sensitive goods.

Shipping temperature and environmentally-sensitive products require a reliable logger

that provides accurate data each and every time. Monitor the transport of cold chain products

with the testo 184 data loggers.

With the testo 184 data loggers, you can monitor every step of the

cold chain. The loggers travel during freight and in loading rooms,

monitoring temperatures throughout the transportation of sensitive

goods on the rail, in the air, or on the road.

At their destination, you can quickly confi rm that the proper storage conditions have not been exceeded. To obtain detailed

information, simply connect the logger to a PC, and a PDF report

is immediately generated with all relevant data.

For even more e ciency and convenience, all required fi les and

information are stored directly and securely, including:

confi guration fi le, calibration certifi cate, instruction manual and

PDF report of your recorded data.

DeliveryTransportStorageProduction

2

Page 3

Temperature monitoring for

pharmaceutical logistics

A visit from a GMP (Good Manufacturing Practice) inspector can

be a serious issue for your company if you don’t have the correct

equipment. Neither insufficient refrigeration

during the transport of the last delivery, nor the incomplete

documentation of the temperature values in your paperwork will

pass inspection. In the worst case, there is a threat of product

recall, huge financial deficits and the loss of your good reputation

in the pharmaceutical industry.

Or, a visit from a GMP inspector can be a breeze. With the testo

184 data loggers, all (bio-)pharamceuticals can be protected from

unnoticed gaps in the cold chain. The entire distribution process

is monitored and documented simply, securely and compliantly

with all common standards, guidelines and regulations:

• The temperature data loggers T1, T2, T3 and T4 are delivered

with a calibration certificate traceable according to ISO 17025,

which is stored as a PDF directly in the logger.

• Thanks to the use of the validatable ComSoft CFR software, 21

CFR Part 11-compliant applications with all testo 184 data

loggers is possible.

• For the purposes of the analysis of stability data, the logger

supports you with an automatic MKT-value calculation, and the

option of setting MKT alarms.

• The comprehensive alarm management allows the setting of

multiple alarm limits. It is also possible to set cumulative alarms,

e.g. when the temperature may not exceed the limit value of 45

°F for longer than 30 minutes.

• The extremely intuitive operation and the easy identification of

alarms lead to a low training requirement for your staff.

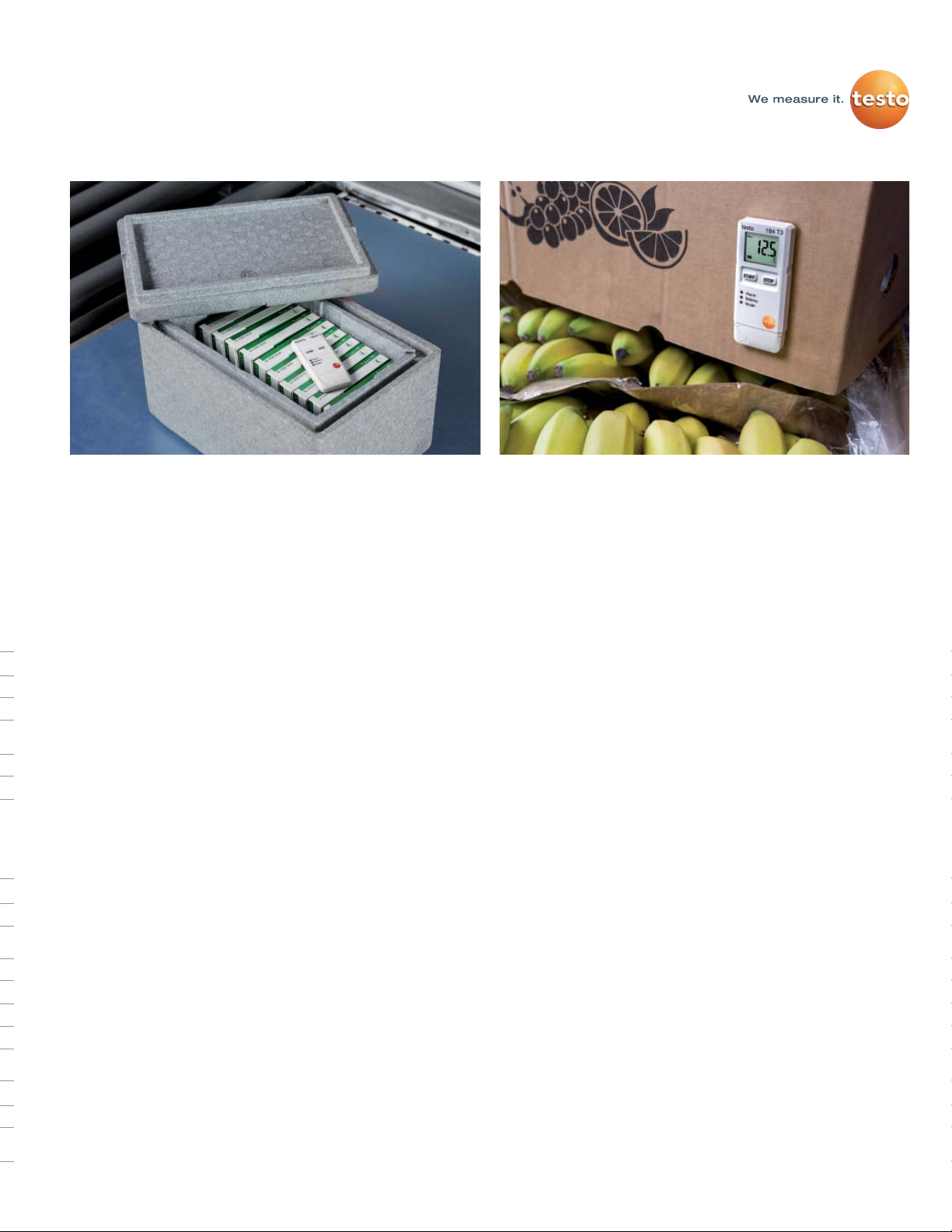

Temperature monitoring for

food logistics

The adherence to pre-defined temperature values is of paramount

significance in the transportation of food. This is the only way

legal hygiene standards can be fulfilled and the quality, safety and

preservation of food goods guaranteed. The precise monitoring of

the complex processes and procedures is defined in the HACCP

guidelines (Hazard Analysis Critical Control Points), whose

purpose is the prevention of health risks in the food sector.

The testo 184 data loggers are certified by HACCP International,

and critical for the monitoring of food product storage in transport

from the farmer all the way to the supermarket customer. The

documentation of the quality data is extremely easy thanks to the

convenient readout function by an automatically generated PDF

report. Temperature-sensitive foods arrive safely and your brand

stays protected.

3

Page 4

testo 184

Plug and Play.

All the advantages of the testo 184 data loggers at a glance.

Simple confi guration - no software required

A simple, easy to follow, configuration file in

on board every 184 so that no software is

needed for downloads or set-up. Even different

languages can be selected for shipper and

receiver.

Easy operation

testo 184 is intuitively operated, and can

be used without special training or previous

knowledge: The "Start" button begins data

recording. "Stop" ends it.

Actual size

Clear indication of alarms

A glance at the display or the LEDs is

enough to know whether limit values have

been exceeded during transport.

Convenient readout

A PDF report with the transport data is

created immediately upon connection of the

testo 184 data logger to the USB port of a

computer. This is suitable for long-term

archiving according to PDF/A standard.

Mobile readout/printout on site

All testo 184 data loggers can be read out

on-site with an NFC-capable Android

smartphone. Data transfer from the data

logger to a compatible Testo printer also

functions wirelessly via NFC.

IT-safe

The testo 184 data loggers work securely

without software installation or download,

so that IT problems are triggered neither by

the firewall nor a virus scanner.

4

Page 5

ISO, GxP, CFR, HACCP and EN 12830.

The most important standards for the transport of pharmaceuticals and foods.

GxP-guidelines

In a GxP-regulated environment, especially high demands are

placed on quality management. Not only GMP or GLP, but also

GDP (Good Distribution Practice) guidelines play an increasingly

important part. Since the distribution of pharmaceutical and

medicinal products is nothing more than mobile storage, the

same rules apply here as in production, with regard to monitoring

and quality assurance. With the help of the testo 184 data logger,

GxP-compliant work is no problem for you.

ISO 9001:2008

ISO 9001:2008 is the most significant international norm for

quality management systems, and guarantees the framework

conditions for a high level of quality-capability for products and

processes. However, in connection with this, it is also

indispensable to be fully informed of the professional quality

assurance of the the suppliers involved in the process. Testo AG,

as an ISO 9001:2008-certified company, fully complies with these

requirements, and ensures the adherence to the norms through

internal audits as well as accredited external audits.

FDA 21 CFR Part 11

The FDA regulation 21 CFR Part 11, on which, among others,

Appendix 11 of the EU-GMP is based, makes stipulations on

electronically stored documents in which electronic signatures are

made. The use of the testo 184 data loggers (in combination with

the validatable ComSoft CFR software) provides: Limitation of

access to authorized persons, Audit Trails with time stamp, as

well as electronic signatures, allowing a 21 CFR Part 11compliant use of the data loggers.

HACCP International certifi cation

HACCP International is a leading organization in the field of food

safety, and tests products for their suitability for food

environment processes according to the International HACCP

guidelines. The testo 184 data loggers are certified as “food-safe”

by HACCP International, and thus can be recommended without

restriction for use in the HACCP

environment.

EN 12830

The standard EN 12830 establishes the technical and functional

properties of temperature registration instruments for transport,

storage and distribution plants for chilled, frozen or deep-frozen

foods and ice-cream. The transport loggers testo 184 T1, T2, T3

and T4 fulfil these requirements, and have been correspondingly

certified by TÜV.

ISO

9001:2008

CERTIFIED

CFR ready

5

Page 6

testo 184

Safe monitoring of

temperature, humidity and shock.

Overview of the testo 184 data loggers.

Measurement parameters

Exchangeable battery

Operating time

Battery life

Measuring range

Resolution

Accuracy

Storage temperature

Measurement rate

Memory

Protection class

Alarm identification

Readout via NFC

Automatic PDF generation

Temperature calibration certifi cate

traceable according to ISO 17025

EN 12830-certified

HACCP-certified

Compatible with testo ComSoft

CFR 21 Part 11

testo 184 T1

Order No. 0572 1841

Temperature

–

90 days

–

-31° to 158 °F (-35° to 70 °C)

0.18 °F (0.1 °C)

±0.9 °F (±0.5 °C)

-67° to 158 °F (-55° to 70 °C)

1 min to 24 h

16,000 readings

IP67

by LEDs

testo 184 T2 testo 184 T3

Order No. 0572 1842 Order No. 0572 1843

Temperature

–

150 days

–

-31° to 158 °F (-35° to 70 °C)

0.18 °F (0.1 °C)

±0.9 °F (±0.5 °C)

-67° to 158 °F (-55° to 70 °C)

1 min to 24 h

40,000 readings

IP67

by LEDs and display

(at +77 °F and 15 min. meas. cycle)

Temperature

Unlimited

500 days

-31° to 158 °F (-35° to 70 °C)

0.18 °F (0.1 °C)

±0.9 °F (±0.5 °C)

-67° to 158 °F (-55° to 70 °C)

1 min to 24 h

40,000 readings

IP67

by LEDs and display

6

Page 7

testo 184 T4 testo 184 H1 testo 184 G1

Order No. 0572 1844 Order No. 0572 1845 Order No. 0572 1846

Temperature Temperature/humidity Temperature/humidity/shock

Unlimited Unlimited Unlimited

100 days

(at -112 °F (-80 °C) and 15 min. meas. cycle)

-112° to 158 °F (-80° to 70 °C)

0.18 °F (0.1 °C) 0.18 °F (0.1 °C) / 0.1 %RH 0.18 °F (0.1 °C) / 0.1 %RH / 0.1 g

±1.4 °F (± 0.8 °C) (-112° to -31.2 °F)

(-80° to -35.1 °C)

±0.9 °F (± 0.5 °C) (-31° to 158 °F)

(-35° to 70 °C)

-112° to 158 °F (-80° to 70 °C)

1 min to 24 h

40,000 readings

IP67

by LEDs

(at 77 °F (25 °C) and 15 min. meas. cycle)

500 days

-4° to +158 °F (-20° to 70 °C) / 0 to 100 %RH

±0.9 °F (± 0.5 °C) (32 to +158 °F) (0° to 70 °C)

±1.4 °F (± 0.8 °C) (-4 to 32 °F) (-20° to 0 °C)

±1.8 %RH + 3% of m.v. at 77 °F (25 °C)

(5 to 80 %RH)

±0.03 %RH / K (0 to 140 °F) (0° to 60 °C)

-67° to 158 °F (-55° to 70 °C)

1 min to 24 h

64,000 readings

IP30

by LEDs and display

(at +77 °F (25 °C) and 15 min. meas. cycle)

-4° to +158 °F (-20° to 70 °C) / 0 to 100 %RH / 0 to 10 g

±0.9 °F (± 0.5 °C) (32 to 158 °F) (0° to 70 °C)

±1.4 °F

±1.8 %RH + 3% of m.v. at 77 °F

±0.03 %RH / K (0 to 140 °F)

-67° to 158 °F (-55° to 70 °C)

64,000 readings (temperature and humidity)

120 days

(± 0.8 °C)

(-4 to 32 °F)

(5 to 80 %RH)

±0.1 g + 5 % of m.v.

1 min to 24 h

+ 1,000 readings (shock)

IP30

by LEDs and display

(-20° to 0 °C)

(25 °C)

(0° to 60 °C)

–

––

–

7

Page 8

testo 184

Ordering information

testo 184 data logger.

testo 184 T1

• Measurement parameter: Temperature

• Operating time: 90 days

• Available in packs of: 1, 10 and 50

testo 184 T3

• Measurement parameter: Temperature

• Operating time: unlimited

• Available in packs of: 1, 10 and 50

Part no. 0572 1843 Part no. 0572 1844

Wall holder

Part no. 0192 1963

testo 184 H1

• Measurement parameters: Temperature

and humidity

• Operating time: unlimited

• Available in packs of: 1, 10 and 50

testo 184 T2

• Measurement parameter: Temperature

• Operating time: 150 days

• Available in packs of: 1, 10 and 50

Part no. 0572 1842Part no. 0572 1841

Wall holder

Part no. 0192 1963

testo 184 T4

• Measurement parameter: Temperature

• Operating time: unlimited

• Available in packs of: 1 and 10

Wall holder

Part no. 0192 1963

testo 184 G1

• Measurement parameters: Temperature,

humidity and shock

• Operating time: unlimited

• Available in packs of: 1

Part no. 0572 1845

Wall holder

Part no. 0192 1963

Part no. 0572 1846

Wall holder included

Order Information: 1-800-227-0729 | www.testo.com

0981 3984/msp/I/11.2013 Subject to change without notice.

Loading...

Loading...