Forced Air Ovens

Operation and Service Manual

TestEquity LLC

6100 Condor Drive

Moorpark, CA 93021

Support: 877-512-3457 Toll Free

805-480-0638

Corporate: 800-732-3457

805-498-9933

http://www.testequity.com

FS Series

Copyright © 2003-2015 TestEquity LLC Rev. 1.4, Oct. 13, 2015

Table of Contents

Chapter 1 – Safety Instructions ________________________________________________ 1-1

Introduction ____________________________________________________________________ 1-1

Safety Notices ___________________________________________________________________ 1-1

Chapter 2 – Receiving and Installation __________________________________________ 2-1

Inspection ______________________________________________________________________ 2-1

Return Shipment ________________________________________________________________ 2-1

Installation______________________________________________________________________ 2-1

Power Requirements ____________________________________________________________________ 2-2

Location _____________________________________________________________________________ 2-2

Lifting / Handling ______________________________________________________________________ 2-2

Leveling _____________________________________________________________________________ 2-2

Initial Burn-In _________________________________________________________________________ 2-2

Initial Cleaning ________________________________________________________________________ 2-2

Chapter 3 – Operation _______________________________________________________ 3-1

Front Panel Controls _____________________________________________________________ 3-1

Power Switch _________________________________________________________________________ 3-1

Timer Switch __________________________________________________________________________ 3-1

Overtemperature Protection Thermostat _____________________________________________________ 3-1

Overtemperature Light __________________________________________________________________ 3-1

Timer ________________________________________________________________________________ 3-1

Temperature Controller __________________________________________________________________ 3-1

Heating Light _________________________________________________________________________ 3-1

Operating the Oven ______________________________________________________________ 3-2

Turning the Oven On ___________________________________________________________________ 3-2

Setting the Temperature Controller _________________________________________________________ 3-2

Setting the Overtemp Protection Thermostat _________________________________________________ 3-2

Setting the Timer _______________________________________________________________________ 3-3

Chapter 4 – Maintenance _____________________________________________________ 4-1

Cleaning ________________________________________________________________________ 4-1

Storage _________________________________________________________________________ 4-1

Calibration _____________________________________________________________________ 4-1

Troubleshooting Guide ___________________________________________________________ 4-2

Parts List _______________________________________________________________________ 4-5

Specifications____________________________________________________________________ 4-5

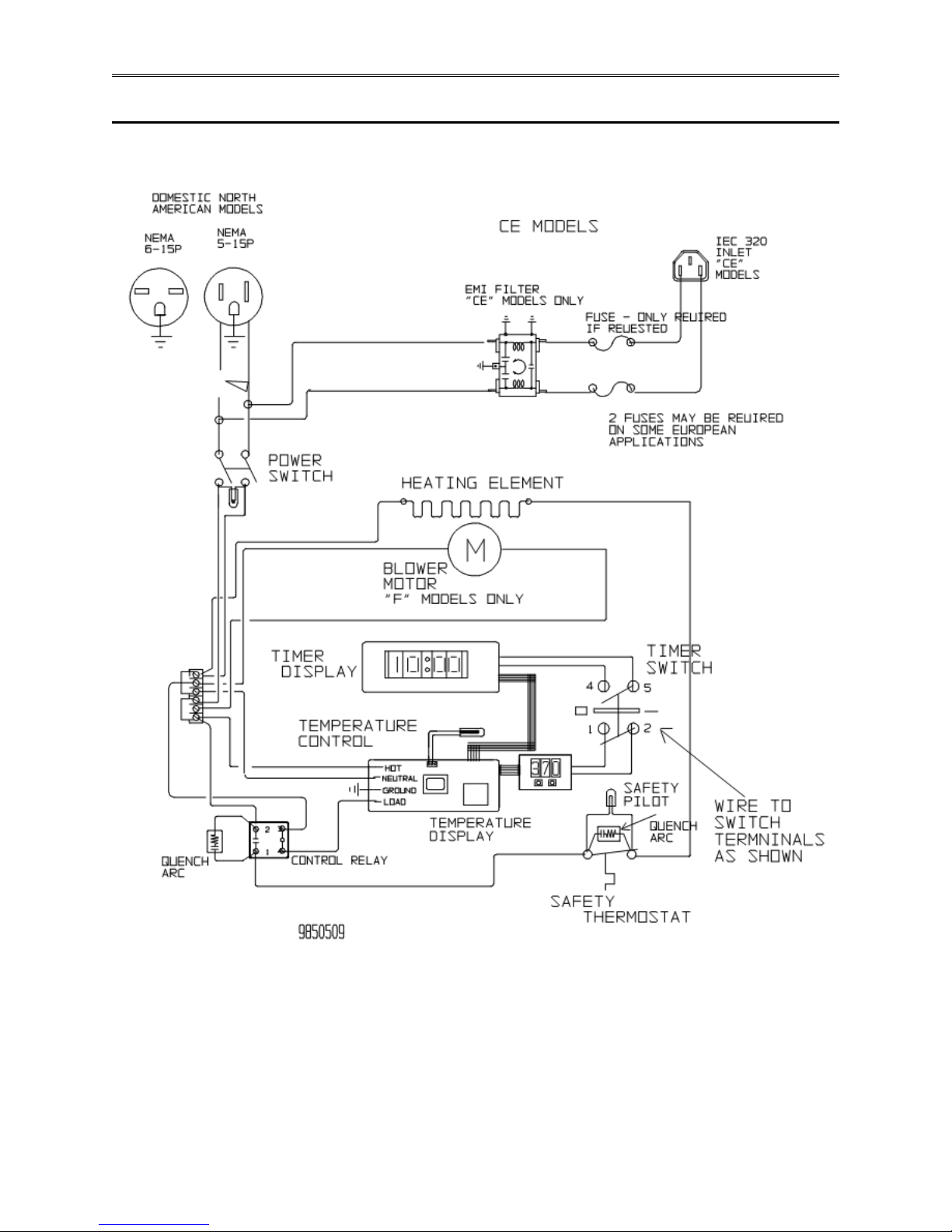

Wiring Diagram _________________________________________________________________ 4-6

Chapter 5 - Warranty ________________________________________________________ 5-1

Chapter 1 – Safety

Chapter 1 – Safety Instructions

Introduction

Follow all CAUTION notices to prevent damage to the chamber or your test sample. Failure to

follow all CAUTION notices may void your warranty. CAUTION may also indicate a

potentially hazardous situation which, if not avoided, may result in minor or moderate personal

injury.

WARNING indicates a potentially hazardous situation which, if not avoided, could result in

death or serious injury.

The safety alert symbol ! precedes a general CAUTION or WARNING statement.

The electrical hazard symbol 2 precedes an electric shock hazard CAUTION or WARNING

statement.

Safety Notices

! WARNING: These units are general purpose air ovens for professional, industrial or

educational use where the preparation or testing of materials is done at

approximately atmospheric pressure and no flammable, volatile or

combustible materials are being heated. These units are not intended for

hazardous or household locations or use.

! WARNING: THIS OVEN IS NOT DESIGNED TO HANDLE COMBUSTIBLE GASSES

AND IS NOT AN EXPLOSION PROOF UNIT. Do not place explosive,

combustible, or flammable materials into the chamber.

! WARNING: Some outgassed byproducts may be hazardous or unpleasant to operating

personnel. If this is the case, the oven exhaust should be positively ventilated

to the outside according to local regulations. A power exhaust is optionally

available which greatly helps under these applications.

! WARNING: Do not operate near noxious fumes.

! CAUTION: Do not place sealed or filled containers in the oven chamber.

! CAUTION: If a mercury thermometer is used for calibration and breakage should occur,

all spilled mercury MUST be completely removed from the chamber before

continuing operation.

! CAUTION: Be sure that the power supply is of the same voltage as specified.

2 WARNING: Do not cut or remove the ground prong from the power cord. Do not use a 2-

prong adapter plug.

TestEquity FS Series Ovens Page 1-1

Chapter 1 – Safety

2 WARNING: Disconnect the unit from its electrical source before proceeding to make any

electrical repairs or replacements.

! CAUTION: This oven is NOT designed for the use in Class I, II, or III locations as defined

by the National Electric Code.

2 WARNING: This oven is not intended, nor can it be used, as a patient connected device.

Page 1-2 TestEquity FS Series Ovens

Chapter 2 – Receiving and Installation

Chapter 2 – Receiving and Installation

Your satisfaction and safety require a complete understanding of this unit. Read the instructions

thoroughly and be sure that all users are given adequate training before attempting to use this

unit. Note: This equipment must be used only for its intended purpose; any alterations or

modifications will void your warranty.

Inspection

The carrier, when accepting shipment, also accepts responsibility for safe delivery and is liable

for loss or damage claims. On delivery inspect for visible exterior damage, note and describe on

the freight bill any damage found and enter your claim on the form supplied by the carrier.

Inspect for concealed loss or damage on the unit itself, both interior and exterior. If any, the

carrier will arrange for official inspection to substantiate your claim.

Verify that your accessory package is complete. All units should have a set of four (4) Leveling

feet, two (2) shelves and eight (8) shelf clips.

Return Shipment

Save the shipping crate and all packaging material until you are sure the oven has not been

damaged and is functioning correctly. If for any reason you must return the unit, contact your

customer support representative for authorization and supply data plate information. Make sure

to include the model and serial number. The service representatives will furnish you with a return

authorization number and address for return. Note: Make sure this return authorization number

appears on the unit packaging and shipping papers. Units returned without proper authorization

may not be accepted at the factory. For information on where to contact customer support please

see the manual cover.

Installation

Local city, county or other ordinances may govern the use of this equipment. If you have any

questions about local requirements, please contact the appropriate local agency. Installation may

be performed by the end user.

This unit is intended for use indoors, at room temperatures between 5° to 40°C (41° to 104°F), at

no greater than 80% Relative Humidity (at 25°C/77°F) and with a supply voltage that does not

vary by more than ±10%. Customer support should be contacted for operating conditions outside

these limits.

TestEquity FS Series Ovens Page 2-1

Chapter 2 – Receiving and Installation

Power Requirements

The power requirements are listed on the oven’s data plate located on the rear. Make sure your

power supply matches that shown on the data plate. VOLTAGE SHOULD NOT VARY MORE

THAN ±10% FROM THE DATAPLATE RATING. These units are intended for 50/60 Hz

application. A separate circuit is recommended to preclude loss of product due to overloading or

circuit failure.

Location

Select a site for the oven which is free from extreme heat, cold or excessive air movement such

as areas near steam radiators, stoves, other ovens, autoclaves, direct sun, heating and cooling

ducts, etc. Avoid high traffic areas which may reduce the accessibility to the oven. Allow at least

2 inches of space between the oven and surrounding walls or partitions which might prevent free

airflow.

Lifting / Handling

These ovens are heavy and care should be taken to use appropriate lifting devices that are

sufficiently rated for these loads. Ovens should only be lifted from their bottom surfaces. Doors,

handles and knobs are not adequate lifting or stabilization. The oven should be completely

restrained from tipping during lifting or transport. All moving parts, such as shelves and trays

should be removed and doors need to be positively locked in the closed position during transfer

to prevent shifting and damage.

Leveling

The oven must sit level and solidly. Leveling feet (supplied) are to be installed in the holes at the

base of the oven. Turn them counterclockwise to raise the level and clockwise to lower the level.

If the oven must be transported, turn the leveling feet in all the way to prevent damage.

Initial Burn-In

It is recommended that the unit go through a “burn-in” process prior to operation. This is to

eliminate the smoking of protective coatings on the element. Read the operating instructions

carefully to understand the operating requirements. To burn-in, turn the OVERTEMP

PROTECTION to maximum and set the TEMPERATURE controller to 200°C. Open the

exhaust vent damper on the top of the oven. Run for a minimum of one hour under ventilation

until smoke dissipates.

Initial Cleaning

The oven’s interior was cleaned at the factory. If you need to clean it further, use a cleaner that is

suitable for your application. Make sure to rinse the cleaned surface with a damp cloth, using

water only, and dry the surfaces with a clean cloth. DO NOT USE chlorine-based bleaches or

abrasives as they will damage the stainless steel surface. DO NOT USE spray cleaners that might

leak through openings and cracks and get on electrical parts or that may contain solvents that will

harm the coatings. A similar periodic cleaning is recommended.

! WARNING: Never clean the unit with alcohol or flammable cleaners with the unit

connected to the electrical supply. Always disconnect the unit form the

electrical service when cleaning and assure all volatile or flammable cleaners

are evaporated and dry before reattaching the unit to the power supply.

Page 2-2 TestEquity FS Series Ovens

Chapter 3 – Operation

B E F

G

l 0 l

Chapter 3 – Operation

Front Panel Controls

0

Power Switch

(A) The POWER switch controls all power to the oven. It must be in the I (ON) position before

any systems are operational. The green light in the switch will be lit when the switch is ON.

Timer Switch

(B) The TIMER switch controls power to the timer circuit. In the O (OFF) position, the oven

heat is controlled with no timed duration. In the I (ON) position, heat is controlled for a timed

interval and then the heat shuts off at the end of that interval.

Overtemperature Protection Thermostat

(C) The OVERTEMP PROTECTION thermostat is an independent controller to protect against

any failure which would allow temperature to rise past the TEMPERATURE controller’s set

point. The adjustment knob points to a relative scale from 0 to 10.

Overtemperature Light

(D) The OVERTEMPERATURE pilot lamp is directly below the OVERTEMP PROTECTION

thermostat. The light will come on when the OVERTEMP PROTECTION is activated and has

taken control of the oven. This pilot lamp should never be on under normal operating conditions.

Timer

(E) The TIMER consists of a digital display, UP/DOWN arrow pads, a RESET pad, a

START/STOP pad and a TIMER ACTIVE light. The TIMER provides the ability to have the

oven maintain heat for a specified period of time.

Temperature Controller

(F) The TEMPERATURE controller consists of digital display and UP/DOWN arrow pads for

entering the temperature set point and for calibration.

Heating Light

(G) The HEATING pilot lamp will be lit whenever the heating elements are energized. It will

cycle on/off when the oven approaches and stabilizes at the desired temperature set point.

TestEquity FS Series Ovens Page 3-1

Chapter 3 – Operation

Operating the Oven

Assure that the electrical power source is properly configured and rated for the oven and plug the

unit cord into the receptacle.

Turning the Oven On

Push the POWER switch to the I (ON) position. Push the timer switch to the O (OFF) position.

The digital temperature display will indicate a temperature value. Turn the OVERTEMP

PROTECTION Thermostat to its maximum clockwise position using a coin or flat head

screwdriver.

Setting the Temperature Controller

To enter the desired set point temperature, press either the UP or DOWN arrow pad once on the

TEMPERATURE digital display. The display will start to blink from bright to dim. While

blinking, the display is showing the temperature set point. You can change the set point by

pushing the UP or DOWN arrow pads to raise or lower the value. If the arrow pads are not

pushed within five (5) seconds, the display will stop blinking and return to read the chamber

temperature. Allow several hours for the temperature to stabilize.

Setting the Overtemp Protection Thermostat

The OVERTEMP PROTECTION should be initially set to its maximum position when

stabilizing the set point temperature. Once the oven is stable at the desired set point, turn the

OVERTEMP PROTECTION counterclockwise (using a coin or flat-head screwdriver) until the

OVERTEMPERATURE light comes on. Next, turn the OVERTEMP PROTECTION clockwise

just until the OVERTEMPERATURE light goes off. Next, turn the OVERTEMP PROTECTION

two (2) minor increments on its scale past the point where the light went out. This sets the

OVERTEMP PROTECTION at approximately 10°C above the current temperature set point.

Page 3-2 TestEquity FS Series Ovens

Chapter 3 – Operation

TIMER

TIMER

Blinking Decimal > Hour 10 Min. 1 Min.

Hours 10 Min. 1 Min.

Setting the Timer

(Optional for timed operation only) Turn the timer switch to the I (ON) position. TIMER

display digits will light with no decimals showing. Note that if several seconds elapse with no

arrow or reset pad activity during any of the following steps, the TIMER will default to the

present displayed setting and it will be necessary to restart all functions over again. The values

must be entered in a consecutive manner with no delays between settings or the default will

occur.

Hour Function: Press and hold the RESET pad until the digits start blinking, and the left most

decimal blinks. In this mode, pressing the UP or DOWN arrow pads increases or decreases the

whole hour value from 0 to 99.

10 Minute Function: After the desired value for hours is set, push the RESET pad again. The

middle decimal will now blink. Pushing the UP or DOWN arrow pads will increase or decrease

the 10 Minute function allowing values between 0 and 5 to be set.

1 Minute Function: After the desired 10 Minute value is set, push the RESET pad again. The

right most decimal point will blink. Pushing the UP or DOWN arrow pads will increase or

decrease the 1 Minute function allowing values between 0 and 9 to be set.

Activation: Wait until the timer stops blinking. After all settings are made, push the

START/STOP button. The TIMER ACTIVE light will come on and after a brief pause, the oven

temperature set point will be active. The oven will now heat up, control at the set point and stop

after the timed period has elapsed.

Note that when the system is in the timer mode, the heating circuit is de-energized until the

START/STOP button is pushed or the TIMER switch is turned OFF. If a time change or

correction is necessary and the timer has already been activated, push the START/STOP button

to stop the timer, then repeat the above steps.

To set the timer so that timed operation will not start until the oven is stable at set point, pre-heat

the oven with the TIMER switch OFF until the desired temperature has stabilized. Turn the

TIMER switch ON. Push and hold the RESET button until the TIMER display blinks (to be sure

that the pre-set timed value is correct). Press the START/STOP button to activate the timer.

TestEquity FS Series Ovens Page 3-3

ACTIVE

Chapter 4 – Maintenance

Chapter 4 – Maintenance

2 WARNING: Disconnect the power cord from the power source before performing any

service or maintenance on this unit.

No maintenance is required on the electrical components. If the unit fails to operate as specified,

please see the Troubleshooting Guide, before calling for service.

Cleaning

Cleaning and decontamination are recommended on a regular basis. To prepare the unit for

cleaning, remove all interior parts if assembled, such as shelves and shelf clips.

First, clean the oven interior with soap and water, rinse and let dry. To decontaminate use a

solution that is appropriate for your application. DO NOT USE chlorine-based bleaches or

abrasives as this can damage the stainless steel components. DO NOT USE spray cleaners that

might leak through openings and cracks and get on electrical parts or that may contain solvents

that will harm the coatings. Use care when cleaning the door gasket to prevent damage which

could impair the positive door seal.

! WARNING: Never clean the unit with alcohol or flammable cleaners with the unit

connected to the electrical supply. Always disconnect the unit form the

electrical service when cleaning and assure all volatile or flammable cleaners

are evaporated and dry before reattaching the unit to the power supply.

Storage

To prepare the unit for storage, remove all shelves and shelf clips and disconnect the power

supply. Be certain that the chamber is completely dry and door is positively secured in the closed

position. See Lifting / Handling for proper transport procedures.

Calibration

Controller Accuracy is ±1°C at the calibrated single set point using the procedure below.

It is recommended that calibration is verified with the unit is installed in its working

environment, and has been stable at set point for several hours. Place a reference temperature

measurement device in the oven. Be certain the sensor does not touch any shelving. Allow again

for the temperature to stabilize until five (5) consecutive readings at one minute intervals show

no temperature change. Compare the reading on the reference thermometer with the front panel

digital display. If there is an unacceptable difference, put the display in calibrate mode by

pressing the UP and DOWN arrow pads at the same time until the decimal points blink on and

off. While blinking, the display can be changed to match the reference thermometer by pushing

the UP or DOWN arrow pads to raise or lower the temperature until the display reads the correct

value. If no arrow pads are pressed within five (5) seconds the display will revert to displaying

the temperature within the chamber.

TestEquity FS Series Ovens Page 4-1

Chapter 4 – Maintenance

TEMPERATURE

Temperature too high.

1. Controller set point is too high.

2. Controller failed on – call Customer Service.

Display reads “HI” or “400”+.

1. Probe is unplugged, is broken or wire to sensor is broken – trace

wire from display to probe.

Temperature too low

1. OVERTEMP PROTECTION set too low.

lights that safety thermostat is operating correctly.

Display reads “LO”

1. Bad probe or disconnected – call Customer Service.

points and ambient temperature to rated specifications.

Oven will not heat over a

1. Confirm that fan is moving and that amperage and voltage match

4. Check calibration using a calibrated instrument.

Unit will not heat up at all

1. Check amperage – amperage should be virtually at maximum rated

or diagnostics, should be

5. Has timer turned unit off?

Will not maintain set point

1. Assure that set point is at least 10 degrees over ambient.

HVAC duct openings – stabilize ambient conditions.

Display and reference

1. Calibration error – Controller needs re-calibration.

5. Verify that reference thermometer is certified.

Calibrated at one temperature, but

1. This can be a normal condition when operating temperature varies

close to the set point temperature.

Can’t adjust set points or

calibration

1. Turn entire unit off and on to reset.

Troubleshooting Guide

2. TEMPERATURE controller set too low.

3. Unit needs time to recover from door opening – wait for display to

stop changing.

4. Unit not recovered from power failure or being turned off – ovens

will need several hours to warm up and stabilize.

5. Element failure – compare current draw to data plate.

6. Temperature controller failure – call Customer Service.

7. OVERTEMP PROTECTION failure – confirm with front panel

2. If ambient temperature is lower than range of unit – compare set

temperature that is below set point

thermometer don’t match

not at another

data plate – check for air movement in chamber.

2. Confirm that set point is set high enough – turn OVERTEMP

PROTECTION all the way clockwise and see if

OVERTEMPERAURE light comes on.

3. Check connections to sensor.

(data plate) amperage.

2. Do all controller functions work?

3. Is the Safety Thermostat set high enough? F

fully clockwise with the OTP light never on.

4. Has the fuse/circuit breaker blown?

2. See if ambient is fluctuating; check for adjacent open doors or

2. Temperature sensor failure – call Customer Service.

3. Controller failure – call Customer Service.

4. Allow at least two hours to stabilize.

widely. For maximum accuracy, calibration should be done at or as

2. If repeatedly happens, call Customer Service.

Page 4-2 TestEquity FS Series Ovens

Chapter 4 – Maintenance

TEMPERATURE (continued)

Indicated chamber temperature

1. ±0.1°C variation is normal.

display for erratic behavior; check sensor and wiring for mechanical

signs of arcing or other visible deterioration.

MECHANICAL

Motor doesn’t move

1. If shaft spins freely: check connections to motor and check voltage

2. If shaft rubs or is frozen, relieve binding and retest.

Motor makes noise

1. If noise is from the motor, tap the top of motor shaft with ball peen

3. If there is no change, call Customer Service.

Door not sealing

1. Adjust hinge blocks, chamber latch bracket or twist the door.

3. Check physical condition of gasket for tears or punctures.

unstable

2. Make sure fan is working. Verify movement of air in chamber.

3. Room temperature is radically changing – either door opening or

room airflow from heaters or air conditioning. Stabilize the ambient

conditions.

4. This may happen if exhaust stack is 100% open or if power exhaust

is cycling – adjust stack to at least ¼ closed.

5. Sensor miss-located, damaged or wires may be damaged. Check

mounts for control and overtemperature sensors, then trace wires or

tubing between sensors and controls.

6. Defective temperature controller. Call Customer Service.

7. OVERTEMP PROTECTION set too low. Be sure that

OVERTEMP PROTECTION is set more than 5 degrees over

temperature set point; check if OVERTEMPERATURE light is on

continuously; turn OVERTEMP PROTECTION knob completely

clockwise to see if problem solved then follow operating

instructions for correct setting.

8. Electrical noise. Remove nearby sources of RFI including motors,

arcing relays or radio transmitters

9. Bad connection on temperature sensor or faulty sensor. Check

connectors for continuity and mechanical soundness while watching

damage.

10. Bad connections or faulty solid state relay. Check connectors for

mechanical soundness and look for corrosion around terminals or

to motor.

hammer.

TestEquity FS Series Ovens Page 4-3

2. If the sound gets worse, tap the other end of the shaft – avoiding

touching the blower wheel.

2. Confirm that unit has not been damaged and body is not square.

Chapter 4 – Maintenance

OTHER

HEATING light is on all the time

1. Adjust set point to room temperature. If the unit is still heating,

Service.

Controller timer resets on its own

1. Confirm that power from wall is consistent and within

2. Timer is defective.

Front panel displays are all off

1. Check connections to the temperature display control board and

2. Check for wire damage.

Unit or wall fuse/circuit breaker is

1. Check wall power source.

3. See what other loads are on the wall circuit.

Unit will not turn on

1. Check wall power source.

4. Check all wiring connections, especially around the on/off switch.

Unit is smoking after initial

1. This is not an uncommon occurrence when first operating new

smoke dissipates.

Contamination in chamber

1. See cleaning procedure.

maintenance schedule.

Contamination on sample

1. See “Contamination in chamber”.

inlet air ducts.

and temperature is running away

blown

operation

replace the solid state relay.

2. If cannot change any condition on the front panel, call Customer

specifications.

assure that all are tight and in the correct orientation.

2. Compare current draw and compare to specs on data plate.

2. Check fuse/circuit breaker on unit or in wall.

3. See if unit is ON, e.g., fan or heater, and just controller is off.

units. Run at high temperature with vent open for one hour or until

2. Develop and follow standard operating procedure for specific

application; include definition of cleaning technique and

2. Reduce air flow in chamber by dampening down exhaust port; be

sure to verify adequate temperature uniformity at the reduced air

flow.

3. Protect open samples from areas of maximum air current, e.g.,

Page 4-4 TestEquity FS Series Ovens

Chapter 4 – Maintenance

Description

Part Number

Adjustable Feet

200129

Blower Motor

4880549

Control Knob

4450506

Cord Set

1800529

Door Latch

X1000456

Fuse Holder

3300501

Fuse 16 Amp

3300513

Heating Element, FS2

9570523

Heating Element, FS4

9570537

I/O (On/Off) Power Switch

100351

Main Control W/Timer, FS Models

1750612

Overtemperature Safety Thermostat

1750615

Pilot Lamp, OTP

200020

Pilot Light Heating

200021

Shelf Clips

200116

Shelf FS2

5130543

Shelf FS4

5130516

Shelf FS5

5130522

Solid State Relay

101168

Timer Switch

X1000124

FS2

FS4

Inside Volume

1.55 cu ft

3.3 cu ft

Inside Dimensions*

13 x 14 x 14.75

18.25 x 19 x 6.5

Outside Dimensions*

21.25 x 23.75 x 33

27 x 25 x 34.75

Shipping Weight

120 lbs.

185 lbs.

Net Weight

93 lbs.

115 lbs.

Temperature Range

10°C above ambient to 250°C

Uniformity

±2°C at 150°C

Controller Accuracy

±1°C at the calibrated single set point

Heat up time

15 minutes to 150°C

Recovery

2 minutes at 150°C after 30 sec. door opening

* W x D x H (inches)

Parts List

Specifications

TestEquity FS Series Ovens Page 4-5

Chapter 4 – Maintenance

Wiring Diagram

Page 4-6 TestEquity FS Series Ovens

Chapter 5 - Warranty

TestEquity LLC Limited Warranty

TestEquity LLC (TestEquity) warrants Environmental Chambers (Equipment) manufactured by TestEquity and supplied under

this contract to be free from defects in materials and workmanship under normal use and proper maintenance.

TestEquity will repair or replace any defective part for a period of THREE YEARS from the date of invoice. TestEquity reserves

the right to require any defective part be returned, freight prepaid, to TestEquity’s factory or to inspect any defective part at the

Purchaser’s site. TestEquity shall have sole discretion to determine whether any part is defective and whether any defective part

will be repaired or replaced. This limited warranty shall extend to any standard chamber accessory and component part which is

normally sold by TestEquity. Non-standard accessories and component parts specified by the Purchaser shall be warranted only

to the extent of the original manufacturer's warranty, if any exists.

If the repair or replacement is performed in the FIRST YEAR from the date of invoice, TestEquity will also pay for the labor

associated with the repair at the Purchaser’s site, subject to TestEquity’s prior approval. During the SECOND and THIRD YEAR

of the warranty period, Purchaser will be responsible for the installation and cost of installation of replacement or repaired parts.

Purchaser shall notify TestEquity in writing of any alleged defect within 10 days after its discovery within the warranty period.

TestEquity reserves the right to satisfy the labor portion of this limited warranty either through its own service personnel or an

authorized agent. In order to provide expeditious service, TestEquity reserves the right to satisfy its limited warranty obligation

by sending replacement parts to be installed by the Purchaser if they can be installed easily without special tools or training.

TestEquity reserves the right to satisfy this limited warranty by requiring the Purchaser to return the Equipment to TestEquity

when such return is feasible.

TestEquity must initiate field service for in-warranty claims. Purchaser will not be reimbursed for labor if they initiate service on

their own without prior approval from TestEquity. Replacement parts must be supplied by TestEquity for in-warranty claims.

Purchaser will not be reimbursed for parts they buy on their own without prior approval from TestEquity.

The following parts are excluded from this limited warranty and are sold as-is or are considered expendable: paint and cosmetic

surface finishes and treatments, and port plugs.

This limited warranty shall extend in full to Equipment installed within continental United States and Canada. For all other

locations, Purchaser is responsible for all labor costs for repairs or parts installation, and for all shipping costs associated with

providing replacement parts.

This limited warranty does not cover: (1) Defects or damages arising as the result of shipment by common carriers or private

transportation, unless TestEquity undertakes shipment and transportation of the Equipment to Purchaser’s site or contractually

assumes the risk of damage to the Equipment in shipment; (2) Defects or damages arising out of, or as the result, of mishandling,

modification, or improper start up, installation or maintenance of the Equipment (including start up, installation or maintenance

not in accordance with TestEquity’s written procedures); (3) Defects or damages resulting from, or arising out of, abuse, misuse,

neglect, intentional damage, accident, fire, flood, earthquake, or any other act of God.

This warranty as to Equipment is LIMITED to repair or replacement of parts or Equipment in the determination of TestEquity

LLC THE FORGOING LIMITED WARRANTY IS IN LIEU OF ALL OTHER WARRANTIES INCLUDING THE IMPLIED

WARRANTIES OF FITNESS FOR A PARTICULAR PURPOSE AND MERCHANTABILITY. TestEquity LLC DISCLAIMS

ANY LIABILITY FOR ANY DAMAGES RESULTING FROM DELAY OR LOSS OF USE IN SERVICE OR REPAIR, OR

FOR INCIDENTAL OR CONSEQUENTIAL DAMAGES ARISING OUT OF OR IN CONNECTION WITH THE USE OR

PERFORMANCE OF THE EQUIPMENT, EXCEPT AS STATED IN THIS PARAGRAPH.

This limited warranty cannot be modified in any way except in writing by both TestEquity and Purchaser. Invalidation of any one

or more of the provisions of this limited warranty shall in no way affect any of the other provisions hereof, which remain in full

force and effect.

This limited warranty shall be extended only to the first Purchaser of this Equipment and is not transferable.

Loading...

Loading...